Patents

Literature

859 results about "Yarn tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

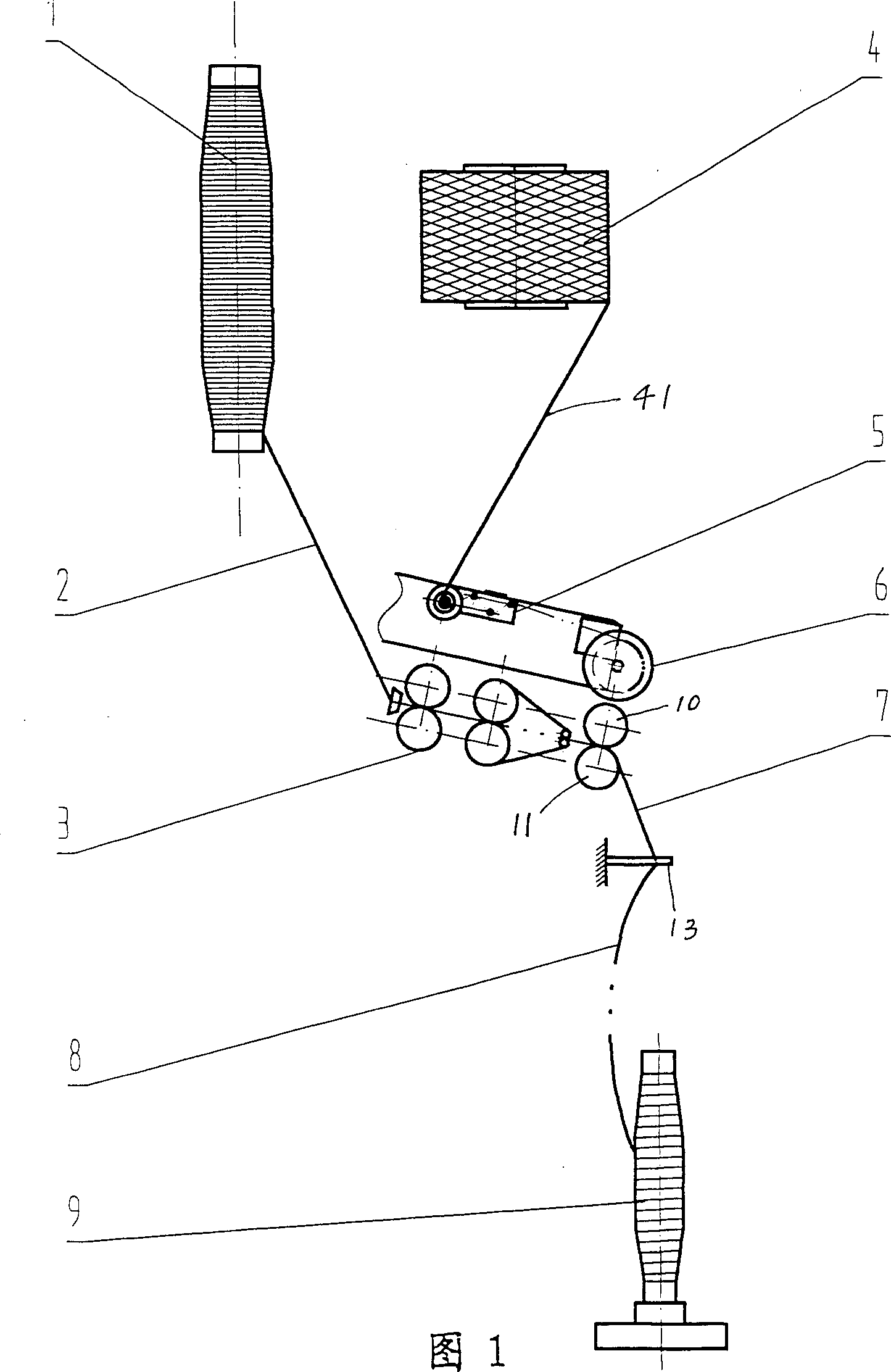

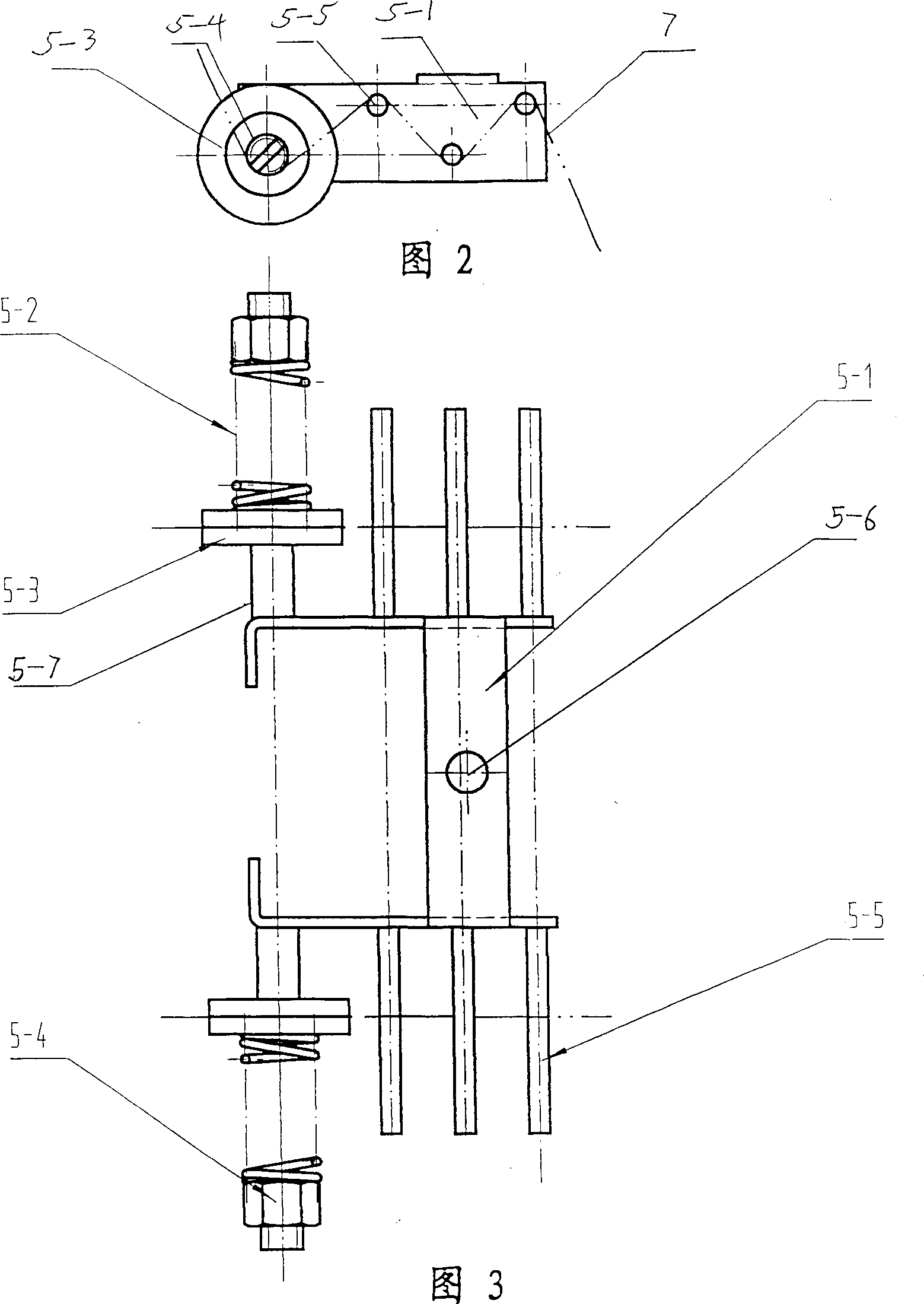

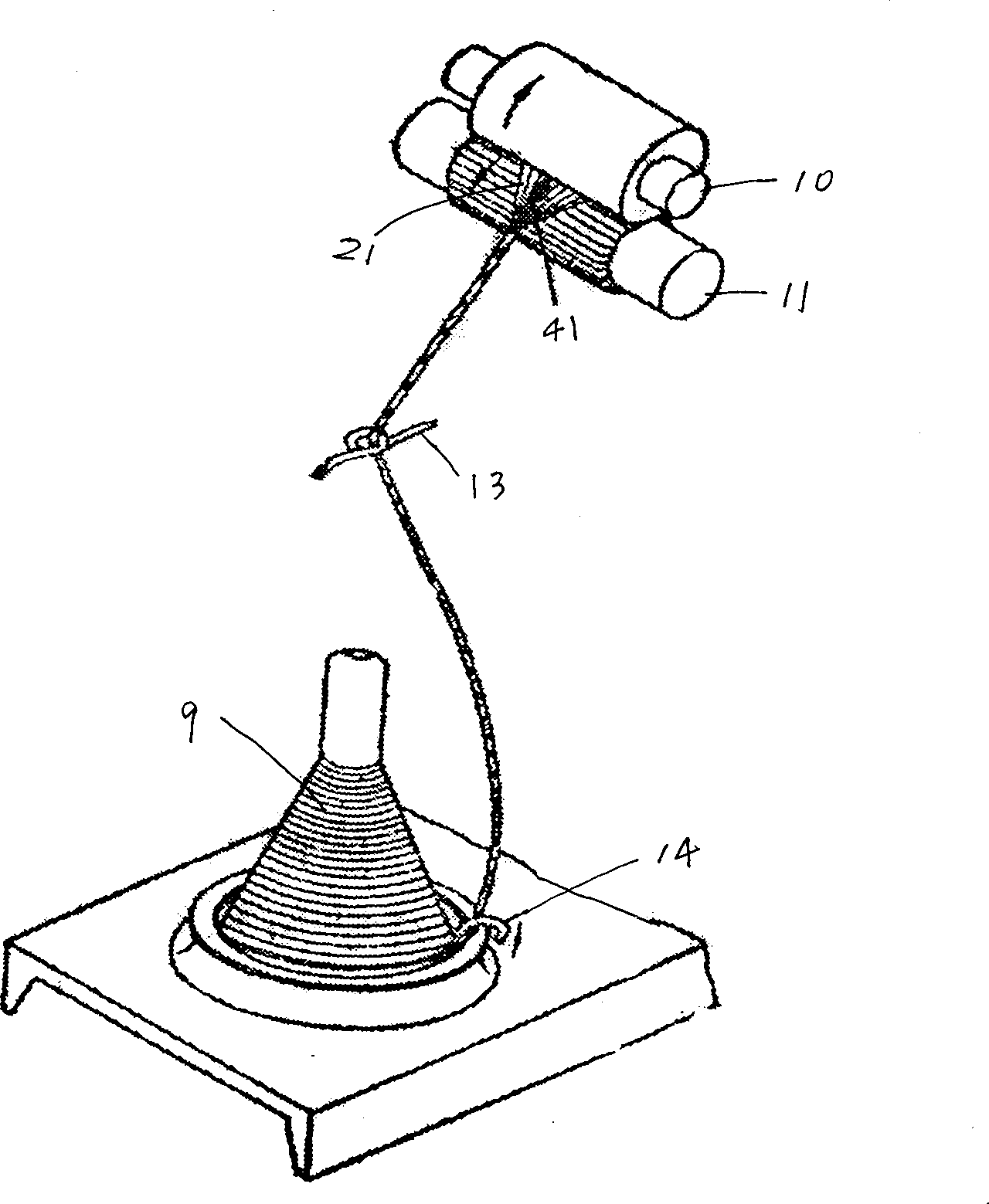

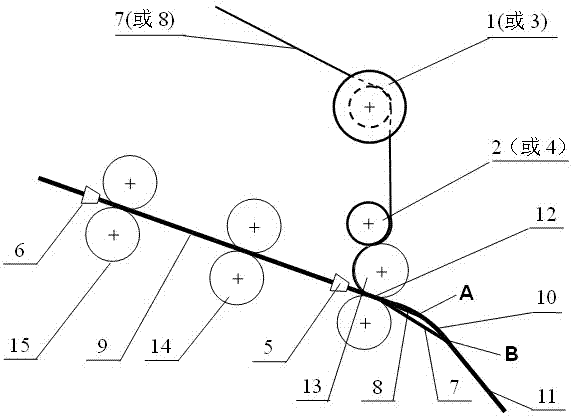

Method and apparatus for making core-spun yarn of steple-fibre covered filament

The present invention is characterized by that on the spinning machine it utilizes addition of a yarn tension control device and simple renovation of guide wheel to spin the invented core-spun composition yarn whose yarn is covered with staple fiber, and its covering rate is high. Said composite core-covered yarn not only has the appearance style, hand property, fluffy property and other advantages of staple fibre, but also possesses the strength and elongation, conformal property and drapping property, etc. of yarn.

Owner:薛元

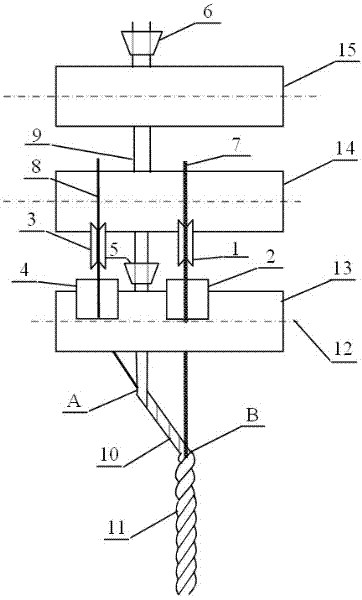

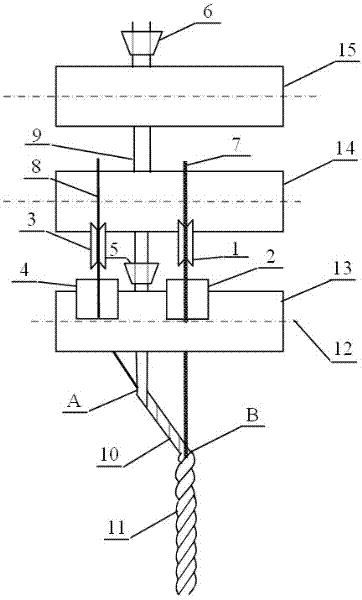

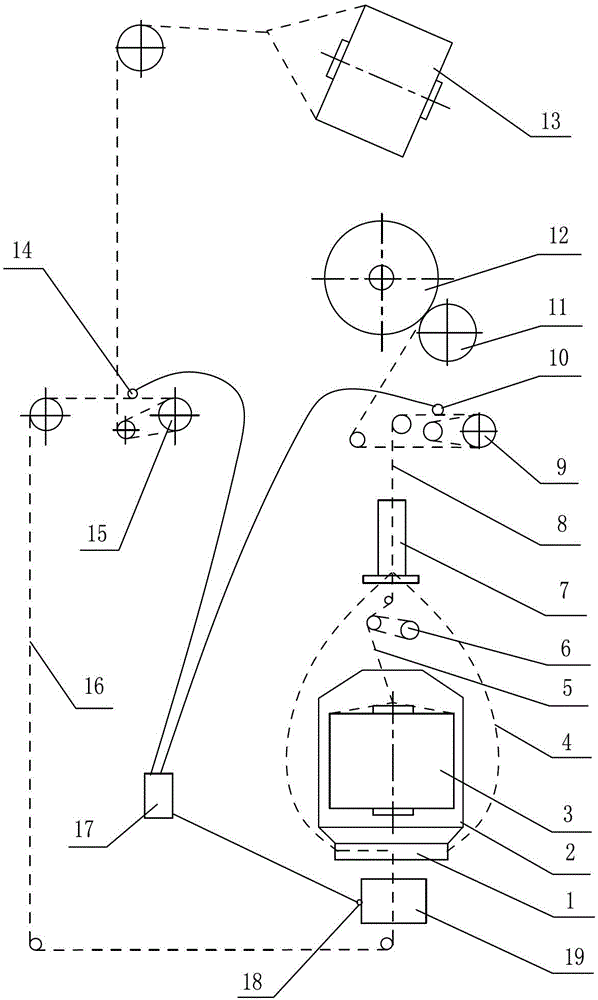

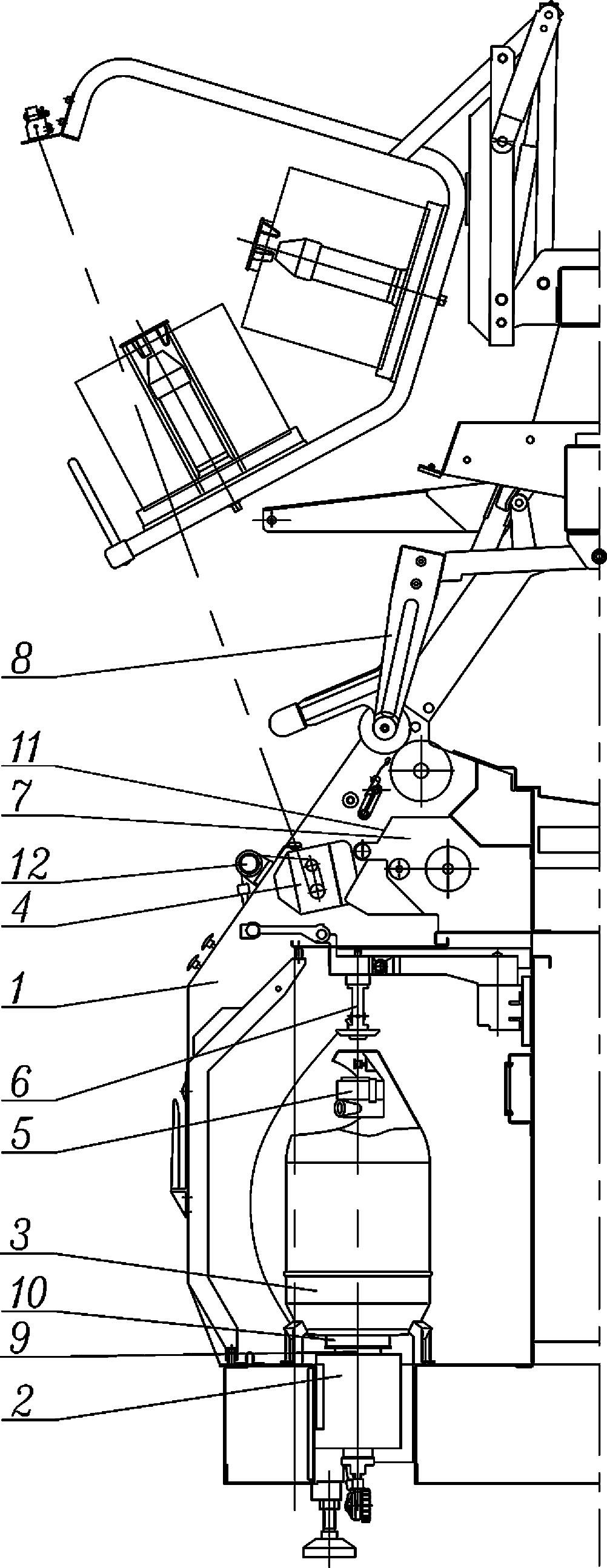

Wave-absorbing high-elasticity yarn and production equipment and production method thereof

The invention relates to a wave-absorbing high-elasticity yarn and production equipment and a production method thereof. The wave-absorbing high-elasticity yarn is characterized in that the wave-absorbing high-elasticity yarn comprises an elastic yarn, a core-spun structural yarn section is wound on the external side of the elastic yarn, and the core-spun structural yarn section comprises a metal wire and a staple strand which is wound on the external side of the metal wire. The production equipment of the wave-absorbing high-elasticity yarn comprises a ring spinning machine and is characterized in that the equipment additionally comprises an elastic yarn tension disc, an elastic yarn holding roll, a metal wire tension disc, a metal wire holding roll, a staple strand front bell mouth and a staple strand rear bell mouth. Only by adding a pair of tension plates, two holding rolls and two bell mouths on a common spinning machine, the high-elasticity composite spinning of the non-elastic metal wire can be realized. Therefore, the method is simple and practical.

Owner:DONGHUA UNIV

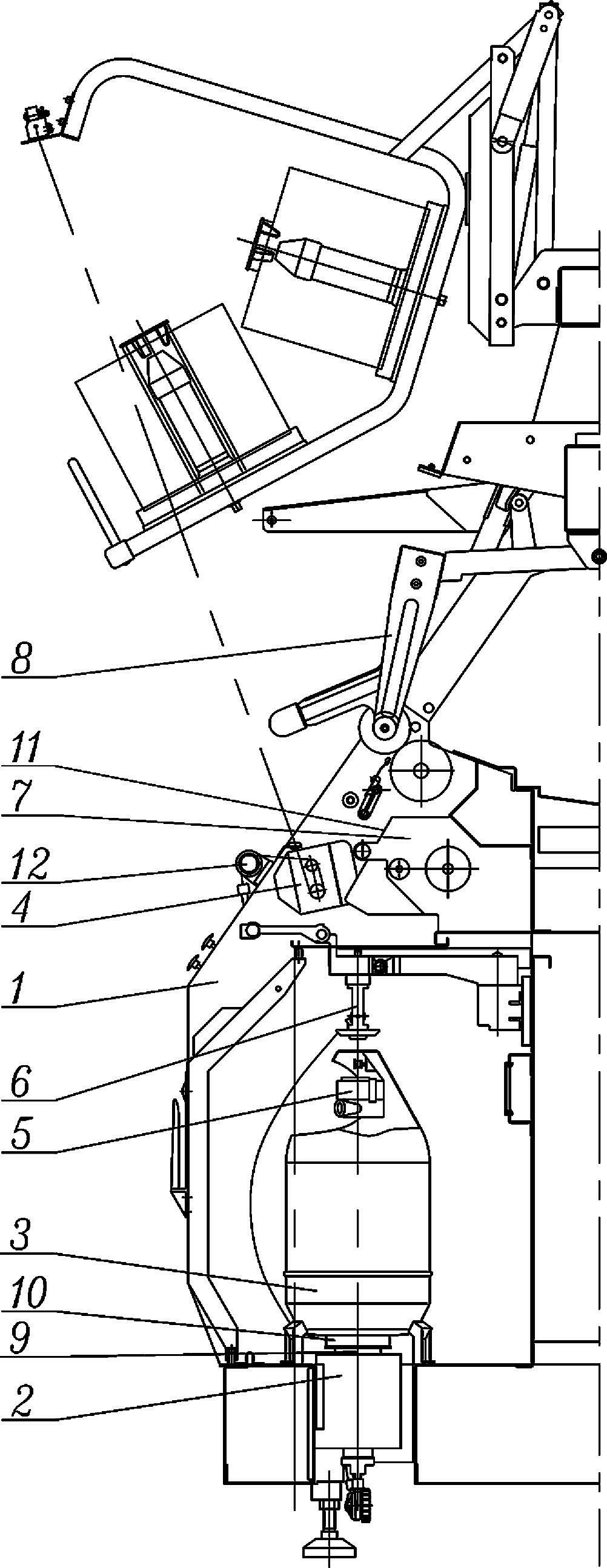

High-tenacity and low-tension spinning device

ActiveCN101892533AHigh strengthReduce spinning tensionDrafting machinesContinuous wound-up machinesEngineeringHardness

The invention relates to a high-tenacity and low-tension spinning device, which is used for ring spinners in textile industry. In the invention, a frame member is arranged along the length direction of a ring spinner in the middle of a spinning section between a front jaw and a yarn guide hook, a false twisting unit arranged corresponding to a spindle is fixed on the two borders of the frame member by two bearings and makes tangential transmission by a driving belt driven by a motor, and a yarn tension damping needle rod is arranged in the false twisting unit. By using the invention, the spinning tenacity is greatly improved, the spinning tension is reduced, and the spinning tension difference of large cop, middle cop and small cop is reduced, thereby realizing low-tension spinning; yarn filoplume is reduced, rubber roller is not wound by fibre frequently, and flyings are reduced, thereby improving spinning environment and spinning quality; heavy twist torsional moment is featured, the device can be applied to yarn with bigger hardness and cruder fibre, fibre material scope is enlarged, and raw material cost is reduced; and installation of the low-tension spinning device keeps the mechanism of the traditional ring spinners unchanged and is fit for modification of ring spinners for cotton / yarn / ramie / silk spinning.

Owner:SHANGHAI TEXTILE GRP DETECTION STANDARD CO LTD

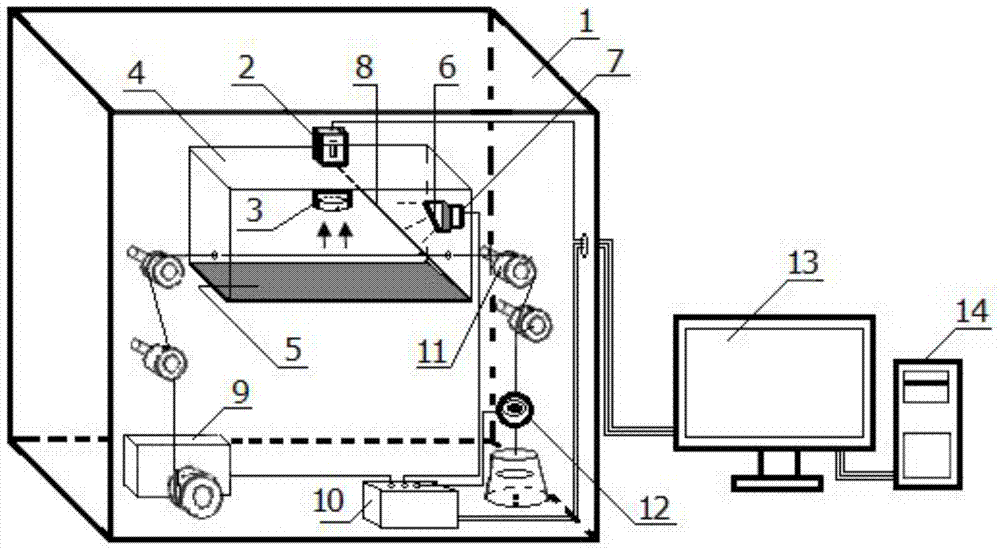

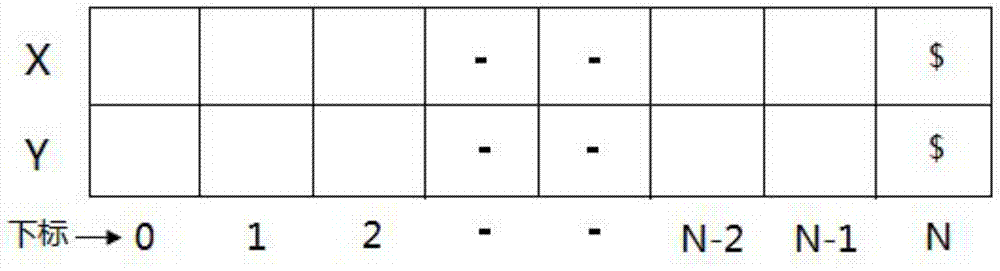

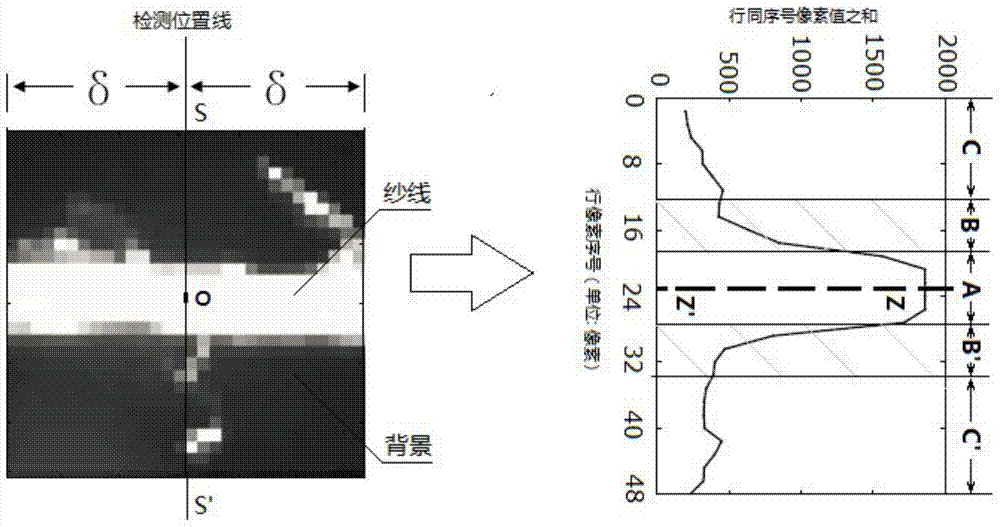

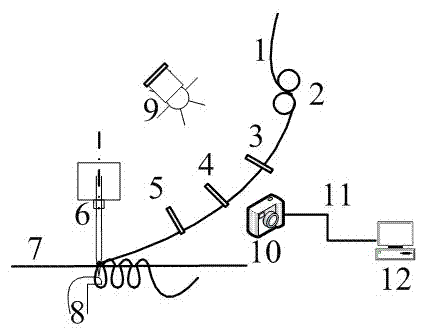

Dynamic textile yarn diameter rapid-measuring device and method

InactiveCN103759662AMeet the test requirementsEliminate reflectionsUsing optical meansBatch processingTextile yarn

The invention relates to a dynamic textile yarn diameter rapid-measuring device and method. The device comprises a box body, a yarn tension controller, a control cabinet, a lighting source, an image acquiring device and a computer. According to the method, a detecting point neighborhood length subimage is captured to serve as a process object, and the subimage is rapidly divided into a yarn body area, a yarn body suspicious area and a background area according to the gray scale projection curve distribution characteristics of the subimage; a classifier is established with the grey scale characteristics of pixels of the yarn body suspicious area and the direction connectivity between the yarn body suspicious area and the yarn body area as the constraint condition, and the classifier is used for classifying the pixels of the yarn body suspicious area to extract a complete yarn body image area; the average value of the diameters of all yarn detecting point axial neighborhood length location points serves as the diameter of the yarn at the detecting point. By establishing a detecting point and image serial number address mapping table, automatic batch processing of image sequences of moving yarn captured continuously is achieved. The dynamic textile yarn diameter rapid-measuring device and method can achieve rapid detection of diameters of all detecting points of yarn with a preset length automatically.

Owner:DONGHUA UNIV

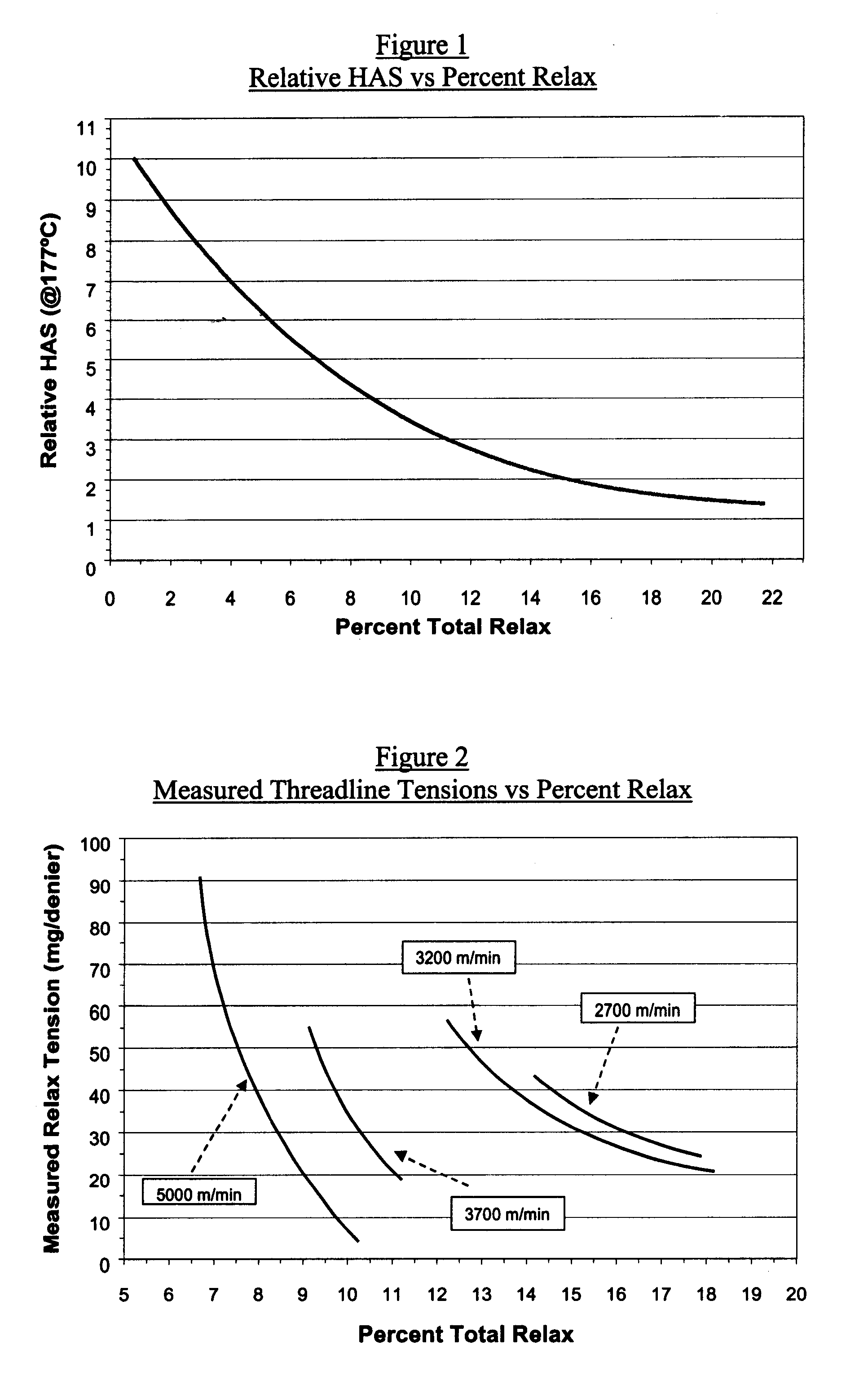

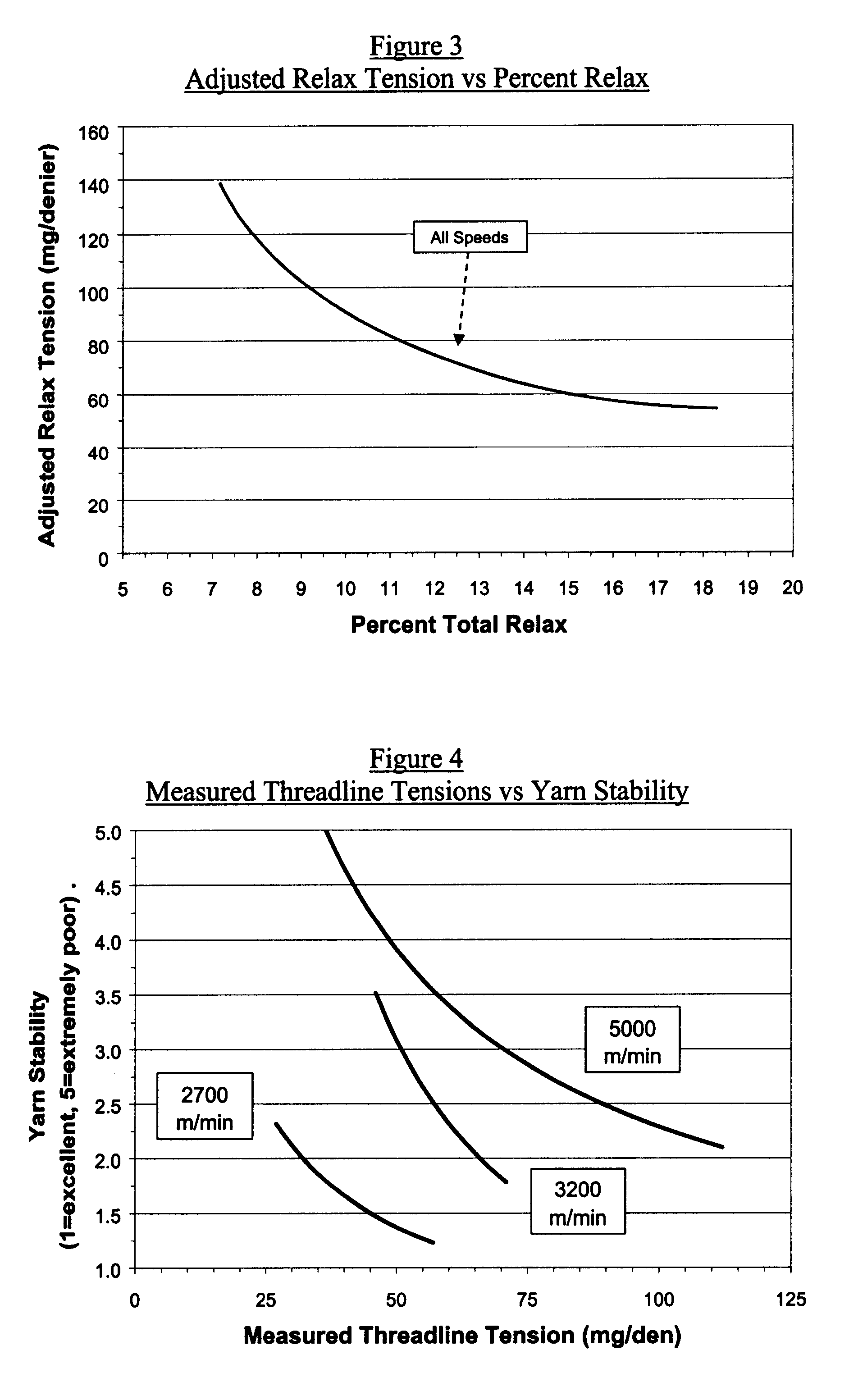

High tenacity low shrinkage polyamide yarns

Multi-filament polyamide yarns characterized by high tenacity and low shrinkage are disclosed. Such yarns or fabrics made therefrom can be used in industrial applications in which such a combination of properties is desirable. Such yarns are particularly useful in the manufacture of automobile airbag fabrics. Also disclosed is a process for making such yarns. The yarn manufacturing process involves spin-drawing molten nylon, relaxing and controlling the yarn tension, and then winding the yarn. Yarns made according to this process exhibit linear density in the range of 110-940 decitex, tenacity equal to or greater than 80 cN / tex, and shrinkage, measured at 177° C., of less than 5%.

Owner:INV PERFORMANCE MATERIALS LLC

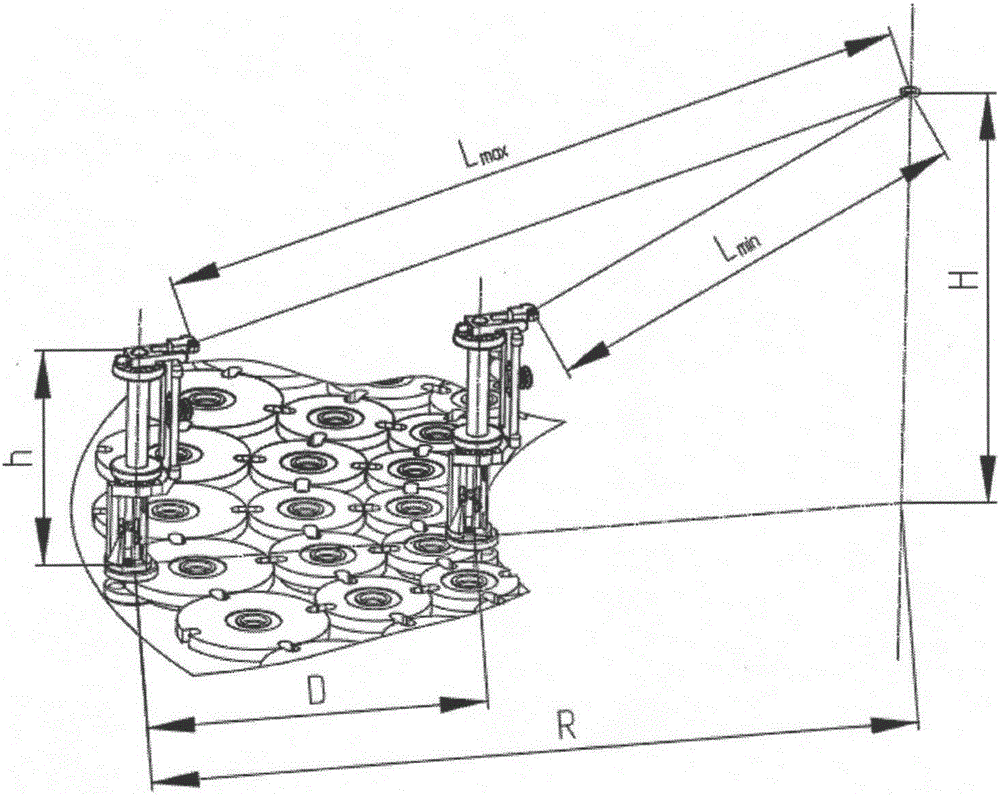

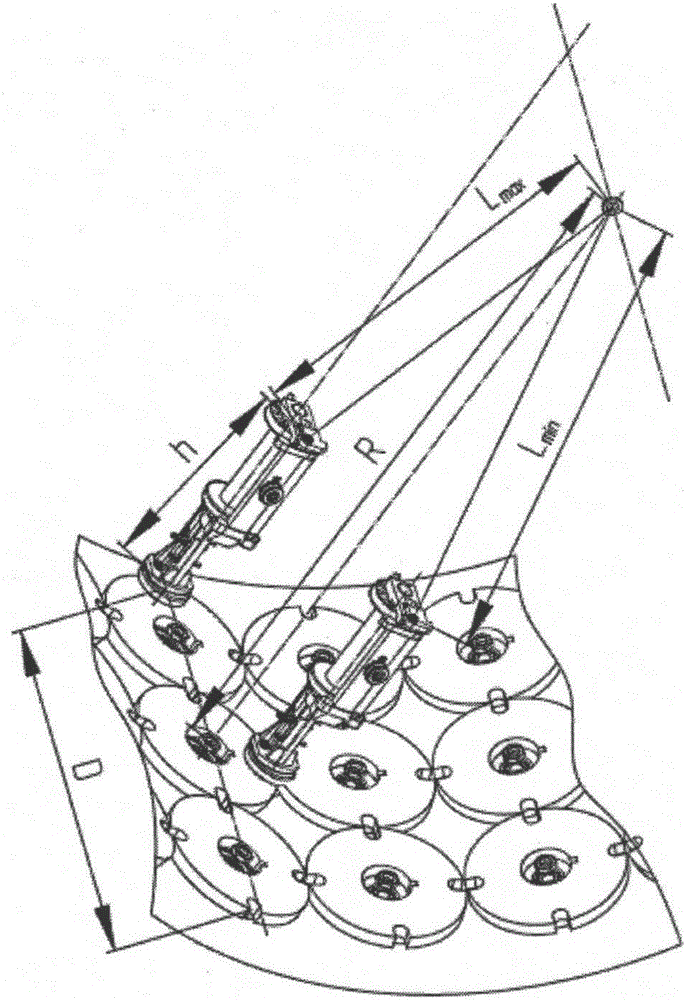

Inner-ring horizontal three-dimensional braiding machine and robot core traction system

The invention relates to an inner-ring horizontal three-dimensional braiding machine, which is characterized by comprising an annular braiding chassis which is vertically arranged. A spindle track is formed on the inner ring surface of the braiding chassis. A circle of spindles are distributed along the circumference of the inner ring surface of the braiding chassis. A boat-shaped block of each spindle is installed in the spindle track through a driving groove of a driving plate. Each driving plate is corresponding to a spindle driving part. A power unit drives the spindle driving part. The spindle driving part drives respective driving plate such that the driving groove of the driving plate drives the spindle to move in a staggered manner in the track. Meanwhile, axial yarn passes through a fixed mandrel of the spindle driving part. Another technical scheme of the invention is to provide a robot core traction system. The invention provides guarantees for braiding large size of complex-shape preforms. Yarn tension fluctuation is effectively reduced, and the improvement effect is more obvious during multilayer braiding.

Owner:DONGHUA UNIV +1

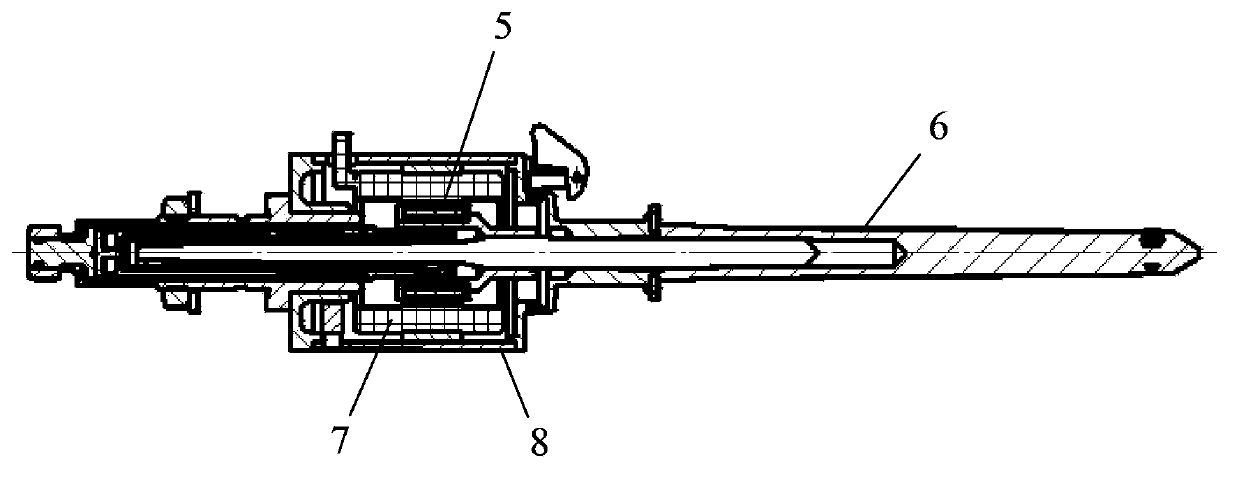

Non-contact yarn tension testing device by utilization of CCD technology

InactiveCN102517812AAccurate detectionHigh-resolutionTufting apparatusTension measurementEngineeringDynamic Tension

The invention relates to a non-contact yarn tension testing device, which contains a constant tension thread guide roller, an auxiliary light source and a CCD image sensor. The invention is characterized in that the auxiliary light source and the CCD image sensor are respectively arranged at two sides of a yarn transport path between the constant tension thread guide roller and a tufting needle of a carpet tufting machine, and the CCD image sensor is connected to a computer through a USB interface data transmission device. The non-contact yarn tension testing device provided by the invention can be used to realize accurate detection of dynamic tension and raise carpet resolution, and is of great significance for dynamic tension measurement of yarn during operation.

Owner:DONGHUA UNIV

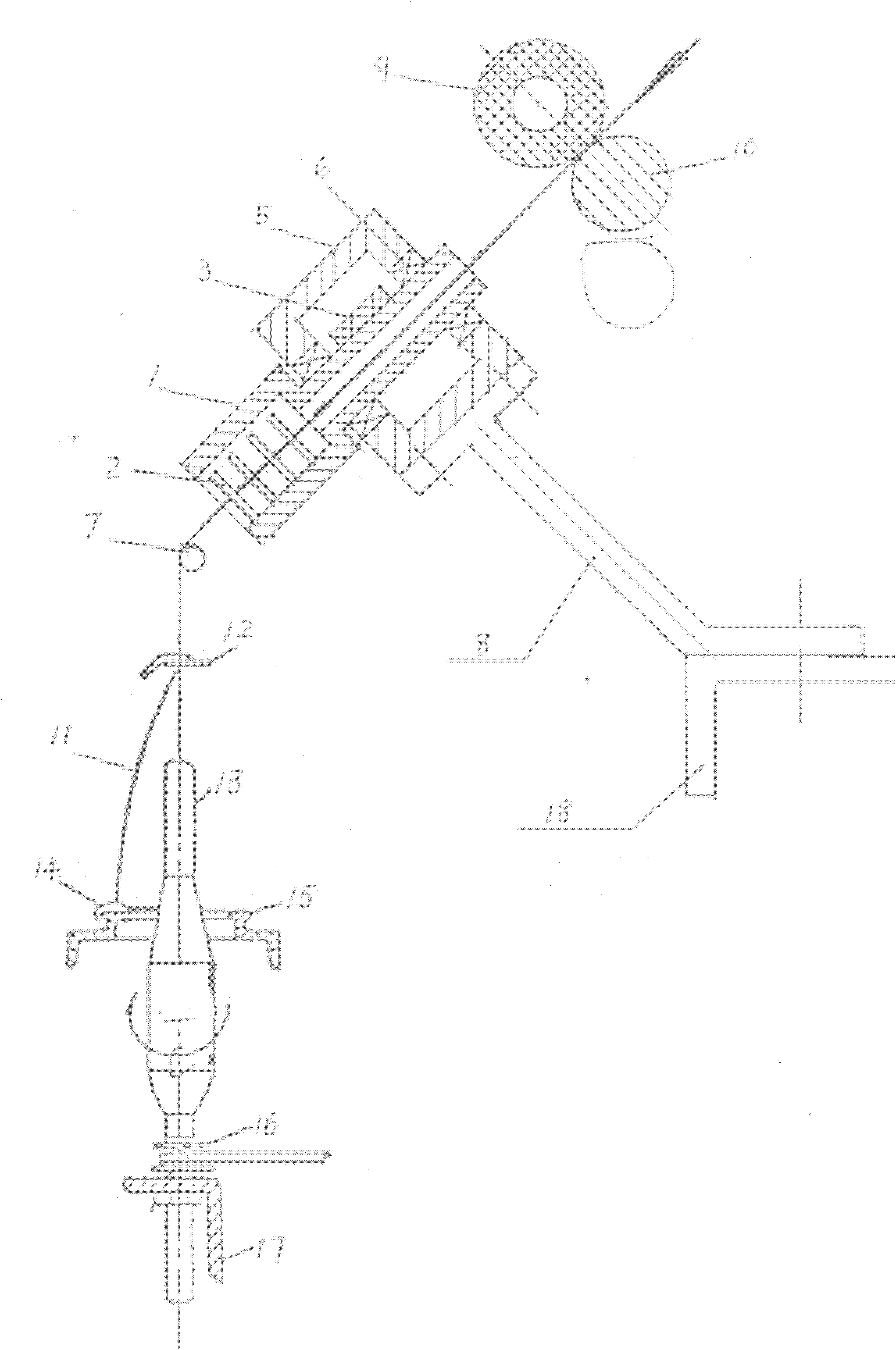

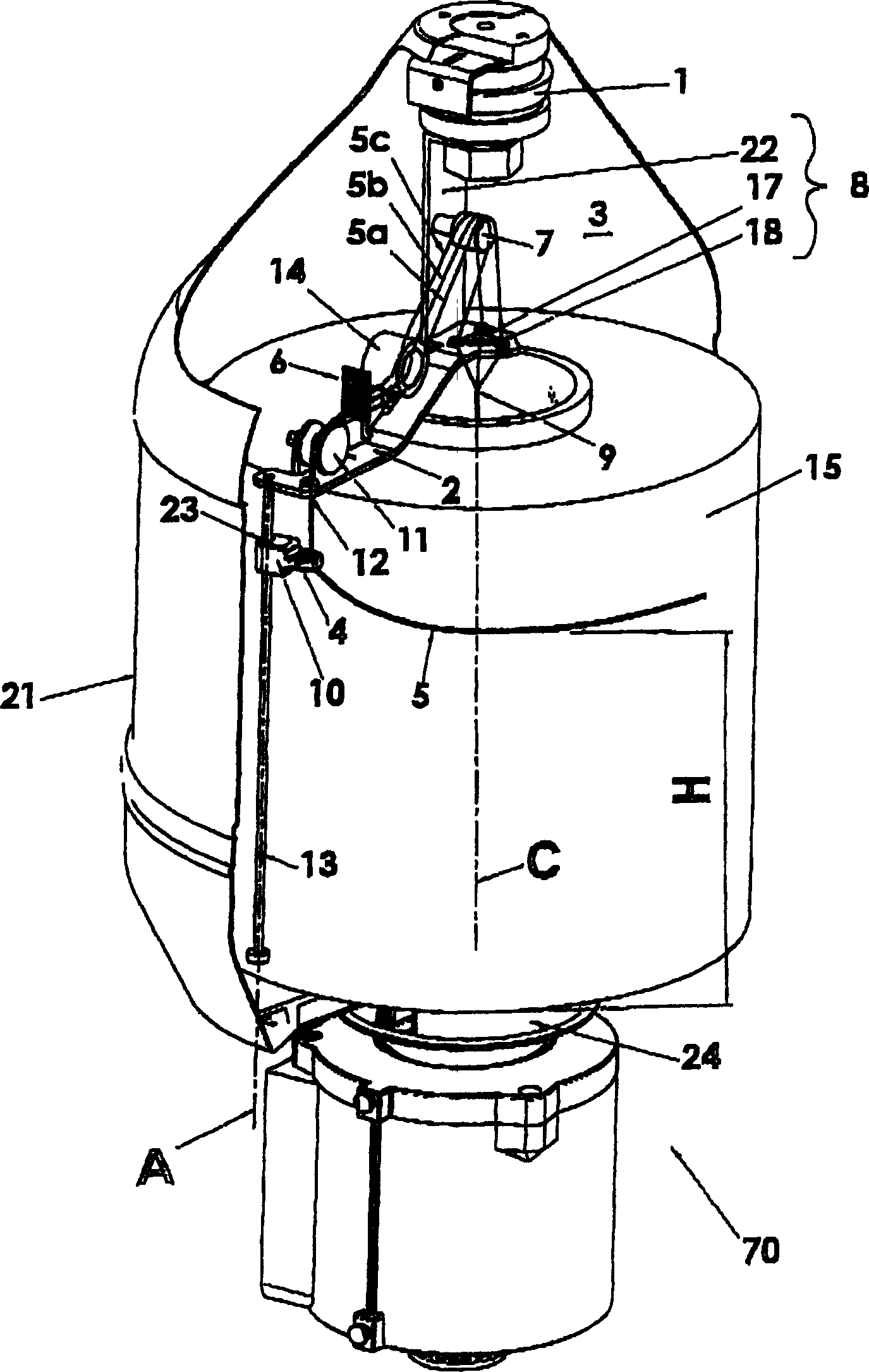

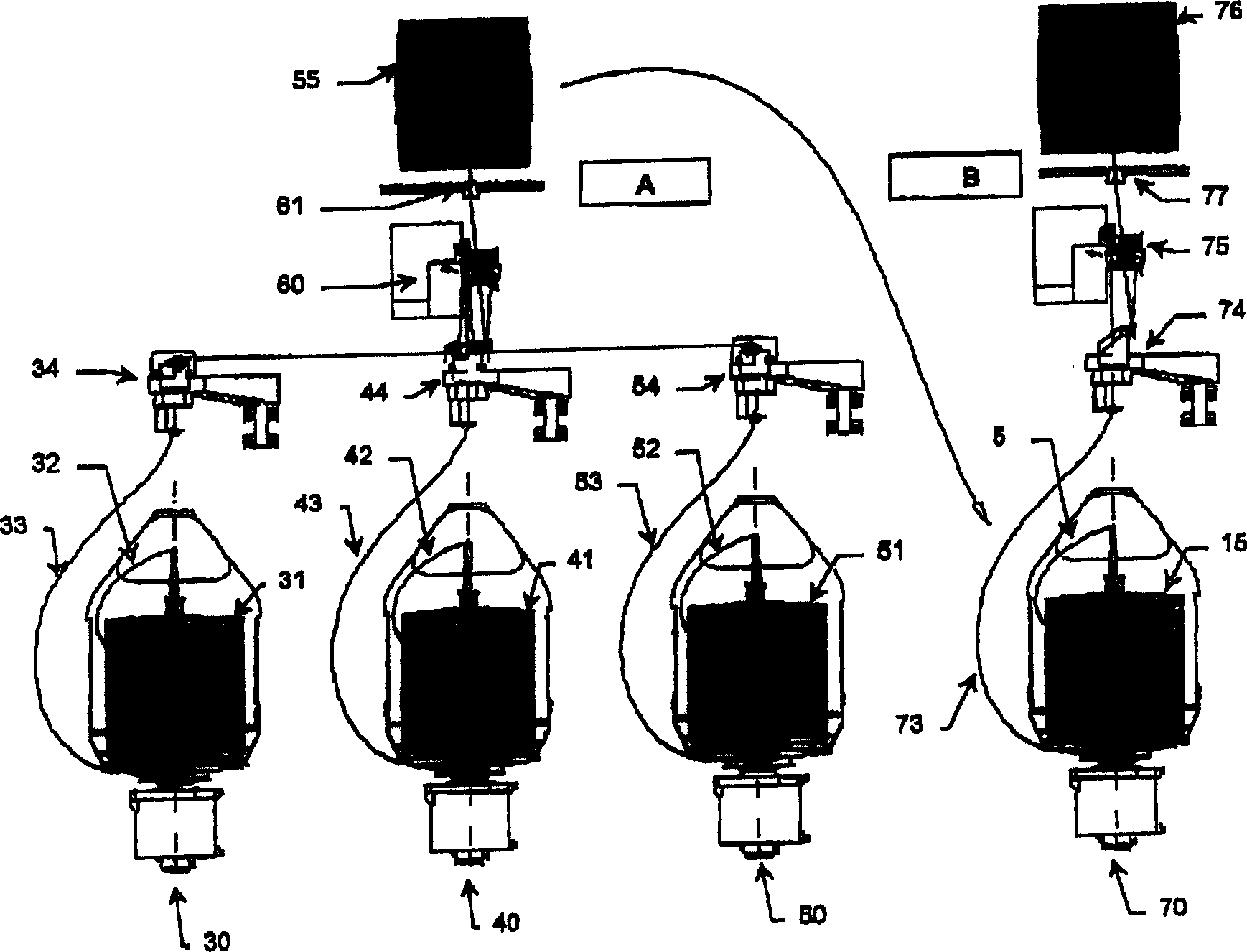

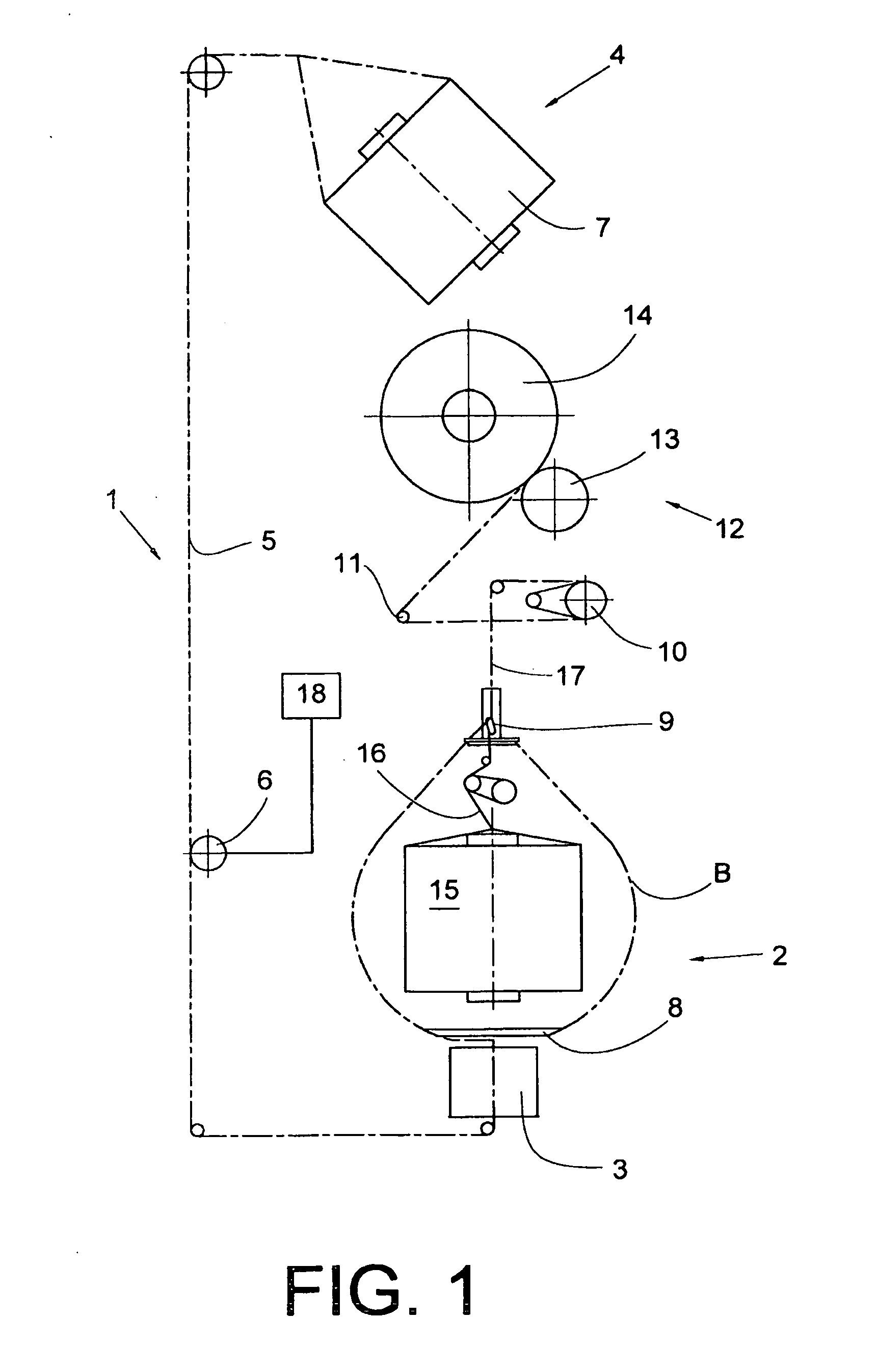

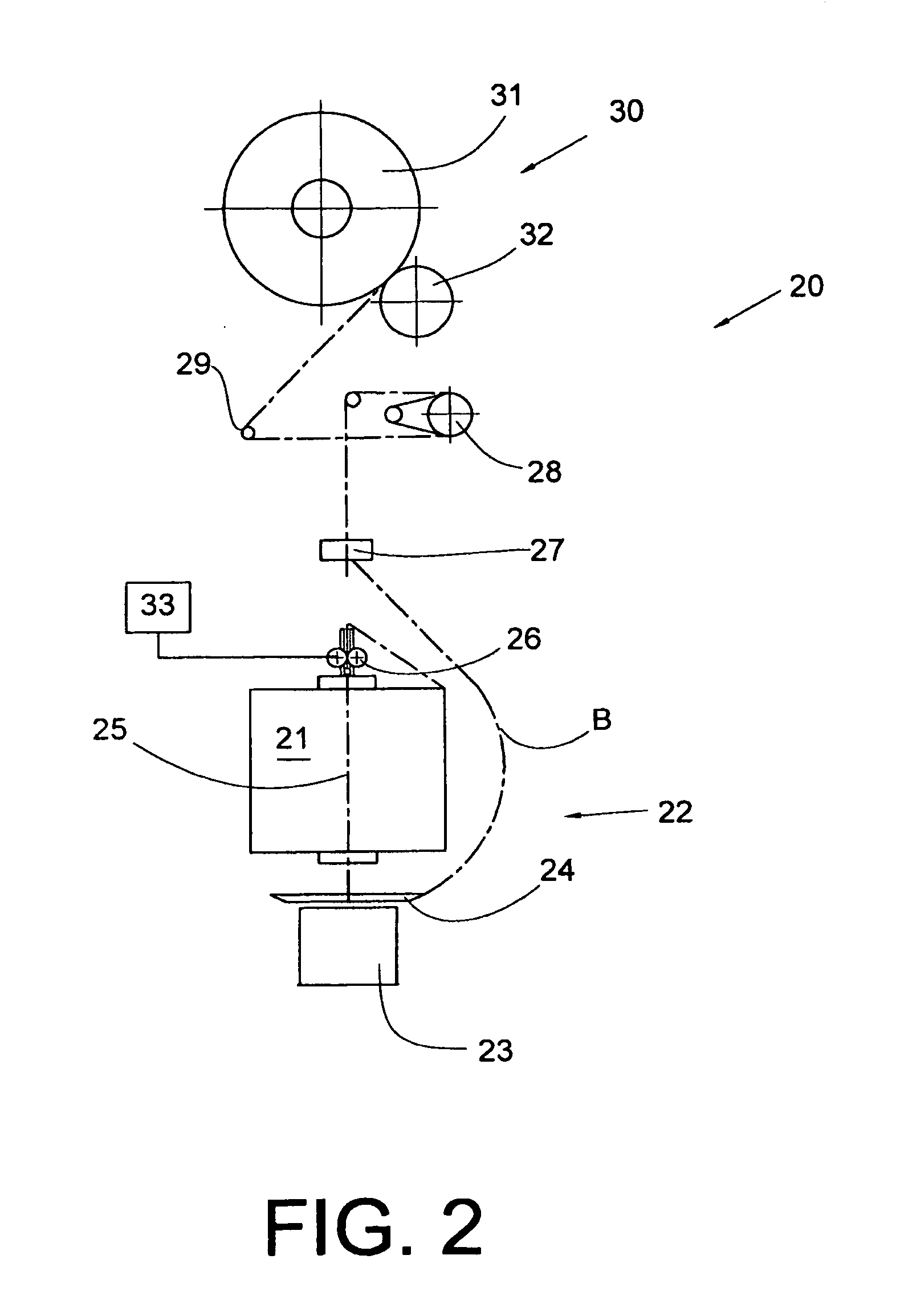

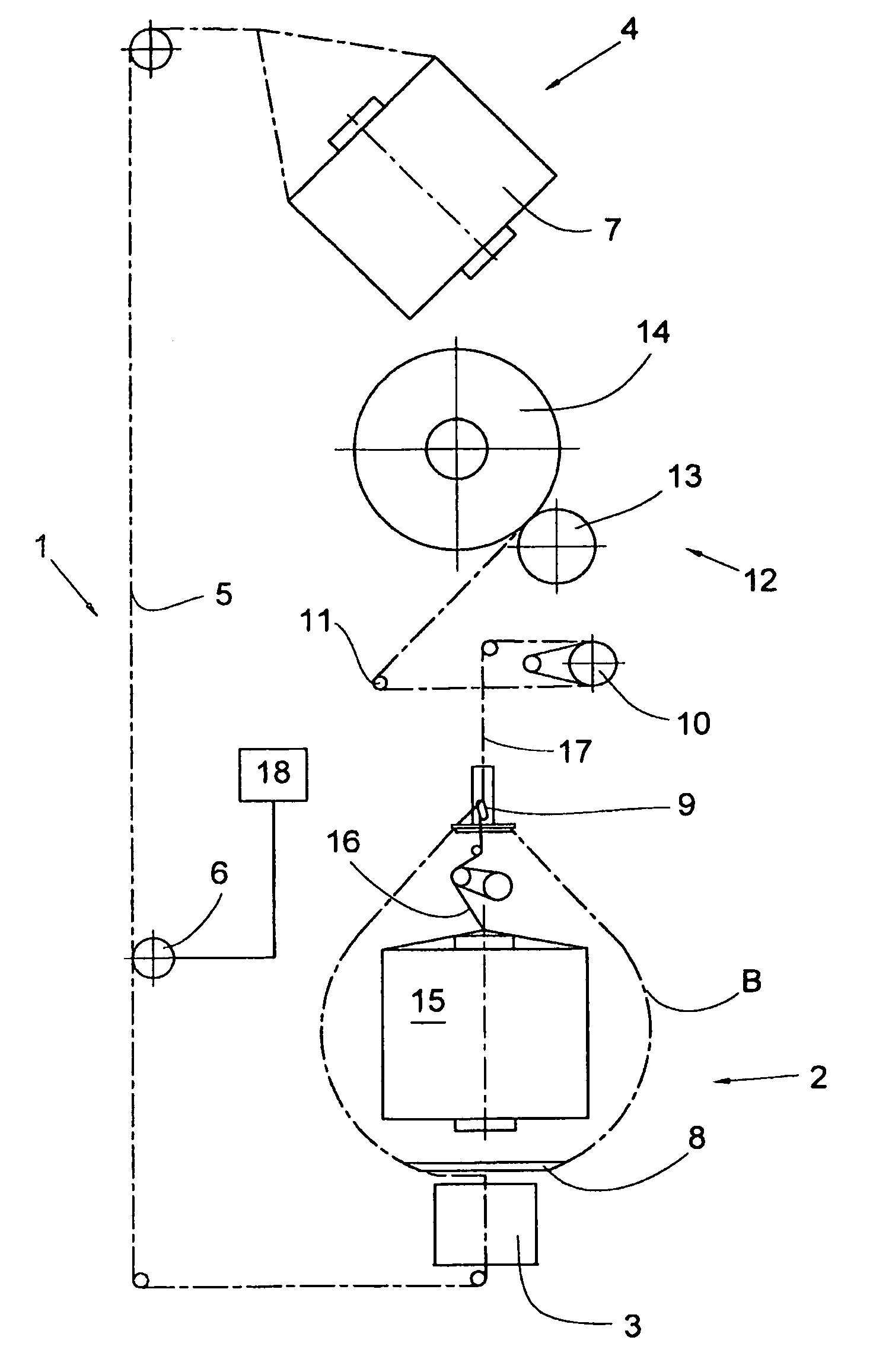

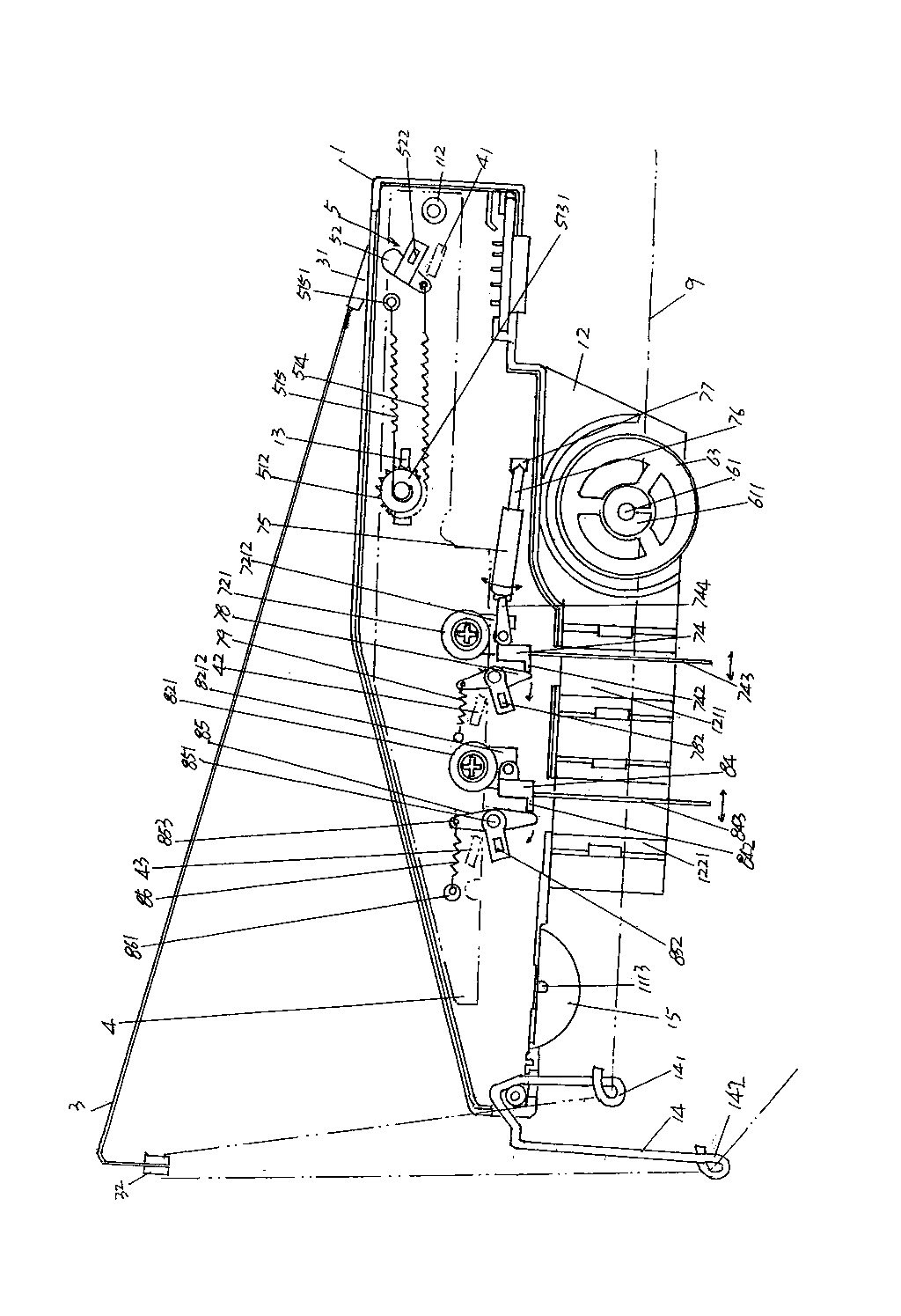

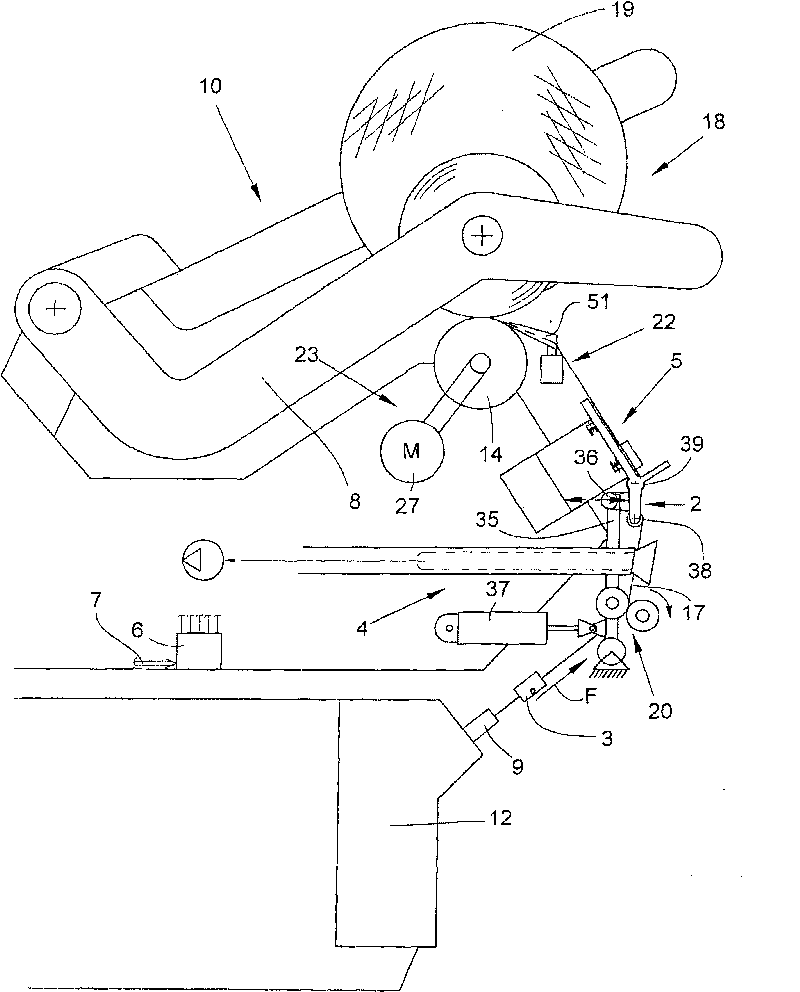

Textile machine for producing plied yarn and method

The invention relates to a method for producing ply yarn, firstly in a ply-twisting step a plurality of yarns (5) are twisted and combined into a ply-twisting bobbin (15) and then the ply-twisting bobbin (15) is twisted The yarns (5) are further processed into final twisted yarns on the wire spindles by plying them with each other. In order to be able to produce plied yarns with as homogeneous a structure as possible and at the highest possible feed speed, the invention proposes that the yarns (5) adjacent to one another on the primary twist bobbin (15) are first separated in order to form the finish twist And pass through the yarn brake (14) separately from each other, so that the feeding yarn tension of the yarn (5) matches each other, then the yarn (5) is introduced into the yarn feeding port of the twisting spindle through the ply yarn guide (8), In order to ply at the double twist point (9). The invention also relates to a textile machine for the production of a ply yarn consisting of a plurality of yarns paralleled on a primary twist bobbin.

Owner:SAURER GERMANY GMBH & CO KG

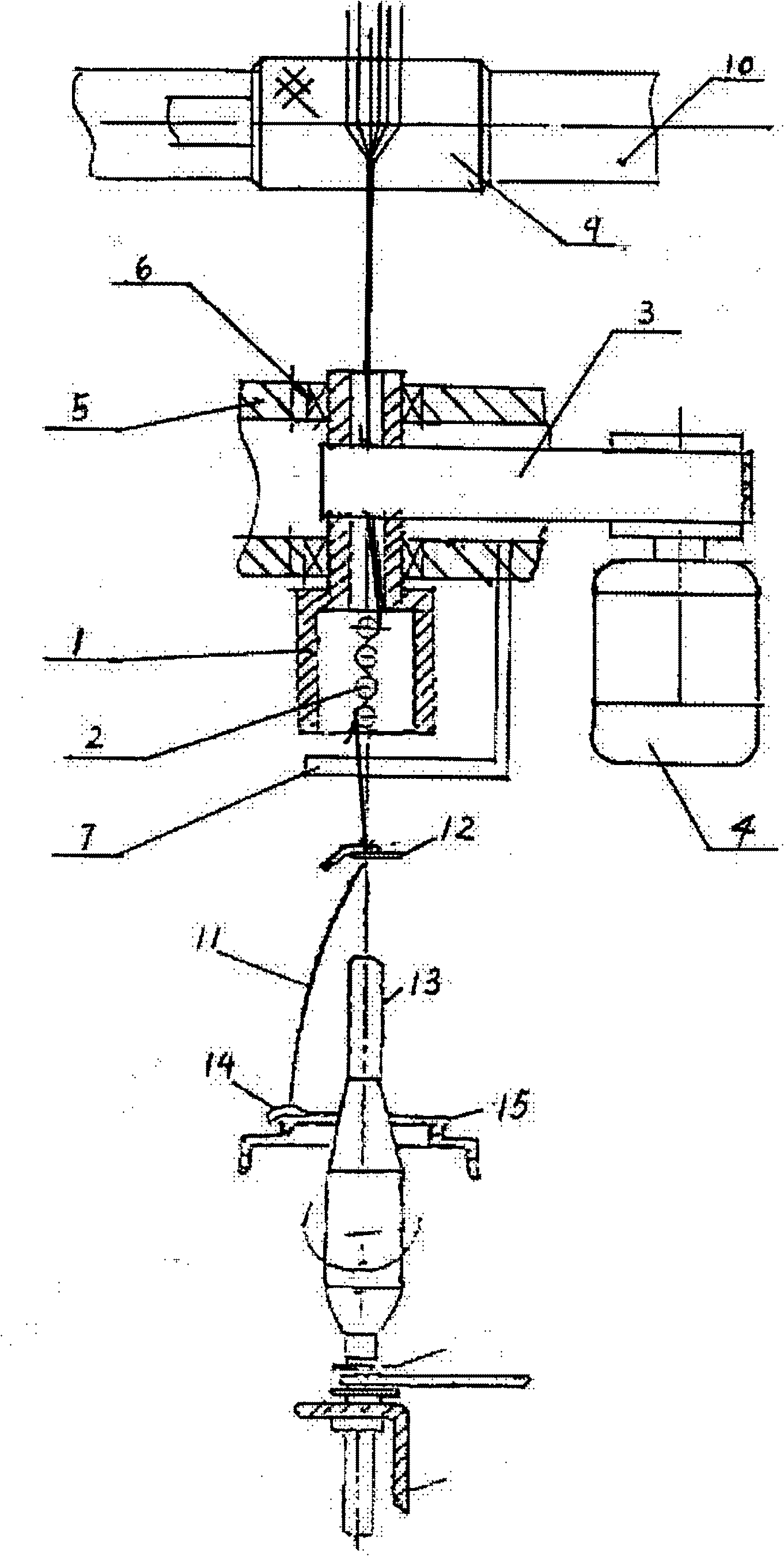

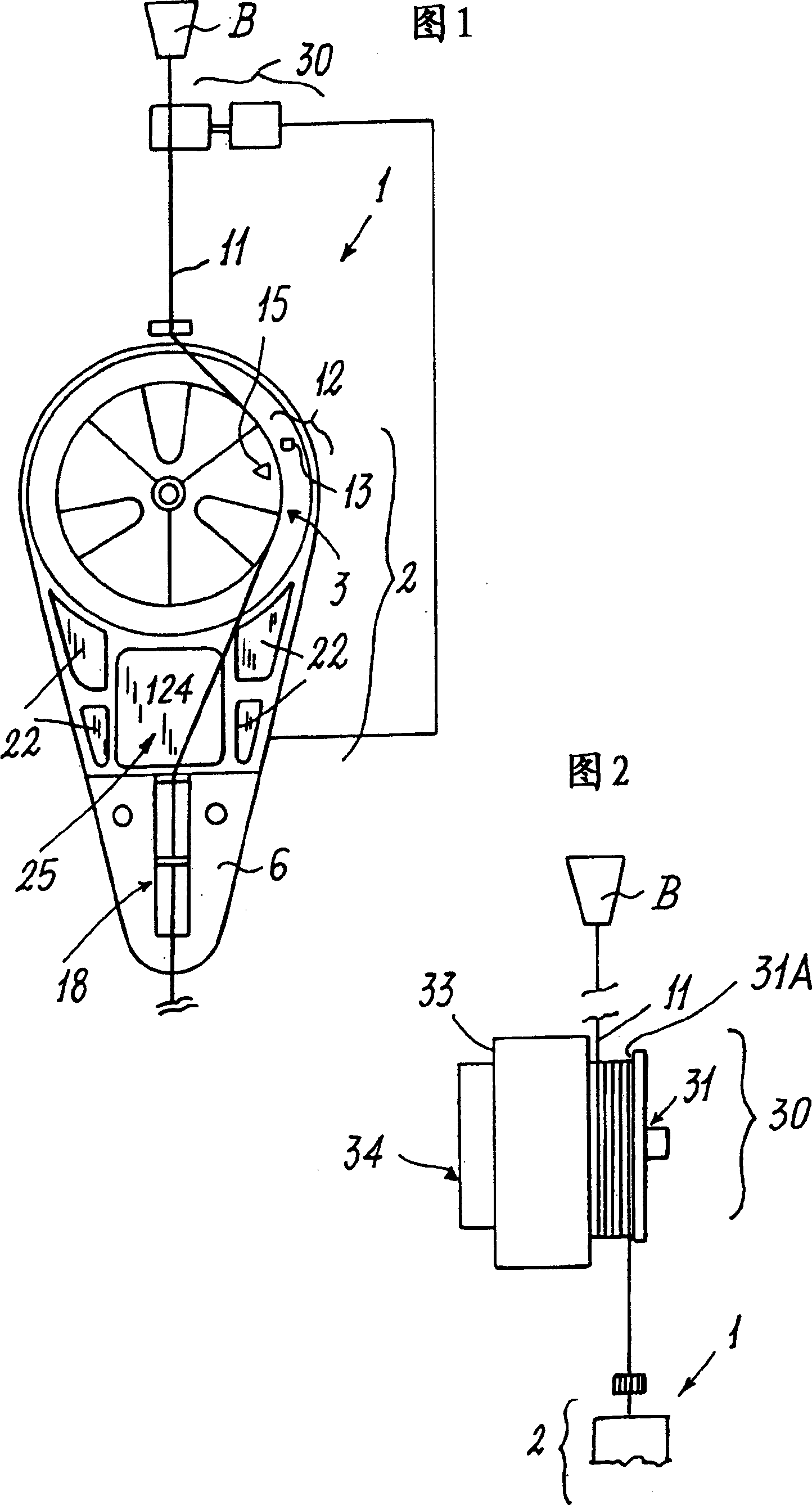

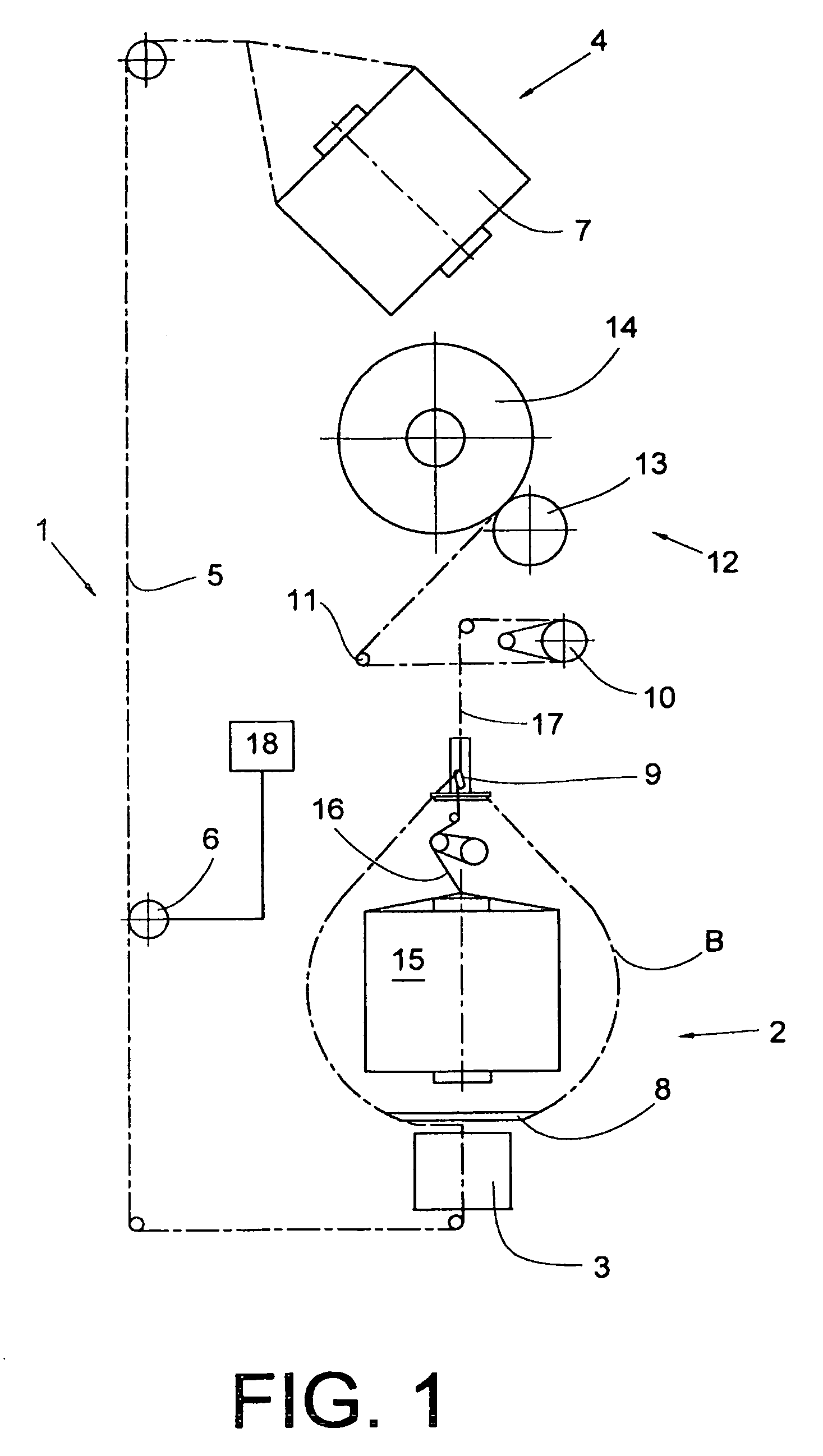

Method for operating a spindle of a two-for-one twister or cabling machine

ActiveUS20110126506A1Reduce energy consumptionDiameter minimizationContinuous wound-up machinesYarnBobbinCable machine

A two-for-one twister or cabling machine and a method for operation thereof, wherein a yarn (5, 25) is withdrawn from a supply bobbin (7, 21) and fed to a guide device below a twisted yarn plate (8, 24) of the spindle (2, 22) and from which the yarn (5, 25) exits virtually perpendicular to the axis of the spindle (2, 22) and is deflected to the outer edge of the twisted yarn plate (8, 24) and runs along the spindle (2, 22) as a free yarn balloon (B) encompassing the spindle (2, 22), until the yarn (5, 25) is fed into the twist or cabling point of a yarn guide device (9, 27) above the spindle (2, 22). The supply speed of the yarn (5, 25) is adjusted to achieve a yarn tension which minimizes the yarn balloon diameter as a function of the spindle geometry.

Owner:ZHUOLANG INTELLIGENT MACHINERY CO LTD

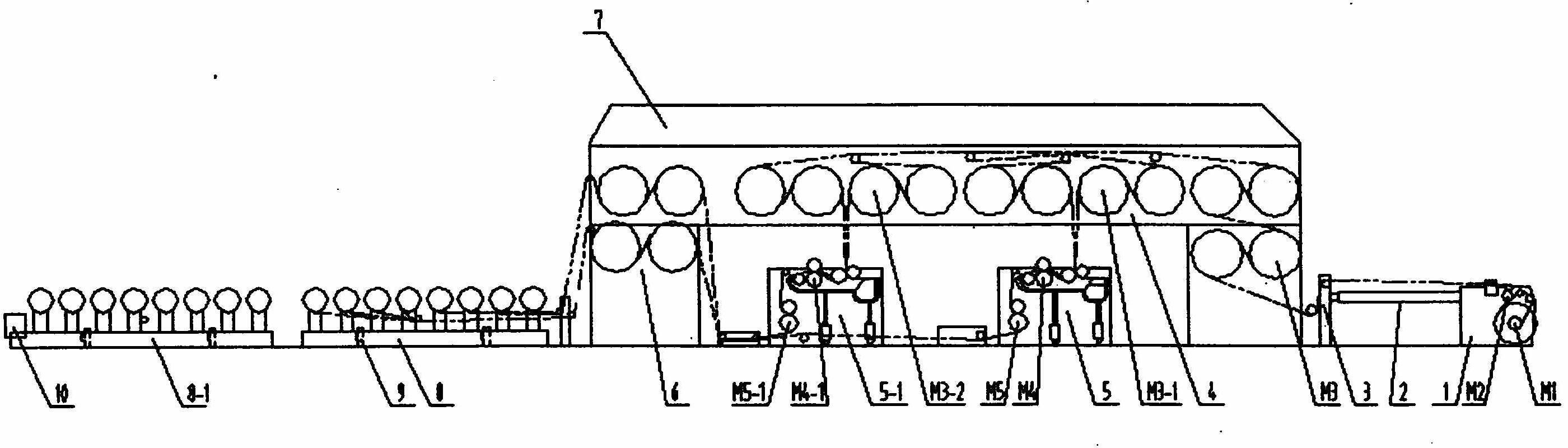

Beam dyeing sizing machine suitable for dyed sizing production

InactiveCN102146623ASolve production timeRealize continuous productionLiquid/gas/vapor removalOther manufacturing equipments/toolsMulti unitAutomatic control

The invention discloses a beam dyeing sizing machine suitable for dyed sizing production, which comprises a winding headstock, a dry leasing device, a tension waxing device, a main drying room, double parallel size vats, a dyed yarn pre-drying room, beam creels and an overall transmission and control system. The beam dyeing sizing machine is characterized in that: the beam creels are in two groups of mobile structures, the mobile beam creels are provided with dragging motors and moving wheel sets, and ground rails of the two groups of beam creels are arranged in a ''7'' shape or ''-'' shape. The beam dyeing sizing machine has the advantages that: 1, two groups of alternated mobile beam creels are adopted, so the production time occupied by frequently hoisting beams up and down is solved, inter-varietal continuous production is realized and the production efficiency is improved; 2, the loose beams can be directly intensively placed on the beam creels of the sizing machine for sizing, and a multifunctional composite chuck is designed, so the clamping and loading problems of multiple loose beams are solved; and 3, by adopting multi-unit synchronous control, piece yarn tension difference between the two size vats due to total warp number difference is solved, and automatic control of tension in each area is realized.

Owner:CHTC HEAVY IND

Composite processed filament and processing method thereof

The invention discloses a composite processing yarn and a preparation method thereof. The core yarn is composed of polyester multifilament, the sheath yarn is composed of ultrafine polyester multifilament, and the polyester multifilament constituting the core yarn has a monofilament fineness of ≥1.5 after being drawn. dtox, the polyester multifilament constituting the sheath filament after drawing has a monofilament fineness ≤ 0.5dtox, and the length difference between the sheath filament and the core filament is 2-10%. The preparation method includes doubling two kinds of polyester multifilaments, drawing and false twisting at the same time under the condition that the ratio of untwisting tension TB to twisting tension TA TB / TA≥1.0 to obtain the product. The product obtained by the present invention has the fluffy feeling, soft feeling, dry loose feeling and moderate tension of staple fiber style.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

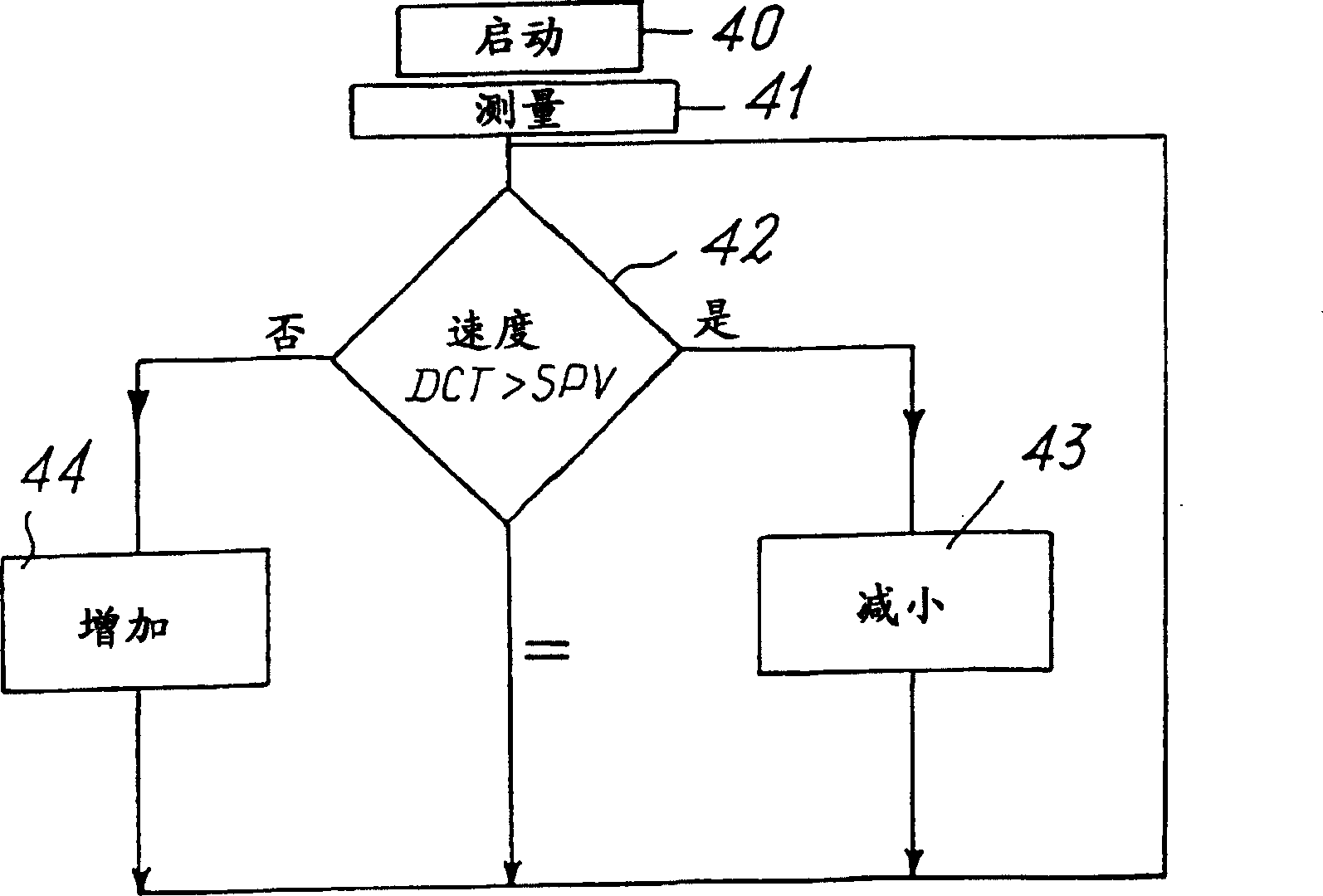

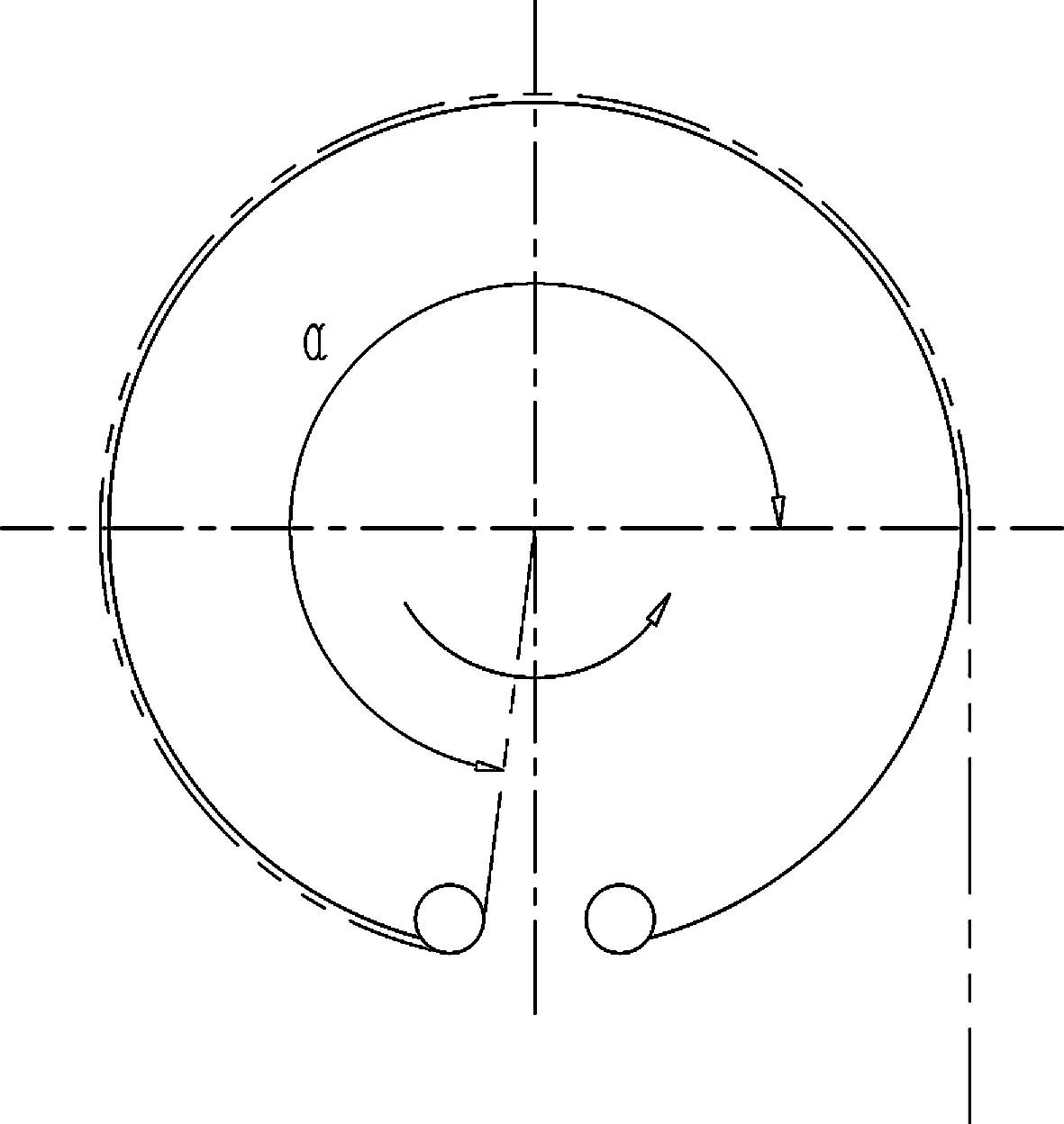

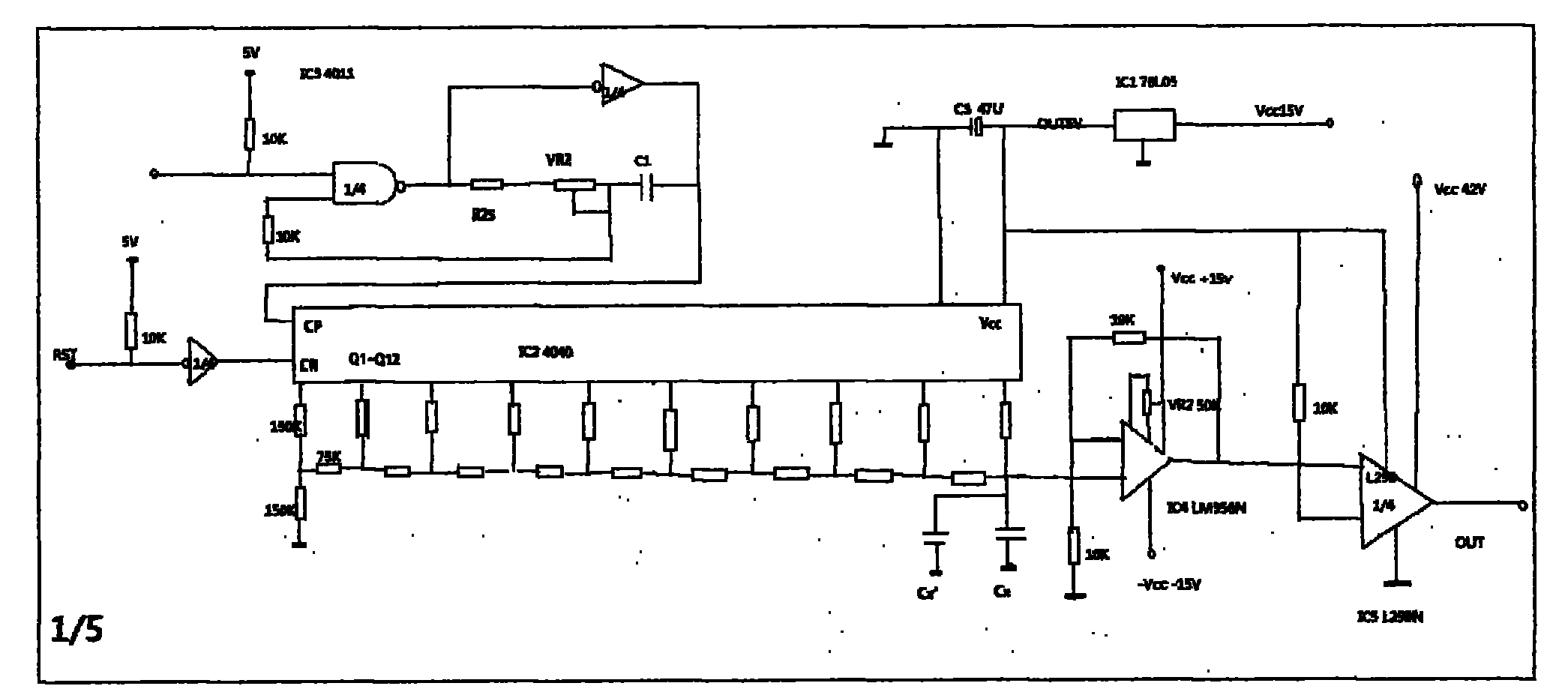

Control method for yarn ballooning size of straight twisting machine

ActiveCN103147188ASmall wrapping angleReduce energy consumptionContinuous wound-up machinesMotor speedSensori motor

The invention discloses a control method for a yarn ballooning size of a straight twisting machine, and belongs to the technical field of textile machinery. The problems that external yarn tension control is not accurate, and an optimum ballooning shape cannot be reached exist in the existing straight twisting machine. The straight twisting machine is characterized in that an external yarn sensor is arranged in a yarn path between a twisting tray and an external yarn tensioner and used for detecting an external yarn linear speed and yarn tension; a strand yarn sensor is arranged in a yarn path between an overfeeding device and an even twisting device and used for detecting a strand yarn linear speed and tension; or / and a motor sensor is arranged on a spindle drive motor and used for detecting a motor speed and motor current; the external yarn tensioner is driven by a separate motor to feed yarns actively; an overfeeding wheel of the overfeeding device is driven by a separate motor; and by taking one, two or three detection results of the three sensors as separate or combined control parameters, a control system controls a speed of the motor connected with the overfeeding wheel, adjusts a strand yarn pulling speed, and ensures that an external yarn tension value meets a requirement of the optimum yarn ballooning shape capable of allowing a wrapping angle to be minimum.

Owner:ZHEJIANG RIFA TEXTILE MACHINERY TECH CO LTD

Coiling apparatus of yarn

InactiveCN1530308AInhibition of tension changesEasy maintenanceFilament handlingPiercing arrangementsYarn tensionEngineering

The present invention stabilizes a yarn tension in a yarn winder in which a plurality of winding units are disposed, each of the winging units being provided with a yarn slack eliminating device. A transmitted force adjusting mechanism is provided to adjust a rotative driving force transmitted by a slack eliminating roller of a yarn slack eliminating device to an unwinding tension applying member. The transmitted force adjusting mechanism can be set so that when a load acting on the unwinding tension applying member increases above a predetermined value, the unwinding tension applying member rotates or rotatively moves independently of the slack eliminating roller. When winding tension is weak, the unwinding tension applying member rotates integrally with the slack eliminating roller to tense a yarn. When the winding tension exceeds a predetermined value, the unwinding tension applying member prevents the winding tension from becoming excessive to suppress a variation in tension. When the transmitted force adjusting mechanism is configured so as to vary the force transmitted to the unwinding tension applying member, it is easy to deal with spinning conditions.

Owner:MURATA MASCH LTD

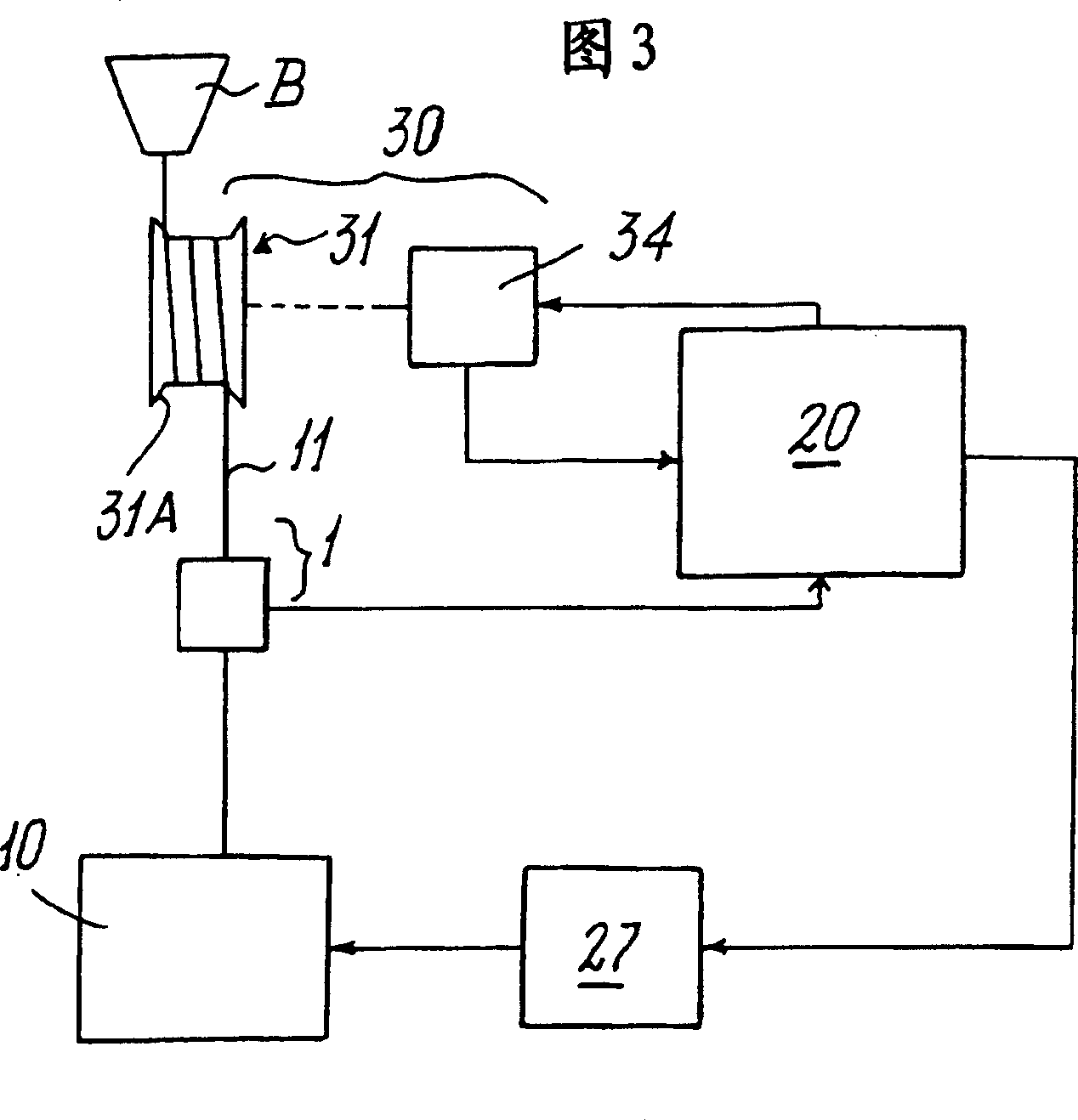

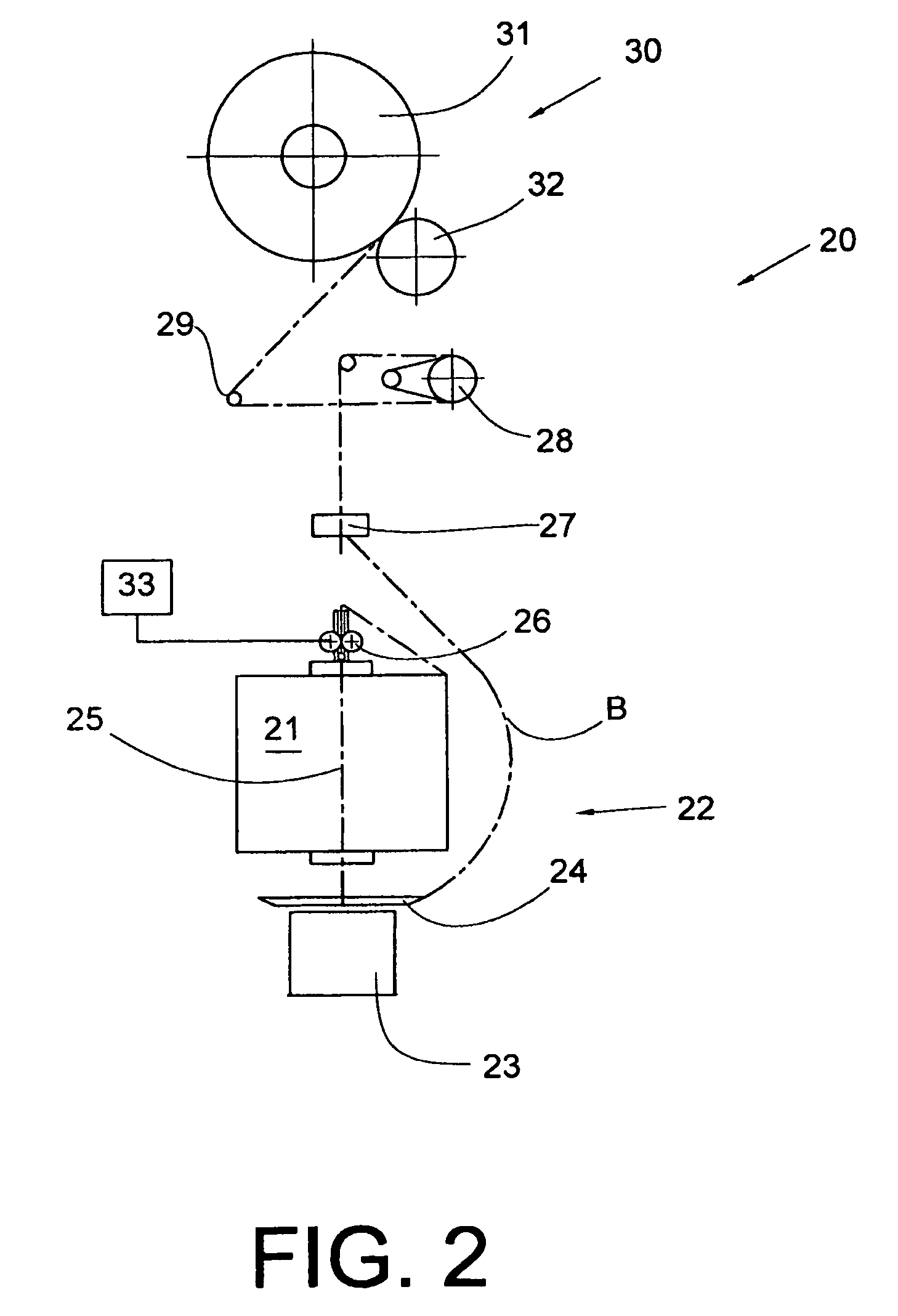

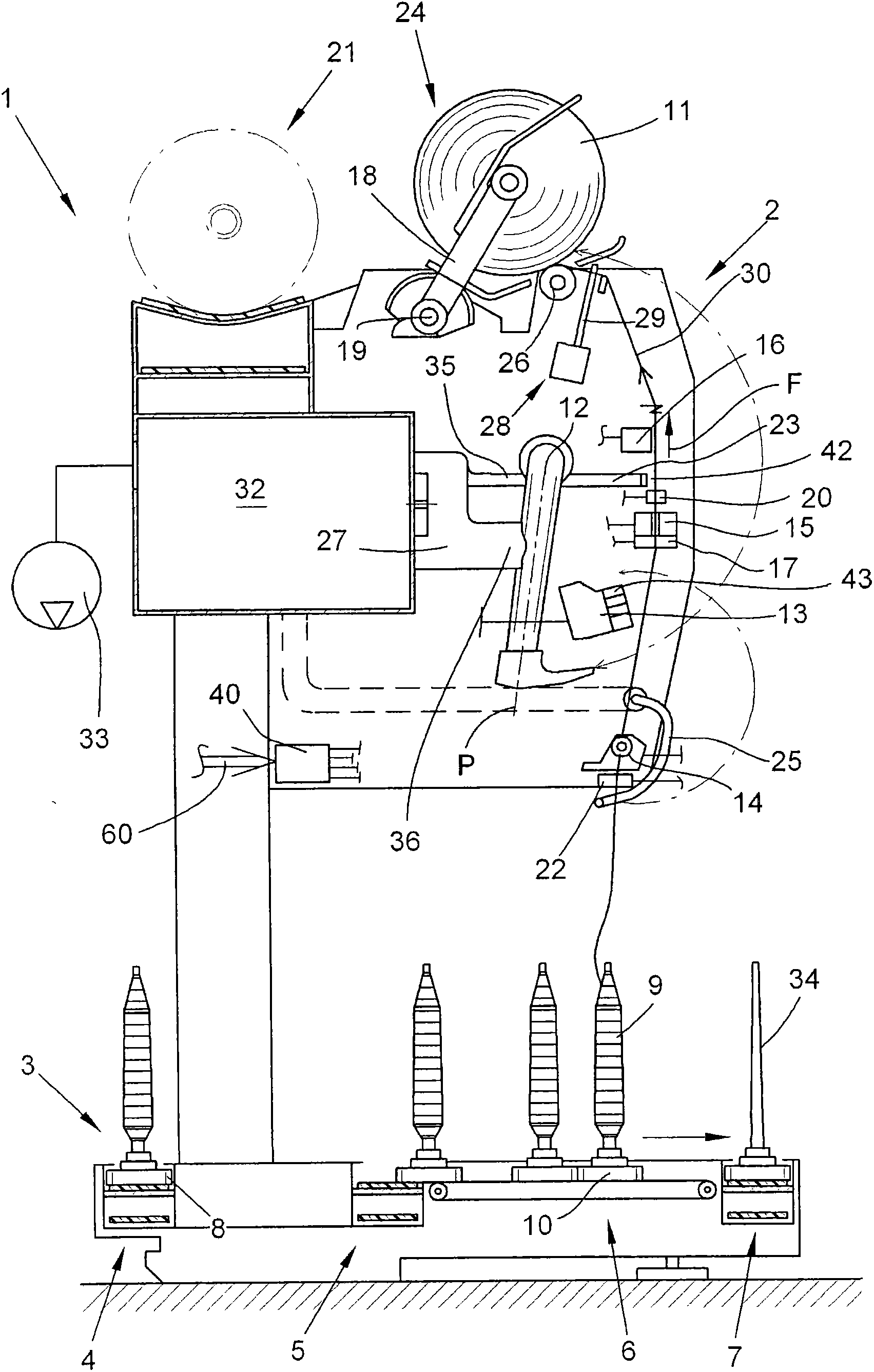

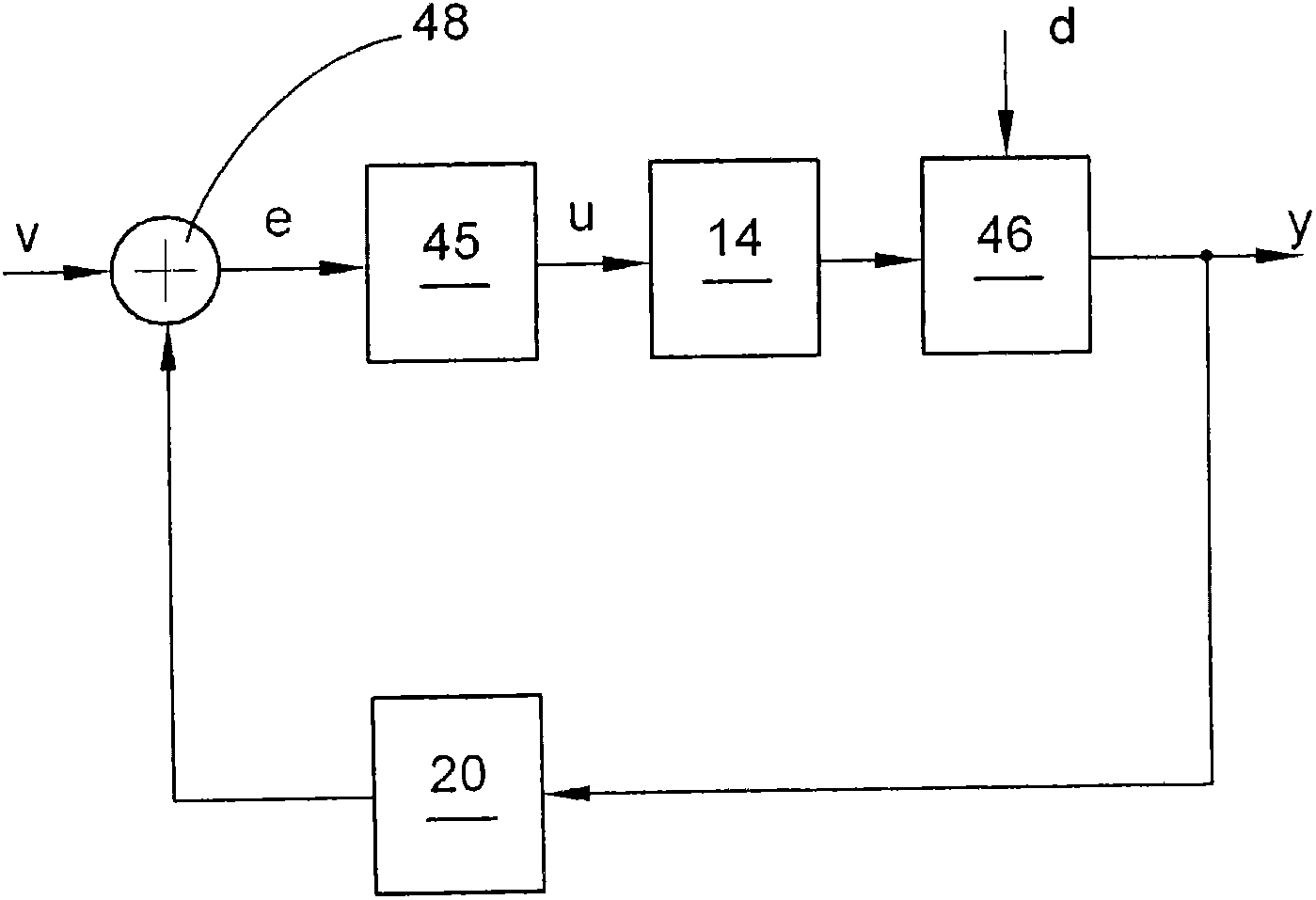

Device and method for feeding an elastomeric yarn to a textile machine

A device for controlling the feeding of elastic yarn (11) having known elasticity and withdrawing from the yarn bobbin (B) to feed textile machines (10) such as knitting machines, hosiery machines, winding machines In a machine, or other textile machine, the yarn has inherent elasticity and is fed into the textile machine at an inherent speed, a device (18) for detecting the tension of the yarn (11) and a device (18) for measuring and a device (3, 12) for changing the yarn speed, the detection device (18) and the measuring and changing device (3, 12) are connected to the device (20) for controlling and adjusting the tension and speed parameters ), the control and adjustment device (20) continuously measures the values of two parameters during the process of feeding the yarn (11) to the textile machine, and is characterized in that it also includes a compensation device (30), which compensates for the deviation from the yarn bobbin. (B) The dimensional characteristics of the withdrawn elastic yarn (11) before cooperating with the tension detection device (18) and the speed measurement device (3, 12), thereby enabling the yarn to be fed into the textile with constant dimensional characteristics The entire production of textiles is provided in the machine (10). A method implemented by the above device is also disclosed.

Owner:蒂齐亚诺・巴里亚

Outer yarn tension regulating method for direct twisting machine

The invention relates to a method for fulfilling the aim of energy conservation by reducing a balloon in the operating state of the conventional direct twisting machine, in particular to a method for regulating the tension of outer yarns by controlling an outer yarn tensioner, which comprises the following steps of: A, driving a spindle by a motor, so that the outer yarns rotate to form the balloon; and B, after the balloon is formed, regulating the tension of the outer yarns by utilizing a control device through the outer yarn tensioner, so that a wrapping angle alpha of wrapping a yarn storage disc by the outer yarns is reduced to 0 degree gradually to achieve the effect of reducing the balloon. According to the technical scheme, the direct twisting machine also comprises an outer yarn tension detection sensor for controlling the tension of the outer yarns in real time. Therefore, by the outer yarn tension regulating method, the noise of equipment is reduced, power consumption is reduced, and the effect of energy conservation is achieved.

Owner:YICHANG JINGWEI TEXTILE MACHINERY

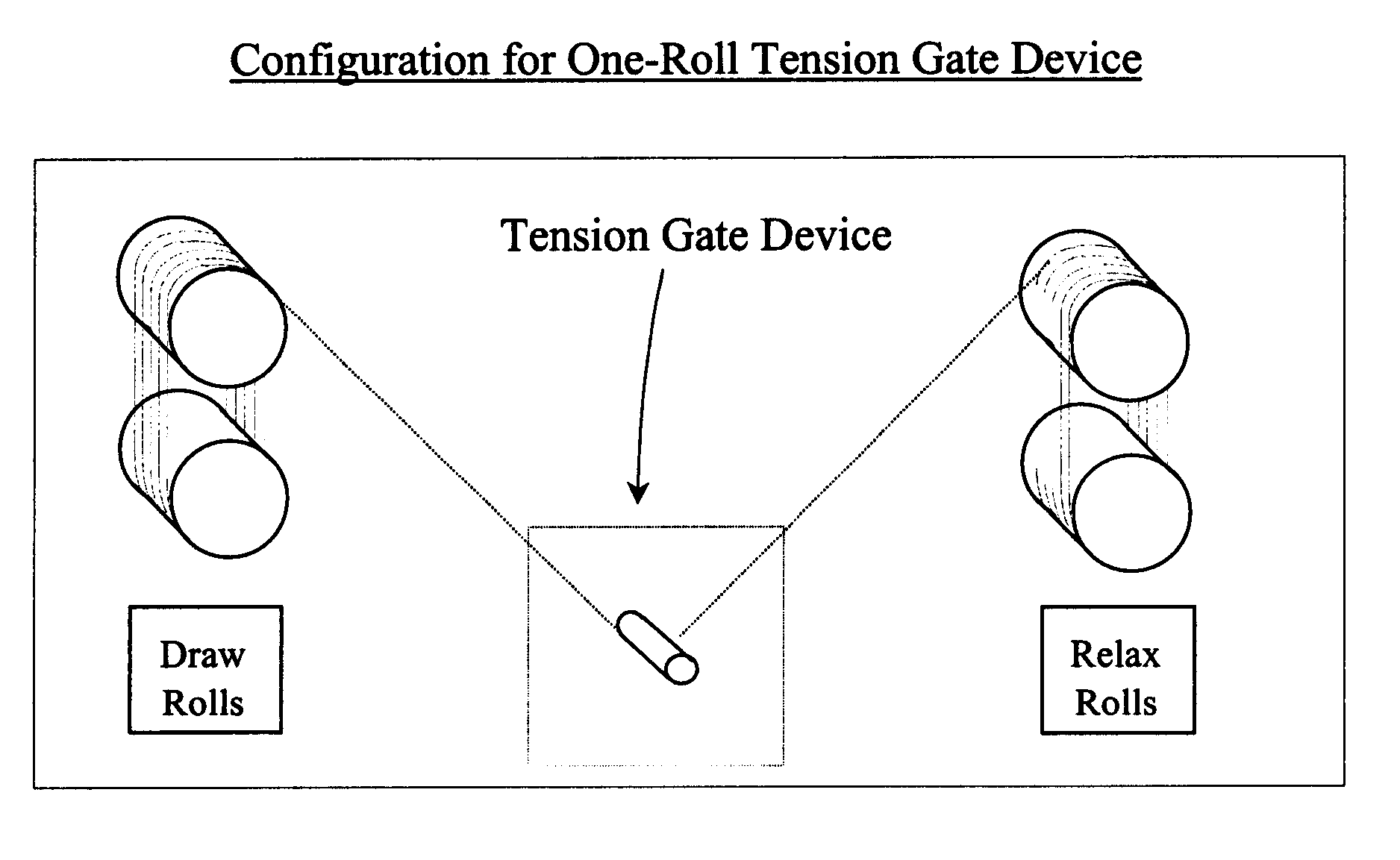

Ultra low-tension relax process and tension gate-apparatus

The invention describes a low tension relax process and corresponding apparatus, wherein a tension gate is incorporated into a relax zone in a yarn production process. The tension gate can be anything that produces a drag on the yarn threadline such as an air drag device, a liquid drag device, or a solid surface contact drag device, or a combination of these. A tension gate is a device which when used in a relax zone has an outlet yarn tension greater than the inlet yarn tension thus creating a tension differential. The tension gate provides a tension differential of at least 5 mg per denier. A relax zone is typical found in a spin-drawing process, a draw-twisting process, a draw-winding process, or a draw-bulking process. The invention describes a yarn making process with a tension gate in the relax zone wherein the tension gate creates a tension differential on said yarn of at least 5 milligrams per denier.

Owner:PERFORMANCE FIBERS OPERATIONS

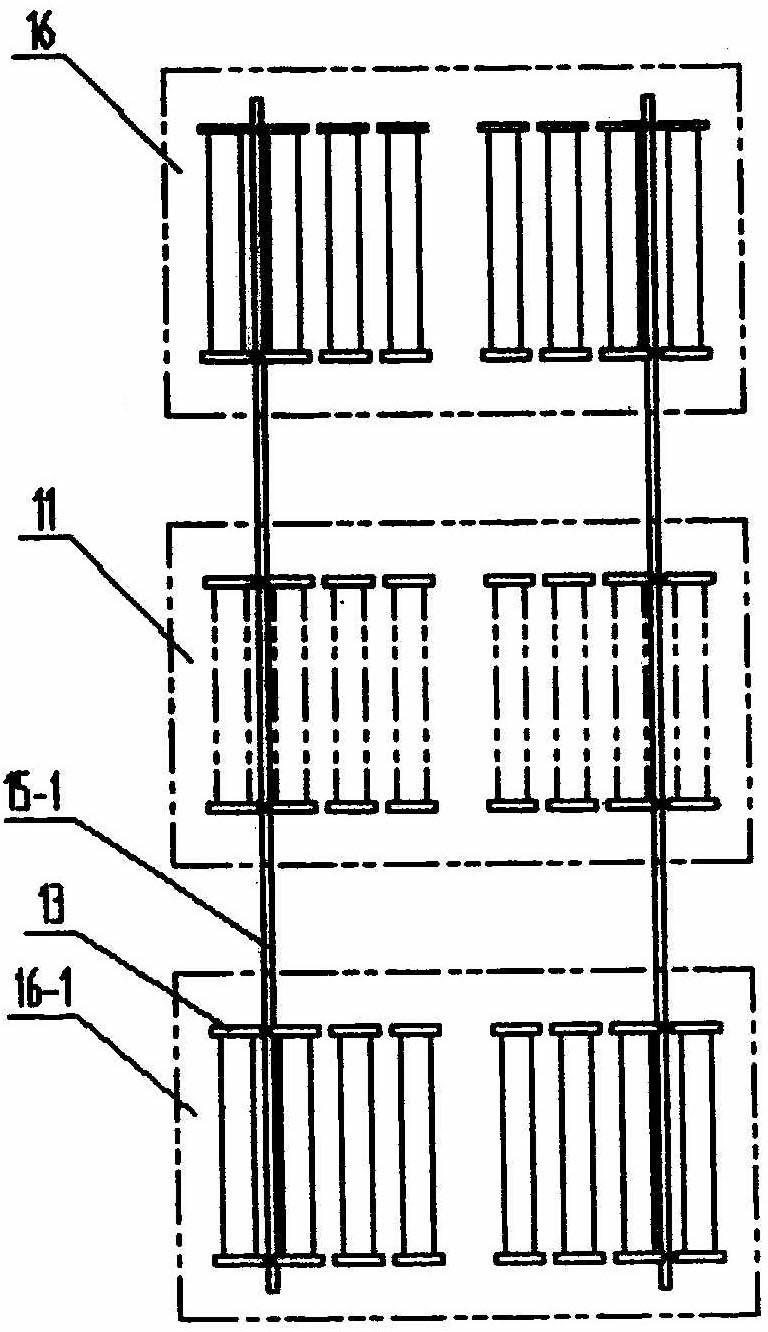

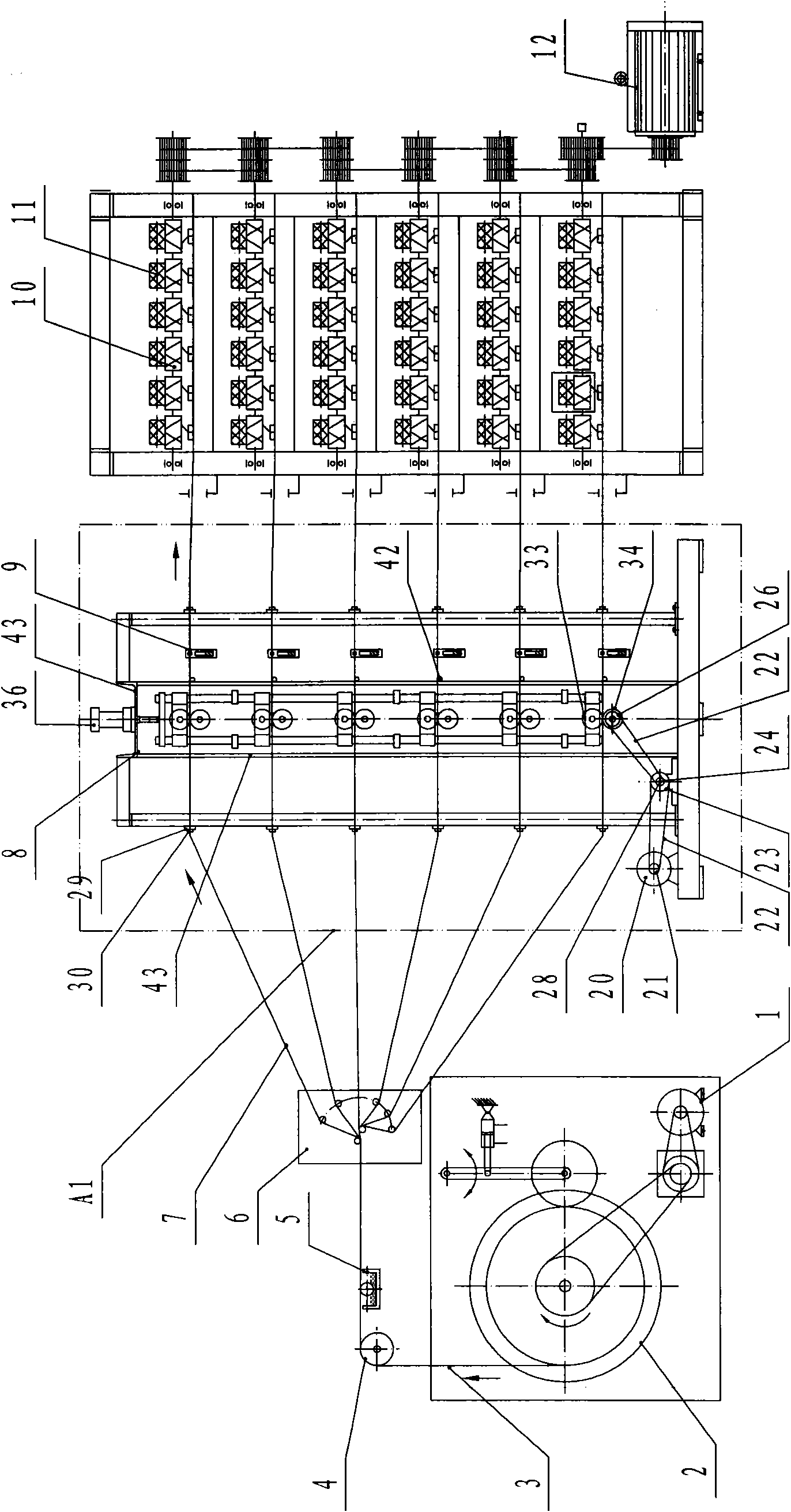

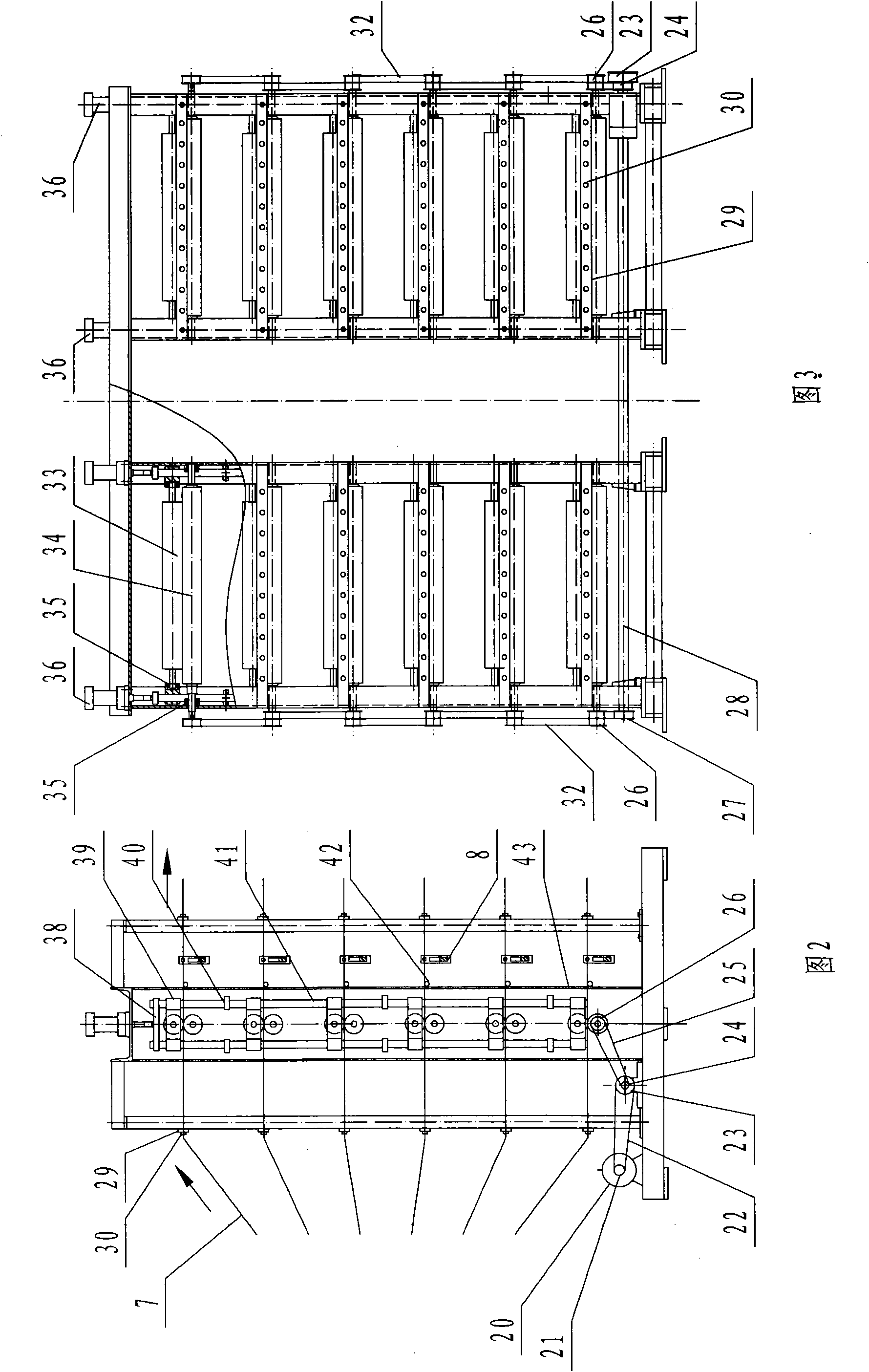

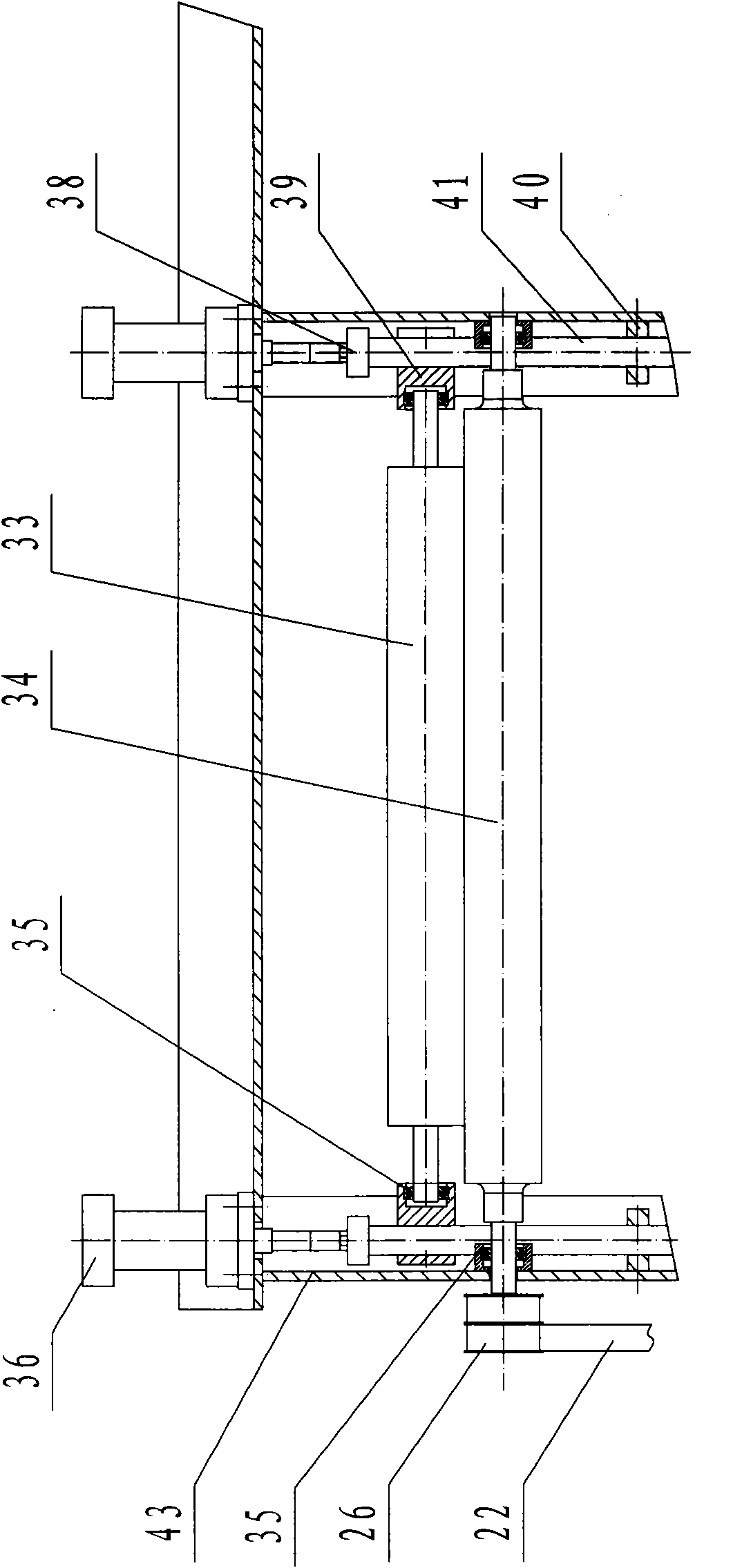

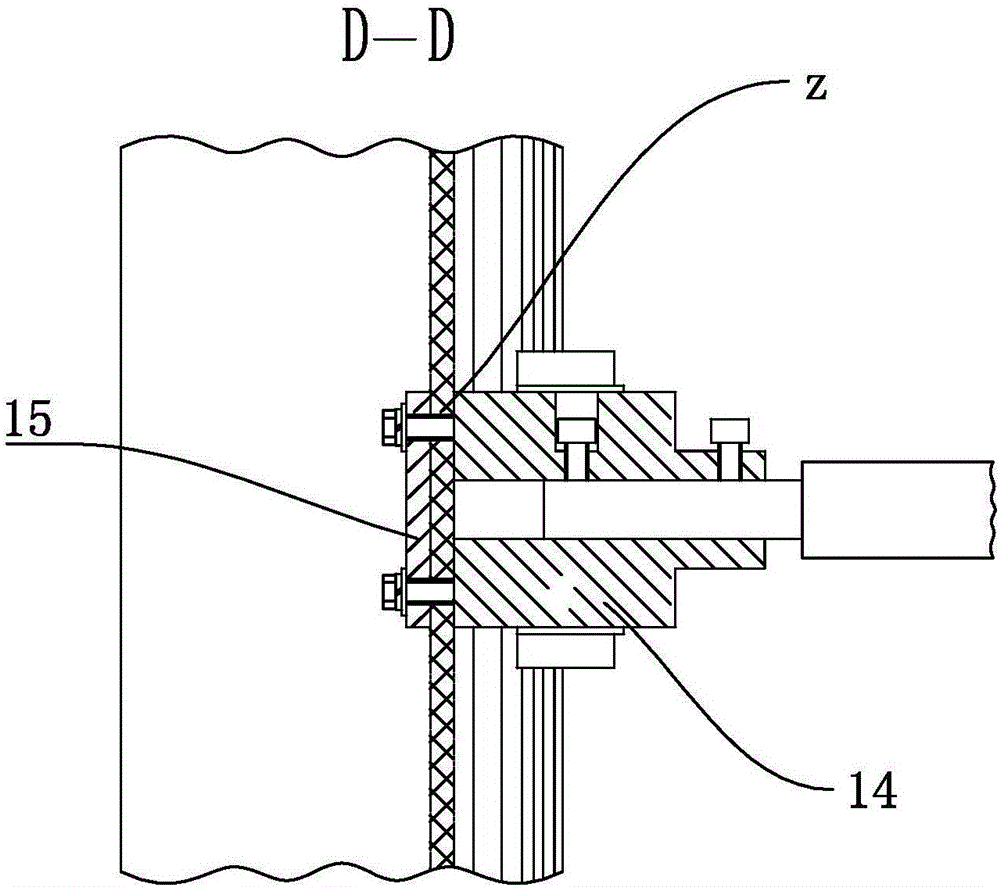

Yarn dividing tension control device of coating yarn bobbin winder

InactiveCN101992973ASolve the difficult problem of yarn separationHigh speedFilament handlingBobbinYarn tension

The invention relates to a yarn dividing tension control device of a coating yarn bobbin winder. The invention is characterized in that a tension control device is arranged behind a lease device and in front of a tension adjusting device; the tension control device and the tension adjusting device are in an integrally connected frame structure, the frame is in a type with front and back symmetric synchronously-transmitted groups and extended multi-layer, a plurality of yarn dividing plates corresponding to the release device are respectively arranged on the left and right sides of the frame, and porcelain eyes are arranged in the yarn dividing plates; the tension control device is arranged in the middle of the frame, and a plurality of yarn carrying rods corresponding to the porcelain eyes are arranged on the exterior of the right side of a channel steel frame on the tension control device; and the tension adjusting device is arranged in the right-section frame of the frame. In the device of the invention, the yarn tension of coating yarn winding is under sectional control, the requirement for the winding technique of dividing yarn under great tension and winding a bobbin under small tension is realized, the winding speed and efficiency are enhanced and a break stop caused by ambiguous yarn division is reduced, thus wound bobbin yarns are softer.

Owner:胡卫红

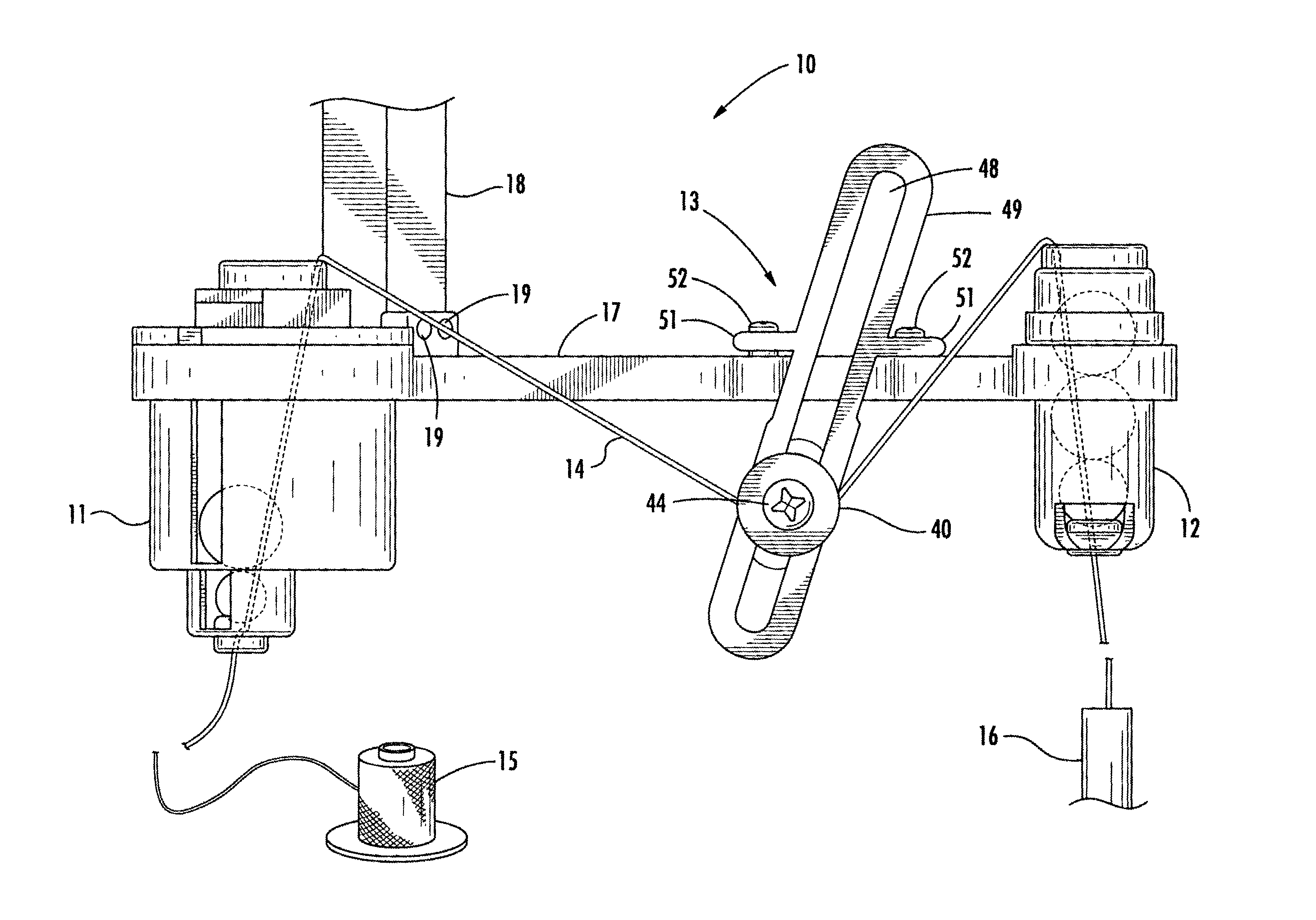

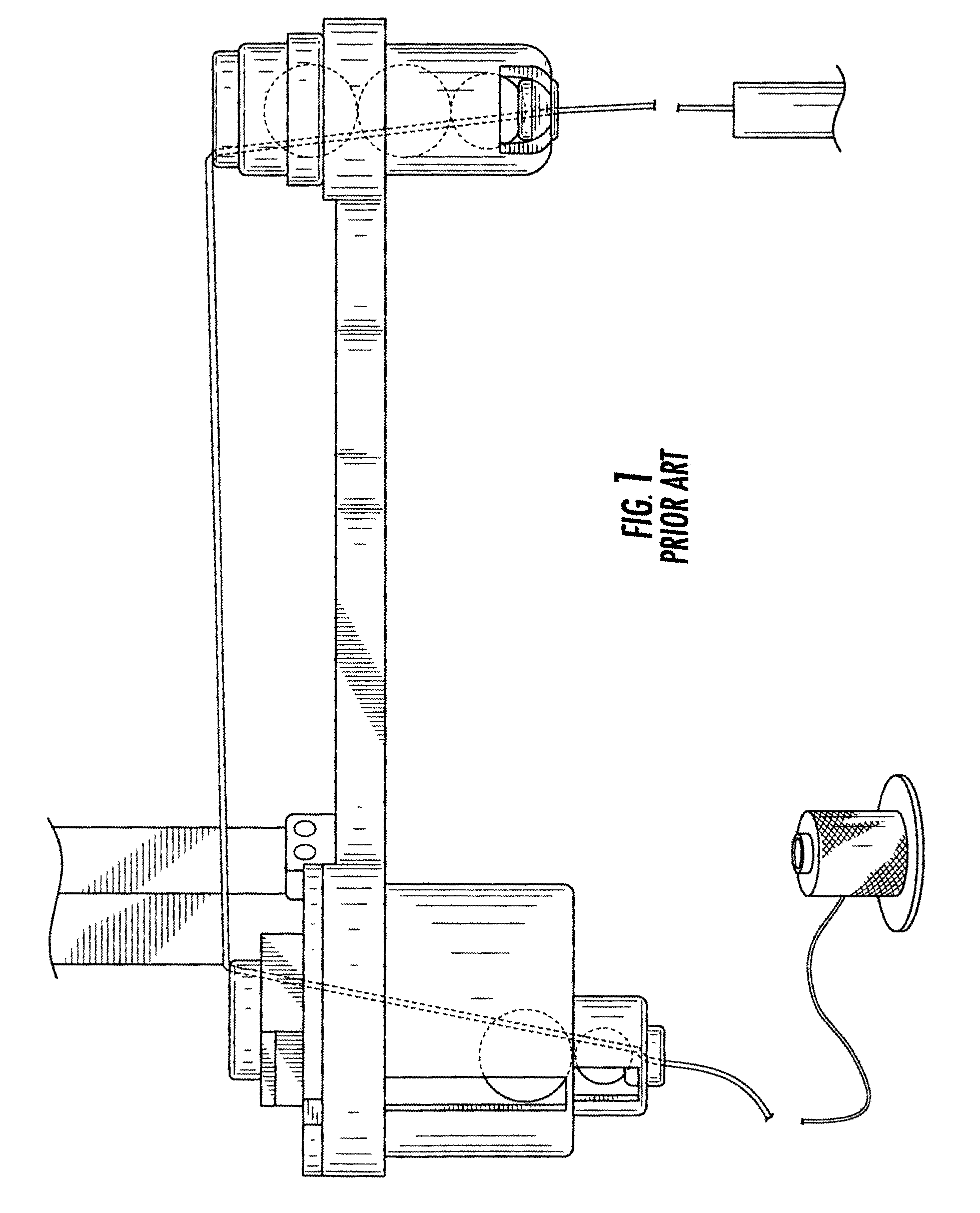

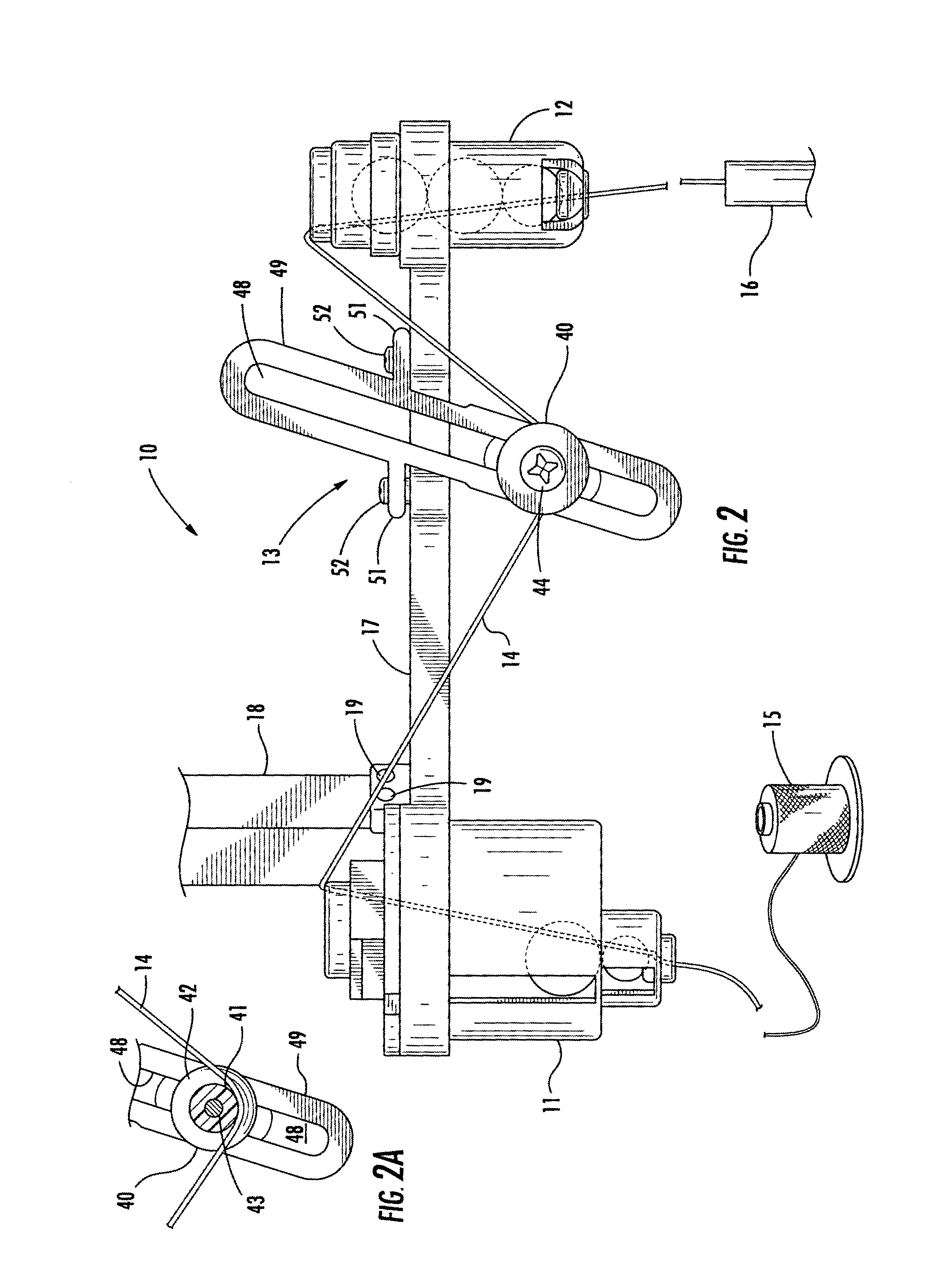

Traveling yarn tension compensating system

A traveling yarn tension compensating system having a pair of vertically disposed, horizontally spaced ball-type yarn tensioning units and a yarn tension compensating device disposed therebetween. The device has a yarn engaging element with a yarn engaging surface that is downwardly convex for engaging a yarn thereunder. The surface is fixed so as not to rotate or otherwise move in the direction of travel of the yarn and is made of a material that imposes a tension increasing frictional drag on the traveling yarn. The surface engaging element is mounted to be freely movable vertically in response to tension in the traveling yarn. The convex shape of the yarn engaging surface results in a greater extent of surface engagement of the yarn when the surface engaging element is in a lower position resulting from lesser tension in the yarn and at which position it deflects the yarn downwardly over the yarn guides. When there is greater tension in the traveling yarn, the yarn raises the surface engaging element to upper positions at which the extent of surface contact by the surface and the yarn guides is less.

Owner:ZOLLINGER RICHARD V

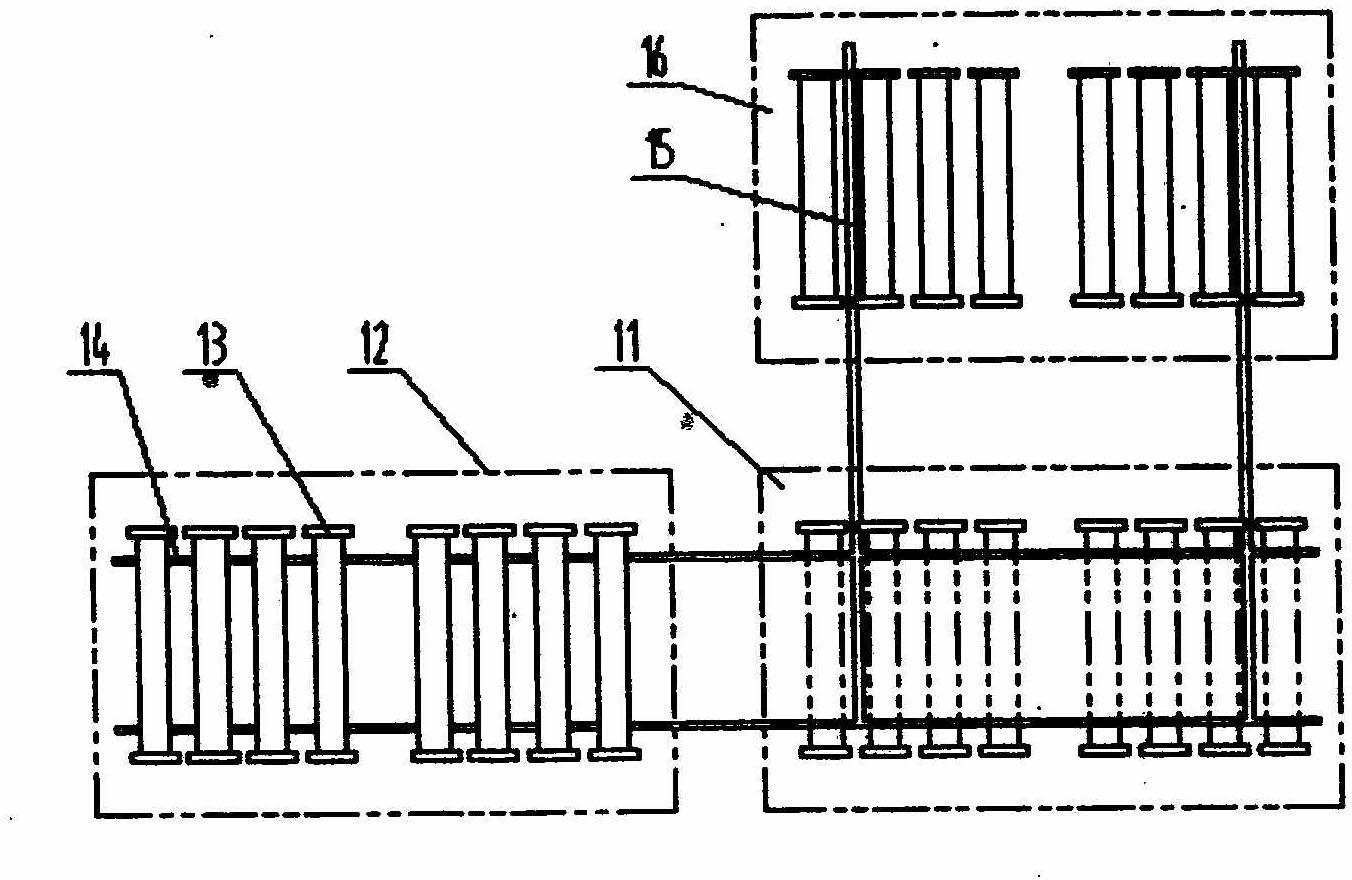

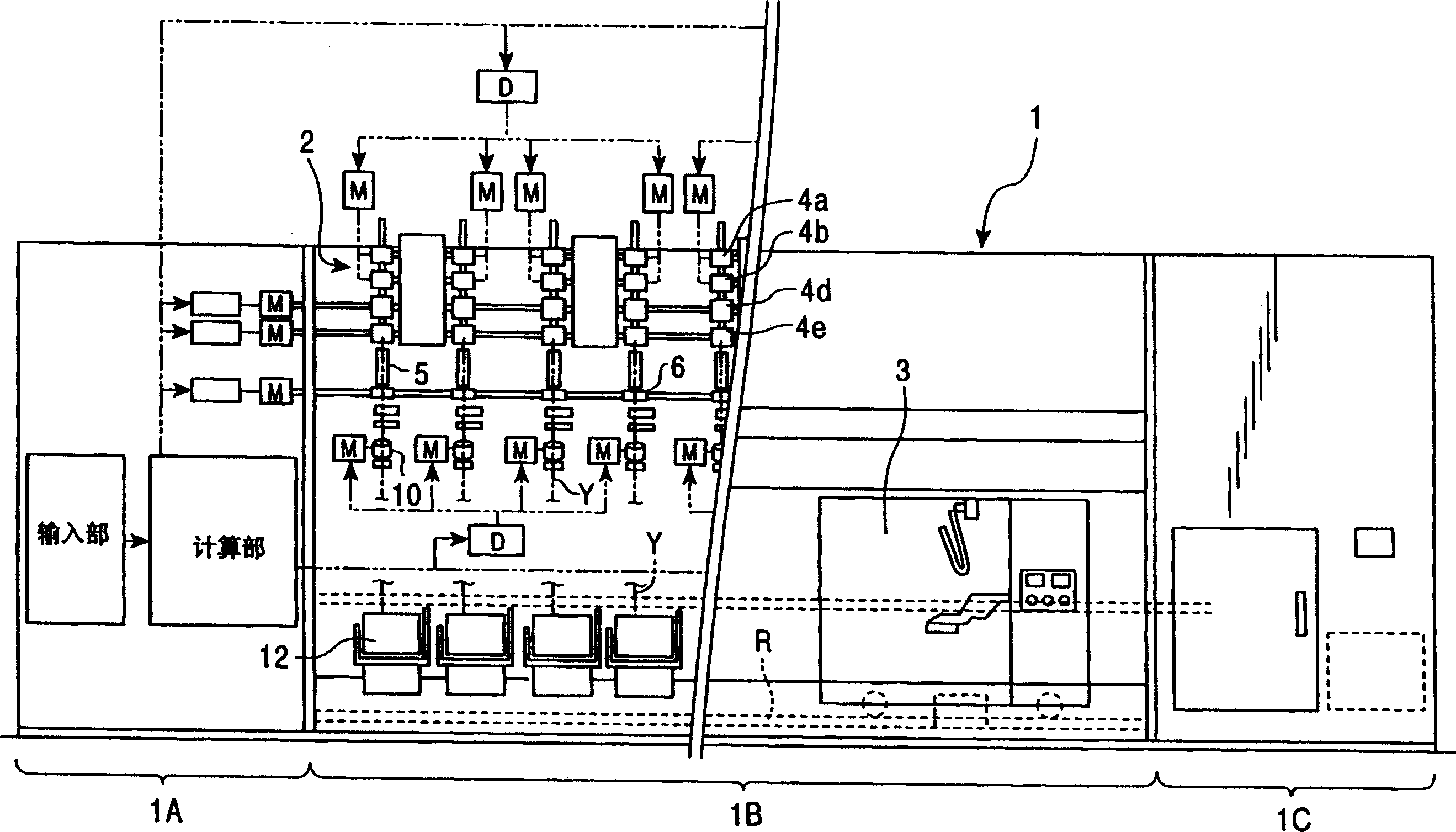

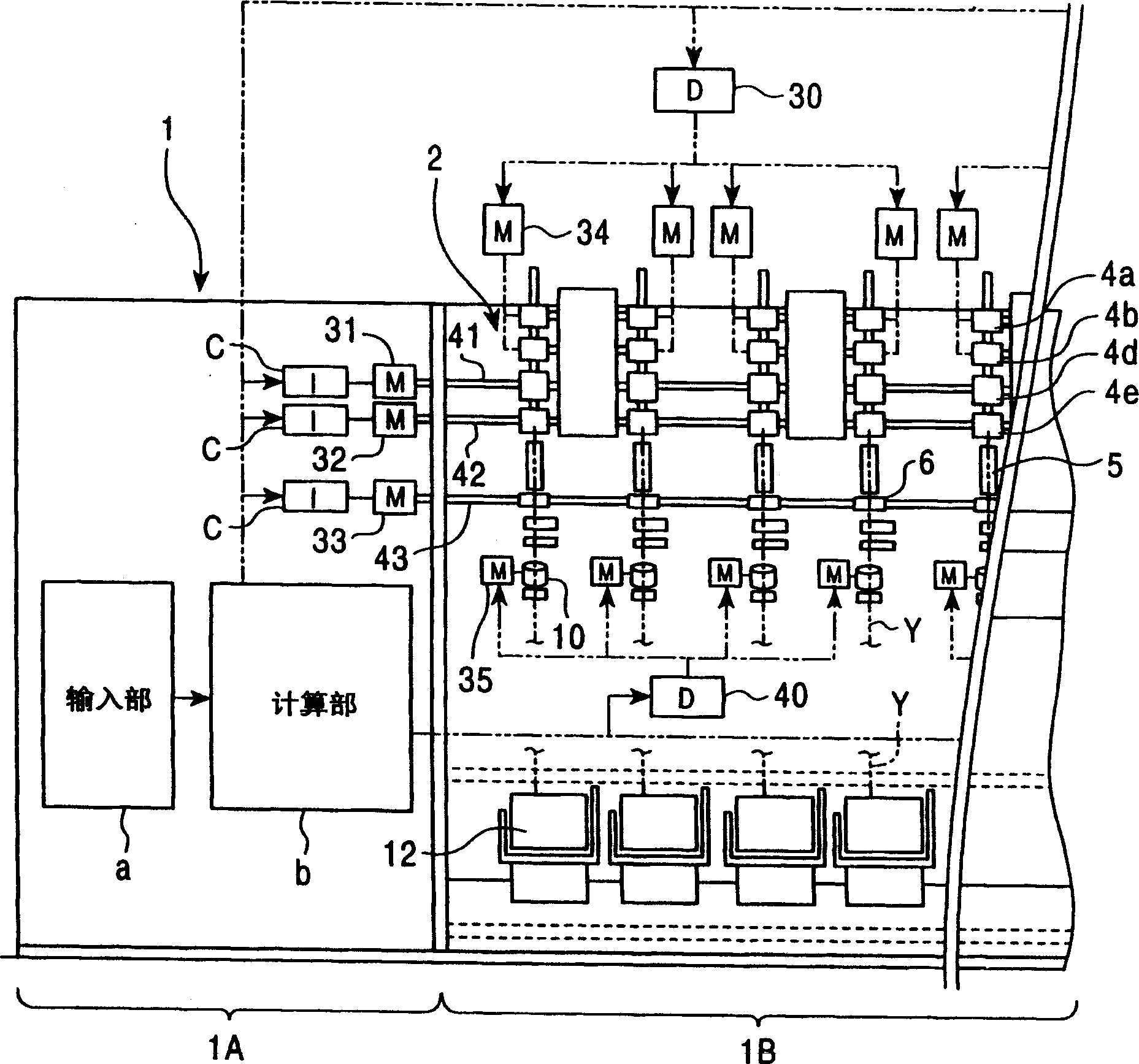

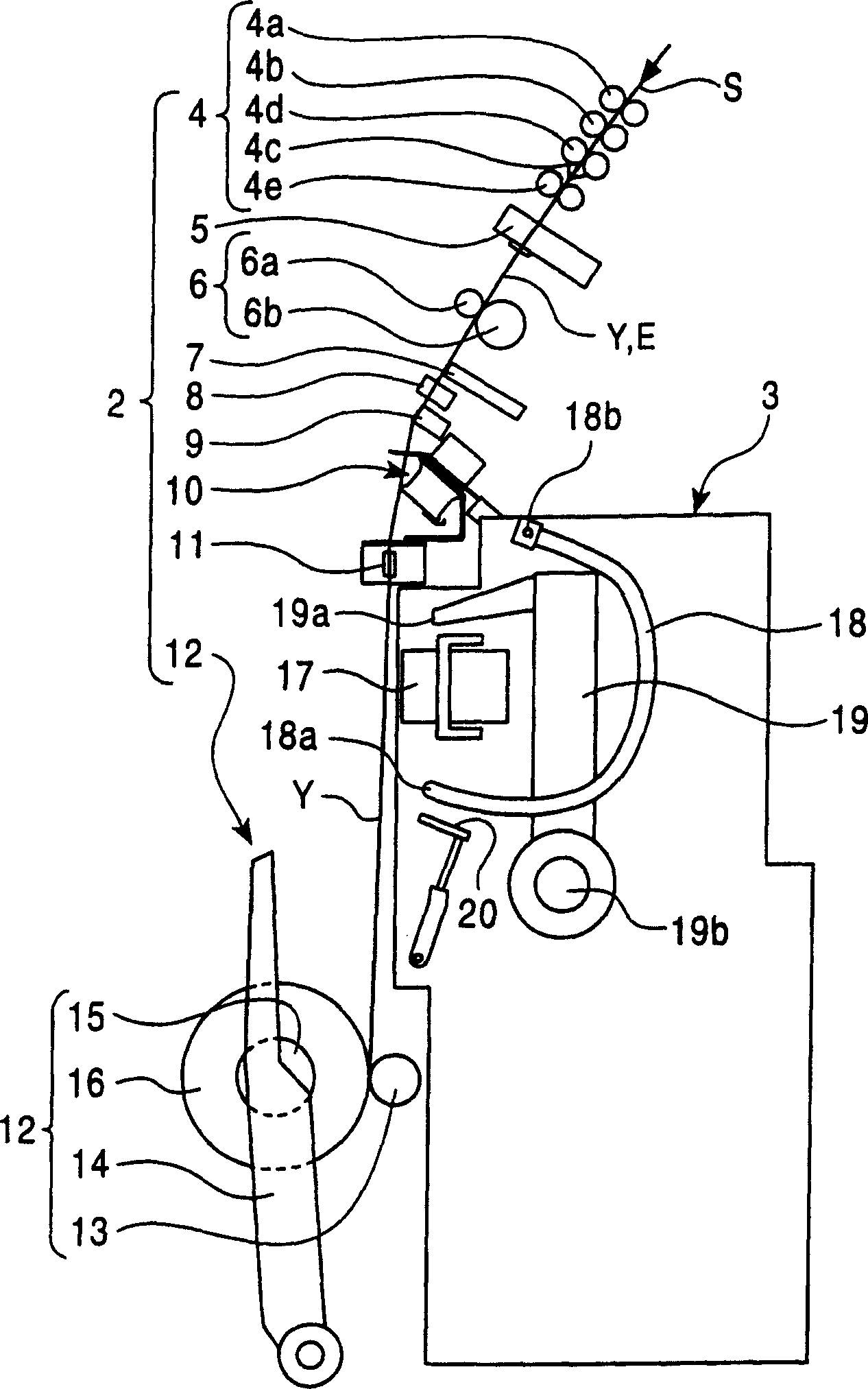

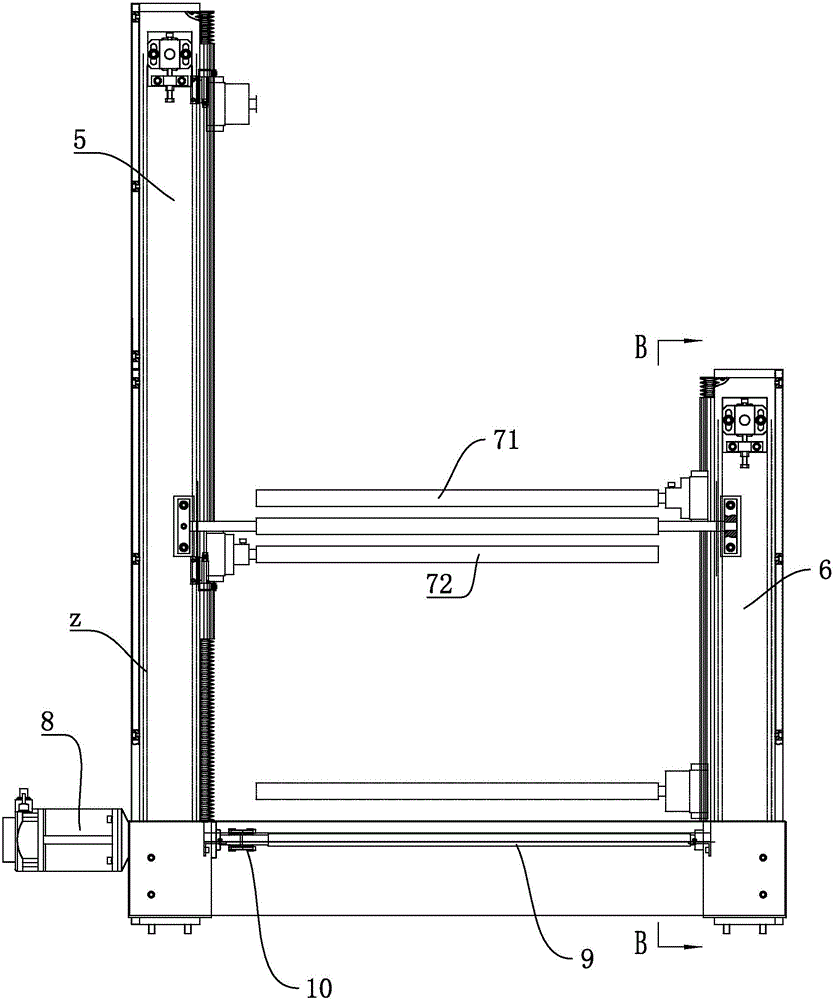

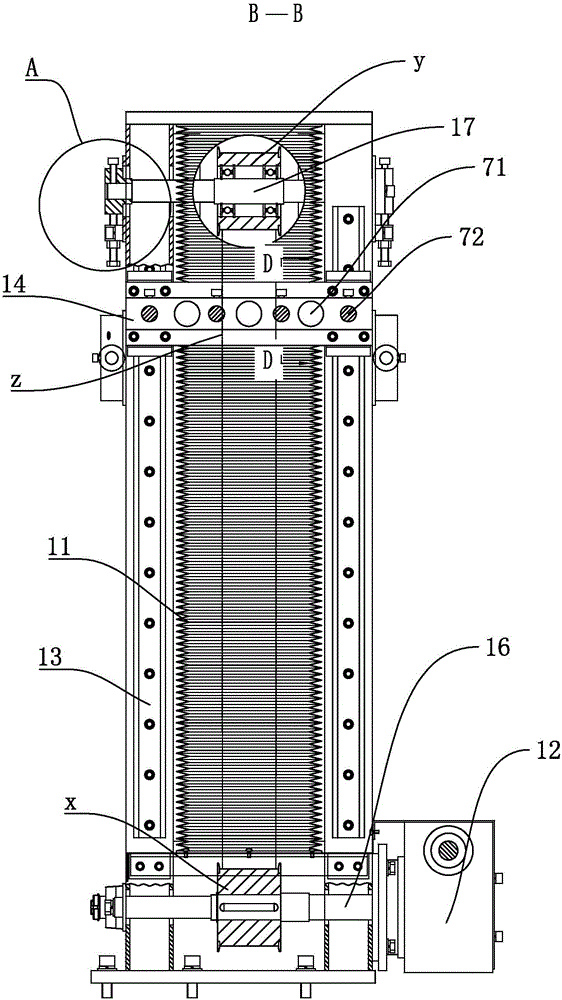

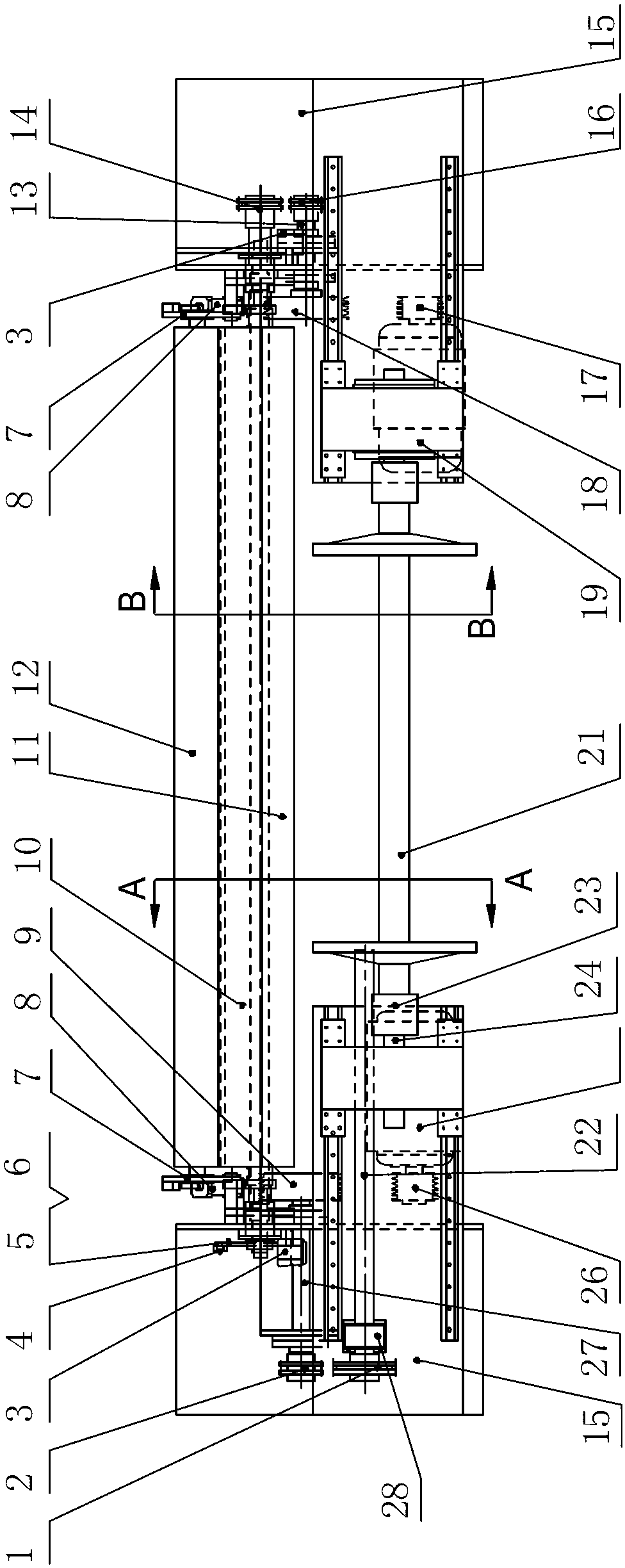

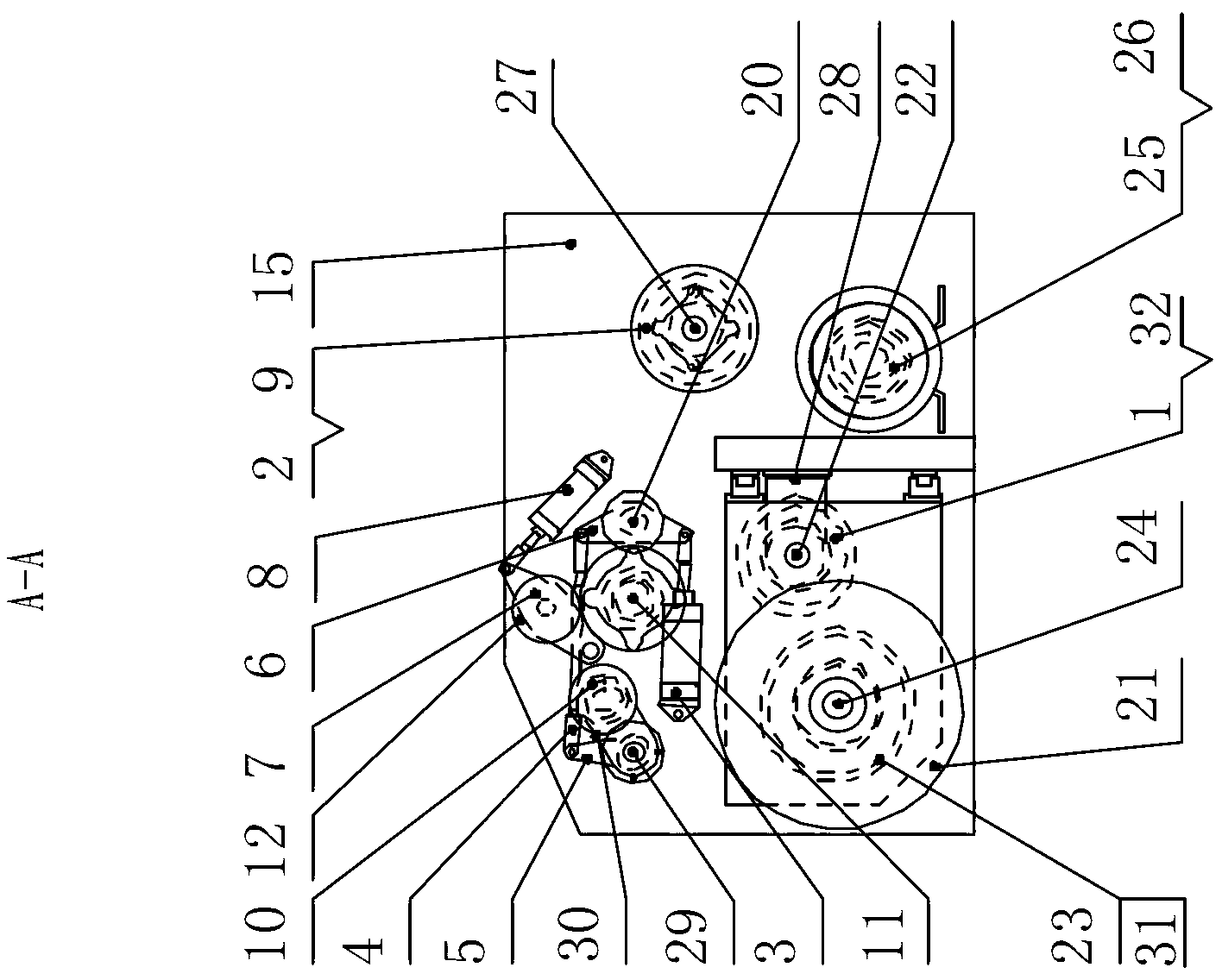

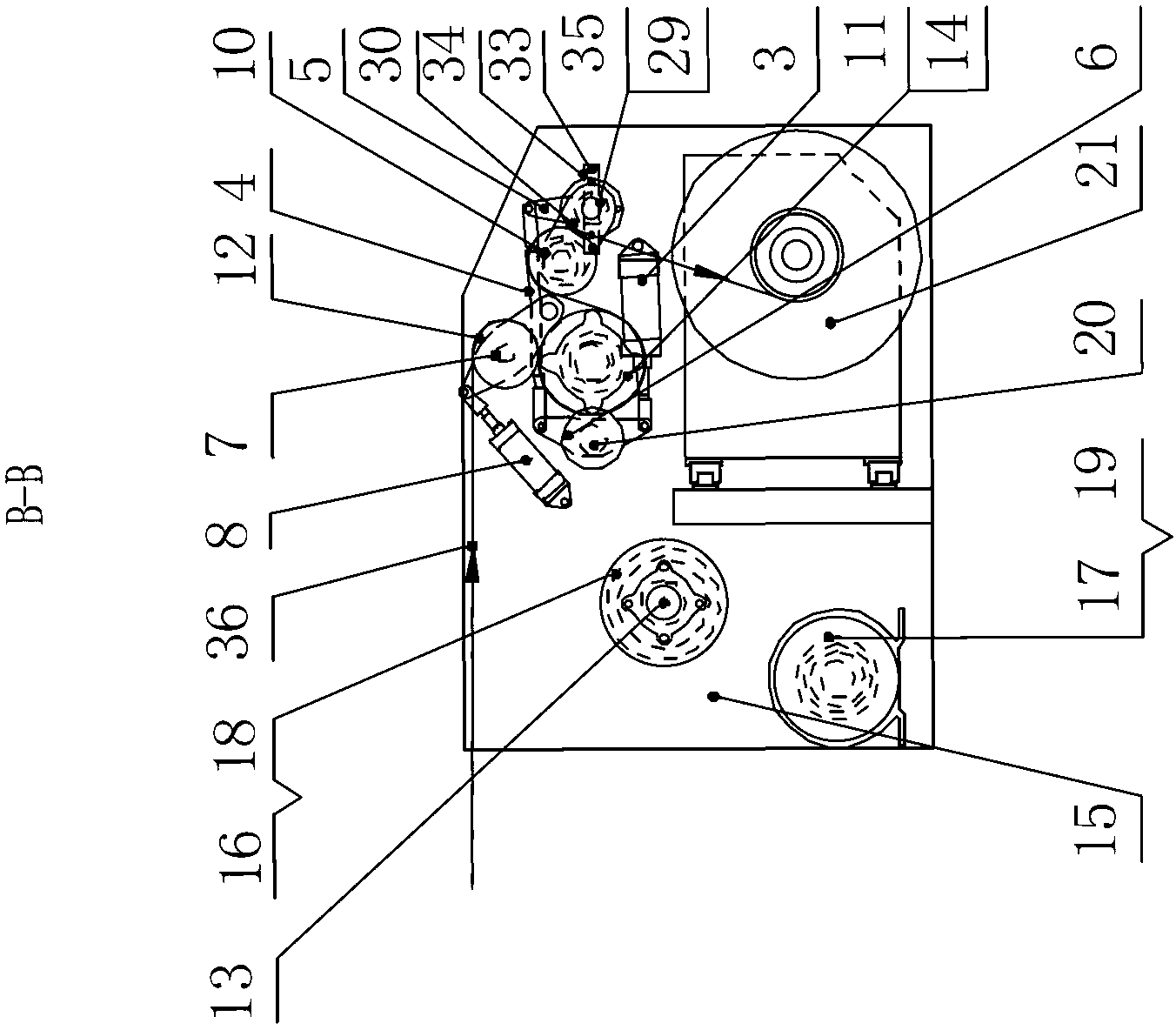

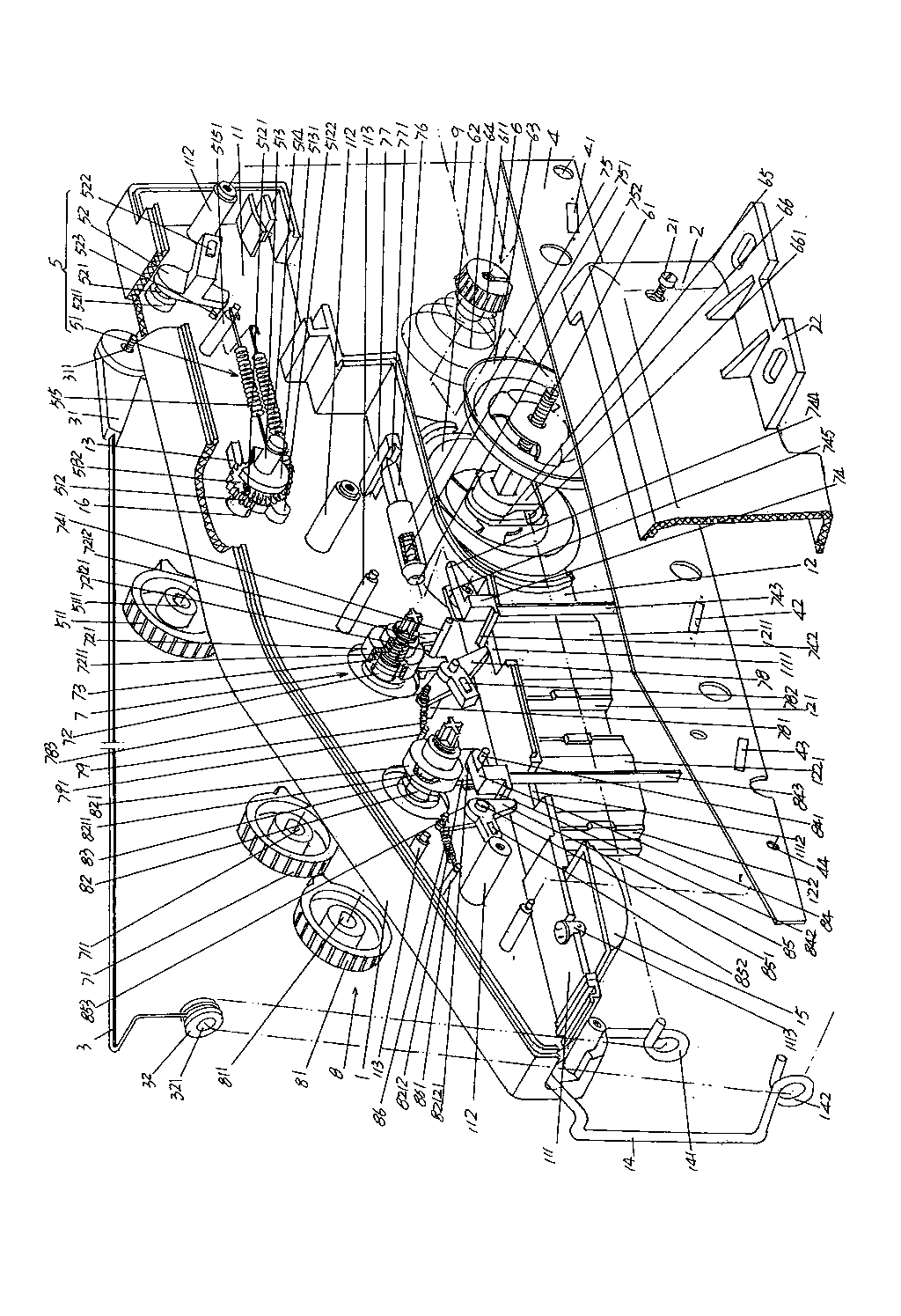

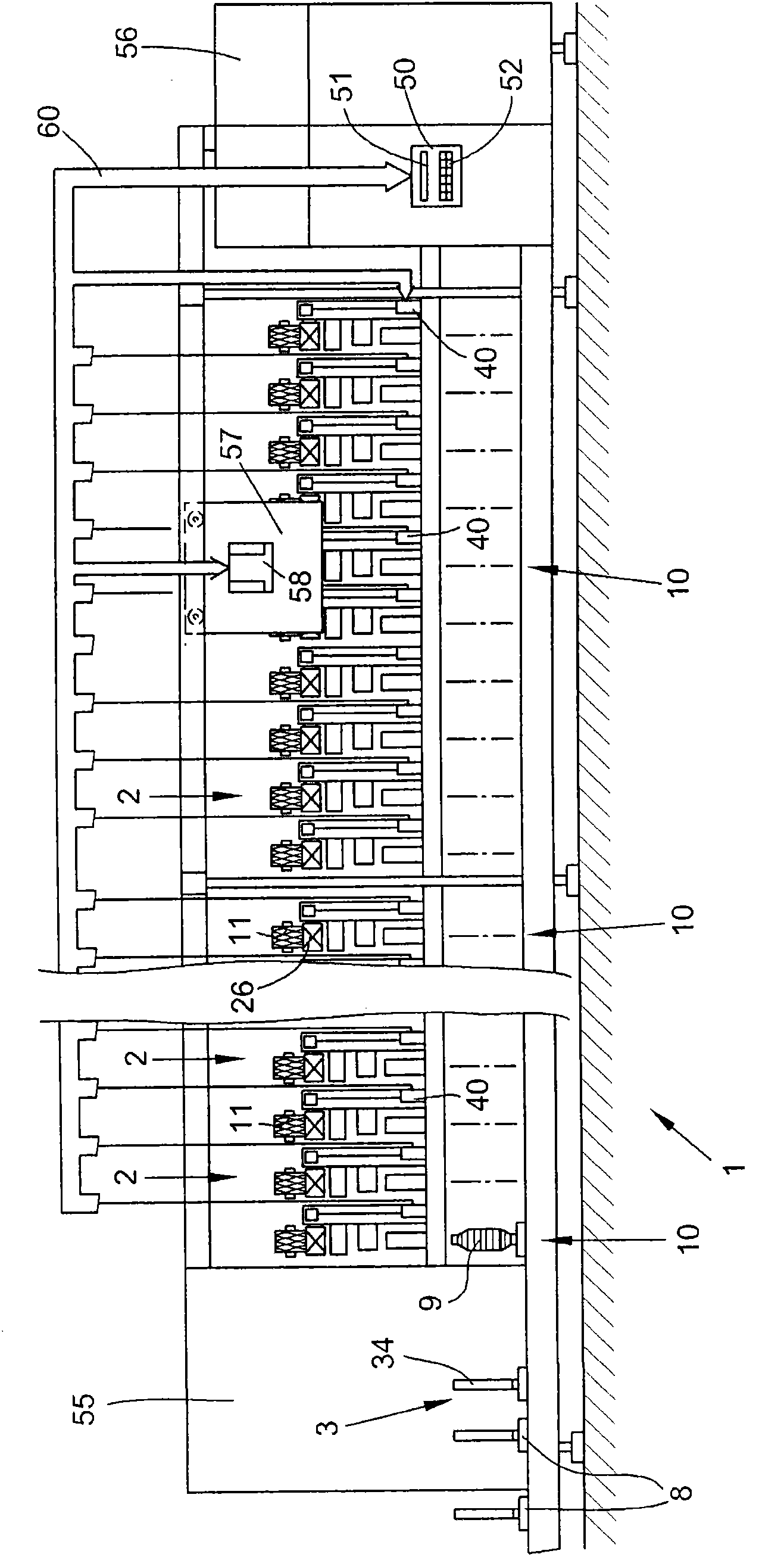

Sectional warping machine and yarn storing, yarn feeding and leasing system thereof

ActiveCN105908314AImprove transmission stabilityHigh precisionWarping machinesLeasingYarn tensionLinear drive

The invention discloses a yarn storing, yarn feeding and leasing system of a sectional warping machine. The system is characterized in that a yarn storing unit, a yarn feeding unit and a leasing unit which are sequentially arranged are included; the yarn storing unit comprises a long stand column, an upper yarn storing roller arranged on the long stand column, a short stand column, a lower yarn storing roller arranged on the short stand column and a linear driving device used for driving the upper yarn storing roller and the lower yarn storing roller to vertically rise and fall; the yarn feeding unit comprises a box, a yarn pressing rubber roller and a yarn guiding roller which are arranged on the box, a driving device d used for driving the yarn guiding roller to rotate and a reciprocating mechanism used for driving the yarn pressing rubber roller to abut against and be separated from the surface of the yarn guiding roller; the leasing unit comprises wallboards, linear guide rails, a leasing reed and a three-segment driving device used for driving the leasing reed to slide on the linear guide rails. Accordingly, the same length and equal tension among yarn and among strips during sectional warping are guaranteed through the yarn storing unit, the yarn feeding unit and the leasing unit, and the sheet yarn tension also can be strictly controlled when broken ends are processed.

Owner:江阴市四纺机新科技制造有限公司

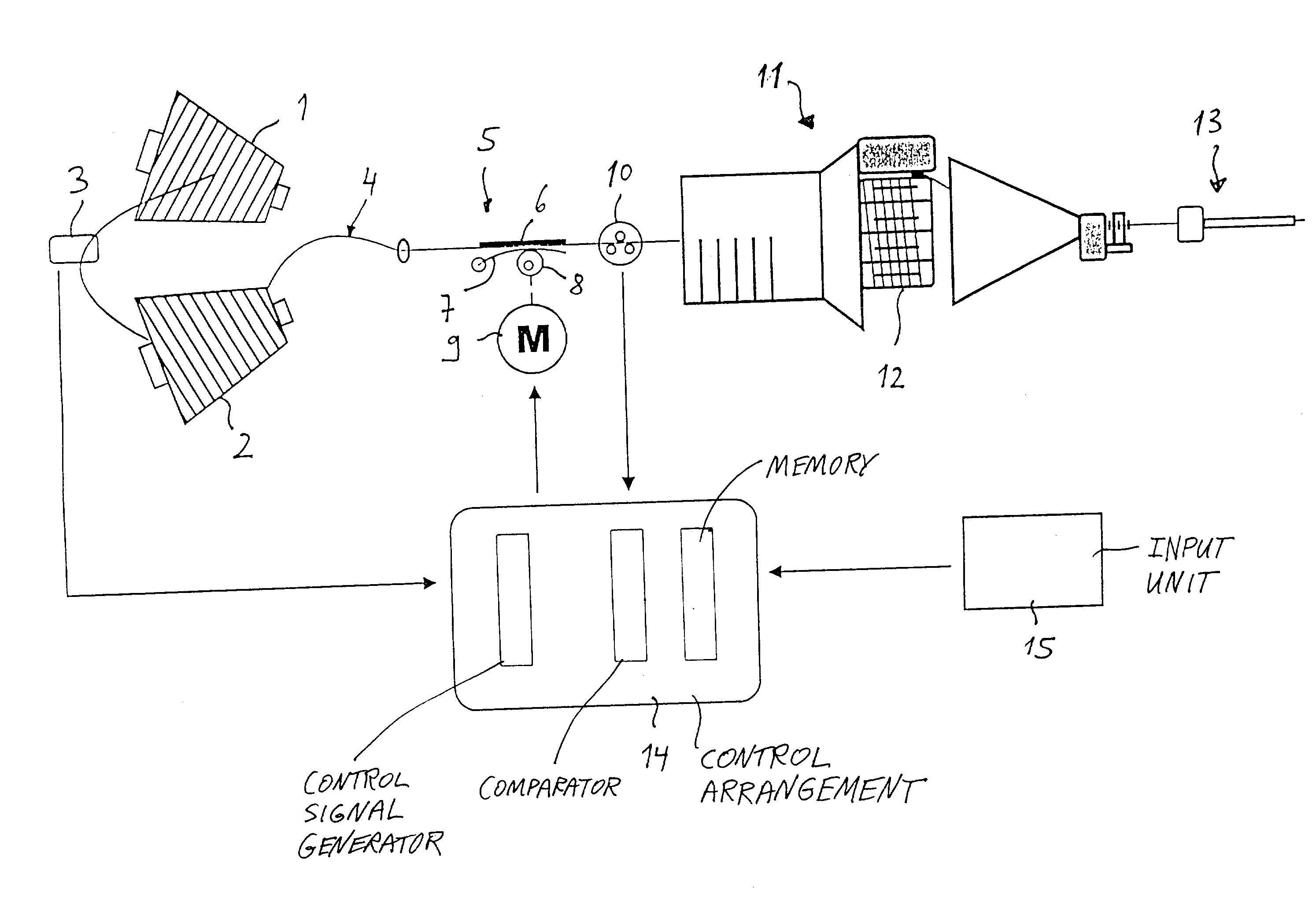

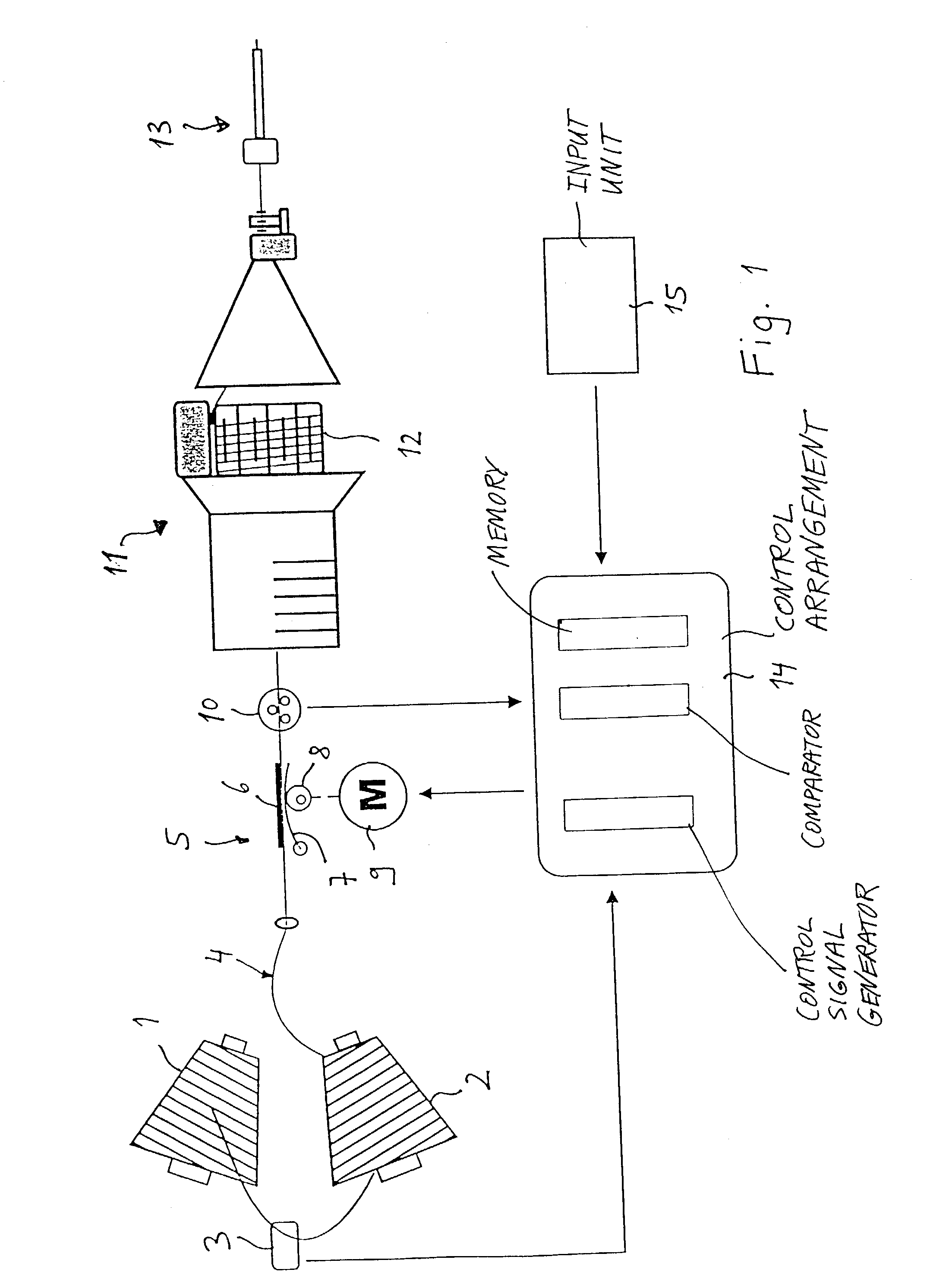

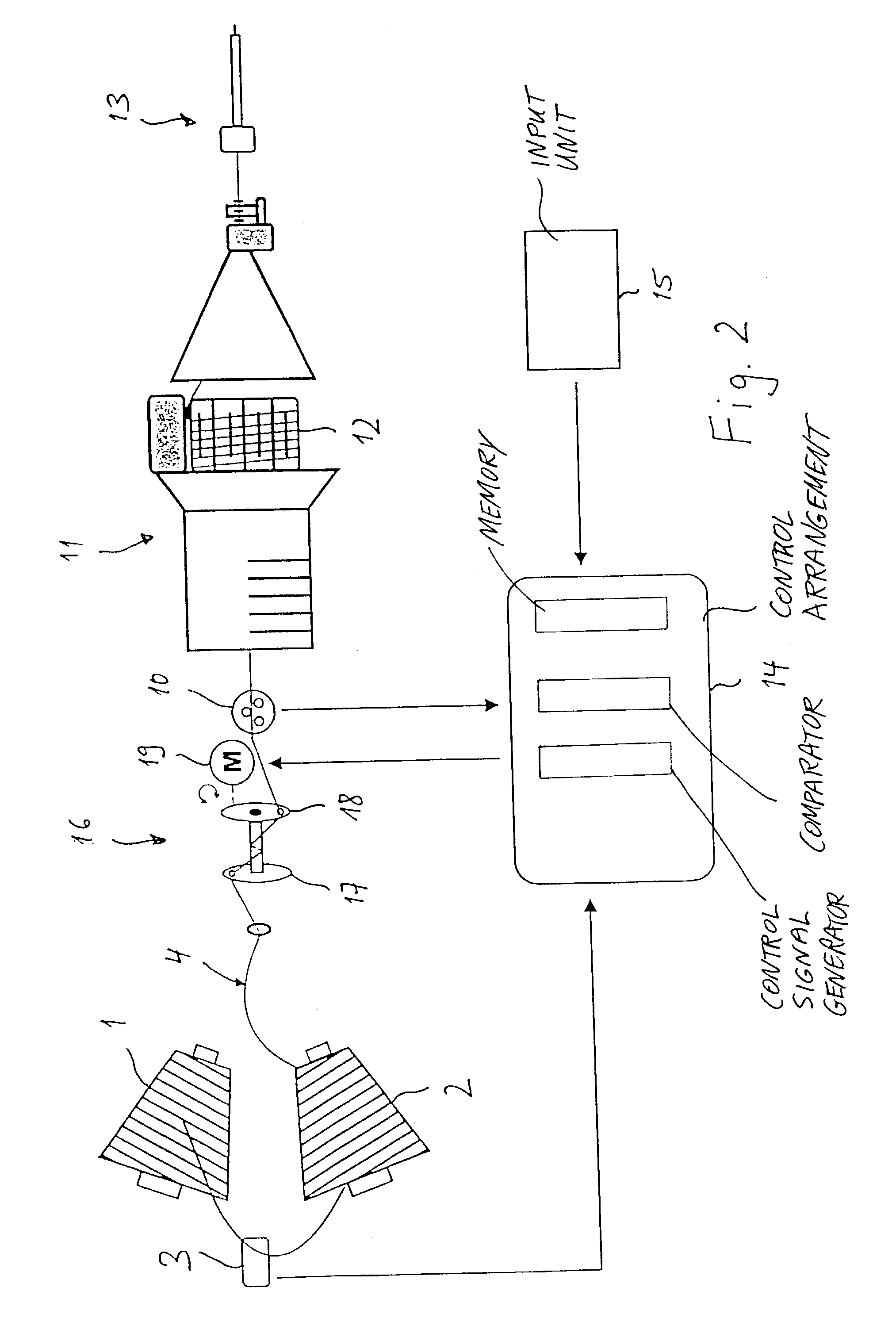

Method and apparatus for variably braking the weft thread between a supply spool and a thread store in a loom

A supply spool supplies a weft thread through an adjustable actuated thread brake and a thread tension sensor to a weft thread accumulator, from which an accumulated insertion length of the thread is provided to a weft insertion device. The tension sensor provides a measured actual thread tension signal to a control arrangement, which compares the actual tension to a selected rated tension, and, dependent on the deviation therebetween, provides a control signal to an actuator of the thread brake, so that the actual thread tension constantly corresponds to the selected rated tension. Another sensor provides a signal indicating a change from an empty spool to a full spool. Responsive thereto, the control arrangement actuates the thread brake to an adjustable starting brake setting as a coarse adjustment. Then the self-regulating fine adjustment is continued. A constant winding tension and thread accumulation length are achieved in the thread accumulator.

Owner:LINDAUER DORNIER GMBH

Method for operating a spindle of a two-for-one twister or cabling machine

ActiveUS8256199B2Reduce energy consumptionDiameter minimizationContinuous wound-up machinesYarnBobbinCable machine

A two-for-one twister or cabling machine and a method for operation thereof, wherein a yarn (5, 25) is withdrawn from a supply bobbin (7, 21) and fed to a guide device below a twisted yarn plate (8, 24) of the spindle (2, 22) and from which the yarn (5, 25) exits virtually perpendicular to the axis of the spindle (2, 22) and is deflected to the outer edge of the twisted yarn plate (8, 24) and runs along the spindle (2, 22) as a free yarn balloon (B) encompassing the spindle (2, 22), until the yarn (5, 25) is fed into the twist or cabling point of a yarn guide device (9, 27) above the spindle (2, 22). The supply speed of the yarn (5, 25) is adjusted to achieve a yarn tension which minimizes the yarn balloon diameter as a function of the spindle geometry.

Owner:ZHUOLANG INTELLIGENT MACHINERY CO LTD

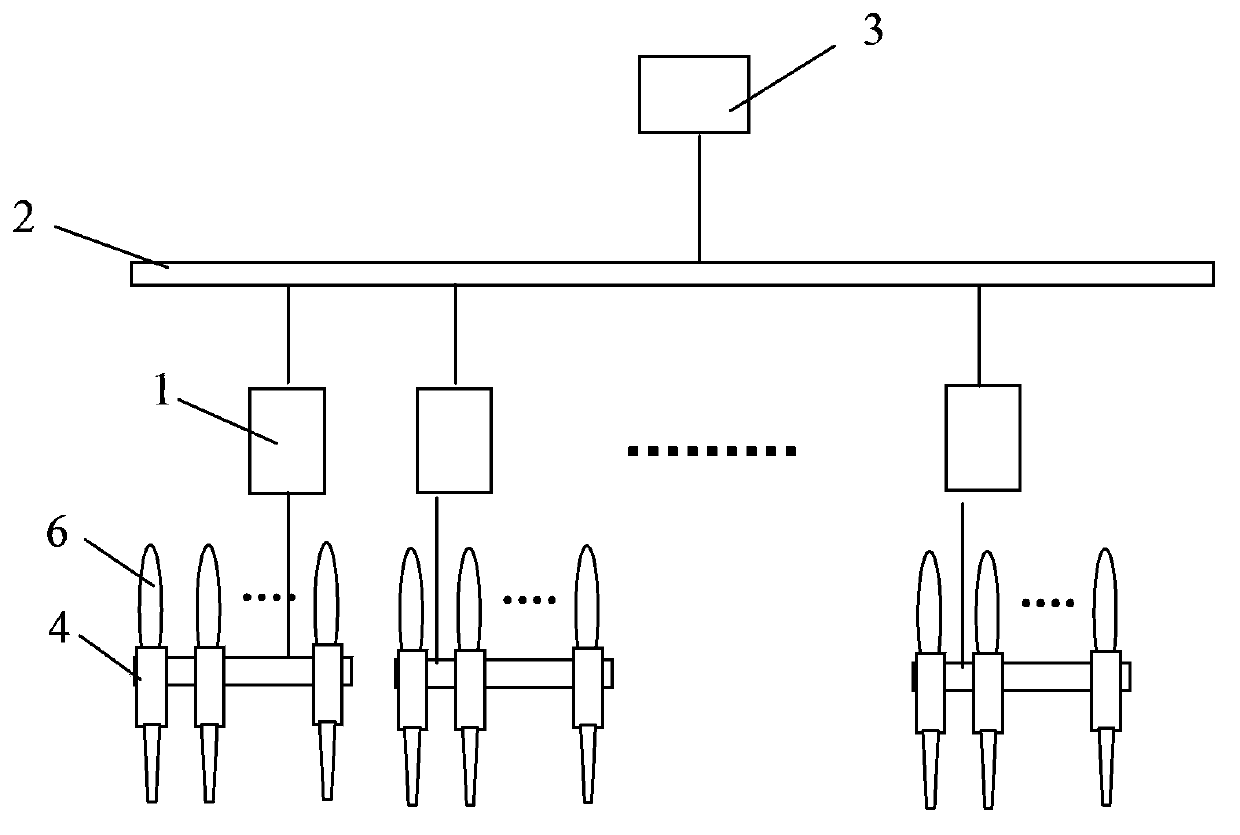

Method and device for detecting electric spindle tension and broken yarn in spinning machine

InactiveCN103966714AReduce lossEasy to shapeTextiles and paperDigital signal processingElectric machinery

The invention discloses a method for detecting electric spindle tension and broken yarn in a spinning machine. The method comprises the following steps: a motor independently drives a spindle, the input end of the motor is connected with a drive circuit; a detection circuit is used for detecting the current value and the speed value passing through the motor in real time, and the change of the tension on a yarn is judged according to the change of the current value or the speed value; during the spindle spinning operation process, the fact that the yarn on the spindle is broken is judged when the current value suddenly decreases or the speed value suddenly increases. The detection circuit and the drive circuit are connected with a control circuit; the control circuit reads the current value and the speed value and outputs a signal or adjusts the output of a control circuit according to the change of the current value or the speed value. The method is implemented through the control circuit. The control circuit comprises a programmable controller and a digital signal processing system. According to the yarn tension, the following commands are outputted including stopping feeding roving in the case of yarn breakage, stopping operation of an electric spindle or decelerating operation, so that cop is formed in an excellent manner, the difference between spindles is reduced, after yarn is broken, feeding of the roving is automatically stopped, and loss of the roving is reduced.

Owner:PACIFIC MECHATRONIC GRP

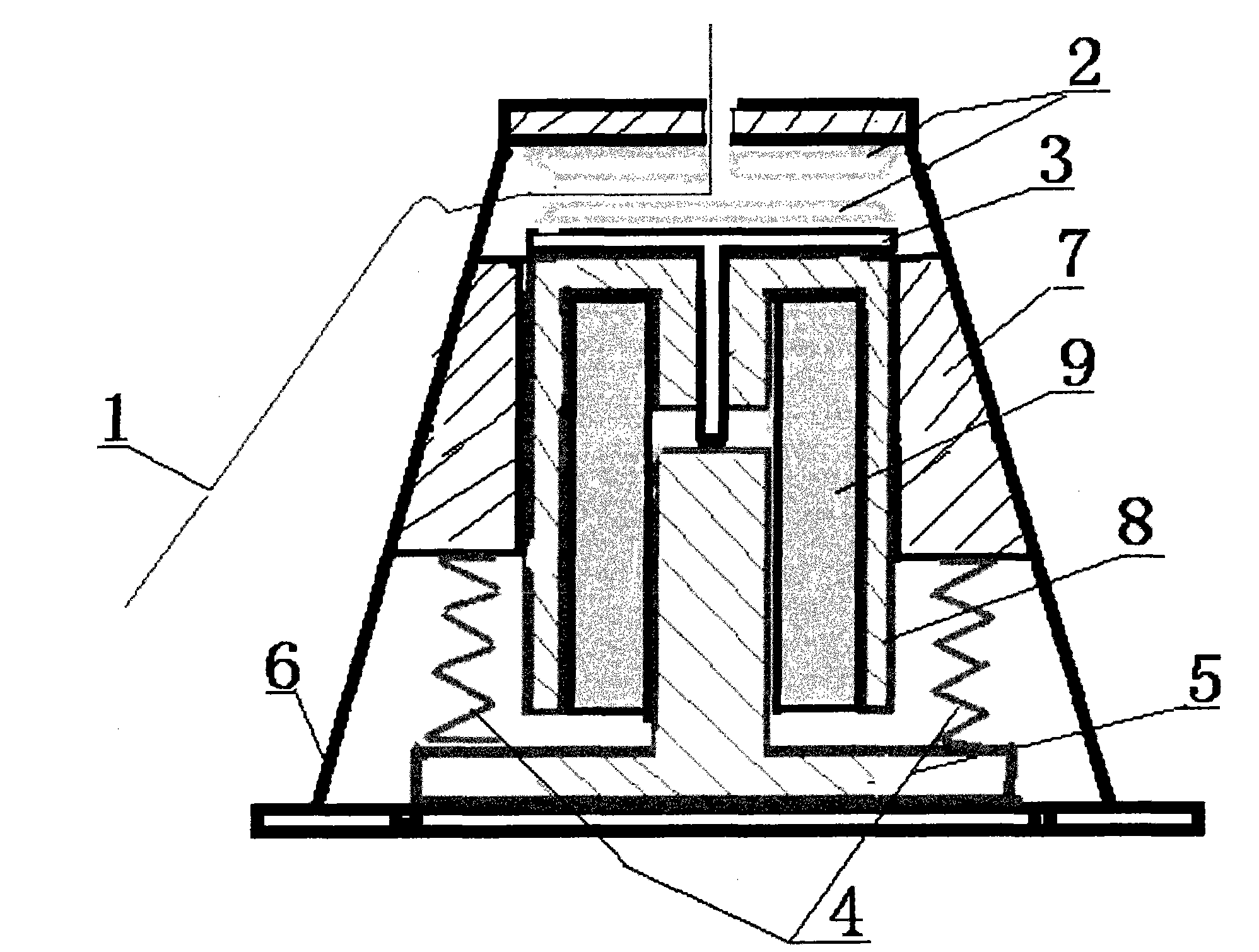

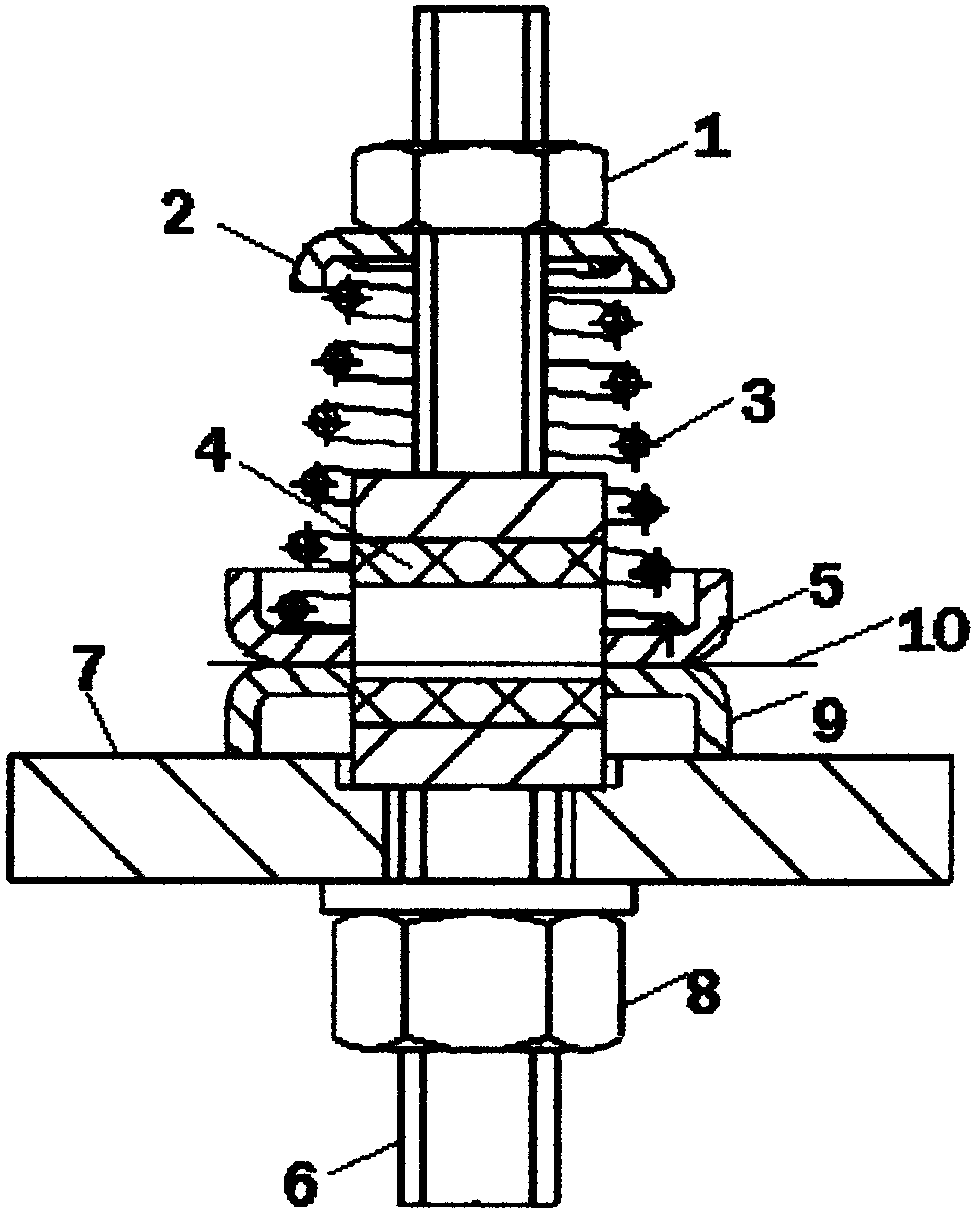

Coaxial electromagnetic compensating tensioner

The invention relates to a coaxial electromagnetic compensating tensioner. The coaxial electromagnetic compensating tensioner solves the problems of poor consistency and uniformity of tension of weft yarn passing through a shed in the prior art. According to the coaxial electromagnetic compensating tensioner, electromagnetic force and spring force are used for jointly controlling clamping force, acting on the yarn, of a ceramic tension clamping piece. By changing the current waveform of an electromagnetic coil, clamping force of a yarn clamping device, which has multiple shifts synchronous with the weaving speed, is outputted for compensating for various wefting insertion characteristics. The coaxial electromagnetic compensating tensioner comprises the ceramic tension clamping piece for adjusting the yarn tension, a plastic bracket, thrust springs, an electromagnet with a controller and an armature. The armature pushes the plastic bracket upwards under the combined action of tensile force of an electromagnetic field of the electromagnet and reactive force of the thrust springs, the plastic bracket transmits the tensile force to the ceramic clamping piece, and therefore the clamping force, acting on the yarn, of the clamping piece is controlled. The coaxial electromagnetic compensating tensioner has the advantages of being high in adjusting fineness, wide in adjusting range, simple in structure, durable, low in price and the like. The tensioner can compensate for the yarn tension under the different wefting insertion conditions, the consistency and uniformity of the tension of the weft yarn passing through the shed can be improved, and the coaxial electromagnetic compensating tensioner has great market demand prospects.

Owner:杨欣圃 +1

Floating roll feedback type yarn tension control device of one-time warping machine

InactiveCN103010838ALarge adjustment rangeHigh control precisionSustainable packaging industryFilament handlingFrequency changerControl system

The invention relates to a floating roll feedback type yarn tension control device of a one-time warping machine. The control device comprises a frame, a circuit, a gas path control system, a weaving shaft driving mechanism and a yarn pulling mechanism. The floating roll feedback type yarn tension control device is characterized in that a tension feedback mechanism is arranged between the weaving shaft driving mechanism and the yarn pulling mechanism. According to the floating roll feedback type yarn tension control device, because a floating roll feedback mechanism is additionally arranged between the weaving shaft driving mechanism and the yarn pulling mechanism, a pulling roll is driven to rotate at constant speed by a variable frequency motor of the pulling roll of the yarn pulling mechanism in accordance with set speed, and the rotation speed of a variable frequency motor of a weaving shaft is automatically regulated by a frequency converter of the variable frequency motor of the weaving shaft of the weaving shaft driving mechanism in accordance with the swinging condition of a floating roll, so that the rotation speeds of the two variable frequency motors are coordinated. The yarn tension can be regulated through the air pressure of an air cylinder of the floating roll. When the air pressure is certain, the strength of the air cylinder is kept unchanged, and therefore, the yarn tension is kept unchanged. Therefore, the yarn tension can be precisely controlled with large scale and constant tension by the floating roll feedback type yarn tension control device.

Owner:窦其勇

Yarn tension adjusting device of computer flat knitting machine

InactiveCN102888705AEmbody reliabilityQuality assuranceWeft knittingStructural engineeringYarn tension

The invention relates to a yarn tension adjusting device of a computer flat knitting machine, belonging to the technical field of computer flat knitting machines. The yarn tension adjusting device comprises a box body, a box cover, a yarn guide rod, a circuit board, a broken yarn alarm mechanism and a yarn pretension adjusting mechanism, wherein a thread passing board extends from the box body, the yarn guide rod is arranged outside the box body, the right end of the yarn guide rod is fixed on a yarn guide rod seat, the left end of the yarn guide rod forms a free end, the circuit board is arranged in a box cavity and is electrically connected with a computer controller, the broken yarn alarm mechanism is connected with the yarn guide rod seat and is matched with the circuit board, and the yarn pretension adjusting mechanism is arranged on one side of the thread passing board and at the right end of a passing thread. The yarn tension adjusting device has the characteristics that the broken yarn alarm mechanism comprises a broken yarn signal rod applied force adjusting device and a broken yarn signal rod, the broken yarn signal rod applied force adjusting device is arranged on the box wall (of the box body) facing one side of the box cover and is also connected with the broken yarn signal rod, and the broken yarn signal rod is connected with the yarn guide rod seat and is also matched with the circuit board. The yarn tension adjusting device has the advantages that a signal can to be timely fed back to the circuit board when a yarn is broken so as to reflect the reliability of broken yarn alarm, thus guaranteeing the quality of braided fabric.

Owner:JIANGSU JINLONG TECHNOLOGY CO LTD

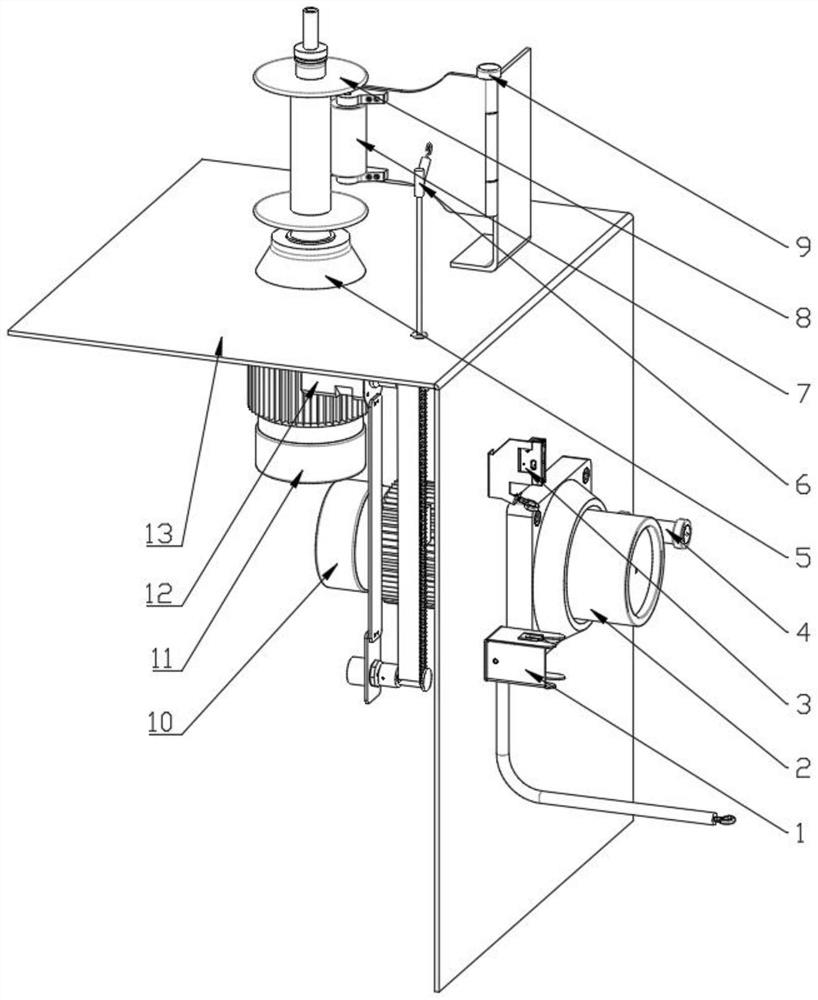

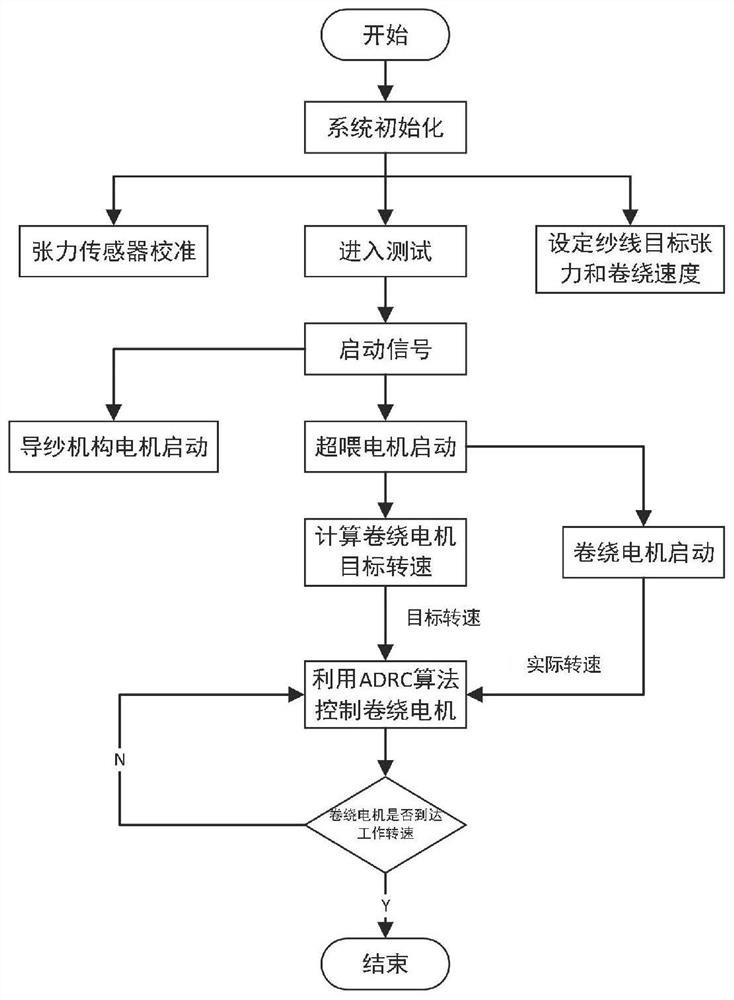

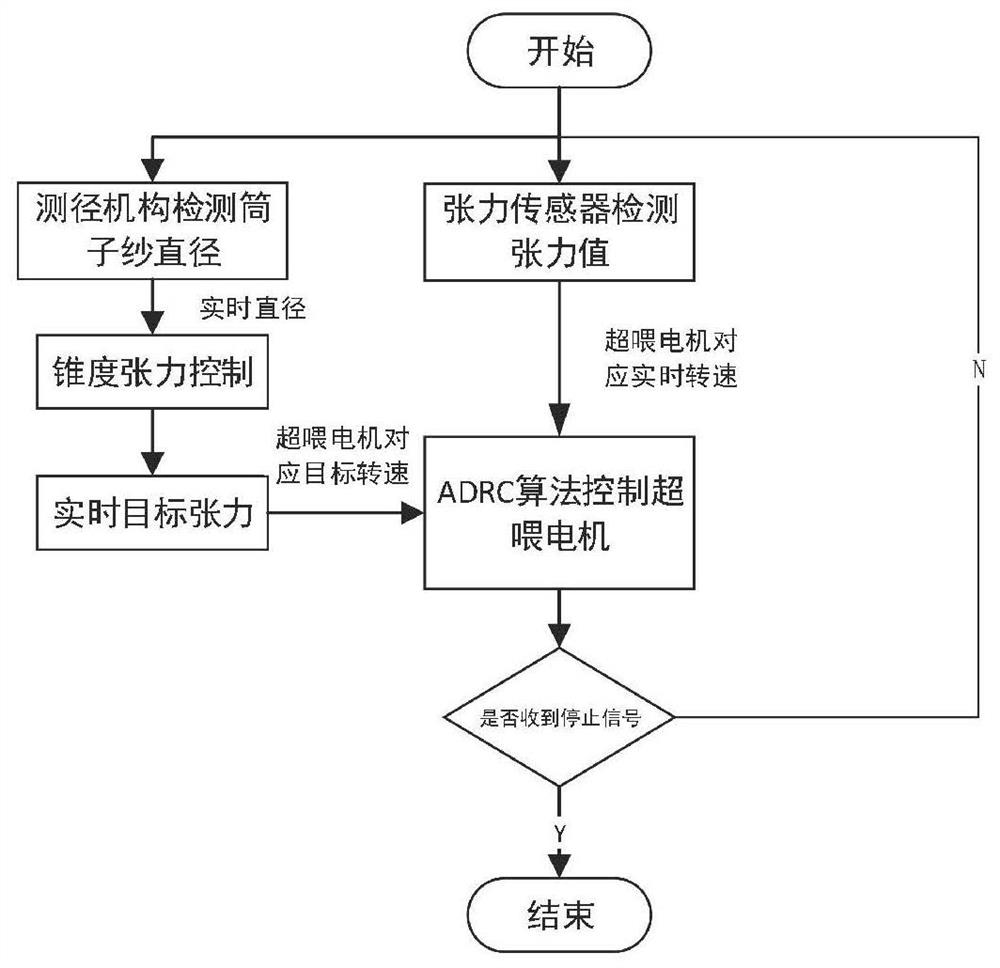

Winding forming control method capable of detecting and dynamically adjusting tension in real time

ActiveCN112960477AReduce tension fluctuationsImprove stabilityFilament handlingClassical mechanicsEngineering

The invention discloses a winding forming control method capable of detecting and dynamically adjusting tension in real time. The winding forming control method capable of detecting and dynamically adjusting the tension in real time comprises the following steps: 1, a winding starting stage: an overfeeding wheel begins to rotate, and a yarn core begins to rotate after delay; the overfeeding wheel does uniformly accelerated motion; the target rotating speed of the yarn core is calculated according to the rotating speed of the overfeeding wheel; and the rotating speed of the yarn core is driven to dynamically follow the target rotating speed; 2, a stable operation stage: the target tension of a yarn roll is dynamically adjusted along with winding of a yarn roll; and under the state that the linear speed of the yarn roll is kept constant, the target rotating speed of the overfeeding wheel is dynamically calculated and updated according to the change of the target tension F, and the rotating speed of the overfeeding wheel is driven to dynamically follow the target rotating speed; and 3, a machine stopping stage: the yarn core does uniformly retarded motion, and after delay, the overfeeding wheel starts to retard; the target rotating speed of the overfeeding wheel is calculated and updated according to the rotating speed change of the yarn core; and the rotating speed of the overfeeding wheel is driven to dynamically follow the target rotating speed. According to the winding forming control method capable of detecting and dynamically adjusting the tension in real time provided by the invention, the tension of yarns is accurately adjusted, so that cheeses are uniformly wound, no yarn broken ends exist, and the number of yarn faults is small.

Owner:ZHEJIANG SCI-TECH UNIV +1

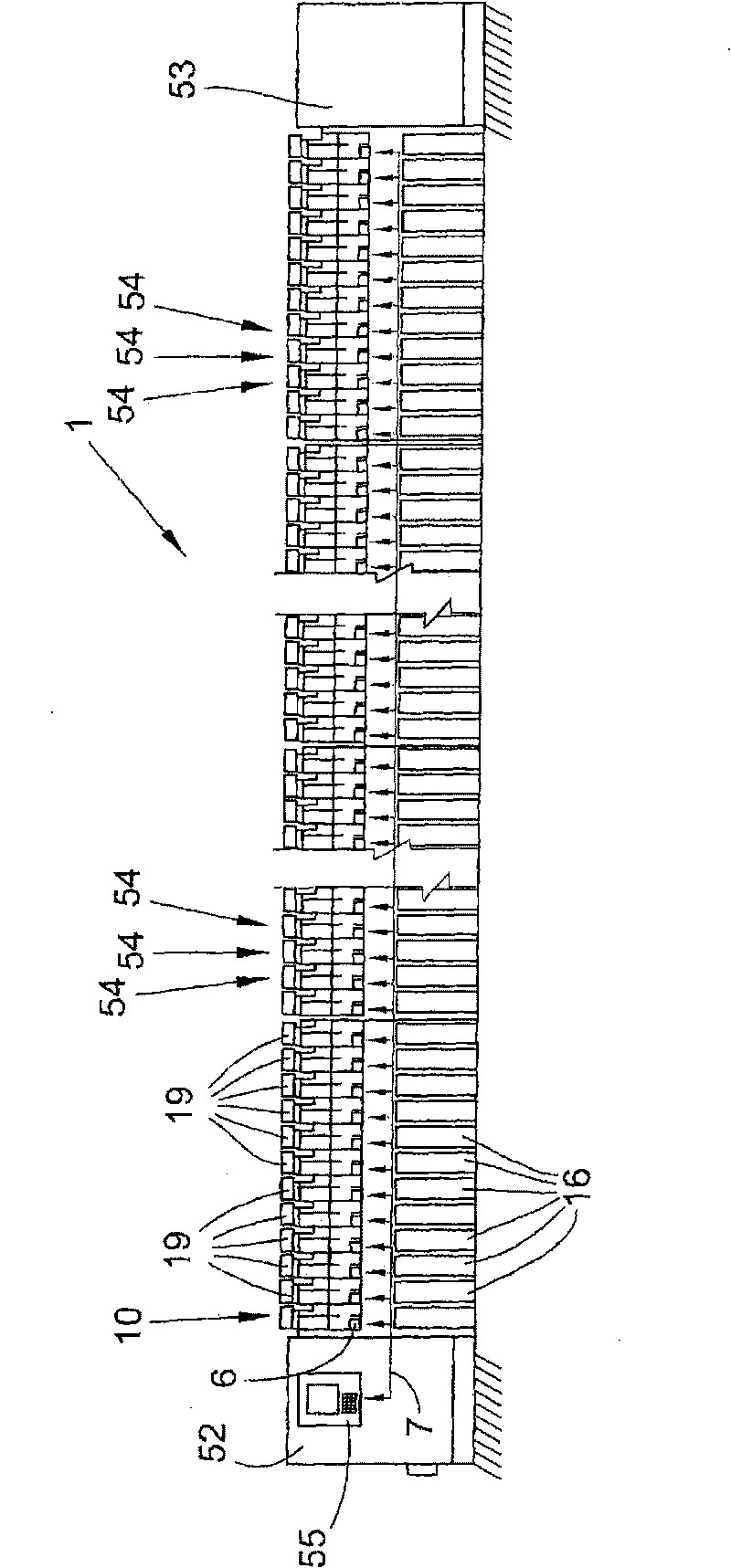

Method for operating free end spinning machine and free end spinning machine thereof

The present invention relates to a method for operating a free end spinning machine and the free end spinning machine with a plurality of stations, wherein, each station is provided with a spinning device and a winding device used for manufacturing cross wounding bobbins. Furthermore a yarn storing device temporarily stores the yarn amount generated because of different accelerations of the spinning device and the winding device in the accelerated operation period of station. According to the invention, at a state of new batch, the tension of yarn in acceleration is measured on at least one station for aiming at various diameters of the cross wounding bobbins, wherein, the tension of yarn is a scale of the filling state of the yarn storing device. acceleration characteristic curves are confirmed for various diameters of the cross wounding bobbin depending on the acceleration speed of the yarn tension regulation winding device according to the regulated speed. Then the acceleration characteristic curves related with the diameters are applied for aiming at the corresponding batches in the acceleration period of the stations.

Owner:SAURER GERMANY GMBH & CO KG

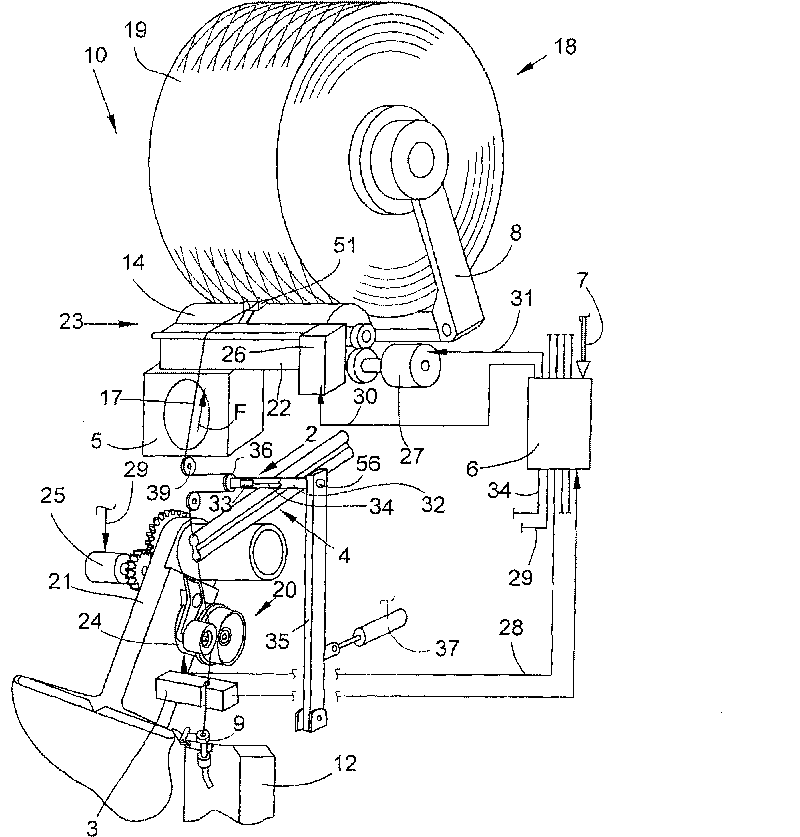

Method for operating a winding machine and winding machine thereof

The present invention relates to a method for operating a winding machine (1) and the winding machine (1) with a plurality of stations (2). The stations respectively wind the yarn (30) from a spinning cop (9) to intercross winding bobbins (11). An advancing route of the yarn is respectively provided with a sensor (20) and a yarn tensioner (14). The sensor measures a value which represents yarn tension. Furthermore the yarn tension is adjustable for confirming sensor failure, thereby controlling the yarn tension. According to the invention, a value which represents the length of corresponding residual yarn is detected. An experience value of the adjusting signal is determined according to at least one adjusting signal which is detected through a mode that is related with the residual yarn length on the spinning cop in a tension coiling period of the adjusted yarn. Furthermore when the sensor failure occurs, the experiment value which is predetermined according to a mode that is related with the residual yarn length on the spinning cop as the adjusting signal, and the yarn tension is controlled through the yarn tensioner.

Owner:SAURER GERMANY GMBH & CO KG

Yarn tension device

InactiveCN102689817AEasy to unwindImprove lateral stabilityFilament handlingChinese charactersBobbin

The invention discloses a yarn tension device, comprising a supporting plate, wherein a shaft hole is arranged on the supporting plate, and a tension adjusting shaft with a structure shaped like a Chinese character 'zhong' is arranged in the shaft hole; a perforated ceramic column is fixed in an inner hole of the tension adjusting shaft by glue, and the lower end of the tension adjusting shaft is fixedly arranged on the supporting plate through a second nut; the upper end of the tension adjusting shaft is provided with a first nut, and a conical spiral spring is arranged below the first nut and is sleeved on the tension adjusting shaft; the upper end of the conical spiral spring is provided with an upper positioning disc, and the lower end of the conical spiral spring is provided with a lower positioning disc; and a first fixing disc is arranged below the lower positioning disc and is fixedly arranged on the supporting plate, and a yarn penetrates through the hole of the perforated ceramic column and is clamped between the two planes of the lower positioning disc and the fixing disc. According to the yarn tension device provided by the invention, a selvedge bobbin yarn has more stable tension in winding, and the unwinding of the yarn is favorable.

Owner:JIANGSU WANGONG TECH GRP CO LTD

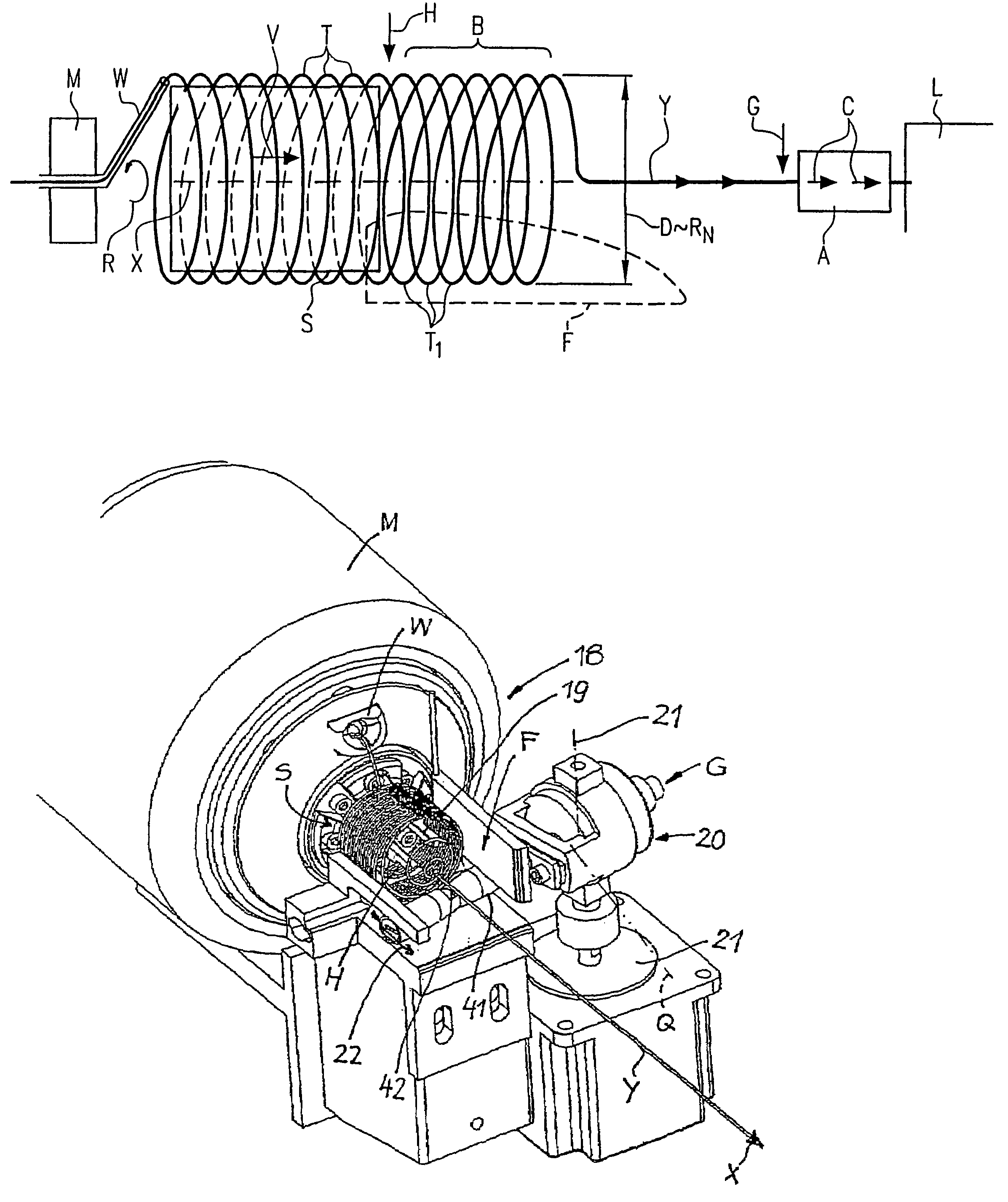

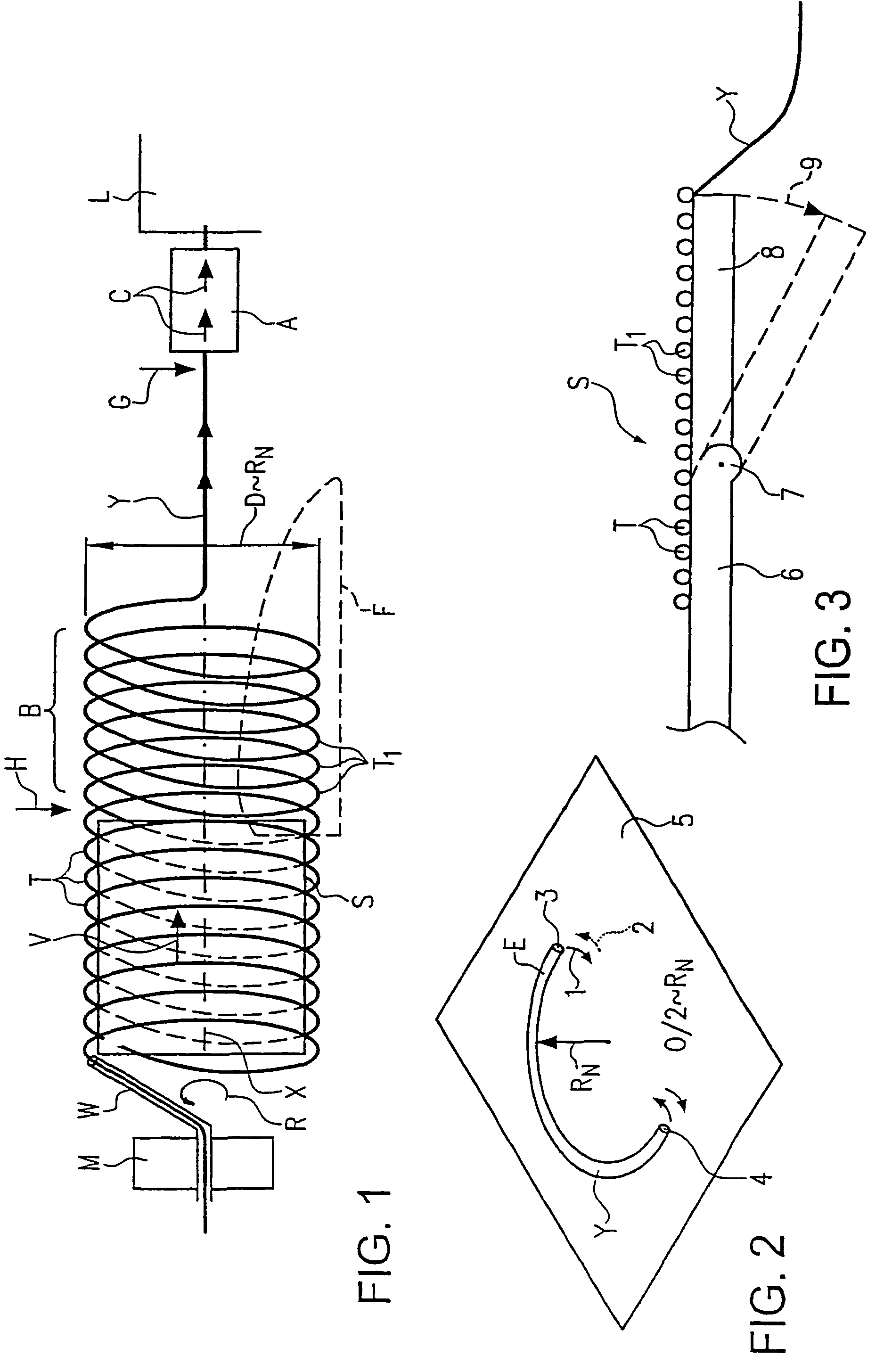

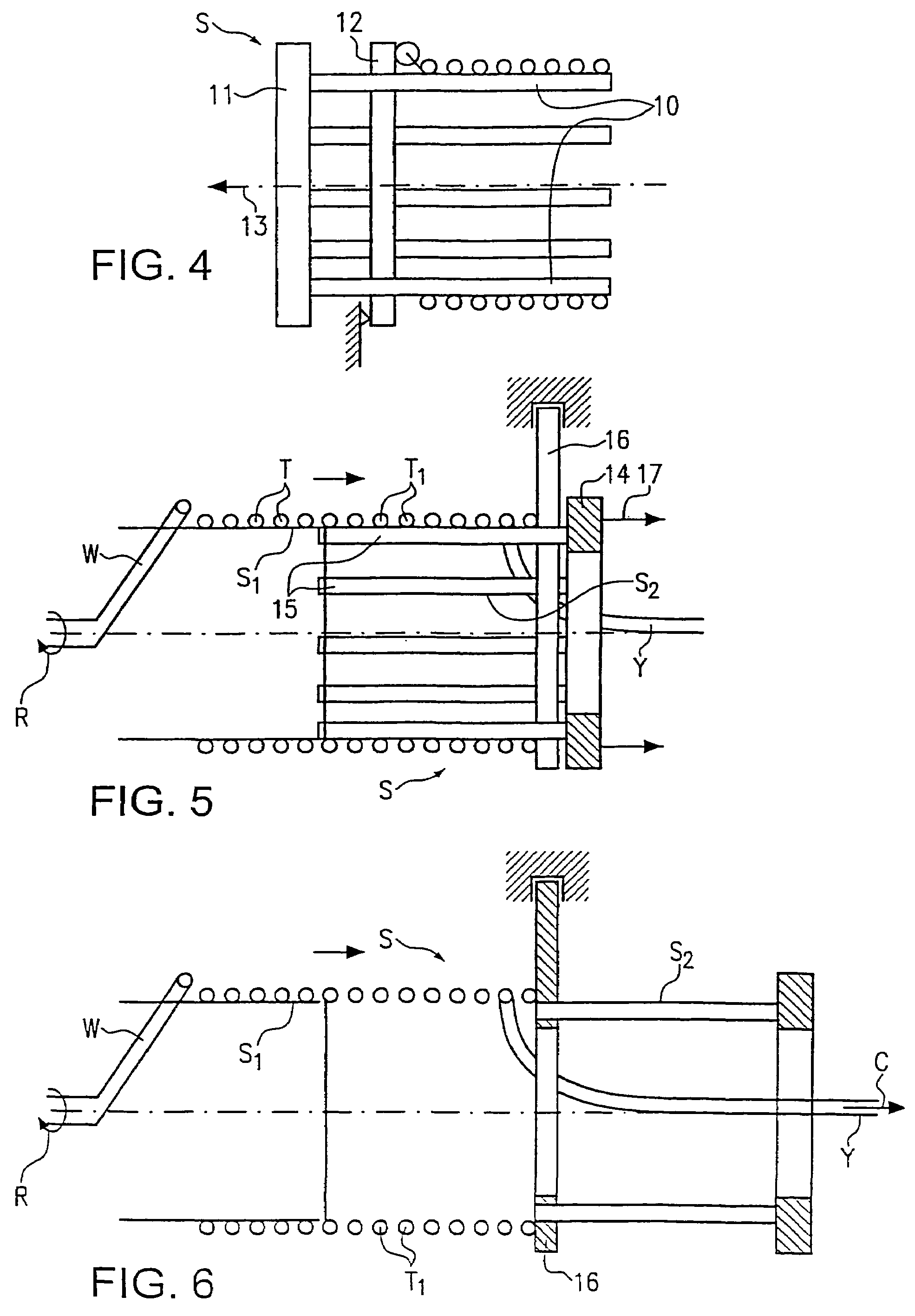

Method for inserting weft yarns

InactiveUS7156337B2Small shapeDampening and attenuating yarn tension riseWeft knittingLoomsEngineeringYarn tension

The invention relates to a method for inserting weft yarn material, comprising an insertion system in a loom. According to the invention, for every insertion the insertion system (A) is supplied with a substantial part of the weft yarn required for the insertion in a loose and substantially tension-free manner so as to be intermittently pulled off. A tubular package of adjacent windings is produced from the weft yarn material on an inner mechanical support (S) by way of an at least substantially continuous winding process and is conveyed forward in withdrawal direction. For an insertion, a number of windings that corresponds at least approximately to the weft yarn section intended to be inserted is detached or set free from the support while maintaining its tubular configuration without yarn tension. The weft yarn material is withdrawn directly inwardly from the frontmost winding and then further along the tube axis (X).

Owner:IROPA AG (CH)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com