Patents

Literature

108 results about "Power walking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power Walking or speed walking is the act of walking with a speed at the upper end of the natural range for the walking gait, typically 7 to 9 km/h (4.5 to 5.5 mph). To qualify as power walking as opposed to jogging or running, at least one foot must be in contact with the ground at all times (see walking for a formal definition).

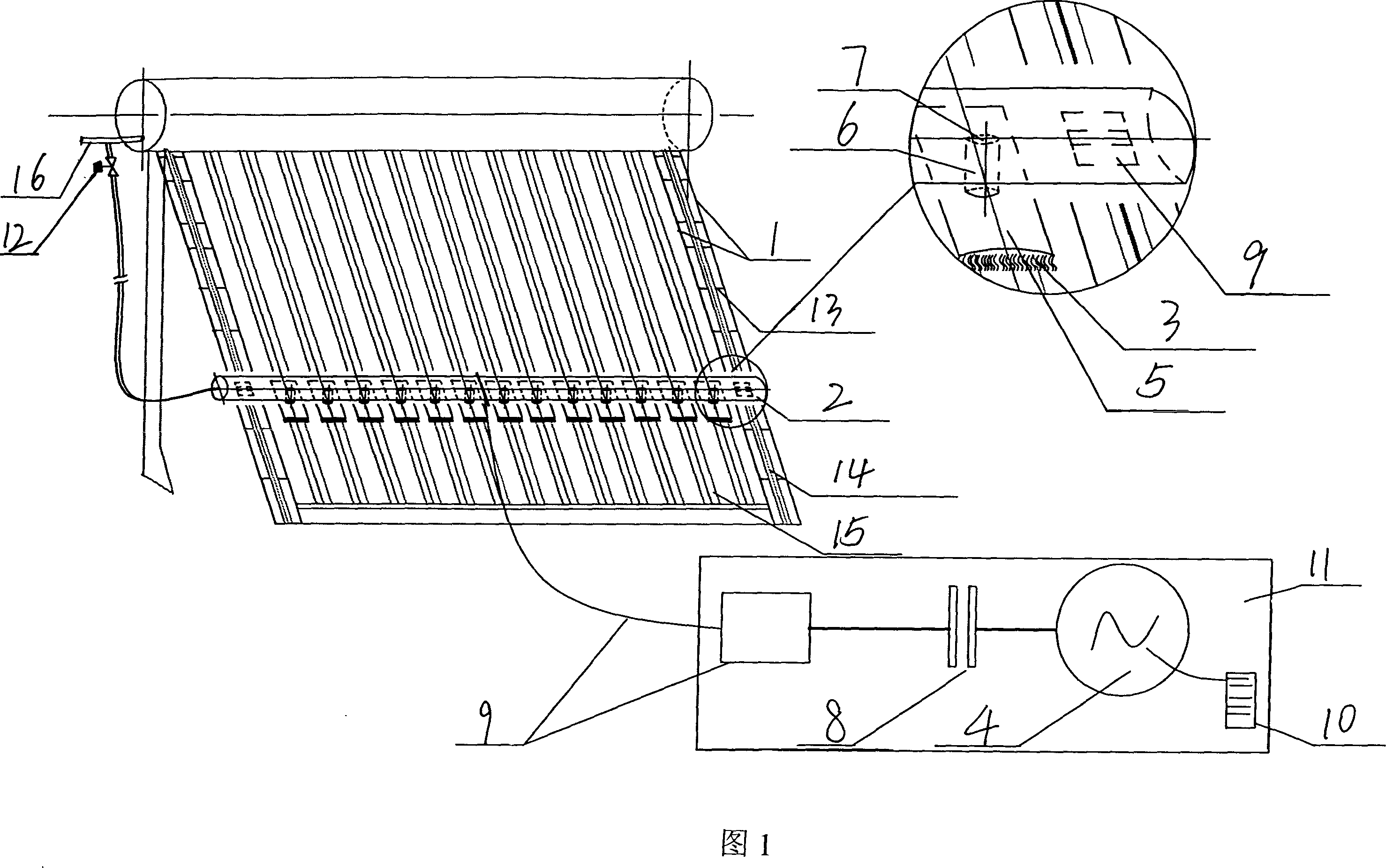

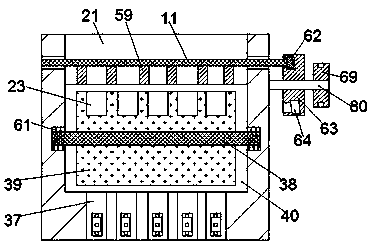

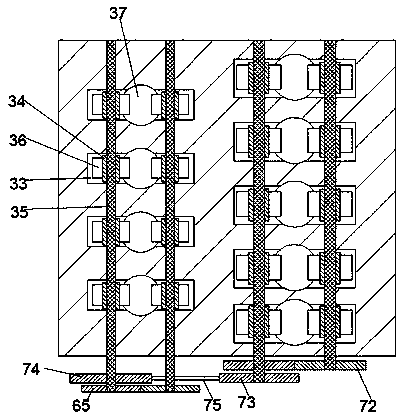

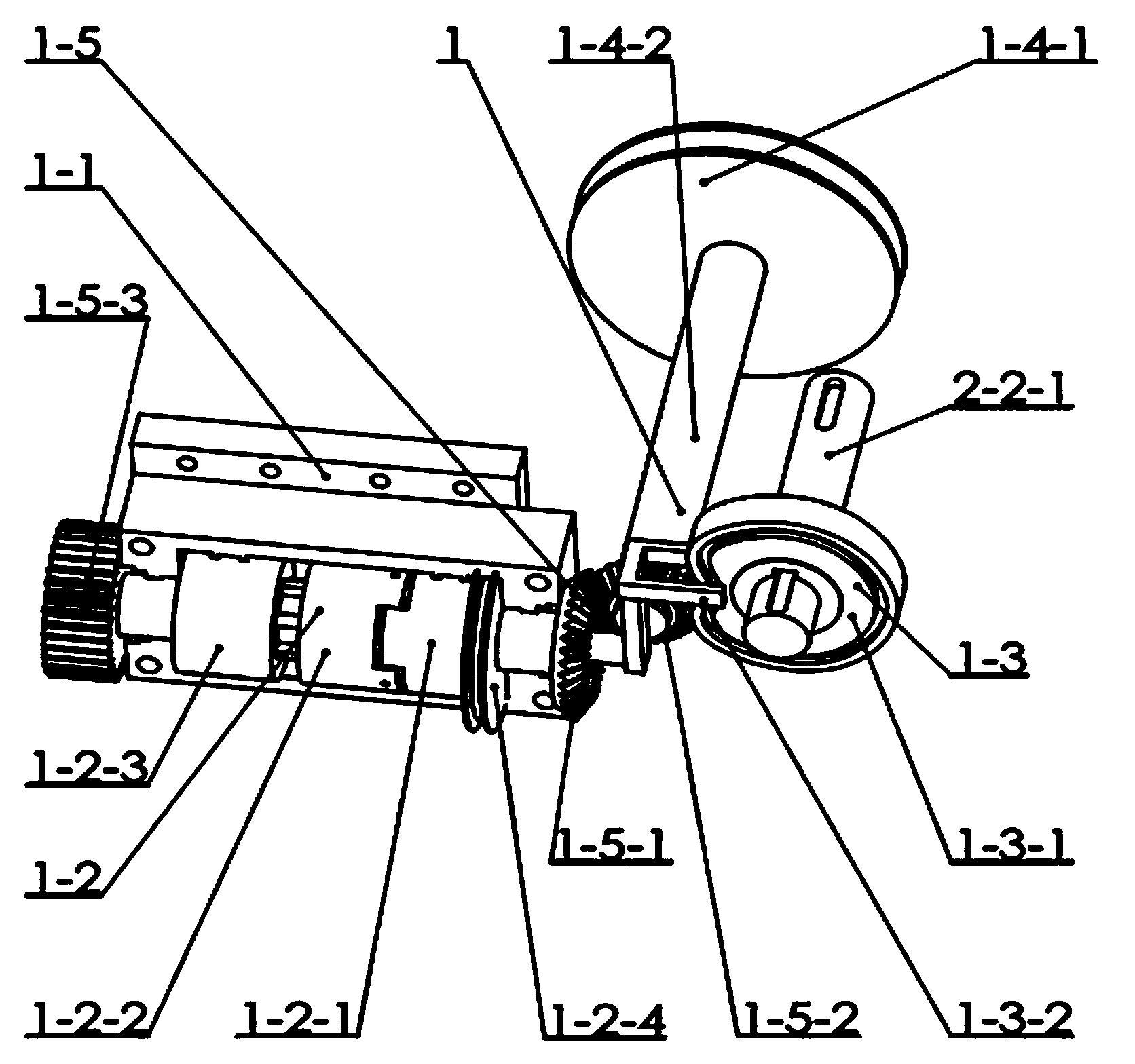

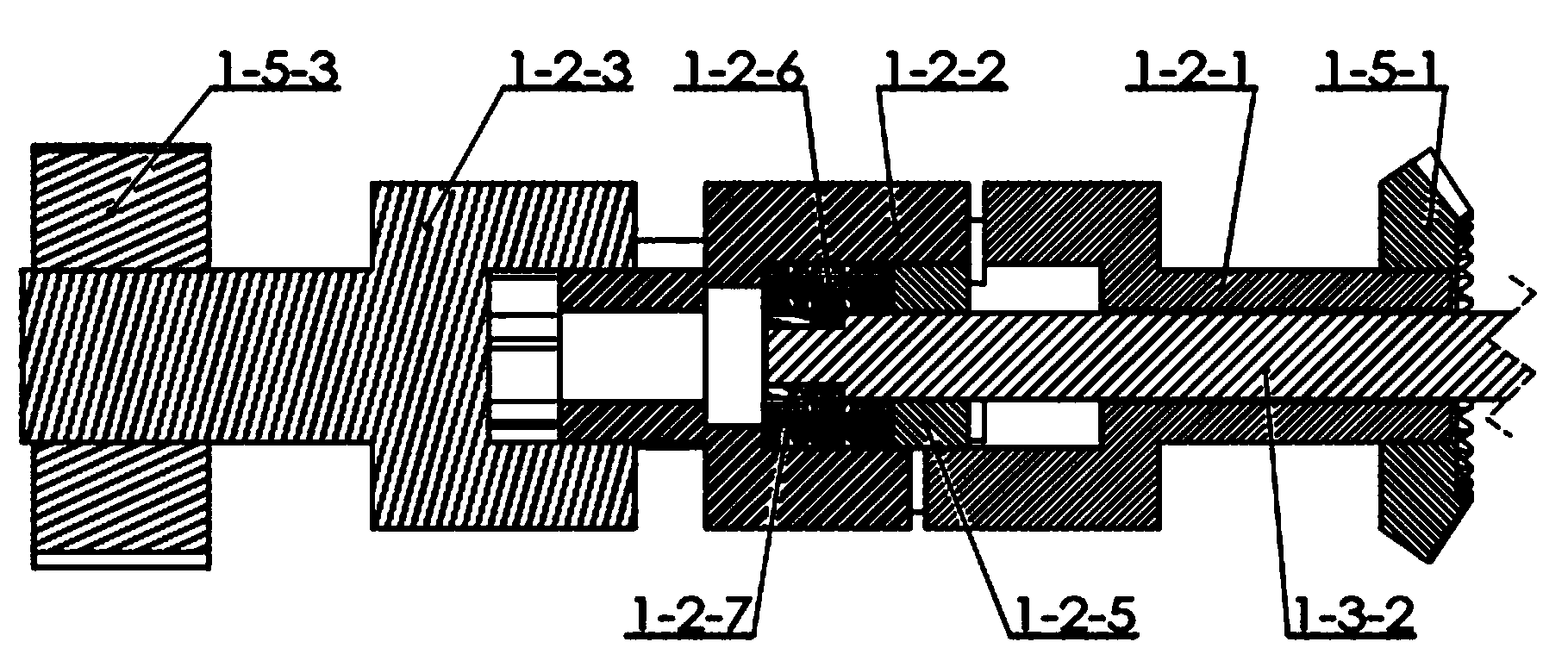

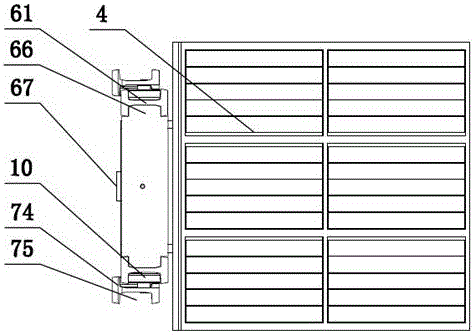

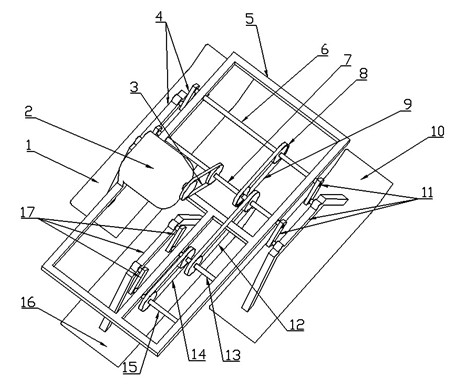

Solar vacuum tube heat-collector superficial dust automatic cleaning device

InactiveCN1970175ASolve the heatEasy to cleanSolar heating energySolar heat devicesCollector deviceEngineering

The automatic cleaning device for the accumulated dust on the surface of the solar vacuum tube heat accumulator comprises the track on the heat accumulator along its surface, sliding bar moving up and down on the said surface along the track, with soft wiping block on the slide bar connecting with the solar vacuum tube, and drive moving device moving up and down along the solar heat accumulator surface driven by the electric motor reacting with the said surface on the slide bar with good solution for the heating issue due to accumulated dust on the vacuum tube surface, with simple structure, safe, reliable and good dust eliminating effect.

Owner:ZHONGYUAN ENGINEERING COLLEGE

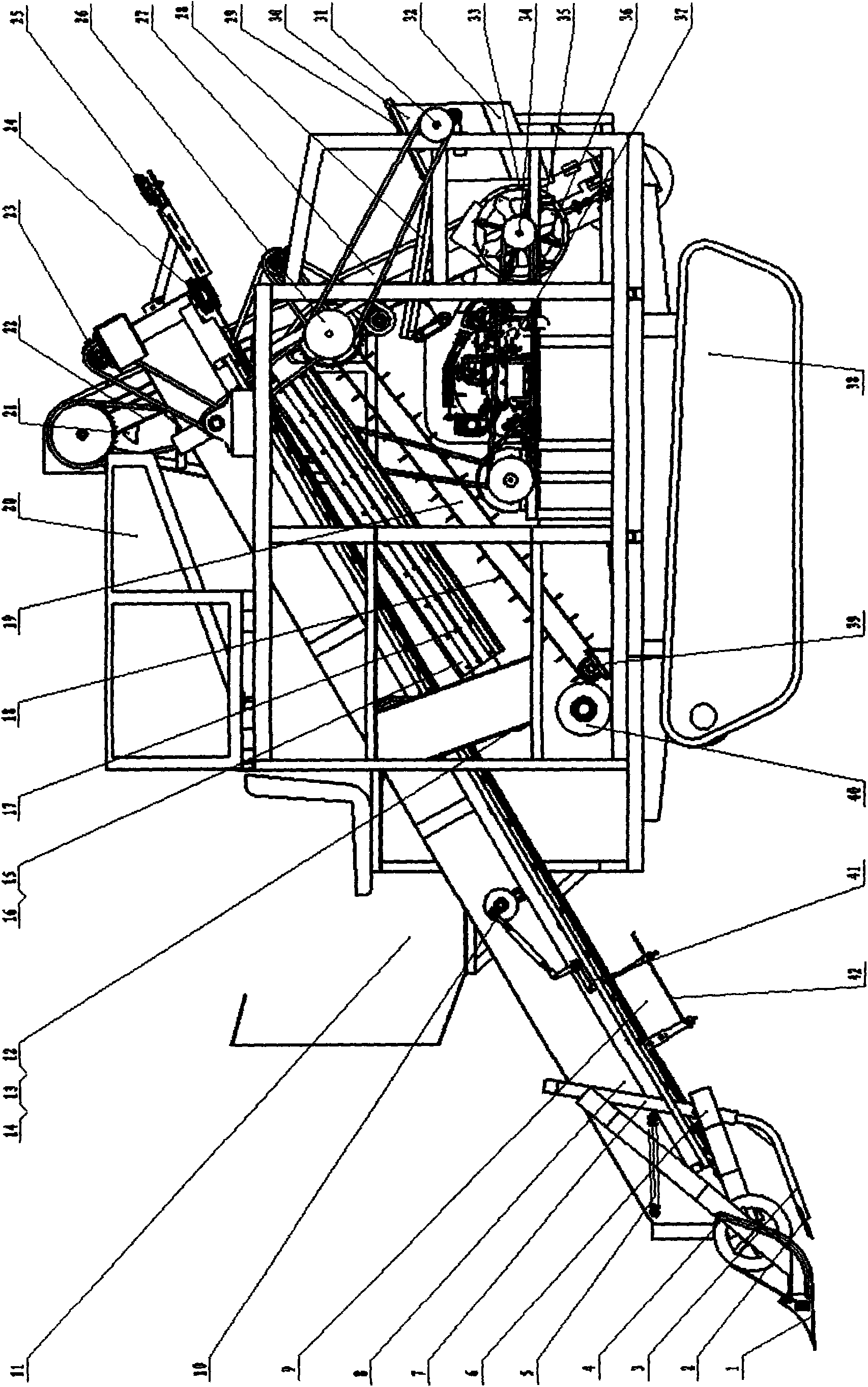

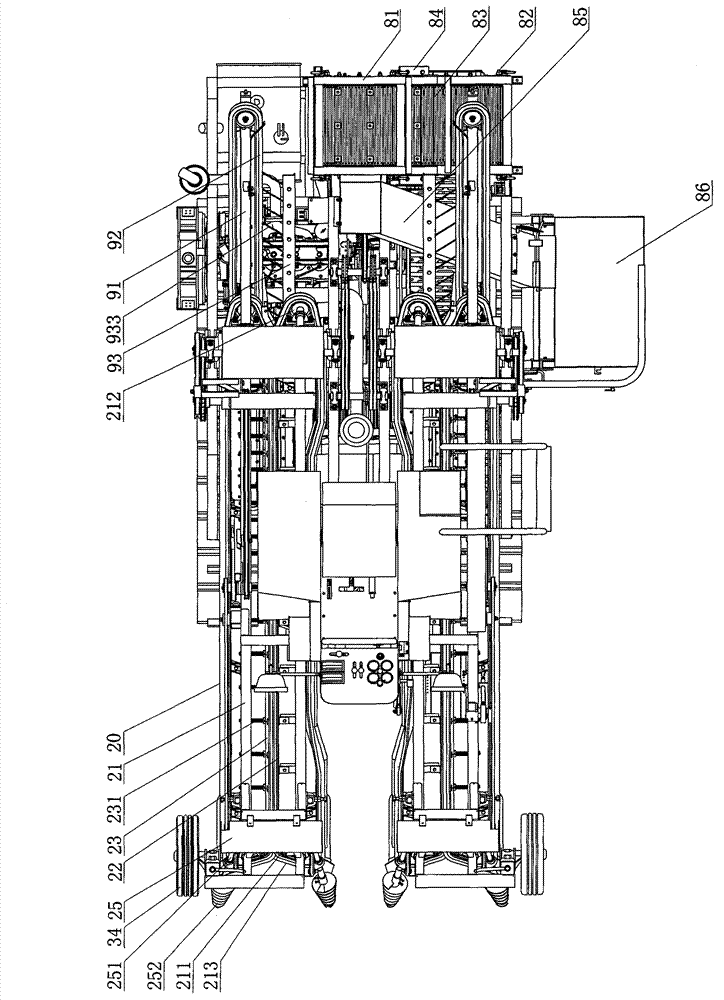

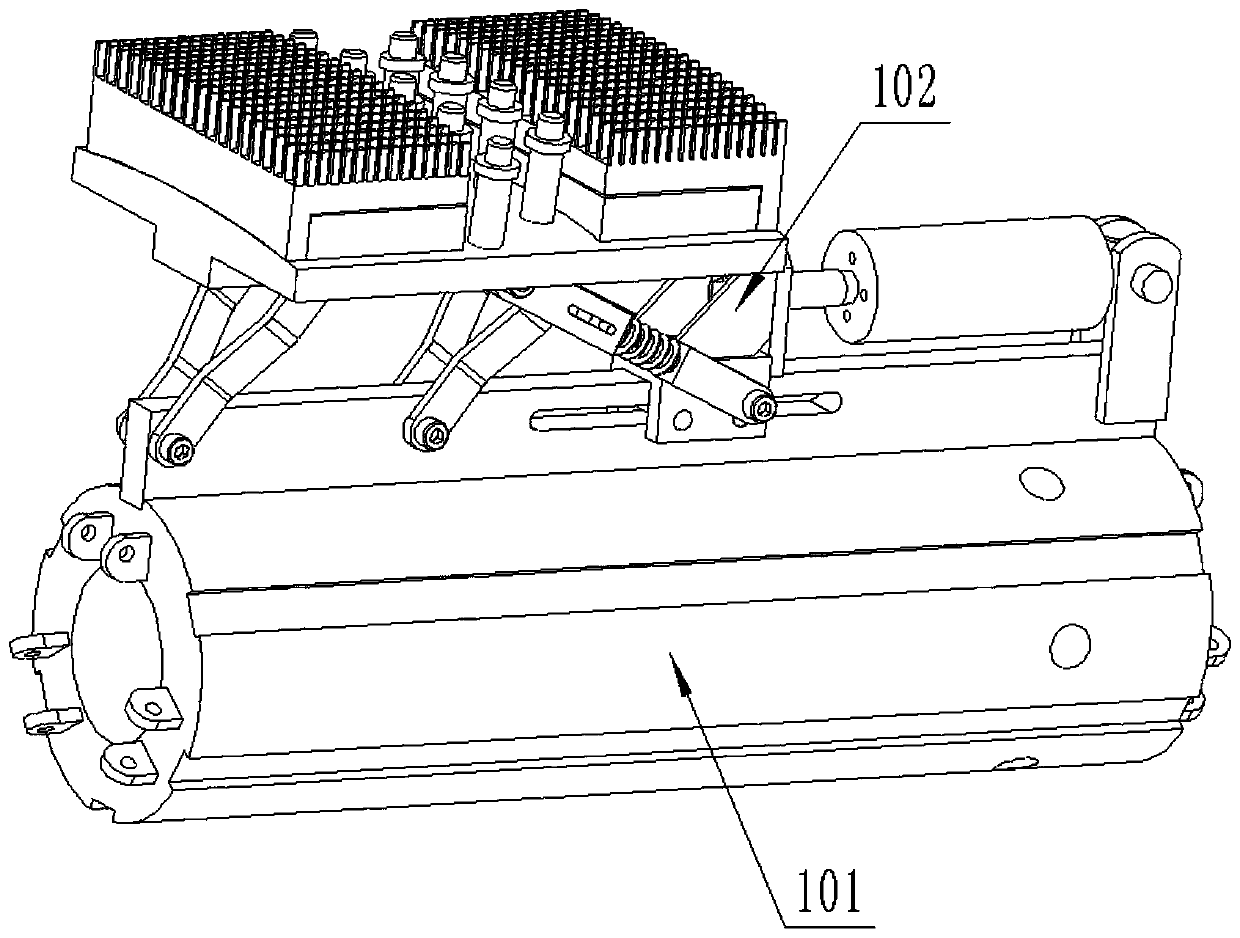

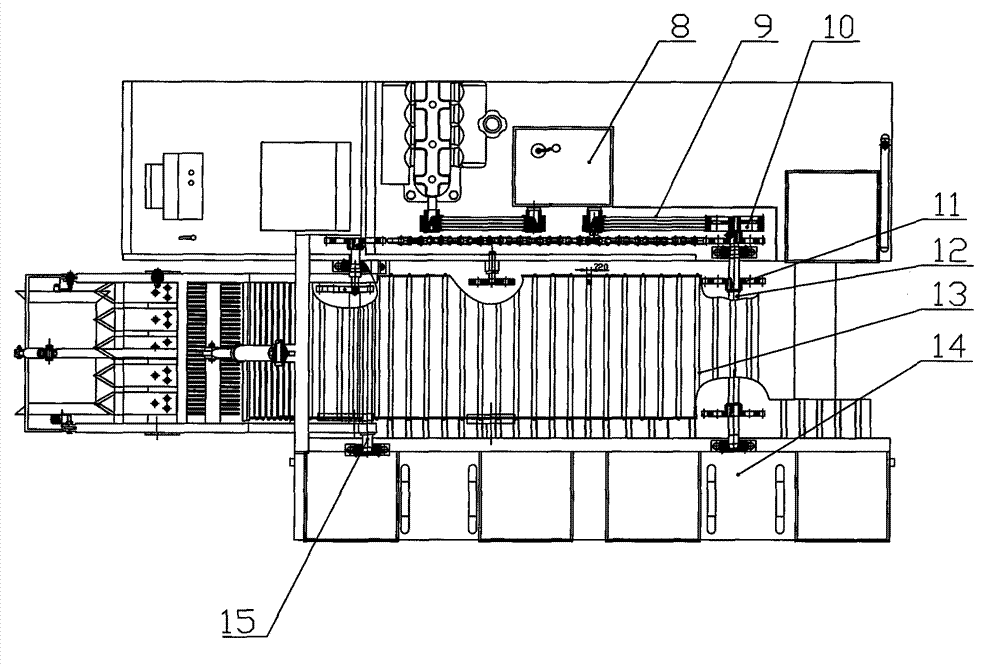

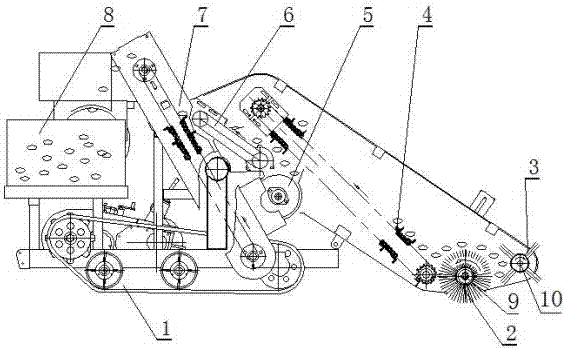

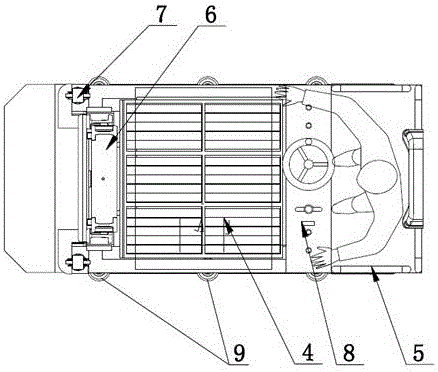

Peanut combine harvester

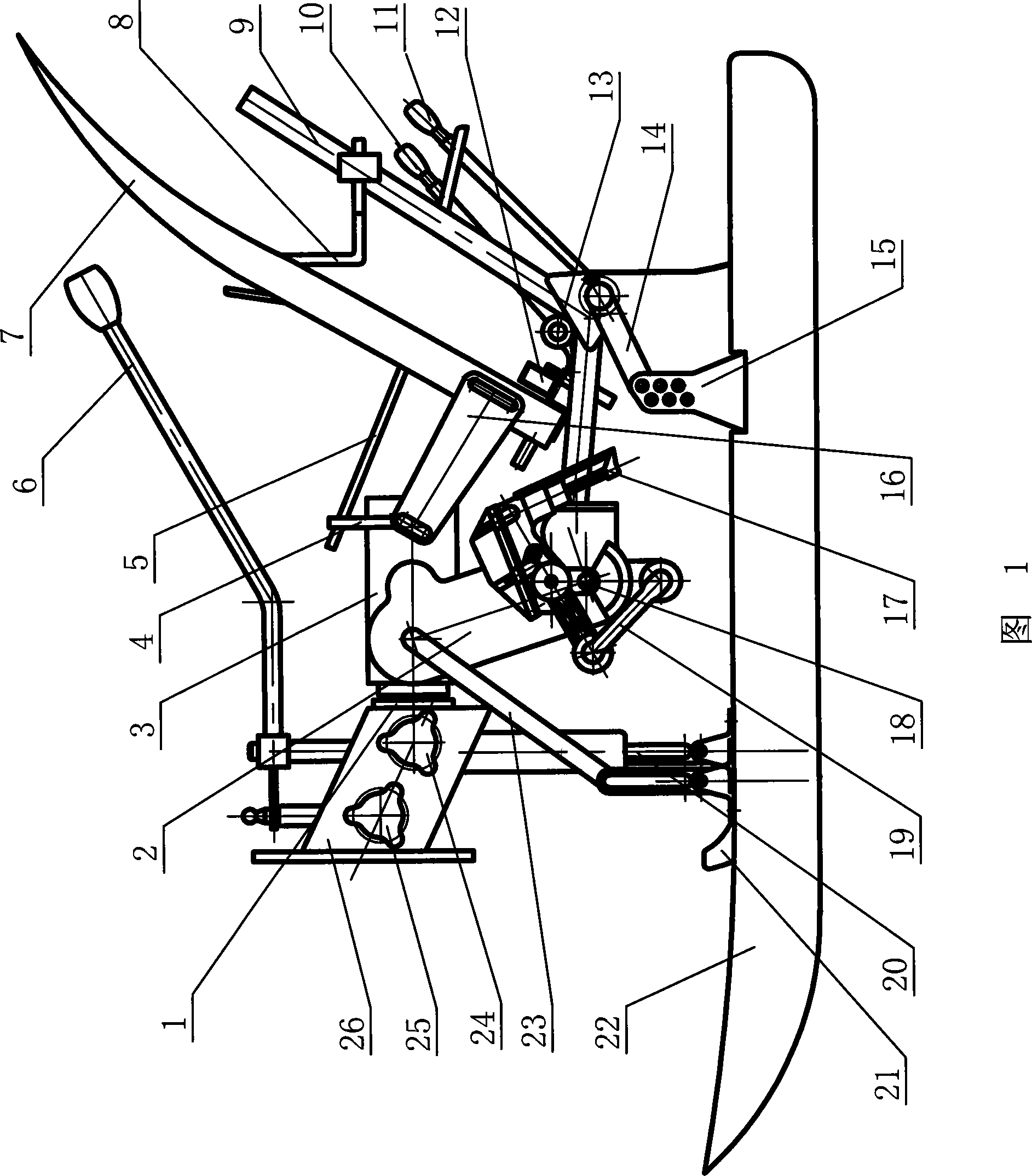

The invention relates to a peanut combine harvester. A harvester body is provided with a power travelling mechanism, a digging mechanism, a clamping-conveying mechanism, a peanut picking mechanism, a cleaning mechanism and an elevating-storing mechanism, wherein the power travelling mechanism is arranged at the lower part of the harvester body; the clamping-conveying mechanism is arranged at the upper part of the harvester body; the digging mechanism is arranged at the front end part of the clamping-conveying mechanism; a soil patting mechanism and the peanut picking mechanism are arranged at the lower part of the clamping-conveying mechanism in sequence; the cleaning mechanism is arranged at the rear part of the clamping-conveying mechanism; the elevating-storing mechanism is arranged at one side of the harvester body; and the power input shafts of the clamping-storing mechanism, the peanut picking mechanism and the cleaning mechanism are connected with a power mechanism through a power transmission device. With the peanut combine harvester, the working efficiency and the working quality are improved.

Owner:QINGDAO AGRI UNIV +1

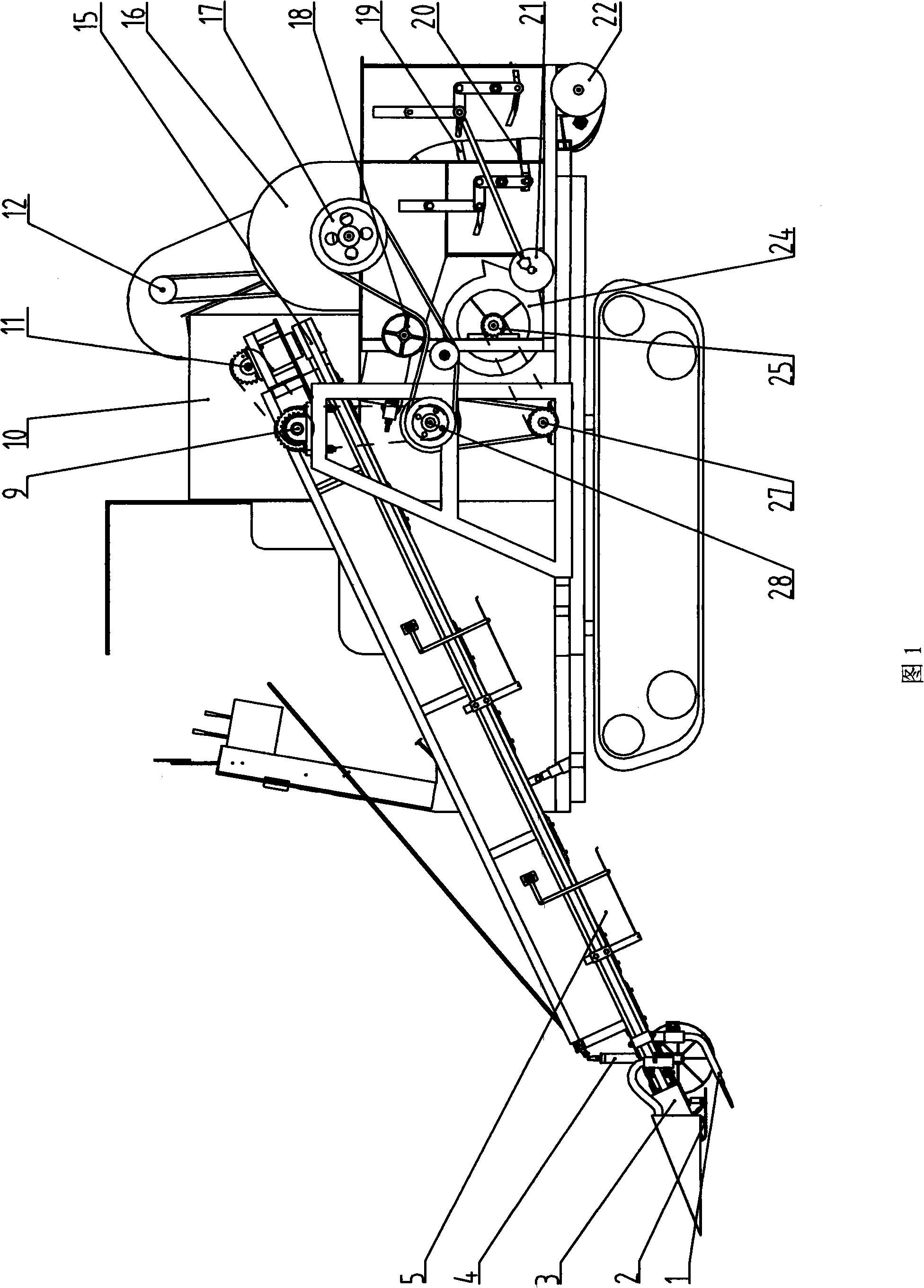

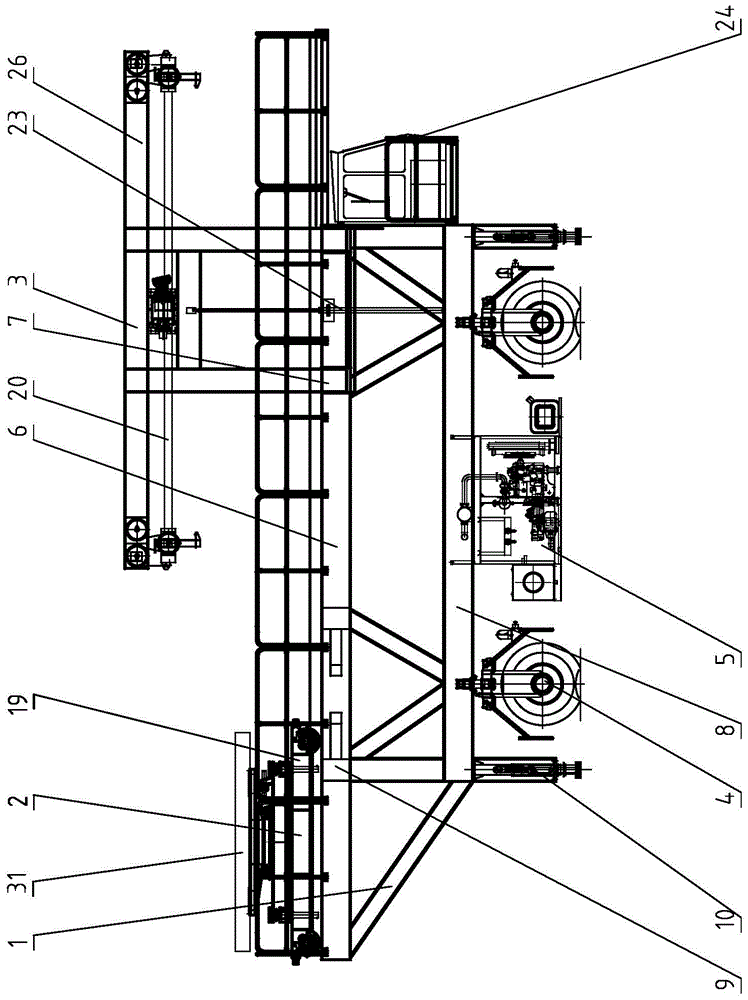

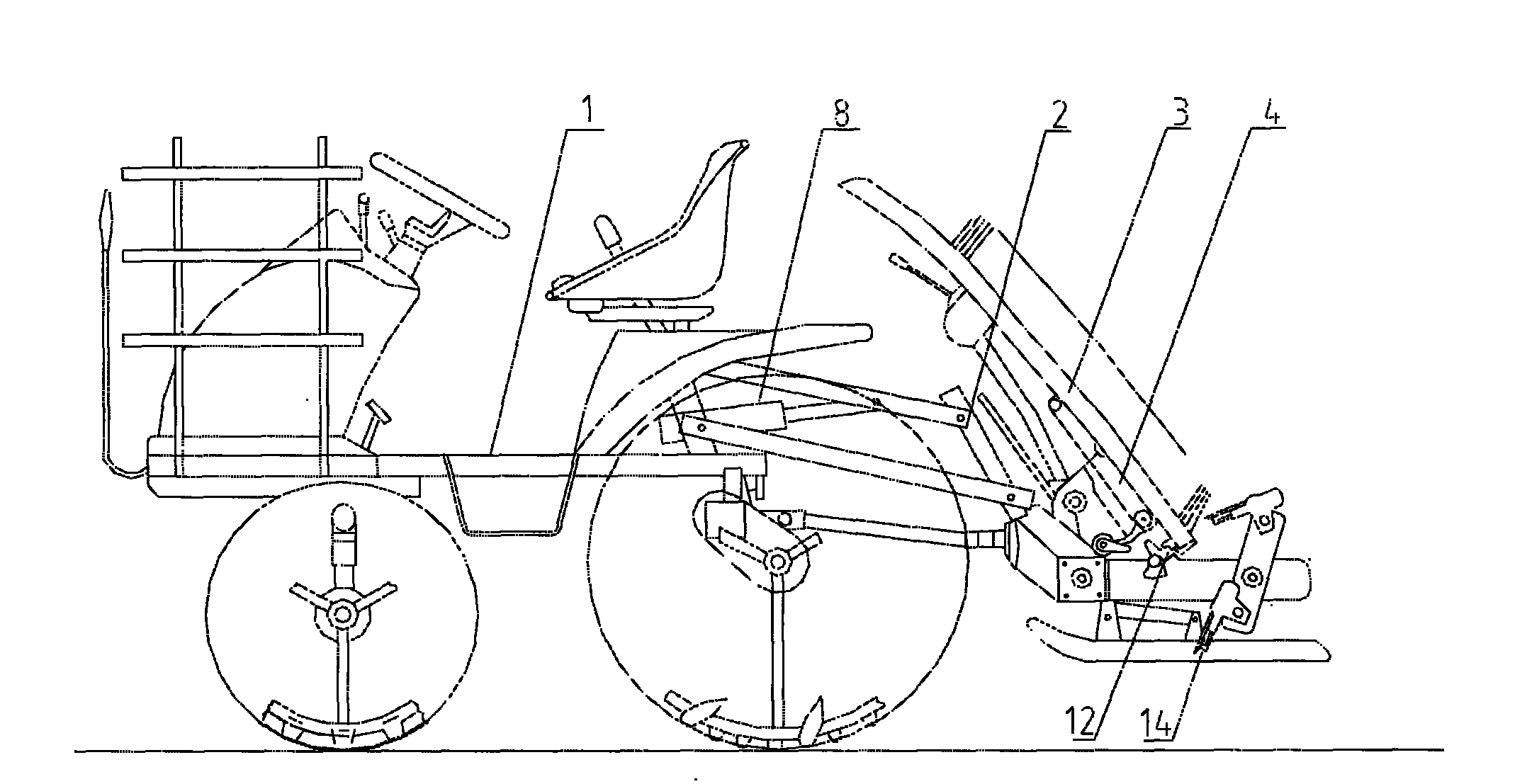

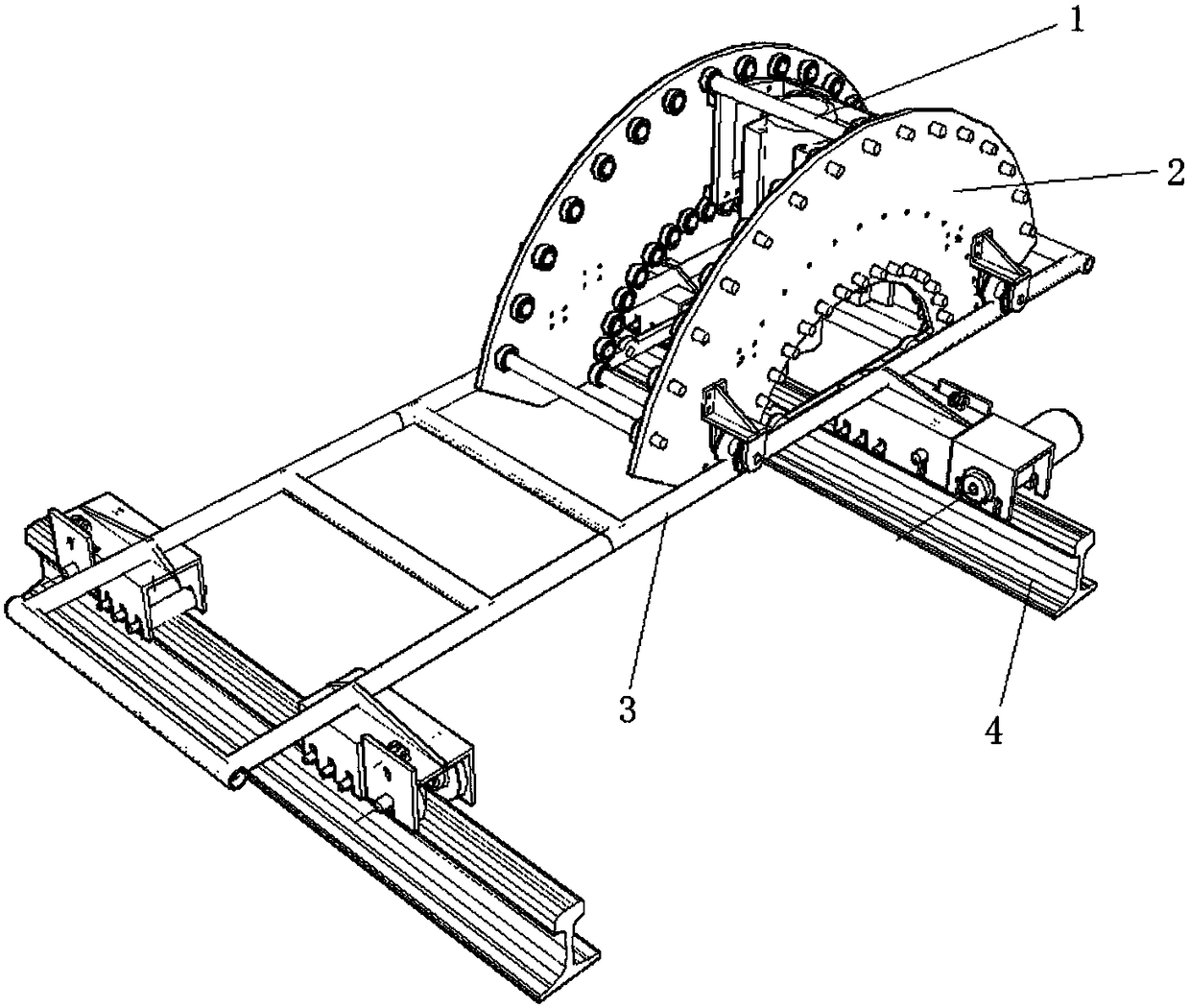

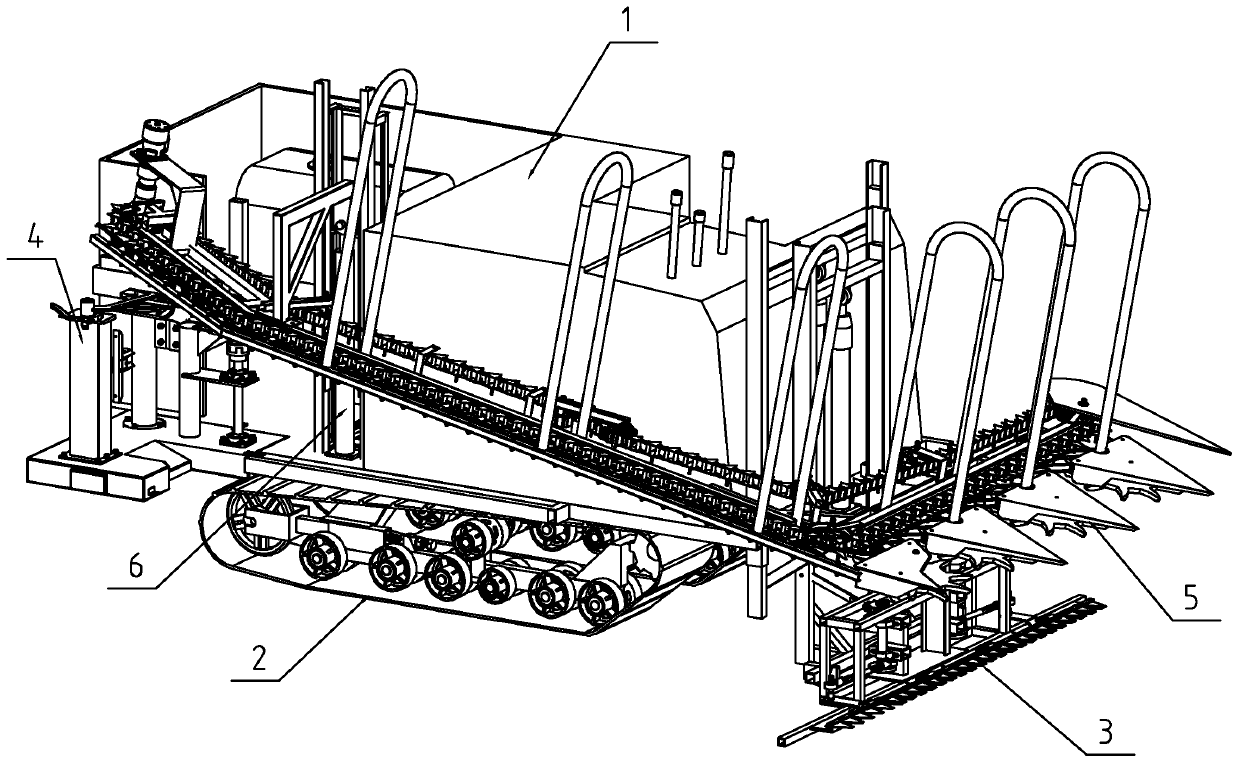

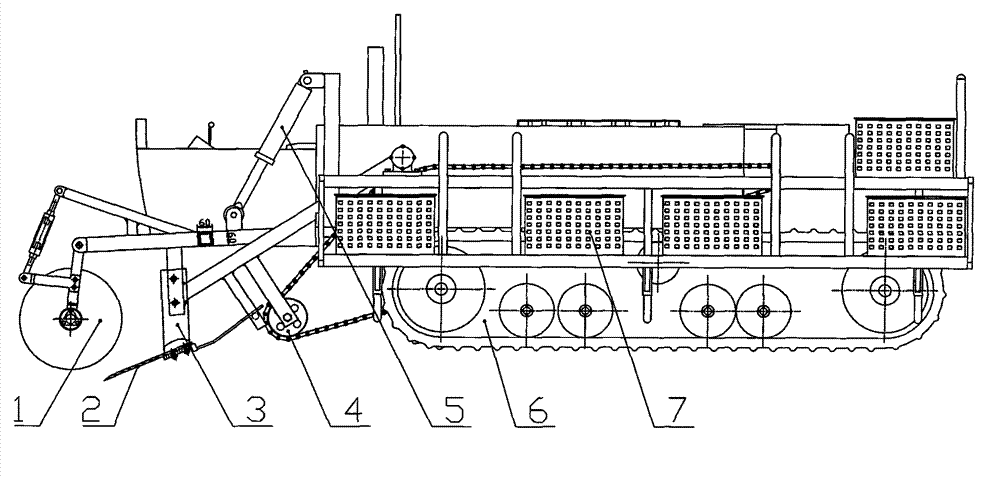

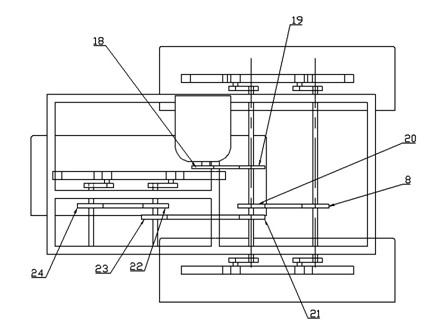

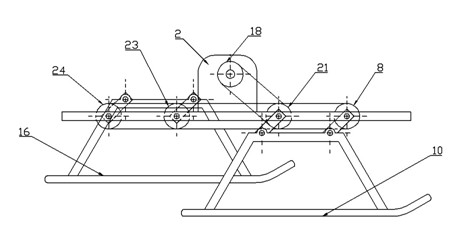

Combine for harvesting peanut

InactiveCN101297613AGuaranteed reliabilityReduce weightGearingDigger harvestersEngineeringCombine harvester

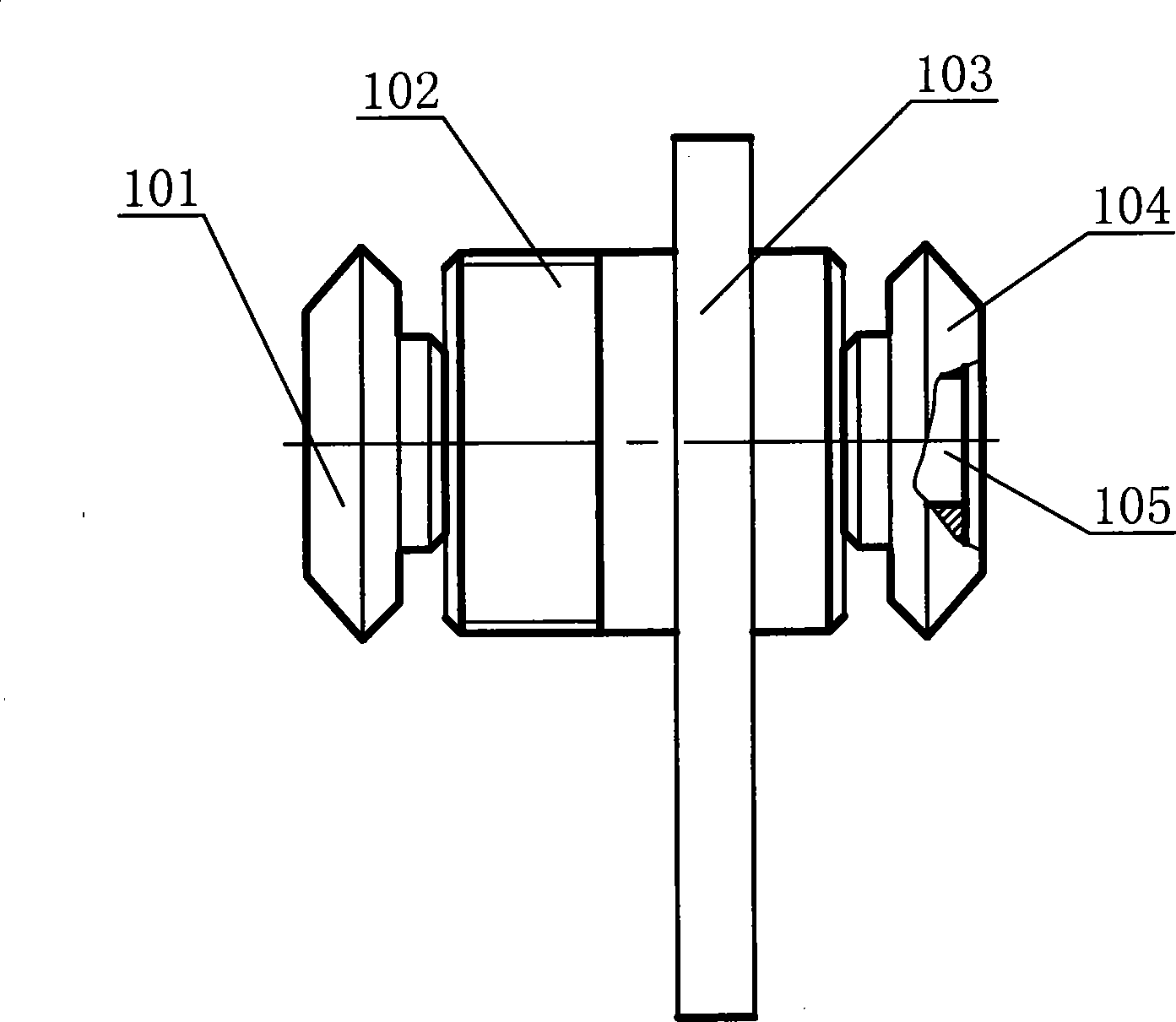

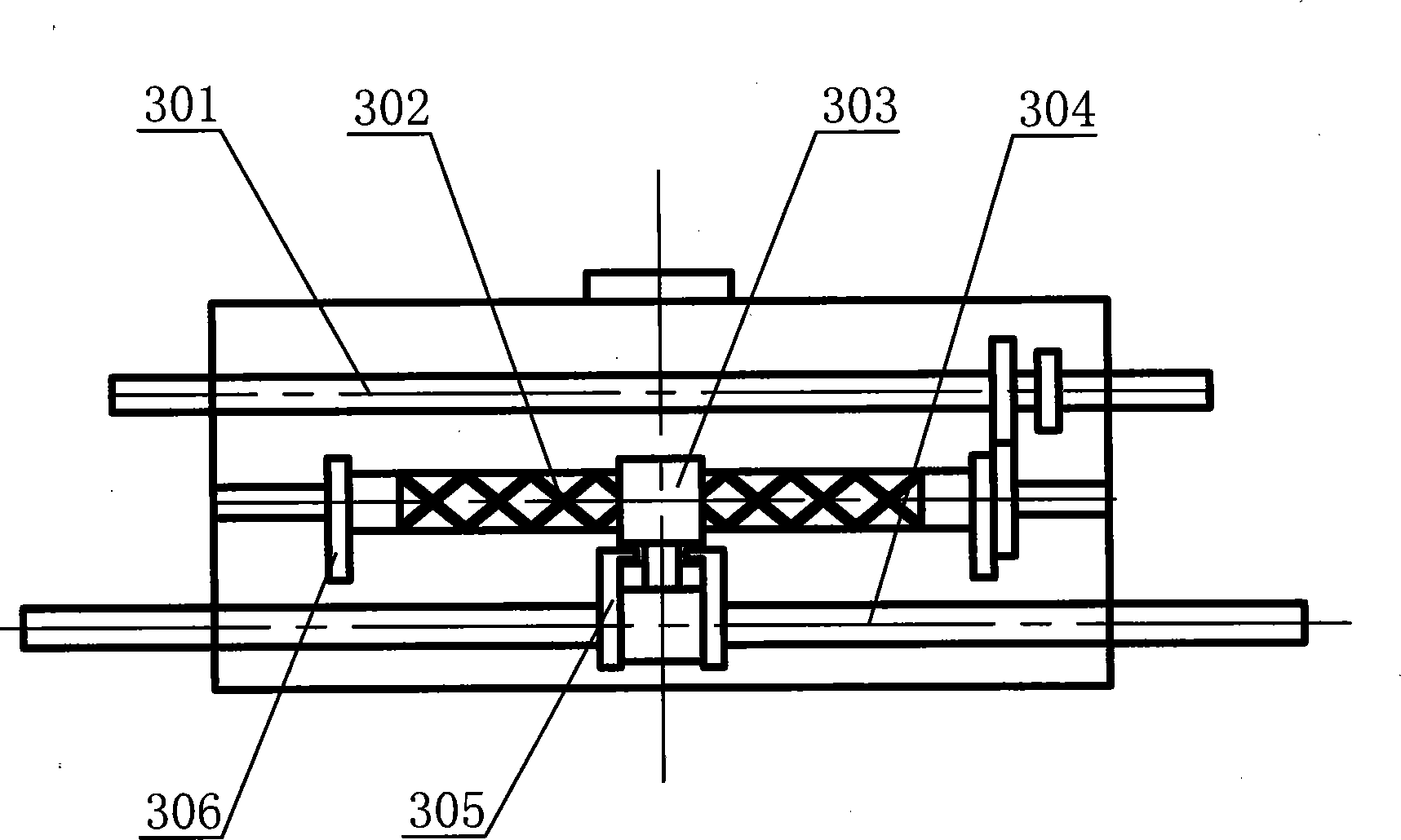

The invention relates to a peanut combine harvester, comprising a power travelling mechanism, an excavating mechanism, a gripping conveying mechanism, a fruit-picking mechanism, a cleaning mechanism and a cross conveying elevating and storing mechanism, wherein, the front of the power travelling mechanism is provided with the excavating mechanism connected with the gripping conveying mechanism; the fruit-picking mechanism is positioned at the back part of the gripping conveying mechanism, the lower part of the fruit-picking mechanism is provided with the washing mechanism and one side thereof is provided with the elevating and storing mechanism; power input shafts of the gripping conveying mechanism, the fruit-picking mechanism and the washing mechanism are connected with the output power of the power travelling mechanism by power transmission device. The peanut combine harvester of the invention integrates excavation, conveying, soil-removing, fruit-picking, separation, cleaning and storing into a whole, a machine frame receives pressure evenly, a mulching film is not damaged, the soil pollution is avoided, the operation resistance is little, and the operation is smooth; besides, the peanut combine harvester is characterized by compact mechanism, low cost, low consumption, little harvesting loss and high efficiency.

Owner:QINGDAO AGRI UNIV +1

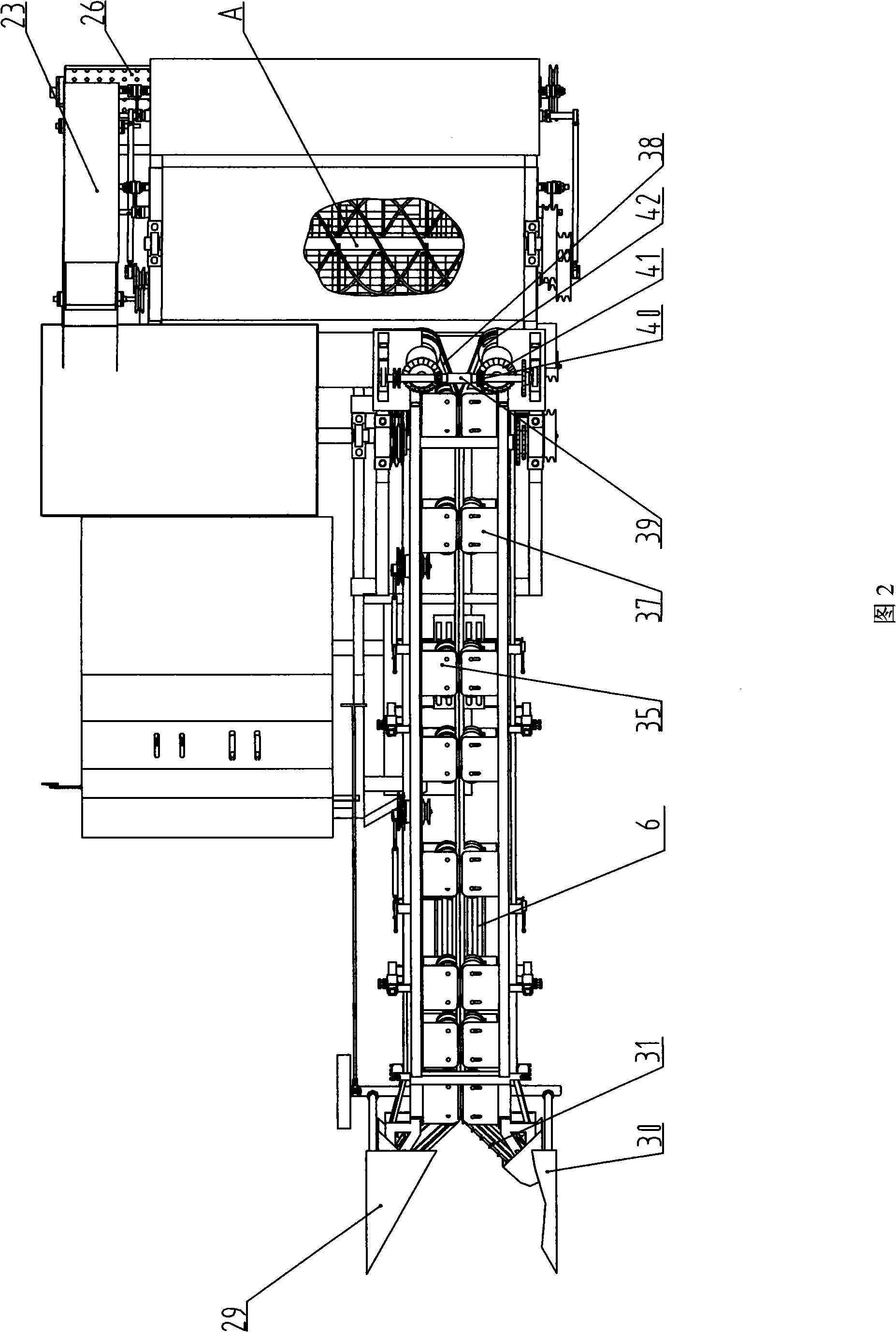

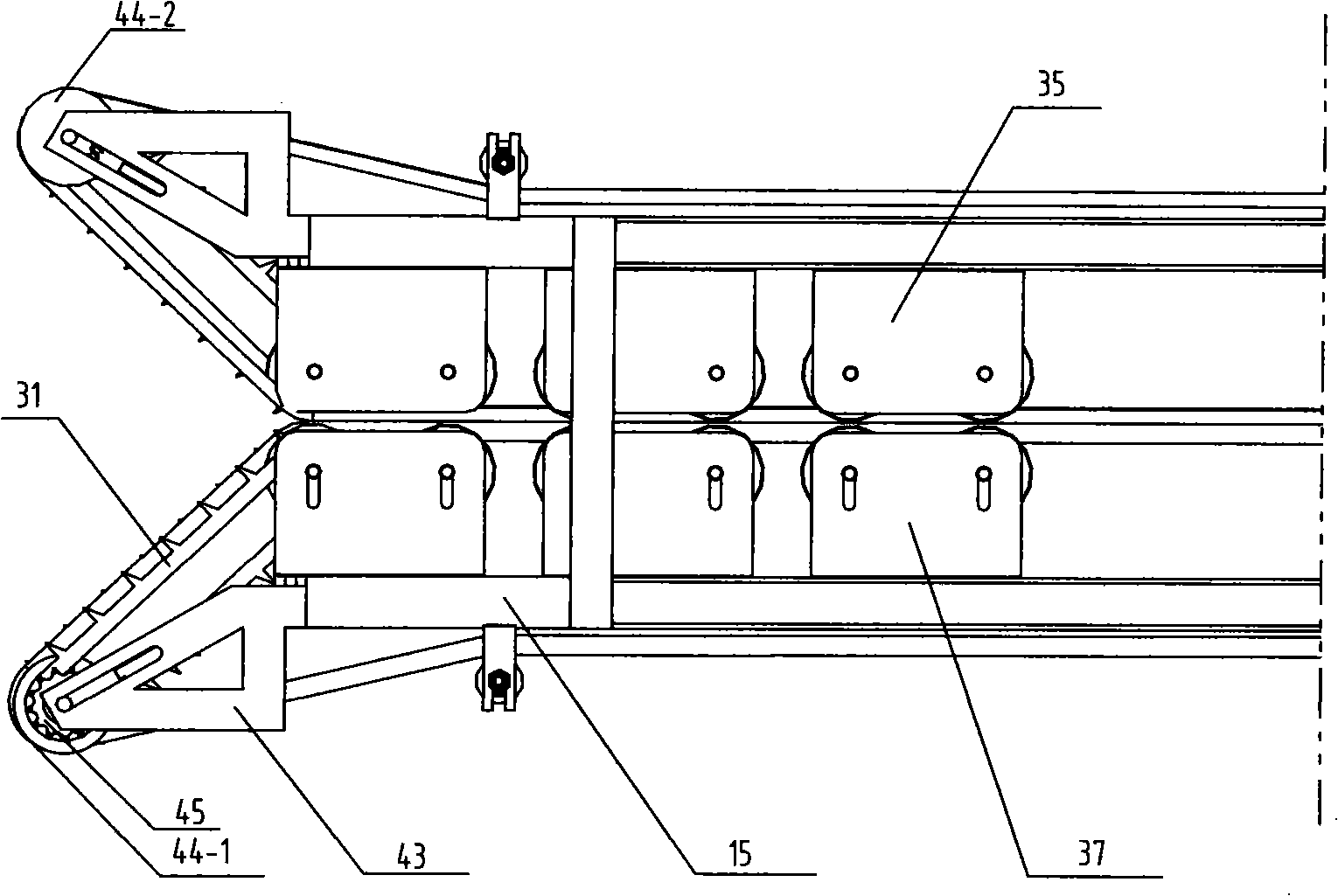

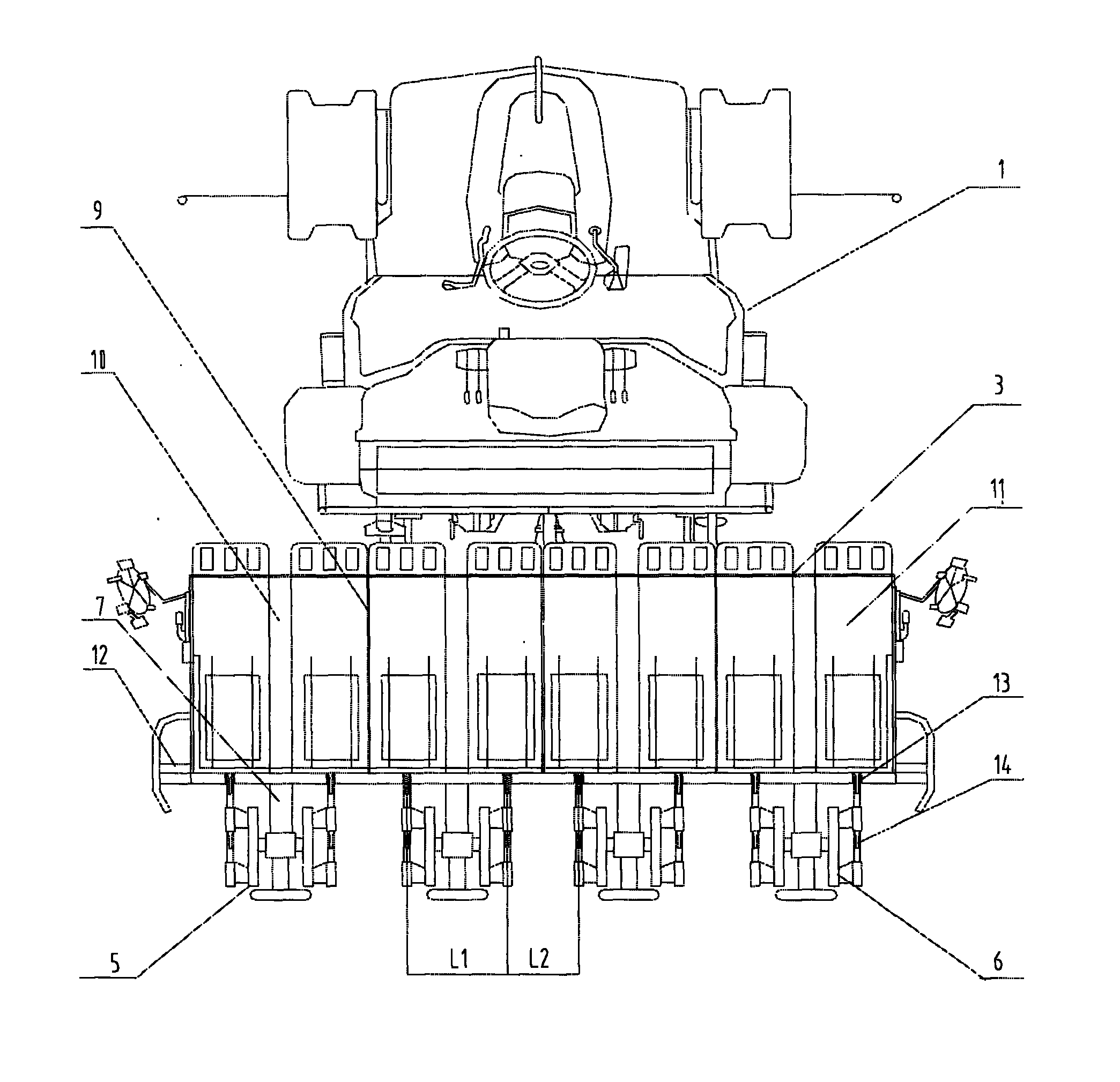

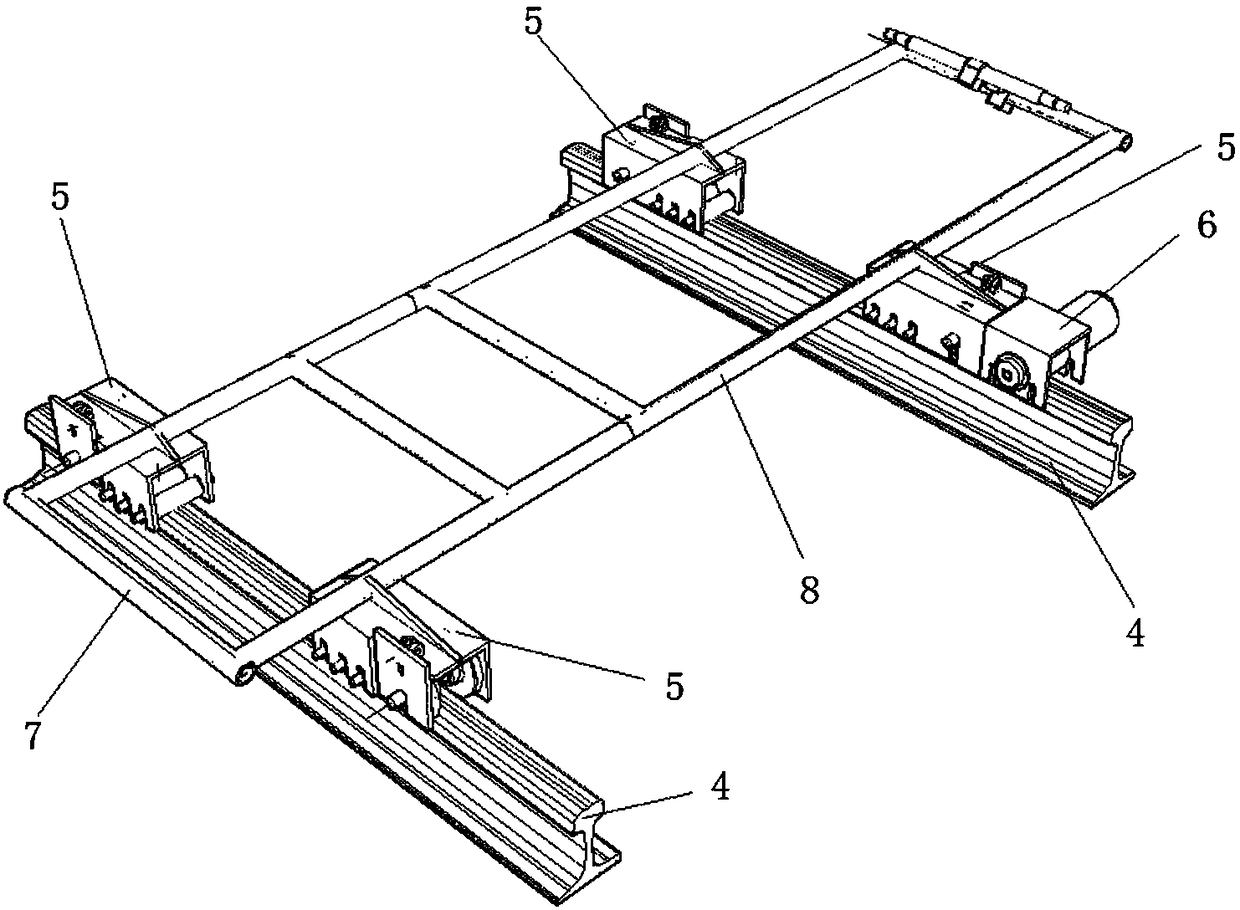

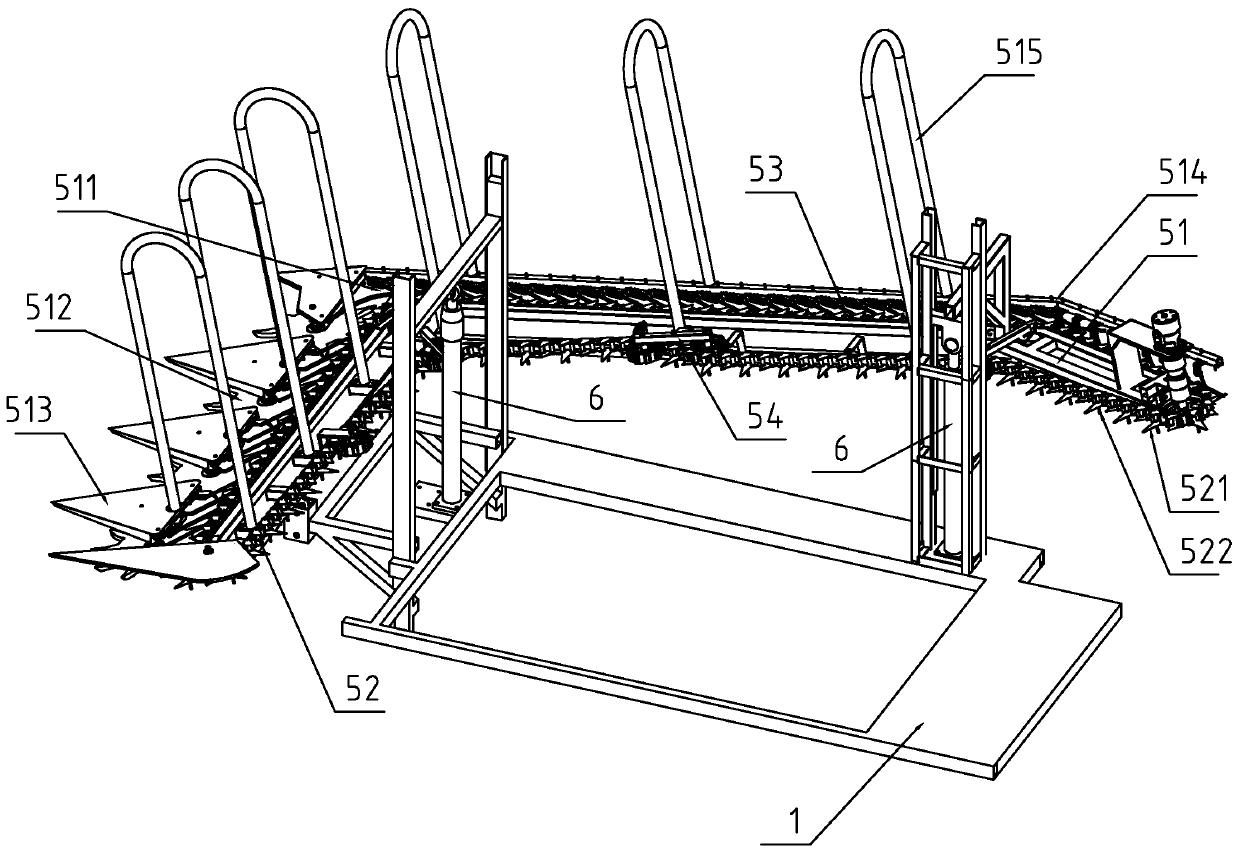

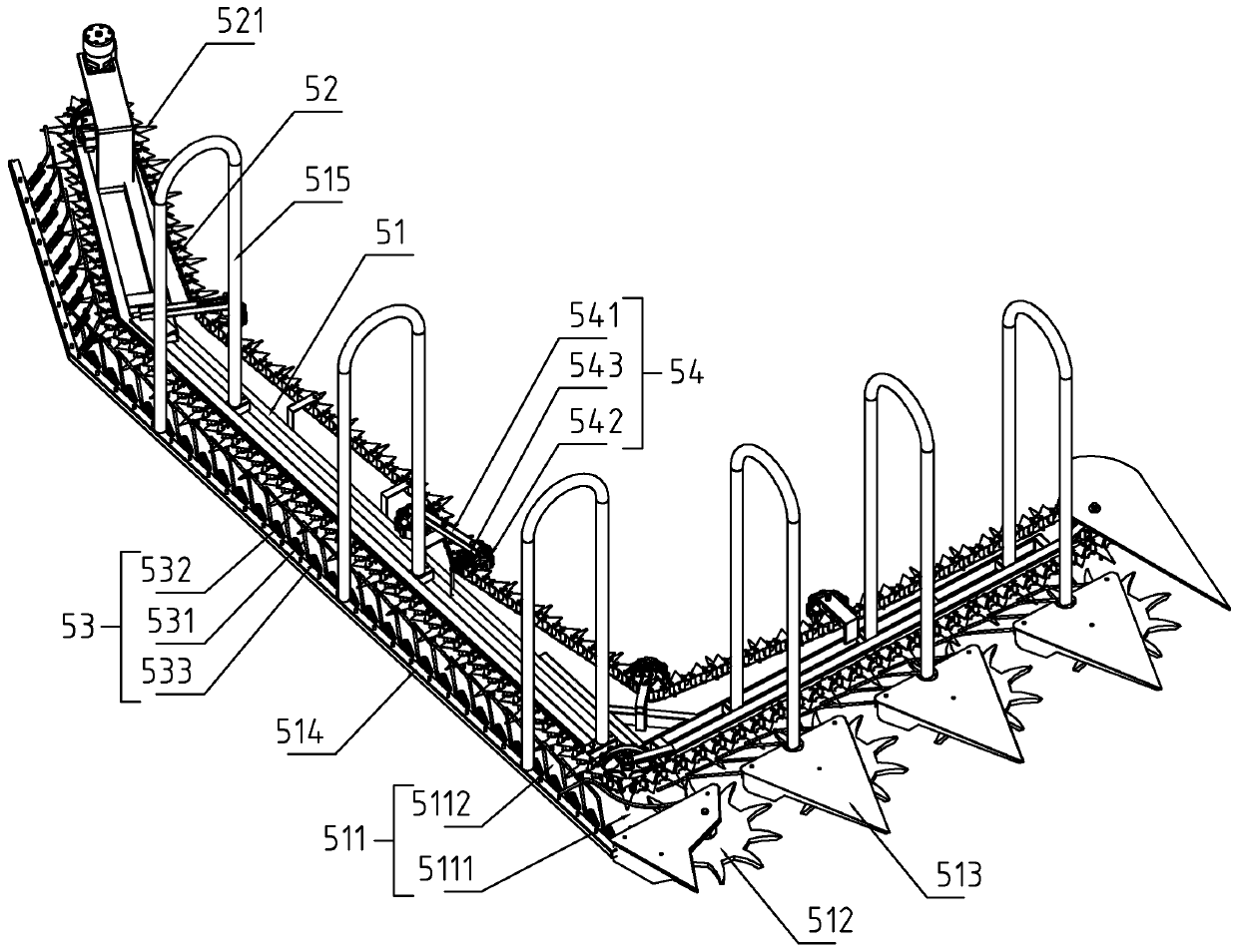

Peanut combine harvester

InactiveCN102812811AEasy to pick fruitEasy to collect and storeDigger harvestersBalingEngineeringCombine harvester

The invention discloses a peanut combine harvester, which comprises a frame, clamping and conveying devices, digging devices, soil removing devices, fruit picking devices, a transverse conveying device, a cleaning device, a lifting and flow guide device, and a peanut plant discharge device, wherein a power walking device is installed at the bottom of the frame; the clamping and conveying devices are obliquely installed on the frame; the digging devices are respectively installed at the front lower ends of the two clamping and conveying devices; the soil removing devices are respectively installed at the rear parts of the two digging devices; the fruit picking devices are respectively installed at the rear parts of the two soil removing devices; the transverse conveying device is installed between the fruit picking devices on two sides; the cleaning device is installed below the outlet end of the transverse conveying device; the lifting and flow guide device is installed at the outlet end of the cleaning device; and the peanut plant discharge device is installed at the rear part of the fruit picking devices and is connected with the clamping and conveying devices. The peanut combine harvester has the advantages that the structure is reasonable, the harvester works stably, the soil adaptability is strong, the fruit crushing rate during operate is low, the fruits are thoroughly picked, the harvesting rate is high, the peanut plants are tidily discharged, the treatment after harvesting is facilitated, the automation level and the operating efficiency are high, and the harvester is suitable for harvesting peanuts planted in large area.

Owner:WUZHENG

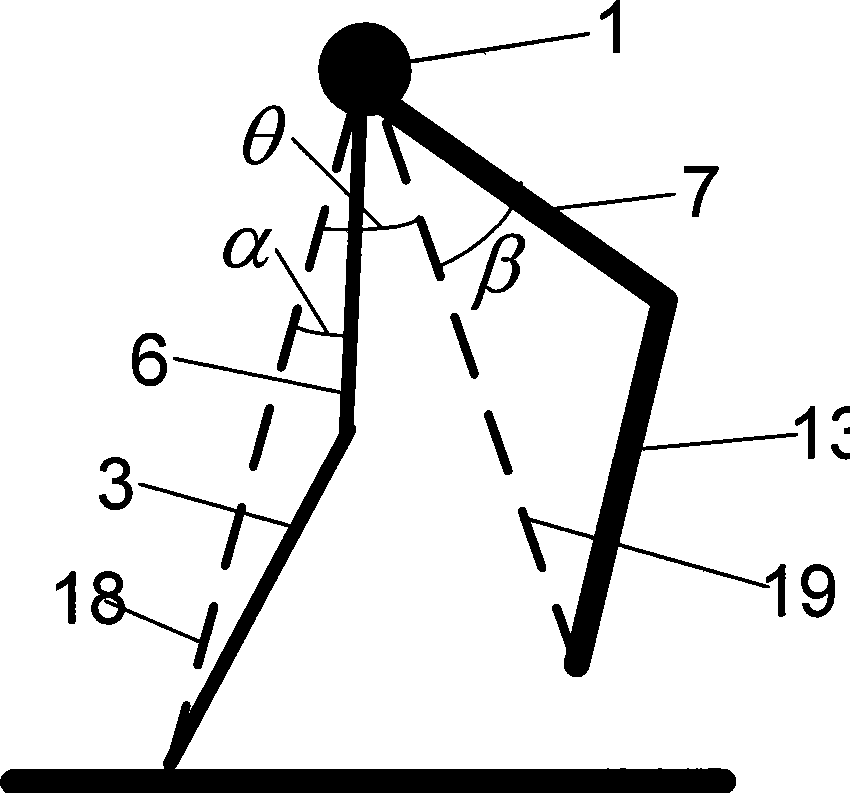

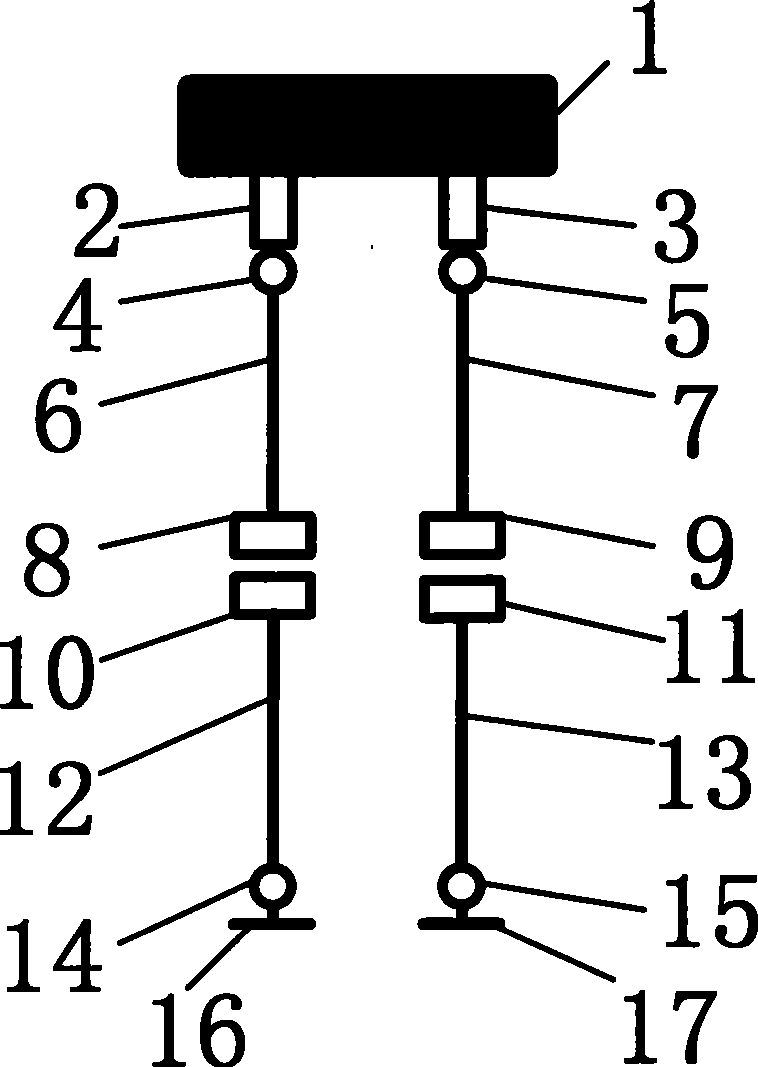

Power type walking method for biped robot

A power type walking method for a biped robot belongs to the technical field of robot walking method. The invention is characterized in that the method is a power type walking method for a biped robot which can walk in all directions under the condition of open-loop control, namely, under the control of an upper machine, three different power walking modes of advancing, side-swaying and rotational walking are respectively controllably arranged at the hip joint, the knee joint and the ankle joint of the biped robot. According to the relation between the motion angle in each calculation step length Delta t under each period and the walking times, the angle during different motion mode of each step length is calculated to control the intersection angle of each servo motor accordingly, thus satisfying the condition of power type steady walking and correspondingly proposing the control method of motion angle of all the joints under the set state. The invention has the advantage of walking steadily in all directions.

Owner:TSINGHUA UNIV

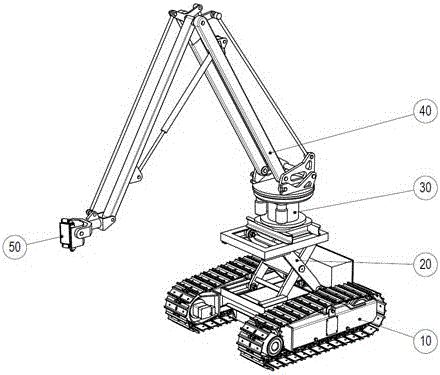

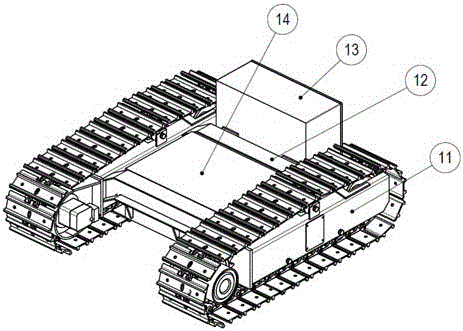

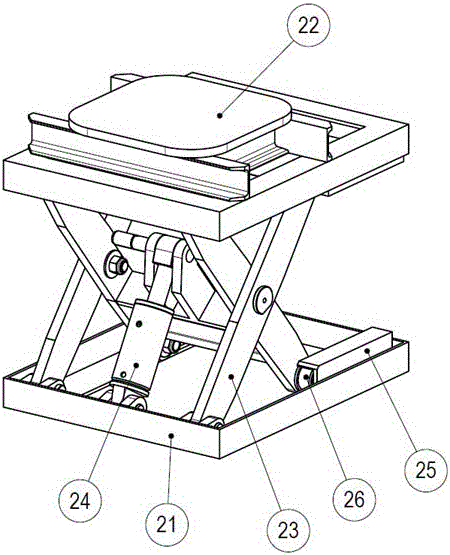

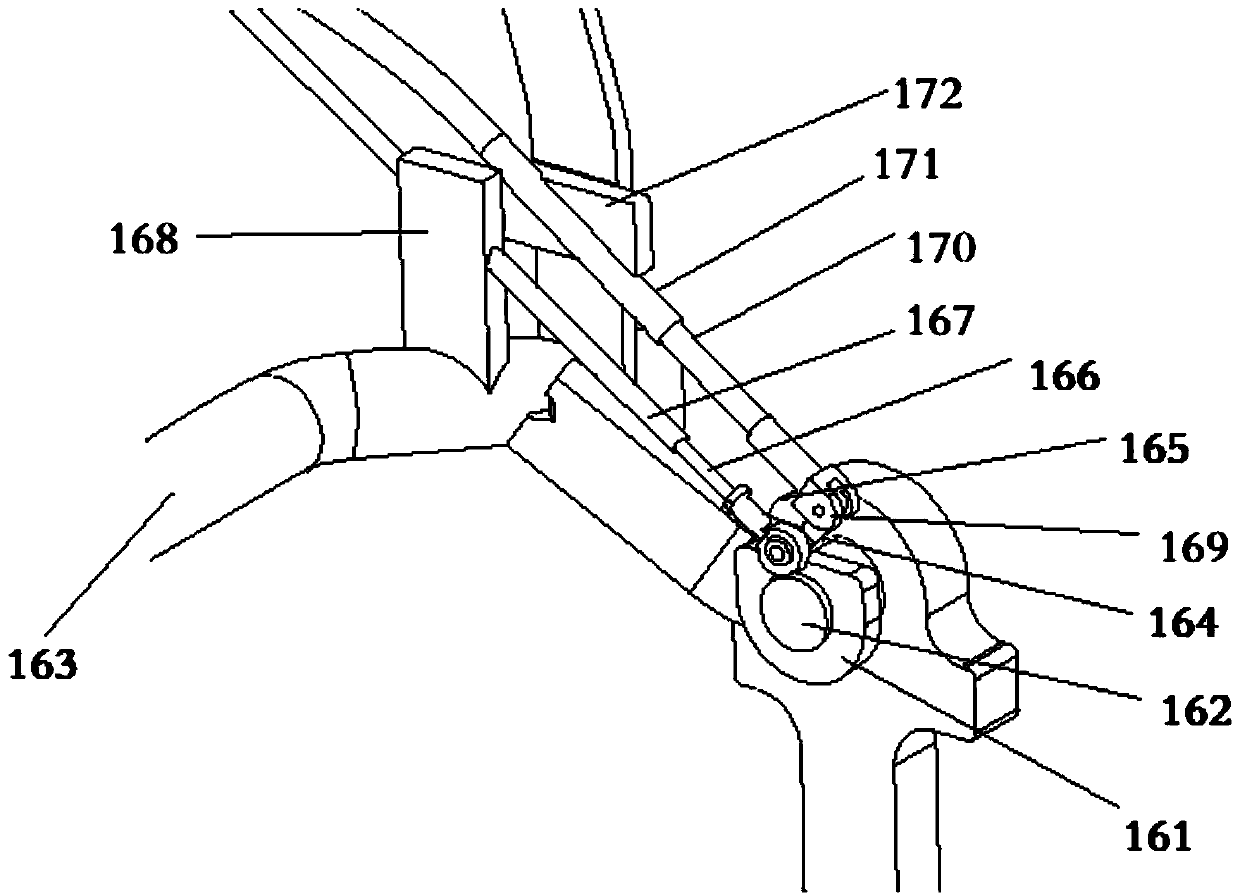

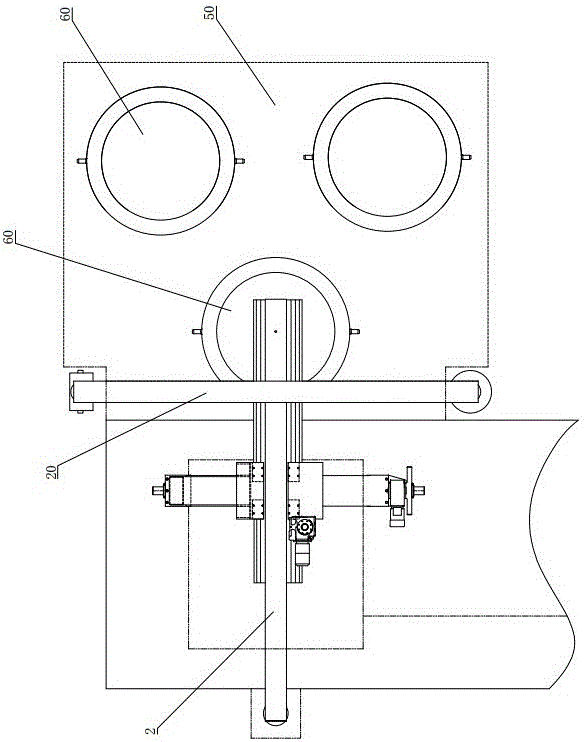

Movable drill floor pipe arranging robot for petroleum well drill

ActiveCN106593325AReduce labor intensityReduce accident rateDrilling rodsDrilling casingsPower stationWell drilling

The invention relates to a movable drill floor pipe arranging robot for a petroleum well drill. According to the technical scheme, the movable drill floor pipe arranging robot comprises a crawler chassis, a lifting table, a rotary table, a telescopic arm and an electromagnetic tong; a power traveling function of the crawler chassis is achieved through the hydraulic power station, and meanwhile, the hydraulic power station and an electric cabinet are integrated; the lifting table is installed in the middle of the crawler chassis, the rotary table is installed on the upper side of the lifting table, one end of the telescopic arm is connected to the rotary table, the other end of the telescopic arm is connected with the electromagnetic tong, and the telescopic arm controls the electromagnetic tong to move forwards and backwards; and the electromagnetic tong serves as a final actuating component, tubular columns can be adsorbed and fixed through the electromagnetic effect, and accurate displacement and arrangement of the tubular columns are achieved. The movable drill floor pipe arranging robot has the beneficial effects that the labor intensity of operators is greatly relieved, the accident rate of drilling operation is greatly decreased, meanwhile, the operation dangerousness is reduced for workers, the safety is greatly improved, labor cost is reduced, and full-mechanical continuous operation of automatic drill floor tubular column arrangement is achieved.

Owner:DONGYING RUIAO IND & TRADE CO LTD

Rice transplanter

The invention relates to a kind of farm machine, particularly a kind of rice transplanting machine, which includes a power running mechanism, a power transmission mechanism fixed on the power running mechanism, the supporting mechanism, the transplanting mechanism fixed on the supporting mechanism and the shoots carrying mechanism, the characteristic thereof resides in that: the supporting mechanism, the planting mechanism and the shoots carrying mechanism are detachably fixed on the power transmission mechanism. That is, the structure relationship between the transplanting mechanism and the power running mechanism is not the inseparablely one-to-one relationship, the transplanting mechanism can be matched with various power running mechanisms for planting, the power running mechanism also can be worked for other farm machines to fulfill other farming works. The power transmission mechanism of the invention also can be matched with rotary machine, ditching machine, weeding machine, planter, fertilizer and other farm machines for farmland farming, it achieves multiple functions, and solves the problem of single-function of traditional rice transplanting machine, and the waste of production resources.

Owner:湖北黄鹤插秧机制造有限公司

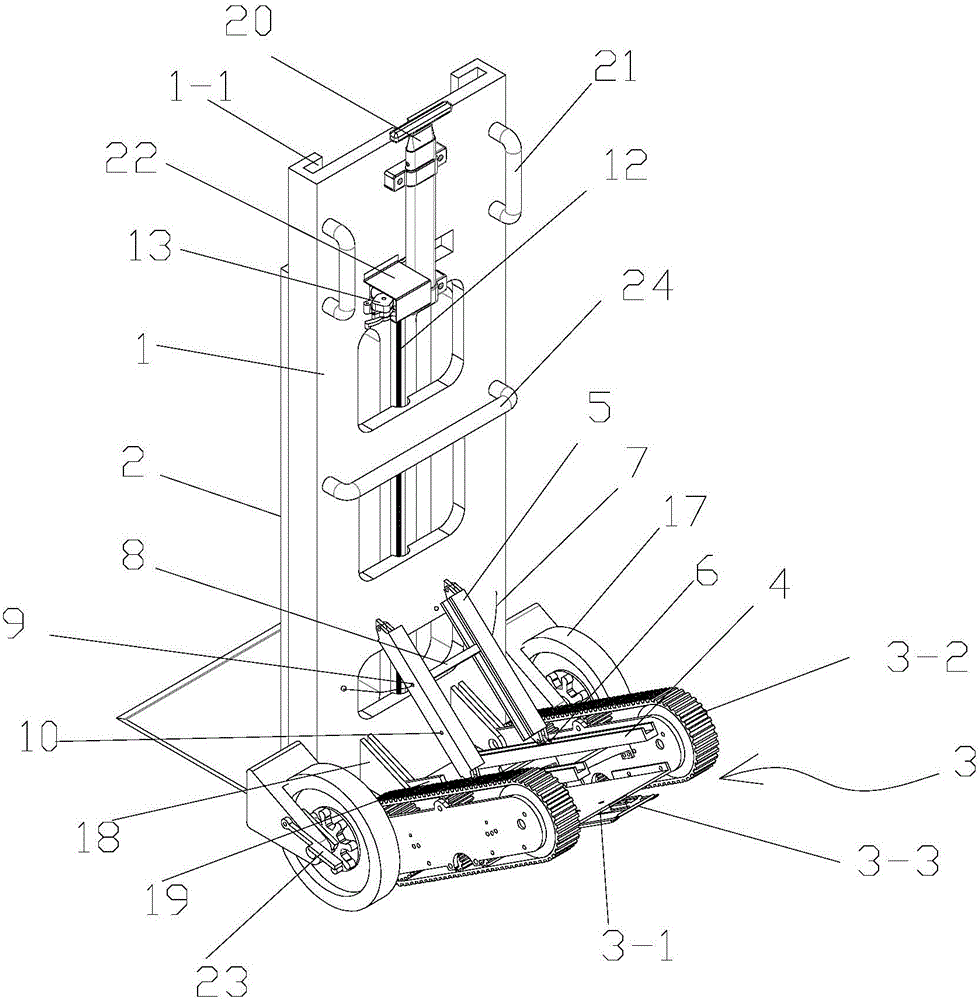

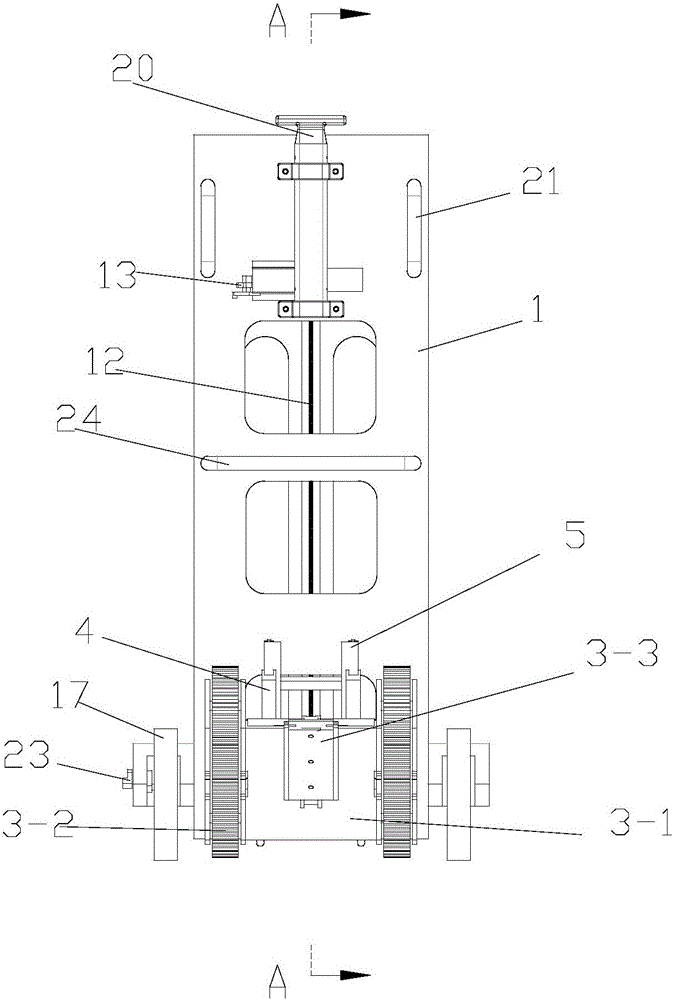

Heavy-load carrier

ActiveCN105835929AIncrease the load carrying weightReduce workloadHand carts with one axisEndless track vehiclesVehicle frameVertical plane

The invention discloses a heavy-load carrier. The heavy-load carrier comprises a vehicle frame, a goods shelf, a power traveling device and a supporting and adjusting assembly, wherein the goods shelf is matched with the vehicle frame in a relatively sliding mode and used for bearing heavy goods; the power traveling device is matched with the vehicle frame in the mode of being capable of rotating in a vertical plane and can travel on the flat ground and stairs; the supporting and adjusting assembly is used for controlling the opening and closing angles of the power traveling device relative to the vehicle frame and used for supporting the vehicle frame when the power traveling device makes contact with the ground. The heavy-load carrier can travel on the flat ground and the stairs through the power traveling device. Smooth loading and unloading can be realized through relative sliding of the vehicle frame and the goods shelf, so that the workload is small. The supporting and adjusting assembly can support the vehicle frame on the premise of meeting the requirements for the opening and closing angles of the power traveling device, so that the goods bearing weight of the whole carrier is greatly increased, and the requirement for heavy load is met. The heavy-load carrier is compact in structure, good in heavy loading performance and convenient to use. The heavy-load carrier can be operated just by one person to effectively complete loading, unloading, stair climbing delivery and the like of goods, so that the time cost and labor cost are reduced, and the safety during the operation process is greatly improved.

Owner:CHONGQING UNIV

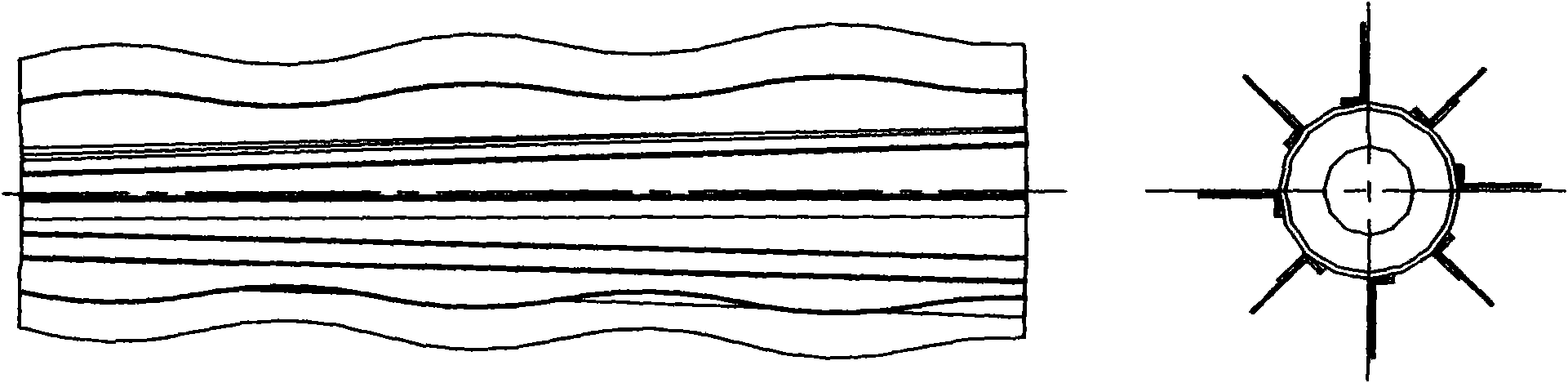

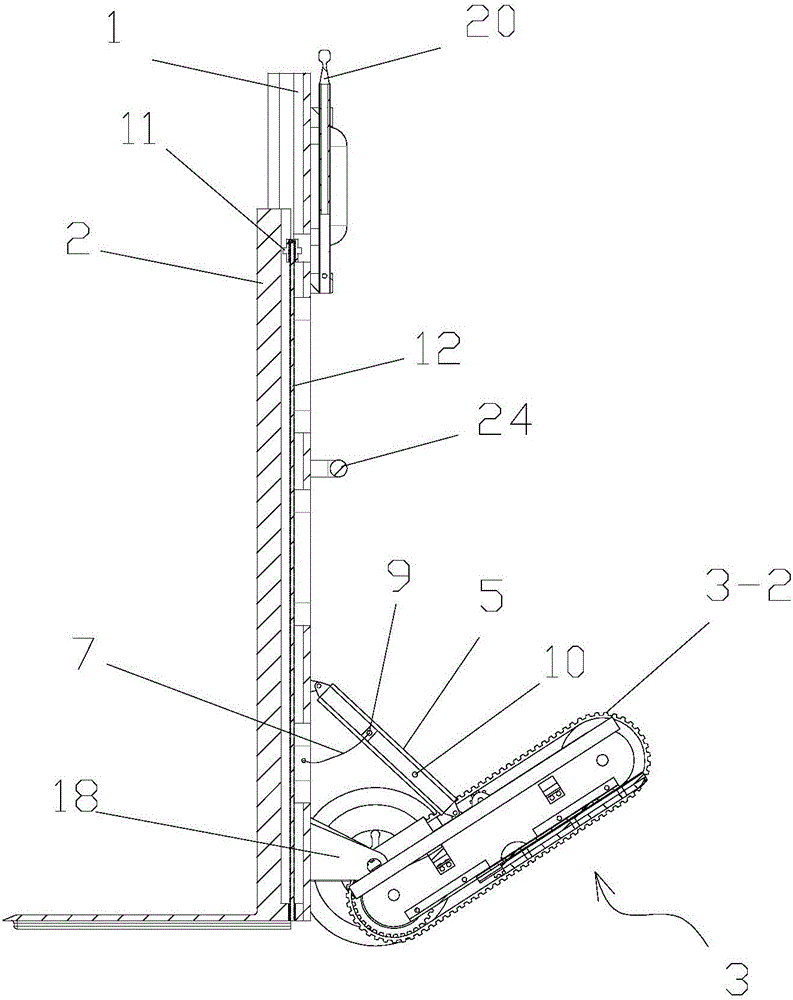

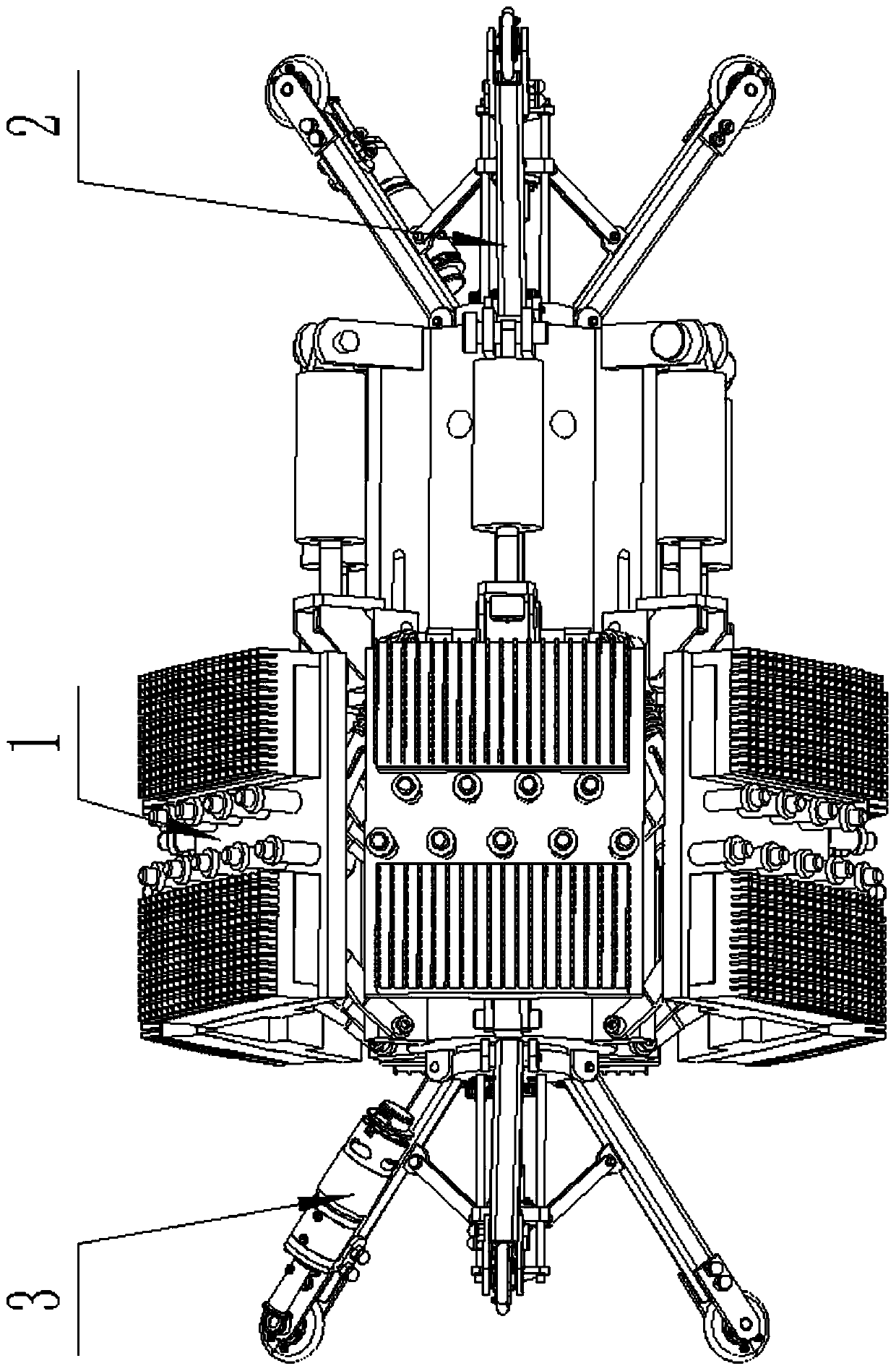

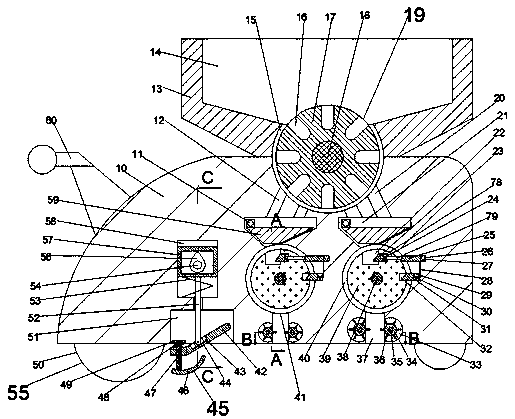

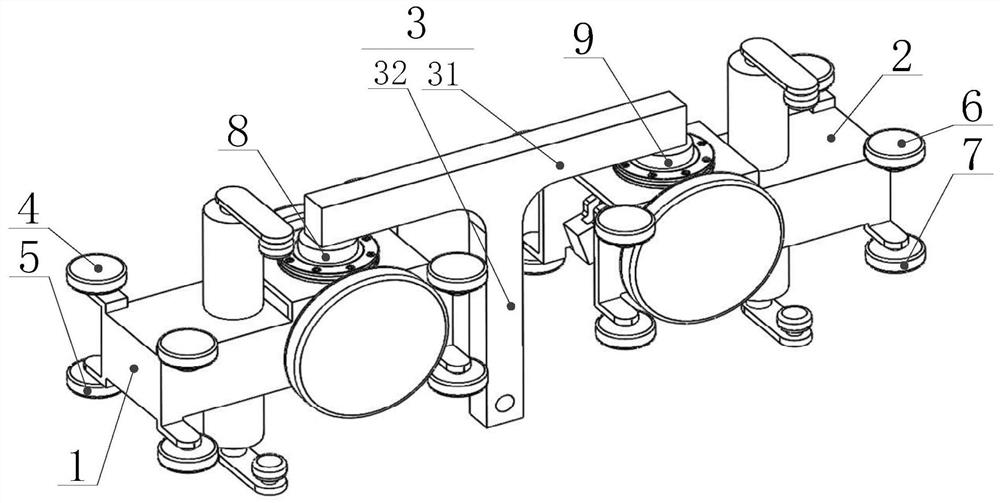

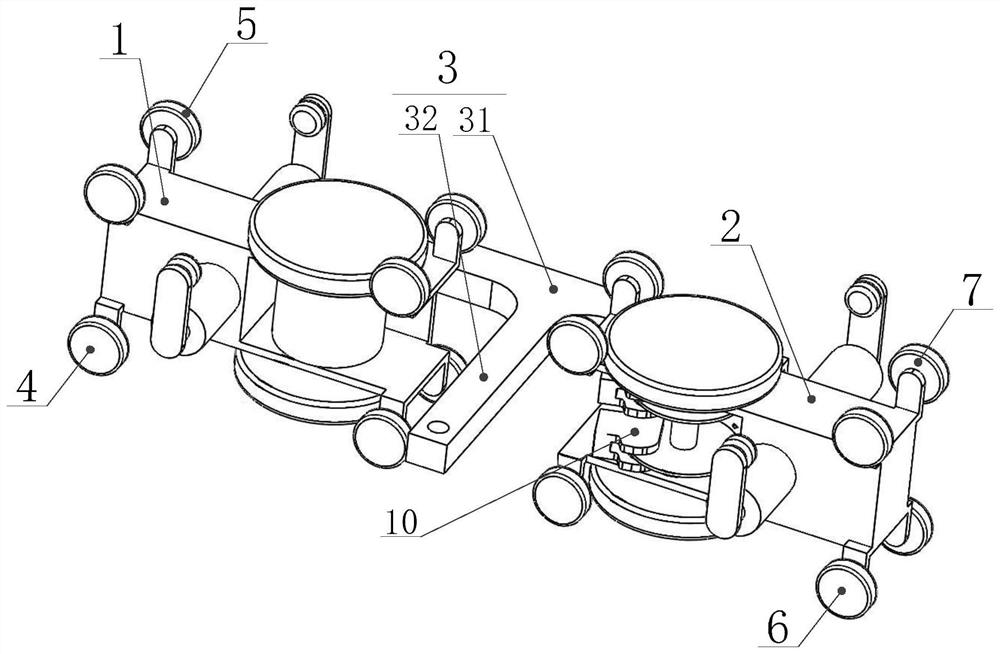

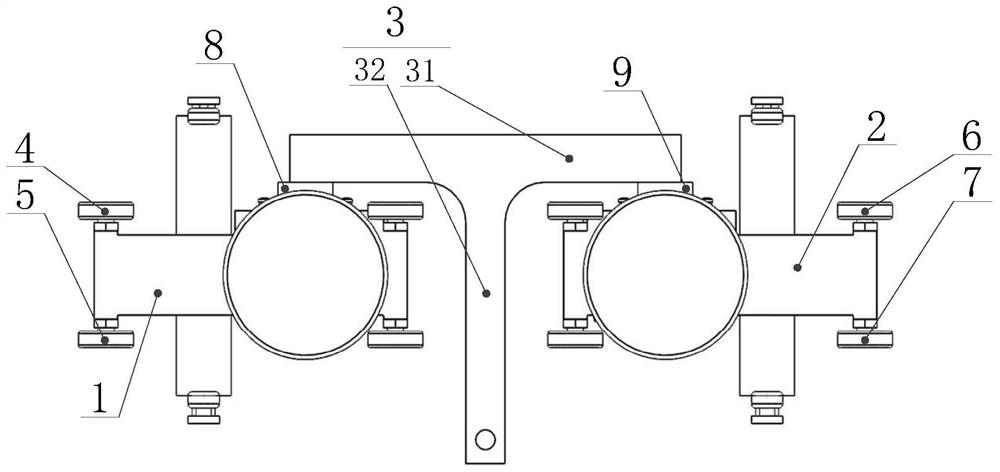

Pipeline magnetic flux leakage internal detection device capable of performing variable diameter measuring and variable diameter moving actively

PendingCN111425767ACompact structureVersatilePipeline systemsMaterial magnetic variablesSupporting systemMotion system

The invention provides a pipeline magnetic flux leakage internal detection device capable of variable diameter measuring and variable diameter moving actively. The pipeline magnetic flux leakage internal inspection device comprises a variable diameter magnetic flux leakage detection system, a variable diameter support system, walking motion systems, a system control module, a system power module and a system recording module, wherein the system control module, the system power module and the system recording module are installed in the variable diameter support system, the variable diameter magnetic flux leakage detection system is sleeved outside the variable diameter support system, the walking motion systems are installed at the two ends of the variable diameter support system, the system power module can supply power to the whole device, and the system recording module records sensing results and mileage results. The internal detection device has the functions of active variable diameter measurement, variable diameter support and active movement walking, the overall structure is compact, the system function is diversified, one machine has multiple functions, the device adapts to pipes with different diameters, so that the overall adaptability is stronger, the detection coverage area is large, and the measurement results are more precise, and the walking motion system can achieve independent power walking of front and rear wheels without the need of an external power traction device.

Owner:智云安科技(北京)有限公司

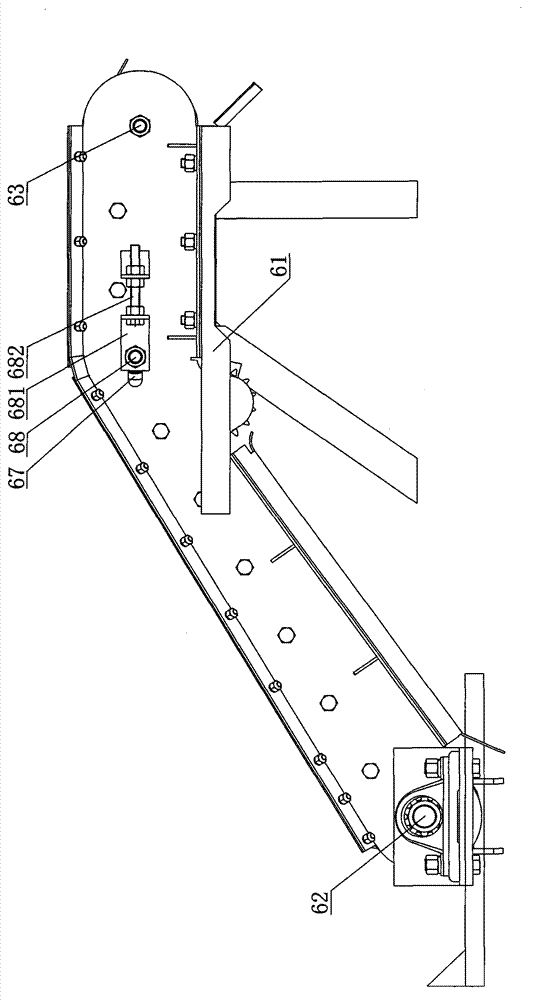

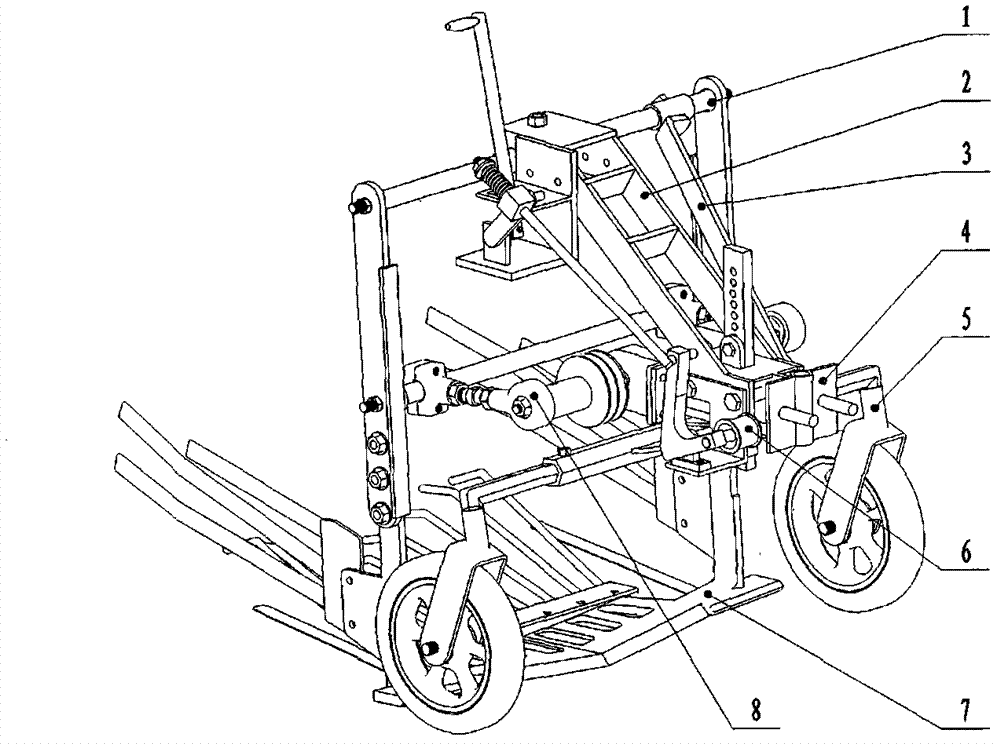

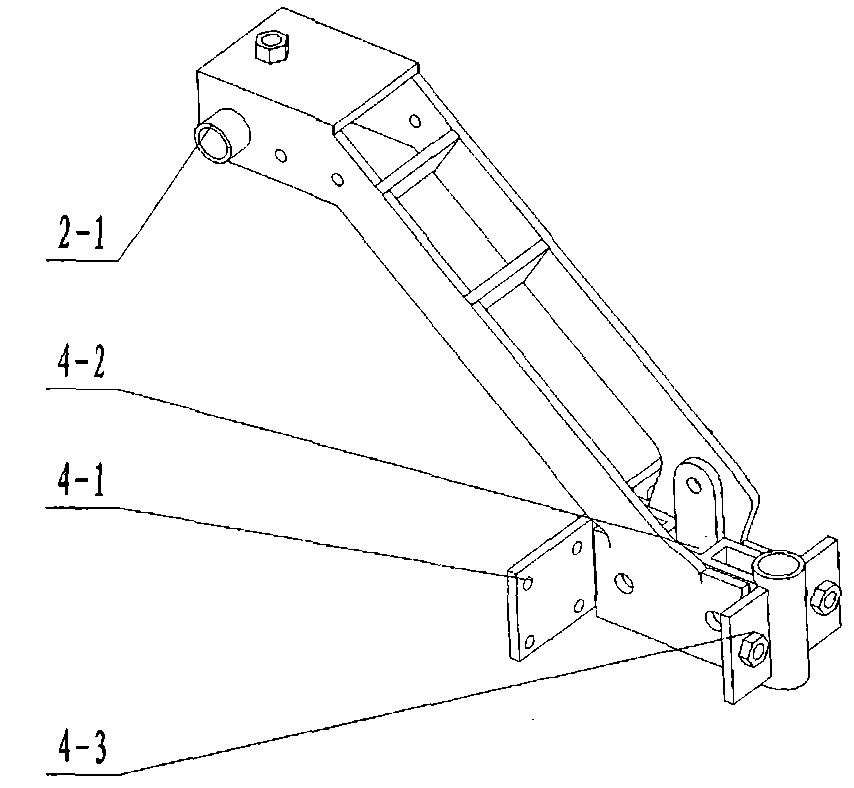

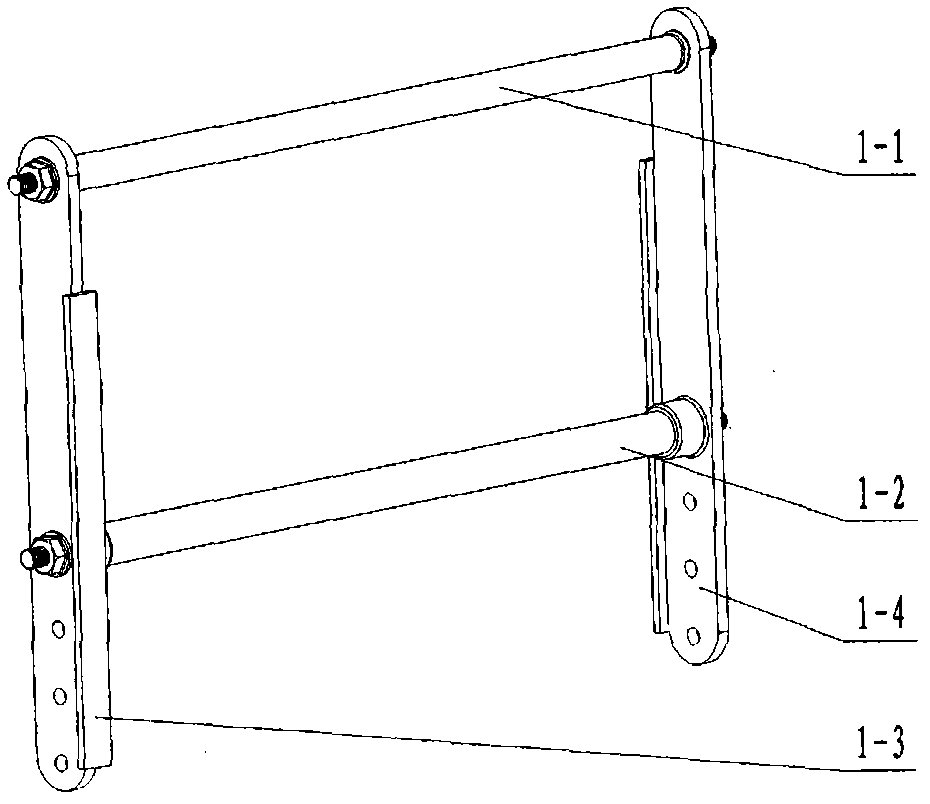

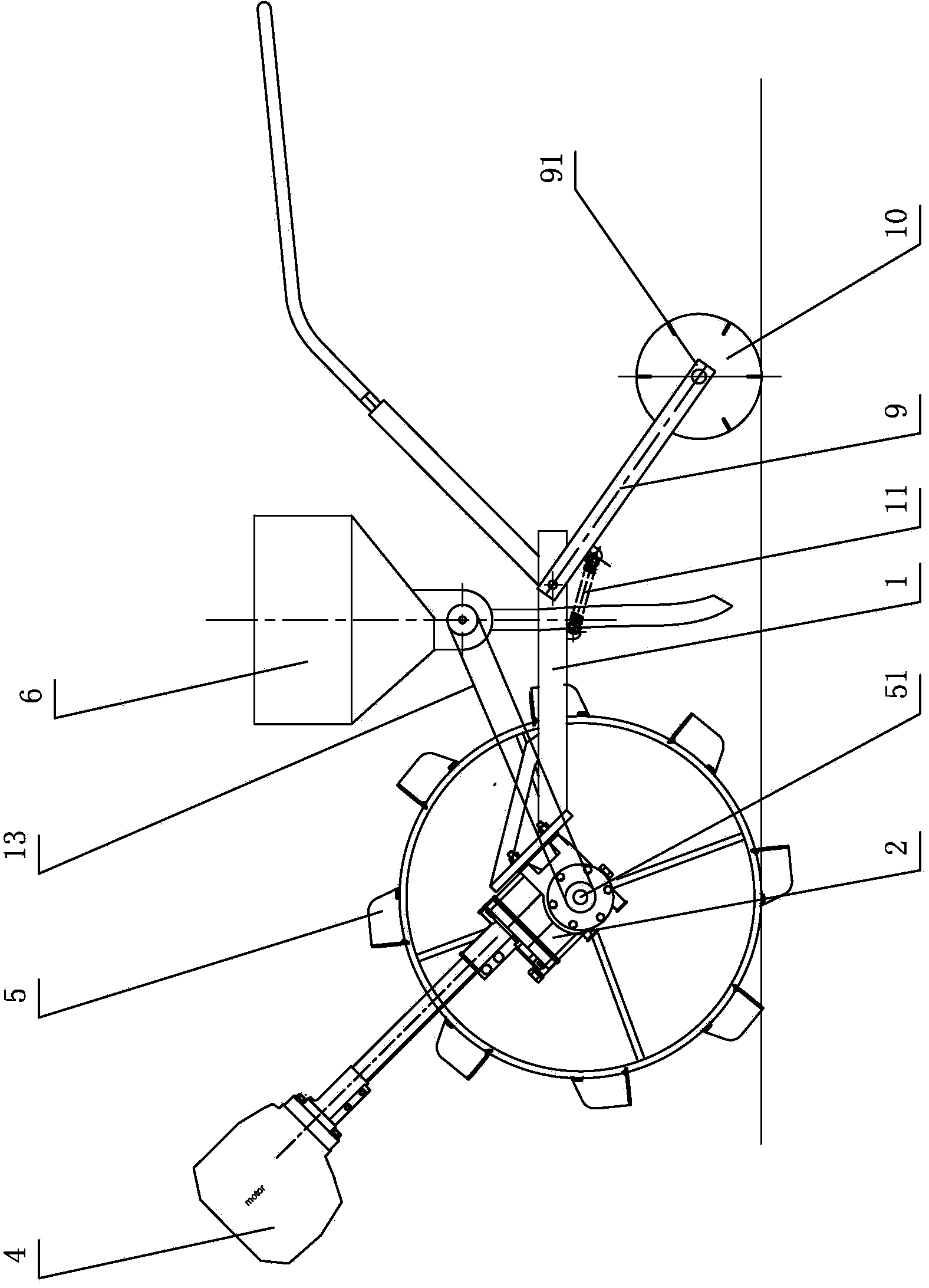

Small vibration-sieve type potato digger

The invention relates to the technical field of mechanized potato sowing equipment, in particular to a digger for potatoes in dry land with all membrane double ditches. The small vibration-sieve type potato digger comprises a frame (2), a diagonal draw bar (3), a digging shovel component (7), a swing mechanism (1), a driving mechanism (8), a limit mechanism (5), a clutch (6) and a hanging mechanism (4). The frame (2) is hooked to a tractor traction box. A rectangular sliding groove is formed in the hanging mechanism (4), a beam frame of the limit mechanism (6) penetrates the sliding groove, and the position, where the beam frame of the limit mechanism (6) is positioned, can change the depth of the digging. The digging shovel component (7) is fixedly jointed to the swing mechanism (1) through bolts. The driving mechanism (8) is disposed between the hanging mechanism (4) and the swing mechanism (1). The diagonal draw bar (3) is disposed between the swing mechanism (1) and the hanging mechanism (4). Due to the fact that the small vibration-sieve type potato digger can be matched with a small-power walking tractor to meet the requirements for digging potatoes in small plots such as terraced fields and hilly mountains, the problems that small potato diggers are large in digging resistance and unadjustable in penetrating angles of the digging shovels are solved.

Owner:吴建民 +2

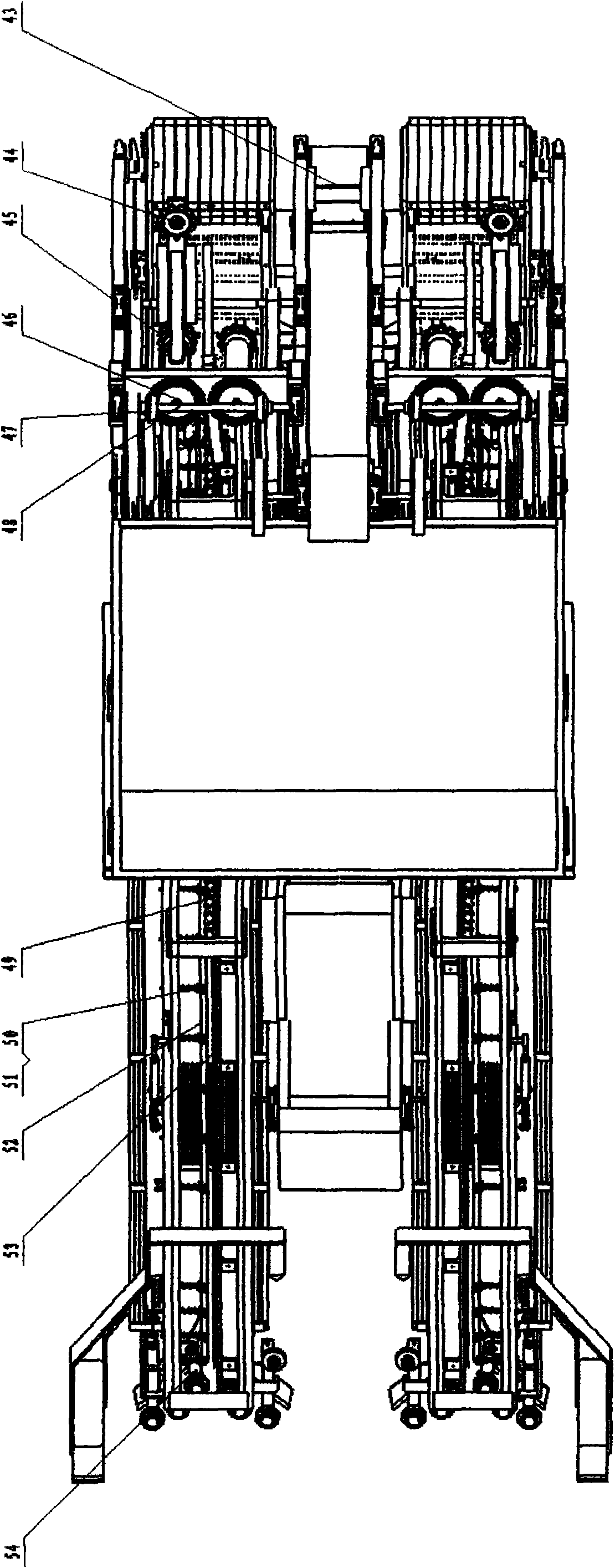

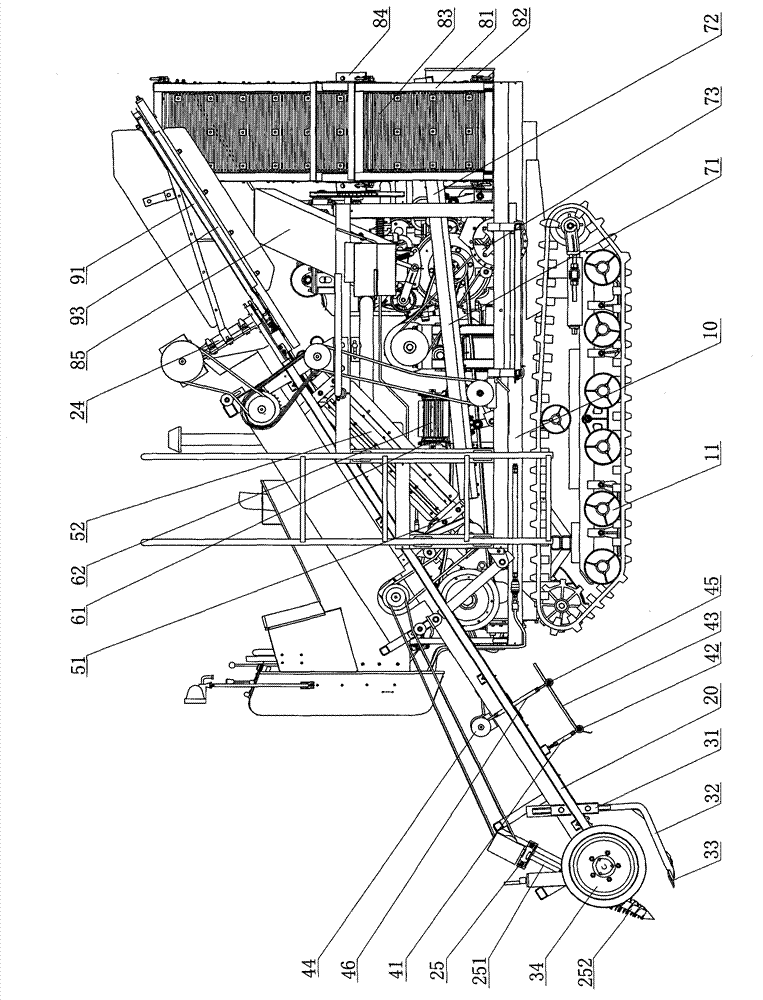

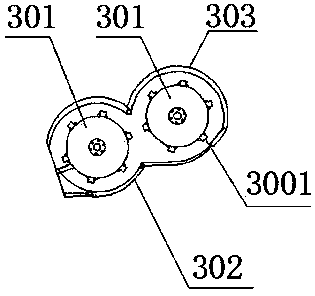

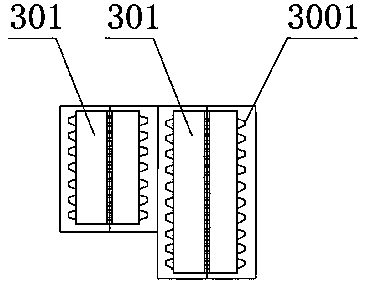

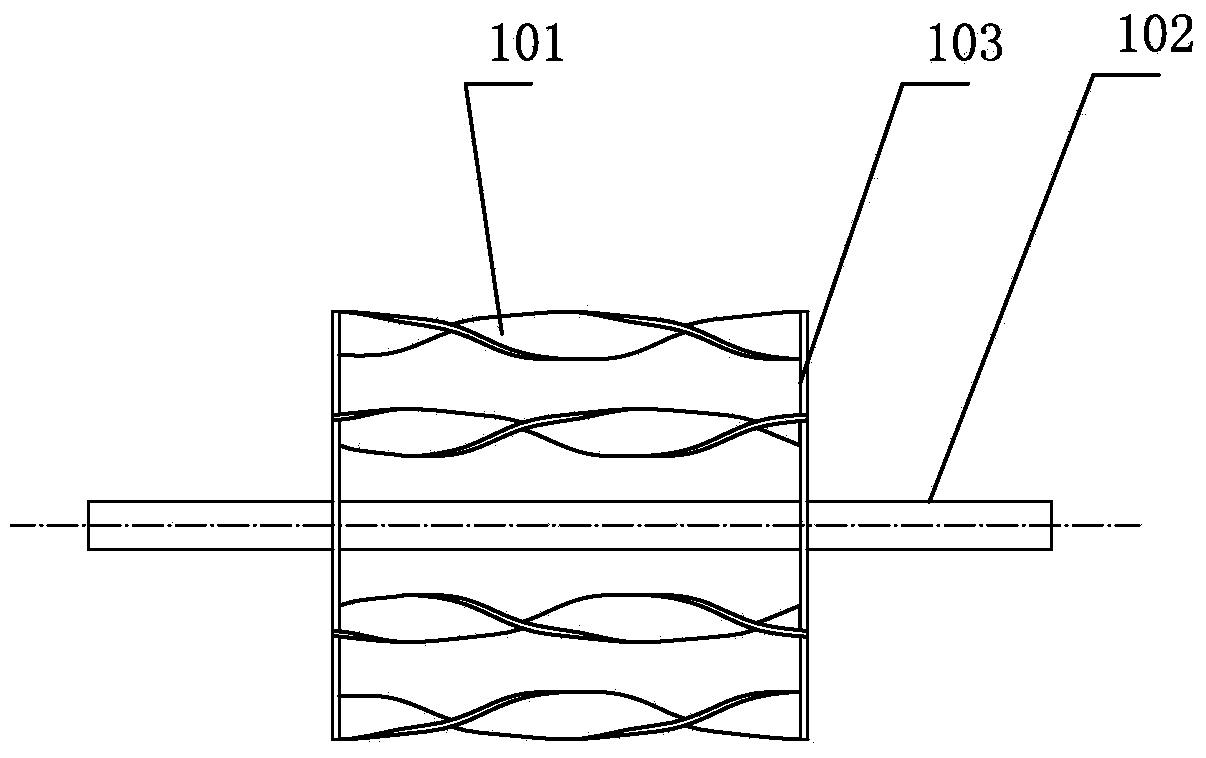

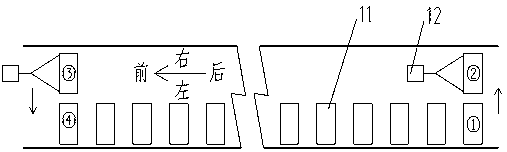

Automatic walking wheel type rice straw gathering bundler

ActiveCN103988643ACompact designImprove the level of comprehensive utilizationBalingAgriculture gas emission reductionAgricultural engineeringIntegrated operations

The invention provides an automatic walking wheel type rice straw gathering bundler which comprises a rice straw gathering and conveying system, a rice straw compressing and bundling system and a power walking system. A rice straw gathering device, an inclined rice straw conveying device, a drum-type rice straw conveying device, a pre-pressing padding device and a compressing and bundling device are connected in sequence end to end and are located on the upper left side of a running chassis device. Plank-tooth type rollers are two in number, six grass discharge plates are symmetrically arranged on each plank-tooth type roller in the axial direction, and smooth concave plates are arranged on the lower sides of two rollers respectively. A profiling wheel and a tension spring are arranged on the side face of a rice straw gathering mechanism. Rice straws are fed by the rice straw gathering device, conveyed to the drum-type rice straw conveying device by the inclined rice straw conveying device, and conveyed to the pre-pressing padding device and the compressing and bundling device through the drum-type rice straw, and the bundling device finishes compressing, bundling and bundle discharge of the rice straws. The automatic walking wheel type rice straw gathering bundler can achieve integrated operation of gathering, compressing, bundling and other operations of the rice straws, and provides a new workable technical device which can reduce burning of the rice straws and save resources.

Owner:JIANGSU UNIV

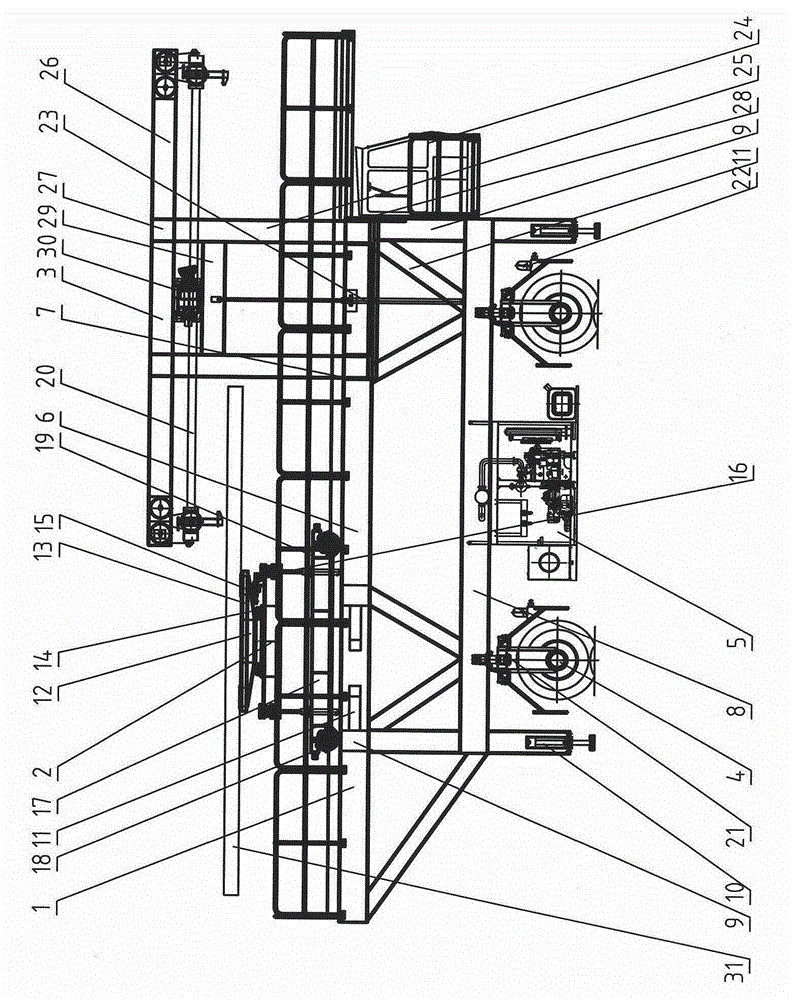

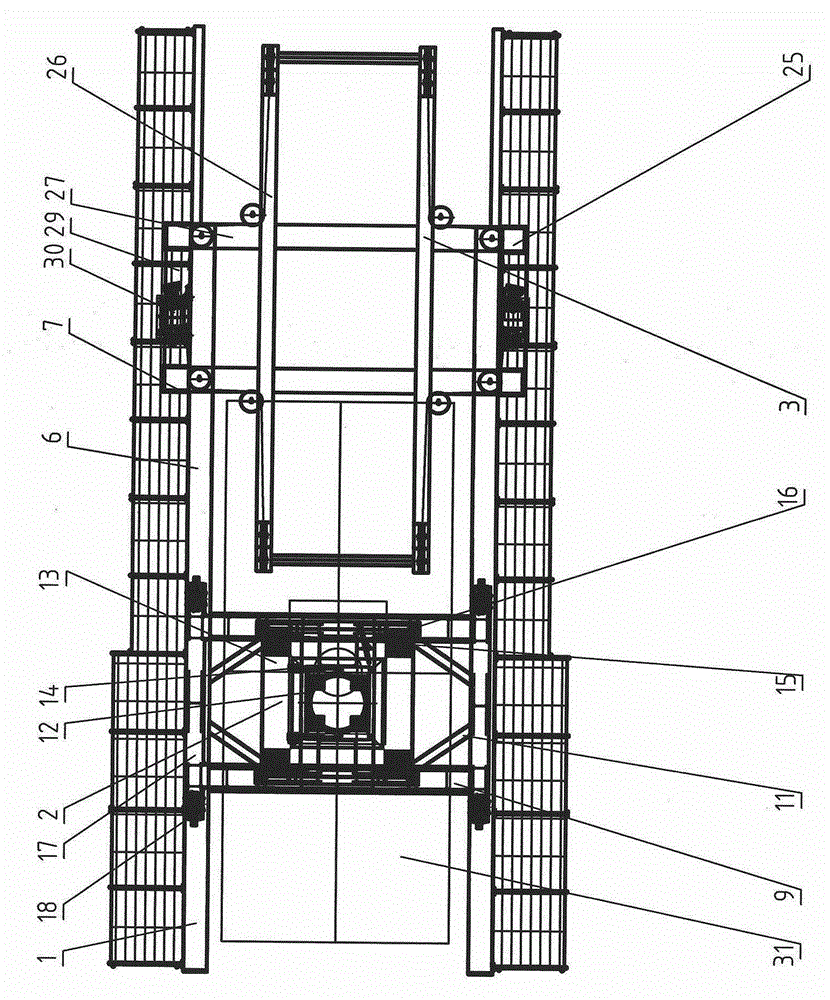

Assembling machine of high altitude prefabricated slabs

InactiveCN106285020AFlexibleReliable driveUnderground chambersBuilding material handlingAgricultural engineeringTruck

The invention discloses an assembling machine of high altitude prefabricated slabs, relates to construction equipment for the assembly of high altitude prefabricated slabs, and aims to provide an assembling machine of high altitude prefabricated slabs for accomplishing the assembly of high altitude prefabricated slabs in the environment that height and width are limited and the passing at the lower part of the machine is guaranteed. The machine comprises a main structure, a movable lifting truck, a crane, a walking wheel unit, an engine unit and a driving cab, wherein the movable lifting truck and a crane structure are arranged at the upper part of the main structure; a walking beam and a power walking mechanism are arranged below the main structure; the driving cab is mounted at the front part of the main structure and can control various operations of the complete machine; the movable lifting truck mounted above the main structure can move laterally and can jack and turn the prefabricated slabs; a crane vertical column mounted above the main structure can adjust the height; the crane can lift or lower down the prefabricated slabs under the control of the driving cab, so that the assembly of top prefabricated slabs can be accomplished while the height and width are limited and internal empty passing space is guaranteed.

Owner:北京联桥智能装备技术有限公司

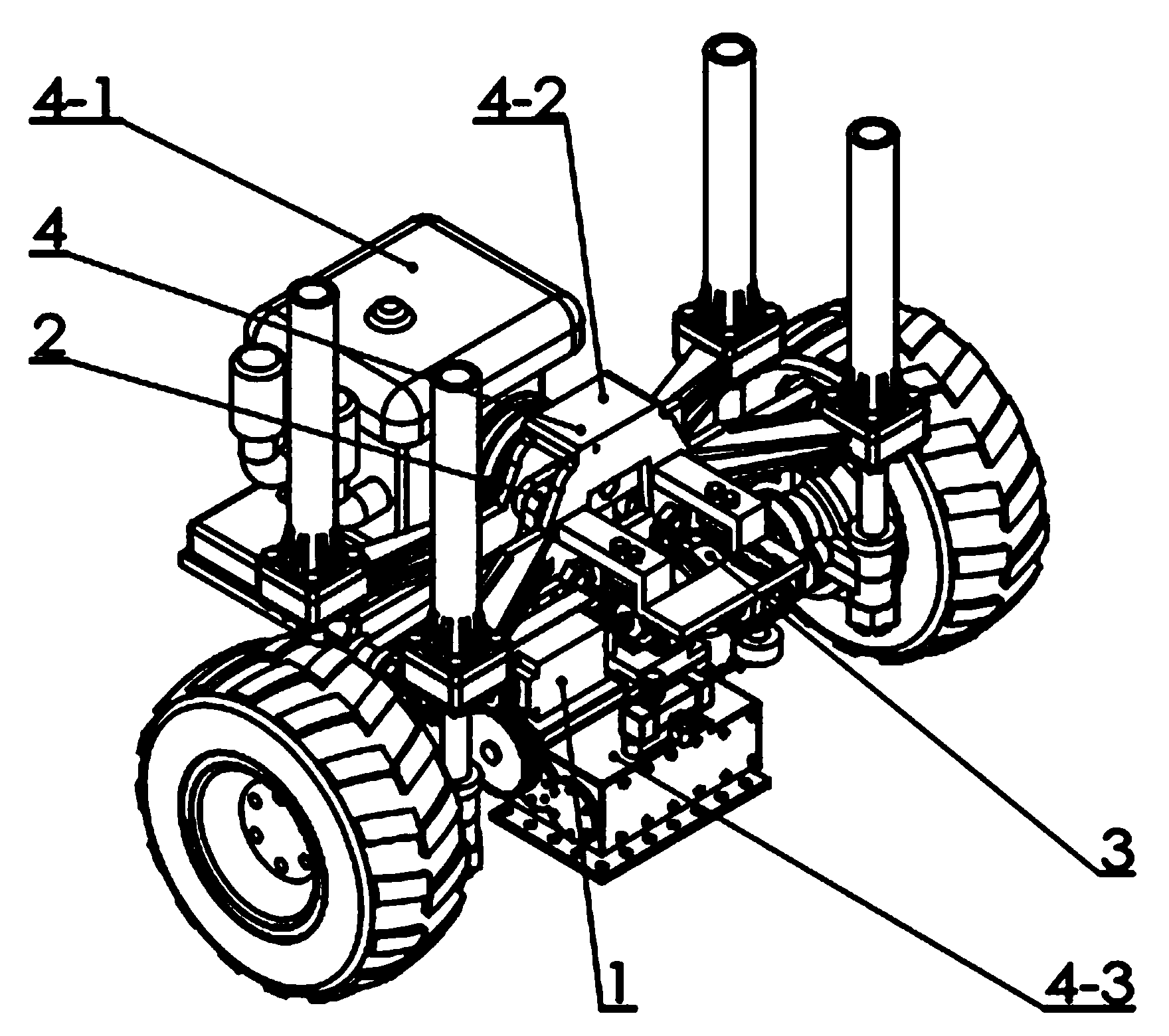

Crawler self walking type garlic harvesting machine

The invention provides a crawler self walking type garlic harvesting machine, which comprises a clamping conveying cutting part, a soil digging part, a power walking part and a transmission transportation collecting part, wherein the clamping conveying cutting part is a main work unit of the crawler self walking type garlic harvesting machine; the back side of the clamping conveying cutting part is connected and provided with the power walking part; the power walking part consists of a vehicle underpan, a driving operation and control system, an oil tank, an engine and a crawler walking mechanism. The transmission transportation collecting part comprises a garlic head gathering inclined plate, a garlic head conveying belt, a garlic head back collecting box, a carrying plate, a garlic stalk conveying belt, a garlic conveying motor and a garlic stalk conveying motor.

Owner:SHANDONG MARIA MACHINERY

Trolley for regularly laying cobblestones

ActiveCN111305014AImprove aestheticsGuaranteed fixed effectRoads maintainenceStructural engineeringMechanical engineering

The invention discloses a trolley for regularly laying cobblestones. The trolley comprises a trolley body and a trolley hopper, wherein a compaction cavity with a downward opening is formed in a lowerleft end in the trolley body, two overturning cavities are formed in the middle in the trolley body, a cobblestone sorting mechanism for sorting cobblestones is arranged in the trolley hopper, a regular laying mechanism for regularly laying the cobblestones is arranged in the overturning cavity, a compacting and bulldozing mechanism for compacting and fixing the paved cobblestones is arranged ina compacting cavity, and a power walking mechanism for device transmission is arranged at a lower end of the trolley body. The trolley is advantaged in that during working, required power can be provided through manual pushing, manufacturing cost is saved, operation convenience is further improved, the cobblestones are sorted according to the sizes of the cobblestones during working, when the cobblestones are laid, the cobblestones with larger sizes and the cobblestones with smaller sizes are alternately and orderly laid, so attractiveness of cobblestone laying is improved, and the laid cobblestones can be compacted to ensure that the positions of the cobblestones are fixed.

Owner:临沂高新置业有限公司

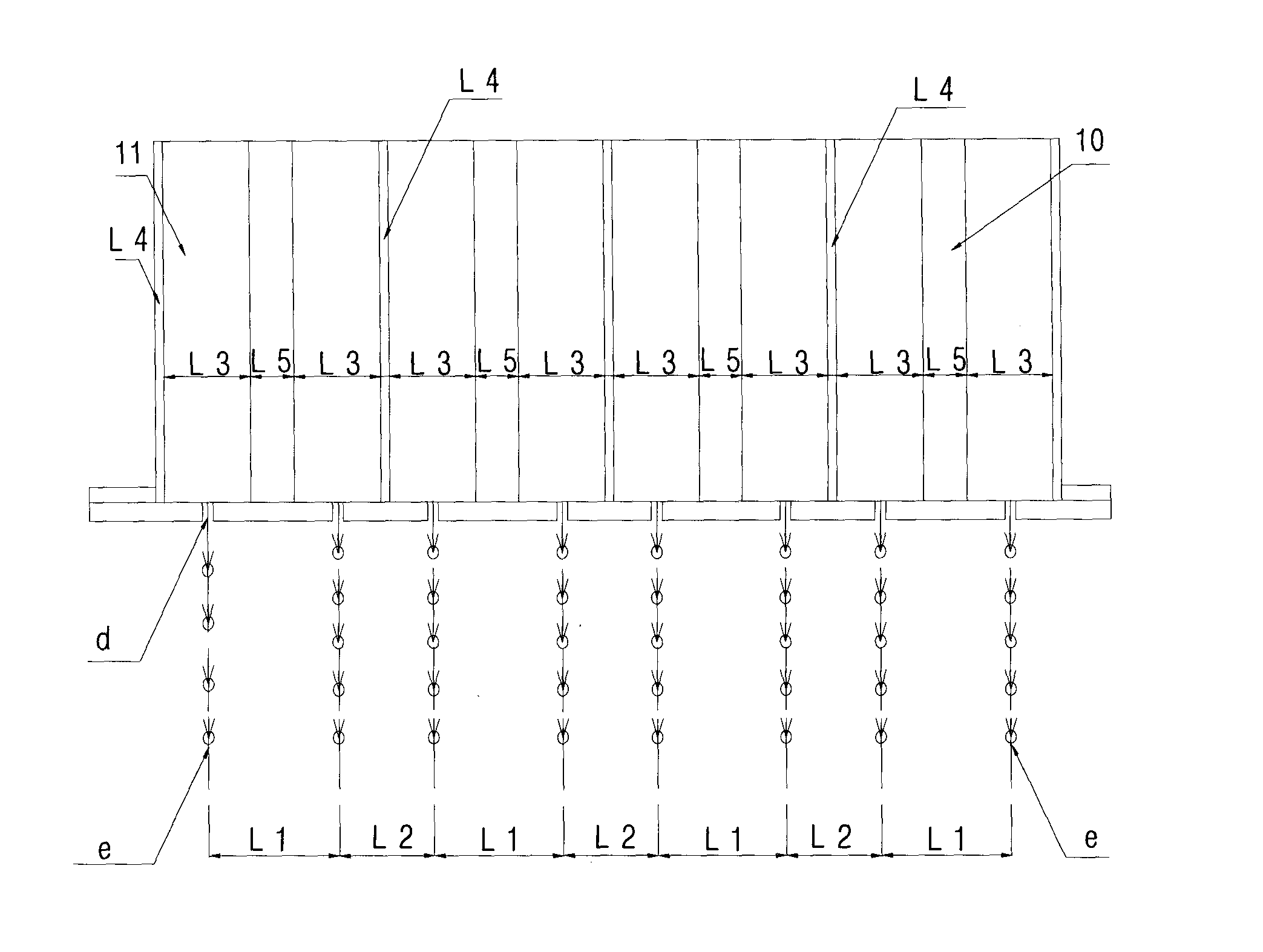

Wide and narrow row spacing type rice transplanter

InactiveCN103518443AReasonable and novel structure designImprove job qualityTransplantingAgricultural engineeringPower walking

The invention provides a wide and narrow row spacing type rice transplanter capable of planting rice with wide and narrow row spacings. The wide and narrow row spacing type rice transplanter comprises seedling boxes, left and right transplanting mechanisms, seedling box moving mechanisms and a rear suspension rack connected with a power running device; the seedling boxes can horizontally move left and right on the rear suspension rack under the rotation of the seedling box moving mechanisms; the spacings among seedling taking and transplanting mechanisms in the same group are the width of the wide row, and the spacings among seedling taking and transplanting mechanisms of different groups of transplanting mechanisms are the width of the narrow row, and wide rows and the narrow rows are arranged at intervals; the seedling boxes are separated into a plurality of equal seedling placing units; units are separated by groove-shaped plates, and the widths of the groove-shaped plates of the adjacent seedling placing units are not equal, namely, the wide groove-shaped plates correspond to the wide rows, and the narrow groove-shaped plates correspond to the narrow rows, so that under the same transplanting stroke, seedlings form an alternant wide and narrow row transplanting mode.

Owner:杨永生

Numerical control fine grinding machine for rail contours and rail lines

InactiveCN108166341AAchieve fine grindingEasy to operateRailway track constructionNumerical controlDrive wheel

The invention discloses a numerical control fine grinding machine for rail contours and rail lines. The numerical control fine grinding machine comprises walking and shape-keeping assemblies, a walking and shape-keeping device, a traversing device and a grinding device, wherein the plurality of walking and shape-keeping assemblies are separately arranged on the left and right sides of the walkingand shape-keeping device and used for moving along steel rails; the traversing device comprises a grinding support frame, driven connectors and driven wheels; and the grinding device comprises a sliding block assembly, a first motor, a first reducer, a first gear, a sliding groove assembly, a vertical rack, a second motor, a second reducer, a second gear, a main motor and a grinding wheel. The numerical control fine grinding machine for the rail contours and the rail lines allows the walking and shape-keeping assemblies and a self-powered walking and shape-keeping assembly to move along the steel rails by arranging connection support frames, the walking and shape-keeping assemblies and the self-powered walking and shape-keeping assembly at the walking and shape-keeping device, and drives the grinding wheel to move to the to-be-ground position of the steel rails for grinding by arranging the sliding block assembly and the driven wheels at the traversing device, so as to realize the finegrinding of any position of the rail contours of the steel rails and to facilitate the operation.

Owner:中国铁路北京局集团有限公司保定工务段

Sheaf-binding reaping machine for ramie

PendingCN110122050AEfficient deliveryRealize deliveryReaper-bindersEngineeringMechanical engineering

The invention discloses a sheaf-binding reaping machine for ramie. The technical scheme is characterized in that the machine comprises a machine body, a power walking mechanism, a cutter mechanism, aclamping and conveying mechanism and a binding mechanism, wherein the feeding end of the clamping and conveying mechanism is located above the cutter mechanism, the binding mechanism is located at thedischarging end of the clamping and conveying mechanism, and the clamping and conveying mechanism comprises a rack and a conveying channel arranged on the rack; a conveying chain is rotationally connected to the rack and located on one side of width of the conveying channel, and stirring pieces are arranged on the conveying chain; a pushing device is arranged on the other side of width of the conveying channel and comprises elastic stirring rods which are arranged in the length direction of the conveying channel, and blocking rods are arranged at the ends of the elastic pulling rods; stirringwheels and blocking plates are rotationally connected with the feeding end of the conveying channel, and are located on two opposite sides of the feeding end of the conveying channel. The sheaf-binding reaping machine can overcome unstable conveying, easy blockage, easy breaking of ramie and the like.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Miniature terrain-simulating automatic differential height power walking machine

InactiveCN103847511AAvoid offsetImprove stabilityResilient suspensionsControl devicesTerrainDrive wheel

The invention discloses a miniature terrain-simulating automatic differential height power walking machine, which comprises a power device, a safety clutch device and a differential height executing device, wherein the safety clutch device and the differential height executing device are respectively connected with the power device. The machine is characterized by also comprising a terrain-simulating differential height control device, wherein the terrain-simulating differential height control device is respectively connected with an engine and the safety clutch device; the terrain-simulating differential height control device is connected with a connecting rod power shaft of the differential height executing device through a worm gear which is arranged in the terrain-simulating differential height control device, the power is inputted for a connecting rod swinging beam structure and a slide rod sleeve tube limiting mechanism of the differential height executing device, and then the differential height of driving wheels at the two sides of the machine is realized. The machine has the advantages that the structure is simple, and the operation is easy and convenient; the tilting degree of a vehicle body can be automatically identified according to the concave-convex conditions of operation grounds, such as mountains and hills, and the relative heights of the driving wheels at the two sides are adjusted, so the body of the walking machine is stable, and the easiness in side tilting is avoided.

Owner:GUANGXI NORMAL UNIV

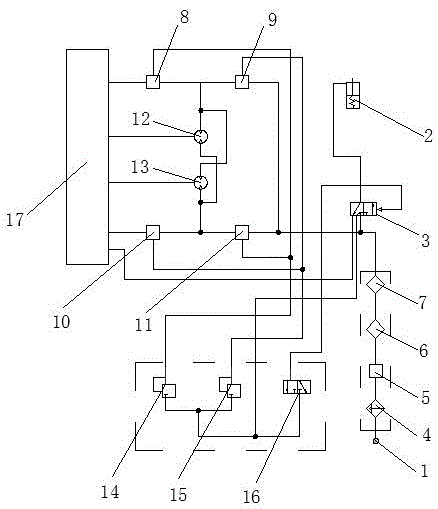

Stepless speed regulating control system of pneumatic monorail crane

ActiveCN105041743AImprove reliabilityImprove securityBraking action transmissionServomotor componentsControl systemEngineering

The invention provides a stepless speed regulating control system of a pneumatic monorail crane. The stepless speed regulating control system consists of an air source processing system, a speed regulating reversing handle, a pneumatic motor power system and a pressure flow speed regulating system, wherein the air source processing system consists of an oil-water separator, a pressure reducing valve, a filter and an atomized lubricator; the speed regulating reversing handle is integrated by control handles of two pressure adjusting valves and an auxiliary reversing valve; the pressure flow speed regulating system consists of four speed regulating valves; and compressed air is supplied to a pneumatic motor, a cylinder and the speed regulating reversing handle for use by the air source processing system. The control system can precisely control the air pressure and flow to realize the stepless speed regulating power walking and the brake stopping of the pneumatic monorail crane, and can realize slow starting and braking to prevent quick starting / stopping phenomenon, so that the wear of a brake friction wheel is reduced, the monorail crane can operate more smoothly, and the stepless speed regulating purpose of the monorail crane can be realized; and the stepless speed regulating control system improves the operation reliability and safety of the monorail crane.

Owner:徐州华东机械有限公司

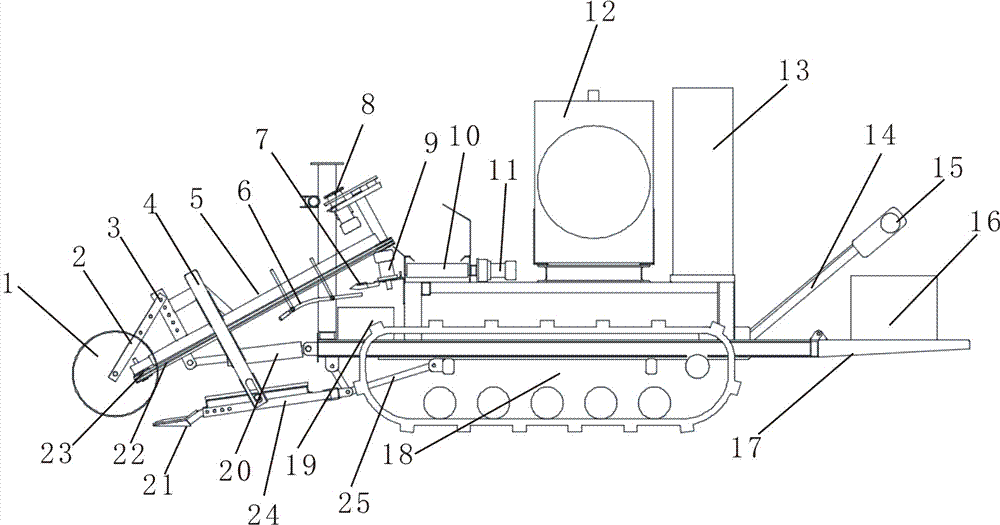

Small crawler type tuber combine harvester

The invention discloses a small crawler type tuber combine harvester which comprises a power walking mechanism, wherein an excavation mechanism and a conveying and cleaning mechanism are arranged on the power walking mechanism; the excavation mechanism is located in front of the conveying and cleaning mechanism and fixedly connected to the conveying and cleaning mechanism; the power walking mechanism comprises a crawler type walking chassis on which a gearbox is arranged; the gearbox is connected with a belt pulley through a belt; the belt is connected with a driving rotation shaft through a driving wheel; the conveying and cleaning mechanism comprises a conveying device, a support wheel and an intermediate shaft; the support wheel and the intermediate shaft are used for bearing the conveying device; and the conveying device comprises a plurality of conveying chains and is connected with the crawler type walking chassis through the driving rotation shaft. The small crawler type tuber combine harvester has the beneficial effects that by using the crawler type walking chassis, stepless speed change walking is realized, the center of gravity of the whole harvester is low, the safety coefficient is high and the miniaturization and compaction of the harvester are conveniently realized; and by using a sing-step conveying chain structure, the combination process of excavation, separation, cleaning and box collection is realized.

Owner:QINGDAO AGRI UNIV +1

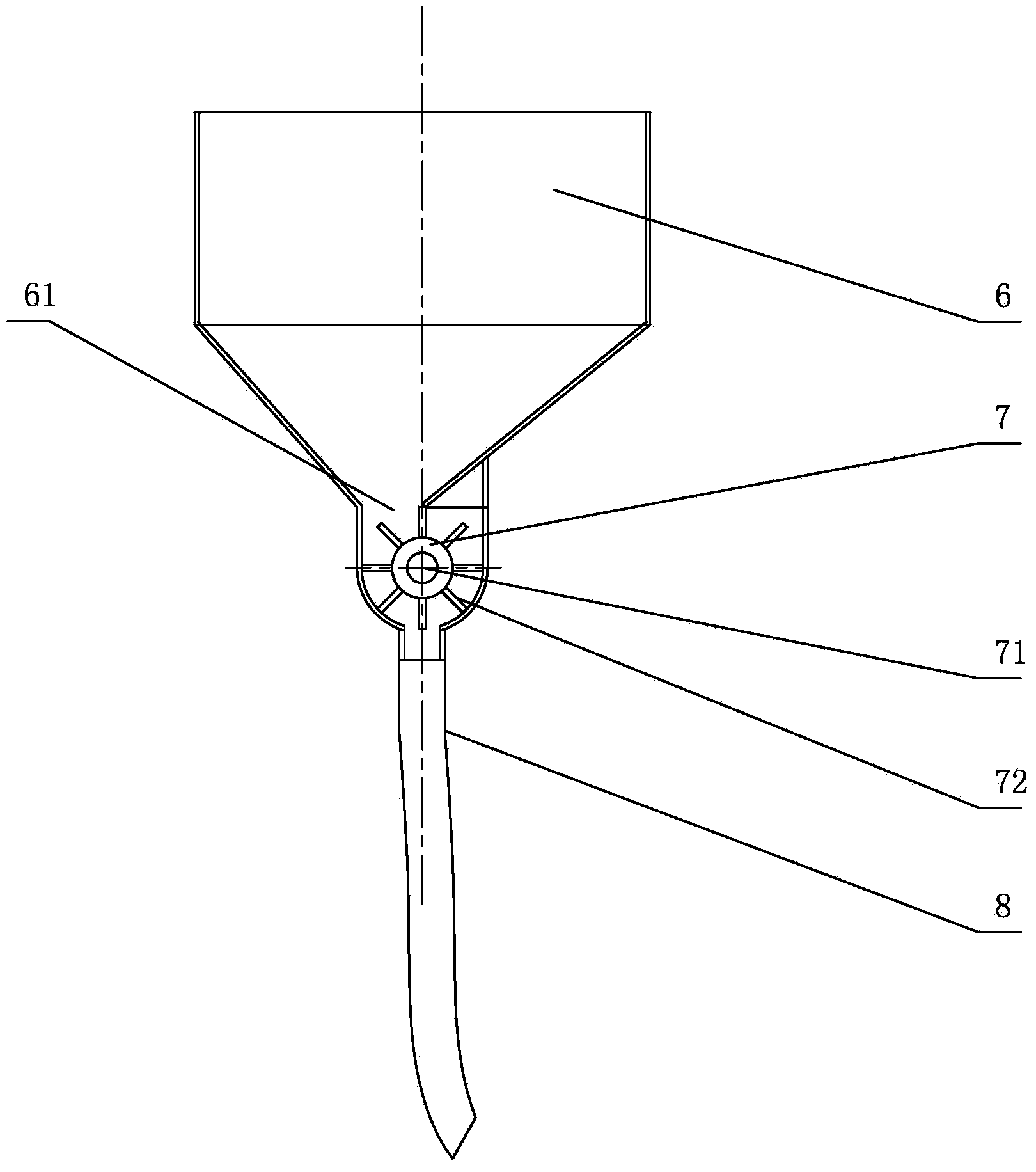

Paddy field chemical fertilizer burying device

The invention provides a paddy field chemical fertilizer burying device. The paddy field chemical fertilizer burying device comprises a paddy field power walking part, a fertilizer discharging part and a slurry stirring part, wherein the slurry stirring part comprises a slurry stirring wheel which rotates in a paddy field in a driving or driven manner so that slurry in a field walking track is stirred; the fertilizer discharging part comprises a fertilizer box for storing fertilizers, and a fertilizer discharging mechanism mounted at the bottom of a box body; the fertilizer discharging mechanism is used for discharging the fertilizers from the fertilizer box into the field along a fertilizer applying pipe; the slurry stirring wheel is located behind an outlet of the fertilizer applying pipe; and the stirring part and the fertilizer discharging part are connected with the power walking part into a whole body by a rack. According to the paddy field chemical fertilizer burying device, after a fertilizer is applied into the paddy field, the slurry in the paddy field is stirred by the stirring wheel and then is mixed with the applied fertilizers, so that the fertilizers are fused into mud and the aim that the effect by using the device is same with the deep application effect is realized.

Owner:CHINA NAT RICE RES INST

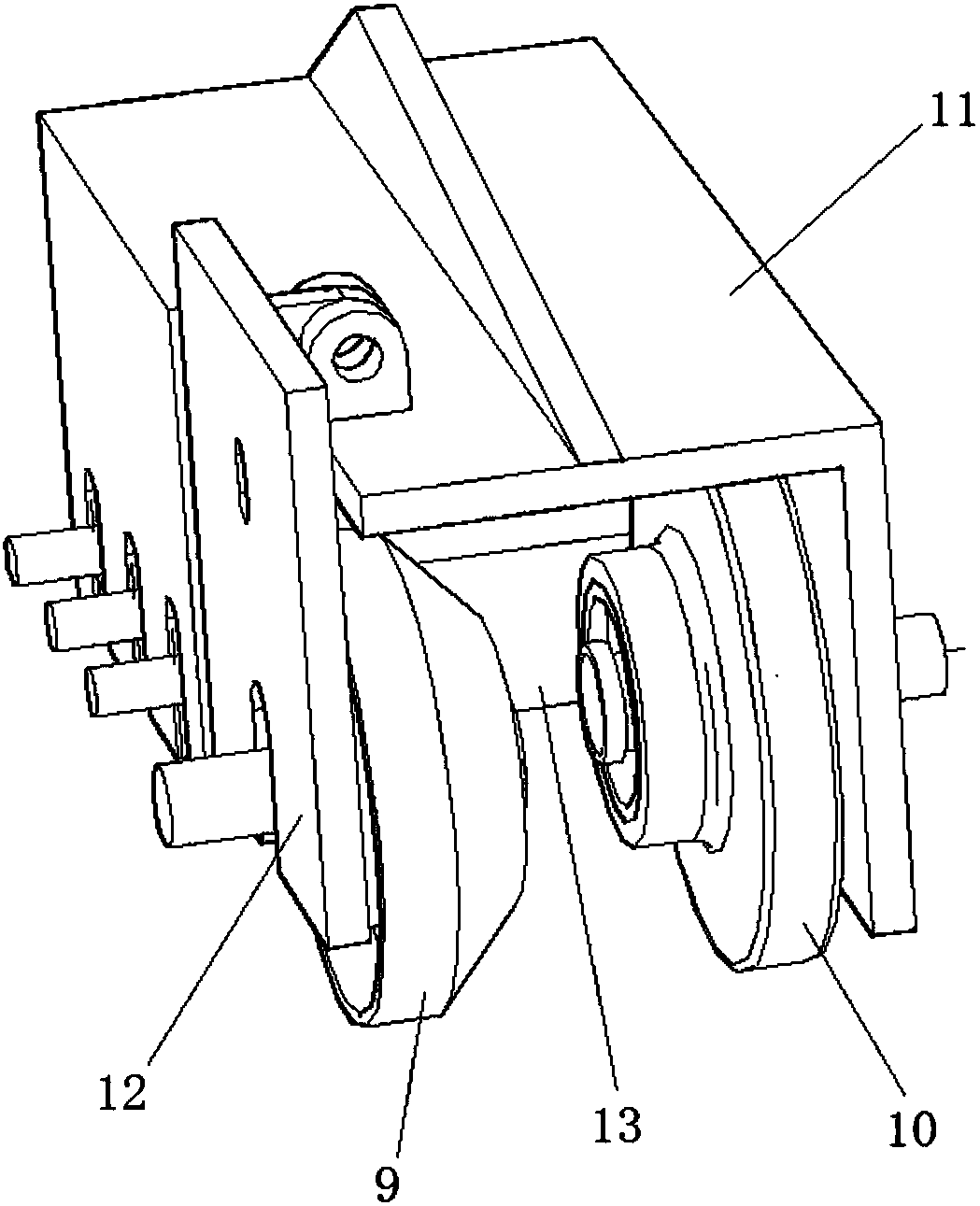

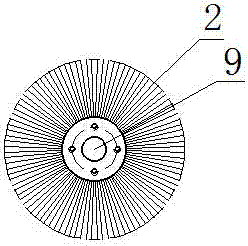

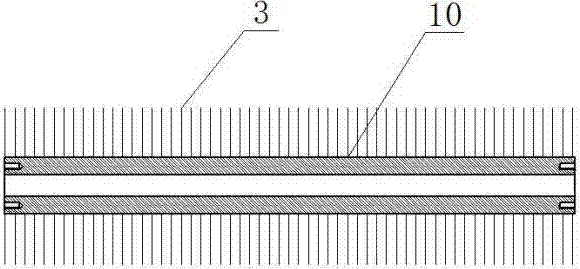

Brush type double separating dried date pickup machine

The invention discloses a brush type double separating dried date pickup machine which comprises a crawler-type dynamic walking chassis (1), wherein a pickup rack is arranged on the crawler-type dynamic walking chassis (1), two wallboards (11) are arranged on the front end of the pickup rack, a pickup (2) with a cleaning brush (9) is arranged at the front end of each of the wallboards (11), a throwing shaft (10) with a throwing member (3) is parallelly arranged on the front end of the pickup (2) on the pickup rack, a conveying separating chain (4) is arranged on a closed chain on the back end of the pickup (2), a residue separating belt (6) is arranged on the lower portion of the other end of the conveying separating chain (4), a pushing auger (5) is arranged on the lower portion of the residue separating belt (6), a lifter (7) is arranged on the lower portion of the pushing auger (5) on the pickup rack, and a fruit box (8) is arranged on an outlet of the lifter (7) on the back end of the pickup rack. With adoption of the brush type double separating dried date pickup machine disclosed by the invention, the effects of being simple in effect, reducing the labor intensity, being high in mechanical degree, intact and scratch-free in fruit, capable of continuously working and high in efficiency are achieved.

Owner:山东江华机械制造有限公司

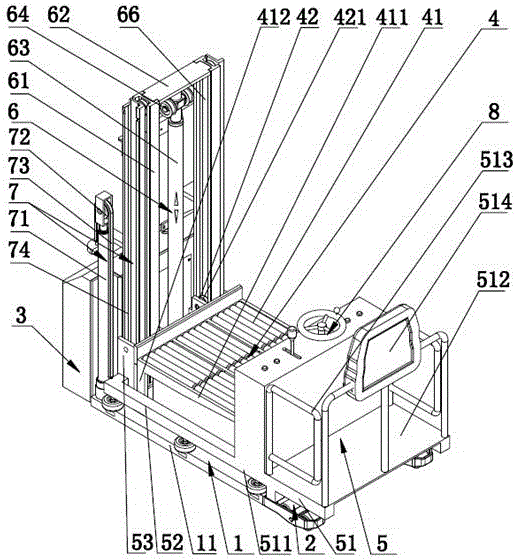

Electric goods taking trolley

The invention discloses an electric goods taking trolley. The electric goods taking trolley comprises a supporting chassis. A walking mechanism is arranged at the bottom of the supporting chassis and connected with a drive device driving the walking mechanism to move. The drive device is further connected with a goods carrying platform lifting mechanism arranged on the supporting chassis and driving a goods carrying platform to rise and fall, and a human carrying platform lifting mechanism arranged on the supporting chassis and driving a human carrying platform to rise and fall. A control console synchronously rising and falling together with the human carrying platform and partitioning the space of the goods carrying platform and the personnel operation space of the human carrying platform is arranged on the human carrying platform. The control console is connected with the drive device. The electric goods taking trolley can walk with the help of power under control of operating personnel and is convenient to operate; by means of the goods carrying platform and the human carrying platform which are independent and can rise and fall, separation of the goods containing space and the operating personnel operation space can be effectively achieved, and the problem that interference exits between the two spaces in one platform in the prior art is effectively saved; and by arranging the control console to partition the spaces, operating personnel can have a larger operation space, and meanwhile the operating personnel are protected to a certain extent.

Owner:SUZHOU GP LOGISTICS SYST

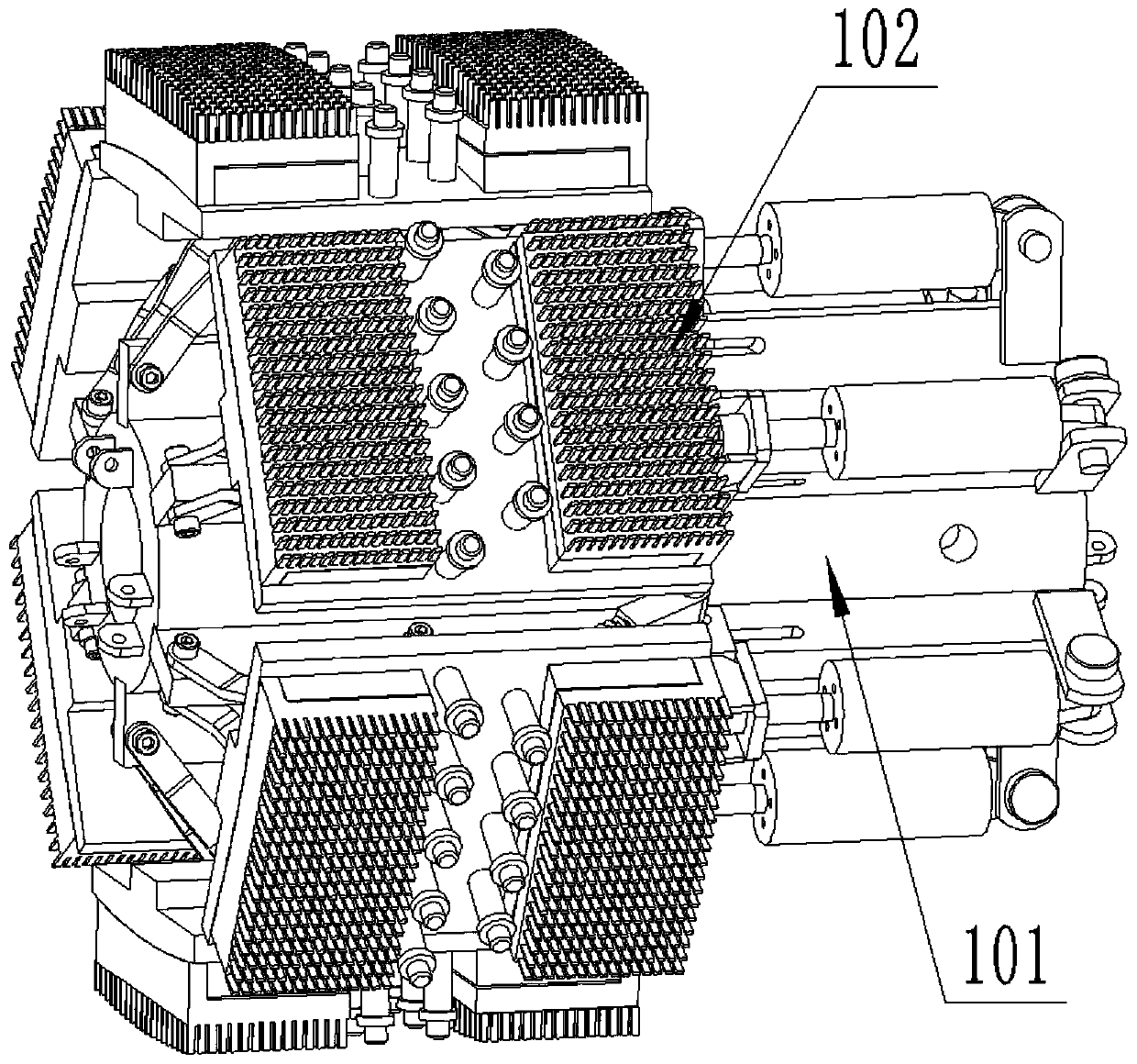

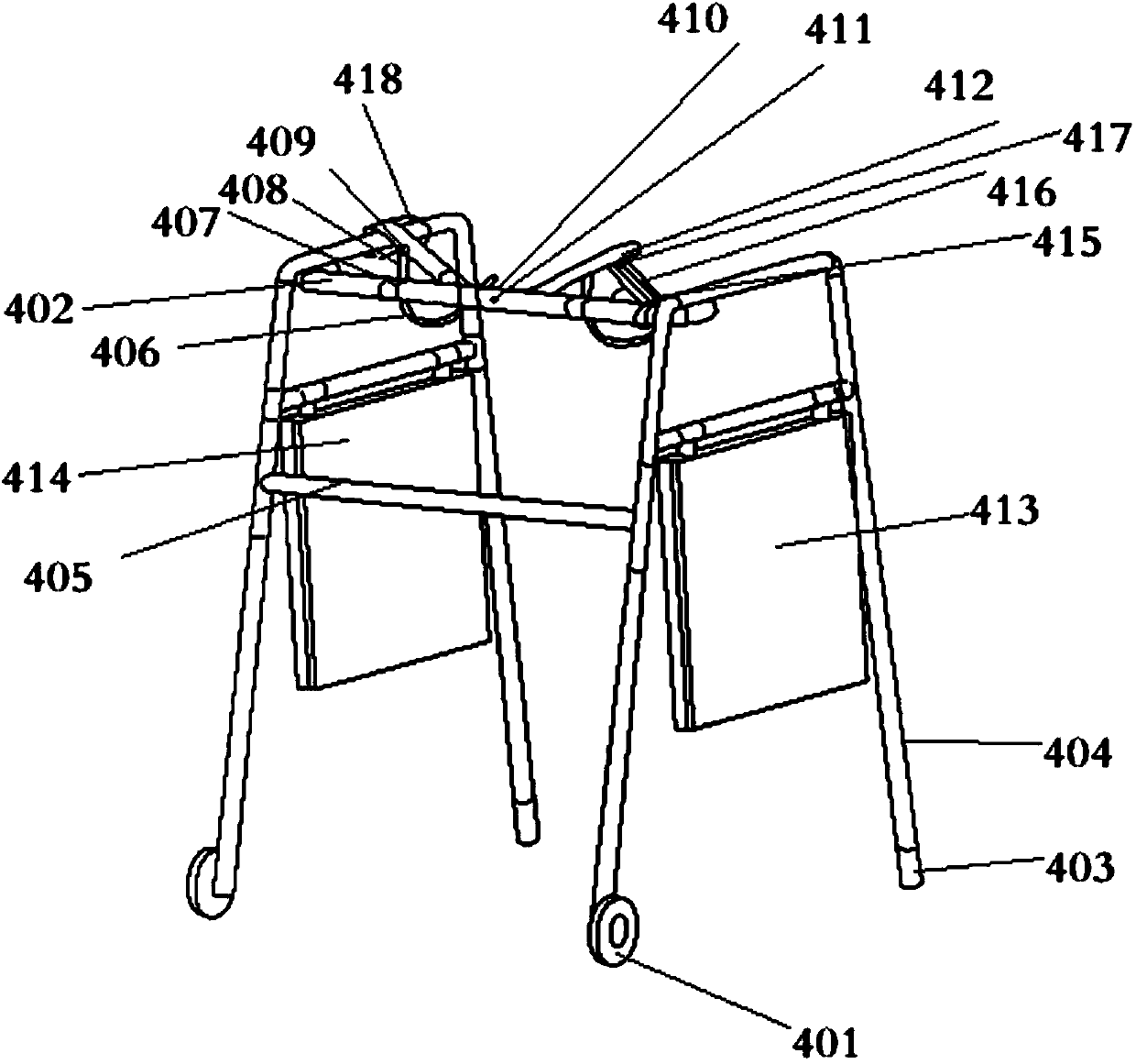

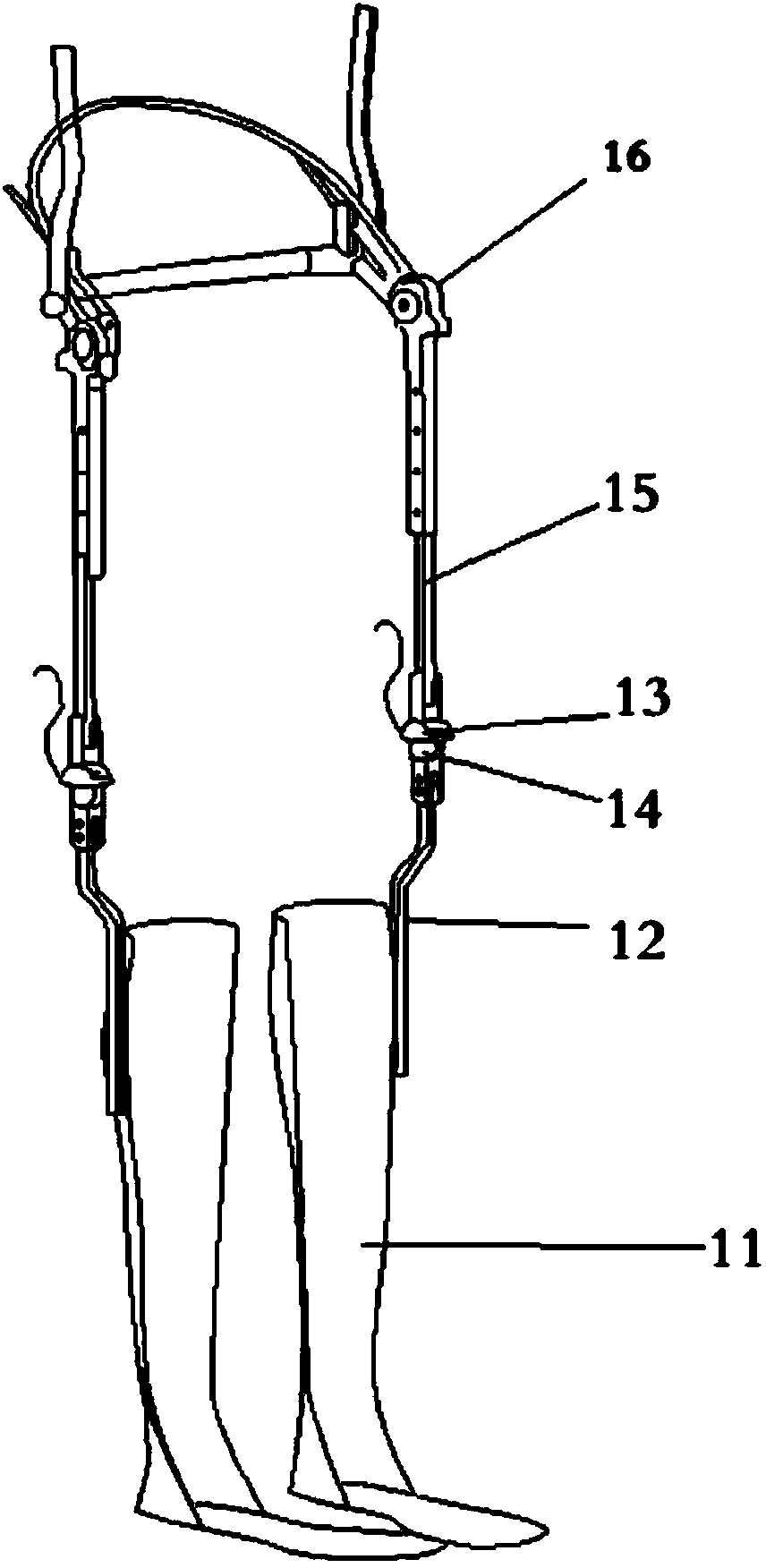

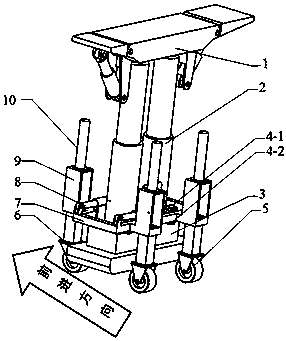

Interactive paraplegia walking-assisting outer bone driven by external power

InactiveCN103989570ACompact structureReduce energy consumptionChiropractic devicesWalking aidsMotor driveEnergy consumption

The invention relates to an interactive paraplegia walking-assisting outer bone driven by external power. The outer bone comprises a walking-assisting trolley and a walking-assisting outer bone body, wherein the walking-assisting trolley is provided with a motor drive mechanism, the walking-assisting outer bone body is provided with a power pull rod mechanism, and the motor drive mechanism is connected with the walking-assisting outer bone body through the power pull rod mechanism. The outer bone has the advantages that the motor drive mechanism is designed on the walking-assisting trolley, drive power provided by the motor drive mechanism is transmitted to an RGO interaction mechanism through a power pull rod, and energy consumption of a paraplegia patient walking by means of the RGO interaction mechanism is reduced; an electric push rod, a controller and a battery are placed on the trolley, the advantage that the RGO structure is compact and ingenious can be maintained, assisting power can be provided for interaction walking of the paraplegia patient, and the advantages of the powered walking-assisting outer bone and unpowered walking-assisting outer bone are integrated.

Owner:CHINA REHABILITATION RES CENT

Wheeled mobile support unit

ActiveCN109236341ASimple structureAccurate at short distances laterallyMine roof supportsPush pullEngineering

The invention discloses a wheeled mobile support unit, and relates to mine mobile support equipment. The unit is used for temporary support of gob side entry retaining or work advance heading, and solves the problem that an existing mobile support equipment system is complicated and has poor adaptability. A wheel frame is added on the basis of a unit bracket, a pair of universal wheels are arranged in front of the wheel frame, and a pair of fixed wheels are arranged at the rear. The universal wheels and the fixed wheels cooperate with a sliding groove in a body of the wheel frame through a guide column, and a lifting jack fixed to an upper support frame vertically raises and lowers walking wheels; the body of the wheel frame and a support unit base are horizontally connected in the left and right directions through a push-pull jack, a walking wheel lifting state is based on the support unit to push the wheel frame, a walking wheel landing state pushes the support unit on the basis of the wheel frame, and the overall lateral movement is alternately achieved; during the long distance transportation, the walking wheels touch the ground and walk through external traction power. The unit adds the self-shifting function of a wheeled walking bracket and improves the system adaptability.

Owner:TIANDI SCI & TECH CO LTD

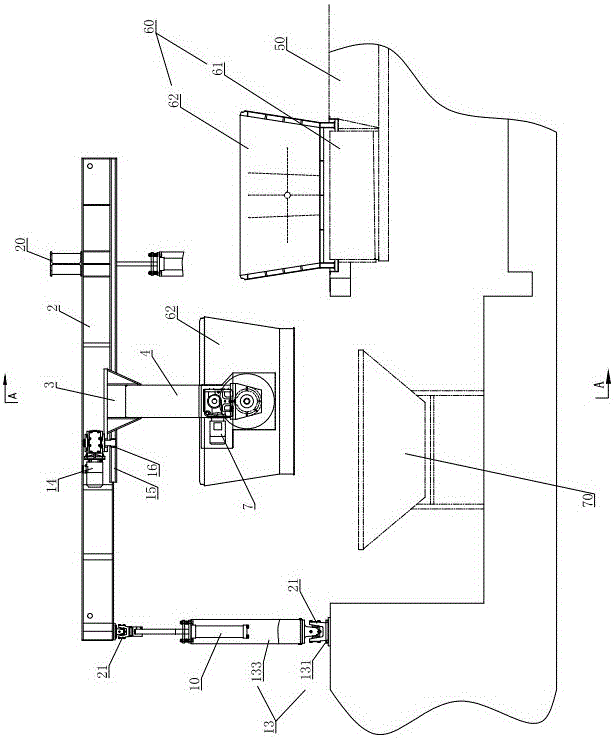

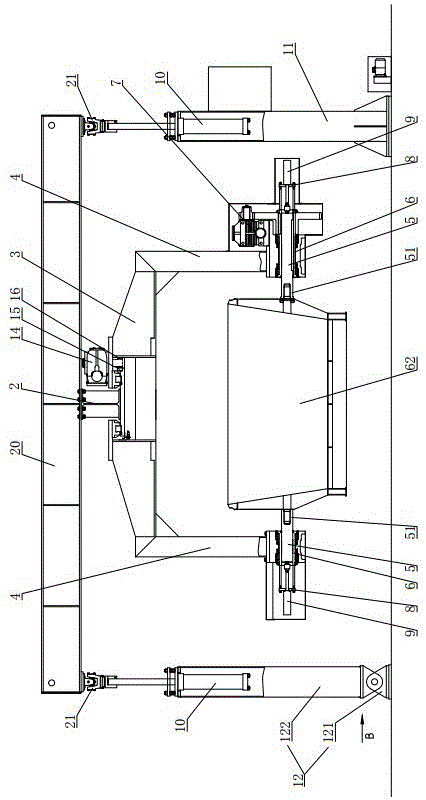

Walking device of rail car

ActiveCN112141134AFlexible steeringImprove passabilityRailway tracksRail derailment preventionVehicle frameSuspension (vehicle)

The invention relates to a walking device of a rail car. The walking device comprises a power walking part, a driven walking part and a suspension beam. The suspension beam and the power walking partare connected by a slewing bearing, the suspension beam and the driven walking part are connected by the slewing bearing, and the driven walking part can oscillate in a walking direction of the walking device of the rail car relative to the power walking part. The walking device comprises the three parts: the power walking part, the driven walking part and the suspension beam. The suspension beamis mounted on the power walking part and the driven walking part by the slewing bearing. According to the structure, the walking device of the rail car is flexible to turn and good in curve trafficability characteristic. By adopting frames with two double shafts, one shaft is provided with one wheel. As two frames are arranged, that is, the power walking part frame and the driven walking part frame, the two frames are connected together by using the suspension beam. The slewing bearing is used at a connection of the suspension beam and the frame. When a vehicle passes a turnout and a curve ofa box type rail, the walking device is more flexible to turn and a phenomenon of stagnation or suspension of a single wheel is avoided.

Owner:云的(辽宁)智能交通科技有限公司

Automatic overturning retort unloading device

InactiveCN105132229AAutomatic retort unloadingComplete unloadingAlcoholic beverage preparationDrive shaftEngineering

The invention discloses an automatic overturning retort unloading device. The automatic overturning retort unloading device comprises a supporting frame; a beam which is driven to lift through a lifting power mechanism and is transversely arranged above a retort bucket and a feeding hopper is arranged on the supporting frame; the cross beam is connected with a walking frame which is driven to slide along the beam through a power walking mechanism; the walking frame is provided with two hanging arms which are arranged longitudinally and are arranged oppositely; drive shafts which are arranged horizontally and oppositely and can rotate and slide are correspondingly connected with the lower parts of the two hanging arms; a driving head which can be connected with a supporting column on the retort bucket is arranged at the inwards extending end of each drive shaft, wherein a retort overturning power device which drives the corresponding drive shaft to rotate is arranged on one hanging arm; a sliding driving device which drives each drive shaft to slide horizontally is arranged at the lower part of the corresponding hanging arm. The automatic overturning retort unloading device has the advantages that retorts can be overturned and unloaded automatically, and the retorts are unloaded thoroughly.

Owner:ANQIU YAOFA MACHINE

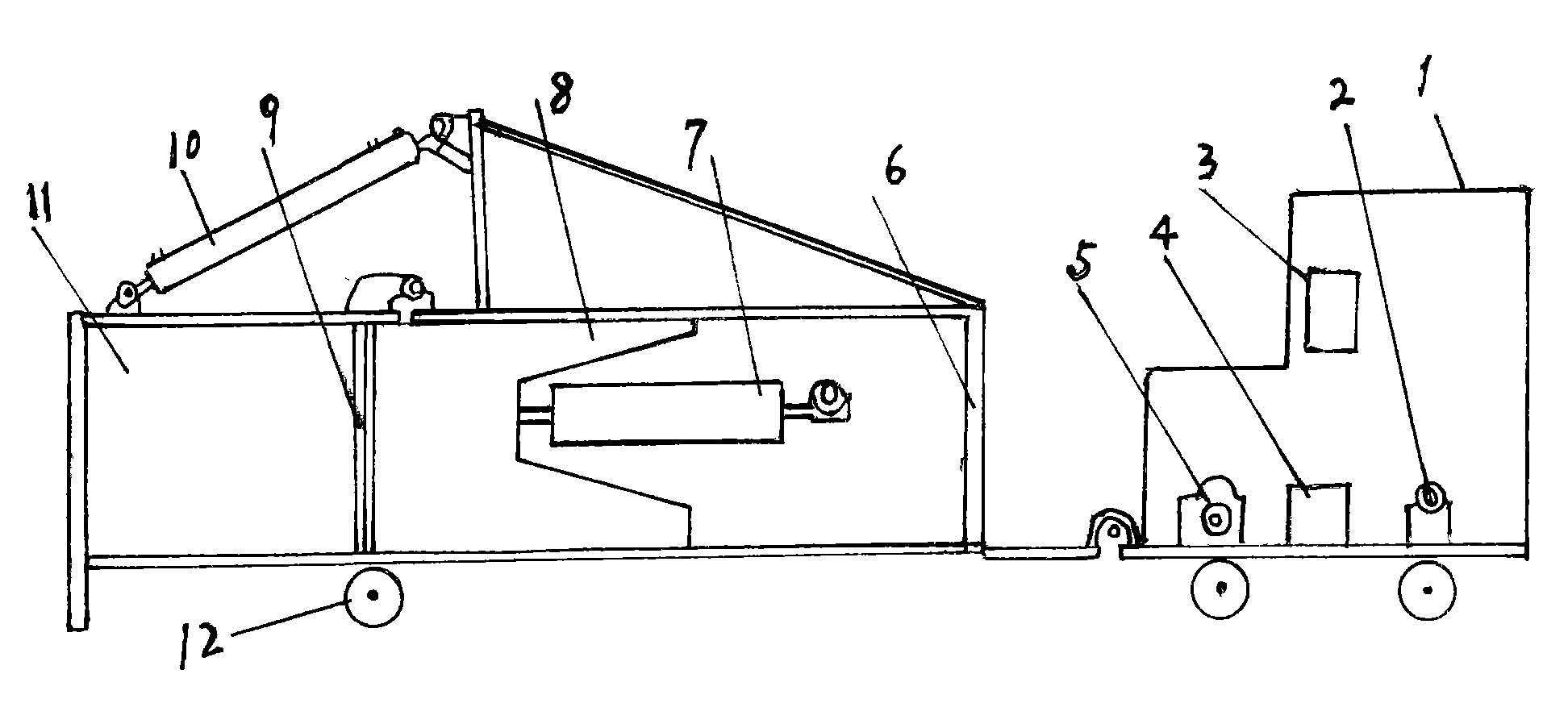

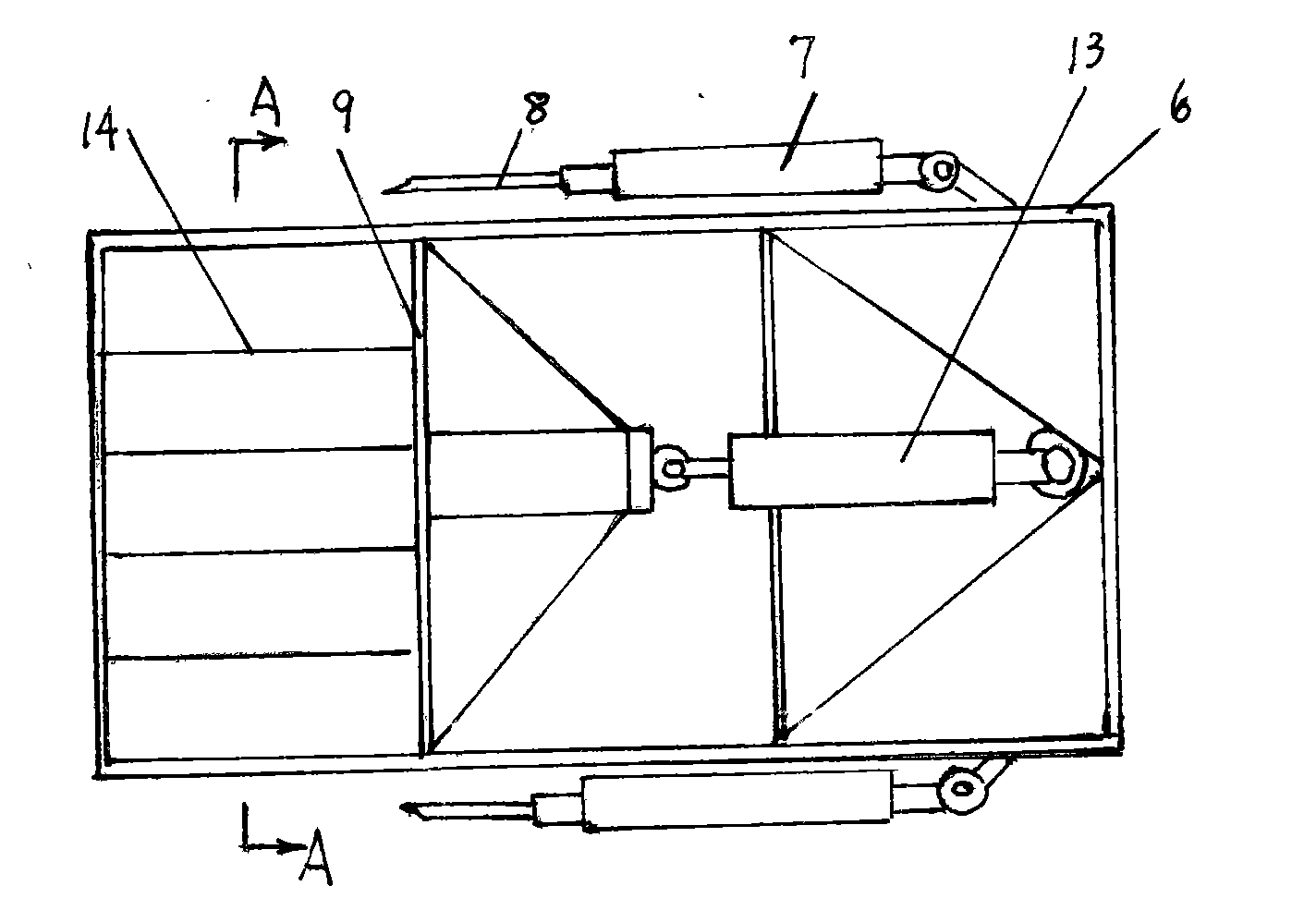

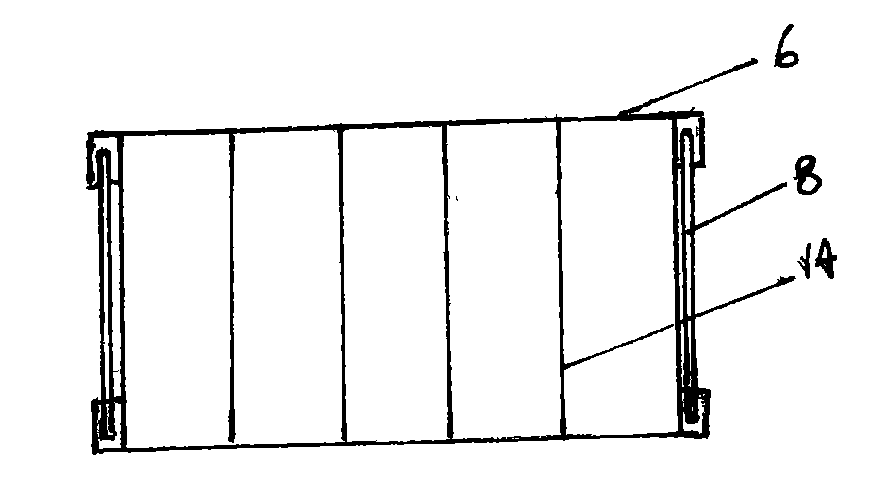

Movable miscanthus sacchariflorus bundling machine

InactiveCN101658093ASolve the problem of bulky and difficult to moveConvenient for field workIndependant bindersEngineeringMiscanthus sacchariflorus

The invention discloses a movable miscanthus sacchariflorus and reed bundling machine, which comprises a power traveling mechanism, a bundling case, a baling device, a miscanthus sacchariflorus and reed cutting device, a movable rope gripping device and a hydraulic system. The moving miscanthus sacchariflorus and reed bundling machine is characterized in that: one end of the bundling machine caseis connected with the power traveling mechanism, while the other end is provided with the bundling device; two side plates of the case are provided with guide grooves respectively; a swallowtail-shaped miscanthus sacchariflorus and reed cutter is arranged between every two guide grooves; each miscanthus sacchariflorus and reed cutter is connected with a miscanthus sacchariflorus and reed cutting oil cylinder; a front cavity of the case is provided with the baling device consisting of a pressure cover plate and a miscanthus sacchariflorus and reed pushing plate; a baling oil cylinder is arranged in a rear cavity of the case; the moving rope gripping device is arranged at the bottom of the front cavity of the case; and the top of the front cavity is provided with a movable pressure cover plate of which the top end is connected with a pressure cover oil cylinder. The bundling machine has good mobility, can freely travel in miscanthus sacchariflorus and reed fields in rivers and lakes, completely solves the cutting and bundling difficulty and the problem that the machine is heavy and hard to move when miscanthus sacchariflorus and reed are bundled, has high bundling quality and high speed, can greatly save the labor force and reduce the waste of the miscanthus sacchariflorus and the reed, and is suitable for use in miscanthus sacchariflorus and reed producing regions all over the country.

Owner:李泽湘

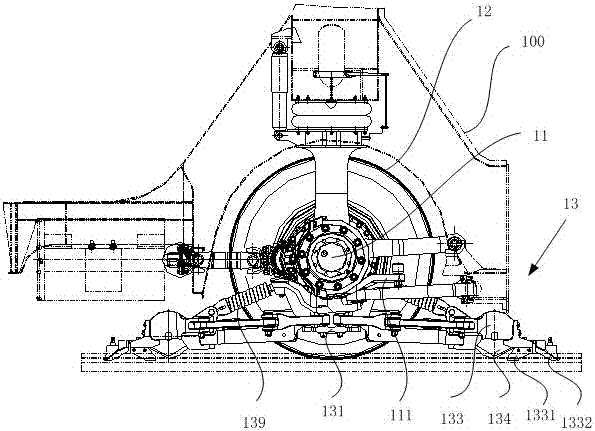

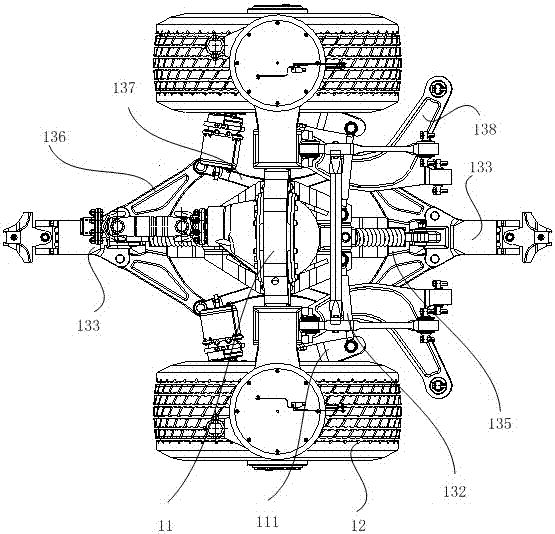

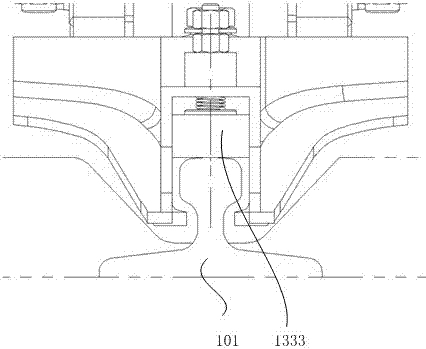

Power walking device and rubber wheel guide rail trolleybus

InactiveCN107512273AImprove operational reliabilityBi-directionalRail derailment preventionRope railwaysCarrying capacityEngineering

The invention provides a power running device and a rubber-tyred guide rail tram. The power running device includes: two beams, a longitudinal beam fixed between the two beams, and a mounting seat fixed on the beams; the upper surface of the front end of the beams is provided with a downwardly inclined first a sloped surface. The power running device can be fixed and assembled on the chassis conveniently through the mounting base, and by setting the first inclined surface at the front end of the crossbeam, the first inclined surface can extend to the bottom of the driver's cab in the dual-purpose railway and road, so that the power can be effectively The center of gravity of the running device is moved forward, so that the rigidity and carrying capacity of the chassis of the rubber-tyred guide rail tram can be improved through the power running device. Realize that the power running device can be guided in two directions, and improve the operation reliability of the guided rubber-tyred guide rail tram.

Owner:CRRC SIFANG CO LTD

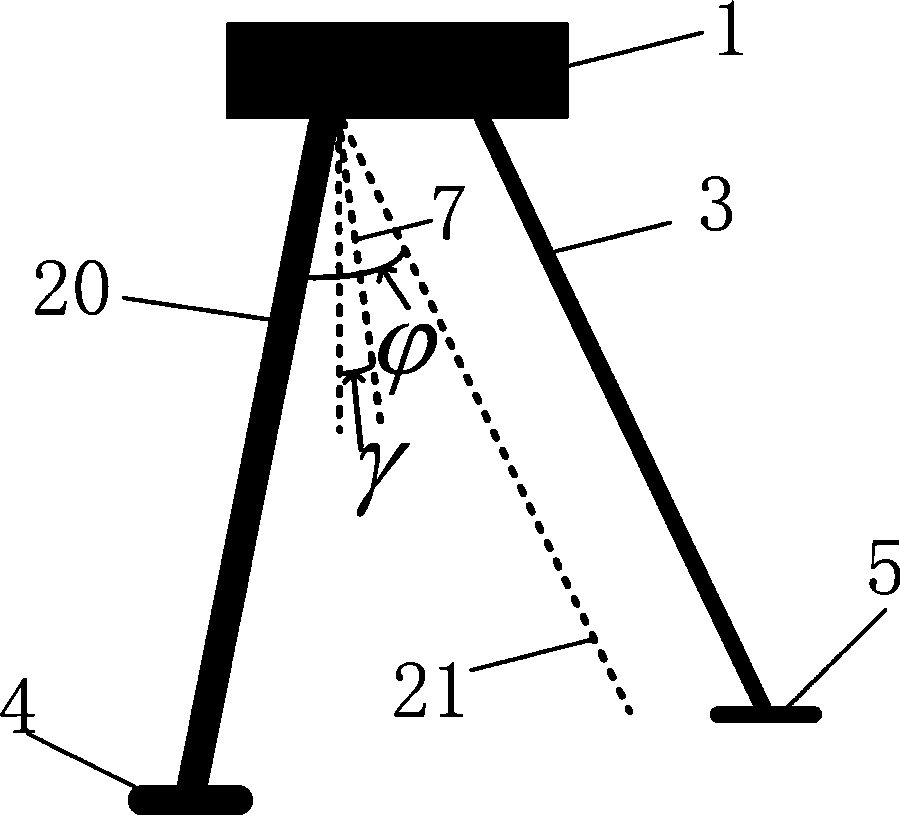

Power travelling device for rice transplanter

InactiveCN102523805AReduce quality problemsImprove work efficiencyGearingTransplantingDrive wheelEngineering

The invention discloses a power travelling device for a rice transplanter. The power travelling device has the following key points: the power travelling device comprises a first crank mechanism and a second crank mechanism which are symmetrically arranged at two sides of the front part of a stander; the first crank mechanism and the second crank mechanism are respectively connected with a first travelling foot and a second travelling foot; a third crank mechanism is arranged at the rear part of the stander; the third crank mechanism is connected with a third traveling foot; a crank of the first crank mechanism and a crank of the second crank mechanism are parallel to each other; and a crank of the third crank mechanism deviates from the crank of the first crank mechanism by 180 degrees. Due to the adoption of the travelling device without driving of wheels, the defects that the traditional drive wheel easily sinks to cause larger resistance to travelling and difficult steering, the adhesive force of the wheel is small to easily cause skid to further cause pit distances in planting to be unequal and the like are overcome; and meanwhile, the overall weight of the transplanter is reduced, and the work efficiency and the work quality of the transplanter are improved.

Owner:SOUTHWEST UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com