Patents

Literature

33results about How to "Inhibition of tension changes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

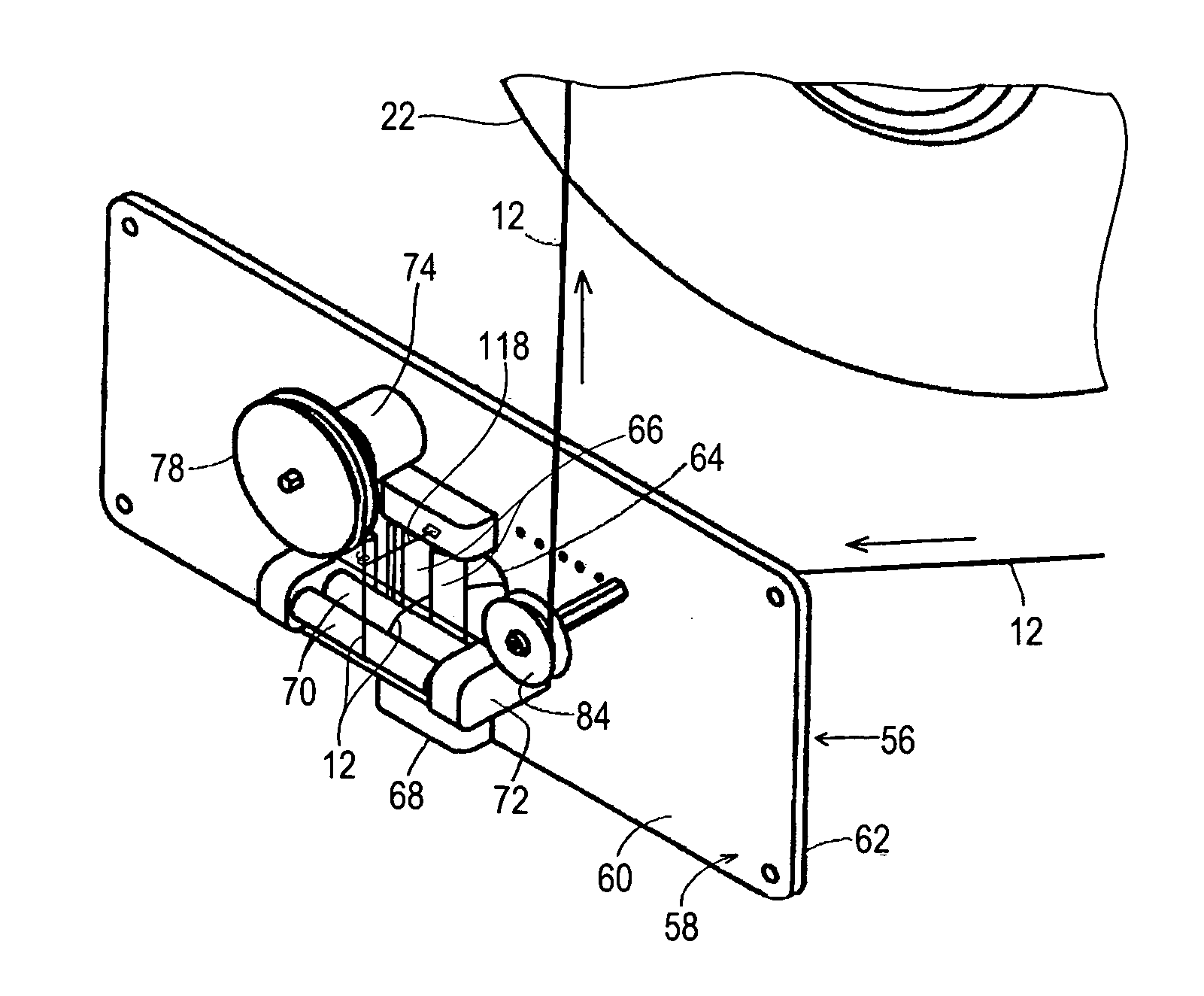

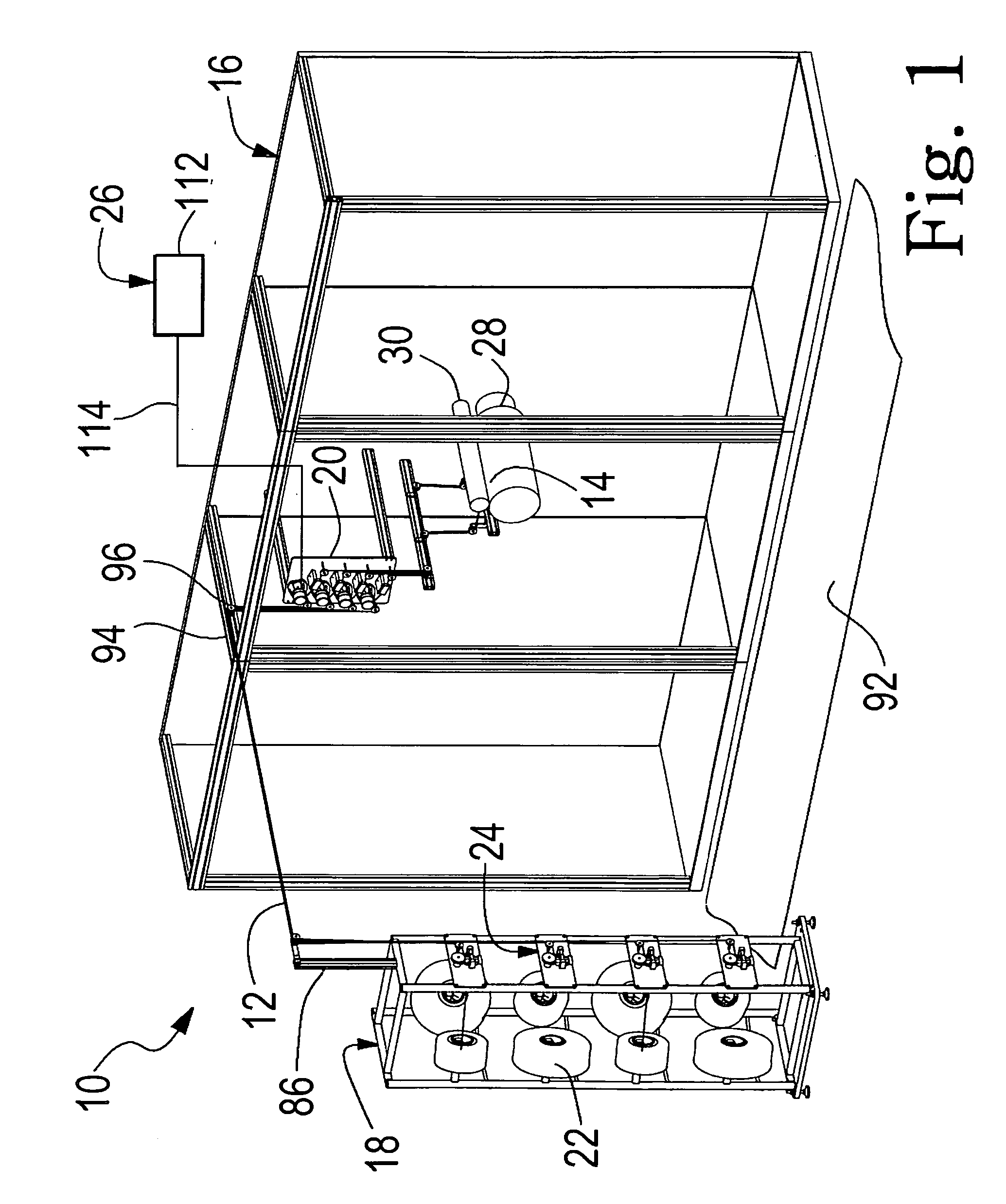

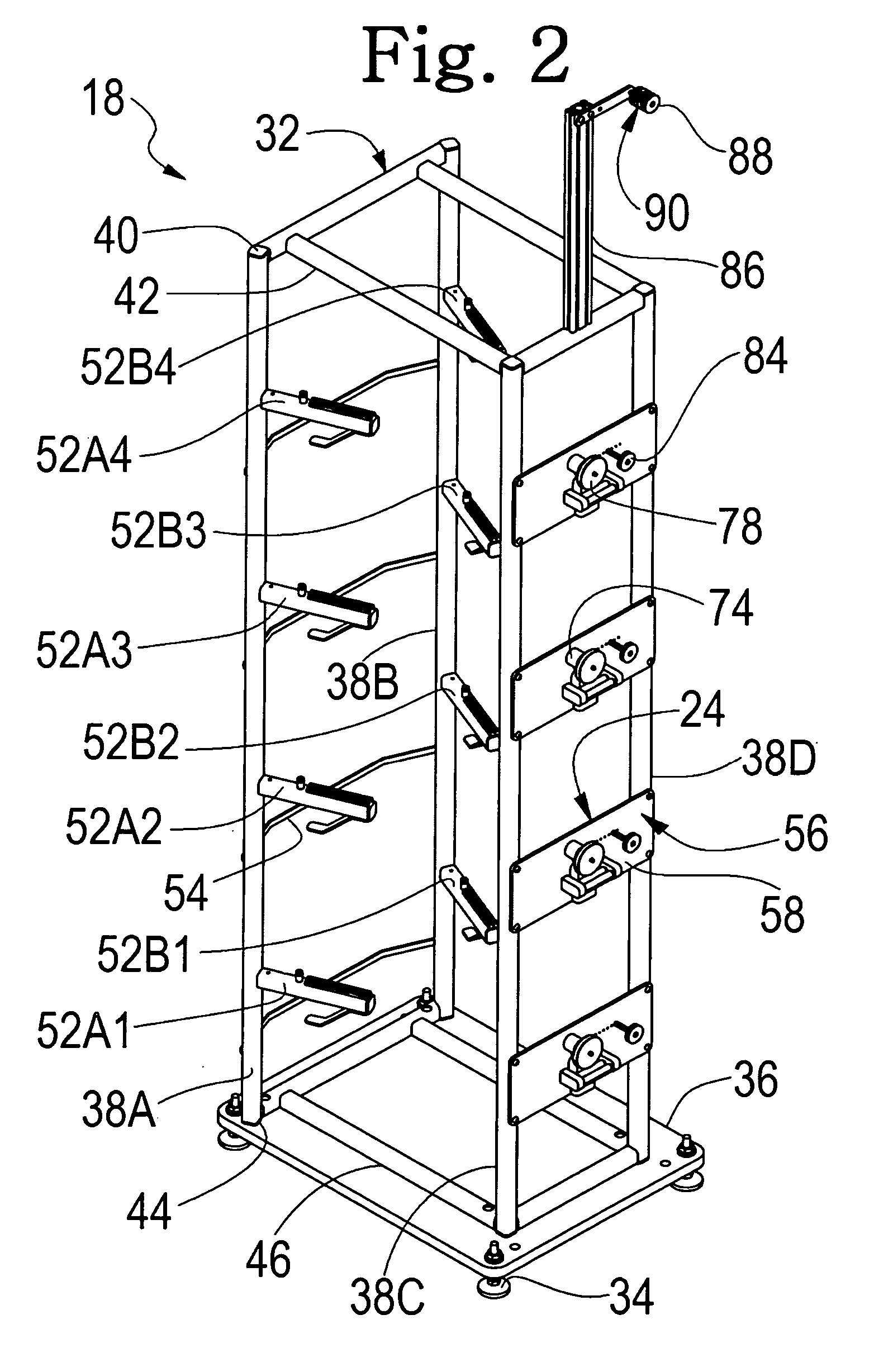

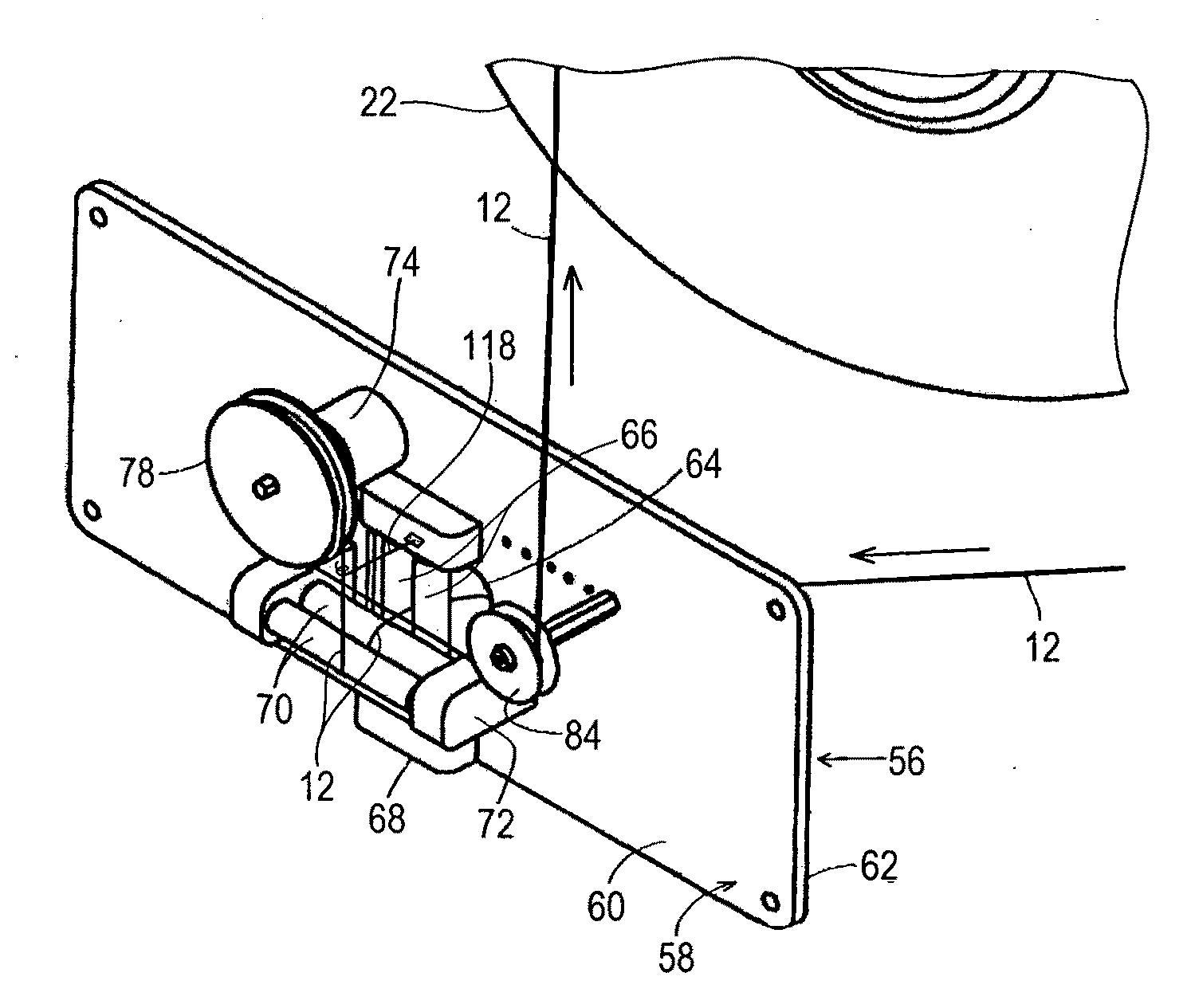

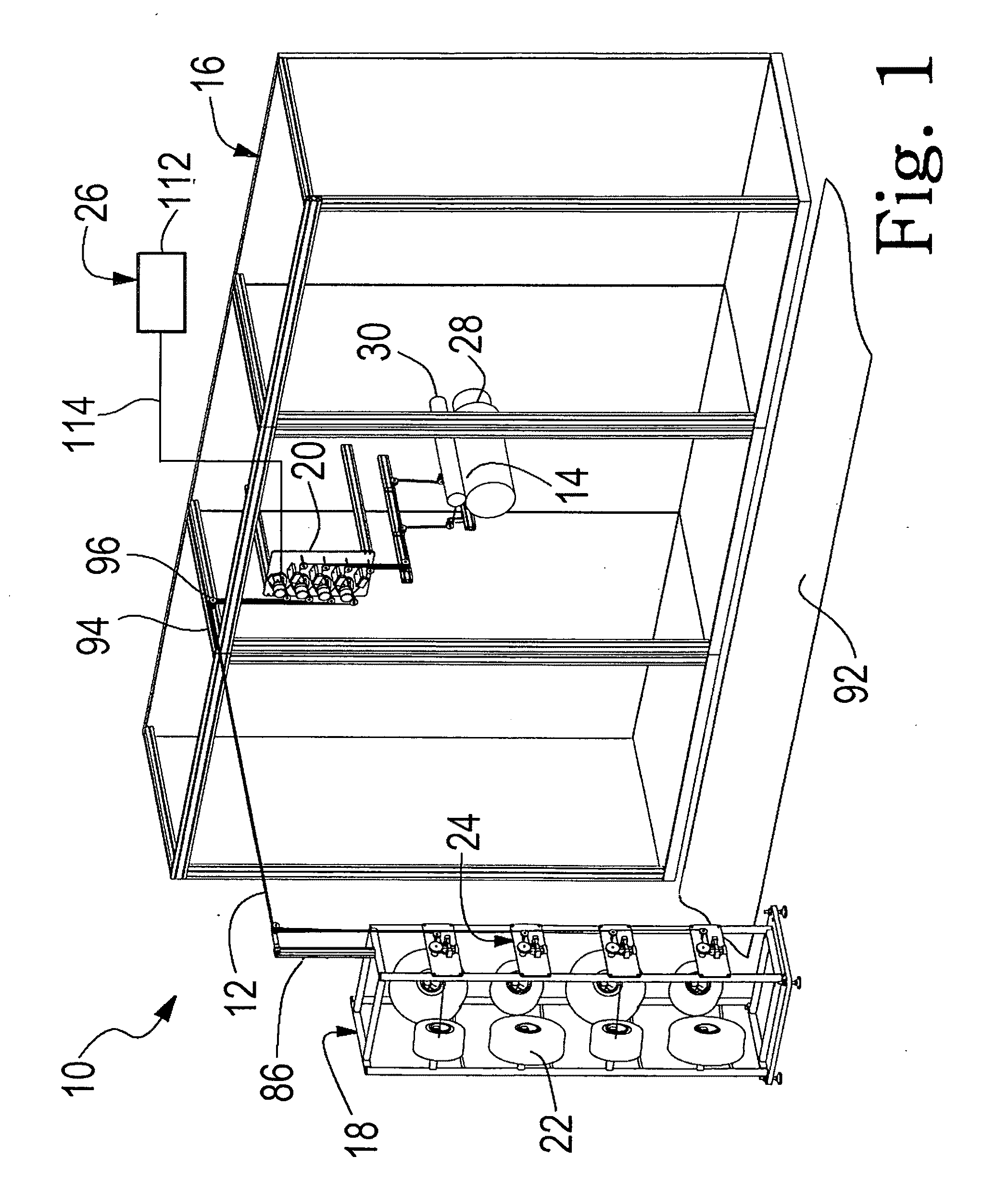

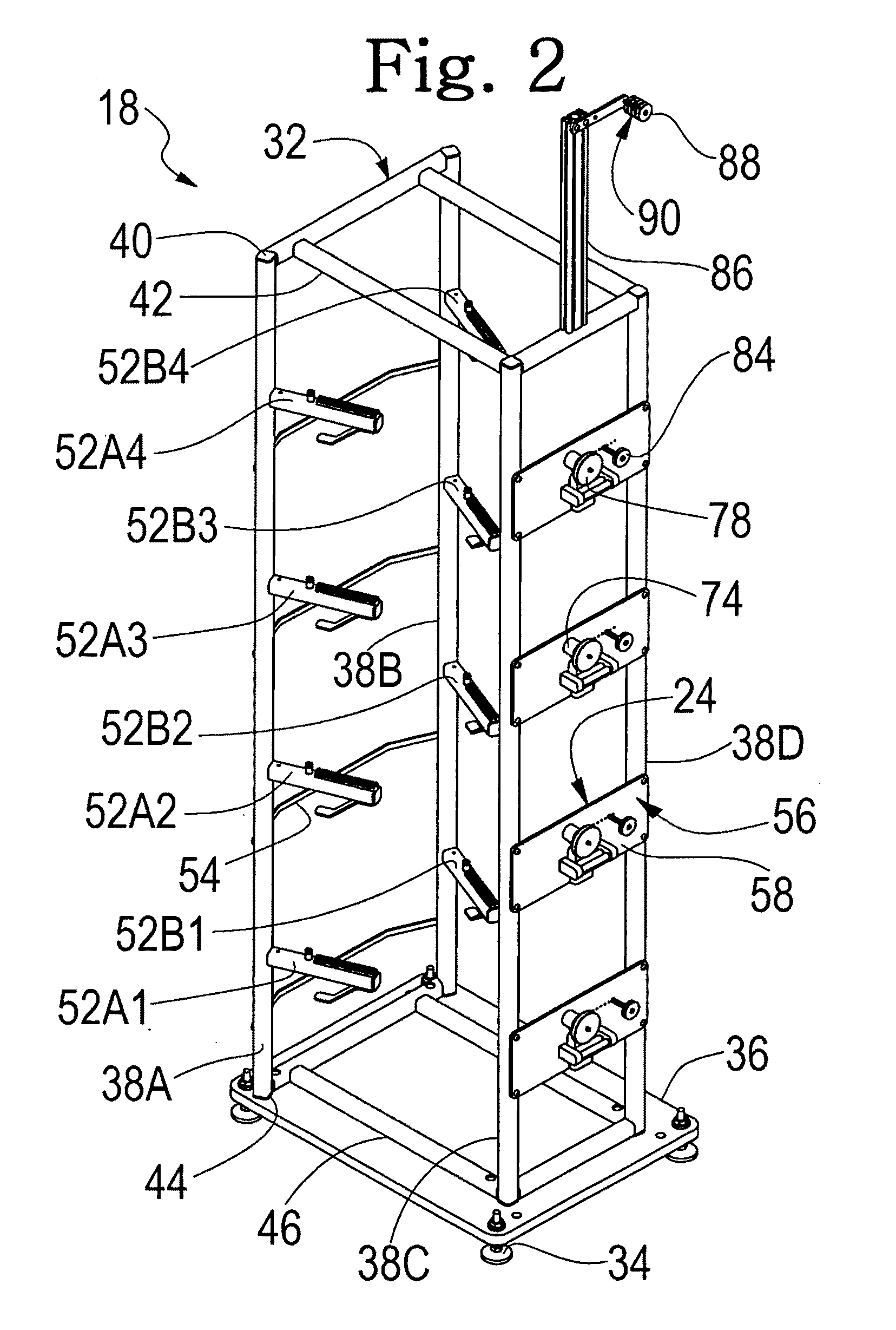

Unwind and feed system for elastomeric thread

ActiveUS20070152093A1Smoothes out tension variationInhibition of tension changesProjector film strip handlingFilament handlingFiberTension control

An overend unwind system for unwinding tacky elastomeric fiber threads such as uncoated spandex thread, capturing the ballooning affect of the thread as the thread leaves the spool, applying a first-stage tension control on the thread adjacent where the thread leaves the spool, feeding the unwound thread to a nip in a downstream process, and applying a final tension increment to the thread adjacent where the thread enters the downstream process. All thread guide surfaces encountered by the thread after leaving the spool, and while the thread is under designed operating tension, are moving surfaces, such that the tensioned thread thereby experiences a reduced level of drag as the thread traverses its path of travel from the spool to the downstream process.

Owner:HARTZHEIM ENG

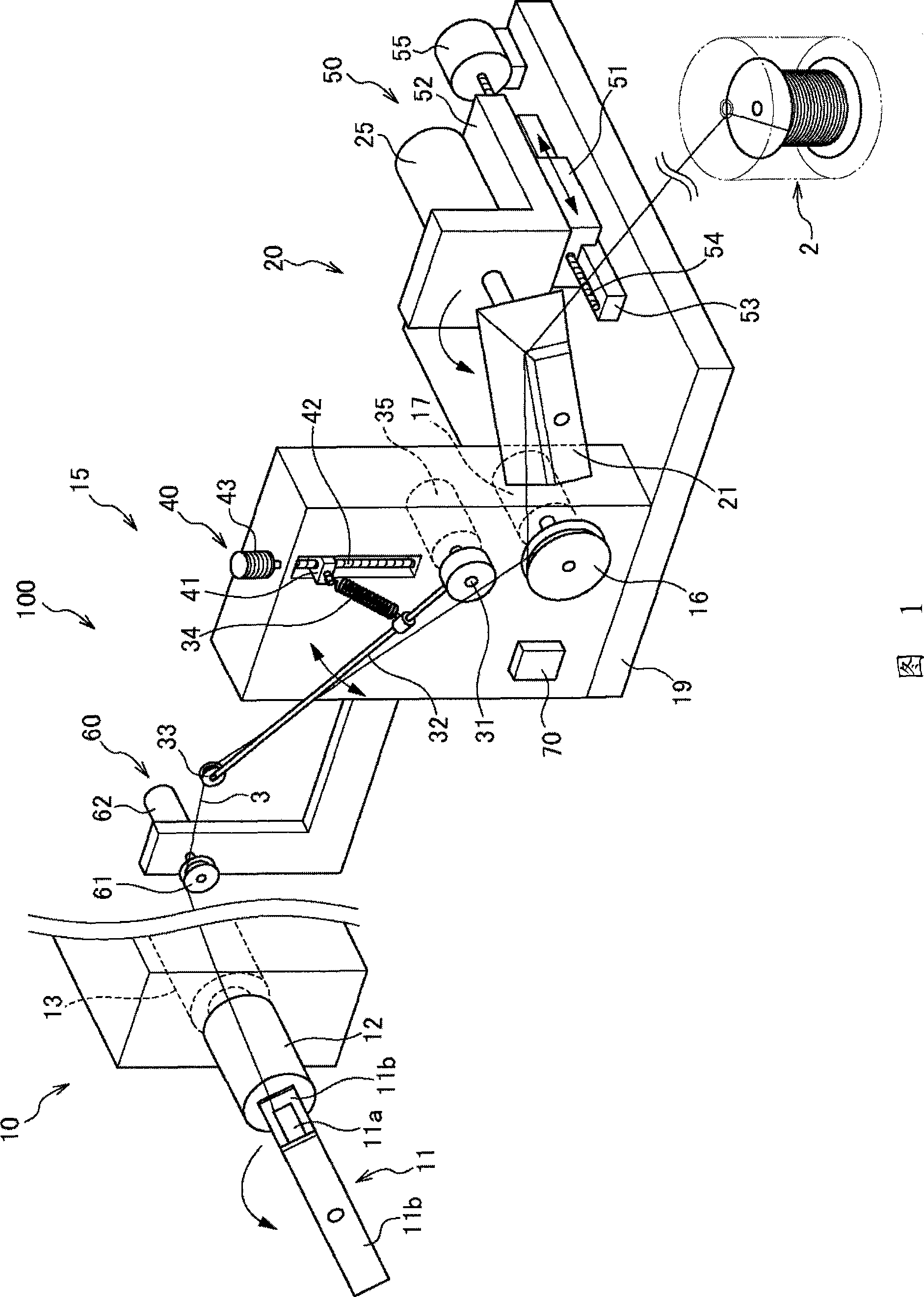

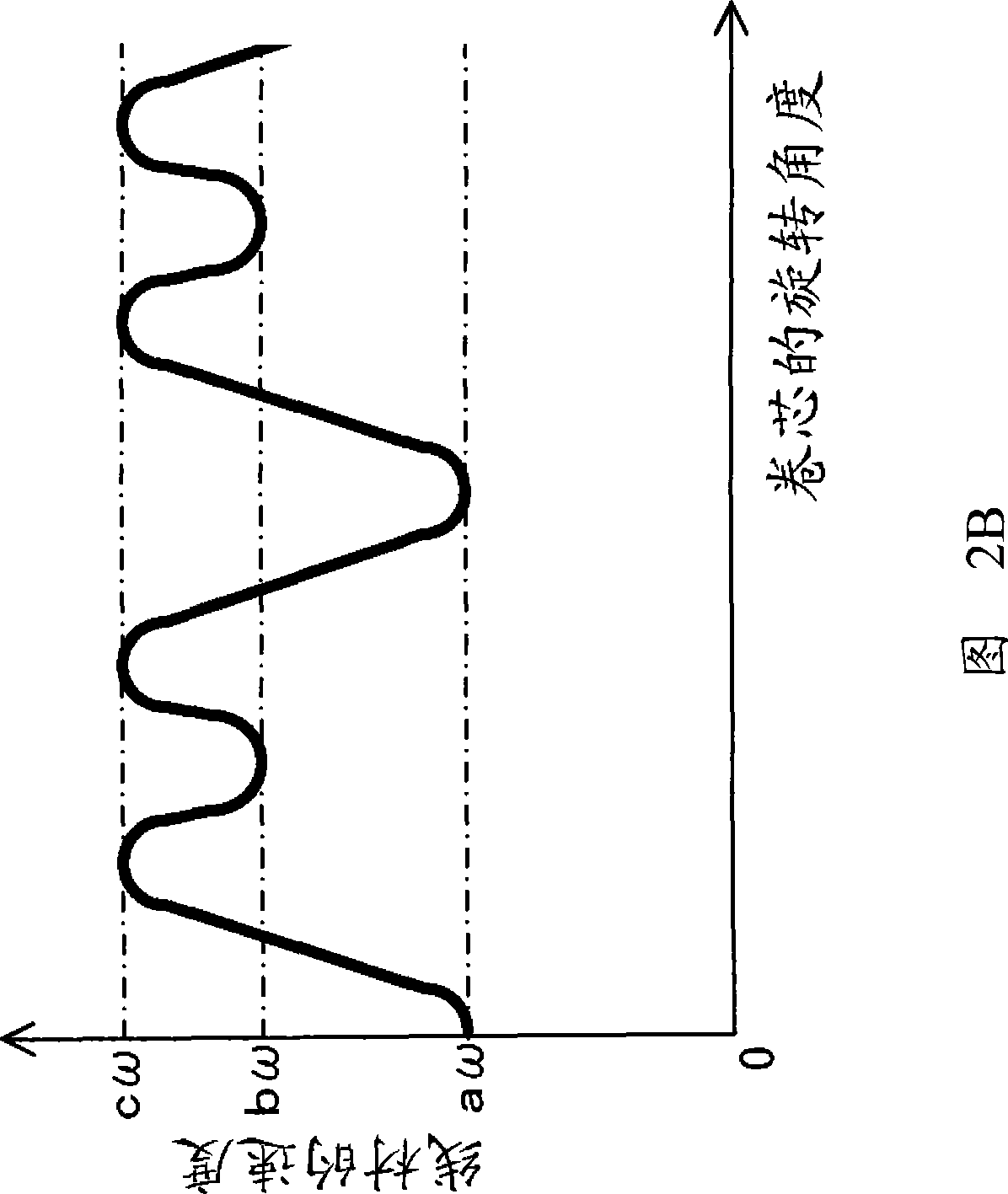

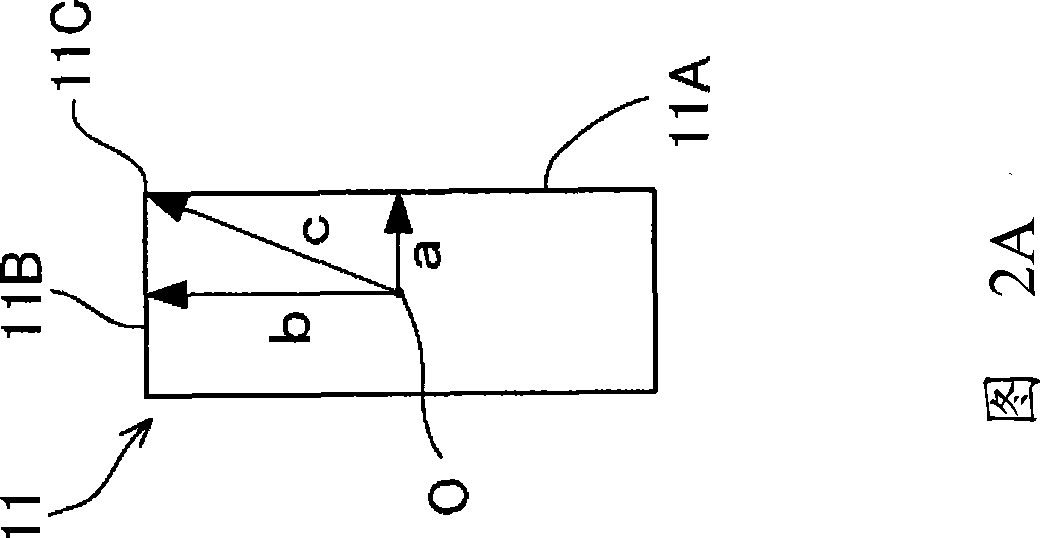

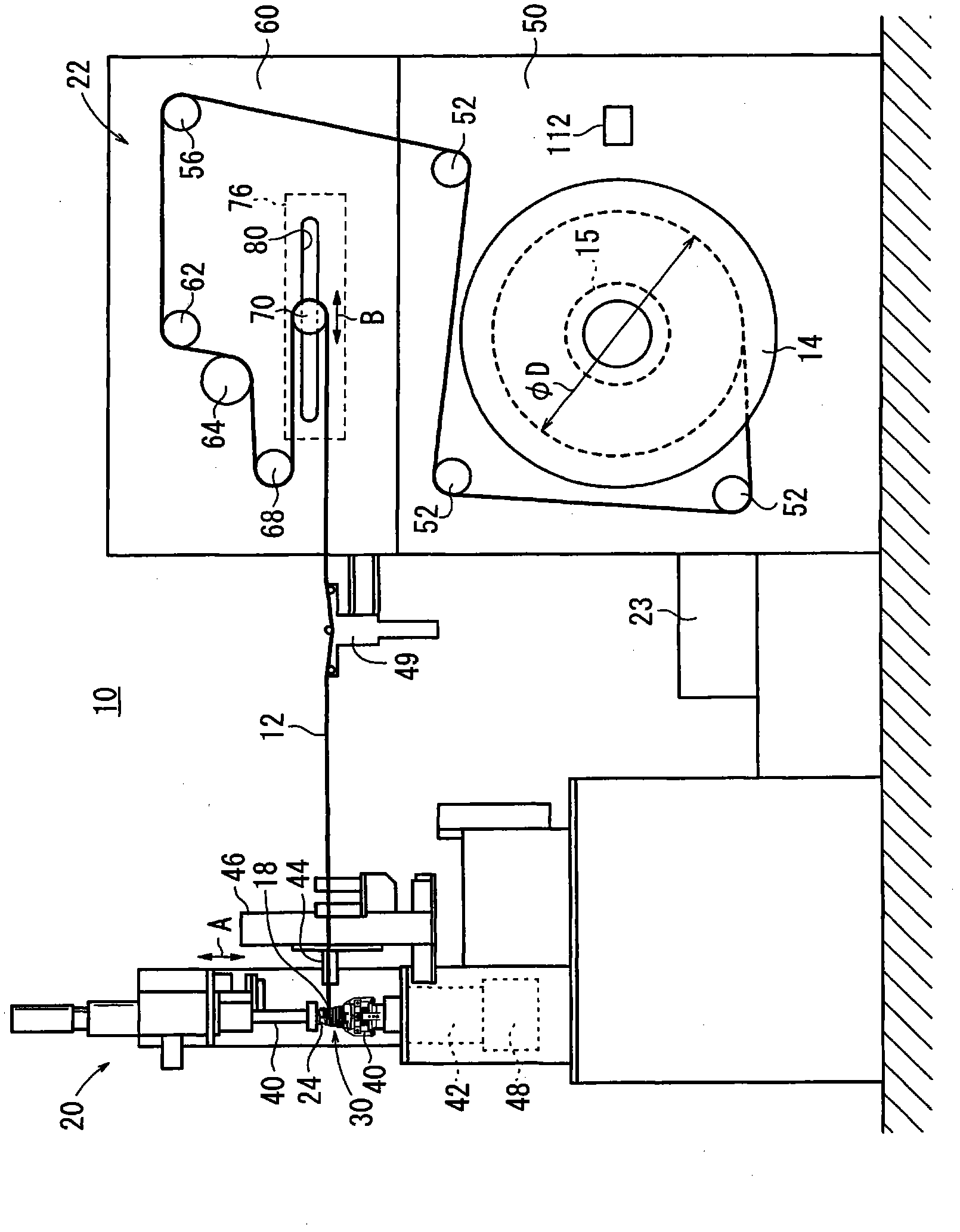

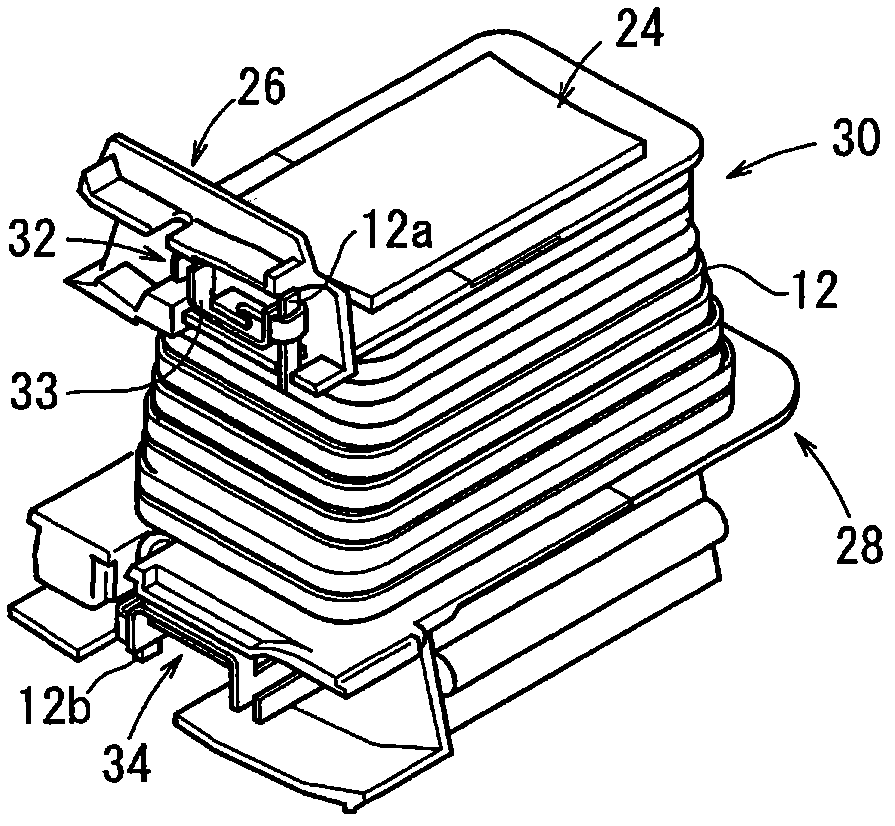

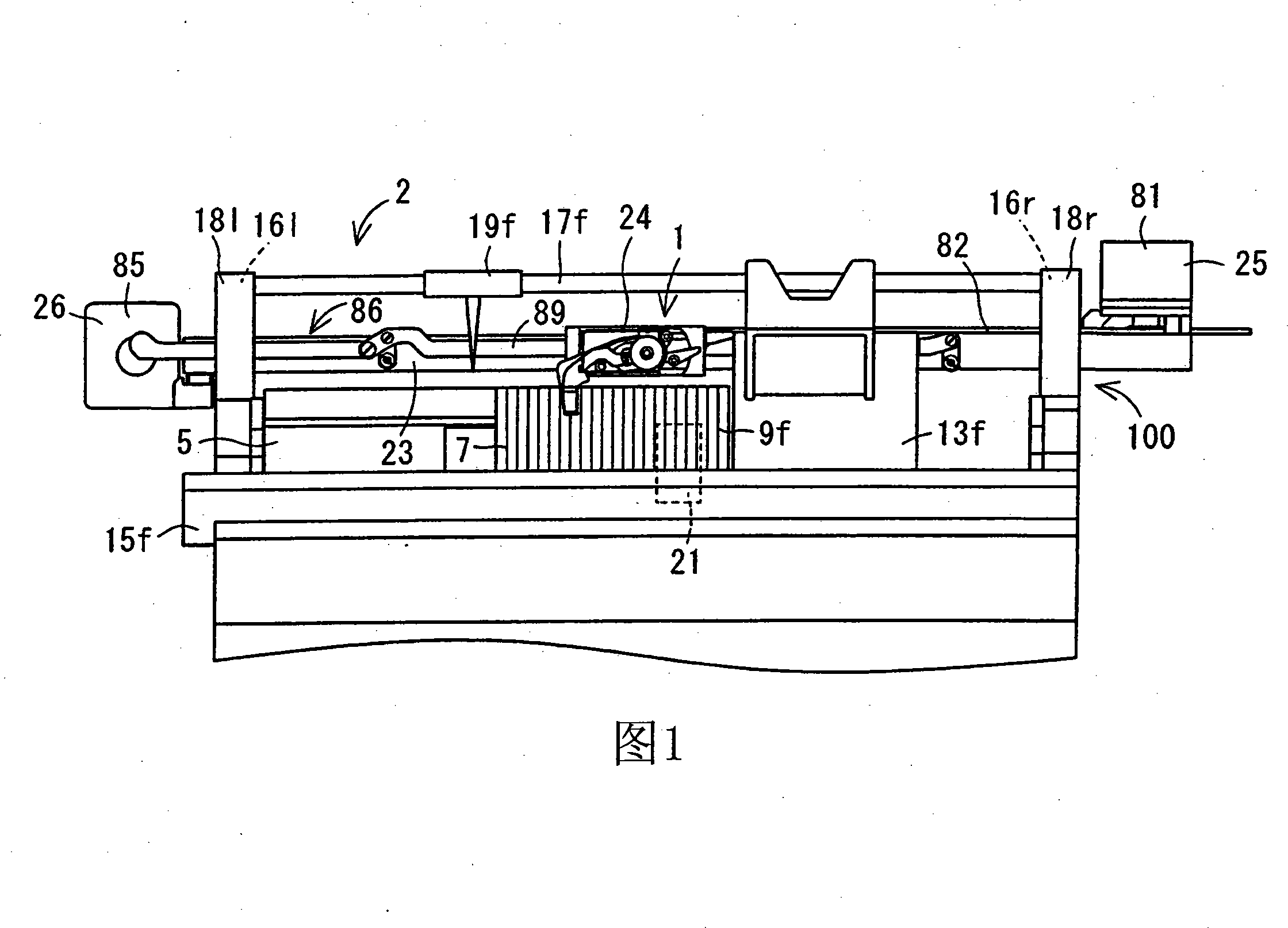

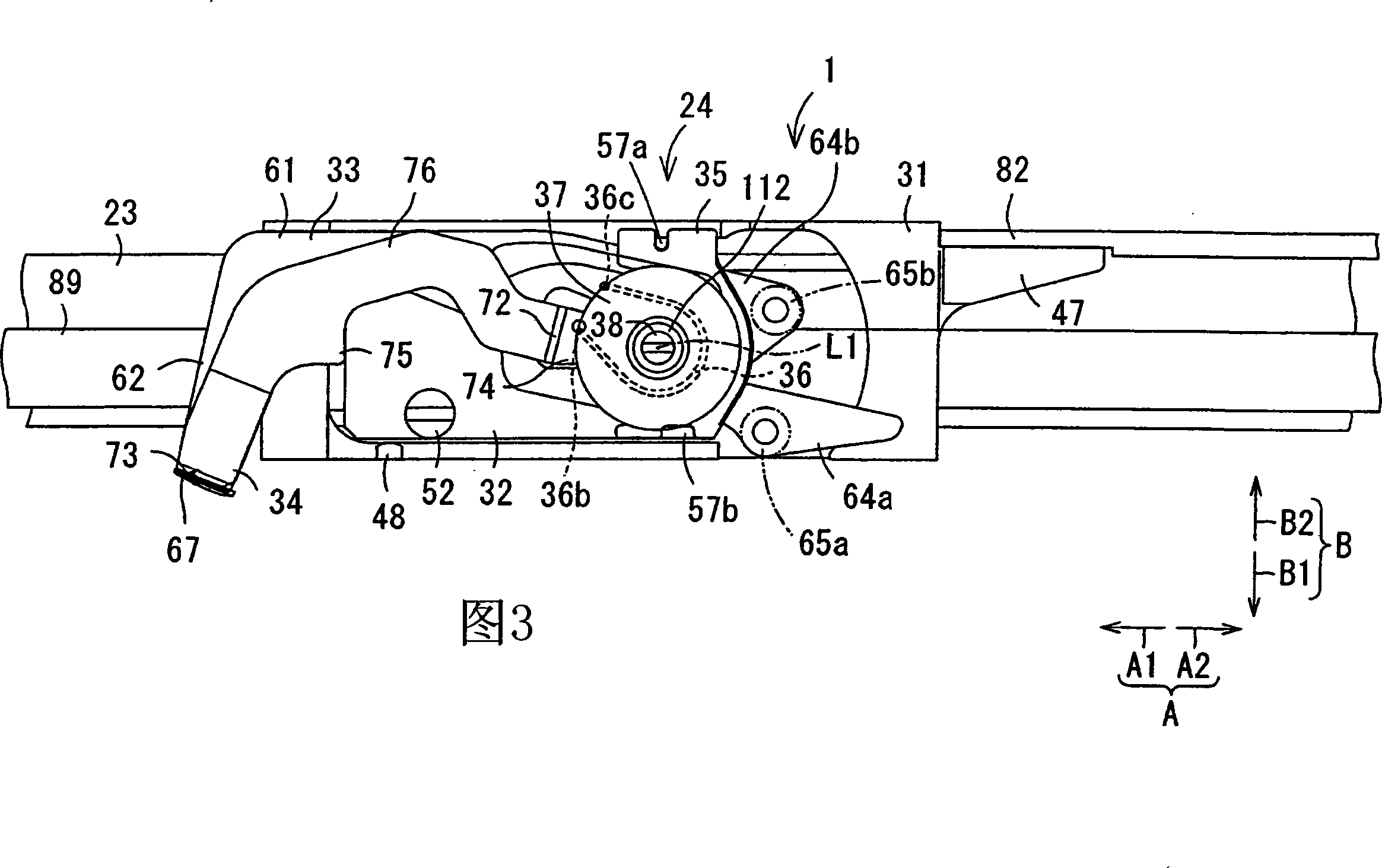

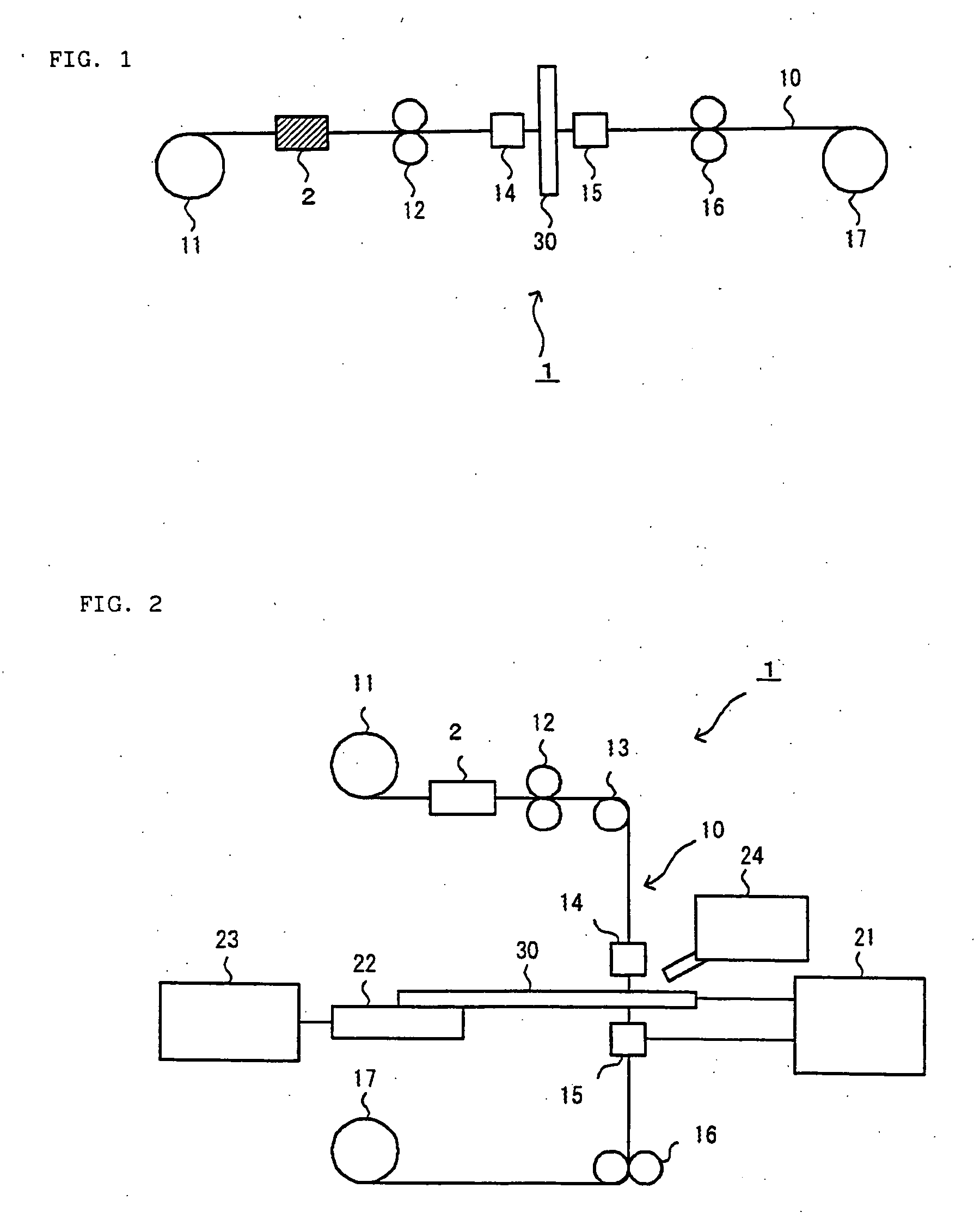

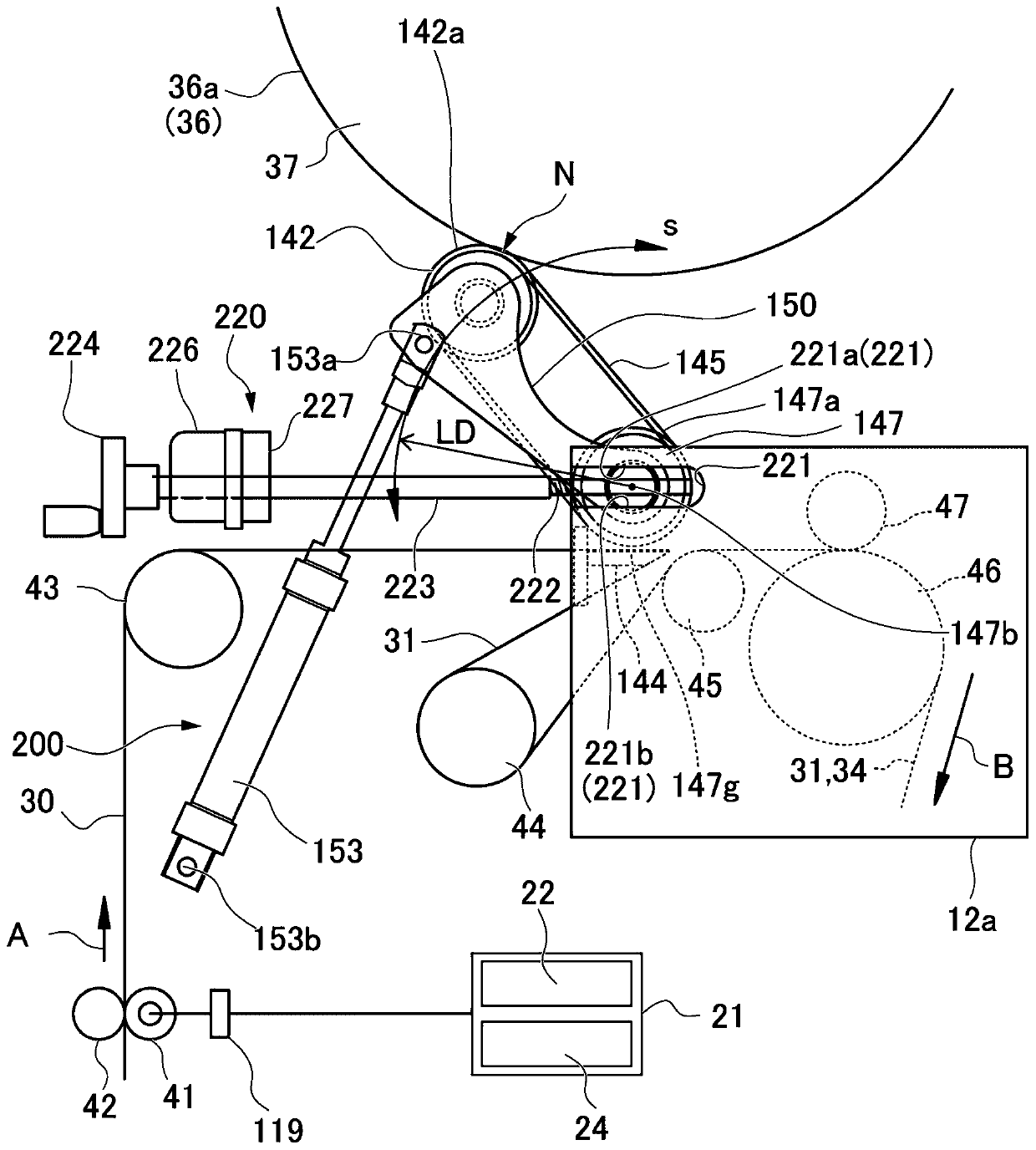

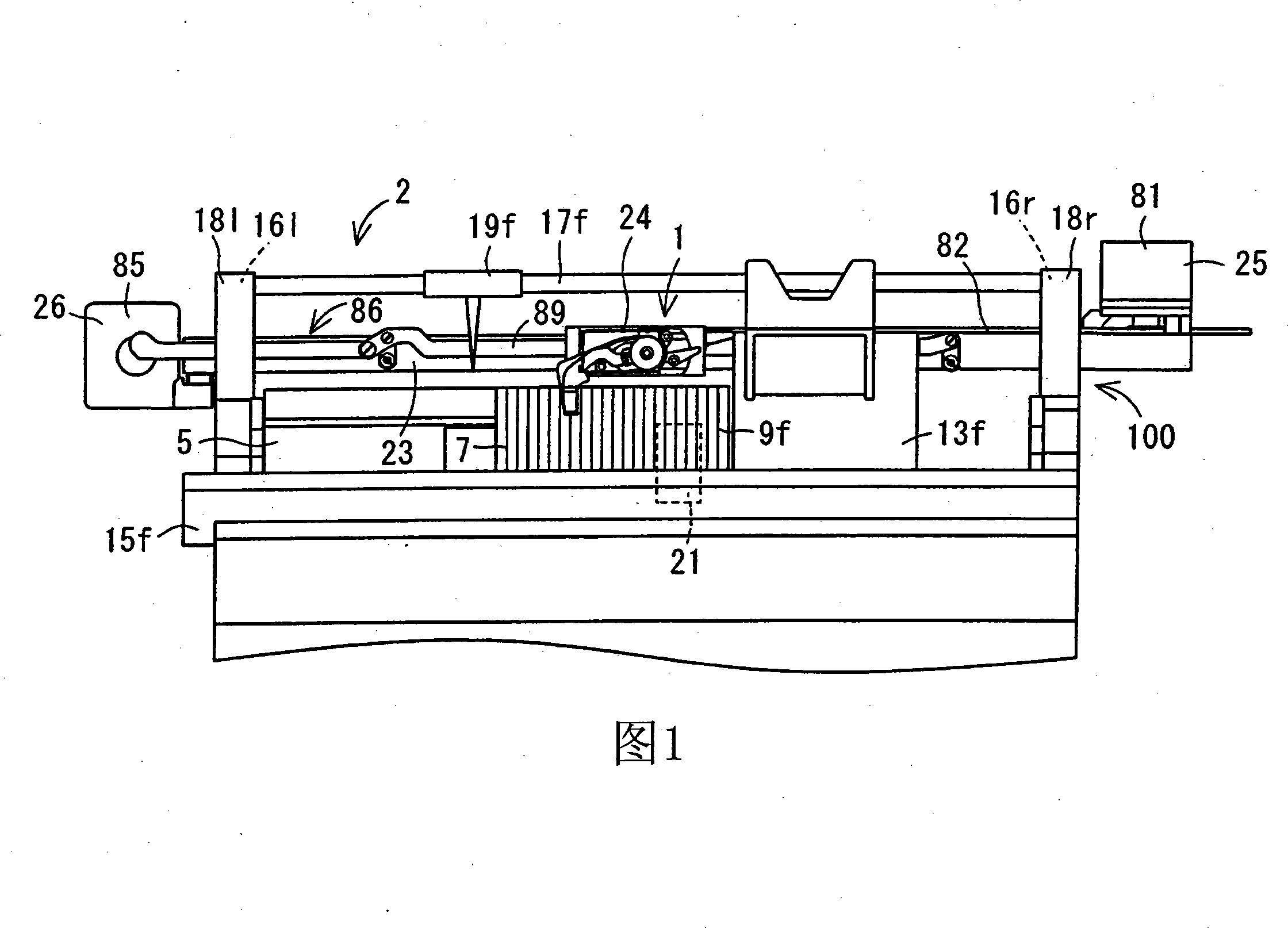

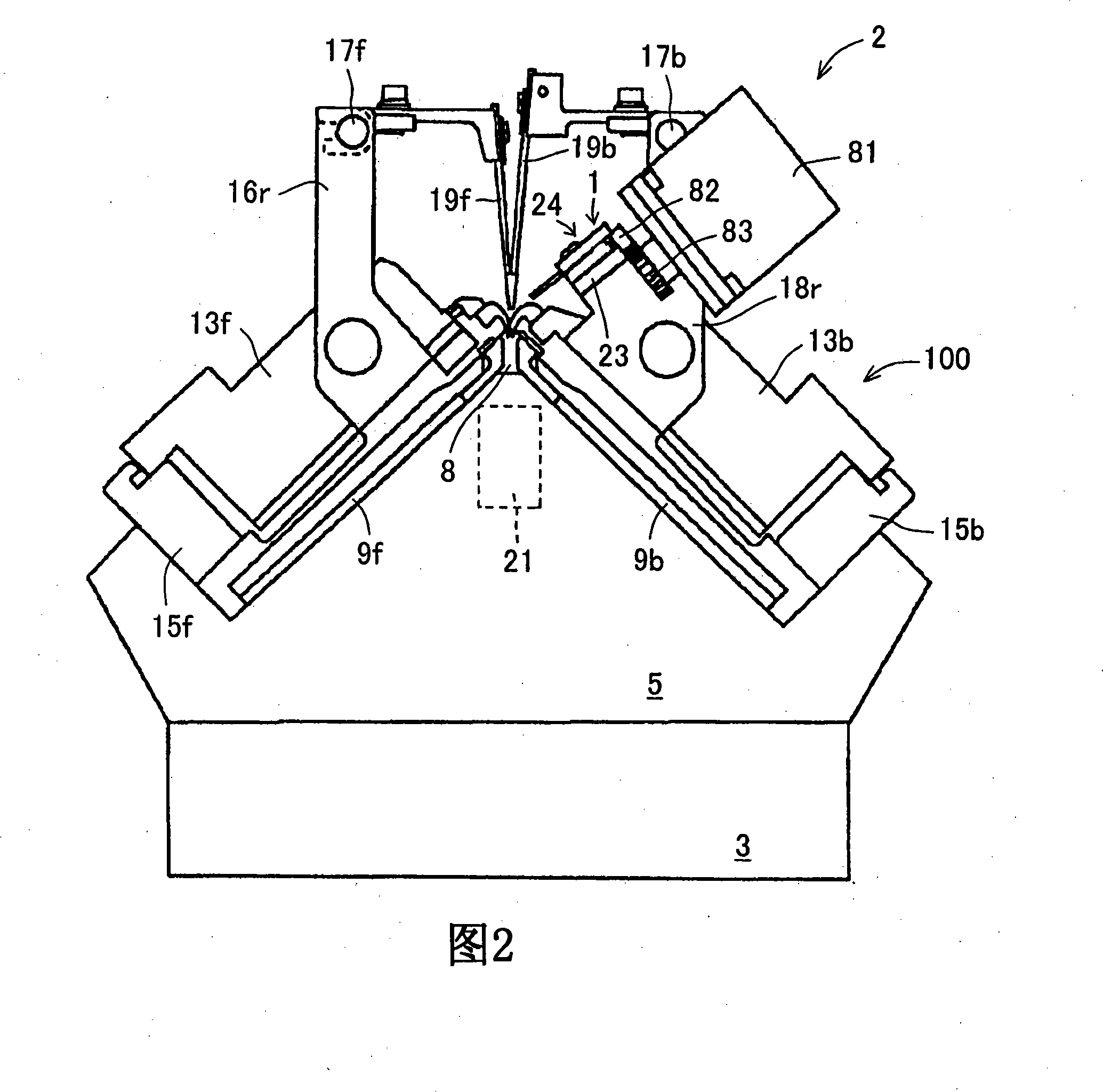

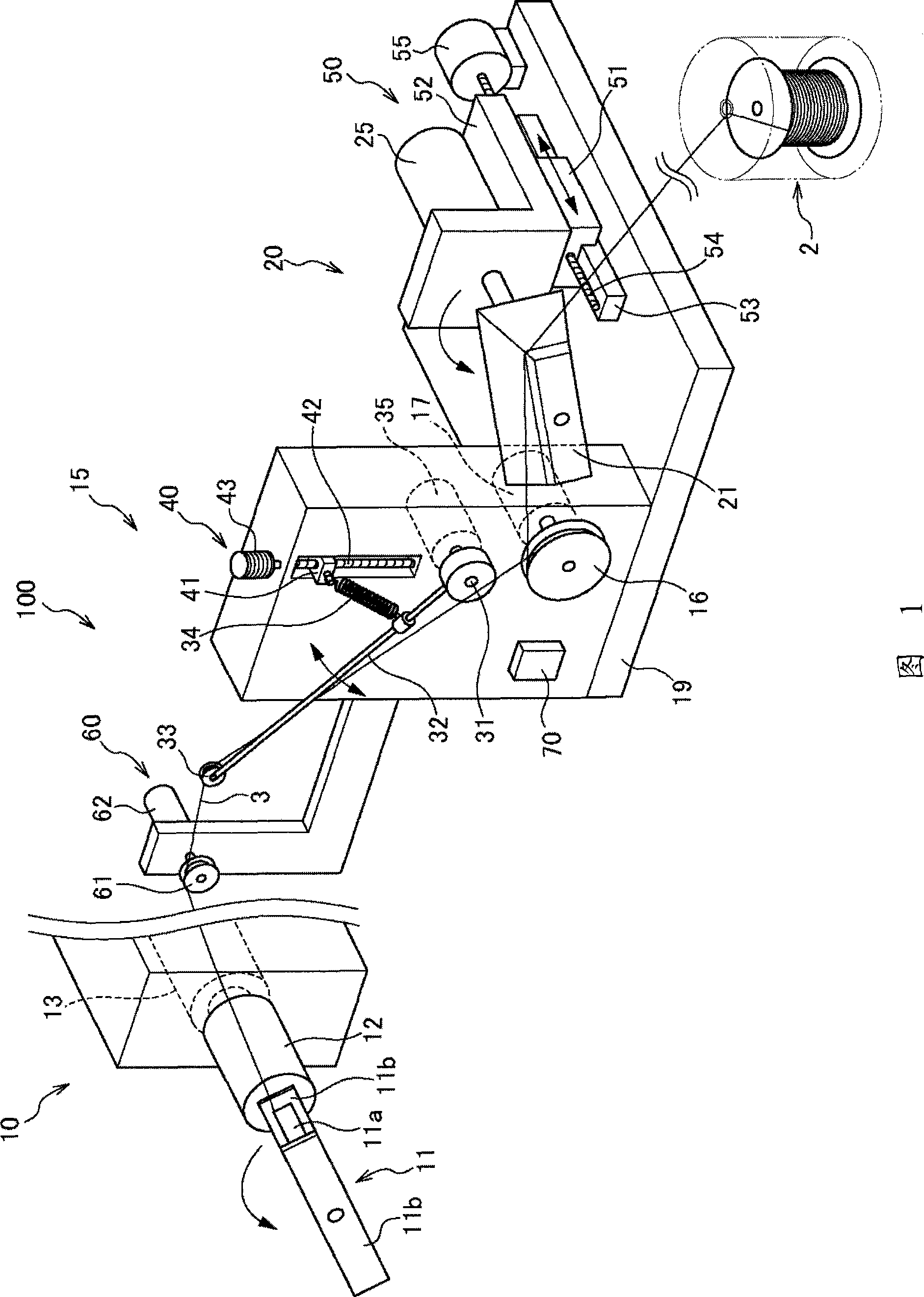

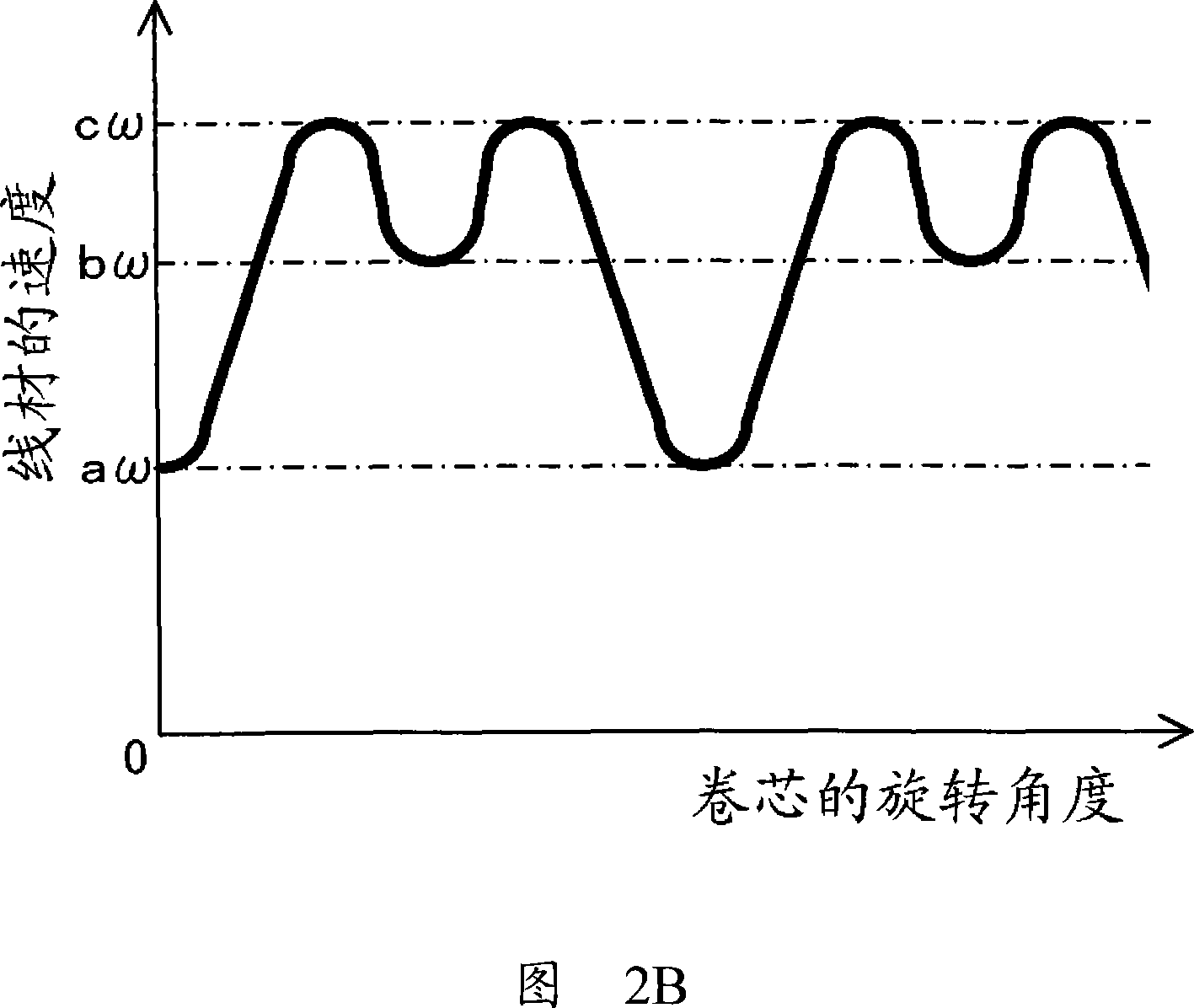

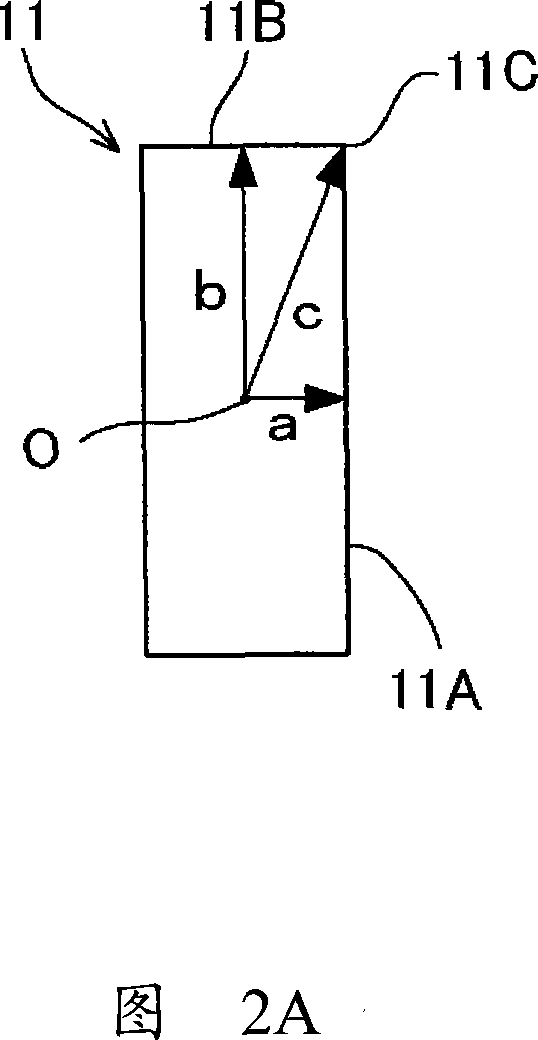

Wire winding system, tension device, and wire winding method

InactiveCN101454850AInhibits changes in tensionInhibition of tension changesFilament handlingCoils manufactureEngineeringConductor Coil

The invention provides a winding device, a tension device and a winding method. A winding device 100 which winds a wire 3 around a core 11 includes the core 11, which rotates axially and around which the wire 3 is wound; a roller 21 which rotates axially and feeds the wire 3, which is wound around the roller 21, to the core 11; and a tension device 15 which adjusts a tension of the wire 3 that is supplied to the core 11 from the roller 21. A winding shape and a winding diameter of the wire 3 wound around the roller 21 are substantially identical to a winding shape and a winding diameter of the wire 3 wound around the core 11.

Owner:NITTOKU ENG CO LTD

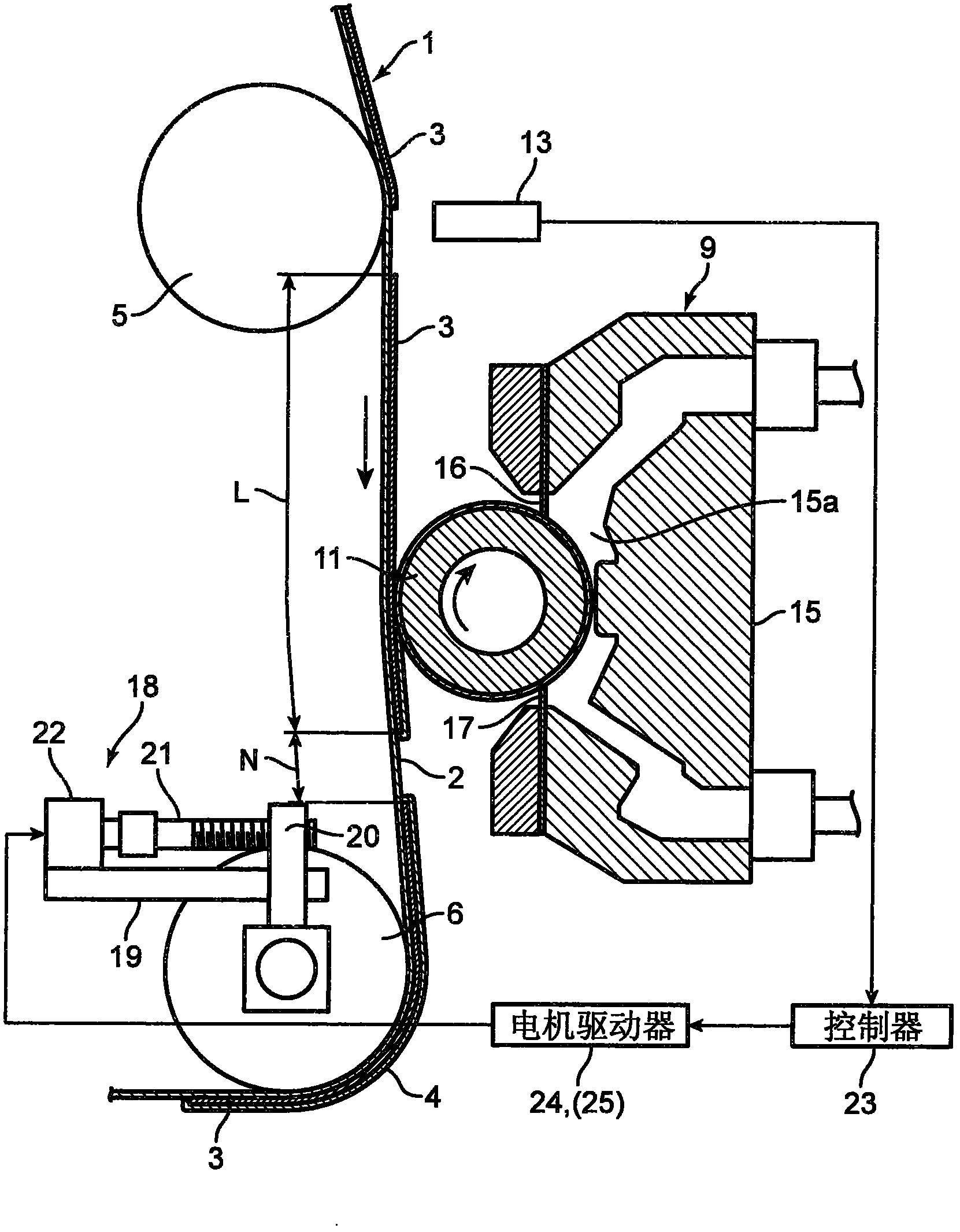

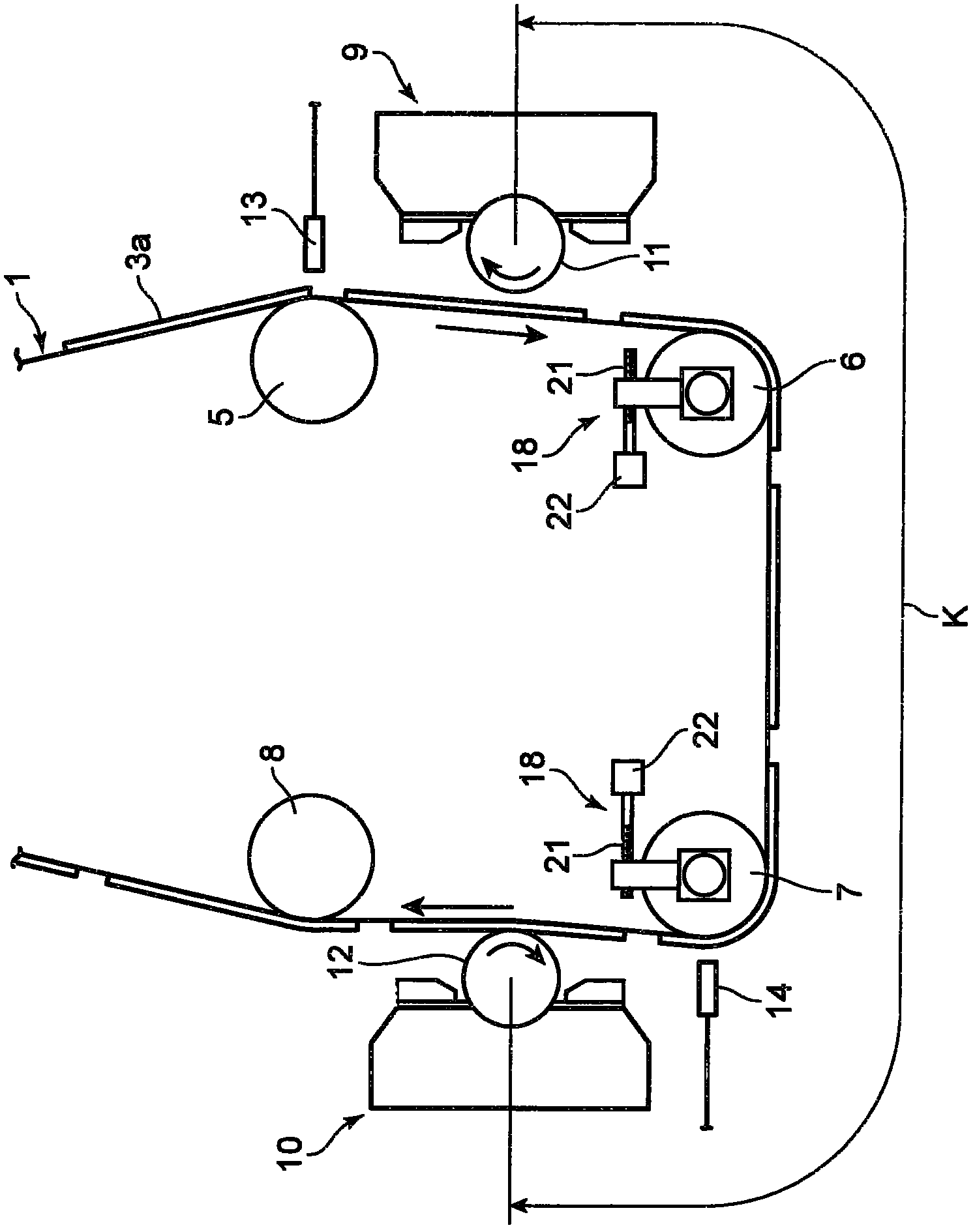

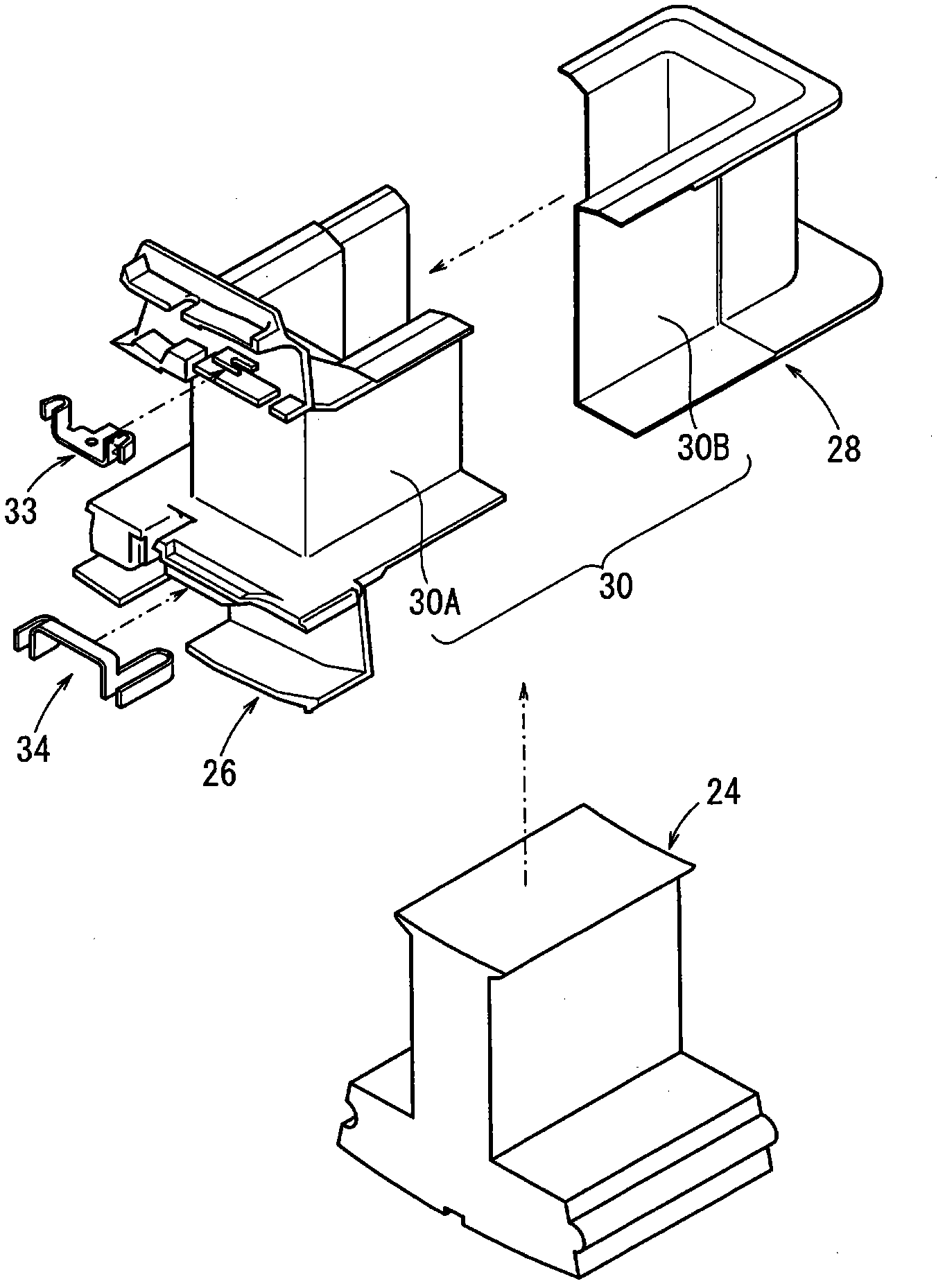

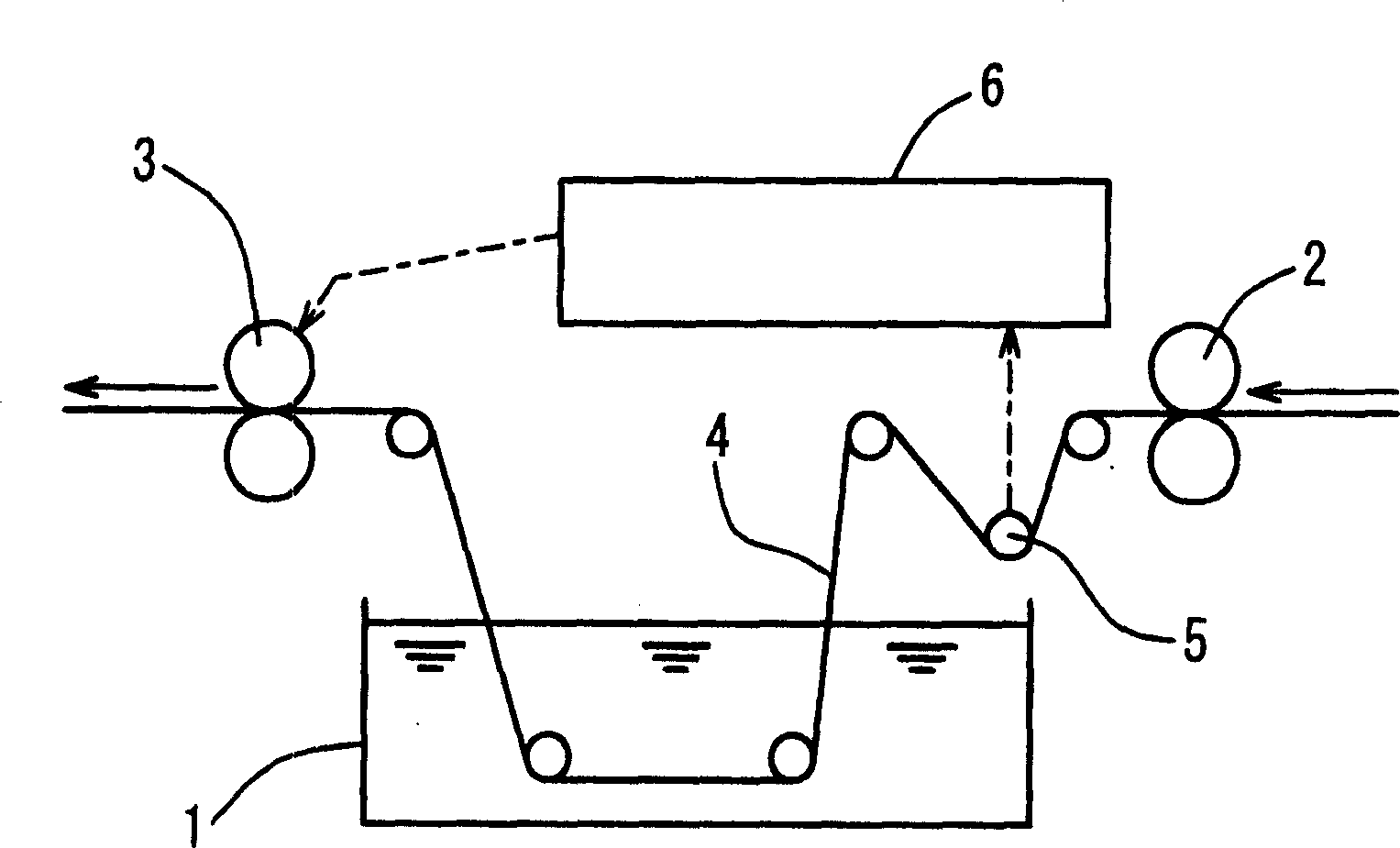

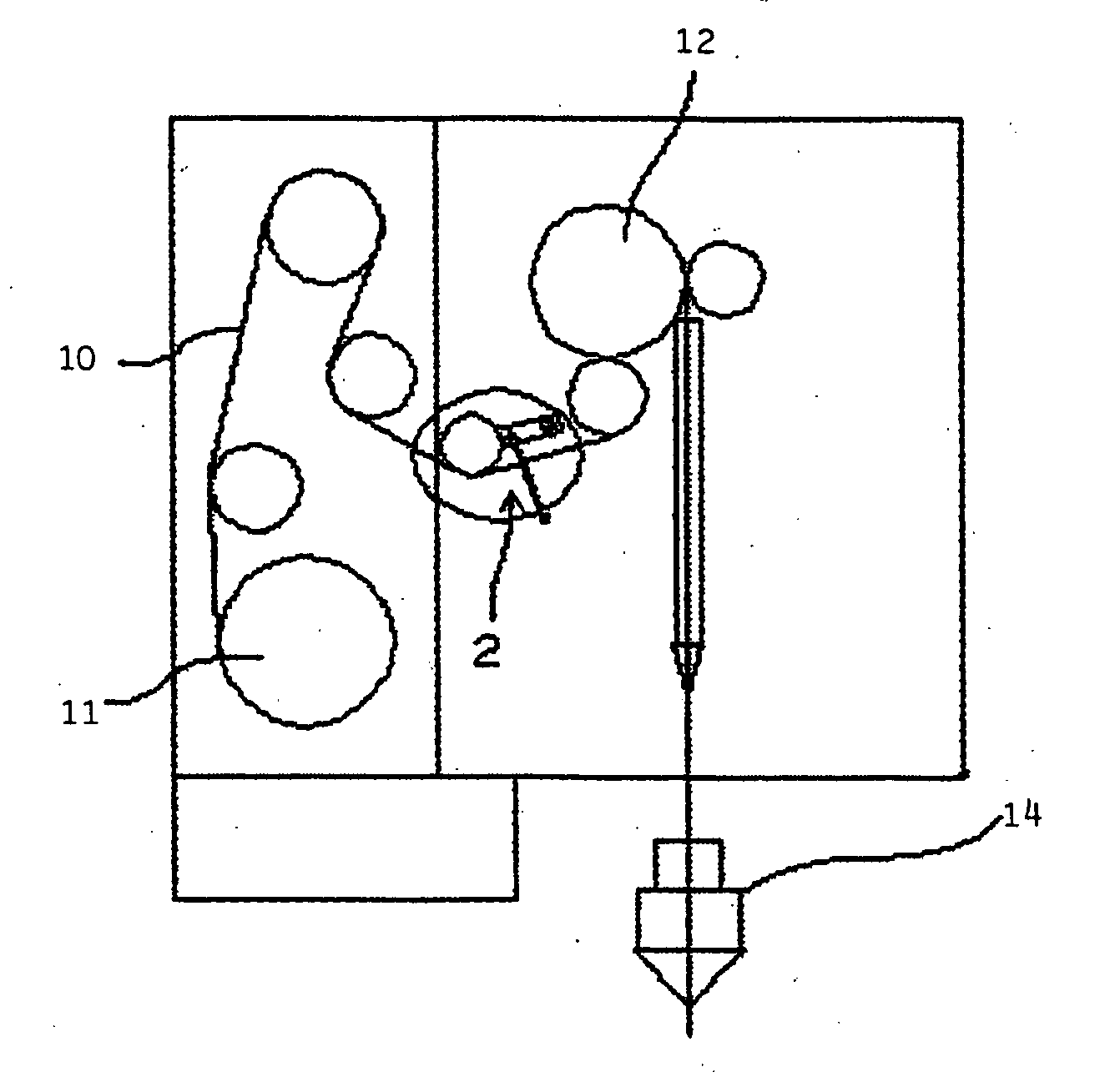

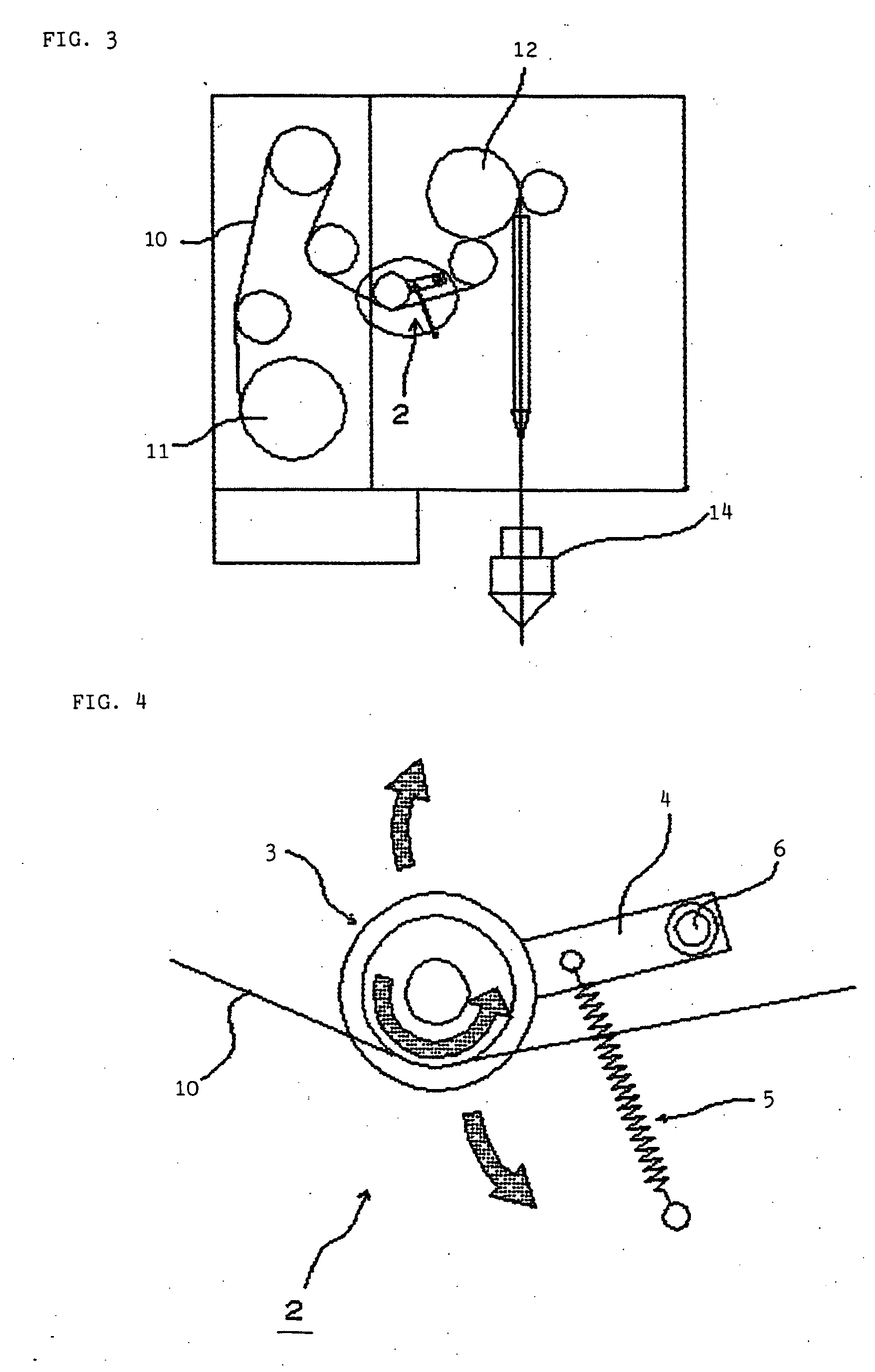

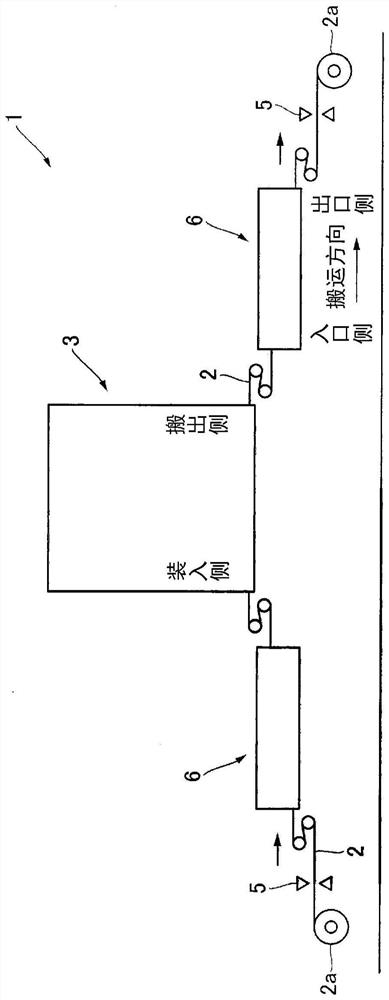

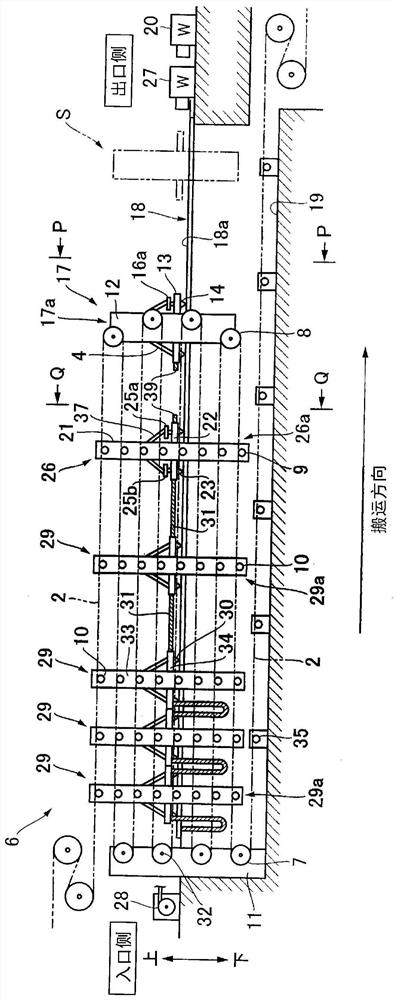

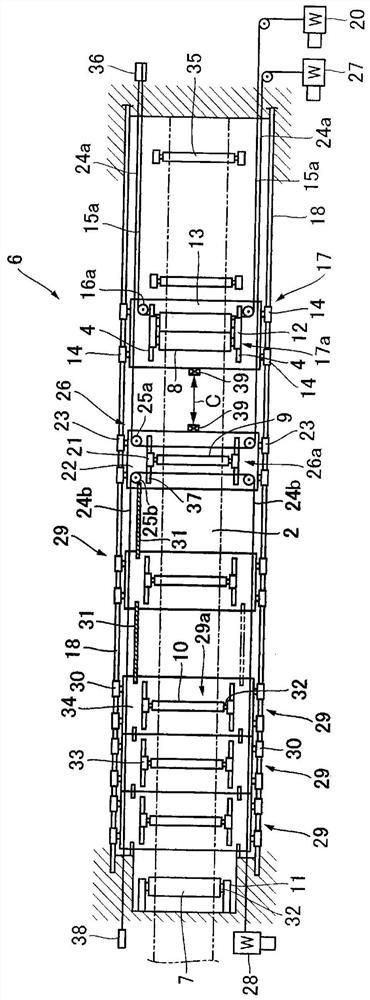

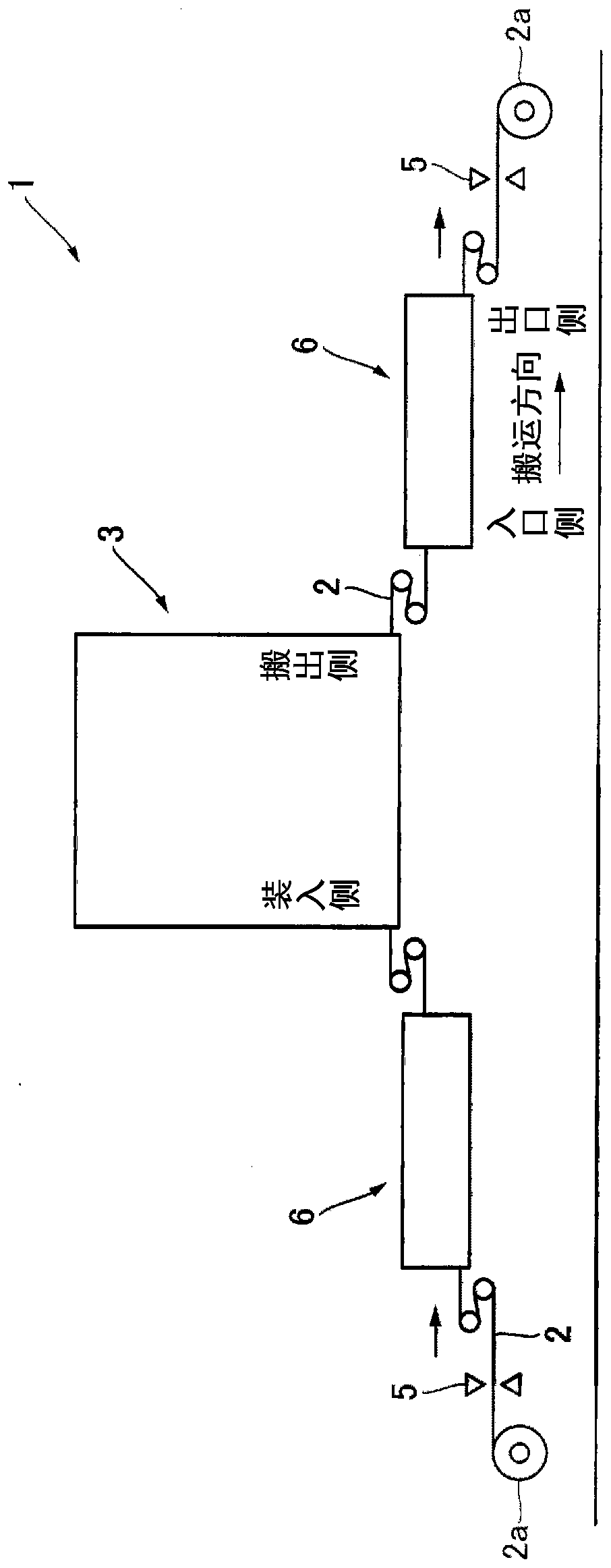

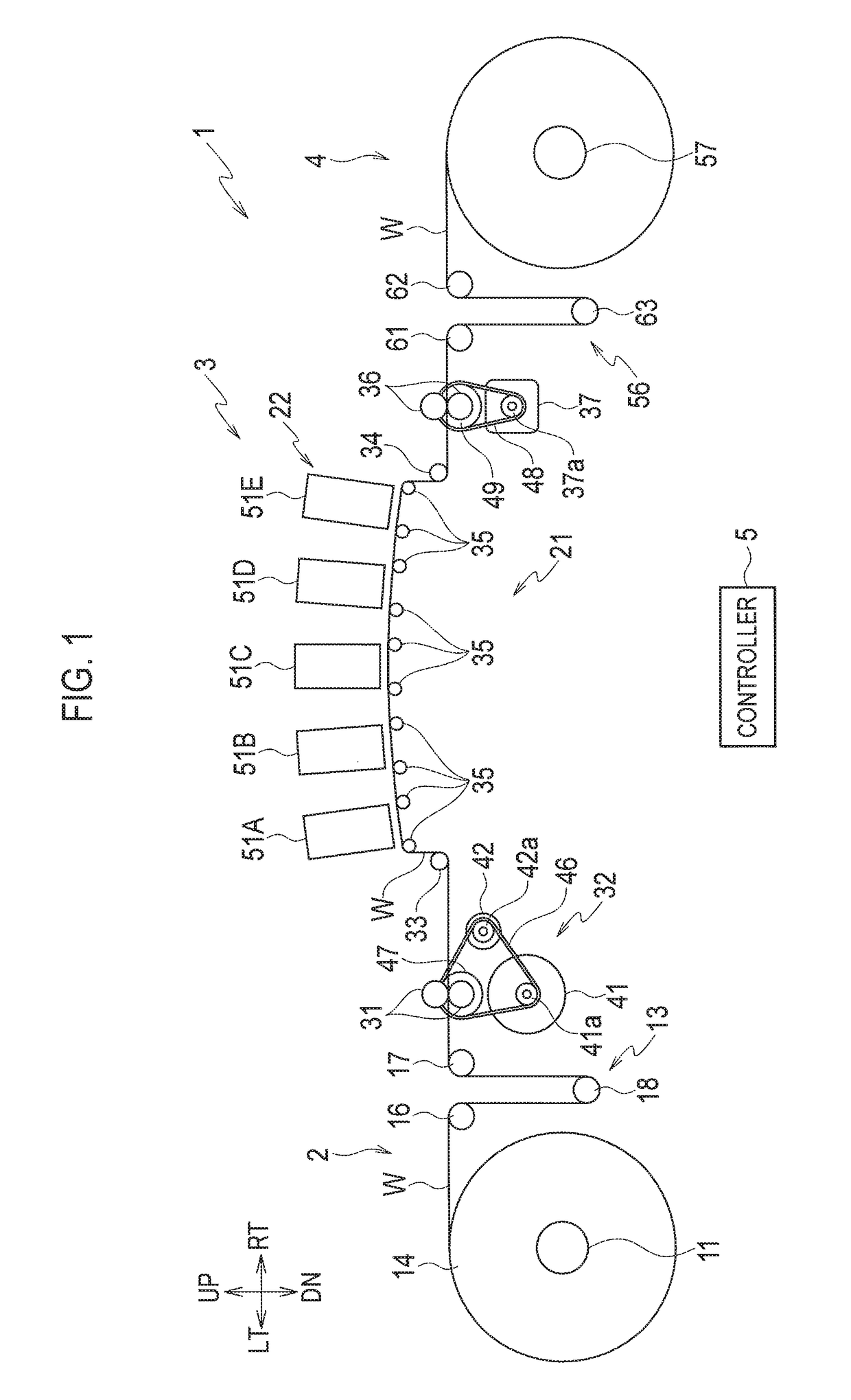

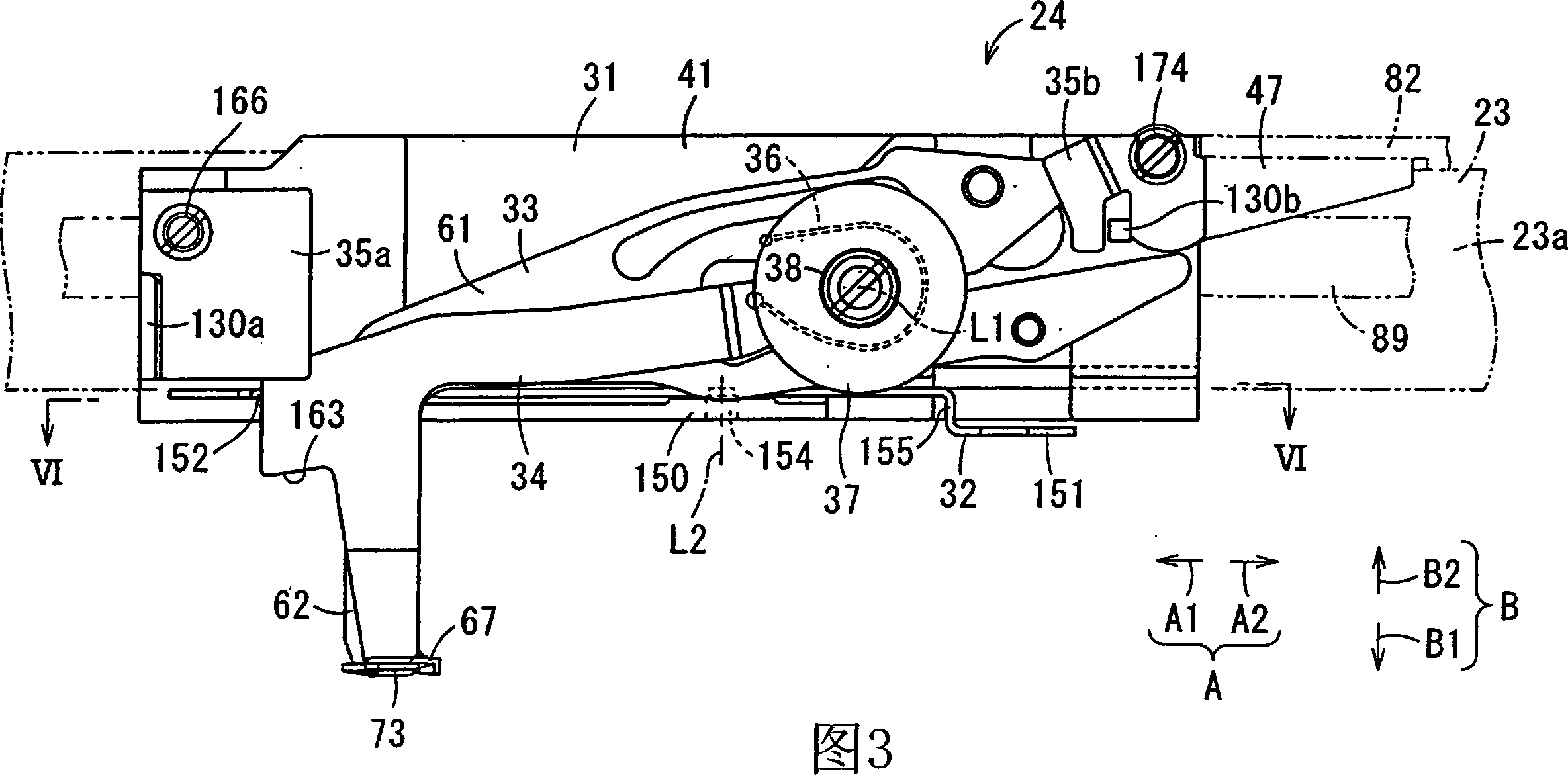

Intermittent coating apparatus

InactiveCN102580886AAvoid tension changesInhibition of tension changesLiquid surface applicatorsElectrode manufacturing processesEngineeringMechanical engineering

The invention provides an intermittent coating apparatus, wherein a substrate (1) to be conveyed in a conveying path is intermittently contacts coating rollers (11, 12). The intermittent coating apparatus comprises guide rollers (6, 7) arranged close to a plurality of coating rollers (11, 12) along the conveying path of the substrate (1) for limiting the movement direction of the substrate (1); a driving mechanism (18) for individually driving each of the guide rollers (6, 7). Therefore, the substrate (1) contacts or gets away from the coating rollers (11, 12), so that the coating agent is uniformly and respectively coated onto different regions of the substrate (1).

Owner:FUJI KIKAI IND

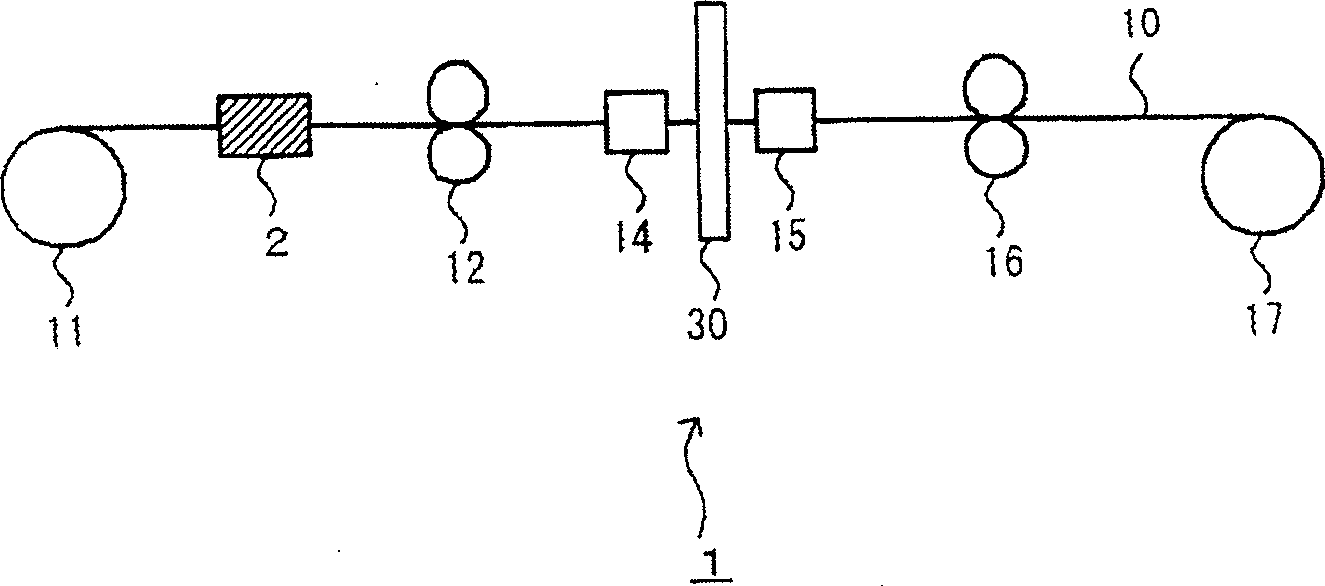

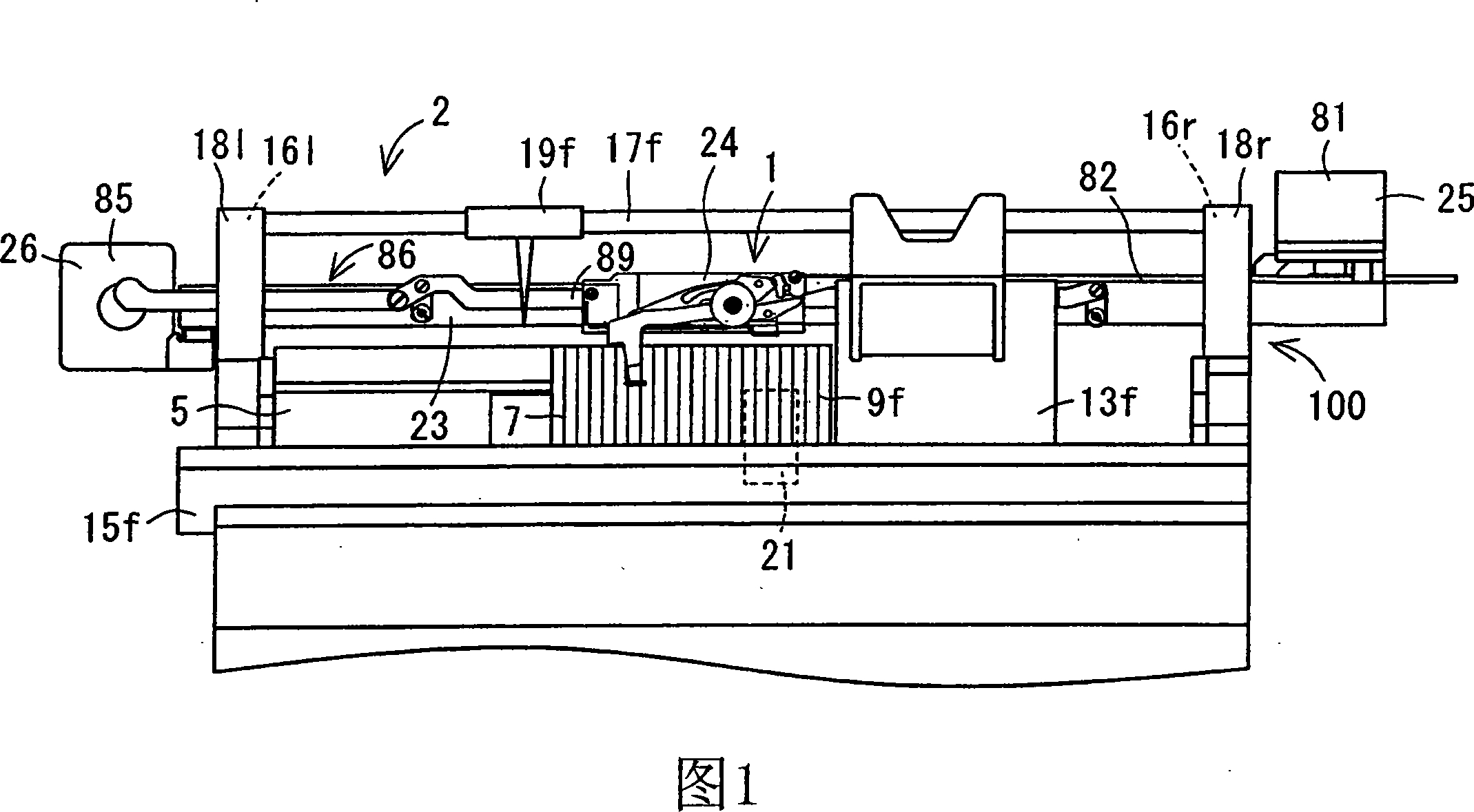

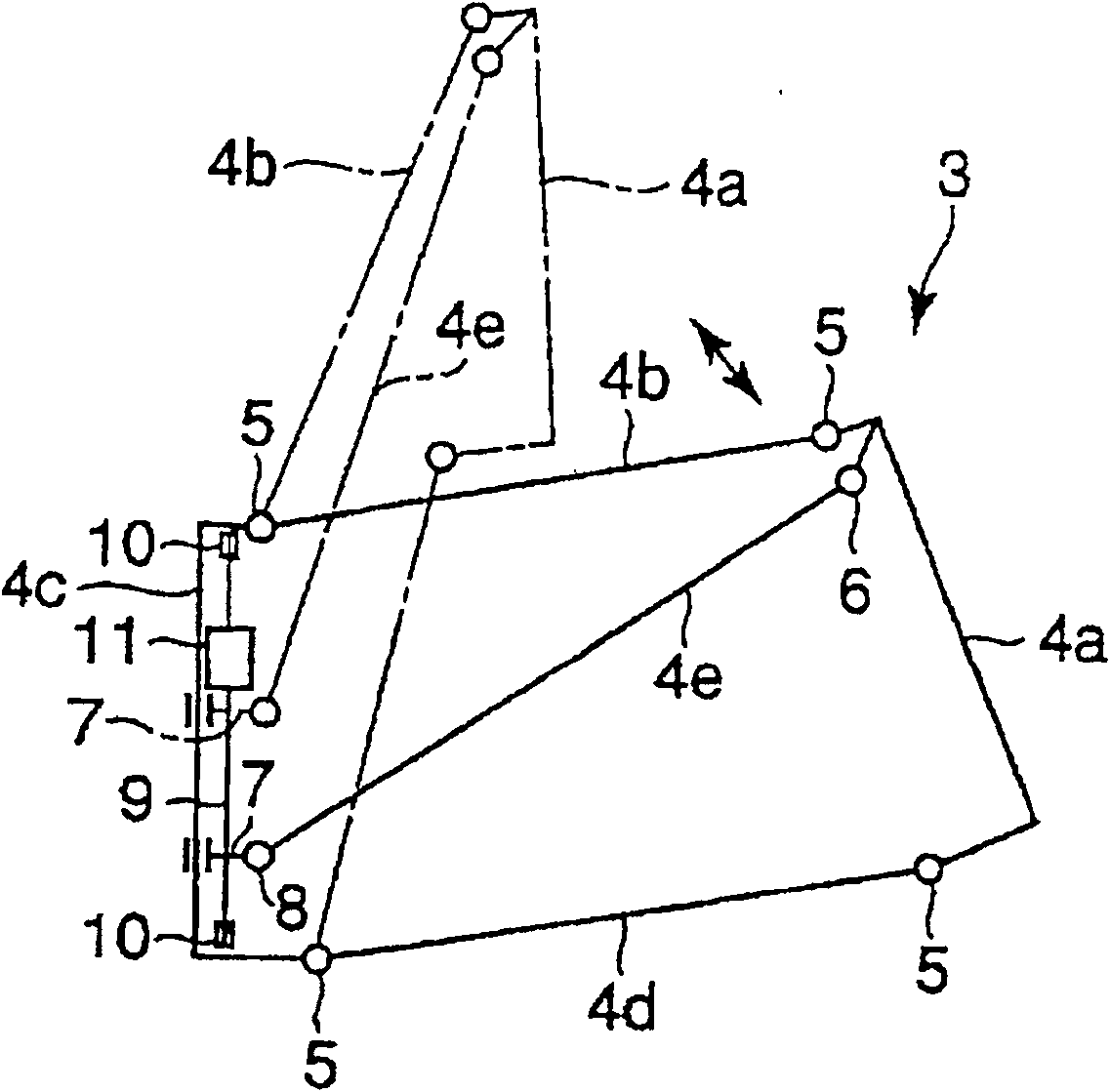

Wire winding device

InactiveCN102067255AControl tension changesEliminate cumulative winding errorsWindingsFilament handlingBobbinLarge capacity

A wire winding device (10) uses a large-sized supply bobbin (14), which has a large capacity and a large diameter, to highly precisely suppress a variation in tension which variation occurs when a coil (18) is formed by winding a wire material (12) at high speed with the wire material aligned with a winding frame (30). Rotation (the number of rotation, and timing) of the supply bobbin (14) relative to rotation of the coil (18) is controlled based on the difference between the amount of take-up of the wire material (12) taken up on the winding frame (30) side and the amount of pay-out of the wire material (12) paid out from the supply bobbin (14), and the control is performed such that the amount of the take-up and the amount of the pay-out agree with each other every moment. This can highly precisely suppress a variation in tension even if there are large differences between inertia of and the diameters of the coil (18) and the supply bobbin (14).

Owner:HONDA MOTOR CO LTD

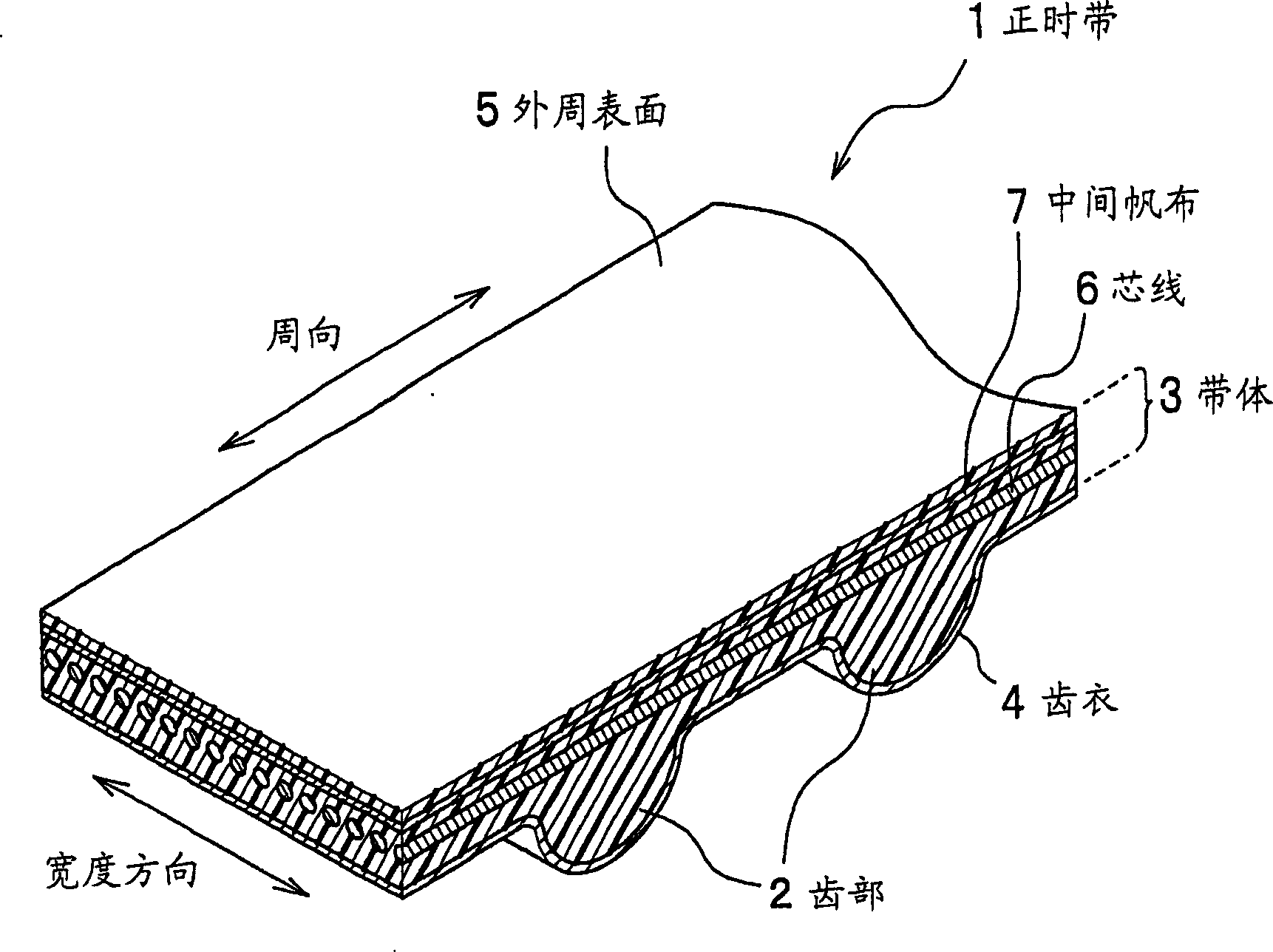

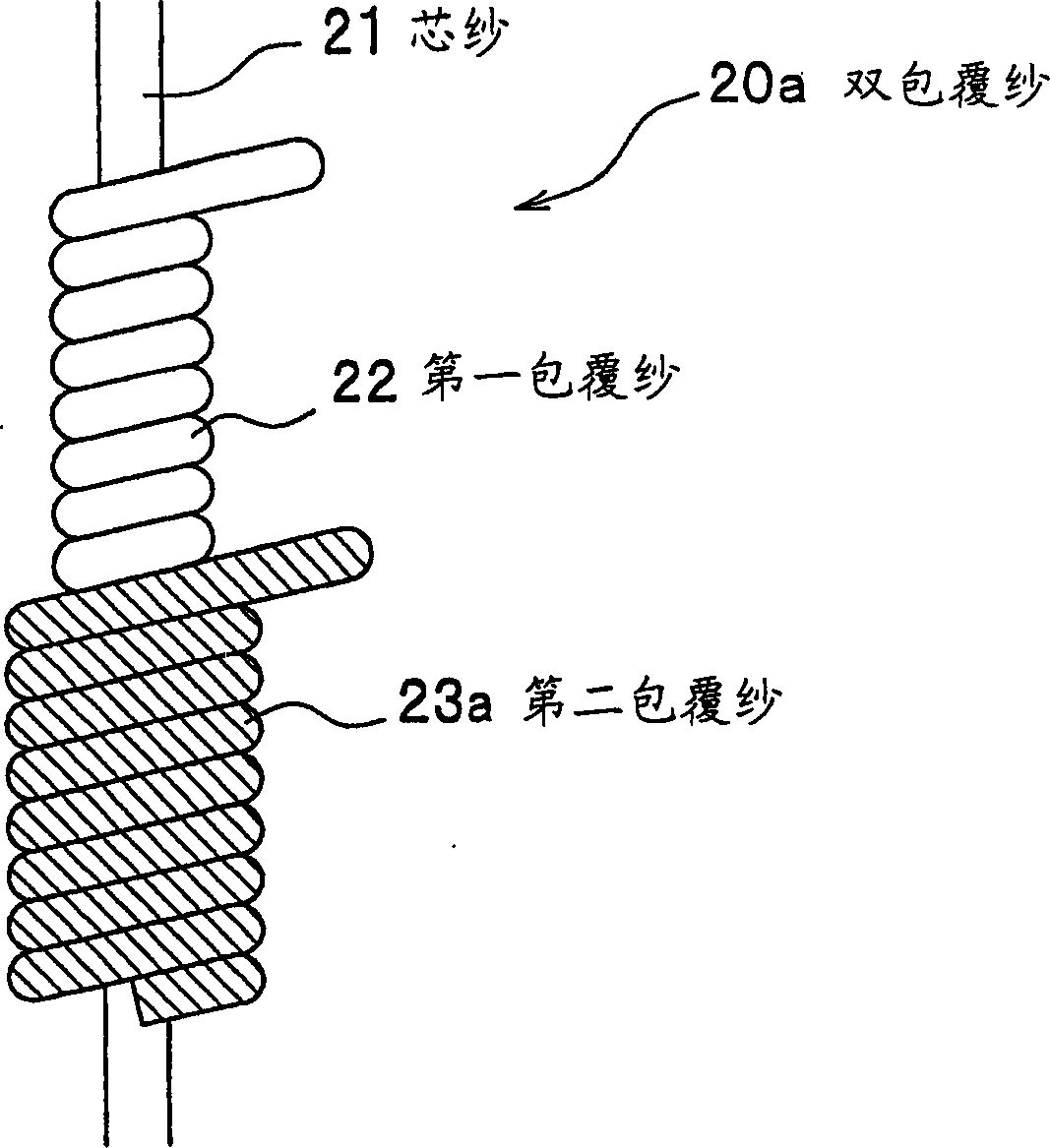

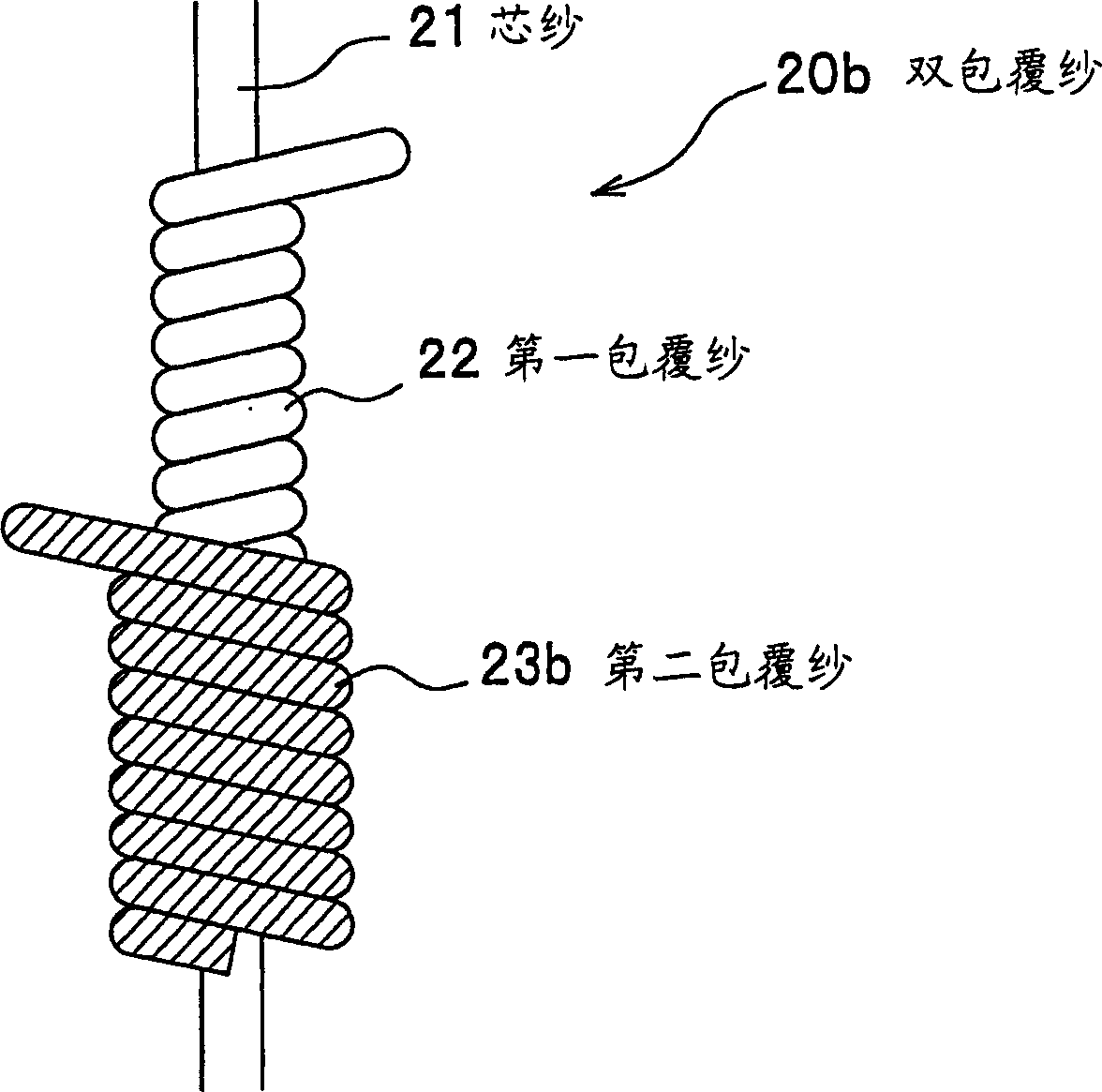

Timing belt

InactiveCN1776249AInhibition of tension changesSuppress noiseDriving beltsEngineeringMechanical engineering

The object of the present invention is to provide a timing belt capable of reinforcing the tensile rigidity of the belt, preventing local deflection of the core wire due to polygonal engagement by adjusting the flexibility on the outer peripheral side of the pitch wire, and improving the timing belt. resistance to flex fatigue. The timing belt (1) includes: an endless belt body (3); a plurality of teeth (2) formed at predetermined intervals along the inner peripheral surface of the belt body (3); The core wire (6); and the intermediate canvas (7) arranged on the outer peripheral side of the core wire (6) in the belt body (3), wherein the intermediate canvas (7) has stretchability along the circumferential direction.

Owner:HONDA MOTOR CO LTD

End-yarn insertion device

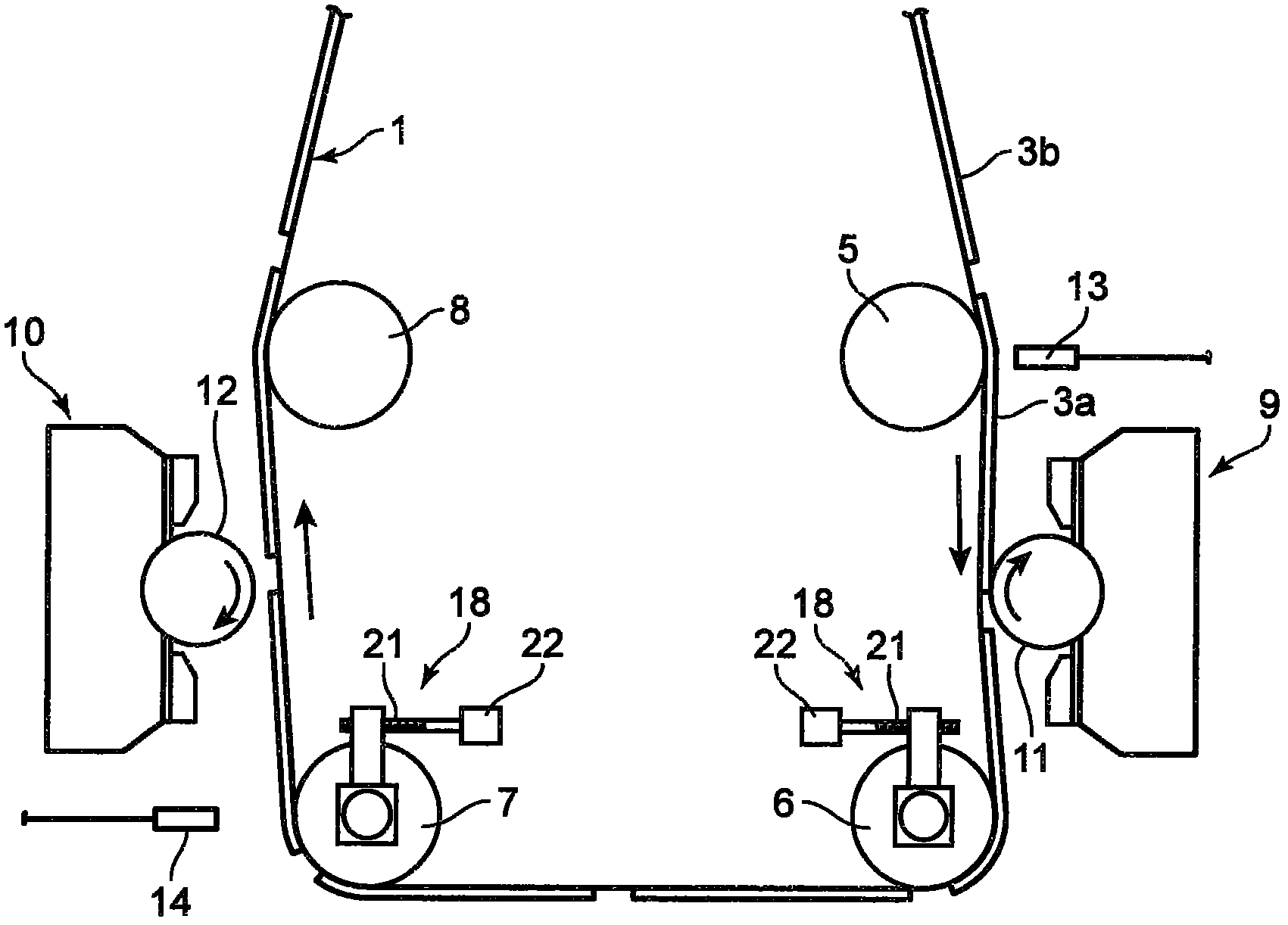

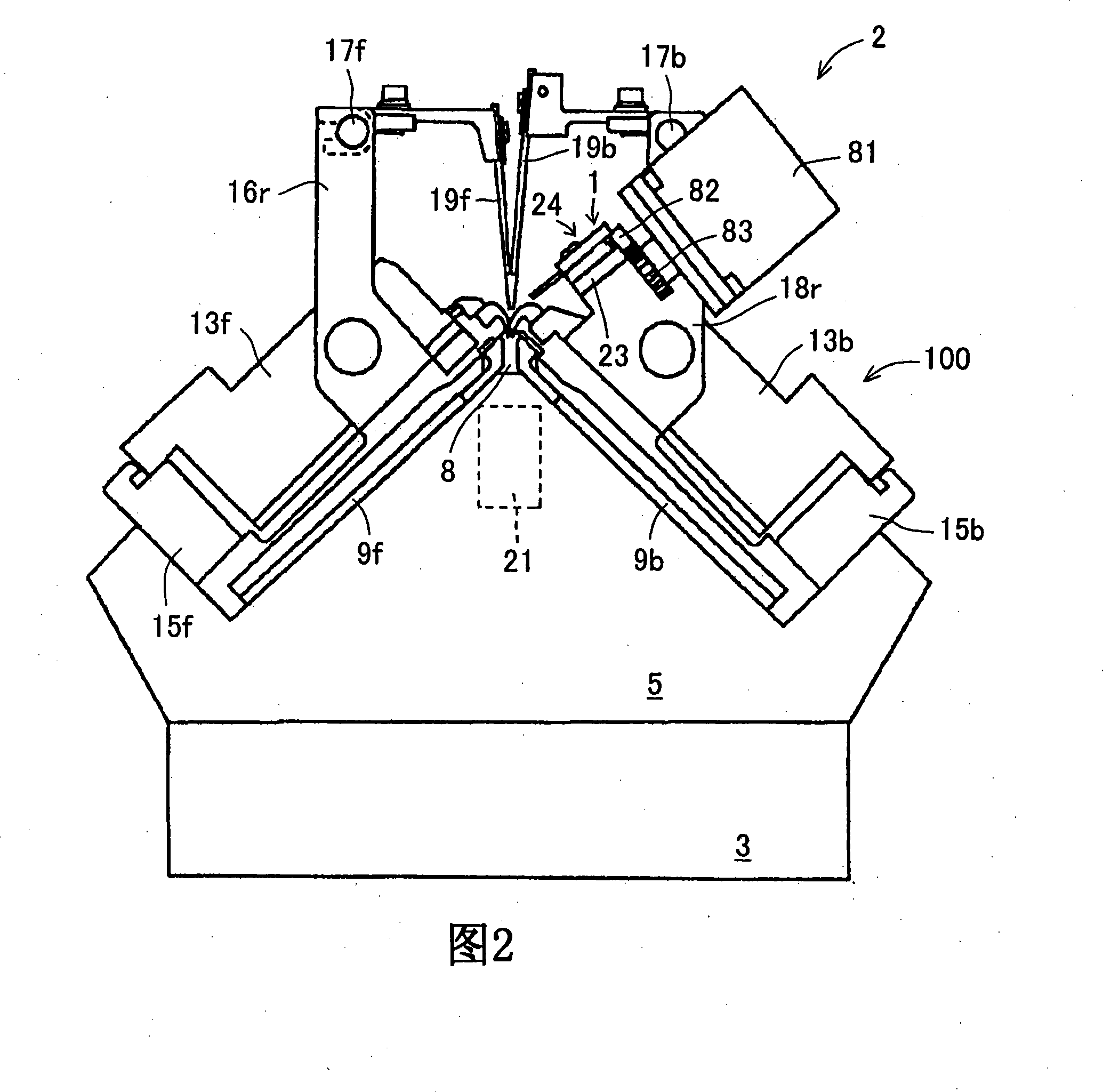

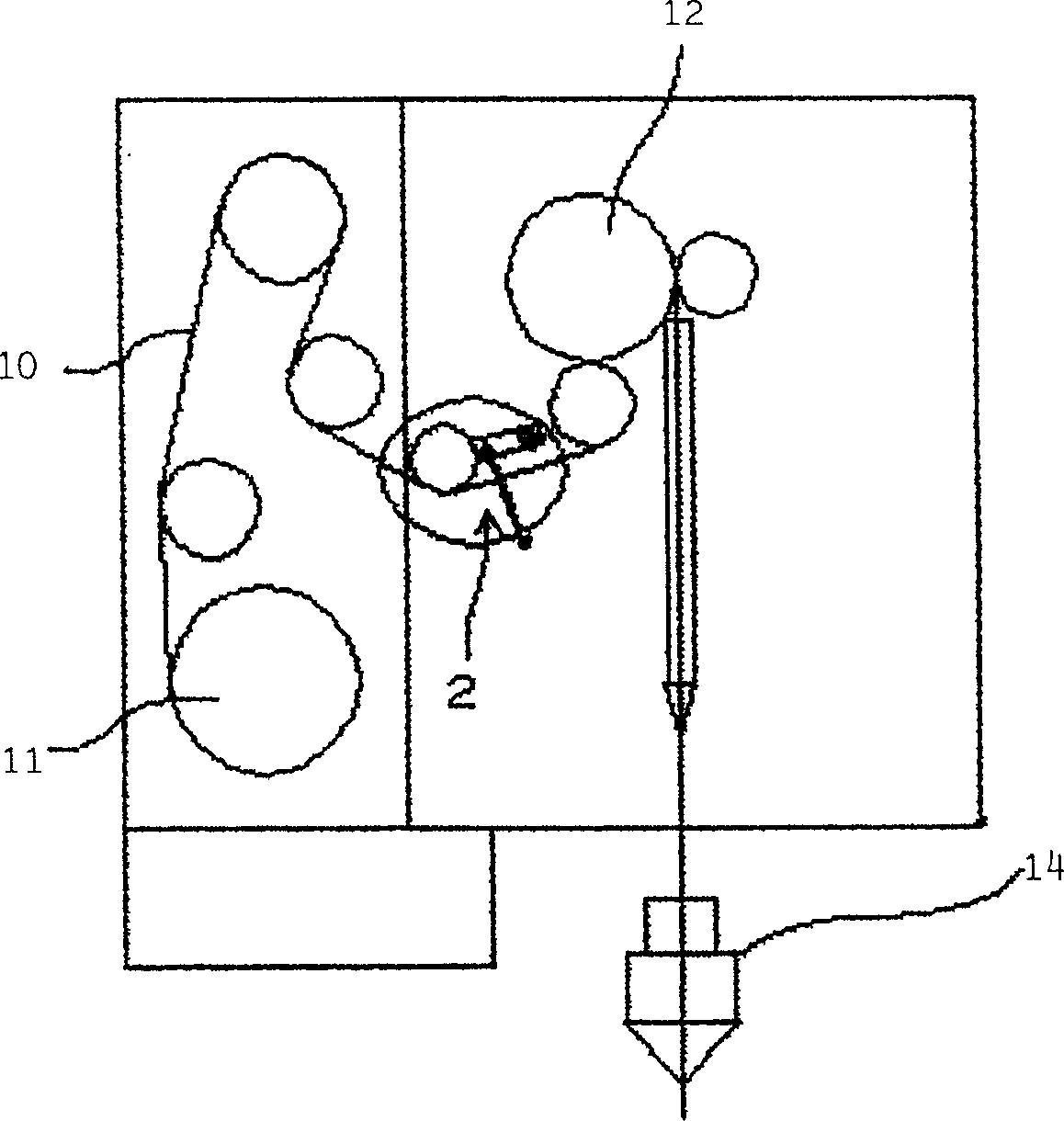

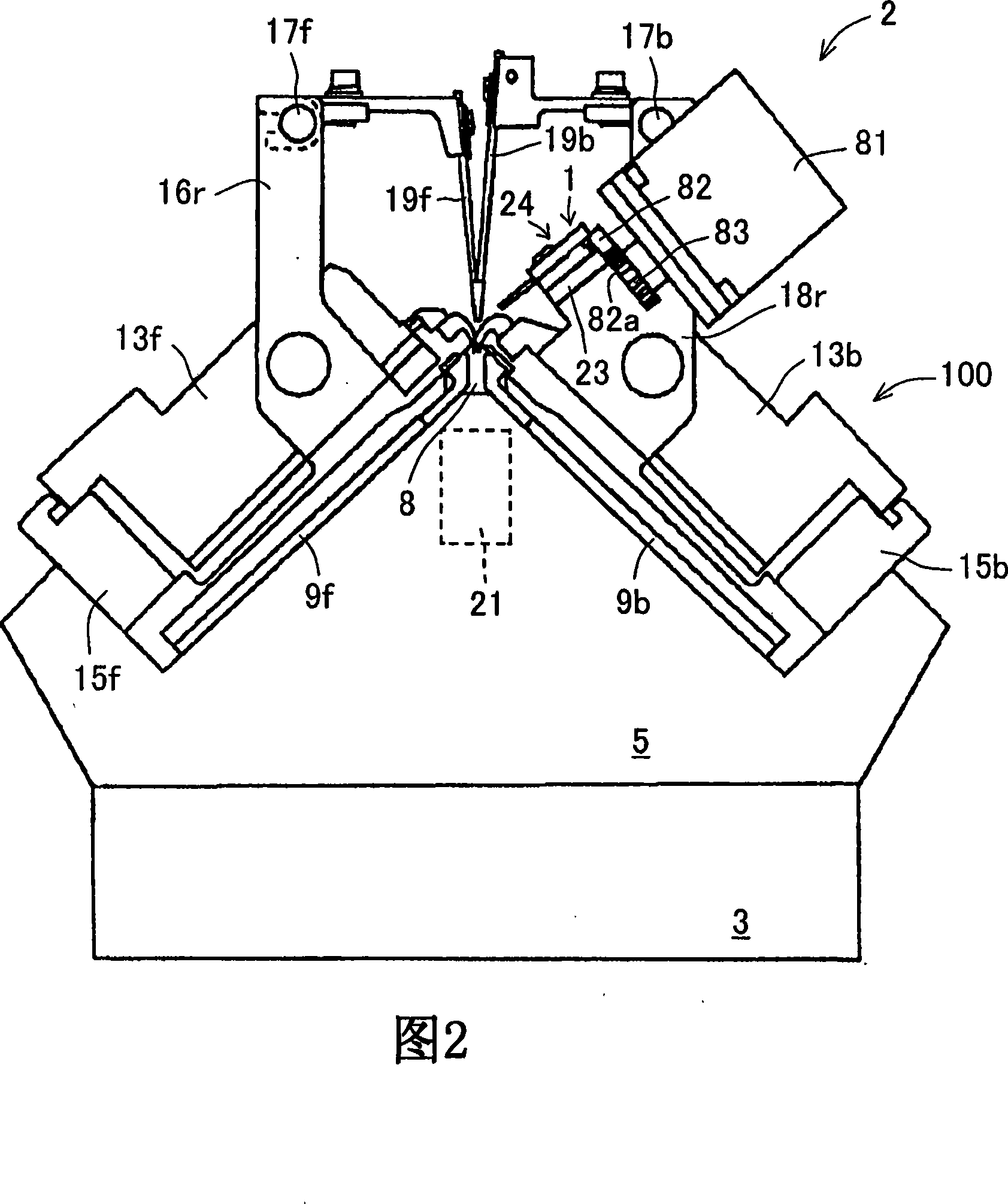

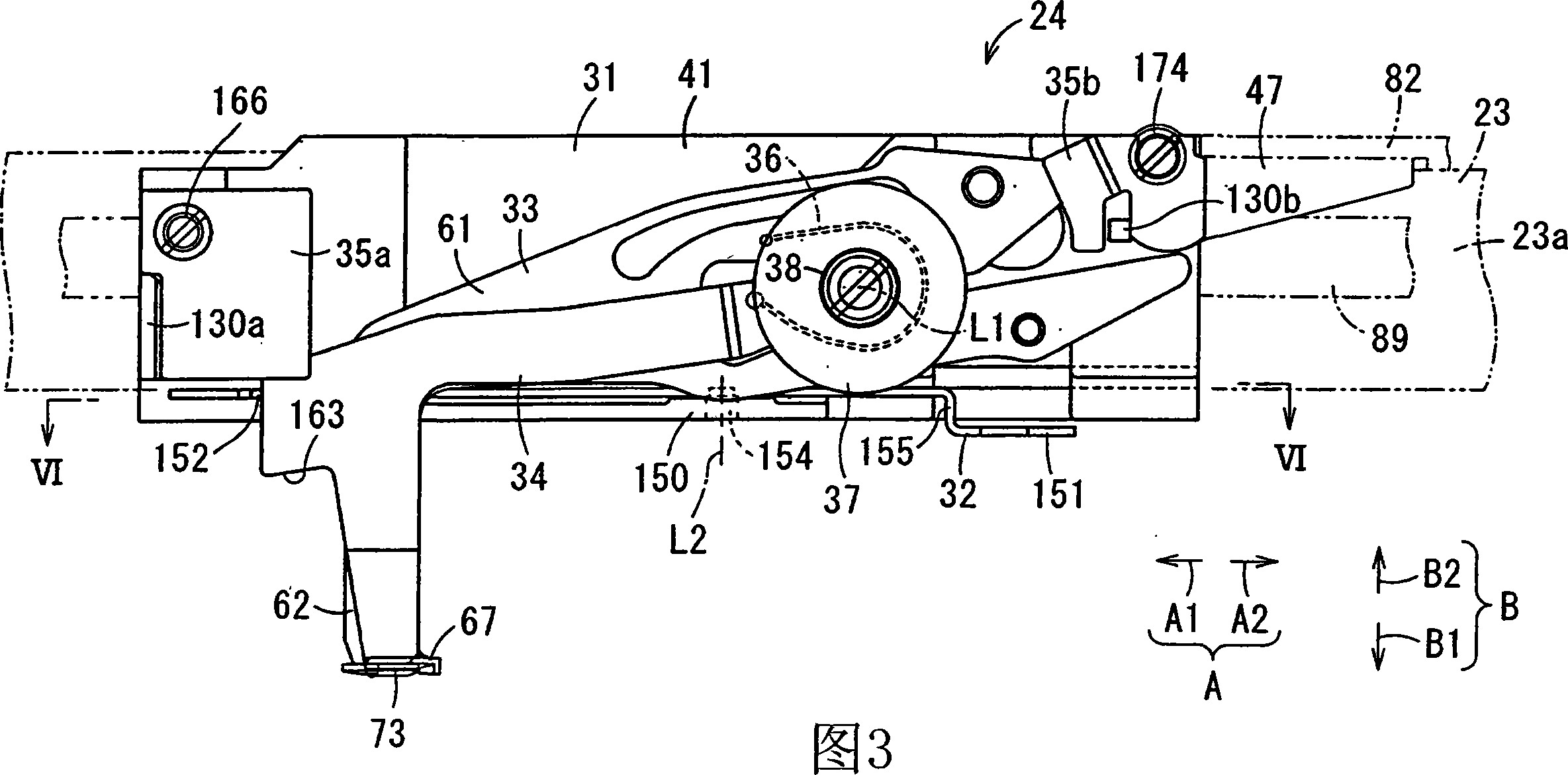

InactiveCN101158086AInhibition of tension changesReliable clampingGlovesFlat-bed knitting machinesYarnEngineering

The invention provides an end yarn insertion device which clamps the end yarn to insert into the internal of knitted fabrics. End yarn insertion device (1) is set on a flat knitting machine for glove (2), with a guide track (23) and a base (31) sliding transitionally along the guide track (23). The base (31) is equipped with a movable object (32) shifting relatively relative to the base (31). The movable object (32) is equipped with an end yarn hook (33) and an end yarn pressing foot (34). The end yarn hook (33) shifts between the capture position of capture yarn and the hook backoff position of knitting needle backoff. The end yarn pressing foot (34) acts continuously with the end yarn hook (33), shifting on the clip position where it coordinates with the end yarn hook on the capture position to span support position supporting yarn captured by the end yarn hook and on the pressing foot backoff position where it yields with the knitting needle and the end yarn hook (33). A second driving mechanism (26) drives the end yarn hook (33) to shift between the capture position and the hook backoff position. The base (31) is equipped with a stopper (48). The stopper (48) jams and fixes the end yarn pressing foot(34) shifting from the pressing foot backoff position to the support position to prevent shifting, ensure that the end yarn pressing foot stands by on the stand-by position where the yarn of yarn feeding yields. And the end yarn pressing foot (34) is detached from the stopper (48) by shifting the movable object (32) relatively relative to the base(31).

Owner:SHIMA SEIKI MFG LTD

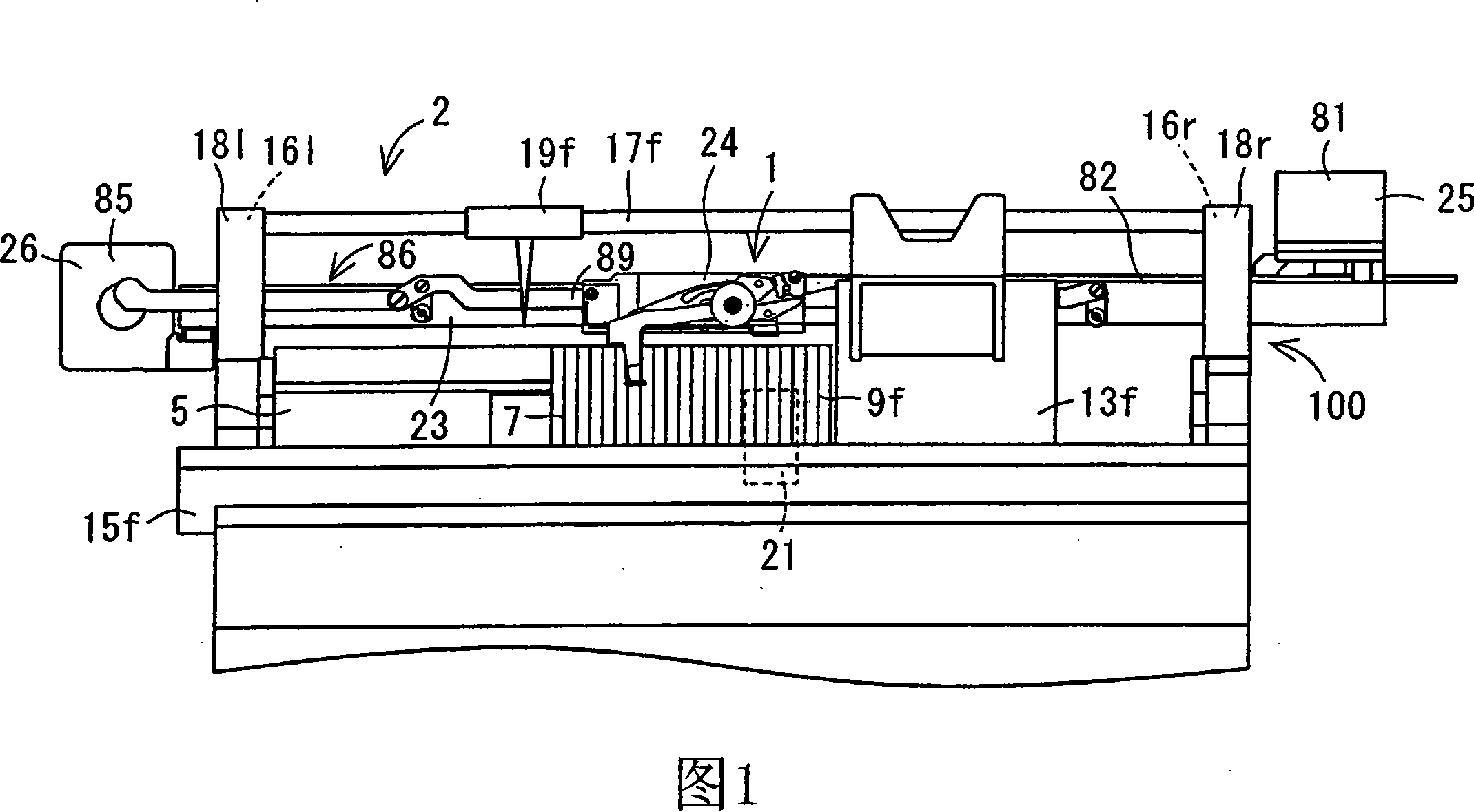

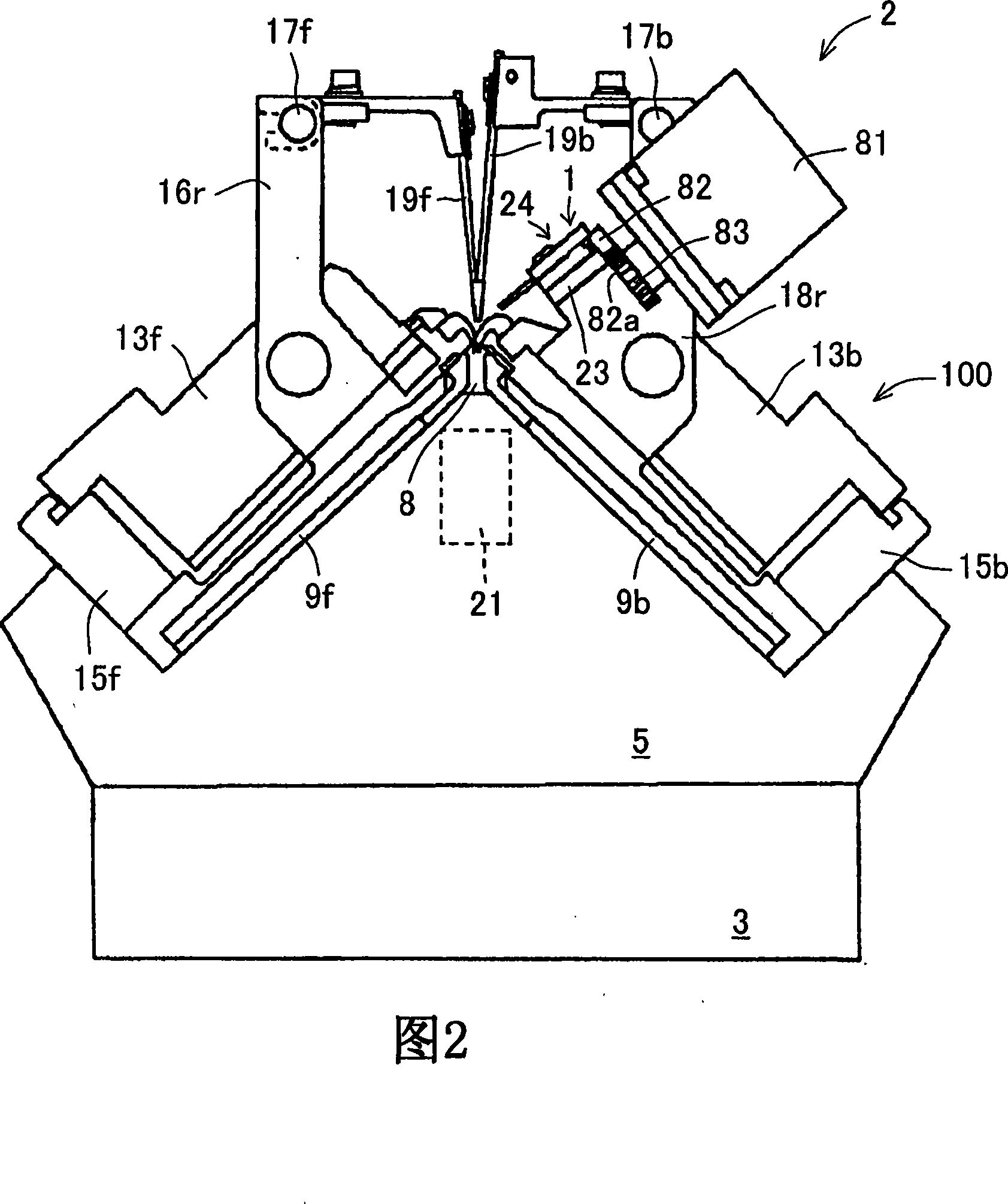

Wire-cut electric discharge machine

InactiveCN1689743AHigh precisionImprove straightnessElectrical-based machining electrodesElectric dischargeWire tension

To effectively restrict wire tension fluctuation generated on the wire supply side from a brake roller.

Owner:FANUC LTD

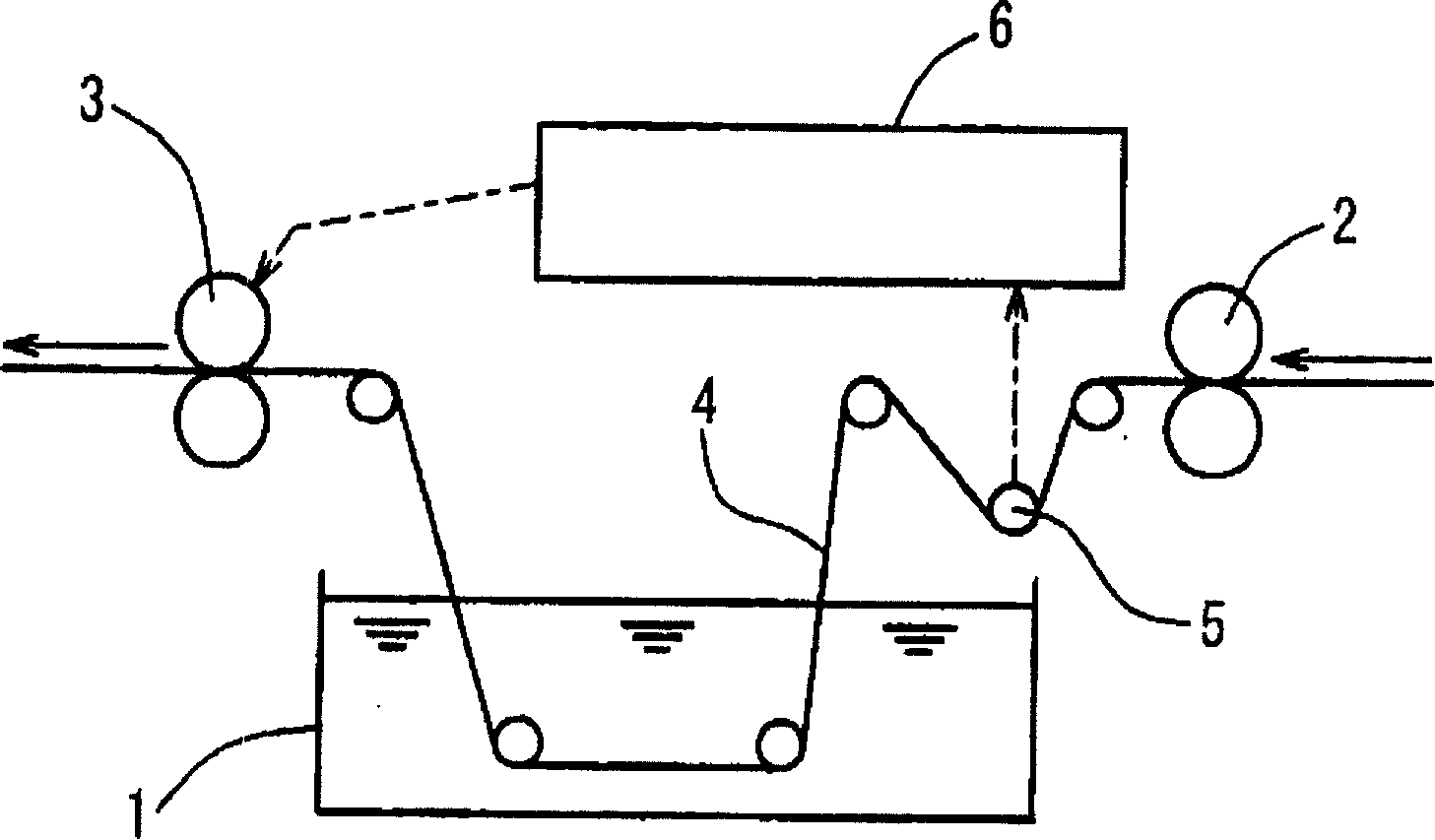

Polarization film and its manufacturing method, polarization sheet and optical laminating body

ActiveCN1595211AGuaranteed uptimeReduce dark spotsSynthetic resin layered productsPolarising elementsHuePolarizer

Provided is a polarizing film free of the unevenness in hue. The polarizing film is obtained by treating a polyvinyl alcohol film in order of swelling, dyeing, boric acid treatment and rinse treatment, subjecting the film to uniaxial stretching in a boric acid treatment step and / or a step before the same and further maintaining the tension acting on the film respectively substantially constant in the respective steps after the stretching treatment, wherein the polyvinyl alcohol film is successively treated in order of the swelling treatment, the dyeing treatment, the boric acid treatment and the rinse treatment, the film is subjected to the uniaxial stretching in the boric acid treatment step and / or the step before the same and further tension control of the film is performed in the respective steps after the stretching treatment, so that the travel of the film is stabilized and the unevenness of the hue can be reduced.

Owner:SUMITOMO CHEM CO LTD

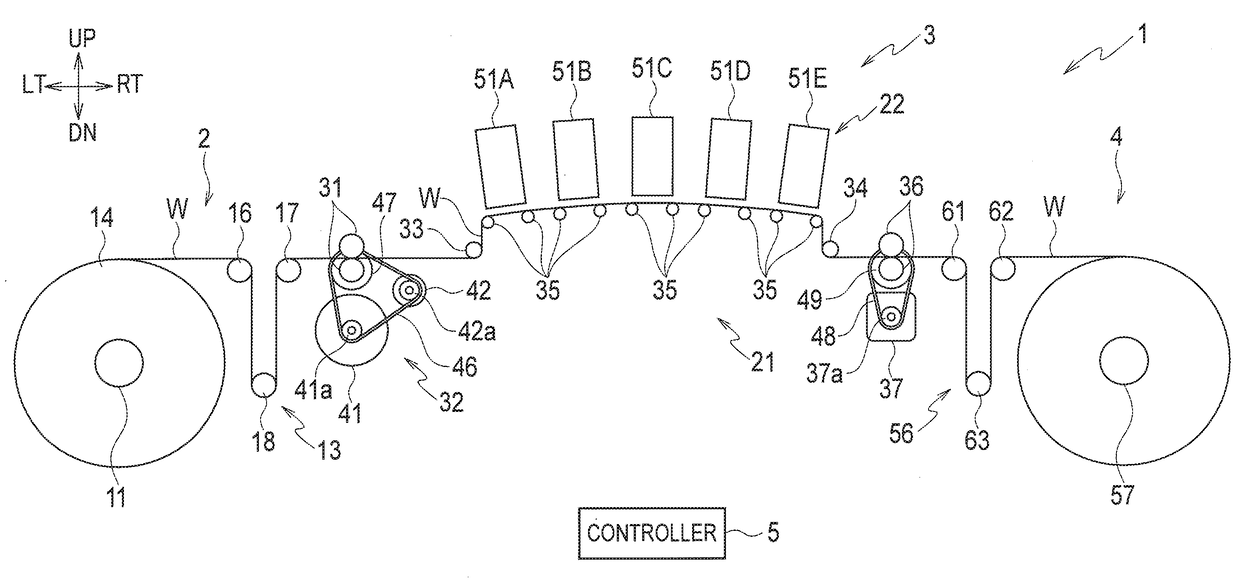

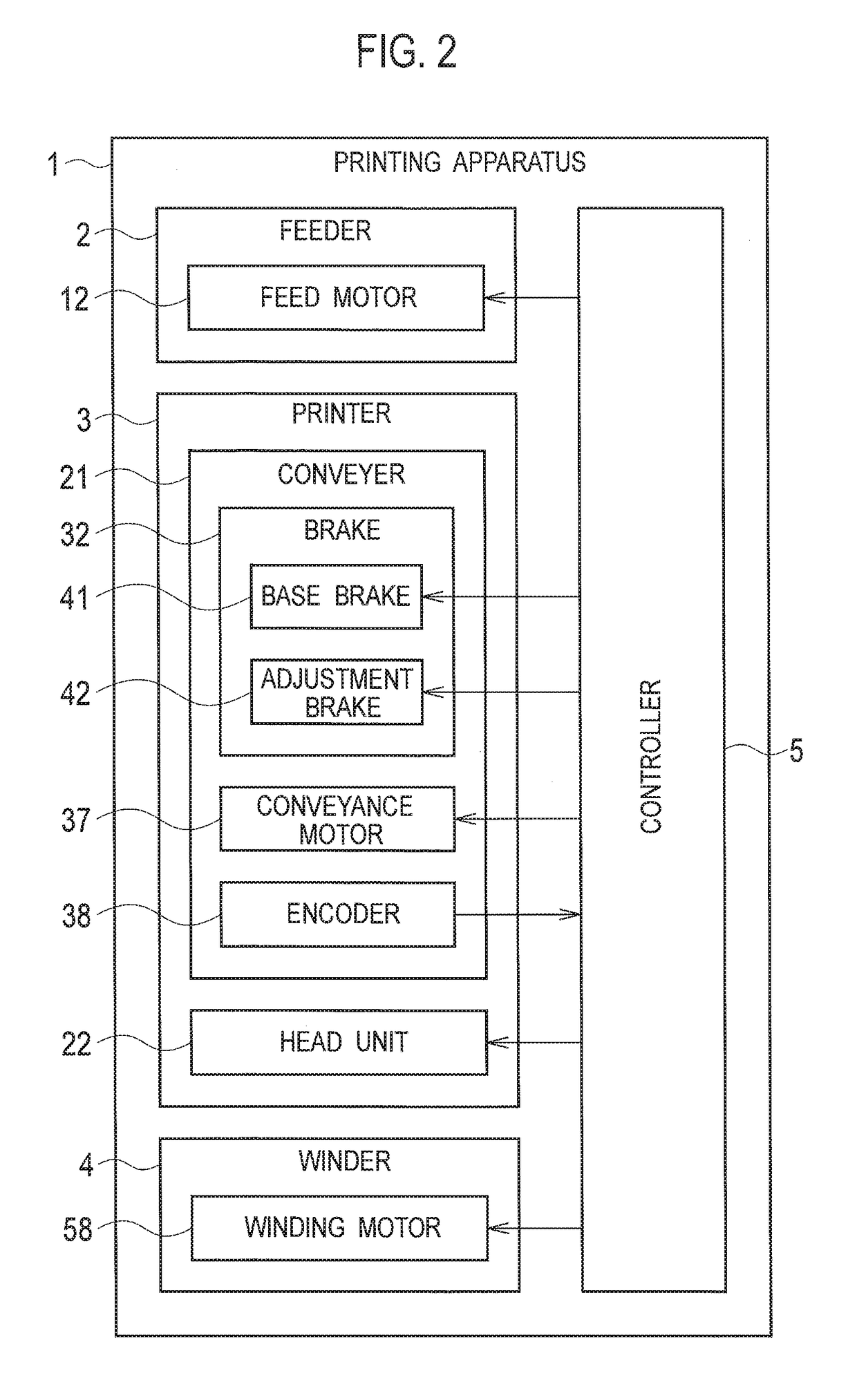

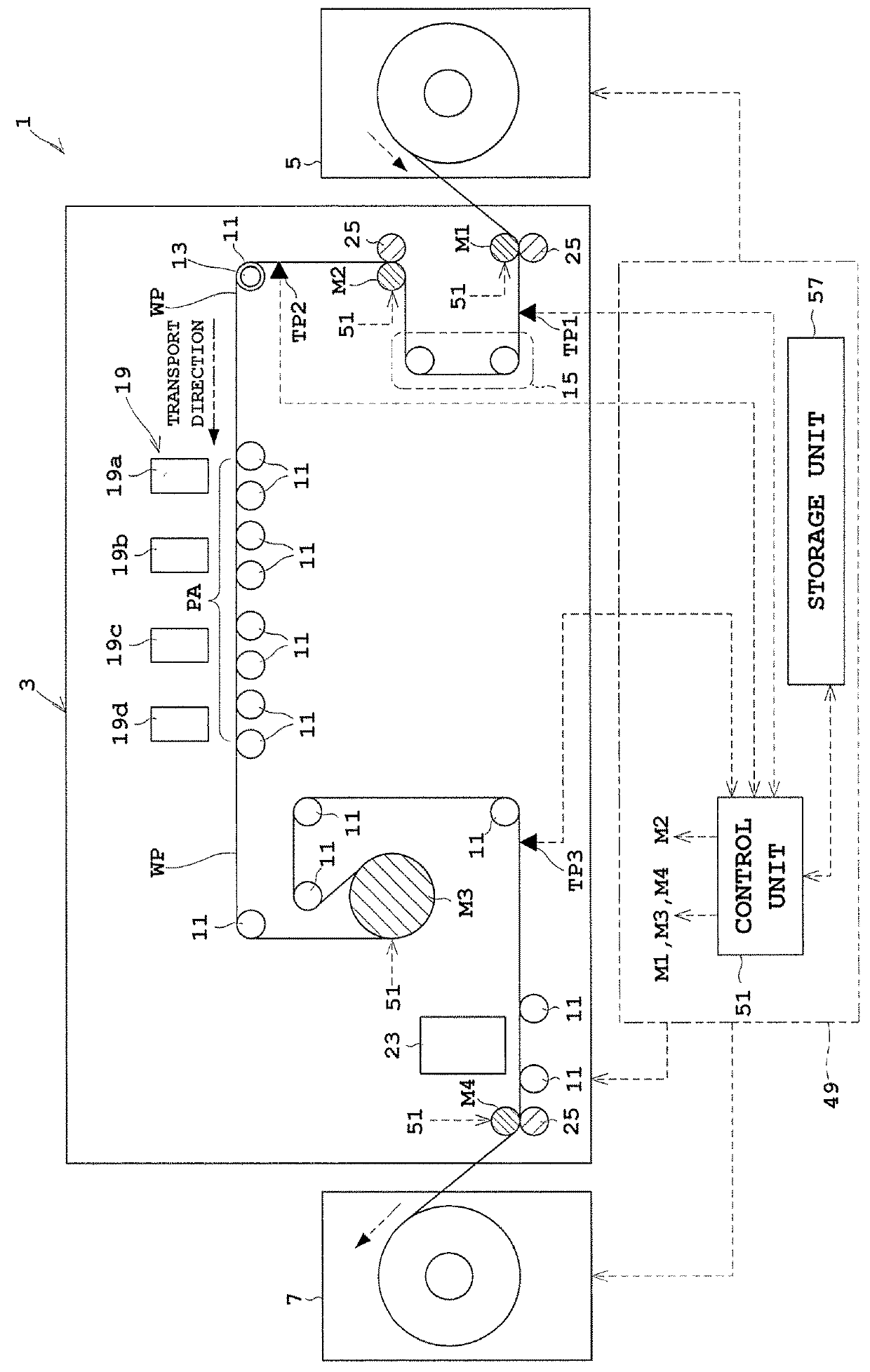

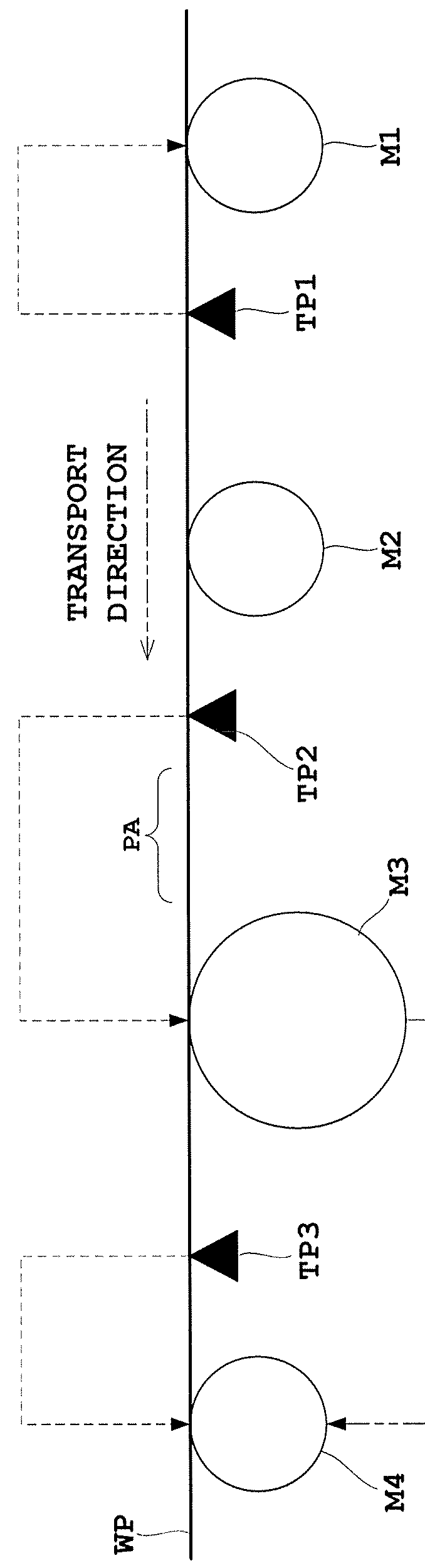

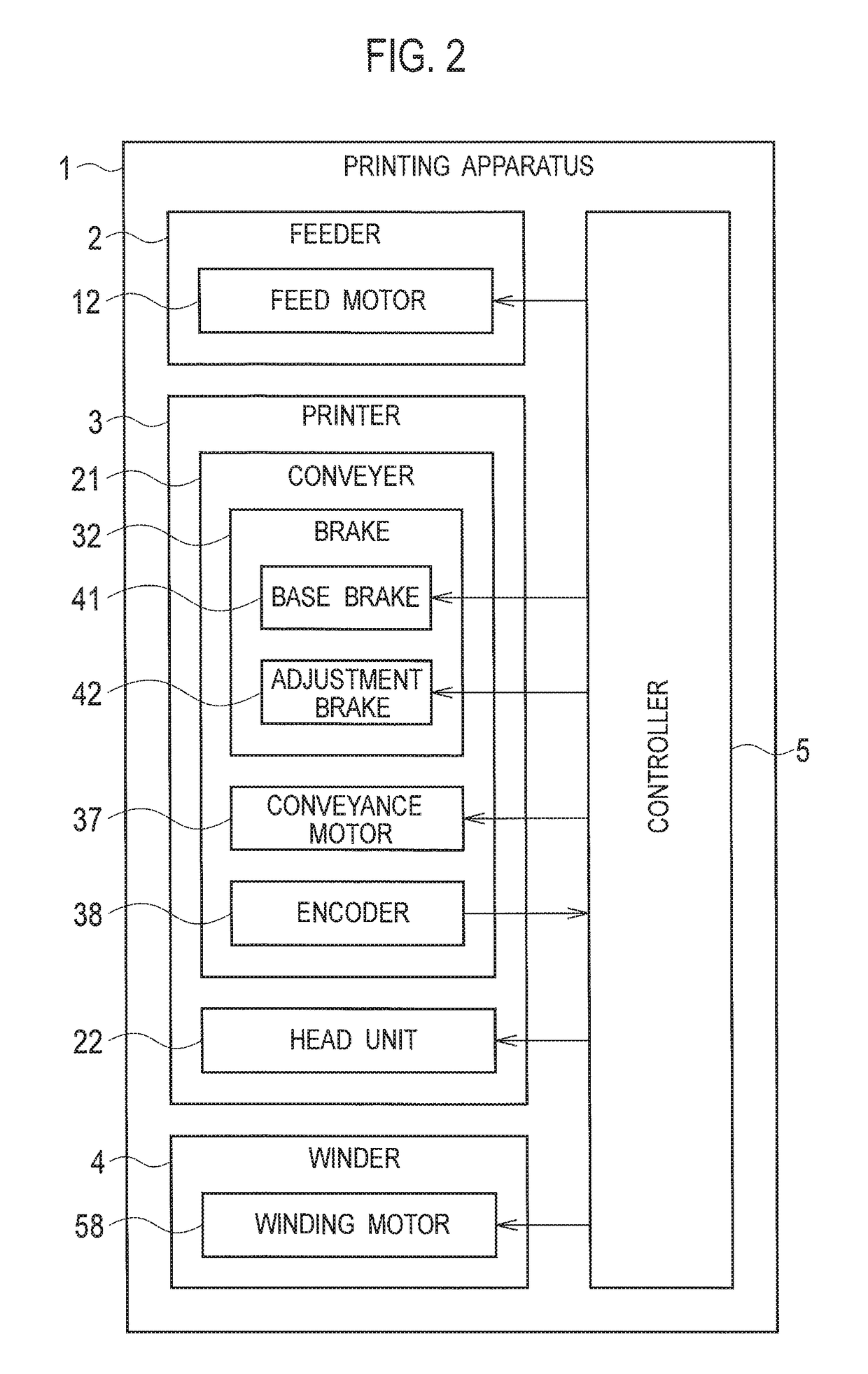

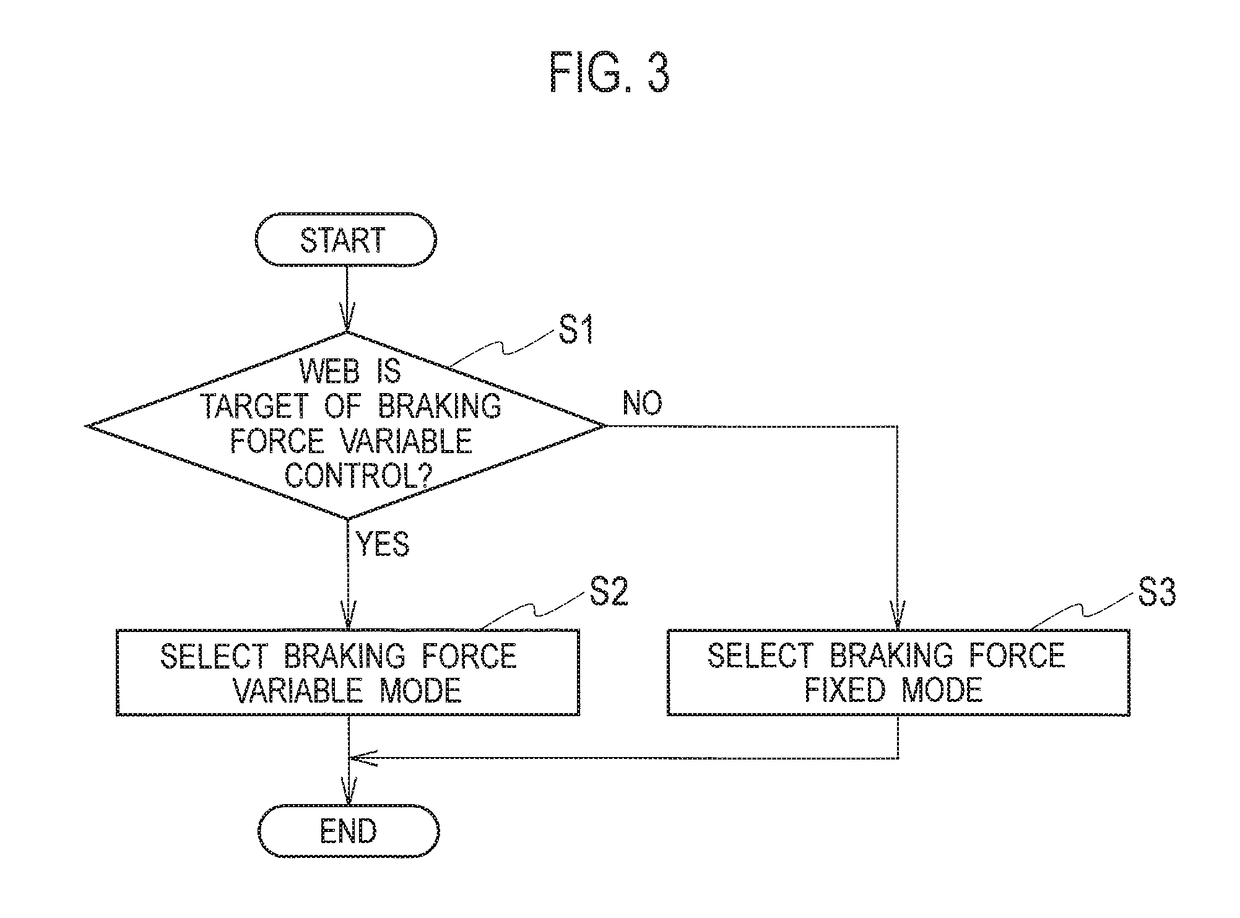

Conveyance apparatus of web being print medium

ActiveUS20170282602A1Simple brake controlOscillation suppressionOther printing apparatusWebs handlingControl parametersBrake force

A conveyance apparatus includes a conveyance roller, a conveyance motor, a back tension roller, a conveyance speed detector, a brake, and a controller. The controller is configured to: based on a conveyance speed of a web detected by the conveyance speed detector, control a value of a drive control parameter of the conveyance motor such that the conveyance speed of the web is equal to a target speed; and, based on an output torque of the conveyance motor corresponding to the value of the drive control parameter, adjust a braking force of the brake applied to the back tension roller which applies a tension to the web such that the tension of the web is equal to a target tension.

Owner:RISO KAGAKU CORP

Unwind and feed system for elastomeric thread

ActiveUS20100072316A1Smoothes out tension variationReduce variationProjector film strip handlingCamera film strip handlingFiberScrew thread

Owner:HARTZHEIM ENG

Wire-cut electric discharge machine

InactiveUS20050242065A1Applied tension is satisfactoryMagnitude can be adjustedElectrical-based machining electrodesWire rodBobbin

A wire-cut electric discharge machine comprises a wire running system, in which a wire is run through a wire bobbin, brake rollers, a wire guide, and a wire take-up device in the order named. As a device for reducing the variation in wire tension is arranged between the wire bobbin and the brake rollers in the wire running system, variation of the wire tension that is caused on the wire supply side of the brake rollers can be restrained effectively.

Owner:FANUC LTD

End-yarn insertion device

InactiveCN101158087AReliable clampingPrevent handling damageGlovesFlat-bed knitting machinesYarnEngineering

The invention provides an end yarn insertion device which clamps the end yarn to insert into the internal of knitted fabrics. End yarn insertion device (1) is set on a flat knitting machine for glove (2), with a guide track (23) and a base (31) sliding transitionally along the guide track (23). The base (31) is equipped with a movable object (32) shifting relatively relative to the base (31). Themovable object (32) is equipped with an end yarn hook (33) and an end yarn pressing foot (34). The end yarn hook (33) shifts between the capture position of capture yarn and the hook backoff positionof knitting needle backoff. The end yarn pressing foot (34) acts continuously with the end yarn hook (33), shifting on the clip position where it coordinates with the end yarn hook on the capture position to span support position supporting yarn captured by the end yarn hook and on the pressing foot backoff position where it yields with the knitting needle and the end yarn hook (33). A second driving mechanism (26) drives the end yarn hook (33) to shift between the capture position and the hook backoff position. The base (31) is equipped with a stopper (48). The stopper (48) jams and fixes the end yarn pressing foot(34) shifting from the pressing foot backoff position to the support position to prevent shifting, ensure that the end yarn pressing foot stands by on the stand-by position where the yarn of yarn feeding yields. And the end yarn pressing foot (34) is detached from the stopper (48) by shifting the movable object (32) relatively relative to the base(31).

Owner:SHIMA SEIKI MFG LTD

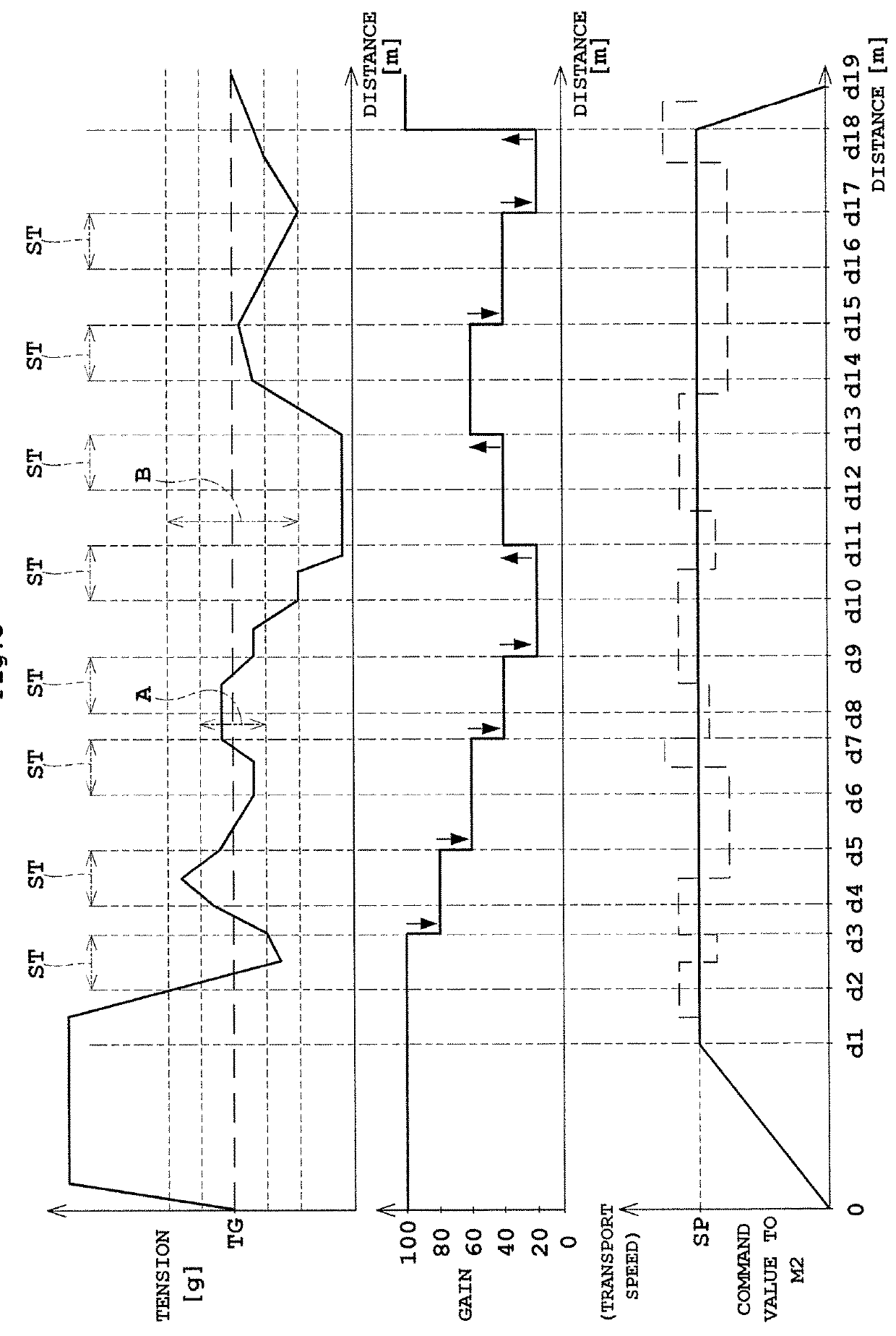

Transport control method, a transport apparatus, and a printing apparatus

InactiveUS20180273330A1Inhibition of tension changesIncrease the amount of controlWebs handlingStable stateControl theory

A transport control method for use in transporting a medium in a predetermined direction by an upstream drive roller and a downstream drive roller, to operate the downstream drive roller by using PID control based on a detection value of a tension sensor disposed downstream of the upstream drive roller and upstream of the downstream drive roller for detecting tension. The transport control method includes a stable state determining step for determining, at time of the operation, whether a difference between the detection value of the tension sensors and a target value is within a stable width to make a stable state which maintains a stability time; and a gain decreasing step for decreasing a gain of the PID control to be less than an initial value when the difference is determined to be in the stable state.

Owner:DAINIPPON SCREEN MTG CO LTD

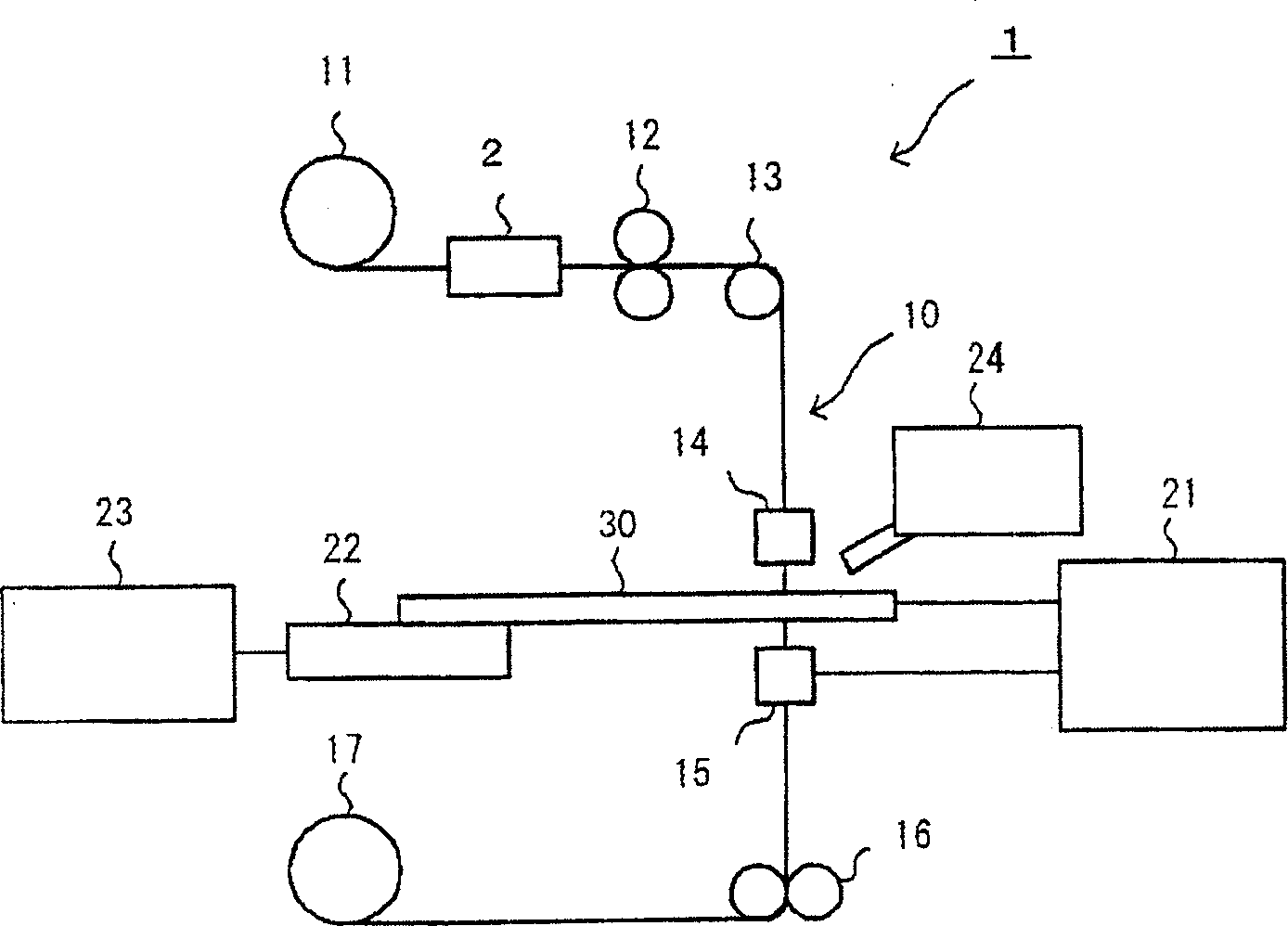

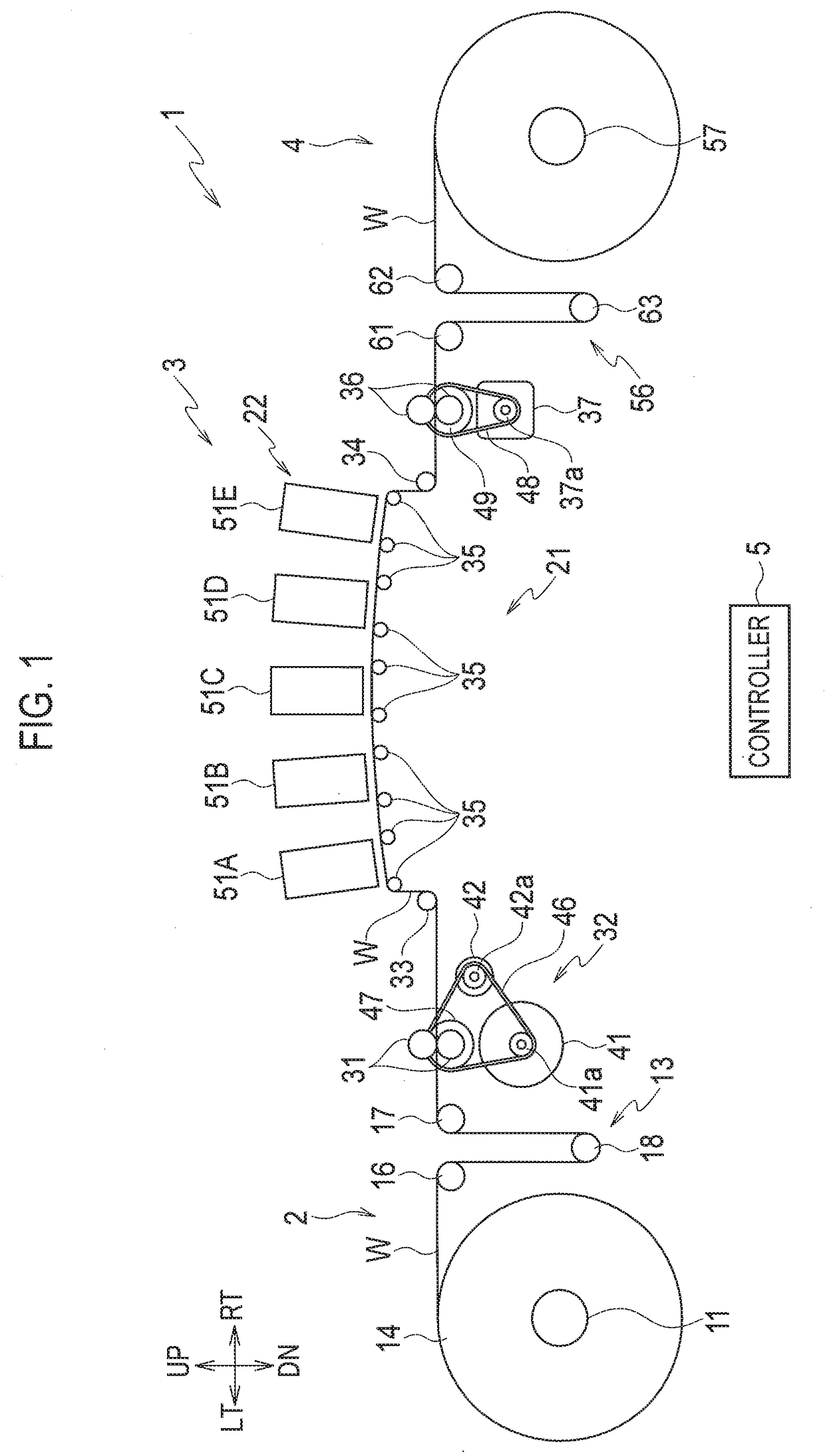

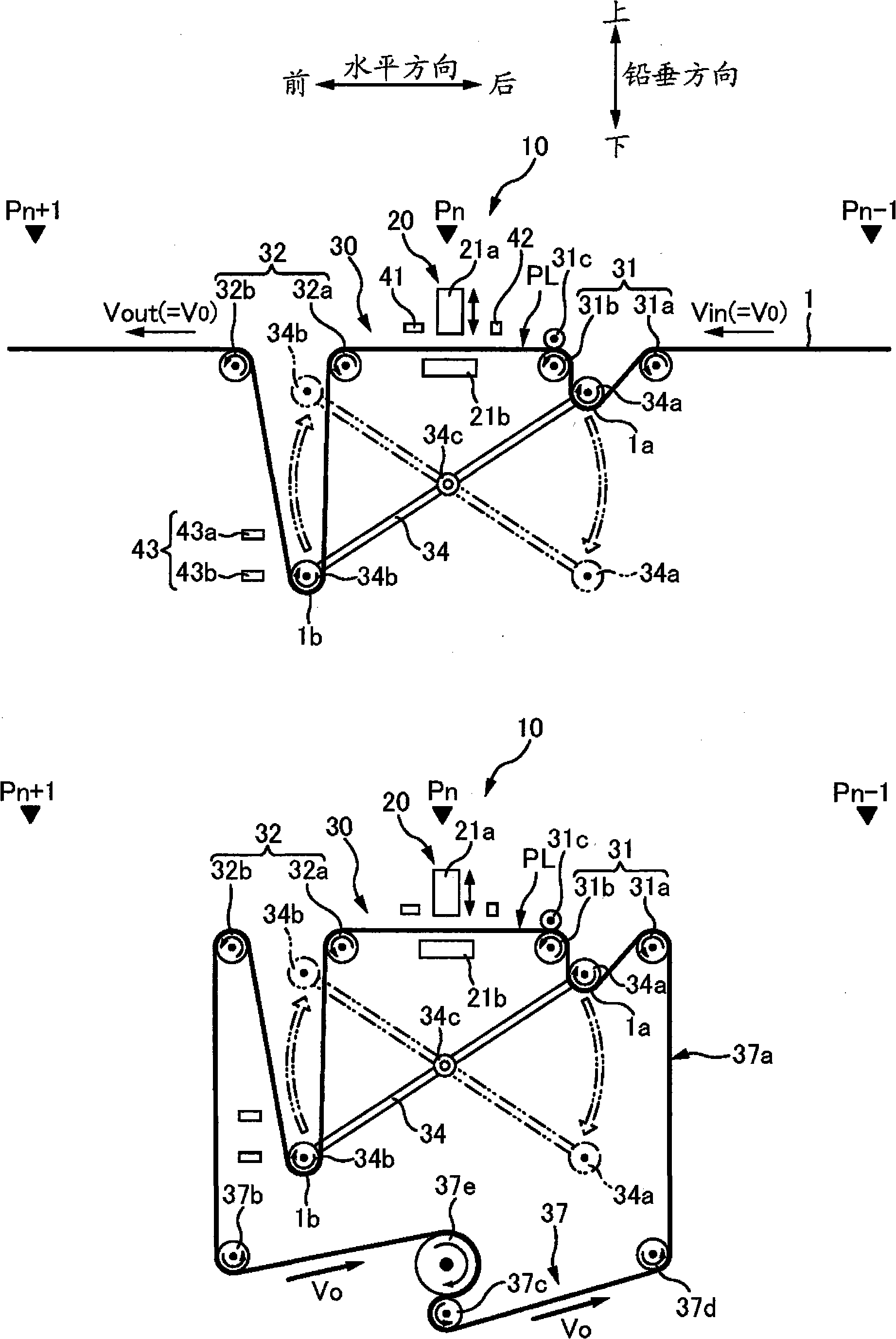

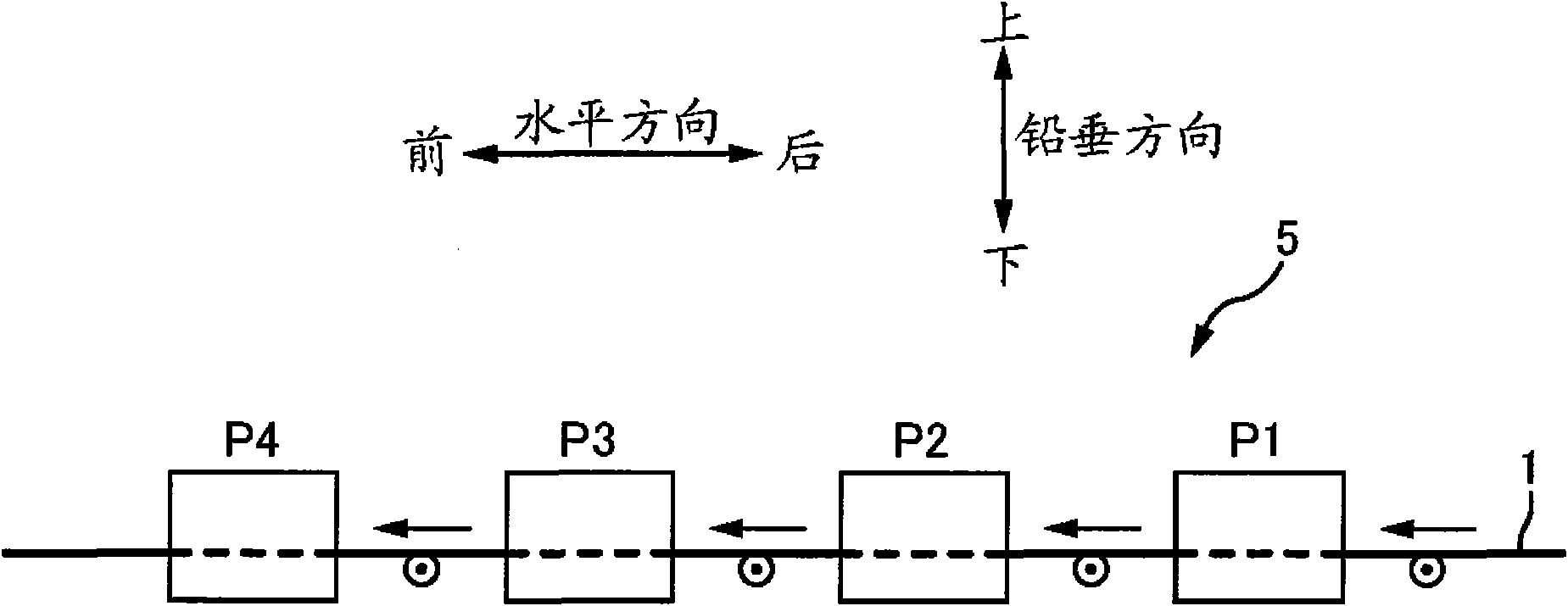

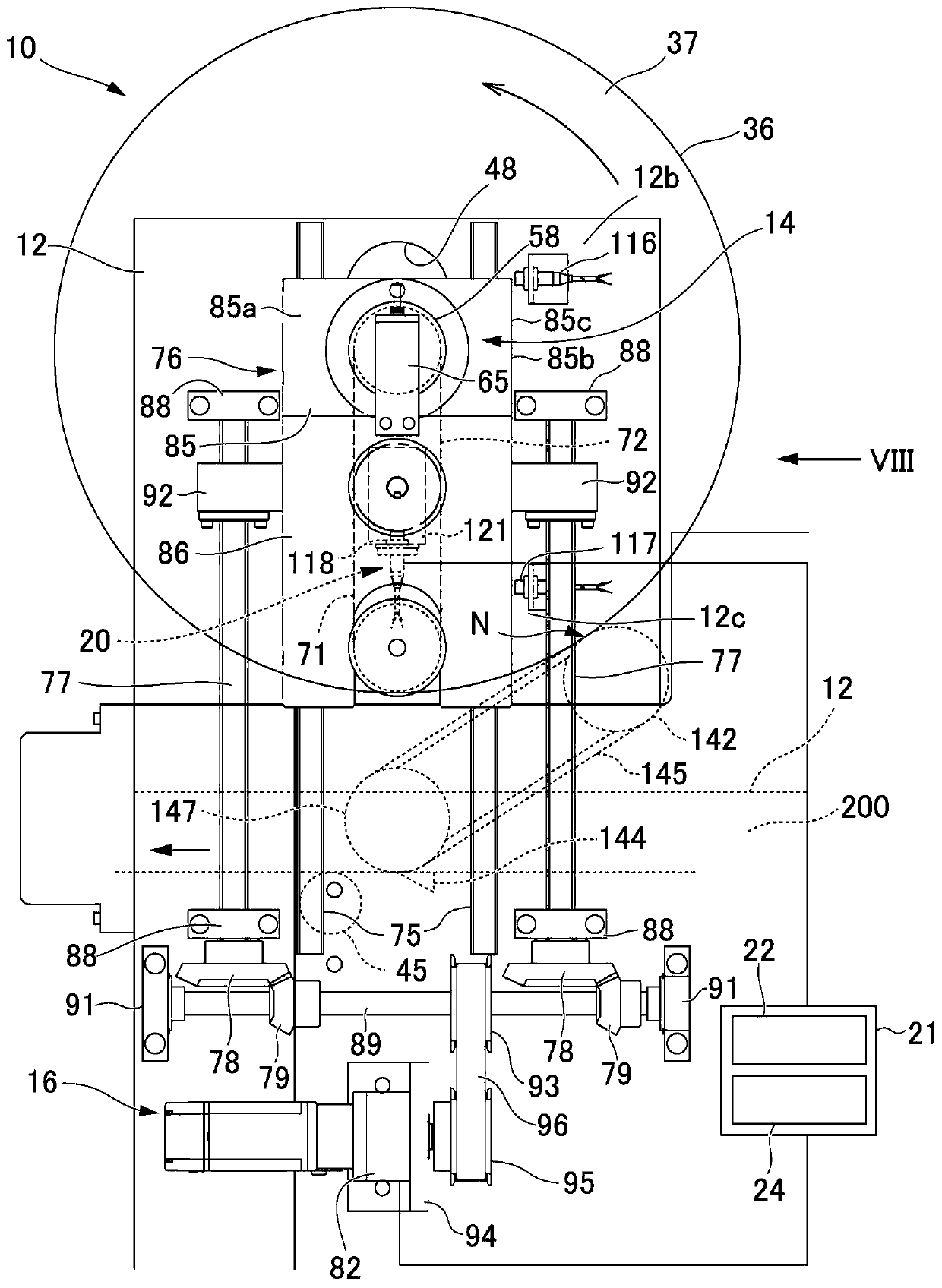

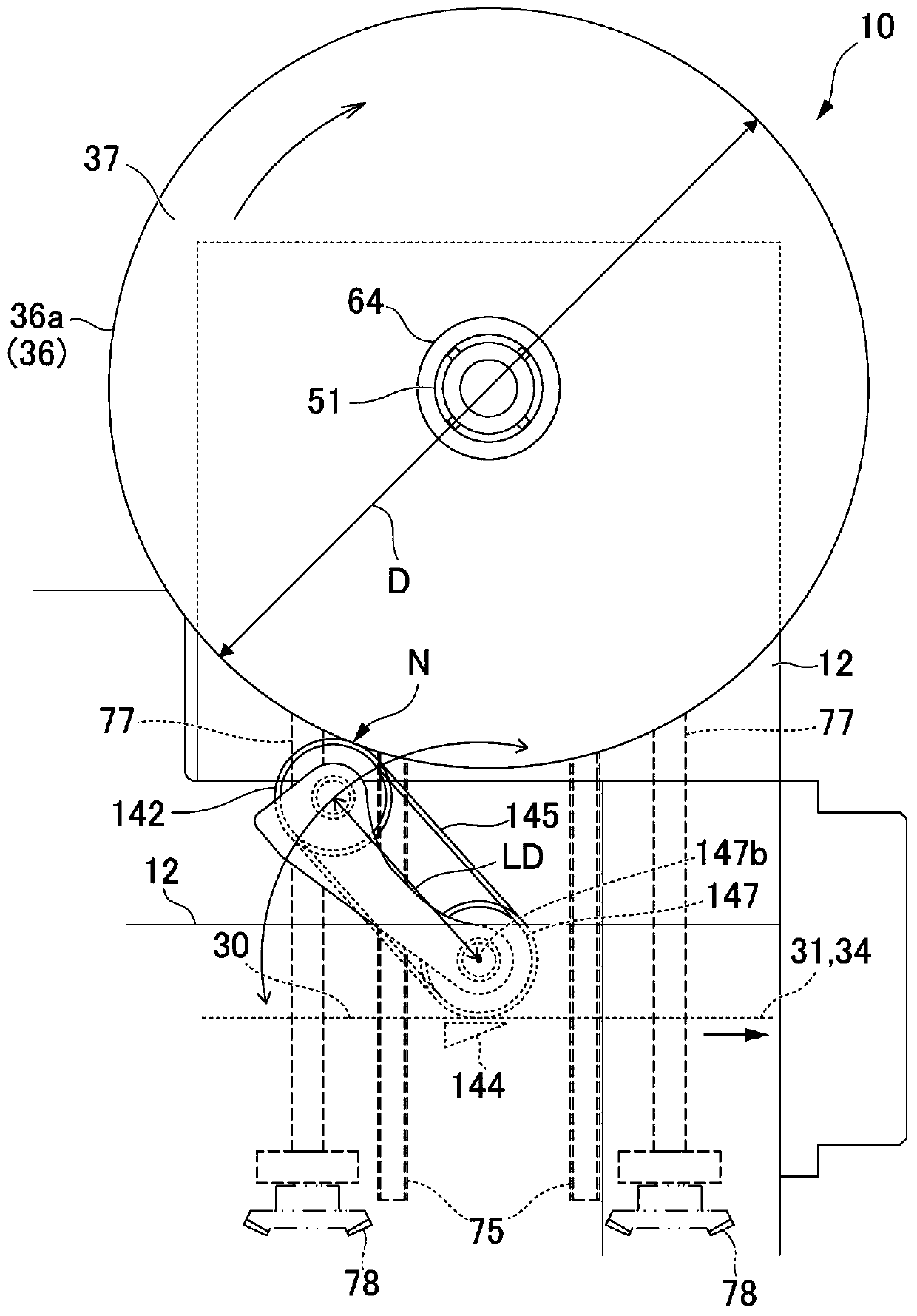

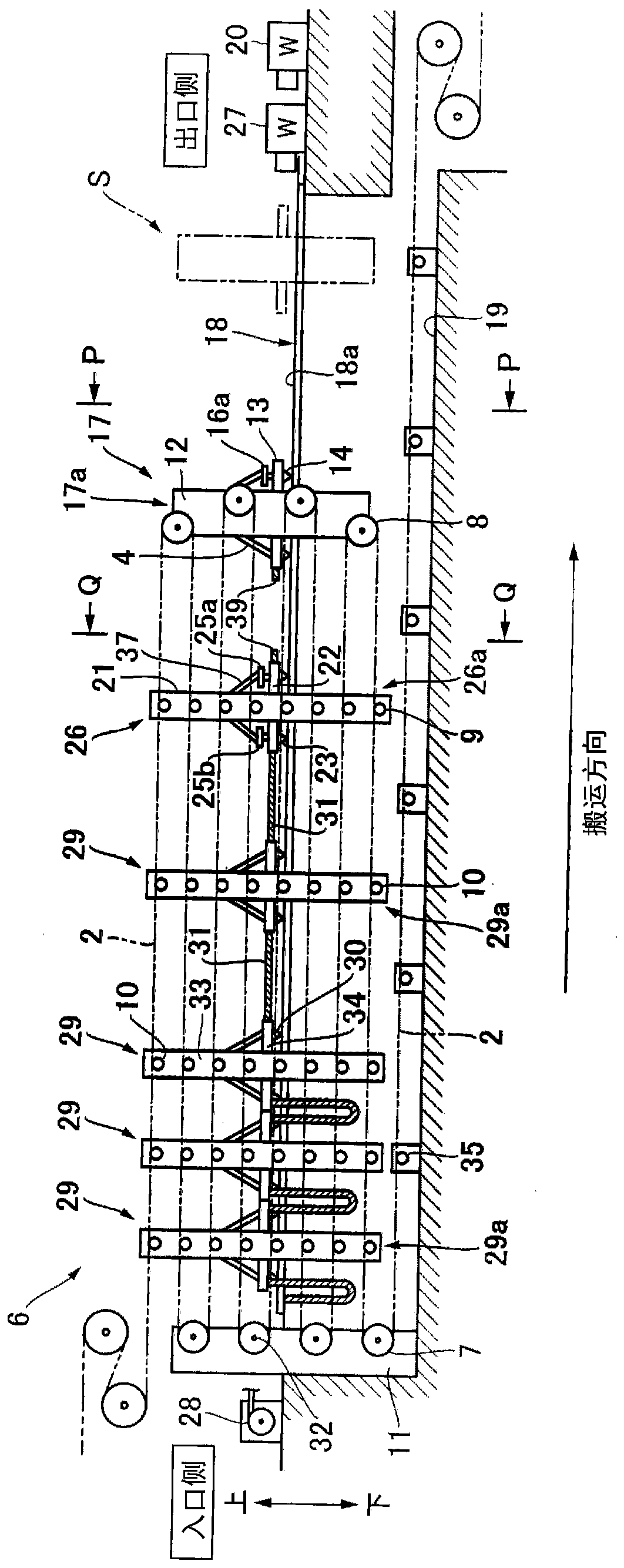

Processing apparatus

A processing apparatus (10) applies a processing (Pn) to a continuous band-shaped work (1) by intermittently stopping the work (1) which is running along a predetermined running path (PL). In the processing apparatus, a variation in the tension of the work (1) which may be produced by the intermittent stoppage of the work (1) is effectively suppressed. A work conveying part (30) comprises an endless annular body (37a) wrapped around conveying rolls (31, 32), a first mobile body (34a), and a second mobile body (34b). A first drive roll (37e) circulatingly drives the endless annular body (37a) continuously at a predetermined speed so that the endless annular body (37a) performs the same running operation and accumulating operation as the work (1) in the area where the endless annular body (37a) is arranged along the running path. An intermittent feeding part (31b) intermittently stops the endless annular body (37a) when the work (1) is stopped.

Owner:UNI CHARM CORP

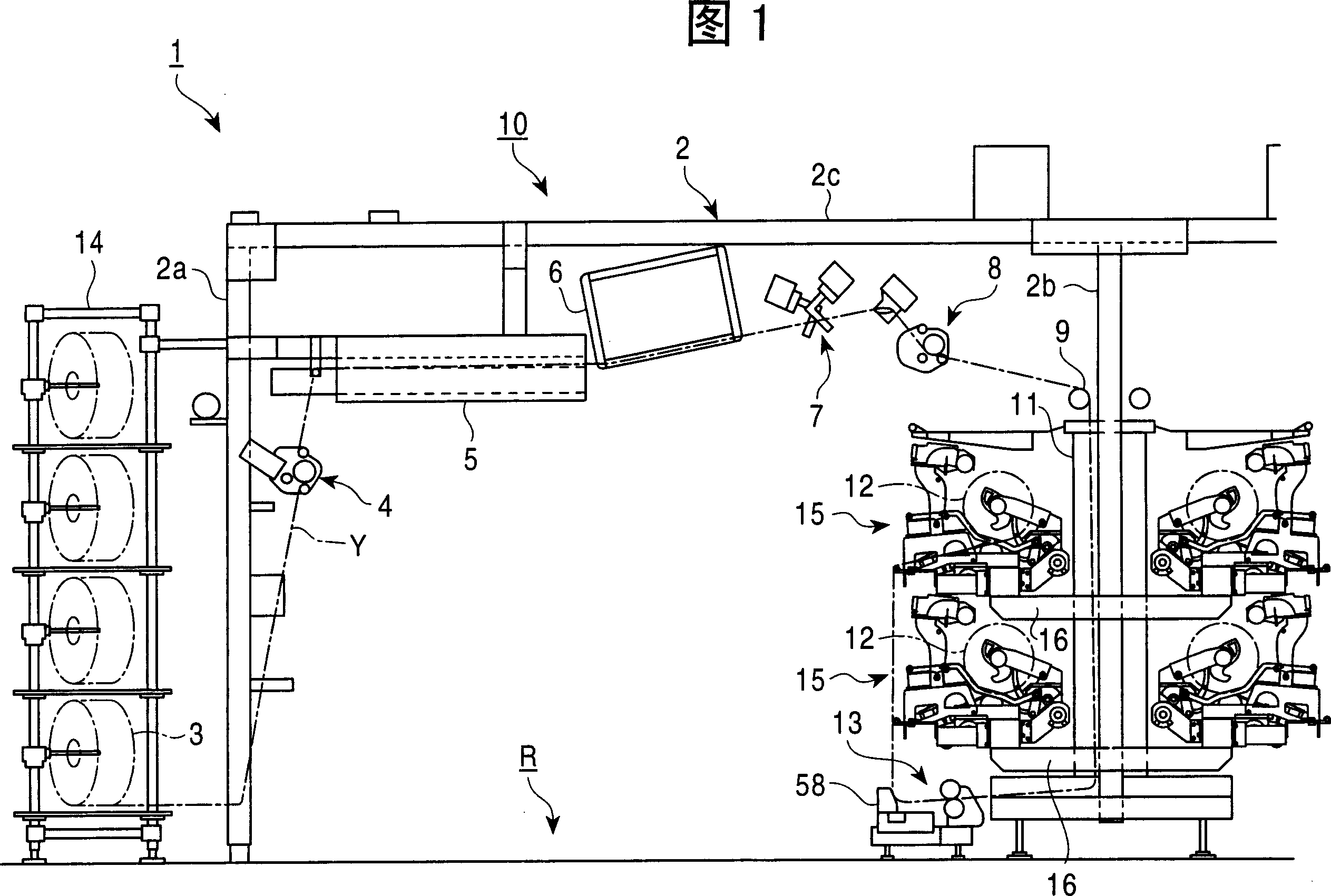

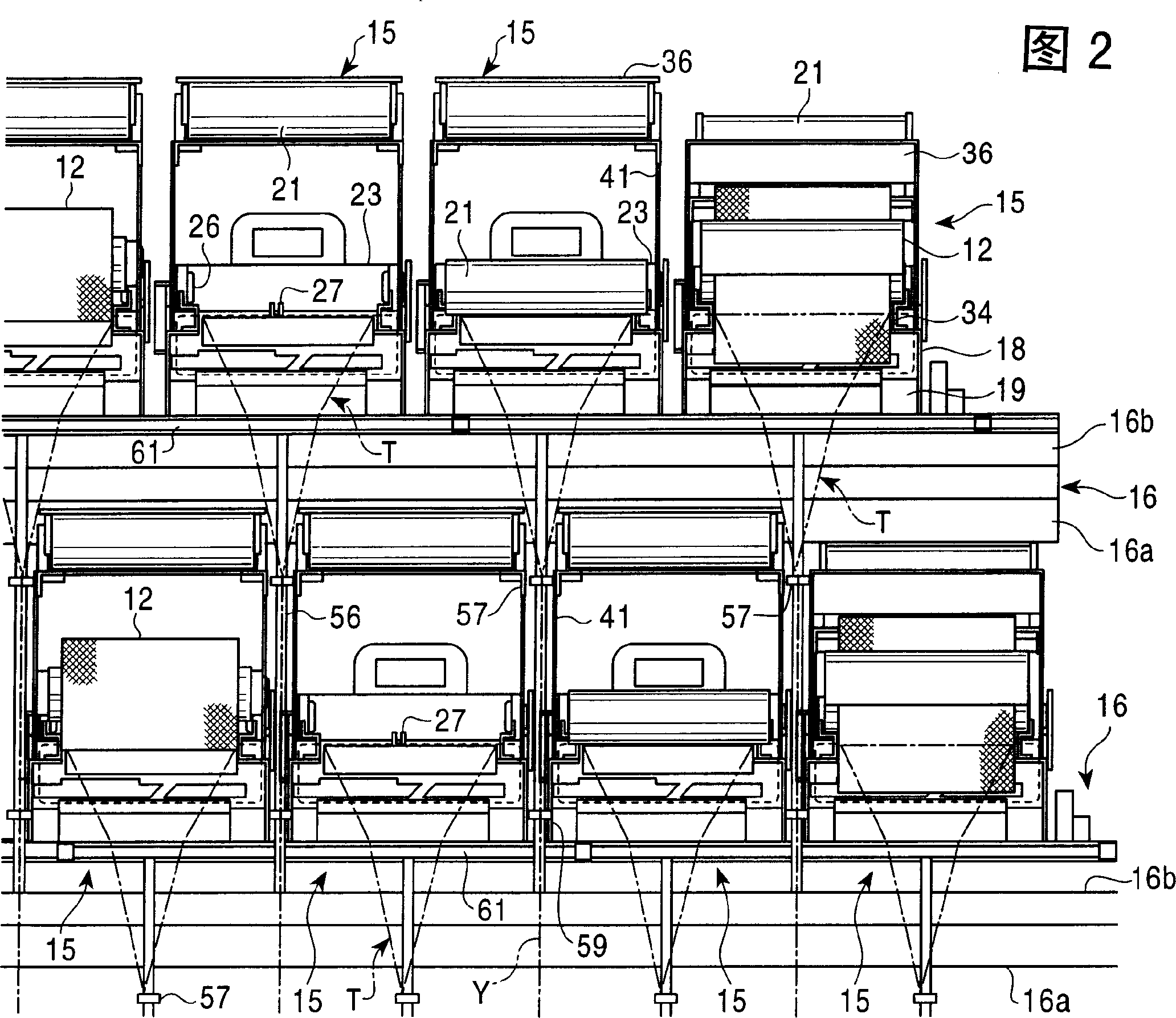

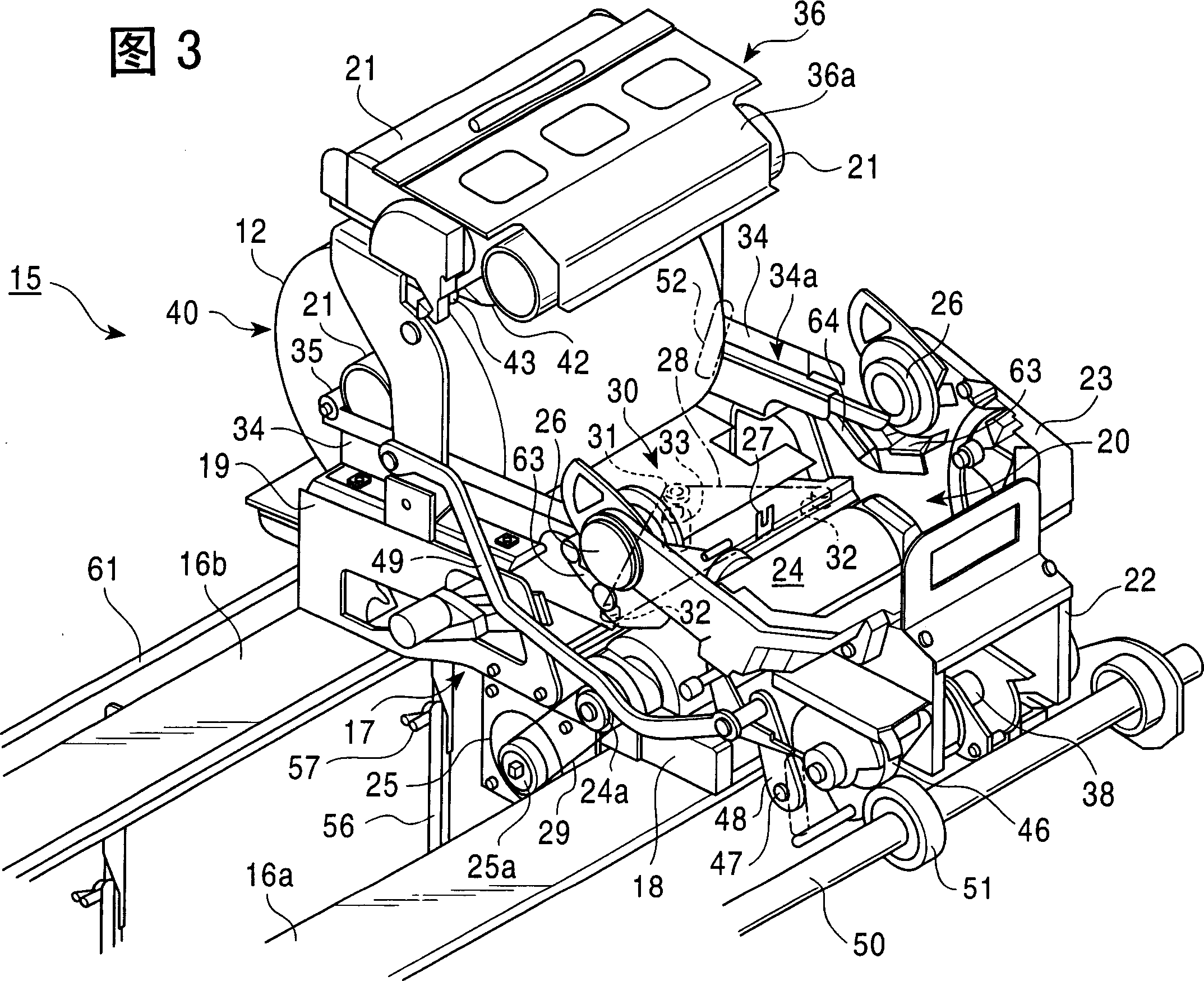

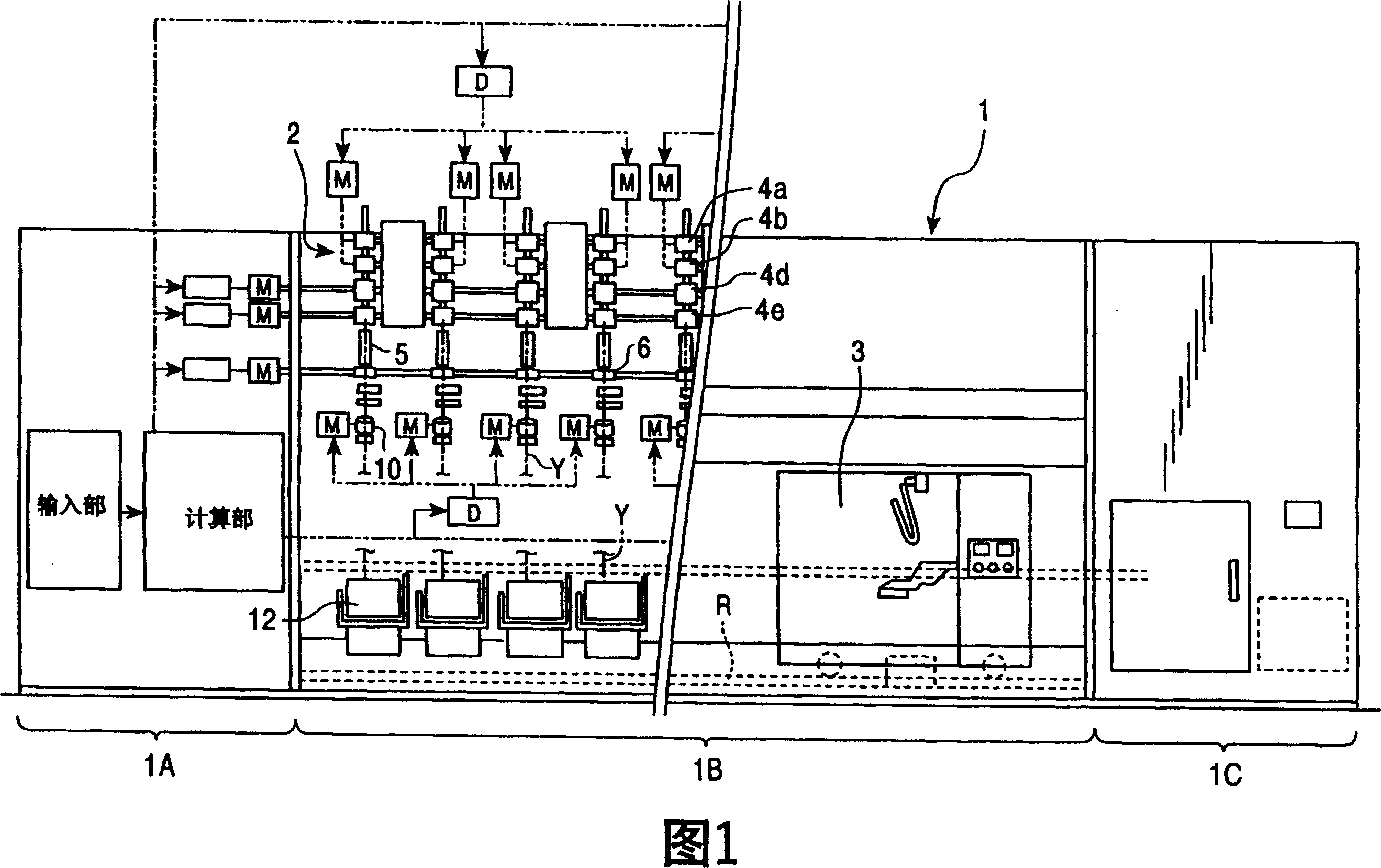

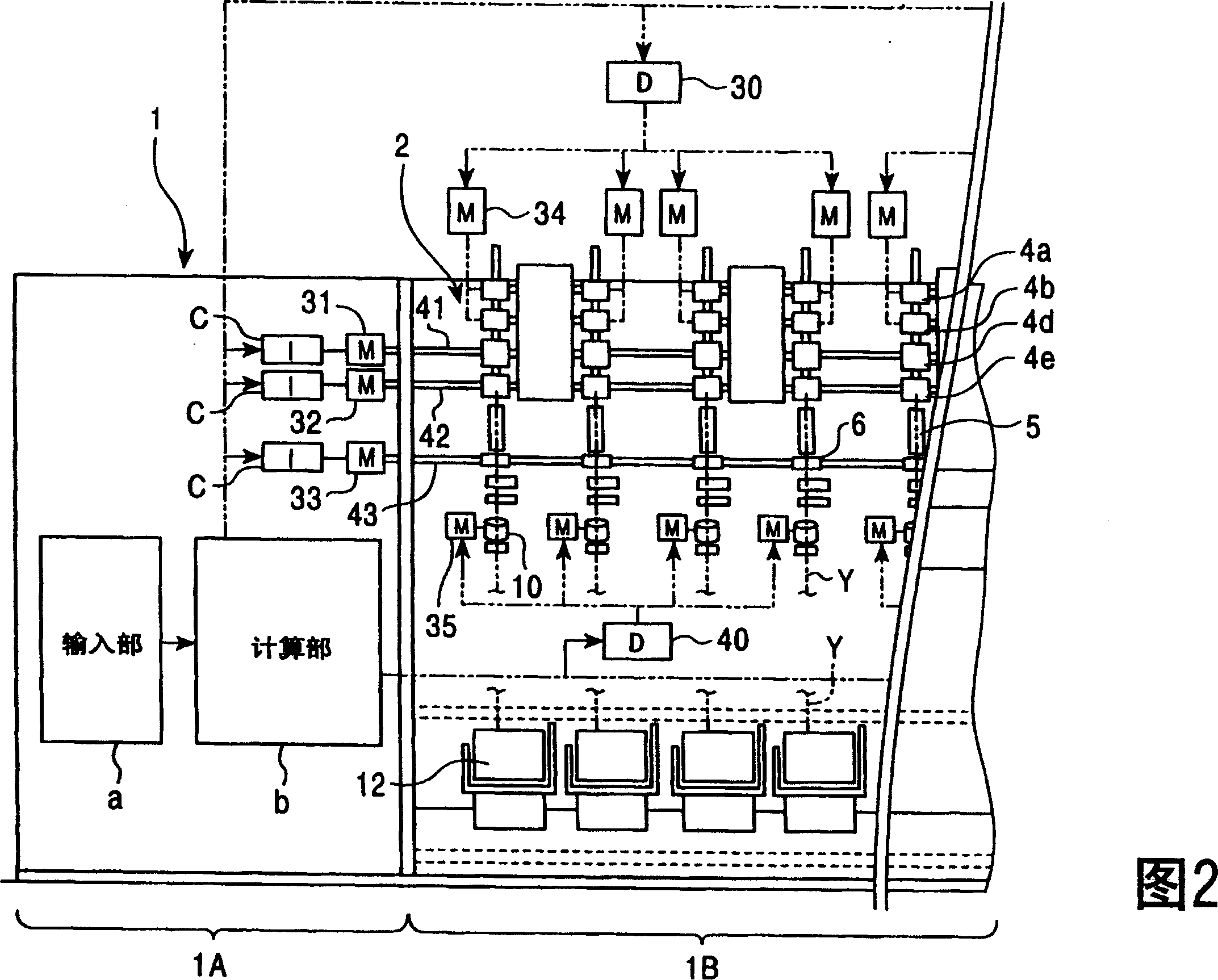

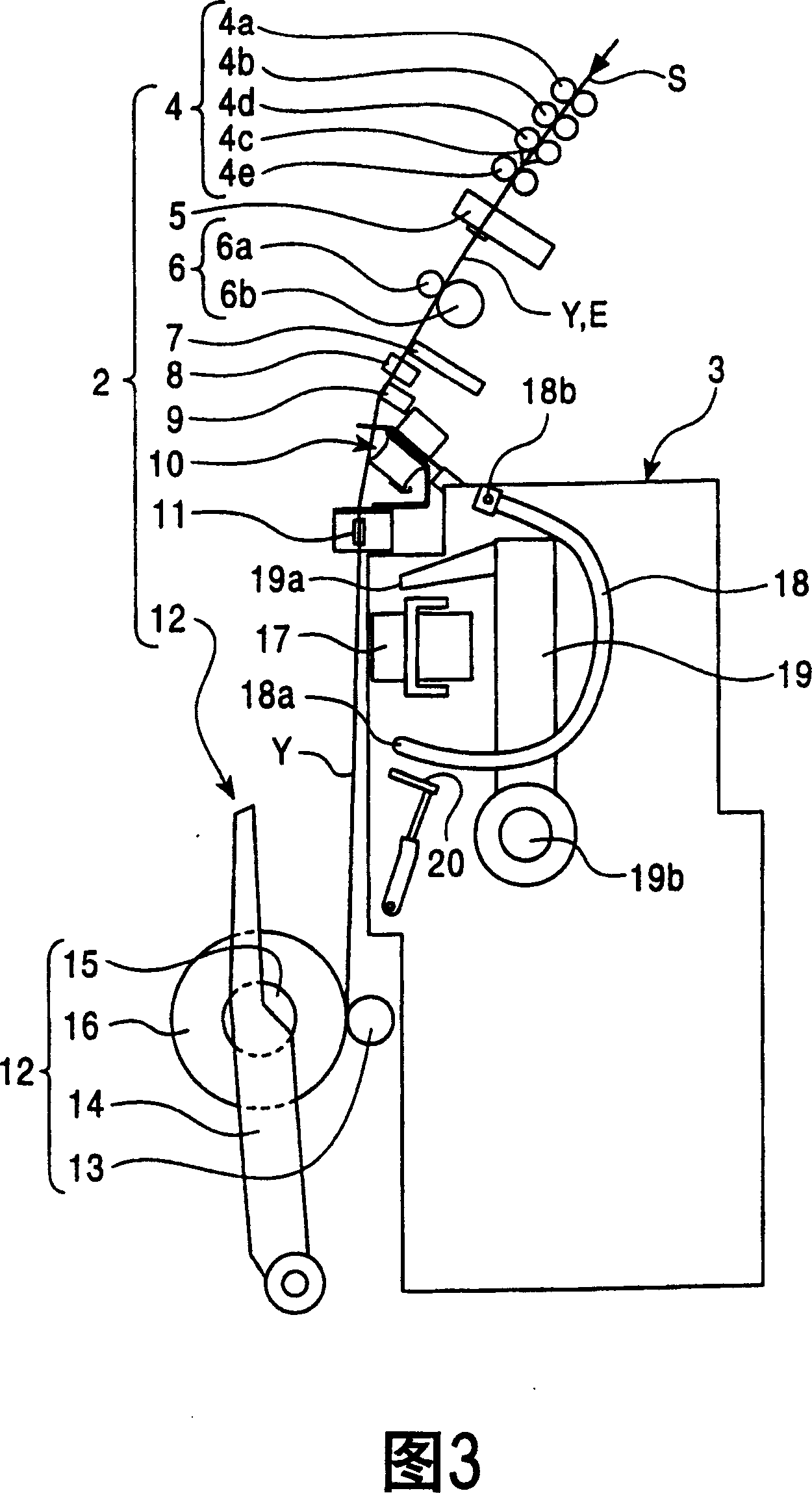

Textile machine

Provided is a fiber machine capable of eliminating the problems in the conventional technique wherein it requires a yarn threading device to be particularly devoted to thread a thread guide to a hidden position behind each takeup device, the easiness to conduct the maintenance work of its traversing device remains poor, yarn severance weights are difficult to find, and the yarn type to admit processing is restricted owing to the refraction angle of the thread guide. The fiber machine includes a provisionally twining machine 1 arranged so that taking-out of a yarn package 12 from each takeup device 15 and supplying an empty bobbin 21 to the takeup device 15 are conducted from the side with the working passage R, wherein the takeup devices 15 are arranged zigzag along the in-line laid direction of the weights 10 in such a fashion that the takeup devices 15 of adjoining weights 10 are positioned different in the up-and-down positioning, and a guide for yarn running is installed so that each yarn Y led into the takeup device 15 runs outside the space in which taking-out of the produced package 12 out of an other takeup device 15 and supplying a bobbin 21 to other takeup device 15 take place.

Owner:TMT MACHINERY INC

Polarization film and its manufacturing method, polarization sheet and optical laminating body

ActiveCN100388023CGuaranteed uptimeReduce dark spotsSynthetic resin layered productsPolarising elementsHuePolarizer

Owner:SUMITOMO CHEM CO LTD

Coiling apparatus of yarn

InactiveCN100352751CInhibition of tension changesEasy maintenancePiercing arrangementsFilament handlingYarn tensionEngineering

The present invention stabilizes a yarn tension in a yarn winder in which a plurality of winding units are disposed, each of the winging units being provided with a yarn slack eliminating device. A transmitted force adjusting mechanism is provided to adjust a rotative driving force transmitted by a slack eliminating roller of a yarn slack eliminating device to an unwinding tension applying member. The transmitted force adjusting mechanism can be set so that when a load acting on the unwinding tension applying member increases above a predetermined value, the unwinding tension applying member rotates or rotatively moves independently of the slack eliminating roller. When winding tension is weak, the unwinding tension applying member rotates integrally with the slack eliminating roller to tense a yarn. When the winding tension exceeds a predetermined value, the unwinding tension applying member prevents the winding tension from becoming excessive to suppress a variation in tension. When the transmitted force adjusting mechanism is configured so as to vary the force transmitted to the unwinding tension applying member, it is easy to deal with spinning conditions.

Owner:MURATA MASCH LTD

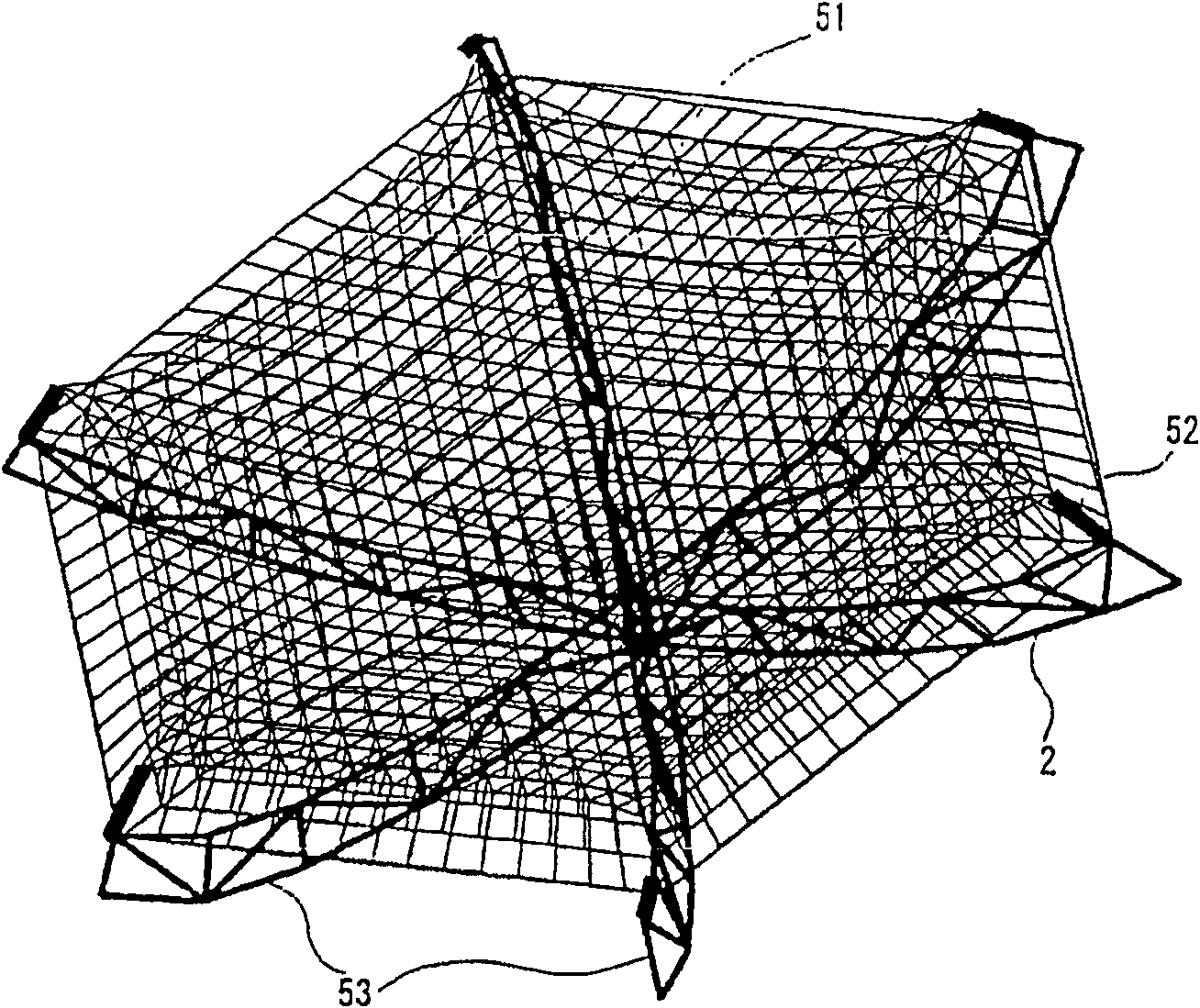

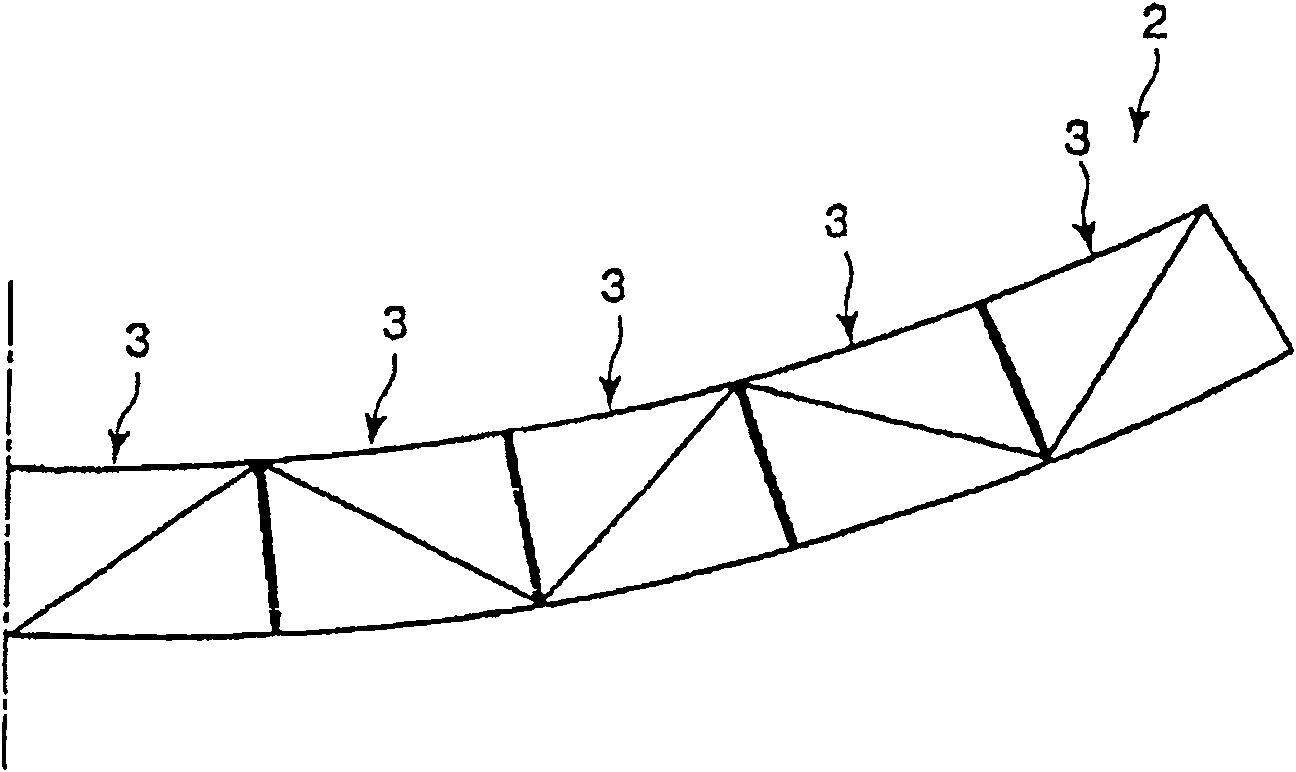

Expansion-type reflection mirror

InactiveCN100541911CReduce Warp SensitivityInhibition of tension changesAntennasMedial surfaceEngineering

The unfolded reflector of the present invention has a connecting device, which is erected between a plurality of telescopic parts constituting the unfolded truss, and connects the part corresponding to the antinode of the buckling mode and the part corresponding to the node, and the buckling mode is Created on telescoping members when tension is applied to surface cables. In addition, the surface cable is composed of the inner surface cable and the outer peripheral surface cable bonded to its outer periphery. The inner surface cable uses a cable with high rigidity and less length change due to tension changes. A cable with low rigidity and small tension changes due to length changes. The inner surface cables are tensioned from the unfolded trusses through the outer peripheral surface cables to form a predetermined mirror shape.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

Blanked refuse winding apparatus for continuous label paper

ActiveCN111348474AUncovered smoothlyAvoid cutsArticle deliveryWebs handlingProcess engineeringPaper sheet

The invention provides a blanked refuse winding apparatus for continuous label paper. The apparatus has a releasing roller that is configured to carry continuous label paper subjected to a half-blanking process and separate into blanked products and blanked refuse that adhere to backing paper, and the blanked refuse winding apparatus for continuous label paper includes: a refuse winding shaft; a moving mechanism; a first detector; a second detector; a calculator; a refuse pressing roller; and a guide belt.

Owner:MIYAKOSHI PRINTING MACHINERY

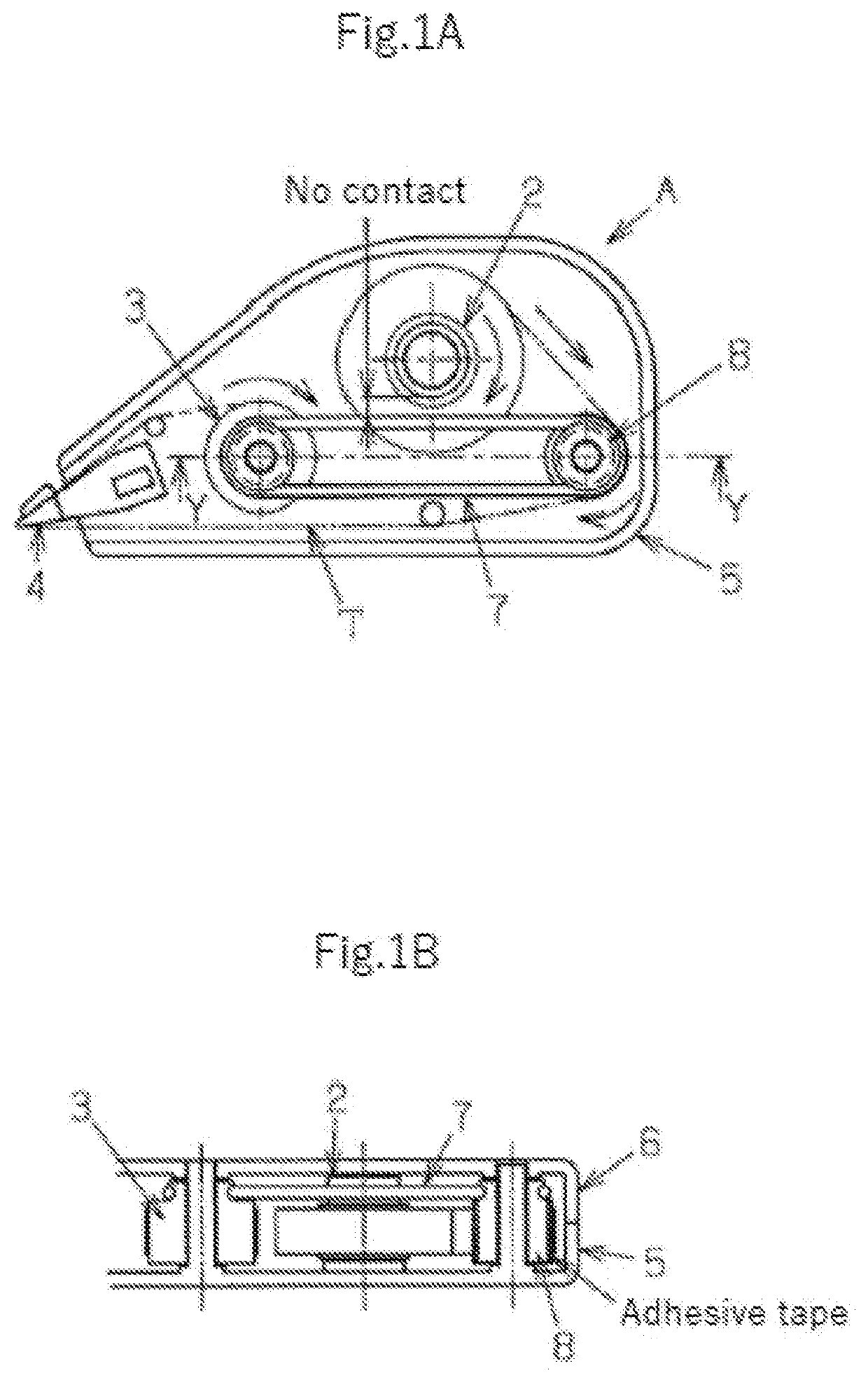

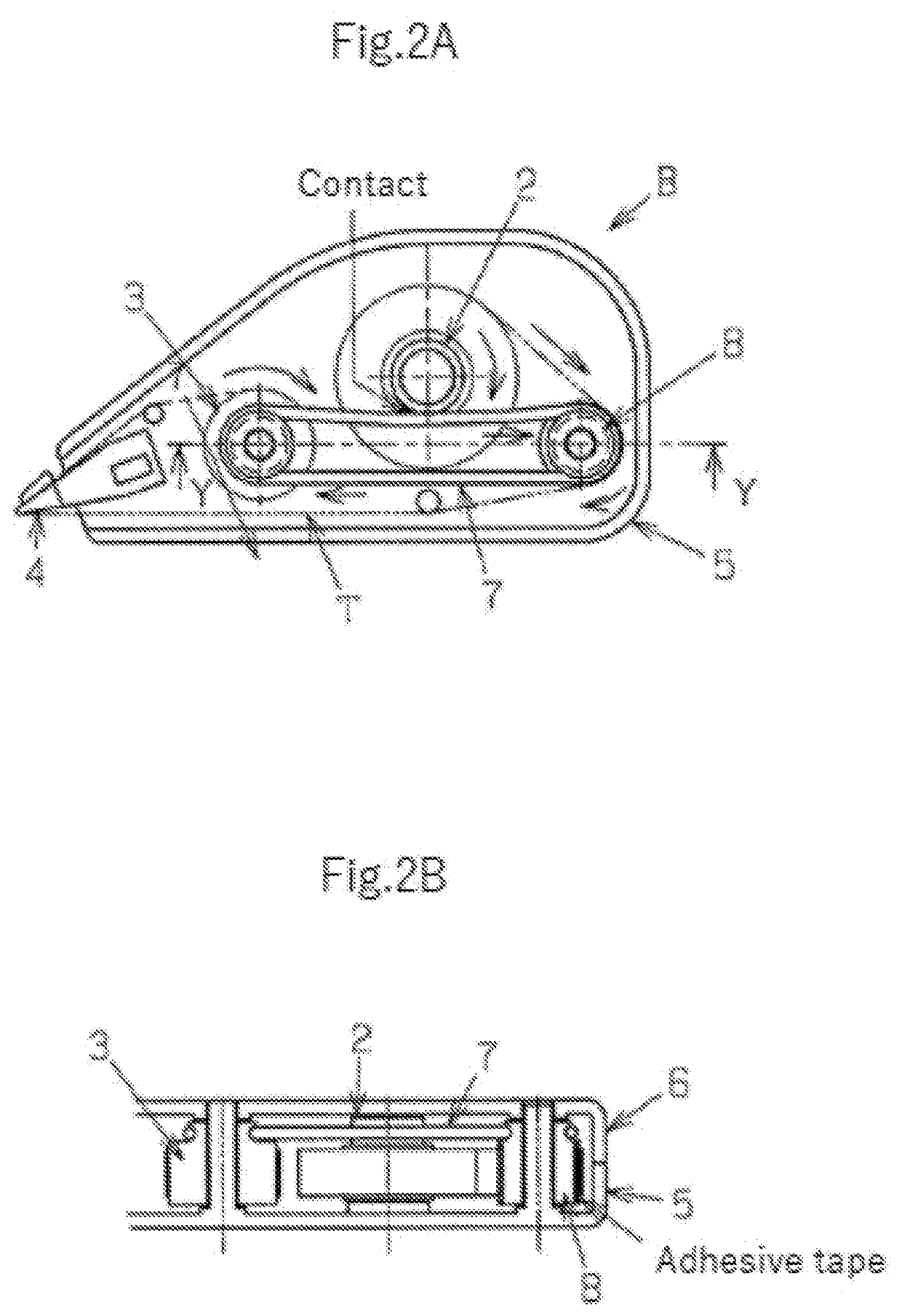

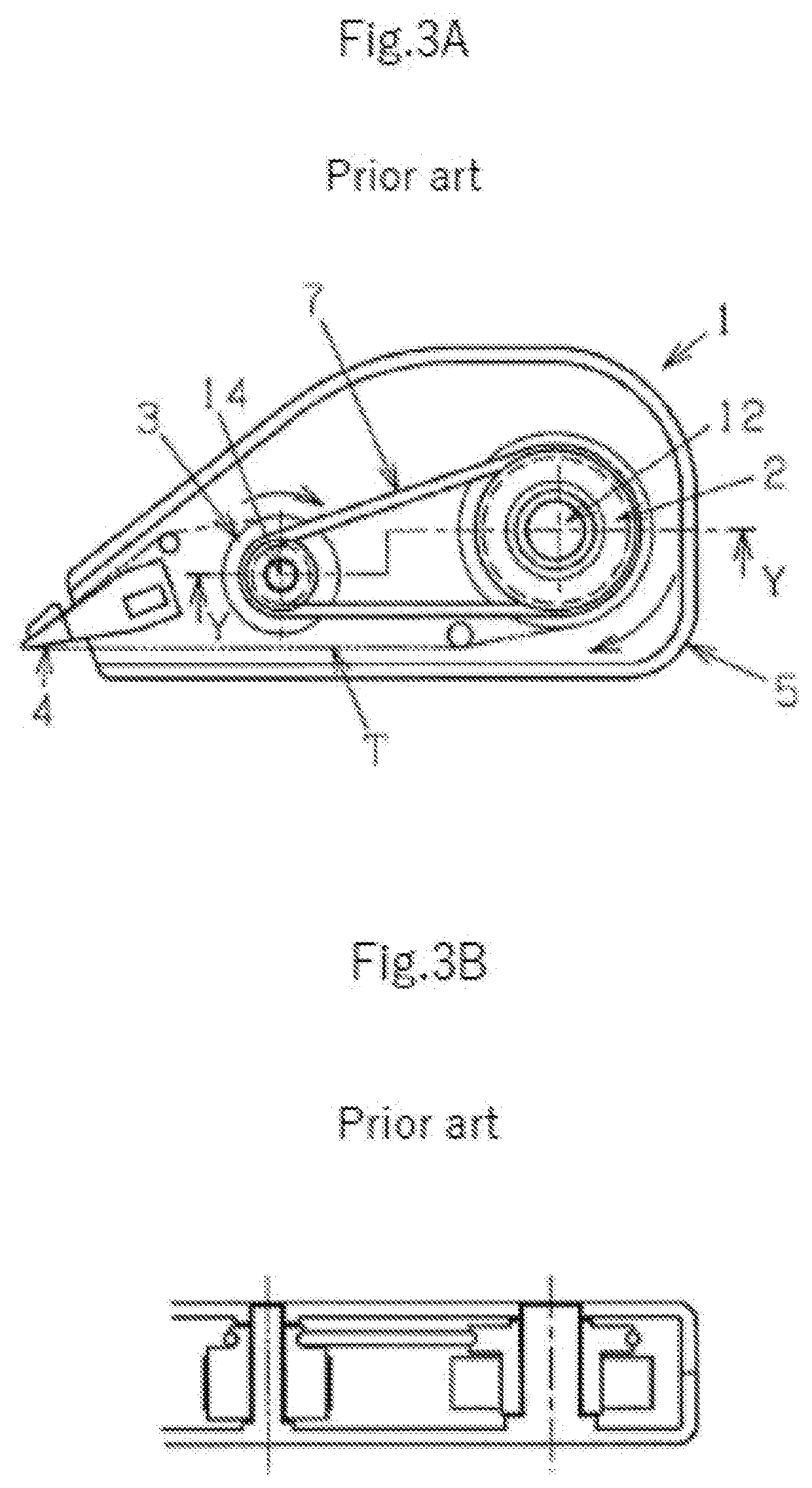

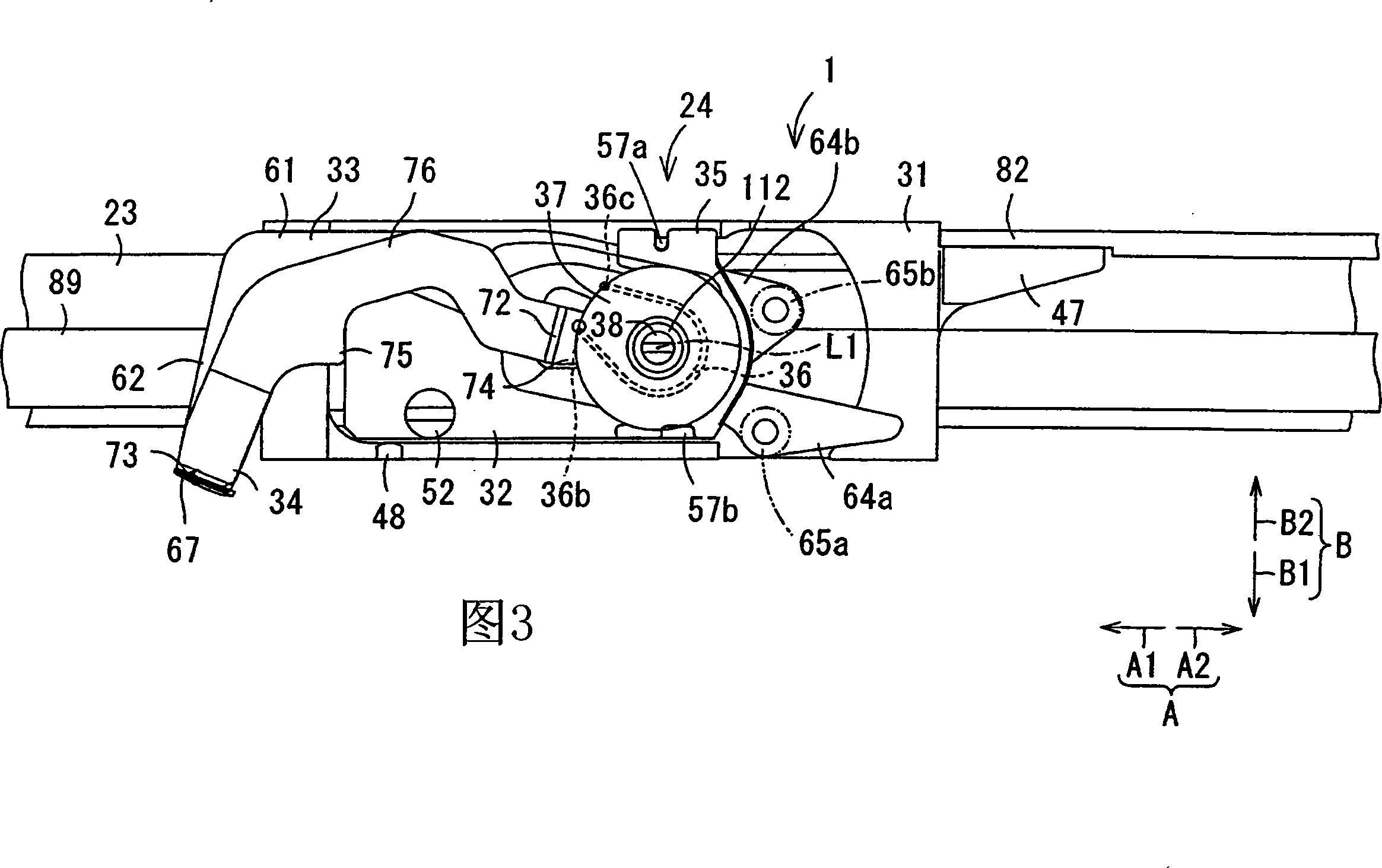

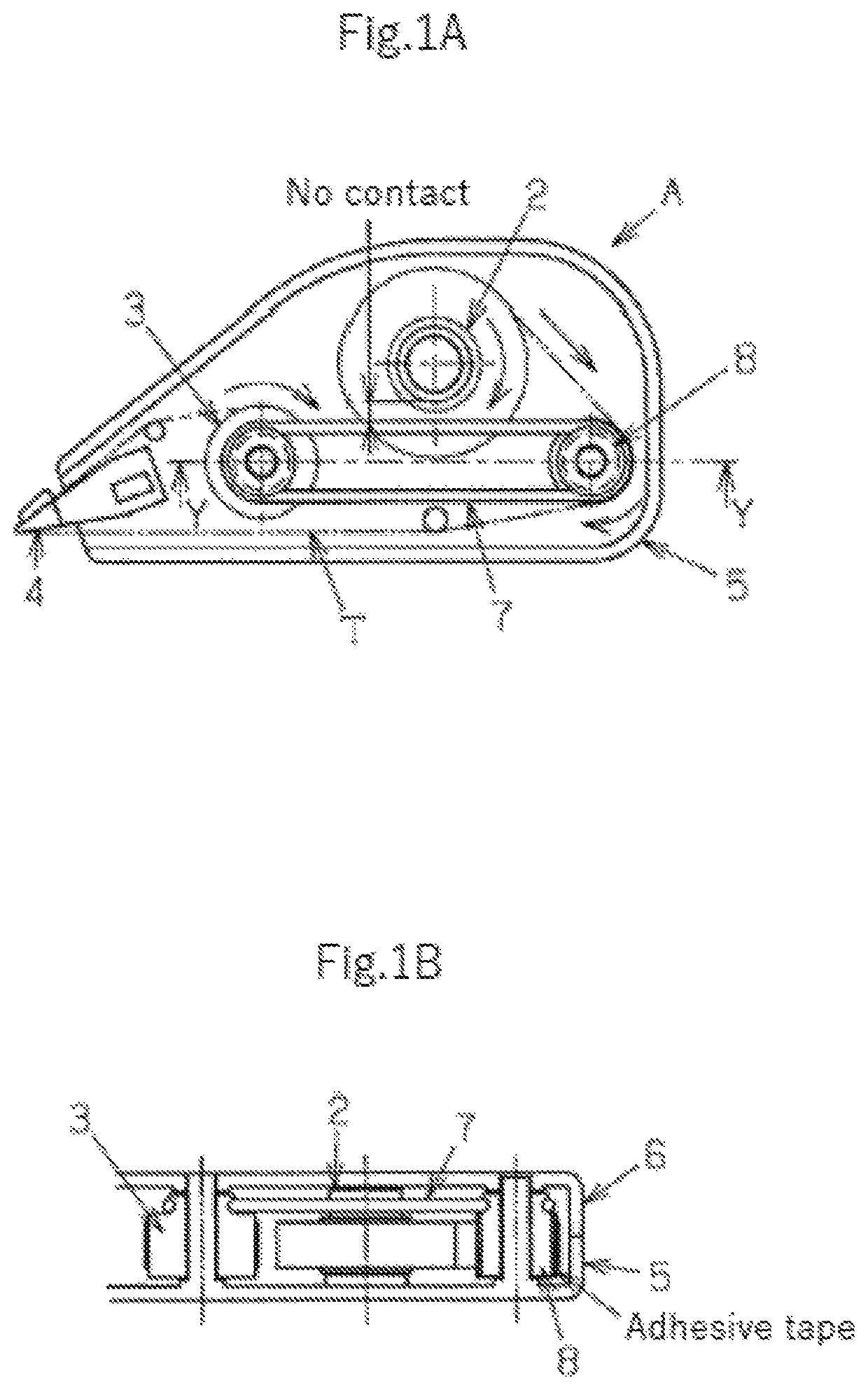

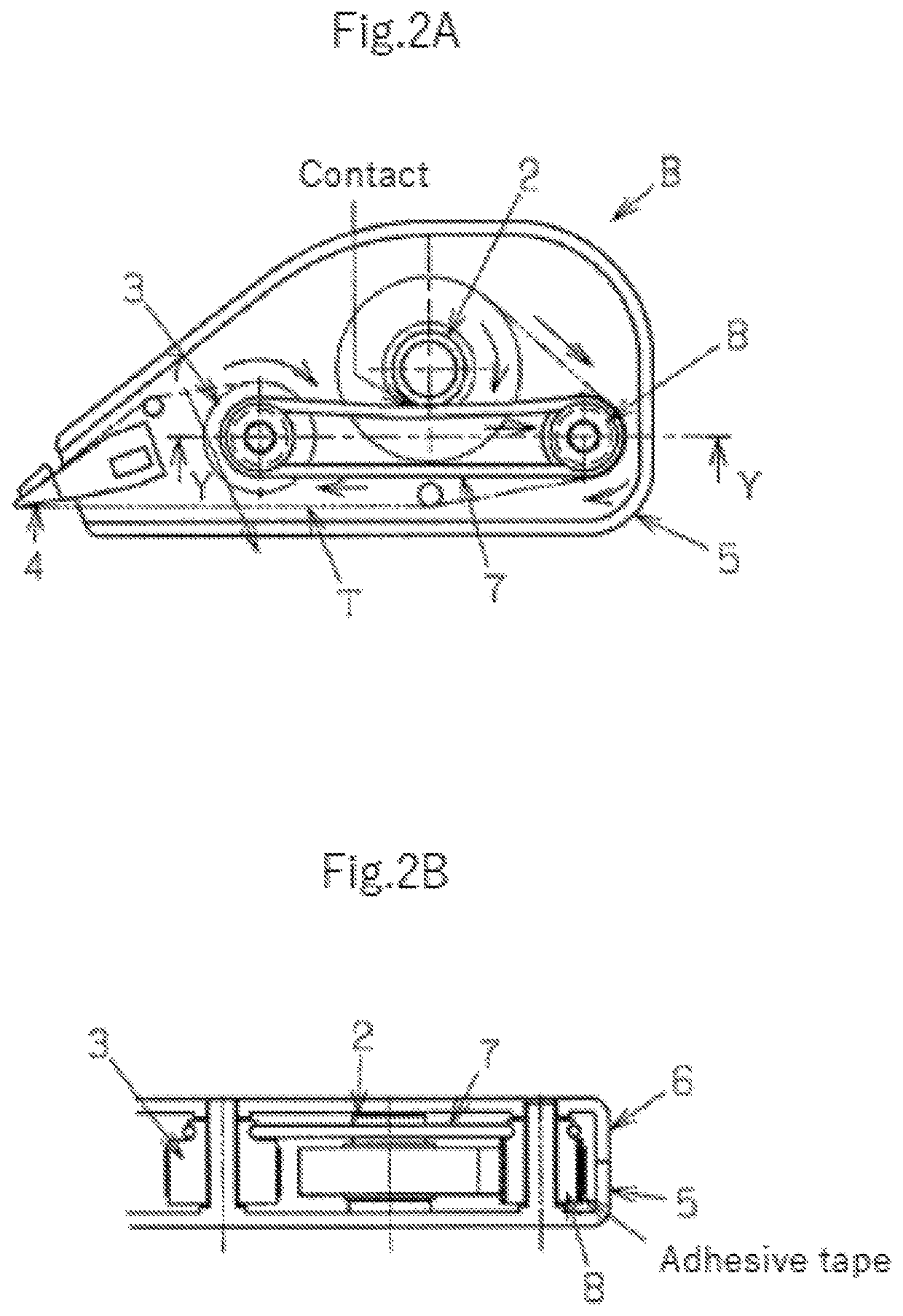

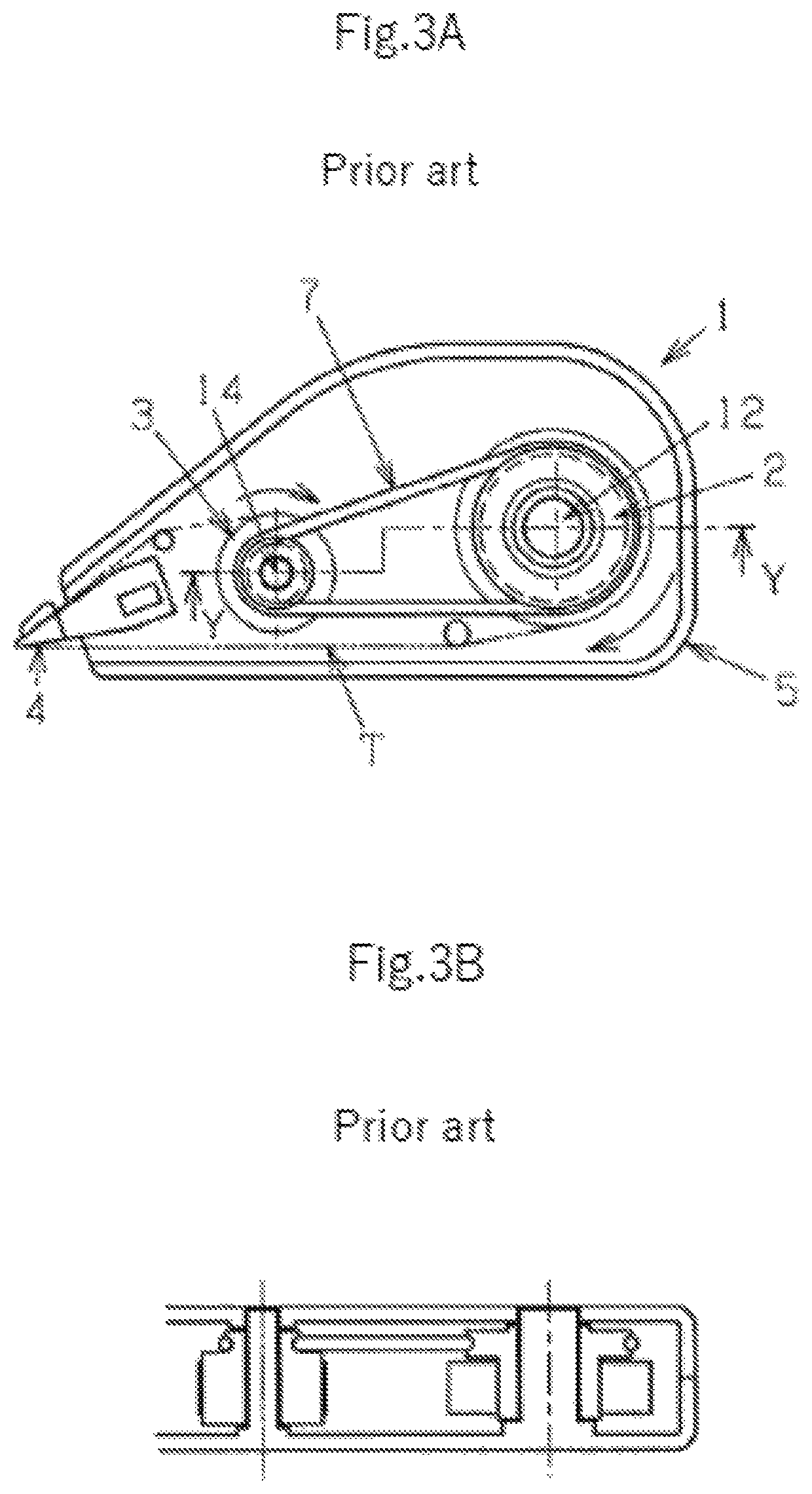

Coating film transfer tool

ActiveUS20200299092A1Suppress changeLow failureErasing devicesHand devicesManufacturing engineeringMechanical engineering

The coating film transfer tool includes: a feeding core around which transfer tape is wound and that feeds a piece of transfer tape, the piece of transfer tape including a piece of base tape and a coating film that is provided on one surface of the piece of base tape; a transfer head that presses the coating film against a transfer target and transfers the coating film thereonto; a winding core that winds up the piece of base tape from which the coating film has been transferred; and an intermediate roller that rotates as the piece of transfer tape travels, in contact with a first surface of the piece of transfer tape fed from the feeding core, the first surface being a surface on which the coating film is not provided. A second surface of the intermediate roller is adhesive with respect to the first surface.

Owner:FUJI COPIAN

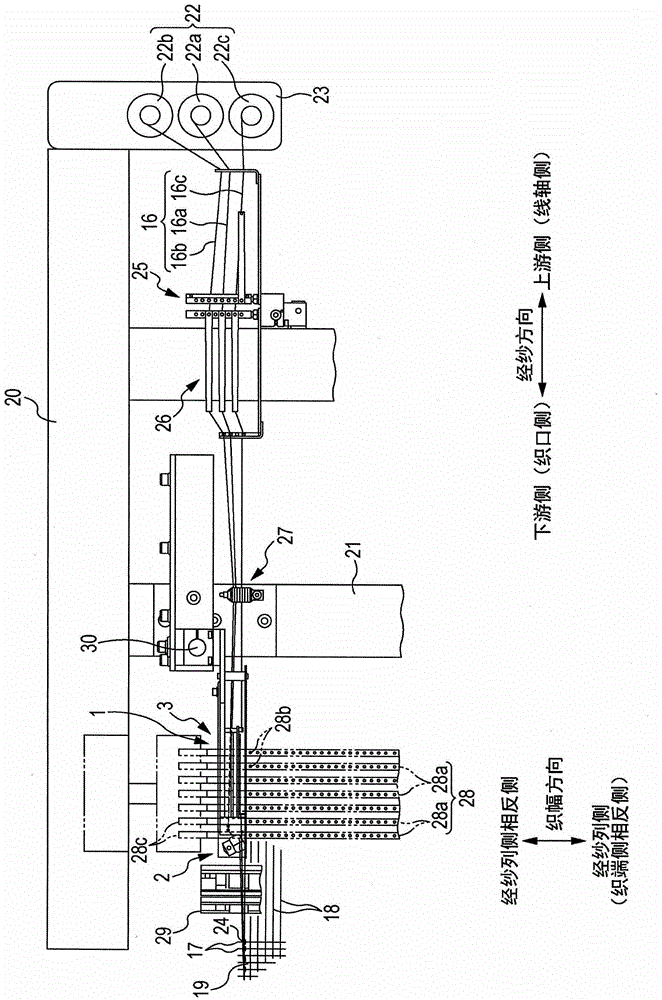

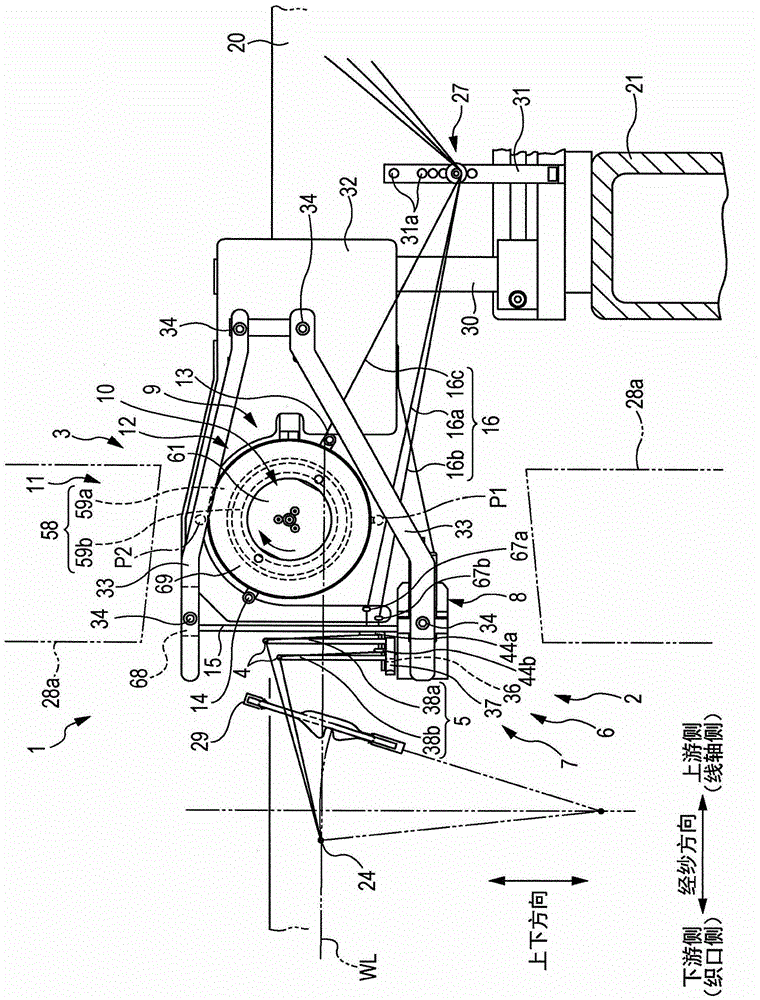

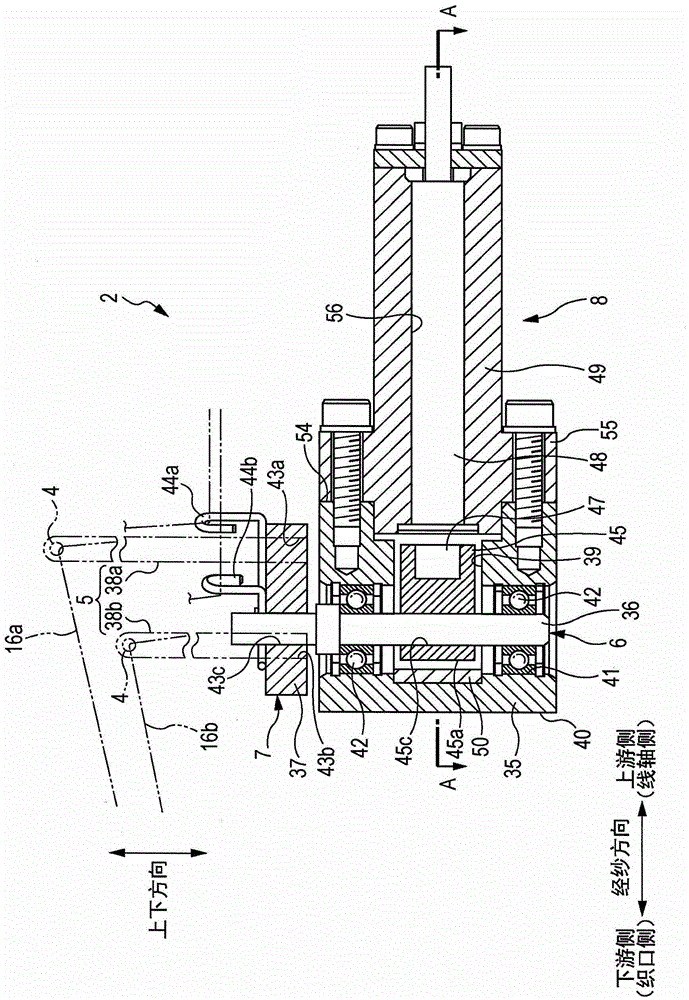

Edge forming device for loom

The present invention provides an edge forming device of a loom, which is capable of increasing the speed of the loom. The edge forming device (1) forms a hemmed weave using the first edge yarns (16a, 16b) and the second edge yarns (16c), which includes means for displacing the path of the first edge yarns (16a, 16b) in the weaving direction. A side yarn path switching device (2) and a side yarn opening device (3) for displacing the path of the second side yarn (16c) in the up and down direction, the side yarn path switching device (2) has: a first side yarn (16a , 16b) the side yarn guiding member (5) of the pierced eyelet (4) and the drive device (8) for switching the position of the eyelet (4) between the left and right positions across the second side yarn (16c), the side yarn opening The device (3) includes a matching part (9) that displaces the path of the second side yarn (16c) in the up-down direction by cooperating with the second side yarn (16c) and displacing the second side yarn (16c). The two side yarns (16c) pass through the position on the side of the side yarn guide member (5) relative to the vertical direction relative to the eyelet (4) on the side of the first driving device (8) and through the front end of the side yarn guide member (5). Revolving on the revolving track at the position opposite to the first driving device (8).

Owner:TSUDAKOMA KOGYO KK

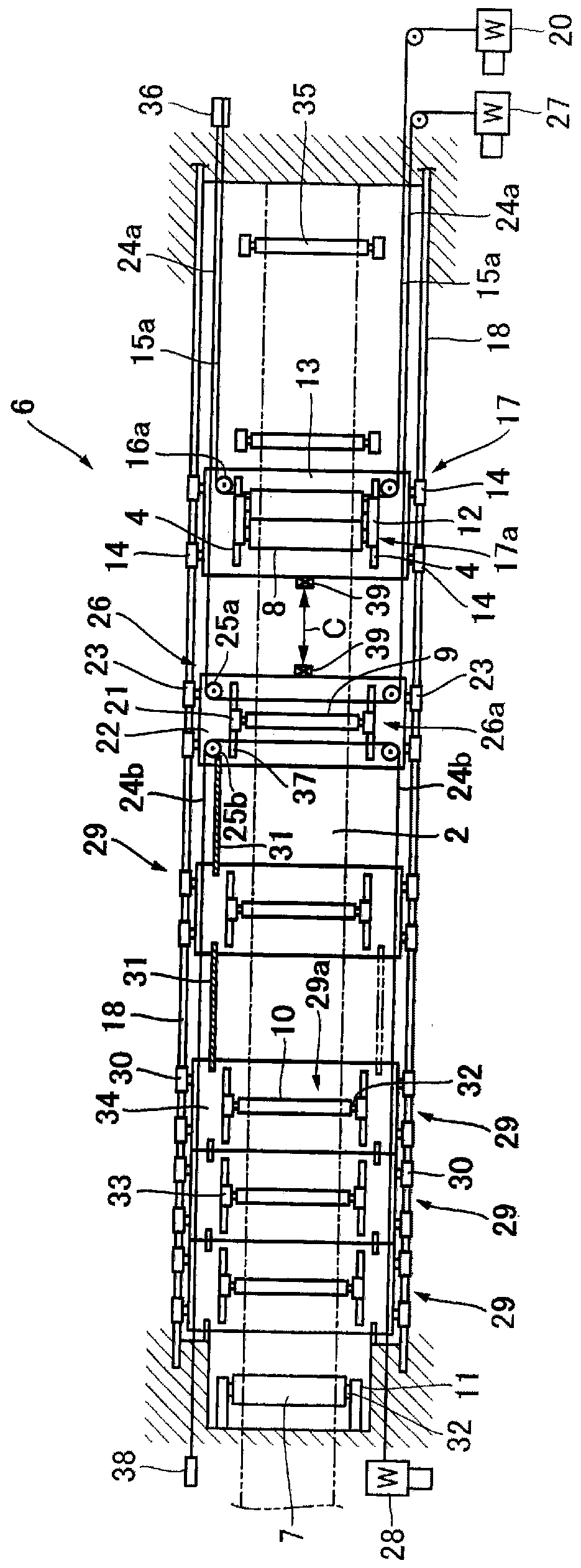

Horizontal looper

ActiveCN111050940BInhibition of tension changesMaterial accumulating devicesMetal stripsControl theory

An object of the present invention is to provide a transverse looper in which fluctuations in tension of a metal strip are suppressed. A transverse looper (6) in a continuous processing line for metal strips (2), which has: fixed rollers (7); a looper (17), which has coils for winding the metal strip together with the fixed rollers Roller (8), and the looper moves in order to change the distance between the fixed roller and the winding roller in the conveying direction of the metal strip, thereby changing the position of the metal strip in the transverse looper. the accumulation volume; and the main support roller car (26), which has backup rollers (9) supporting the metal strip erected between the fixed roller and the winding roller, and moves in the same direction as the looper car, The looper car and the main support roller car have independent looper winches (20), exit side winches (27), and entrance side winches (28), respectively, and can move independently.

Owner:CHUGAI RO CO LTD

End-yarn insertion device

InactiveCN101158086BInhibition of tension changesReliable clampingGlovesFlat-bed knitting machinesYarnEngineering

The invention provides an end yarn insertion device which clamps the end yarn to insert into the internal of knitted fabrics. End yarn insertion device (1) is set on a flat knitting machine for glove (2), with a guide track (23) and a base (31) sliding transitionally along the guide track (23). The base (31) is equipped with a movable object (32) shifting relatively relative to the base (31). Themovable object (32) is equipped with an end yarn hook (33) and an end yarn pressing foot (34). The end yarn hook (33) shifts between the capture position of capture yarn and the hook backoff positionof knitting needle backoff. The end yarn pressing foot (34) acts continuously with the end yarn hook (33), shifting on the clip position where it coordinates with the end yarn hook on the capture position to span support position supporting yarn captured by the end yarn hook and on the pressing foot backoff position where it yields with the knitting needle and the end yarn hook (33). A second driving mechanism (26) drives the end yarn hook (33) to shift between the capture position and the hook backoff position. The base (31) is equipped with a stopper (48). The stopper (48) jams and fixes the end yarn pressing foot(34) shifting from the pressing foot backoff position to the support position to prevent shifting, ensure that the end yarn pressing foot stands by on the stand-by position where the yarn of yarn feeding yields. And the end yarn pressing foot (34) is detached from the stopper (48) by shifting the movable object (32) relatively relative to the base(31).

Owner:SHIMA SEIKI MFG LTD

Horizontal looper

ActiveCN111050940AInhibition of tension changesMaterial accumulating devicesMetal stripsControl engineering

The purpose of the present invention is to provide a horizontal looper wherein changes in tension for a metal strip are suppressed. A horizontal looper 6 for a continuous processing line for a metal strip 2 is provided with: a loop car 17 that has a fixed roller 7 and a winding roller 8 on which the metal strip is wound along with the fixed roller, and that moves so as to change the gap between the fixed roller and the winding roller in the direction in which the metal strip is conveyed, thereby changing the amount of the metal strip accumulated in the horizontal looper; and a main support roller car 26 that has a support roller 9 for supporting the metal strip crossing between the fixed roller and the winding roller, and that moves in the same direction as the loop car. The loop car and the main support roller car have a loop car winch 20, an output side winch 27, and an introduction side winch 28 that are independent from each other, and can move independently.

Owner:CHUGAI RO CO LTD

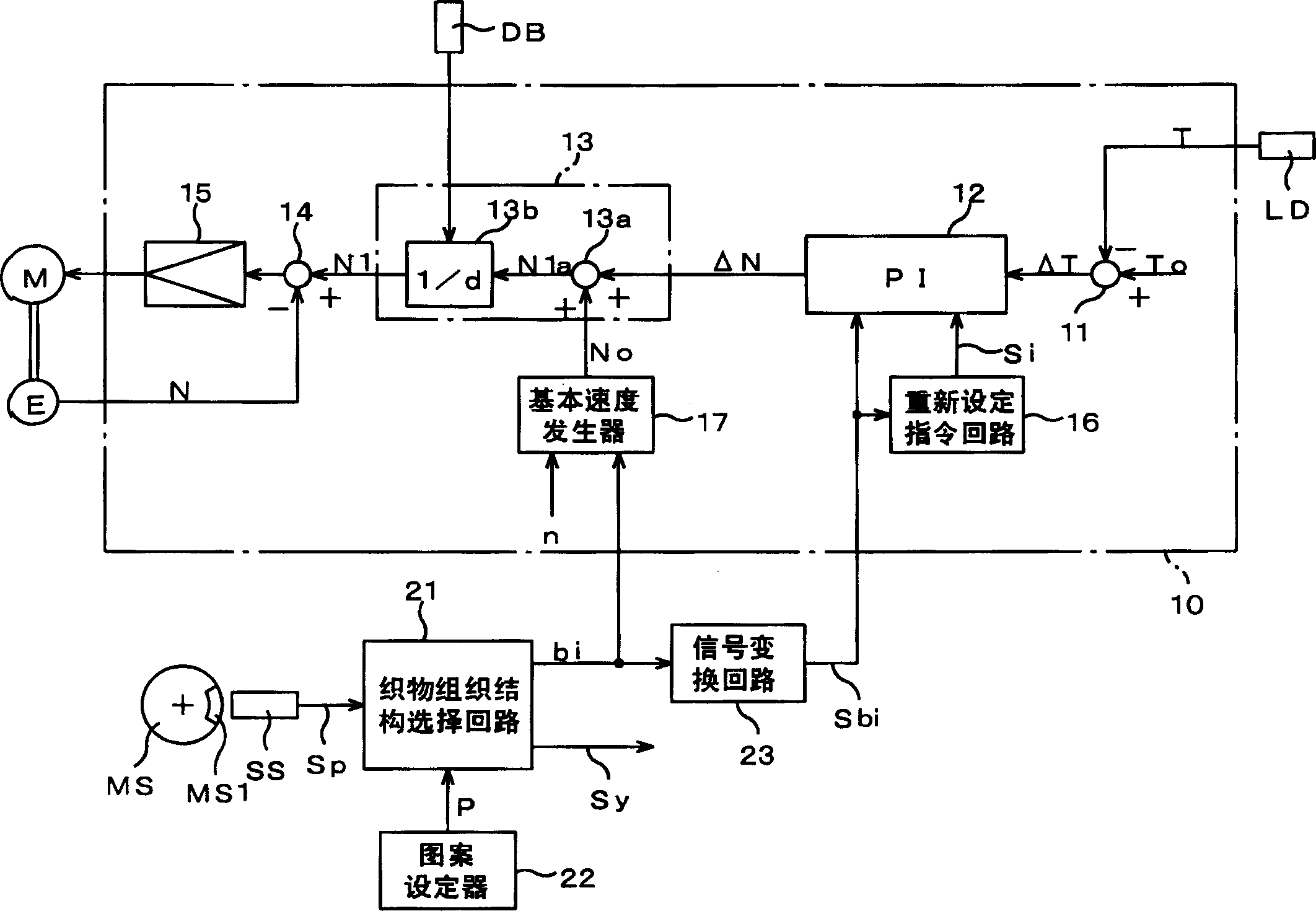

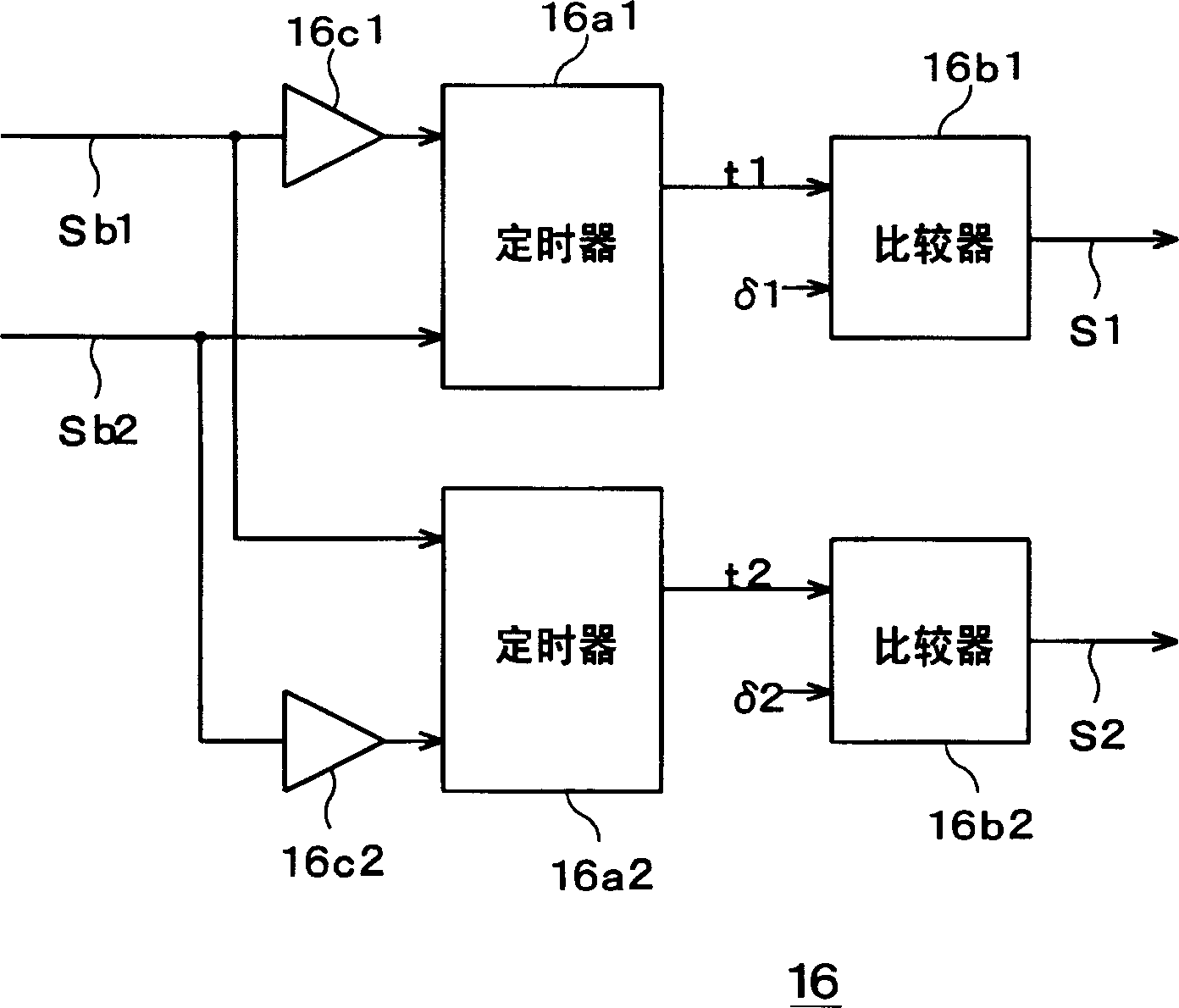

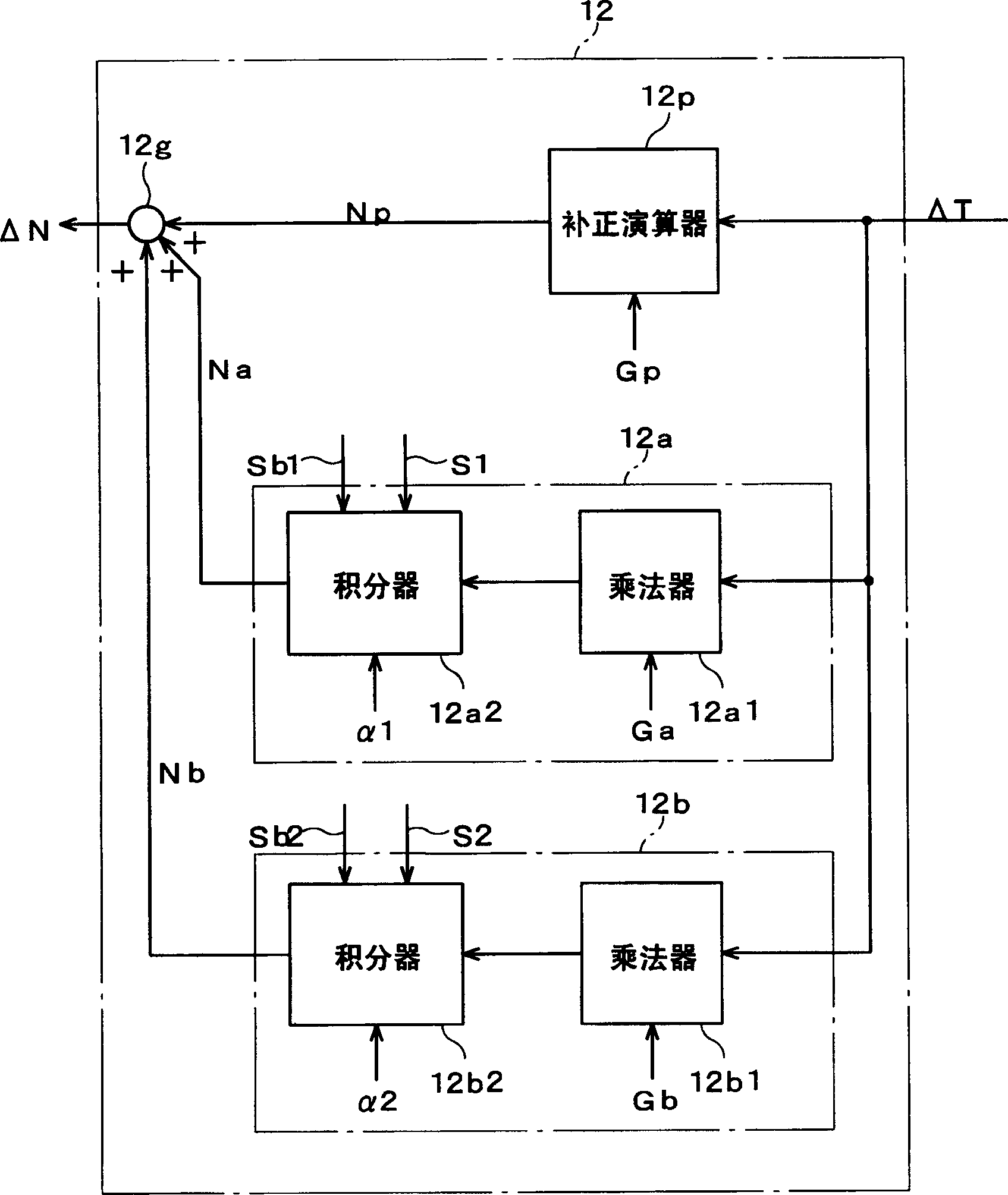

Method and device for controlling febric output for loom

The invention is the method and device for controlling febric output for loom. The aim of which is to provide a method of the feed control for a loom capable of clearly expressing a border of textile weave on the woven cloth. This system includes an integration element-containing corrective arithmetic means 12 and a command speed arithmetic means 13; wherein the means 12 functions to selectively couple the integral value of the integration element with either the final integral value in the preceding selective period or a preset value each time weaving conditions P change, thus quickly moving the position of a cloth fell.

Owner:TSUDAKOMA KOGYO KK

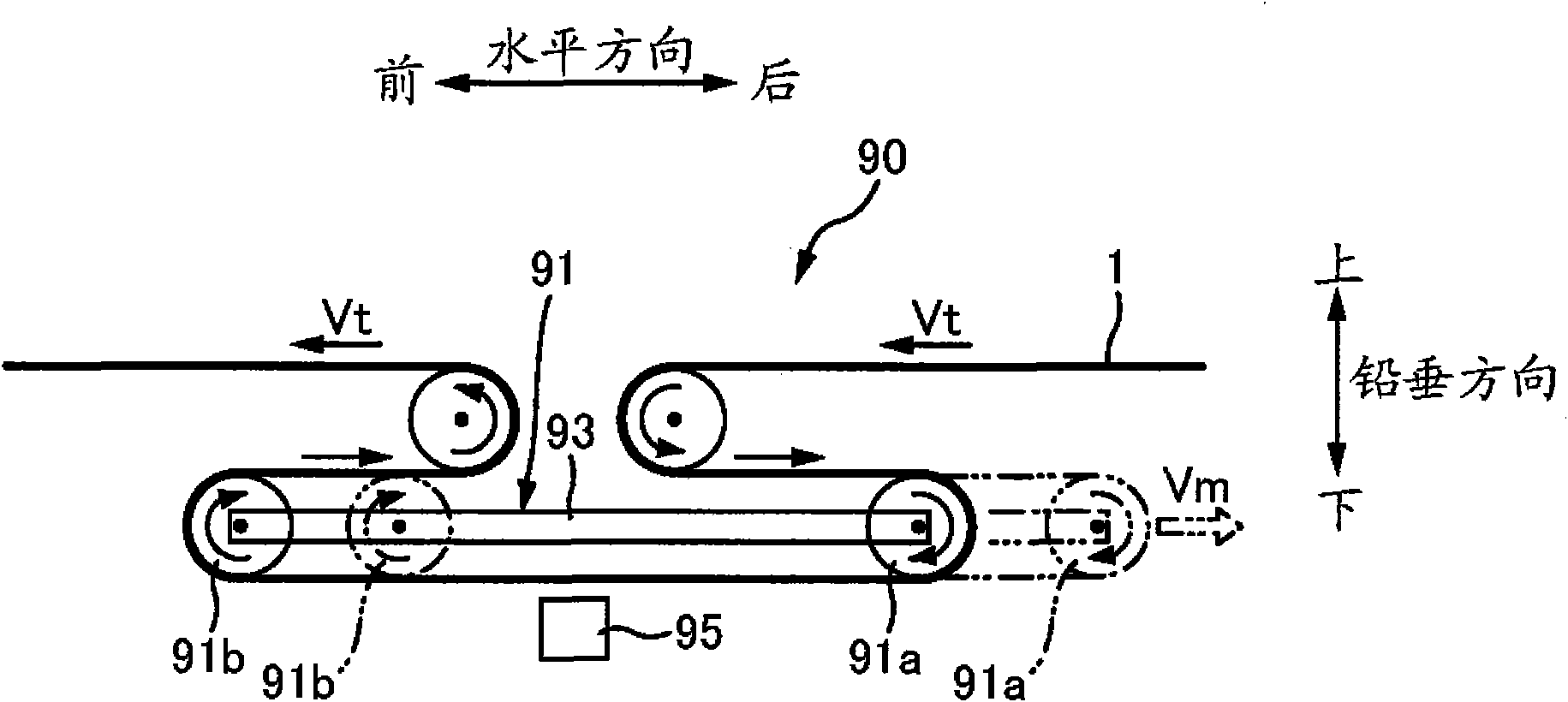

Conveyance apparatus of web print medium

ActiveUS10189286B2Inhibition of tension changesTension change of the web can be suppressedOther printing apparatusWebs handlingEngineeringControl parameters

A conveyance apparatus includes a conveyance roller, a conveyance motor, a back tension roller, a conveyance speed detector, a brake, and a controller. The controller is configured to: based on a conveyance speed of a web detected by the conveyance speed detector, control a value of a drive control parameter of the conveyance motor such that the conveyance speed of the web is equal to a target speed; and, based on an output torque of the conveyance motor corresponding to the value of the drive control parameter, adjust a braking force of the brake applied to the back tension roller which applies a tension to the web such that the tension of the web is equal to a target tension.

Owner:RISO KAGAKU CORP

End-yarn insertion device

InactiveCN101158087BReliable clampingPrevent handling damageGlovesFlat-bed knitting machinesYarnEngineering

The invention provides an end yarn insertion device which clamps the end yarn to insert into the internal of knitted fabrics. End yarn insertion device (1) is set on a flat knitting machine for glove (2), with a guide track (23) and a base (31) sliding transitionally along the guide track (23). The base (31) is equipped with a movable object (32) shifting relatively relative to the base (31). Themovable object (32) is equipped with an end yarn hook (33) and an end yarn pressing foot (34). The end yarn hook (33) shifts between the capture position of capture yarn and the hook backoff positionof knitting needle backoff. The end yarn pressing foot (34) acts continuously with the end yarn hook (33), shifting on the clip position where it coordinates with the end yarn hook on the capture position to span support position supporting yarn captured by the end yarn hook and on the pressing foot backoff position where it yields with the knitting needle and the end yarn hook (33). A second driving mechanism (26) drives the end yarn hook (33) to shift between the capture position and the hook backoff position. The base (31) is equipped with a stopper (48). The stopper (48) jams and fixes the end yarn pressing foot(34) shifting from the pressing foot backoff position to the support position to prevent shifting, ensure that the end yarn pressing foot stands by on the stand-by position where the yarn of yarn feeding yields. And the end yarn pressing foot (34) is detached from the stopper (48) by shifting the movable object (32) relatively relative to the base(31).

Owner:SHIMA SEIKI MFG LTD

Coating film transfer tool

ActiveUS11492225B2Inhibition of tension changesErasing devicesHand devicesMechanical engineeringCoating

The coating film transfer tool includes: a feeding core around which transfer tape is wound and that feeds a piece of transfer tape, the piece of transfer tape including a piece of base tape and a coating film that is provided on one surface of the piece of base tape; a transfer head that presses the coating film against a transfer target and transfers the coating film thereonto; a winding core that winds up the piece of base tape from which the coating film has been transferred; and an intermediate roller that rotates as the piece of transfer tape travels, in contact with a first surface of the piece of transfer tape fed from the feeding core, the first surface being a surface on which the coating film is not provided. A second surface of the intermediate roller is adhesive with respect to the first surface.

Owner:FUJI COPIAN

Wire winding system, tension device, and wire winding method

InactiveCN101454850BInhibition of tension changesFilament handlingCoils manufactureEngineeringConductor Coil

The invention provides a winding device, a tension device and a winding method. A winding device 100 which winds a wire 3 around a core 11 includes the core 11, which rotates axially and around which the wire 3 is wound; a roller 21 which rotates axially and feeds the wire 3, which is wound around the roller 21, to the core 11; and a tension device 15 which adjusts a tension of the wire 3 that issupplied to the core 11 from the roller 21. A winding shape and a winding diameter of the wire 3 wound around the roller 21 are substantially identical to a winding shape and a winding diameter of the wire 3 wound around the core 11.

Owner:NITTOKU ENG CO LTD

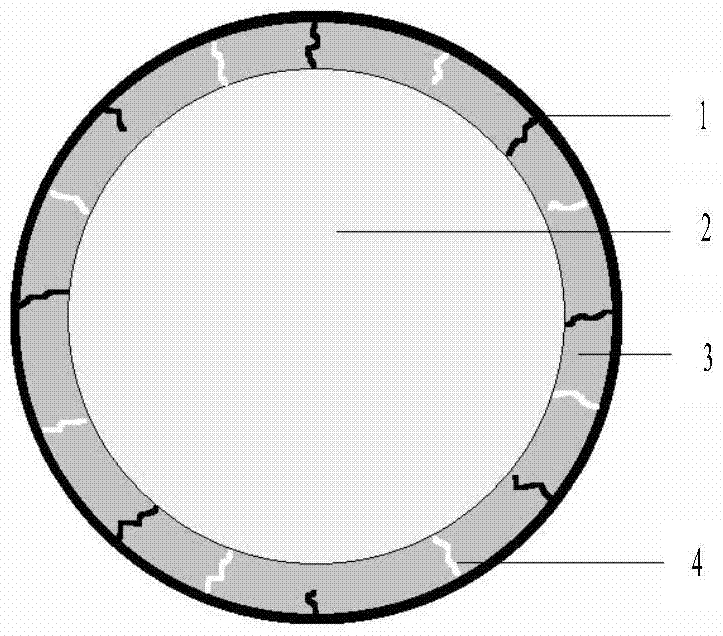

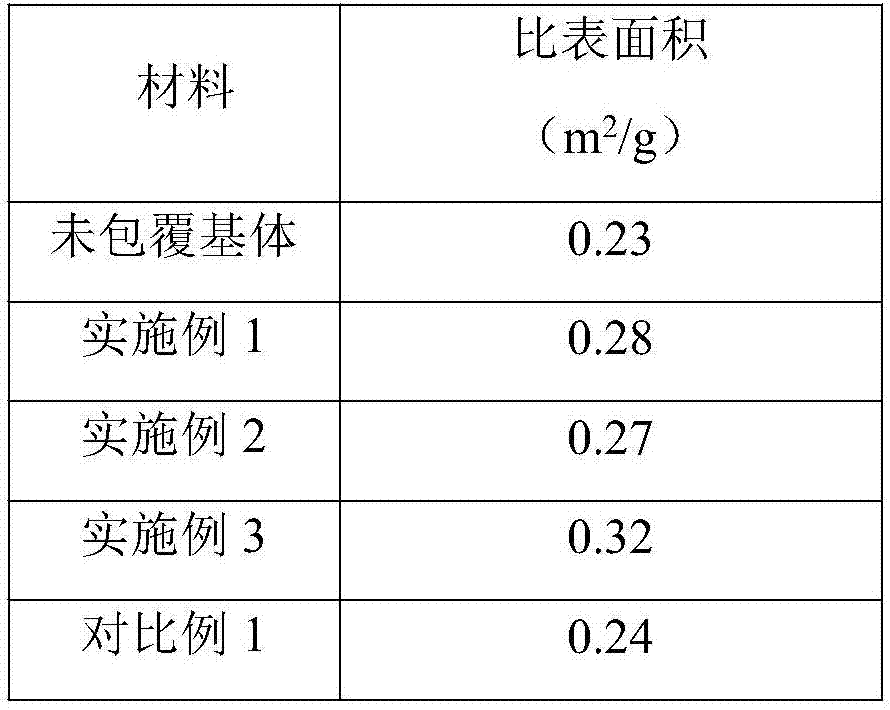

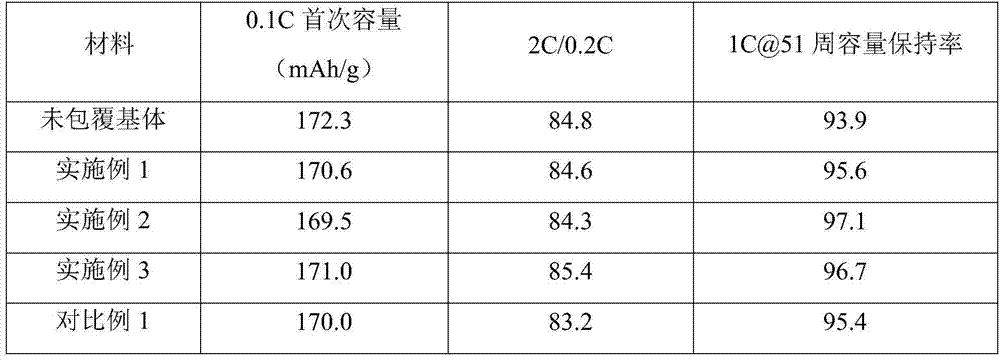

A kind of lithium-ion battery composite coated cathode material and preparation method thereof

ActiveCN105244488BLarge specific surface areaFacilitate adjustment of tension changesCell electrodesSecondary cellsCyclic processSurface layer

The invention provides a compound cladding positive pole material of a lithium ion battery and a preparation method of the compound cladding positive pole material. The positive pole material comprises a positive pole material base body and a cladding layer, wherein the cladding layer comprises two parts: a metal oxide main body framework layer with a porous three-dimensional structure, a surface layer distributed on the main body framework layer and a rapid ion conductor layer located in a pore. The compound cladding layer produced by the method has a relatively large and controllable specific surface area, and the contact between the cladding layer and electrolyte can be effectively improved, and the rate performance of the material can be effectively improved; meanwhile, the compound cladding layer has good chemical stability, and a contact side reaction between the positive pole material base body and the electrolyte is inhibited; and meanwhile, the damages to the surface cladding layer of the material, caused by the deformation in a rolling process of a pole piece, and the tension change of the cladding layer in a circulating process are inhibited; and the degradation of the positive pole material in the circulating process can be effectively improved and the circulating stability of the battery is improved.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com