Beam and column modules that can be assembled into building frames

A frame and building technology, applied in the direction of construction, building structure, etc., can solve the problems that cannot be disassembled and assembled, there is no beam and column module, labor-intensive and time-consuming, etc., and achieve the effect of short construction period, fast speed, quick and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

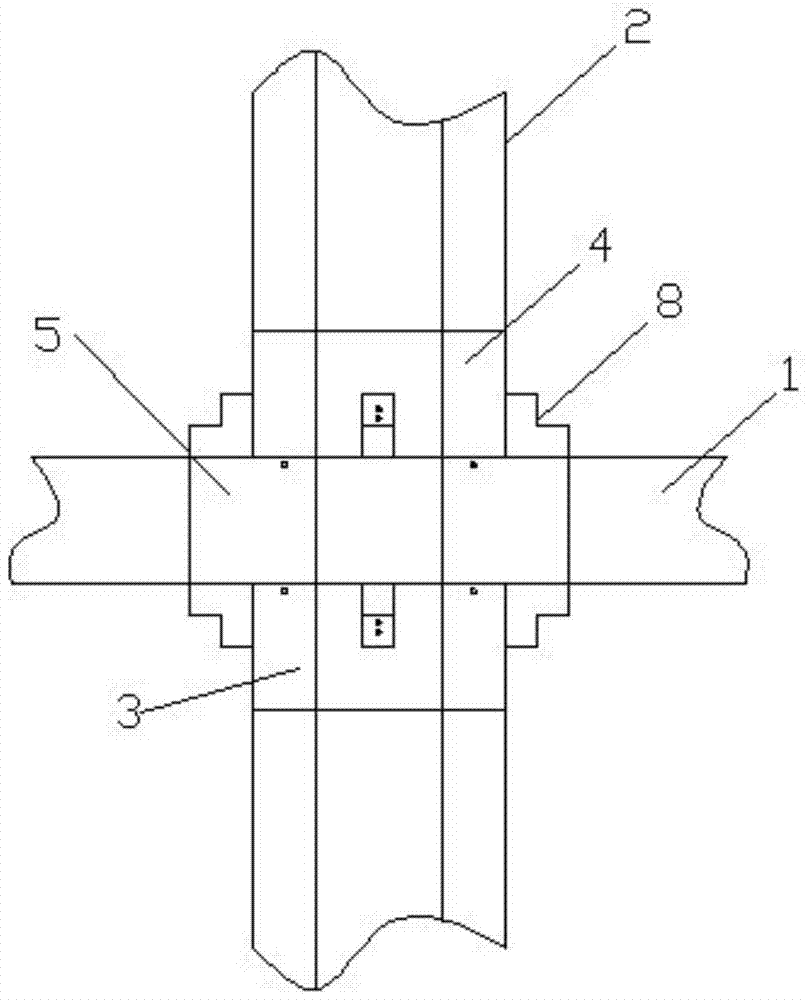

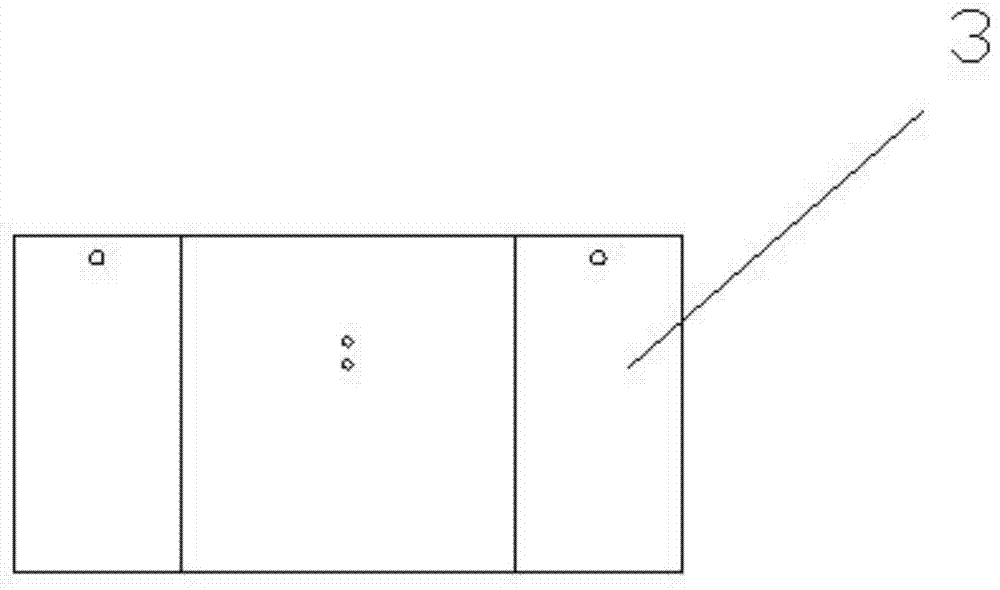

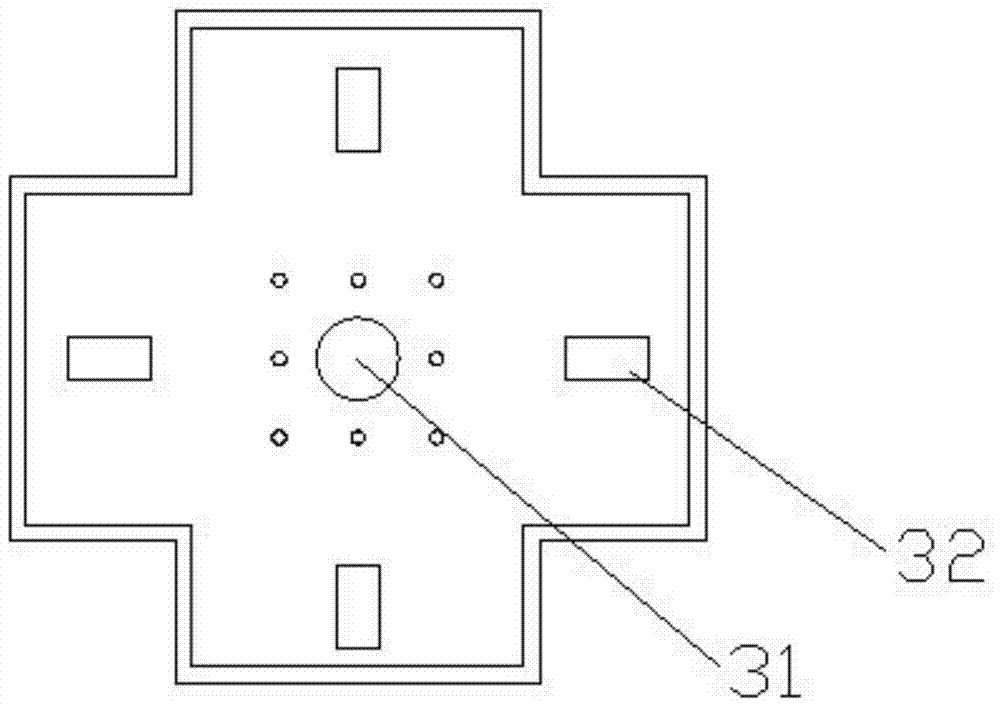

[0033] The beam and column module that can be assembled into a building frame includes beams and columns. Both ends of the beam and column have steel plate sleeves made of steel plates. The steel plate sleeves at both ends and the reinforced concrete column in the middle are cast as a whole to become beams and columns. Moreover, through several accessories, the heads of the beams and columns are tightly connected together to form the frame of the building. The building frame assembled by this beam and column has the same solid performance as the overall building frame made of reinforced concrete, and can be dismantled and reassembled, so that the building can be dismantled, transported to other places, and reassembled. This allows the building t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com