Movable miscanthus sacchariflorus bundling machine

A baler and mobile technology, which is applied to individual balers, harvesters, agricultural machinery and implements, etc., can solve the problems of inability to pack reeds into bales, poorly designed cutters, single materials, etc. Manual handling, convenient field operation, good maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

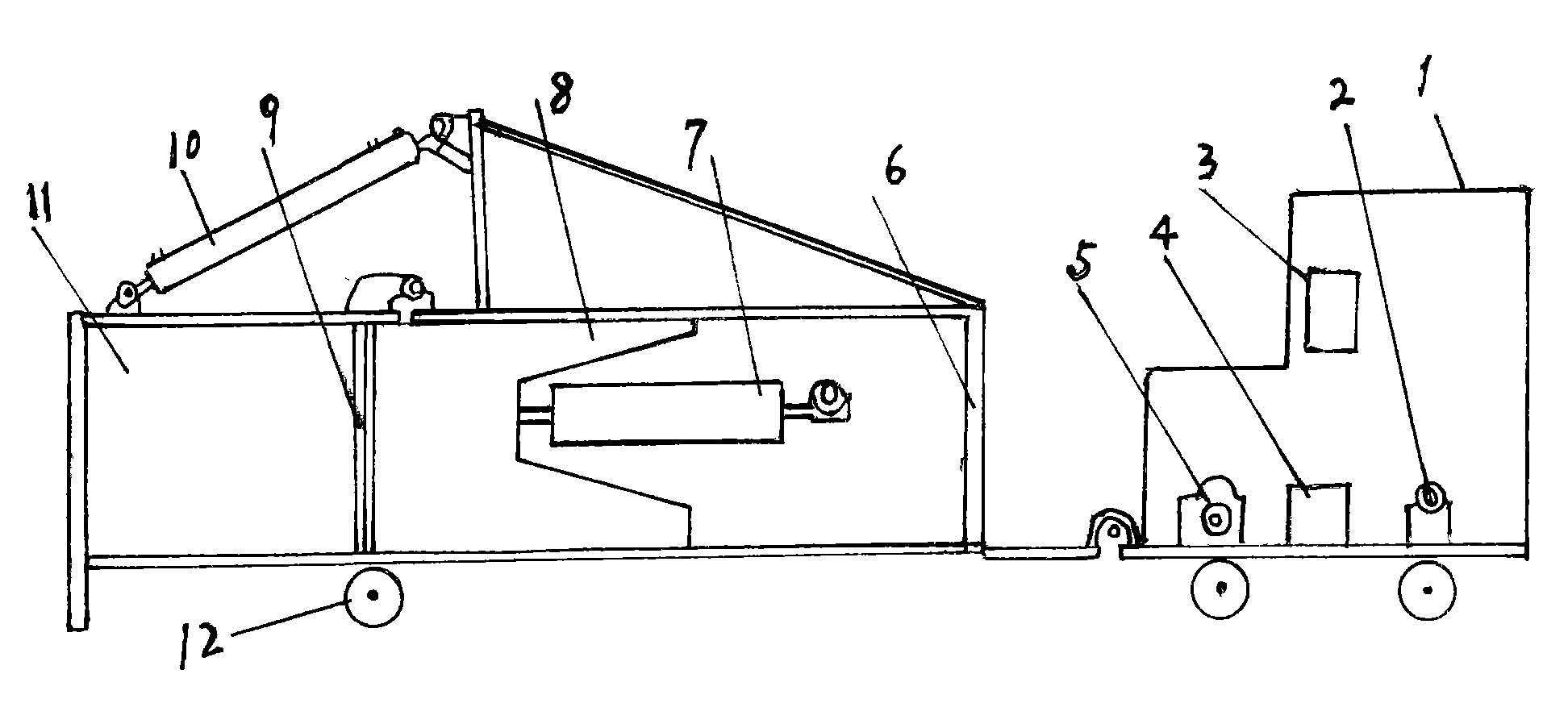

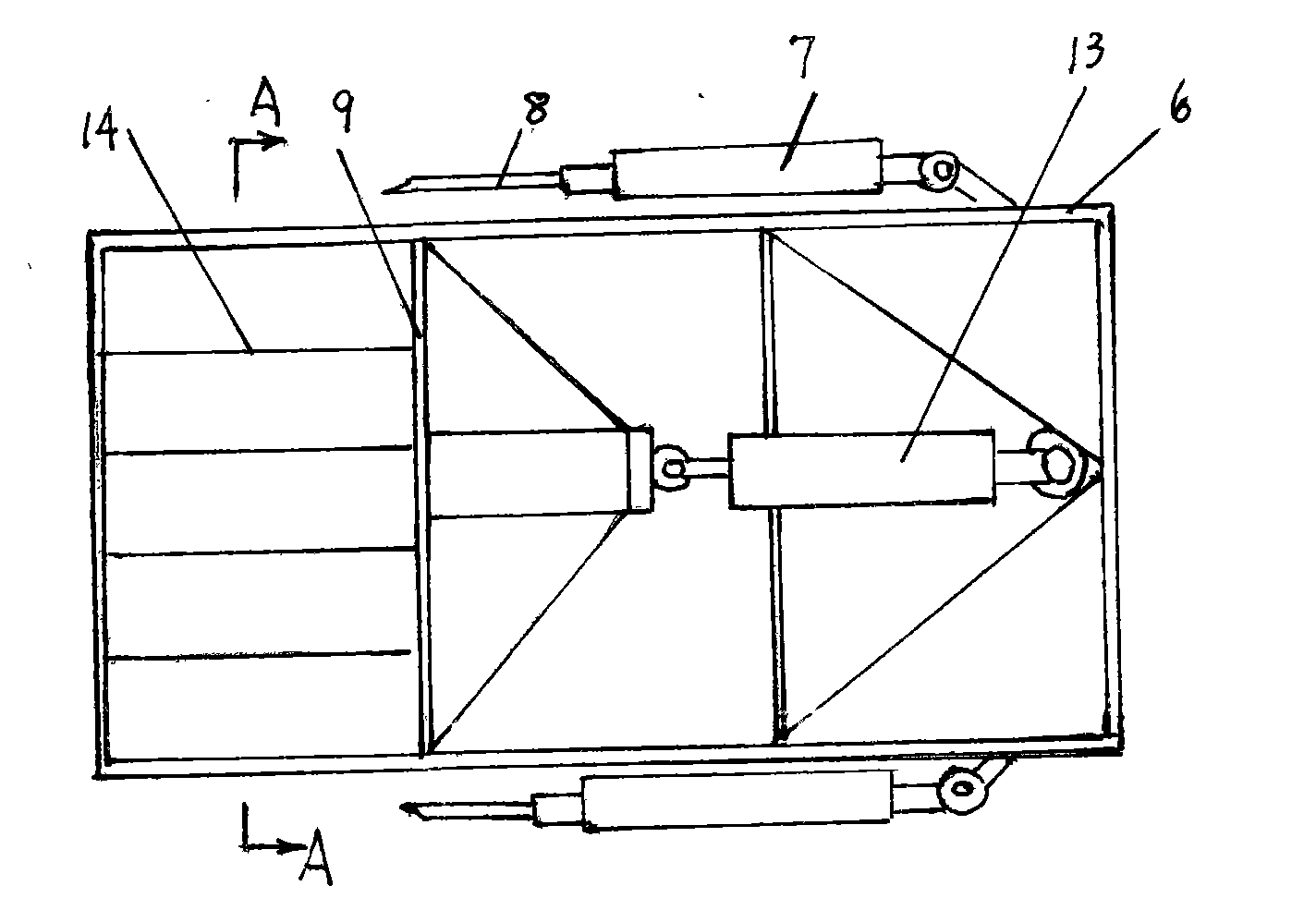

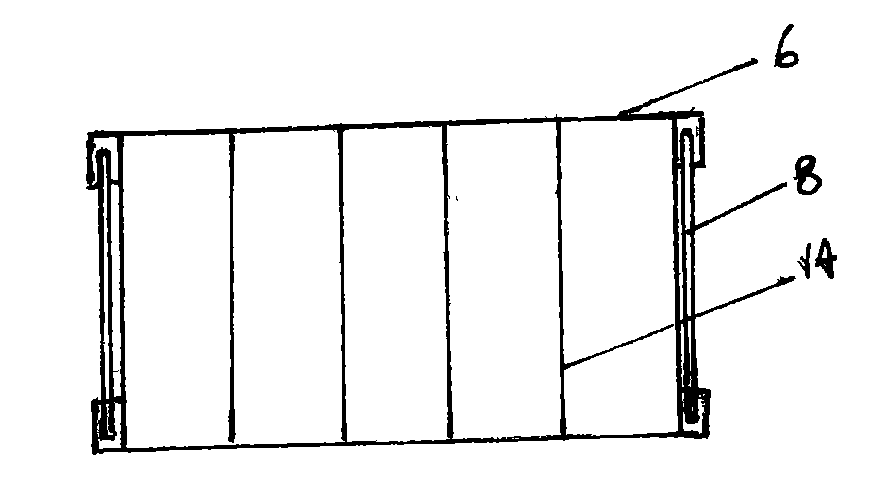

[0016] Refer to the drawings: at one end of the baling box body 6 is connected with a power walking mechanism 1 through a connecting buckle. The walking mechanism is provided with a rolling device 2, a console 3, a power 4 and a hydraulic device 5. The rolling device consists of two It consists of two pairs of rollers with pulleys, and the two pairs of rollers are connected with the power transmission shaft. A guide rail 12 is provided below the bottom plate of the box body 6, two upper and lower concave guide grooves are provided on both sides of the box body 6, the concave guide groove notches are opposite, and the concave guide groove at the bottom of the box body is one Integral guide groove. The concave guide groove on the top of the box body is divided into two sections. One section is set on the upper rear part of the side plate of the box body, and the other section is set on the side plate of the cover plate of the front cavity of the box body. There is an open guide g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com