Powder material tank with automatic discharging

An automatic unloading and material tank technology, which is applied in the direction of conveying bulk materials, conveyors, containers, etc., can solve the problems of poor manual operation safety, long unloading time of semi-trailer tanks, and large surplus materials, so as to save manpower, Energy saving, environmental protection, unloading time and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

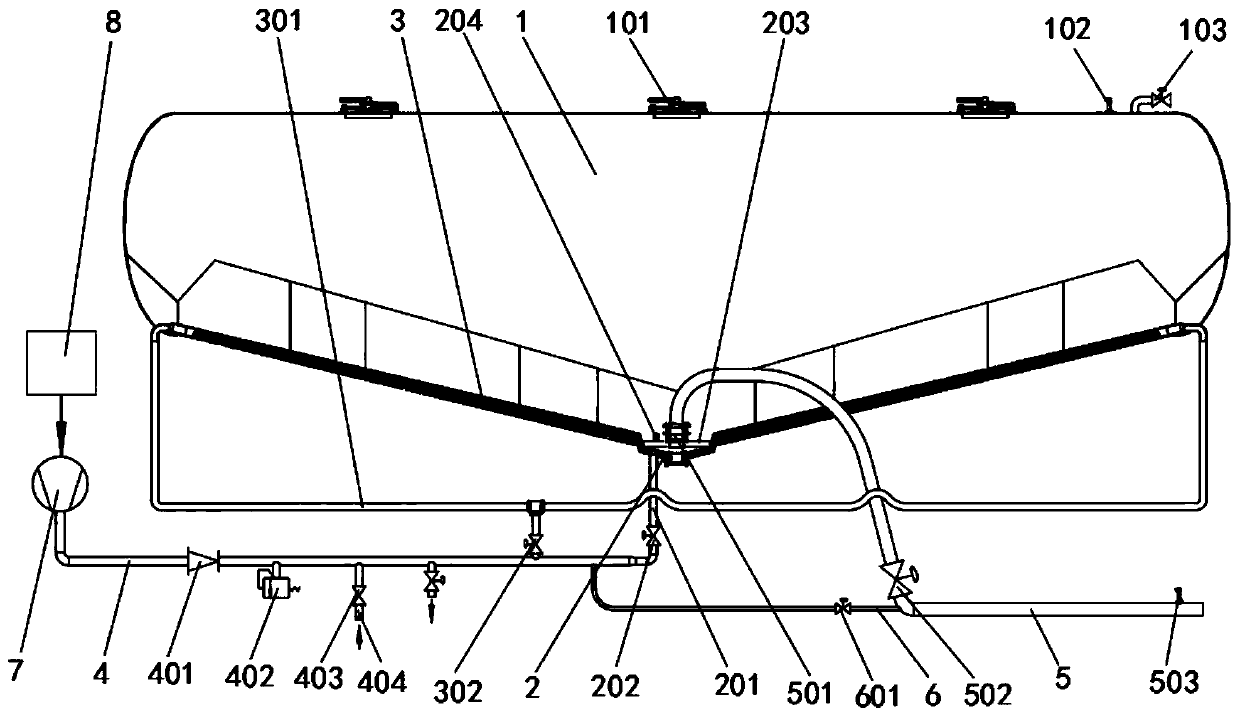

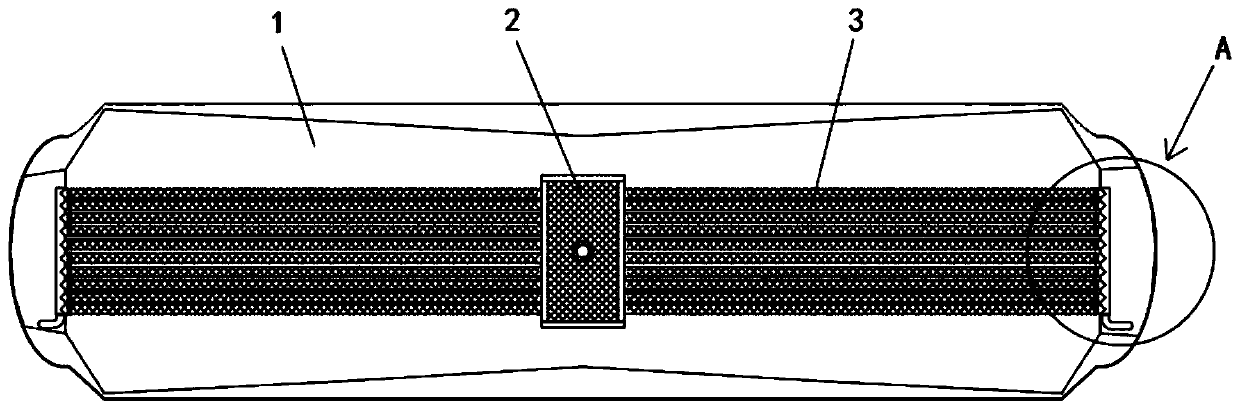

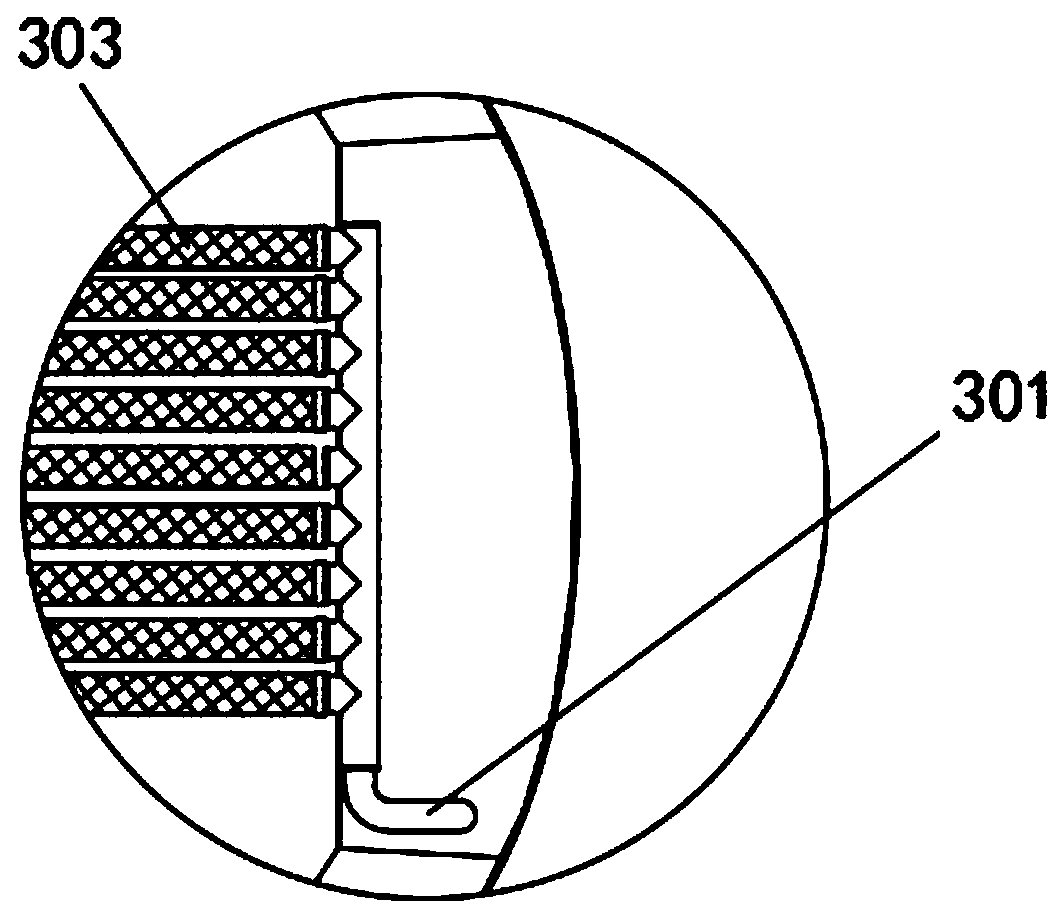

[0029] Such as Figure 1-3 Shown: an automatic unloading powder material tank, including a tank body 1 and a controller 8, a number of feeding holes 101 and pressure sensors 102 are arranged on the top of the tank body 1, and a main flow is arranged in the center of the bottom of the tank body 1 Bed 2, auxiliary fluidized bed 3 is arranged on both sides of main fluidized bed 2, auxiliary fluidized bed 3 extends from both ends of tank 1 to main fluidized bed 2 and slopes downward, main fluidized bed 2 passes through main fluidized bed Trachea 201 is connected with total intake pipe 4, main intake pipe 201 is provided with main intake valve 202, auxiliary fluidized bed 3 is connected with total intake pipe 4 through auxiliary intake pipe 301, auxiliary intake pipe 301 is provided with auxiliary intake valve 302, The main air intake pipe 4 is connected to the air compressor 7, and the air compressor 7 is connected to the controller 8. The top of the mainstream fluidized bed 2 is ...

Embodiment 2

[0032] Such as Figure 4 As shown, in the same tank 1, two sets of settings such as the main fluidized bed 2 and the auxiliary fluidized bed 3 in Embodiment 1 are adopted, and corresponding pipelines, valves and material sensors are set, which can further shorten the unloading time and improve unloading efficiency.

Embodiment 3

[0034] Such as Figure 5 As shown, in the same tank 1, three groups are adopted such as the setting of the main fluidized bed 2 and the auxiliary fluidized bed 3 in embodiment 1, and corresponding pipelines, valves and material sensors are set, which can further shorten the unloading time and improve unloading efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com