Patents

Literature

94results about How to "Reduce space occupation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

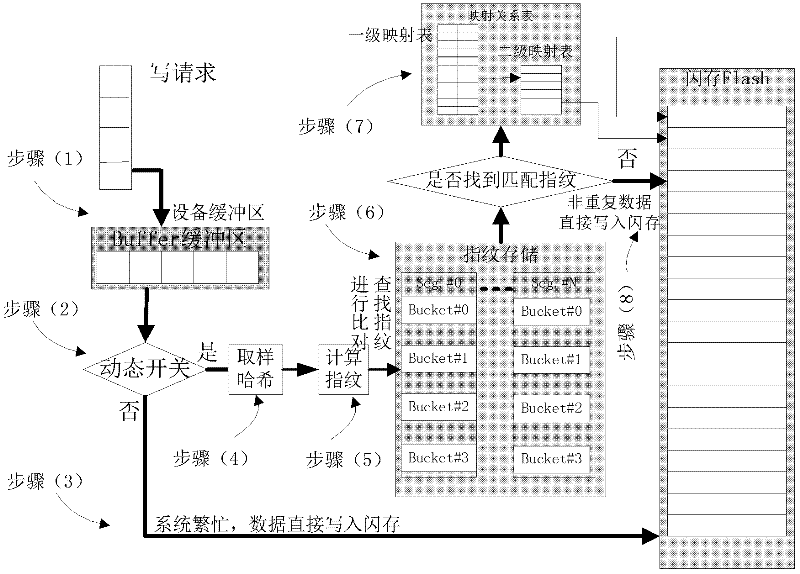

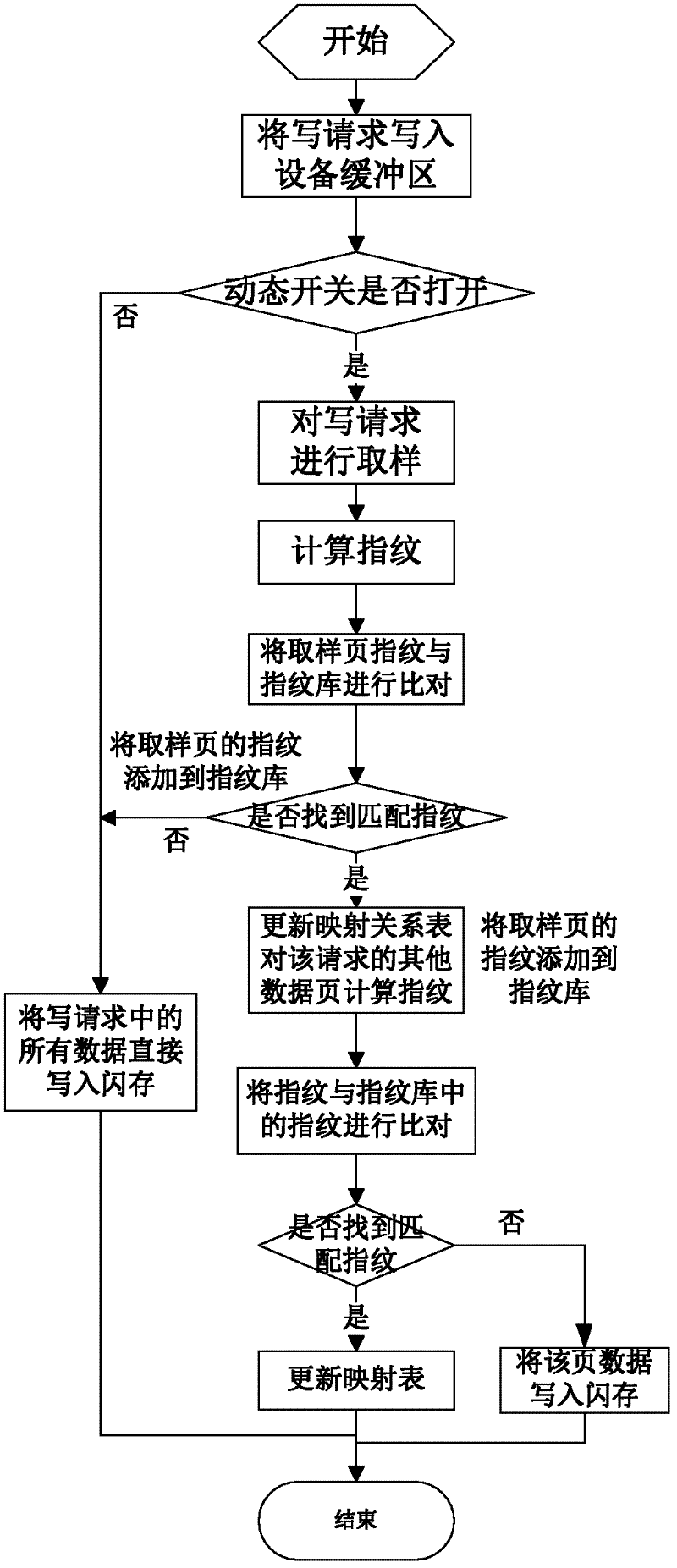

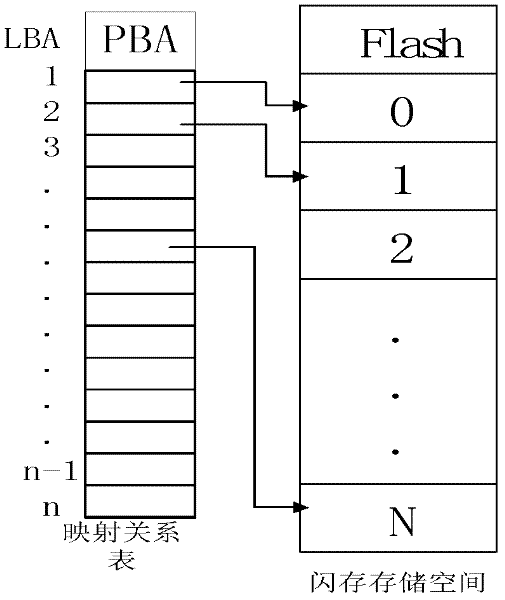

Method for prolonging service life of solid-state disk

ActiveCN102646069AReduce occupancyLow costMemory adressing/allocation/relocationSoftware engineeringFingerprint

The invention discloses a method for prolonging the service life of a solid-state disk, which comprises the following steps of: (1) adding a write request into a write request queue in a buffer area of a solid-state disk; (2) selecting a data page in the write request as a sampling page; (3) calculating the fingerprint of the sampling page and also comparing with fingerprints in a fingerprint library so as to carry out matching; (4) if no matching fingerprint is found, writing the rest data pages in the sampling page and the request into a flash memory of the solid-state disk directly; and (5) if a matching fingerprint exists, carrying out fingerprint calculation on each of the rest pages respectively and also comparing with the fingerprints in the fingerprint library respectively so as to carry out matching: updating a corresponding mapping table directly for the data page in which the matching fingerprint is found and writing the data page in which the matching fingerprint is found into the solid-state disk. According to the method for prolonging the service life of the solid-state disk, the actual physical occupation of data in the solid-state disk on the flash memory is reduced, the redundant space of a system is indirectly increased, and the frequency of the garbage recovering operation of the system is reduced, so that the service life of the solid-state disk is enhanced.

Owner:HUAZHONG UNIV OF SCI & TECH

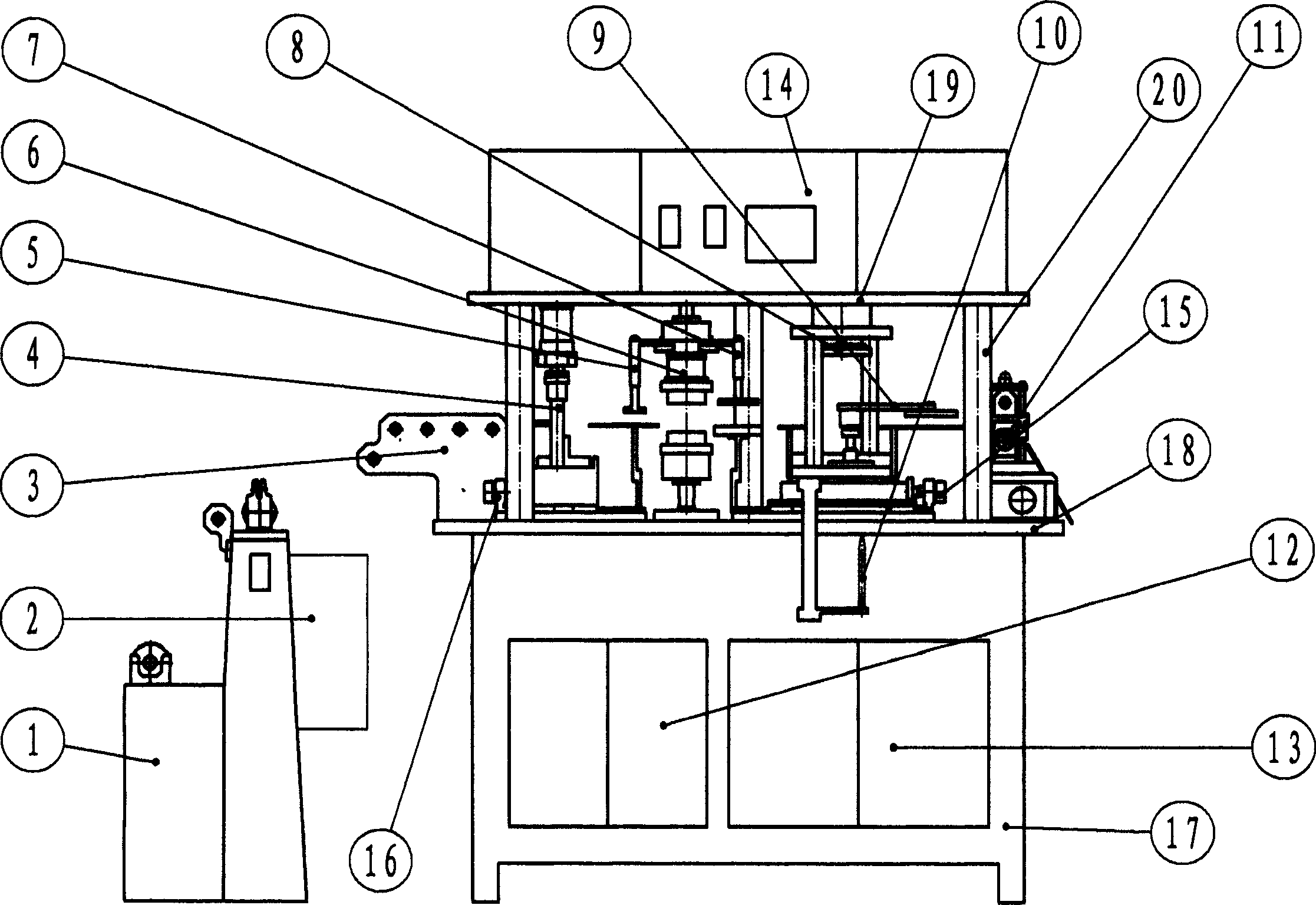

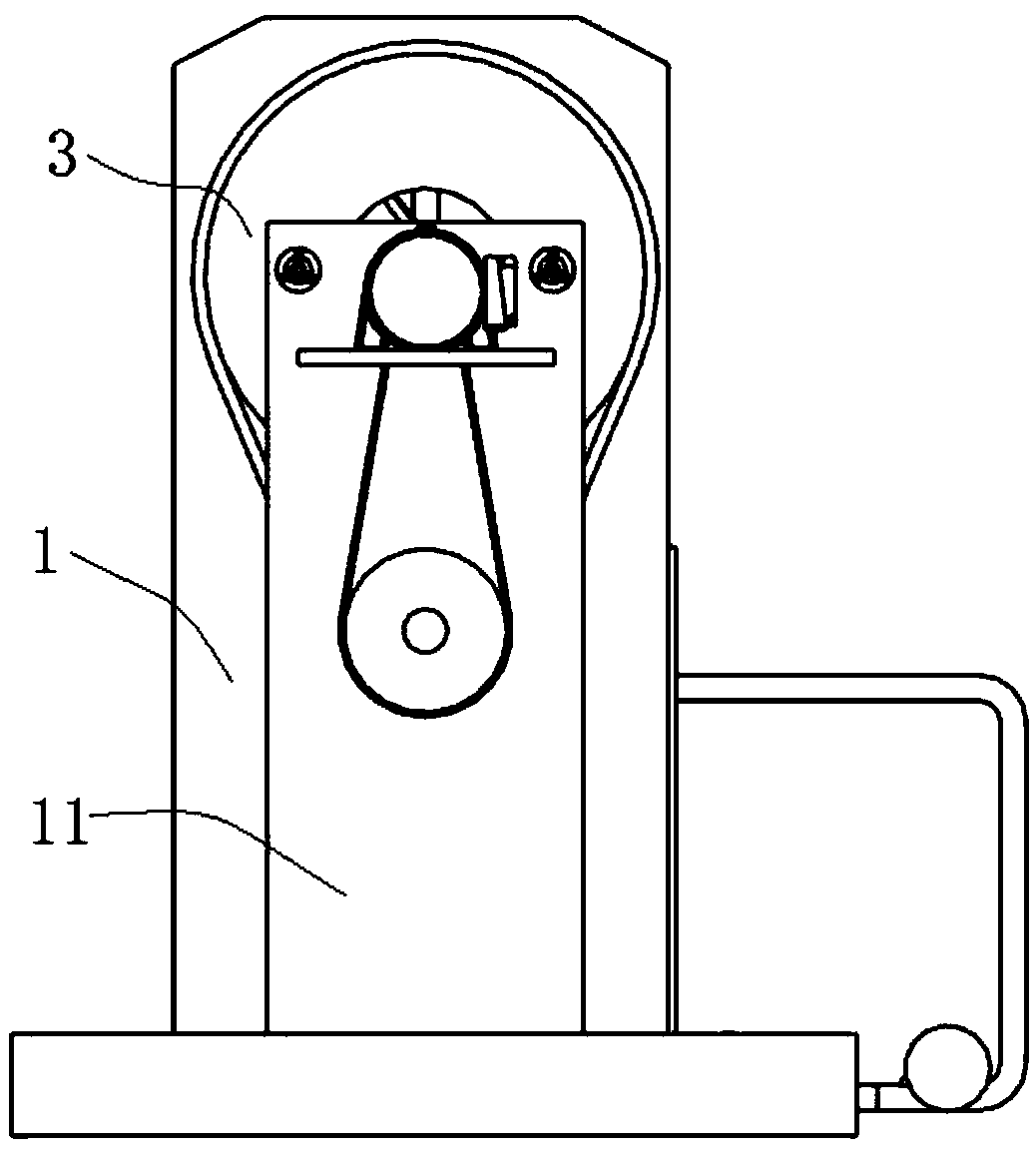

Automatic machine for fabricating localized supporting sheet

InactiveCN1761367AEnsure stabilityConsistent tensionElectrical transducersExecution controlEngineering

Following mechanisms and parts of automatic machine are installed on a main tabletop board: guiding arrangement mechanism, mechanism for cutting strap material and position adjustment mechanism, positioning mechanism, hot pressing mechanism, cold pressing mechanism, cutting press and position adjustment mechanism, mechanism for hauling material. Fetching hand and machine for stacking pieces are installed on adjustment mechanism for cutting position. Executive control component box and electric control component box are installed inside housing. Integrating functions of feeding, hot pressing, cutting, fetching pieces and stacking pieces, the disclosed machine realizes automatic fabrication for localized supporting sheet. The invention prevents parameters of production process from optional adjustment so as to guarantee quality of production and consistency of products.

Owner:浙江天乐集团有限公司

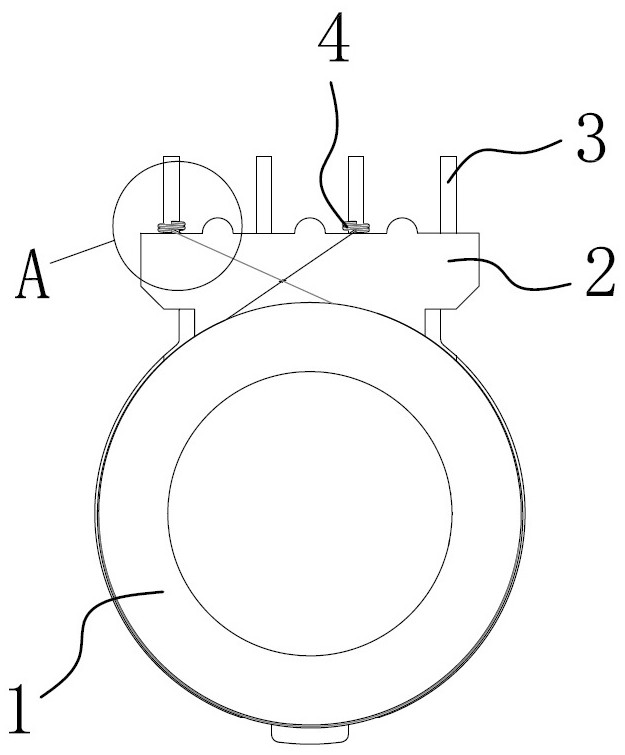

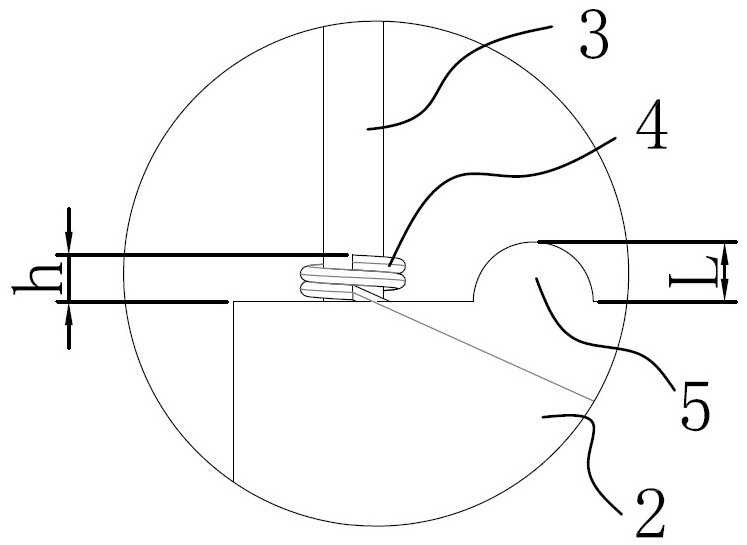

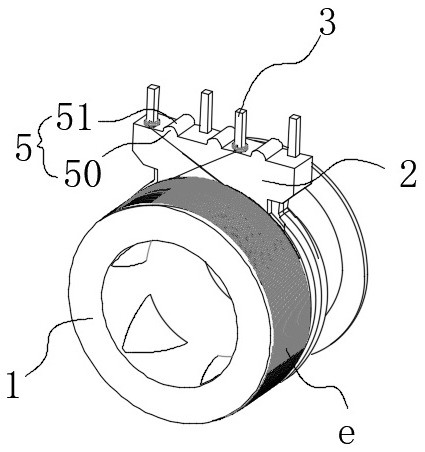

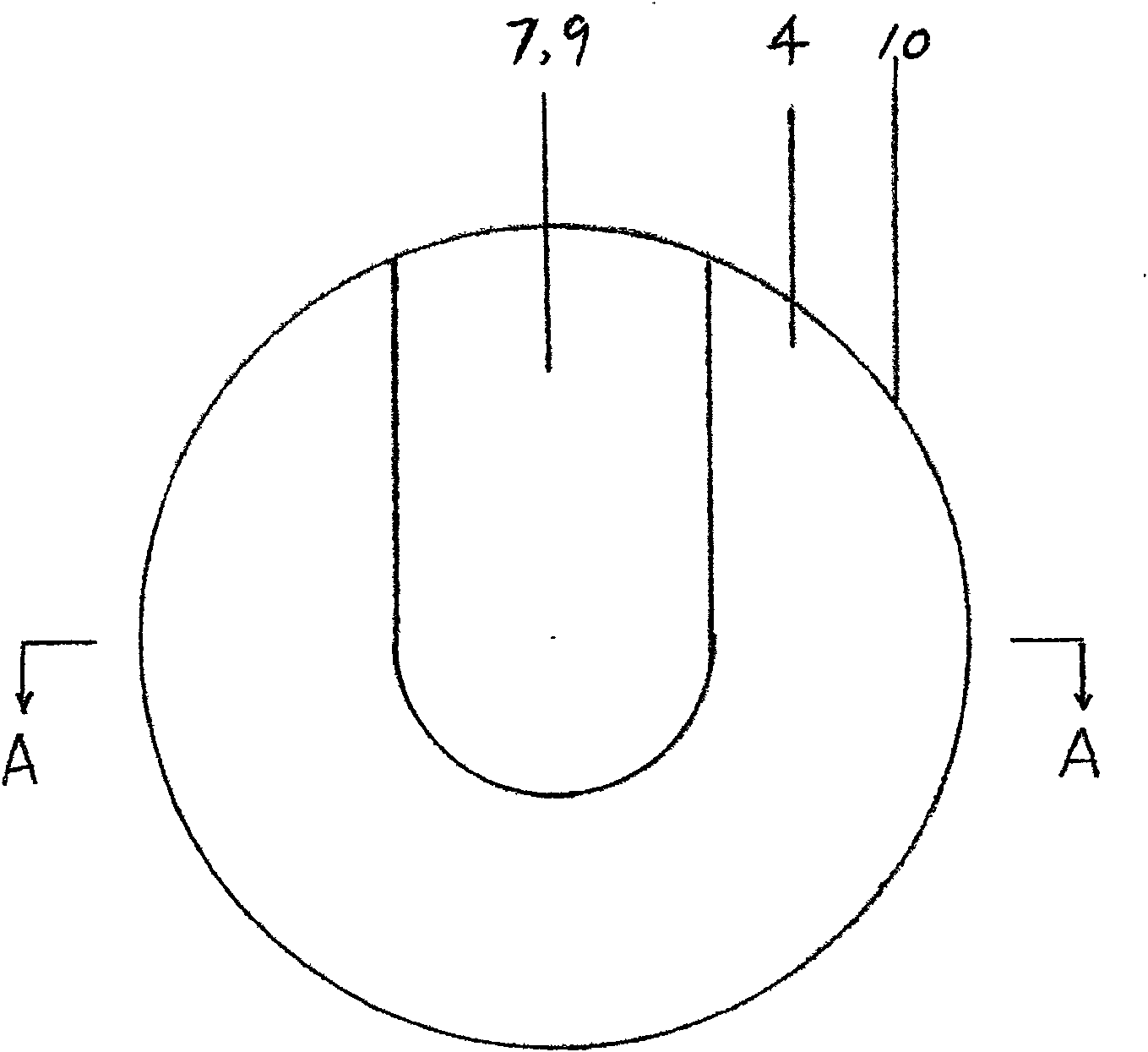

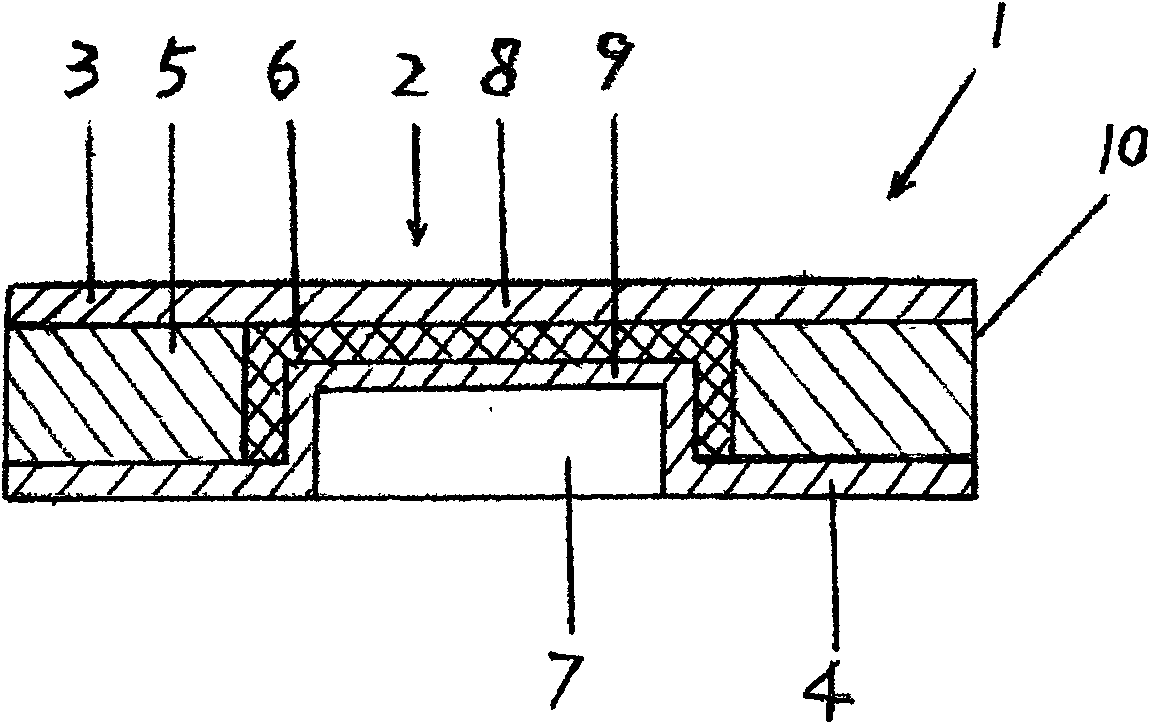

Rotary contact socket and plug

InactiveCN102655289AReduce space occupationIncrease contact surfaceCoupling contact membersTwo-part coupling devicesElectrical and Electronics engineeringElectrode

The invention relates to rotary contact socket and plug. A three-pole jack slide and a two-pole jack slide are arranged on a socket front housing, each jack slide comprises a jack and a narrow slide which are communicated, a horizontal electrode clamping spring is fixed in the front shell, and a rear cover is fixed on the front shell to form a housing. A three-pole cascade insert, a three-pole power lead jacket and a three-pole power lead are fixed on a three-pole plug; and a two-pole cascade insert, a two-pole power lead jacket and a two-pole power lead are fixed on the plug II. According to the rotary contact socket and plug, under the condition of reaching the rated load of the traditional socket and plug, the ultrathin structure is realized; after the pug is inserted into the socket, the plug is locked with the socket, the plug can not be vertically pulled out, no shaking exists between the socket and the plug, so that the socket and the plug can keep better contact for a long time; and the rotary contact socket and plug are safe in use and convenient for operation.

Owner:侯永昌

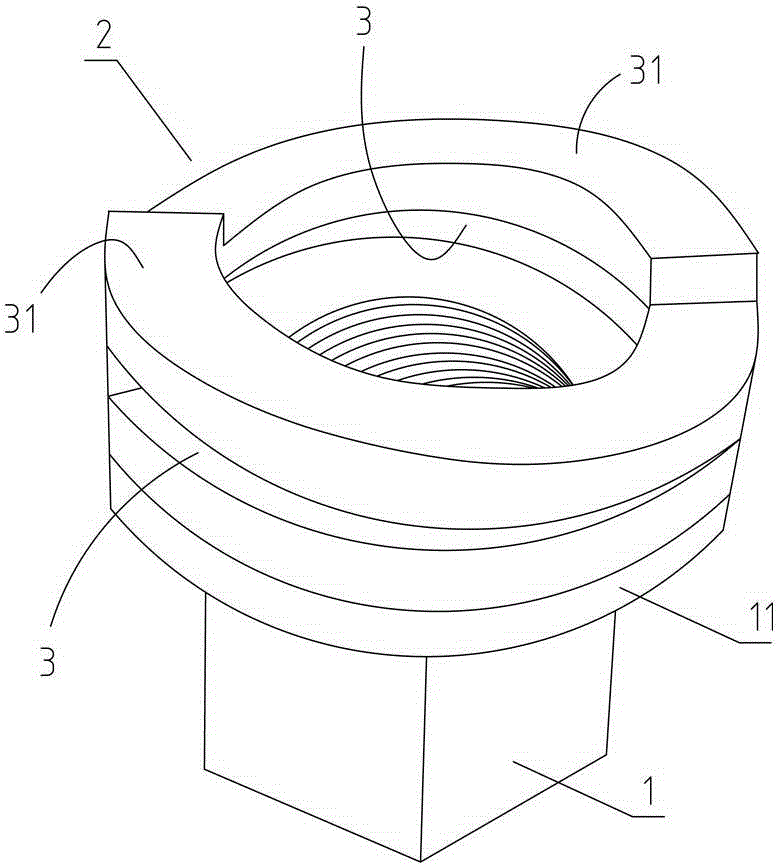

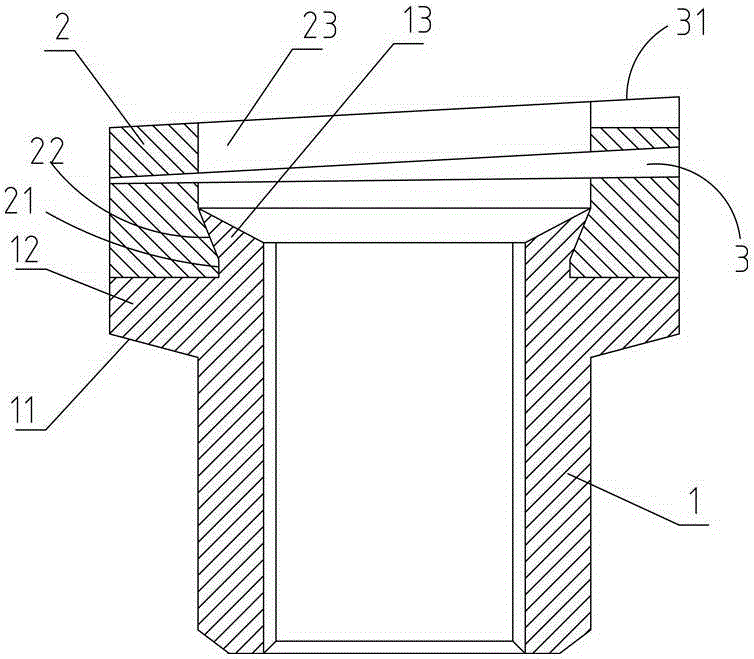

Elastic anti-knock anti-loose nut

The invention discloses an elastic anti-knock anti-loose nut. The elastic anti-knock anti-loose nut comprises a nut body, and connecting threads are machined on the nut body; an elastic gasket is arranged at the end of the nut body, and an elastic press-fit groove which can generate press-fit deformation along with pressing of the upper end of the elastic gasket is formed in the wall of the elastic gasket; through the improvement on the end of the nut body, the aim that a conventional spring gasket prevents looseness in the bolt connection process is achieved, a spring gasket is prevented from being placed at the end of the nut body, the space occupying at the position where the spring gasket is placed is reduced, it is ensured that when a bolt and the nut are connected, the enough effective length is achieved, and the connecting strength between the bolt and the nut is further ensured; and meanwhile, in the connecting process of the bolt, the elastic anti-knock anti-loose effect is achieved, the elastic gasket does not need to be additionally arranged, and the effective length of connection between the bolt and the nut is not shortened.

Owner:QUANZHOU LITAI AUTO PARTS MFG

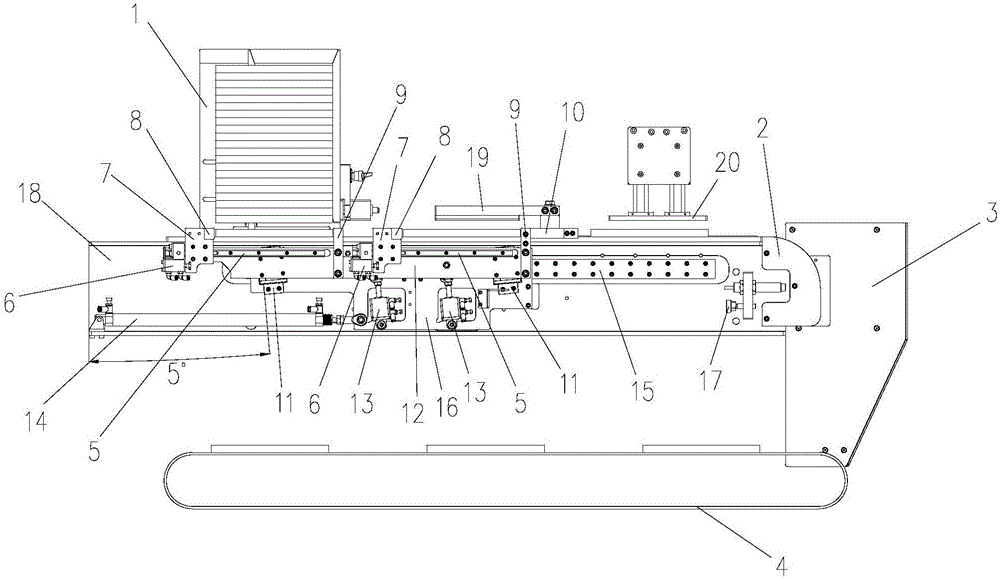

Material clamping type automatic feeding and receiving device

PendingCN106426417ASimple structureReduce space occupationDrilling machinesFeeding devicesMechanical engineeringEngineering

Owner:曾德明

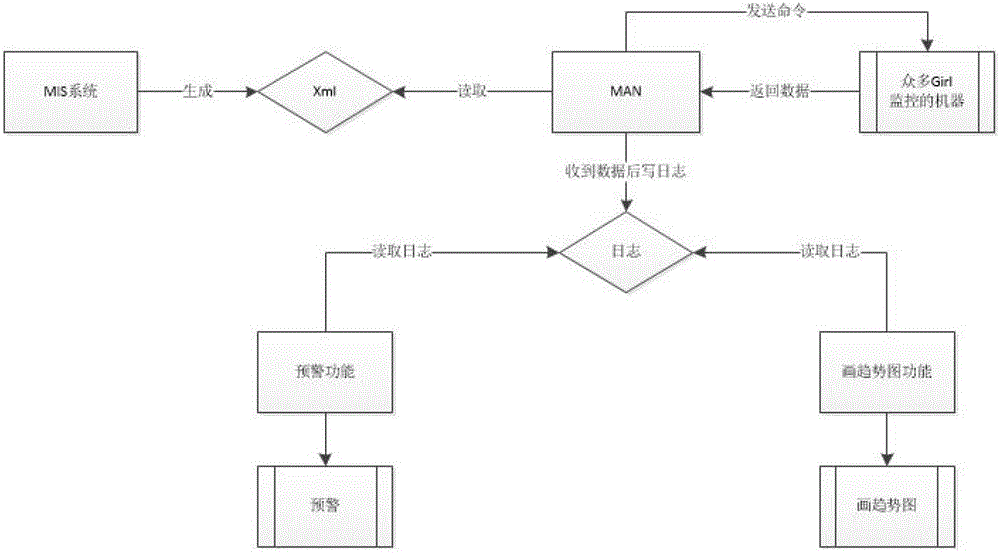

Flexible log storage and acquisition method

ActiveCN102880718ASpeed up readingReduce space occupationHardware monitoringSpecial data processing applicationsFile storage

The invention relates to a flexible log storage and acquisition method, which comprises a data writing process and a data reading process. The method is based on multi-file hash, and under the condition of single file reading-writing entry when a plurality of files are required to be frequently read and written, an index-based file storage and reading mode is provided, so that the files can be conveniently stored in a hash way, and required logs can be easily read.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

Elution and restoration device for heavy metal contaminated soil and restoration and treatment method of heavy metal contaminated soil

ActiveCN109465288ACompact layoutReduce space occupationSievingRotating receptacle mixersSolventContaminated soils

The invention discloses an elution and restoration device for heavy metal contaminated soil. The elution and restoration device comprises a machine frame, a driving device, a crushing device and a soil elution device, wherein the crushing device comprises a crushing rotating cylinder and a crushing mechanism arranged inside the crushing rotating cylinder, the crushing rotating cylinder is transversely arranged and is rotationally arranged on the machine frame, the soil elution device is arranged right below the crushing rotating cylinder, crushed soil particles are transited into the soil elution device through a feeding and discharging port, moreover, an elution solvent is contained in the soil elution device, and the soil elution device is used for eluting and restoring the soil particles. According to the elution and restoration device for the heavy metal contaminated soil and a restoration and treatment method of the heavy metal contaminated soil, the soil particles can be fully crushed, the soil particles can be timely eluted and repaired, and the restoration degree of soil elution restoration can be improved.

Owner:核工业井巷建设集团有限公司

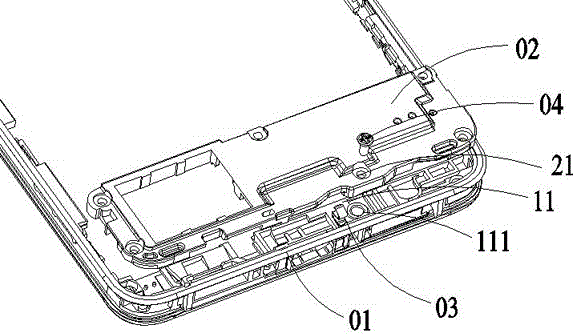

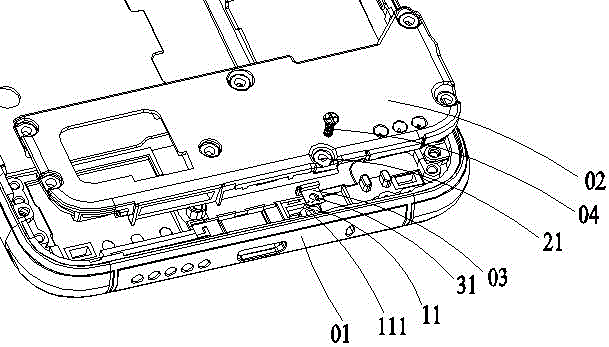

Mobile terminal

ActiveCN105914449AImprove reliabilityReduce space occupationAntenna supports/mountingsInterior spaceEngineering

The invention discloses a mobile terminal which comprises a metal frame for a casing, an antenna support, and an elastic sheet. The elastic sheet is fixedly arranged on the antenna support; the metal frame for the casing is provided with an extending platform. The extending platform is provided with a first through hole. The antenna support is provided with a second through hole. The elastic sheet is provided with a third through hole. A screw nail penetrates the first hole, the second hole and the third hole to make the extending platform, the antenna support and the elastic sheet together firmly wherein the elastic sheet is located between the extending platform and the antenna support. The mobile terminal is provided by the invention to address the problem that in prior art, during the use of an elastic sheet to have an antenna support and a metal frame for a casing fixed through a screw nail, relatively large space is required. And with it, problems relating to an excessively large screen occupying ratio and a narrow frame can be addressed as well.

Owner:青岛海信移动通信技术有限公司

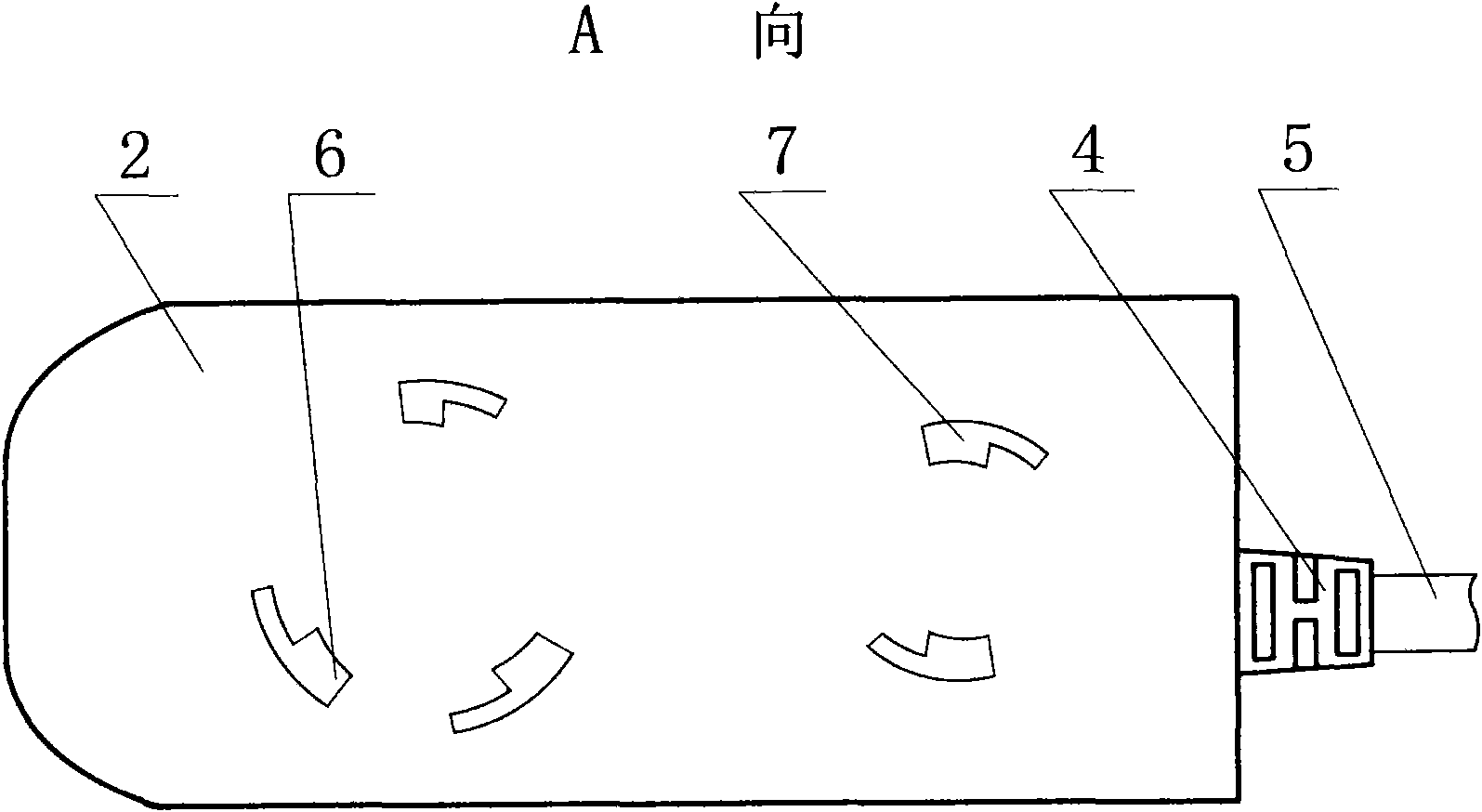

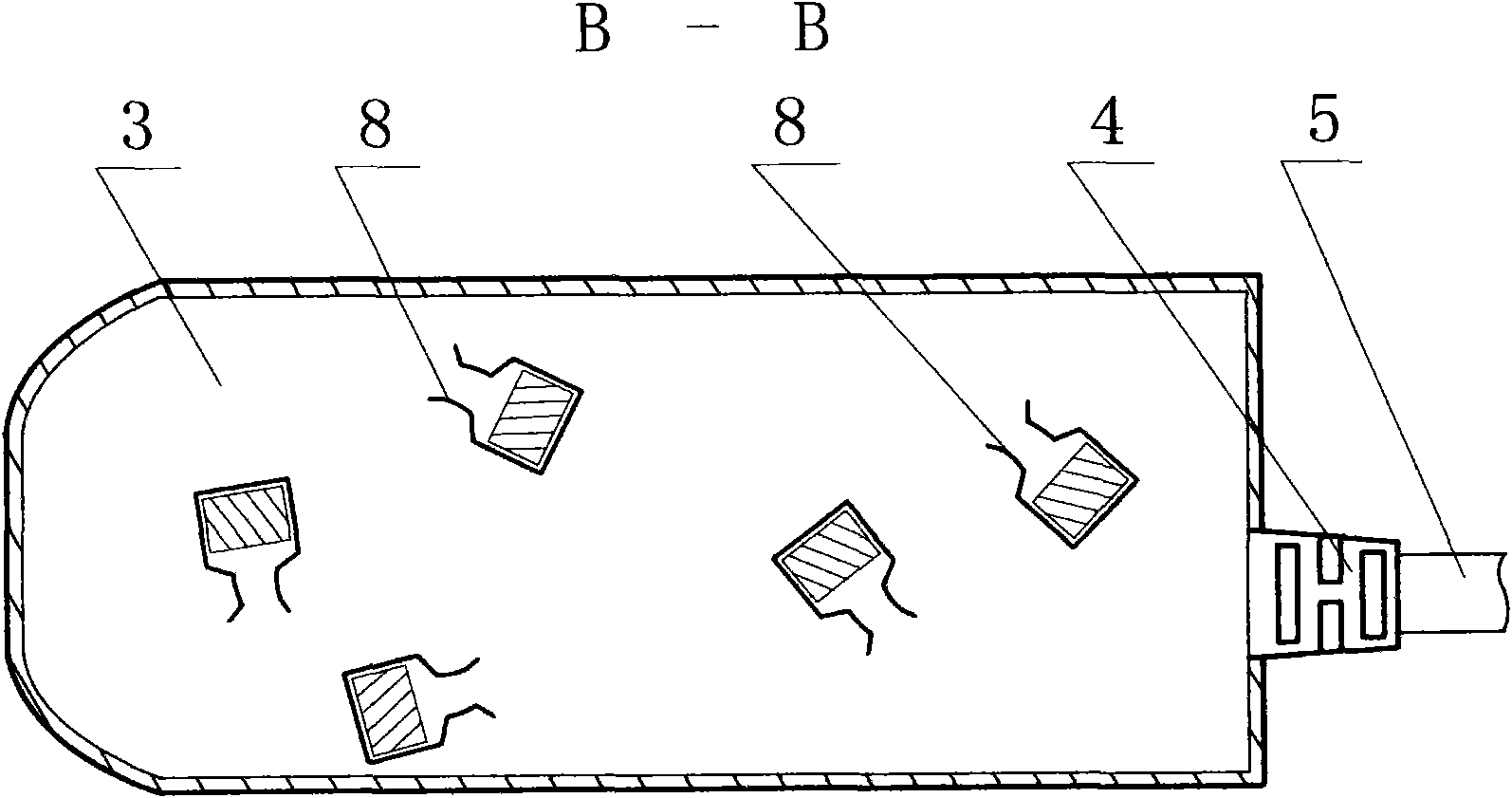

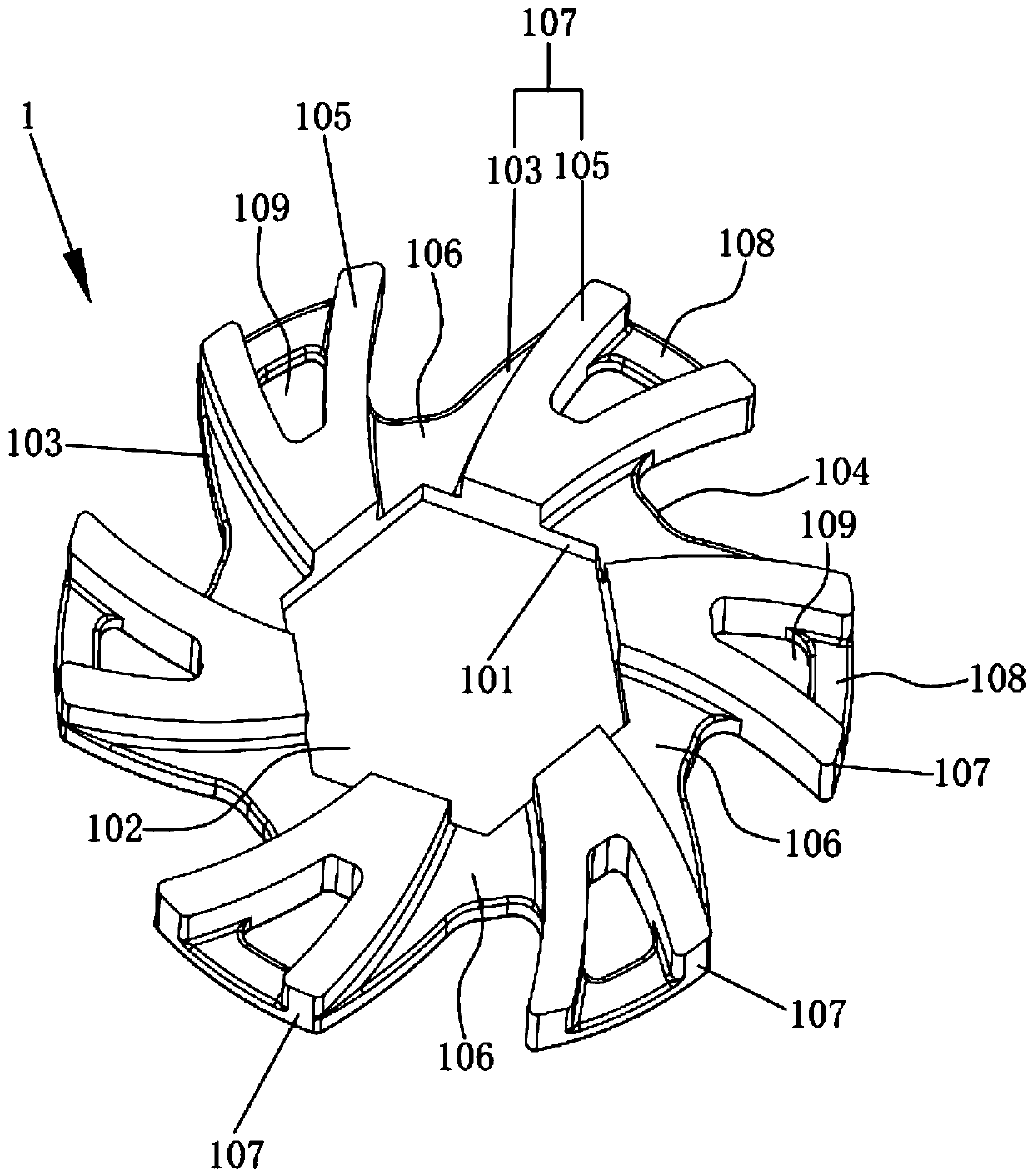

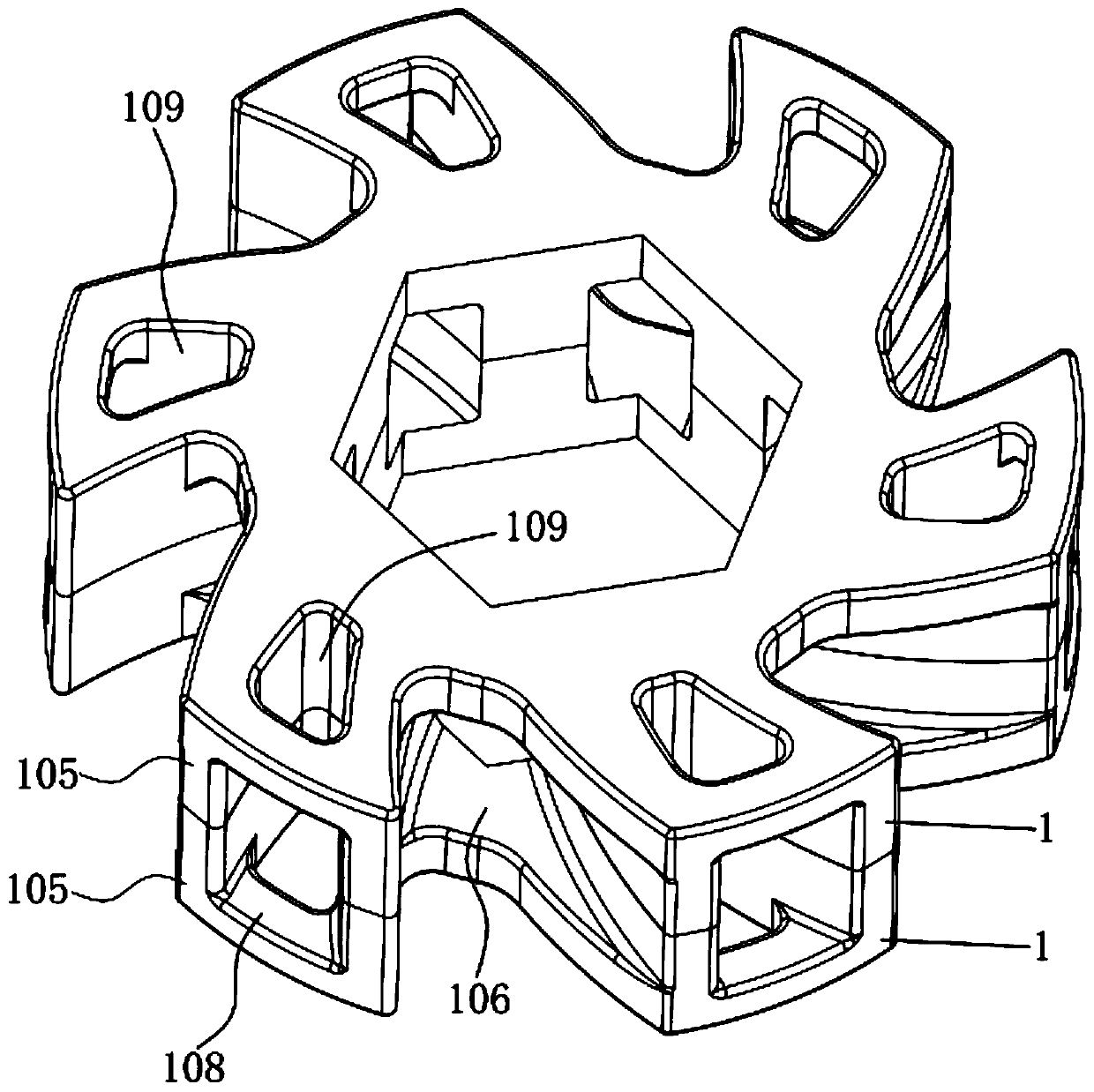

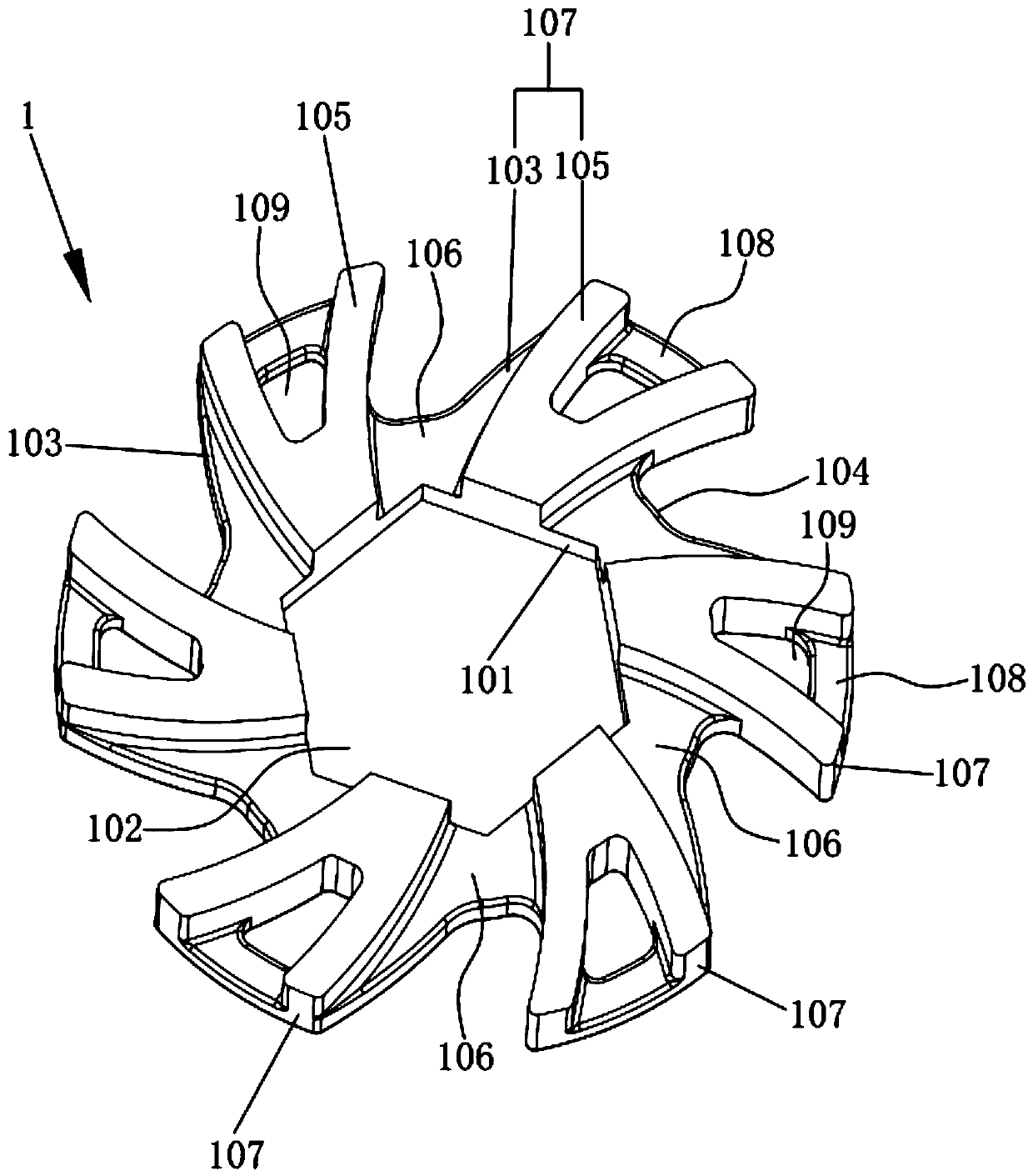

Turbine blade, grinding turbine and grinding device

The invention discloses a turbine blade, a grinding turbine and a grinding device. The turbine blade comprises a turbine body and grinding teeth. A center through hole formed in the axial direction ofthe turbine body is formed in the middle of the turbine body, multiple convex pins being convex outwards are formed in the circumferential direction of the periphery of the turbine body, and an opengroove is formed between every two adjacent convex pins. The multiple grinding teeth are arranged on at least one surface of the turbine body in the circumferential direction of the center through hole. The multiple grinding teeth are formed on the multiple convex pins in one-to-one correspondence. A radial hollowed channel allowing a grinding medium to flow in or out of the center through hole inthe radial direction of the turbine body is formed on one surface of the turbine body by every two adjacent grinding teeth. The radial hollowed channels of the turbine blade have no end faces stopping outflow motion of the grinding media, kinetic energy losses are low in the process that the grinding media flow out, grinding of the grinding media is more sufficient in the radial direction, exchange of the grinding media at different positions is more frequent, and grinding efficiency is greatly improved.

Owner:GUANGZHOU HONGKAI MACHINERY CO LTD

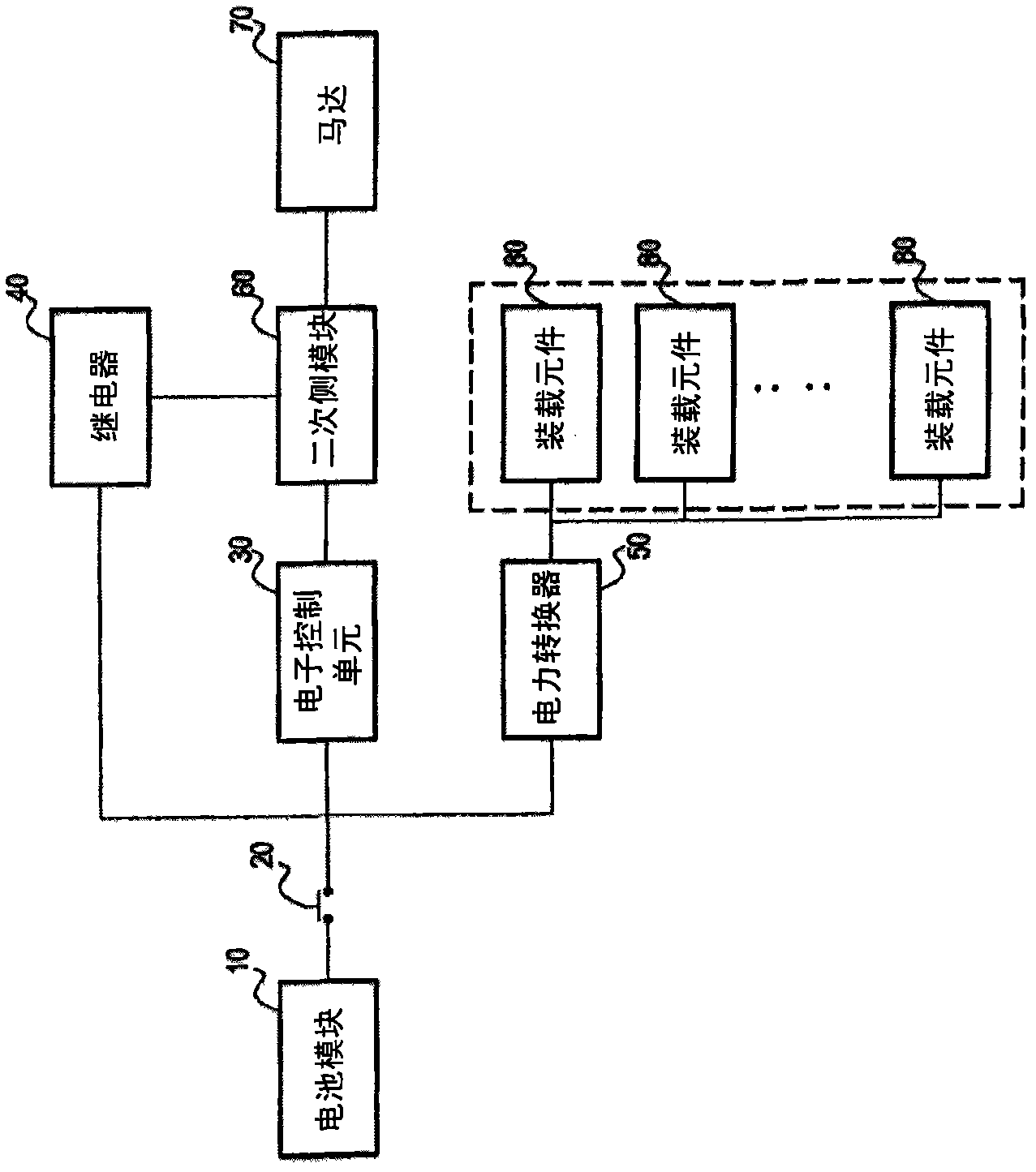

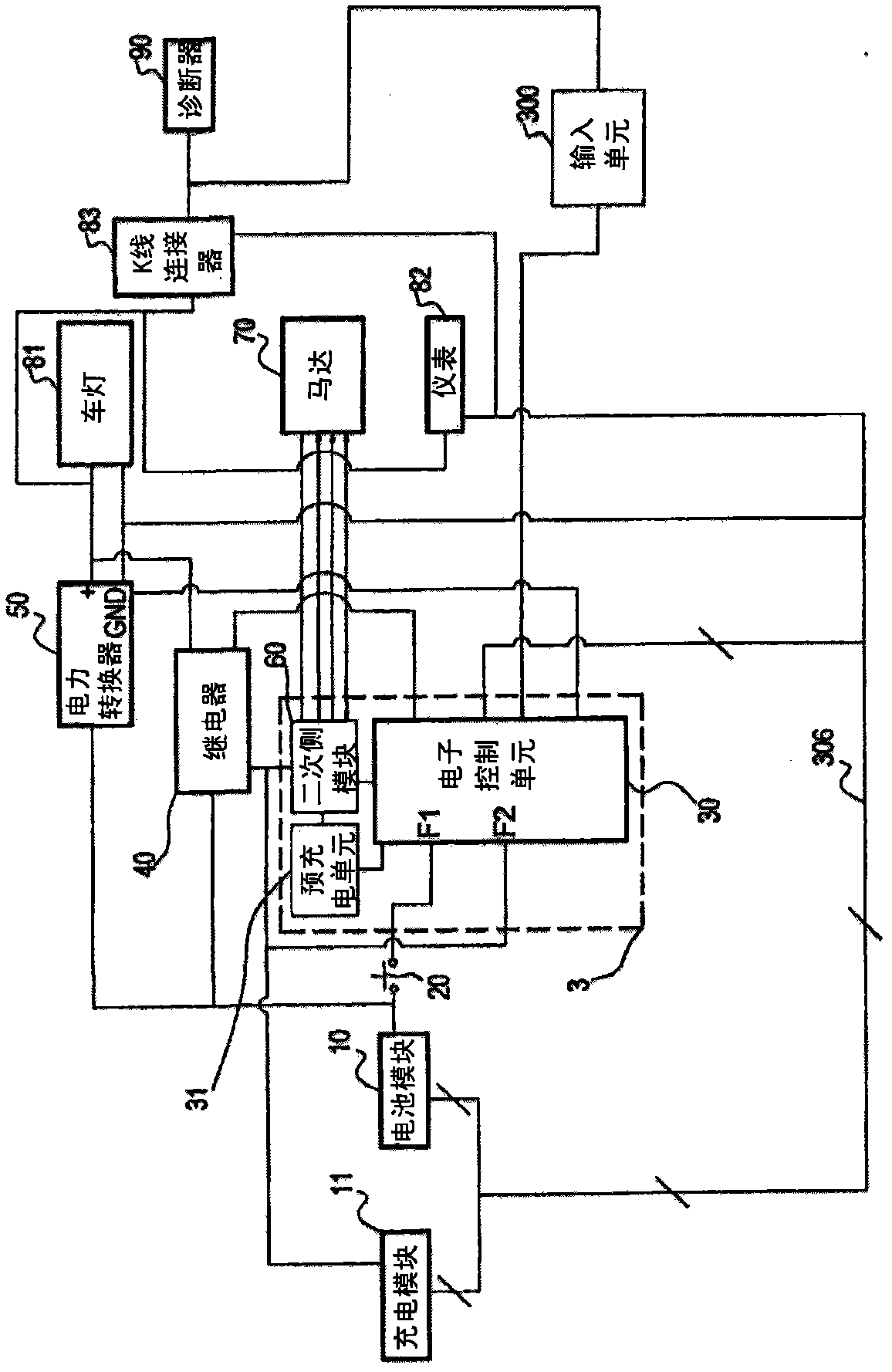

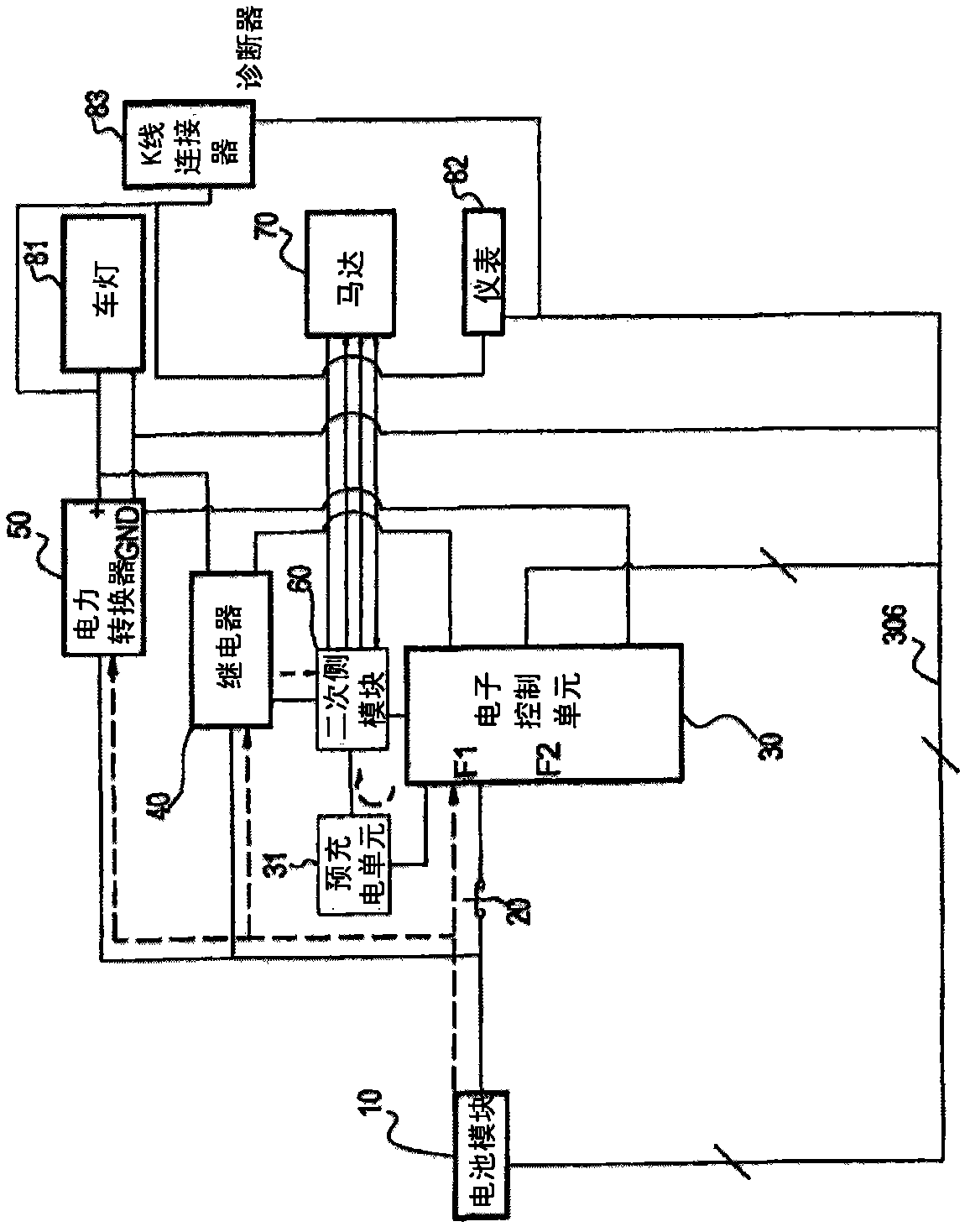

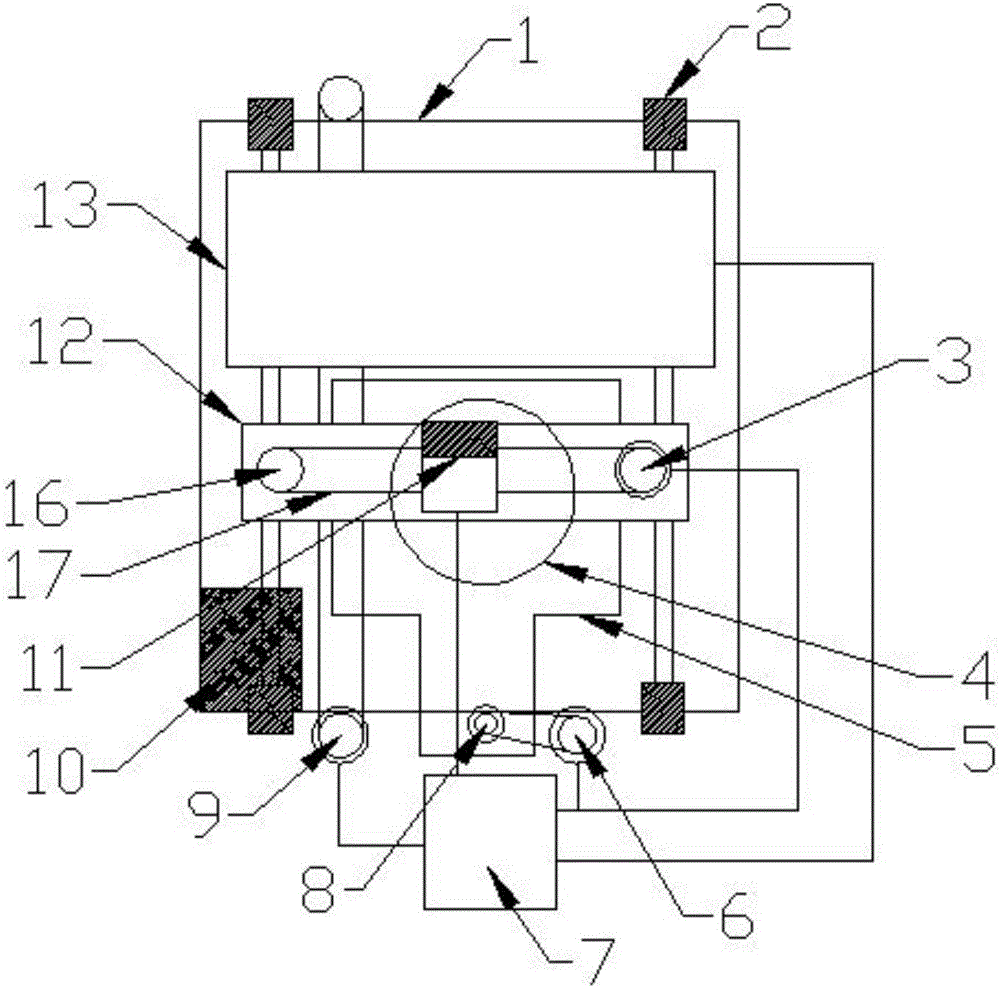

Power control system of electrical vehicle and charging and discharging method of electrical vehicle

ActiveCN103029594AReduce space occupationImprove operational coordinationSpeed controllerVehicular energy storageElectricityElectrical battery

The invention discloses a power control system of an electrical vehicle and a charging and discharging method of the electrical vehicle. The system comprises a motor, a battery module, a power converter, a relay, a secondary side module, an electronic control unit, a pre-charging unit and a key switch module, wherein the electronic control unit is electrically connected with the battery module when the key switch module is conducted, and is used for controlling the pre-charging unit to pre-charge the secondary side module and controlling the driving of the power converter and the relay so as to finish power supplying of the battery module to drive the motor and the discharging control actions of parts relevant with the electrical vehicle. The electronic control unit is electrically connected with a charging module and runs with power, and is used for controlling the actions of the relay when the key switch module is in disconnection and controlling the charging actions of the charging module on the battery module.

Owner:KYMCO +1

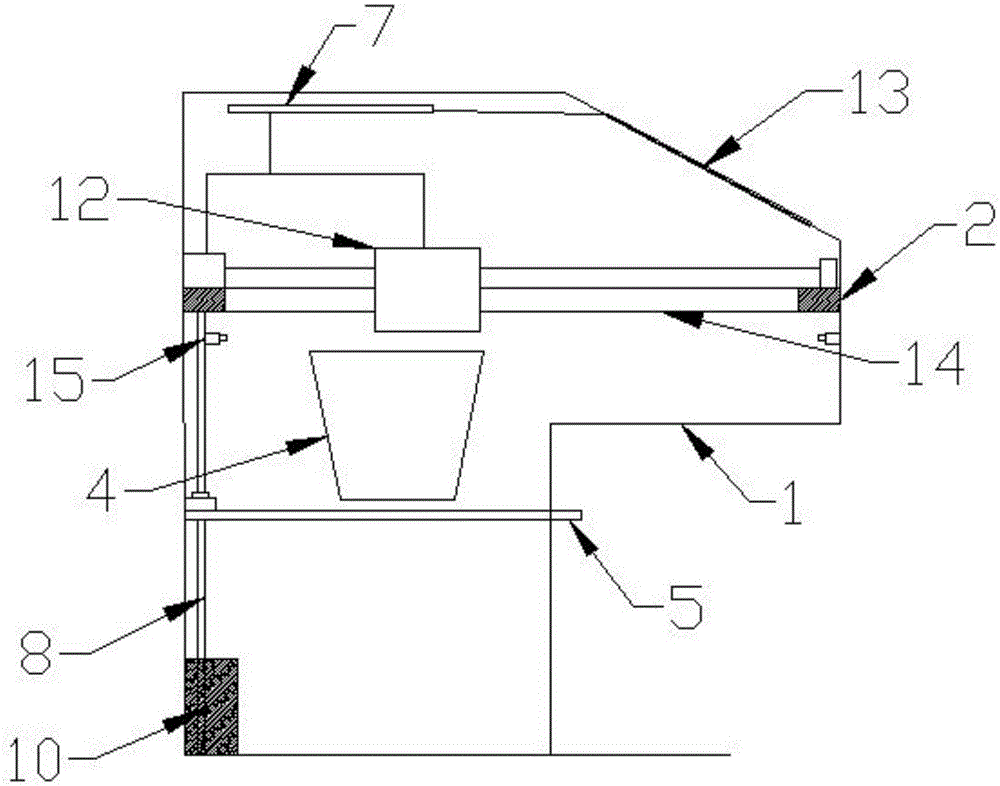

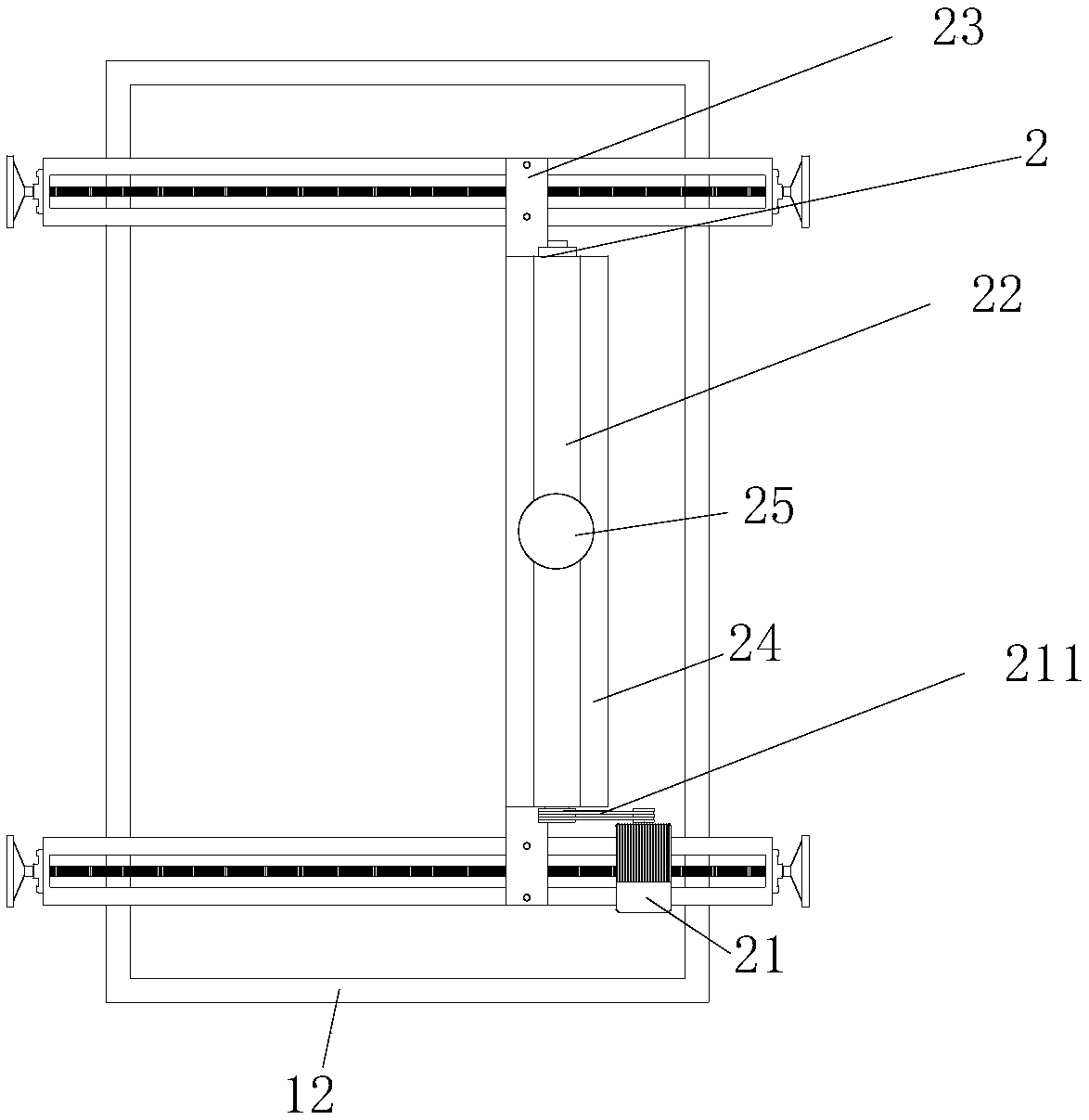

Coffee latte intelligent printer

PendingCN106419558AImprove clarityReduce space occupationTypewritersBeverage vesselsNetwork levelLimit switch

The invention discloses a coffee latte intelligent printer. The printer comprises an outer frame, fixing feet, an X-direction motor, a coffee cup, a pallet, a Z-direction motor, a control circuit board, a screw rod, a Y-direction motor, a power adapter, a nozzle, a nozzle trolley, a touch screen, a slide rod, an infrared limit switch, a follower pulley and a conveyor belt. The design applies the Y-direction level displacement of the nozzle trolley to replace the level displacement of the printed object to keep the printed object static during the printing process and upgrade the lucidity of the printed image. Compared with other latter machine the printer integrates an ARM chip and supports embedded system which transforms the latter machine into an independent all-in-one machine. Printing can be directly conducted without computer connection, and thus the space occupied by the application is reduced. Furthermore WIFI or the optional RJ45 port is adopted for online connection, on which basis a whole set of online DIY system for cellphones is developed to substantially upgrade the intelligent level and network level of the latte machine. Through the integration of software and hardware the latte printer provides abundant and astonishingly gorgeous user experiences to consumers.

Owner:福州市智派软件有限公司

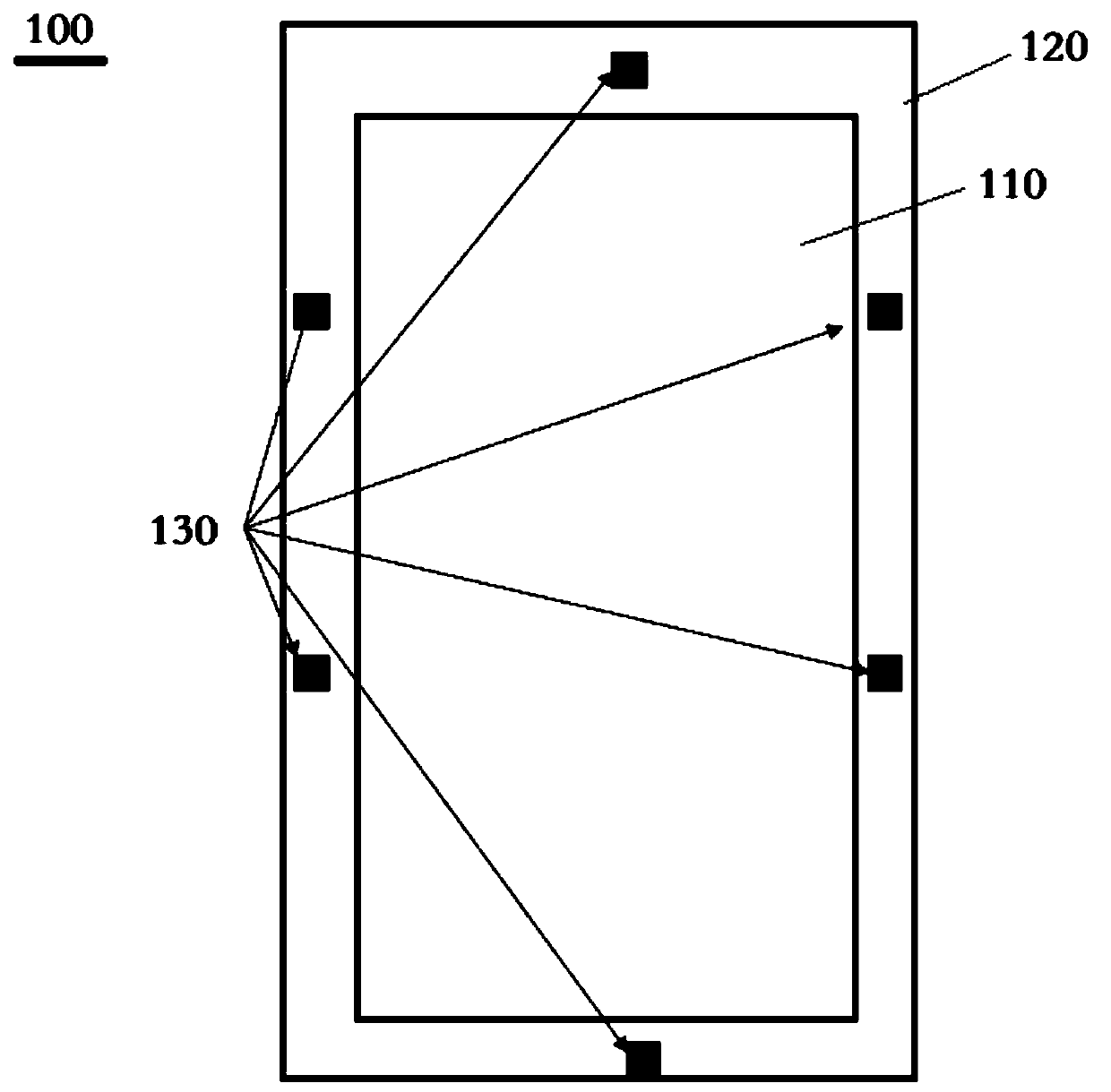

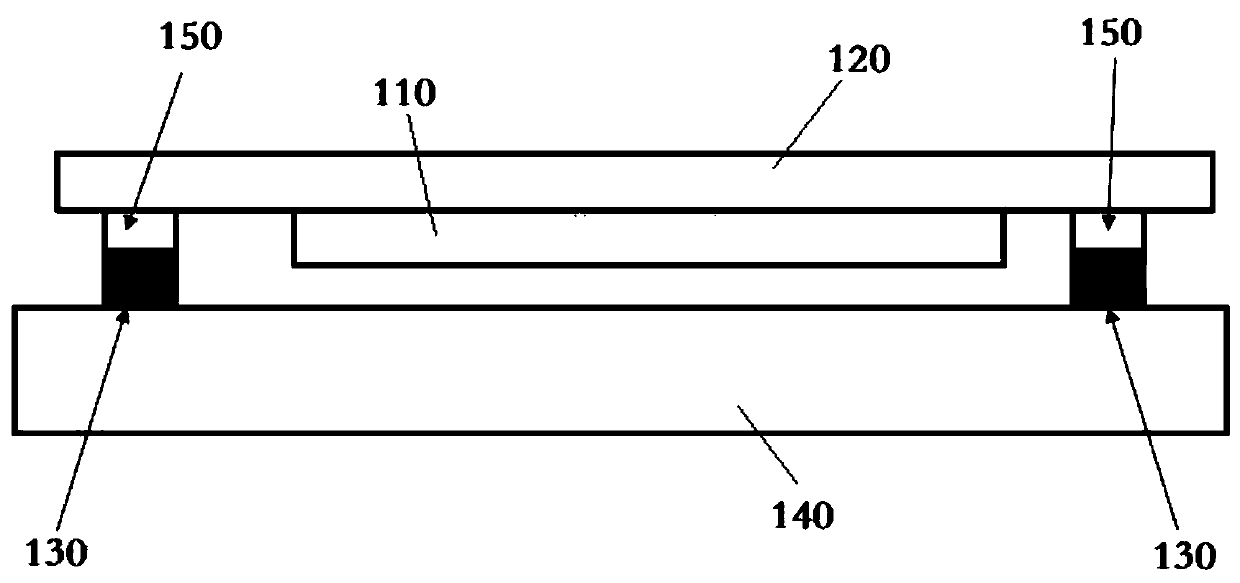

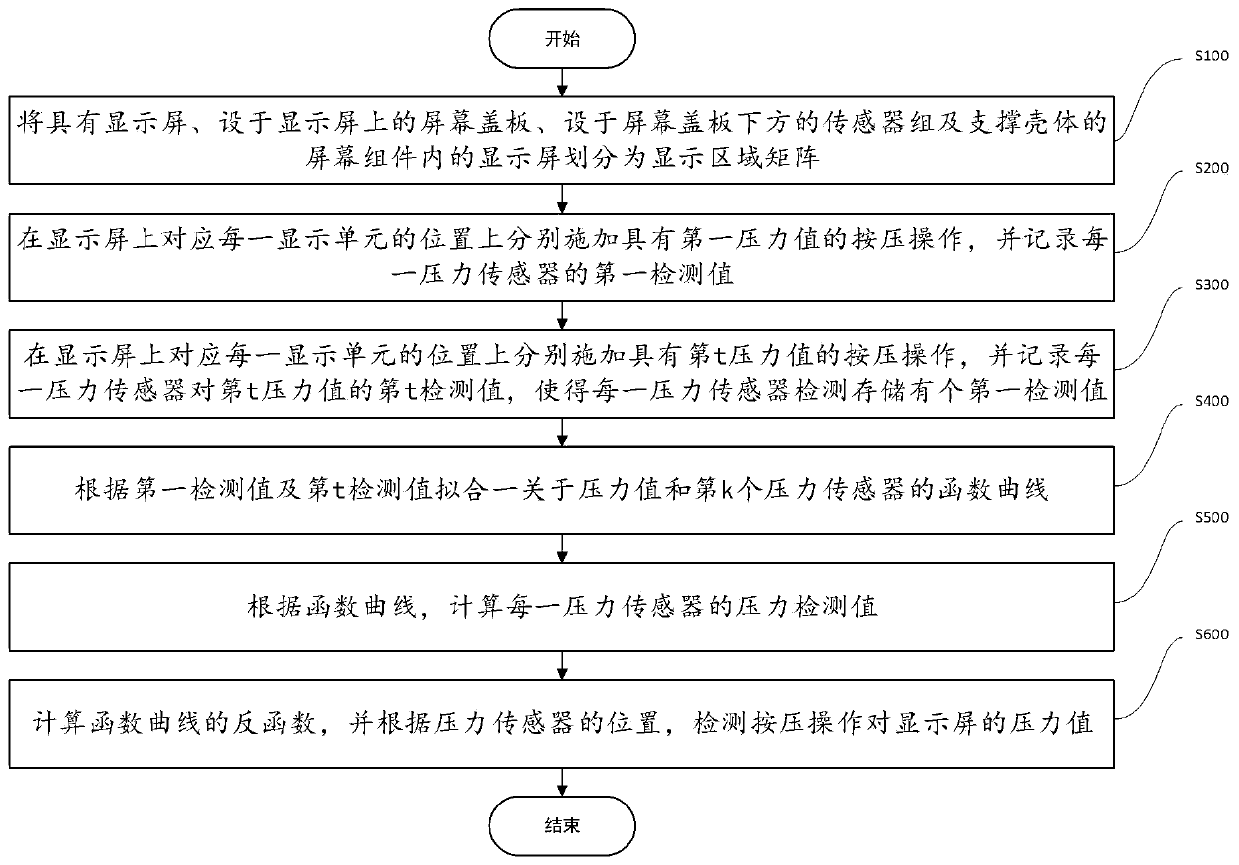

Screen component of intelligent terminal, intelligent terminal, screen pressure sensing detection method and computer readable storage medium

PendingCN110908542AReduce space occupationAccurate results of pressure sensingInput/output processes for data processingComputer hardwareEmbedded system

The invention provides a screen component of an intelligent terminal, an intelligent terminal, a screen pressure sensing detection method and a computer readable storage medium. The screen component comprises a display screen, a screen cover plate, a sensor set and a supporting shell, wherein the sensor set comprises at least four pressure sensors which are arranged below the four side edges of the screen cover plate respectively, and at least one pressure sensor is arranged below each side edge; one end face of each pressure sensor is connected with the screen cover plate, and the other end face of each pressure sensor is connected with the supporting shell, and when the screen cover plate receives a pressing operation, the pressure sensors detect the pressure of the pressing operation; one end face of the display screen is attached to the lower portion of the screen cover plate; a gap is formed between the other end face of the display screen and the supporting shell; and when pressing operation is implemented, the display screen is isolated from the supporting shell. After the technical scheme is adopted, a pressure sensor does not need to be arranged below the display screen, so that a pressure sensing blind area is avoided, and full-screen pressure sensing is realized.

Owner:深圳市灰鲨科技有限公司

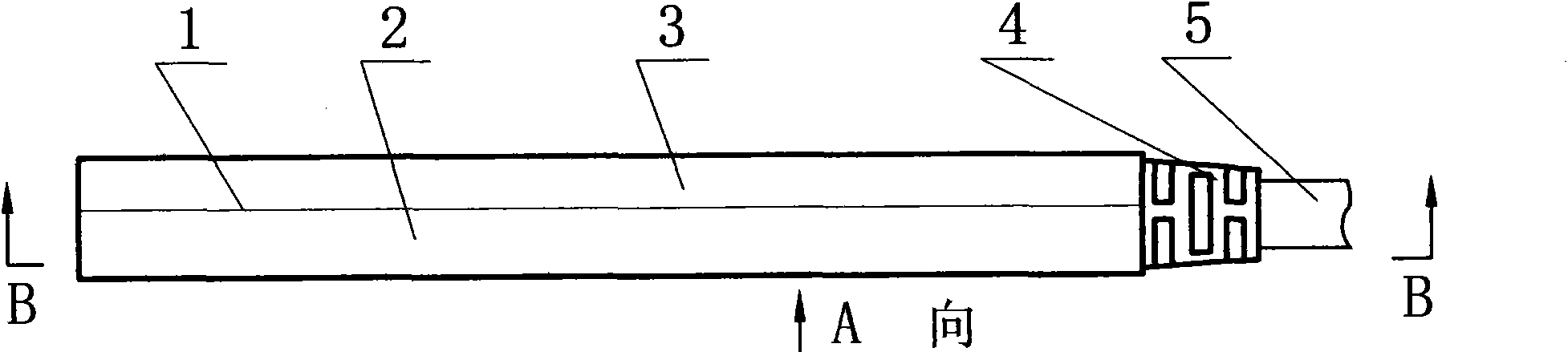

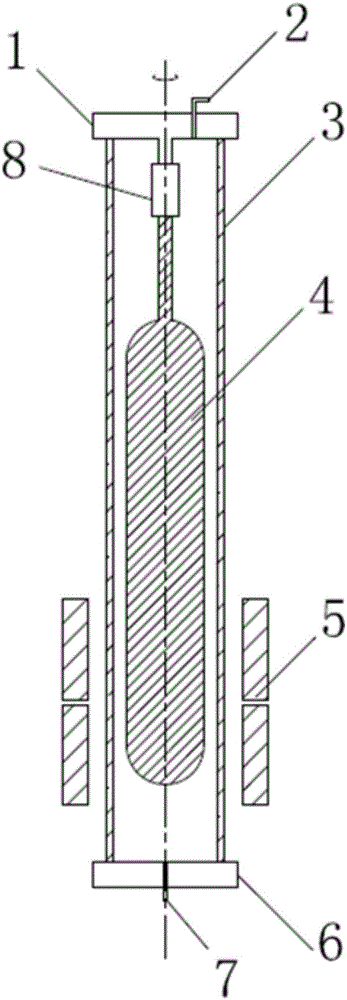

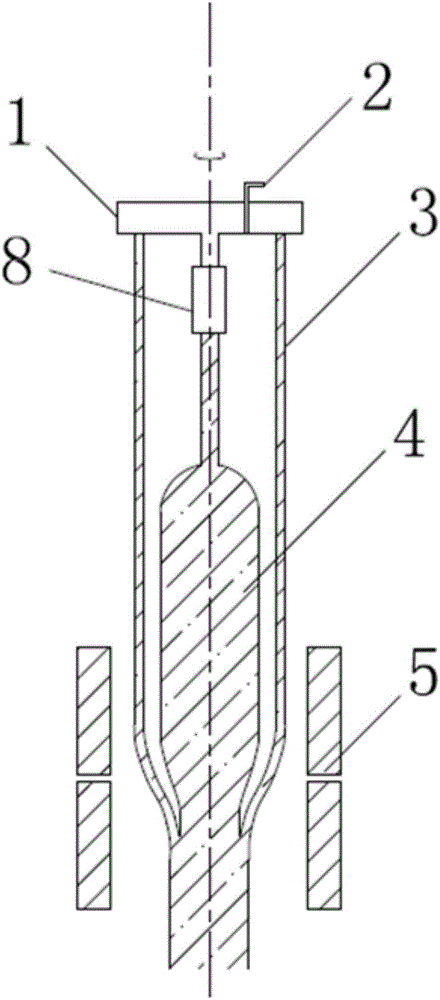

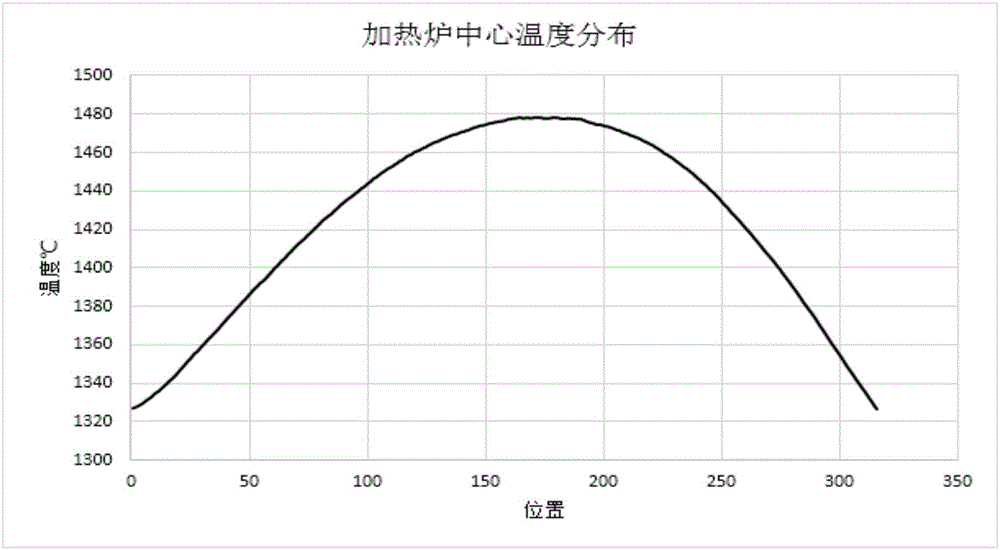

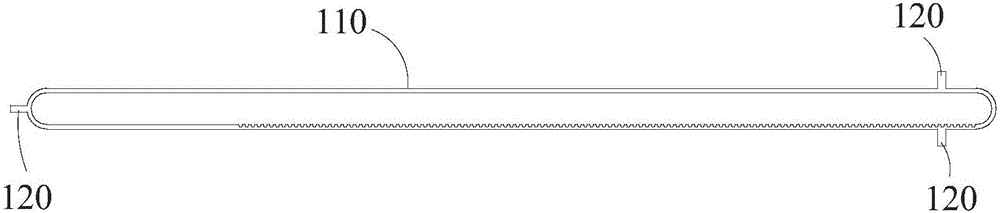

Optical fiber perform rod casing tube sintering device, and sintering method thereof

InactiveCN106396361AQuality improvementAvoid damageGlass making apparatusGlass productionVacuum pumpingHeating furnace

The invention discloses an optical fiber perform rod casing tube sintering device. The optical fiber perform rod casing tube sintering device comprises a casing tube, an upper fixing device, a lower fixing device, and a heating furnace; the casing tube is vertically arranged in the heating furnace via the upper fixing device and the lower fixing device; an optical fiber perform rod loose body is arranged in the casing tube, and is connected with the upper fixing device; an air exhausting mechanism is arranged on the upper fixing device; the air exhausting mechanism is connected with an exhaust system and a vacuum pump via a valve switch; and an air intake mechanism is arranged on the lower fixing device. The invention also provides a sintering method. According to the sintering method, casing tube vacuum pumping is adopted for sintering of the optical fiber perform rod loose body, so that application of a furnace core tube which is expensive and is easy to be damaged is avoided, and loose bodies with large sizes can be prepared; at the same time, vacuum environment is beneficial for improving perform rod quality, accelerating sintering speed, and increasing production efficiency; and in addition, furnace core tube-free sintering method is adopted, so that production cost is reduced, equipment complex degree is reduced, and equipment space occupied degree is reduced.

Owner:HENGTONG OPTICAL MATERIAL CO LTD +1

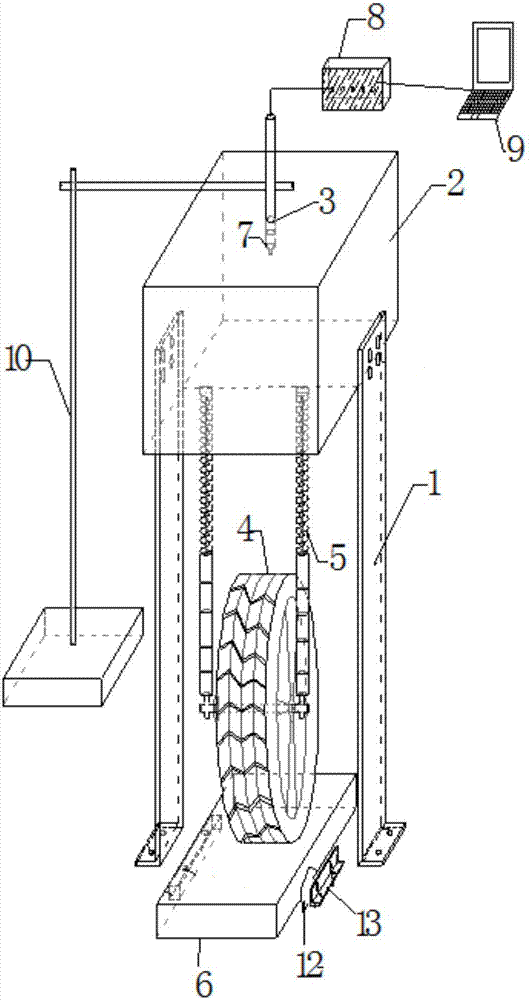

Vehicle-inside noise indoor testing device and testing method thereof

InactiveCN107290046AQuick changeImprove measurement efficiencySubsonic/sonic/ultrasonic wave measurementEngineeringRoad surface

The present invention discloses a vehicle-inside noise indoor testing device and a testing method thereof. Through the arrangement of a closed testing cavity and through the use of a spring support to connect a testing tire, the device provides a way to separately study the noise in the vehicle caused by the road surface excitation, and is absent from the interference with the testing results from engine vibration, ambient noise and other external disturbances; and then, the testing tire is raised to a certain height and released to achieve impact of the road surface on the vehicle wheel and the excitation under the condition of vehicle driving. This reduces the length and workload required for the paving of an indoor road surface testing piece. The manner featuring the arrangement of the closed testing cavity and the collection of the vehicle-inside noise meets the transmission mode of the vehicle-inside noise caused by the road surface excitation. According to the invention, based on the research on the relationships of the vehicle-inside noise and the road surface paving structure and the surface texture characteristics, the main factors including the vehicle-inside noise can be determined. The device of the invention can be manufactured at a low cost, occupies small space and does not have to be paved with corresponding road surface. In addition, the testing is convenient and the result reappearance is also good.

Owner:CHANGAN UNIV

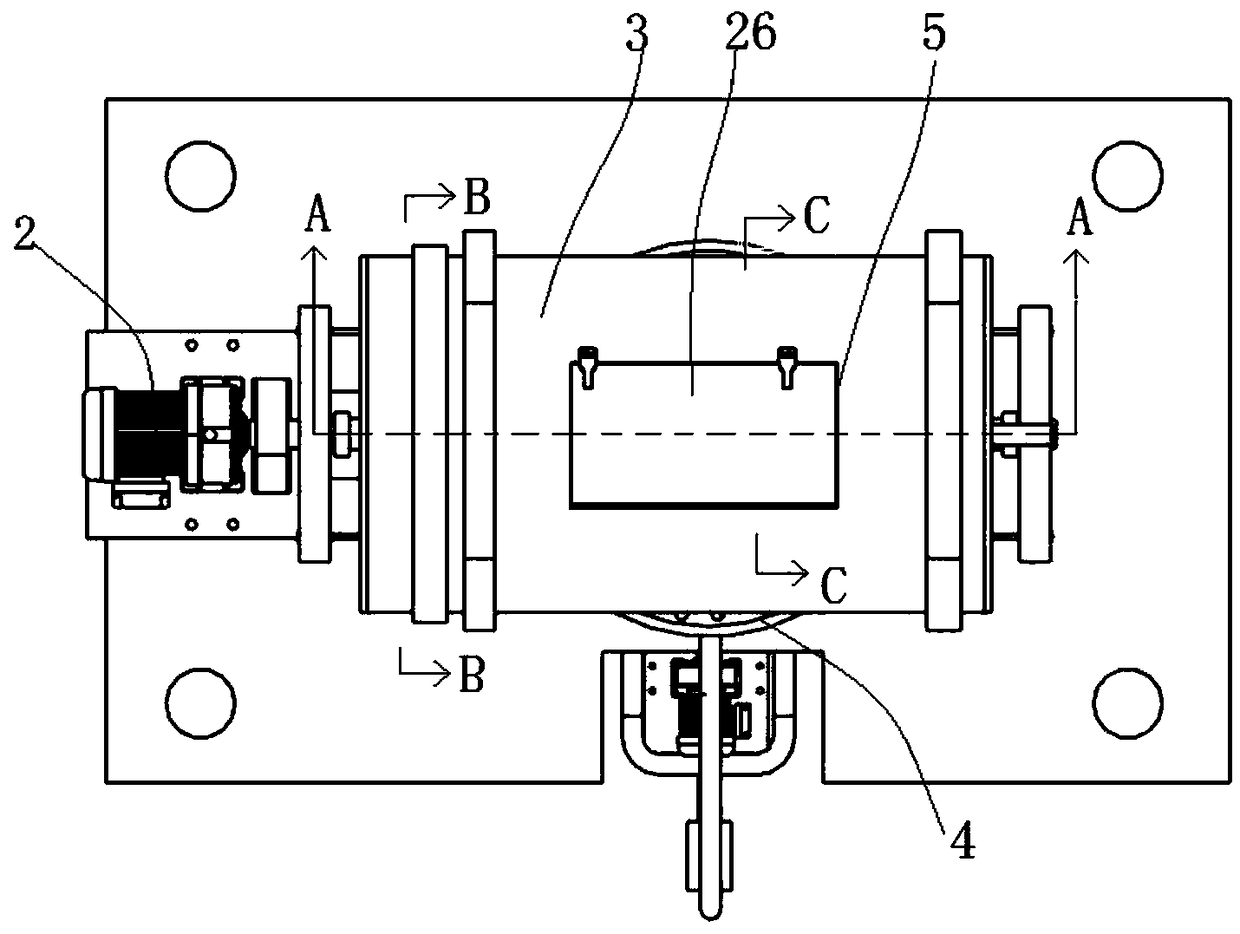

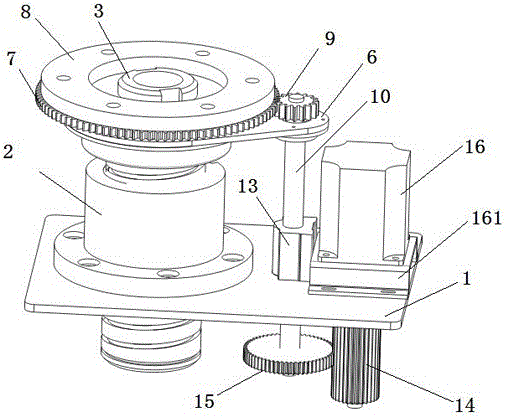

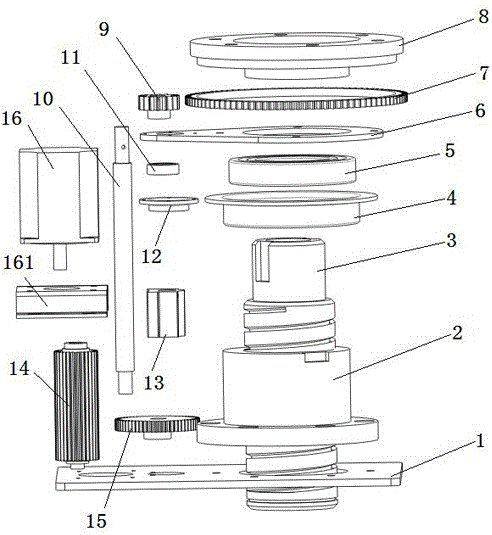

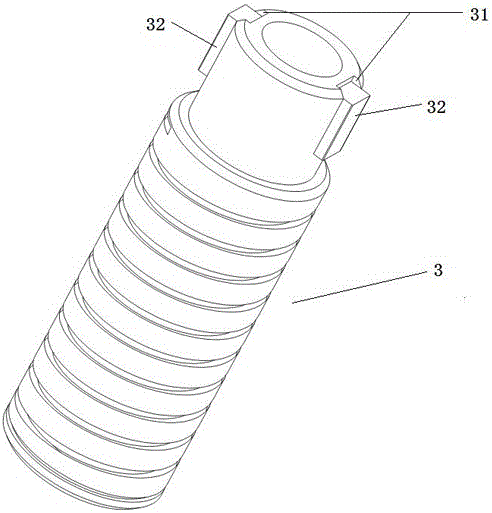

A rotary jacking mechanism and an agv trolley including the rotary jacking mechanism

ActiveCN104192762BGood self-lockingReduce space occupationLifting framesVehiclesDrive wheelElectric machinery

A rotary jacking mechanism and an AGV trolley including the rotary jacking mechanism belong to the field of automatic conveying devices. The rotary jacking mechanism of the present invention includes a base fixing plate, a rotating motor, a transmission assembly, a lead screw, a lead screw nut, a large bearing bracket, a large bearing and a hollow tray; The rod is supported on the base fixing plate; the large bearing bracket, the large bearing and the tray are sequentially installed on the lead screw from bottom to top; the rotating motor is connected with the transmission component, and the transmission component is connected with the tray and the lead screw. The AGV trolley including the rotating jacking mechanism of the present invention includes two driving wheels, four universal wheels, a battery pack, two driving motors, a driving motor driver, a body frame, two control boards, a tray bracket, and two right-angle drives. Motor gearbox, navigation unit and two infrared sensors. The invention has the advantages of flexible and compact structure, large load capacity, strong self-locking performance, stable rotation and rising operation of the lead screw, and can meet the requirements of flexible handling.

Owner:湖州上电科电器科学研究有限公司 +3

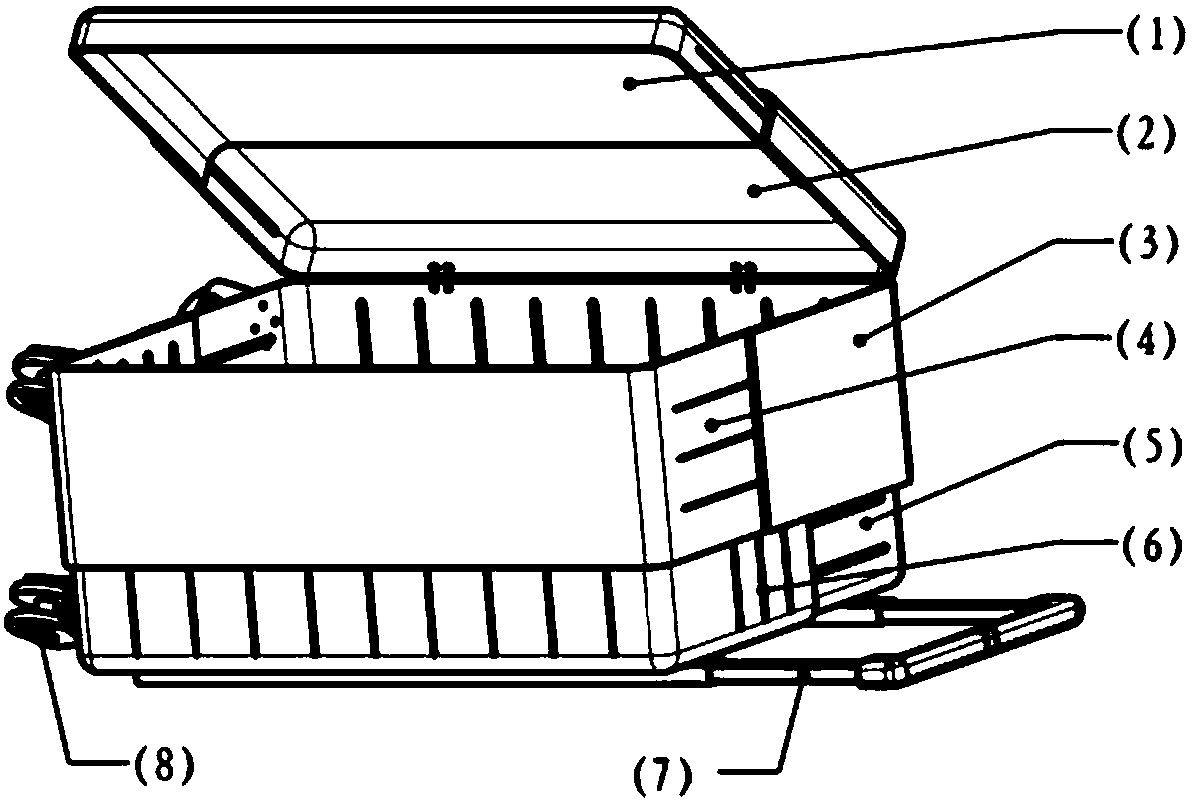

Adjustable-capacity easily-disassembled suitcase

PendingCN109793328ASimple structureReduce space occupationLuggageOther accessoriesEngineeringLeft wall

The invention belongs to the field of design of luggage products and particularly relates to an adjustable-capacity easily-disassembled suitcase, comprising a cover, a sidewall and a bottom. The coverincludes a left cover and a right cover; the sidewall includes a left wall and a right wall; the bottom includes a left bottom and a right bottom; left and right parts are connected through fitting of tongues and slide grooves; the sidewall and the bottom are also vertically positionally adjusted through tongues and slide grooves. The adjustable-capacity easily-disassembled suitcase is simple instructure and handy, has adjustable size, and can be adjusted in width and height directions by a user according to application needs and trip conditions; conveniences can be provided for a trip, space can be as less as possible, and conveniences are brought to otherness. In addition, the adjustable-capacity easily-disassembled suitcase can be disassembled and stored when idle, so that storage space is maximally decreased.

Owner:SOUTHWESTERN INST OF PHYSICS +1

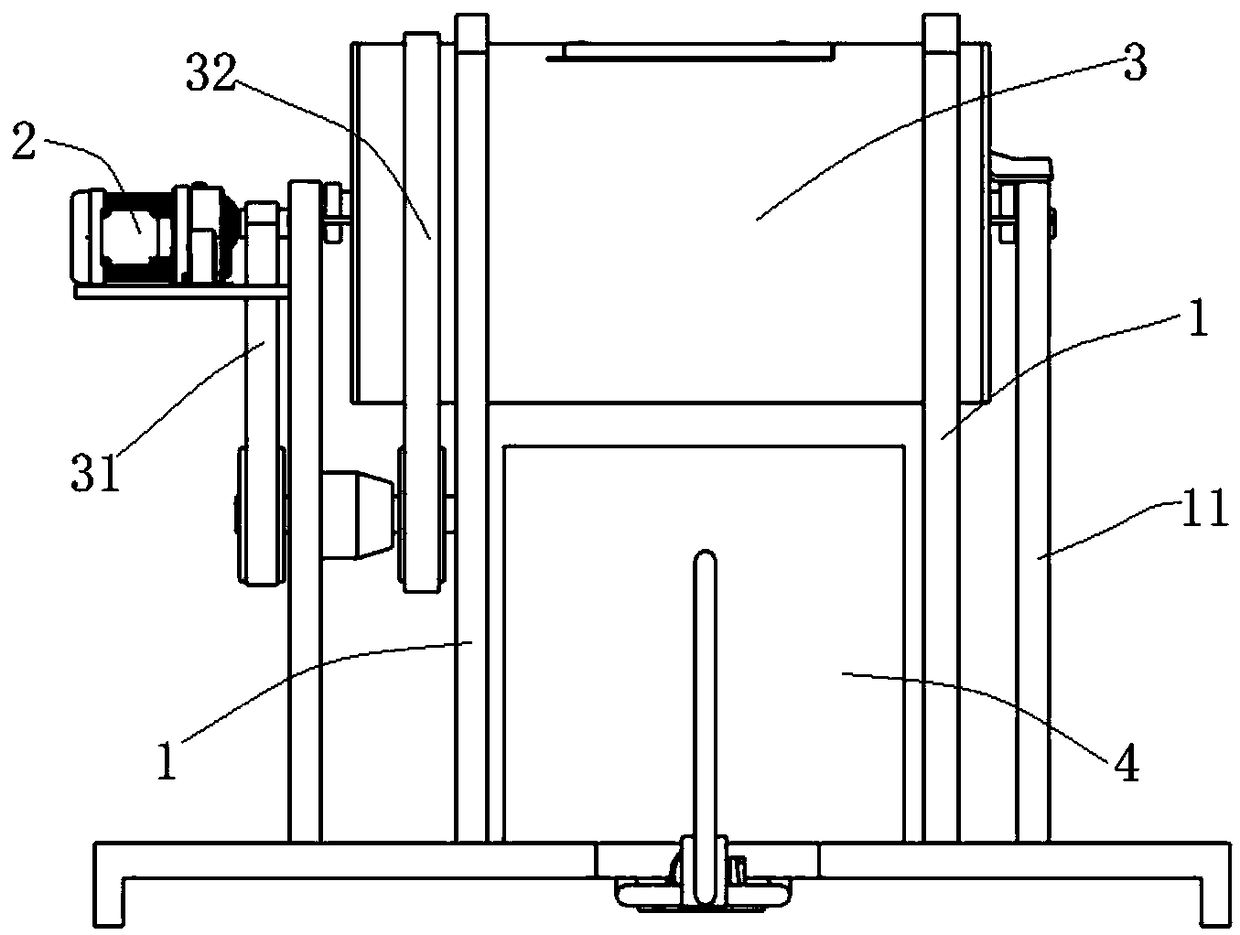

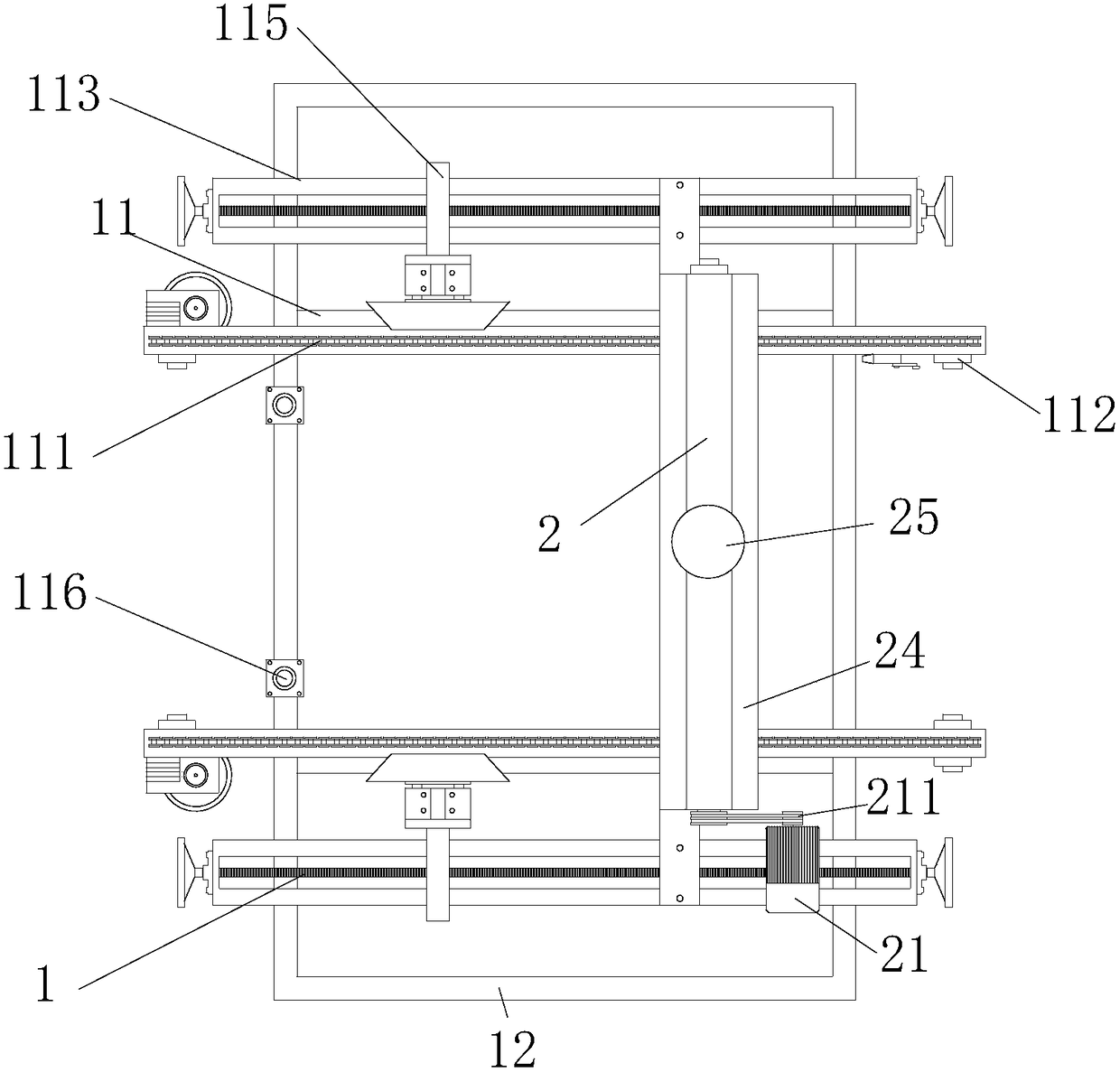

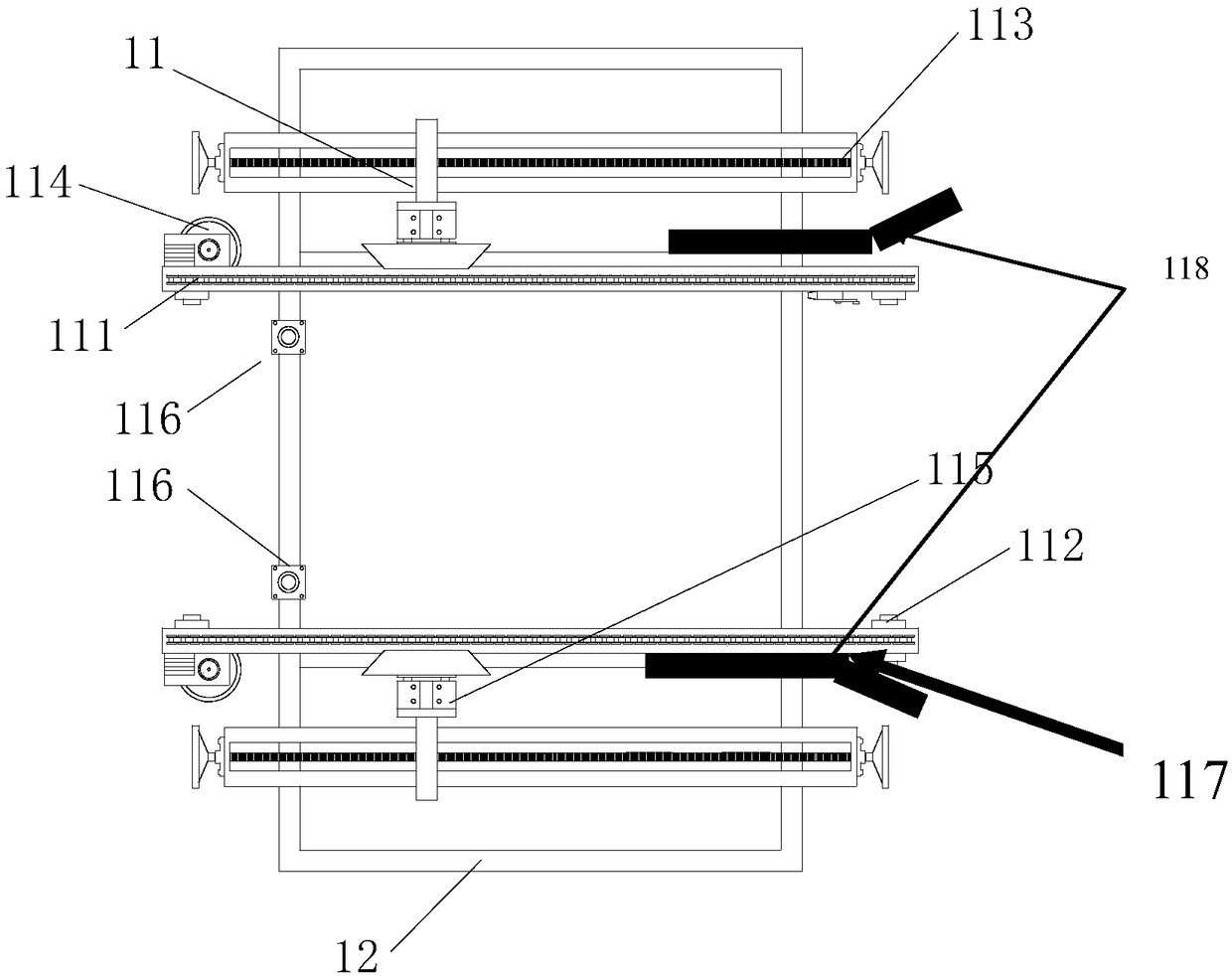

Automatic tray sweeping device

ActiveCN108188106ASolve the problem of flying aroundSolve labor intensityDirt cleaningCleaning using toolsEngineeringUltimate tensile strength

The invention relates to an automatic tray sweeping device. The automatic tray sweeping device comprises a tray conveying mechanism for conveying a tray to a sweeping zone of a sweeping device, a traysweeping mechanism for sweeping sweeps on the surface of the tray and a controller for controlling the whole sweeping device to operate. One end of the tray conveying mechanism serves as a tray placing end while the other end of the tray conveying mechanism extends to the sweeping zone right below the tray cleaning mechanism; and the control end of the tray conveying mechanism and the control endof the tray sweeping mechanism are electrically connected to the signal output end of the controller, separately. The automatic tray sweeping device provided by the invention has the beneficial effects that 1) the automatic tray sweeping device solves the problems that the labor intensity is great, the work efficiency is low and the cleaning quality is unstable as a result of manual cleaning previously; 2) the automatic tray sweeping device solves the problem that dust flies everywhere during cleaning as the cleaning work is automatically finished by means of equipment, so that the field environment is improved greatly; and 3) the device can finish cleaning work online, so that the problem that the field occupied by manual cleaning is large is solved.

Owner:JUSHI GRP CO

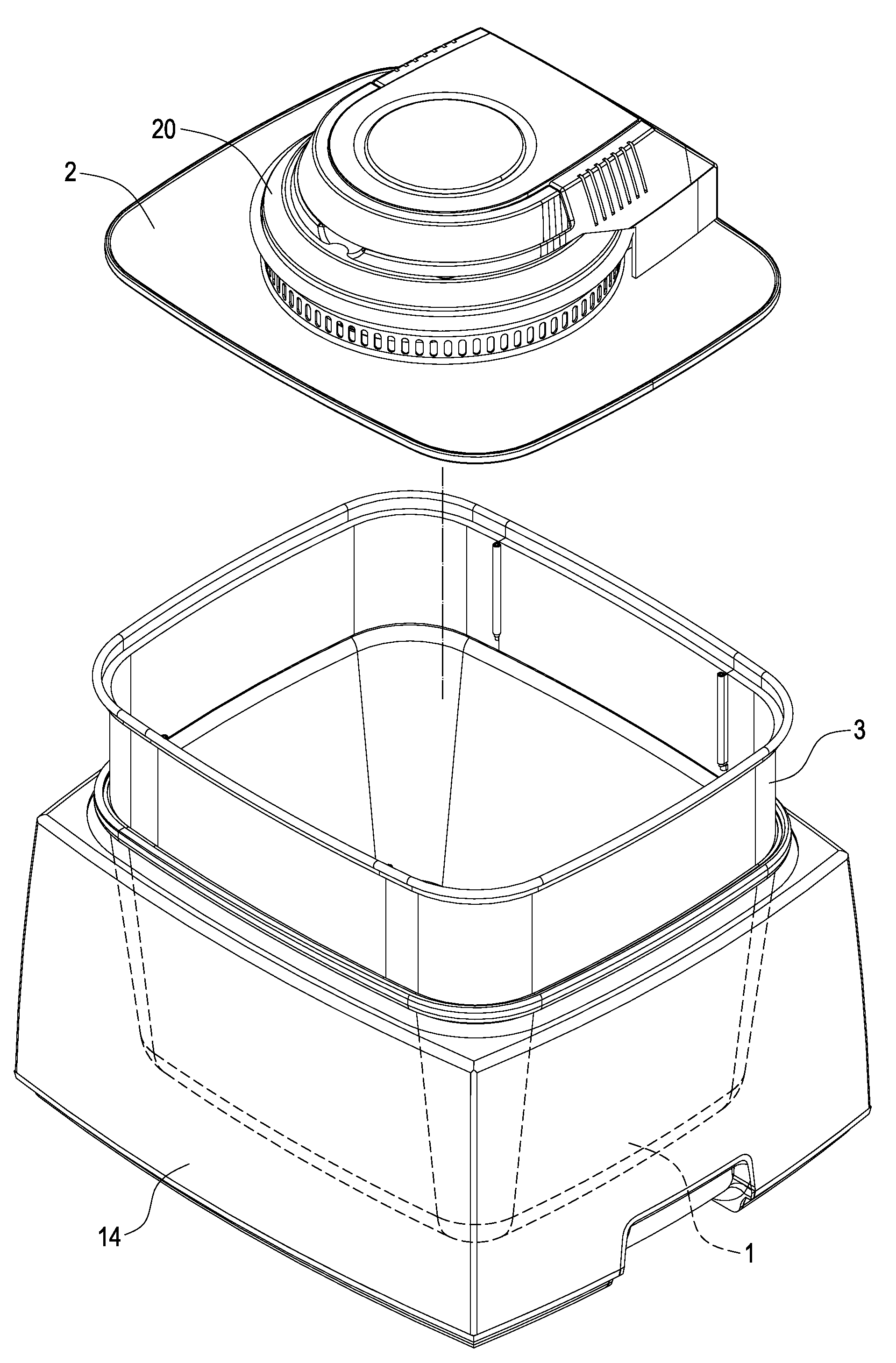

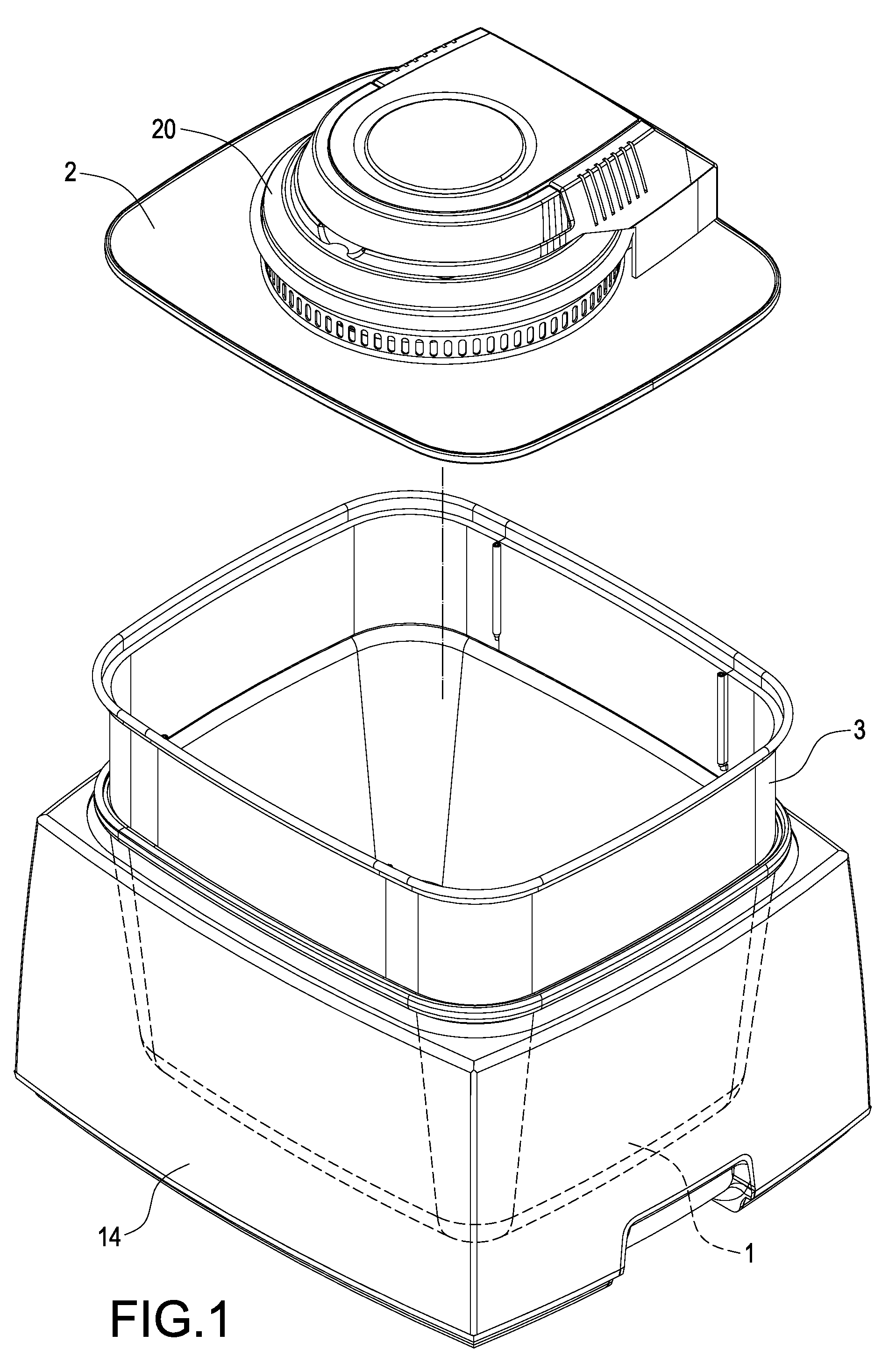

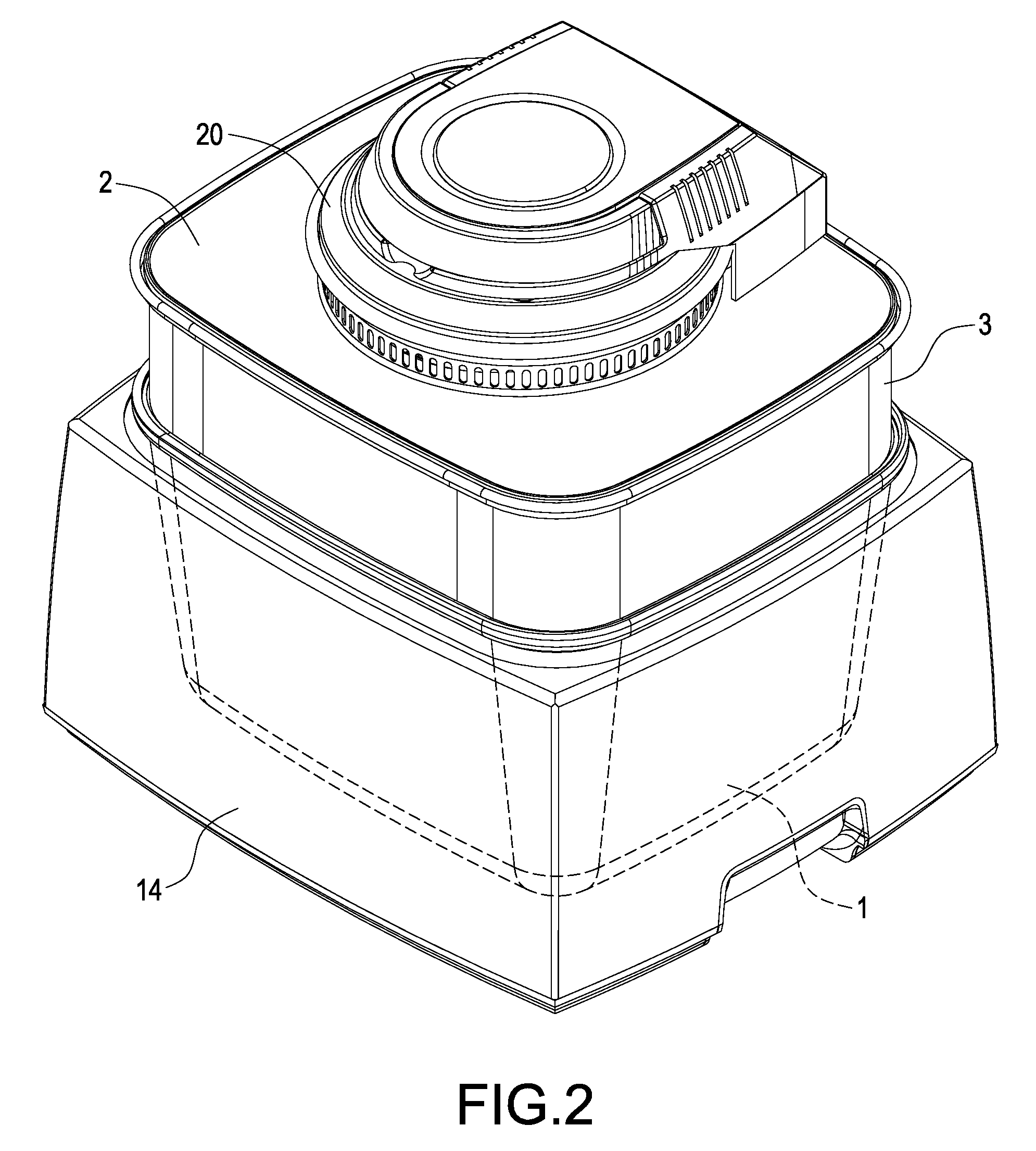

Roasting oven structure and heightened structural improvement of its oven wall

InactiveUS20100199859A1Convenient to accommodateEasy to packStoves/ranges foundationsThermodynamicsEngineering

A roasting oven includes an oven body, an oven lid and a heightened oven wall shown as a ring shape and placed on the oven body, while the oven lid covers the heightened oven wall. The heightened oven wall is assembled by plural sections of wall parts with a capability of being dismantled. The heightened oven wall capable of being disassembled is assembled by connecting each section of wall part together, making the heightened oven wall disassembled when not used to reduce the occupied space by disassembling the plural sections of wall parts, thereby, facilitating the accommodation, the package and the transportation of the product.

Owner:CHANG KUEI TANG

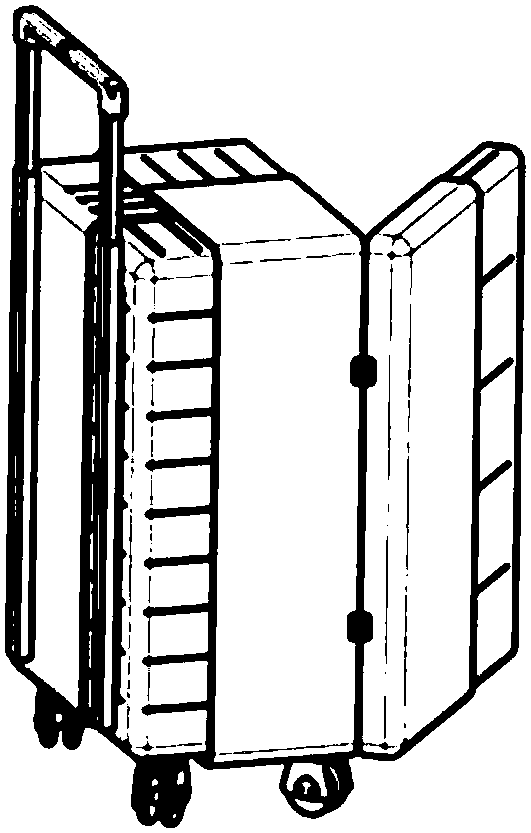

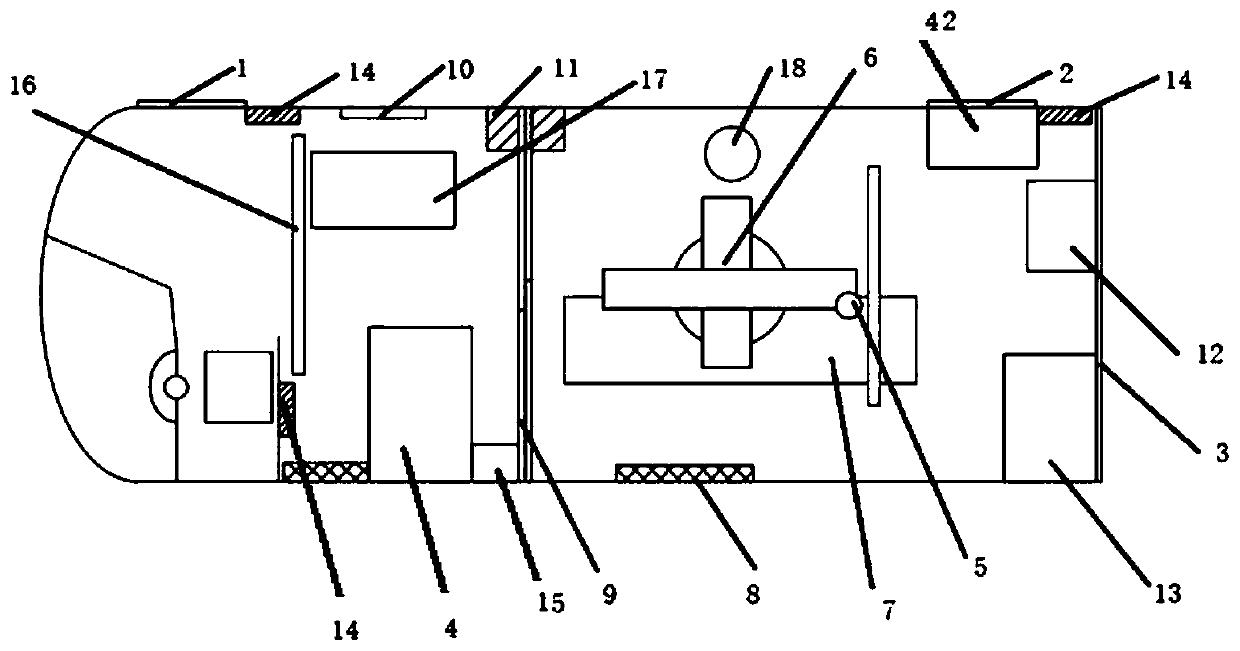

Magnetic control capsule gastroscopy vehicle and control method thereof

ActiveCN111528772AReduce space occupationIncrease profitGas treatmentDispersed particle filtrationMedicineBody compartment

The invention discloses a magnetic control capsule gastroscopy vehicle and a control method thereof. The magnetic control capsule gastroscope examination vehicle comprises an examination vehicle body;the examination vehicle body comprises a carriage; the interior of the carriage is divided into a front cavity and a rear cavity through an isolation door, wherein the front cavity and the rear cavity are arranged front and back; the front cavity is a medical staff control area for medical staff movement, and the rear cavity is a patient disinfection and detection area for patient movement; the isolation door is a push-pull type glass isolation door; the front end of the carriage is provided with a front door for entering the front cavity, the rear end of the carriage is provided with a reardoor for entering the rear cavity, and the rear side of the carriage is further provided with a main rear door for sealing the rear end of the rear cavity; an examination couch is detachably mounted in the rear cavity, and a magnetic body movement mechanism is mounted beside the examination couch; and a console is installed in the front cavity and is in control connection with the magnetic body movement mechanism. The gastrointestinal disease general investigation can be flexibly carried out, non-contact examination is realized, the working range and the benefited crowd of the magnetic controlcapsule gastroscopy vehicle are expanded, and medical assistance can be provided in special environments such as infectious diseases and wars.

Owner:SHANGHAI CHANGHAI HOSPITAL

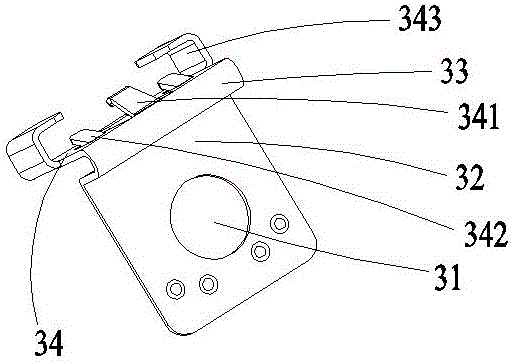

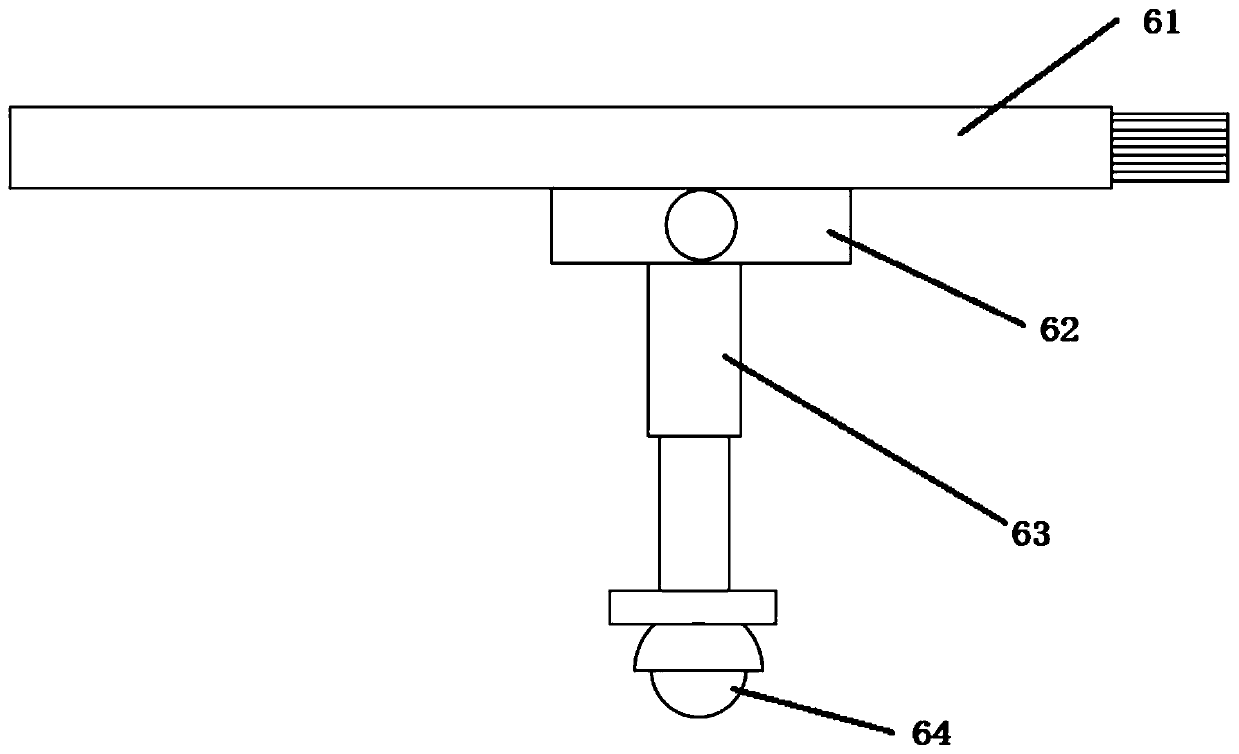

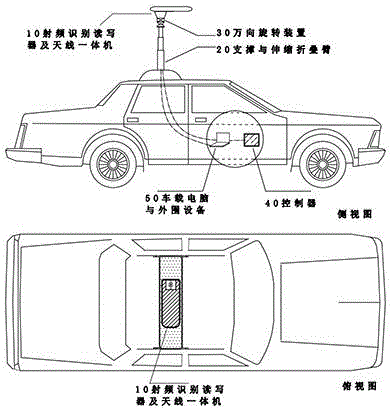

Radio frequency identification reader-writer and antenna vehicle-mounted device

ActiveCN104085358AImprove resource utilizationReduce space occupationAntenna supports/mountingsVehicle componentsResource utilizationComputer terminal

The invention provides a radio frequency identification reader-writer and antenna vehicle-mounted device. A radio frequency identification reader-writer and an antenna for transportation can be mounted on a police law enforcement vehicle and can be stored or stretched out; meanwhile, the stretching heights, the horizontal directions, the vertical directions and the pitch angles of the radio frequency identification reader-writer and the antenna can be adjusted according to requirements, so that the vehicle becomes a movable electronic number plate system read-write base station. The actual use feasibility and convenience of the vehicle-mounted device, the reader-writer and the antenna and the aerodynamic characteristics required for the vehicle-mounted device, the reader-writer and the antenna in the traveling process of an automobile are fully considered. The vehicle is a modern traffic enforcement vehicle which is small in occupied space and high in resource utilization rate. The radio frequency identification reader-writer and antenna vehicle-mounted device is mainly composed of a radio frequency identification reader-writer and reader-writer antenna integrated machine, a telescopic supporting folding arm, a universal rotating device, a controller, a vehicle-mounted computer terminal and a peripheral.

Owner:JIANGSU BELLON TECH

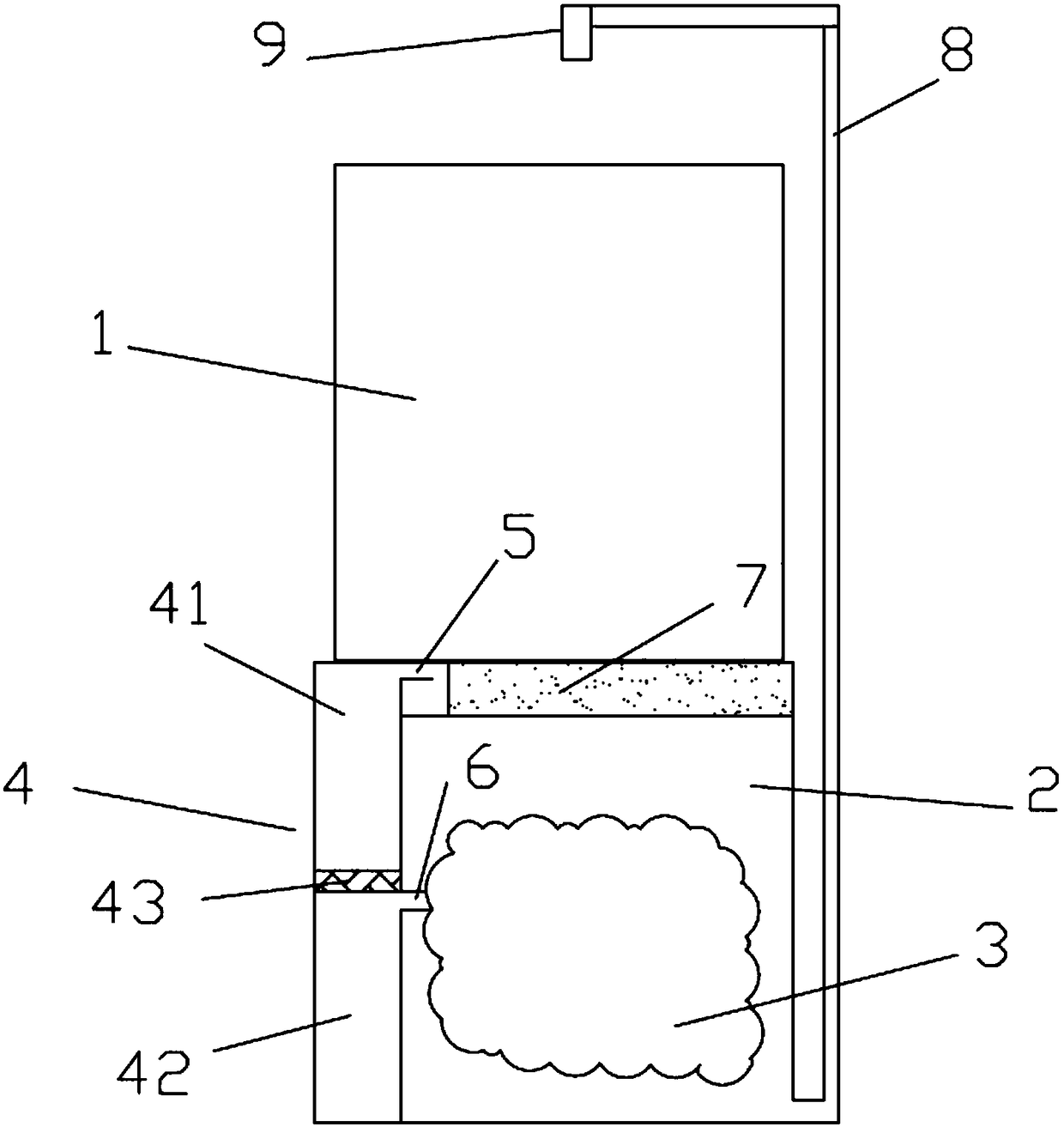

Welding device with smoke purifying function

ActiveCN103386527AReduce space occupationEasy to operateMetal working apparatusSoldering auxillary devicesEngineeringSmoke

The embodiment of the invention discloses a welding device with a smoke purifying function, comprising a columnar shell, wherein a gas inlet and a gas outlet are respectively arranged in the two end faces of the shell; a filter layer, a clapboard and a noise reduction and odor removal layer are arrayed in sequence from the end face where the gas inlet is arranged to the direction of the end face where the gas outlet is arranged; a fan is arranged on the clapboard and is used for driving gas entering the inside of the shell from the gas inlet to flow towards the gas outlet and discharging the gas out of the shell; a welding device drive module which is used for driving the welding device to work is arranged in a space which is encircled by the shell, the clapboard and the noise reduction and odor removal layer; the welding device is arranged outside the shell and is connected with the welding device drive module through a wire. By using the welding device with the smoke purifying function, the existing space which is used for the welding device is capable of containing a smoke purifier and the welding device simultaneously, the occupied space is reduced, and meanwhile, compared with the existing smoke purifier, the welding device with the smoke purifying function has the advantages that the cleaning is more thorough, the noise is small, and the working environment of operating workers is not influenced.

Owner:深圳市谷多普科技有限公司

Automatic irrigator for flowerpots

InactiveCN108142264AReduce space occupationEasy to getProductsReagentsProcess engineeringGas generator

The invention discloses an automatic irrigator for flowerpots, comprising a water container, a deformable gas collector and a gas generator; the deformable gas collector is arranged in the water container; the gas generator comprises a gas generator upper layer and a gas generator lower layer; the gas generator upper layer and the gas generator lower layer are spaced via a partition; the partitionis made of a material that is high in water permeability and poor in breathability; the gas generator lower layer is communicated with the deformable gas collector through a gas guide tube; the watercontainer is communicated with a compensating irrigator through a water supply pipe. Gas generated by reaction in the gas generator is used as irrigating power; potted plants can be automatically irrigated with no assistance from a power system.

Owner:郭雨耕

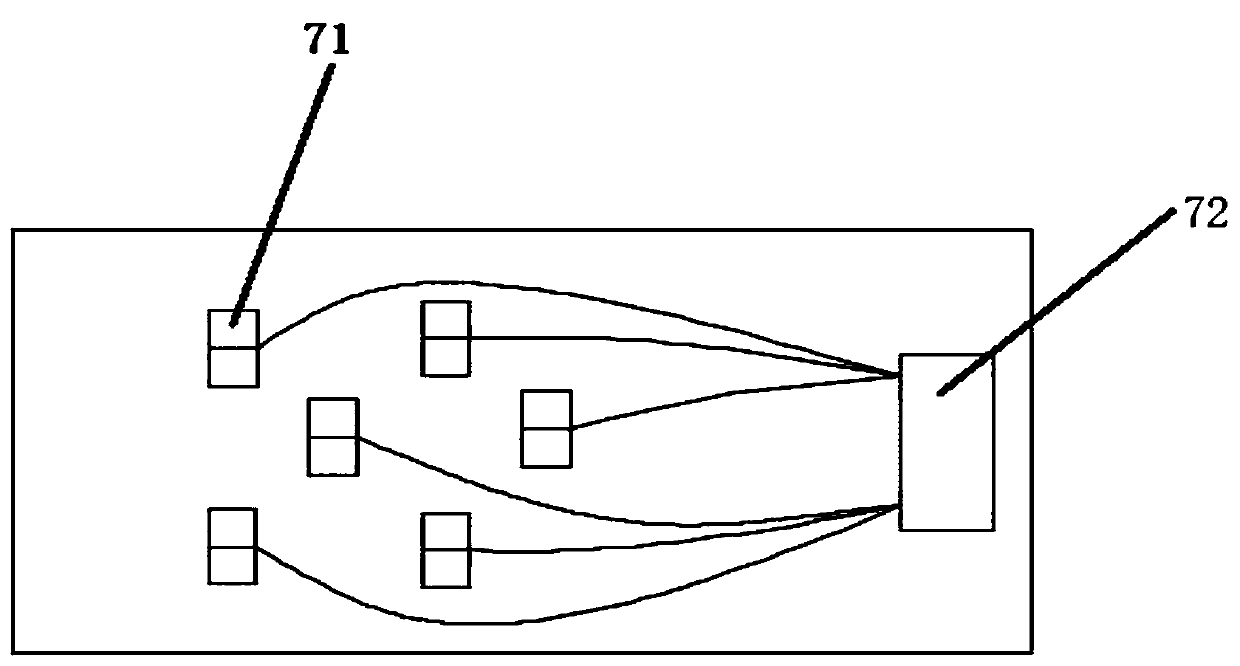

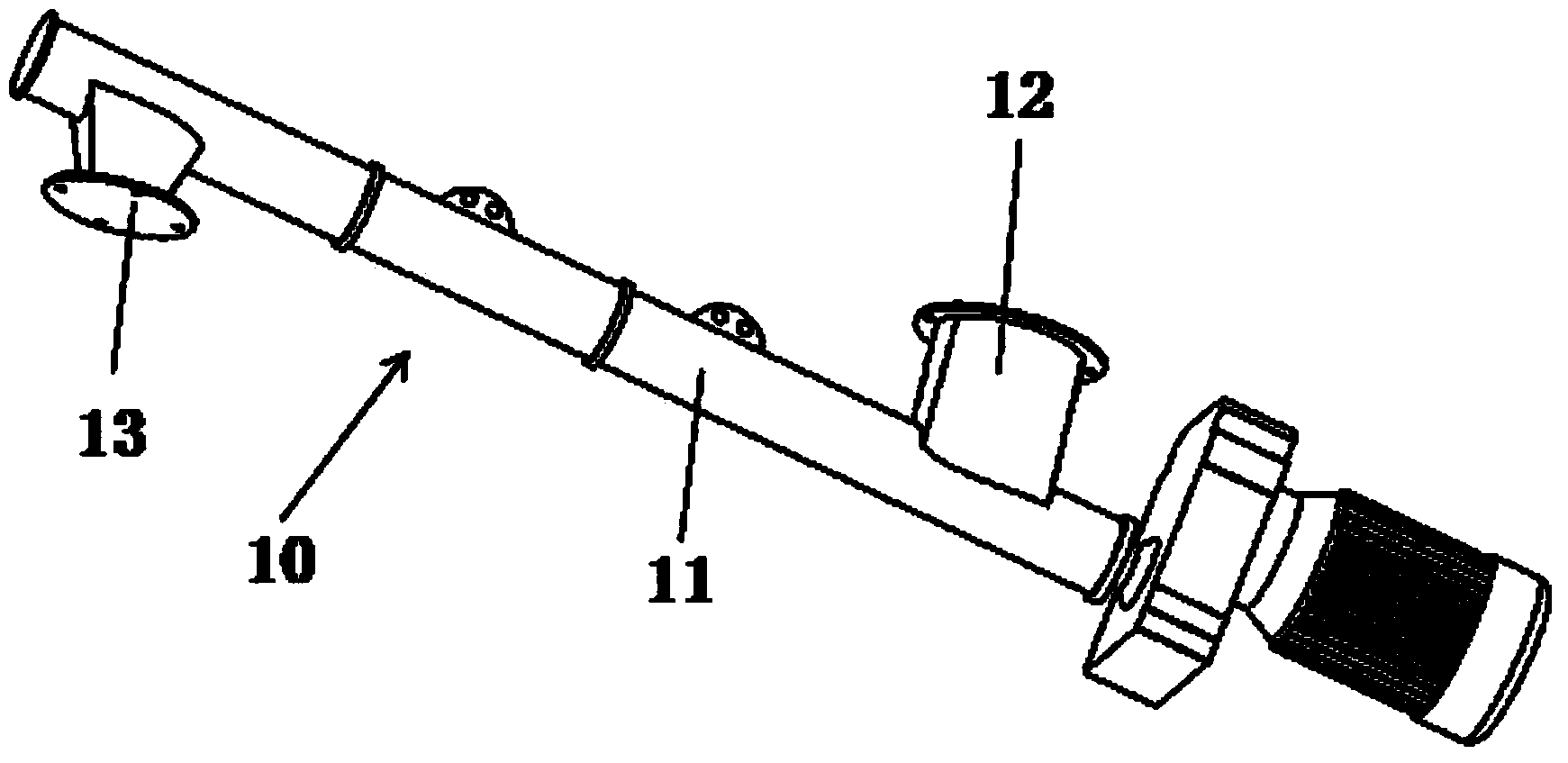

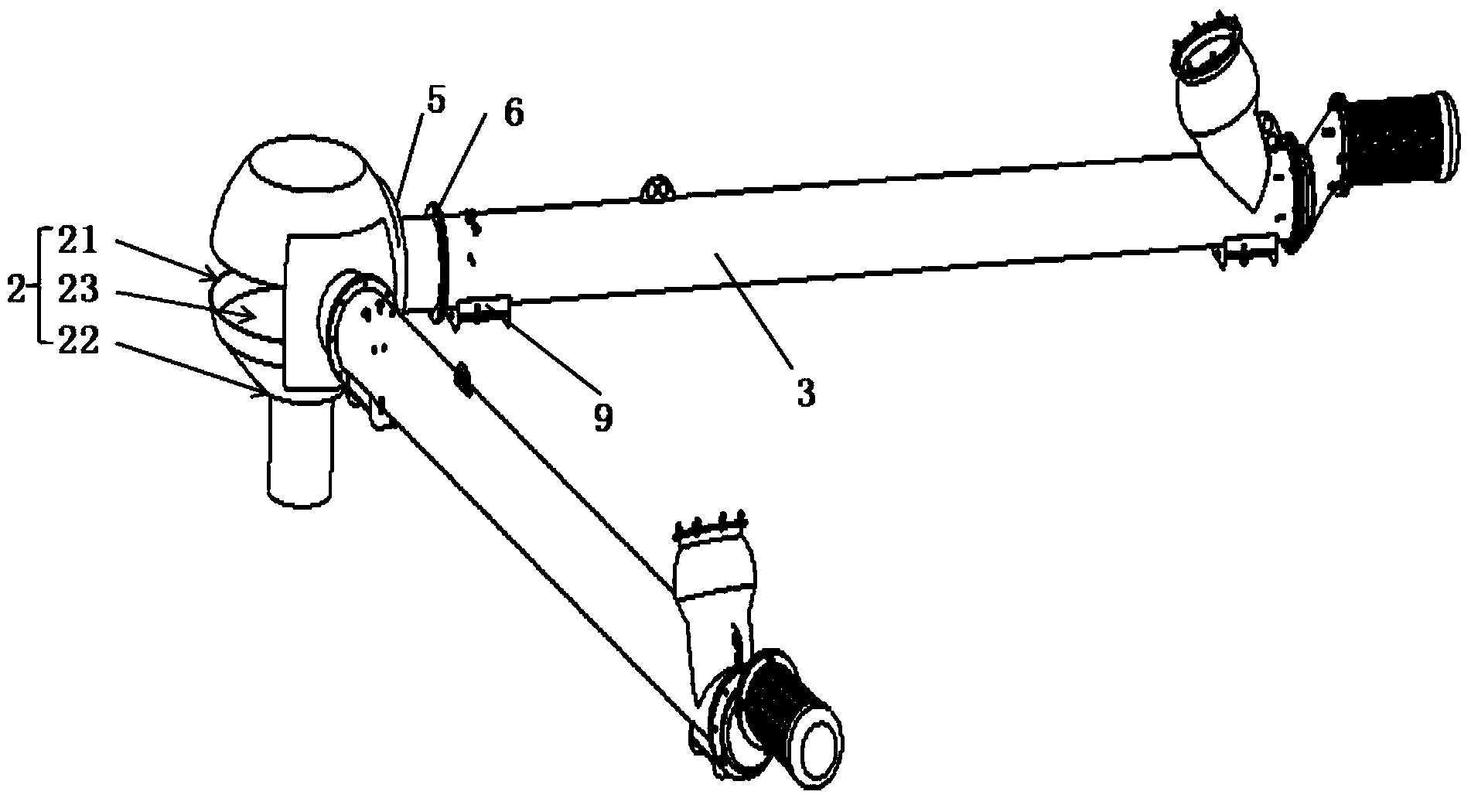

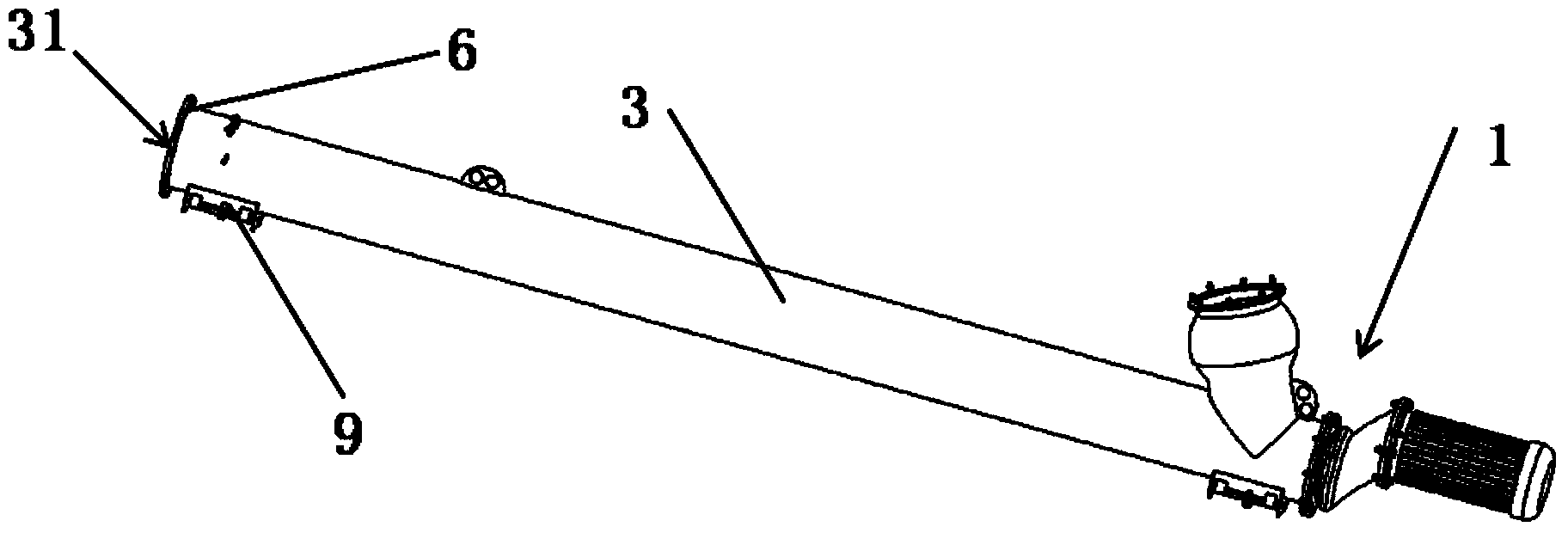

Spiral conveying equipment

ActiveCN103523483AAvoid interferenceReduce space occupationMechanical conveyorsEngineeringScrew conveyor

The invention discloses spiral conveying equipment, and relates to the technical field of engineering machines. The spiral conveying equipment is used for solving the problem that when spiral conveyors are arranged in a concentrated mode in the prior art, staggering, interference and material discharging outlet blocking occurring during conveying in a concentrated mode occur. The spiral conveying equipment comprises a concentrating head and at least two spiral conveyors. The concentrating head is provided with a cavity, an opening and a concentrated material discharging outlet, wherein the opening and the concentrated material discharging outlet are both communicated with the cavity, and the opening is formed above the concentrated material discharging outlet. Each spiral conveyor is provided with a material feeding pipe, wherein each material feeding pipe is provided with a material discharging port, and each material discharging port is communicated with the opening through a detachable connection structure. According to the spiral conveying equipment, a material discharging head of an existing spiral conveyor is eliminated, the spiral conveying equipment is provided with the concentrating head which is provided with the concentrated material discharging outlet, and the problem that when the spiral conveyors are arranged in a concentrated mode, staggering, interference and material discharging outlet blocking occurring during conveying in a concentrated mode occur can be solved.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

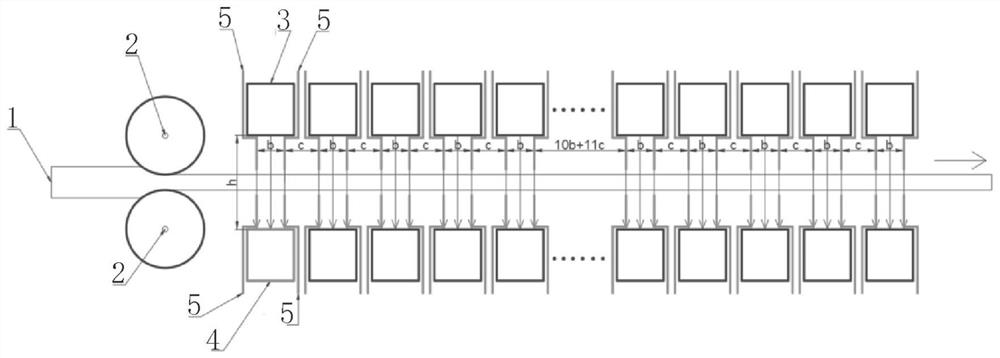

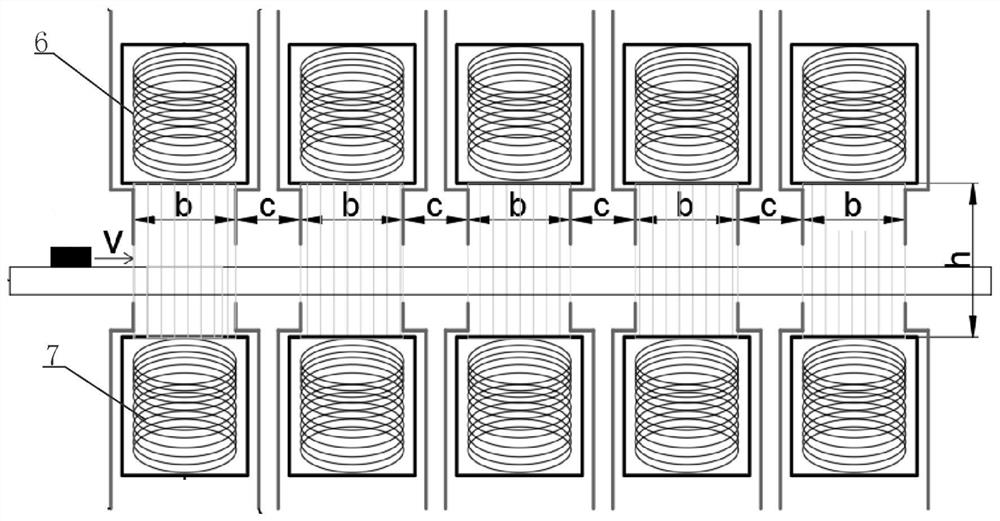

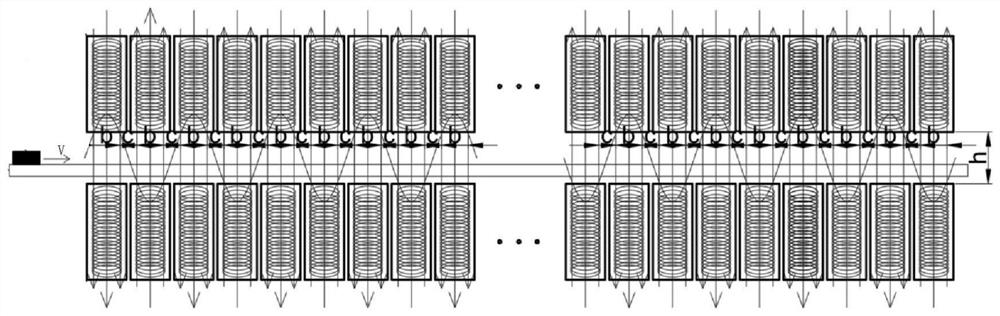

Method for achieving alternating or pulsed magnetic field action through static magnetic field facilities

PendingCN113337704AImprove material propertiesImprove material performanceMagnetic field magnitudeContinuous production

The invention provides a method for achieving an alternating or pulsed magnetic field action through static magnetic field facilities, and relates to the technical field of material processing. The multiple static magnetic field facilities are ingeniously arranged along a production line, the magnetic field intensity and directions of the static magnetic field facilities at the corresponding positions are adjusted according to the original alternating or pulsed magnetic field waveform and waveform parameters required by products conveyed by the production line, and a static magnetic field is infinitely close to the treatment effect of an alternating magnetic field or a pulsed magnetic field in cooperation with the moving speed of the products on the continuous production line. The problem that in the prior art, an alternating or pulsed magnetic field cannot be effectively applied to material stress and performance regulation and control in a continuous production line is solved.

Owner:成都昆吾科技有限公司

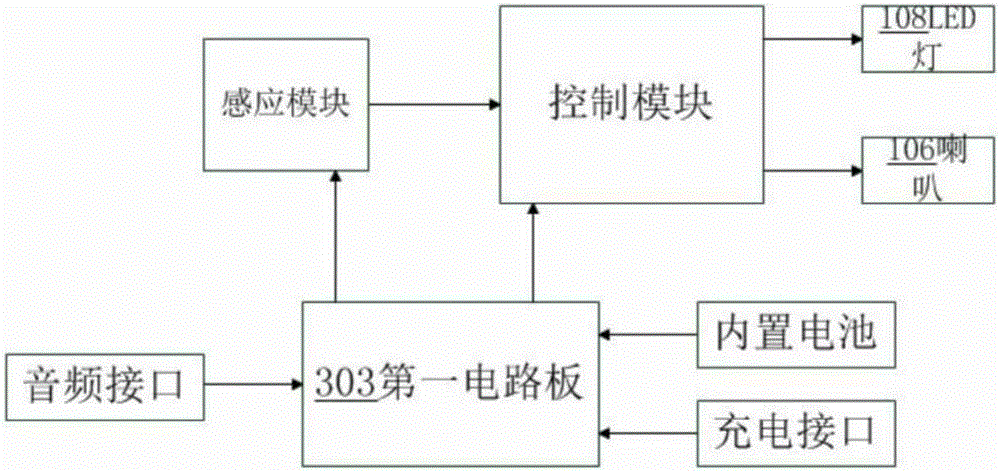

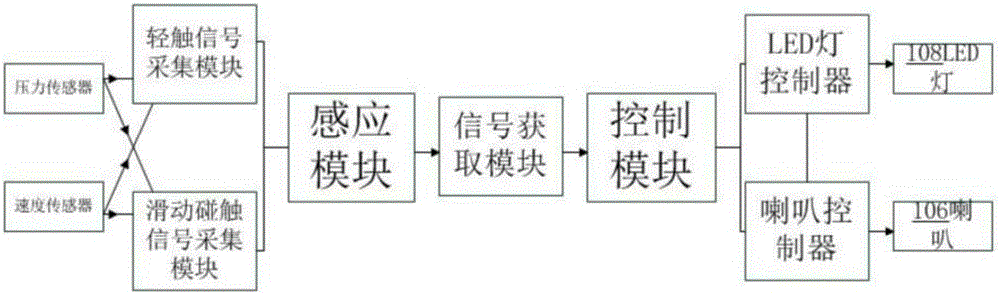

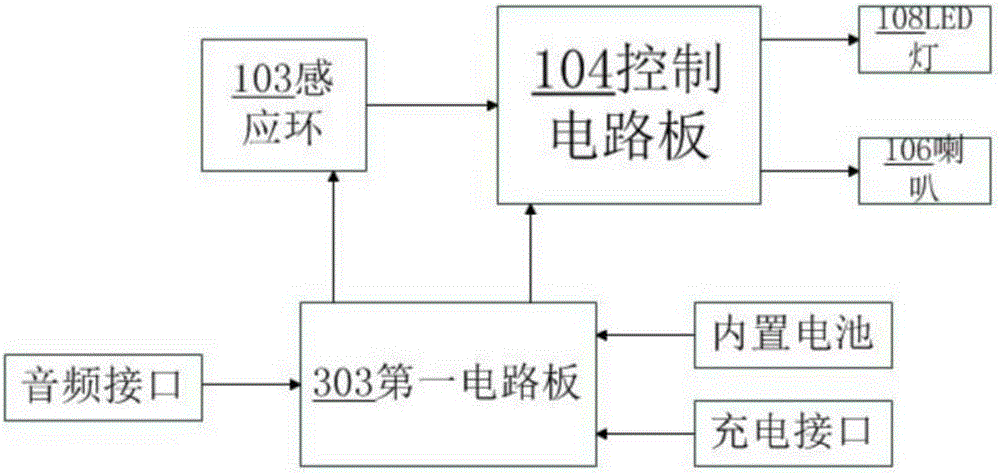

Control method of LED desk lamp sound equipment and the LED desk lamp sound equipment using the method

InactiveCN105120396ARequirements for mechanical structures are reducedSimple device structurePoint-like light sourceLighting elementsMechanical wearMetallic materials

The invention discloses a control method of LED desk lamp sound equipment and the LED desk lamp sound equipment using the method. The LED desk lamp sound equipment is provided with a sensing module and a control module. The sensing module is connected to the control module. The control module is connected to a LED lamp and a horn of the LED desk lamp sound equipment. The sensing module collects signals. The control module acquires the signals so as to control the LED lamp and the horn. The sensing module collects a first signal. The control module controls the LED lamp. The sensing module collects a second signal and the control module controls the horn. Through the sensing module and the control module, usage states of the LED lamp and the horn can be simultaneously controlled and a traditional switch is directly replaced. Operation is comfortable, a hand feeling is good, control is accurate and there is no mechanical wear. Metal materials are saved. Especially for small appliances, such as the LED desk lamp sound equipment, a requirement to a mechanical structure is greatly reduced. A structure apparatus of the LED desk lamp sound equipment is simplified and space occupation is saved.

Owner:尚平

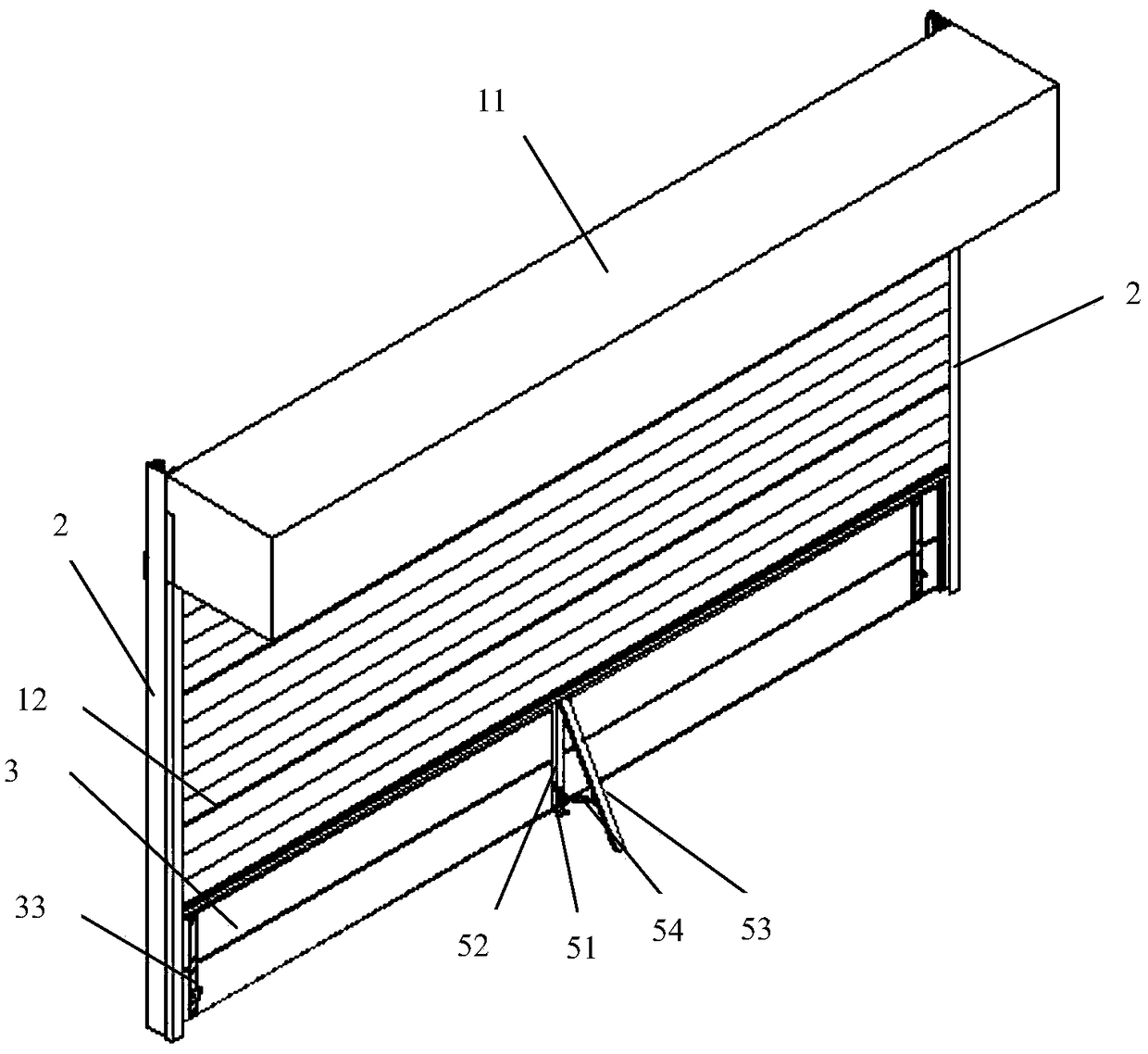

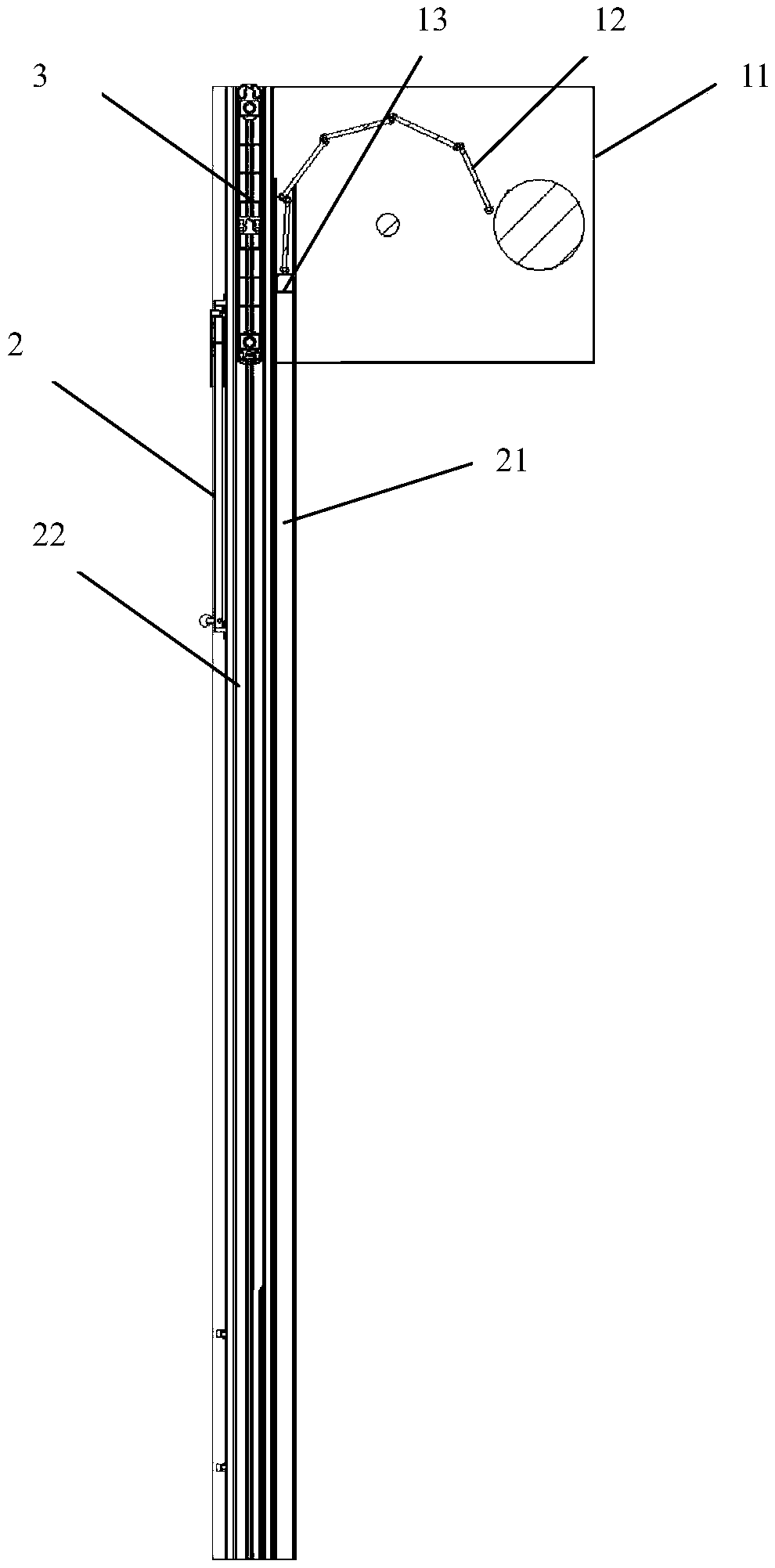

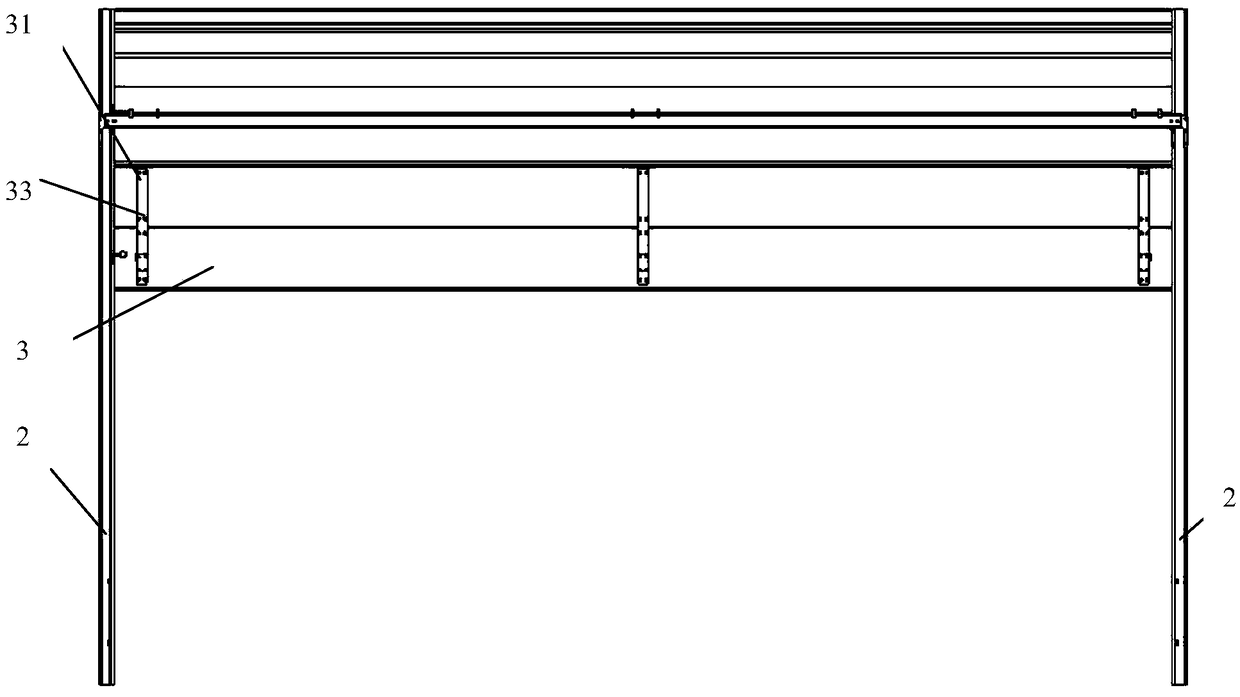

A top-down multifunctional clutch water-blocking and flood-proof door

ActiveCN106869720BFunctionalDoes not affect the use of spaceFlood panelsBurglary protectionFailure rateEngineering

Owner:水母(苏州)科技有限公司

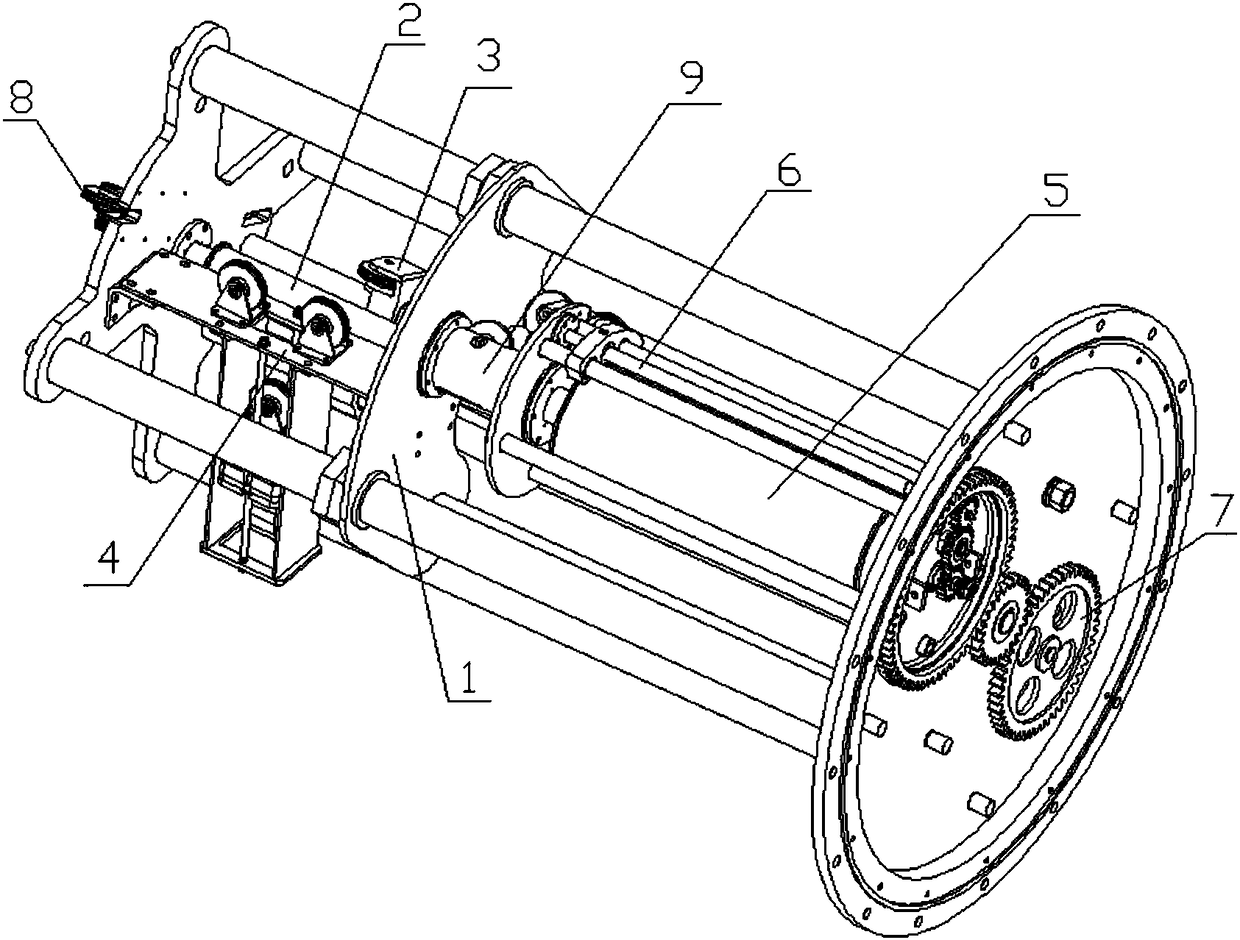

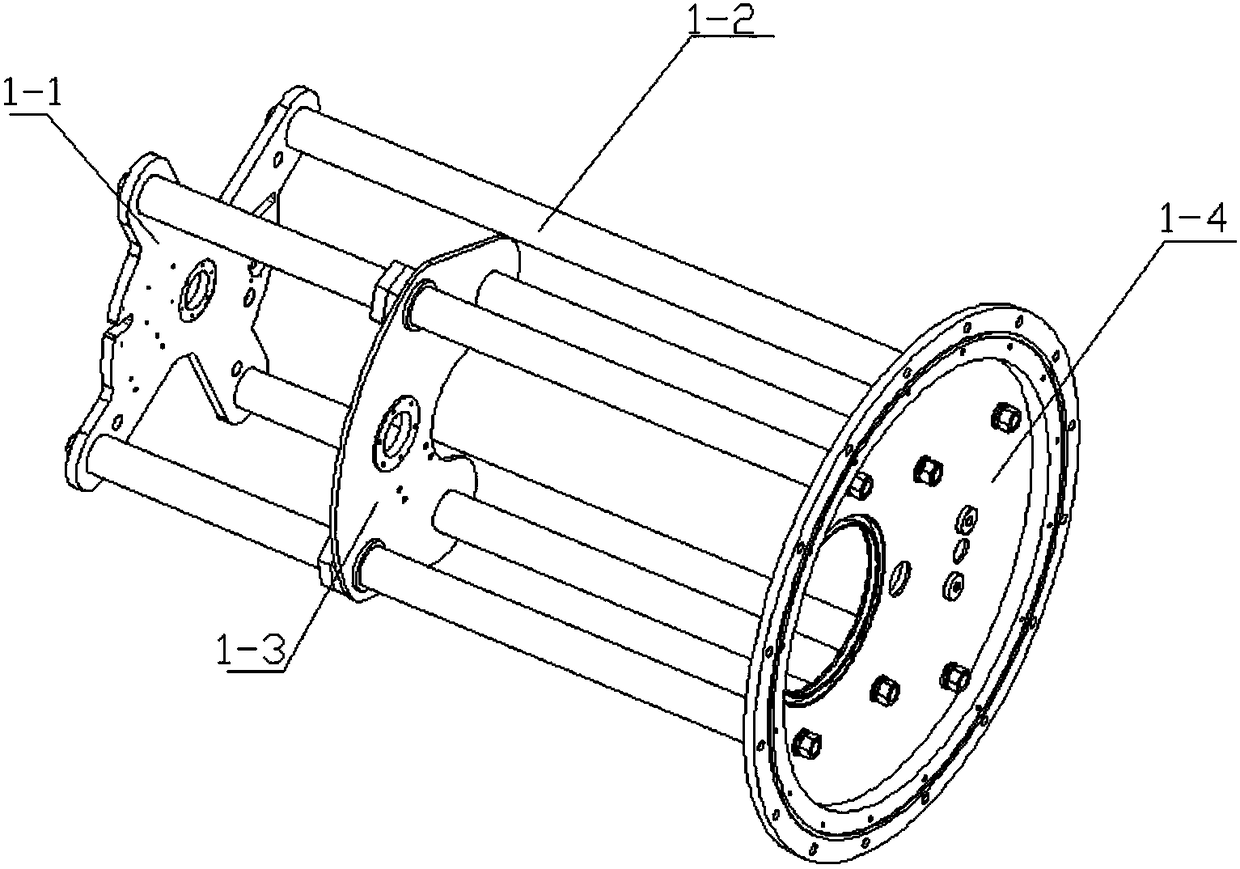

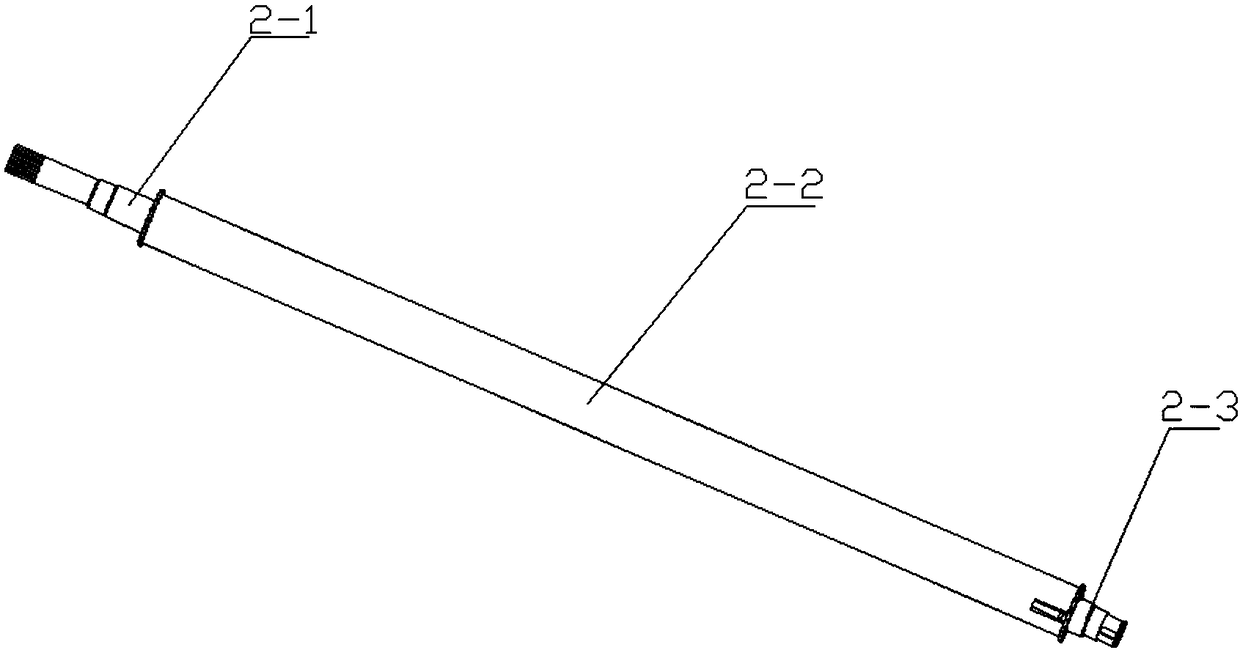

Horizontal-installed integrated non-slide-ring optical signal on-line transmission mechanism and transmission method

PendingCN108285064AImprove work efficiencyReduce space occupationFilament handlingGear driveSignal on

The invention relates to a horizontal-installed integrated non-slide-ring optical signal on-line transmission mechanism which comprises an installation support, a primary driving device and a secondary driving device. The installation support comprises three installation plates arranged in parallel, and multiple fixing rods for connecting the installation plates and limiting relative positions ofthe installation plates; the installation support forms two interlayers through the three installation plates and the fixing rods; the primary driving device and the secondary driving device are fixedly arranged in the two interlayer spaces and are coaxially arranged; and meanwhile, a pulley assembly is assembled on the outer surface of the installation plate on the outer side of the primary driving device, and a gear driving assembly is arranged on the outer surface of the installation plate on the outer side of the secondary driving device. The invention further provides an optical signal on-line transmission method based on the mechanism at the same time. The transmission method is high in control precision and good in effect; and an optical slide ring is saved, so that an optical signal can be transmitted stably and reliably through the overall device design.

Owner:湖南天剑海洋工程设备有限公司

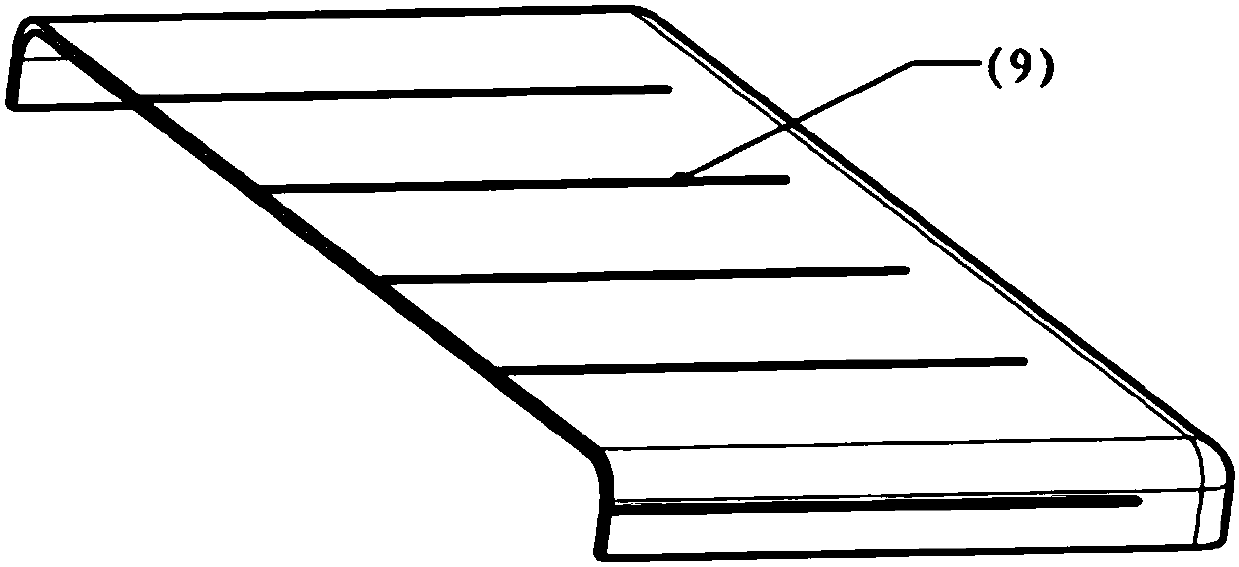

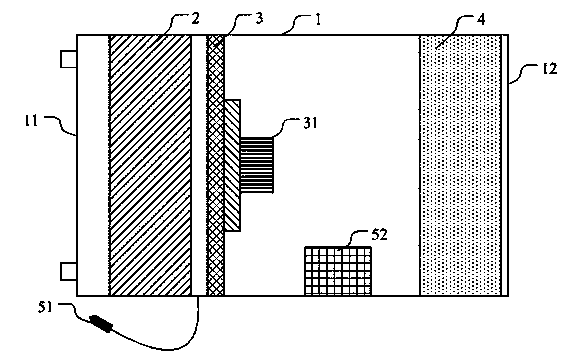

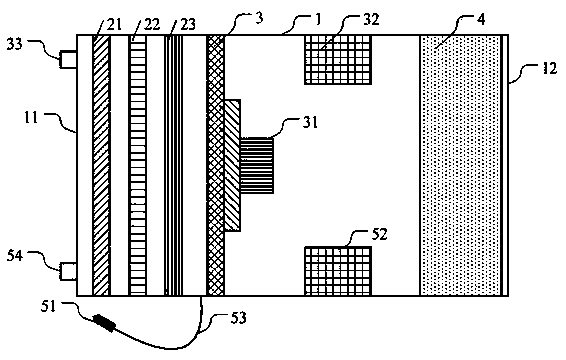

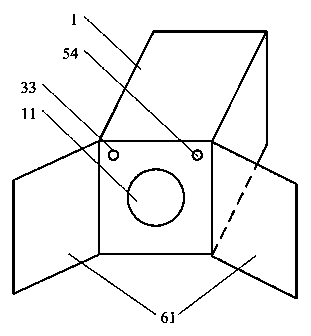

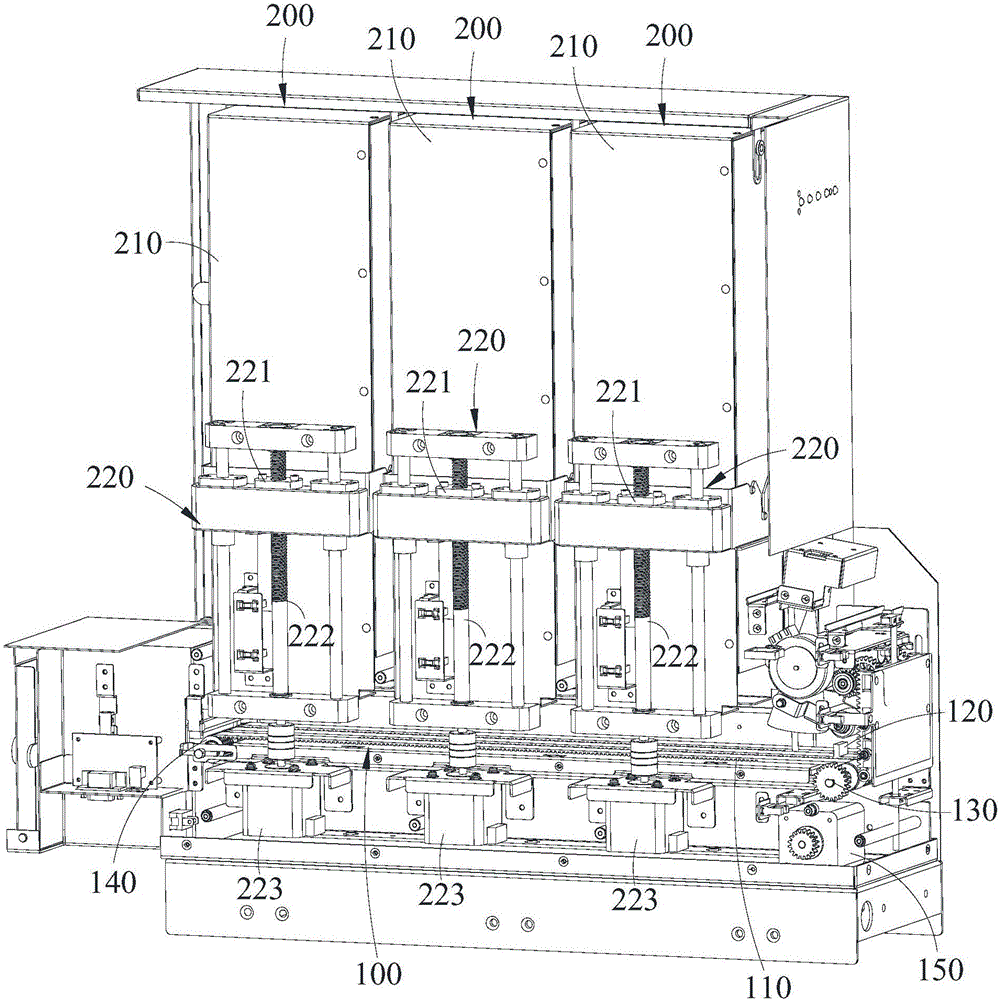

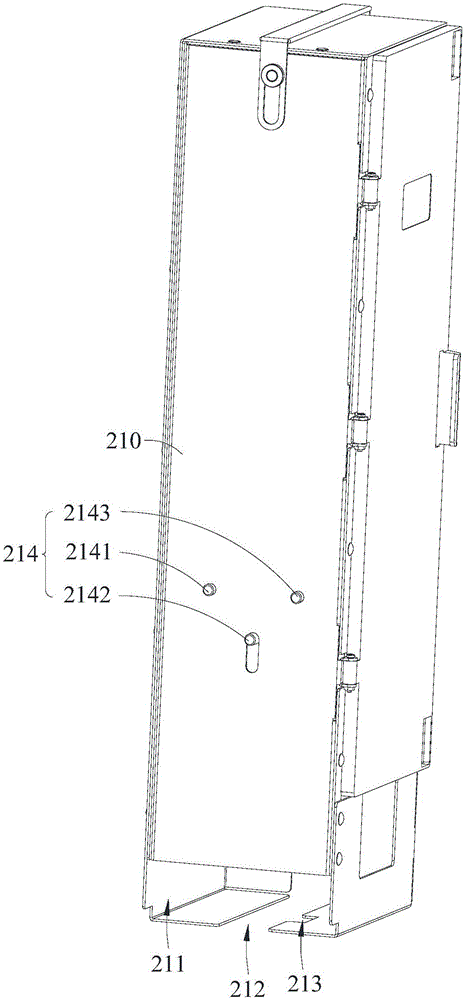

Card distributing device and VTM apparatus

PendingCN106384133AReduce space occupationImprove space occupancyConveying record carriersEngineering

The present invention provides a card distributing device and a VTM apparatus. The card distributing device comprises a conveying mechanism and at least two card storage and discharging mechanisms; the conveying mechanism includes a conveyor belt and pushing blocks arranged on the conveying surface of the conveyor belt; the card storage and discharging mechanisms are distributed sequentially along the card feeding direction of the conveyor belt; each card storage and discharging mechanism includes a card storage box which is arranged above the conveyor belt and is used for storing cards, and a driving assembly which is used for driving the card storage box to move downwards and approach the conveyor belt so as to make the card storage box be in a discharging state and is used for driving the card storage box to move upwards and move away from the conveyor belt so as to make the card storage box be in a to-be-fed state; and a side surface of the bottom of each card storage box, which faces the card feeding direction of the conveyor belt, is provided with a discharging opening and a through opening which allows the corresponding pushing block to pass under the discharging state and push cards out from the discharging opening. The conveying mechanism and the at least two card storage and discharging mechanisms are adopted, so that one conveying mechanism can form one conveying channel to convey at least two types of cards.

Owner:SHENZHEN YIHUA COMP +2

Permanent magnet stepping motor and electronic device

ActiveCN112737266AEasy to fixImprove welding efficiencyWindingsMechanical energy handlingElectric machineryControl theory

The invention relates to a permanent magnet stepping motor and an electronic device, and solves the technical problem that the wiring end of an existing stator terminal is easy to damage. The permanent magnet stepping motor comprises a stator, wherein the stator is cylindrical; aprotruding boss which is connected to the stator; a terminal pin of which the inner end is embedded and fixed in the outer boss, and the outer end penetrates out of one end face, away from the stator, of the outer boss; a conductive wiring end which is wound at one end, close to the outer boss, of the terminal pin and is connected with a coil on the stator; a rotor which penetrates through the stator and can rotate relative to the stator; and a protruding anti-damage structure which is connected to the protruding boss and protrudes out of the end face, provided with the terminal pin, of the protruding boss. The protruding height of the protruding anti-damage structure from one end face of the protruding boss to the highest protruding point of the protruding anti-damage structure is equal to or larger than the axial length of the conductive wiring end after the conductive wiring end is axially compressed in place. The invention has the advantage that the wiring end can be protected.

Owner:NEW SHICOH MOTOR CO LTD

Battery protection PTC device

InactiveCN102737798AEasy to installReduce space occupationCell component detailsPositive temperature coefficient thermistorsThin layerElectrical connection

A battery protection PTC device comprises a PTC material, a first conductive wire, a second conductive wire and an insulating layer. One opening of the PTC material is in a groove shape; and a sandwich thin layer in the groove comprises the first conductive wire, the insulating layer and the second conductive wire, has a thickness less than 1 mm, and is used to achieve electrical connection during PTC device insertion between battery and battery and between battery and battery box spring.

Owner:谢维

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com