Method for operating a winding machine and winding machine thereof

A winding machine and yarn technology, which is applied in the field of operating the winding machine and the winding machine, can solve problems such as incompatibility, and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

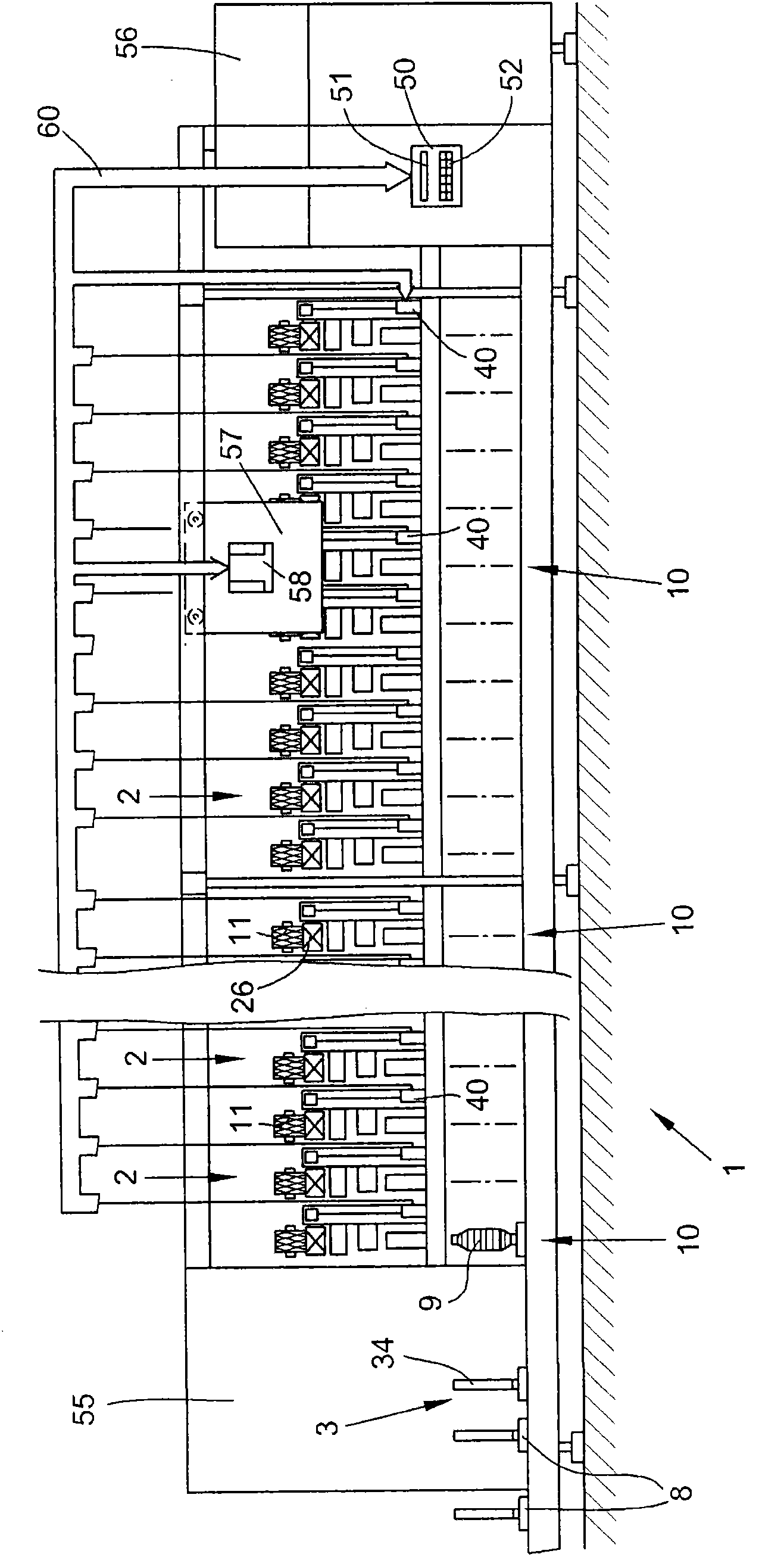

[0030] figure 1 The winding machine 1 is shown with a plurality of stations 2 arranged between the end frames 55, 56 of the winding machine 1. The winding machine has a central control unit 50 that is connected to the station control device 40 via a bus system 60. The central control unit has a keyboard 52 and a display device 51 for operation and display.

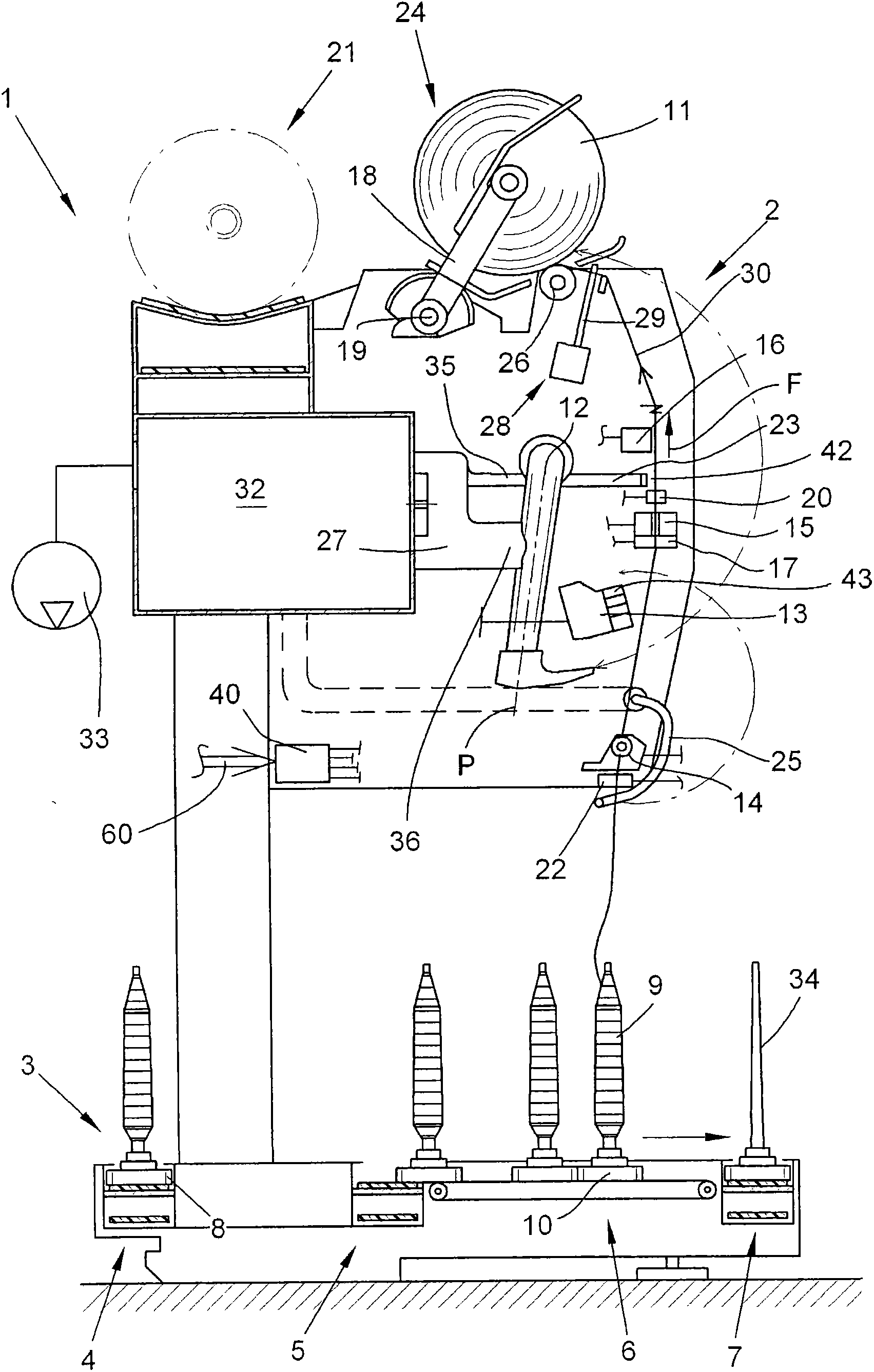

[0031] figure 2 The station 2 during the winding process is schematically shown in a side view. As 2 is known but not explained in detail, at these stations 2, the textile bobbins 9 fed to the bobbins, usually manufactured on a ring spinning machine, with a small amount of yarn material are rewinded into a large-volume cross Winding the bobbin 11. Subsequently, by means of an automatically working service unit 57 (such as a cross-wound bobbin changing device), the finished cross-wound bobbin 11 is transferred to the cross-wound bobbin conveying device 21 arranged in the longitudinal direction of the machine, and the cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com