Patents

Literature

71results about How to "Complete unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sand beach cleaning vehicle and cleaning operation method thereof

InactiveCN102747704AReduce weightNot easy to sinkConstructionsCleaning bleachesOperation modeEngineering

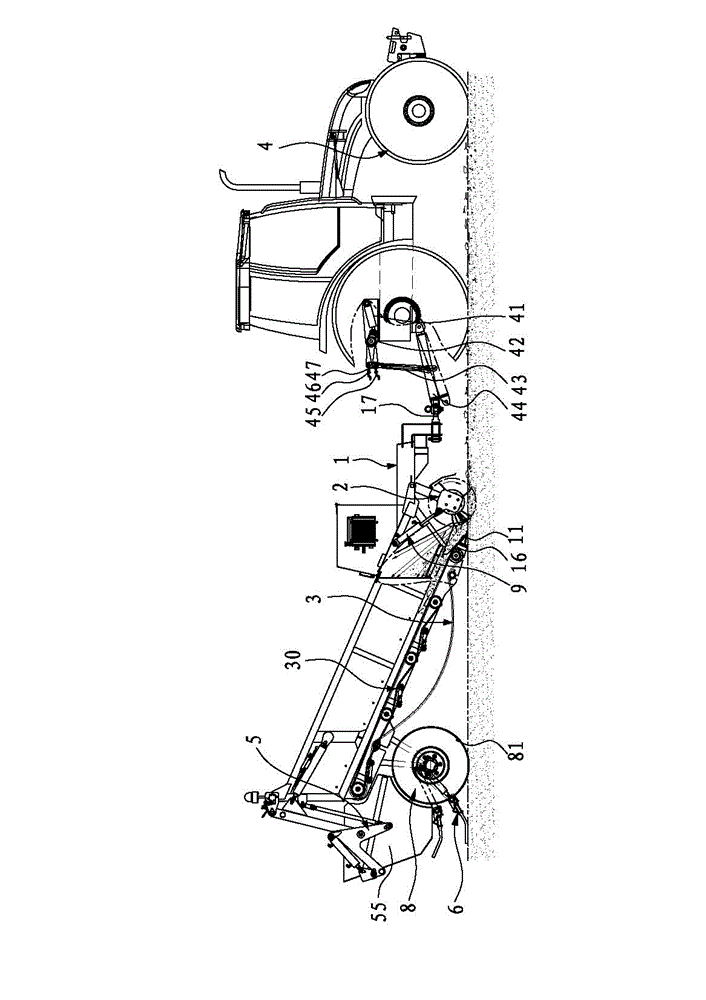

The invention relates to a sand beach cleaning vehicle and a cleaning operation method thereof. The sand beach cleaning vehicle comprises a frame, wherein a sand-stirring idler wheel device is mounted on the front part of the frame; a screening conveying device is mounted on the middle part of the frame; a garbage can and a garbage can lifting turning mechanism are mounted on the rear part of the frame; a push shovel is fixed behind the sand-stirring idler wheel device and on the front lower part of the frame; a sand-guiding plate is fixed on the push shovel; the sand-guiding plate is connected with the screening conveying device; a loading bridge with a wheel is mounted on the rear lower part of the frame; a flattening mechanism which is used for flattening a sand beach is mounted on the loading bridge; a dragging device at the front end of the frame is dragged by a hanging mechanism of a tractor; and the hanging mechanism can control the sand-shoveling depth of the push shovel. When the sand beach cleaning vehicle operates on the dry sand beach, an operation mode of deeply cleaning garbage is adopted; when the sand beach cleaning vehicle operates on the wet sand beach, the operation mode of only cleaning surface garbage is adopted; and during the operation process on the dry and wet sand beaches, the sand beach cleaning vehicle is difficult to sink, has a small running resistance, is high in operation efficiency and can flatten the sand beaches.

Owner:厦门威迪思汽车设计服务有限公司

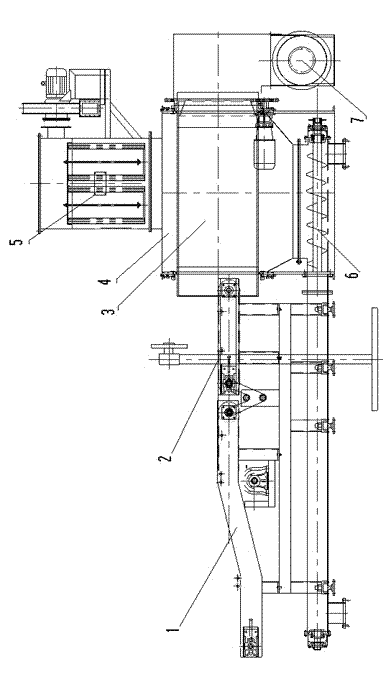

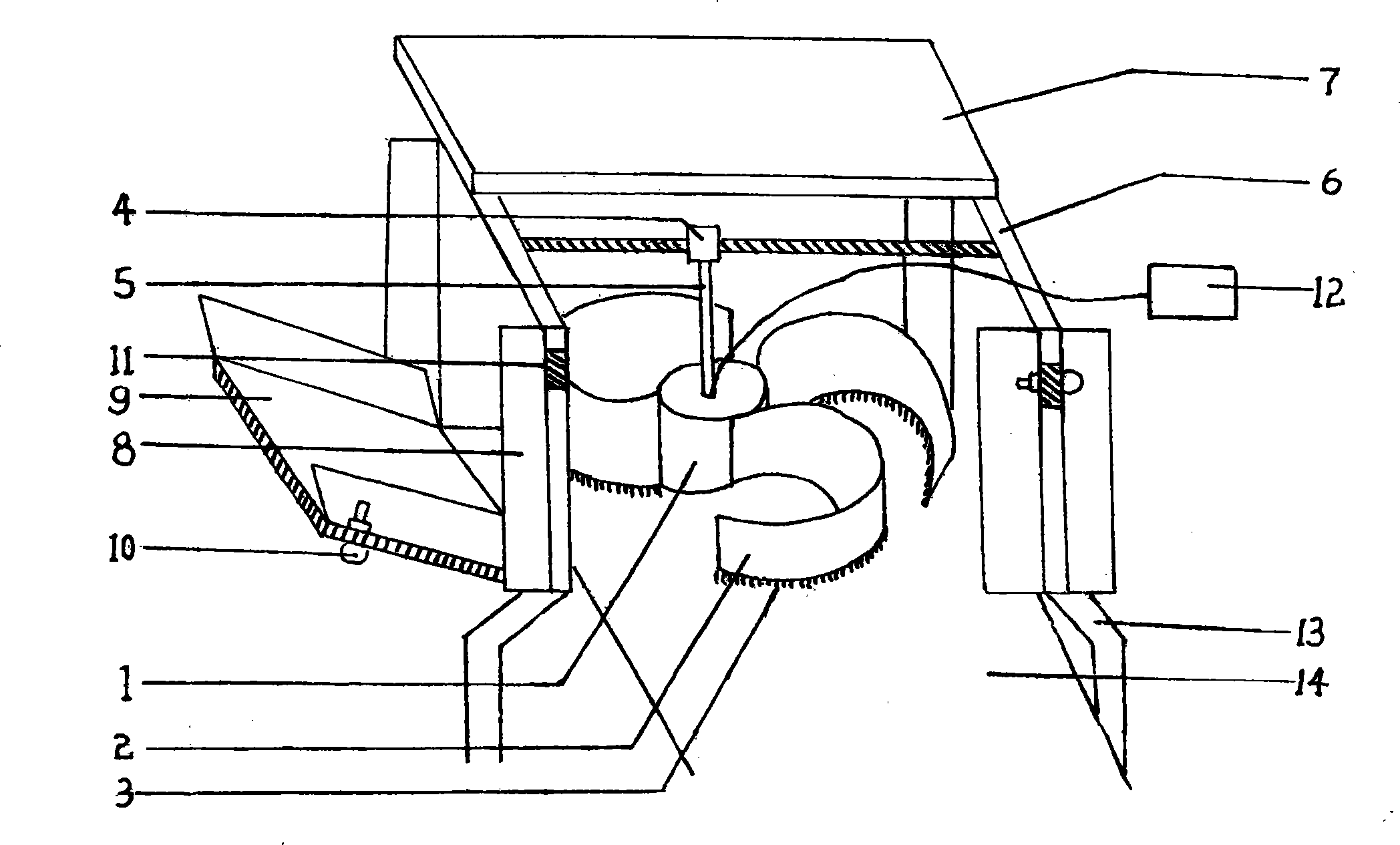

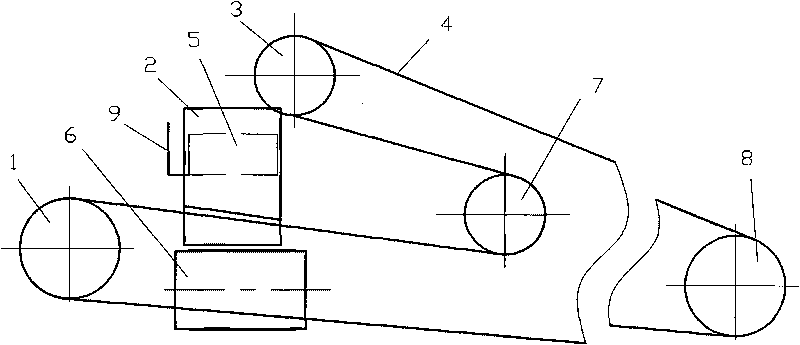

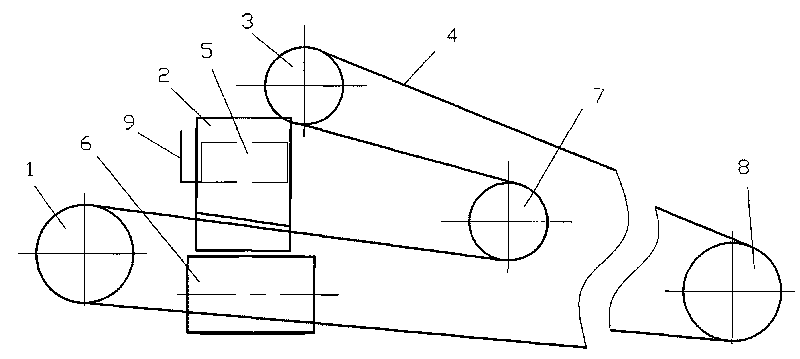

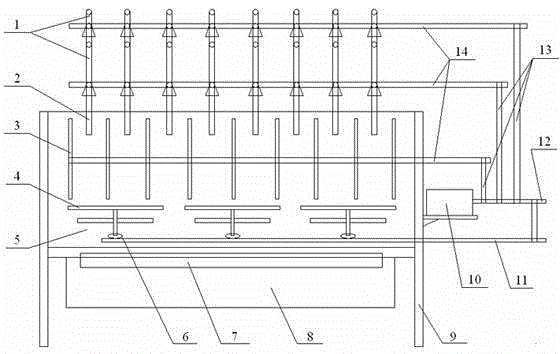

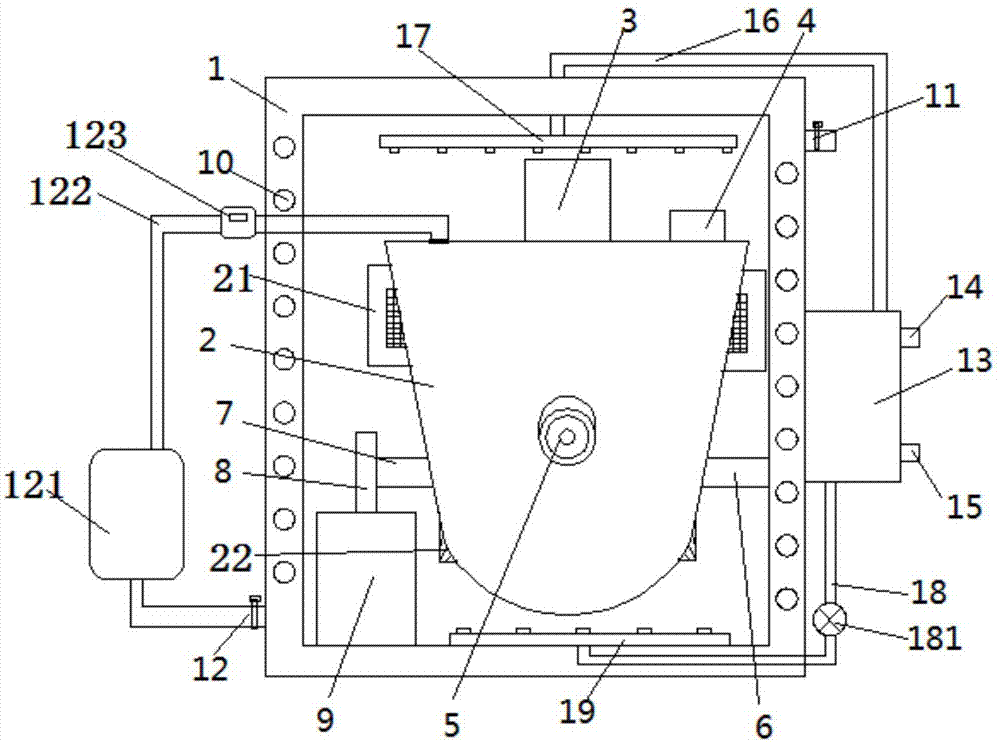

Bag tearing ventilation and dust removing equipment and method

InactiveCN103112630AProtect the environment and workspaceAvoid material wasteDispersed particle filtrationArticle unpackingHazardous substanceUltimate tensile strength

The invention relates to bag tearing ventilation and dust removing equipment and a method. A belt conveyor is arranged on one side of the equipment, a dust remover is arranged at the upper end of a middle support, a rotary screen is arranged at the lower end of the middle support, a spiral conveying device is arranged at the lower end of the rotary screen, a cutting device is arranged on one side of a feed inlet and at the front end of the rotary screen, and a waste bag automatic recycling device is arranged on the rear side of the rotary screen. When material bags are conveyed by the belt conveyor and pass through the cutting device, the material bag are cut, the cut material bags are conveyed to the rotary screen through the belt conveyor after cutting so as to conduct separation of materials and the bags; separated waste bags enter into the waste bag automatic recycling device, the separated materials enter into the spiral conveying device, and generated dust is removed through a ventilation dust remover. No dust is leaked in the process of bag tearing, the waste bags are packaged and recycled automatically, and thus labor intensity of working staff is reduced, dust is removed, waste bags are recycled, environment and working space are effectively protected, and meanwhile damage to the working staff by toxic and harmful substance is avoided.

Owner:山东胜安石油科技有限责任公司

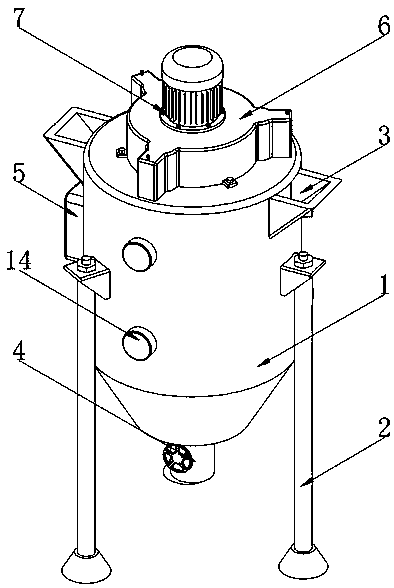

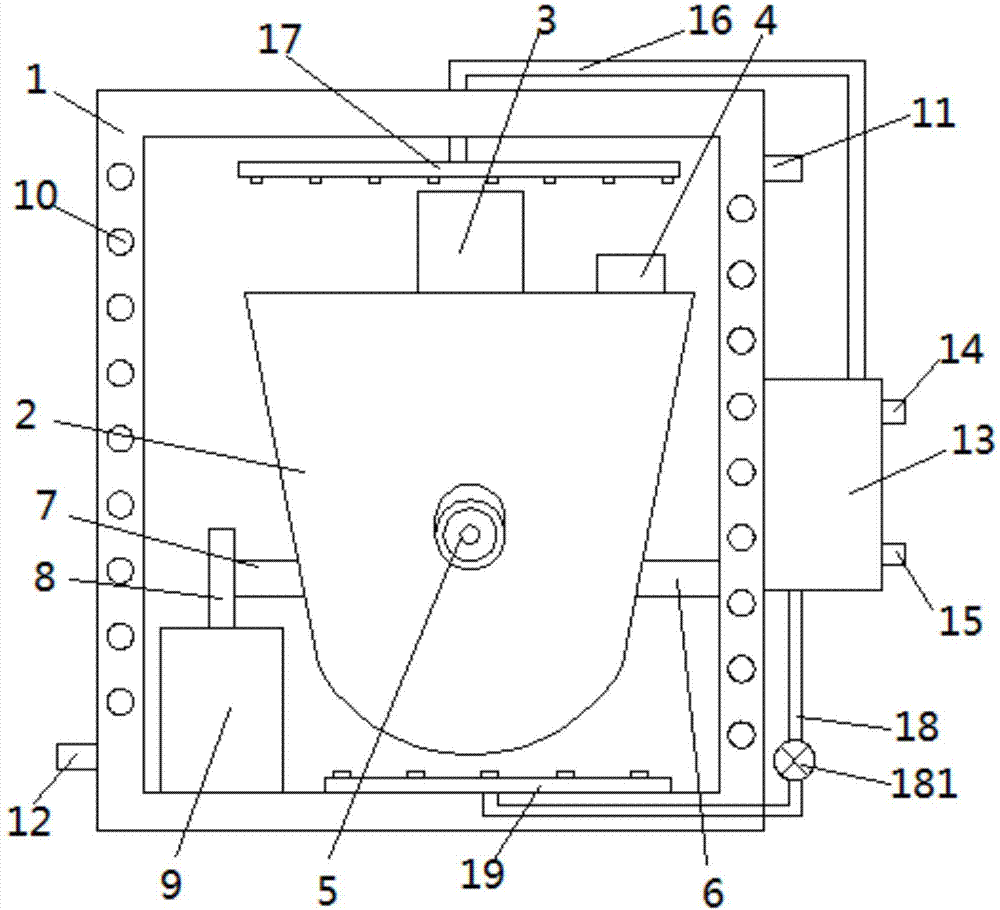

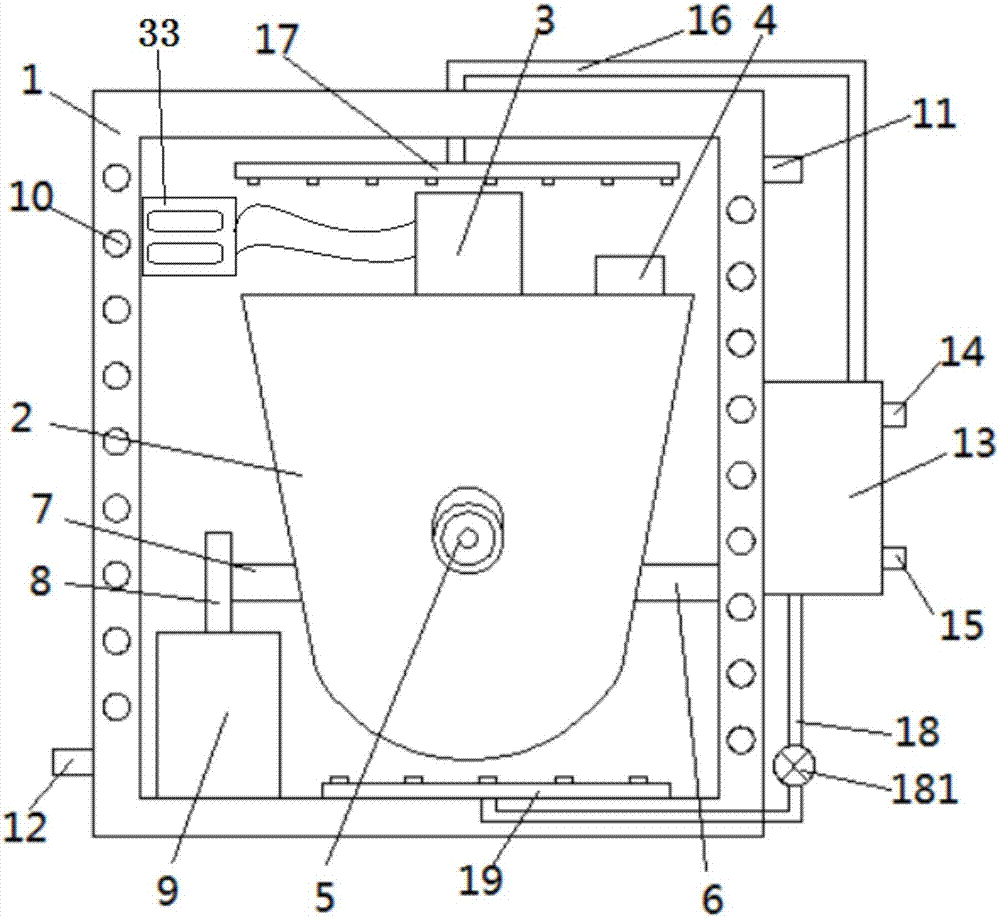

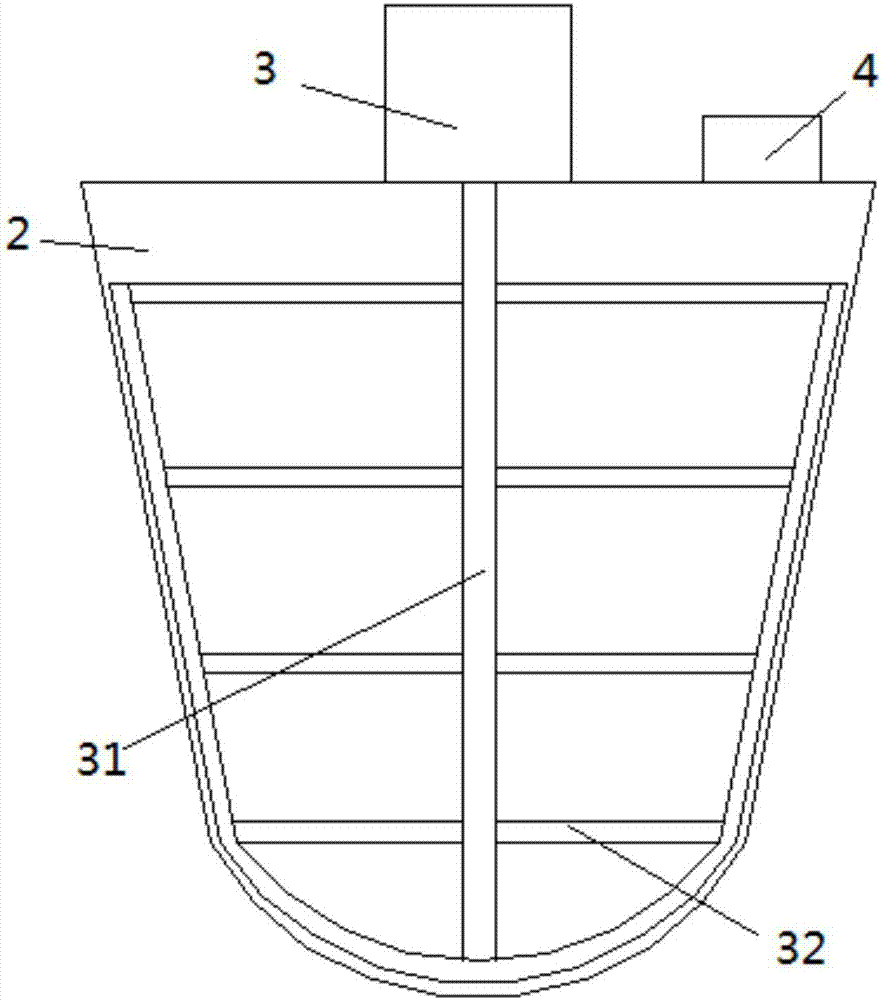

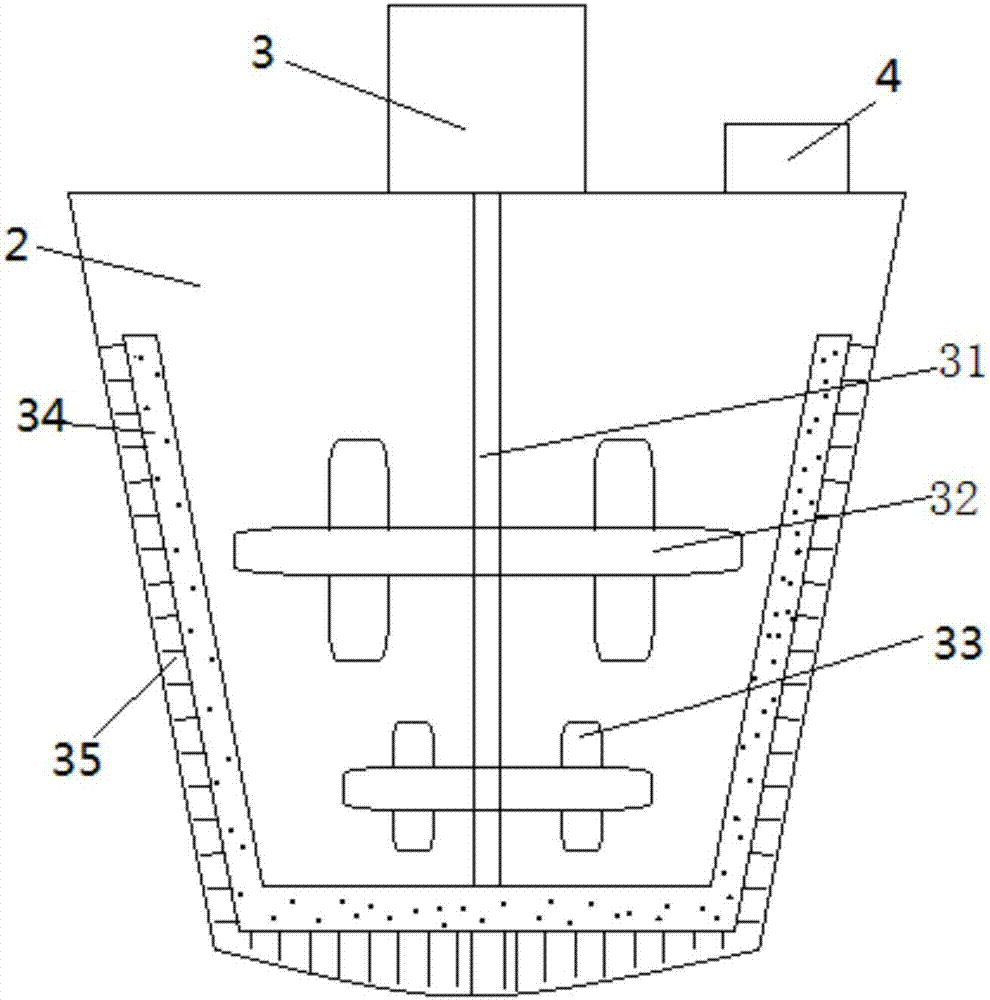

Mixing equipment for processing and producing health-care food

ActiveCN111001340AWell mixedReduce energy consumptionTransportation and packagingMixer accessoriesRotational axisElectric machinery

The invention discloses mixing equipment for health food processing and production, and belongs to the technical field of mixing equipment. The mixing equipment comprises a mixing tank; a protective cover is arranged at the top end of the mixing tank. A pneumatic stirring assembly for realizing gas stirring of raw materials and a pneumatic vibration assembly for realizing vibration of a gas-drivenmixing tank are mounted in the protective cover. The mixing equipment is scientific and reasonable, is safe and convenient to use, and is provided with pneumatic stirring assemblies. A driving motoris used to drive a rotating shaft to rotate. A stirring and extruding airbag is extruded by utilizing a rotary extruding convex block. Gas extruded by the stirring and extruding airbag is sprayed intoraw materials in the mixing tank by utilizing the pneumatic nozzle; the raw materials are stirred, mechanical stirring and pneumatic stirring are conducted on the raw materials at the same time through one driving motor, the health food raw materials are mixed more evenly, meanwhile, energy consumption is reduced, and the production cost is reduced.

Owner:广州赛太特生物医学科技有限公司

Self-cleaning stirring device

ActiveCN110860233APlay a guiding roleAvoid accumulationRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

Relating to the technical field of film production equipment, the invention discloses a self-cleaning stirring device. The device comprises a material holding barrel, a stirring shaft is rotatably connected in the material holding barrel, stirring rods are fixedly arranged on the stirring shaft, telescopic mechanisms are fixedly arranged on the periphery of the stirring shaft, and scraping platesare fixedly arranged at free ends of the telescopic mechanisms. By adopting the scheme, the technical problem that the material holding barrel cannot be automatically cleaned in the prior art can be solved.

Owner:CHONGQING RUITING PLASTIC

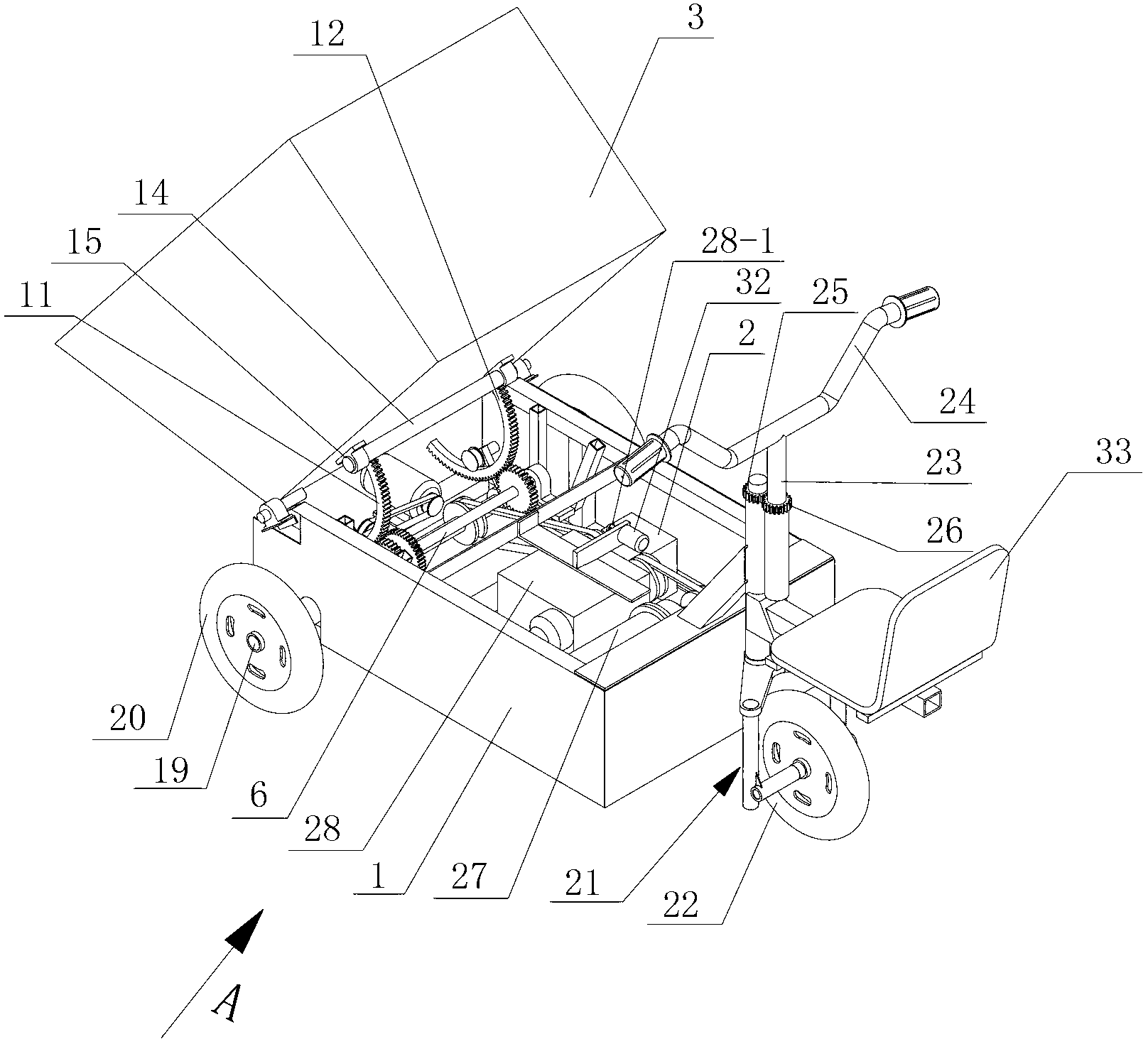

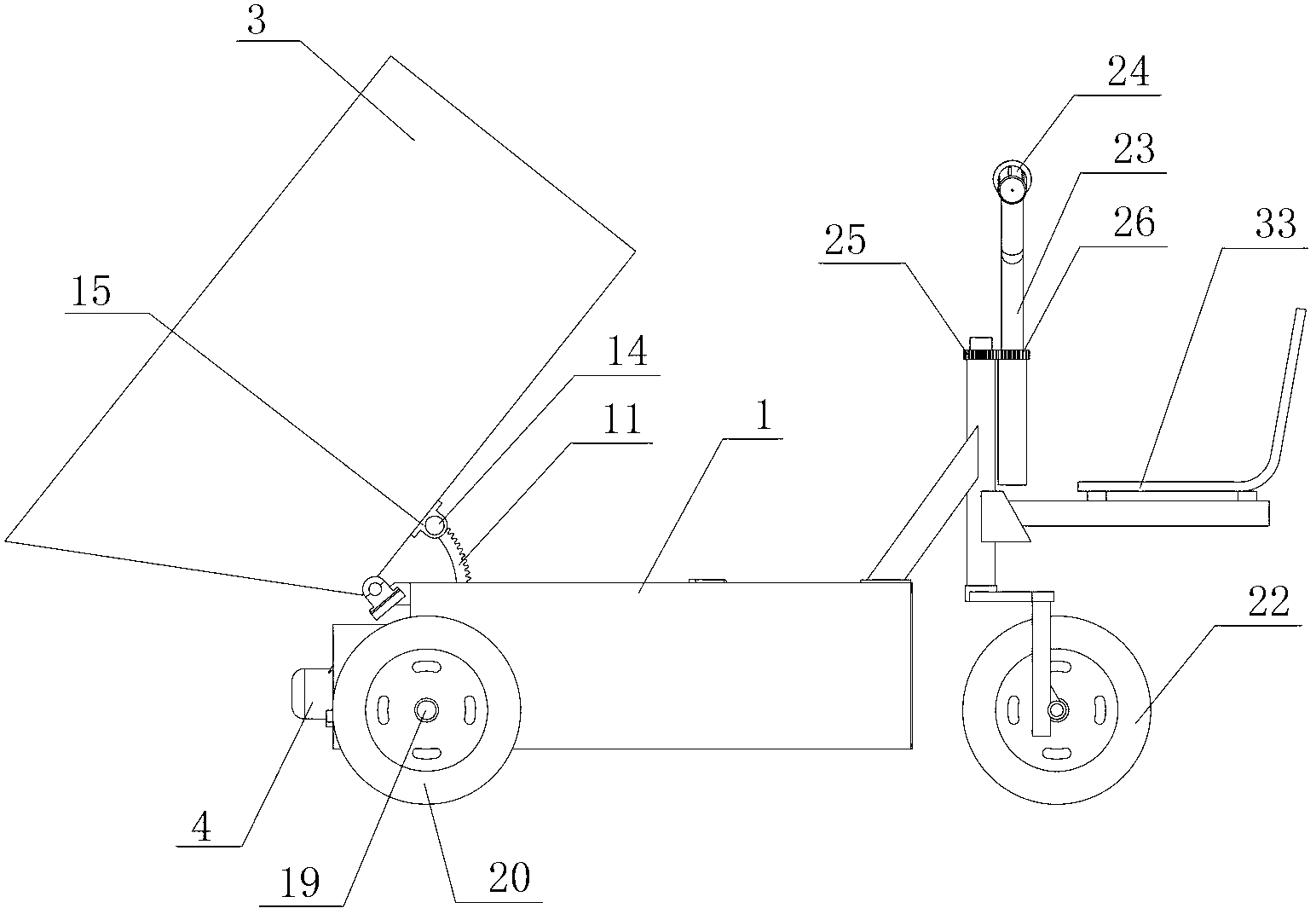

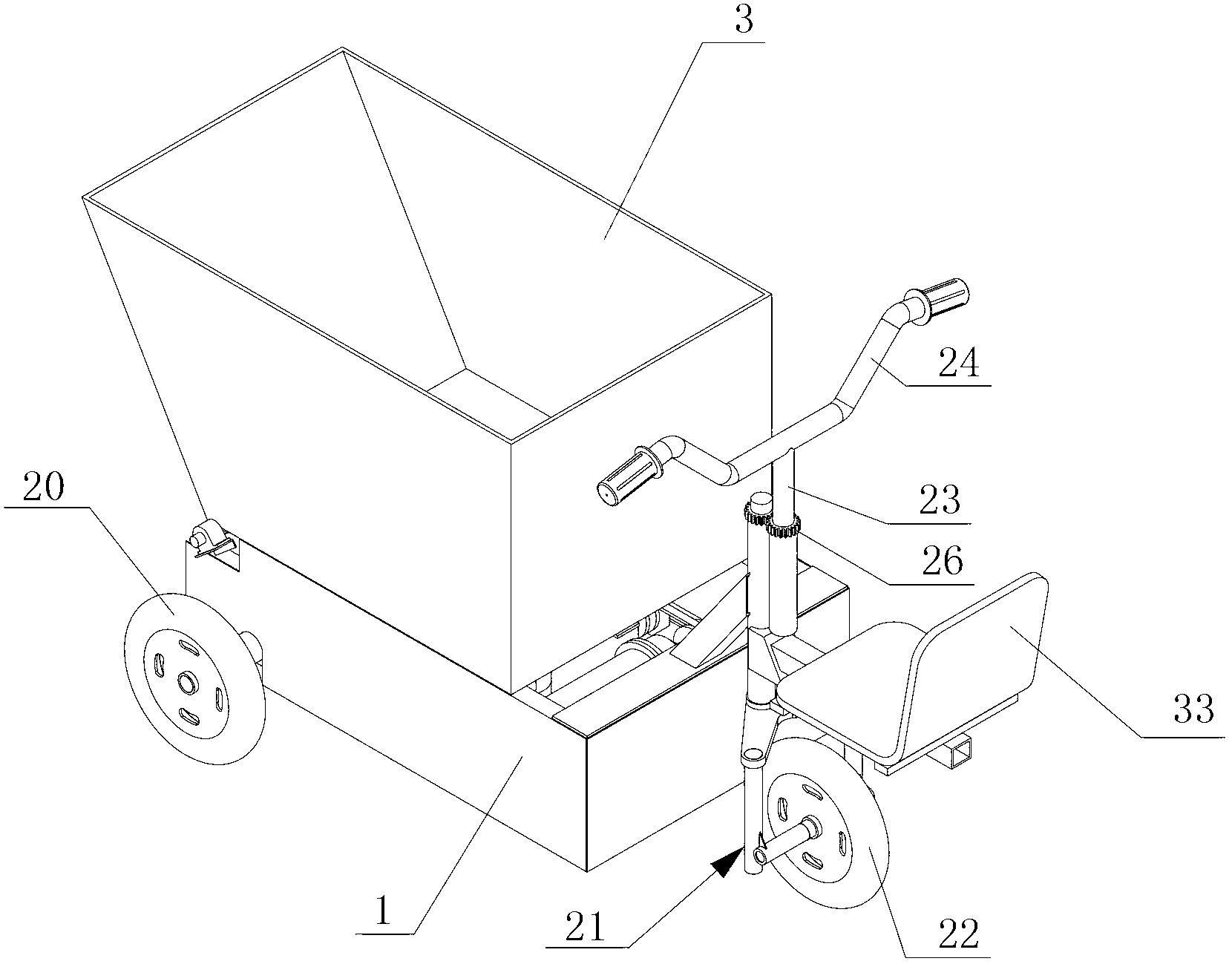

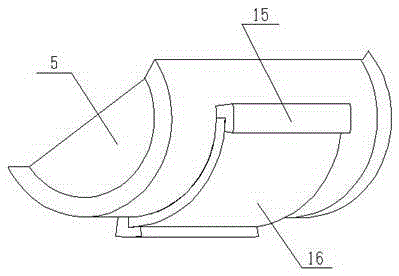

Small tip lorry

InactiveCN102700449AImprove work efficiencyFlexible adjustment of tipping angleVehicle with tipping movementVehicle frameGear wheel

The invention relates to a small tip lorry which comprises a frame, a storage battery, a traveling steering mechanism, a hopper, a tipping driving mechanism and a seat, wherein one end, far away from the seat, of the hopper is rotatably connected with the frame. The tip lorry is characterized in that the tipping driving mechanism is composed of a first motor, a speed reducer and a gear transmission structure; the gear transmission structure is composed of a support shaft, a first gear, a second gear, a third gear, a fourth gear, a first arc-shaped rack and a second arc-shaped rack, the first gear and the second gear are meshed, the first gear and the fourth gear are fixedly arranged on the support shaft, and the first arc-shaped rack and the second arc-shaped rack are respectively meshed with the third gear and the fourth gear; the bottom surface of the hopper is provided with a connecting shaft; the upper ends of the first arc-shaped rack and the second arc-shaped rack are fixedly arranged on the connecting shaft; and the tip lorry further comprises compacting structures arranged inside the two arc-shaped racks. According to the small tip lorry, the gear transmission structure is driven to move by virtue of the positive rotation and the reverse rotation of the first motor, so that the tipping and resetting of the hopper can be realized conveniently. Compared with the existing tip lorry, the small tip lorry has the advantages that the tipping angle during unloading can be flexibly adjusted according to the material properties, so that thorough unloading is ensured, and the working efficiency of the tip lorry is improved.

Owner:天津市帅运科技有限公司

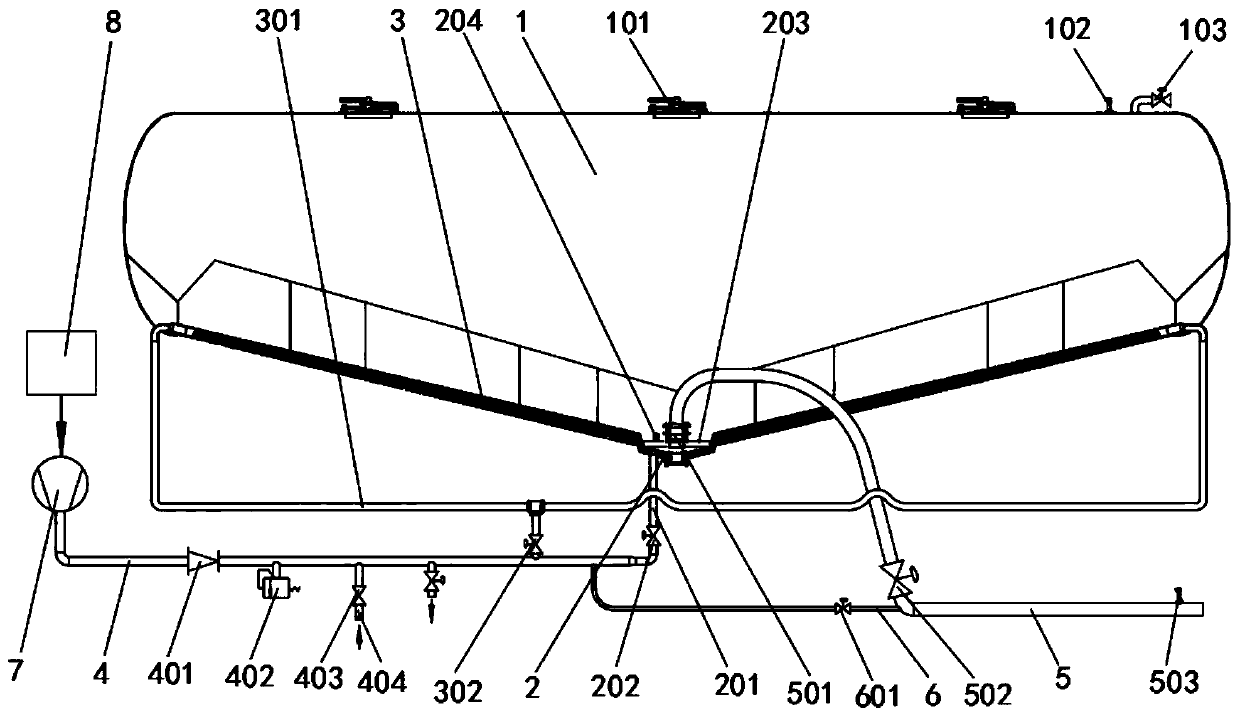

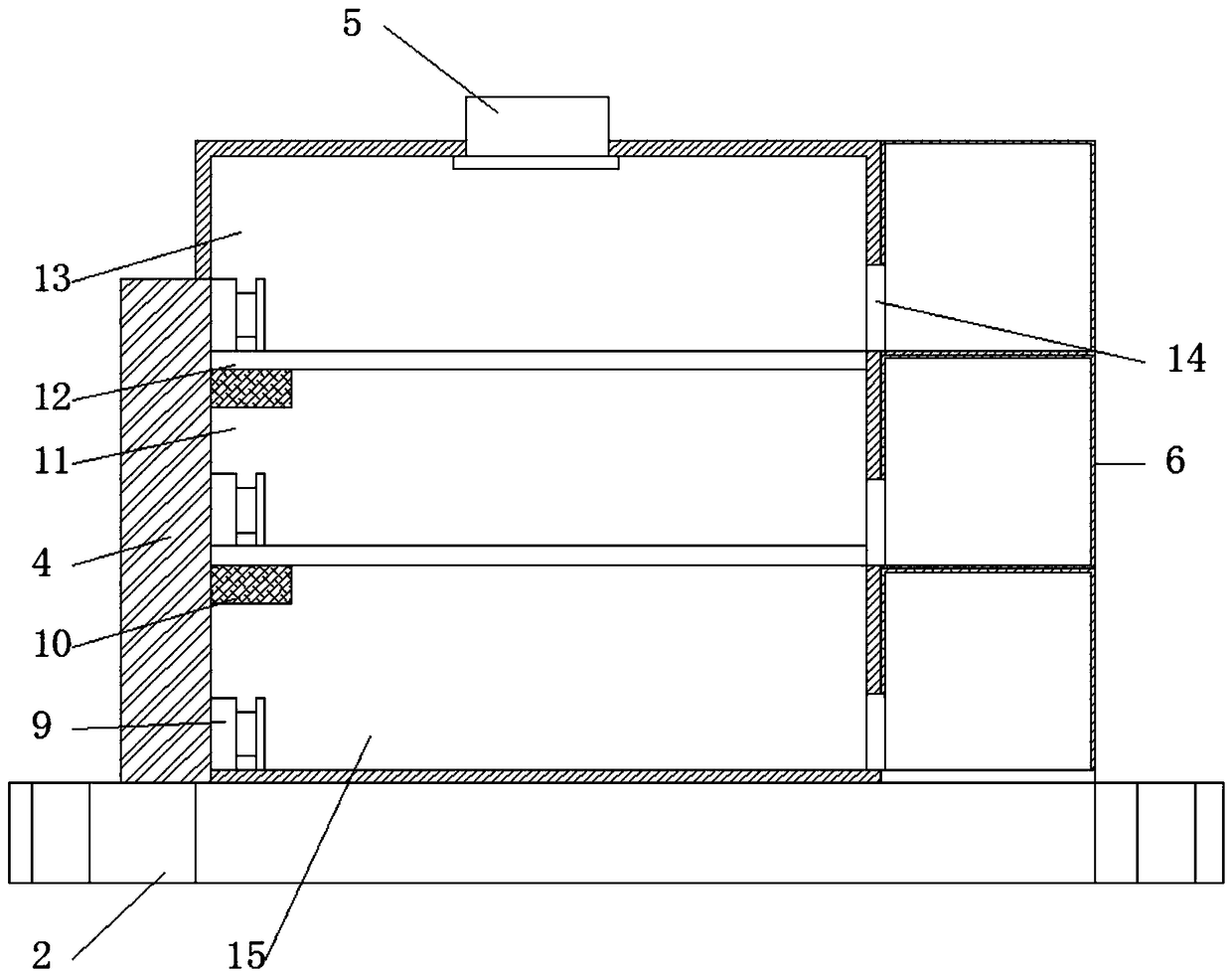

Powder material tank with automatic discharging

PendingCN110482038AShort unloading timeComplete unloadingLarge containersBulk conveyorsDischarge efficiencyFluidized bed

The invention discloses a powder material tank with automatic discharging, and belongs to the technical field of a semi-trailer material tank. The powder material tank with the automatic discharging comprises a tank body and a controller. A plurality of feeding holes and a pressure sensor are arranged at the top of the tank body. The powder material tank with the automatic discharging is characterized in that a main fluidized bed is arranged in the center of the bottom of the tank body, and auxiliary fluidized beds are arranged on both sides of the main fluidized bed. The auxiliary fluidized beds extend from both ends of the tank body to the main fluidized bed and incline downward, the main fluidized bed is connected with a total air inlet pipe through a main air inlet pipe, the main air inlet pipe is provided with a main air inlet valve, the auxiliary fluidized beds are connected to the total air inlet pipe through auxiliary air inlet pipes, the auxiliary air inlet pipes are providedauxiliary air inlet valves, the total air pipe is connected to an air compressor, the air compressor is connected with the controller, a perforated plate is arranged on the upper part of the main fluidized bed, the perforated plate is provided with a level sensor and a discharging tube, and the discharge tube is provided with a discharging valve and a flow sensor. The discharging efficiency is greatly improved, labor is reduced, energy is saved, and the environment is protected.

Owner:浙江超宇汽车科技有限公司

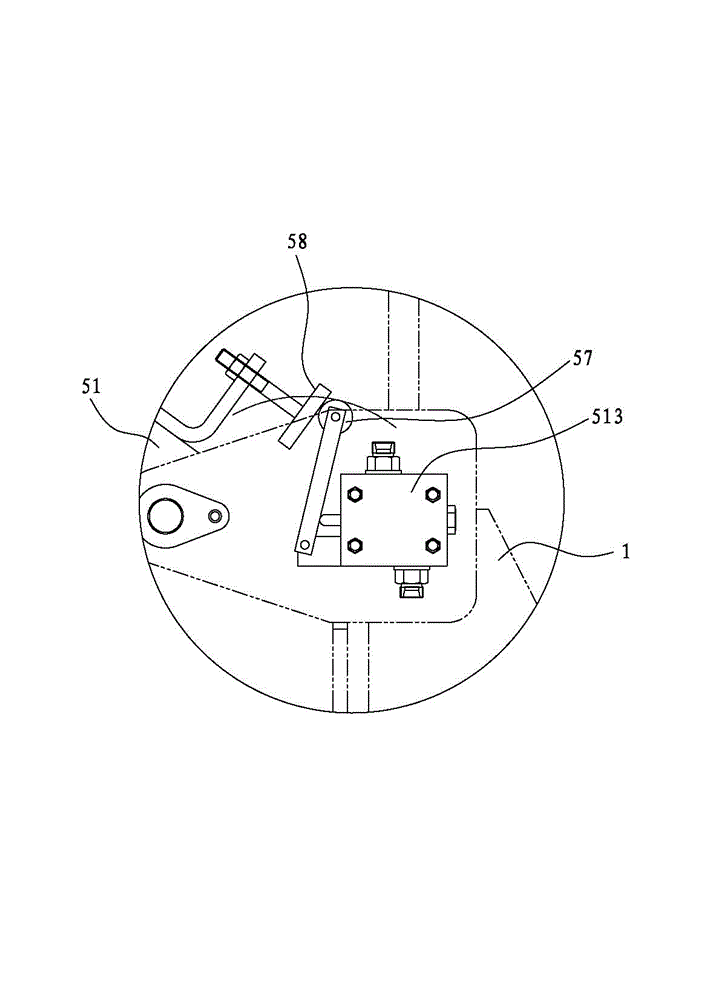

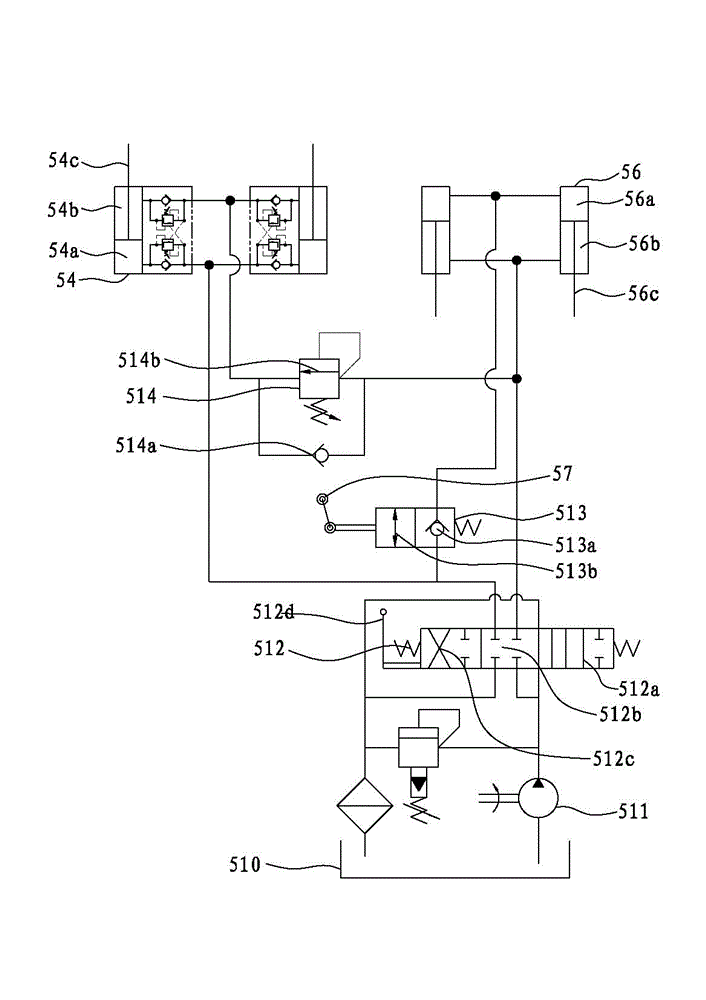

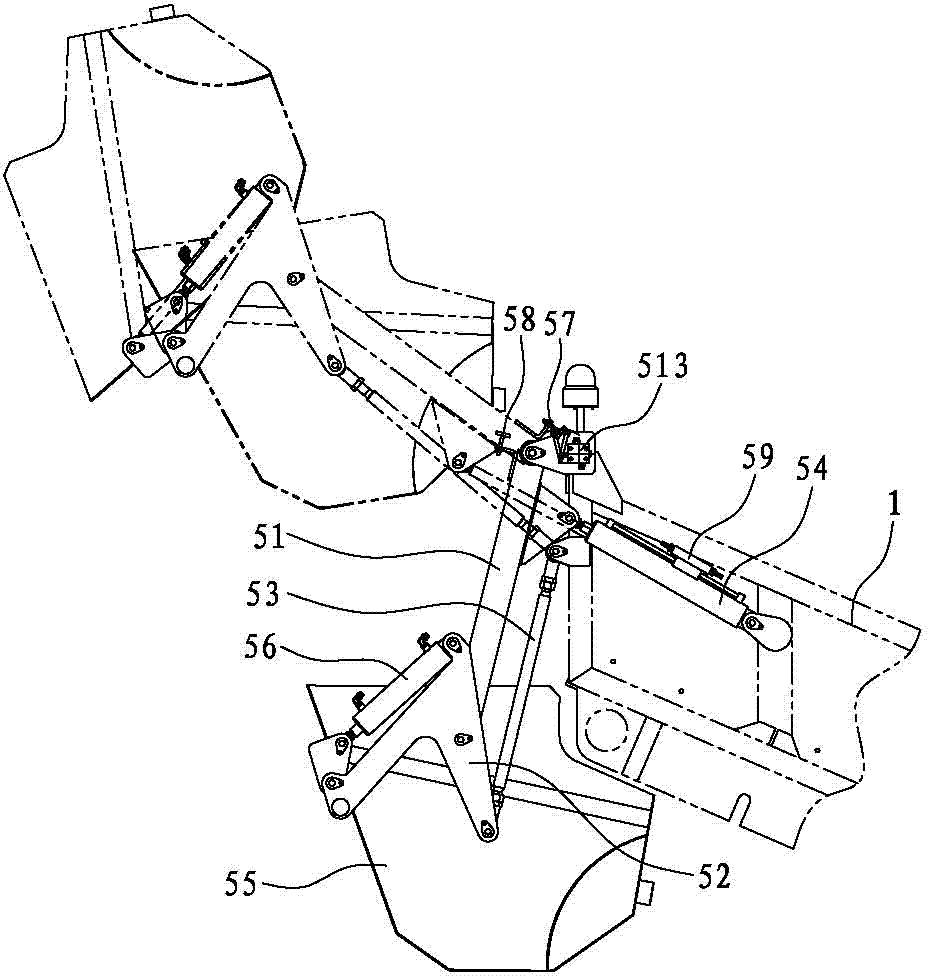

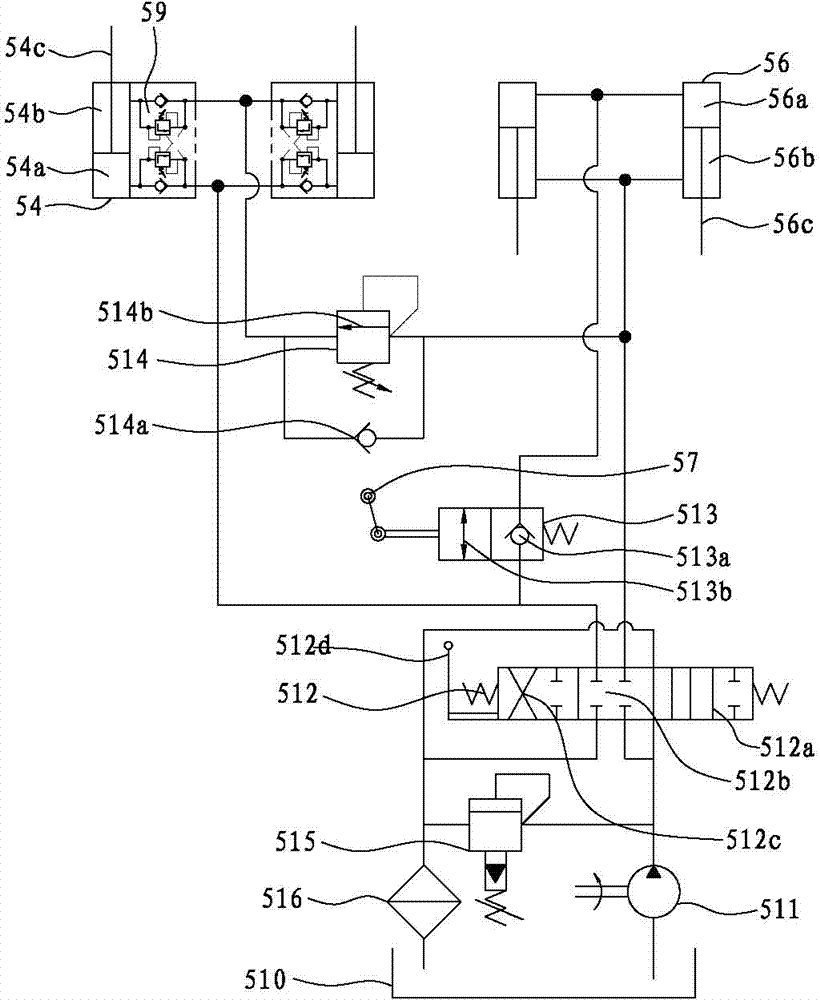

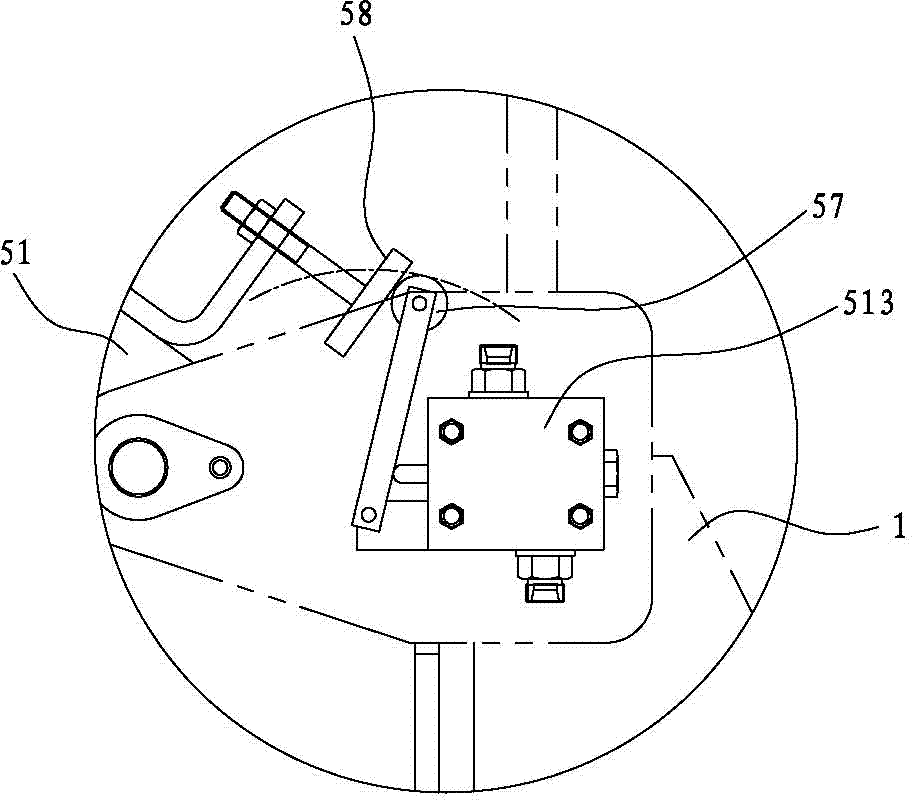

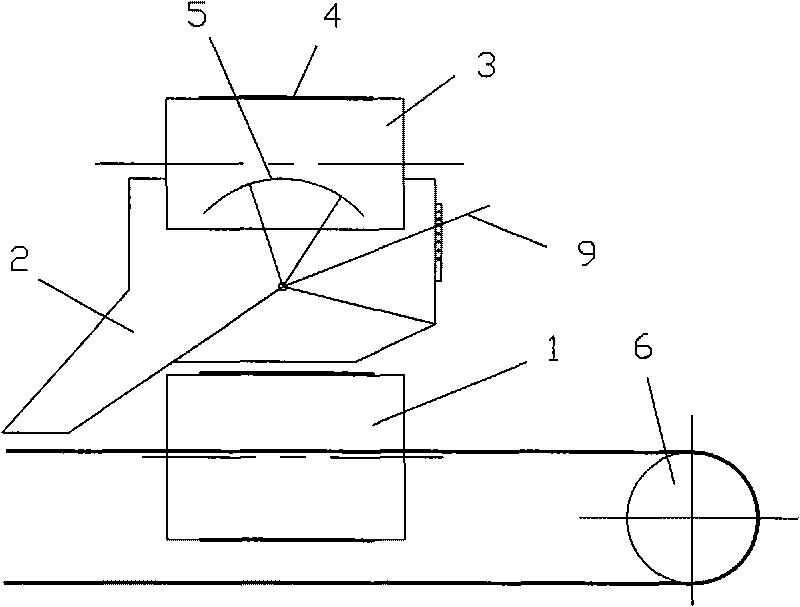

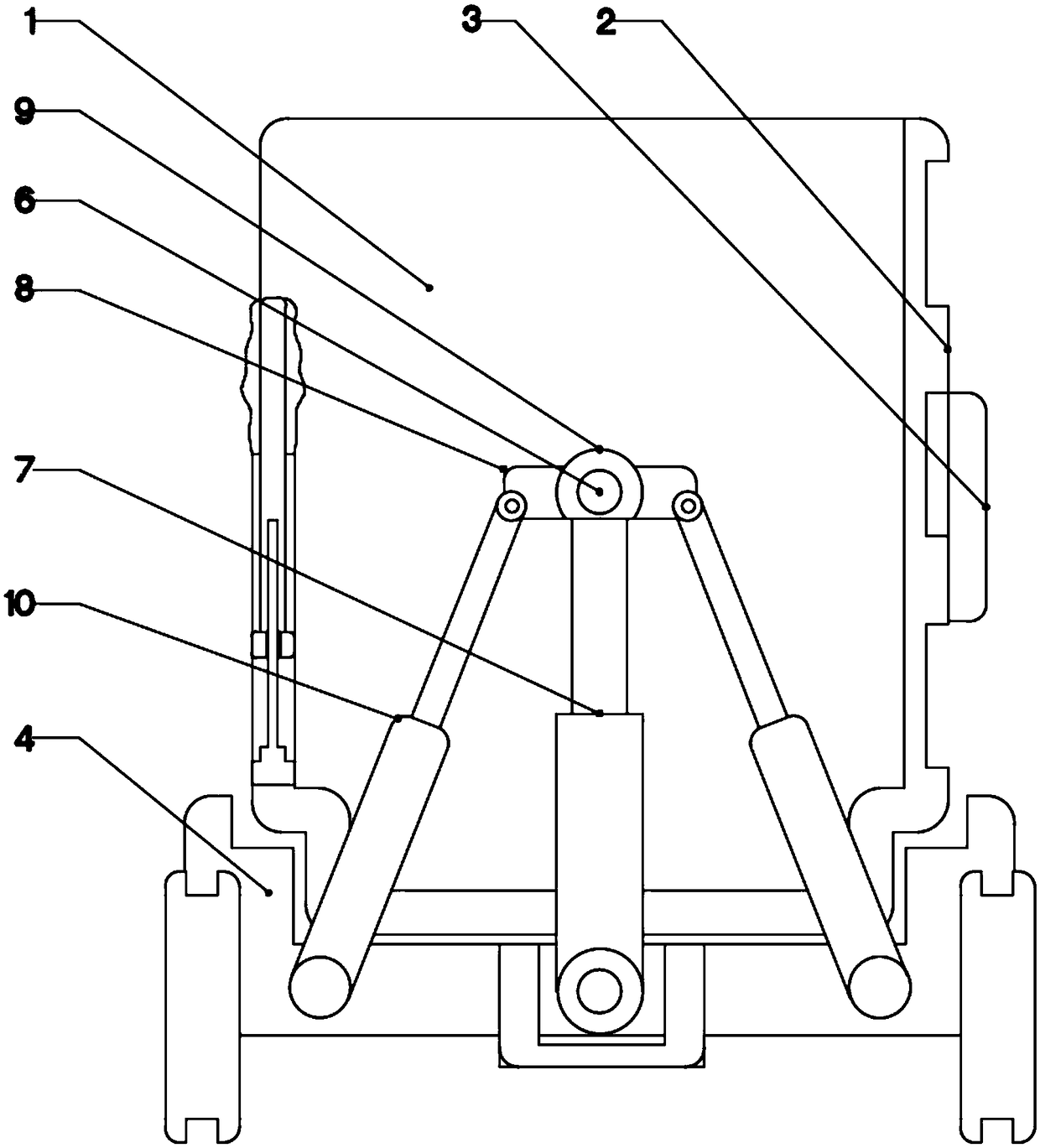

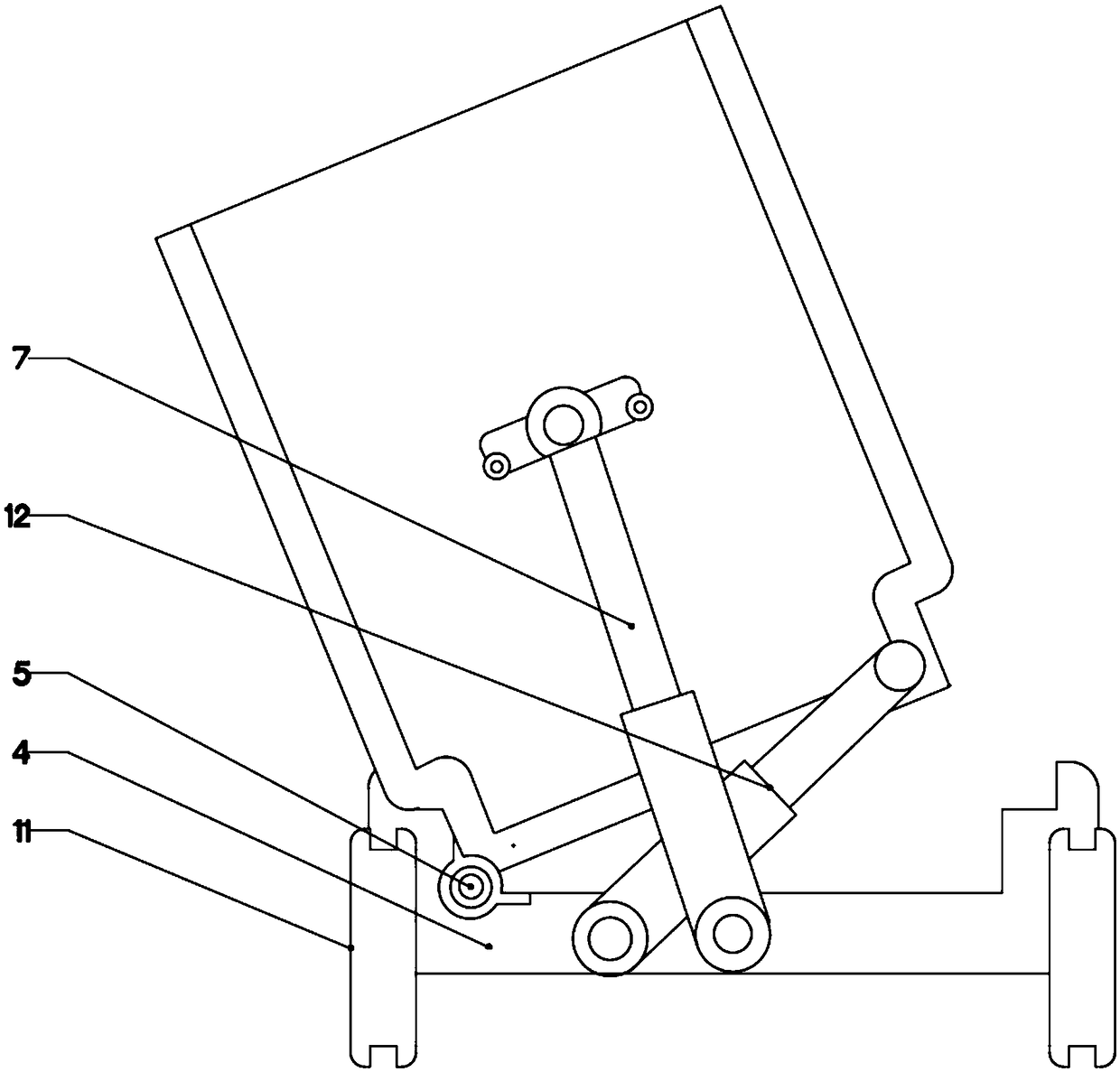

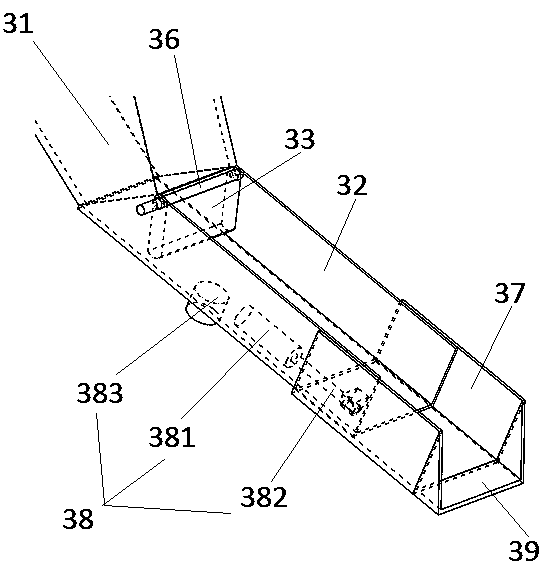

Lifting and turning-over mechanism of cleaning vehicle garbage bin and control method thereof

InactiveCN102758414APrevent leakageLarge flip angleRoad cleaningCleaning bleachesControl systemJunk box

The invention discloses a lifting and turning-over mechanism of a cleaning vehicle garbage bin, which is fixed on the frame of the cleaning vehicle, and includes a lifting arm, a turning-over seat, a connecting rod, a lifting oil cylinder, a garbage bin and a turning-over oil cylinder, wherein the lifting arm, the turning-over seat, the connecting rod and the frame are hinged to form a plane four-connecting rod mechanism; one end of the cylinder barrel of the lifting oil cylinder is hinged onto the frame, and one end of the piston rod is hinged onto the lifting arm, so as to drive the plane four-connecting rod mechanism to be lifted or lowered; and the turning-over seat, the garbage bin and the turning-over oil cylinder are hinged to form a swinging block mechanism, and the turning-over oil cylinder drives the swinging block to enable the garbage bin to turn over. As lifting and turning-over are performed through two mechanisms respectively, by adopting the control system to realize lifting and turning-over sequentially, not only the garbage scattering during the dumping is avoided, but also the independently-controlled turning-over mechanism enables the turning-over angle to be sufficiently large, so as to dump more completely and cleanly. The invention also discloses a control method of the lifting and turning-over mechanism.

Owner:厦门威迪思汽车设计服务有限公司

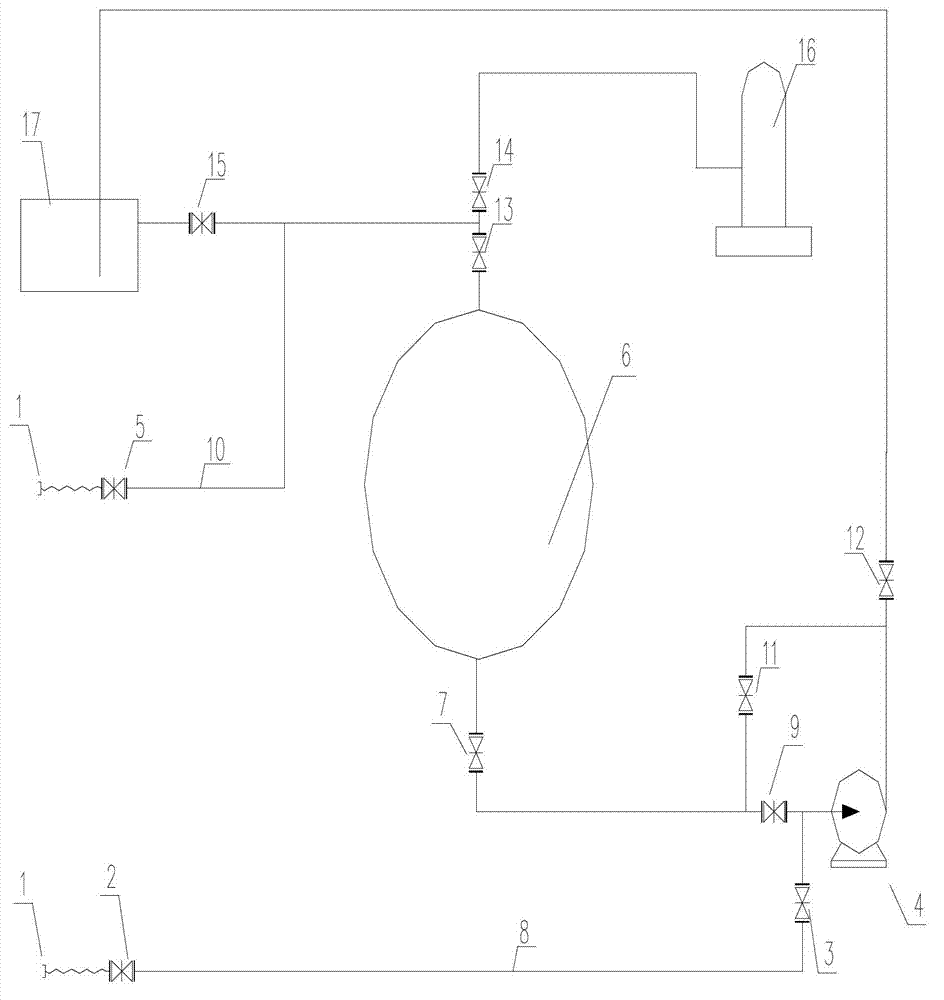

Novel method for unloading and delivering liquid ammonia

ActiveCN102829329AComplete unloadingAvoid safety hazardsPipeline systemsContainer filling under pressureReciprocating pumpChemistry

The invention provides a novel method for unloading and delivering liquid ammonia. The method is implemented by only one liquid ammonia delivery pump, the liquid ammonia can be unloaded and delivered by switching relevant valves, and the liquid ammonia delivery pump is one of a barrel pump, a screw pump and a reciprocating pump. Compared with an existing method for unloading and delivering liquid ammonia, the novel method for unloading and delivering the liquid ammonia has the advantages that a liquid ammonia unloading pump can be omitted, residual ammonia in a tank car after unloading can be further absorbed, the liquid ammonia is unloaded thoroughly, environmental pollution is prevented assuredly, and potential safety hazards are avoided.

Owner:CHINA TIANCHEN ENG +1

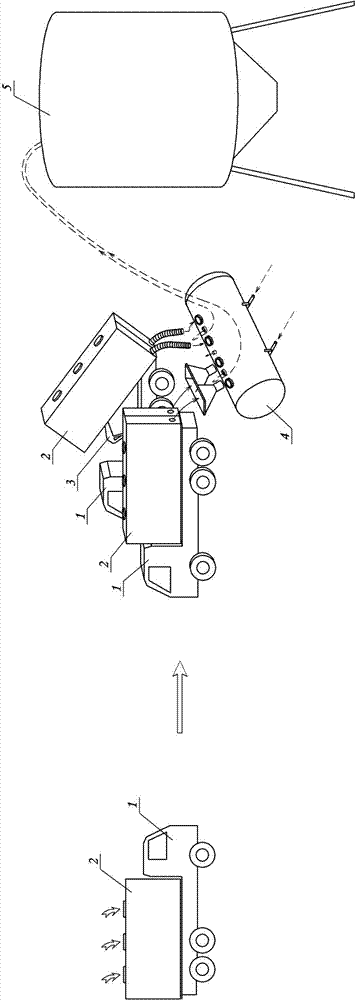

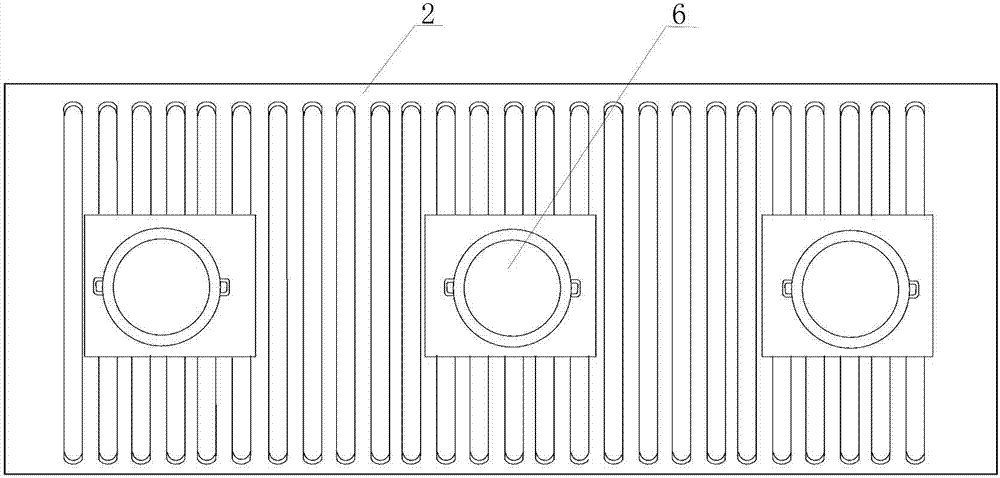

System and method for powder transportation

ActiveCN103086095AImprove loading efficiencyEasy to manufactureLarge containersInternational standardFluidized bed

The invention discloses a system and a method for powder transportation. An international standard container is used, the top of the transformed container is provided with a feeding port, and the bottom of a back door of the transformed container is provided with a discharging port. At the departure place, after the powder is loaded with zero pressure through the feeding port, the feeding port is sealed, the container serves as a multimodal transport device to transport the powder to the destination, a fluidized bed feeding tank is arranged at the destination, the discharging port of the container and an inlet of the fluidized bed feeding tank are aligned, and thereby the powder discharges automatically under own gravity. By means of the system and the method for powder transportation, an international standard container can be utilized directly and transformed, and thereby the advantages of simple production and strong generality are provided, and the purpose of international multimodal transportation is achieved. The method adopted is simple, the transportation efficiency of the powder can be improved greatly, the working environment is improved, the workers and workload are reduced, the transportation cost is reduced, and the market competitiveness is improved.

Owner:姚平

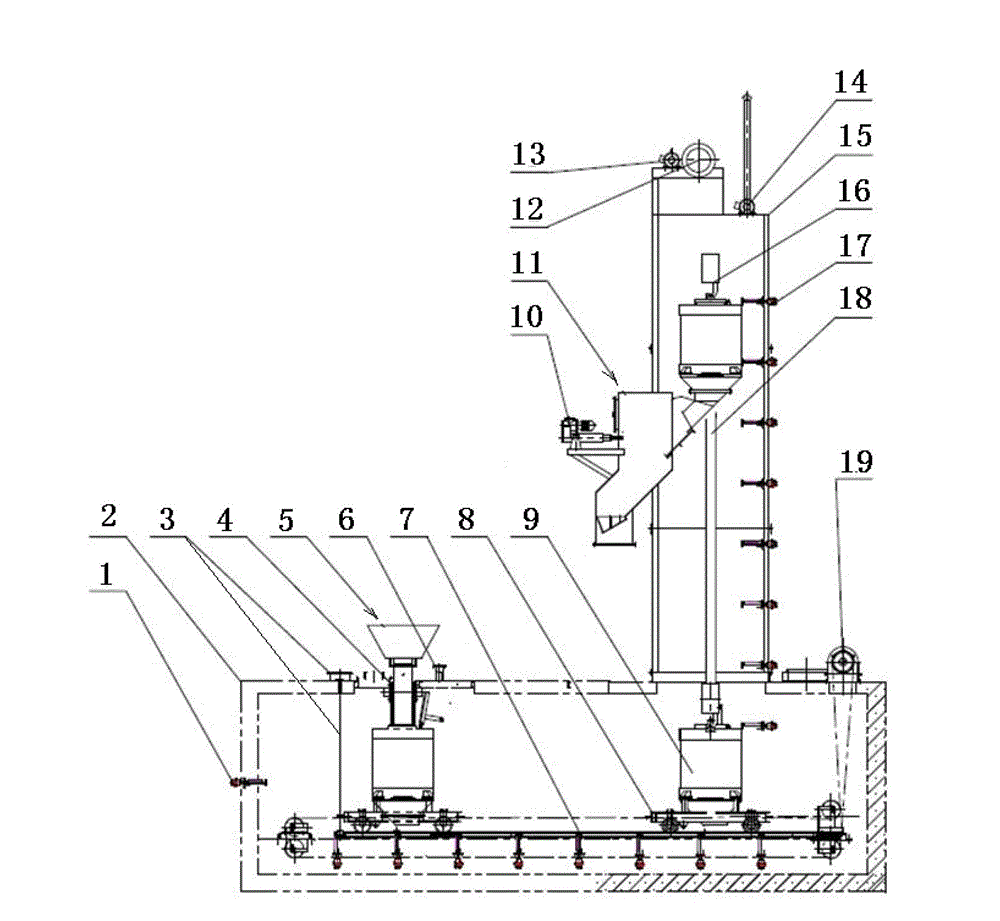

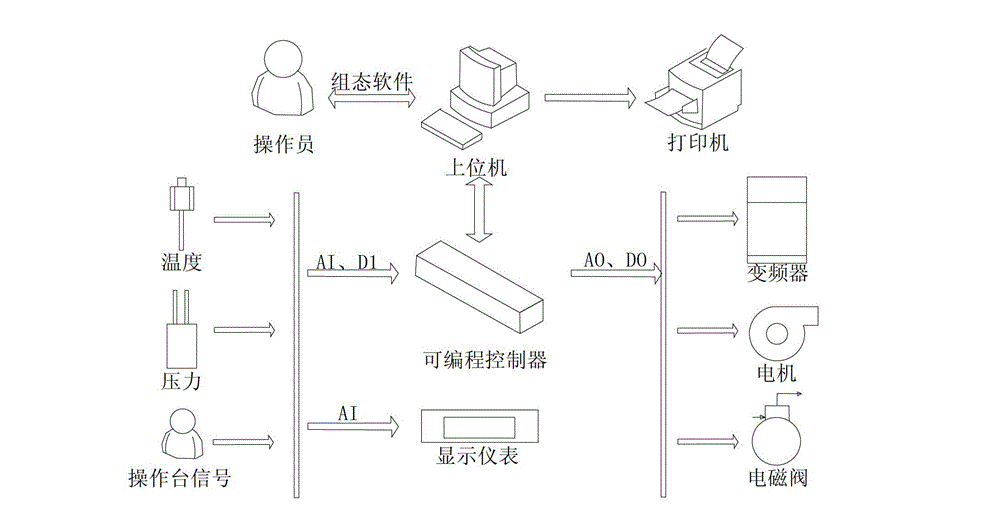

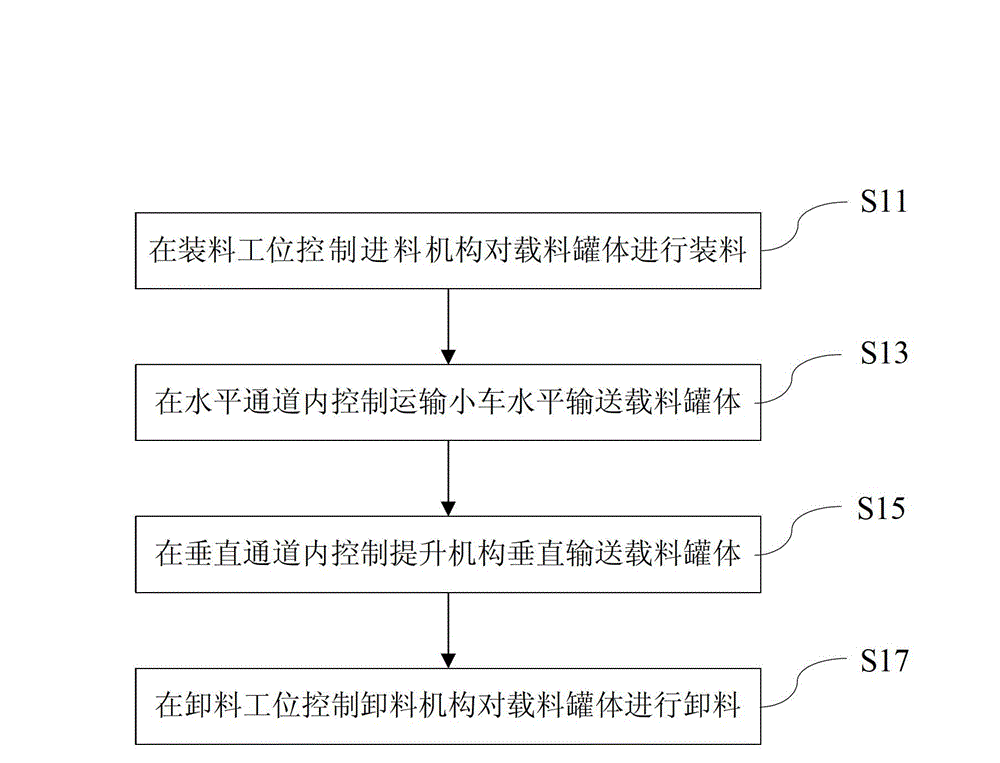

Control method of high-temperature material conveying system

ActiveCN102874578AFulfill material handling requirementsPrevent overflowControl devices for conveyorsEngineeringHolding tank

The invention discloses a control method of a high-temperature material conveying system. The conveying system comprises a horizontal passage with a feeding station, a vertical passage with a discharging station and a material holding tank, wherein the material holding tank uses a conveying trolley for horizontal conveyance in the horizontal passage, uses a lifting mechanism for vertical conveyance in the vertical passage and is kept airtight in each conveying process. The control method includes: controlling a feeding mechanism to feed materials into the material holding tank at the feeding station; controlling the conveying trolley to convey the material holding tank in the horizontal passage; controlling the lifting mechanism to convey the material holding tank in the vertical passage; and controlling a discharging mechanism to discharge the material holding tank at the discharging station. According to the control method of the high-temperature material conveying system, material conveying requirements on the high-temperature material conveying system are met.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Rotating wheel type fixed discharge device

The invention discloses a rotating wheel type fixed discharge device which comprises a rotating wheel, rotating blades, hairbrush cushions, a rotating shaft, a connecting rod, a frame, a sliding top plate, a baffle, a movable frame, bolts, bolt holes, rotating wheel driving device, a support, and a belt. The rotating blades are arranged on the rotating wheel. The hairbrush cushions are arranged on the rotating blades. The rotating shaft and the connecting rod are arranged on the upper portion of the rotating wheel. The rotating wheel is arranged in the frame. The sliding top plate is arranged on the frame. The support is arranged under the frame. The baffle and the movable frame are respectively arranged on the two side faces of the frame. The bolt holes are arranged on side edges of the frame. The movable frame is shaped like a Chinese character 'ji'. The bolts are arranged on one side edge of the movable frame. The movable frame is opened and closed through the bolts and the bolt holes. The rotating wheel is driven by the rotating wheel driving device to run. The rotating wheel type fixed discharge device is dustproof and prevents materials from overflowing. The movable frame can be opened and closed conveniently so as to realize one-side discharging or double-side discharging. The hairbrush cushions are arranged so as to play functions of blocking materials and protecting a belt. The movable frame shaped like a Chinese character 'ji' and the baffle arranged on the frame are more favorable to guiding materials.

Owner:中煤集团山西华昱能源有限公司

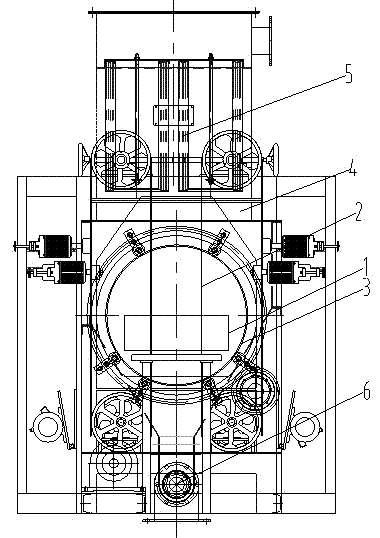

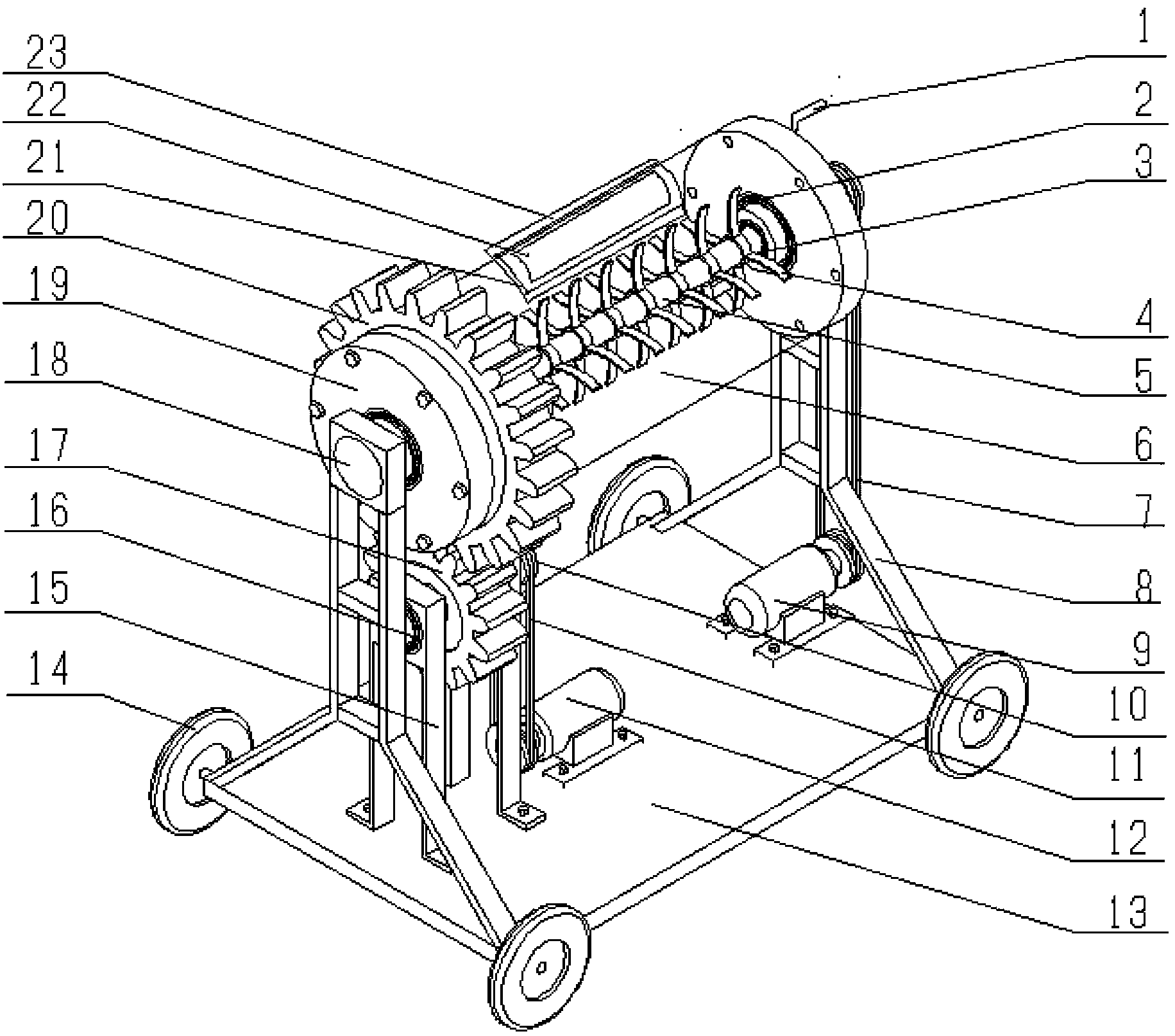

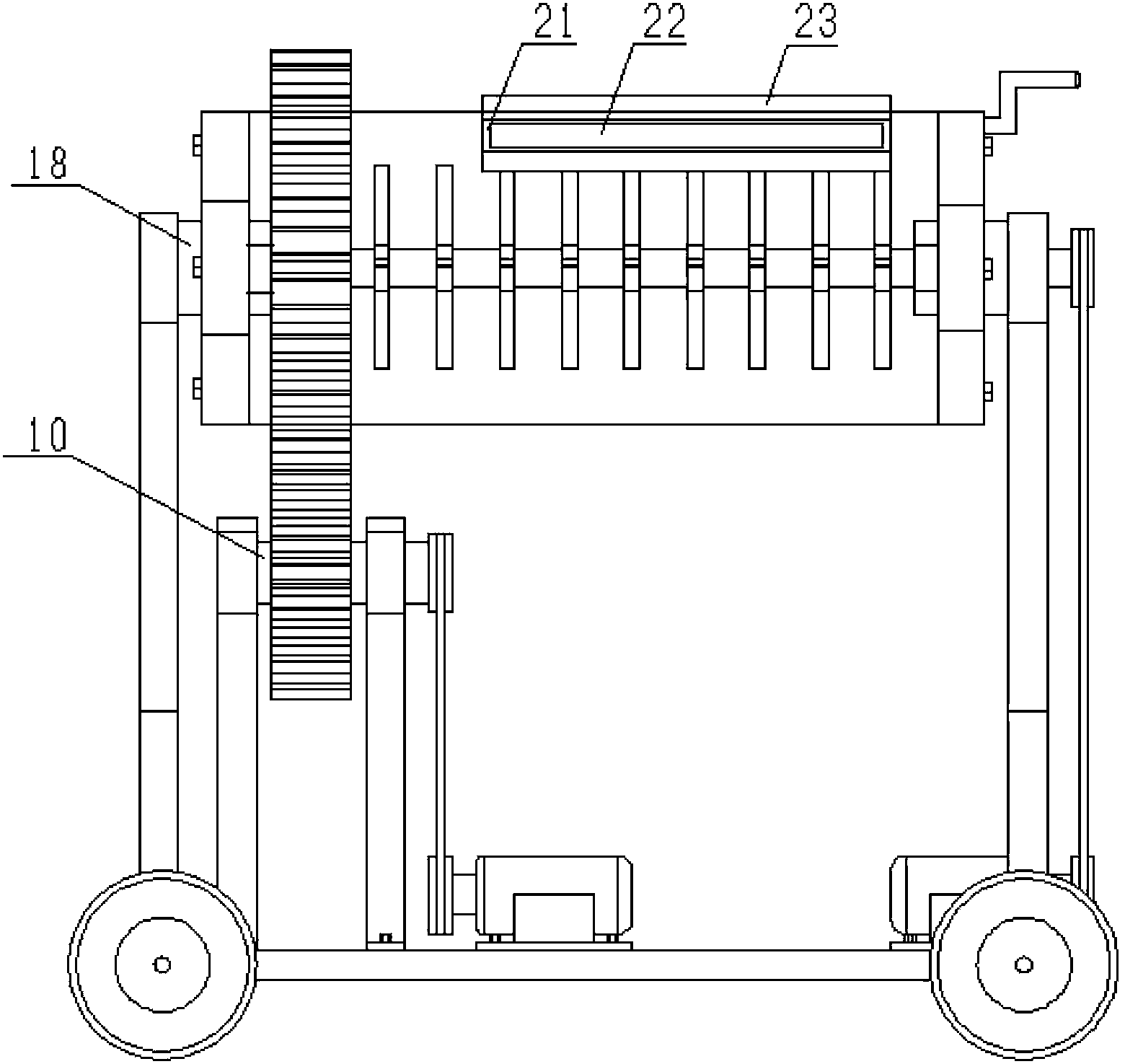

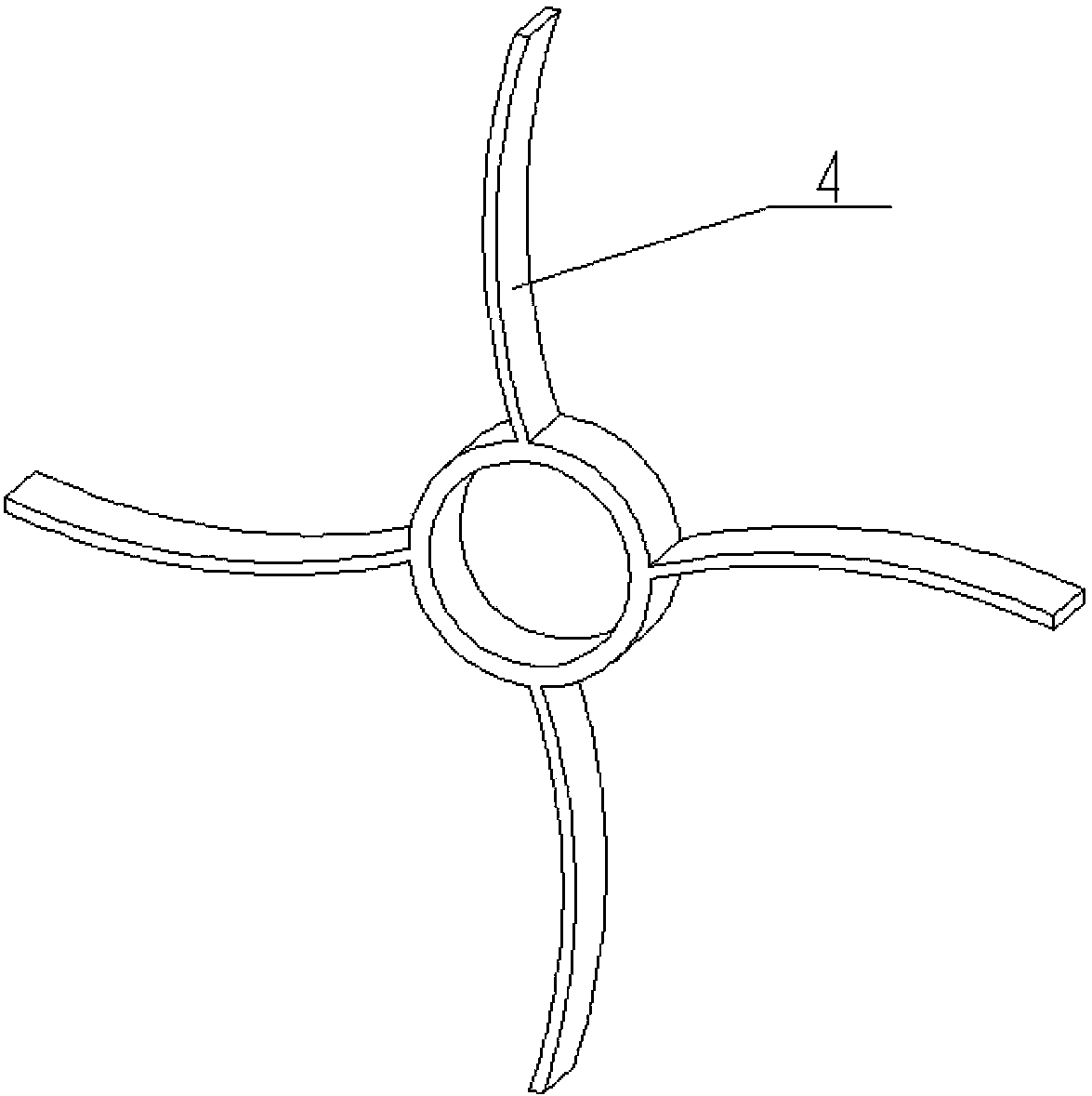

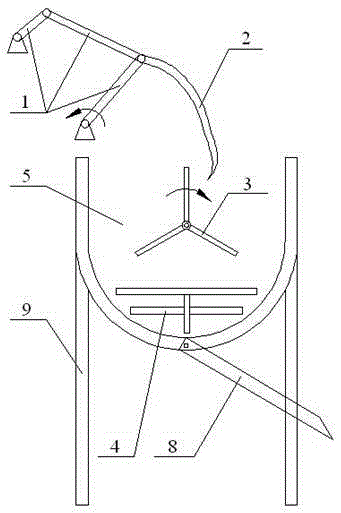

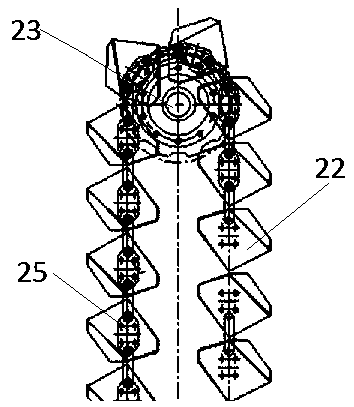

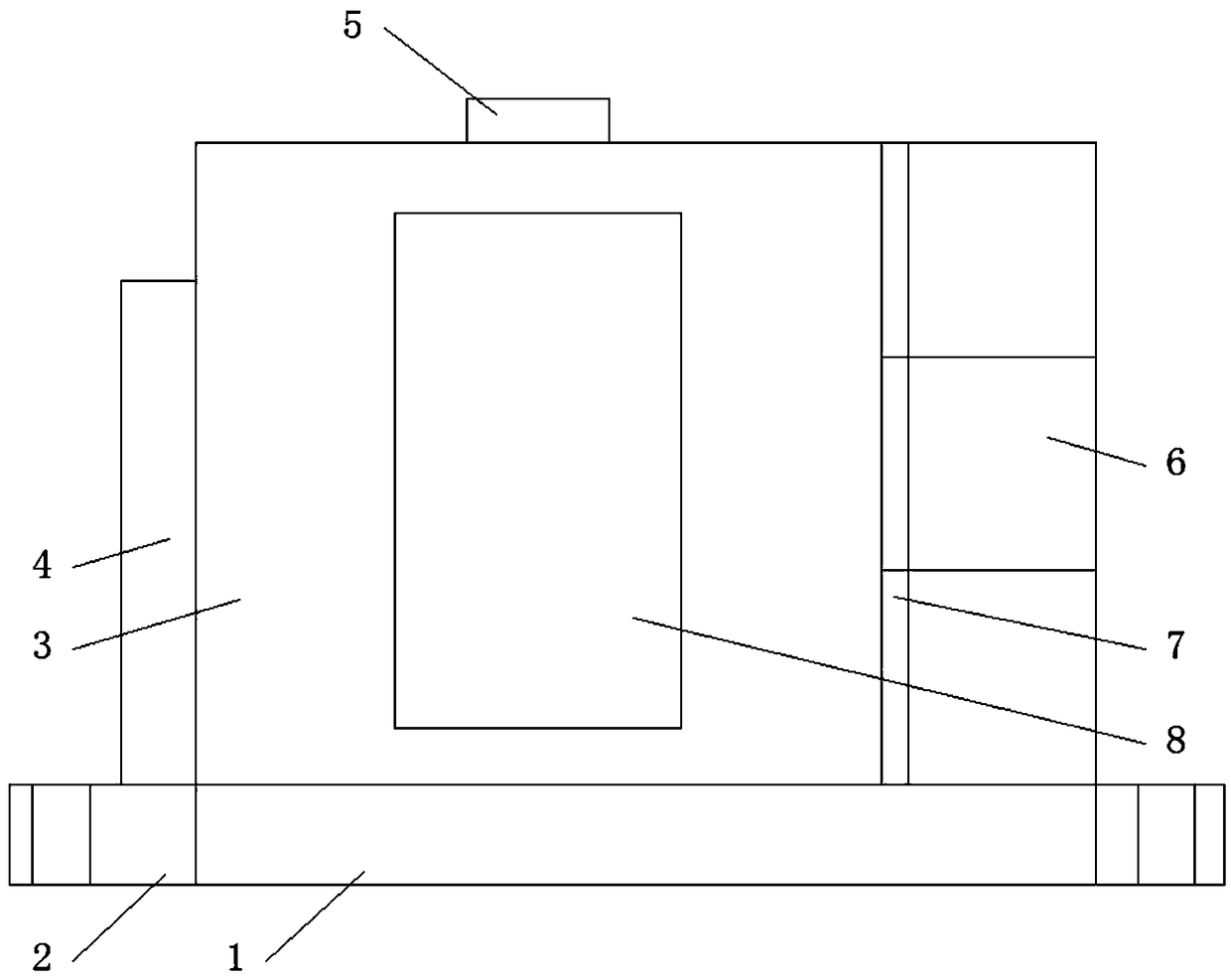

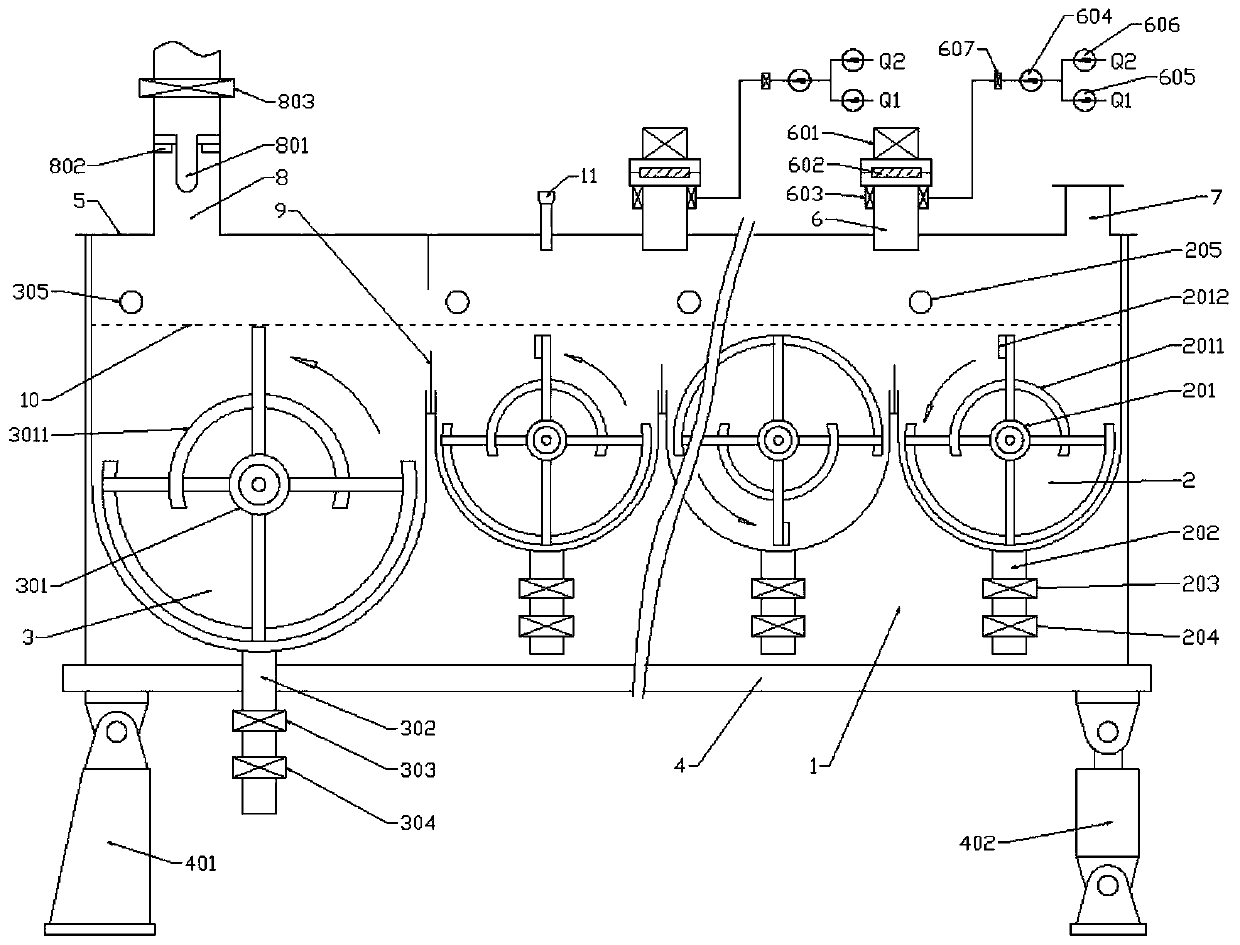

Concentric bidirectional-rotation feed stirring machine

InactiveCN103381344ASimple structureEasy to moveRotating receptacle mixersTransportation and packagingDrive shaftEngineering

The invention mainly relates to a feed stirring machine, in particular to a concentric bidirectional-rotation feed stirring machine suitable for feed stirring operation of large farms. The concentric bidirectional-rotation feed stirring machine comprises a stirring shaft arranged in a stirring barrel and is characterized in that the stirring barrel is arranged on a support shaft through a large bearing, and two sides of the stirring barrel are provided with stirring barrel end covers. The stirring shaft is driven by an electric motor I through a driving belt I and arranged on the support shaft through a small bearing. The stirring barrel is fixedly connected with a gear ring, the gear ring is meshed with a gear, the gear is fixedly connected with a gear transmission shaft and driven by an electric motor II through a driving belt II, and the gear transmission shaft is arranged on a gear transmission shaft support frame through a bearing. The concentric bidirectional-rotation feed stirring machine has the advantages of being simple in structure and good in mobility, the stirring shaft and the stirring barrel form concentric retrograde rotation, and the disadvantages of long stirring time, low stirring efficiency, layered and even feed stirring and the like of a traditional feed stirring machine are overcome. A feeding port and a discharging port of the stirring machine are the same feeding / discharging port, so that an internal space of the stirring barrel is fully utilized. Feeding of the stirring machine is convenient and discharging of the stirring machine is thorough by turning a handle.

Owner:GANSU AGRI UNIV

Chemical reaction crystallization kettle with long service life

PendingCN107376395AAvoid thermal stress damageAvoid breakingProcess control/regulationChemical/physical/physico-chemical stationary reactorsChemical reactionElectric machinery

The invention discloses a chemical reaction crystallization kettle with long service life. The chemical reaction crystallization kettle with long service life comprises a motor, a motor controller, a seal box and a kettle body, wherein the kettle body is arranged in a seal box; a turnover door is arranged on the top of the seal box; two sides of the kettle body are respectively provided with a rotating shaft and a fixed shaft; each of the rotating shaft and the fixed shaft forms an integrated structure together with the kettle body; the other end of the rotating shaft is rotatably mounted on the side wall of the seal box; the other end of the fixed shaft is provided with a gear; and the gear and the fixed shaft are integrally casted. According to the invention, since the inner bottom surface of the seal box is provided with an automatic turnover device, the kettle body is turned over for discharging after completion of a reaction; and the motor is used for driving stirring vanes to scrape off raw materials adhered on the inner wall of the kettle body, so the raw materials is prevented from leaving in the kettle body and corroding the kettle body, loss of the raw materials is reduced, a discharging manner is simple, and thorough discharging is realized.

Owner:华南理工大学云浮研究院

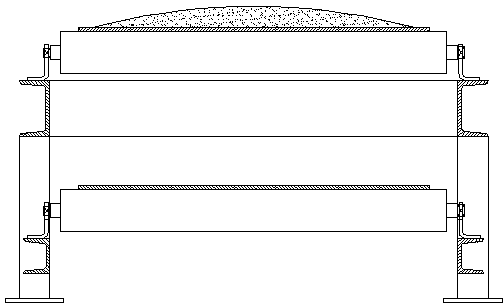

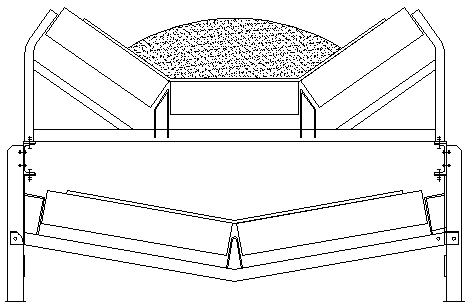

Discharging device of belt conveyor

The invention relates to a discharging device of a belt conveyor. A discharging roll, a turnabout roll and a roll of a charging belt 1 are distributed in a triangle shape, the discharging roll is arranged above, a belt sequentially moves around a stock ground roll, the discharging roll, the turnabout roll and the roll of the charging belt 1, the section of the belt between the stock ground roll and the discharging roll is a climbing section, the section of the belt between the turnabout roll and the roll of the charging belt is a distribution conveyor belt, a discharging funnel is arranged at the left below the discharging roll, the inlet of the discharging funnel is provided with a movable discharging board which is articulated with the discharging funnel, a control handle of the movable distribution board extends out of the discharging funnel, a plurality of adjusting holes of the control handle are arranged on the side wall of the discharging funnel; the discharging funnel is provided with a front discharging hole and a rear discharging hole, the lower end of the front discharging hole is provided with the distribution conveyor belt, and the lower end of the rear discharging hole is provided with a charging belt 2. The invention has thorough discharging, no friction with the belts during the distribution, and long service life of the belts.

Owner:XINXING DUCTILE IRON PIPES CO LTD

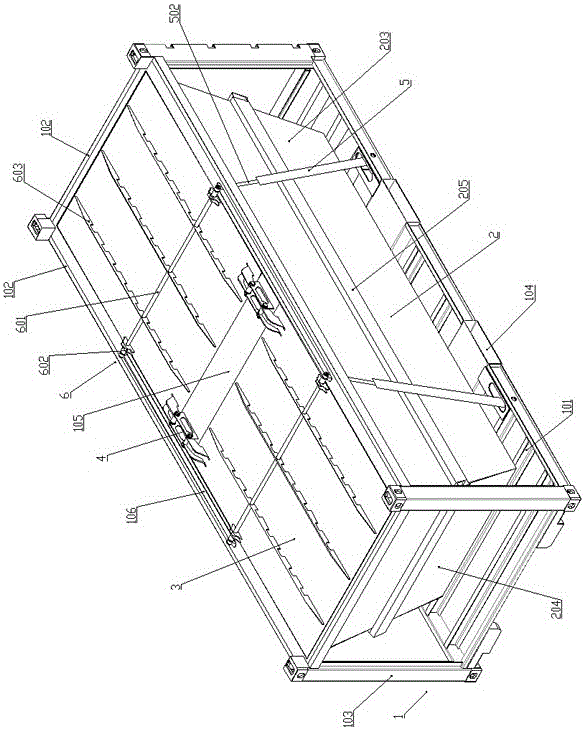

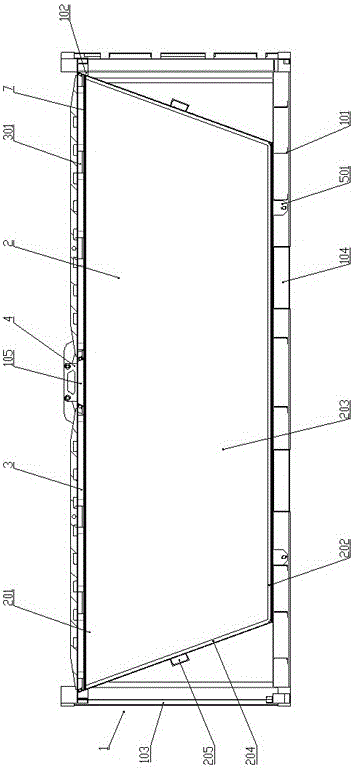

Upper cover opening transportation container

The invention discloses an upper cover opening transportation container, and mainly solves the problems of inconvenience for loading and unloading, easy material leakage and incomplete unloading in a traditional container. The upper cover opening transportation container comprises a container body frame, a container body fixed on the container body frame and two container doors; and the container body is closed, is smooth in inner wall, and is provided with a top-opened container port. The upper cover opening transportation container is characterized in that the two container doors are oppositely and symmetrically hinged to the top of the container body frame for covering the container port of the container body; cylinders are respectively arranged on two sides of each container door; brackets of the cylinders are respectively hinged to the container body frame; and piston rods of the cylinders are hinged to the corresponding container doors by connecting pieces. The upper cover opening transportation container is reasonable in design, convenient for loading and unloading, not easy to leak materials, smooth in inner wall of the container body, non-sticky in materials and thorough in unloading.

Owner:荣成中磊科技发展有限公司

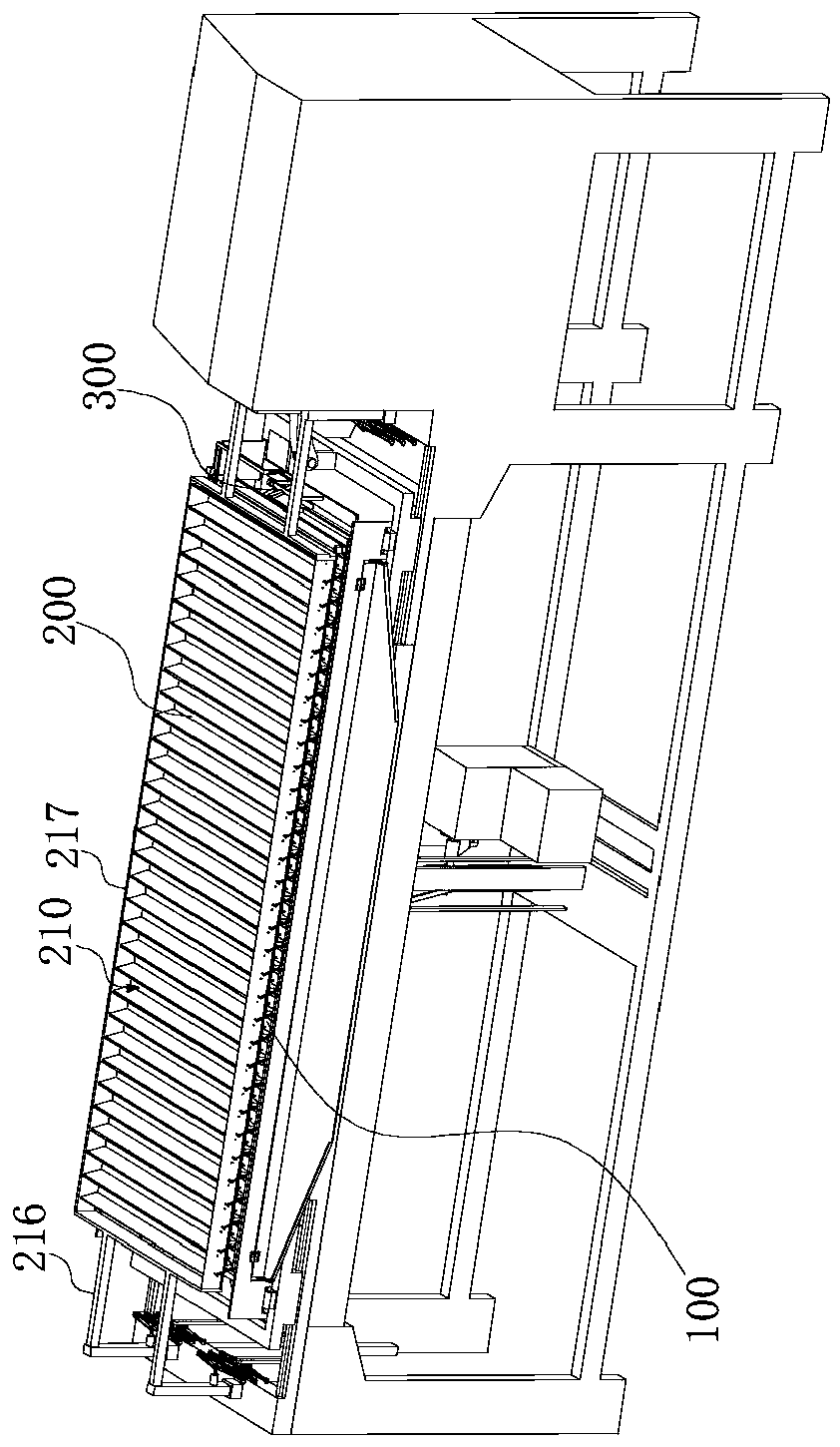

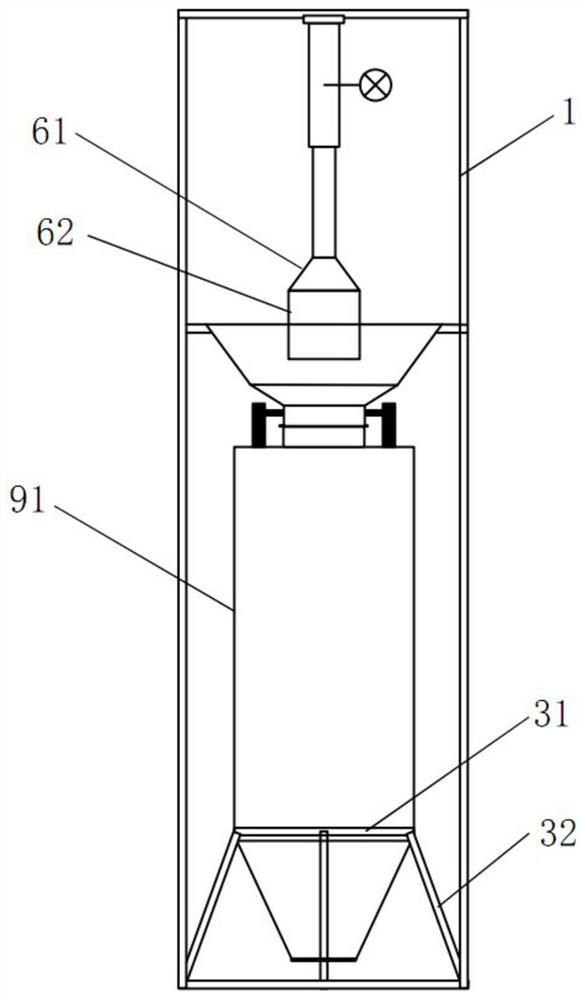

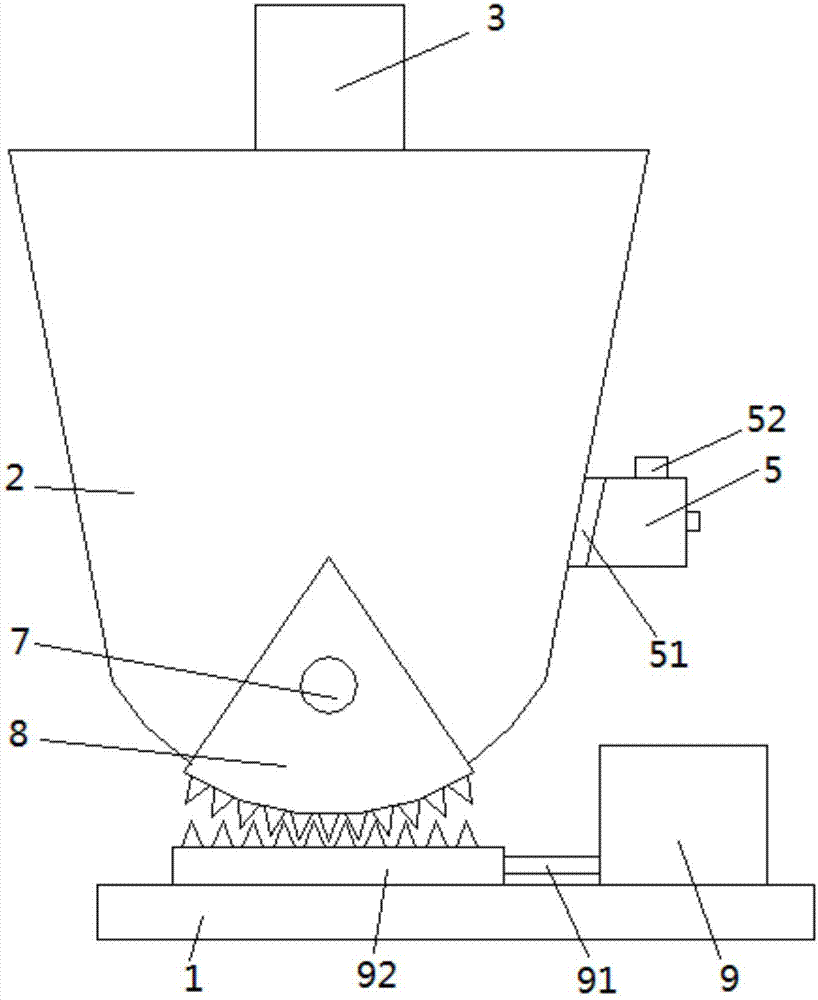

Automatic bag opening machine for powder

PendingCN108357745AReduce lossPrevent overflowLoading/unloadingUnpacking by cuttingPulp and paper industryEngineering

The invention relates to an automatic bag opening machine for powder and belongs to the field of bag powder discharging equipment. The automatic bag opening machine for the powder comprises a rack, ahopper, a bag overturning device, a blade, a bag shaking discharging device and a waste bag discharging device. The hopper is fixed to the lower portion of the rack. The right side of the part, abovethe hopper, of the rack is provided with the bag overturning device. The blade, relative to the bag overturning device, is fixed to the middle position of the left side of the rack. The bag shaking discharging device and the waste bag discharging device are installed on the two sides of the blade in a stagger manner. According to the automatic bag opening machine for the powder, the fixed blade isadopted to cut a powder bag, the powder bag cutting opening is smooth, bag opening is stable, and the service life of the blade is long.

Owner:ANHUI ZEJIAYE POWDER ENG

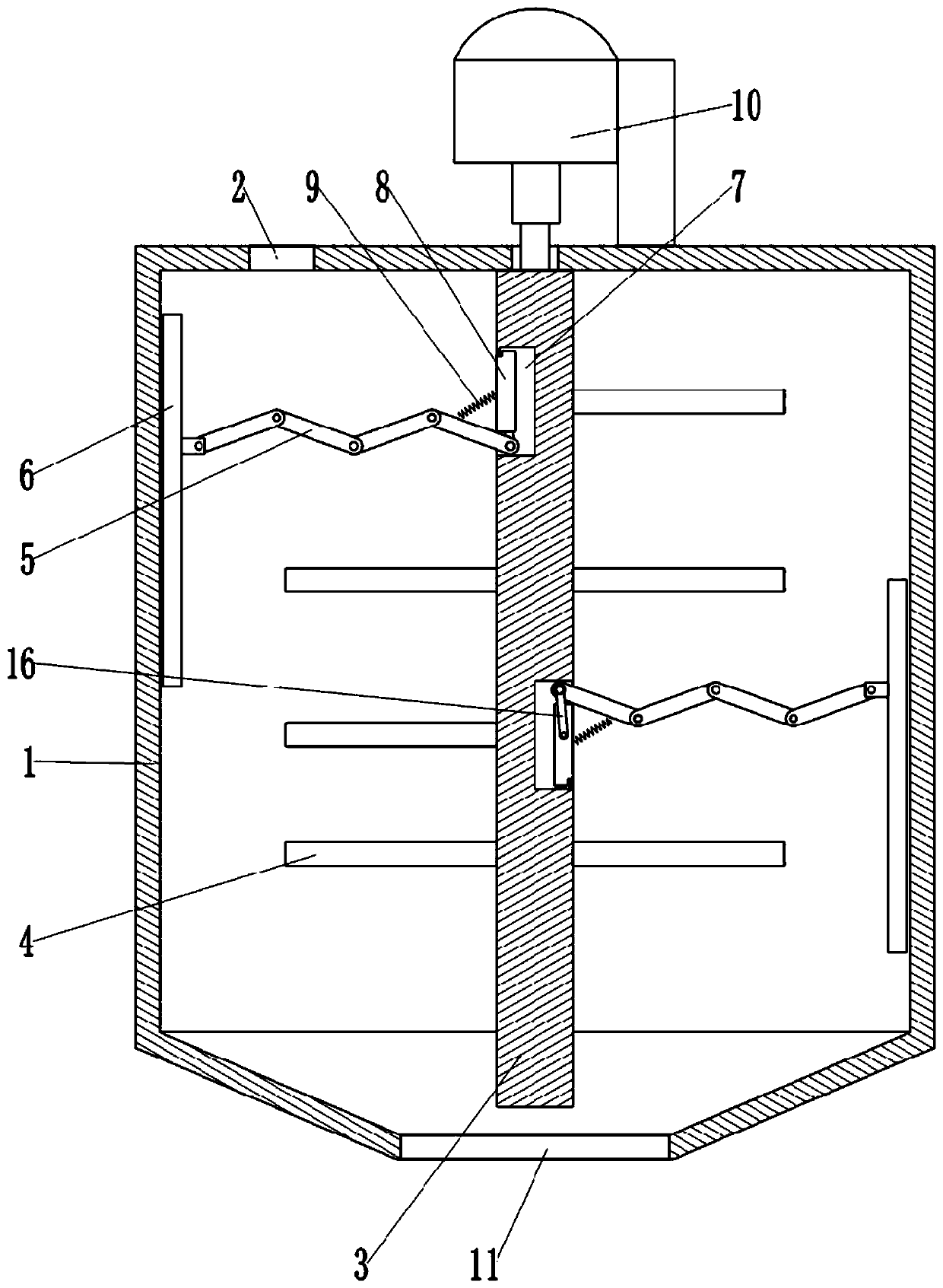

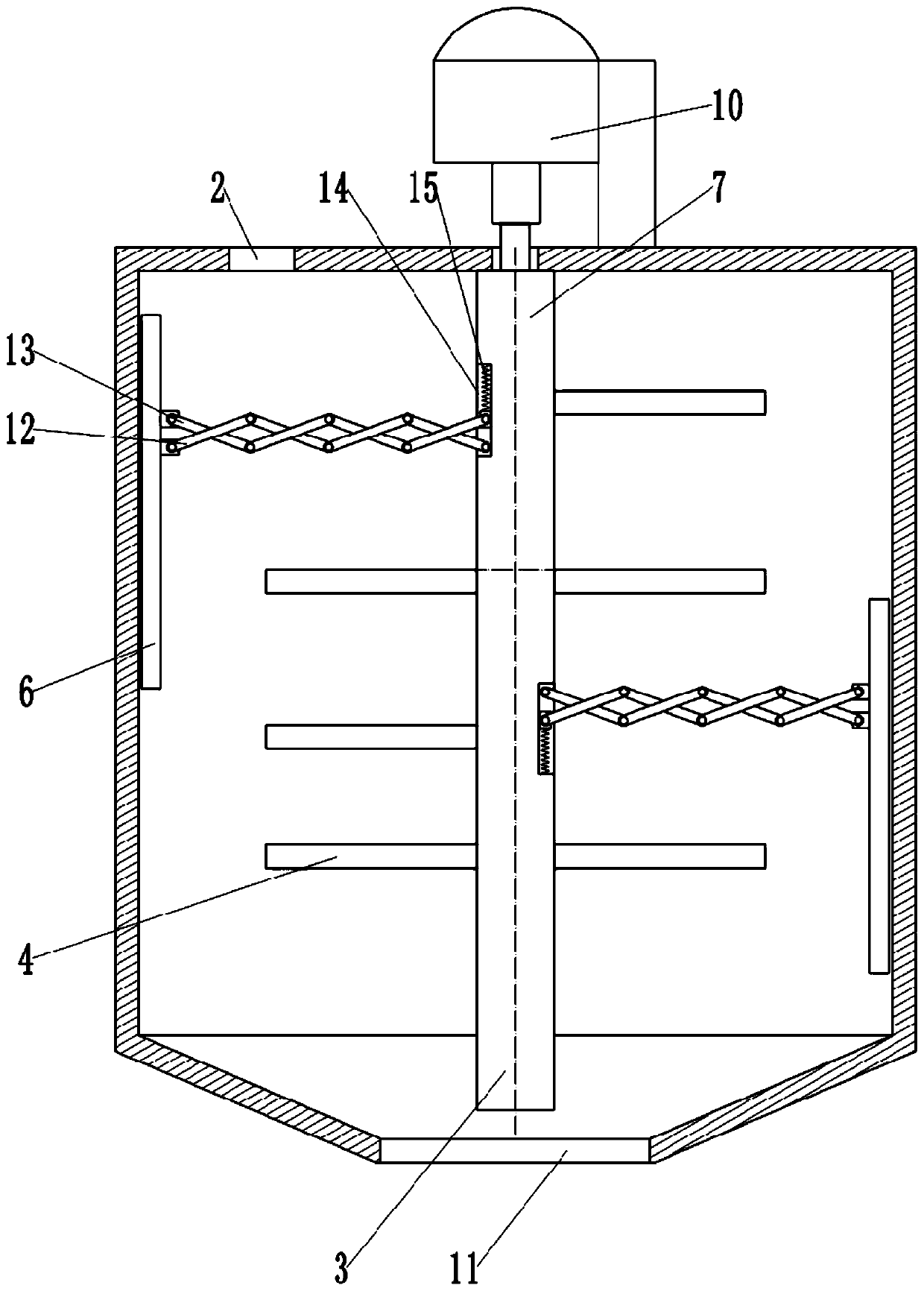

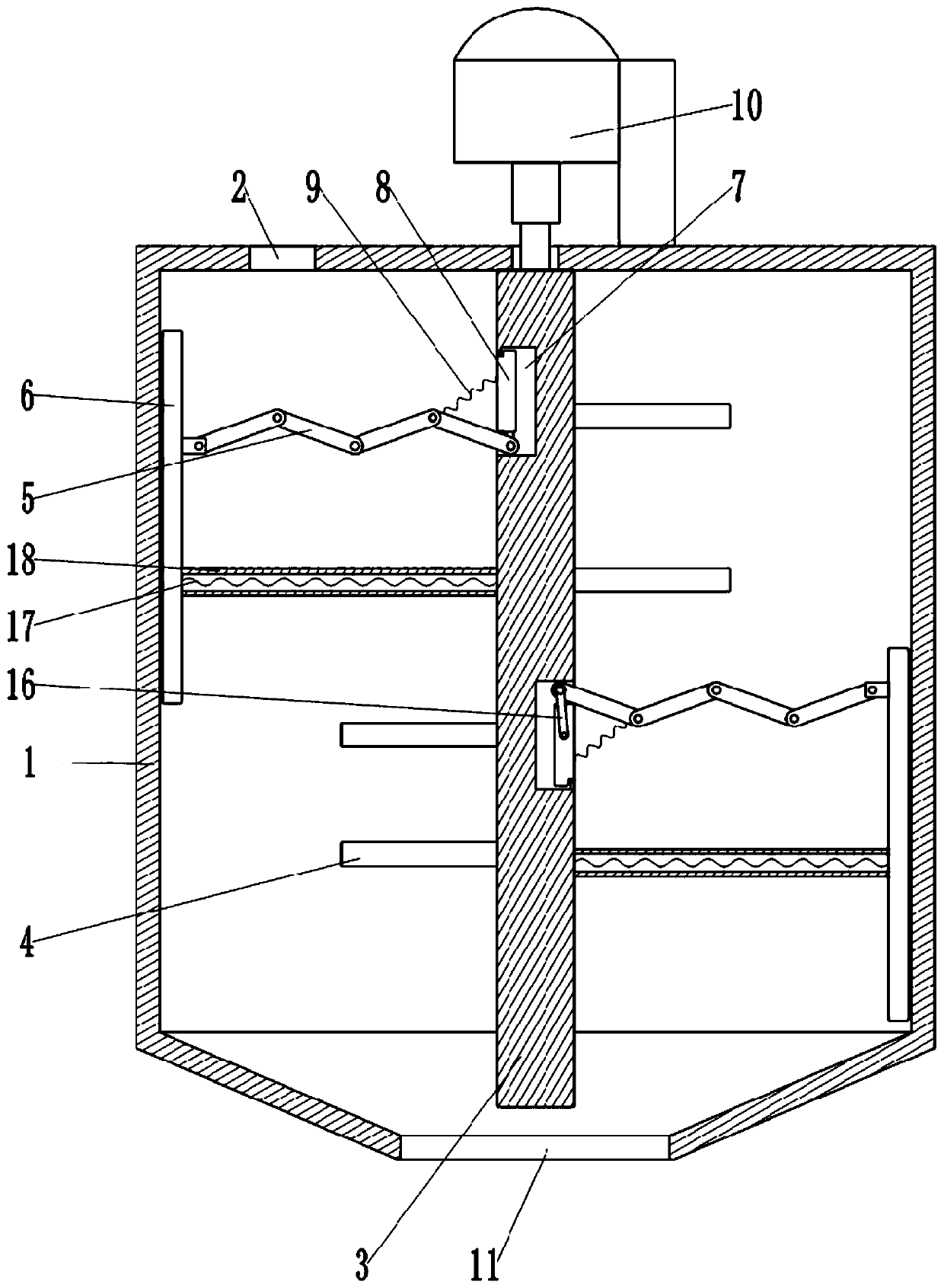

Multi-layer feed stirrer

InactiveCN106669480AAvoid uneven mixingAvoid the problem of stirring stratificationFeeding-stuffRotary stirring mixersEngineeringElectric motor

The present invention belongs to the technical field of agricultural machinery, and more particularly relates to a multi-layer feed stirrer, which comprises a rack, wherein the rack is provided with a stirring cylinder, the interior of the stirring cylinder is respectively provided with a first stirring device, a second stirring device and a third stirring device from top to bottom, the right side of the stirring cylinder is provided with a motor, the bottom portion of the stirring cylinder is provided with a material outlet and is provided with a material outlet slide, the first stirring device is connected to a crank connection rod mechanism, the crank connection rod mechanism is connected to a rotation shaft, the second stirring device is directly connected to the rotation shaft, the third stirring device is connected to a worm wheel, the worm wheel is connected to a worm, and the motor is respectively connected to the rotation shaft and the worm through belts. According to the present invention, the multi-layer feed stirrer has characteristics of simple working principle, easy operation, high stirring efficiency, uniform feed stirring, no feed layering, and convenient and complete material discharging.

Owner:西安发威电子科技有限公司

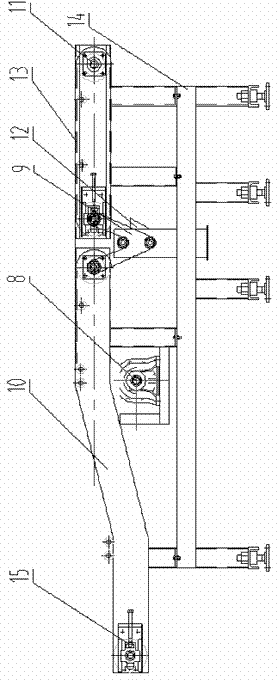

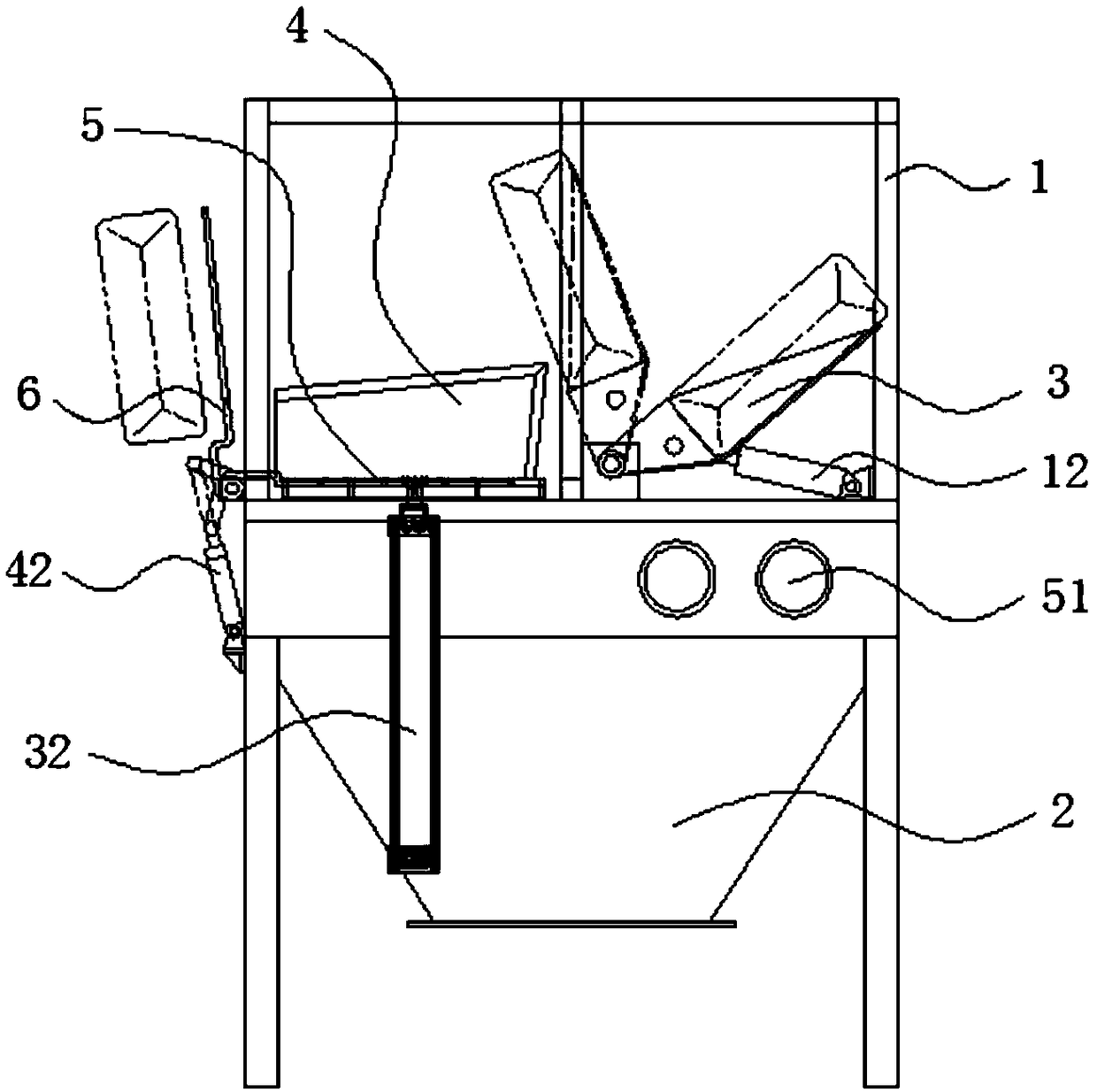

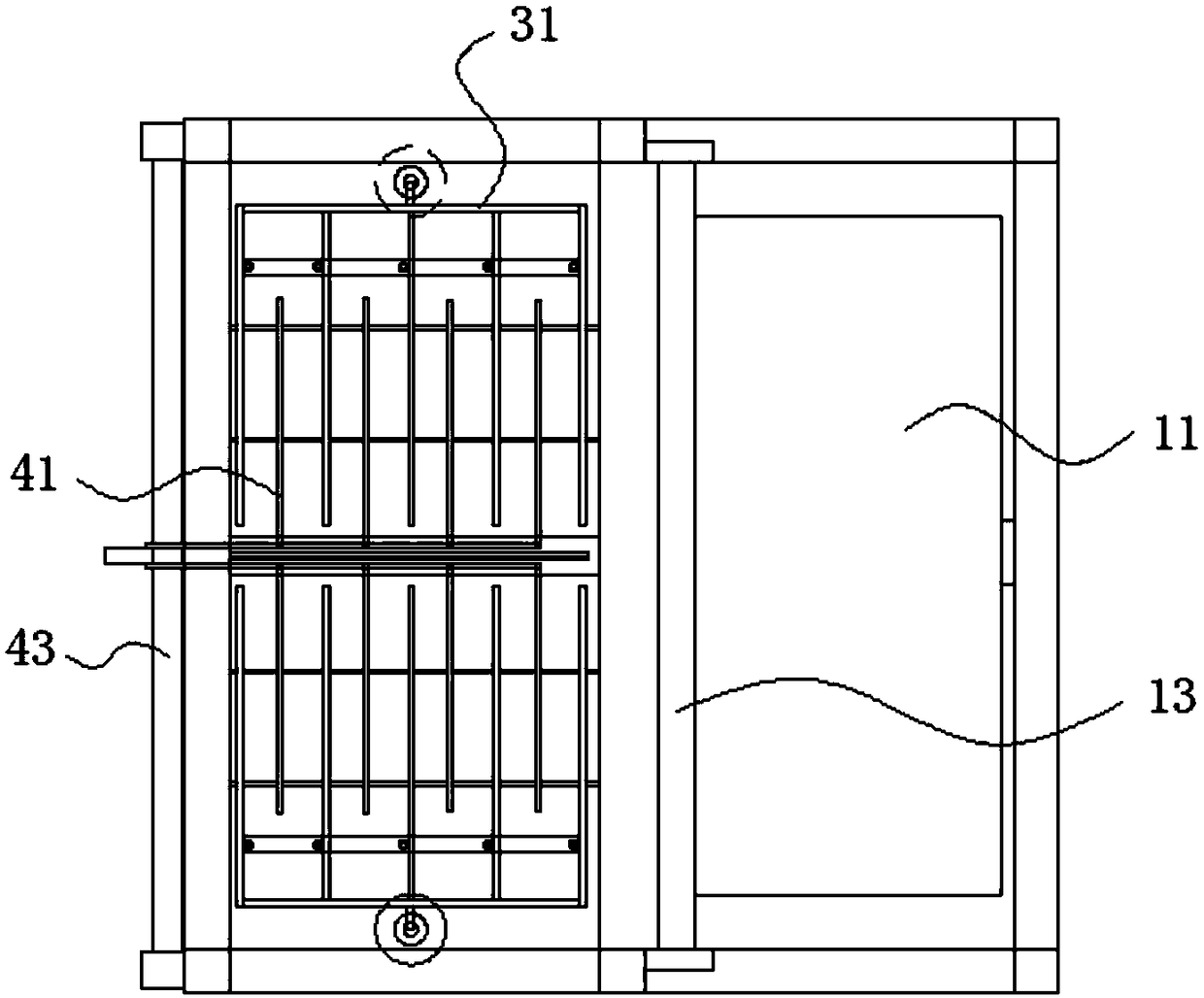

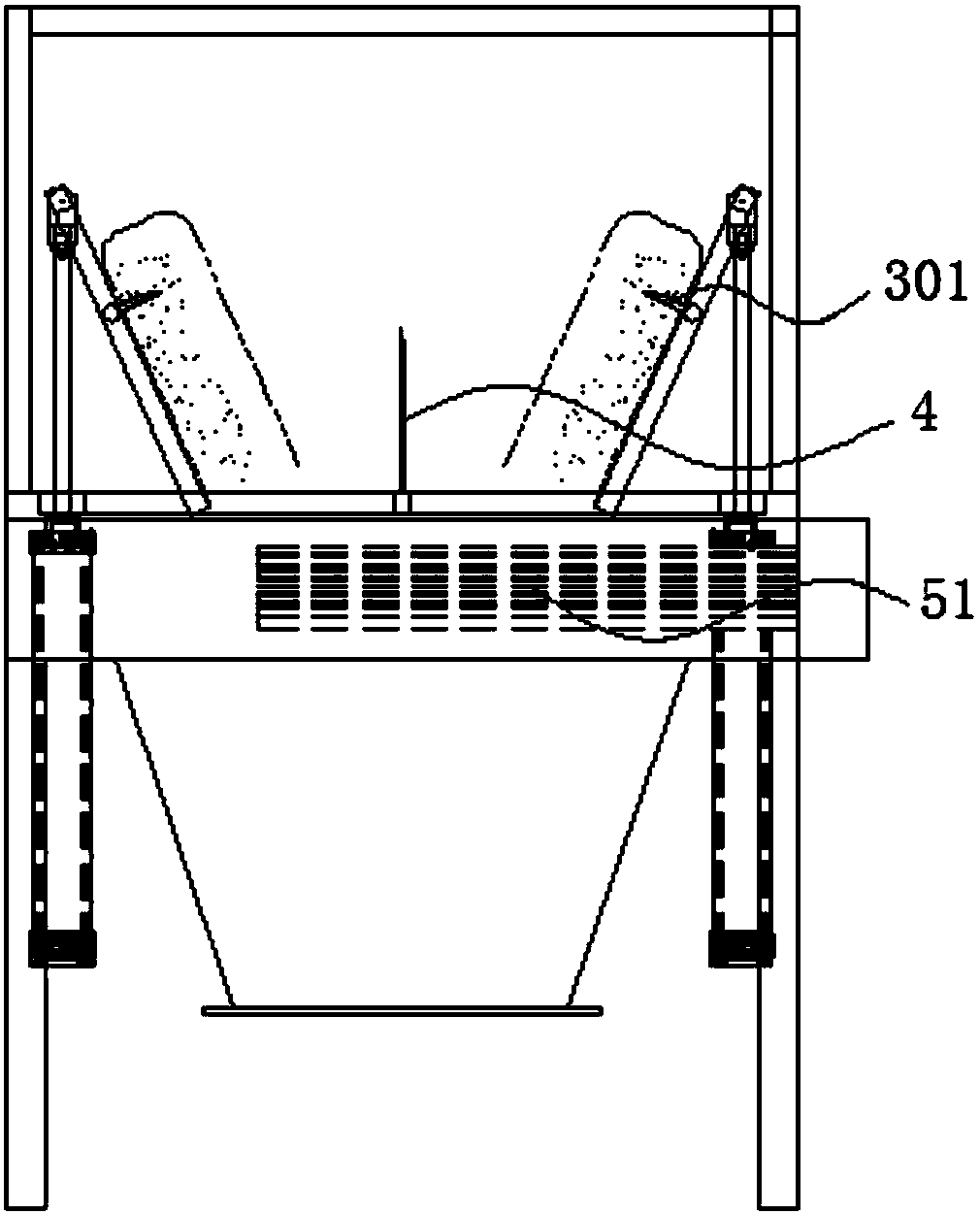

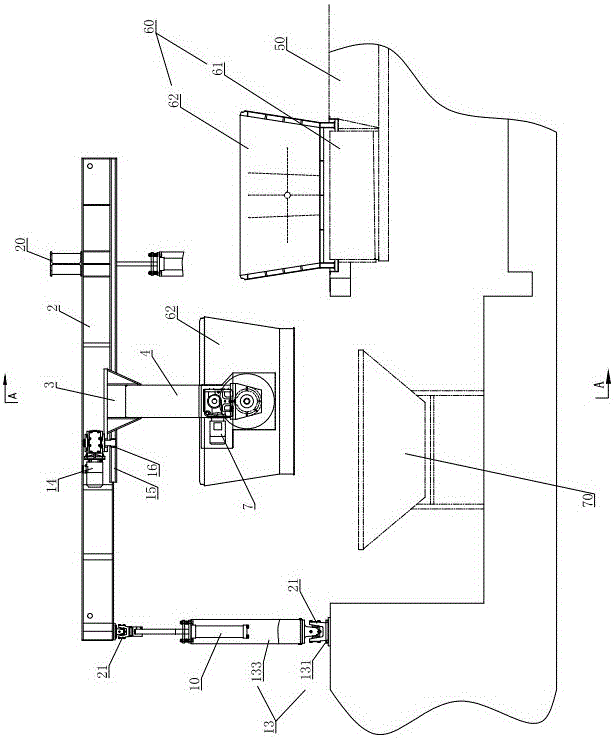

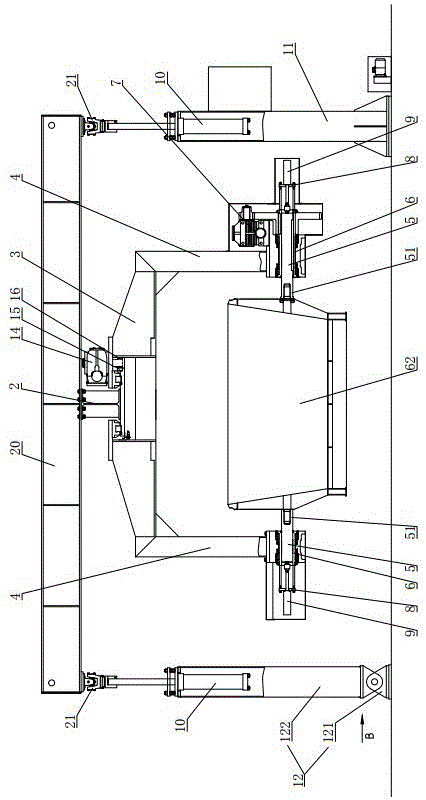

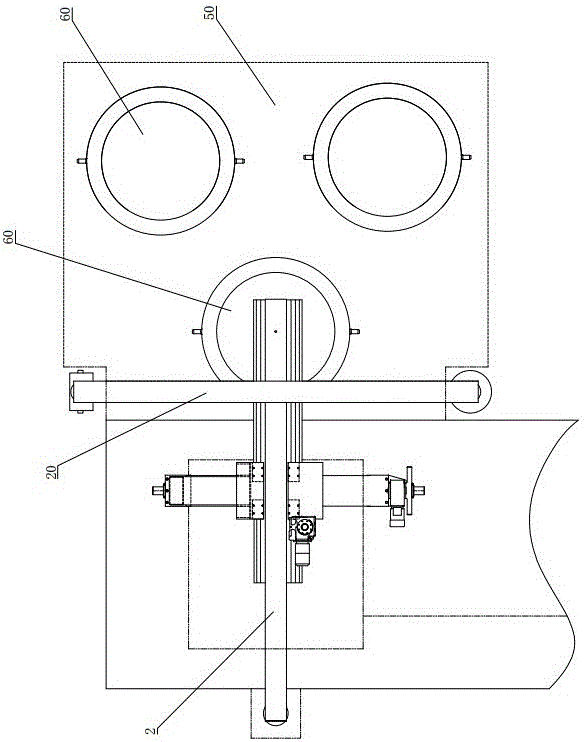

Automatic overturning retort unloading device

InactiveCN105132229AAutomatic retort unloadingComplete unloadingAlcoholic beverage preparationDrive shaftEngineering

The invention discloses an automatic overturning retort unloading device. The automatic overturning retort unloading device comprises a supporting frame; a beam which is driven to lift through a lifting power mechanism and is transversely arranged above a retort bucket and a feeding hopper is arranged on the supporting frame; the cross beam is connected with a walking frame which is driven to slide along the beam through a power walking mechanism; the walking frame is provided with two hanging arms which are arranged longitudinally and are arranged oppositely; drive shafts which are arranged horizontally and oppositely and can rotate and slide are correspondingly connected with the lower parts of the two hanging arms; a driving head which can be connected with a supporting column on the retort bucket is arranged at the inwards extending end of each drive shaft, wherein a retort overturning power device which drives the corresponding drive shaft to rotate is arranged on one hanging arm; a sliding driving device which drives each drive shaft to slide horizontally is arranged at the lower part of the corresponding hanging arm. The automatic overturning retort unloading device has the advantages that retorts can be overturned and unloaded automatically, and the retorts are unloaded thoroughly.

Owner:ANQIU YAOFA MACHINE

Tea fixation and stripping method

Owner:岳西十行机械设备有限公司

A mine transport vehicle

The invention discloses a mine transport vehicle, comprising a rectangular carriage and a supporting device installed under the rectangular carriage. The mine transport vehicle also comprises a railing device arranged on both sides of the rectangular car and a pushing device arranged on the bottom of the rectangular car. A reinforcing rib plate is fixedly connected with the rectangular car, a controller is fixedly connected with the rectangular car, and a power supply interface is arranged at the bottom end of the rectangular car. The invention has the advantages of simple structure and strongpracticability.

Owner:山东蒂辉机械设备有限公司

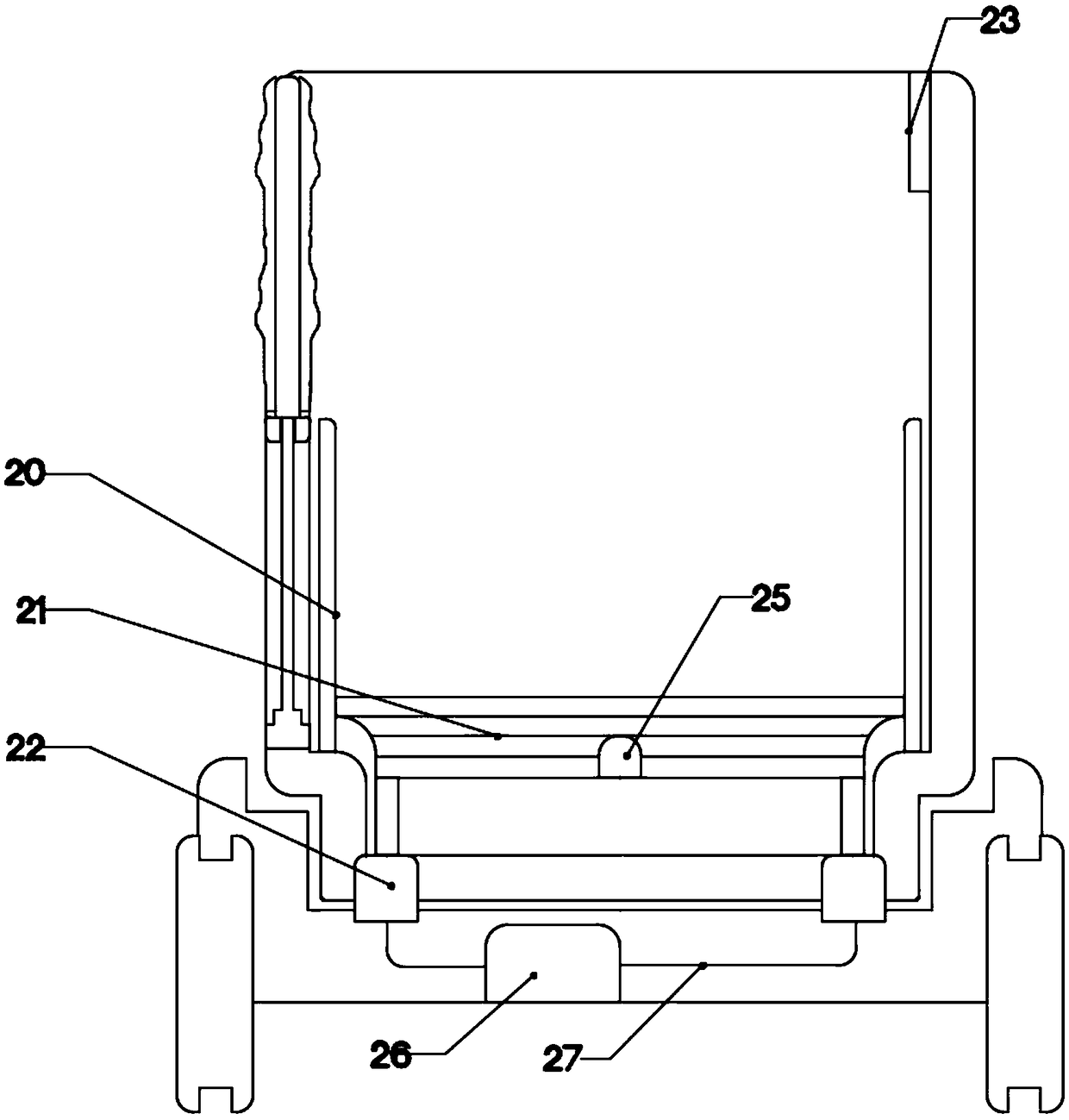

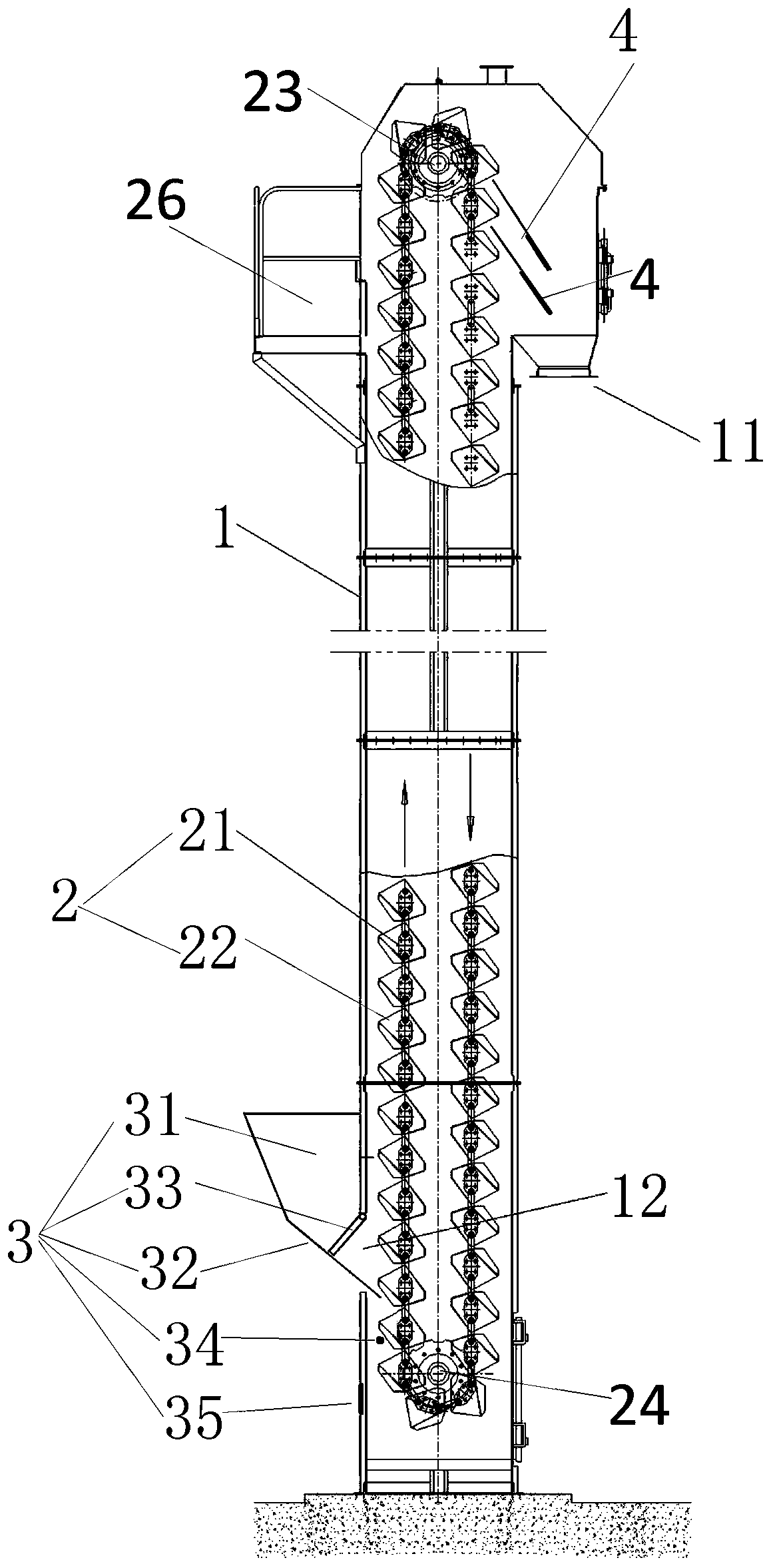

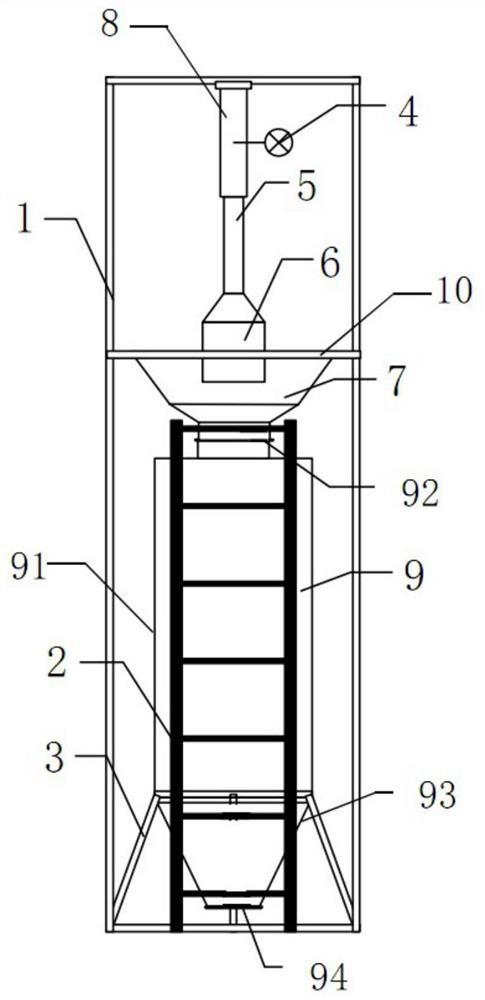

Bucket elevator

PendingCN110239879AAvoid accumulationReduce wearConveyorsControl devices for conveyorsEngineeringBucket elevator

The invention discloses a bucket elevator. The bucket elevator comprises a shell and a hopper component, wherein the hopper component is arranged in the shell, a discharging port is formed in the top of the shell, a feeding hole is formed in the bottom of the shell; the hopper component comprises a conveying part and a hopper, wherein a feeding assembly capable of feeding a proper amount of intermittent feeding to the hopper is arranged at the feeding port, and a material pouring soft plate capable of guiding materials from the hopper to the discharging port is arranged at the discharging port; the feeding assembly comprises a storage hopper, a feeding channel, an electric door, a sensor, and a controller, wherein the electric door is arranged at the joint of the storage hopper and the feeding channel, the sensor is arranged in the shell, and the controller is electrically connected with the sensor and the electric door; the material pouring soft plate is obliquely arranged, the upper end of the material pouring soft plate is located on the descending path of the hopper, and the lower end of the material pouring soft plate communicates with the discharging port. According to the bucket elevator, by arranging the feeding assembly which comprises a telescopic feeding guide plate and an electric door, material accumulation is effectively avoided, and the abrasion of the hopper is reduced; in addition, by arranging the material pouring soft plate, the discharging of materials is carried out thoroughly. The bucket elevator has the advantages of being simple in structure, convenient to install and easy to popularize.

Owner:福建福清万年青水泥有限公司

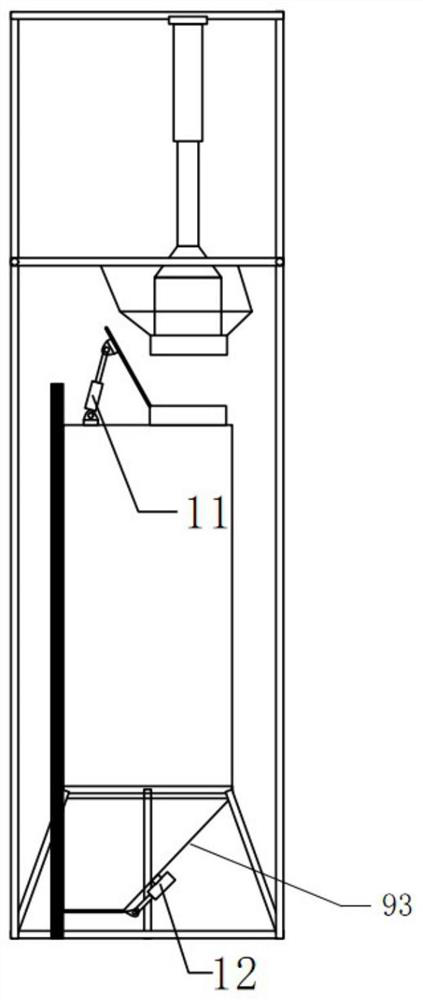

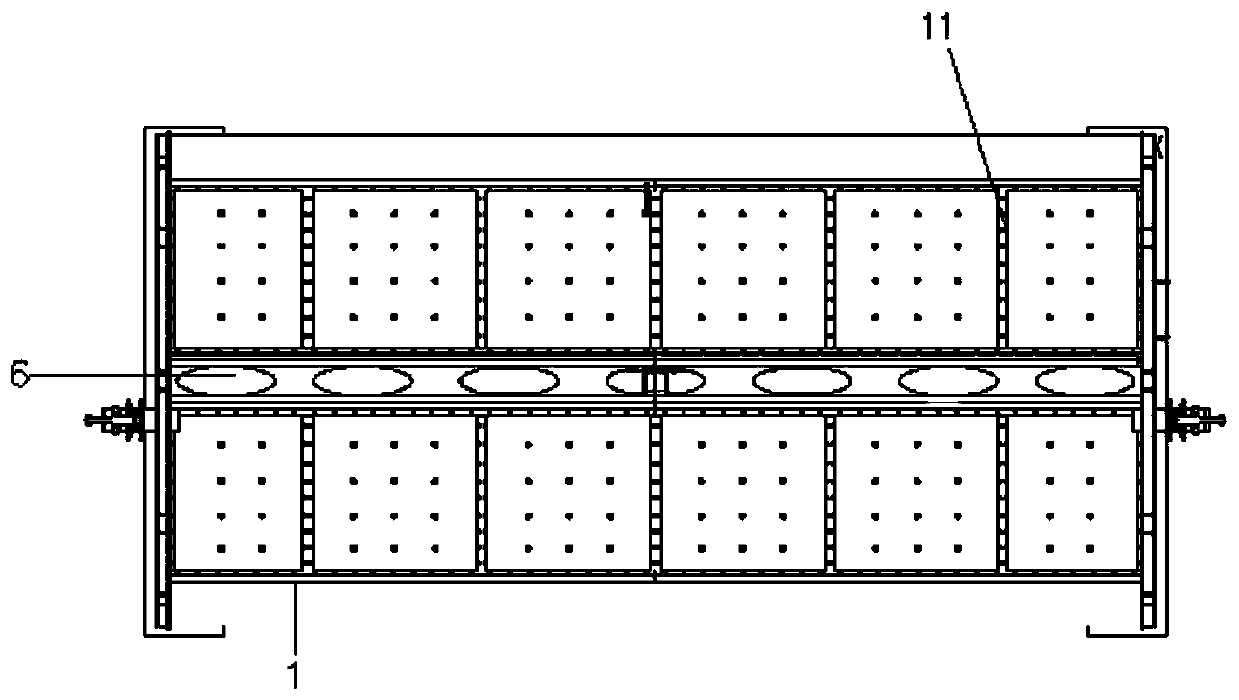

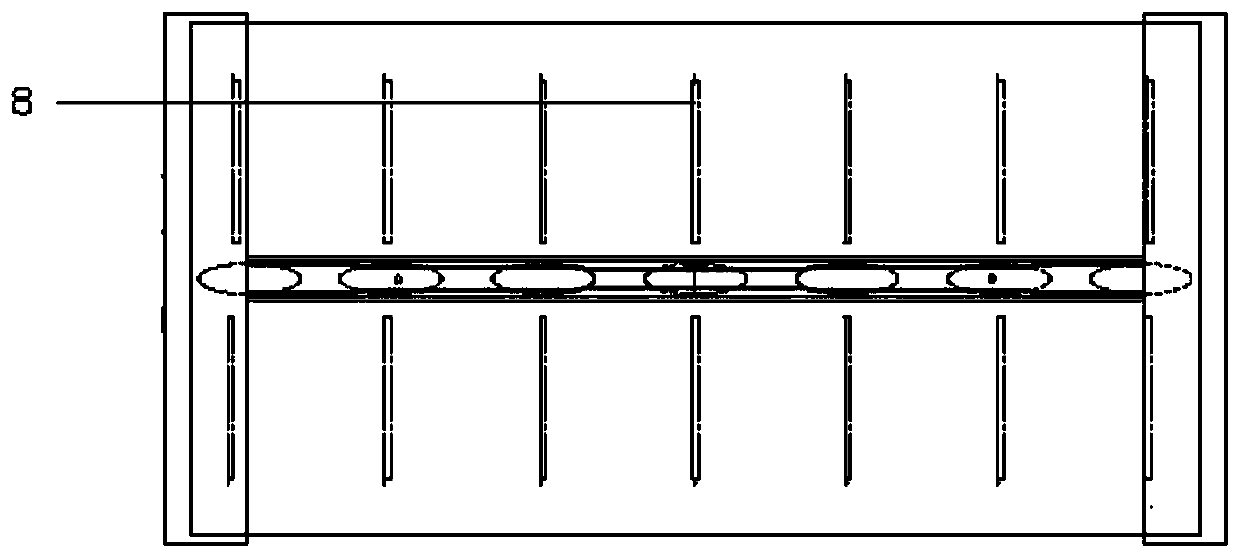

Fully-closed kitchen waste transfer platform

Owner:CHONGQING ENVIRONMENT & SANITATION GRP CO LTD

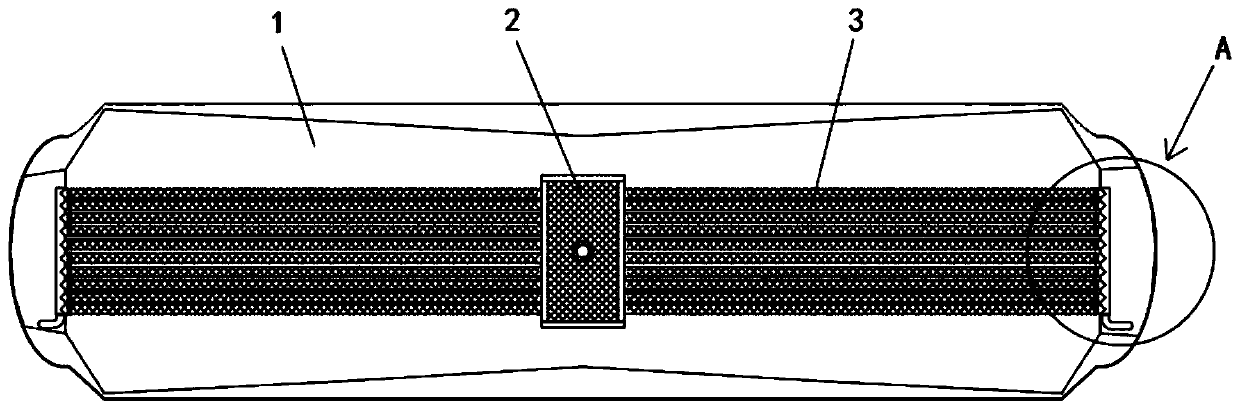

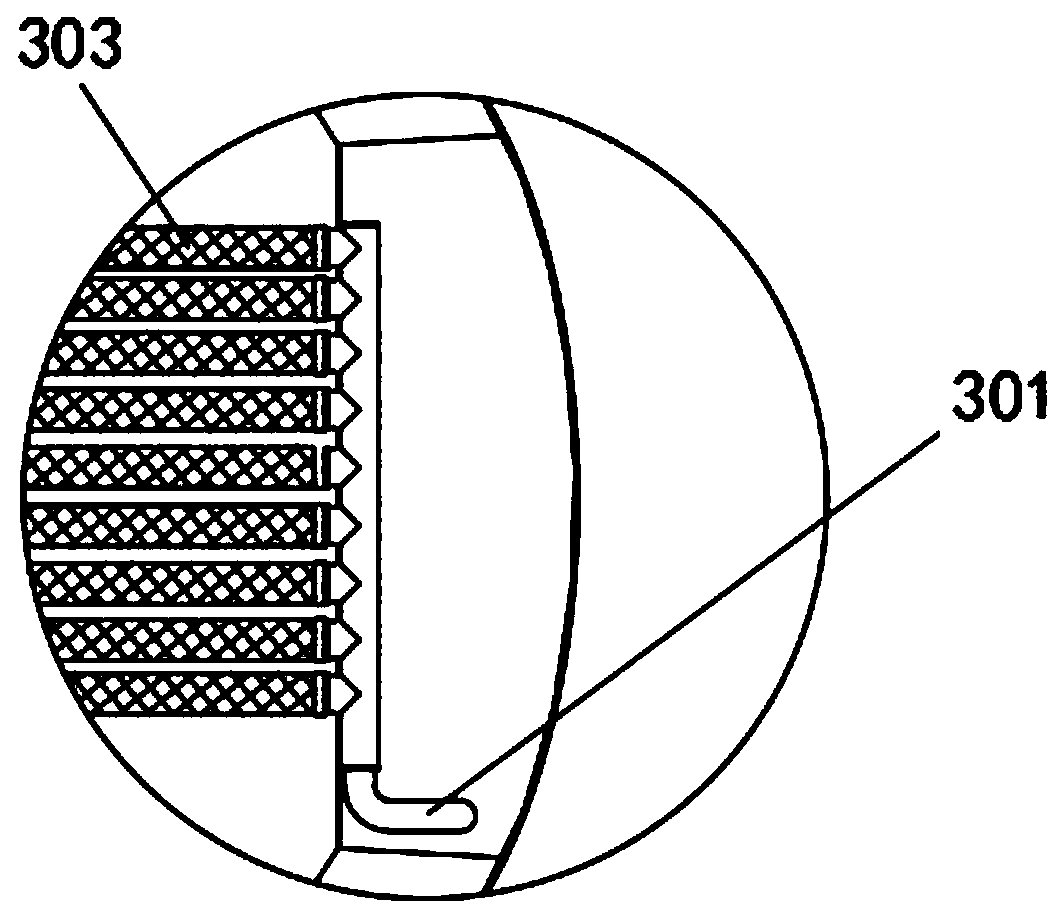

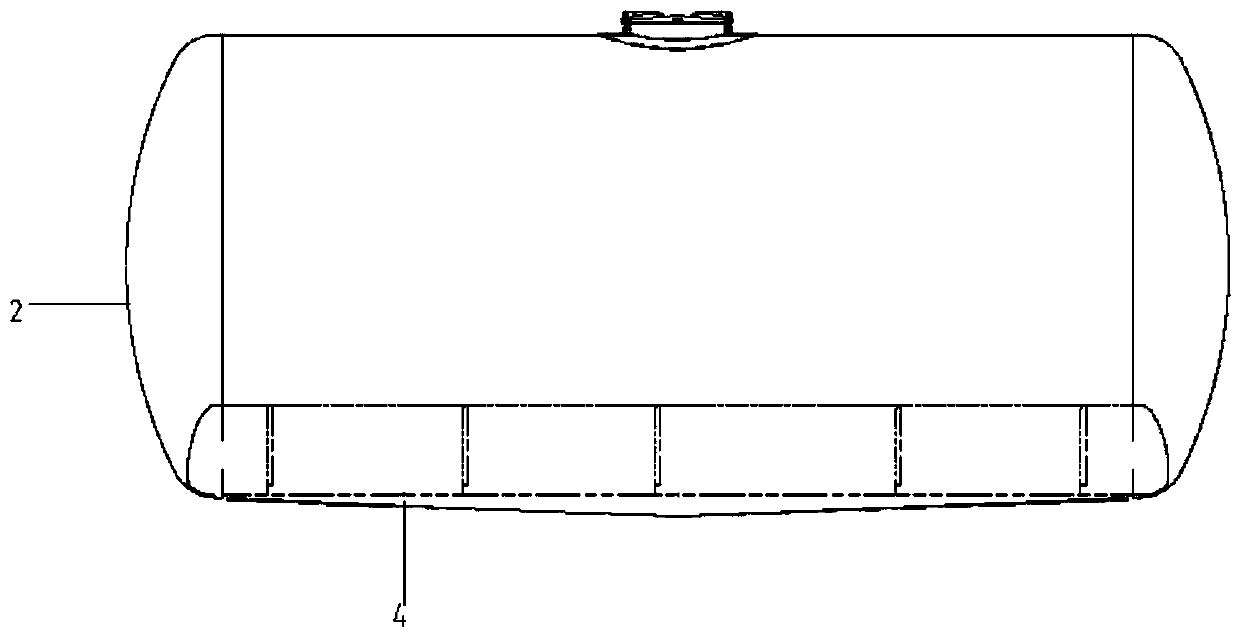

Fluidization device for powder tank-type container

PendingCN111470198AIncrease effective volumeImprove unloading efficiencyLarge containersEngineeringTank container

The invention provides a fluidization device for a powder tank-type container, and belongs to the field of transport equipment for particle materials. The invention provides a fluidization device fora powder tank-type container. The fluidization device for the powder tank-type container comprises a barrel body, sealing heads arranged at the two ends of the barrel body, and at least one group of fluidization beds, wherein a longitudinal flow guide body is arranged below the fluidization beds; the fluidization beds extend in the longitudinal direction of the barrel body; the fluidization beds are arranged in the barrel body; and an air chamber structure is formed between the fluidization beds and the barrel body. The invention provides a fluidization device for a powder tank-type container.The effects of fluidization and flow guide are acted simultaneously through the design of a fluidization bed structure, the in-tank effective volume is furthest increased, and moreover, the unloadingefficiency is increased.

Owner:靖江市亚泰物流装备有限公司

Low-consumption energy-saving reaction temperature-varying automatic-overturning crystallization kettle

InactiveCN107320995AGuaranteed temperatureReduce breakageSolution crystallizationHeat exchange cooling cystallizationBody axisReaction temperature

The invention discloses a low-consumption and energy-saving reaction temperature-changing self-turning crystallization kettle, which comprises a sealed box and a kettle body. The shaft and the fixed shaft, the rotating shaft and the fixed shaft are all integrated with the kettle body, the other end of the rotating shaft is rotatably installed on the side wall of the sealed box, and the other end of the fixed shaft is provided with a gear, and the gear and the fixed shaft are integrally cast Formed, the bottom surface of the kettle body is in the shape of a bowl, the main body of the kettle body is in the shape of a round platform with a large upper part and a smaller lower part, a motor is installed in the center of the top of the kettle body, and the output end of the motor is connected with a rotating rod extending into the interior of the kettle body. The device is equipped with an automatic turning device on the inner bottom of the sealed box. After the reaction is completed, the kettle body is turned over and unloaded, and the stirring blade is driven by the motor to scrape off the raw materials attached to the inner wall of the kettle, so as to avoid the raw materials remaining in the kettle body. The body is corroded and the loss of raw materials is reduced. The unloading method is simple and thorough.

Owner:苏天平

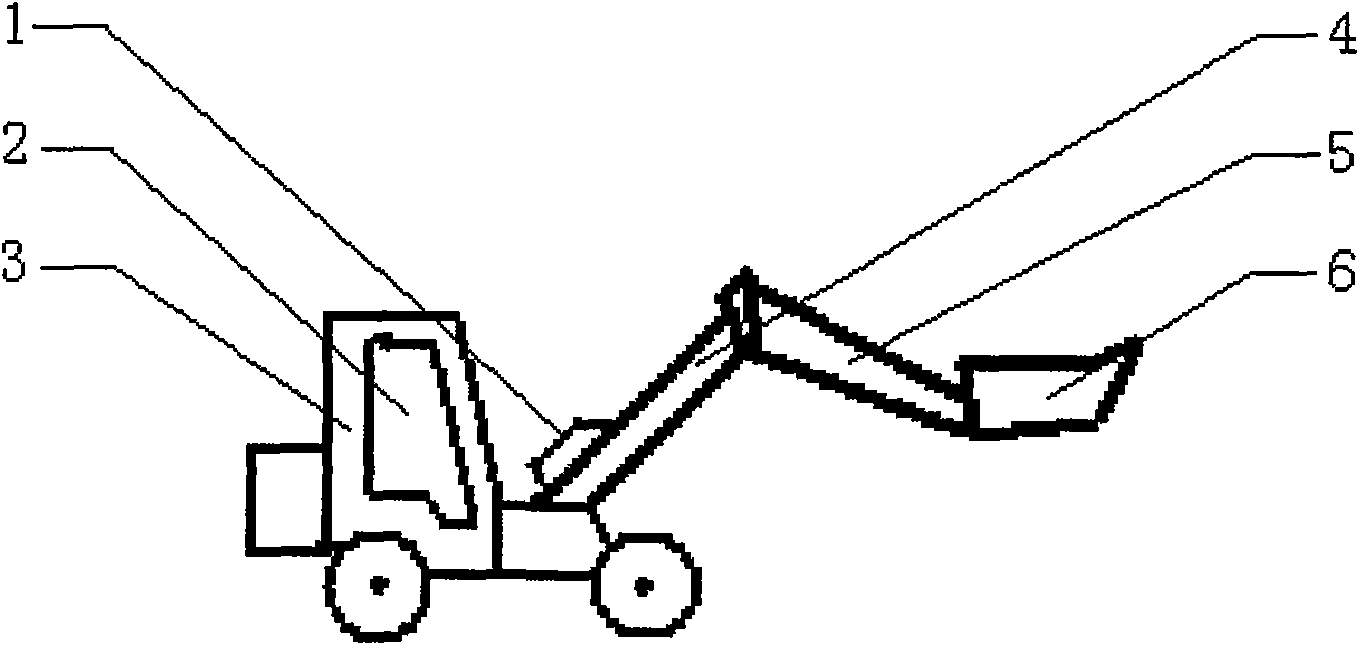

Loading vehicle with vibration exciting structure

InactiveCN101649626ASimple structureComplete unloadingMechanical machines/dredgersAutomotive engineeringTransmission system

The invention discloses a loading vehicle with a vibration exciting structure. The loading vehicle comprises a vehicle body, a transmission system, a shovel and the vibration exciting structure, wherein the transmission system consists of a speed changer and a drive axle, and the drive bridge consists of a front axle and a rear axle; the vibration exciting structure comprises a vibration exciter,a control switch and a wire; the vibration exciter is fixed on the front axle; the control switch is fixed on an operating table of a cab of a vehicle body; and the wire is connected with the vibration exciter, the control switch and a power supply in the vehicle body. The invention has simple structure; when in use, an operator turns on the control switch, and vibration force is transmitted to the shovel through the front axle and the rear axle by the vibration exciter so as to ensure that the shovel can easily shovel materials without consuming large force during shoveling the materials andquickly and thoroughly discharge the materials during discharging the materials. The invention is suitable for all loading vehicles.

Owner:CHENGDU YUZHONGMEI SCI & TECH CO LTD

A star unloader with clean discharge

ActiveCN112027674BImprove unloading efficiencyGood unloading effectBulk conveyorsRotary conveyorsDischarge efficiencyElectric machine

Owner:山东辉泰矿业有限公司

Waste battery classifying device

The invention discloses a waste battery classifying device. The waste battery classifying device comprises a device body and a classifying frame; a base is mounted at the bottom of the device body; mounting bases are mounted on two sides of the base; an observation window is embedded in the external side wall of the device body; the device body is connected with the classifying frame through a mounting table; a discharge port is formed in one side of the classifying frame; the device body is divided into a first-grade cavity, a second-grade cavity and a third-grade cavity by filter plates; vibrators are mounted at the bottoms of the filter plates; a storage table is embedded in the outer side wall of the device body; a hydraulic push plate is fixedly connected to the inner wall of the storage table; and a feed port is formed in the top center of the device body. The waste battery classifying device solves the problems of incapability of moving and stable installing, no function of oscillation unloading and no possession of disassembly convenience and push unloading, and improves the use convenience.

Owner:张一天

Blocking edge for belt conveyor and belt conveyor

The invention discloses a blocking edge for a belt conveyor, which consists of a scraping plate and baffles at the two ends of the scraping plate and integrally takes an I-shape. The invention further discloses the belt conveyor provided with the blocking edges. The belt conveyor comprises a plurality of blocking edges, the bottom surface of the scraping plate of each blocking edge is fixed on the surface of a belt, the baffles are vertical to the surface of the belt, and the number of the installed blocking edges enables the two sides of the belt are completely blocked by the baffles. The belt conveyor provided by the invention has the advantages of both a flat belt conveyor and a wave baffle belt conveyor, is relatively wide in application range, and is applicable to materials with characteristics including blocks, particles and various powder bodies. Compared with the flat belt conveyor with the same style, the belt conveyor is large in output and wide in scope of conveying angle and can convey vertically, and compared with the wave baffle belt conveyor, the belt conveyor is low in construction cost and convenient in fabrication and installation, and is attractive and elegant.

Owner:LIYANG CITY ZHENGXIANG PRECISION MACHINERY

Horizontal continuous microwave heating furnace special for powder and heating method

ActiveCN111526622ASimplify production stepsIncrease productivityOhmic-resistance heatingMicrowave heatingEngineeringHeating furnace

The invention provides a horizontal continuous microwave heating furnace special for powder and a heating method. The horizontal continuous microwave heating furnace comprises a plurality of heating units and cooling units horizontally connected with the heating units in series, wherein each unit is provided with a stirring shaft, a flange discharging pipe is arranged at the bottom of each unit, anon-metal movable baffle is arranged at the joint, a feeding pipe, an exhaust pipe and a microwave input pipe are arranged on a top furnace cover of the horizontal continuous microwave heating furnace, and supporting legs with joints and lifting cylinders are arranged at the bottom. The horizontal continuous microwave heating furnace is advantaged in that resistance heating and microwave heatingof powder can be achieved, a non-intermittent working route including feeding, heating, cooling and discharging is formed, a plurality of procedures can be conducted at the same time, production stepsare simplified, and production efficiency is improved.

Owner:株洲弗拉德科技有限公司

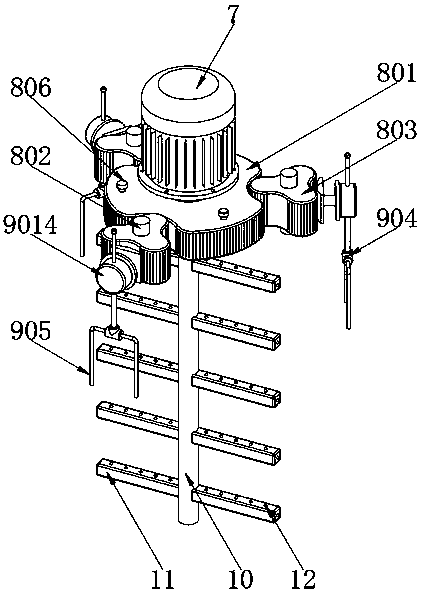

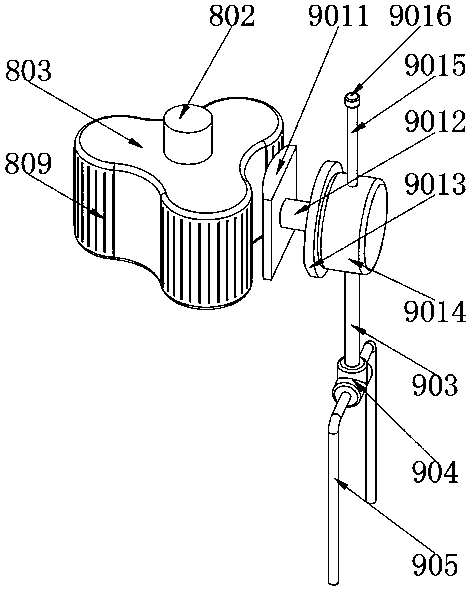

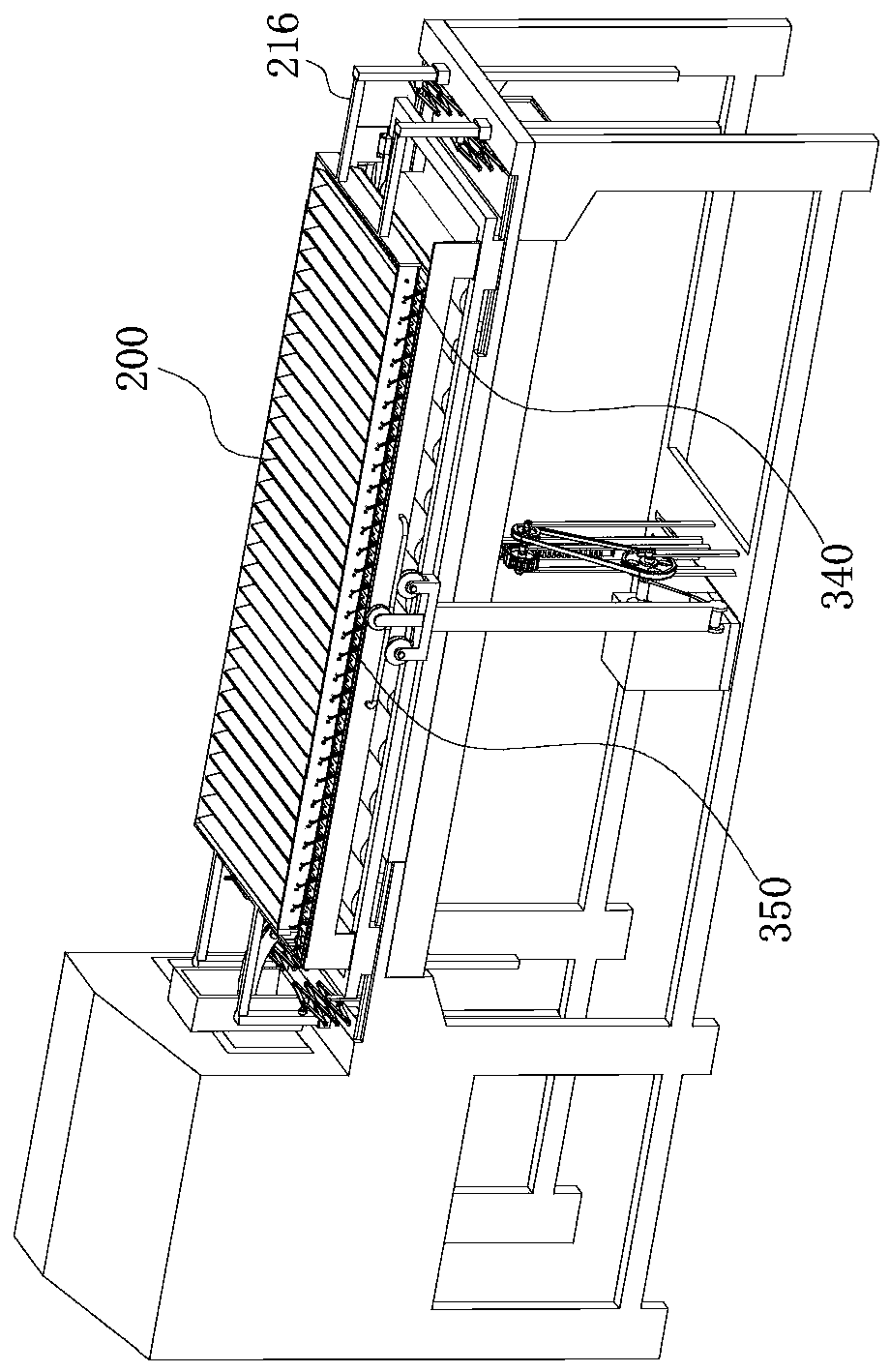

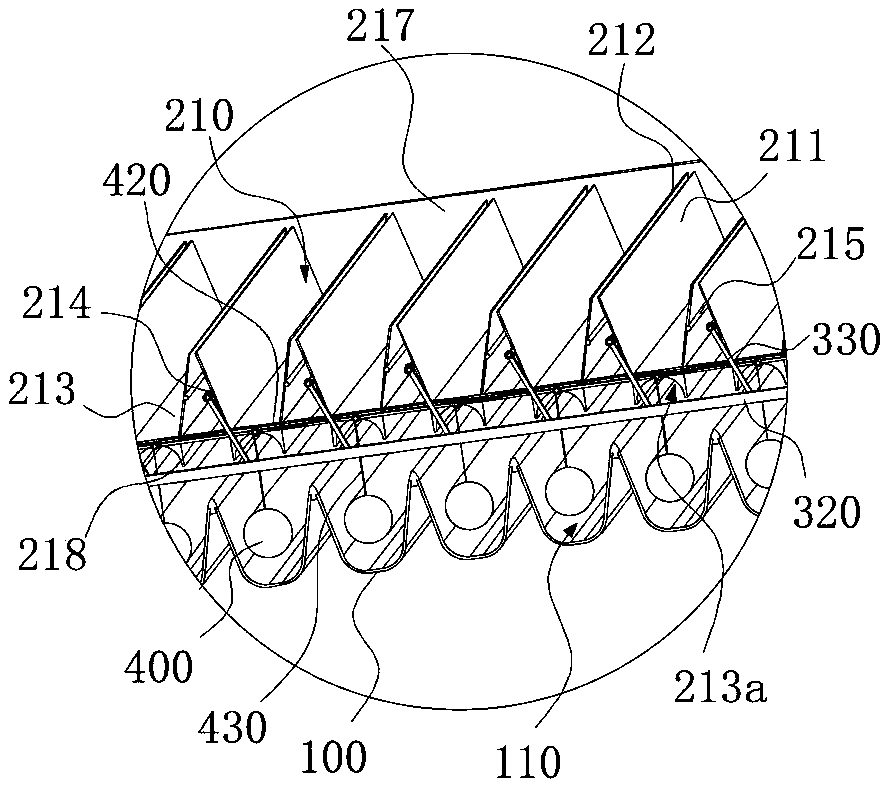

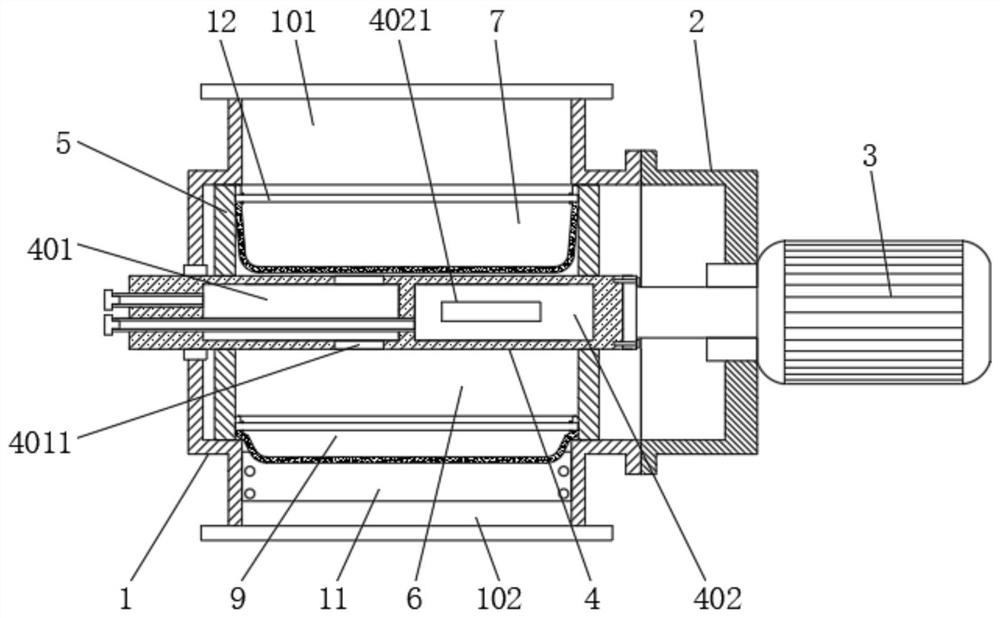

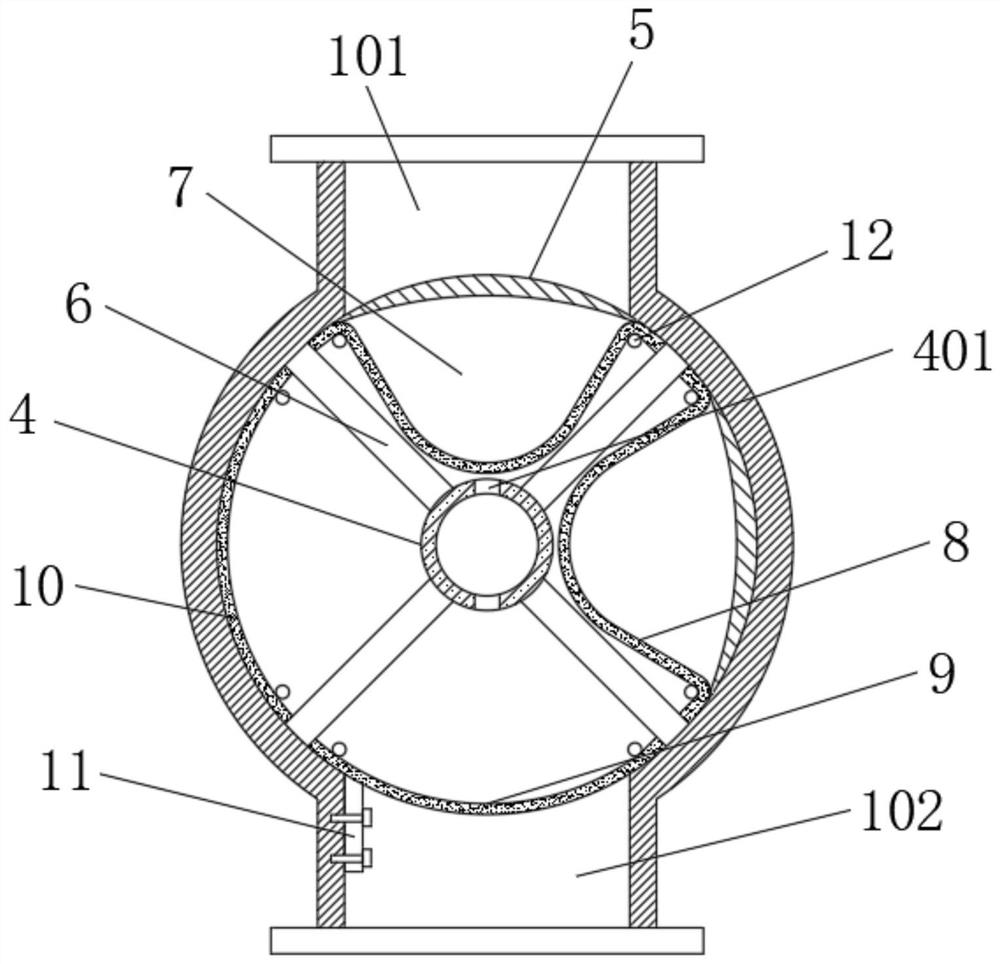

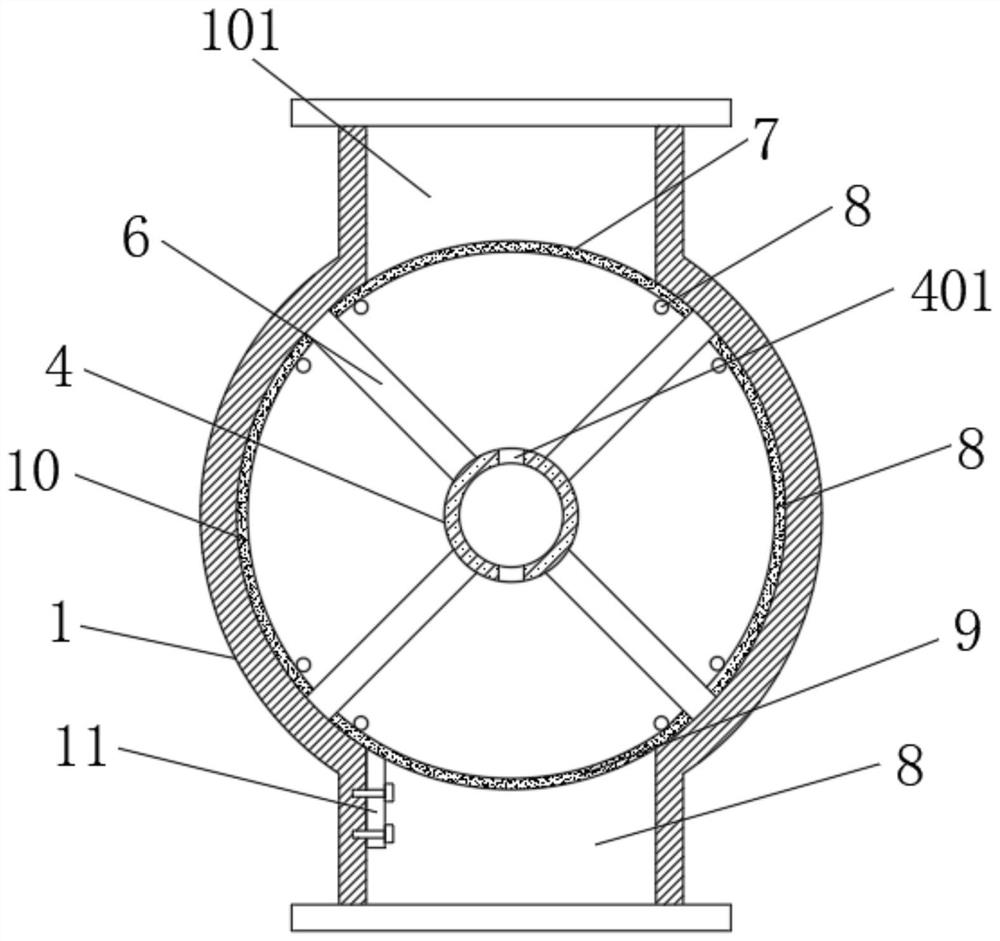

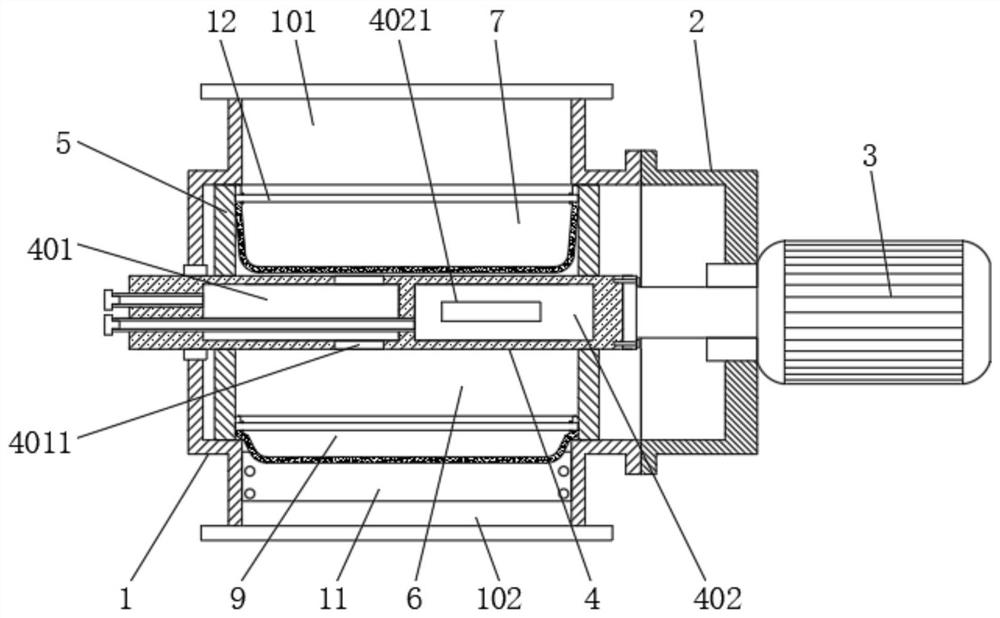

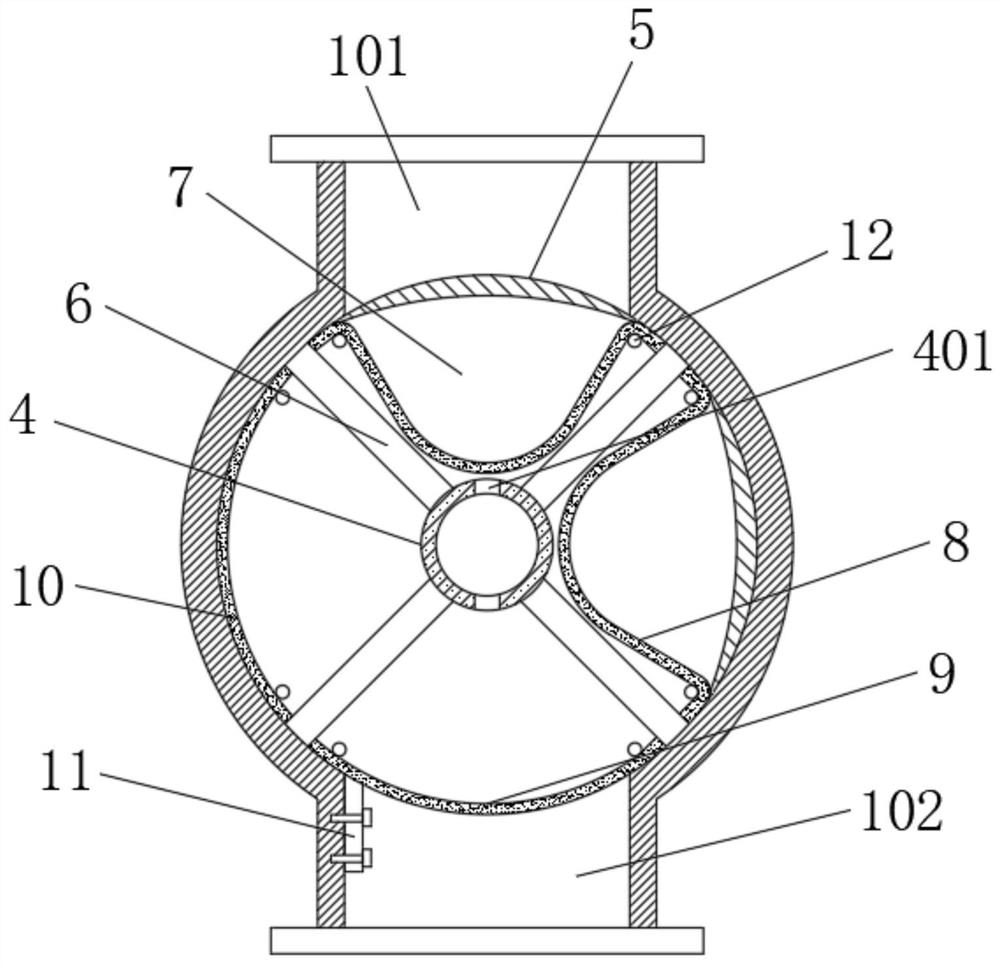

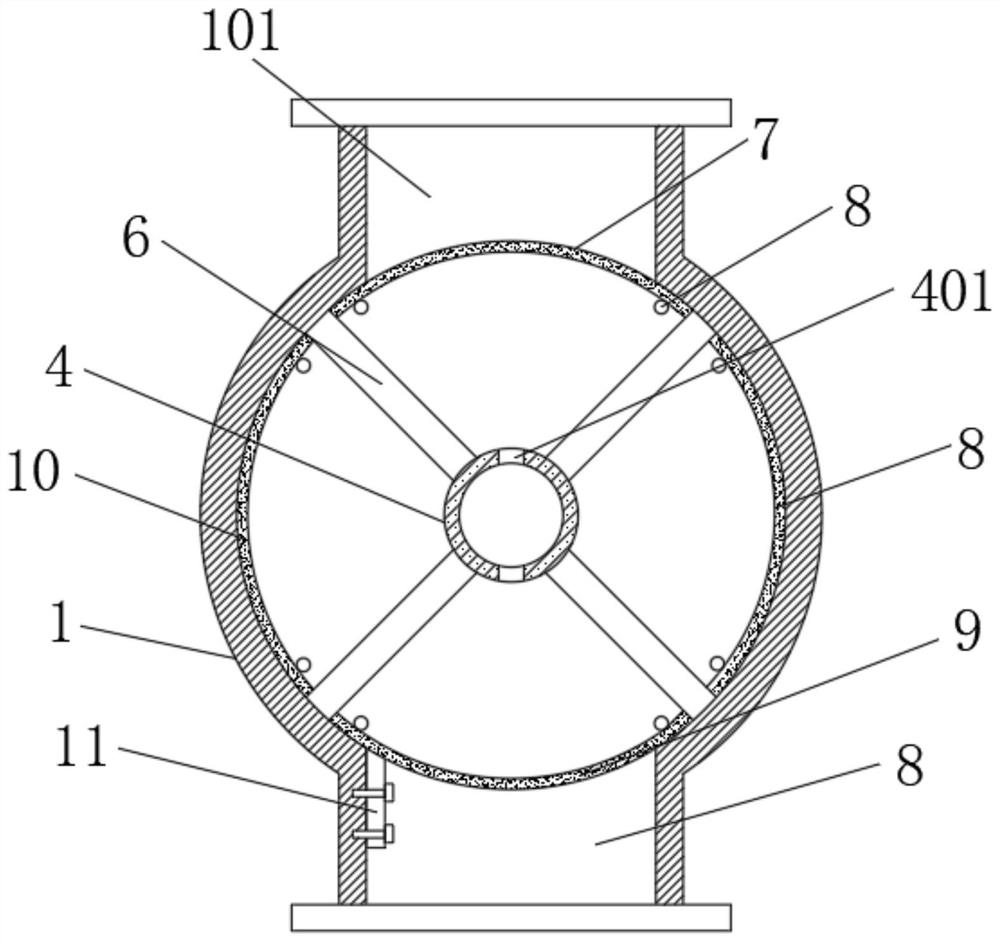

Star-shaped discharger capable of discharging cleanly

ActiveCN112027674AImprove unloading efficiencyGood unloading effectBulk conveyorsRotary conveyorsBlade plateDischarge efficiency

The invention relates to the field of discharging equipment, and discloses a star-shaped discharger capable of discharging cleanly. The star-shaped discharger capable of discharging cleanly comprisesa discharger shell, a feeding pipe, a discharging pipe, a side sealing cover, a driving motor, a rotating pipe and a first air bag film, wherein the side sealing cover is fixedly connected to one sideof the discharger shell through screws; the driving motor is fixedly mounted on the side surface of the side sealing cover; and an output shaft of the driving motor is fixedly connected with the rotating pipe located in an inner cavity in the middle of the discharger shell. According to the star-shaped discharger capable of discharging cleanly, the air bag films are arranged, and the spaces of each two opposite air bag films communicate at the same time, so that in the discharging process, materials in the first air bag film between two blade plates can conveniently and rapidly fall down in the rotating process, the problem that discharging is incomplete due to the fact that viscous materials are discharged slowly and cannot keep up with the rotating speed is also solved, discharging is more thorough under the premise of ensuring discharging efficiency, and the discharging efficiency and a discharging effect of the star-shaped discharger are further improved.

Owner:山东辉泰矿业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com