Particle vacuum intake control method and device and vacuum intake system

A technology of vacuum suction and control method, which is applied in the direction of transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problem of low accuracy of particle quality, and achieve the effect of high accuracy, accuracy and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

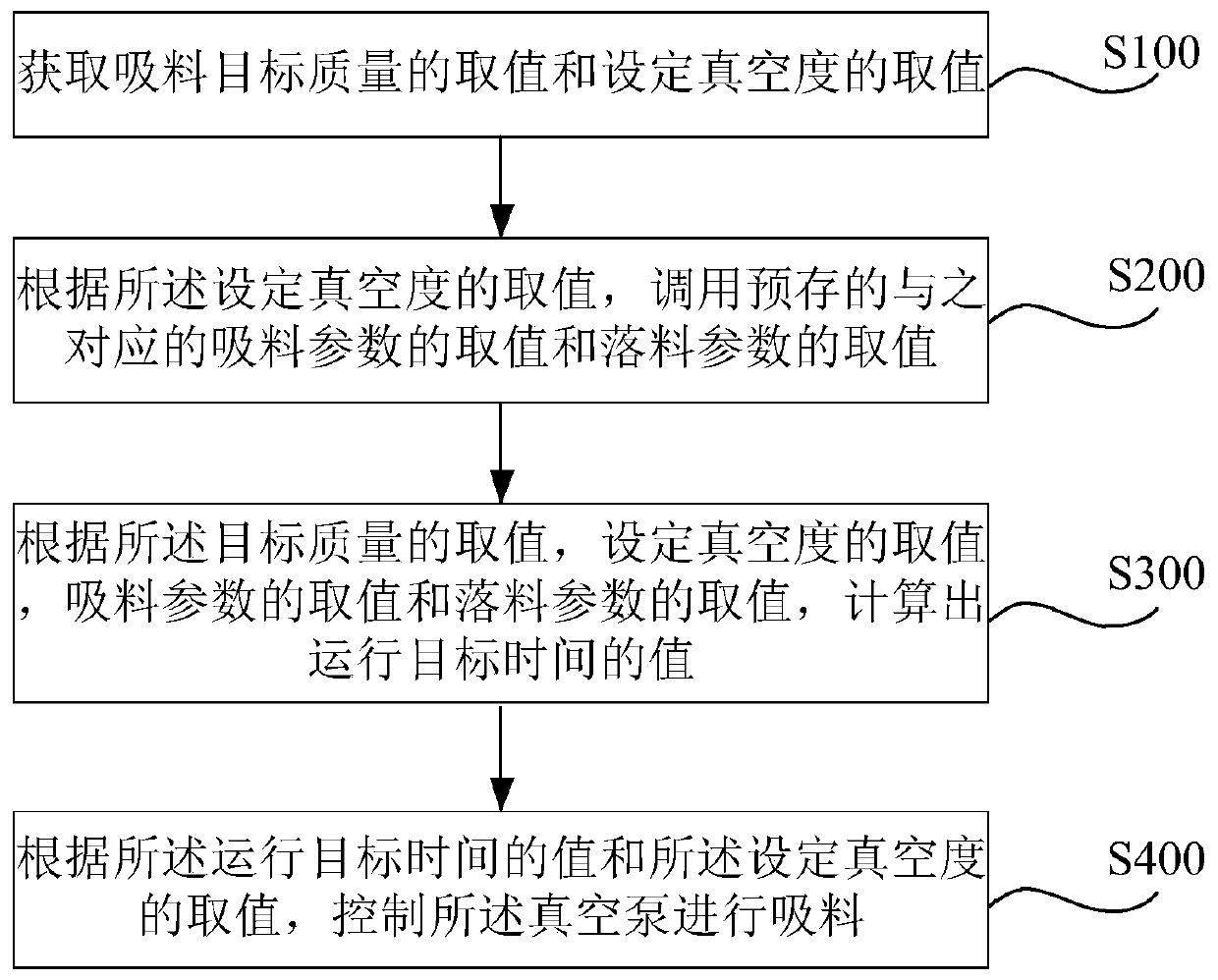

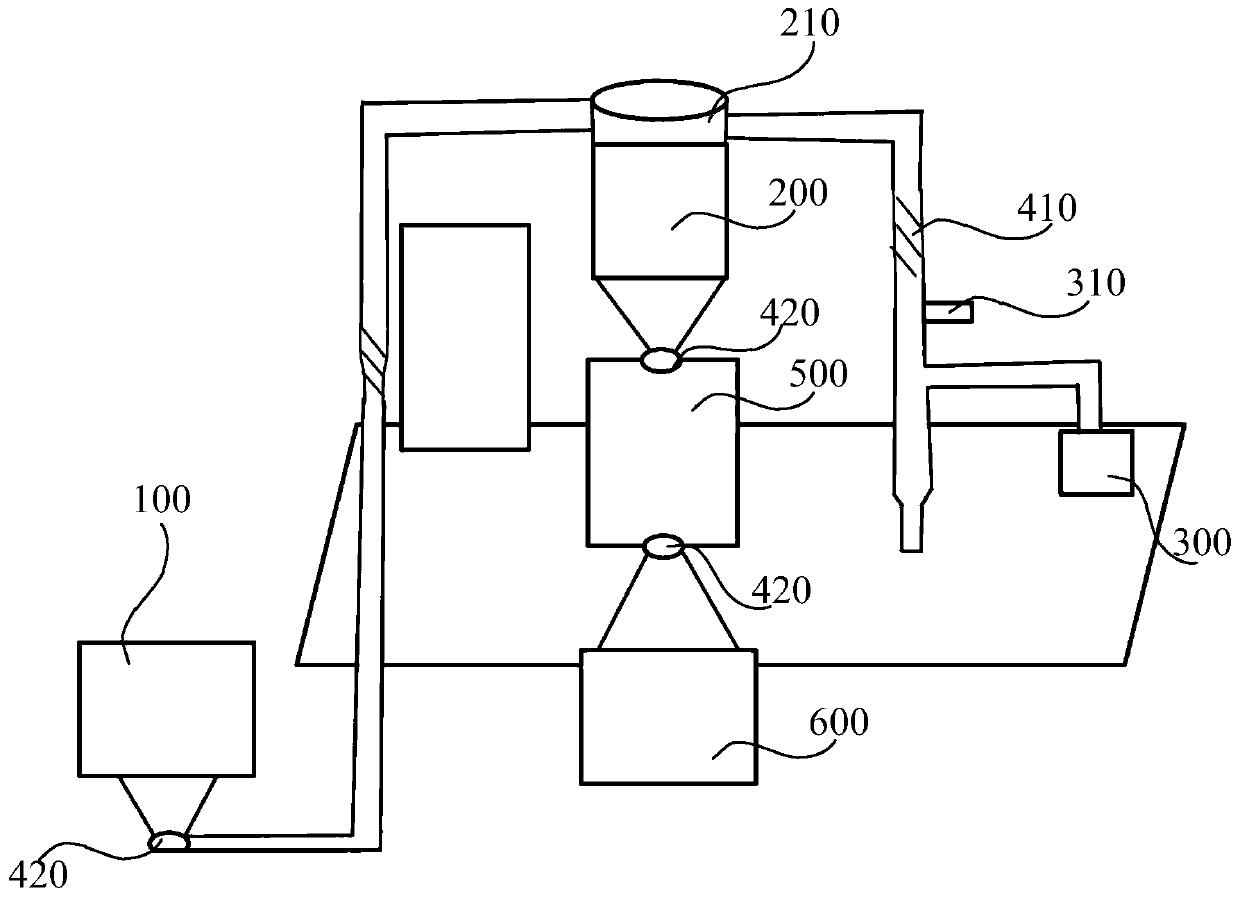

[0035] figure 1 It is a flow chart of a control method for particle vacuum suction according to an embodiment of the present application; figure 2 for use figure 1 Schematic diagram of the particle vacuum suction system shown in the control method of the particle vacuum suction. .

[0036] Such as figure 1 and figure 2 As shown, the control method of the particle vacuum suction of the embodiment of the present application includes:

[0037] Step S100: Obtain the target mass M of suction 目标 The value and the set vacuum degree P 设定 The value of; among them, the set vacuum degree P 设定 is the operating value set for the vacuum pump;

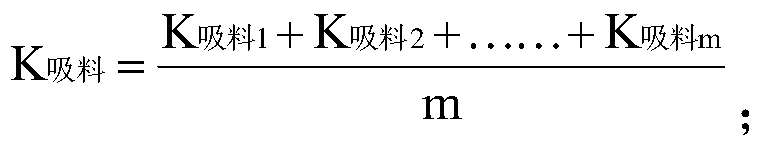

[0038] Step S200: According to the set vacuum degree P 设定 value, call the pre-stored corresponding suction parameter K 吸料 The value of and the blanking parameter K 落料 The value of; wherein, the value of the suction parameter is the vacuum pump with the set vacuum degree P 设定 The value of the negative pressure suction quality per unit of...

Embodiment 2

[0104] The particle vacuum suction control device of the embodiment of the present application includes:

[0105] The target acquisition module is used to obtain the suction target mass M 目标 The value and the set vacuum degree P 设定 The value of; among them, the set vacuum degree P 设定 is the operating value set for the vacuum pump;

[0106] Call module for setting the vacuum level P according to the 设定 value, call the pre-stored corresponding suction parameter K 吸料 The value of and the blanking parameter K 落料 The value of; wherein, the value of the suction parameter is the vacuum pump with the set vacuum degree P 设定 The value of the negative pressure suction quality per unit of time during vacuum suction, the blanking parameter K 落料 The value of is the quality of material sucked from the pipeline by unit negative pressure after the vacuum pump stops vacuuming;

[0107] Calculation module, for according to the target mass M 目标 value, set the vacuum degree P 设定 The value...

Embodiment 3

[0139] A particle vacuum suction control device according to an embodiment of the present application, comprising:

[0140] one or more processors;

[0141] storage means for storing one or more programs;

[0142] When the one or more programs are executed by the one or more processors, the one or more processors are made to implement the particle vacuum suction control method described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com