A kind of lithium-ion battery composite coated cathode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem that the coating uniformity of fast ion conductor materials and metal oxides cannot be guaranteed, affects the rate performance of materials, and destroys the structure of positive electrode materials To improve the contact between the coating layer and the electrolyte, improve the rate performance of the material, and improve the rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

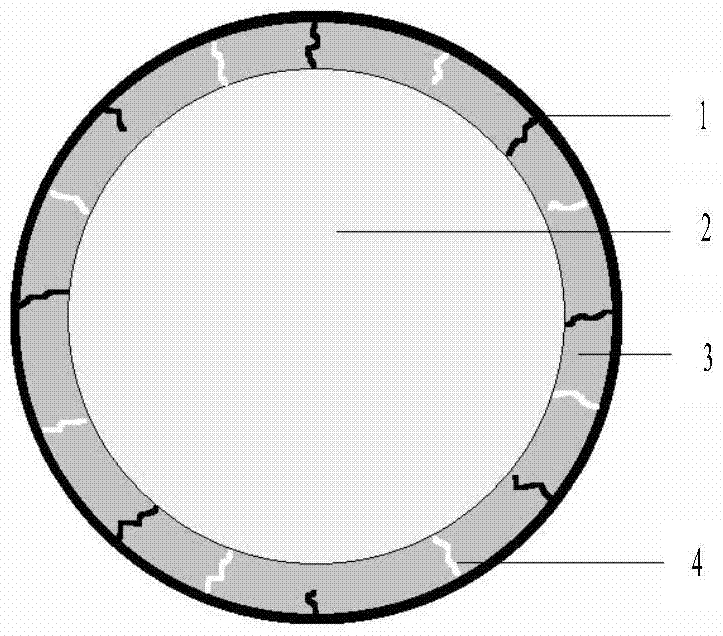

[0034] A composite coated positive electrode material for a lithium ion battery of the present invention, its structural schematic diagram is as follows figure 1 As shown, it includes a positive electrode material matrix 2 and a coating layer, wherein the coating layer includes two parts: a metal oxide main frame layer 3 with a porous three-dimensional structure 4, and a fast ion conductor material 1 distributed on the surface layer of the metal oxide and inside the pores. .

[0035] The preparation method of the lithium-ion battery composite coating positive electrode material of the present embodiment comprises the following steps:

[0036](1) Dissolve 13.903g of aluminum nitrate nonahydrate in 300mL of deionized water, mix and stir evenly to obtain metal salt solution A; put 0.5g of polyvinyl alcohol into solution A, ultrasonically disperse for 15min, then gradually add ammonia water to precipitate, and control solution A The pH value of the solution is 7.0-7.5 to obtain a...

Embodiment 2

[0040] A composite coated positive electrode material for a lithium ion battery of the present invention, comprising a positive electrode material matrix and a coating layer, wherein the coating layer includes two parts: a metal oxide main frame layer with a porous three-dimensional structure, and a layer distributed on the surface layer of the metal oxide and The fast ion conductor layer inside the pores.

[0041] The preparation method of the lithium-ion battery composite coating positive electrode material of the present embodiment comprises the following steps:

[0042] (1) Dissolve 27.807g of aluminum nitrate nonahydrate in 300mL of deionized water, mix and stir evenly to obtain metal salt solution A; put 0.5g of polyvinyl alcohol into solution A, ultrasonically disperse for 15min, then gradually add ammonia water for precipitation, and control solution A The pH value of the solution is 7.0-7.5 to obtain a sol;

[0043] (2) Add 1000g uncoated LiNi to the above sol 0.5 c...

Embodiment 3

[0046] A composite coated positive electrode material for a lithium ion battery of the present invention, comprising a positive electrode material matrix and a coating layer, wherein the coating layer includes two parts: a metal oxide main frame layer with a porous three-dimensional structure, and a layer distributed on the surface layer of the metal oxide and The fast ion conductor layer inside the pores.

[0047] The preparation method of the lithium-ion battery composite coating positive electrode material of the present embodiment comprises the following steps:

[0048] (1) Dissolve 27.807g of aluminum nitrate nonahydrate in 300mL of deionized water, mix and stir evenly to obtain metal salt solution A; put 1g of polyvinyl alcohol into solution A, ultrasonically disperse for 15min, and then gradually add ammonia water for precipitation to control the concentration of solution A. The pH value is 7.0-7.5, and the sol is obtained;

[0049] (2) Add 1000g uncoated LiNi to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com