Automatic machine for fabricating localized supporting sheet

A technology of positioning supports and automata, applied in electrical components, sensors, etc., can solve problems such as affecting the quality of speakers, difficult to control product quality and product consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

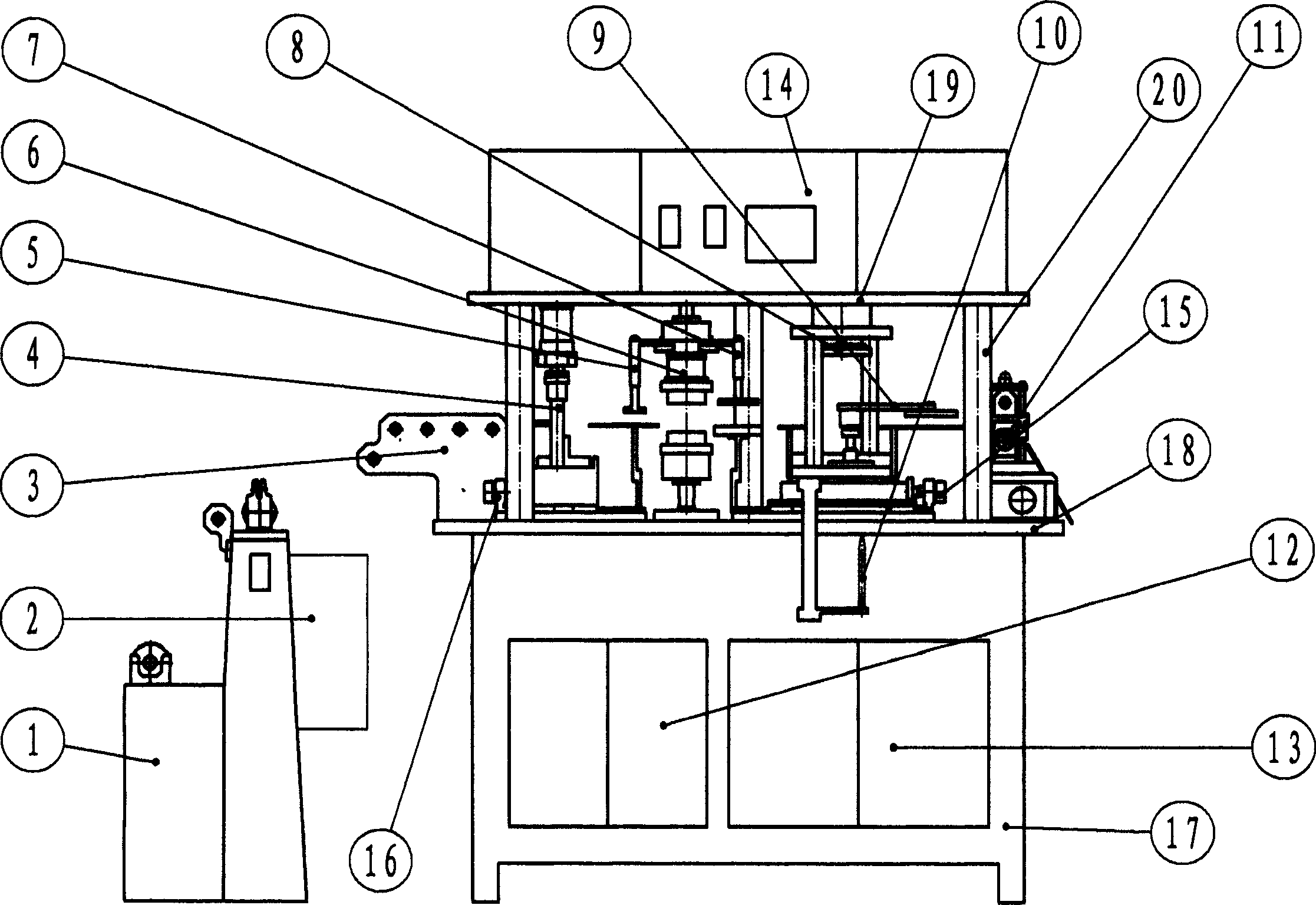

[0006] Combine below figure 1 The specific embodiment of the present invention is described further: the automaton of manufacturing positioning strut is built into main frame by frame (17), main platform panel (18), last platform panel (19), column (20), and on main platform panel (18) is installed with cloth guiding mechanism (3), tape material cutting mechanism (4) and cutting mechanism position adjustment device (16), positioning mechanism (5), hot pressing mechanism (6), cold pressing mechanism (7) , the punching mechanism (8) and the punching position adjustment device (15), the dragging mechanism (11); the pick-up hand (9) and the stacking mechanism (10) are installed on the punching position adjustment device (15); Control component box (12), electric control component box (13) are installed in the frame (17) of bottom; Instrument panel (14) is contained on the upper platform panel (19); Feeding mechanism (1), feeding length control mechanism ( 2) Connected into one bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com