Component mounting line

A technology for installing lines and components, applied in the direction of electrical components, electrical components, etc., can solve problems such as the inability to improve production efficiency, and achieve the effects of improving production efficiency, realizing cycle time, and achieving equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

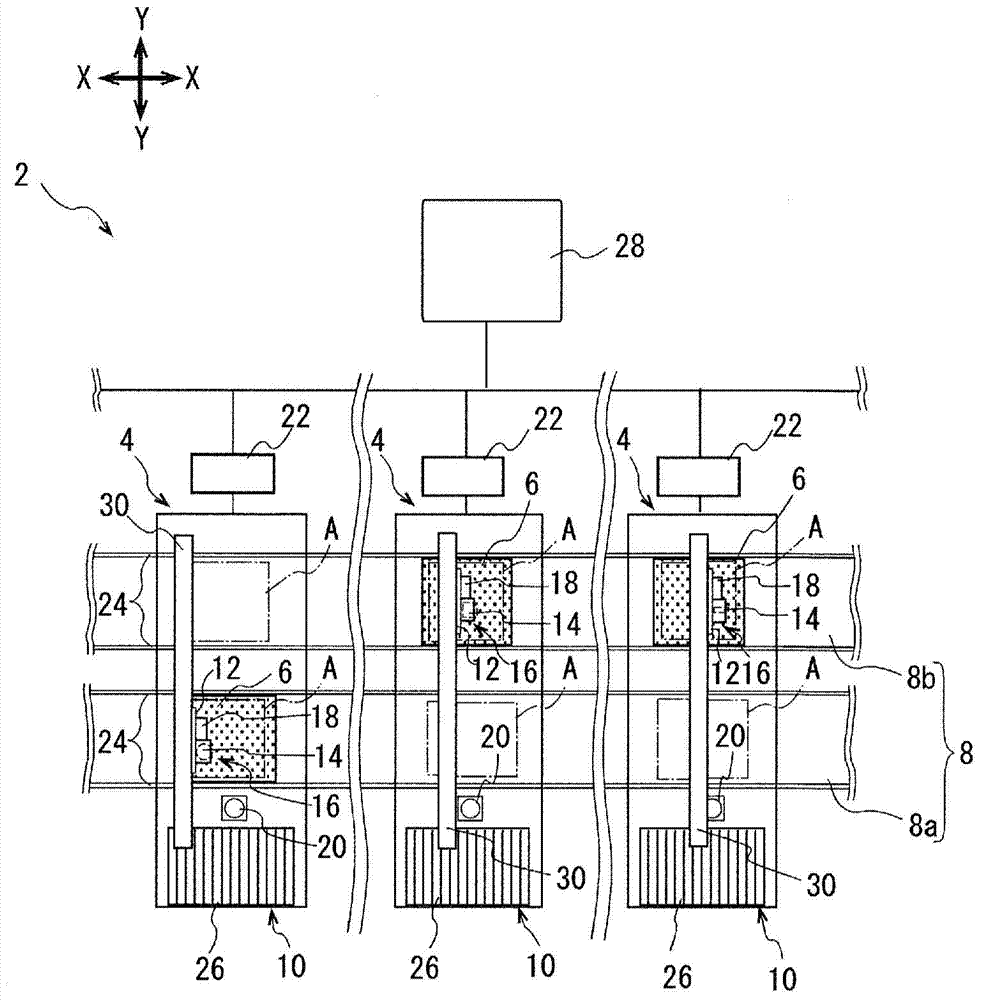

[0037] Hereinafter, a first embodiment of a component mounting line in which electronic component mounting devices of a plurality of modules are arranged in-line according to the present invention will be described based on the drawings.

[0038] The component mounting line 2 has electronic component mounting devices 4 as component mounting devices, and a plurality of them are arranged in series (twelve in total).

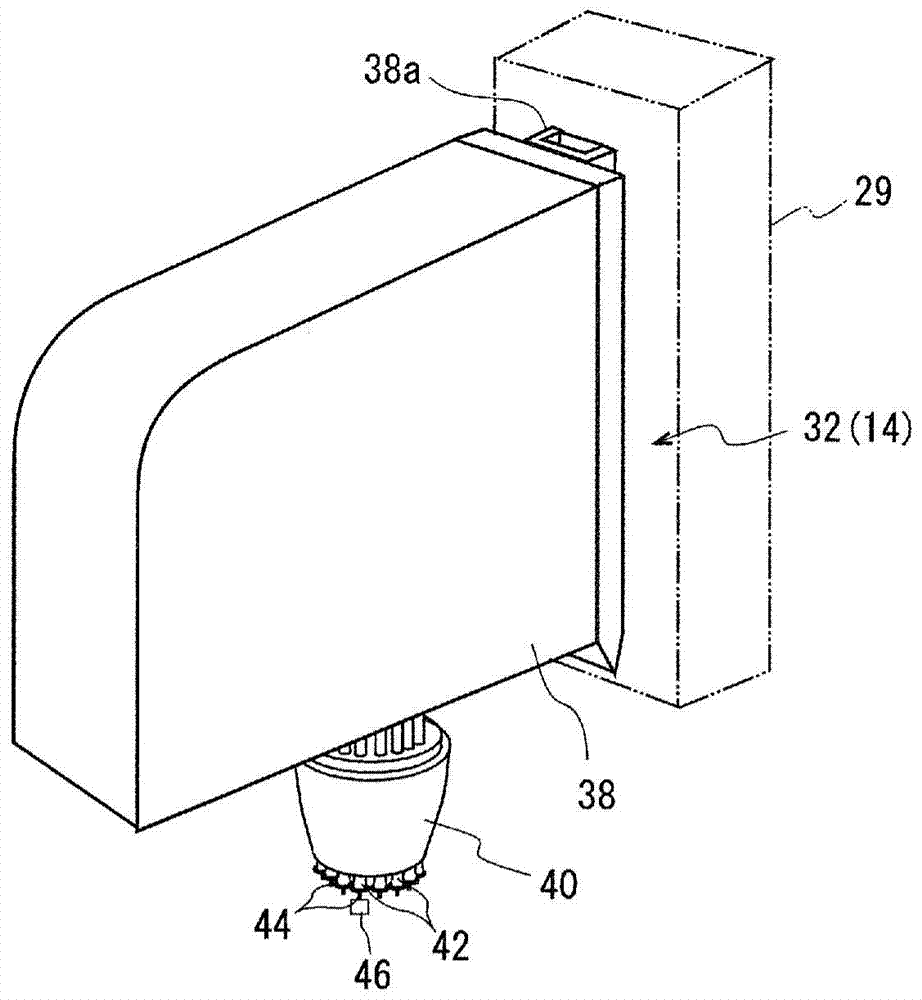

[0039] Such as figure 1 As shown, the electronic component mounting device 4 includes: a substrate conveying device 8, which carries the substrate 6 into the loading position and locates it at a predetermined component mounting position A; a component supply device 10; a component transfer device 16 with a mounting head 14 and a mark identification The camera 18 is provided on the moving table 12 supported so as to be able to move to the conveying direction of the substrate 6, that is, the X direction and the Y direction horizontally perpendicular to the X directio...

Embodiment 2

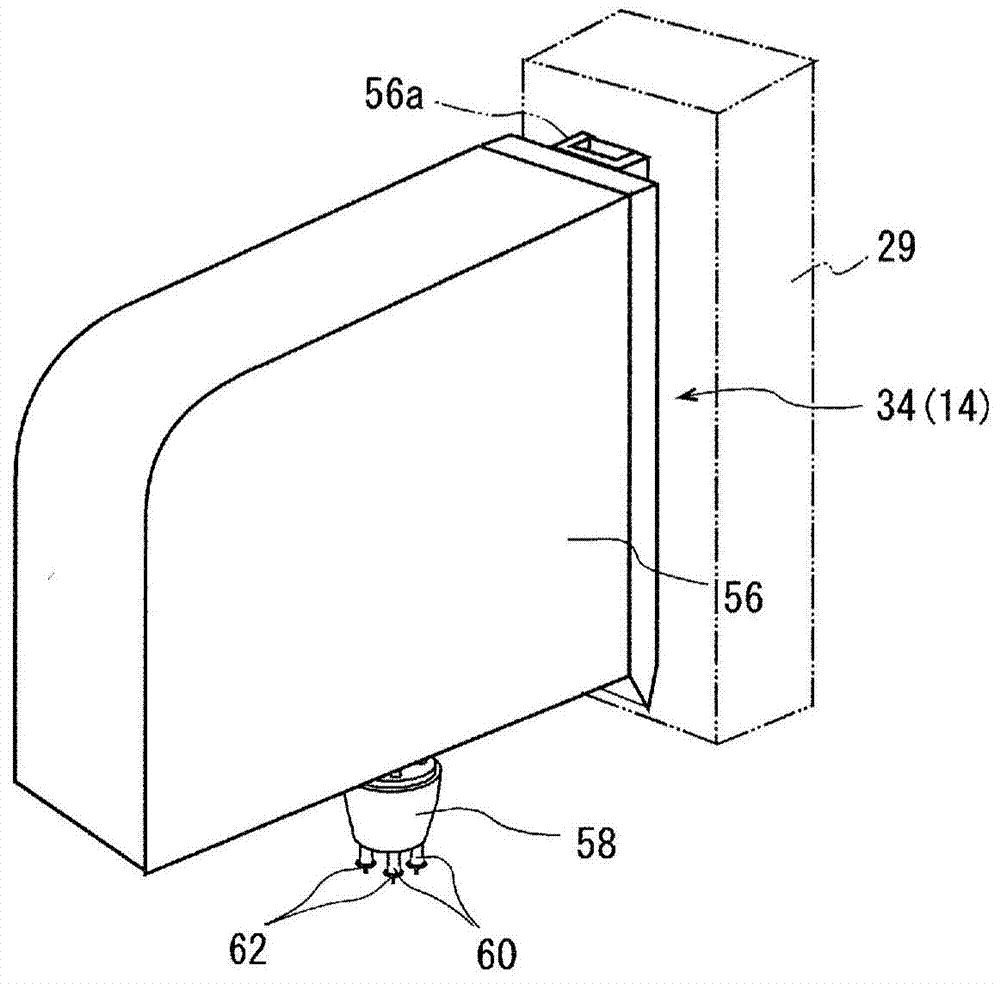

[0077] Next, a second embodiment of a component mounting line in which electronic component mounting devices of a plurality of modules according to the present invention are arranged in series will be described below. The configuration of the device used is the same as that of the first embodiment, and thus description thereof will be omitted.

[0078] This embodiment can be carried out continuously with the flow steps of the first embodiment, and can be implemented as a subsequent process of step 111 . In addition, the medium-speed head 34 in this embodiment corresponds to the high-speed head in Claim 3 and Claim 4 with respect to the general-purpose head 36 .

[0079]The control device 22 determines whether or not there is an electronic component mounting device 4 that can be replaced with the medium-speed head 34 among the modules of the electronic component mounting device 4 including the general-purpose head 36 that has not been replaced in the first embodiment ( S201 ). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com