Patents

Literature

30results about How to "Short unloading time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

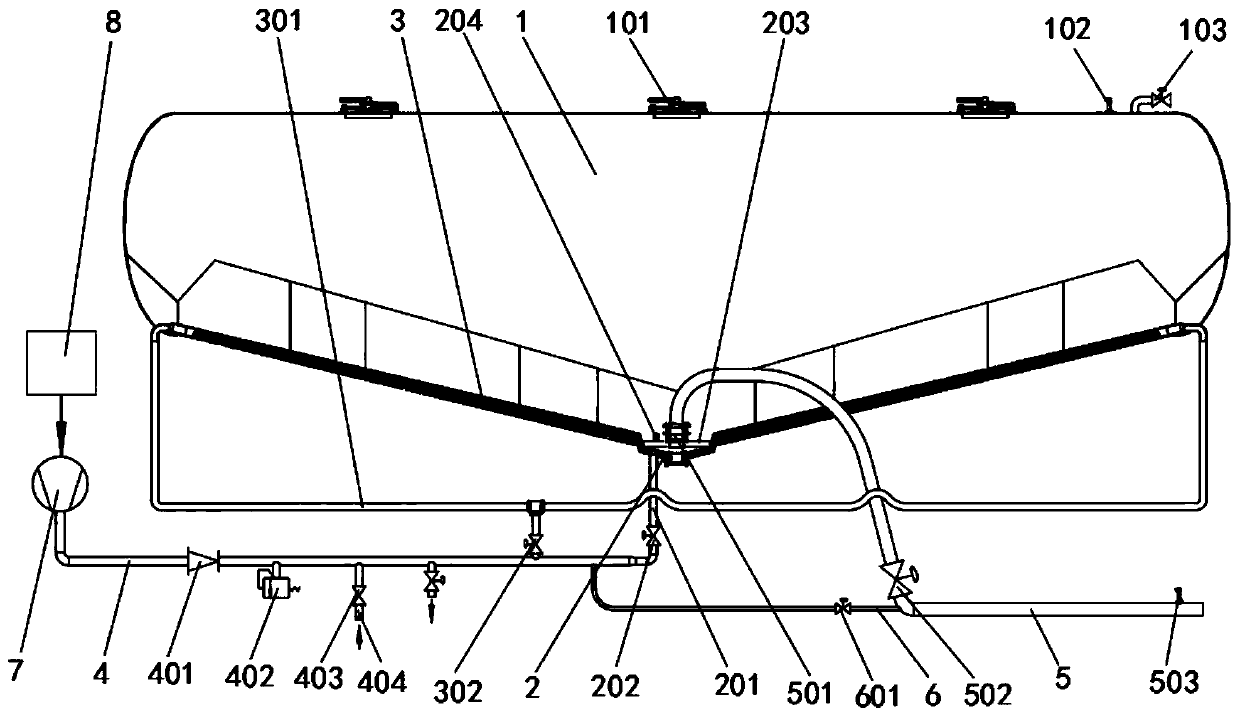

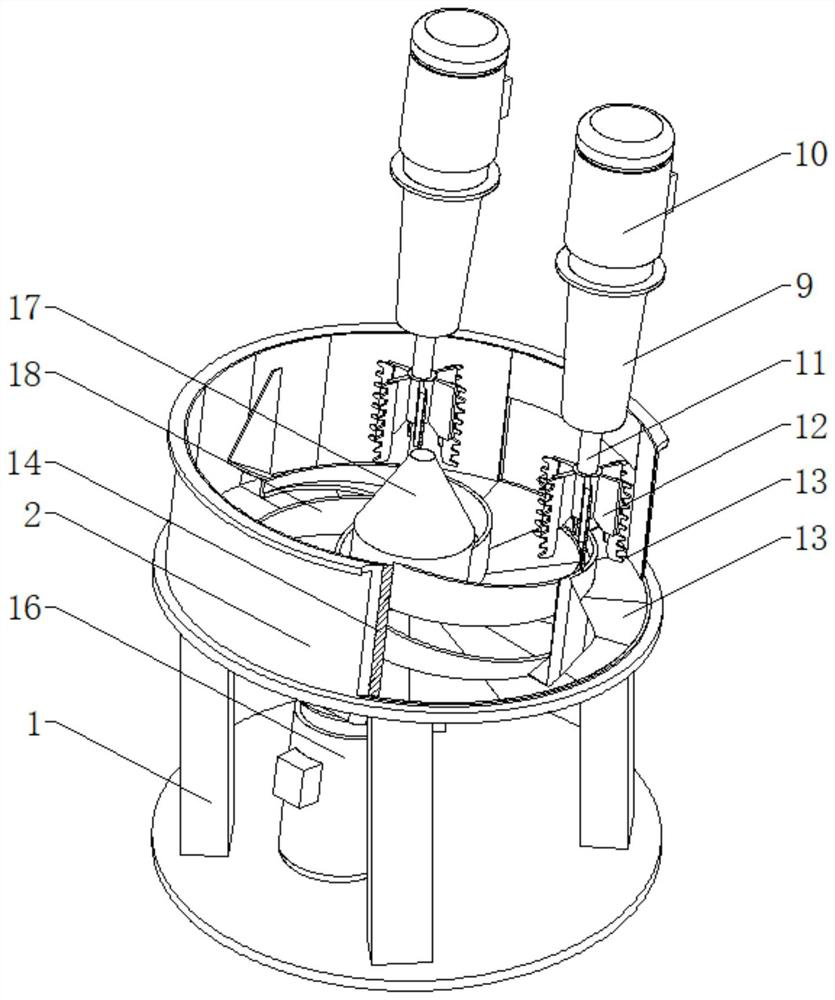

Powder material tank with automatic discharging

PendingCN110482038AShort unloading timeComplete unloadingLarge containersBulk conveyorsDischarge efficiencyFluidized bed

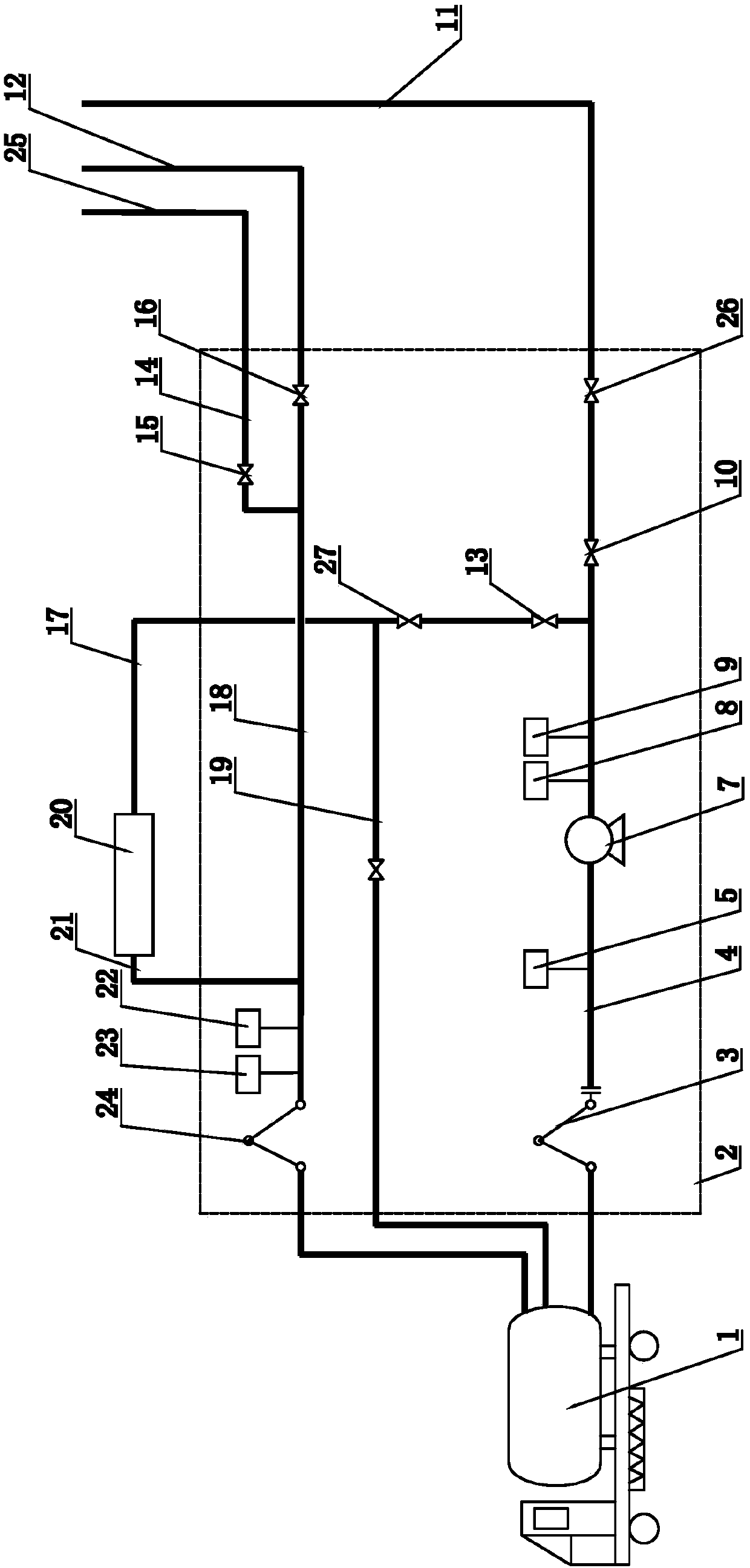

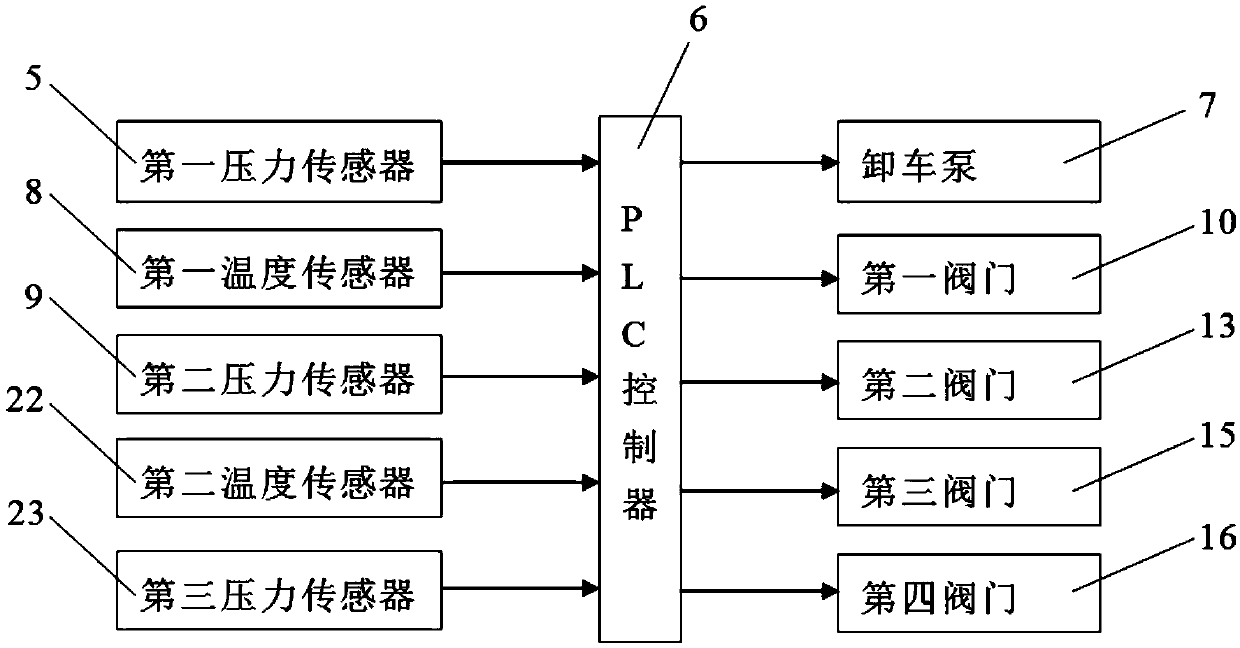

The invention discloses a powder material tank with automatic discharging, and belongs to the technical field of a semi-trailer material tank. The powder material tank with the automatic discharging comprises a tank body and a controller. A plurality of feeding holes and a pressure sensor are arranged at the top of the tank body. The powder material tank with the automatic discharging is characterized in that a main fluidized bed is arranged in the center of the bottom of the tank body, and auxiliary fluidized beds are arranged on both sides of the main fluidized bed. The auxiliary fluidized beds extend from both ends of the tank body to the main fluidized bed and incline downward, the main fluidized bed is connected with a total air inlet pipe through a main air inlet pipe, the main air inlet pipe is provided with a main air inlet valve, the auxiliary fluidized beds are connected to the total air inlet pipe through auxiliary air inlet pipes, the auxiliary air inlet pipes are providedauxiliary air inlet valves, the total air pipe is connected to an air compressor, the air compressor is connected with the controller, a perforated plate is arranged on the upper part of the main fluidized bed, the perforated plate is provided with a level sensor and a discharging tube, and the discharge tube is provided with a discharging valve and a flow sensor. The discharging efficiency is greatly improved, labor is reduced, energy is saved, and the environment is protected.

Owner:浙江超宇汽车科技有限公司

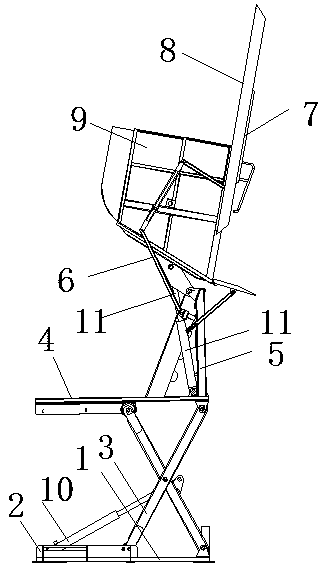

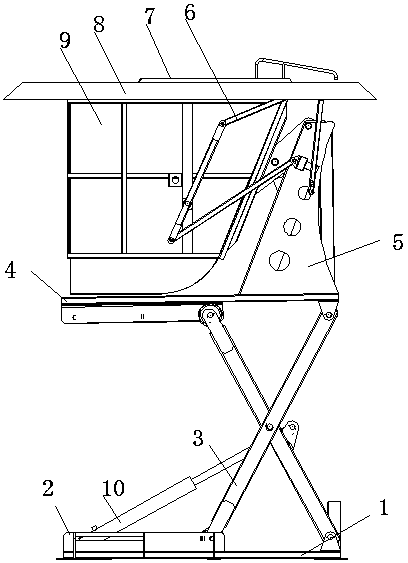

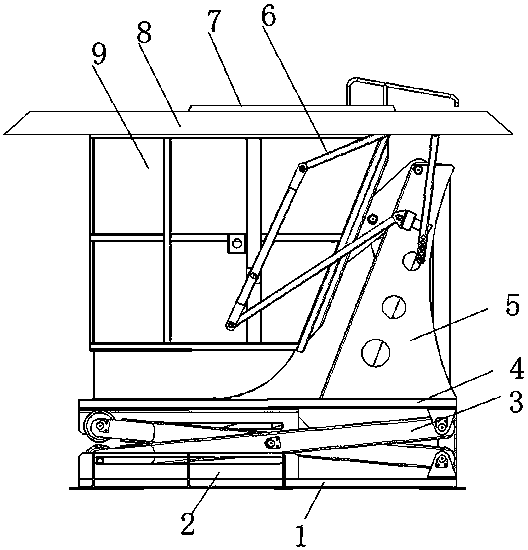

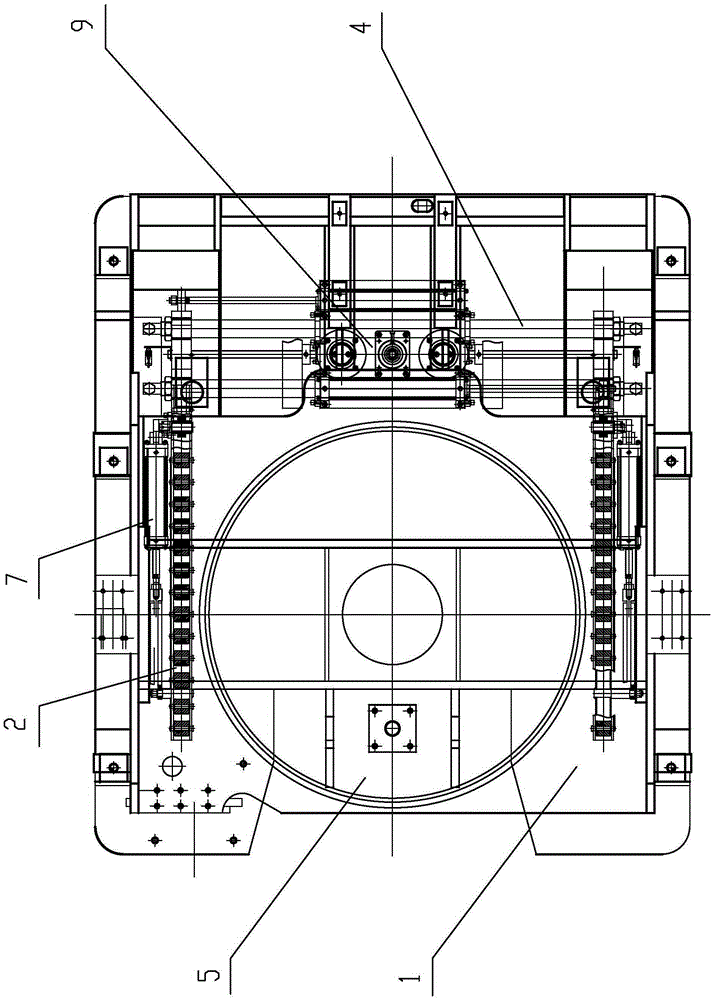

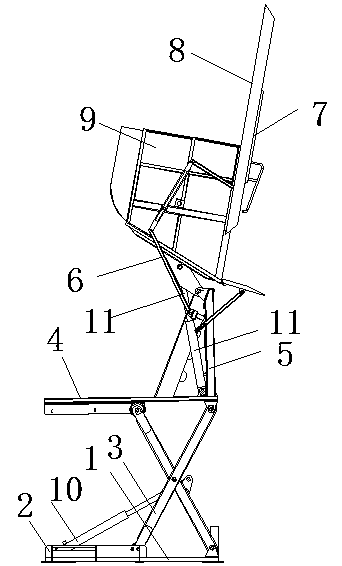

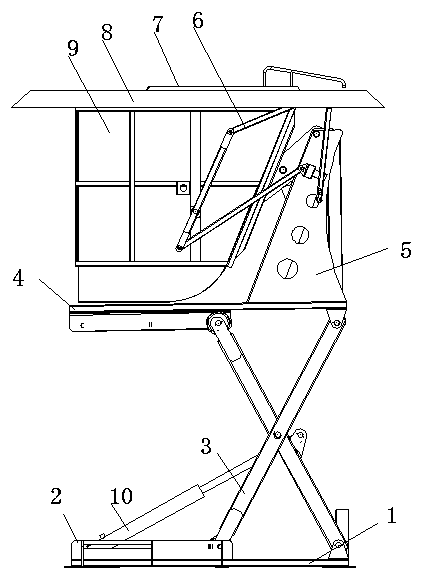

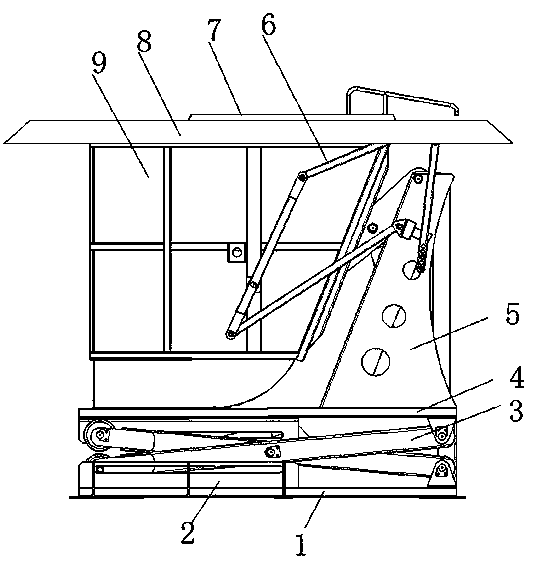

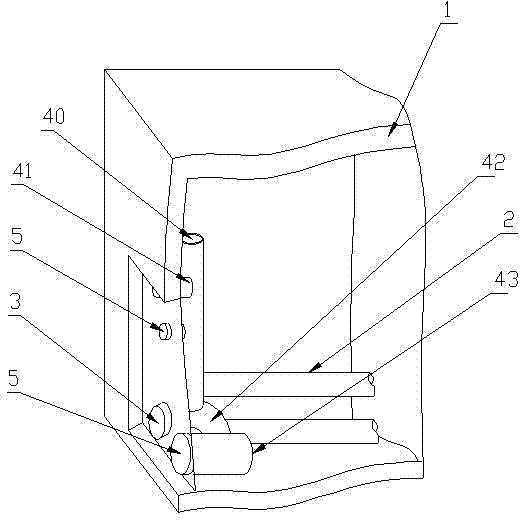

Underground rubbish collection box for storage and collection of urban and rural rubbish

ActiveCN107777188ASatisfy delivery collection needsNo visual pollutionRefuse receptaclesCylinder headEngineering

The invention discloses an underground rubbish collection box for storage and collection of urban and rural rubbish. The underground rubbish collection box comprises a box body lifting device, whereina fixed base is movably mounted at the bottom of the box body lifting device, a box body lift cylinder is fixedly mounted at the top of the fixed base, a cylinder head of the box body lift cylinder and the box body lifting device, a lifting table is movably mounted at the top of the box body lifting device, a box body discharging turning device is fixedly mounted on one side of the top of the lifting table, a box body is hinged to the box body discharging turning device, the bottom of the box body and the top of the lifting table make a contact, a box body top cover is glidingly mounted at the top of the box body, a rapid opening and closing feeding door is arranged at the top of the box body top cover, and top cover opening connecting rod mechanisms are hinged to two sides of the bottomof the box body top cover. The underground rubbish collection box has the advantages of better environmental protection and higher efficiency, the box body can be rapidly lifted from a pit for discharging, the discharging time is short, and passage is not affected.

Owner:安徽标科环境科技有限公司

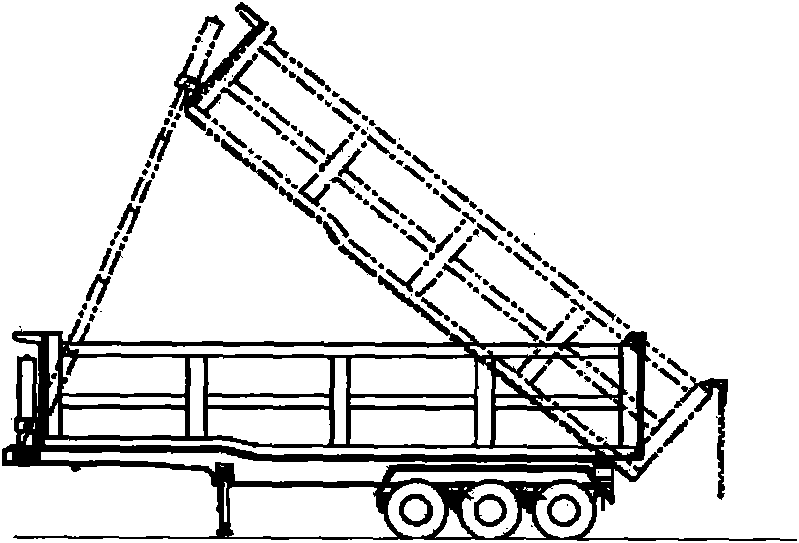

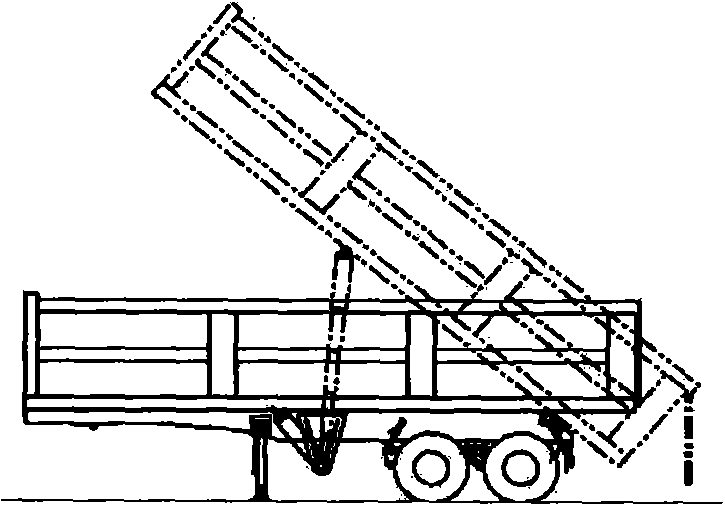

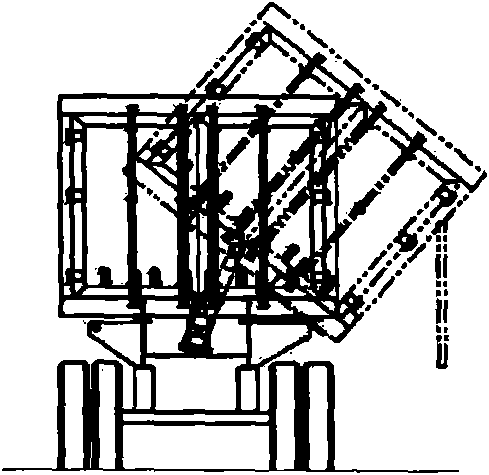

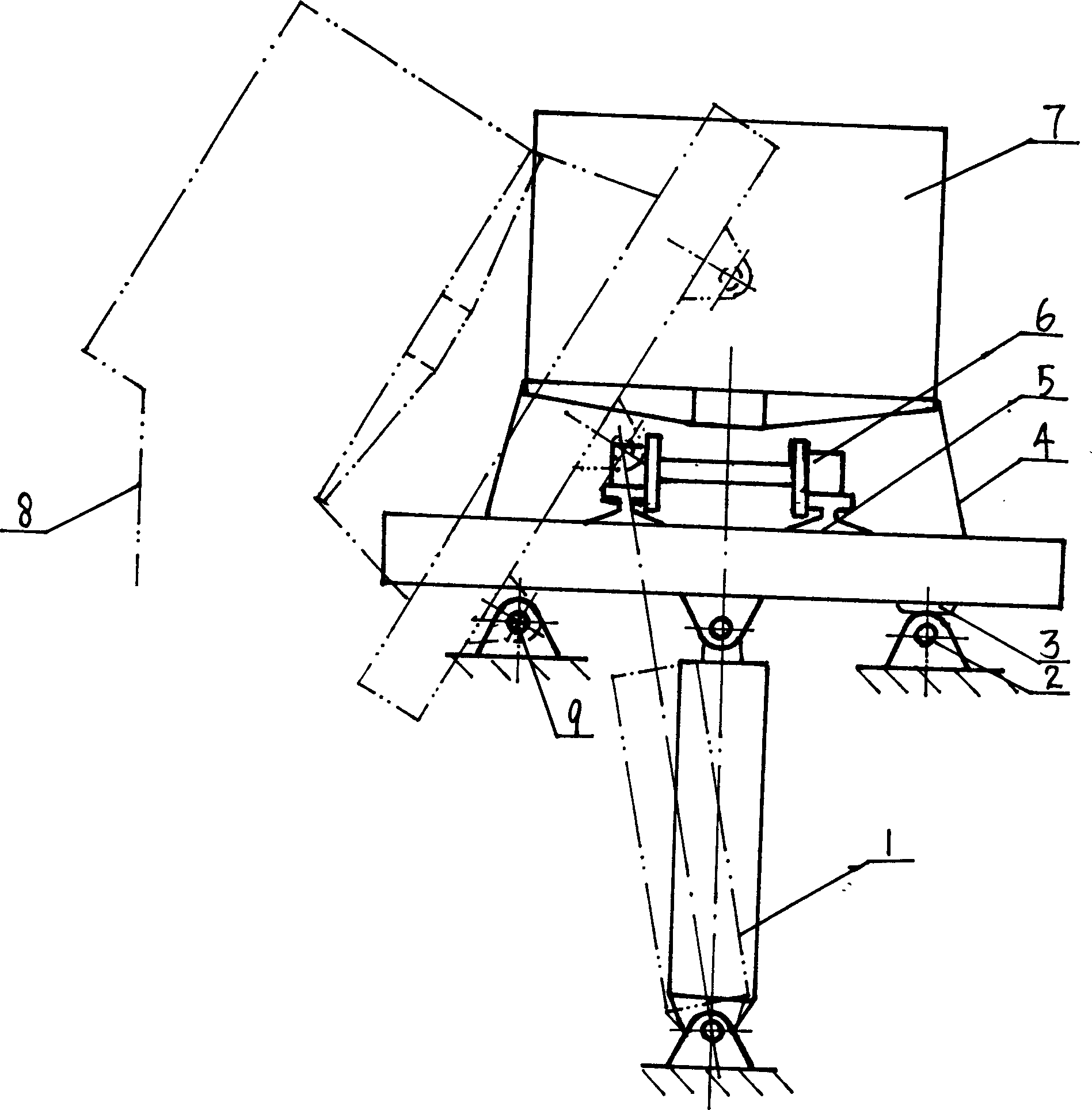

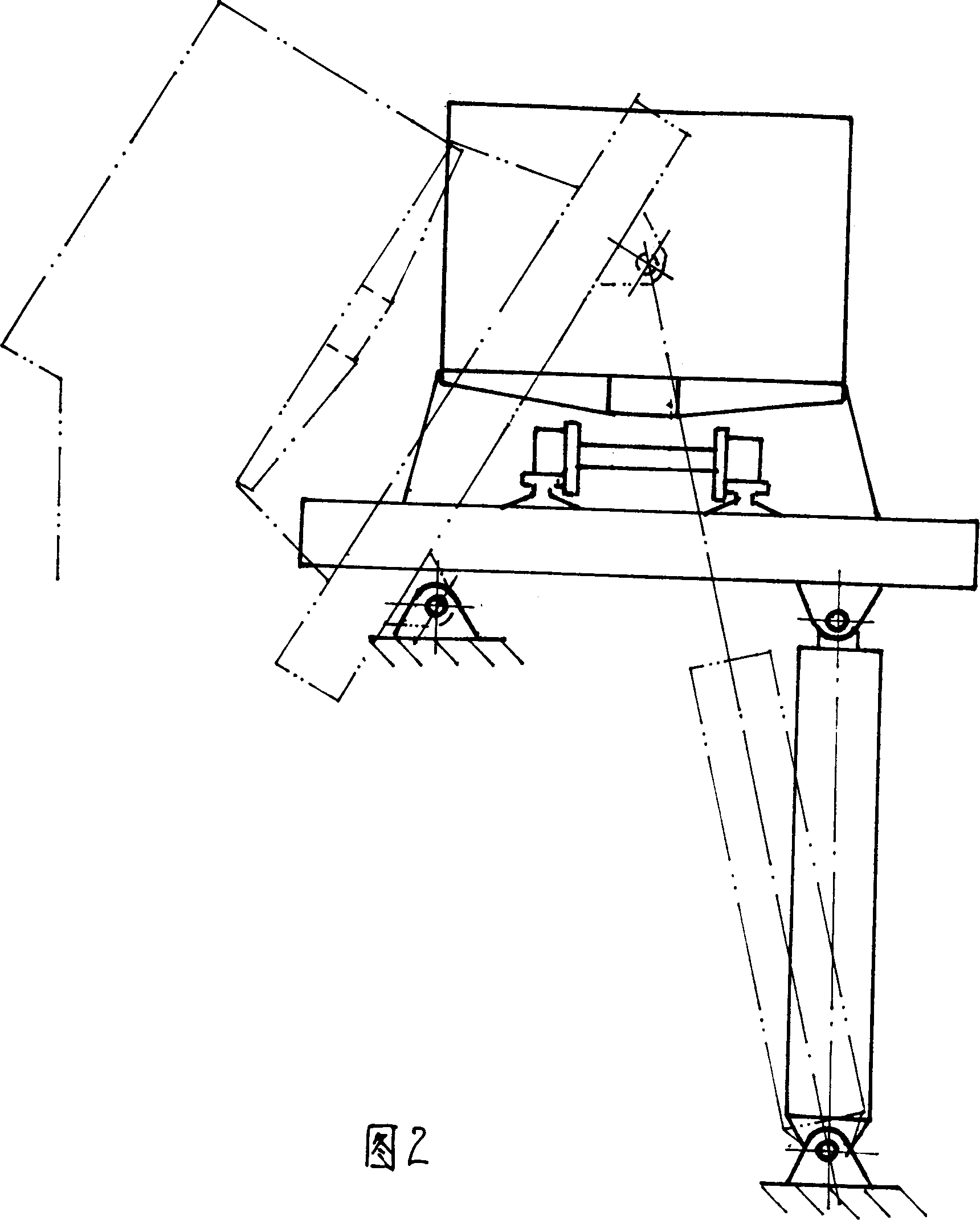

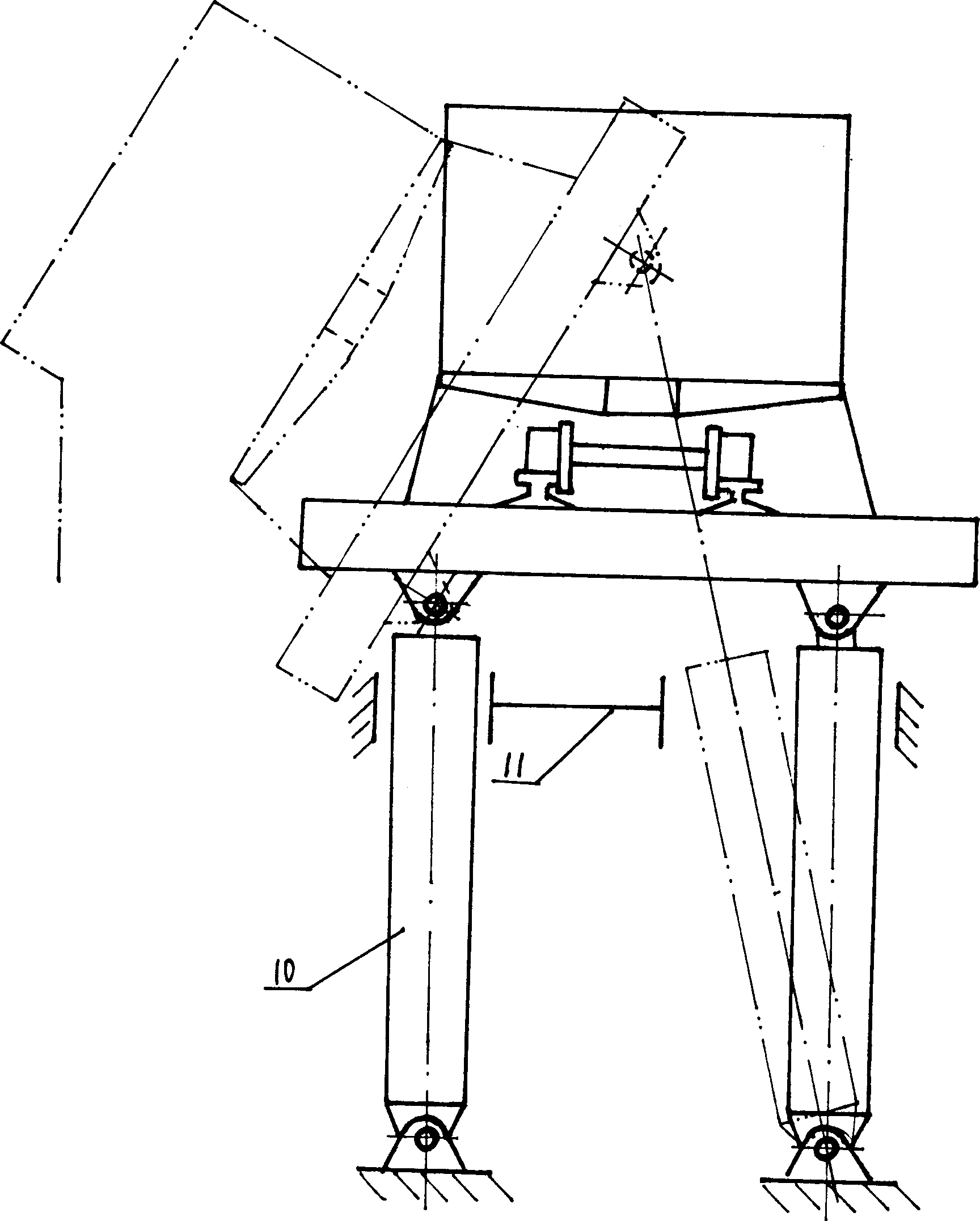

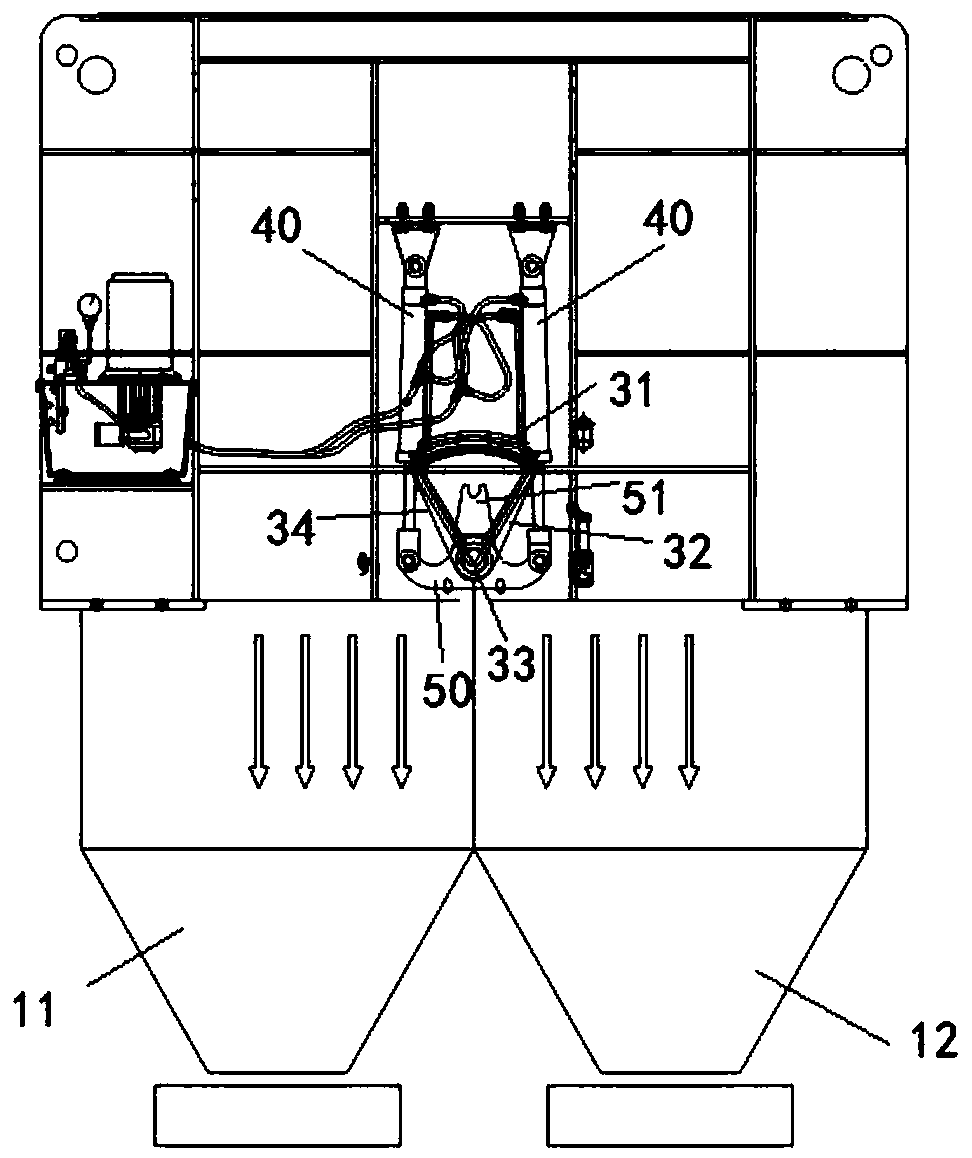

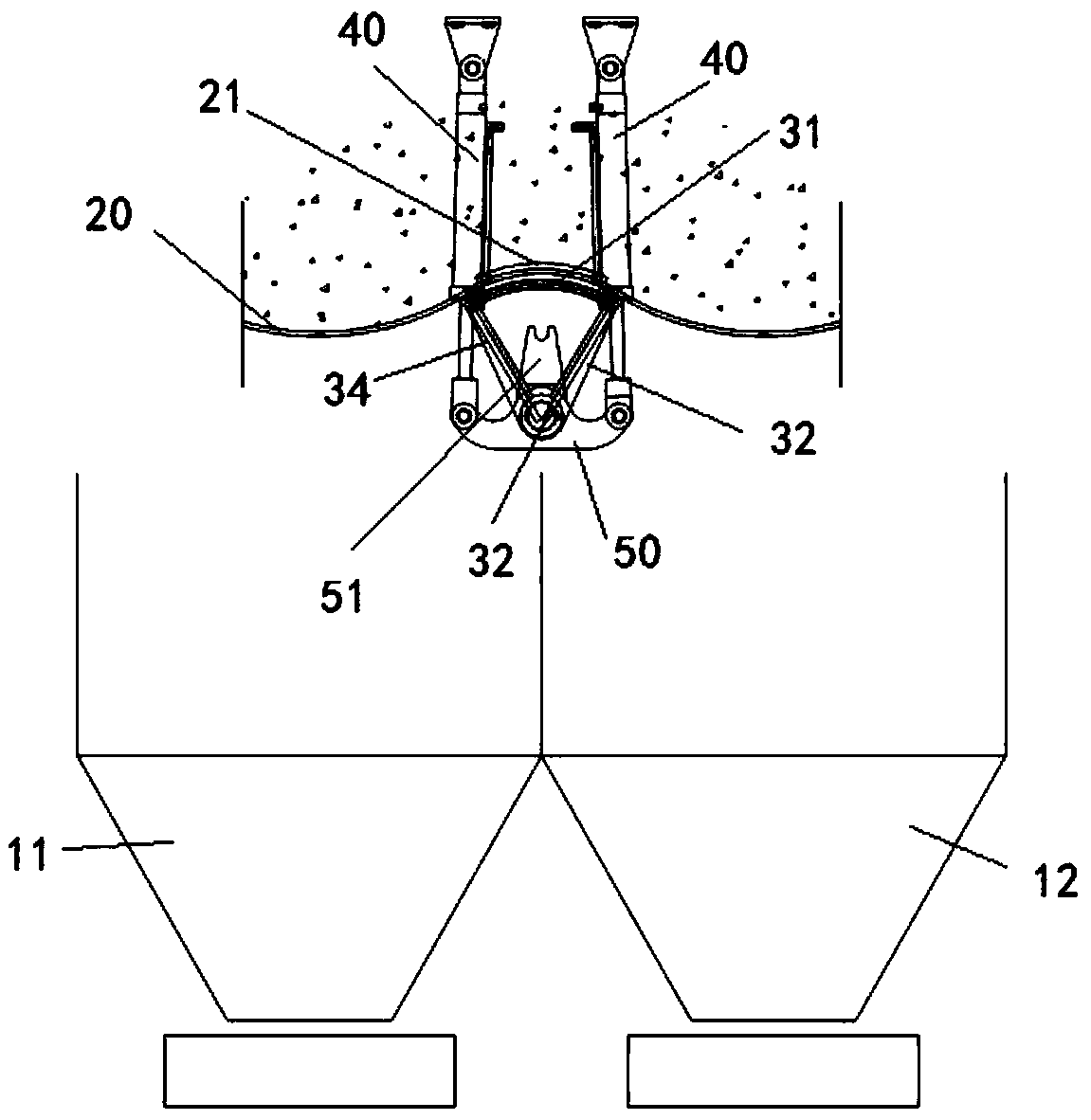

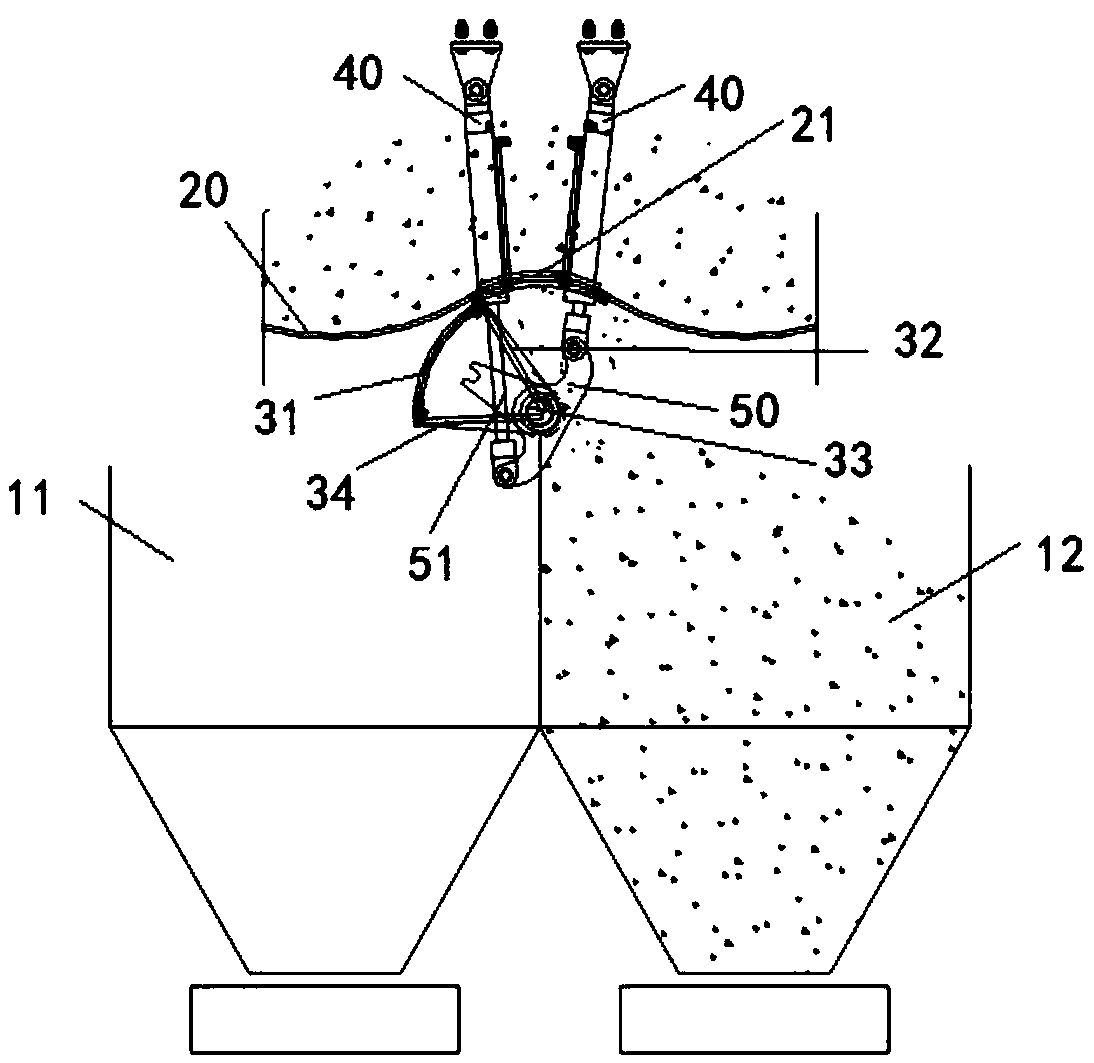

Double-carriage self-discharging semitrailer

InactiveCN102211538AShort unloading timeImprove transportation efficiencyVehicle with tipping movementVehicle frameSemi-trailer

The invention discloses a double-carriage self-discharging semitrailer, which mainly consists of a frame, a supporting device, a wheel device, a front carriage, a rear carriage, a front carriage lifting mechanism and a rear carriage lifting mechanism, wherein the front carriage and the rear carriage are arranged on the frame and driven by a combined lifting mechanism respectively; the front carriage lifting mechanism is in a double-cylinder web placement mode and in left and right bidirectional lateral discharging; the rear carriage lifting mechanism is in a single-cylinder front push connecting rod combined rear discharging mode; and the hydraulic systems of the front and rear carriage lifting mechanisms are in combined control. The double-carriage self-discharging semitrailer is stressed uniformly, has low deformation and good lateral stability, can be used under various complex working conditions, and basically can avoid the turnover accidents caused by the deformation of the frame. Moreover, an auxiliary shifting device is not needed at the tail of the semitrailer, and all operation processes are completed in the cab of the tractor, so the safety performance is high. Meanwhile, the semitrailer has good passing property and can be used in the road conditions with great gradient.

Owner:ANHUI JIANGHUAI YANGTIAN AUTOMOBILE

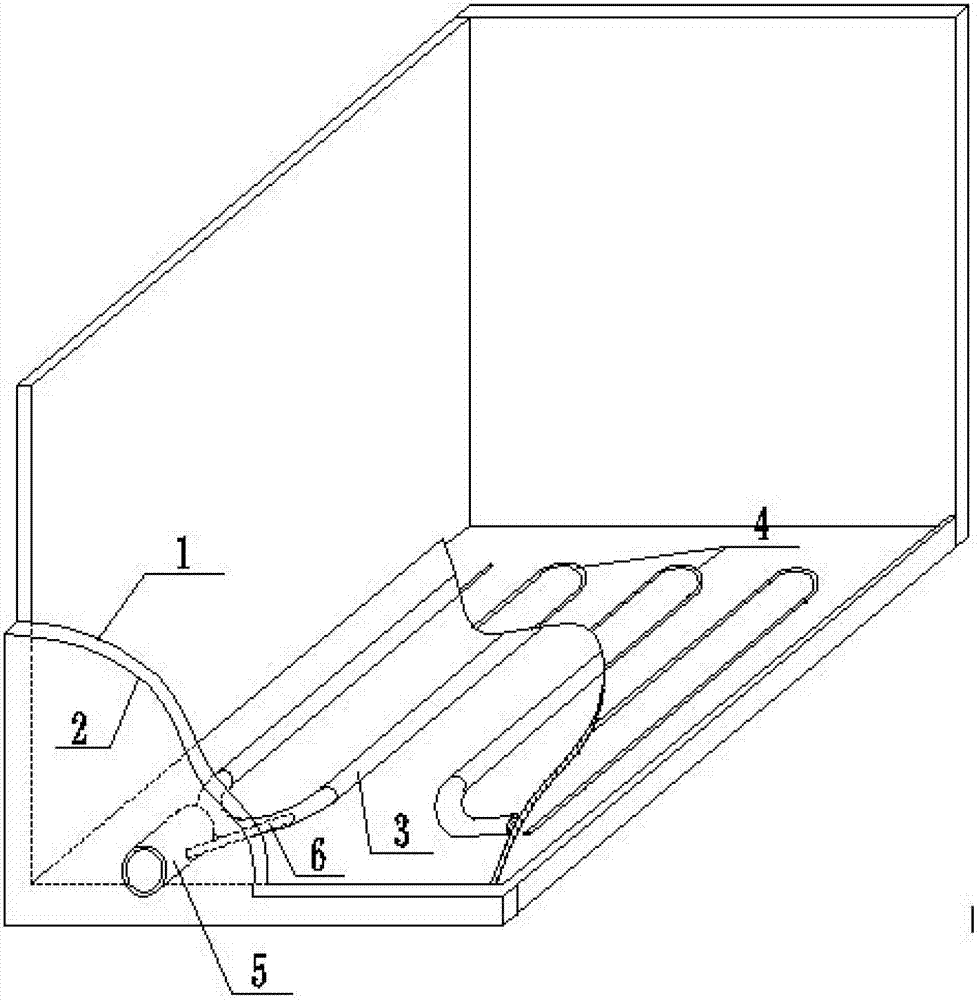

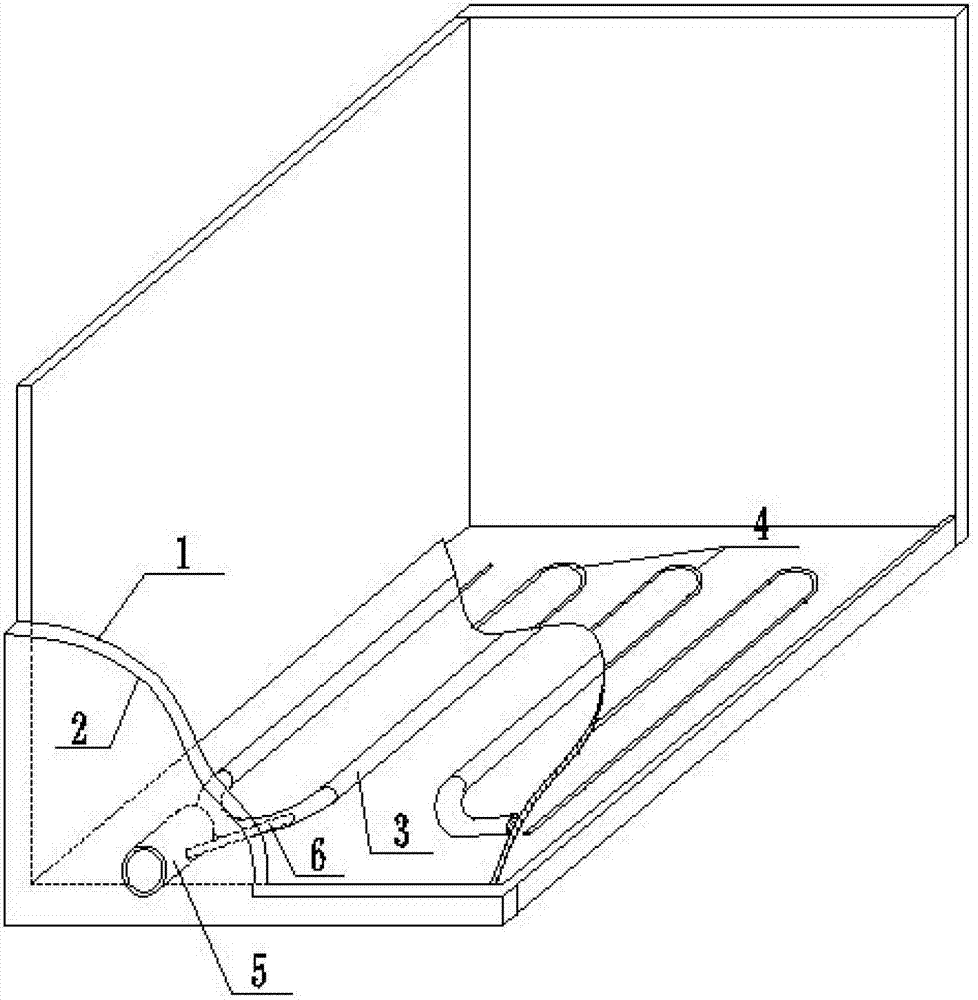

Container with bottom auxiliary heating device and auxiliary heating method

ActiveCN102730346ALiquefaction in timeUnload in timeLarge containersTank wagonsInsulation layerAuxiliary heating

The invention relates to a container with a bottom auxiliary heating device and an auxiliary heating method realized by using the container. The container with the bottom auxiliary heating device comprises an inner container body, an outer container body, a heat insulation layer, a heating pipe and the auxiliary heating device, wherein the outer container body is sleeved at the outer part of the inner container body, the heat insulation layer is arranged between the inner container body and the outer container body, the heating pipe is arranged at the inner part of the inner container body, and the auxiliary heating device is arranged between the bottom of the container and the insulation layer. Materials deposited at the lower part of the heating pipe at the bottom of the inner container body are heated, the materials at the bottom are liquefied in time and conveniently and promptly unloaded in time and the residue amount of the materials at the bottom of the container is decreased by the auxiliary heating device.

Owner:TIANJIN ZHAOHUA LOGISTICS CO LTD

Railroad utilized unloading equipment by using hydraulic force to careen tracks

An unloading mechaniwm which hydraulically tilted rails for ailway car is composed of rail supporter pivoted to base, high-safety fasteners on the rail supporter for fastening the rail way car, and lifting unit linked to the rail supporter for tilting it. The said lifting unit is hydraulic cylinder with lifting member. Its advantages are simple structure and short unloading time.

Owner:黄祖文

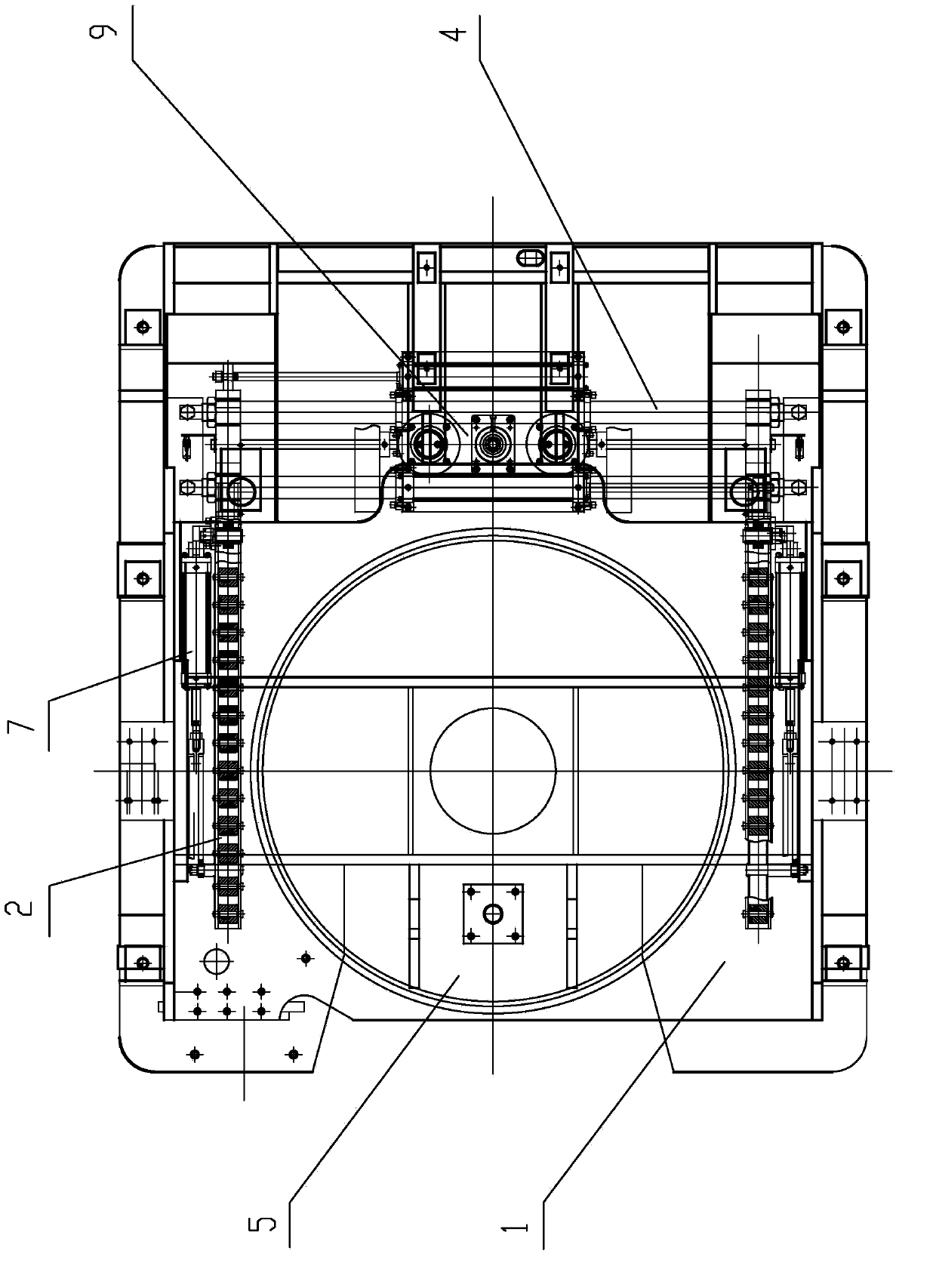

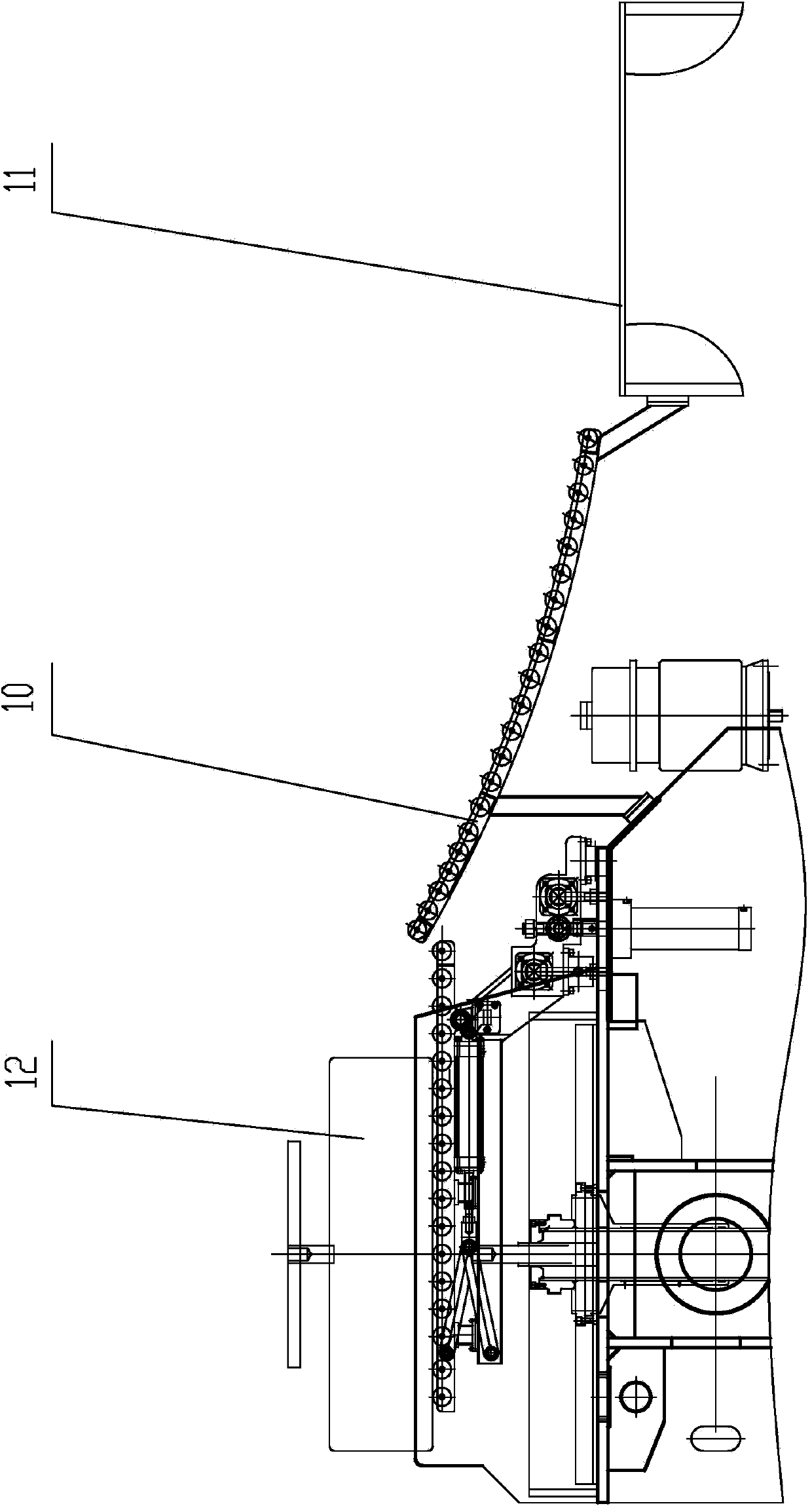

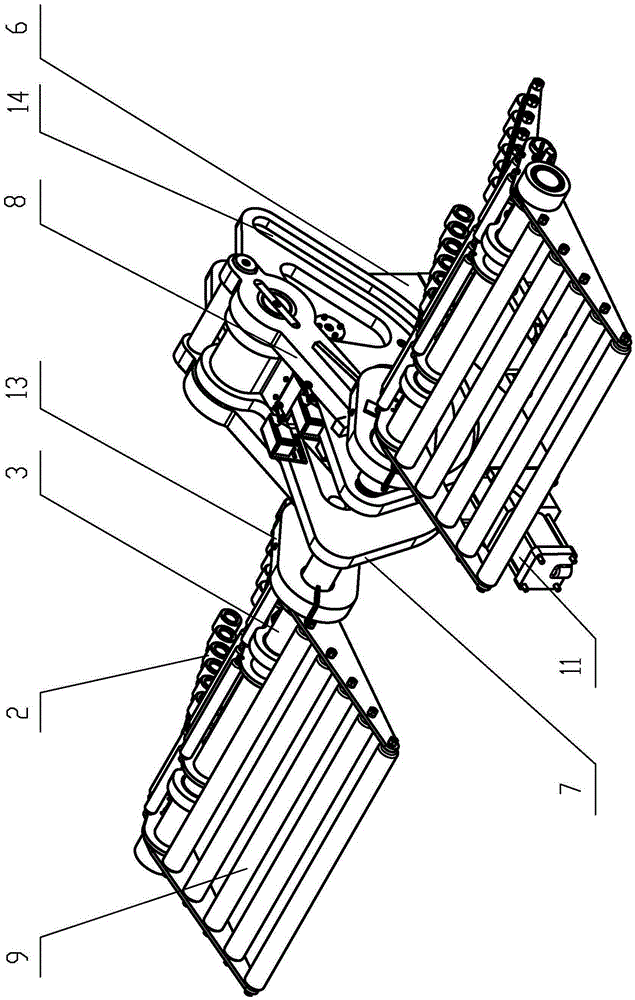

Tire unloading device of single-mode tire vulcanizer

The invention discloses a tire unloading device of a single-mode tire vulcanizer. The tire unloading device comprises a turnover mechanism, an opening and closing mechanism and a lifting mechanism, wherein the turnover mechanism comprises turnover roller racks, turnover support frames and a turnover component; the turnover roller racks are symmetrically arranged at two sides and hinged on the turnover support frames; the turnover component for putting up and putting down the turnover frames around a hinge point is arranged between the turnover roller racks and the turnover support frames; the opening and closing mechanism comprises a slide frame and a flexible component; the slide frame is transversely arranged between the turnover support frames at two sides; the turnover support frames at two sides are arranged on a slide rack in a sliding manner; the flexible component for outwards opening and inwards folding the turnover support frames at two sides is arranged on the slide rack; the slide rack is arranged on the lifting mechanism. The tire unloading device is short in tire unloading time, the non-vulcanization time is reduced, and the efficiency and the automatic degree of the vulcanizer are improved.

Owner:GUILIN RUBBER MACHINERY CO LTD

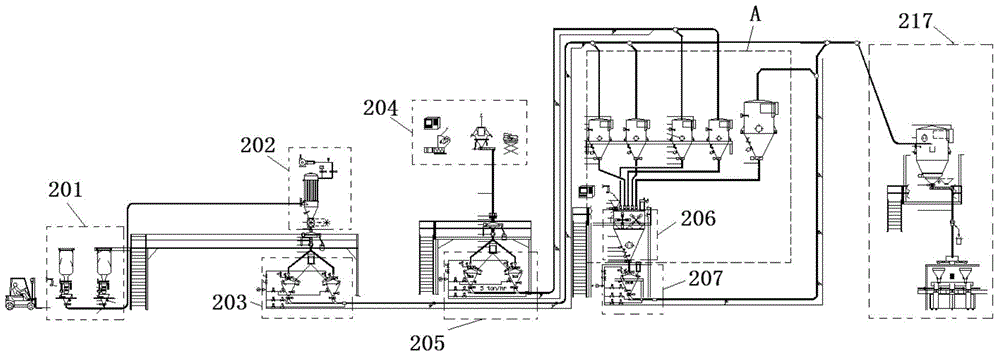

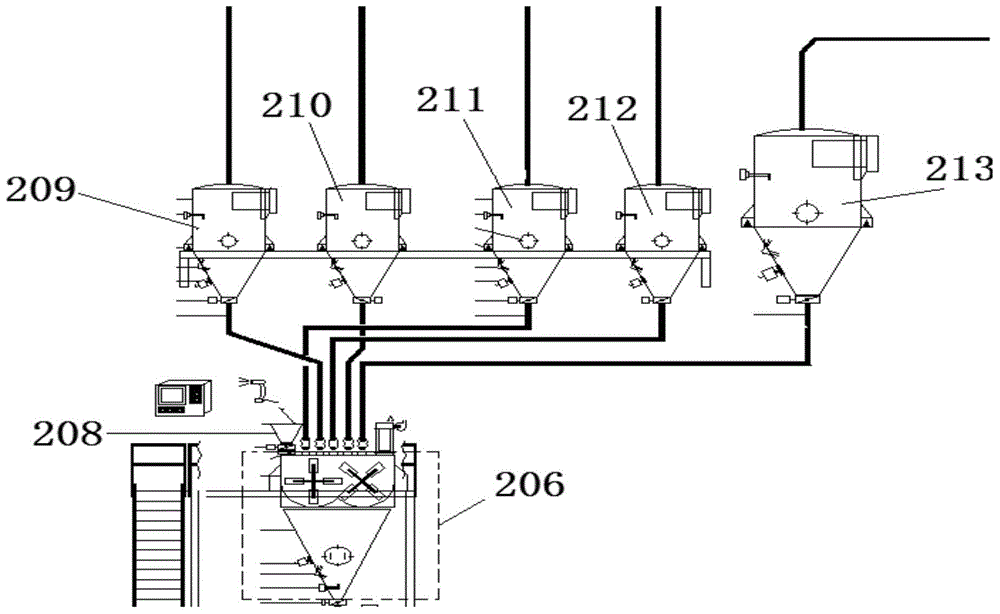

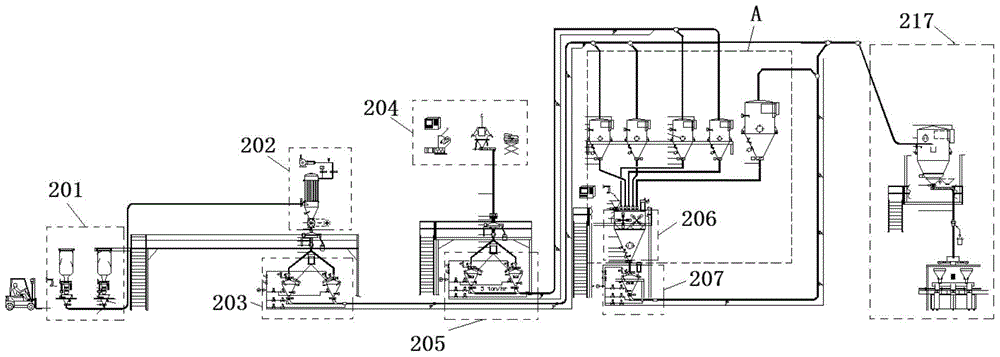

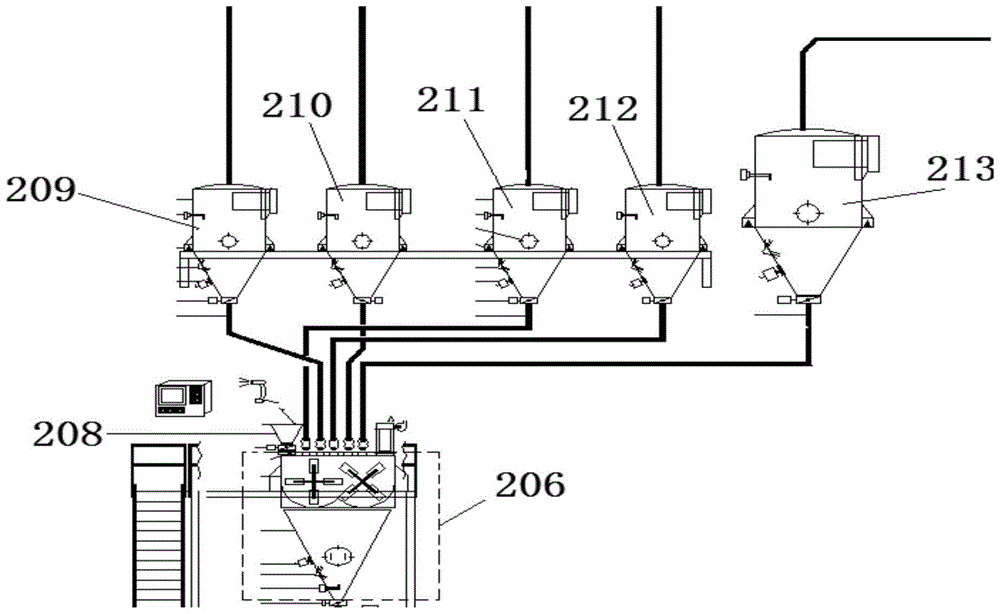

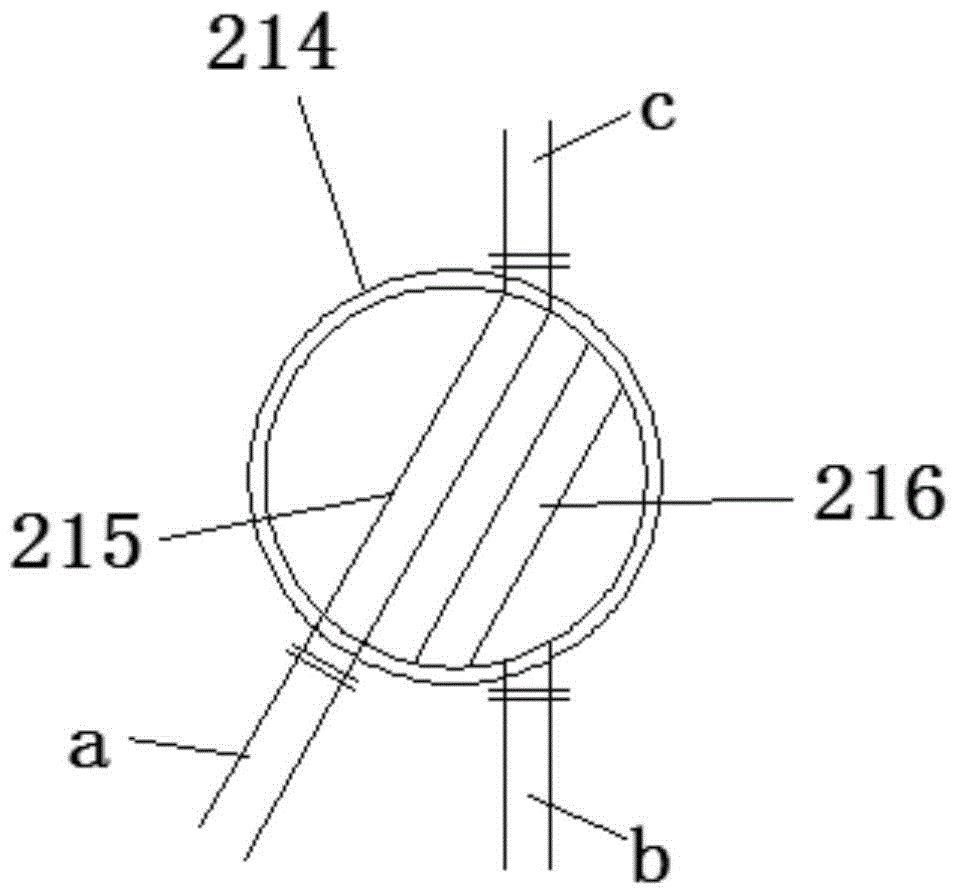

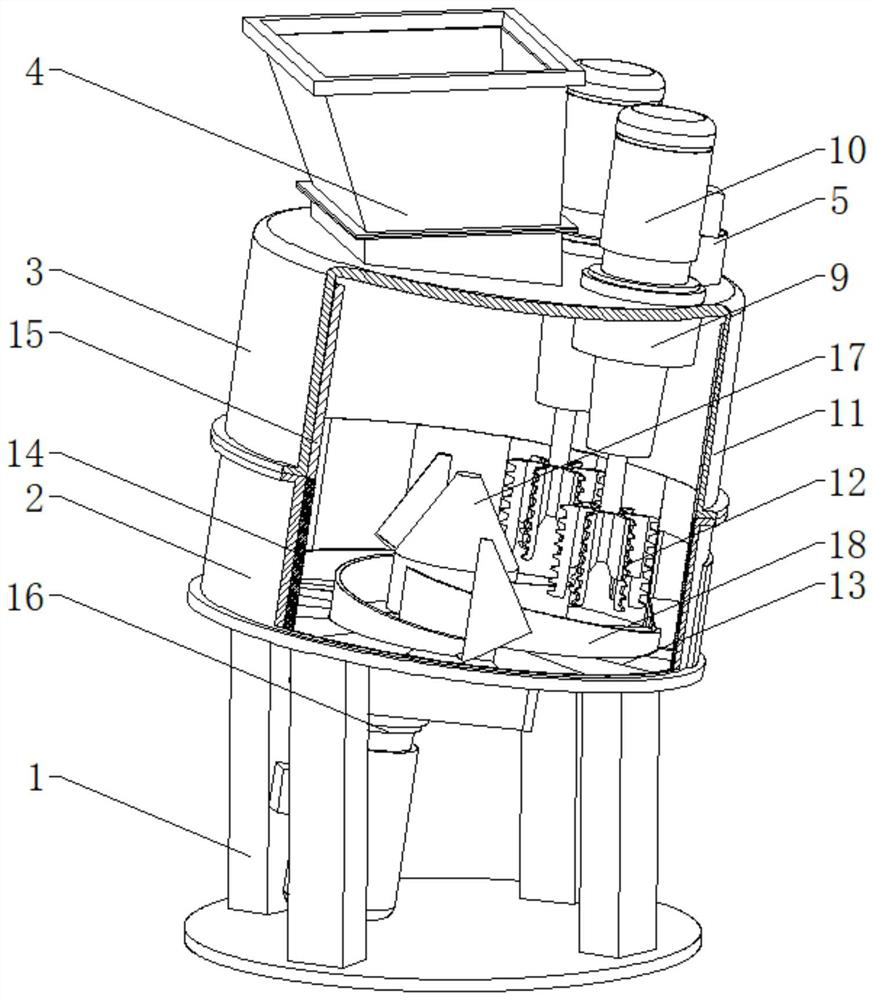

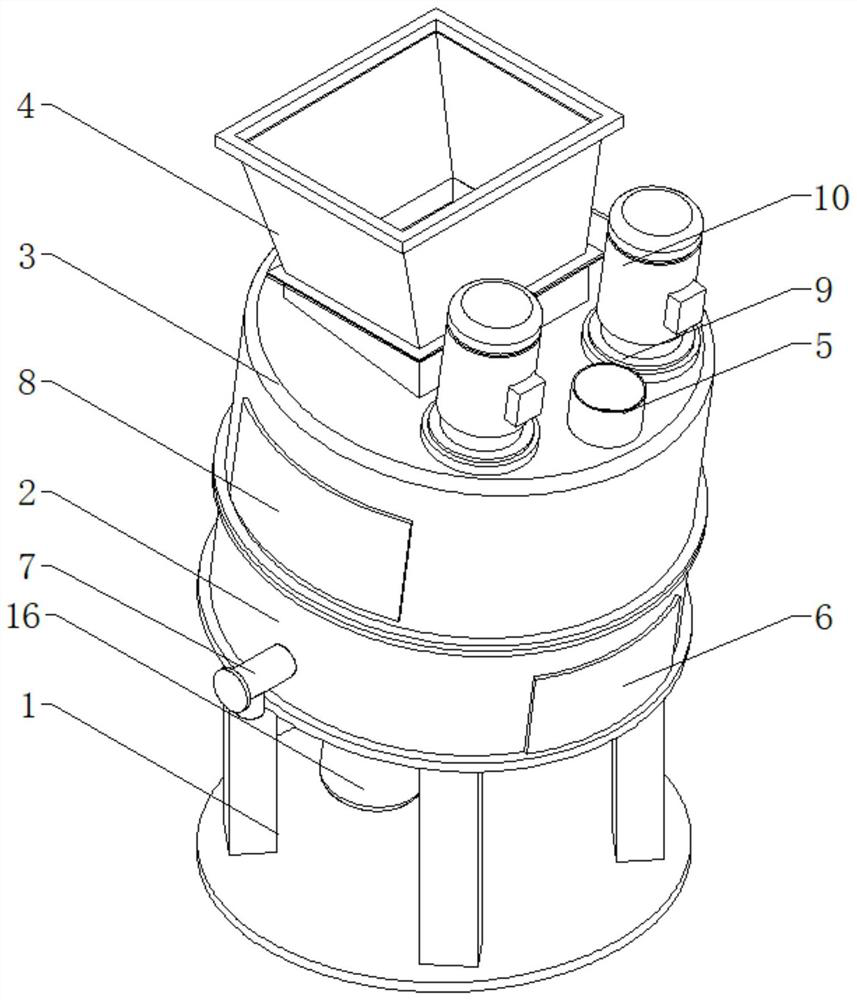

Material mixing equipment at milk powder dry mixing section and material mixing method

ActiveCN104785155AEvenly distributedAvoid segregation, anti-Rotary stirring mixersMixing methodsDairy foodsManufacturing technology

The invention provides material mixing equipment and a material mixing process at a milk powder dry mixing section, relates to milk powder production equipment and a manufacturing technology thereof and aims to solve the problems of uneven mixing during a mixing process, rough dairy food powder dry mixing particles produced in the dry mixing process, and non-uniform nutritional ingredients in a conventional dry mixing device. The material mixing equipment provided by the invention comprises a base powder dump device, a main powder charging device, a trace element charging device, a temporary storage system, a dry-mixing machine, a purpose powder chamber, a base powder pneumatic conveying system, a main powder pneumatic conveying system, a mixed powder pneumatic conveying system and a change-over device, wherein the temporary storage system comprises a first base powder temporary storage tank, a second base powder temporary storage tank, a first main powder temporary storage tank, a second main powder temporary storage tank and a semi-finished product temporary storage tank. According to the material mixing equipment and the material mixing process, provided by the invention, the mixing of all components of the milk powder is enabled to be more uniform, and the quality of produced products is relatively high.

Owner:百跃羊乳(南宁)有限公司

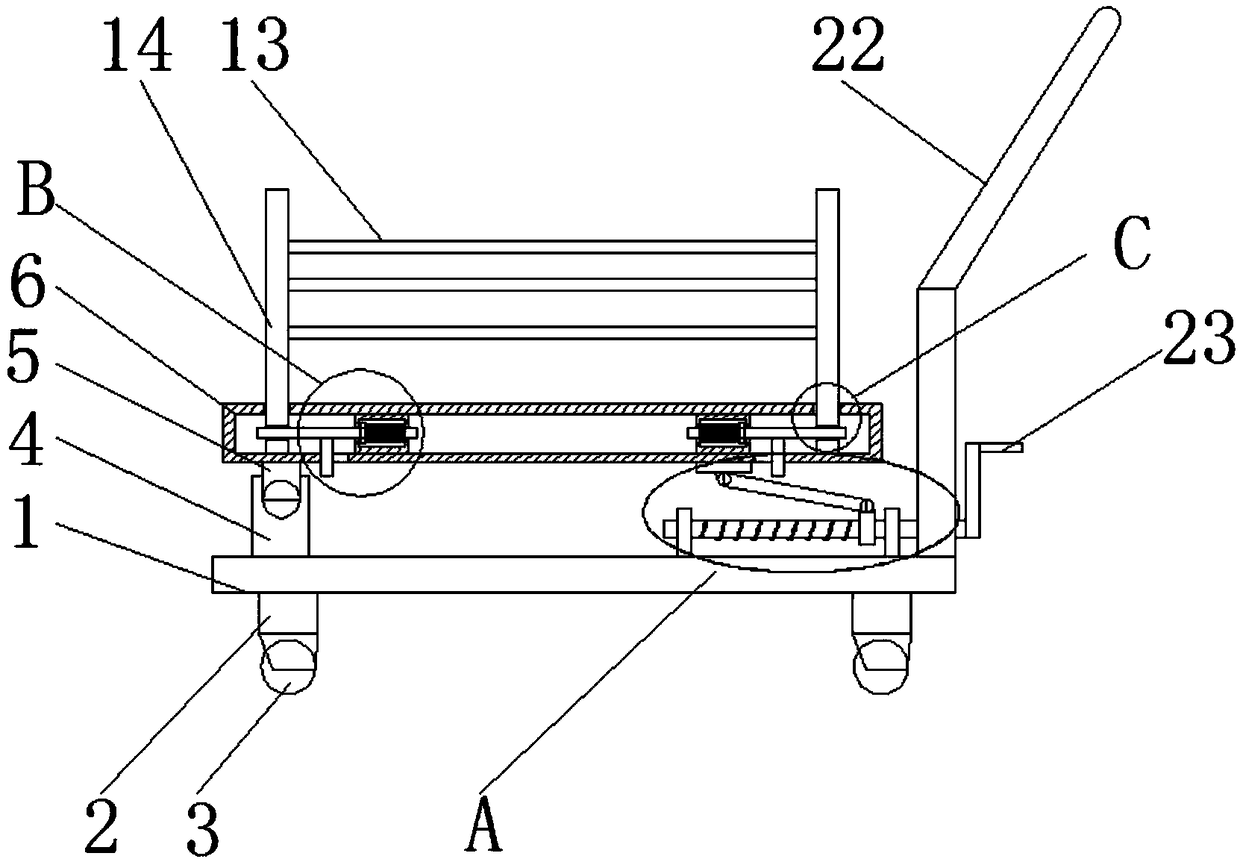

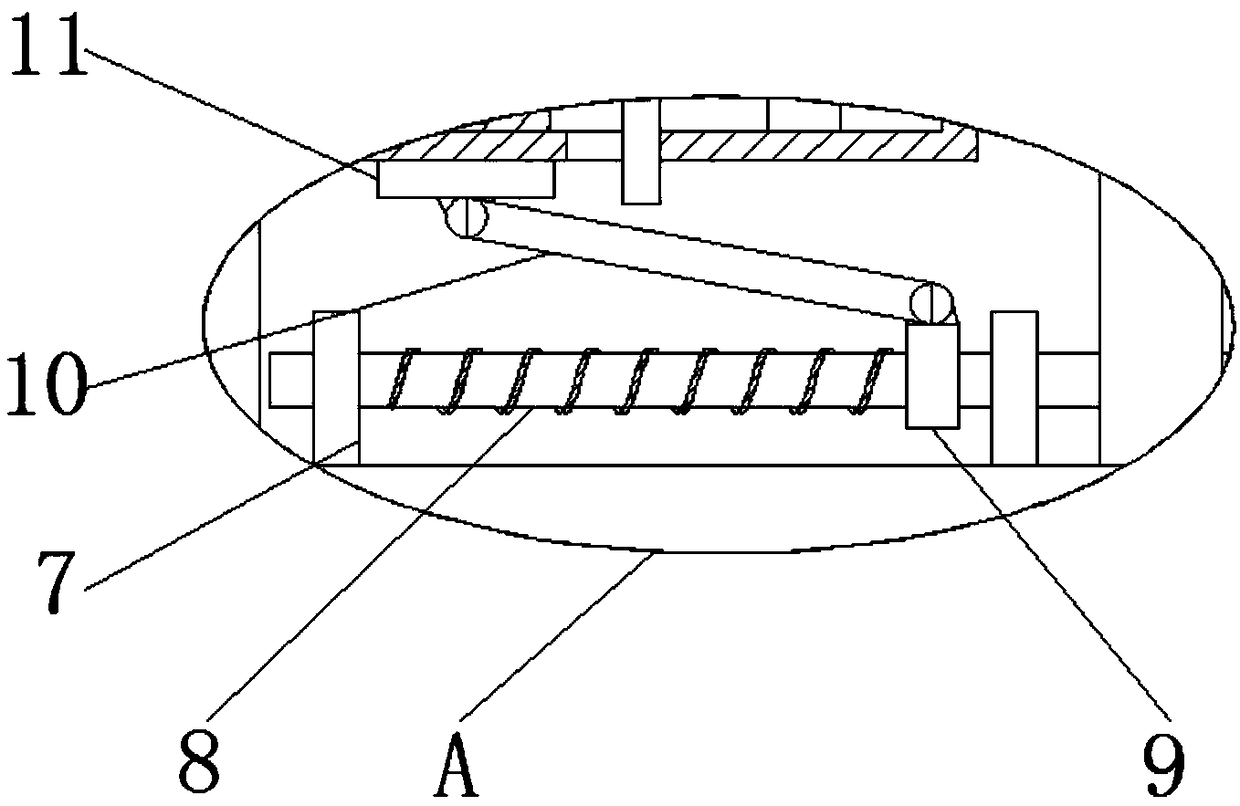

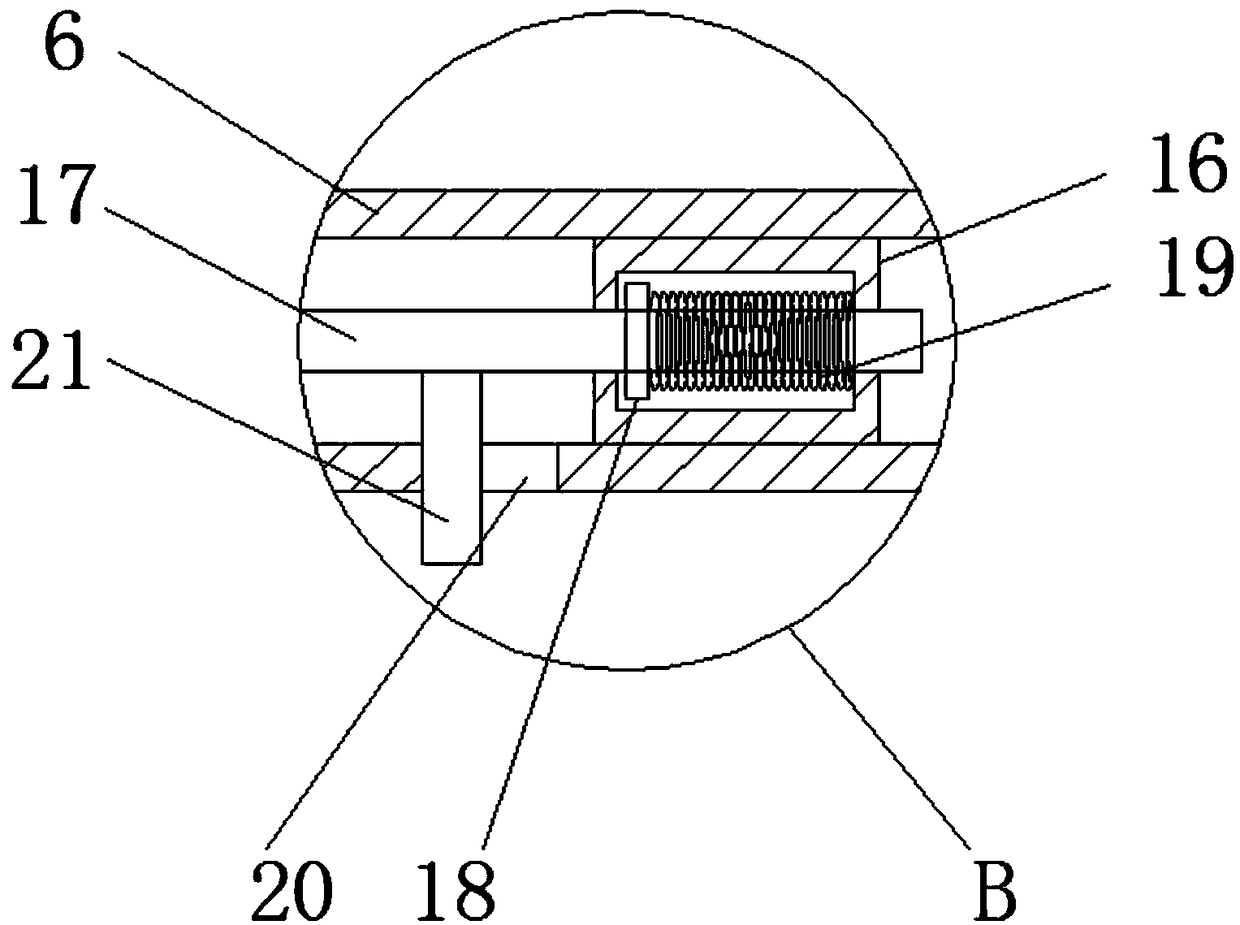

Material trolley for pig-breeding

PendingCN109229185AReduce frictionEasy to removeSupporting partsHand carts with multiple axesPig breedingEngineering

A material trolley for pig-breeding is disclosed. The material trolley includes a chassis. The four corners of the lower end of the chassis are fixedly connected with struts, the lower end of the strut is fixedly provided with a universal wheel, An upper surface of the chassis near one end is fixedly connected with a fixing post, An upper end of that fix pillar is hinged with a fixing block, the upper end of the fixing block is fixedly connected with a movable plate with a hollow structure inside, At an end of that upper surface of the chassis remote from the fix post, two horizontally positioned screw frame are fixedly connected, Two screw frames are arranged on the same horizontal line, and screws are arranged between the two screw frames, the screws penetrate the two screw frames and are rotatably connected with the screw frames, the screws are away from the corresponding screw frames of one end of the fixed column and extend outwardly, and the screws between the two screw frames are threadably connected with nuts. In the unloading process of the material trolley, the unloading time is shorter and the unloading mode is simpler.

Owner:贵州省望谟楷模农业开发有限公司

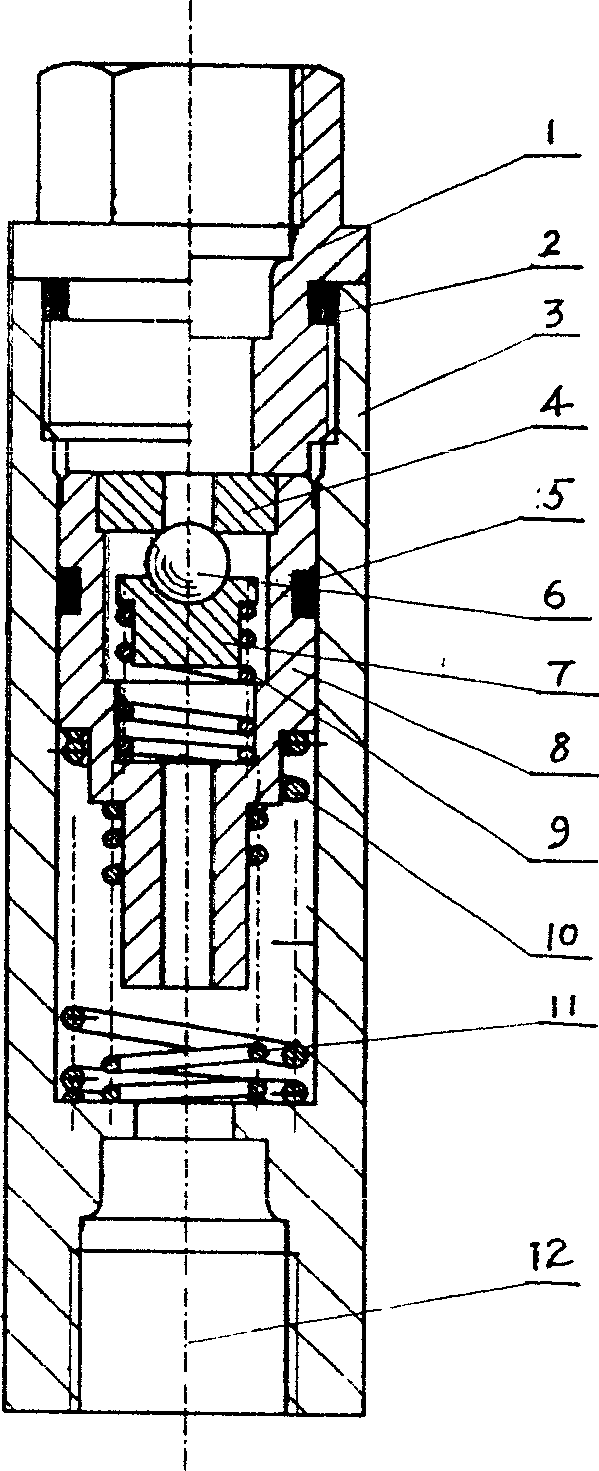

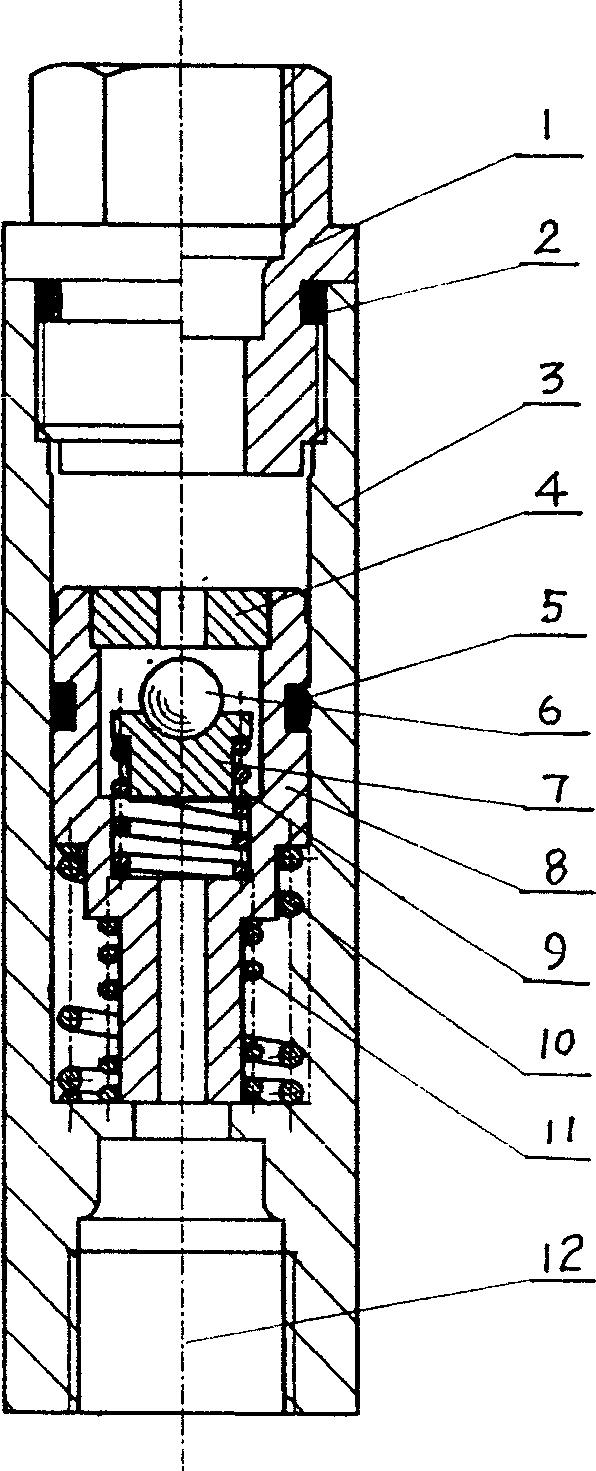

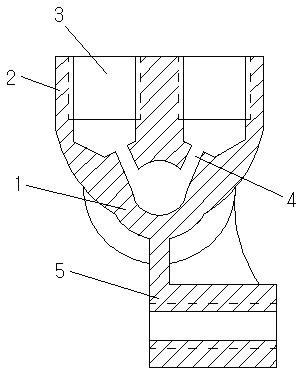

Unloading method for grease multiple point central quantitative lubricating pipeline and self suction load device

InactiveCN1587782AShort unloading timeSimple methodProportioning devicesLubricating pumpsSteel ballEngineering

The invention is a load absorbing device of grease multi-point concentration ration channel lubrication, it arranges automatic load absorbing device on each primary oil channel of the concentrated ration lubrication system, it has a shell, one end of the shell is connected to a connector, another end is arranged with a connecting aperture, in the shell there has a piston, the end of the piston is arranged with a block with oil aperture, another end of the piston has a spring; there has a steel ball facing to the oil aperture, the steel ball is arranged on the steel ball bracket, there arranges with a spring under the steel ball bracket, the bracket can move up and down along the inner wall of the piston, realizes the open or close of the oil aperture. The method is simple, compact, and convenient.

Owner:NINGBO JIUYUAN LUBRICATION EQUIP MFG

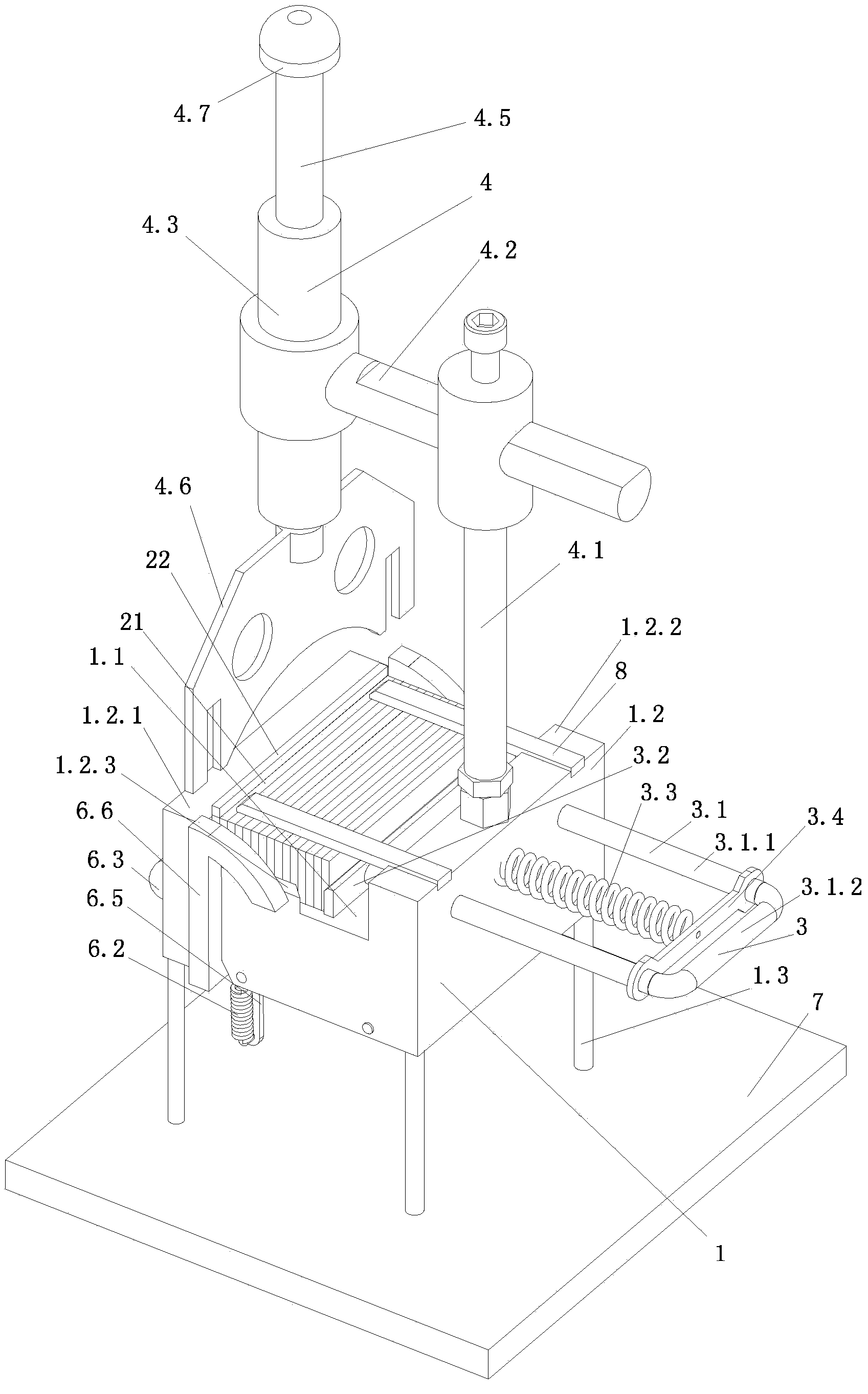

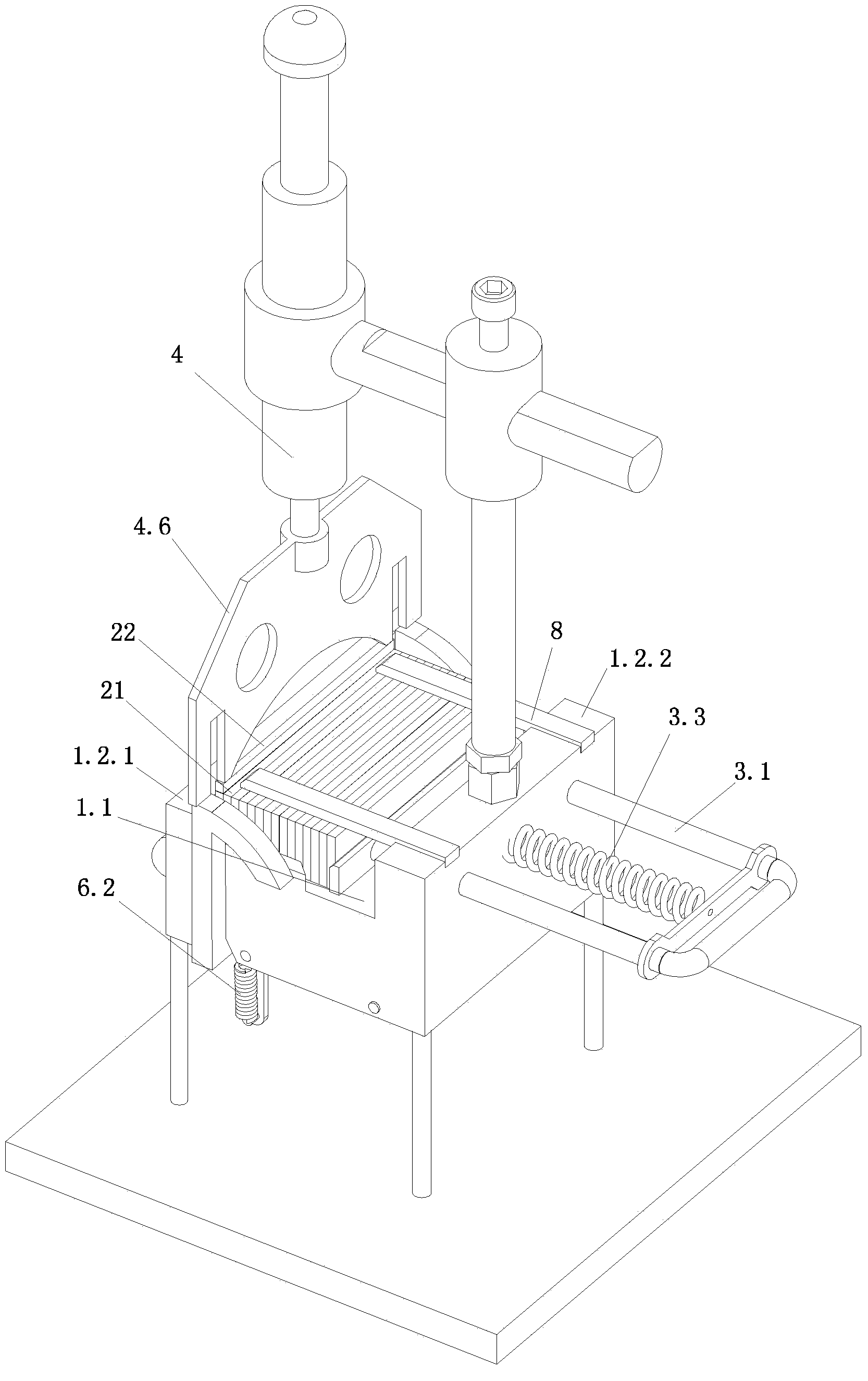

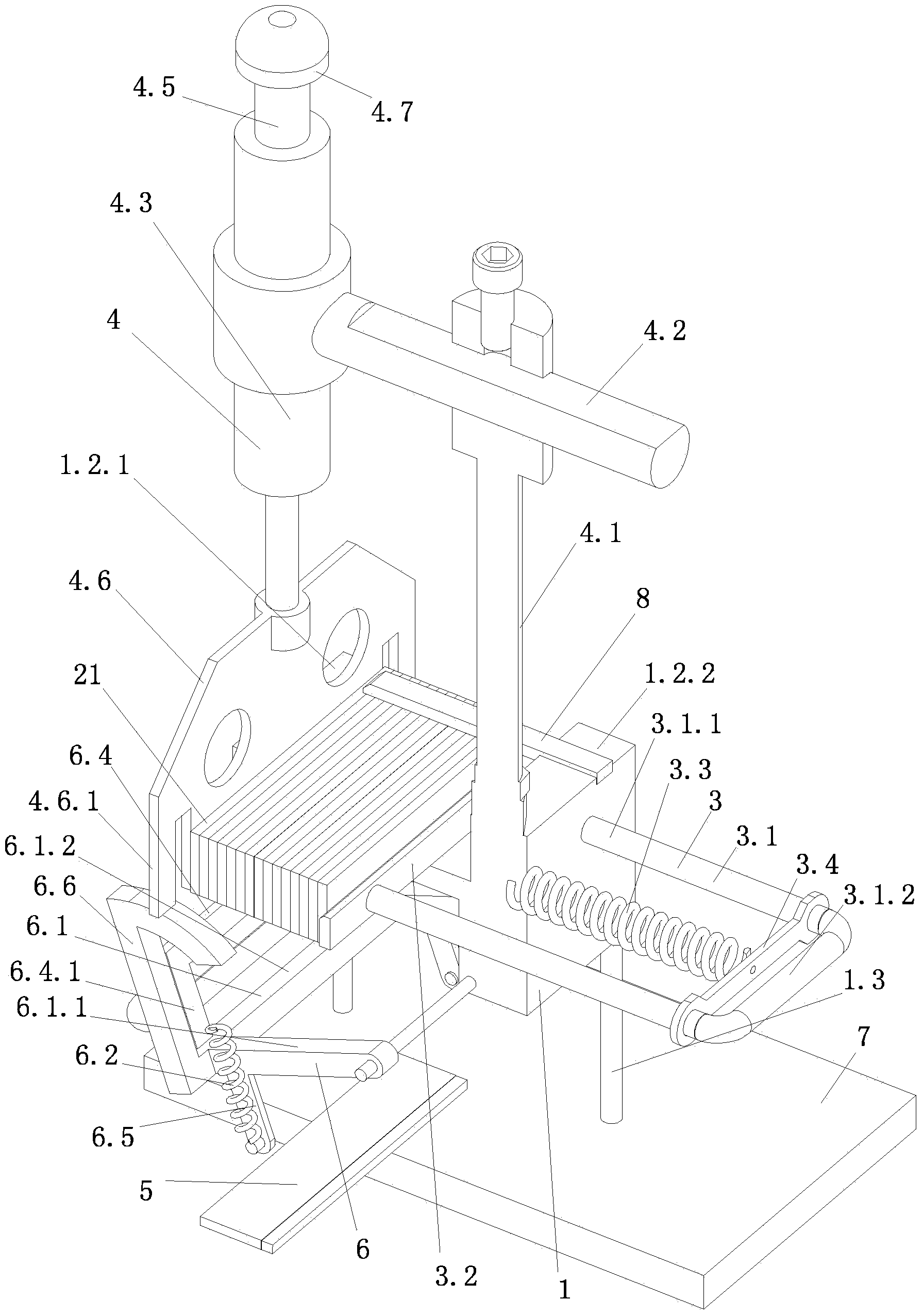

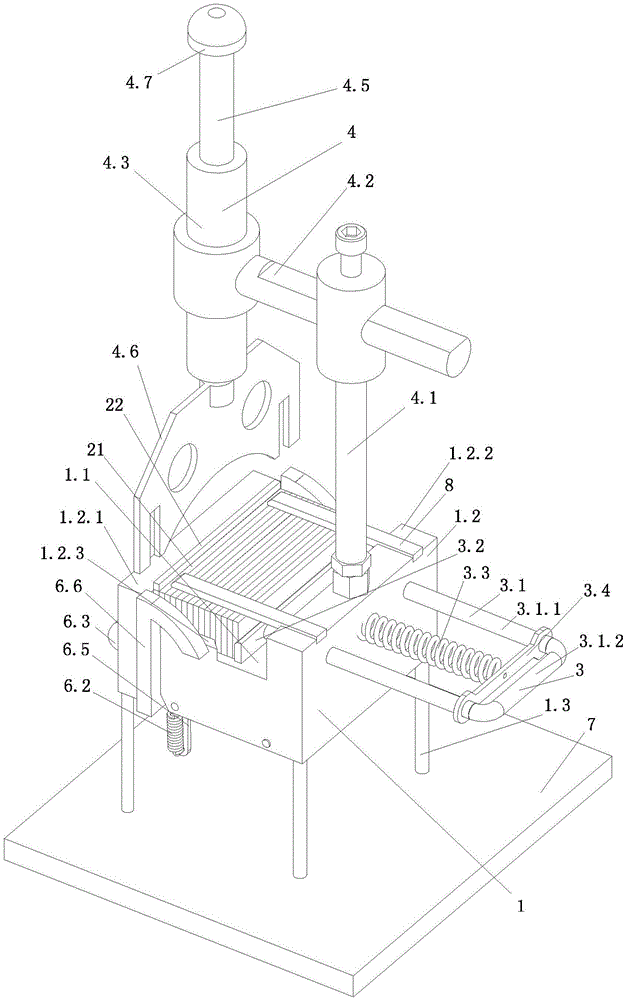

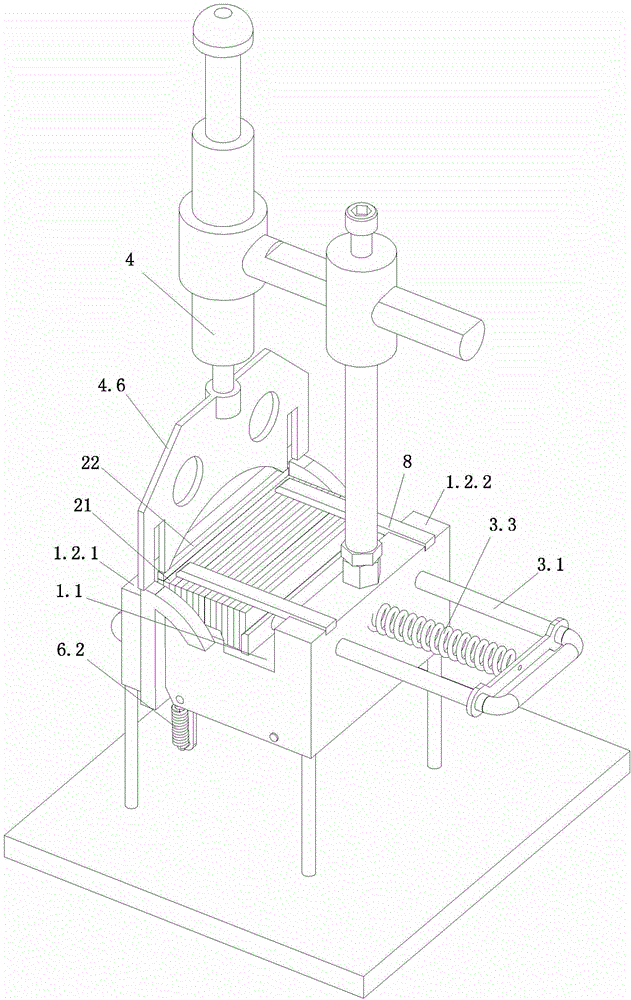

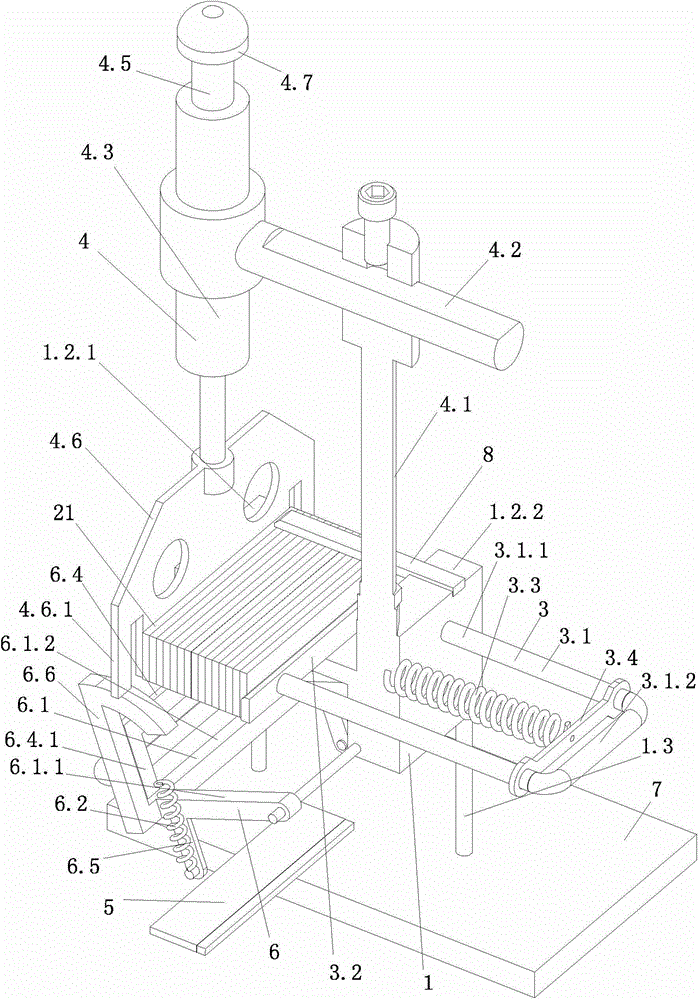

Welding device for honing strips

InactiveCN103846609AEasy to removeEasy to processWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention relates to a welding device for honing strips. The welding device comprises a frame, wherein a bracket mounting part, a bracket clamping mechanism, a honing strip pressing device and a supporting mechanism are arranged on the frame; a plurality of honing strip brackets are stored on the bracket mounting part; the bracket clamping mechanism is used for pushing and clamping the honing strip brackets, which are arranged on the bracket mounting part in turn, on the frame; the honing strip pressing device is used for pressing the honing strips at the upper end of the headmost honing strip bracket for performing the welding operation and detaching the welded honing strip brackets and honing strip welding sets from a discharging hole formed in the frame; the supporting mechanism is used for preventing the honing strip brackets from falling from the discharging hole during a welding process; a vertical pressing plate is arranged on the honing strip pressing device; a plugging baffle for plugging the discharging hole is formed in the supporting mechanism. The welding device for the honing strips has the advantages that the plurality of honing strip brackets can be simultaneously clamped; the operations of centering and clamping the honing strips and the honing strip brackets are easy and the operation efficiency is high; the detaching of the honing strip brackets and the honing strip welding sets for finishing the welding operation is easy and the detaching time is short; the welding device for the honing strips has the advantages of reasonable structure and high welding operation efficiency.

Owner:ZHEJIANG GEELY POWERTRAIN CO LTD +3

Hydraulic truck-carrying unloading machine with translating and locking functions

The invention discloses a hydraulic truck-carrying unloading machine with translating and locking functions. The machine comprises a bottom frame, a translation carrier and a truck carrying platform,wherein the rear end of the truck carrying platform is hinged to the translation carrier, a wheel stopping device for preventing a truck from slipping off is arranged at the rear part of the truck carrying platform, a jacking frame is fixedly connected to the truck carrying platform, one end of a jacking oil cylinder is hinged to the jacking frame, the other end of the jacking oil cylinder is hinged to the translation carrier, the truck carrying platform is turned over by means of stretching and retracting of the jacking oil cylinder, and the translation carrier is moved horizontally and locked in the bottom frame. The machine can adapt to truck-carrying unloading at a port, and is suitable for different bulk materials; the translation carrier is moved horizontally and locked in the bottomframe and extends out backwards to be in butt joint with a cargo ship, and the truck can directly unload the bulk materials onto the cargo ship on the truck carrying platform; and the structure is simple, the manufacturing cost is low, the problem that the truck cannot directly unload the bulk materials onto the cargo ship is solved, and the unloading efficiency is improved.

Owner:HENAN WEITE TRUCK CRANE

Intelligent ultra-low-temperature liquid unloading device and unloading process

ActiveCN109654371AShort unloading timeImprove unloading efficiencyContainer filling methodsFluid handledGas phaseEngineering

The invention discloses an intelligent ultra-low-temperature liquid unloading device which comprises a tank car, a low-temperature skid mounted pump and a pressurizing vaporizer. A tank car liquid phase interface, a tank car gas phase interface and a pressurizing liquid phase interface are arranged on the tank car. The low-temperature skid mounted pump comprises an unloading crane pipe liquid phase arm, an unloading pipeline, an unloading crane pipe gas phase arm and a gas phase pipeline. The tank car liquid phase interface is connected to one end of the unloading pipeline through the unloading crane pipe liquid phase arm while the other end of the unloading pipeline is connected to a storage tank phase general pipe, the tank car gas phase interface is connected to one end of the gas phasepipeline through the unloading crane pipe gas phase arm while the other end of the gas phase pipeline is connected to a storage tank gas phase general pipe, and a liquid phase branch is arranged on the unloading pipeline. In addition, the invention also discloses a process of unloading the ultra-low-temperature liquid by adopting the device. By adopting the device and the process, a certain pressure difference can be maintained between the tank car and the storage tank in the unloading process, so that the condition that the unloading pump operates normally is ensured, and the unloading speedis also improved.

Owner:陕西融科低温设备有限公司

Unloading device for single mold tire vulcanizer

The invention discloses a tire unloading device of a single-mode tire vulcanizer. The tire unloading device comprises a turnover mechanism, an opening and closing mechanism and a lifting mechanism, wherein the turnover mechanism comprises turnover roller racks, turnover support frames and a turnover component; the turnover roller racks are symmetrically arranged at two sides and hinged on the turnover support frames; the turnover component for putting up and putting down the turnover frames around a hinge point is arranged between the turnover roller racks and the turnover support frames; the opening and closing mechanism comprises a slide frame and a flexible component; the slide frame is transversely arranged between the turnover support frames at two sides; the turnover support frames at two sides are arranged on a slide rack in a sliding manner; the flexible component for outwards opening and inwards folding the turnover support frames at two sides is arranged on the slide rack; the slide rack is arranged on the lifting mechanism. The tire unloading device is short in tire unloading time, the non-vulcanization time is reduced, and the efficiency and the automatic degree of the vulcanizer are improved.

Owner:GUILIN RUBBER MACHINERY CO LTD

Unloading method for grease multiple point central quantitative lubricating pipeline and self suction load device

InactiveCN1312428CShort unloading timeSimple methodProportioning devicesLubricating pumpsSteel ballEngineering

The invention is a load absorbing device of grease multi-point concentration ration channel lubrication, it arranges automatic load absorbing device on each primary oil channel of the concentrated ration lubrication system, it has a shell, one end of the shell is connected to a connector, another end is arranged with a connecting aperture, in the shell there has a piston, the end of the piston is arranged with a block with oil aperture, another end of the piston has a spring; there has a steel ball facing to the oil aperture, the steel ball is arranged on the steel ball bracket, there arranges with a spring under the steel ball bracket, the bracket can move up and down along the inner wall of the piston, realizes the open or close of the oil aperture. The method is simple, compact, and convenient.

Owner:NINGBO JIUYUAN LUBRICATION EQUIP MFG

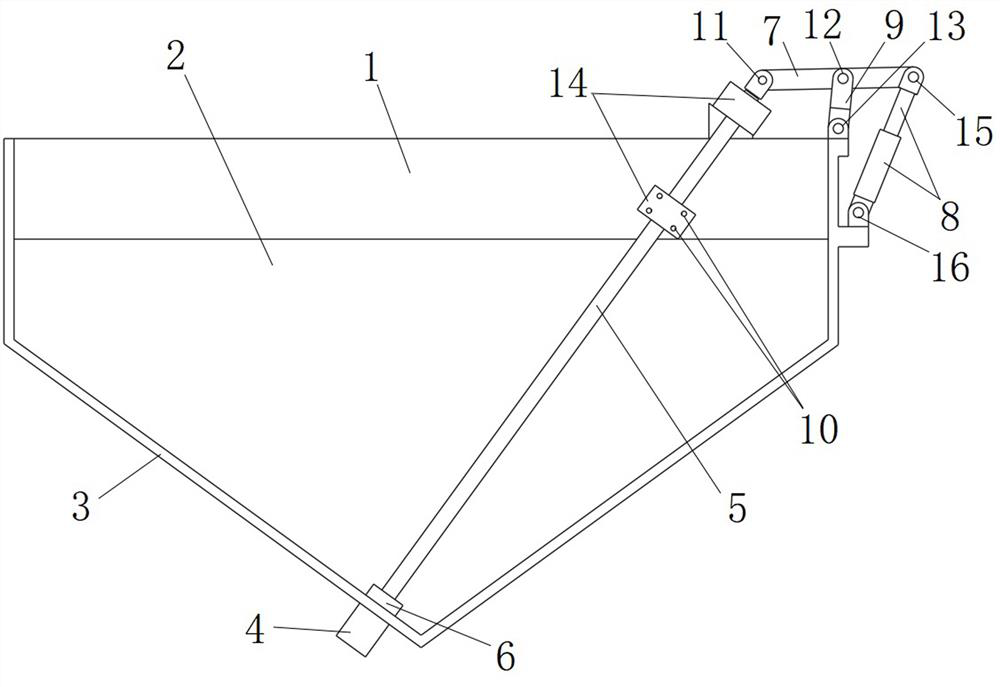

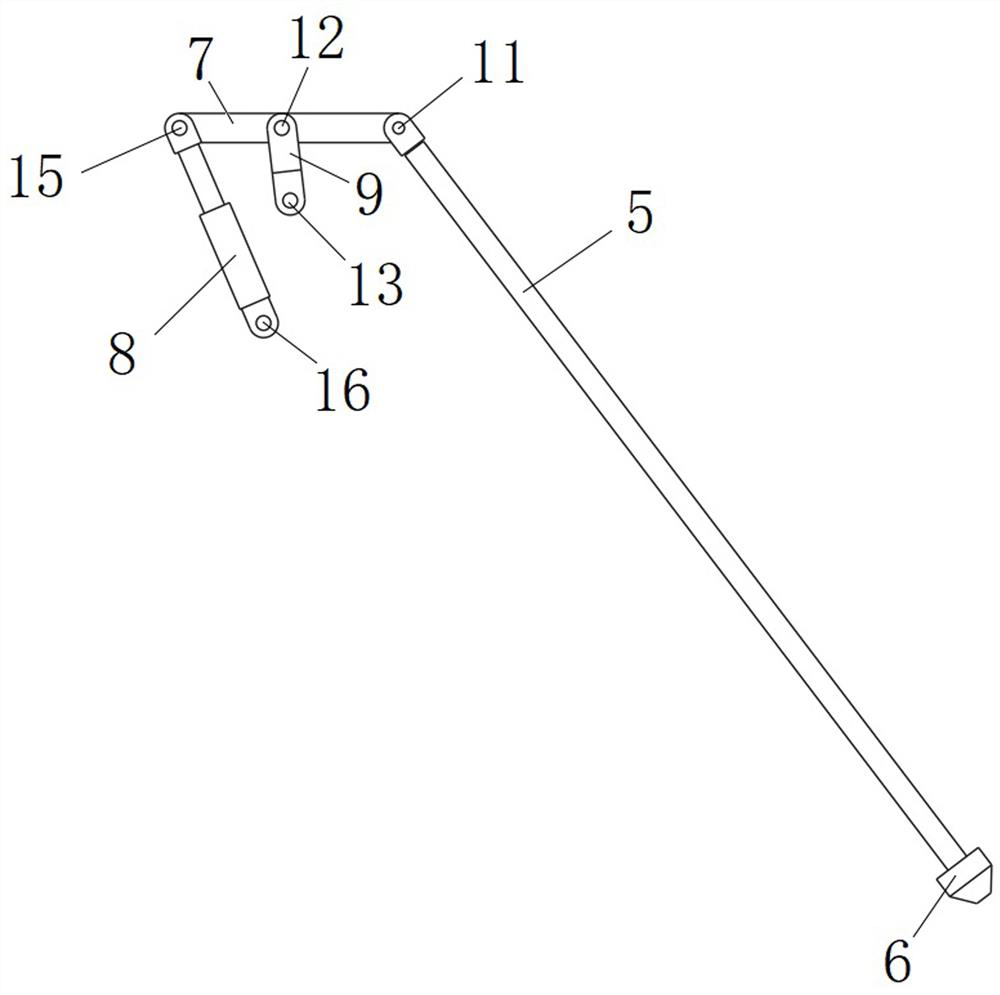

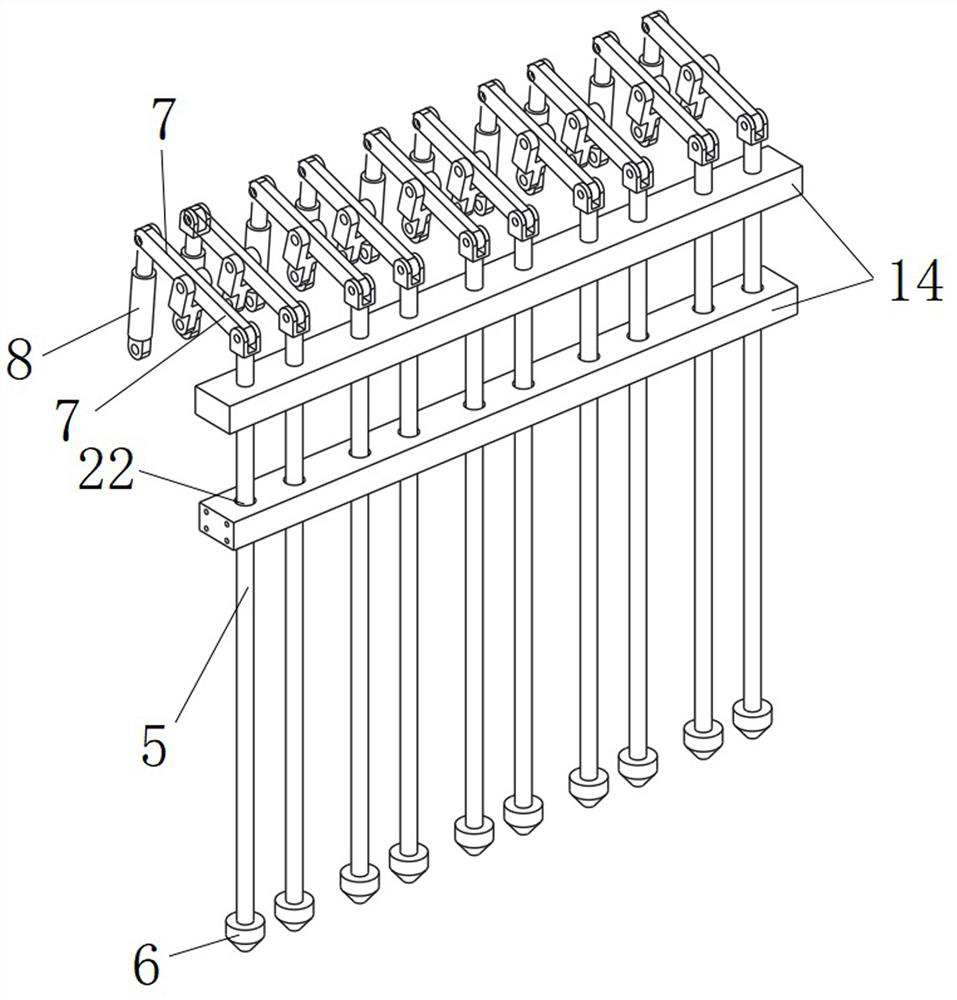

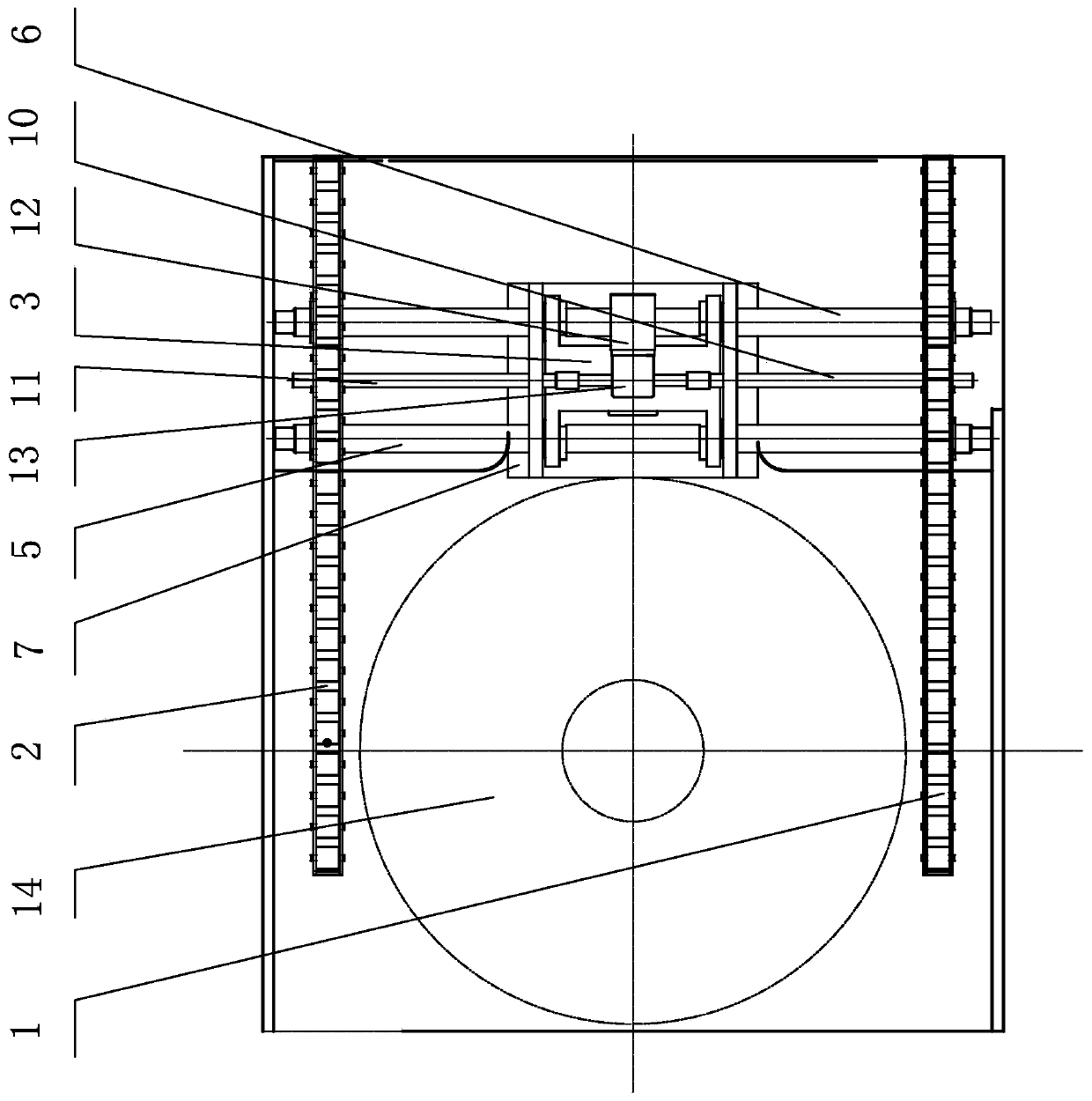

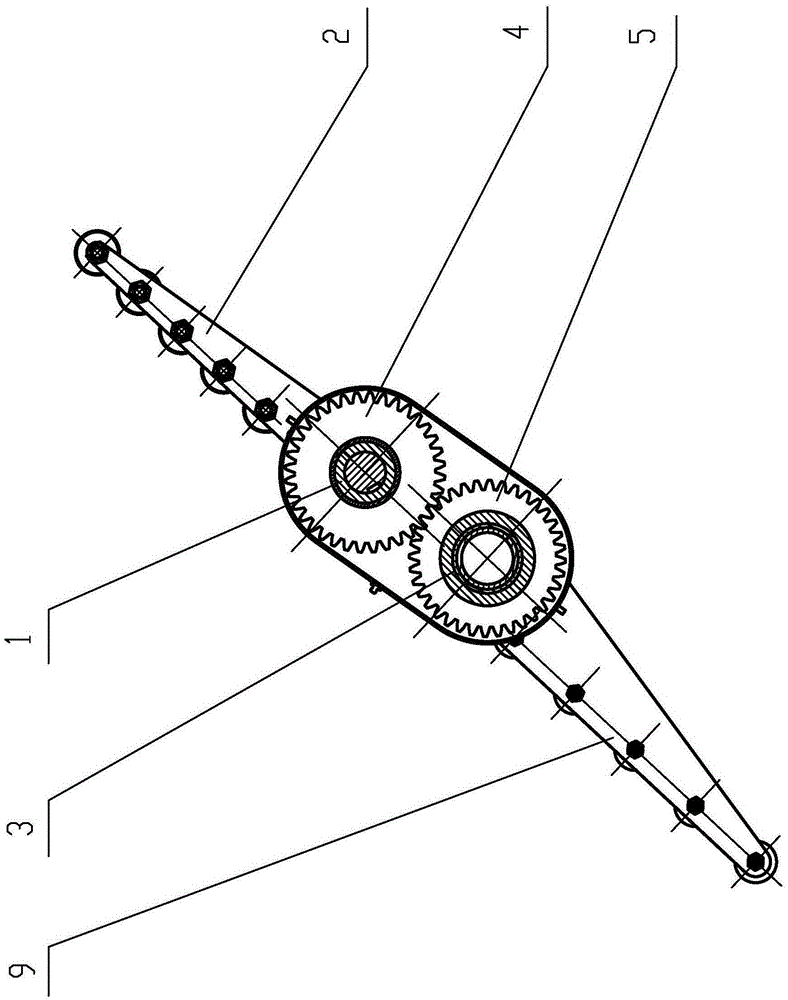

Single-degree-of-freedom connecting rod pulling and inserting multi-opening type wallboard distributing machine

PendingCN113371343AA large amountShort unloading timeLarge containersFeeding arrangmentsDrive by wireIndustrial engineering

The invention discloses a single-degree-of-freedom connecting rod pulling and inserting multi-opening type wallboard distributing machine. The single-degree-of-freedom connecting rod pulling and inserting multi-opening type wallboard distributing machine comprises a hopper, a cross beam and discharging mechanisms, the hopper is divided into a plurality of stock bins through partition plates, the height of the partition plates is lower than that of a hopper arm of the hopper, and a discharging groove is formed in a bottom plate below each stock bin. The cross beam is fixedly mounted on the hopper arm of the hopper, and a plurality of circular holes are formed in the cross beam. Each discharging mechanism is a single-degree-of-freedom connecting rod mechanism and comprises an inserting and pulling rod, a discharging cone, a connecting rod, a supporting rod and a linear driver. The discharging grooves on a bottom plate below the stock bin are controlled by the discharging cone on the inserting and pulling rod to discharge. The hopper comprises the five stock bins, one to two discharging grooves are formed in the bottom plate below each stock bin, and each discharging groove is controlled by the independent discharging mechanisms. In practical application, after the hopper is filled with wallboard mixtures, the discharging grooves at the bottoms of the stock bins are opened under the control of the discharging mechanisms, and discharging ports below the hopper distribute materials at the same time, so that compared with an existing material distributing machine, the material distributing efficiency is greatly improved, and the single-degree-of-freedom connecting rod pulling and inserting multi-opening type wallboard distributing machine is particularly suitable for distributing materials for a wallboard machine.

Owner:SHANDONG TIANYI MACHINERY

A garbage buried collection box for urban and rural garbage collection

ActiveCN107777188BSatisfy delivery collection needsNo visual pollutionRefuse receptaclesRural areaAgricultural science

The invention discloses an underground rubbish collection box for storage and collection of urban and rural rubbish. The underground rubbish collection box comprises a box body lifting device, whereina fixed base is movably mounted at the bottom of the box body lifting device, a box body lift cylinder is fixedly mounted at the top of the fixed base, a cylinder head of the box body lift cylinder and the box body lifting device, a lifting table is movably mounted at the top of the box body lifting device, a box body discharging turning device is fixedly mounted on one side of the top of the lifting table, a box body is hinged to the box body discharging turning device, the bottom of the box body and the top of the lifting table make a contact, a box body top cover is glidingly mounted at the top of the box body, a rapid opening and closing feeding door is arranged at the top of the box body top cover, and top cover opening connecting rod mechanisms are hinged to two sides of the bottomof the box body top cover. The underground rubbish collection box has the advantages of better environmental protection and higher efficiency, the box body can be rapidly lifted from a pit for discharging, the discharging time is short, and passage is not affected.

Owner:安徽标科环境科技有限公司

Honing rod welding device

InactiveCN103846609BSimple unloadingImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesWelding processStructural engineering

The invention relates to a welding device for honing strips. The welding device comprises a frame, wherein a bracket mounting part, a bracket clamping mechanism, a honing strip pressing device and a supporting mechanism are arranged on the frame; a plurality of honing strip brackets are stored on the bracket mounting part; the bracket clamping mechanism is used for pushing and clamping the honing strip brackets, which are arranged on the bracket mounting part in turn, on the frame; the honing strip pressing device is used for pressing the honing strips at the upper end of the headmost honing strip bracket for performing the welding operation and detaching the welded honing strip brackets and honing strip welding sets from a discharging hole formed in the frame; the supporting mechanism is used for preventing the honing strip brackets from falling from the discharging hole during a welding process; a vertical pressing plate is arranged on the honing strip pressing device; a plugging baffle for plugging the discharging hole is formed in the supporting mechanism. The welding device for the honing strips has the advantages that the plurality of honing strip brackets can be simultaneously clamped; the operations of centering and clamping the honing strips and the honing strip brackets are easy and the operation efficiency is high; the detaching of the honing strip brackets and the honing strip welding sets for finishing the welding operation is easy and the detaching time is short; the welding device for the honing strips has the advantages of reasonable structure and high welding operation efficiency.

Owner:ZHEJIANG GEELY POWERTRAIN CO LTD +3

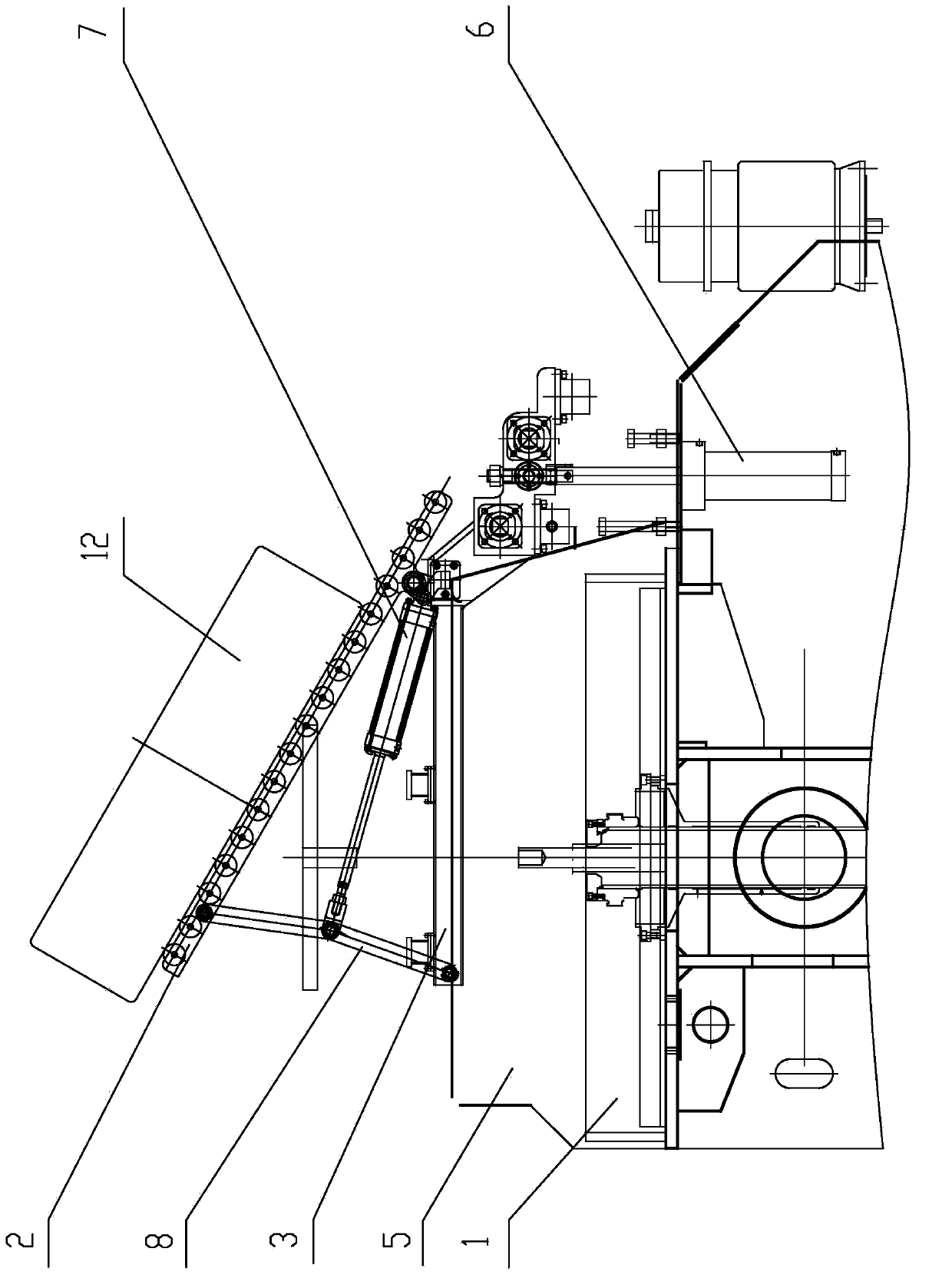

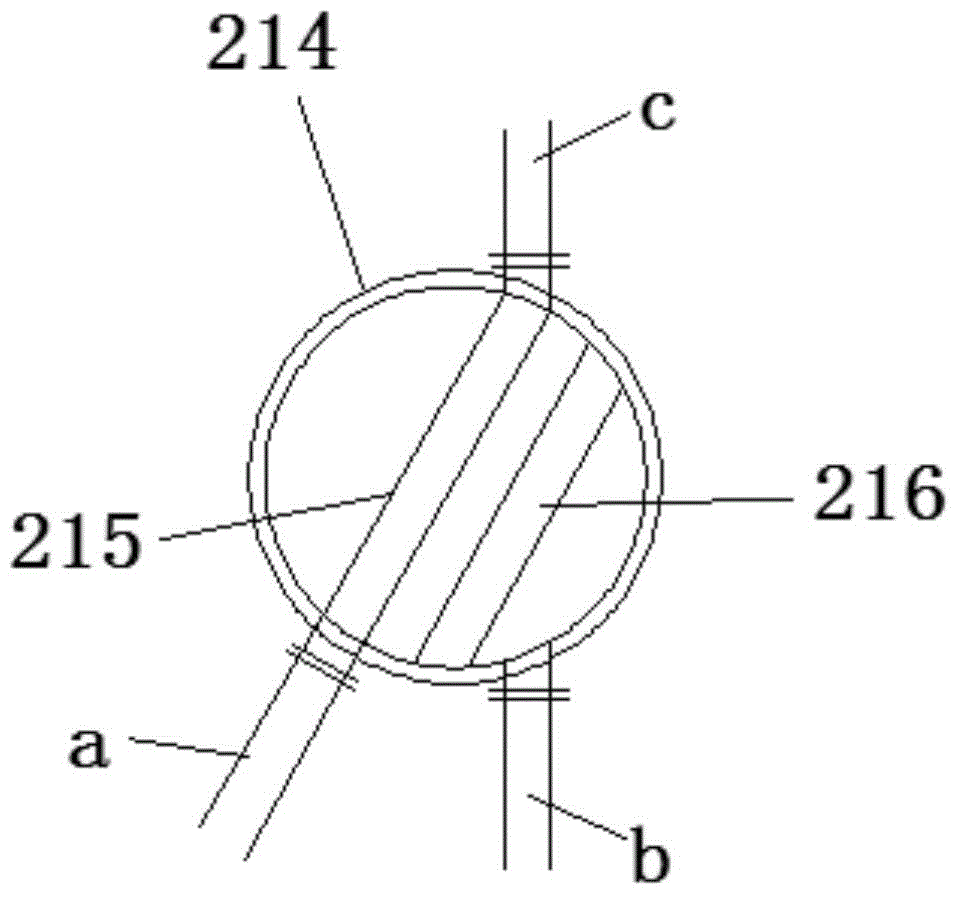

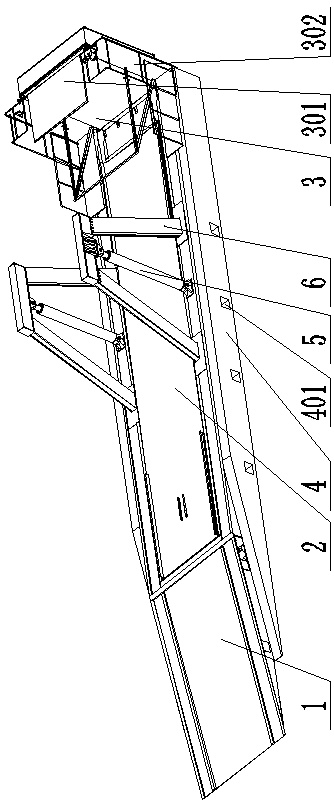

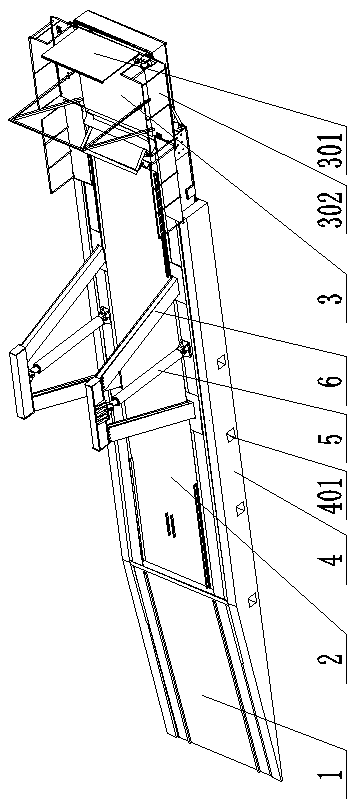

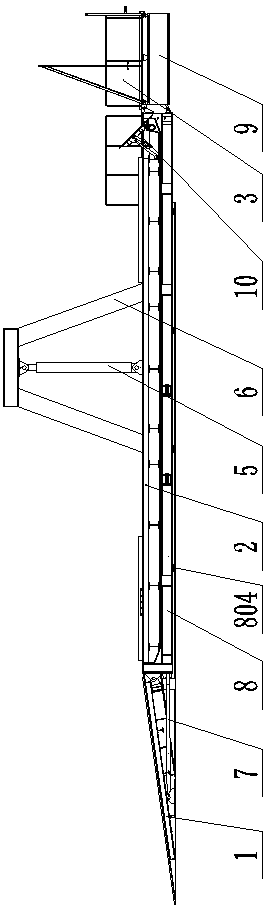

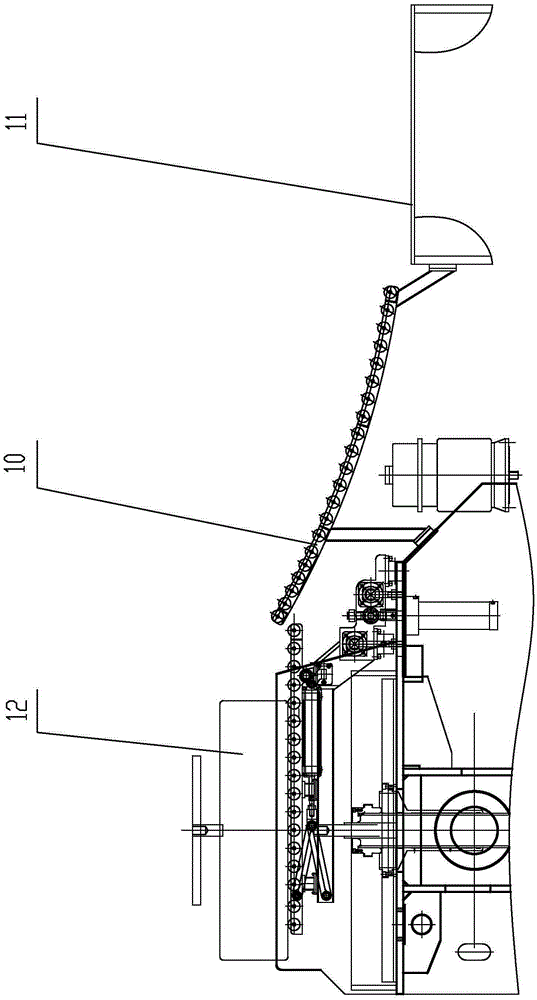

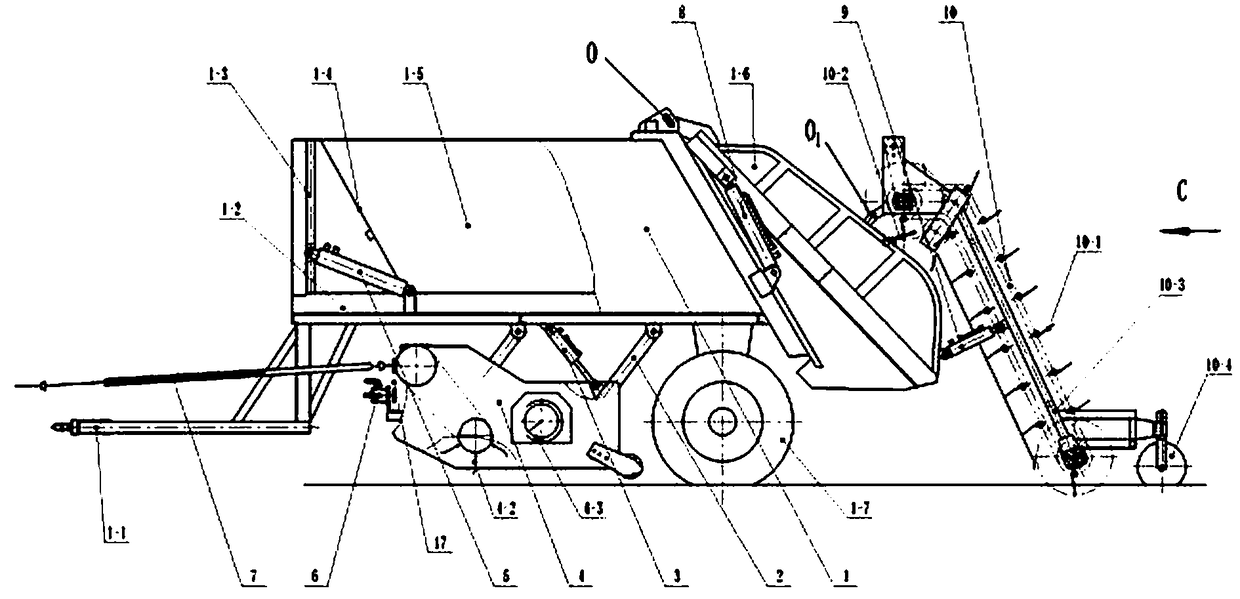

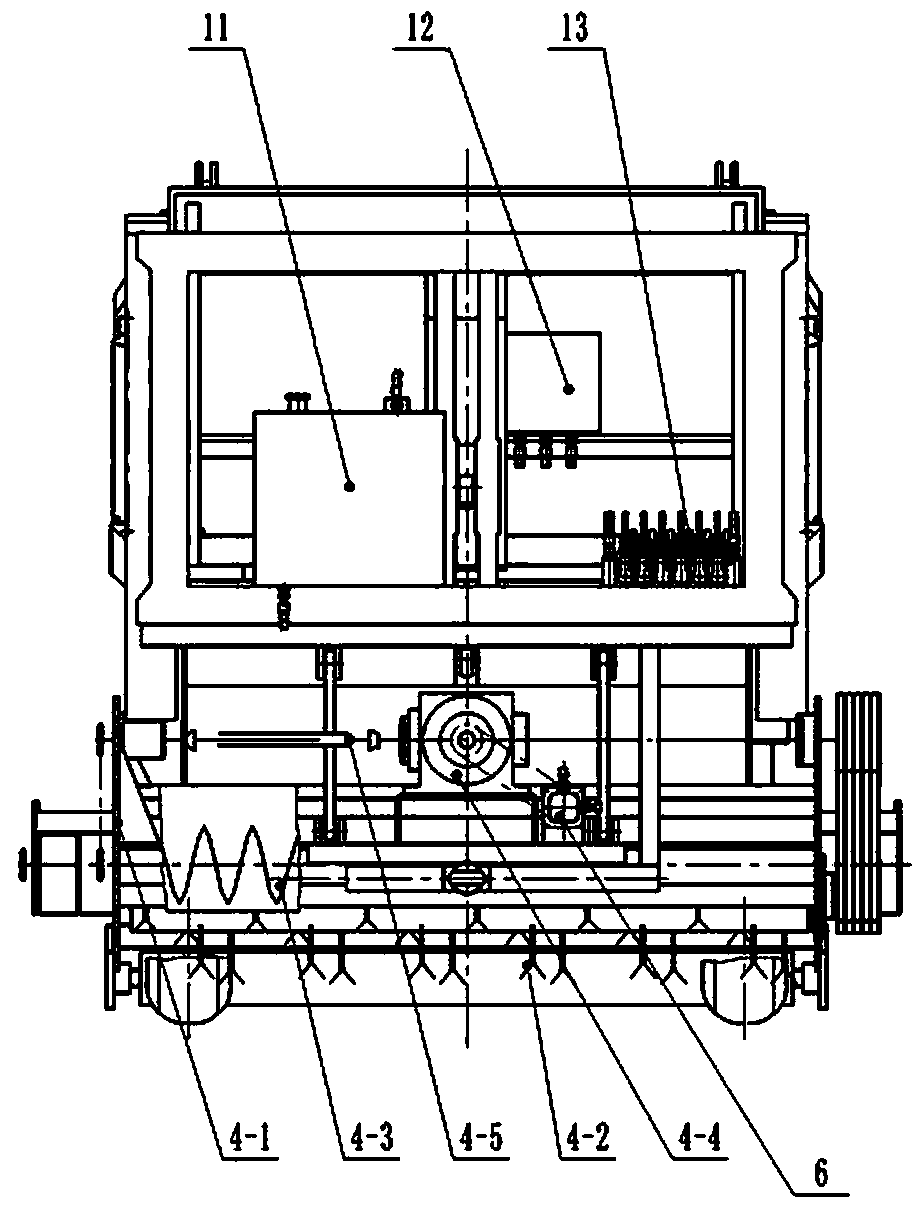

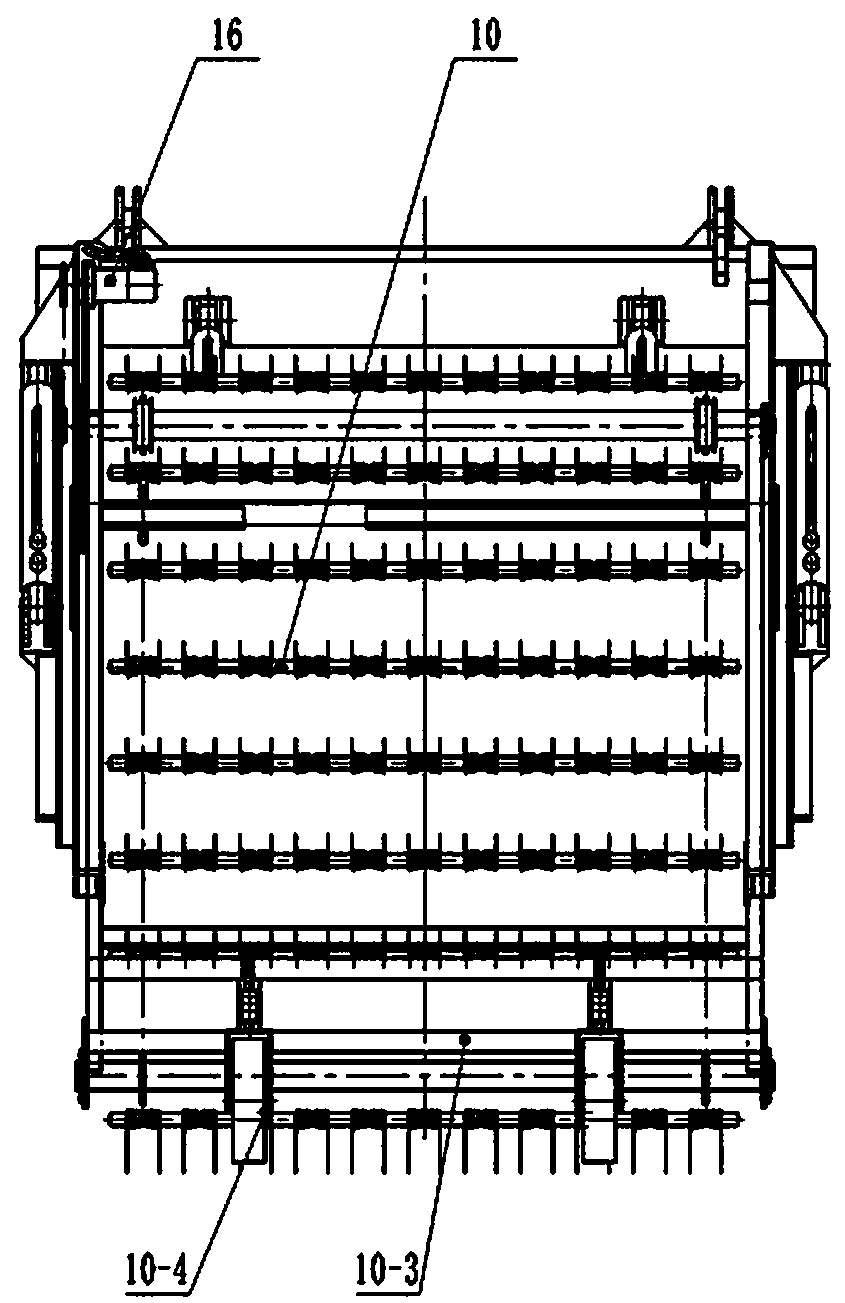

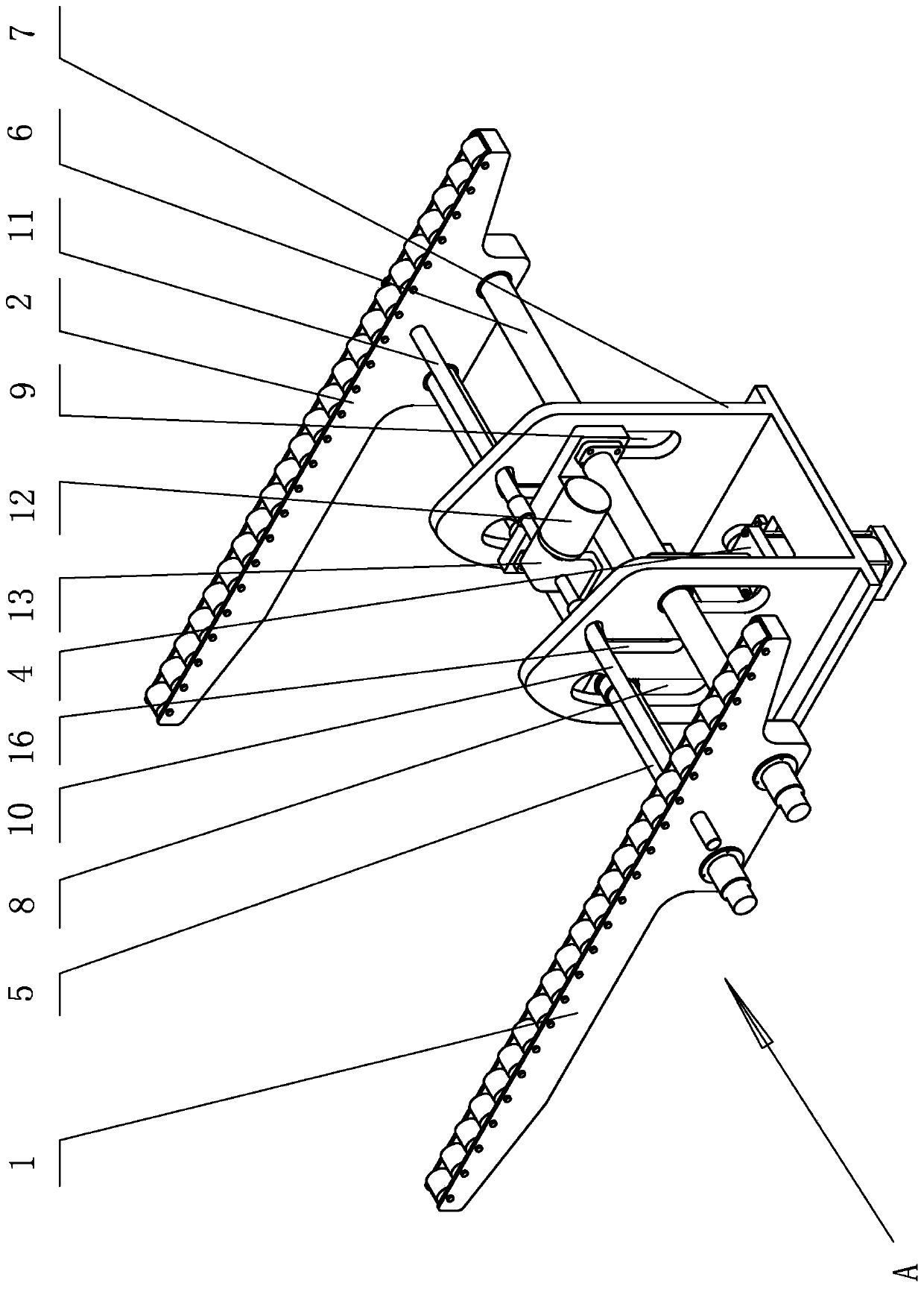

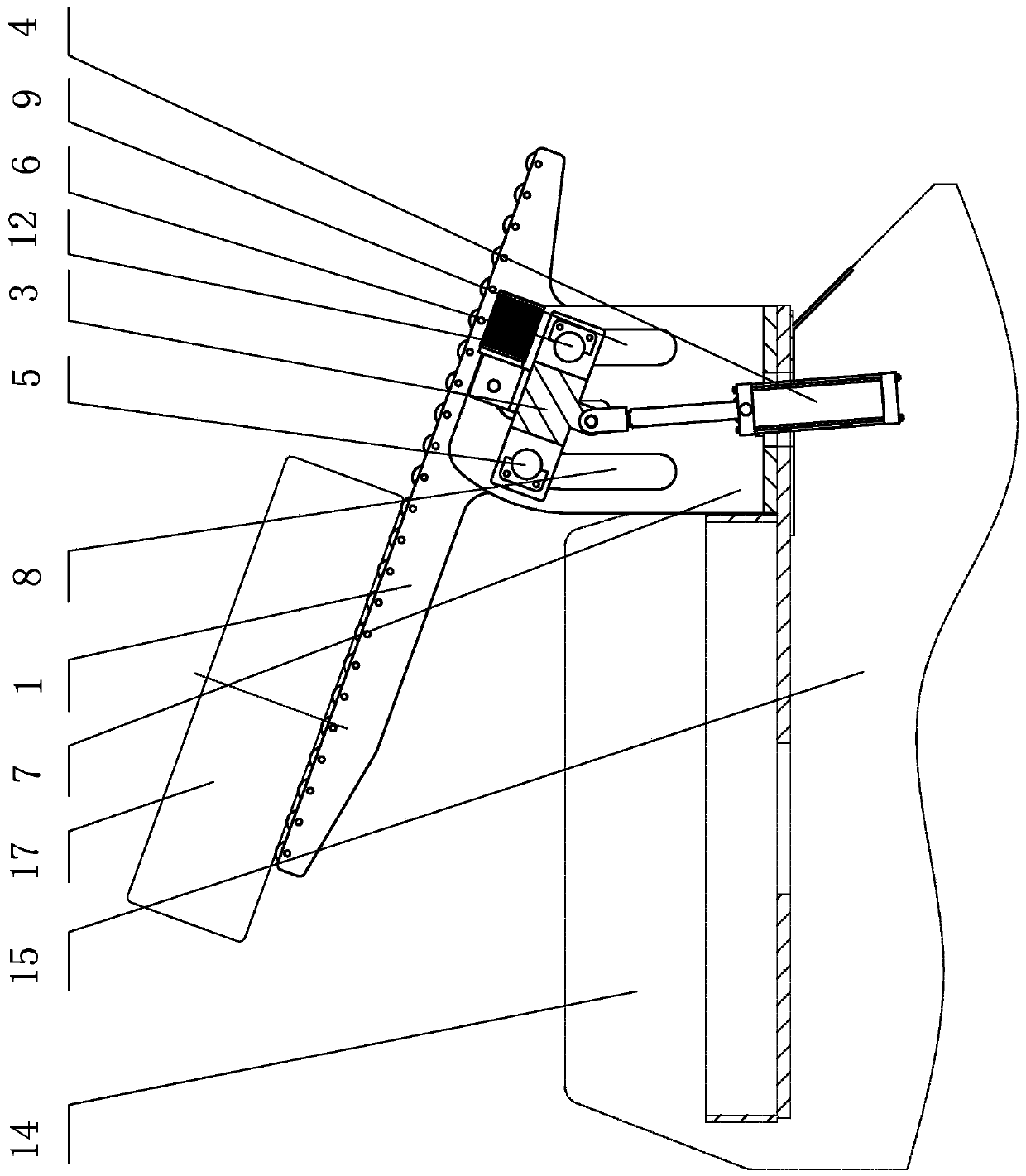

Traction-type residual film recovery compression and straw returning combined operation machine

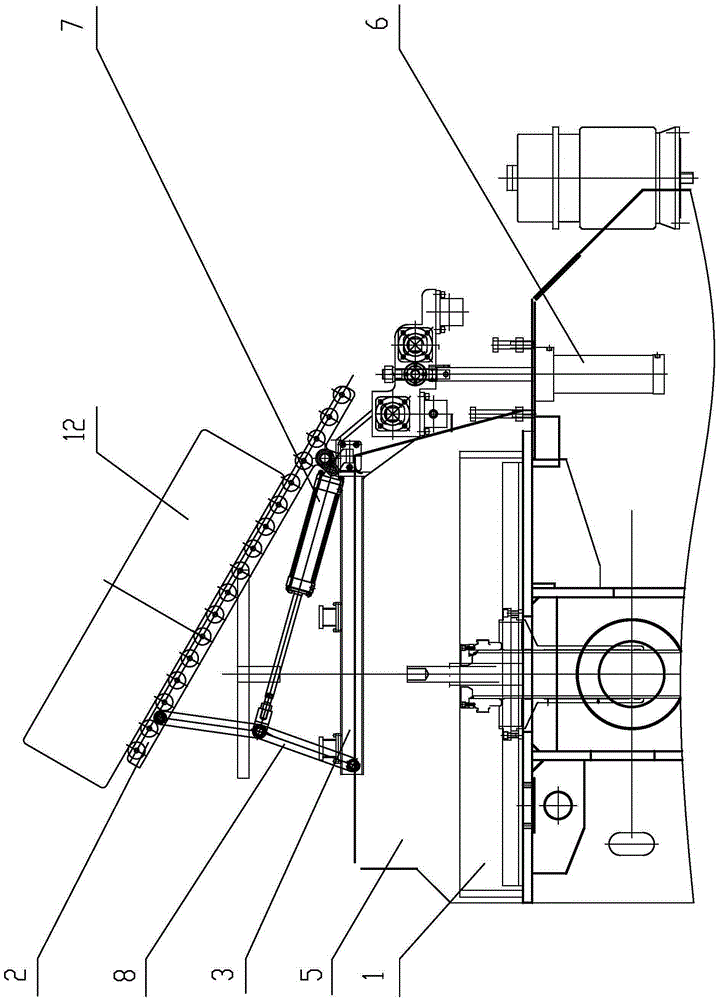

The invention discloses a traction type used plastic film retrieving compressing and straw mulching combined machine. The combined machine comprises a universal joint shaft, an electric control system, a hydraulic system, a used plastic film collecting and compressing part, a straw grinding mulching part and a used plastic film curling and retrieving part, wherein the straw grinding mulching part is positioned under the front of the used plastic film collecting and compressing part, and the used film curling and retrieving part is positioned behind the used film collecting and compressing part; the straw grinding mulching part is connected with a film collection tank of the used plastic film collecting and compressing part through a four-bar mechanism; two ends of an adjusting cylinder I are respectively hinged with the straw mulching machine and the film collection tank; the upper part of the used film curling and retrieving part is hinged with a used plastic film collection device; and the middle part of the used film curling and retrieving part is connected with the used plastic film collection device through an adjusting cylinder II. The used plastic film retrieving compressing and straw mulching combined machine has a large-volume film collection tank, can be used for furthest improving the loading capacity of the film collection tank, and is especially suitable for large strip field operation in farms of the Xinjiang Production and Construction Corps.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

Mixing equipment and mixing method in milk powder dry mixing section

ActiveCN104785155BLow costIncrease profitMixing methodsRotary stirring mixersDairy foodsManufacturing technology

Owner:百跃羊乳(南宁)有限公司

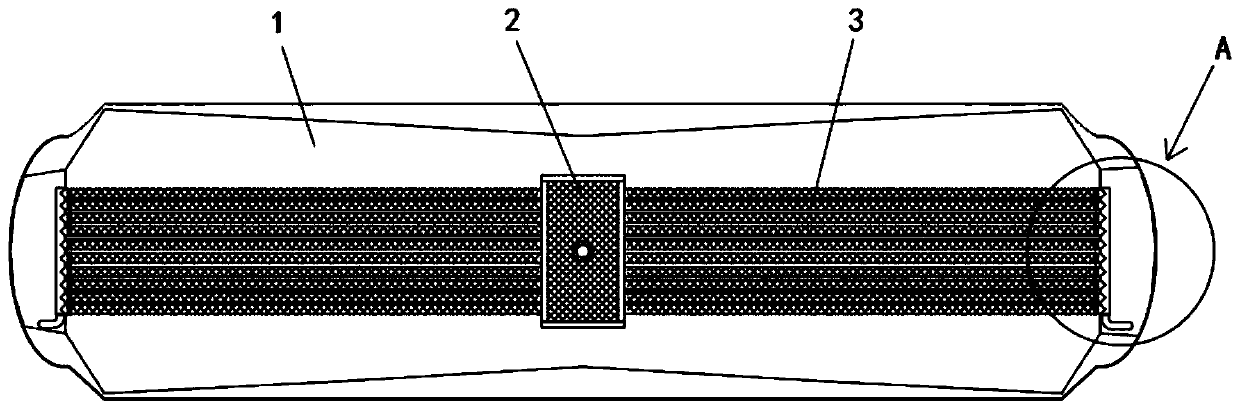

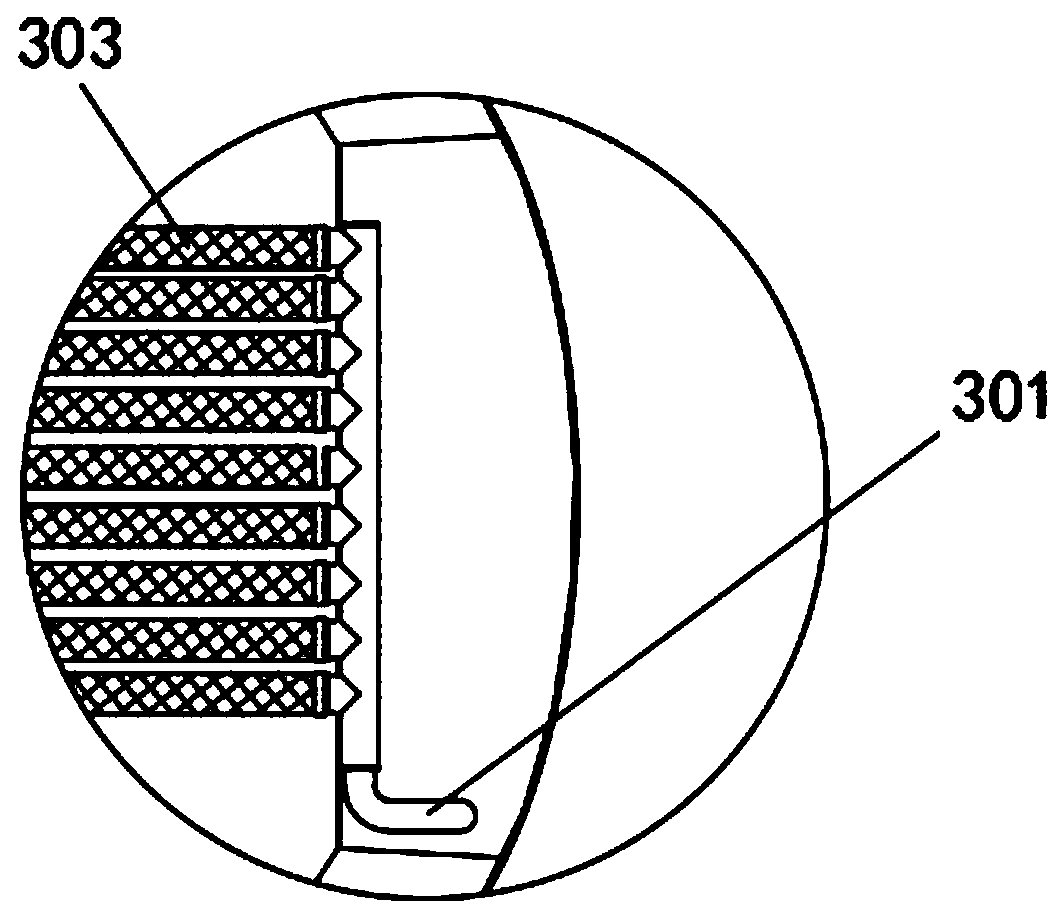

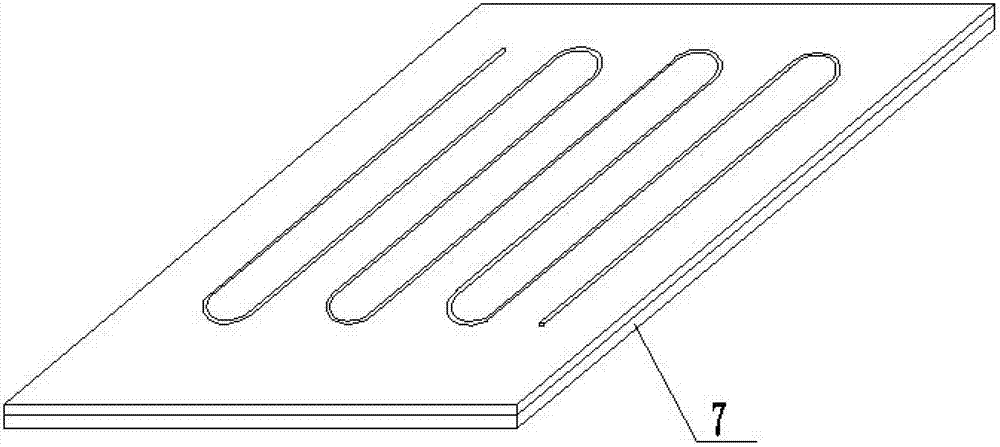

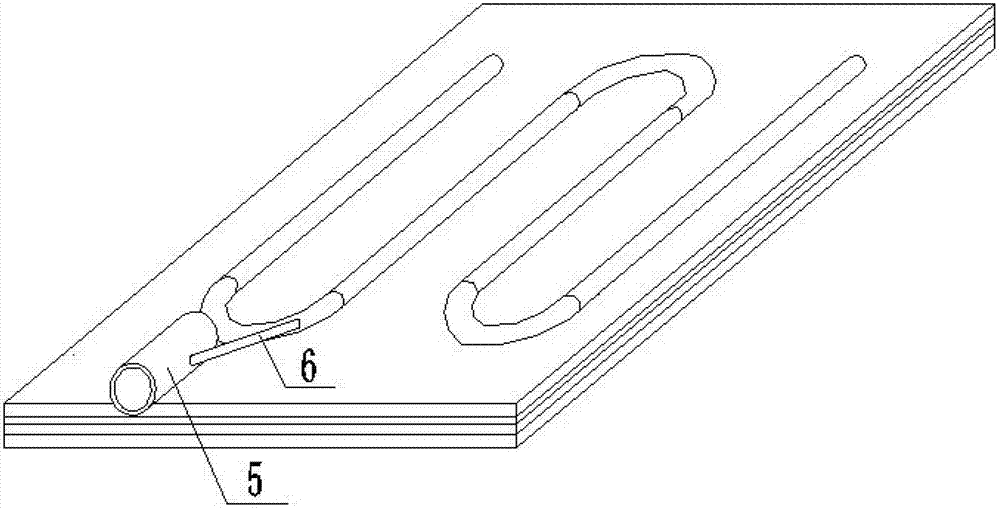

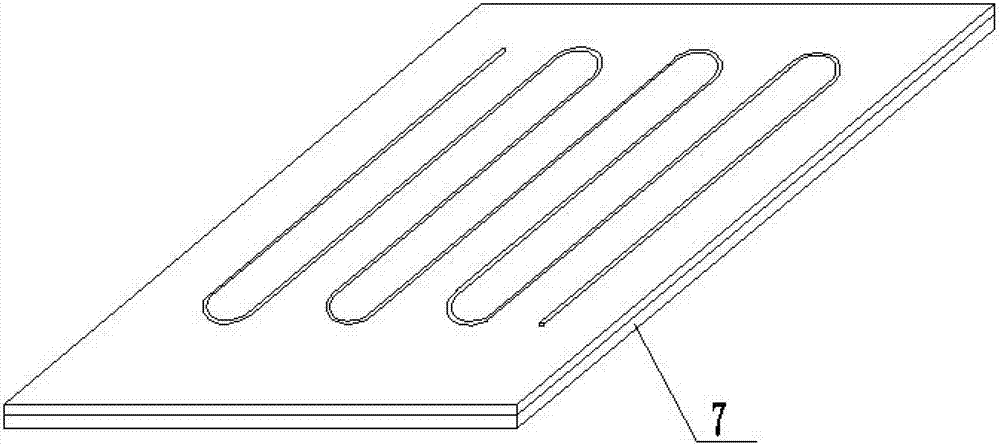

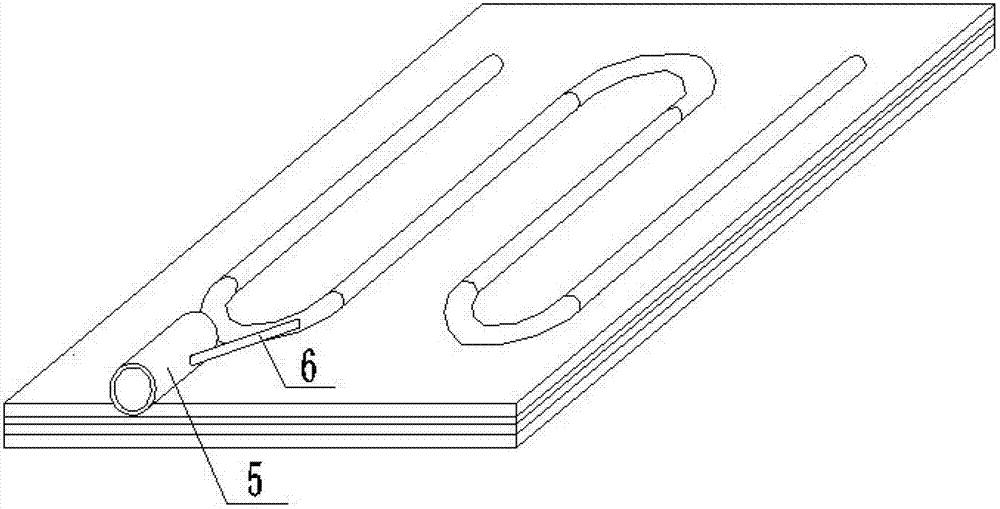

Quick blank pipe type layering discharge device and quickly discharging method thereof

ActiveCN102745436AShorten unloading timeShort unloading timeLarge containersTank wagonsEngineeringElectrical and Electronics engineering

The invention relates to a quick blank pipe type layering discharge device. The blank quick pipe type layering discharge device comprises a container and a heater, and further comprises a feeding pipe, wherein the container is provided with a discharge opening; the heater is arranged in the container and is arranged at the bottom of the container; the feeding pipe is communicated with the discharge opening and is sequentially provided with a plurality of discharge holes from top to bottom, and at least one discharge hole is arranged at the bottom of the container; and each discharge hole is provided with a switch control valve. The invention further discloses a quick discharging method for discharging by utilizing the quick blank pipe type layering discharge device. According to the invention, the technical problem that the discharge device in the prior art is too long in discharge time is solved, and the invention further provides the quick blank pipe type layering discharge device with short discharge time and a smooth discharge operation and the quick discharging method thereof.

Owner:TIANJIN ZHAOHUA LOGISTICS CO LTD

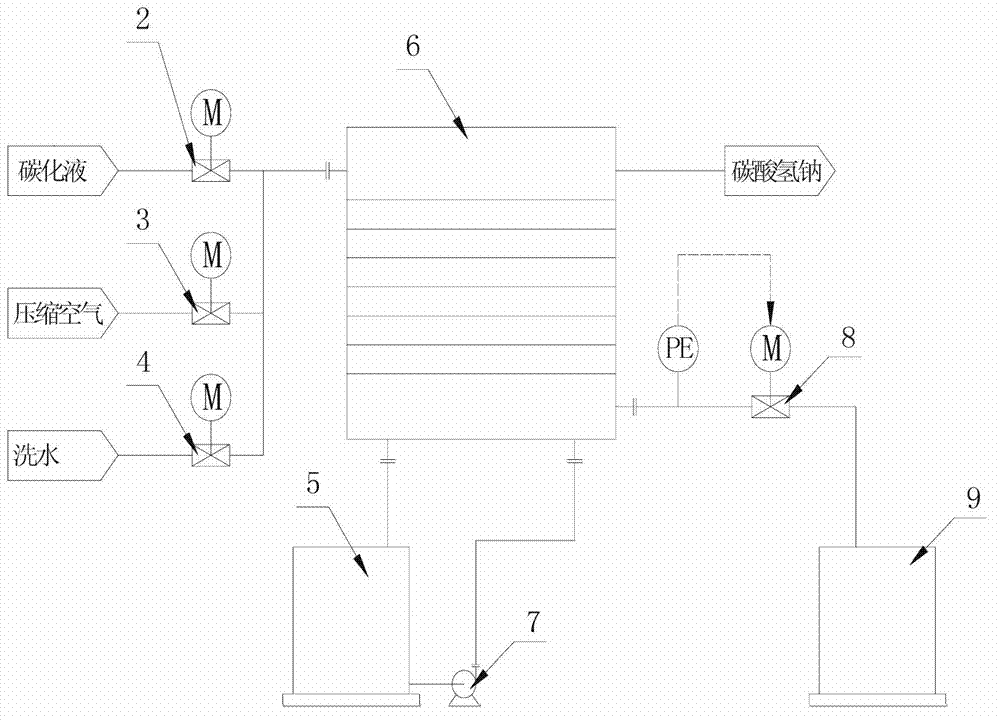

Filtering method of sodium bichromate carbonizing liquid

InactiveCN102847372ANo reverse reactionMeet the requirements of continuous filtrationChromates/bichromatesFiltration separationSodium bichromateChemistry

The invention relates to a filtering method of sodium bichromate carbonizing liquid. The filtering method comprises the following steps: preparing sodium bichromate carbonizing liquid; and filtering the sodium bichromate carbonizing liquid under a condition that a preset pressure is kept. With the adoption of the filtering method of sodium bichromate carbonizing liquid provided by the invention, the sodium bichromate carbonizing liquid which is subjected to qualified carbonizing does not generate reverse reaction due to the reduction of the pressure.

Owner:SICHUAN YINHE CHEM

Container with bottom auxiliary heating device and auxiliary heating method

ActiveCN102730346BLiquefaction in timeUnload in timeLarge containersTank wagonsInsulation layerAuxiliary heating

The invention relates to a container with a bottom auxiliary heating device and an auxiliary heating method realized by using the container. The container with the bottom auxiliary heating device comprises an inner container body, an outer container body, a heat insulation layer, a heating pipe and the auxiliary heating device, wherein the outer container body is sleeved at the outer part of the inner container body, the heat insulation layer is arranged between the inner container body and the outer container body, the heating pipe is arranged at the inner part of the inner container body, and the auxiliary heating device is arranged between the bottom of the container and the insulation layer. Materials deposited at the lower part of the heating pipe at the bottom of the inner container body are heated, the materials at the bottom are liquefied in time and conveniently and promptly unloaded in time and the residue amount of the materials at the bottom of the container is decreased by the auxiliary heating device.

Owner:TIANJIN ZHAOHUA LOGISTICS CO LTD

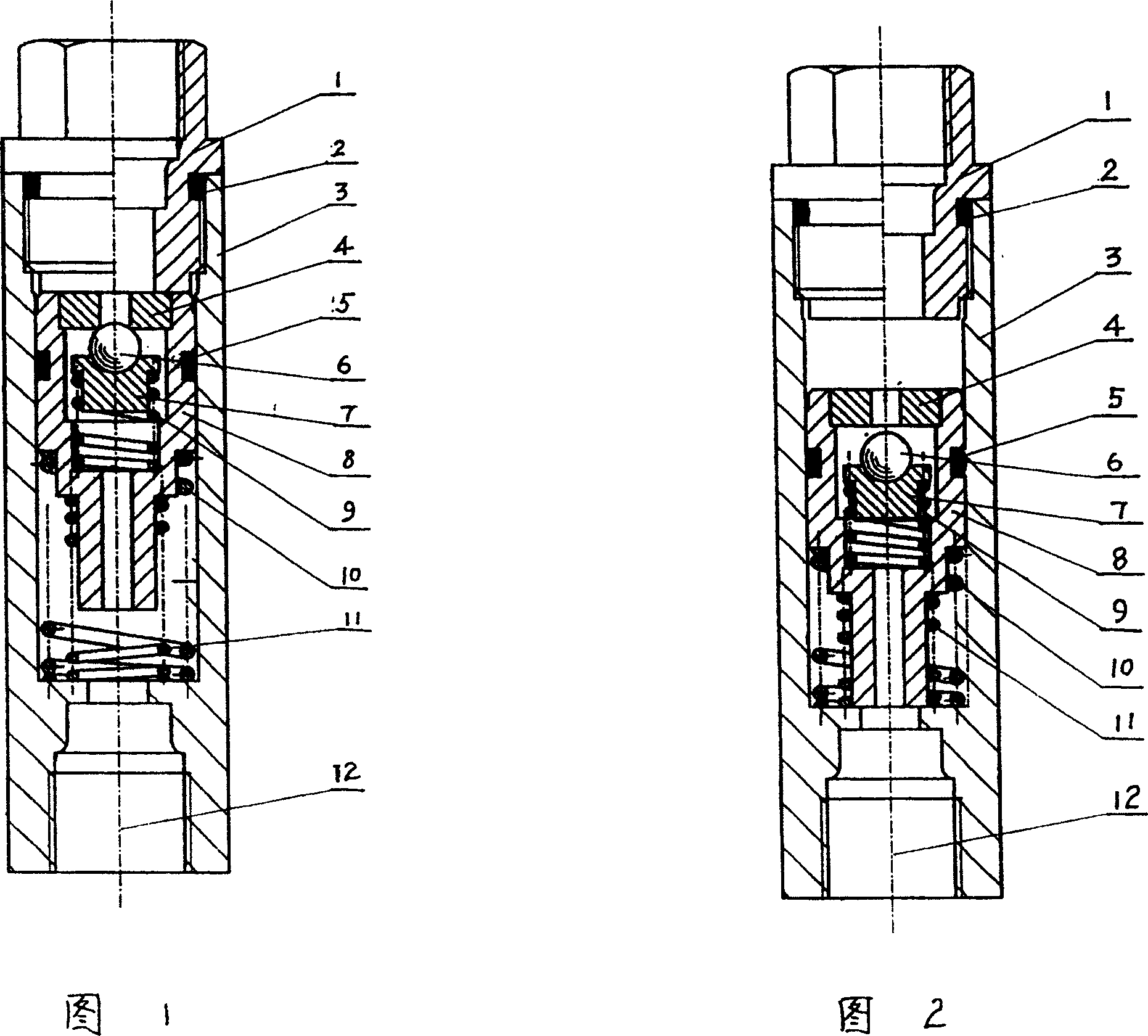

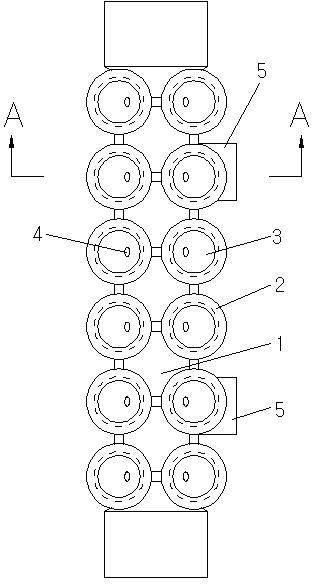

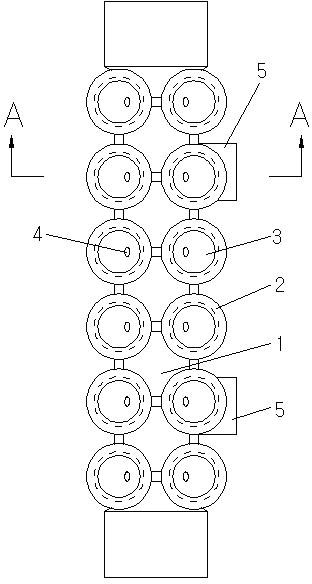

Double-row pressurized volumetric type lubricating medium quantitative distributor

InactiveCN102537637AShorten the lengthHigh sensitivityProportioning devicesDistribution equipmentEngineeringDistributor

A double-row pressurized volumetric type lubricating medium quantitative distributor relates to the technical field of lubrication systems, and solves the technical problem of shortening the unloading time. The distributor includes a main pipeline and a plurality of quantitative valves, wherein at least two main pipeline mounting pieces are fixedly arranged on a pipe wall on one side of the main pipeline at intervals along the axis of the main pipeline; and the distributor is characterized in that a plurality of quantitative valve mounting pieces ranged in two rows and multiple columns along the axis of the main pipeline are arranged on a pipe wall on one side of the main pipeline; each quantitative valve mounting piece is provided with a quantitative valve mounting hole; and further, all the quantitative valves are mounted respectively in the quantitative valve mounting holes in the quantitative valve mounting pieces, a distribution through hole communicated with a pipe cavity of the maim pipeline is formed in the bottom of each quantitative valve mounting hole, and the apertures of the distribution through holes are smaller than the apertures of the quantitative valve mounting holes and the inner diameter of the main pipeline. The distributor provided by the utility model has short unloading time and is convenient to mount.

Owner:宁波市润龙机械科技有限公司

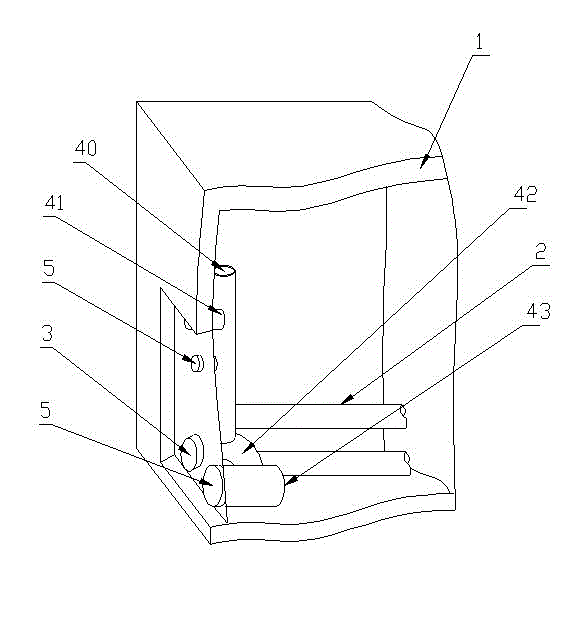

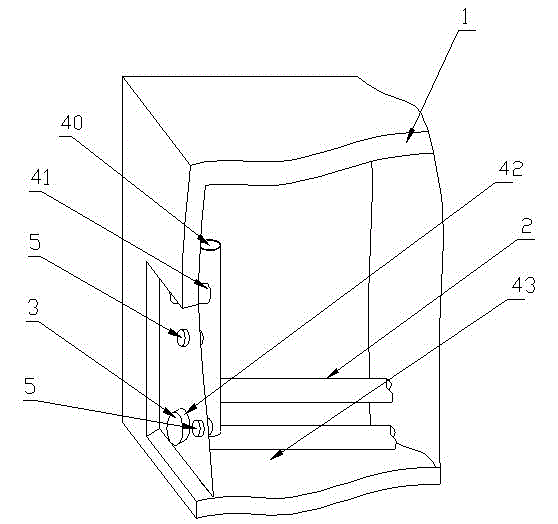

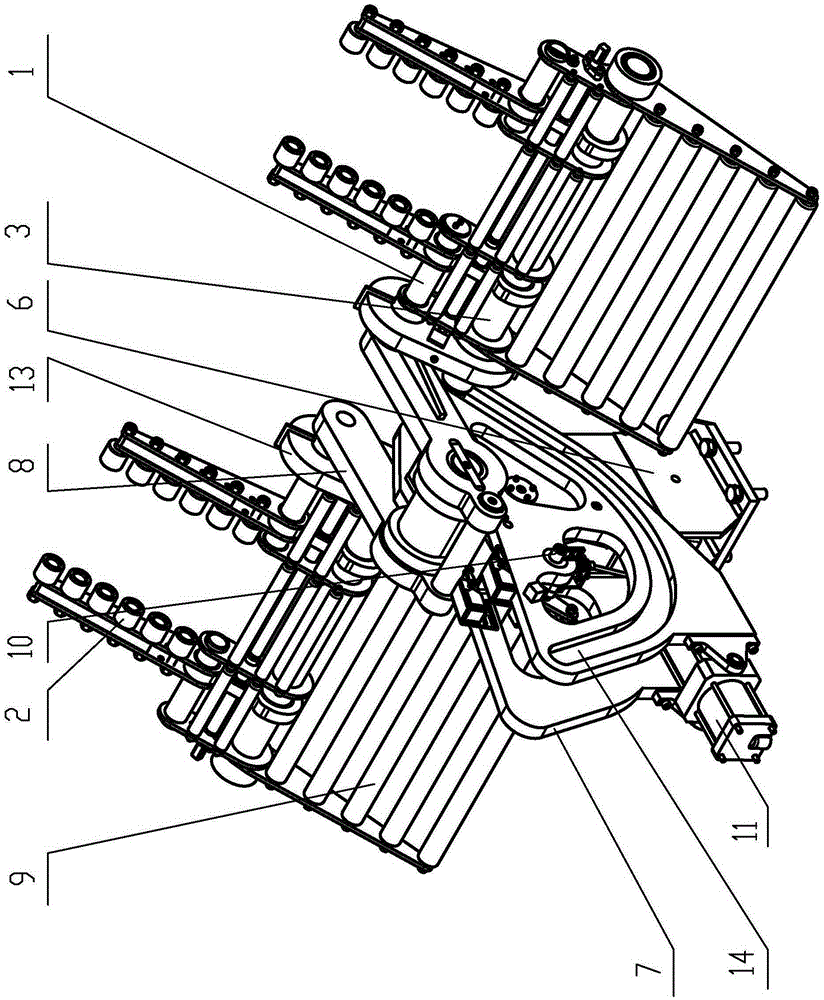

Rear tire unloading device of tire vulcanizer

PendingCN110370513AImprove efficiencySimple structureTyresPlastic recyclingHydraulic cylinderEngineering

The invention discloses a rear tire unloading device of a tire vulcanizer. The rear tire unloading device is characterized in that a left tire unloading arm and a right tire unloading arm are mountedon a lifting and turning mechanism through a left-right synchronous opening and closing mechanism; the lifting and turning mechanism comprises a lifting frame and a lifting hydraulic cylinder; front guiding shafts and rear guiding shafts are respectively mounted at the front and rear ends of the lifting frame, and arranged in front guiding shaft sliding grooves and rear guiding shaft sliding grooves; the front guiding shaft sliding grooves and the rear guiding shaft sliding grooves are vertically formed in the left and right sides of a tire unloading rack; the top of each front guiding shaft sliding groove is designed to be a circular-arc groove higher than the top of the corresponding rear guiding shaft sliding groove; the left tire unloading arm and the right tire unloading arm are slidably mounted at the left and right ends of the front guiding shafts and the rear guiding shafts; the cylinder body of the lifting hydraulic cylinder is mounted on the position, below the lifting frame,of the tire unloading rack in a hinging manner; a hydraulic rod of the lifting hydraulic cylinder is upwardly mounted at the bottom of the lifting frame in a hinging manner; and the lifting frame islifted by the hydraulic rod and backward turned with the tops of the rear guiding shaft sliding grooves as the circle center and with the circular-arc sections of the front guiding shaft sliding grooves as the radius. The rear tire unloading device disclosed by the invention has the beneficial effects that the tire unloading time is short; the efficiency of the tire vulcanizer is high; the structure is simple; the control is convenient; and the manufacturing cost and the use cost are low.

Owner:GUILIN RUBBER MACHINERY CO LTD

Novel efficient mixer with inclined fixed chassis

PendingCN112059108AImprove sand mixing efficiencyShort mixing cycleMould handling/dressing devicesThermodynamicsEngineering

The invention relates to the technical field of casting equipment, in particular to a novel efficient mixer with an inclined fixed chassis. The novel efficient mixer comprises a rack, the end face ofthe rack is connected to the bottom of an inclined sand mixing chamber, a sand mixing chamber upper cover is connected to a port of the inclined sand mixing chamber through bolts, and a used sand feeding hopper is arranged on the sand mixing chamber upper cover; and an accessory feeding port is formed in the position, on the end face of the sand mixing chamber upper cover, of the right side of theused sand feeding hopper. According to the novel efficient mixer, sand mixing and stirring are conducted through interaction of two sets of sand mixing rotor structures and a scraper blade structure,thus, the effects that the sand mixing efficiency is high and the sand mixing period is short are achieved, meanwhile, the sand mixing chamber is arranged to be inclined, and a molding sand discharging door is formed in the lowest position, so that rapid sand discharging is facilitated, the effects of the short sand discharging time, improvement of the production efficiency and reduction of the energy consumption are achieved, the problems of the low sand mixing efficiency, the long sand mixing period, the long sand discharging time and the high energy consumption of an existing sand mixer are solved, thus, the the applicability is higher, and the existing working requirements can be better met.

Owner:五洋百川(青岛)智能设备有限公司

Double-horizontal-shaft concrete stirrer with unloading door being opened towards two sides

PendingCN108858759AUnloading without residueShort unloading timeCement mixing apparatusEngineeringMechanical engineering

The invention provides a double-horizontal-shaft concrete stirrer with an unloading door being opened towards two sides. The double-horizontal-shaft concrete stirrer comprises an unloading apparatus and unloading hopper; the unloading apparatus comprises a driving apparatus and an unloading door; the unloading hopper comprises a left unloading hopper and a right unloading hopper; the driving apparatus controls the unloading door to be opened leftwards or rightwards, so that an unloading opening is aligned at the left unloading hopper or the right unloading hopper. According to the double-horizontal-shaft concrete stirrer with the unloading door being opened towards two sides, a stirring barrel is provided with the unloading apparatus, two unloading hoppers are arranged below the stirring barrel, the unloading apparatus controls the unloading door to enable the concrete to enter the two different unloading hoppers, so that the concrete stirrer can be suitable for the situation requiringtwo discharging trolleys or requiring one trolley or one tank car, can be suitable for the place requiring two discharging devices, has no residue when in unloading, is short in unloading time and saves the cost.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

Unloading device for tire shaping and vulcanizing machine

Owner:GUILIN RUBBER MACHINERY CO LTD

Quick blank pipe type layering discharge device and quickly discharging method thereof

ActiveCN102745436BShorten unloading timeShort unloading timeLarge containersTank wagonsEngineeringControl valves

The invention relates to a quick blank pipe type layering discharge device. The blank quick pipe type layering discharge device comprises a container and a heater, and further comprises a feeding pipe, wherein the container is provided with a discharge opening; the heater is arranged in the container and is arranged at the bottom of the container; the feeding pipe is communicated with the discharge opening and is sequentially provided with a plurality of discharge holes from top to bottom, and at least one discharge hole is arranged at the bottom of the container; and each discharge hole is provided with a switch control valve. The invention further discloses a quick discharging method for discharging by utilizing the quick blank pipe type layering discharge device. According to the invention, the technical problem that the discharge device in the prior art is too long in discharge time is solved, and the invention further provides the quick blank pipe type layering discharge device with short discharge time and a smooth discharge operation and the quick discharging method thereof.

Owner:TIANJIN ZHAOHUA LOGISTICS CO LTD

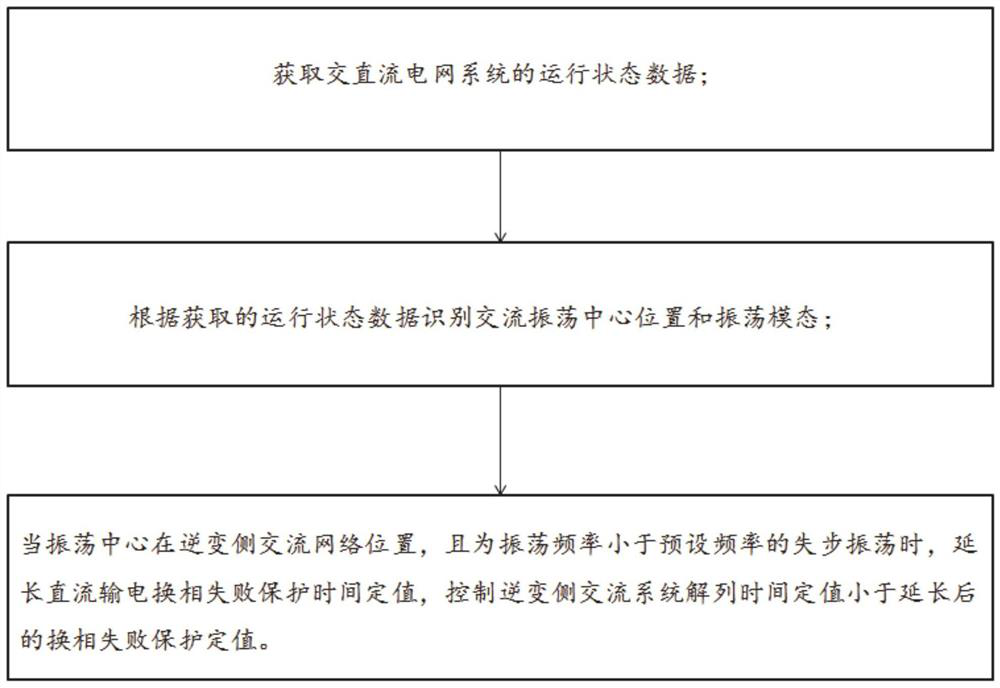

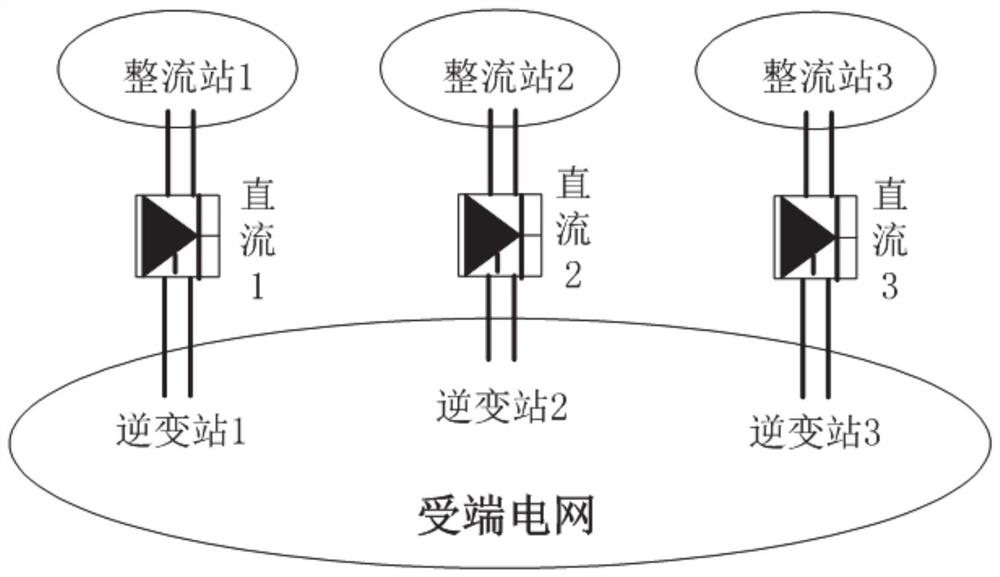

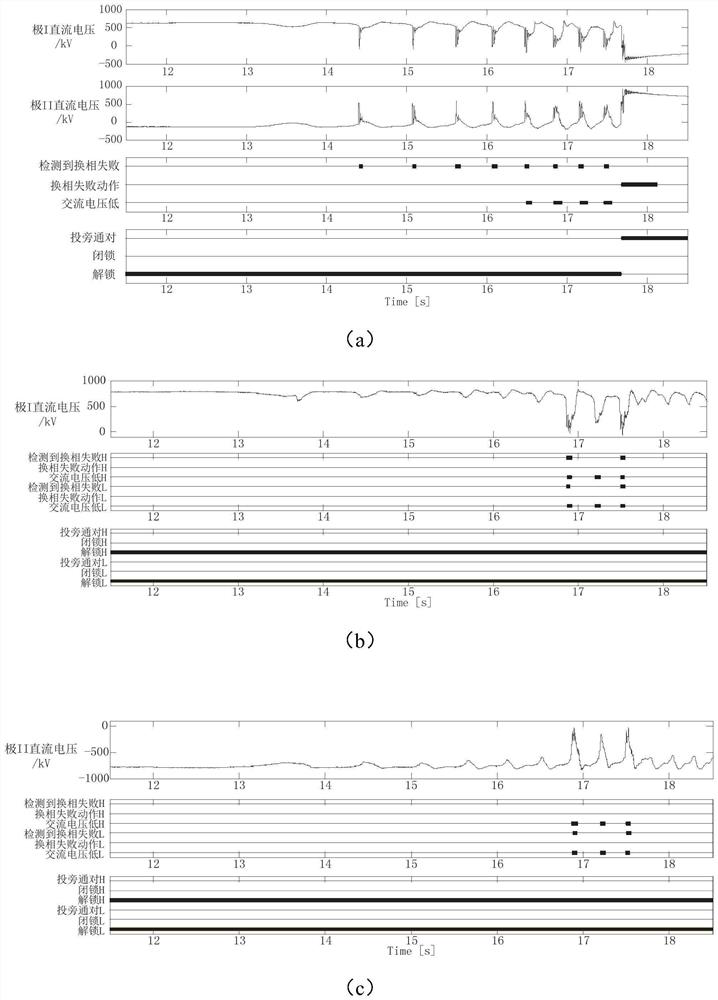

Optimization method of direct-current transmission control protection system during strong oscillation of alternating-current system

InactiveCN112165105AShort unloading timeImprove stabilityElectric power transfer ac networkPower oscillations reduction/preventionAC - Alternating currentPower grid

The invention discloses an optimization method of a direct-current transmission control protection system in a strong oscillation period of an alternating-current system. The method comprises the following steps: acquiring running state data of an alternating-current and direct-current power grid system; identifying an alternating current oscillation center position and an oscillation mode according to the obtained operation state data; when the oscillation center is located at the inversion side alternating current network position and is out-of-step oscillation with the oscillation frequencysmaller than the preset frequency, prolonging the direct current power transmission commutation failure protection time constant value, and controlling the inversion side alternating current system splitting time constant value to be smaller than the prolonged commutation failure protection time constant value. By identifying out-of-step oscillation of the direct-current power transmission receiving-end alternating-current network and automatically switching direct-current control protection logic, commutation failure protection is switched to a long-delay constant value, it is guaranteed that the commutation failure protection long-delay constant value is greater than a receiving-end alternating-current system splitting constant value, and it is guaranteed that before a receiving end alternating current network disconnects an isolation oscillation source, direct current locking is avoided, the secondary impact on a receiving-end power grid due to DC locking is avoided, and system stability is guaranteed.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

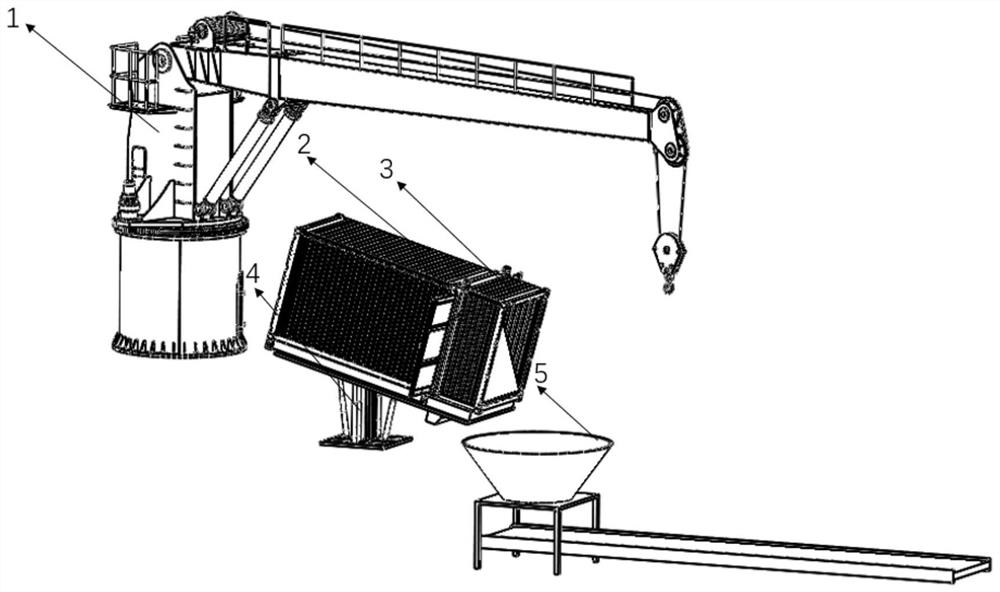

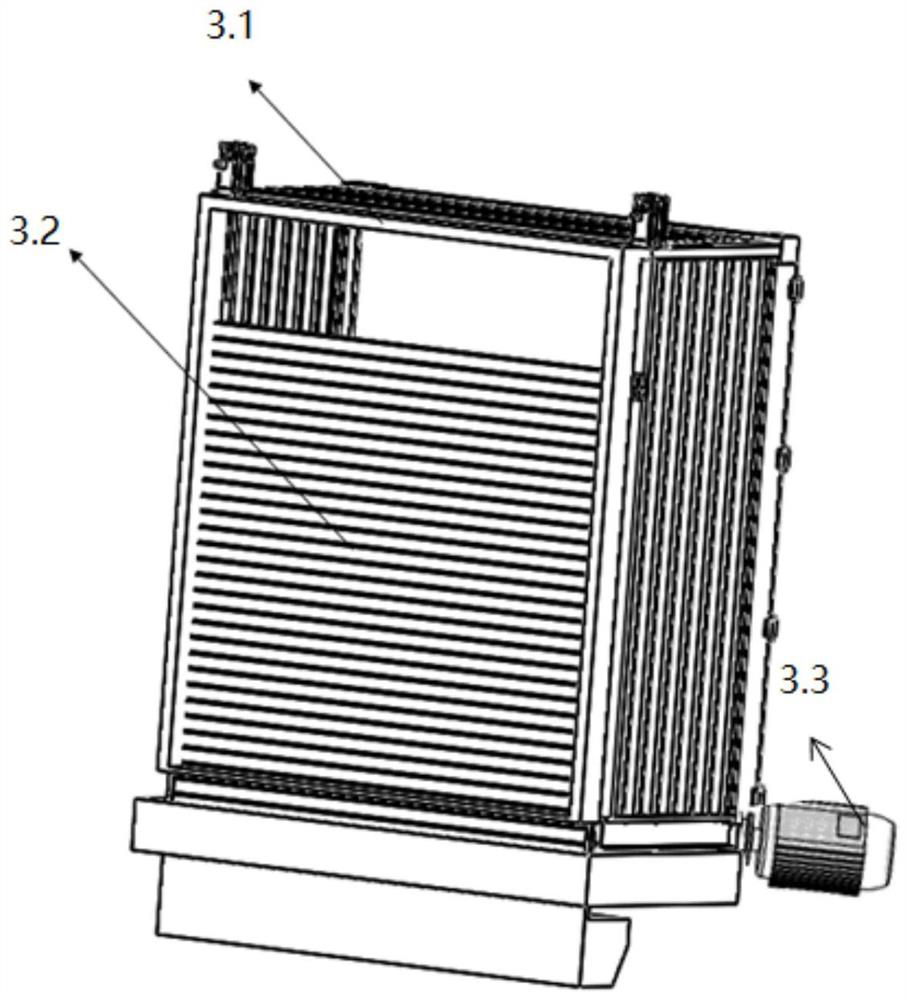

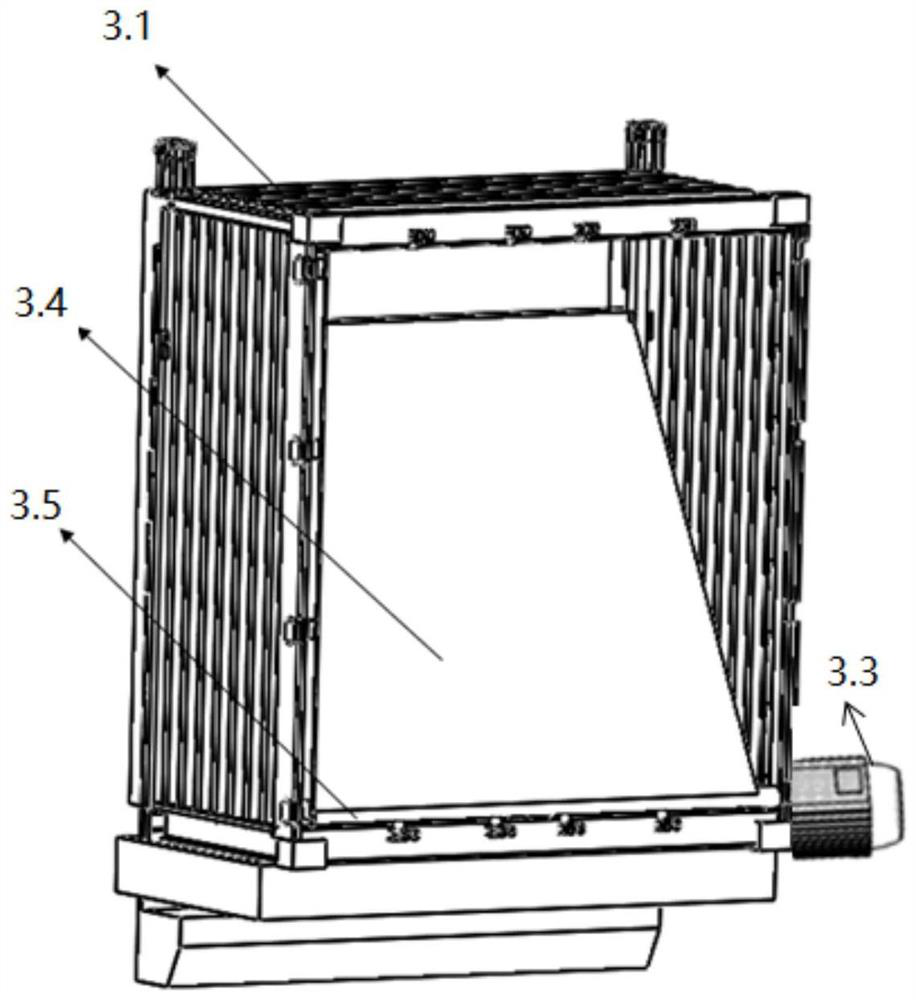

Rapid unloading platform for inclined container

ActiveCN114044271AOperational securityReduce harmLarge containersLoading/unloadingLogistics managementStructural engineering

The invention discloses a rapid unloading platform for an inclined container, and relates to the technical field of logistics transportation, in particular to an inclinable unloading platform for rapid container unloading. The invention comprises a crane, a container, a batch unloading device, a container swinging platform and a funnel type transportation platform, the crane, the container swinging platform and the batch unloading device are arranged on the foundation; the container is hoisted on the container swinging platform through a crane and is fixed; the batch unloading device is detachably arranged on the container swinging platform and is connected with the door end of the container; the funnel type transportation platform is located on the lower portion in front of the outlet end of the batch unloading device. According to the technical scheme, the problems that in the prior art, manual unloading is long in time consumption and low in work efficiency; and although the efficiency of machine unloading is higher than that of manual unloading, the automation degree is not high.

Owner:DALIAN MARITIME UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com