Patents

Literature

230results about How to "Consistent tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

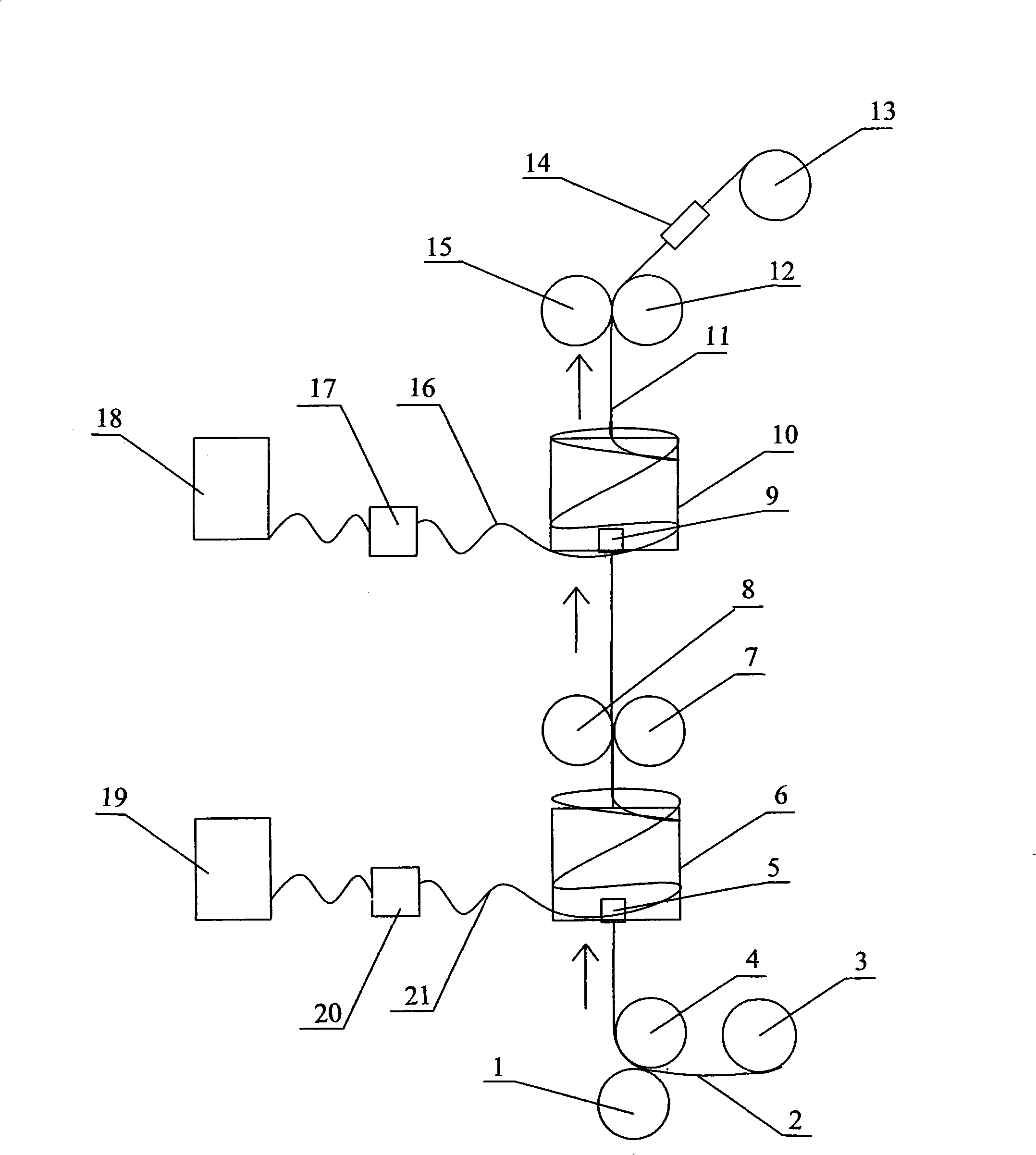

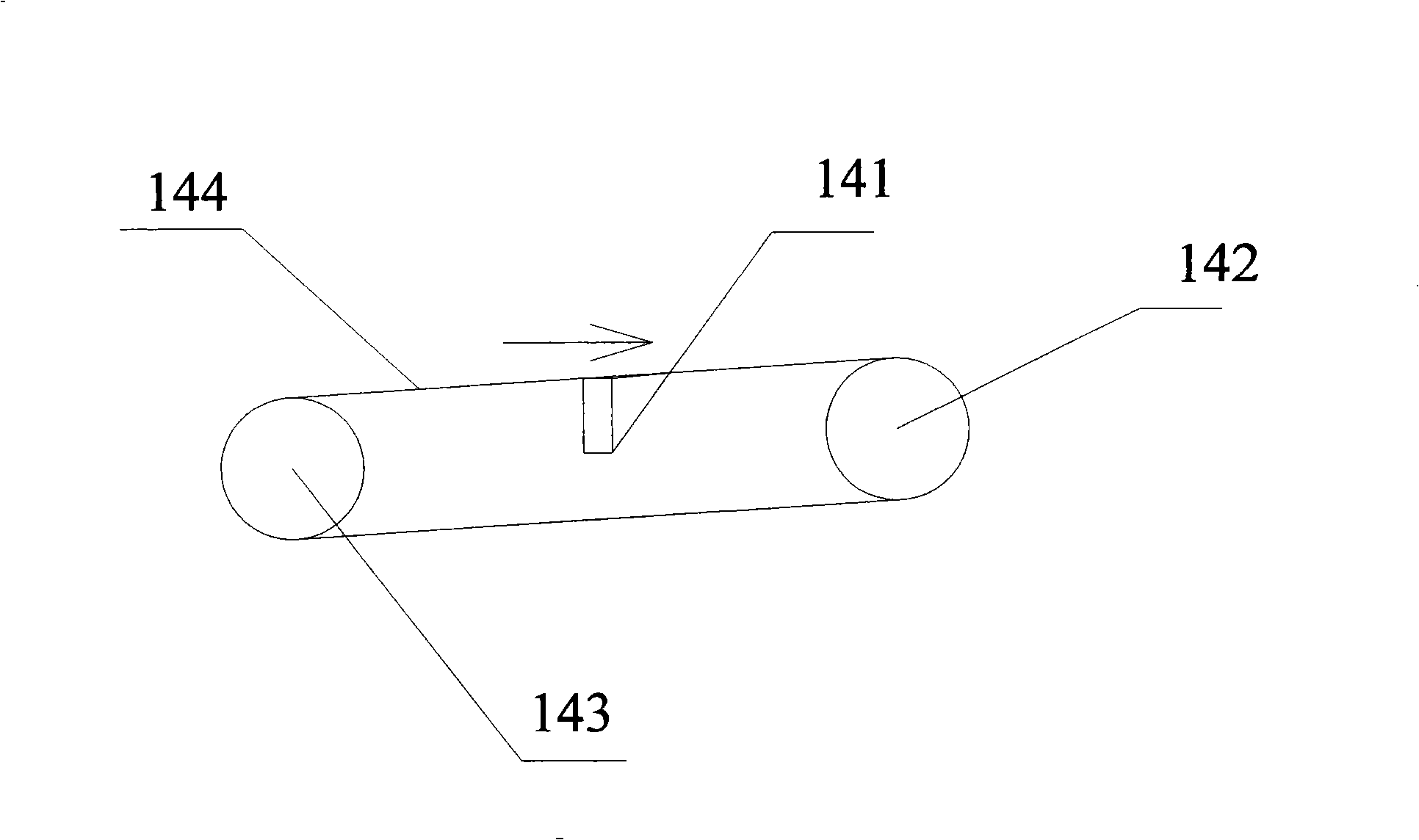

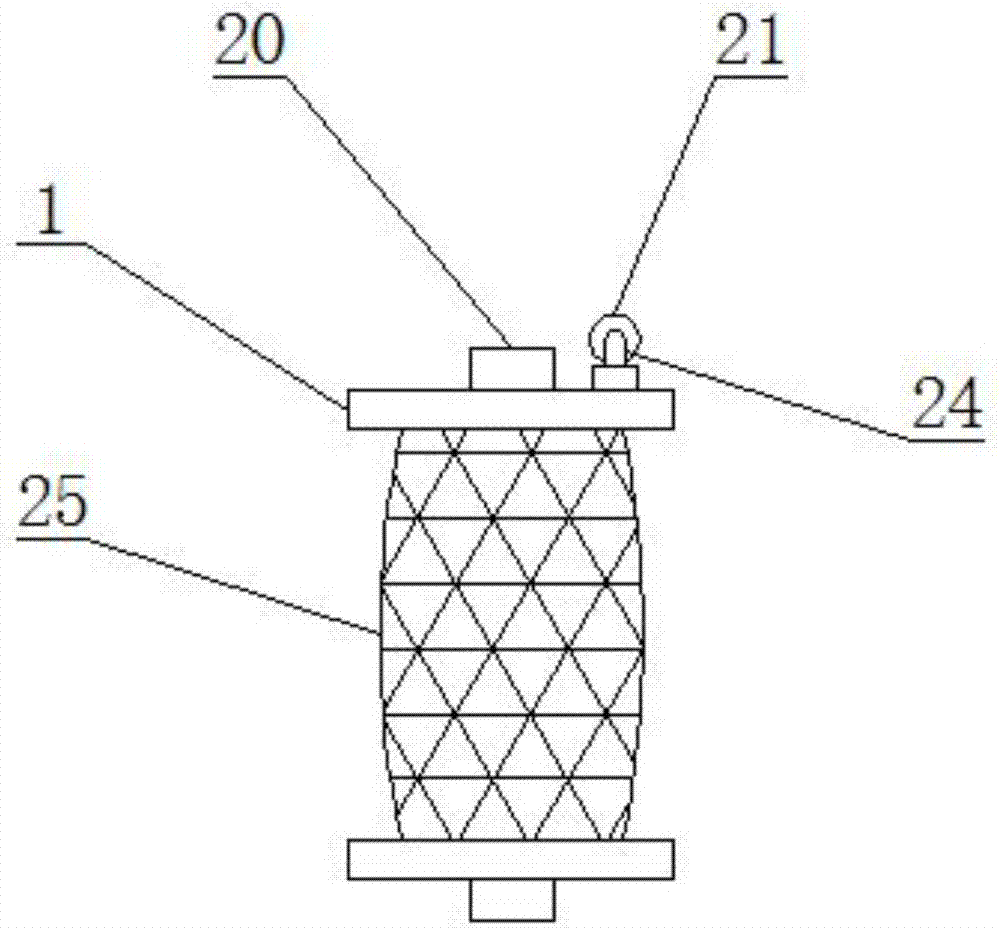

Dissimilar materials double-layer superpacket center thread and manufacturing method thereof

InactiveCN101328637AGuaranteed wrapping tensionFeel comfortableContinuous wound-up machinesYarnYarnFiber

The invention discloses an abnormal material dual-layer composite clad yarn, which comprises an upper fiber-wrapped clad material layer, a lower fiber-wrapped clad material layer and a clad yarn layer which is positioned in the middle, wherein, the clad yarn layer adopts chemical fiber filament clad yarns and fiber-wrapped clad materials with different materials to be compositely processed into a dual-layer composite clad yarn. The invention also discloses a method for manufacturing the dual-layer composite clad yarn. The dual-layer composite clad yarn has the characteristics of comfortable hand feeling, large strength and toughness of chemical fiber filaments of the sandwich layer, burliness and durability, and high performance and use value.

Owner:鲁建国

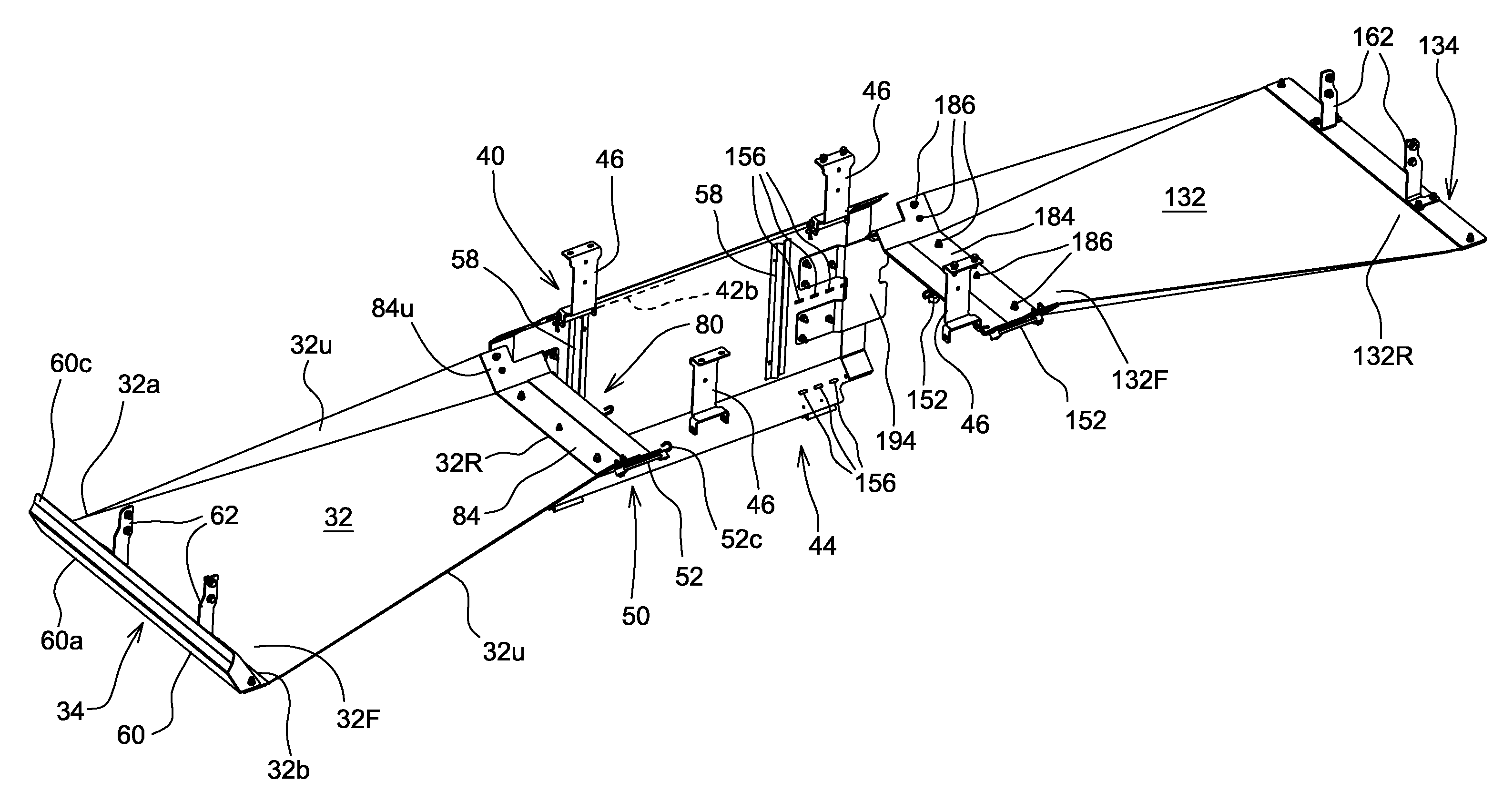

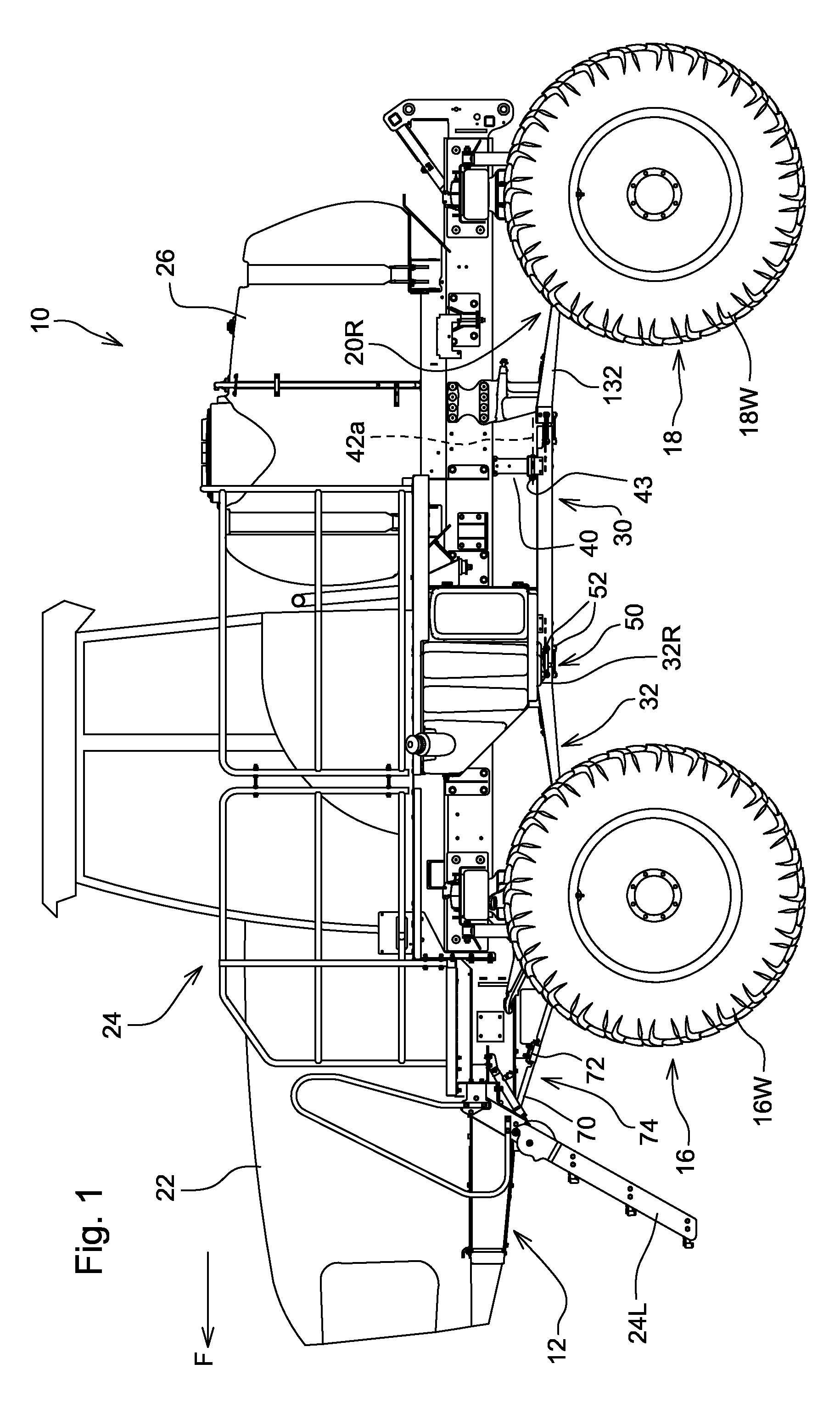

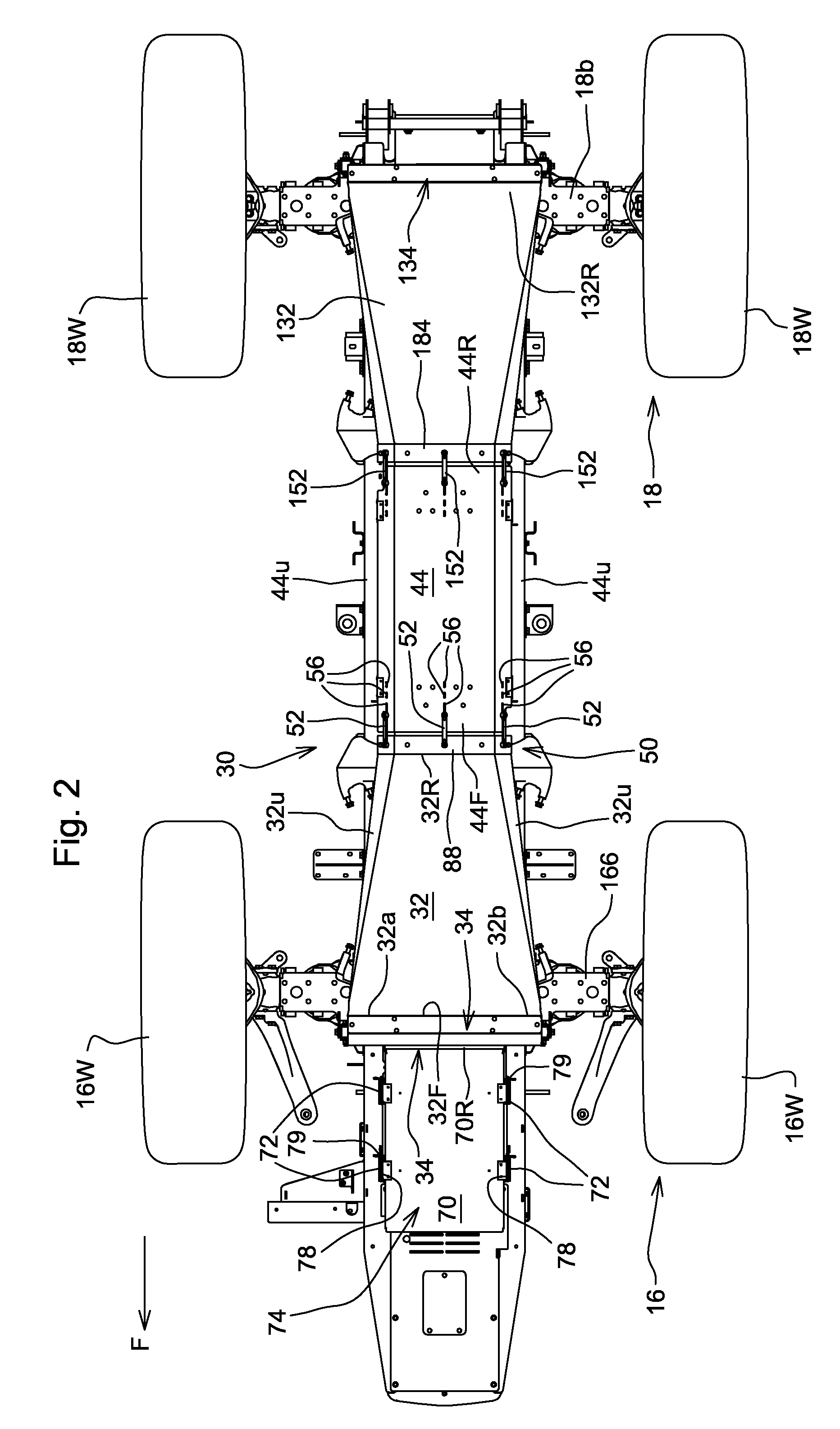

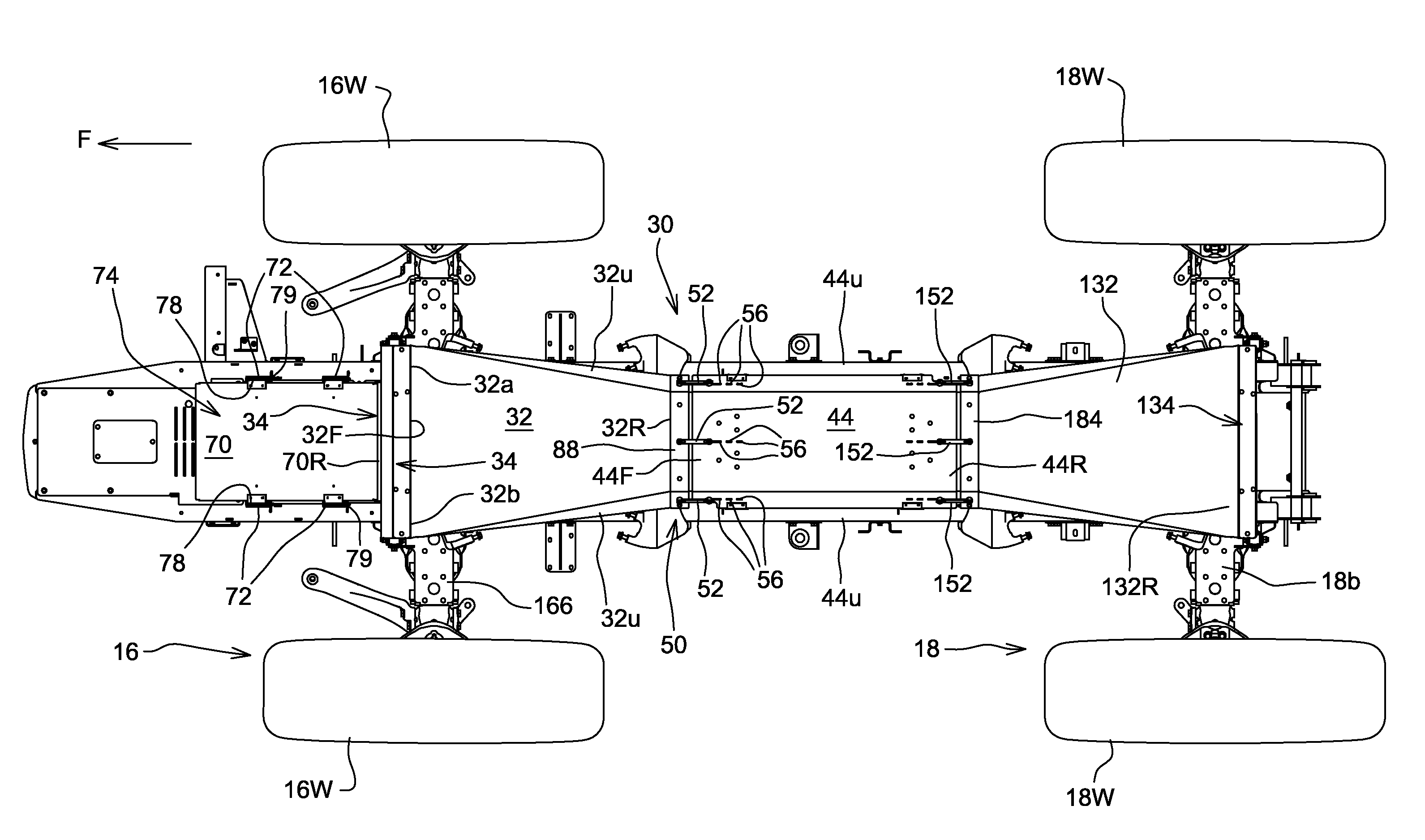

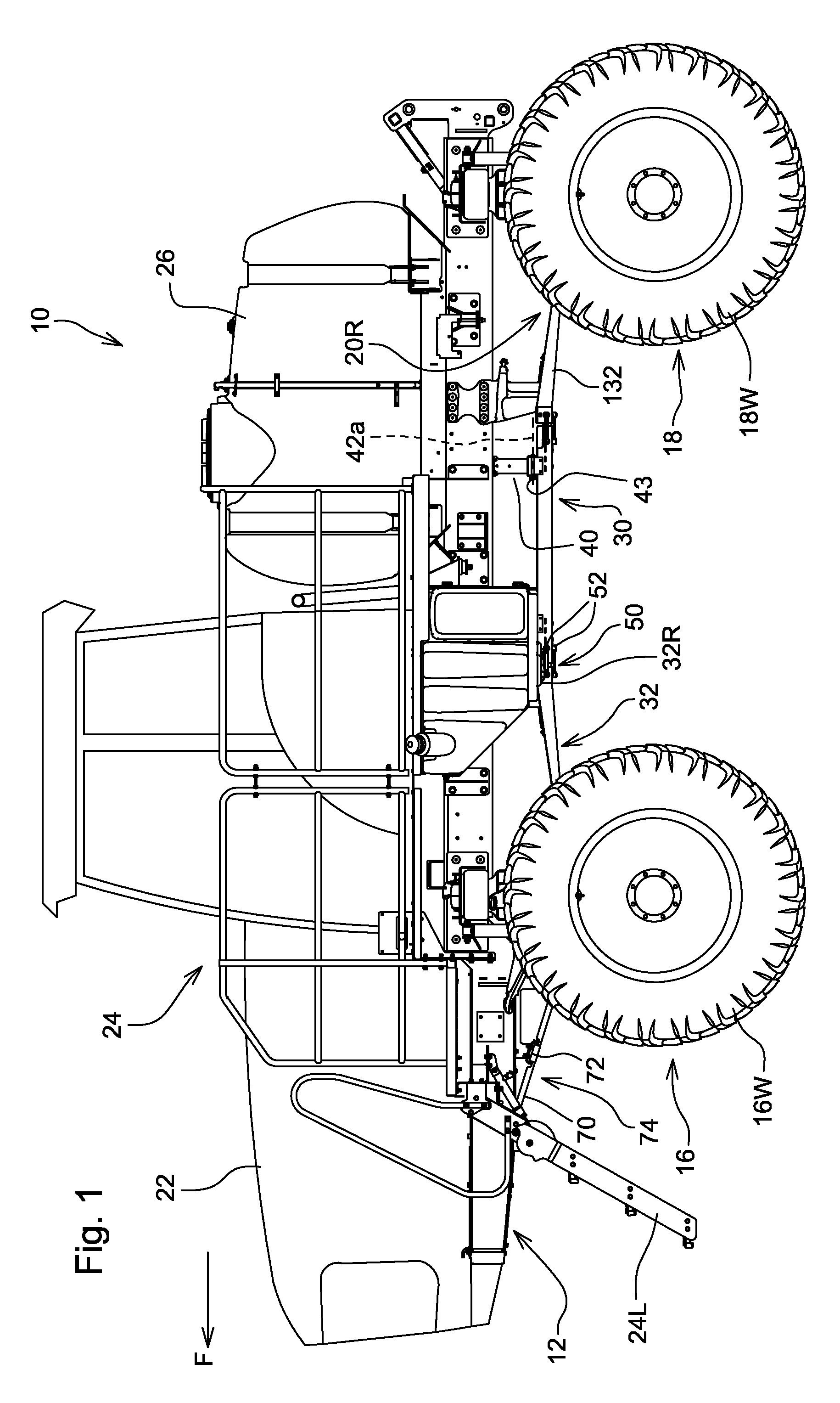

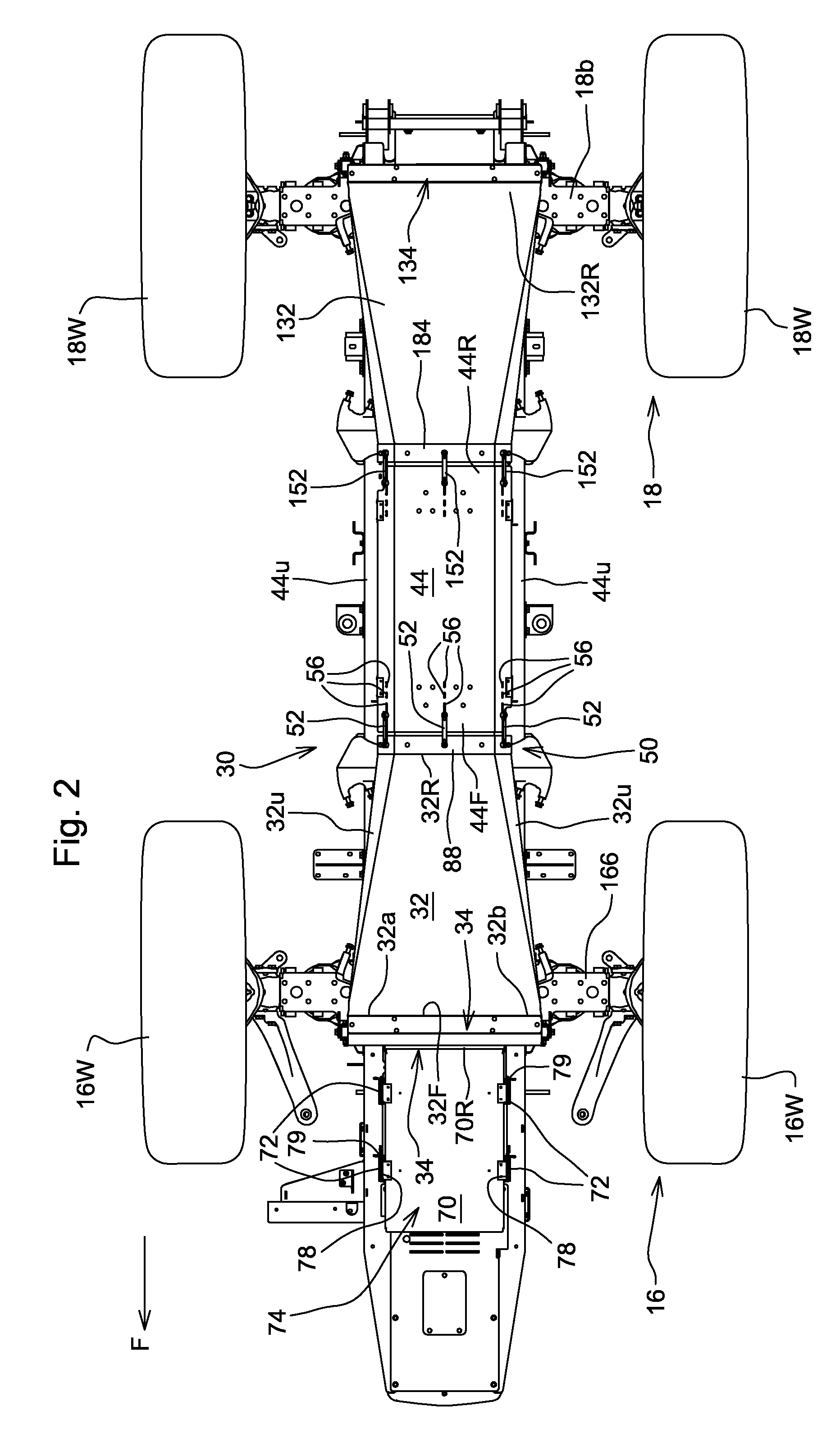

Flexible under-frame shield

An under-frame shield, particularly useful with crop sprayers and other implements which traverse fields of plants, includes one or more flexible sheet material shields connected to axle structure and to a central rigid shield by resilient connectors to facilitate suspension system movement in all directions without sacrificing ground clearance. The connection structure and sheet material shields maintain a smooth, seamless protective surface on the under side of the machine to reduce vehicle and crop damage.

Owner:DEERE & CO

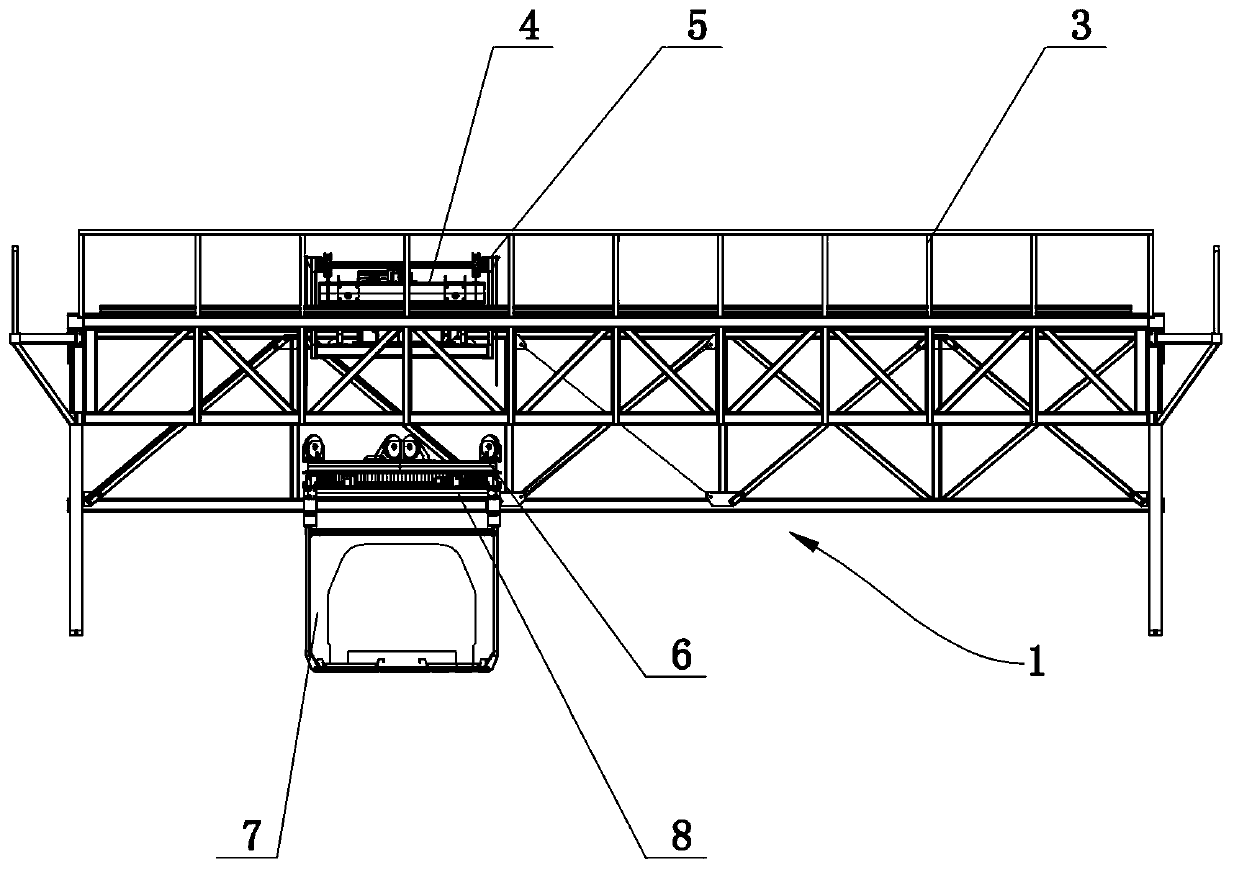

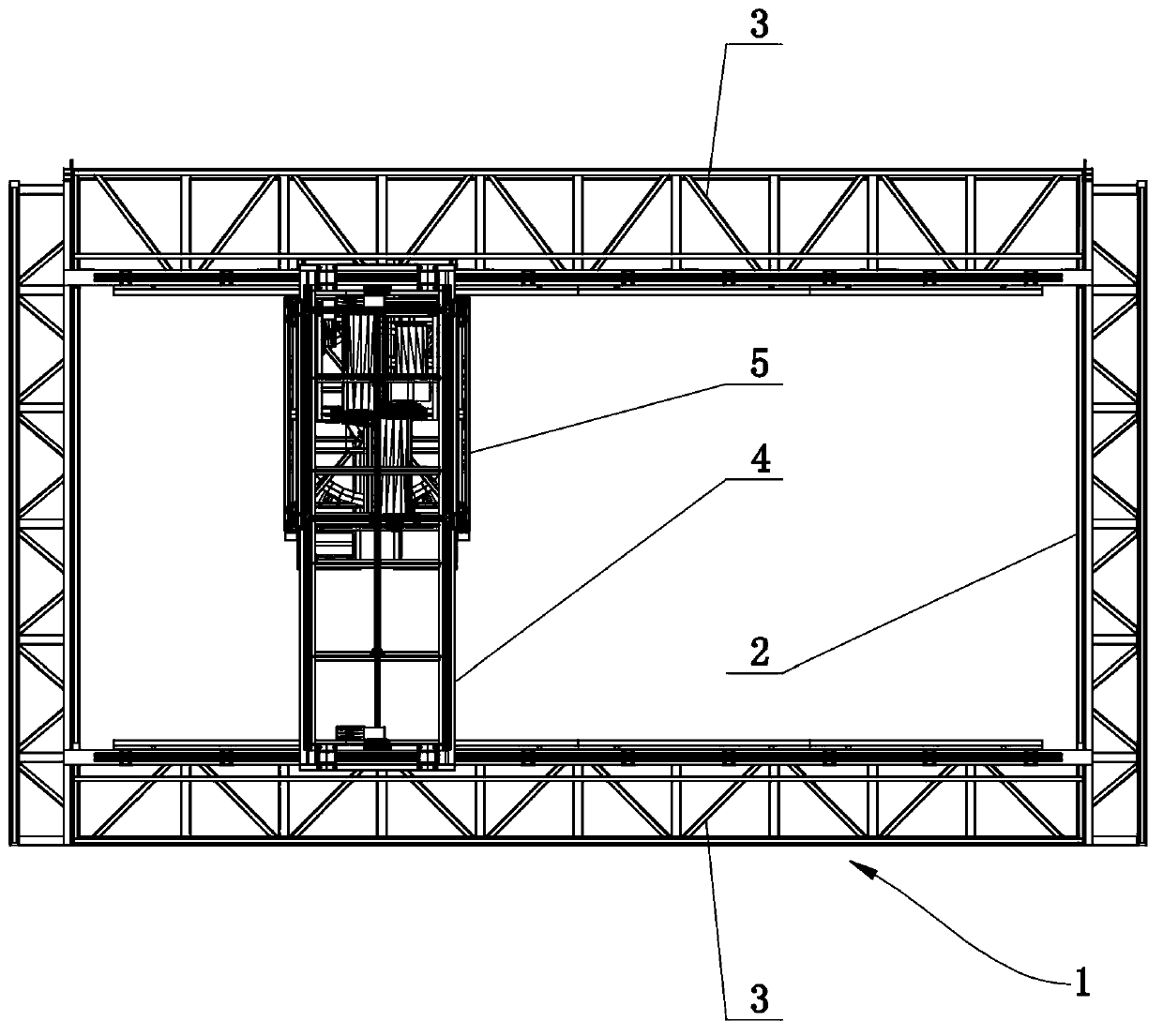

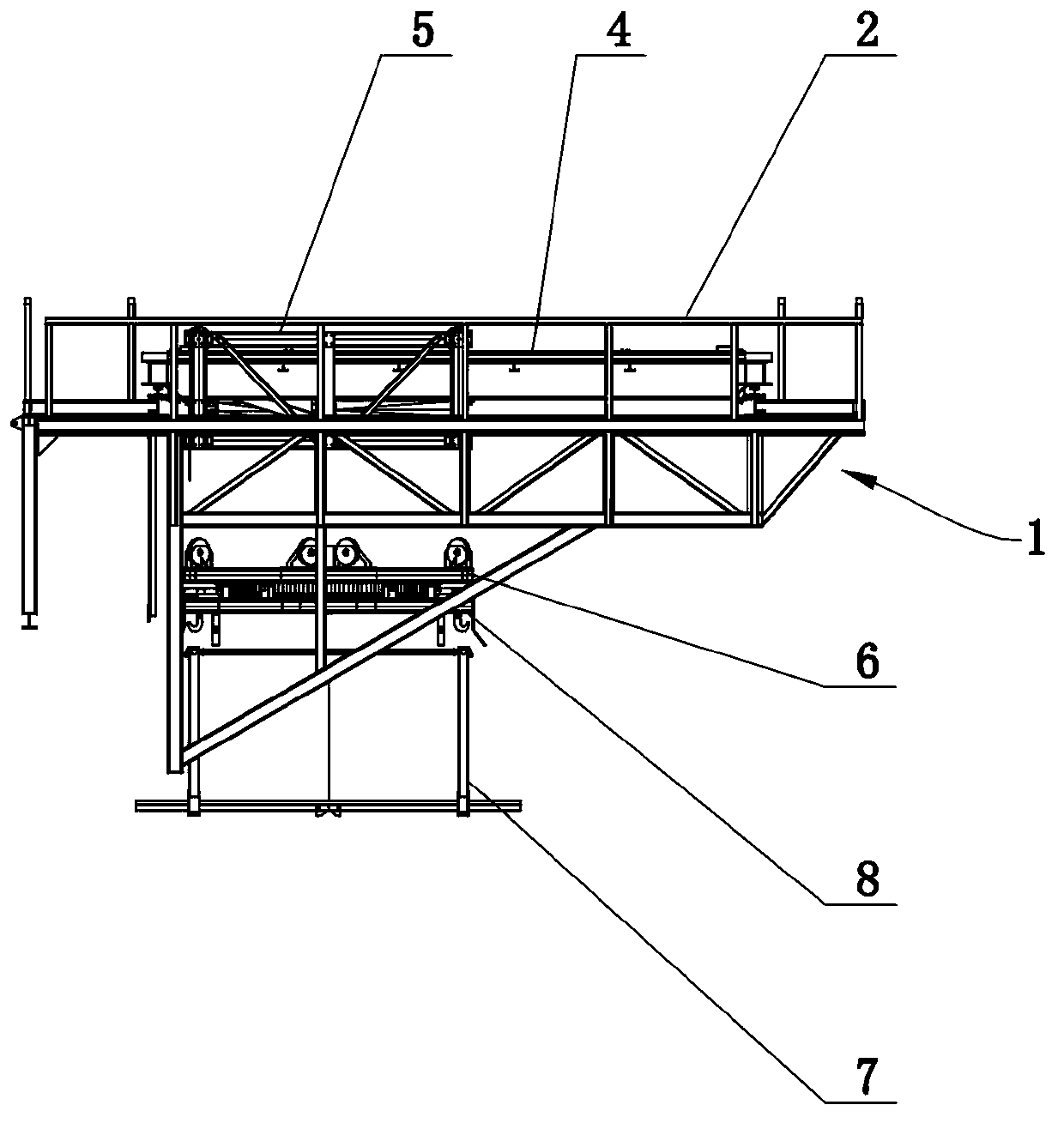

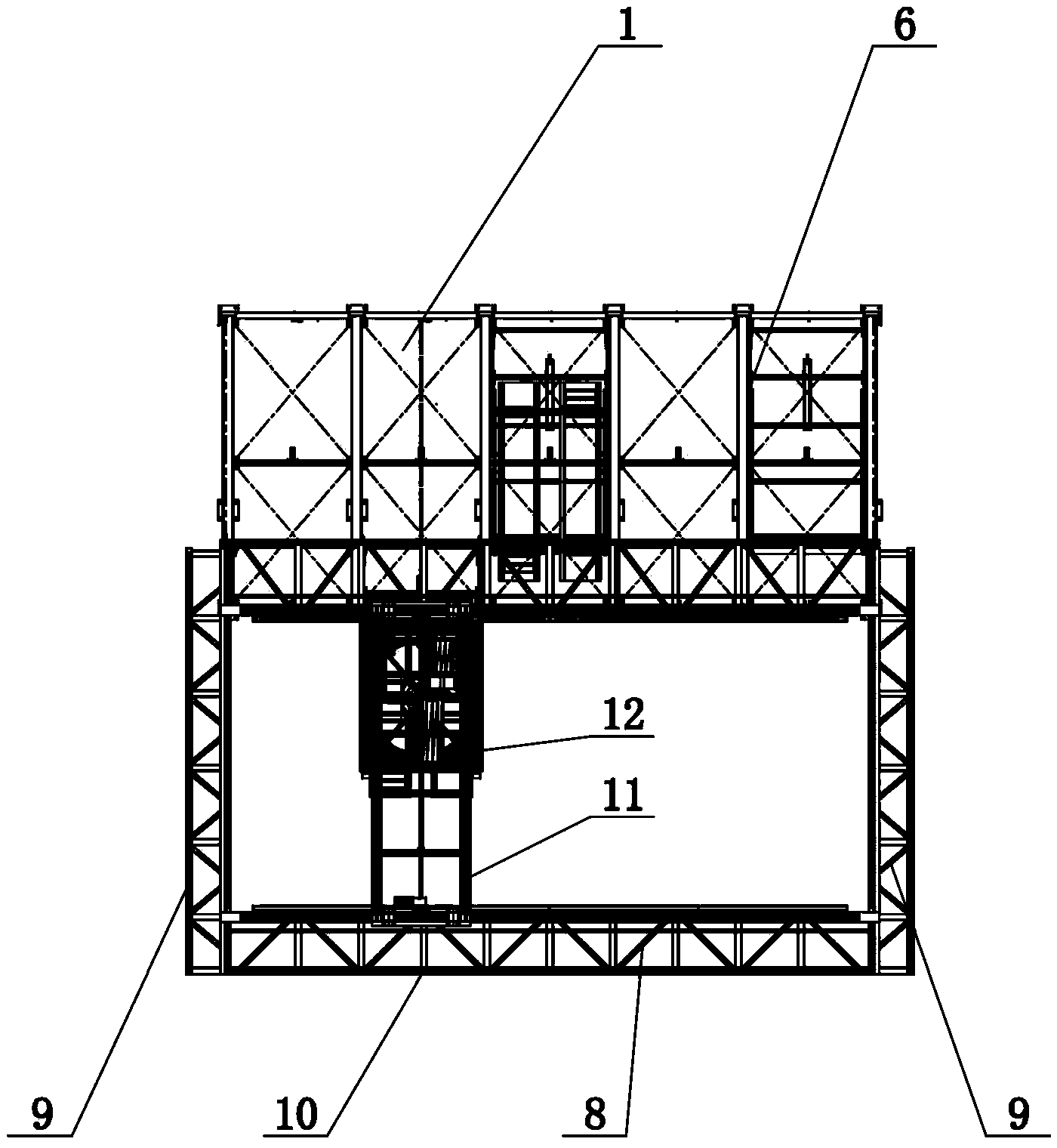

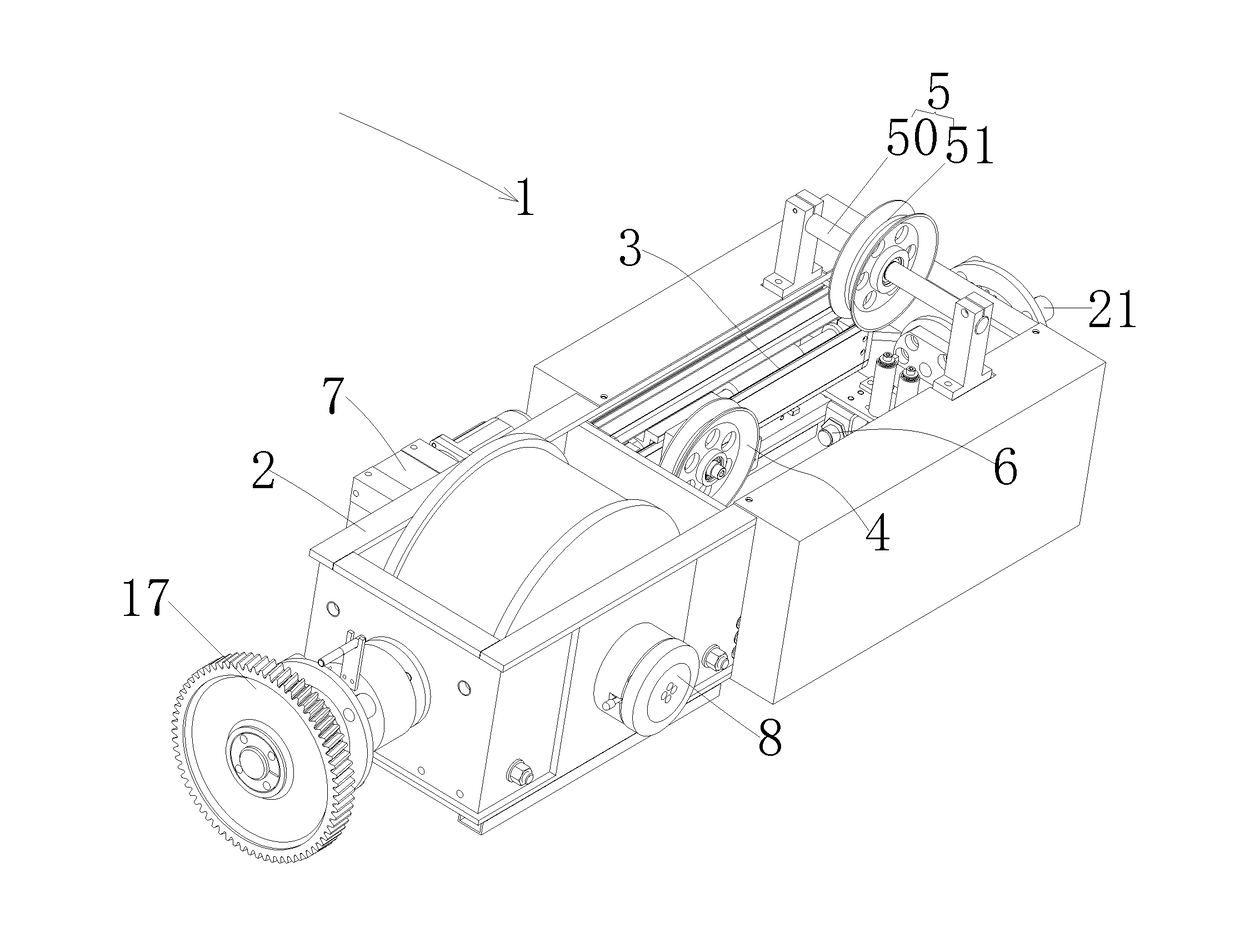

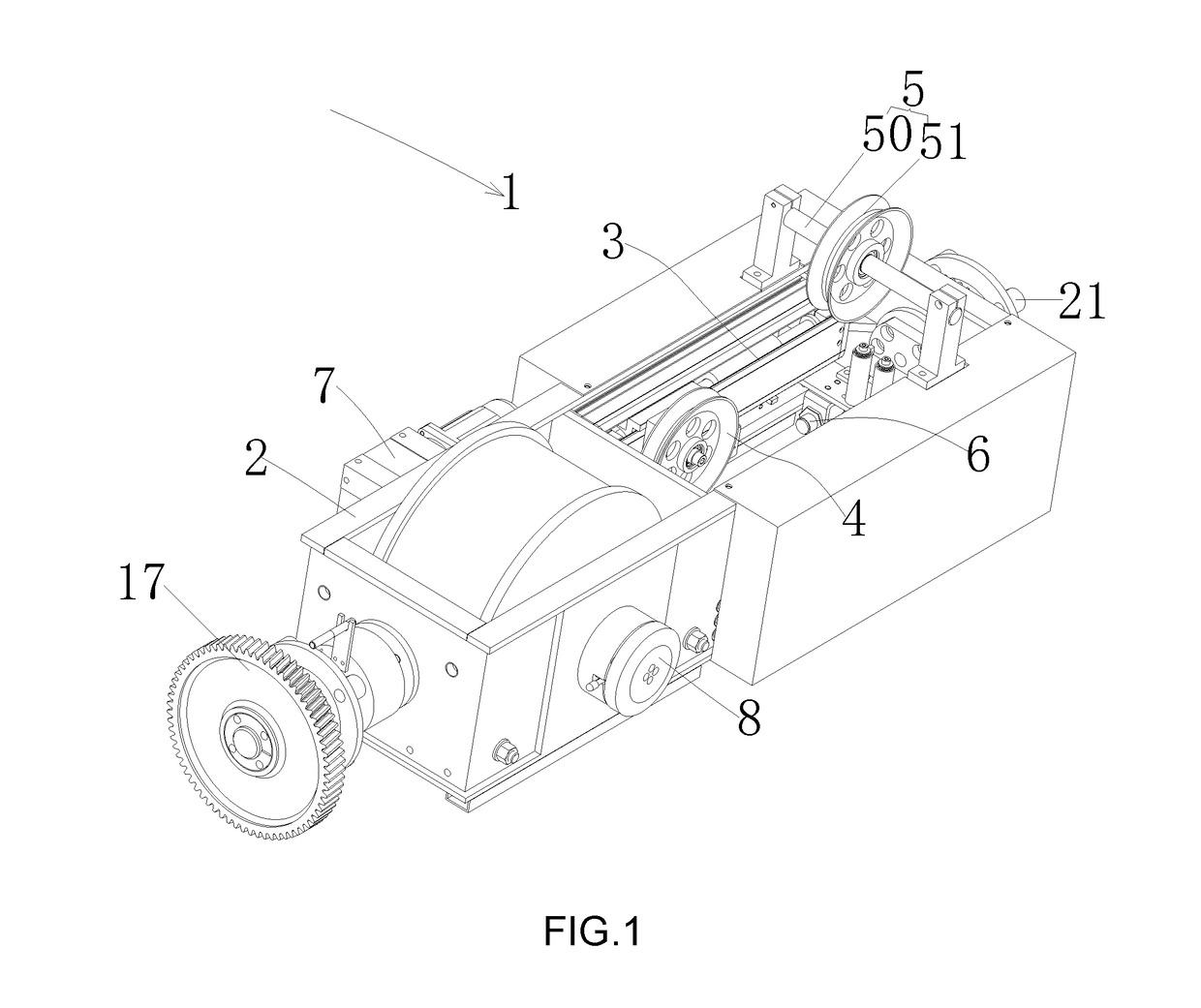

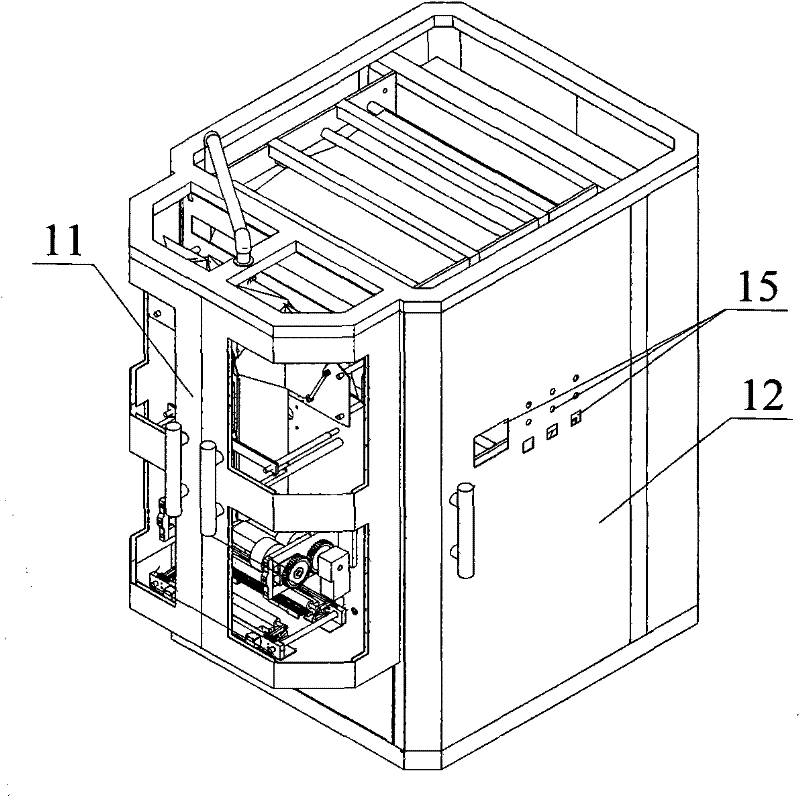

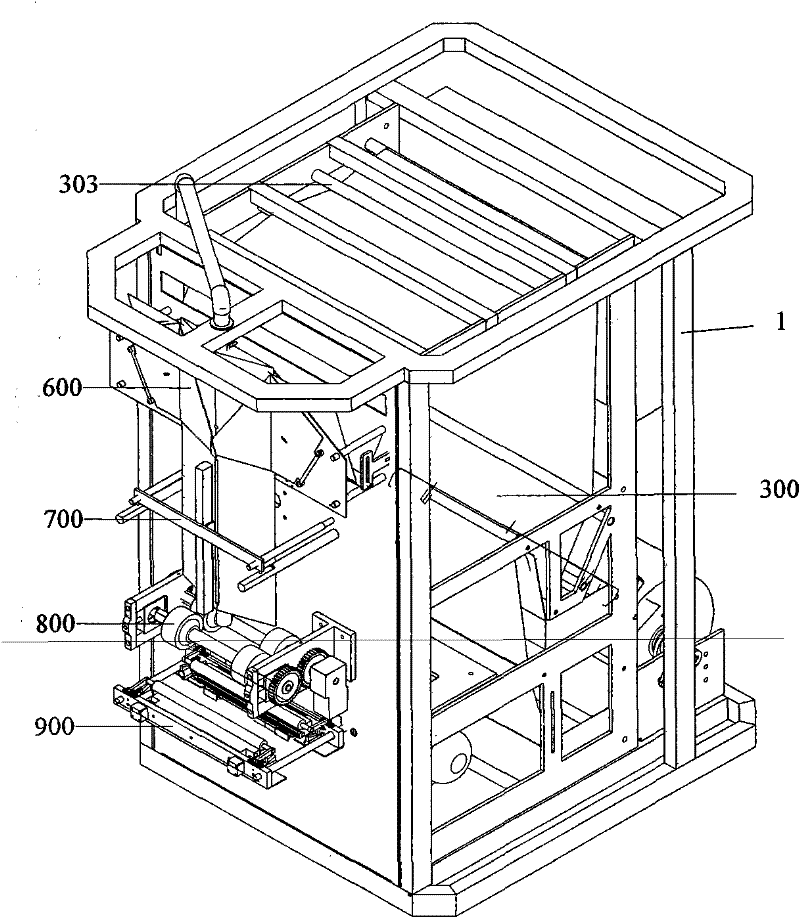

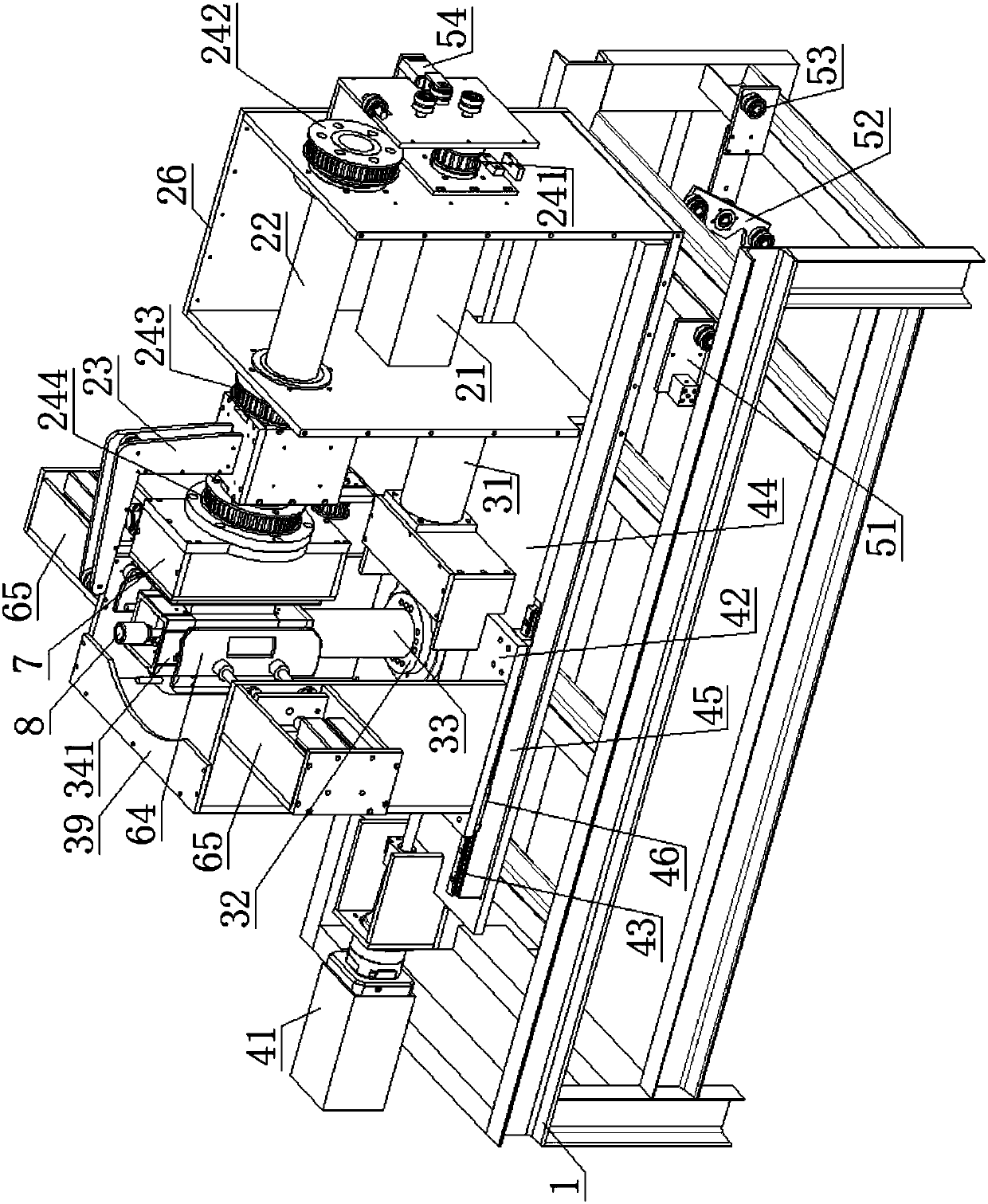

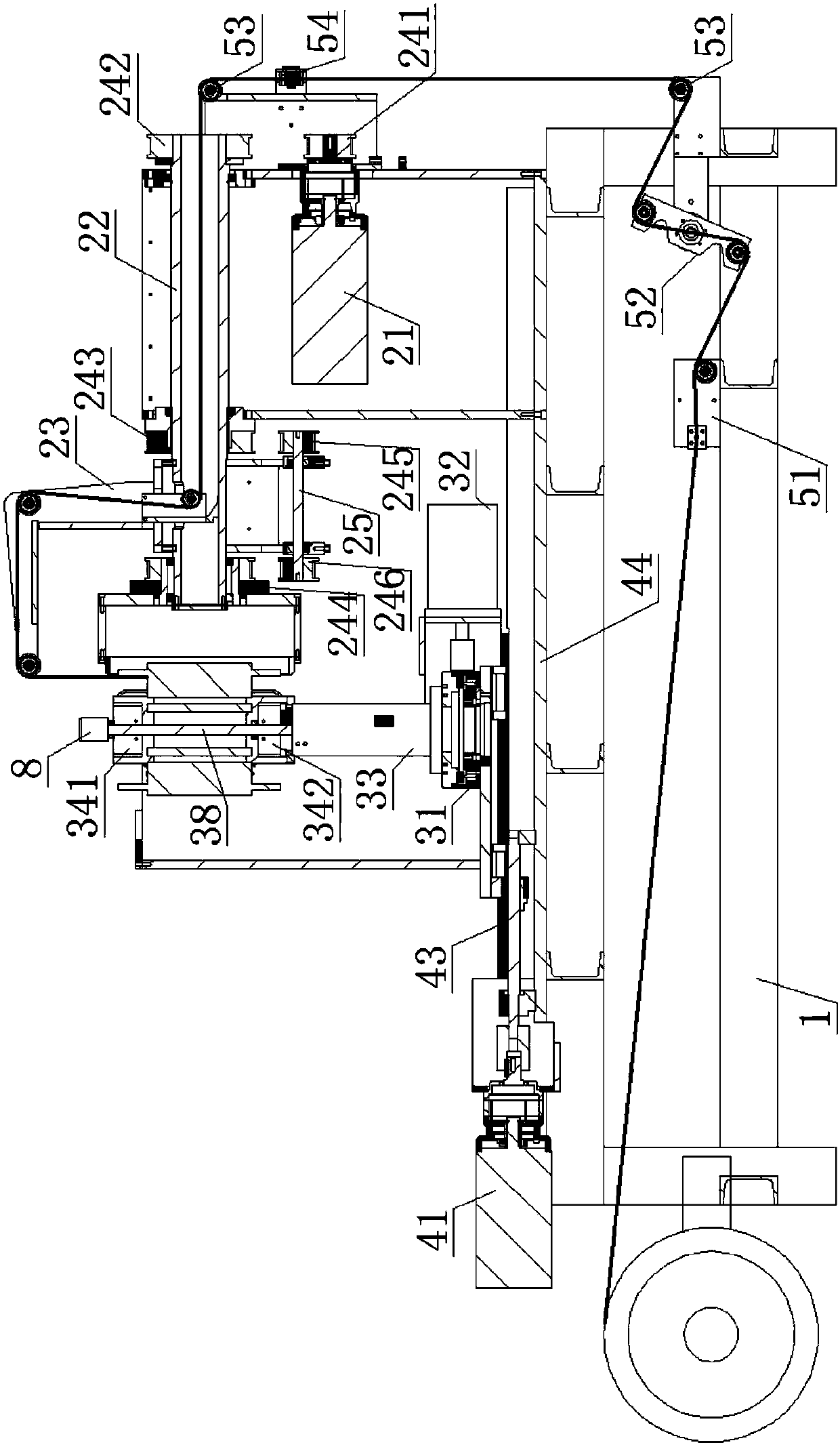

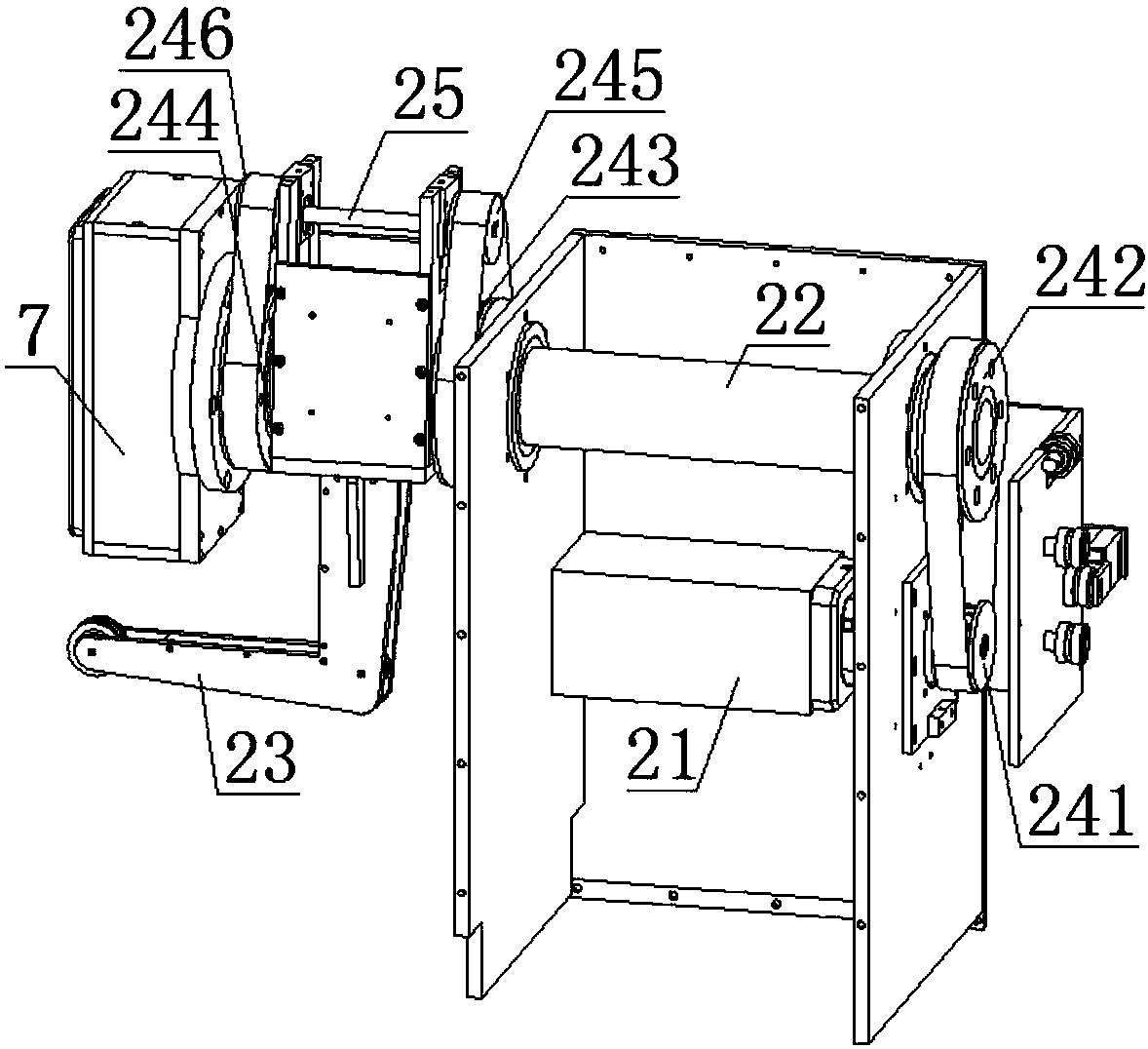

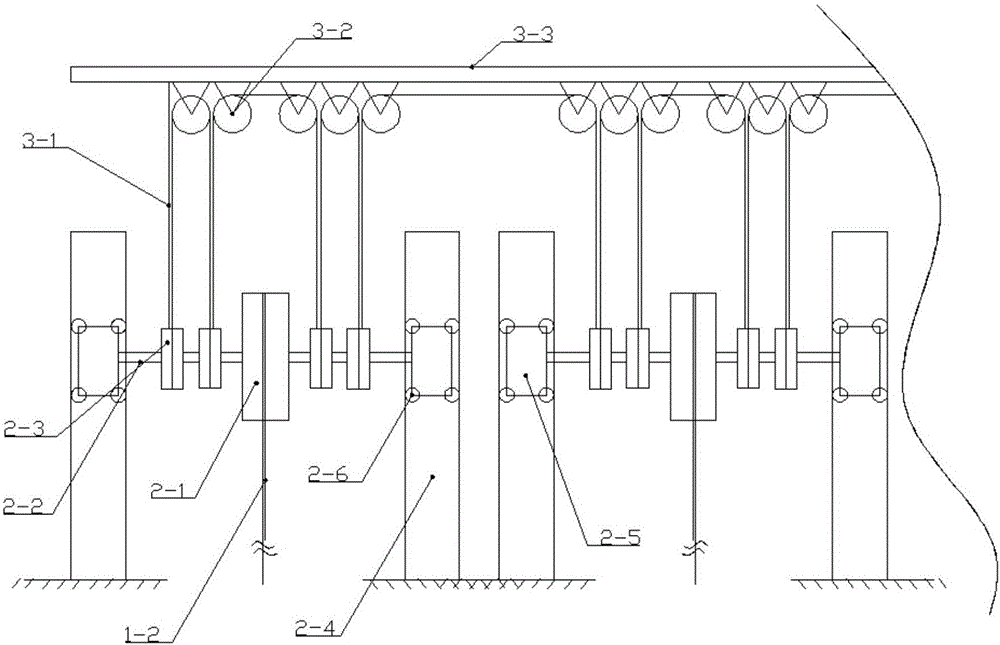

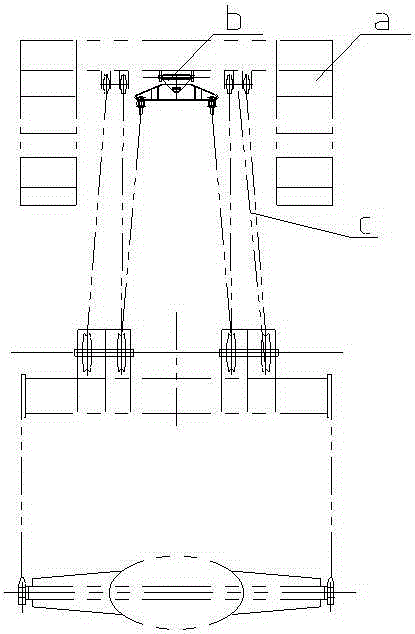

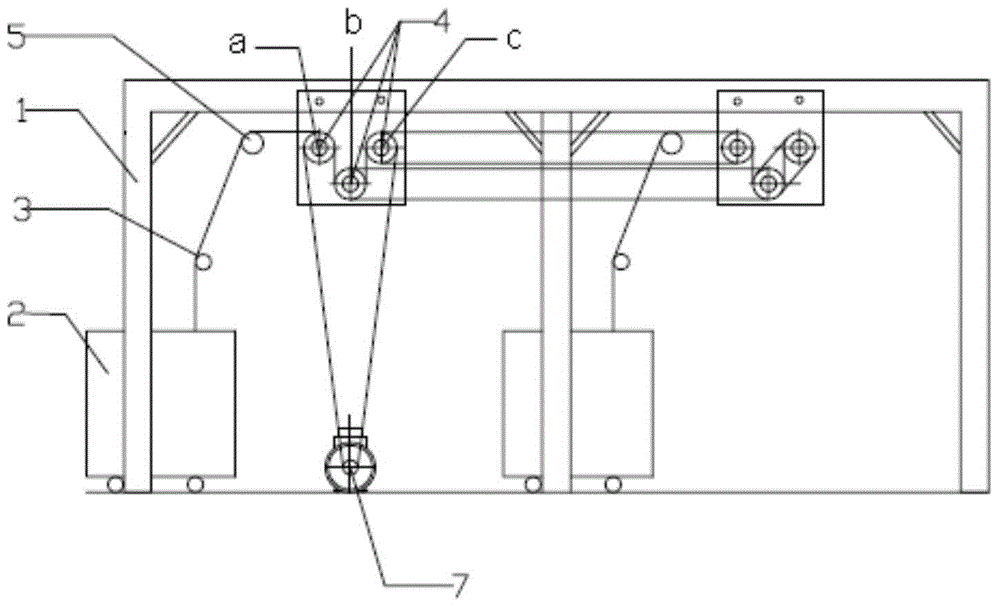

Four-freedom-degree vehicle carrier for three-dimensional parking equipment

The invention discloses a four-freedom-degree vehicle carrier for three-dimensional parking equipment and belongs to the technical filed of mechanical parking devices. The four-freedom-degree vehicle carrier comprises a cantilever support above a top-layer parking space, the cantilever support comprises two oppositely-arranged cantilever longitudinal beams and two oppositely-arranged cantilever cross beams, and the cantilever longitudinal beams and the cantilever cross beams are arranged in a rectangular mode. A transversely-moving mechanism driven by a first power plant is arranged on the cantilever support in a transversely-moving mode, and a longitudinally-moving mechanism driven by a second power plant is arranged on the transversely-moving mechanism in a longitudinally-moving mode. The longitudinally-moving mechanism is provided with a lifting transmission mechanism which is driven by a third power plant and capable of lifting in the vertical direction, and the lifting transmission mechanism is connected with a grabbing rotary mechanism which is driven by a fourth power plant and capable of rotating around a vertical axial line and used for grabbing lifting vehicle platforms. The four-freedom-degree vehicle carrier does not occupy ground space and enables arrangement of garage entrances and exits to be flexible; in the process of parking and taking vehicles, transverse moving, longitudinal moving, lifting and rotating of the vehicles and the lifting vehicle platforms can be finished at the same time, and working efficiency of parking and taking the vehicles is improved.

Owner:DAYANG PARKING CO LTD

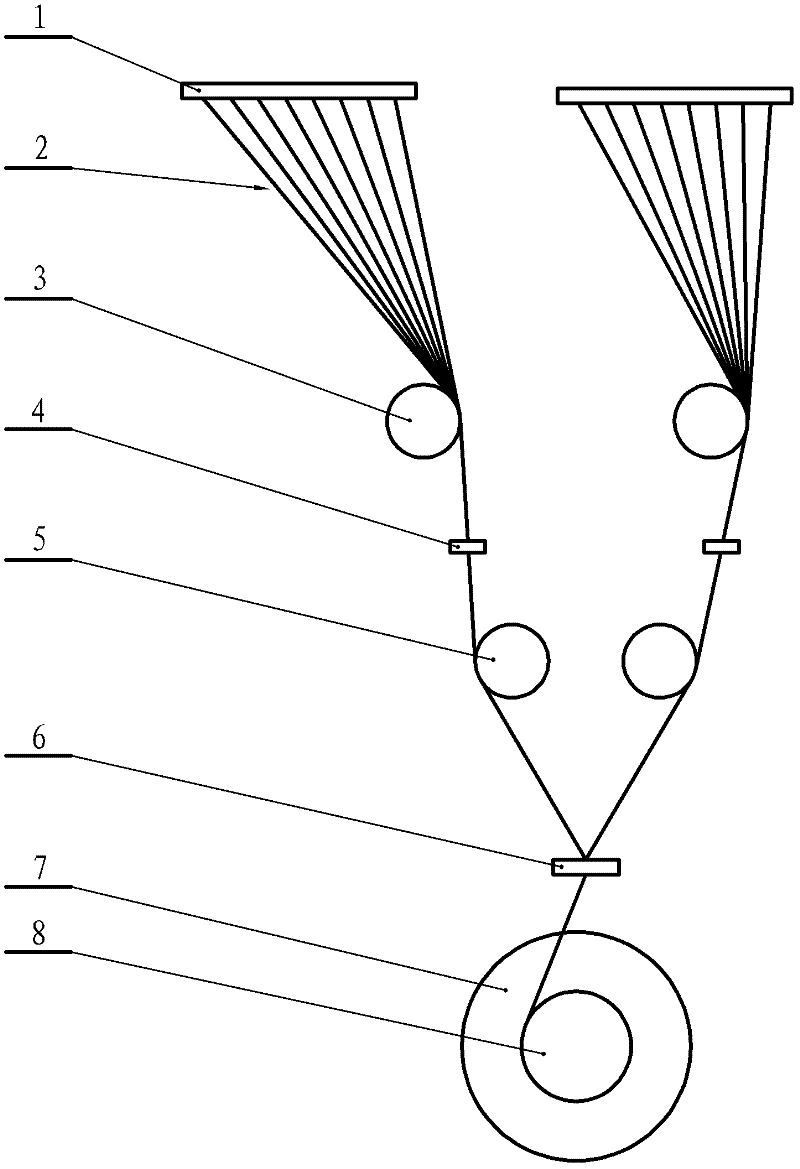

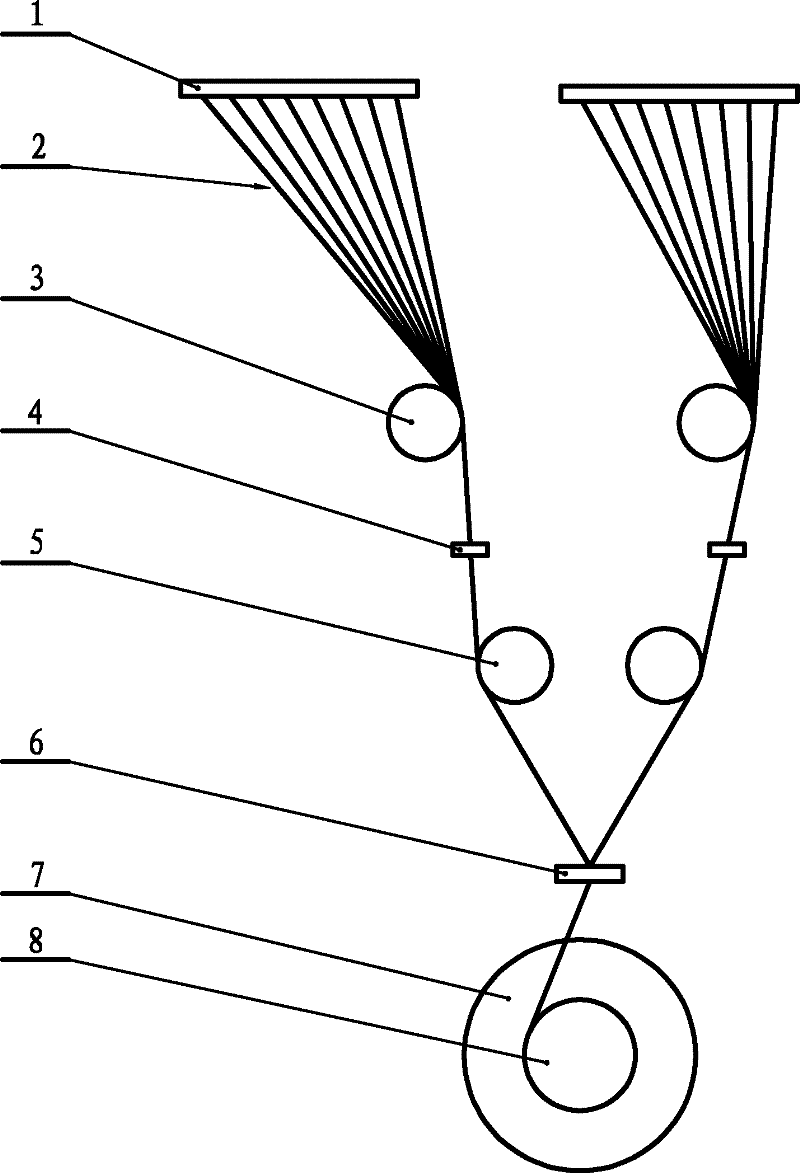

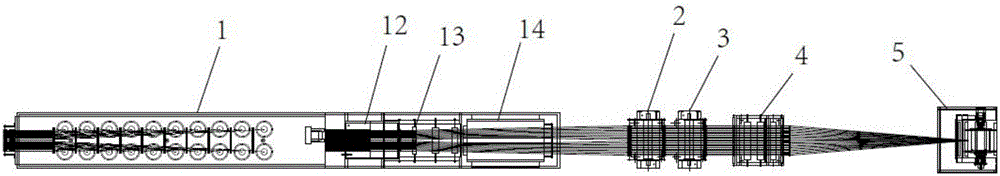

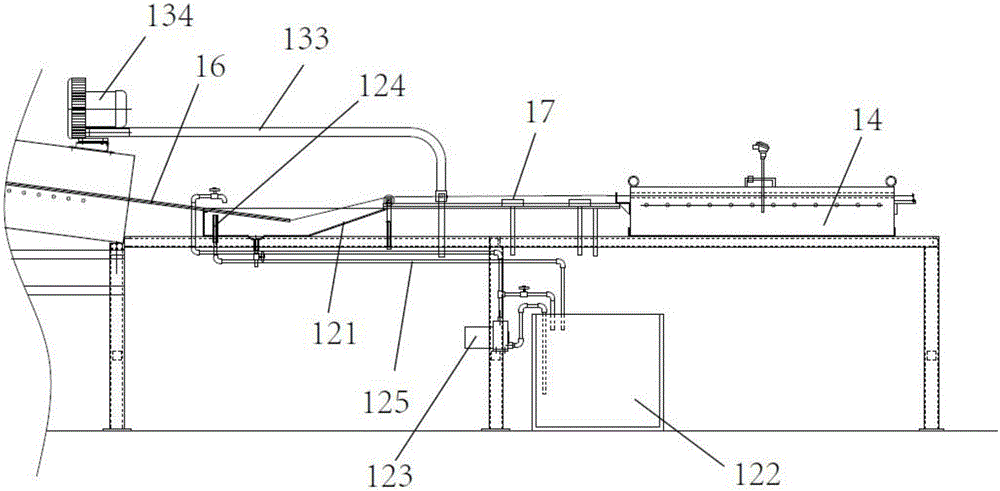

Multi-bushing plate merging wiredrawing technology and multi-bushing plate wiredrawing device employing it

ActiveCN102515504ASimplify temperature controlReduce manufacturing costGlass making apparatusGlass fiberEngineering

The invention provides a multi-bushing plate merging wiredrawing technology. Specifically, 2 or more bushing plates are employed, and each bushing plate is provided with a plurality of leaks. Molten glass flows through each leak of each bushing plate and is cooled, and then a plurality of glass fibers can be obtained through wiredrawing molding respectively. Pulled by a wiredrawing machine driven wire cylinder, the glass fibers respectively pass through multiple upper bunchers and are neatened and gathered into glass fiber bundles, which are then neatened and gathered by a gathering buncher into a complete glass fiber bundle that is then wound on the wire cylinder into a finished glass fiber bundle. A multi-bushing plate wiredrawing device is provided with 2 or more bushing plates, each of which is equipped with a plurality of leaks. An upper buncher is installed behind each bushing plate respectively, a gathering buncher is arranged behind each upper buncher, the wiredrawing machine is disposed behind the gathering buncher, the wire cylinder is positioned on the gathering buncher, and the wire cylinder and the wiredrawing machine are in driving rotary connection. With the technology and device provided in the invention, the manufacturing cost of a bushing plate for a glass fiber bundle with a great weight of per unit length can be reduced, the band forming property of the glass fiber bundle can be improved, and the effect can be obvious.

Owner:CHONGQING POLYCOMP INT

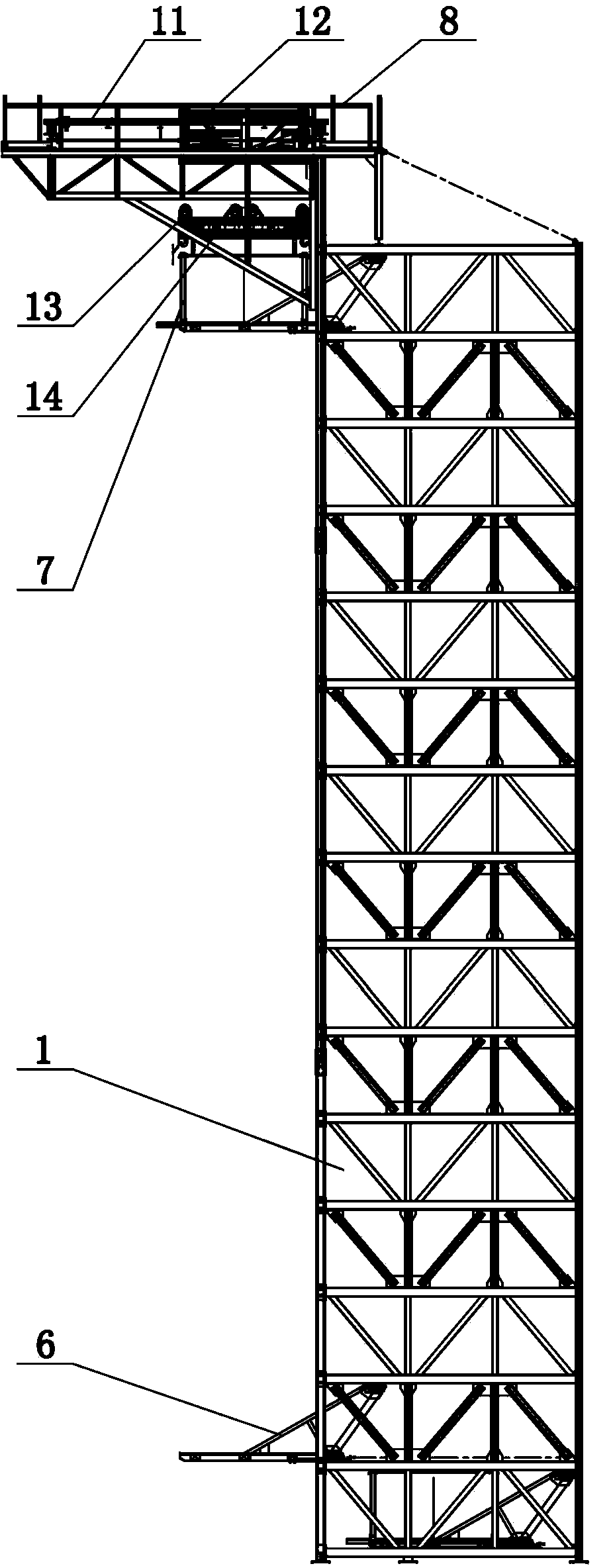

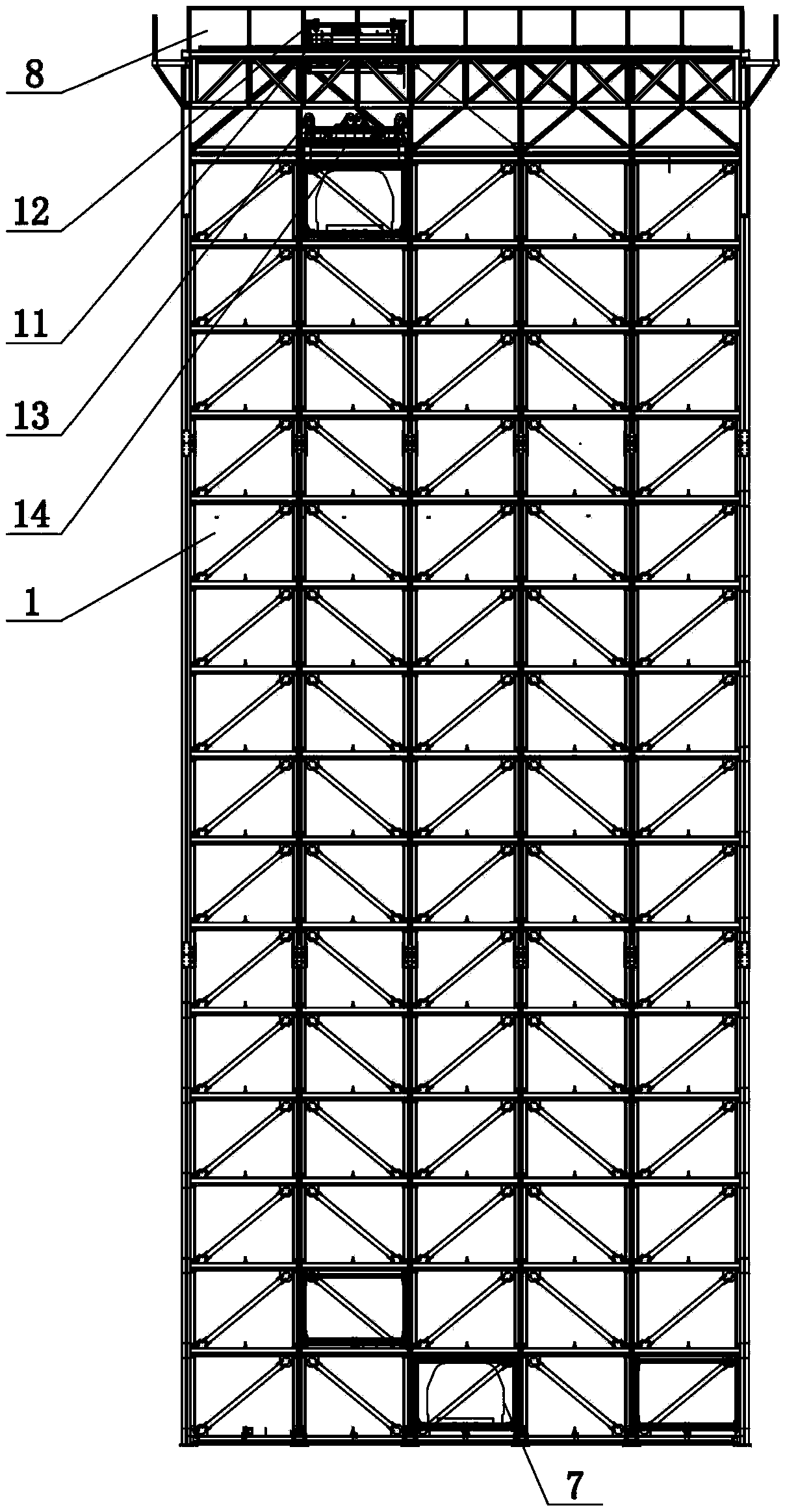

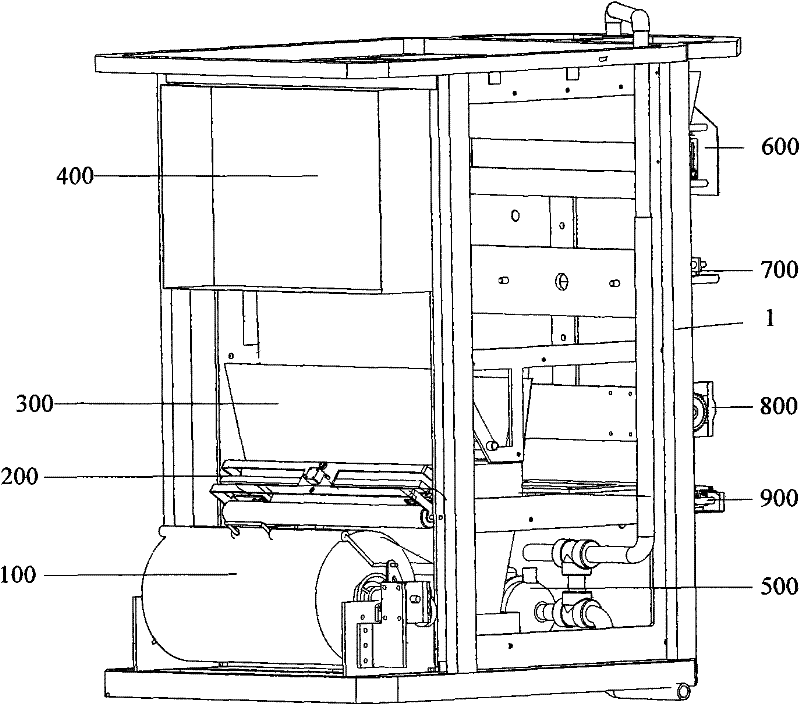

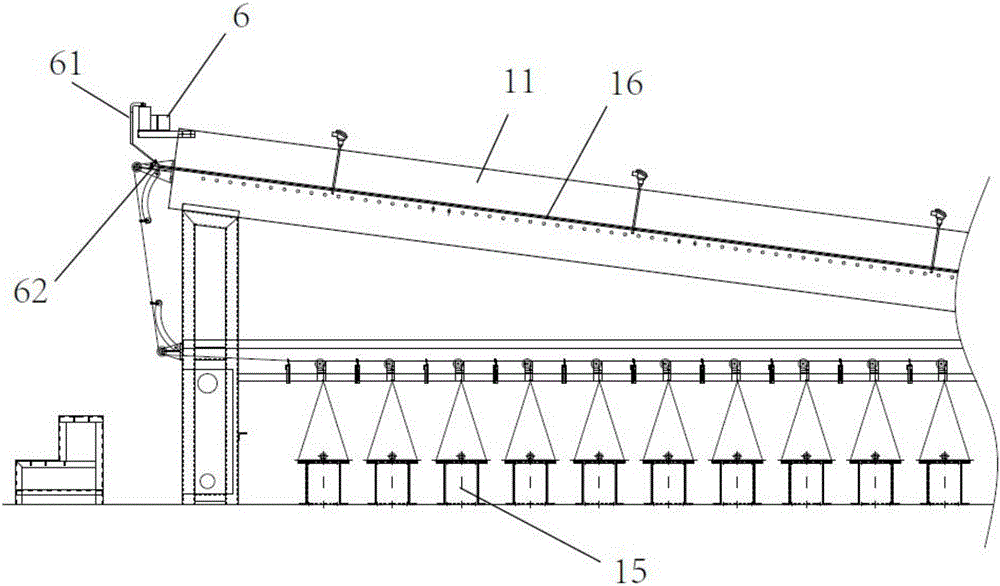

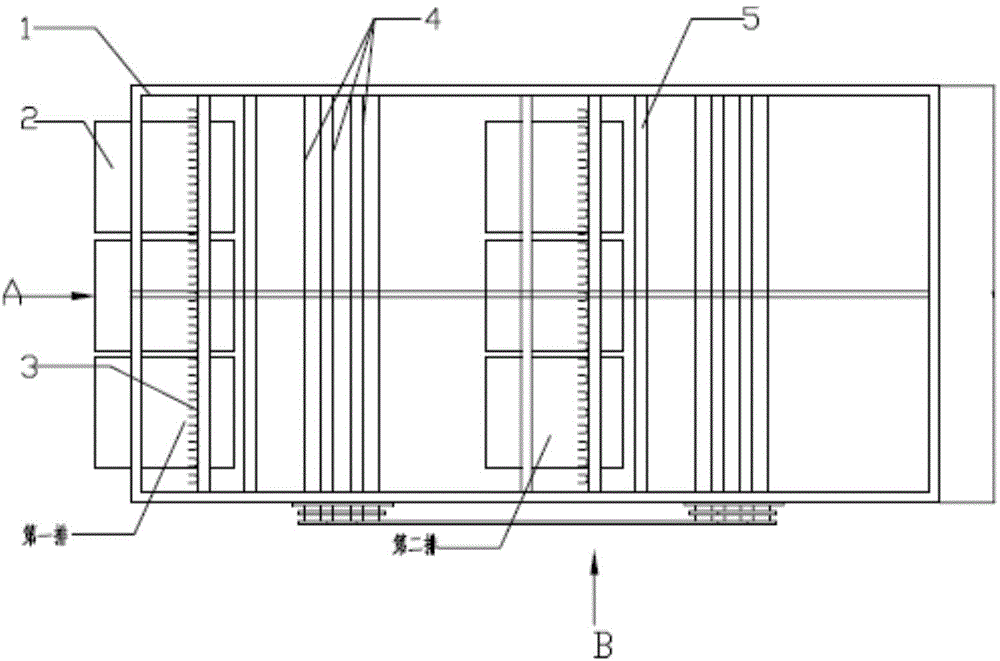

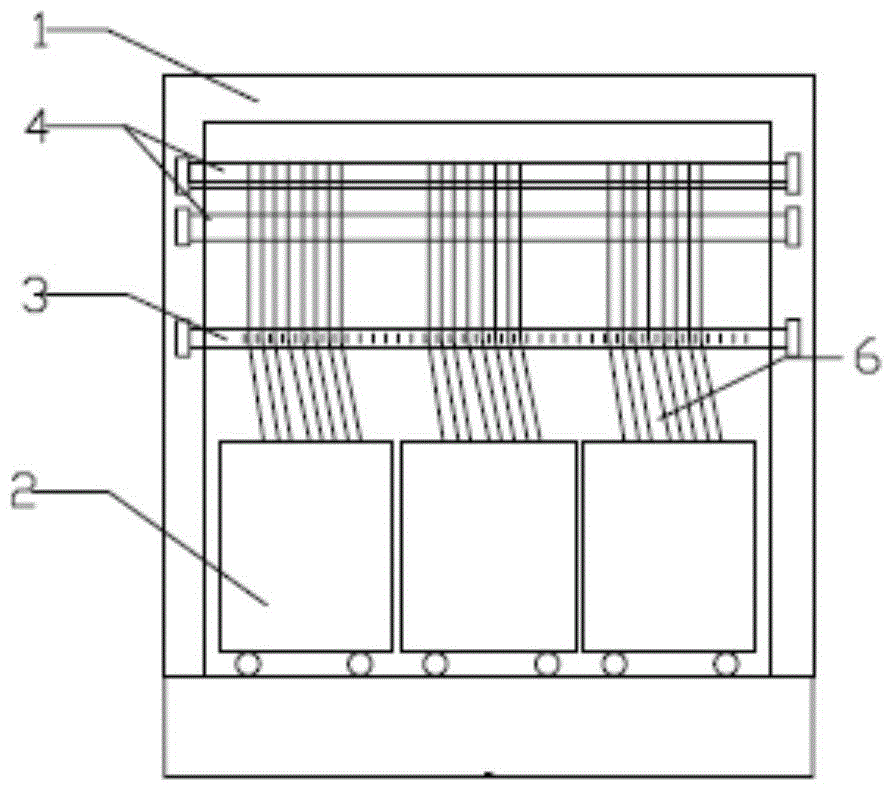

Lifting longitudinal-moving-type stereoscopic parking device

The invention discloses a lifting longitudinal-moving-type stereoscopic parking device, and belongs to the technical field of mechanical parking devices. The lifting longitudinal-moving-type stereoscopic parking device comprises a plurality of rectangular parking places arranged in an array mode. A longitudinal-moving storing and taking mechanism driven by a first power device is installed inside each parking place in a longitudinal-moving mode. A lifting truck platform is placed in each longitudinal-moving storing and taking mechanism. A cantilever support is installed above the top-layer packing place. A transverse-moving mechanism driven by a second power device is installed on the cantilever support in a transverse-moving mode. A longitudinal-moving mechanism driven by a third power device is installed on the transverse-moving mechanism in a longitudinal-moving mode. A lifting transmission mechanism driven by a fourth power device is installed on the longitudinal-moving mechanism. A grabbing swinging mechanism driven by a fifth power device is connected with the lifting transmission mechanism. According to the lifting longitudinal-moving-type stereoscopic parking device, the power devices are independent, the working efficiency of storing and taking trucks is improved, full stations are achieved, namely vacated parking places do not exist, the storage number of the trucks is increased, and the land utilization rate is improved.

Owner:DAYANG PARKING CO LTD

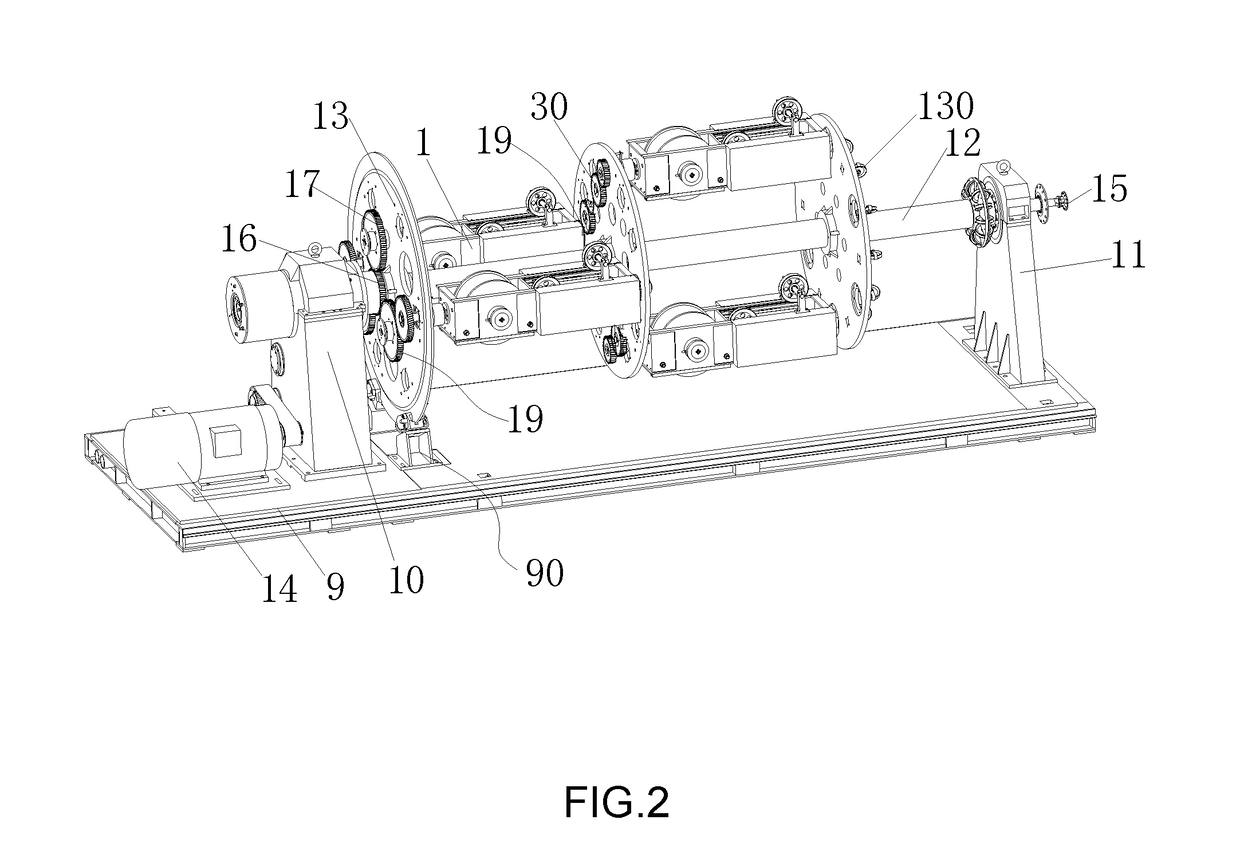

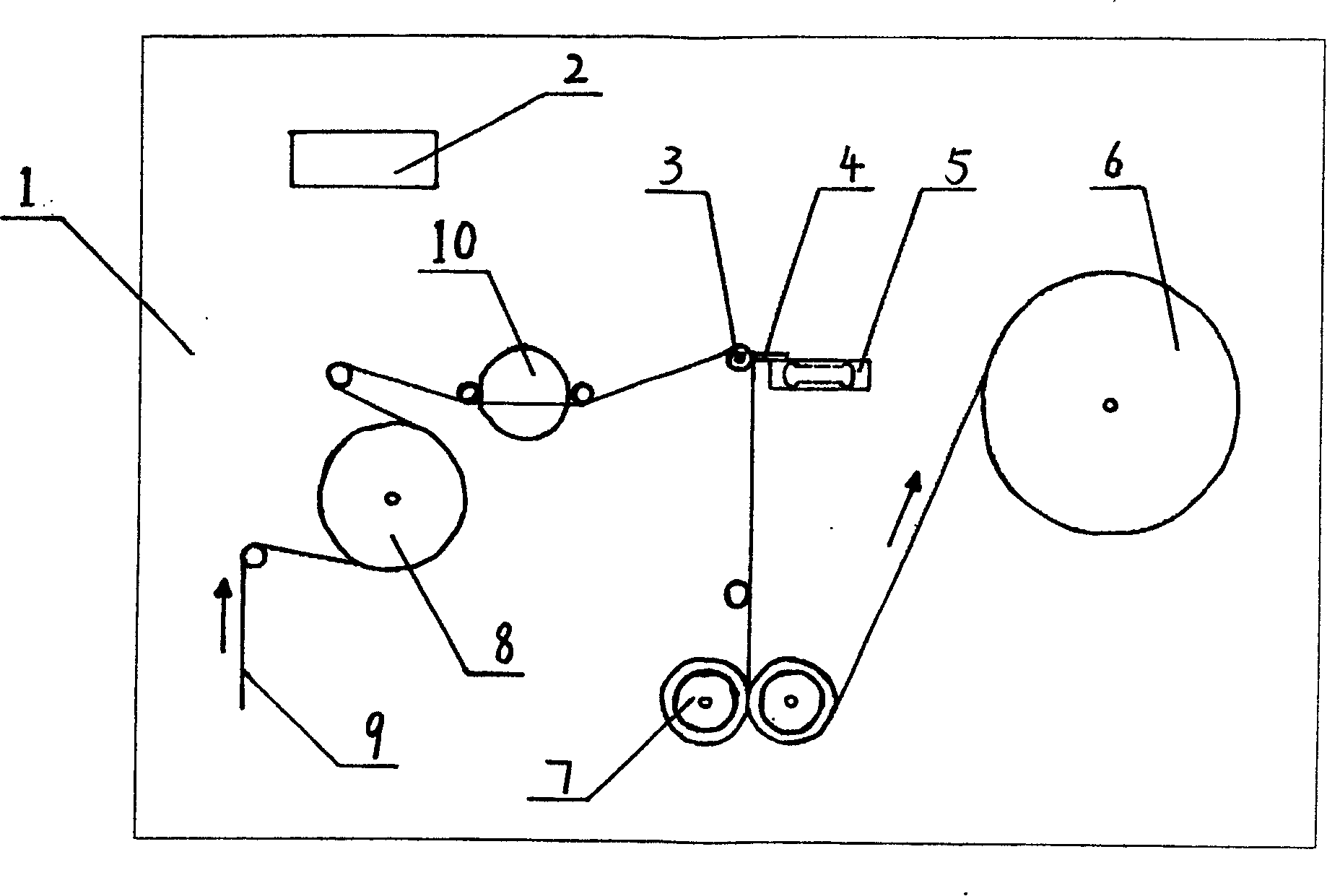

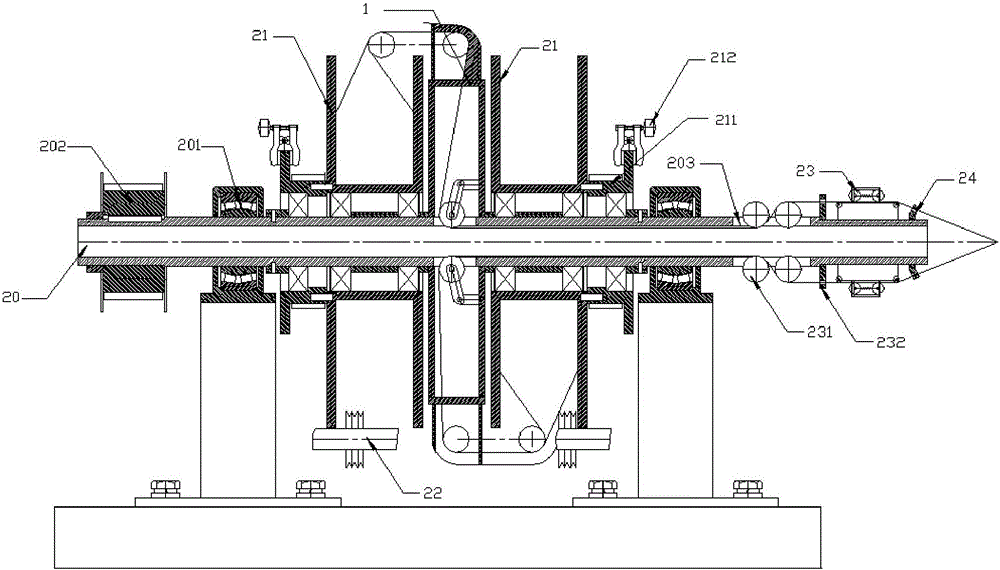

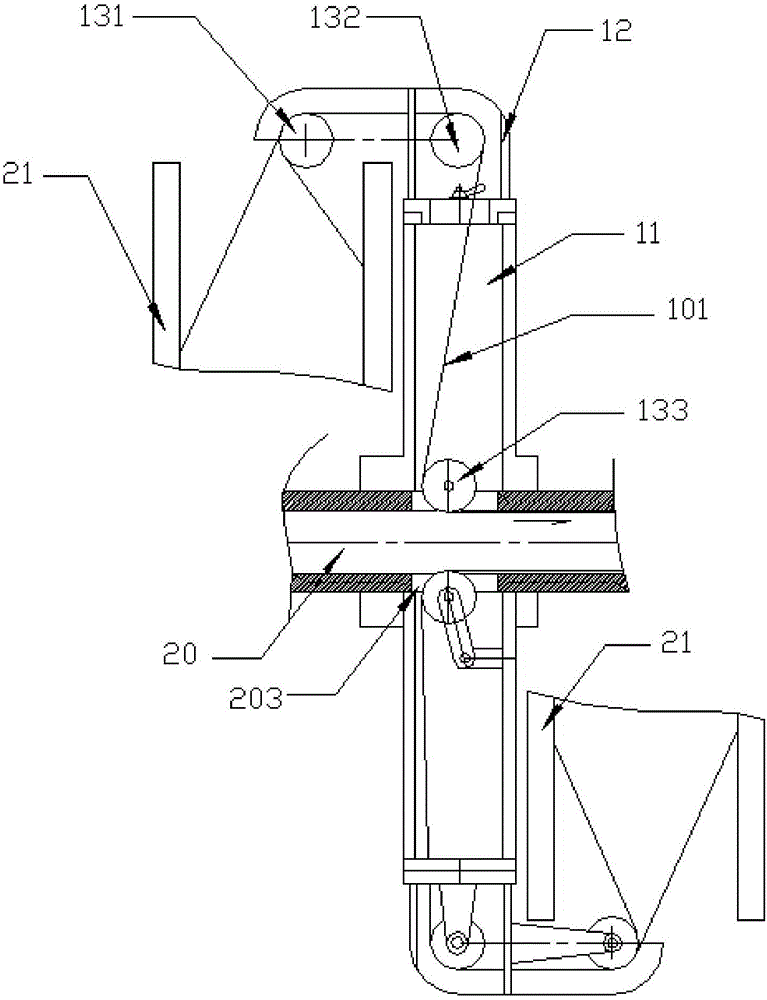

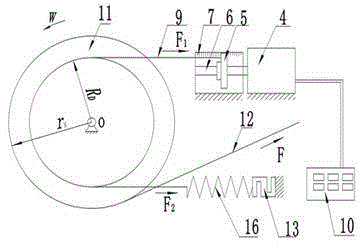

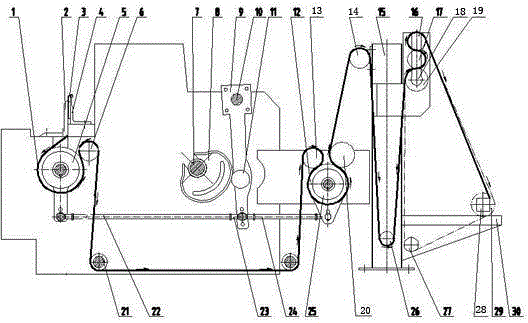

Kind of Power Paying-off Cradle and Power Paying-off Full-automatic Stranding Cable Machine

A power paying-off cradle consisting of power paying-off component and framework. In the framework is a cavity with an upper opening; a wire tension balance mechanism is installed in the cavity; a displacement wheel is installed on the wire tension balance mechanism, and a position detector of the displacement wheel is installed on the inner side wall of the framework; a turning wheel is installed on the front top of the framework; a thread hole is installed in the front of the framework; wire on the paying-off spool enwinds the turning wheel and the displacement wheel successively and passes through the thread hole. The wire tension balance mechanism has damping effect on the displacement wheel. When the tension of the displacement wheel is greater than or less than the damping force, the displacement wheel moves in order to ensure consistency of the tension or the strain of wire.

Owner:DONGGUAN QINGFENG ELECTRIC MACHINERY

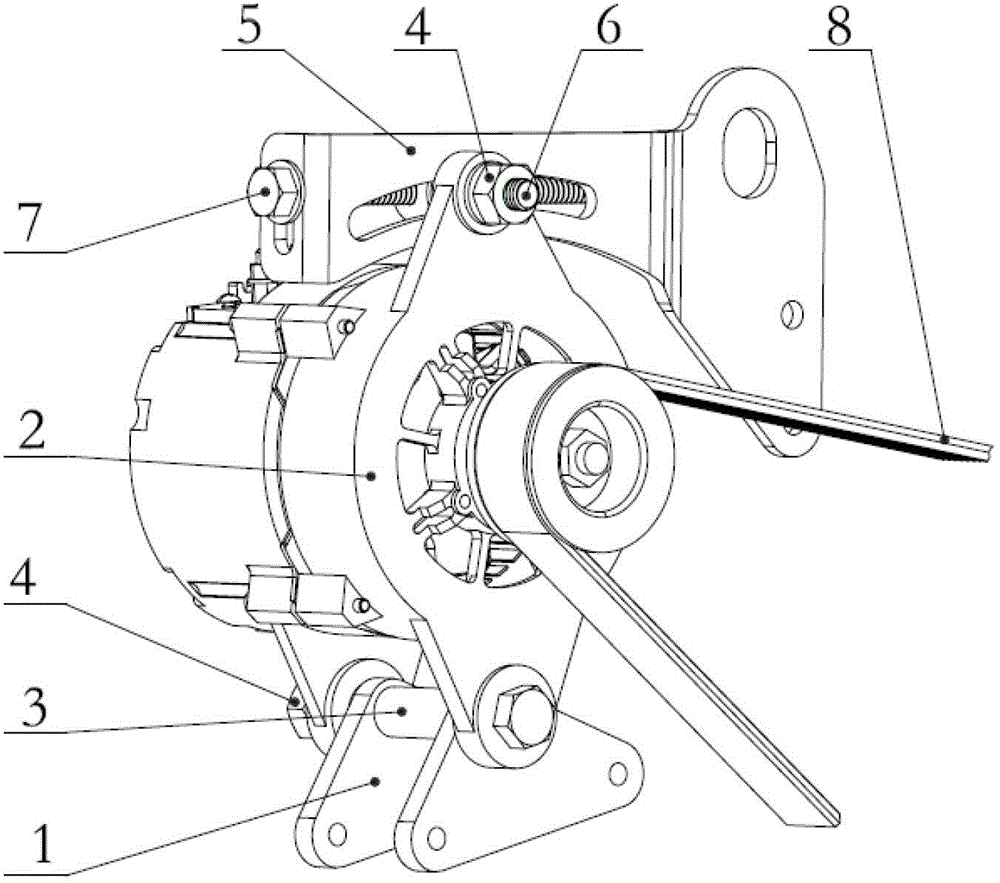

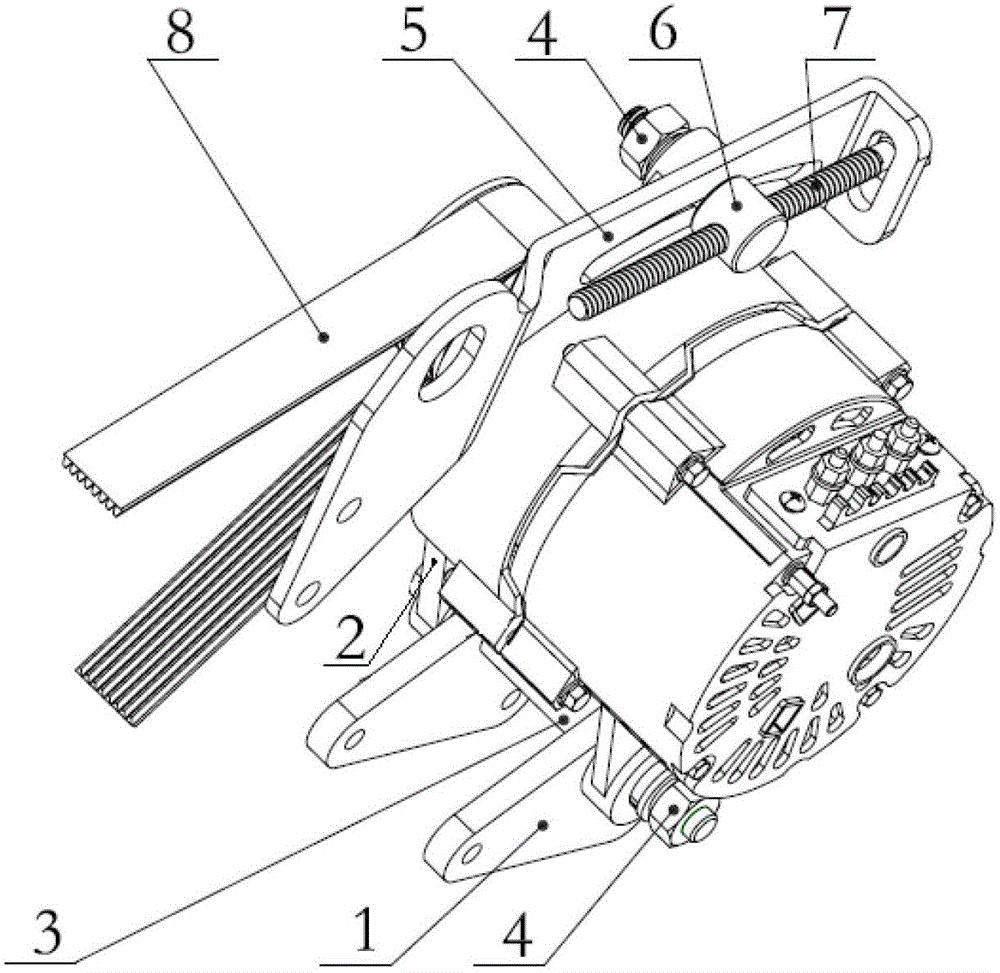

Belt tightening adjusting device of diesel engine

The invention discloses a belt tightening adjusting device of a diesel engine. The belt tightening adjusting device is characterized in that a generator support is arranged on a diesel engine body, installation holes are respectively arranged at the upper end and the lower end of a generator installation disc, and a bolt penetrates through the lower end of the generator installation disc and fixed with the generator support on the installation holes through nuts. A section of arc groove is arranged on the front side of a tensioning support, and a long hole section is arranged on the lateral side of the tensioning support. A sliding block bolt sequentially penetrates through the installation holes arranged at the upper end of the generator installation disc and is fastened with the arc groove of the tensioning support through nuts. A threaded hole is arranged at the cylindrical end of the sliding block bolt, and a screw penetrates through a long hole on the lateral side of the tensioning support and is screwed into the threaded hole at the cylindrical end of the sliding block bolt. A transmission belt is horizontally embedded in a belt groove arranged at the outmost side of a generator, the sliding block bolt is led to displace along the arc groove of the tensioning support by adjusting the screw, and therefore tightening of the transmission belt is adjusted. The belt tightening adjusting device enables belt tightening adjusting to be very convenient, is not limited by small generator peripheral space, and can ensure consistency of tightening of the transmission belt on each trolley.

Owner:东风朝阳朝柴动力有限公司

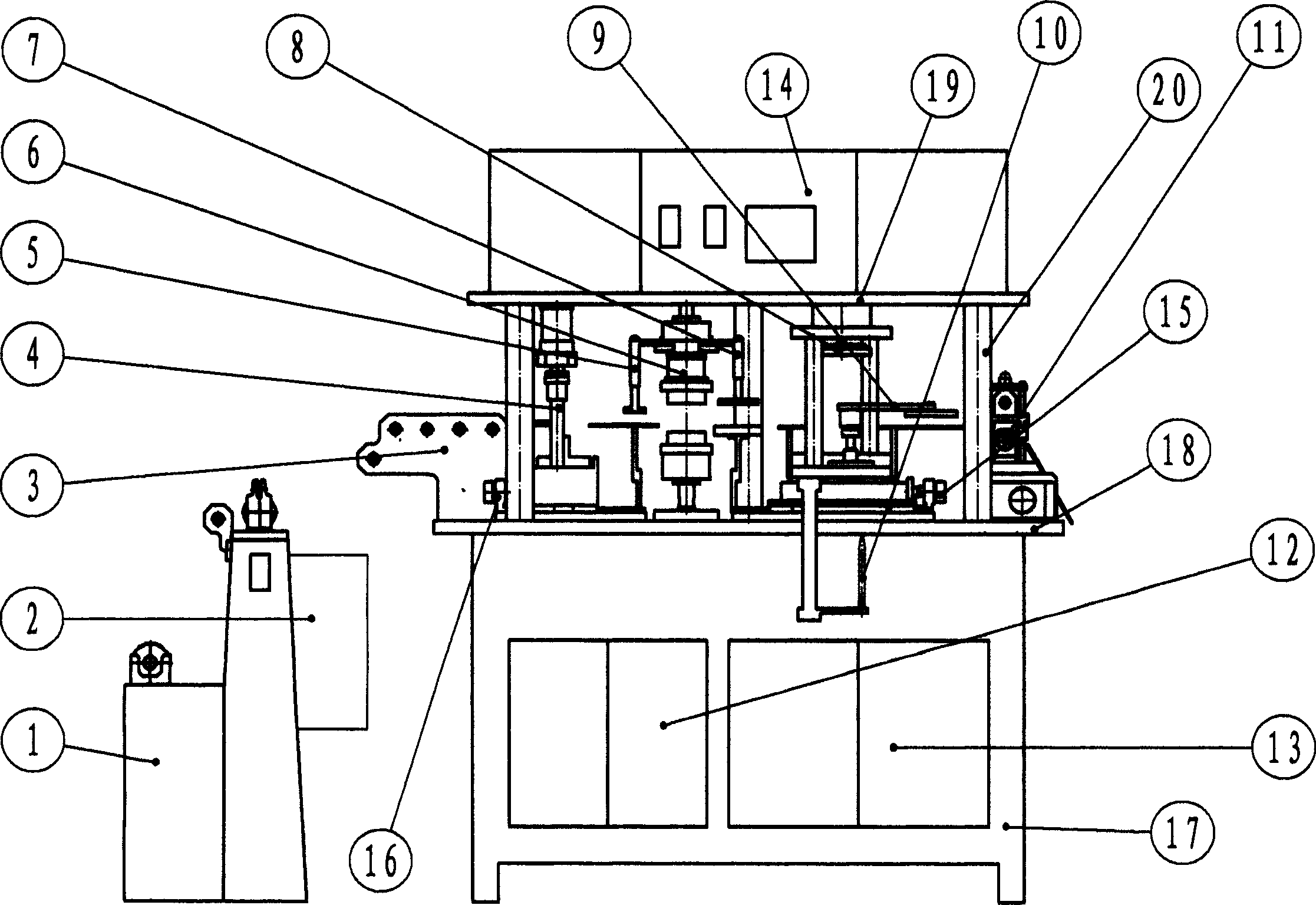

Automatic machine for fabricating localized supporting sheet

InactiveCN1761367AEnsure stabilityConsistent tensionElectrical transducersExecution controlEngineering

Following mechanisms and parts of automatic machine are installed on a main tabletop board: guiding arrangement mechanism, mechanism for cutting strap material and position adjustment mechanism, positioning mechanism, hot pressing mechanism, cold pressing mechanism, cutting press and position adjustment mechanism, mechanism for hauling material. Fetching hand and machine for stacking pieces are installed on adjustment mechanism for cutting position. Executive control component box and electric control component box are installed inside housing. Integrating functions of feeding, hot pressing, cutting, fetching pieces and stacking pieces, the disclosed machine realizes automatic fabrication for localized supporting sheet. The invention prevents parameters of production process from optional adjustment so as to guarantee quality of production and consistency of products.

Owner:浙江天乐集团有限公司

BN ion door and manufacturing method thereof

ActiveCN104051203AUniform radial electric fieldRadial electric field stabilizationBeam/ray deflecting arrangementsCold cathode manufactureMetallurgyElectric field

The invention discloses a BN ion door and a manufacturing method thereof. The method includes the steps that (S1) an insulation substrate and a metal wire are provided, (S2) pretightening force which becomes smaller gradually is applied on the metal wire so that the metal wire can be wound onto the insulation substrate and multiple metal wire sections which are parallel with one another and distributed at an equal interval are formed on the same face of the insulation substrate, and the metal wire sections form a first metal wire set and a second metal wire set which are distributed alternately and are mutually insulated, wherein all the metal sections have identical internal tensioning force, gradually changing pretightening force is applied so that the length of the to-be-wound ith metal wire section which extends after bearing the corresponding tightening force is equal to that of the insulation substrate pressed by the wound i-1th metal wire section, the to-be-wound metal wire section which extends after bearing the tensioning force is as long as the insulation substrate pressed by the wound metal wire section, and i is a positive integer. Radial electric fields, manufactured in the method, of the BN ion door are uniform and stable.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

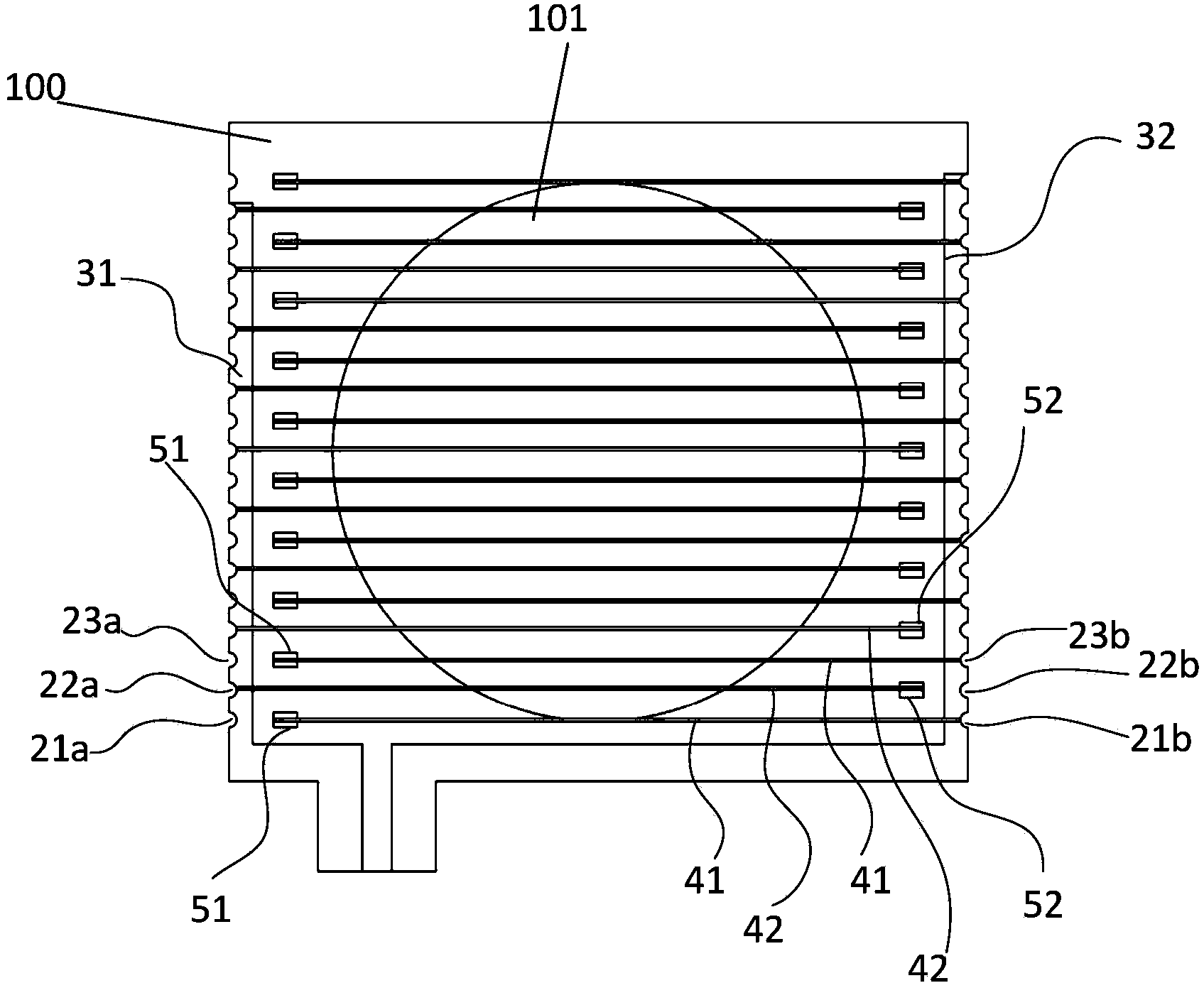

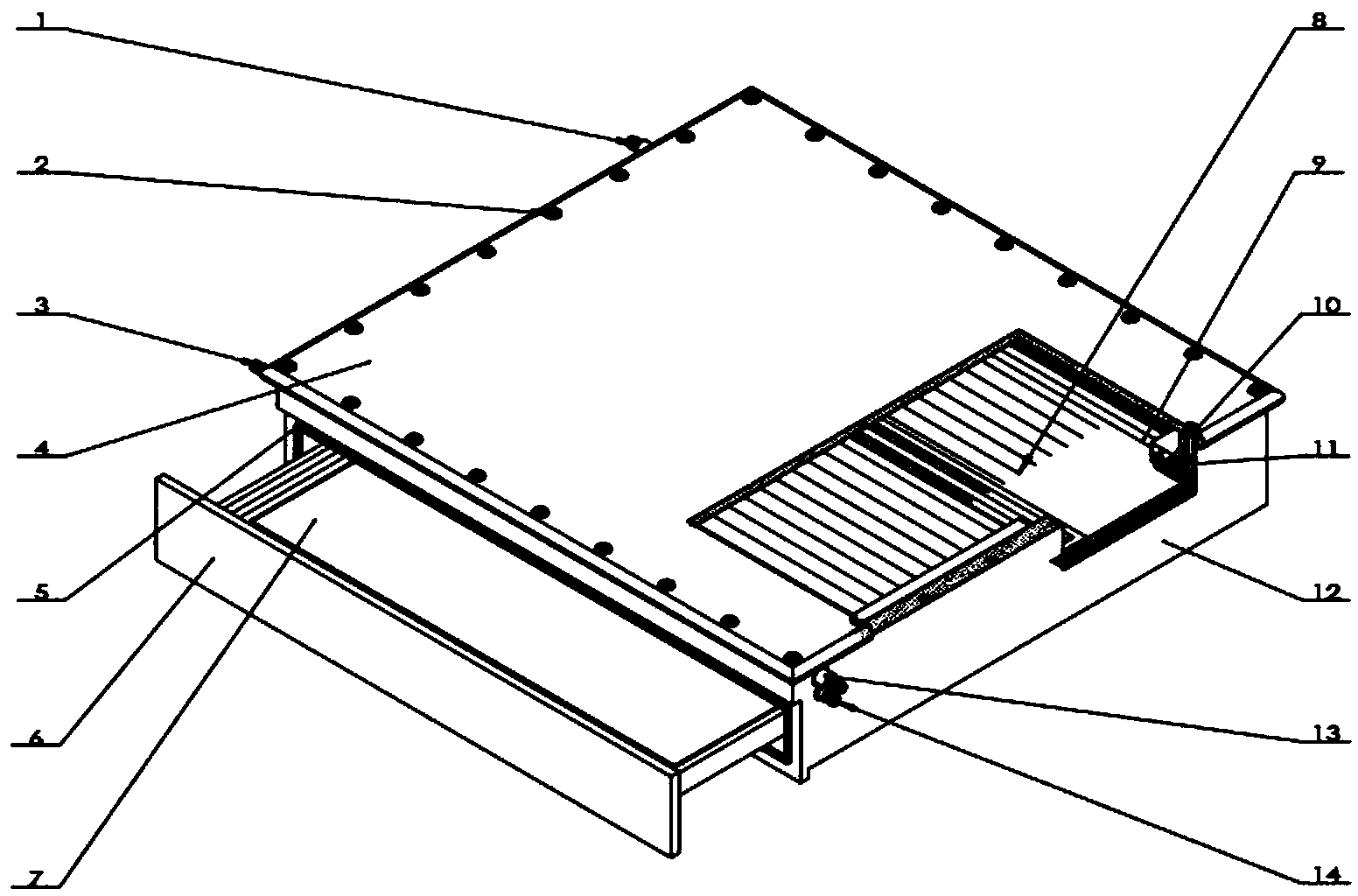

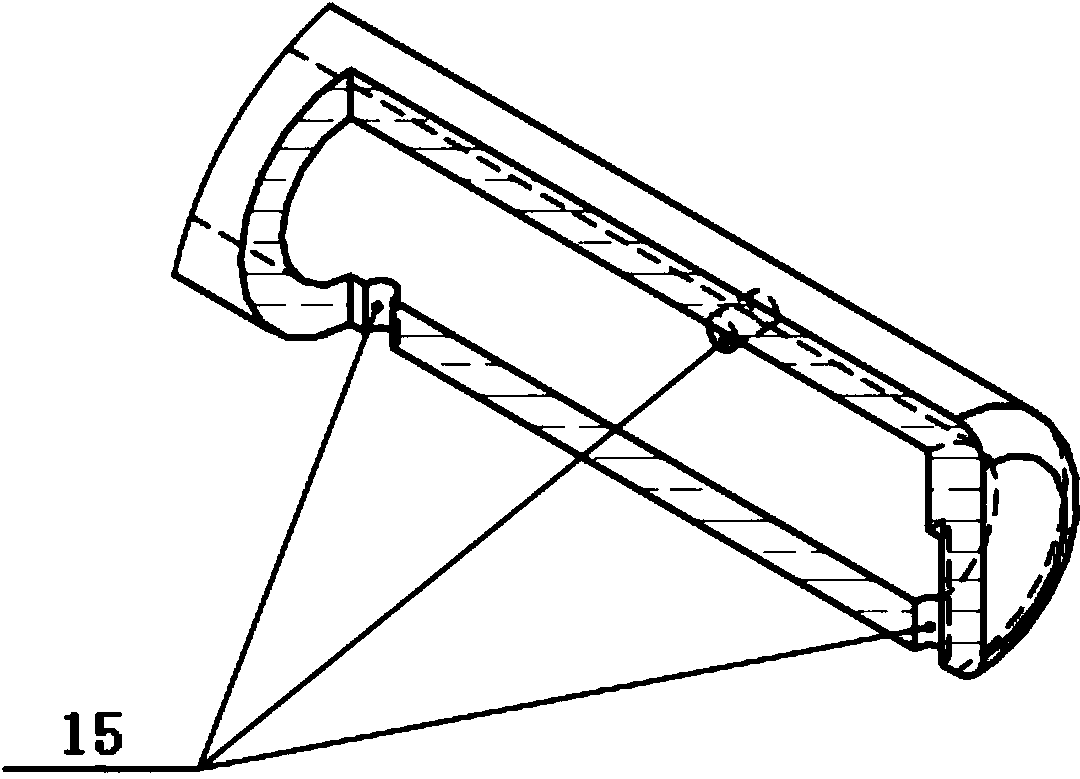

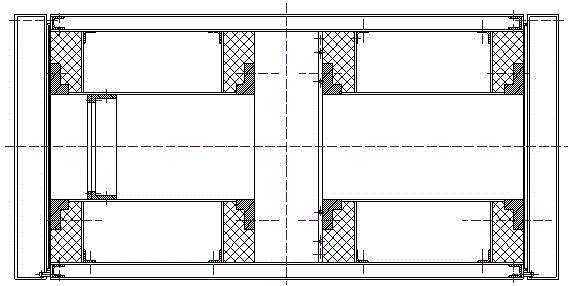

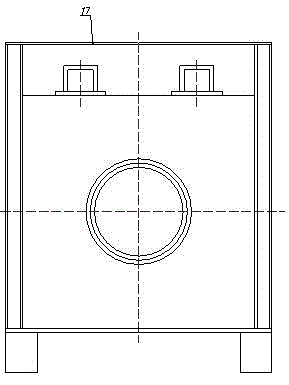

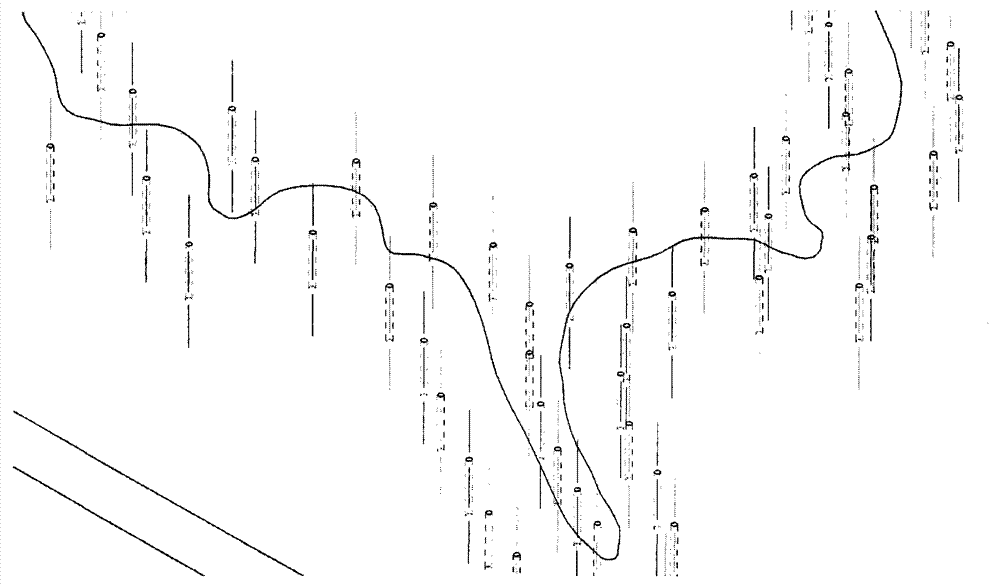

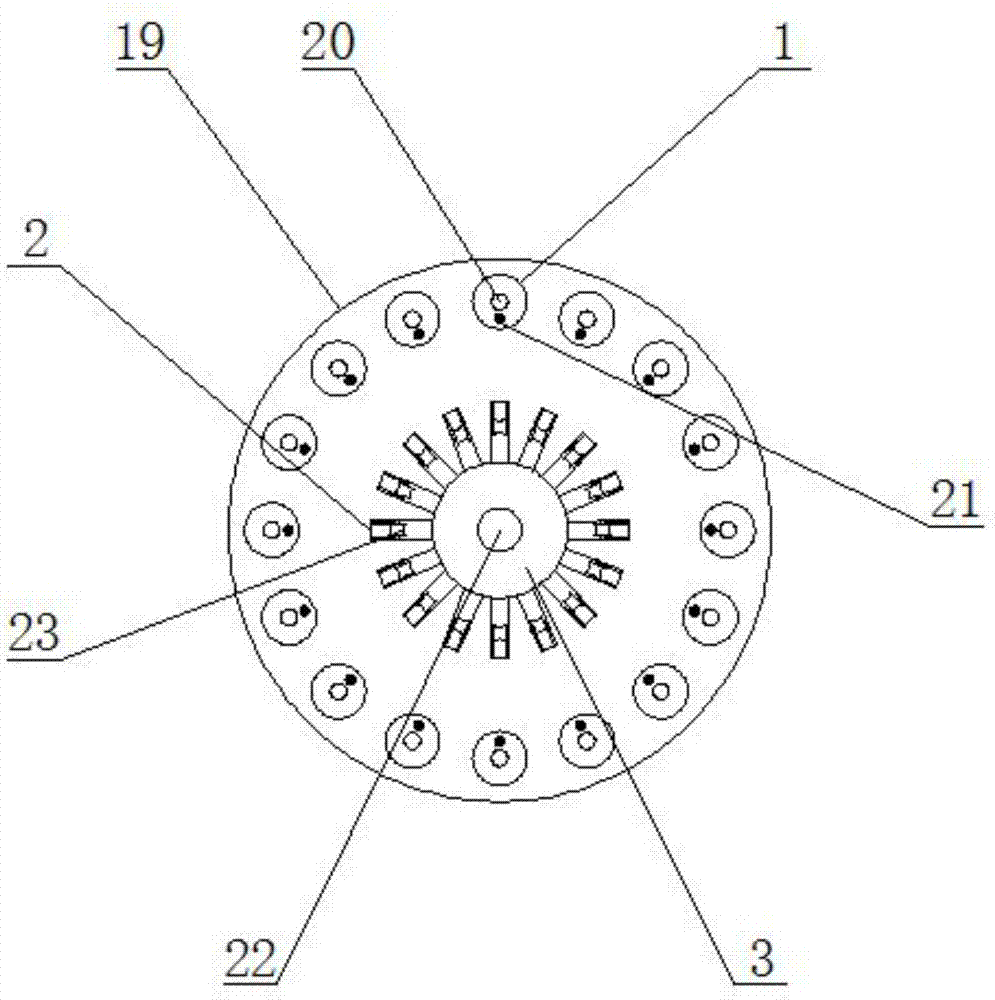

Two-pi multi-wire gas-flow proportional counter

ActiveCN103926615AHigh parallelismPing characteristics are goodRadiation intensity measurementEngineeringTungsten

The invention belongs to the technical field of dosage measurement, and discloses a two-pi multi-wire gas-flow proportional counter. The counter is of a plate-type drawer structure and mainly comprises a counter shell, anode wires, an anode wire frame, insulation frameworks and a source drawer, wherein the counter shell is a square frame composed of an upper cover plate and shell side walls, the source drawer goes into and out of the counter shell through a guide rail, each shell side wall is provided with an air inlet and an air outlet, the anode wire frame is a square frame and is located between the upper insulation framework and the lower insulation framework, the lower insulation framework is fixed to the shell side walls, the upper insulation framework is located below the upper cover plate, the edges of the upper portions of the shell side walls are provided with a sealing ring, the upper cover plate is fixedly connected with the shell side walls, the anode wires are fixed to the anode wire frame, and the anode wires are gold-plated tungsten wires distributed at equal intervals in parallel. The counter has the advantages that the effective detection area is as large as 1000 square centimeters, the anode wires are distributed in parallel, gas disturbance is little, and electric fields are uniformly distributed.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Automatic filling machine

ActiveCN102442628ANo manual operationRealize automatic controlBottle-handling machinesEngineeringElectric control

The invention discloses an automatic filling machine, which comprises a machine frame and an electric control device. A film rolling device for storing and releasing a film, a film connecting device for connecting the film, a disinfecting and cleaning device for disinfecting and cleaning the pulled film, a filling device for filling liquid in a film bag, a forming device for turning and rolling the film into a cylindrical structure, a vertical sealing device for vertically piecing and sealing the cylindrical film, a film pulling device for pulling the film to move and a transverse closing andcutting device for transversely closing and cutting the cylindrical film are arranged on the machine frame in turn. The automatic filling machine provided by the invention is high in production efficiency, lower in cost and high in automation degree.

Owner:SHENZHEN ANGEL DRINKING WATER IND GRP

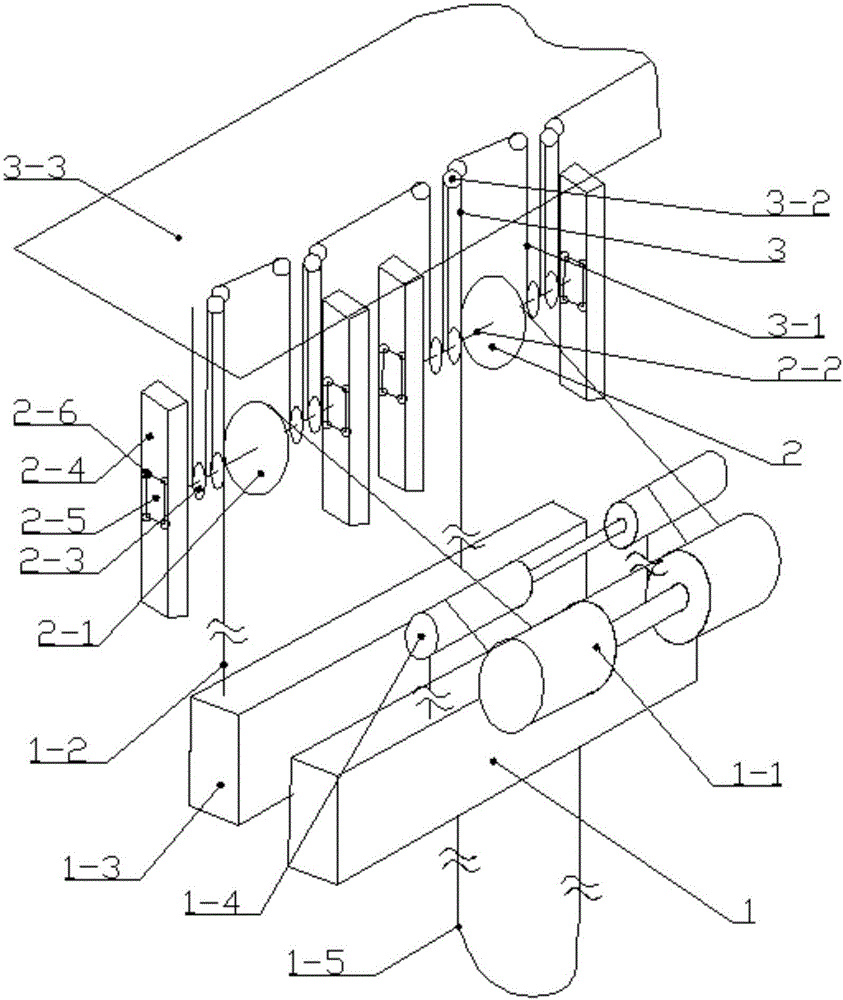

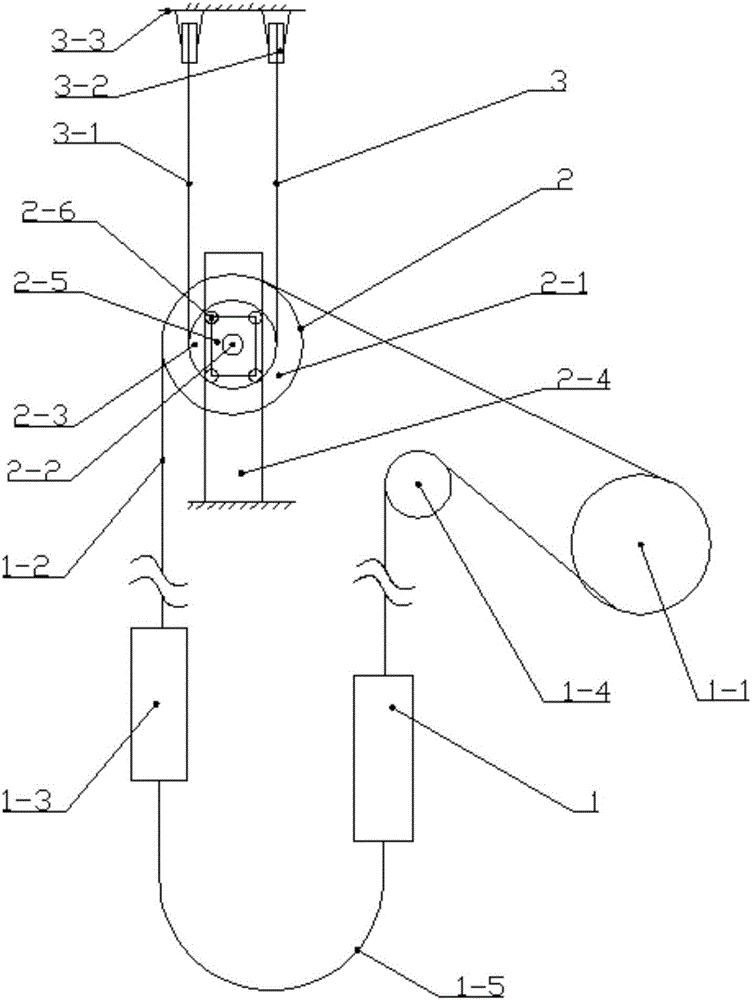

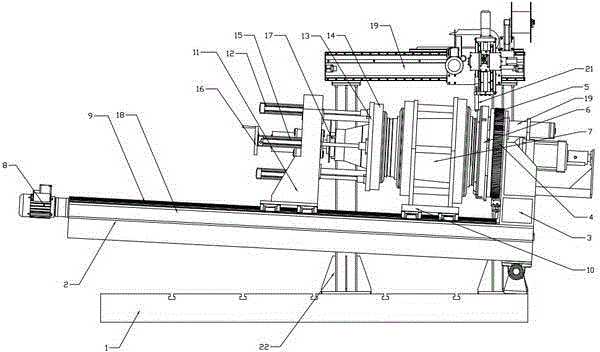

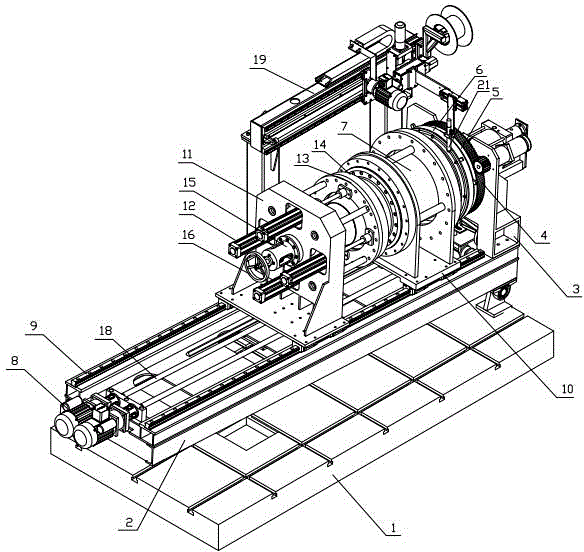

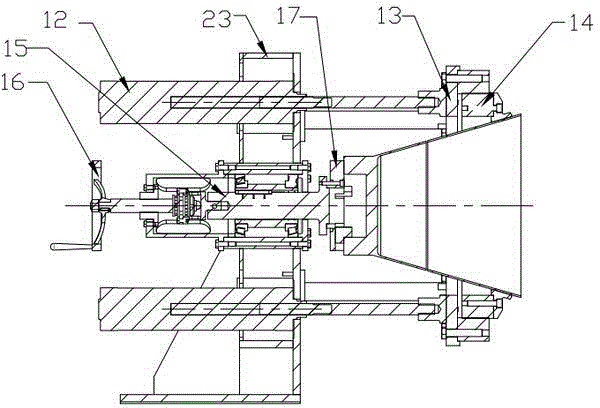

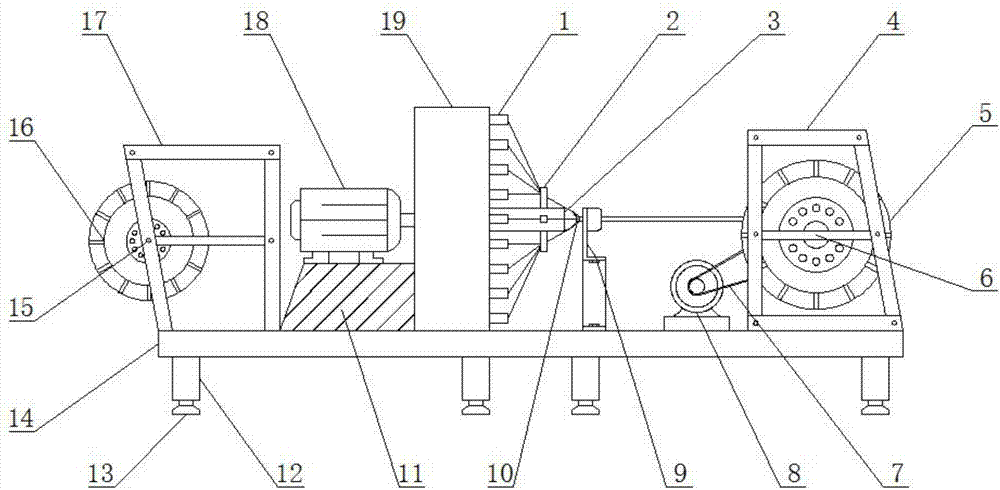

AC synchronous generator rotor full-automatic winding machine

PendingCN107707088ARealize automatic reversal of magnetic polesImprove work efficiencyManufacturing dynamo-electric machinesWinding machineTransducer

The invention relates to an AC synchronous generator rotor full-automatic winding machine which comprises a base, a winding device which can rotate forwardly or reversely, and a pole changing device.The winding device and the pole changing device are oppositely arranged and are installed on the base. A rotor is fastened in the pole changing device. The pole wings of the rotor are aligned with thewinding direction of the winding device. The winding device carries out winding on the pole wings of the rotor. The pole changing device drives the rotor to rotate. The rotor is fastened to the polechanging device, and the winding device carries out winding on the pole wings of the rotor. After winding on one pole wing is completed, the pole changing device drives the rotor to rotate to make next pole wing aligned with the winding direction of the winding device and to continue winding on the pole wing. At the moment, the winding device rotates reversely to reverse an enameled wire coil, andthus, the magnetic poles of the rotor are automatically reversed. The whole winding machine automatically completes all work of rotor winding. There is no need for manual pole changing, there is no need to cut off enameled wire ends, and there is no need to weld enameled wire ends. The work efficiency of generator rotor production and the quality of products are improved.

Owner:王江锋

Automatic tension balancing device and method of multi-rope winding hoisting steel wire ropes for deep vertical shaft

The invention discloses an automatic tension balancing device and method of multi-rope winding hoisting steel wire ropes for a deep vertical shaft. The device comprises a driving system composed of roller hoisters, the hoisting steel wire ropes, hoisting containers, diversion sheaves and a tail rope, the driving system is provided with sliding guide head sheaves capable of moving vertically, and the sliding guide head sheaves are connected to tension balance mechanisms composed of balance ropes. In the operation process of a hoisting system, when the tension of the steel wire ropes is not balanced, tension balance can be realized through the tension balance mechanisms connected to the sliding guide head sheaves. The device has the advantages that the structure is simple, machining is easy, the performance is reliable, installation and maintenance are simple and the tension balance of the steel wire ropes can be automatically adjusted.

Owner:CHINA UNIV OF MINING & TECH

Flexible under-frame shield

ActiveUS8028781B2Slight frictionLittle wearAgricultural machinesHarvestersSprayerAutomotive engineering

An under-frame shield, particularly useful with crop sprayers and other implements which traverse fields of plants, includes one or more flexible sheet material shields connected to axle structure and to a central rigid shield by resilient connectors to facilitate suspension system movement in all directions without sacrificing ground clearance. The connection structure and sheet material shields maintain a smooth, seamless protective surface on the under side of the machine to reduce vehicle and crop damage.

Owner:DEERE & CO

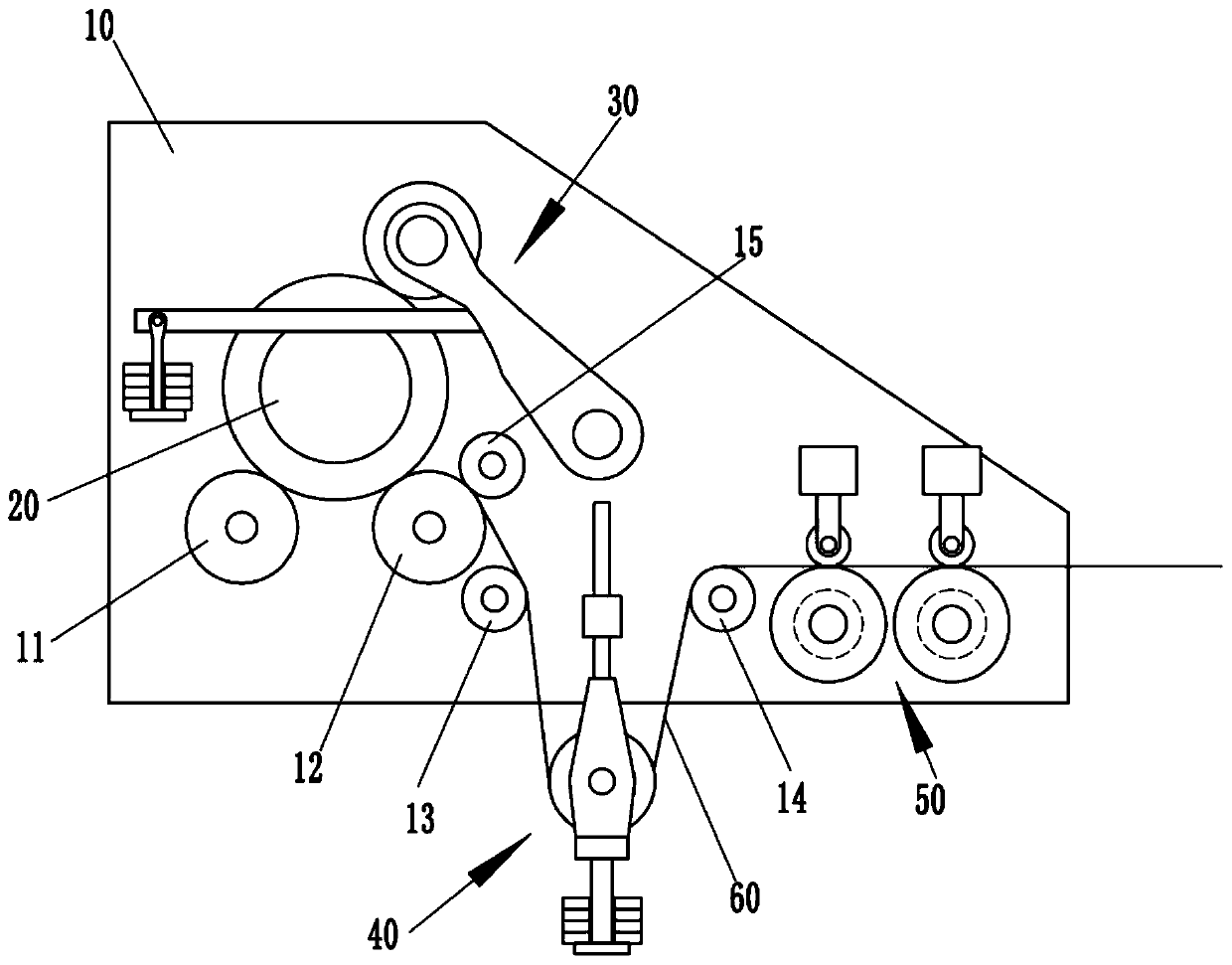

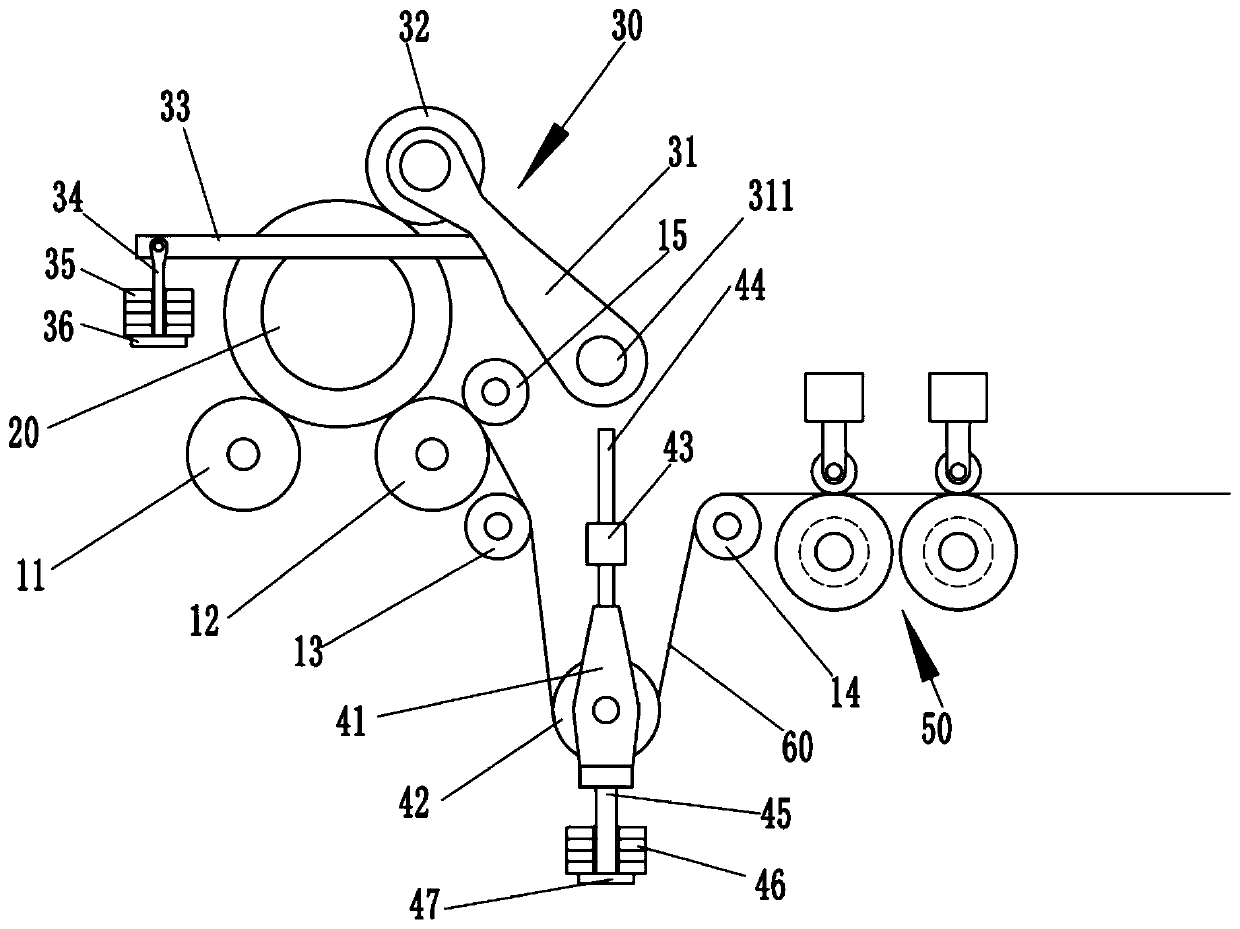

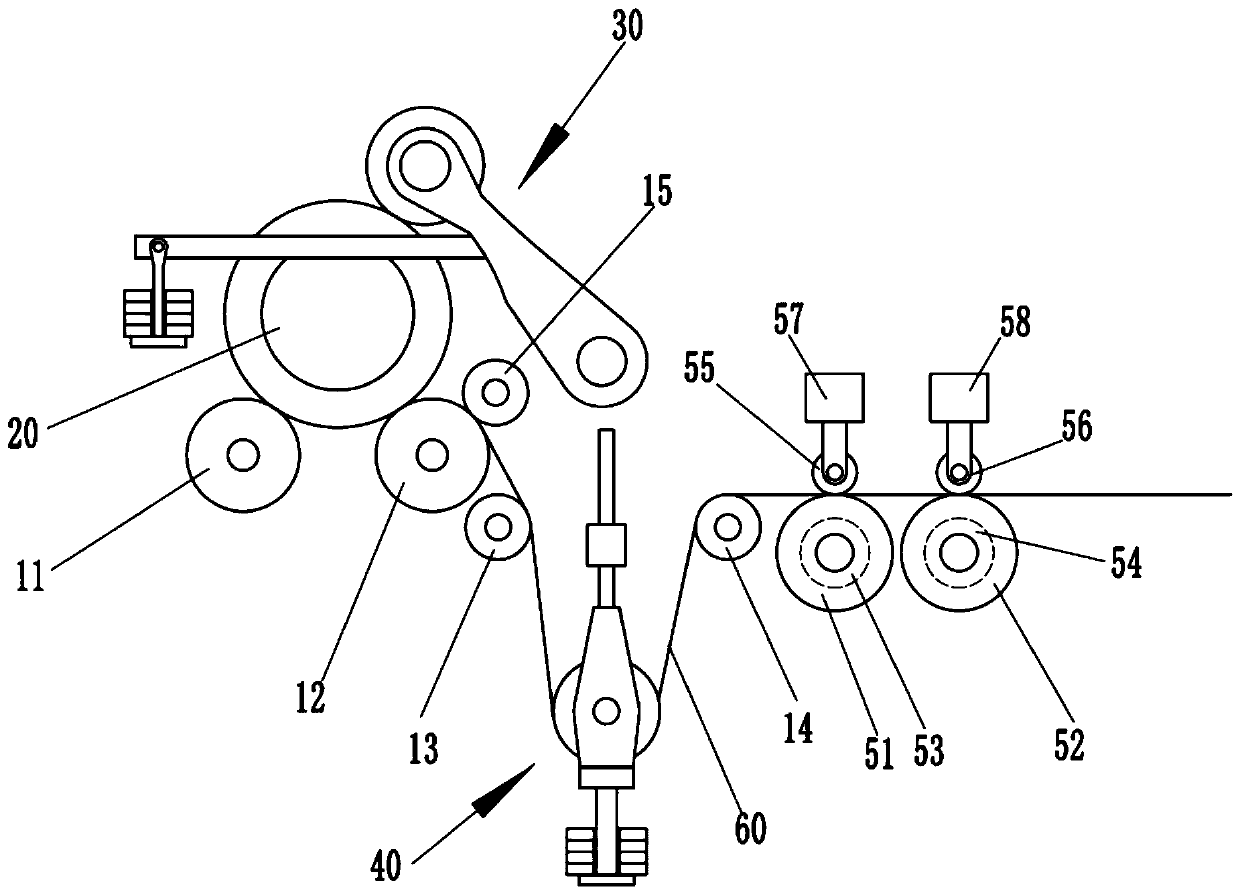

Constant-tension unreeling device of pillow type packaging machine

The invention provides a constant-tension unreeling device of a pillow type packaging machine. The constant-tension unreeling device comprises a base plate, a left supporting wheel, a right supportingwheel, a resisting mechanism, a first guide wheel, a second guide wheel, a balance weight mechanism and a drive wheel set, wherein the left supporting wheel is pivoted to the base plate; the right supporting wheel is pivoted to the base plate, and a film placement roller is supported jointly by the right supporting wheel and the left supporting wheel; the resisting mechanism is arranged on the base plate and abuts against the film placement roller; the first guide wheel is pivoted to the base plate, and the first guide wheel is located on the lower right of the right supporting wheel; the second guide wheel is pivoted to the base plate; the balance weight mechanism is movably arranged on the base plate and located between the second guide wheel and the first guide wheel; and the drive wheel set is arranged at the right end of the second guide wheel and is used for driving a composite film to move so that the film placement roller can carry out unreeling. According to the constant-tension unreeling device of the pillow type packaging machine, the tension of the composite film can be adjusted, and after being adjusted, the tension is in a constant value all the time.

Owner:WENZHOU POLYTECHNIC

Device for testing heat insulating property of fabrics

Owner:南通大学技术转移中心有限公司

Yarn filoplume testing instrument with yarn dynamic tension measurement display equipment

InactiveCN101195962AImprove accuracy and consistencyTension real-time displayInspecting textilesTension measurementYarn tensionTester device

The invention discloses a yarn hairiness testing apparatus with a yarn dynamic tension force measuring display device. A yarn guiding wheel (3) for yarns (9) to pass around is arranged at one position on the pathway of the yarns (9), the yarn guiding wheel (3) is installed on a connecting axis (4) through a bearing, and the connecting axis (4) is fixed on a force measuring sensor (5) which is installed on the testing apparatus; the force measuring sensor (5) is connected with the tension force display device which is installed on the testing apparatus. A yarn tension force detecting sensor on the pathway of the yarns is additionally arranged on the apparatus, and the tension force of the tested yarn is displayed in real time. The yarn tension force is adjusted to the required force value through a yarn tension force adjusting device. The identical yarn tension force can be ensured when the identical yarn is tested, and the accuracy and the consistency of the hairiness testing are improved.

Owner:张雪波

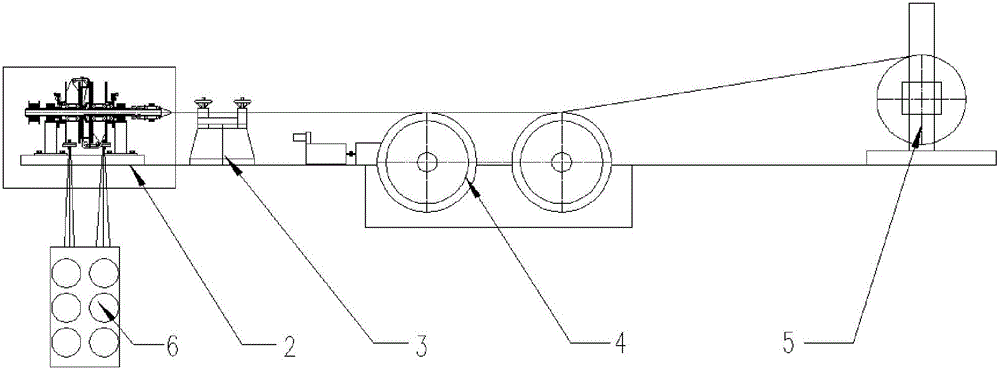

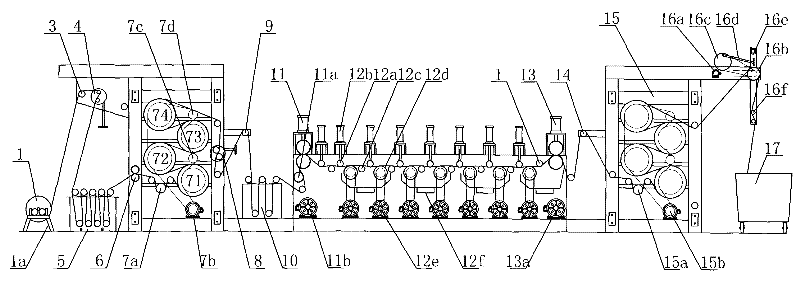

Multi-start annealing and doubling take-up machine

ActiveCN105913970AImprove work efficiencyAdjustable tensionFilament handlingFunction indicatorsComputer moduleMaterials science

The invention discloses a multi-start annealing and doubling take-up machine comprising an annealing machine, an active leading machine, a passive leading machine, a wire break shutdown test stand, and multiple take-up machines, which are arranged in sequence along the wire outgoing direction. The annealing machine comprises an annealing furnace, a cooling device, a blow-drying device and a baking box, which are arranged in sequence. The annealing furnace is arranged obliquely, and a pay-off device is arranged below the annealing furnace. The active leading machine draws wires processed by the annealing machine and sends the wires to the passive leading machine, and the passive leading machine sends the wires to the take-up machines. The wire break shutdown test stand is used for testing whether the wires are broken between the passive leading machine and the take-up machines. A branching module is arranged on the take-up machines. The multi-start annealing and doubling take-up machine is high in efficiency, simple to operate, and safe and reliable. The existing equipment is fully utilized to reduce equipment investment.

Owner:KUNSHAN FUCHUAN ELECTRICAL MACHINERY TECH

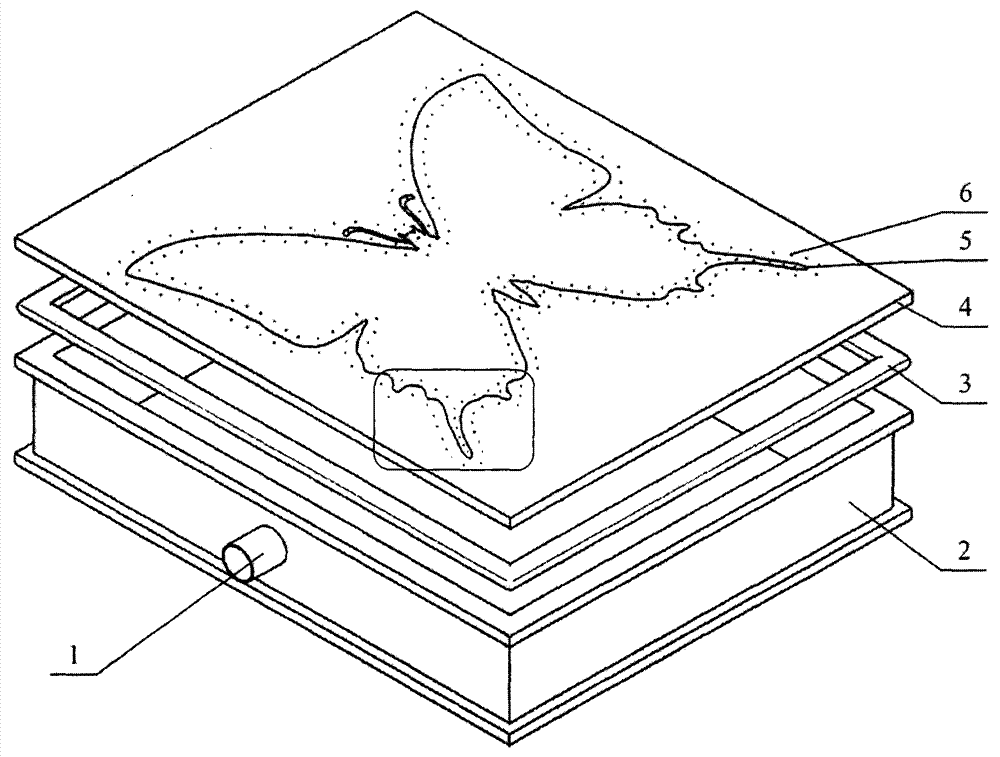

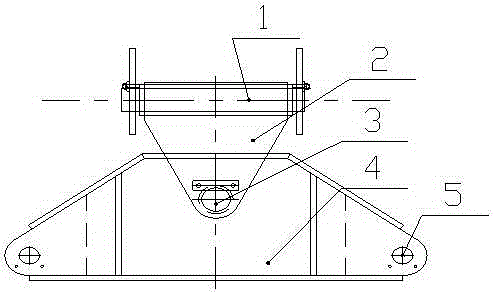

High-accuracy flexible thin film shape preservation cutting device

InactiveCN104723394AConsistent tensionSimple processMetal working apparatusBatch productionEngineering

The invention provides a high-accuracy flexible thin film shape preservation cutting device which mainly solves the problems that a thin film is easily wrinkled and deformed due to stretches in the machining process. According to the technical scheme, the high-accuracy flexible thin film shape preservation cutting device is characterized in that low pressure is generated through a vacuum pump, so that a thin film is attached to a flat model board and is then cut. Thus, the thin film can be tightly attached to the flat board, it is guaranteed that the thin film is not moved and is flat all the time in the thin film cutting process, the tension degrees of all positions of the whole thin film are uniform and identical, and the thin film is prevented from being irrecoverably deformed by stretches. The cutting device is simple in shape and convenient to machine and a finished device product is already completed in a laboratory. In addition, the cutting device is high in flexibility and capable of being used for manual cutting operation and used in cooperation with a numerical control machine tool, the shape accuracy of the thin film can be effectively guaranteed, a small number of complex shapes can be machined, the advantages of the device are more remarkable when the device is used for batch production, and production efficiency can be effectively improved while cutting accuracy is guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

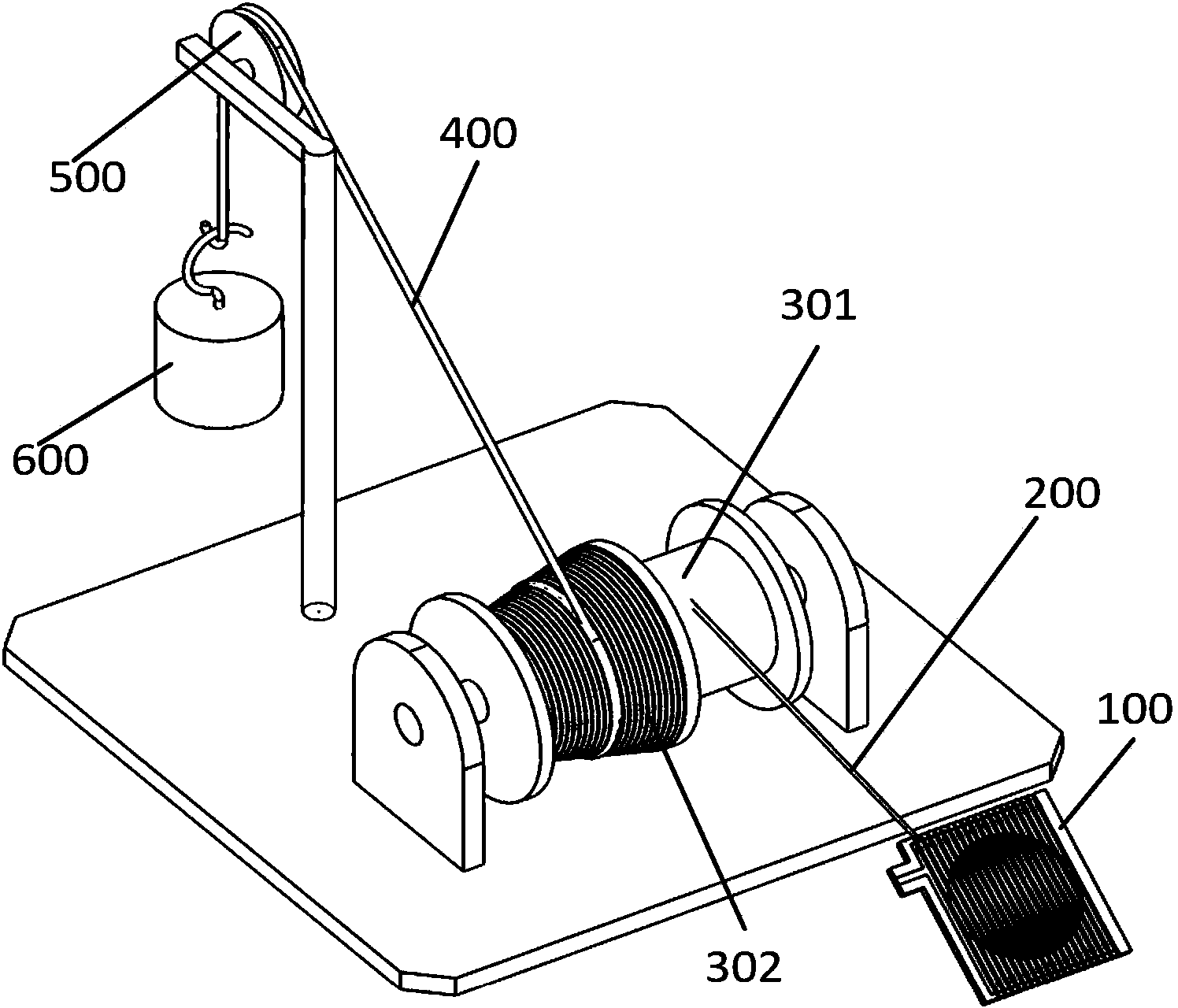

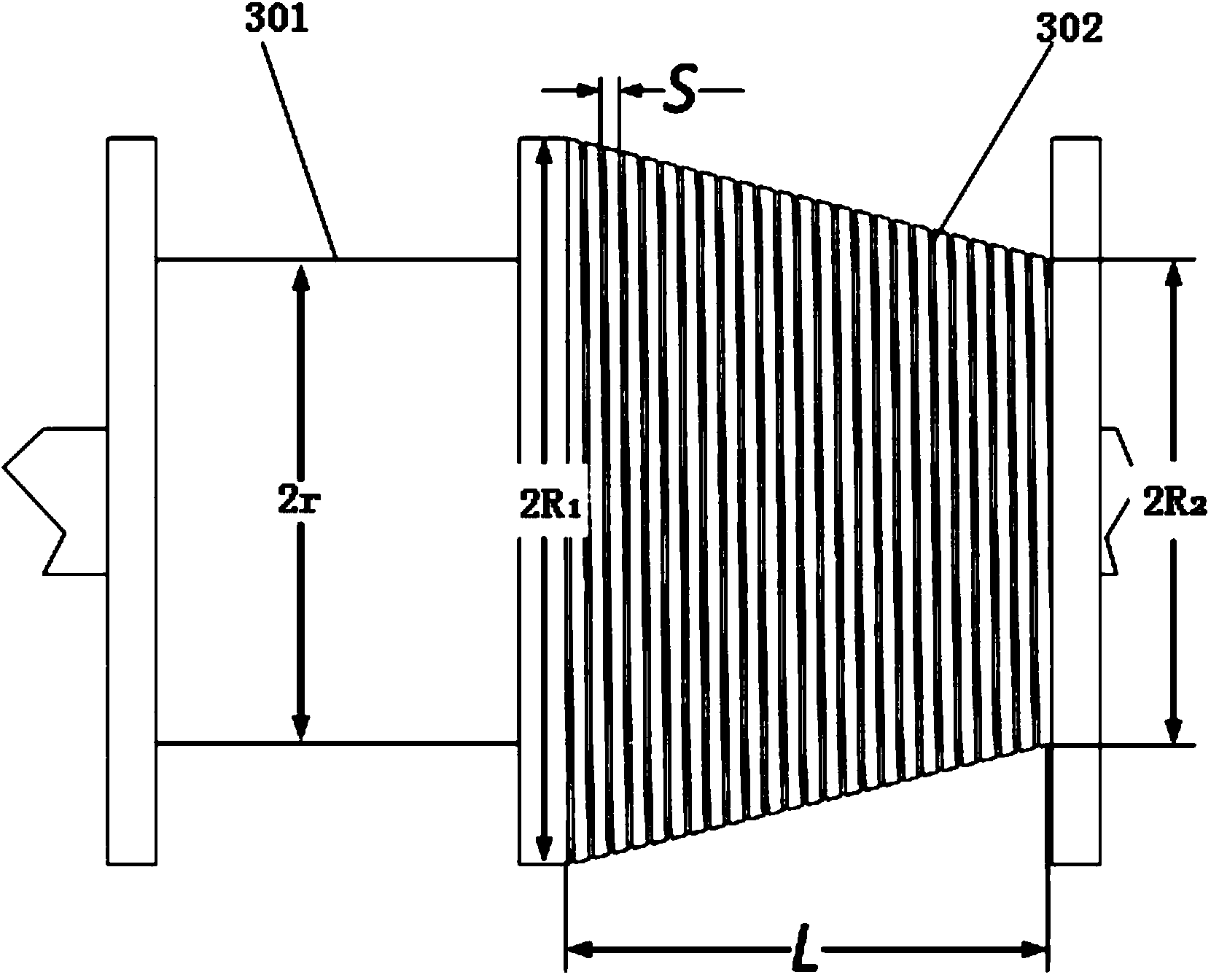

Concentric stranding machine

InactiveCN105719775ARealize rewindingRealize stranded wireCable/conductor manufactureTextile cablesLocking mechanismWinch

The invention discloses a concentric stranding machine, which comprises a pay-off system and a stranding system, wherein the pay-off system pays off core wires to the stranding system; the stranding system comprises a main shaft and a flying wing device; the main shaft is rotationally connected with wire storage winches; the main shaft is driven by a main shaft motor; the wire storage winches are driven by a wire storage motor; the flying wing device comprises a flying wing aircraft body; the flying wing aircraft body is connected with a flying wing rotating head; the flying wing rotating head is rotationally connected with the flying wing aircraft body; a locking mechanism is arranged between the flying wing rotating head and the flying wing aircraft body; and the flying wing device is provided with a flying wing guide wheel assembly. Through adjustment of the flying wing device, the wire storage winch can achieve wire rewinding and stranding, avoids shut-down for loading and unloading wire coils and improves the production efficiency.

Owner:ZHEJIANG CHENGUANG CABLE CO LTD

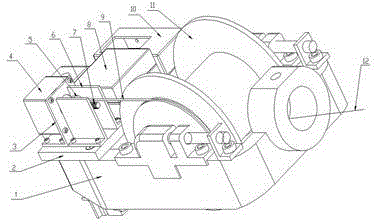

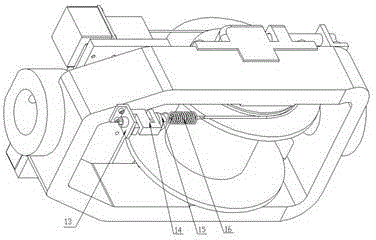

Internal supporting and external hooping non-fixing-and-spot-welding girth welder applicable to one-side welding with back formation

InactiveCN104148868AImprove welding efficiencyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesPhysicsElectric machinery

The invention relates to a welding tool, in particular to an internal supporting and external hooping non-fixing-and-spot-welding girth welder applicable to one-side welding with back formation. The internal supporting and external hooping non-fixing-and-spot-welding girth welder comprises a base platform; an assembly base capable of rotating around a support point is mounted over the base platform. A fixed rotating block is mounted at the right end of the upper surface of the assembly base. The fixed rotating block is connected with an inner supporting device and a first clamping mechanism. A first drive motor is mounted at the upper end of the fixed rotating block. The internal supporting and external hooping non-fixing-and-spot-welding girth welder has the advantages that three or more rotors can be welded with the welder, one-side girth welding with back formation is adopted, no fixing and spot welding process is not preliminarily required during girth welding, welding efficiency is improved, and welding quality is improved.

Owner:CHENGDU AIGRE TECH +1

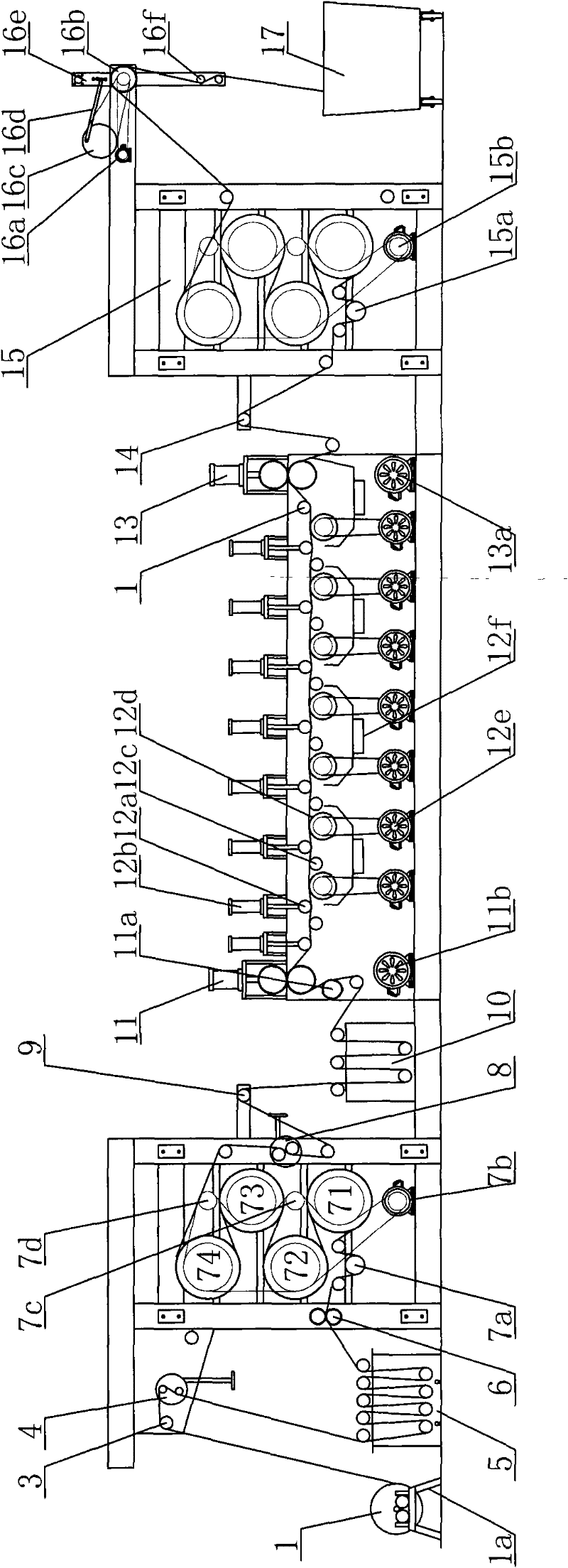

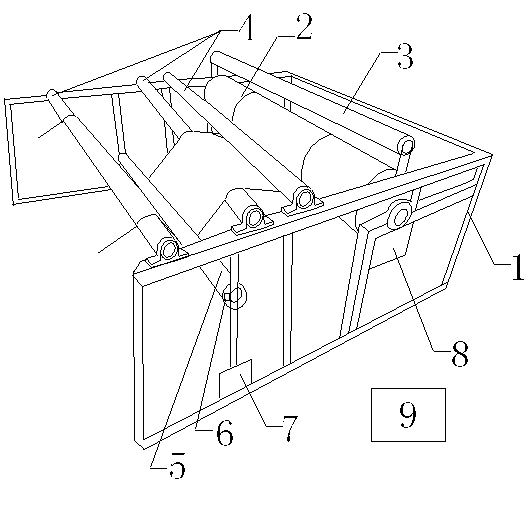

Prewetting and drying sueding machine

InactiveCN102936822AConsistent tensionTightness can be adjustedLiquid/gas/vapor removal by squeezing rollersStretchingEngineeringMechanical engineering

The invention discloses a prewetting and drying sueding machine, and belongs to the field of textile machinery technology. The prewetting and drying sueding machine comprises a machine frame, a sueding area, a cloth feeding mechanism and a cloth discharge mechanism, wherein the sueding area is provided with a plurality of groups of sueding rolls; a dust suction hood is arranged below the sueding rolls; and a spray device is arranged above the sueding rolls; padders are arranged before and behind the sueding area respectively; a centering limited rod and a high position cloth extension roller are disposed at the forefront end of the cloth feeding mechanism in sequence; a front drying device is arranged before the sueding area; a cold water tank is arranged between the front drying device and the sueding area; and a front tension swing rod is arranged between the front drying device and the cold water tank; a back drying device is arranged behind the sueding area; and a back tension swing rod is arranged between the back drying device and the back padder; a tension regulator is arranged between the front drying device and the front tension swing rod; both the front drying device and the back drying device have four drying cylinders; and the cloth is successively wound on the first drying cylinder, the second drying cylinder, the third drying cylinder and the fourth drying cylinder from low to high.

Owner:陈素萍

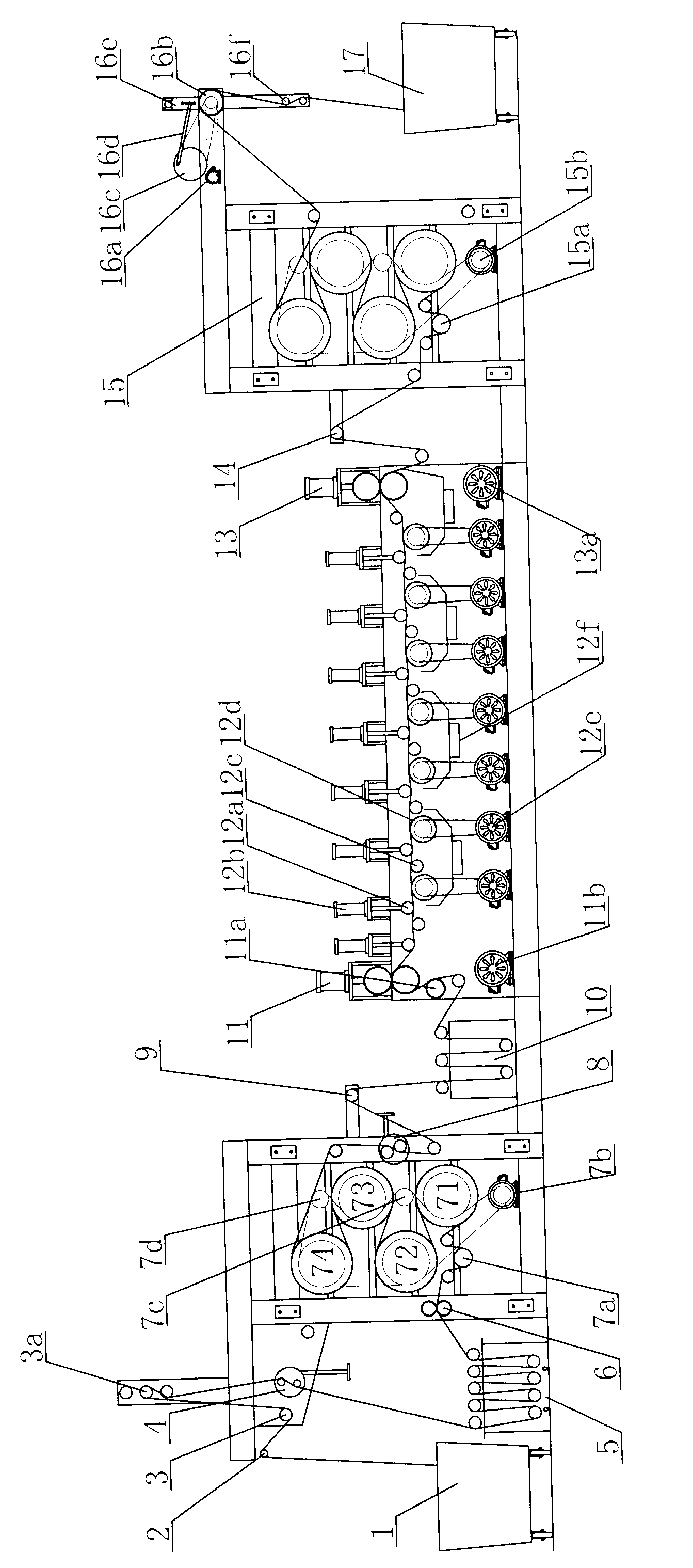

Package fabric-feed prewetting and drying roughening machine

InactiveCN102535076AConsistent tensionFull draftLiquid/gas/vapor removal by squeezing rollersStretchingEngineeringMechanical engineering

The invention discloses a package fabric-feed prewetting and drying roughening machine, belonging to the technical field of textile machinery. The fabric-feed prewetting and drying roughening machine comprises a frame, a roughening area, a fabric feed mechanism and fabric discharge mechanism, wherein the roughening area is provided with a plurality of sets of roughening rolls, a dust suction hood is arranged below the roughening rolls, and a spray device is arranged above the roughening rolls; a padder is respectively arranged before and behind the roughening area, a front drying device is arranged before the roughening area, a cold water tank is arranged between the front drying device and the roughening area, and a front tension swing rod is arranged between the front drying device and the cold water tank; the front drying device is provided with a hot water tank, and rolls are arranged between the hot water tank and front drying expanding rolls; a back drying device is arranged behind the roughening area, and a back tension swing rod is arranged between the back drying device and the back padder; drying cylinders of the back drying device and the front drying device have identical structure and arrangement; a tension regulator is arranged between the front drying device and the front tension swing rod; the front drying device has four drying cylinders, and the back drying device also has four drying cylinders; and the fabric is sequentially wound on the first drying cylinder, the second drying cylinder, the third drying cylinder and the fourth drying cylinder from low to high.

Owner:杨忠芳

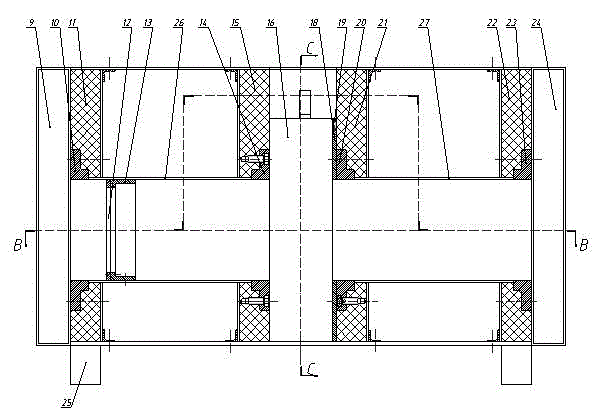

Steel wire rope stress balance device of double-rope windlass

InactiveCN105217505ASolve the problem of unbalanced left and right forcesConsistent tensionWinding mechanismsPull forceEngineering

The invention discloses a steel wire rope stress balance device of a double-rope windlass. The device comprises a transverse shaft, a connecting clamping plate, a longitudinal shaft, a balance beam and tension sensors, wherein the transverse shaft penetrates through the upper end of the connecting clamping plate, and is fixedly mounted between two clamping plates of a fixed pulley frame; one end of the connecting clamping plate is connected with the transverse shaft, and the other end is connected with the longitudinal shaft; the connecting clamping plate is connected with the balance beam through the longitudinal shaft; the transverse shaft, the connecting clamping plate and the longitudinal shaft are formed to a universal shaft structure; the balance beam is fixed on the longitudinal shaft; and the tension sensors are fixed at the two ends of the balance beam. The device solves the problem of unbalanced horizontal stress due to use of two steel wire ropes in a double-steel-wire-rope windlass mechanism by a material piling and taking machine; when the material taking machine works, the stress of two steel wire ropes C is unequal, and is transferred to the balance beam 4; the elasticity of the two steel wire ropes C is adjusted through free rotation of a universal shaft structure to achieve the stress balance; the tension degree is kept consistent; the equipment safety and stability are improved; the service life is prolonged; and the device is safer, more stable and more reasonable, and is applied to the technical field of the material piling and taking machine.

Owner:NORTHERN HEAVY IND GRP CO LTD

Fiber drawing method

ActiveCN104562239AReduce denier deviationSmall dispersionArtificial filament washing/dryingFilament manufacturePolymer scienceFiber drawing

The invention provides a fiber drawing method. The fiber drawing method comprises the steps of preparing gel-spun fibers, bundling and pre-drawing, extracting, drying and hotly drawing, and is characterized in that an initiative fiber feeding procedure is increased before the step of bundling and pre-drawing. With the adoption of the fiber drawing method, the fineness deviation of the fibers can be reduced and the dispersion degree of the fineness of the finished-product fibers is also reduced; meanwhile, waste fibers generated in a drawing procedure are reduced and the cost is saved; the tension of the gel-spun fibers can be conveniently adjusted and keeps constant in a drawing process; meanwhile, the manpower is saved and the labor production efficiency is improved.

Owner:SURREY HI TECH INC

Horizontal cable high-speed braiding machine

InactiveCN107359021AReduce the temperatureReduce frictionCable/conductor manufactureEngineeringFriction force

The invention discloses a horizontal cable high-speed braiding machine. The horizontal cable high-speed braiding machine comprises a smooth skin cable, braiding machine support feet, spindle rotation shafts and ceramic ball support racks, wherein braiding machine support legs are arranged on the braiding machine support feet, a braiding machine body is arranged on the braiding machine support legs, a smooth skin cable disc rack is arranged at a part above a left end of the braiding machine body, and a smooth skin cable disc is arranged at an intermediate position of a left end of the smooth skin cable disc rack. The ceramic is relatively low in friction force, the friction of a braiding line is reduced, the temperature of an outgoing line hole is reduced, and the braiding line is prevented from being broken due to high temperature of the outgoing line hole; a tension wheel is arranged outside a cable passage pipe, so that each braiding line can pass through the tension wheel, the tension degree can be consistent when the braiding line bears a tension force, and the braiding effect during braiding can be better; and moreover, line breakage due to inconsistent tension degree can be prevented, the line breakage frequency of the braiding machine during braiding is reduced, and the production efficiency is improved.

Owner:杨桂芝

Constant tension control device based on time calculation rolling diameter

The invention provides a constant tension control device based on a time calculation rolling diameter. The constant tension control device comprises a bobbin rack and an H-shaped wheel arranged on the bobbin rack in a rotating mode. A power supply for supplying power is arranged on the bobbin rack. A motor is arranged on one side of the bobbin rack. A motor shaft of the motor is fixedly connected with a lead screw. A screw and nut pair is arranged on the lead screw. A tension sensor is arranged on the other side of the bobbin rack. The screw and nut pair is connected with the tension sensor through a damping rope. A spring is connected between the tension sensor and the damping rope. A rotating wheel matched with the damping rope is fixedly arranged on the H-shaped wheel. A tension controller is arranged on the bobbin rack. The tension sensor and the motor are both connected with the tension controller. Through the control method for controlling the tightness of the damping rope through a lead screw stepping motor, according to the constant tension control device, the tension of each strand of steel wires is kept constant in the transmission process, and tension between the steel wires tends to be constant.

Owner:金新民

Net piece tension automatic control device for net weaving machine

ActiveCN104674450AStable and reliable delivery processStable deliveryKnotting netsAutomatic controlPulp and paper industry

The invention provides a net piece tension automatic control device for a net weaving machine. The net piece tension automatic control device is provided with a swinging arm, an active net winding roller group, a passive net winding roller group and a net collecting roller group, wherein a bearing assembly is arranged at the lower part of the swinging arm, a main shaft is arranged beside the swinging arm, a net winding cam seat is arranged on the main shaft, the active net winding roller group is provided with a main net winding roller and a main net winding overrun clutch, the passive net winding roller group comprises a passive net winding roller and a first press roller, a passive net winding overrun clutch is fixedly arranged on the passive net winding roller, a net passing roller is arranged above a tension roller, and the net piece tension automatic control device is arranged in the net weaving machine. The structure is reasonable, the operation is more stable and more reliable in the work process, net pieces output from the middle of a shuttle hook total process can be output to the passive net winding roller group through the net winding roller group, and the identical stability of the tension can be maintained in the conveyance process.

Owner:YANGZHOU HAILI PRECISION MACHINERY MFG

Let-off tension bracket of carbon fiber cloth loom

A let-off tension bracket of a carbon fiber cloth loom comprises a rack, a controller and a let-off roller, a pressing roller, at least two thread passing rods, a floating tension roller, a tension sensor, a tension motor and a let-off motor which are arranged on the rack, wherein a rotating shaft of the let-off roller is connected with an output shaft of the let-off motor through a conveyor belt; the at least two thread passing rods are arranged on an output side of the let-off roller sequentially; the floating tension roller is arranged between any two thread passing rods and can move vertically; the tension sensor is mounted on one side of the floating tension roller; an output of the tension sensor is connected with an input of the controller; the controller drives the thread passing rods to convey warps through the let-off motor; and the tension motor drives the floating tension roller to move vertically, so that the tension of the warps is adjusted. According to the let-off tension bracket of the carbon fiber cloth loom, a variable frequency motor is used for let-off and the tension sensor is used for measuring the tension of the warps, so that the bracket is free from influences of a back rest position and movement of mechanical components, and the tension of the warps is guaranteed to be consistent.

Owner:YIXING HUAHENG HIGH PERFORMANCE FIBER WEAVING

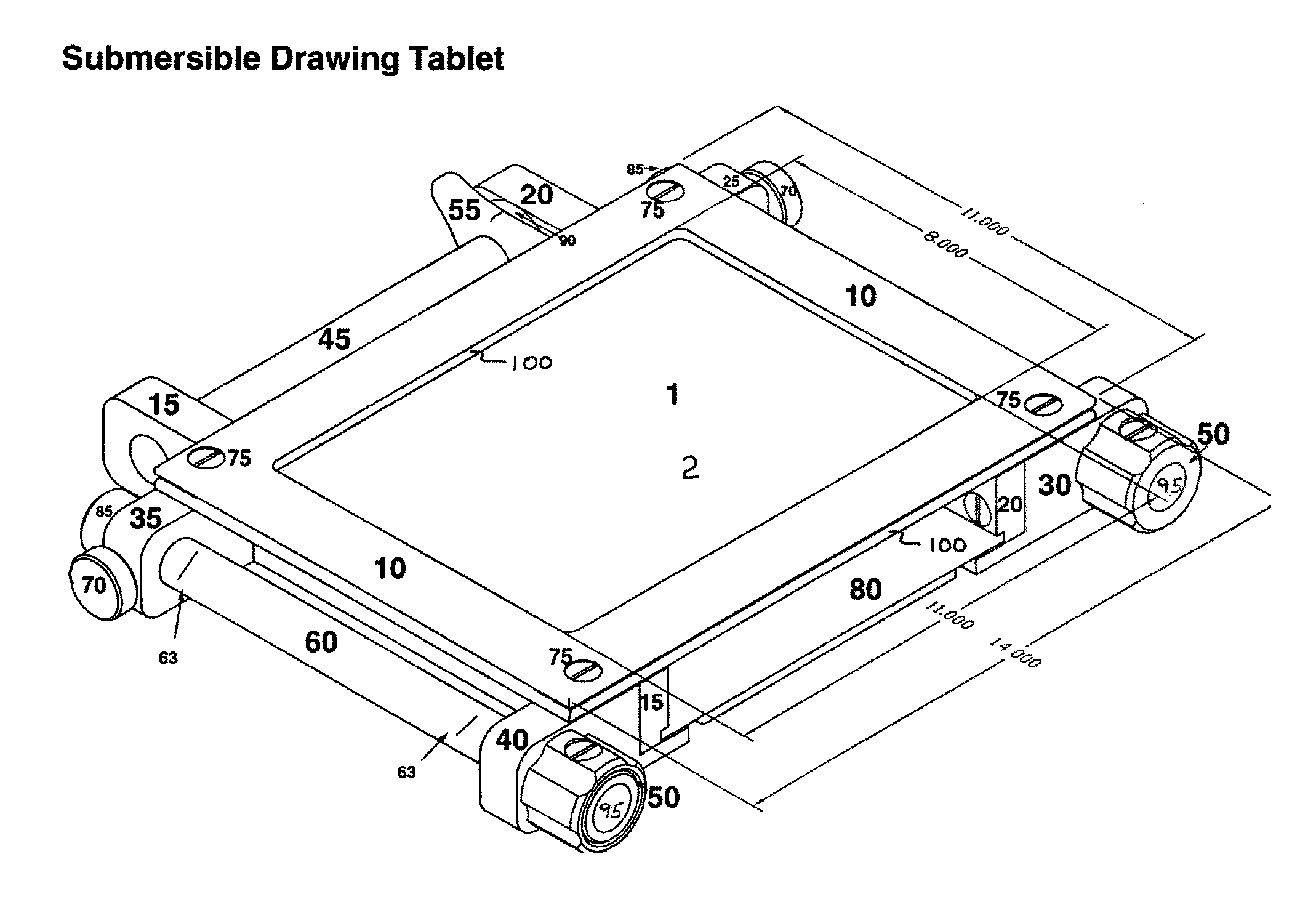

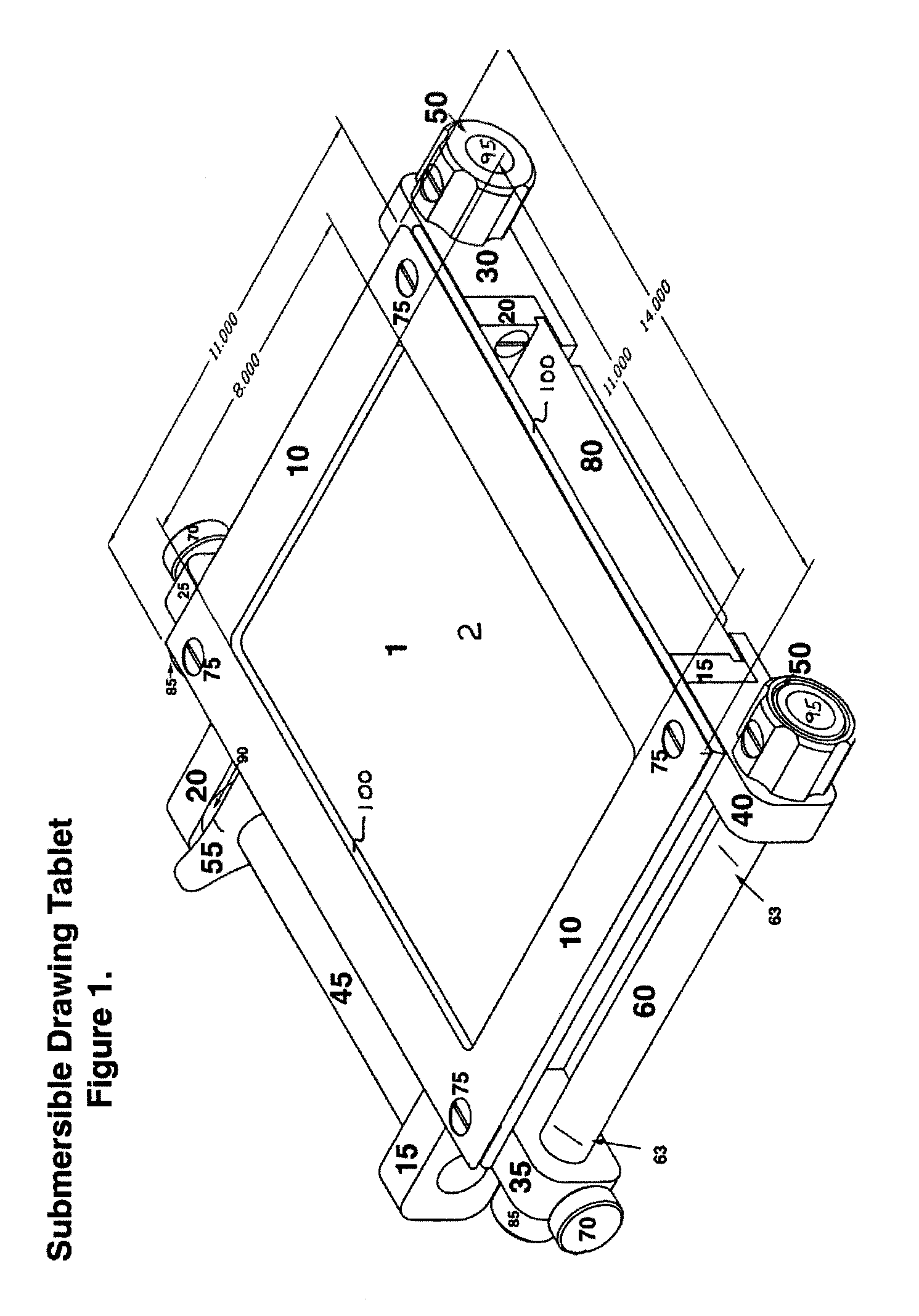

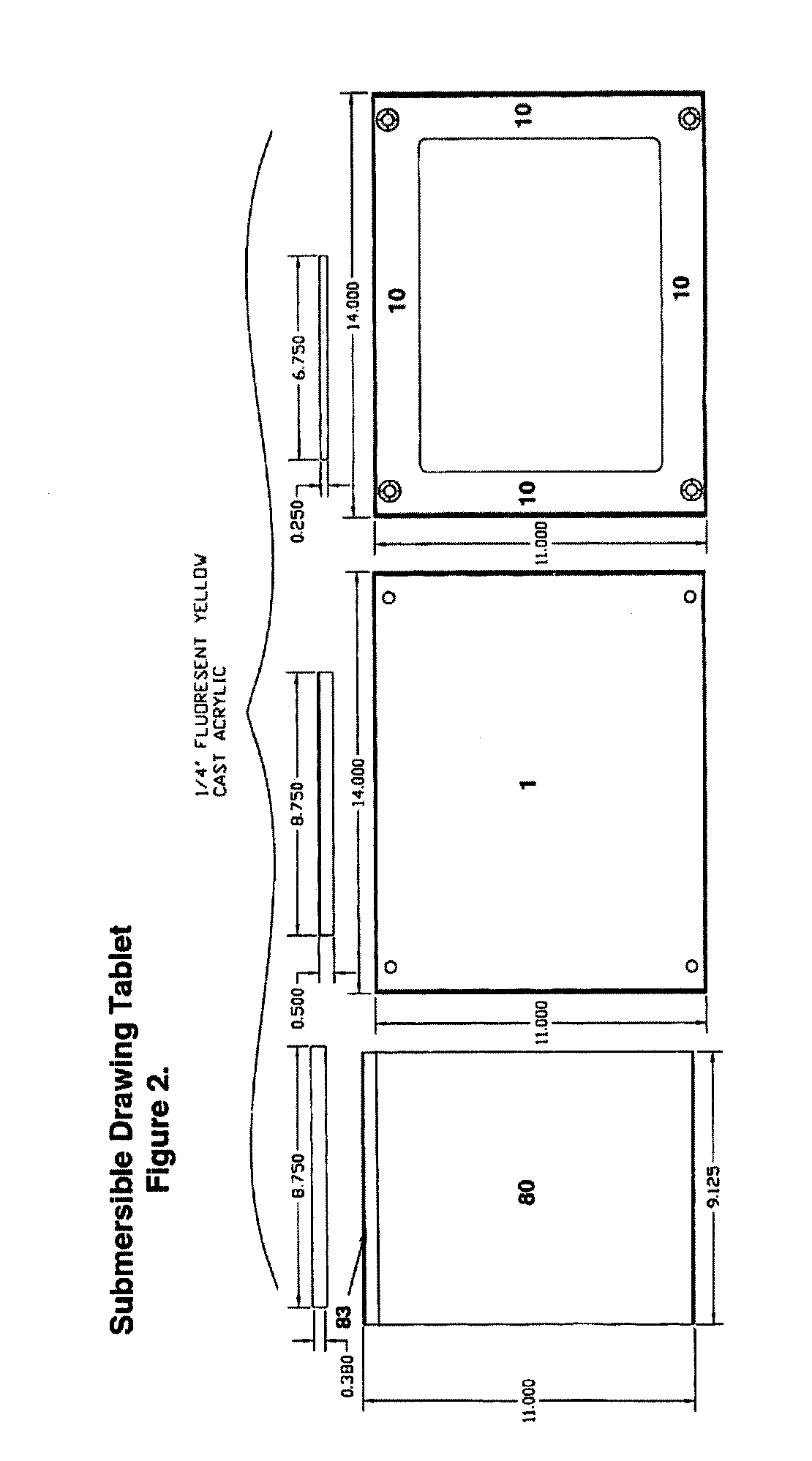

Submersible tablet for underwater or extreme environment

A tablet that is suitable for use underwater or in any extreme environment is provided. The tablet is designed, through the use of buoyant materials such as polystyrene, to have a slightly negative buoyancy at a depth of about fifty feet so that it can be very easy to manipulate underwater and will not sink or ascend rapidly if let go. A length of waterproof (plastic) vellum is stretched between two rollers to form a drawing or writing surface thereby enabling the user to easily record information on the vellum.

Owner:HAGAN MARK L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com