Timing belt

A timing belt and belt body technology, applied in the direction of transmission belts, belts/chains/gears, mechanical equipment, etc., can solve problems such as difficult reinforcement methods, and achieve the effects of enhancing rigidity, reducing wear, and preventing longitudinal tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

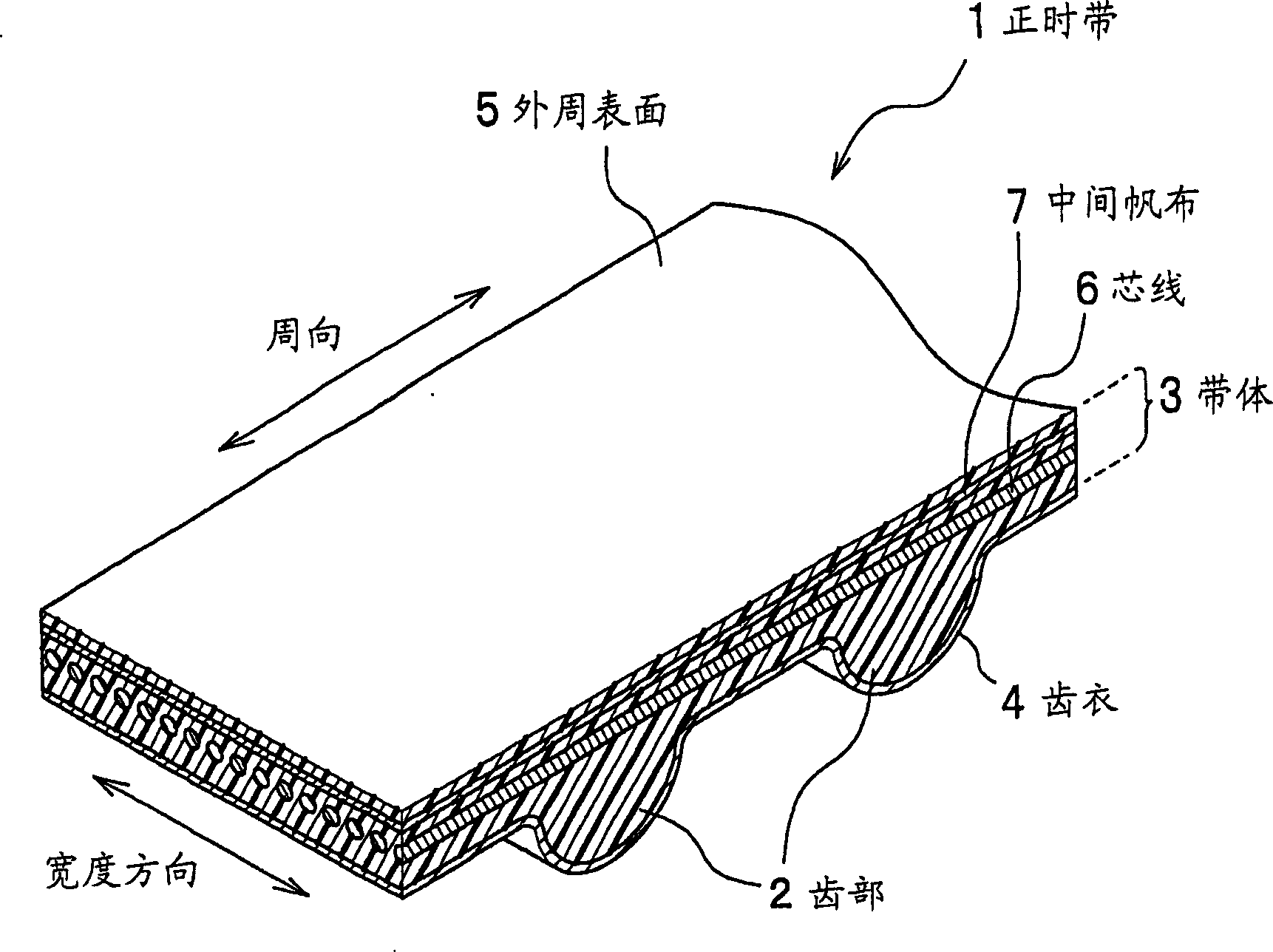

[0028] The best mode for carrying out the present invention will be described in detail below with reference to the appropriate drawings. figure 1 It is a cross-sectional perspective view showing a part of the timing belt of this embodiment. Since the timing belt is generally used in severe environments where the timing belt is liable to deteriorate, such as an increase in ambient temperature and contact with engine oil and cooling water, durability that can withstand these environments is required.

[0029] Such as figure 1 As shown, the timing belt 1 includes: an endless belt body 3; a plurality of tooth portions 2 formed at predetermined intervals along the inner peripheral surface of the belt body 3; a tooth coat 4 covering the surface of the tooth portion 2; The core wire 6 embedded in the circumferential direction; and the intermediate canvas 7 provided on the outer peripheral side of the core wire 6 in the belt body 3 .

[0030] The setting of the middle canvas 7 to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com