Yarn filoplume testing instrument with yarn dynamic tension measurement display equipment

A technology of display device and tester, applied in tension measurement, inspection of textile materials, textiles and papermaking, etc., can solve the problems of inability to know and accurately measure the dynamic tension of yarn, and achieve the goal of improving accuracy and consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

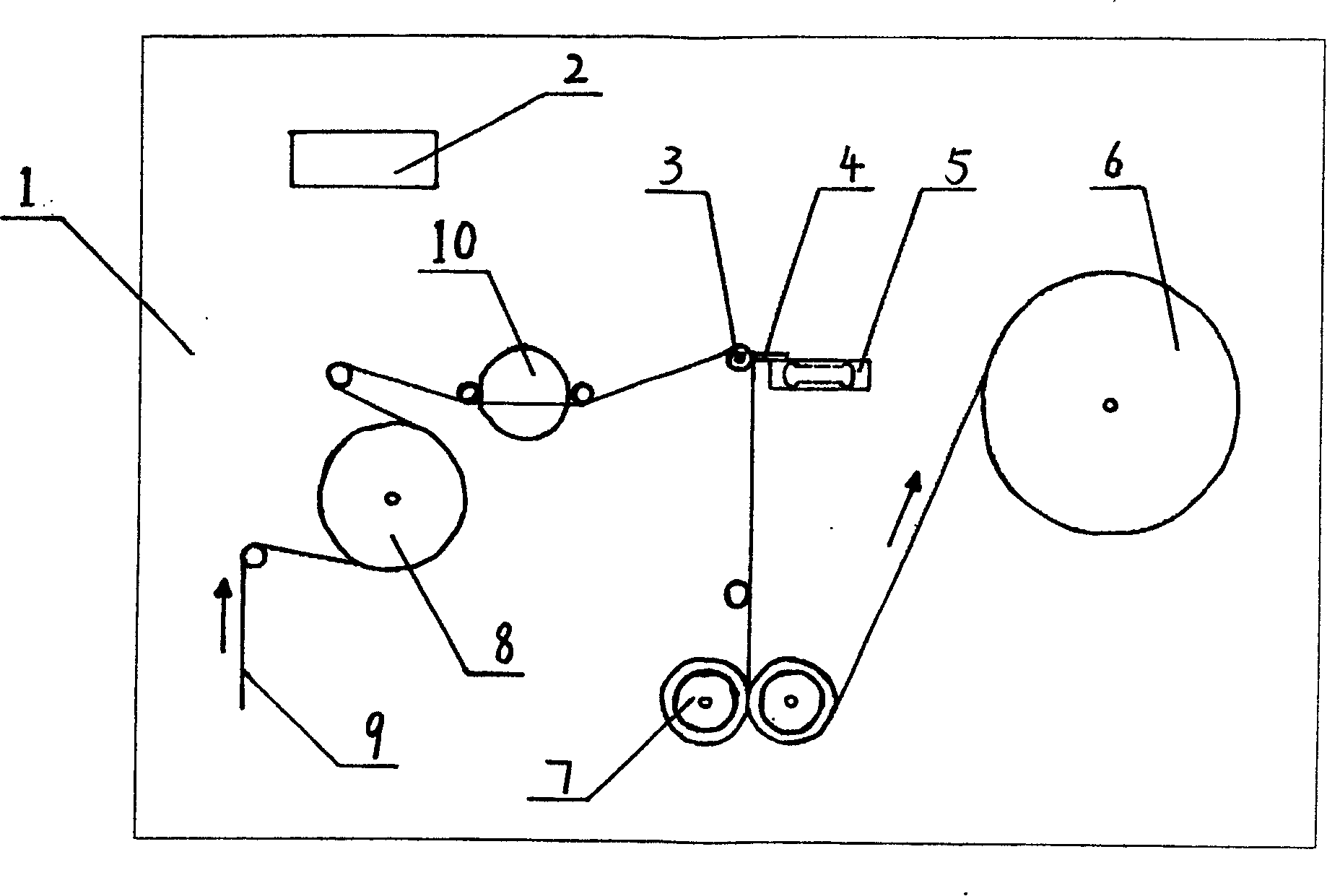

[0009] Such as figure 1 As shown, the embodiment of the invention includes the panel 1 of the tester and the path of the yarn 9 on the panel 1 . One of the paths of the yarn 9 is provided with a guide wheel 3 for the yarn 9 to bypass, and the guide wheel 3 is mounted on the connecting shaft 4 through a bearing, and the connecting shaft 4 is fixed to a tester installed on the tester. On the load cell 5; the load cell 5 is connected with the tension display device 2 installed on the tester.

[0010] Starting from the input end, the yarn 9 passes through the tension adjusting device 8, the testing area 10, the guide wheel 3, the roller 7 and the yarn receiving wheel 6 in sequence.

[0011] The force sensors are various small force sensors.

[0012] The force value display device is various display devices that can be used to display the yarn force value detected by the force value sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com