Staggered supporting wheel type crawler device

A technology of rollers and tracks, which is applied in the field of off-road vehicles, can solve the problems of easy slippage of the transmission rollers, inability to travel smoothly, and tension changes, and achieve the effects of low power consumption, prevention of tension changes, and reduction in amplitude.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

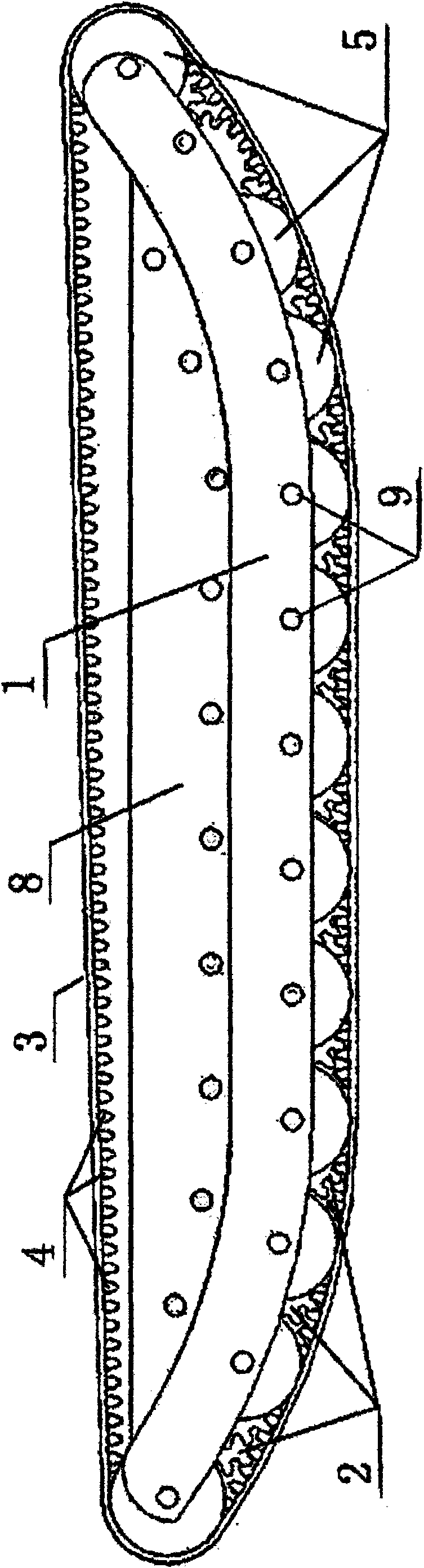

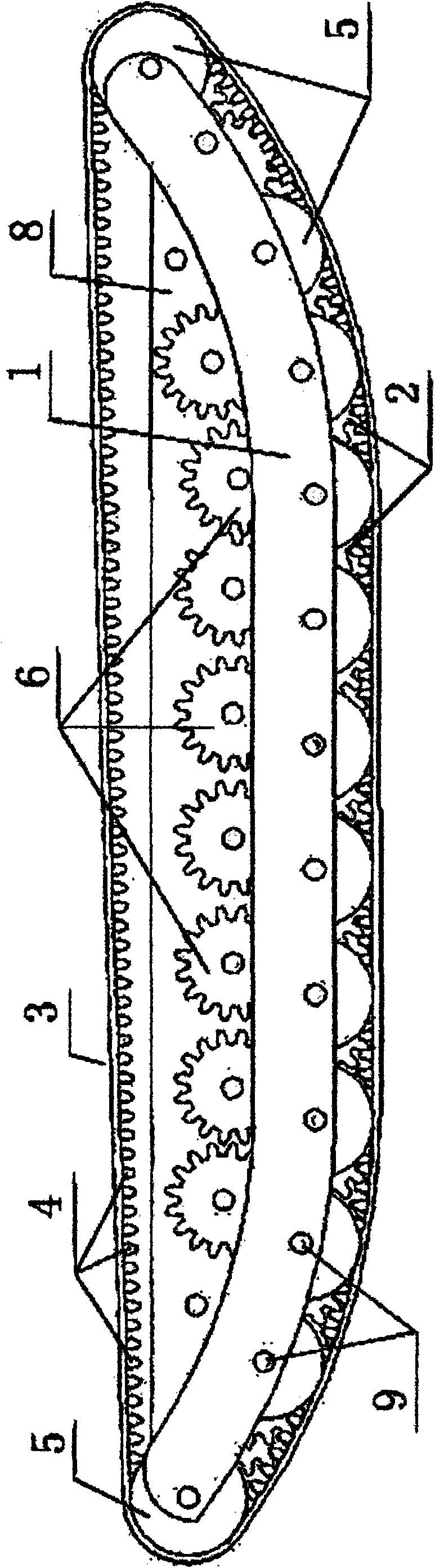

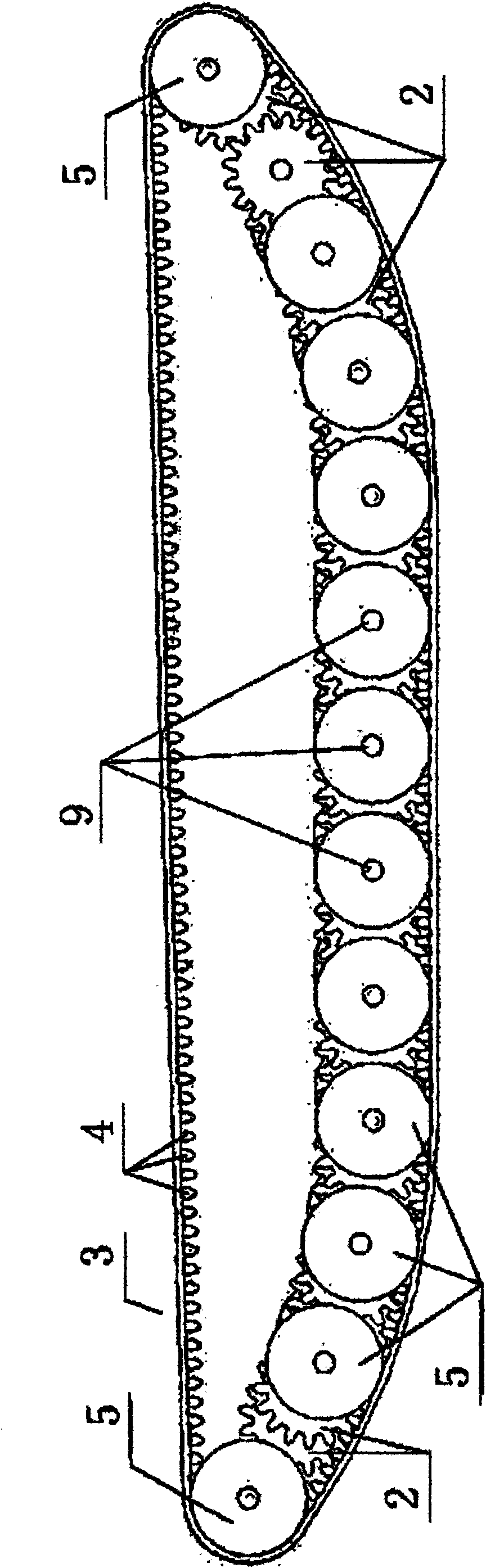

[0016] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 One of the embodiments will be described in detail. This embodiment is a staggered roller crawler type rolling device, which consists of a wheel bridge (1), toothed rollers (2), crawlers (3), crawler teeth (4), and a guide pulley (5). ), a transmission gear (6), a transmission gear frame (8), a wheel shaft (9) and other parts. The bridge wheel frame (1) is made into an arc shape at both ends and a flat-bottomed boat shape in the middle. The arc radius of the wheel bridge frame (1) is set according to the off-road requirements of the crawler rolling device, and the length of the flat bottom can be set according to the The crawler rolling device is set according to the requirements of the trench capacity. The toothed rollers (2) are in the shape of gears, and the four rows of toothed rollers (2) are fixed on the wheel bridge (1) through the axles (9), and one row of toothed rollers (2) As t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com