Multifunctional chemical equipment for preparing chemical raw material

A technology for chemical raw materials and chemical equipment, which is applied to mechanical equipment, supporting machines, machines/supports, etc., can solve the problems of wasting time in installation and disassembly, lack of stability, inconvenient connection, etc., and achieves time-saving and limited effect. , The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

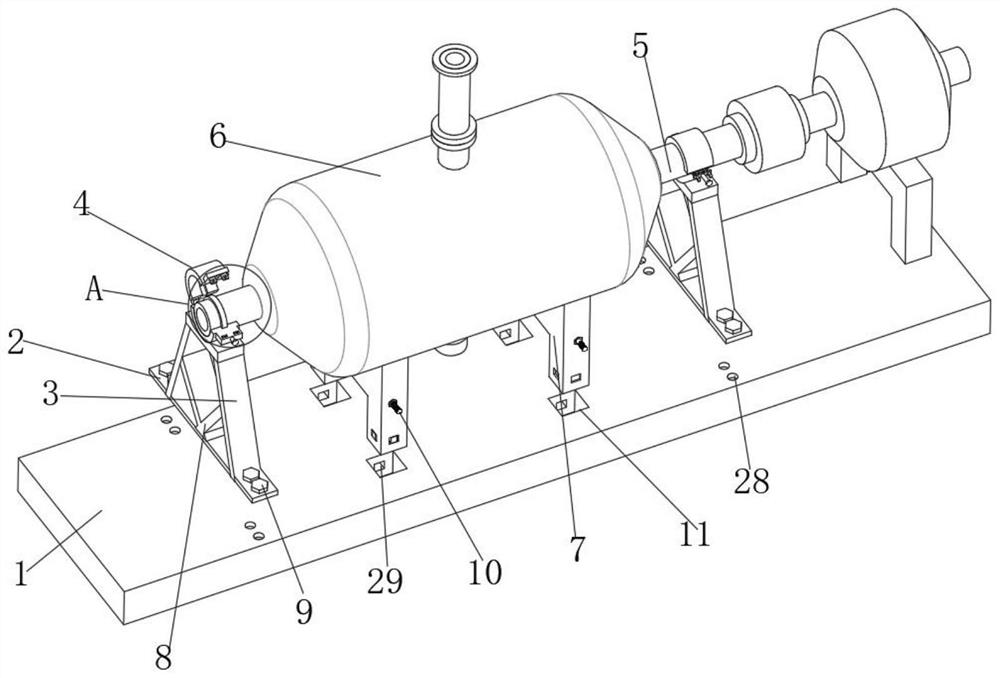

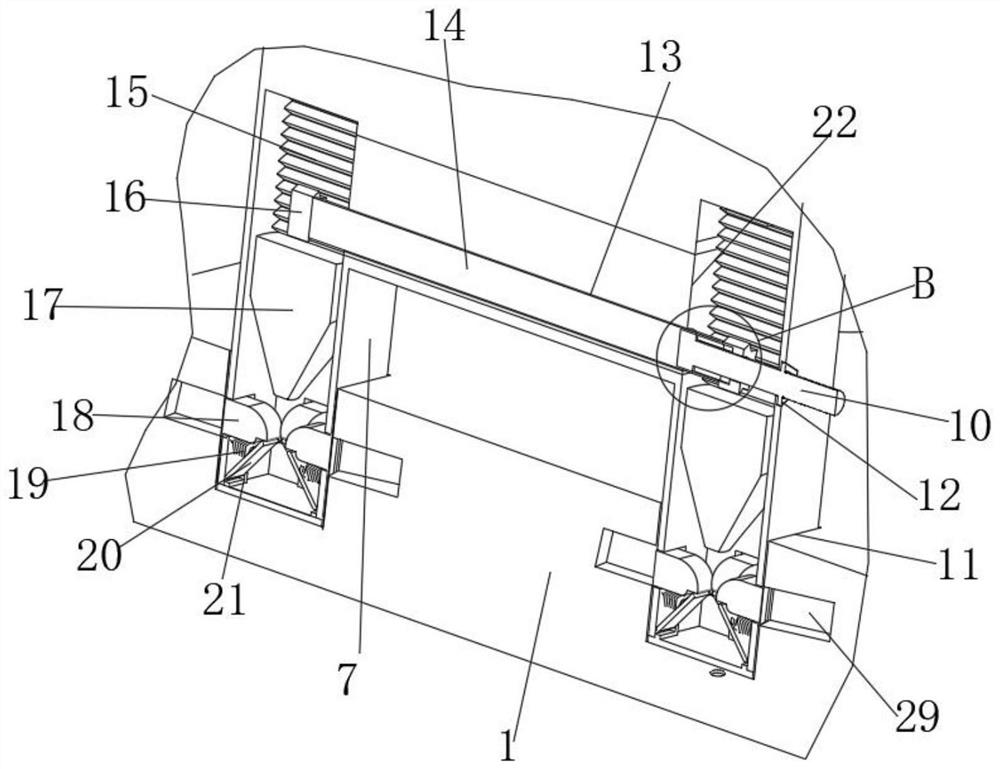

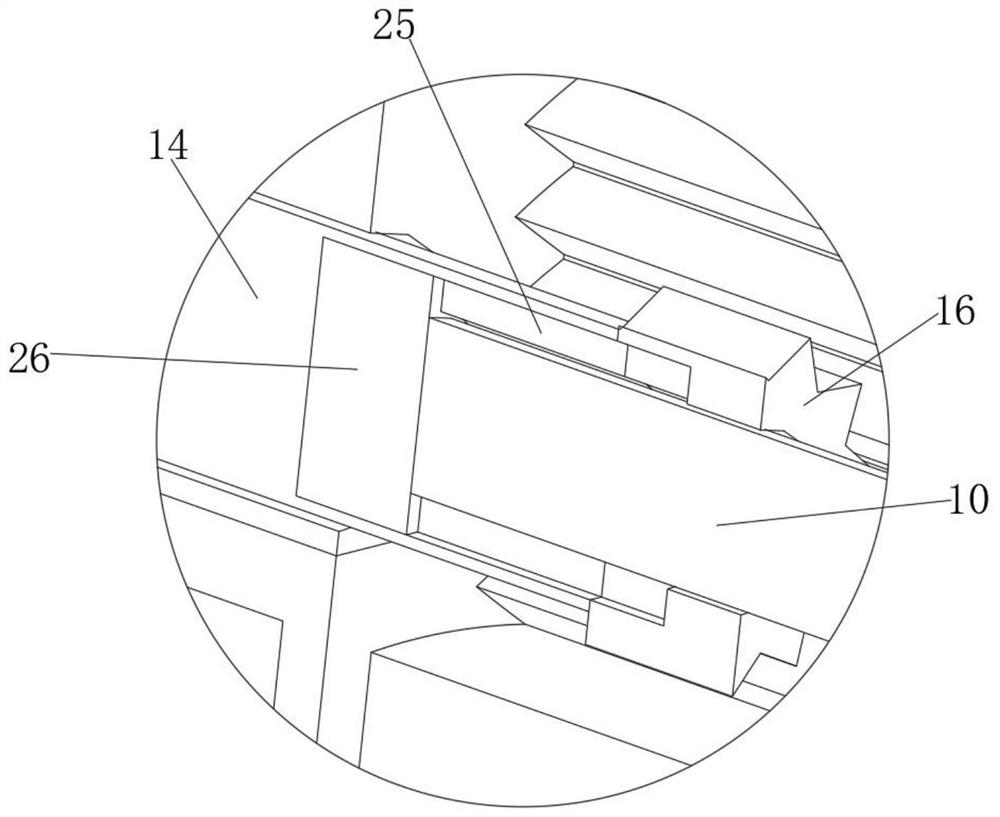

[0024] see Figure 1-5 , the present invention provides the following technical solutions: a multifunctional chemical equipment for preparing chemical raw materials, including a base plate 1, the base plate 1 is screwed and connected with a mounting plate 2 through a bolt 9, and the upper surface of the mounting plate 2 is fixedly connected with a support frame 3. The inside of the support frame 3 is fixedly connected with an auxiliary bracket 8. The upper end of the support frame 3 is provided with a bearing seat 4 that is engaged with the rotating bearing 5. The interior of the bearing seat 4 is provided with a rotating bearing 5, and one end of the rotating bearing 5 is fixed. The main body 6 is connected, and the lower end of the main body 6 is equipped with a supporting foot 7 that is engaged with the bottom plate 1. The inner part of the supporting foot 7 is slidably connected with a rotating handle 10, and the surface of the mounting plate 2 is provided with a jack that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com