Wire winding device

A wire winding device and wire reel technology, which is applied in the directions of electromechanical devices, coil manufacturing, transportation and packaging, can solve problems such as poor ability to suppress tension changes, and achieve the effect of shortening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

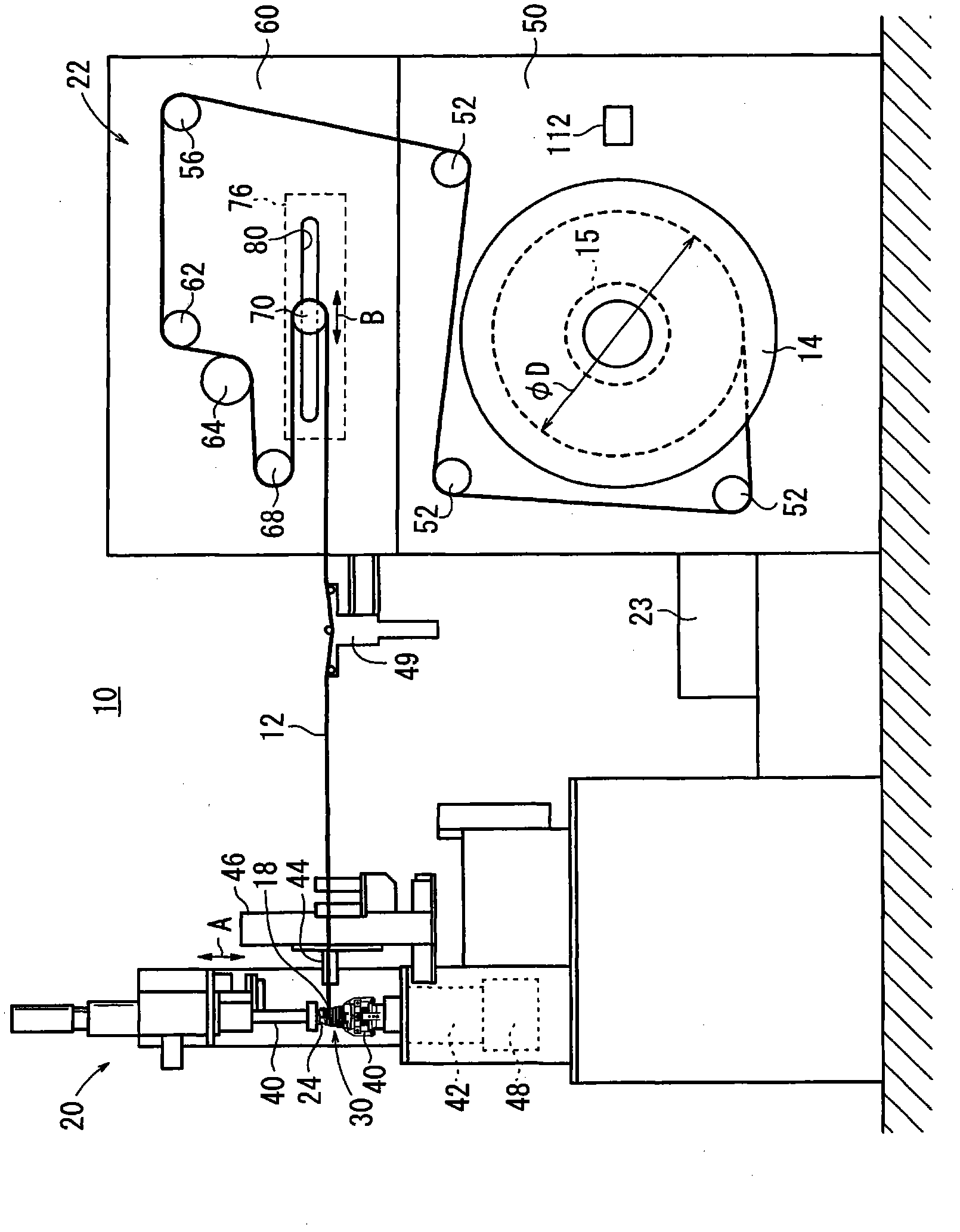

[0034] Embodiments of the winding device according to the present invention will be provided below, and with reference to the attached Figures 1 to 8 Be explained.

[0035] Such as figure 1 As shown, the wire winding device 10 according to the present embodiment includes: a supply reel 14 for supplying (feeding out) the wire 12 (lead wire) wound thereon; and a coil forming part 20 for The coil forming part 20 forms the coil 18 by winding the supplied wire material 12 on the bobbin 30; Tension changes generated when the wire 12 is wound; and a controller 23 used for overall control of the wire winding device 10 . The wire 12 is, for example, a copper wire with an enamel or polyurethane covering.

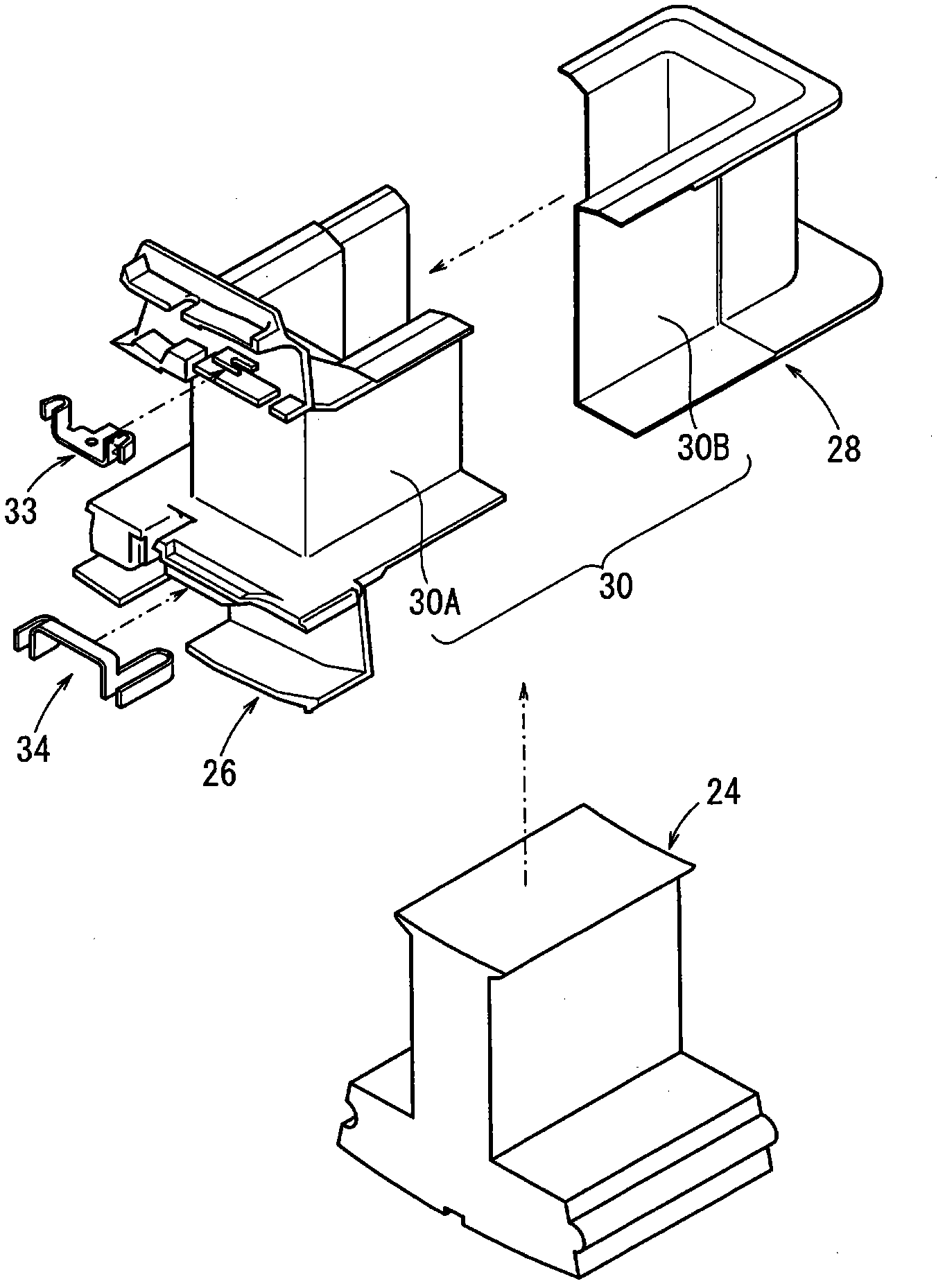

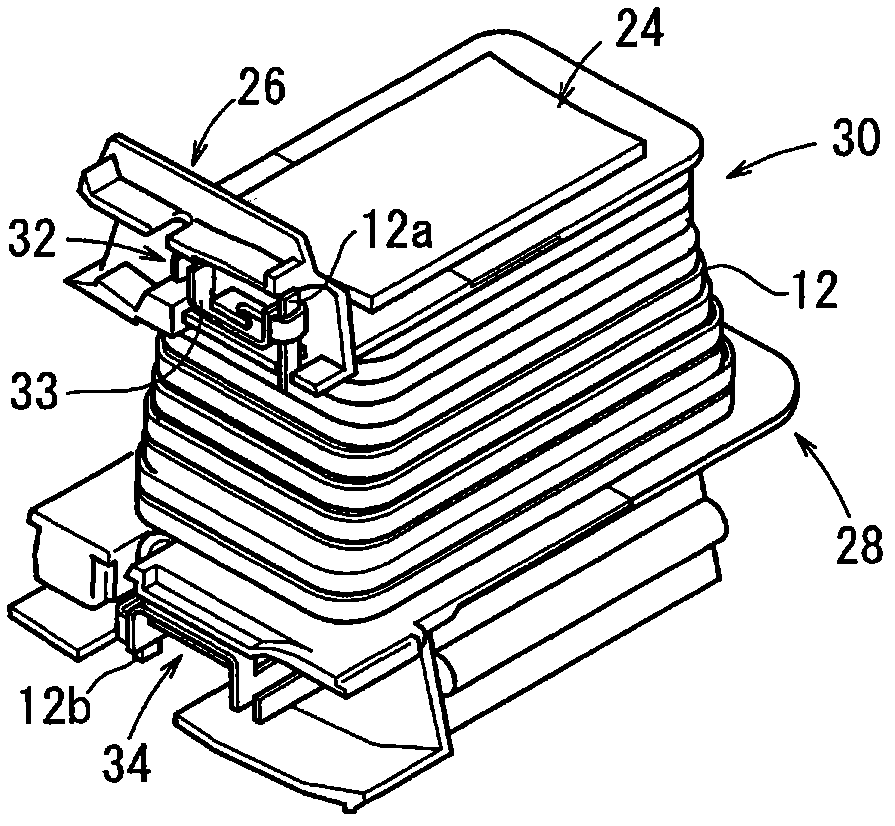

[0036] Such as figure 2 and image 3As shown, the coil 18 includes: a stack of steel plates (core) 24 consisting of a plurality of generally T-shaped steel plates that are perforated by a press and pressed together in one piece; insulated from the wire 12 wound around the stac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com