Patents

Literature

84results about How to "Solve cutting problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

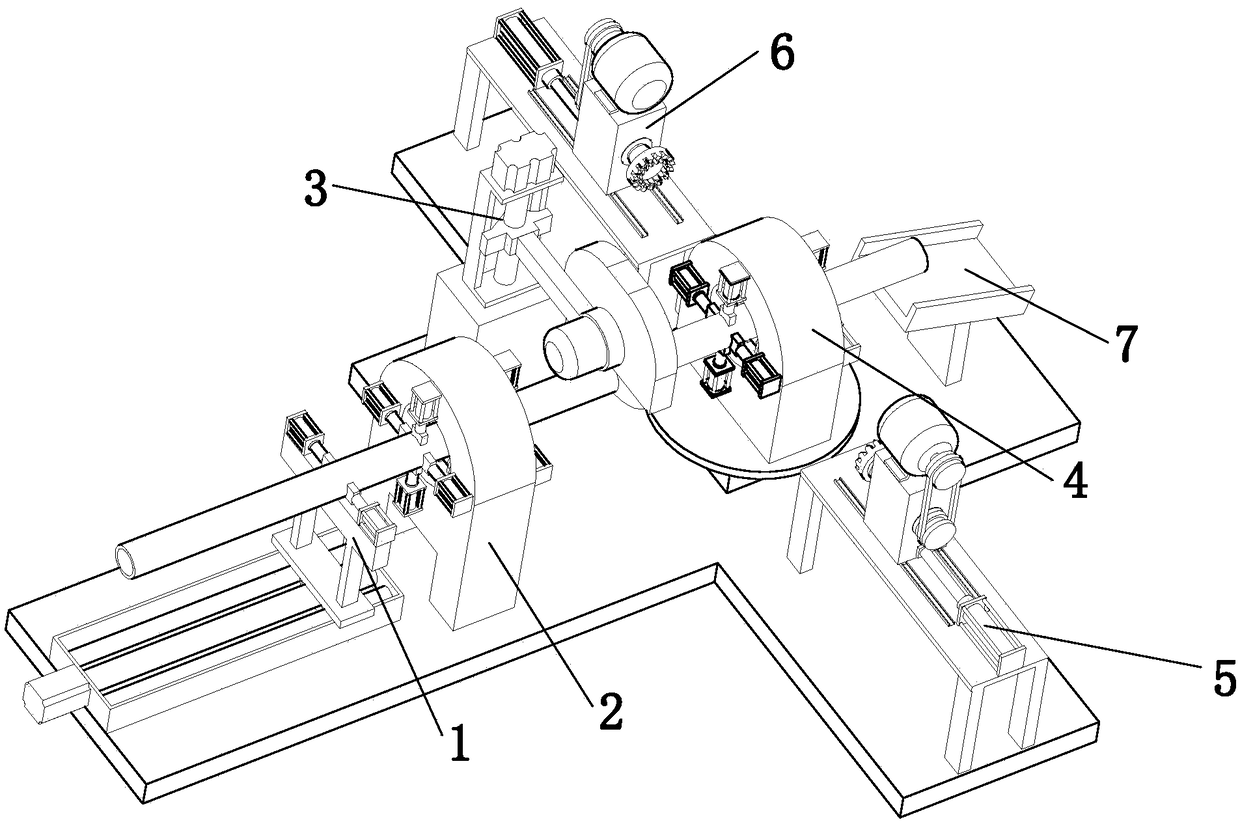

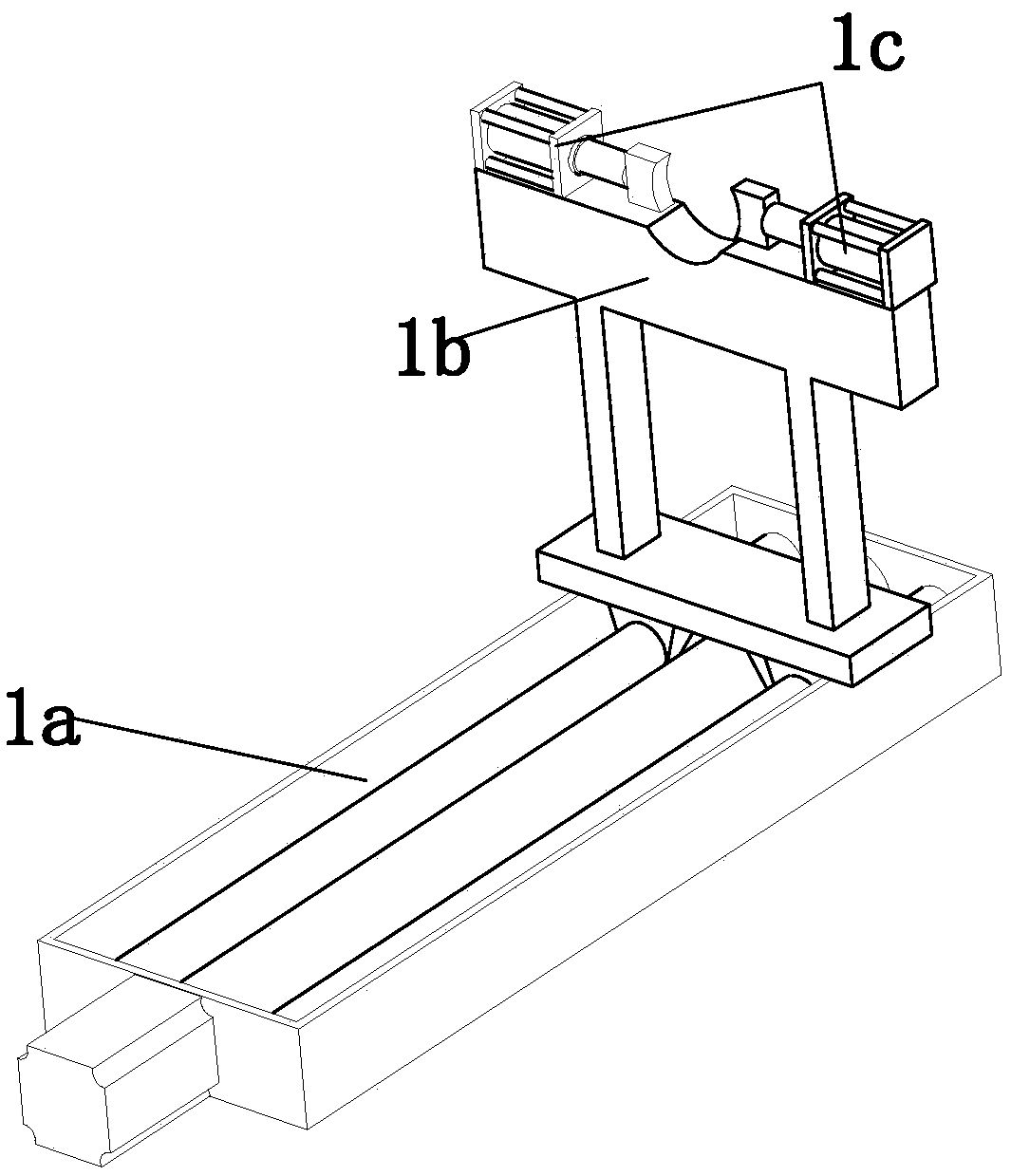

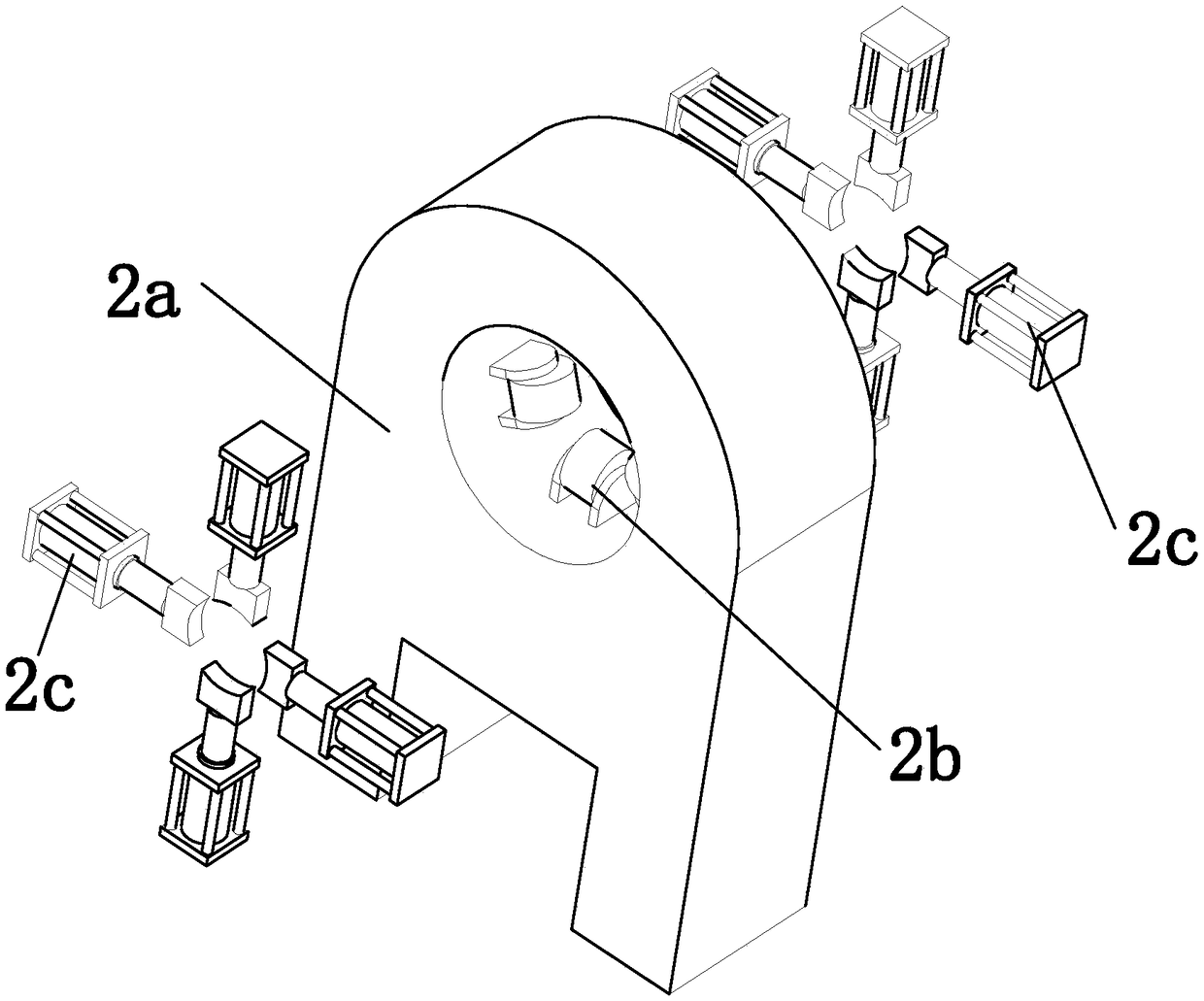

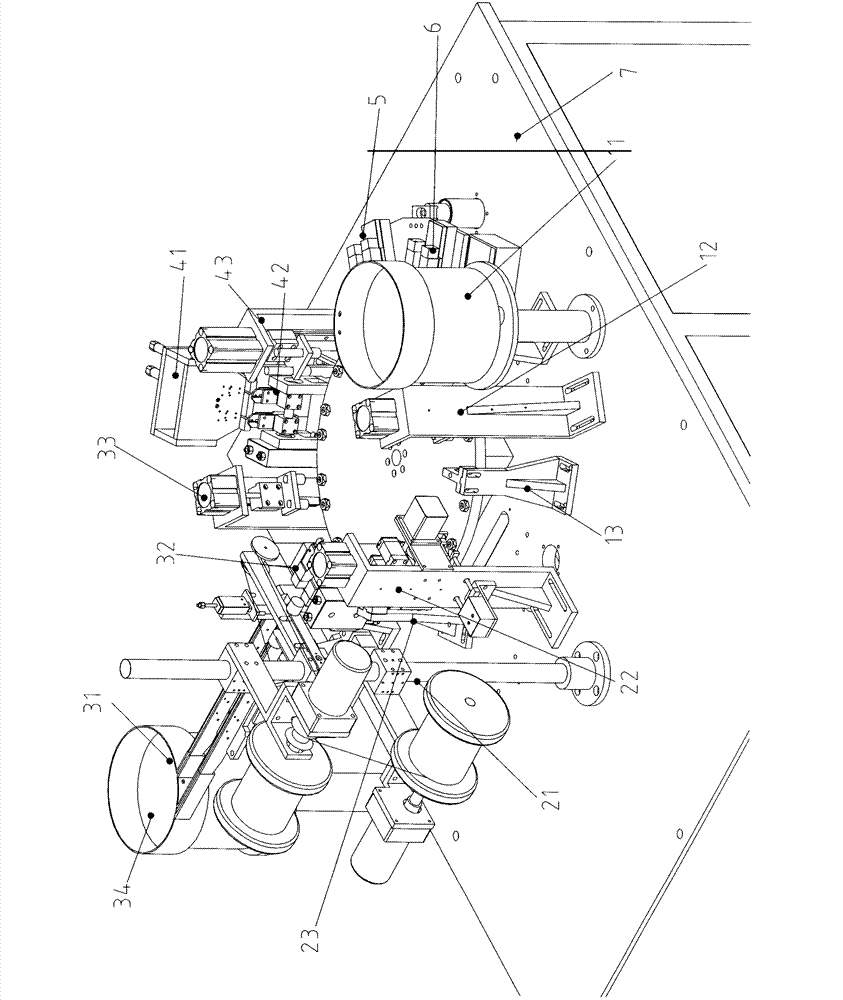

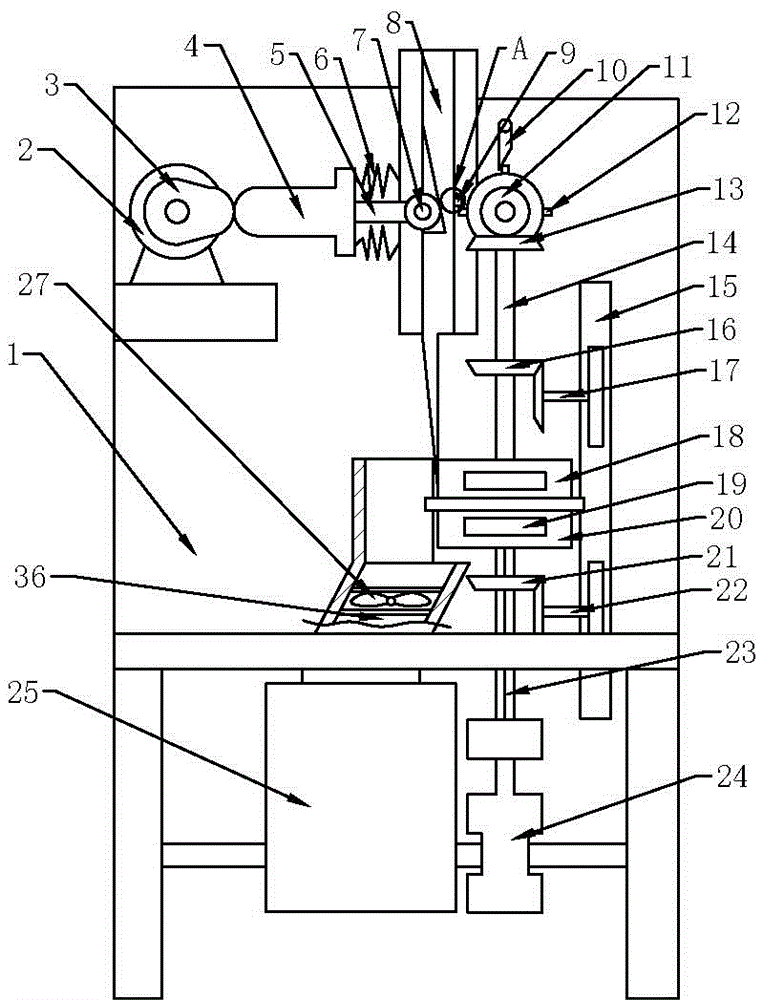

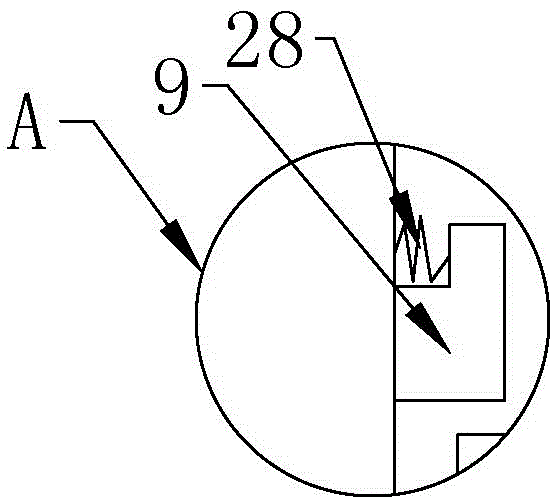

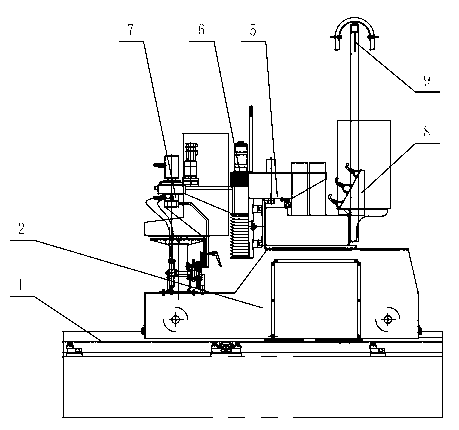

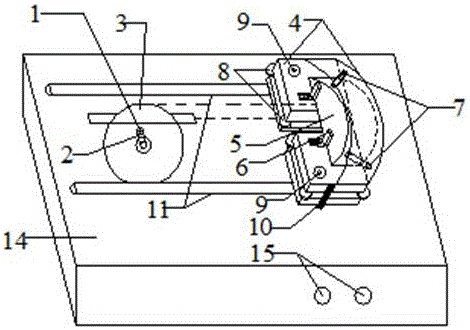

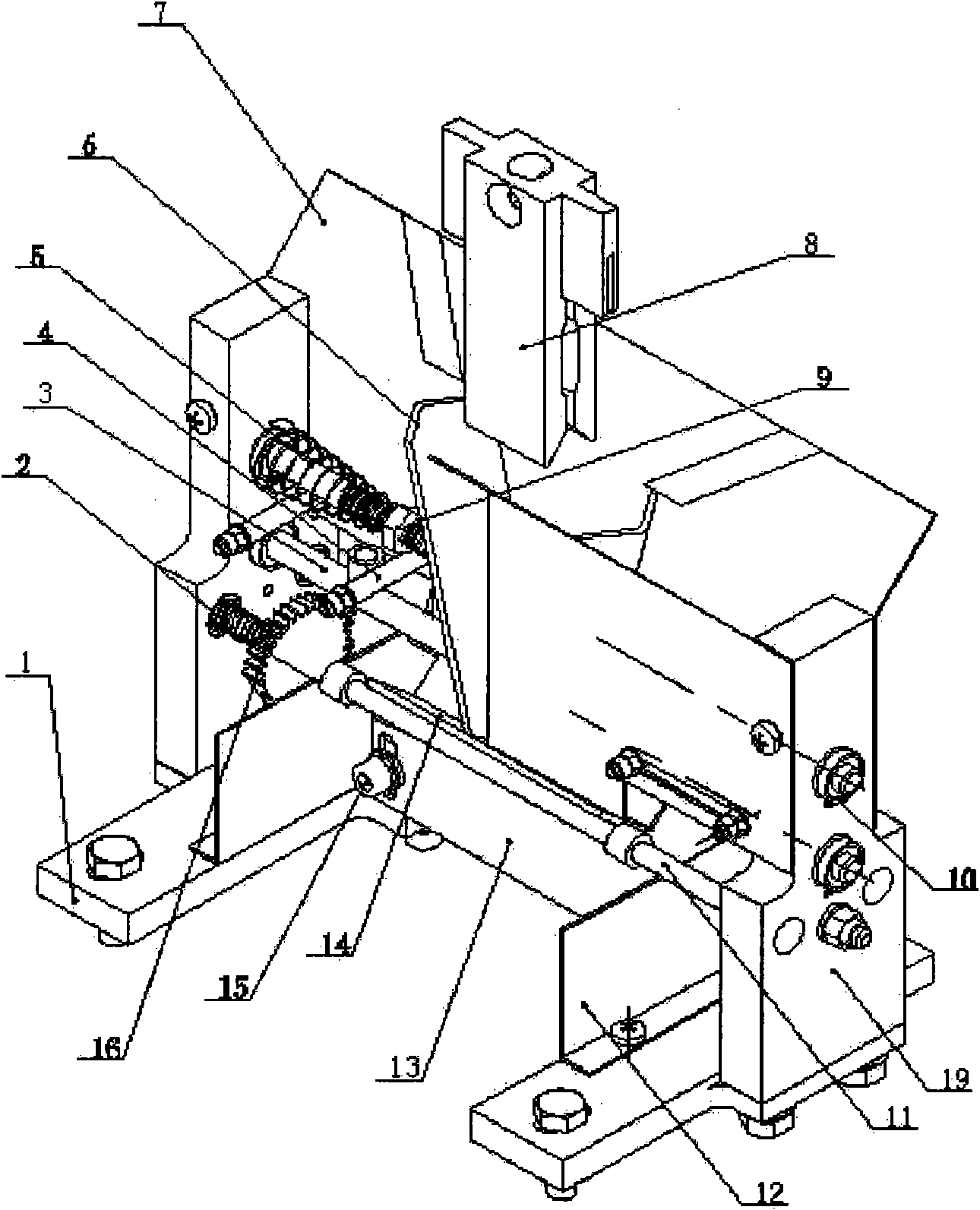

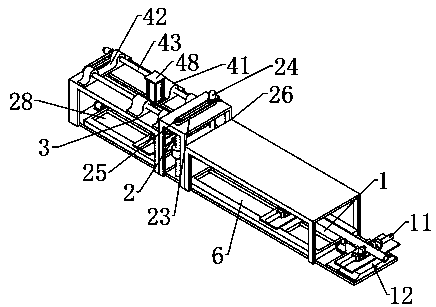

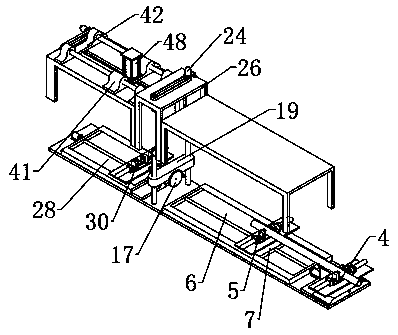

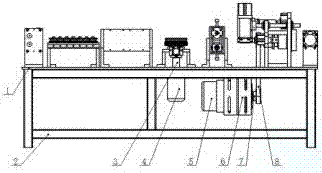

Round pipe cutting and end face grinding integrated machine

InactiveCN108746816ASolve cutting problemsSolve the disadvantages that grinding cannot be completed at one timeOther manufacturing equipments/toolsTube shearing machinesEngineeringMechanical engineering

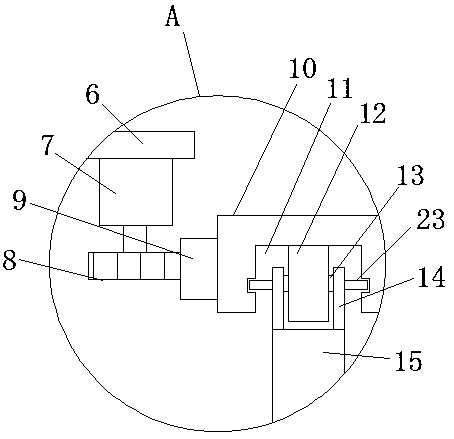

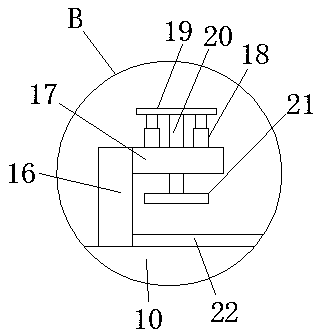

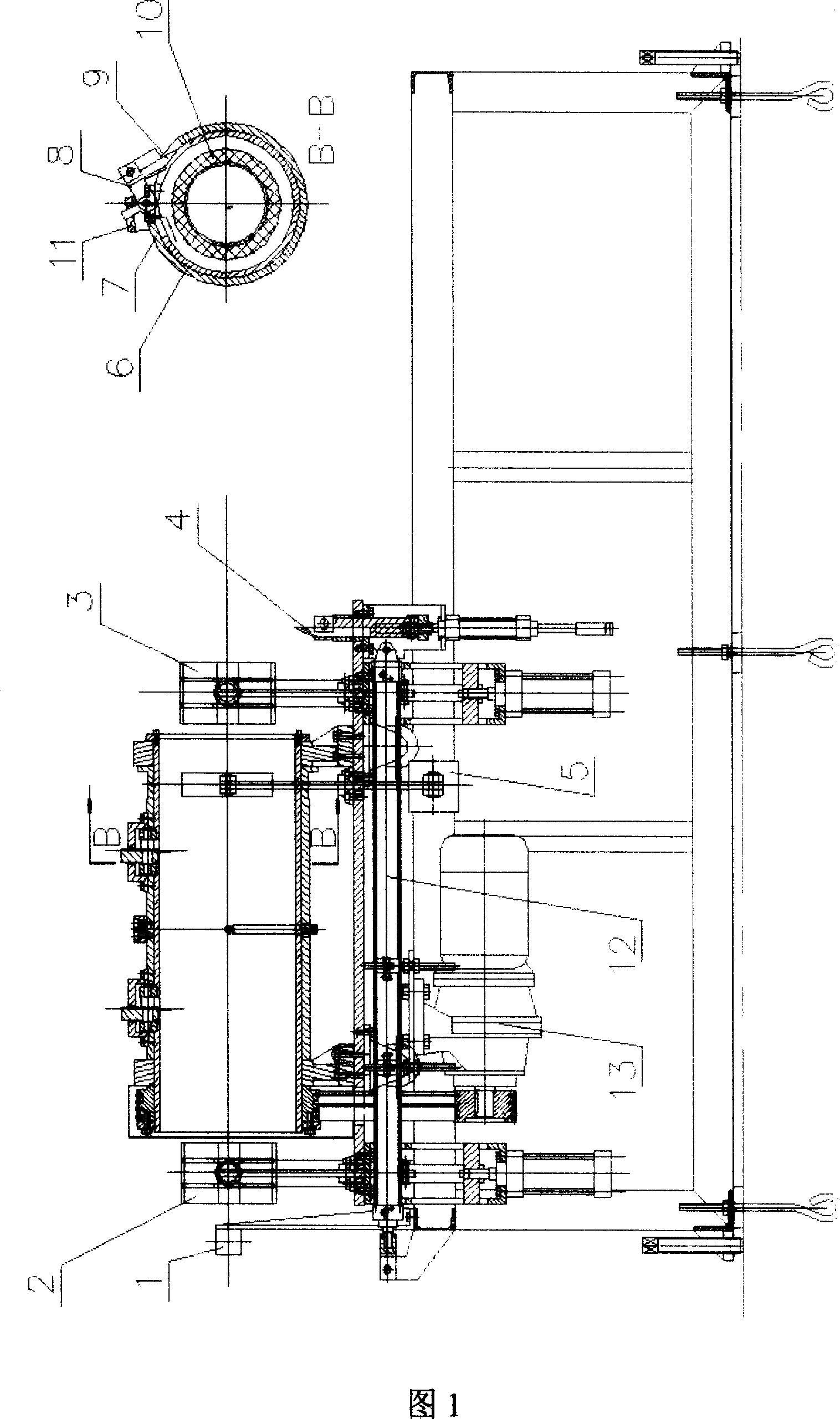

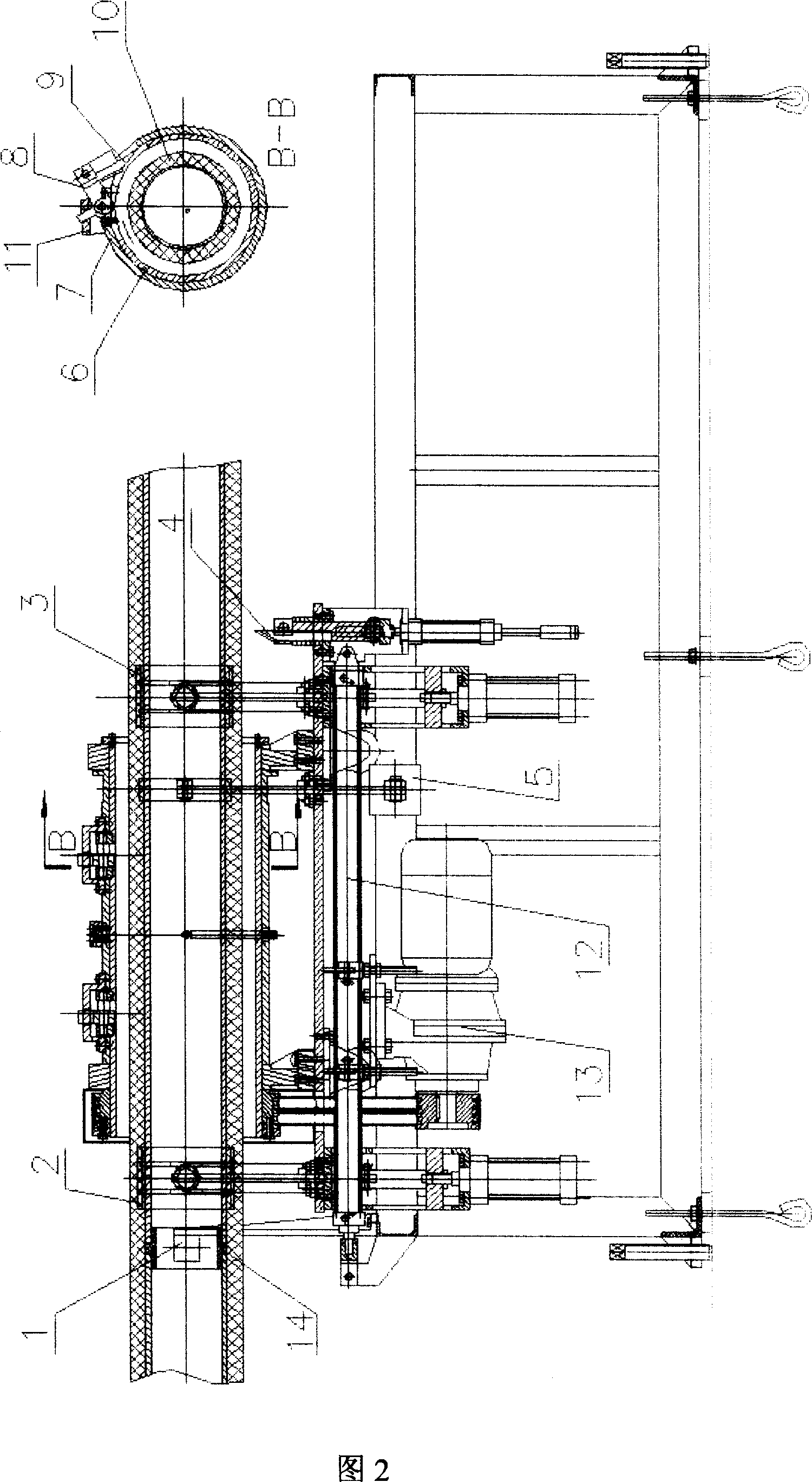

The invention relates to the field of cutting and grinding machines, in particular to a round pipe cutting and end face grinding integrated machine. The round pipe cutting and end face grinding integrated machine comprises a bottom plate, and further comprises a feeding assembly, a first clamping assembly, a cutting assembly, a second clamping assembly, a first grinding assembly and a second grinding assembly; the first clamping assembly is located on one side of the second clamping assembly and fixedly installed on the bottom plate; the cutting assembly is located between the first clamping assembly and the second clamping assembly and fixedly installed on the bottom plate; the feeding assembly is located at the feeding end of the first clamping assembly and fixedly installed on the bottom plate; the feeding assembly, the first clamping assembly, the cutting assembly and the second clamping assembly are sequentially arranged in a linear state; the first grinding assembly is fixedly installed on the bottom plate, and the output end faces the second clamping assembly; the second grinding assembly is fixedly installed on the bottom plate, and the output end faces the output end of the first grinding assembly; the first grinding assembly, the second clamping assembly and the second grinding assembly are linearly arranged; and manpower cost is reduced.

Owner:李达

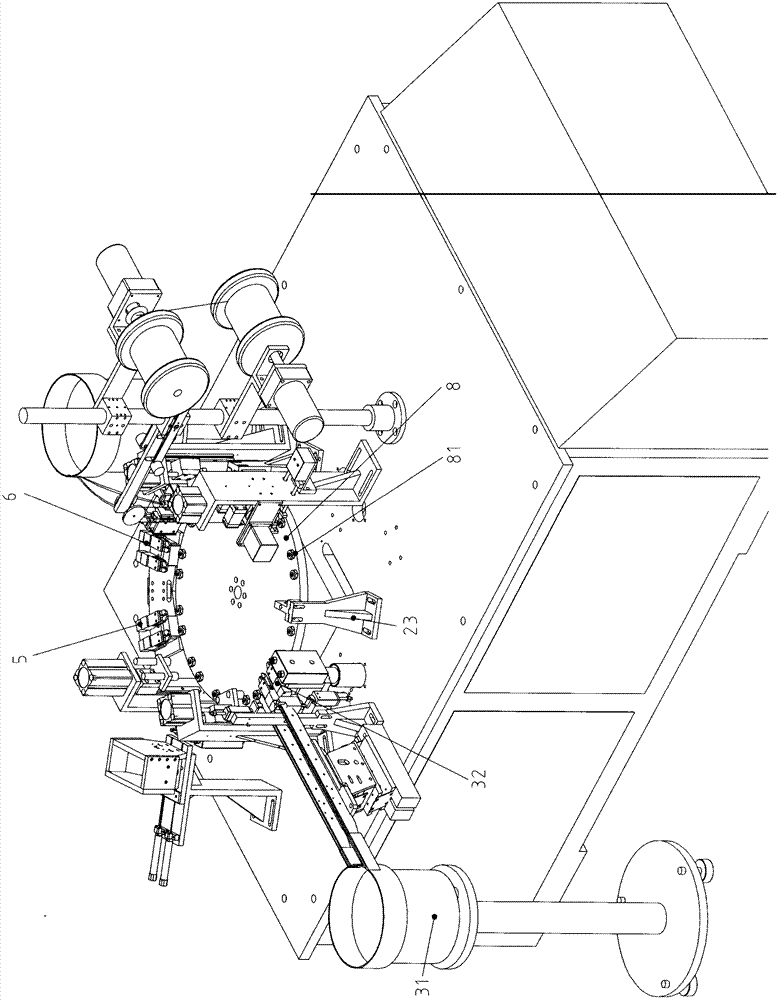

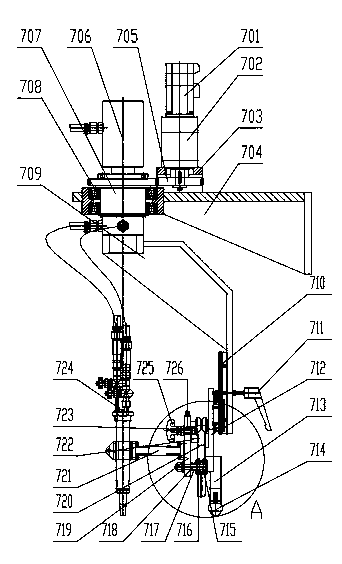

Automatic assembling system of pin type pen head component

InactiveCN102815127ASolve the softness problemSolve the clampingPen repairingFront loadingEngineering

The invention discloses an automatic assembling system of a pin type pen head component. The system comprises a machine frame, a power device and a part conveying system, wherein the machine frame forms an equipment support and a main body; the part conveying system is connected with the power device; and a pen head supplying mechanism, a pen head assembling mechanism, a pen head direction detection mechanism, an ink core supplying mechanism, an ink core cutting and assembling mechanism, an ink core assembly detecting mechanism, a front loading mechanism, a front assembling mechanism, a front assembly detecting mechanism, a relay core loading mechanism, a relay core assembling mechanism, a relay core assembly detecting mechanism, an unqualified product selecting mechanism and a finished product unloading mechanism are sequentially arranged in the movement direction of the part conveying system. By the automatic assembling system of the pin type pen head component, the problem that an ink core is not easy to clamp and cut because the ink core is relatively flexible and elastic is solved, and meanwhile, the technical scheme of automatic material supply, automatic assembly and automatic detection is adopted, so that each part is precisely assembled, and the stability in an assembling process is ensured.

Owner:QINGDAO CHANGLONG STATIONERY

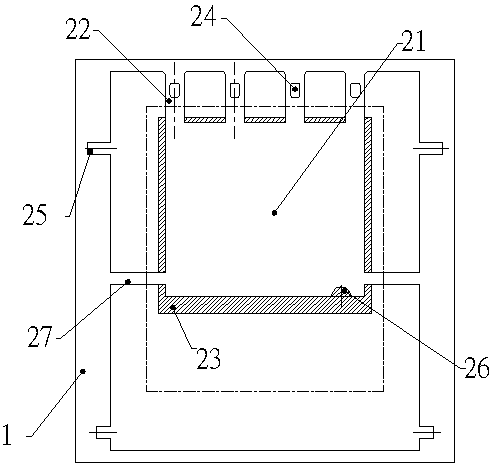

Semiconductor packaging structure and forming method thereof

InactiveCN103531551AReduce usageEasy to useSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

Owner:GREAT TEAM BACKEND FOUNDRY (DONGGUAN) LTD

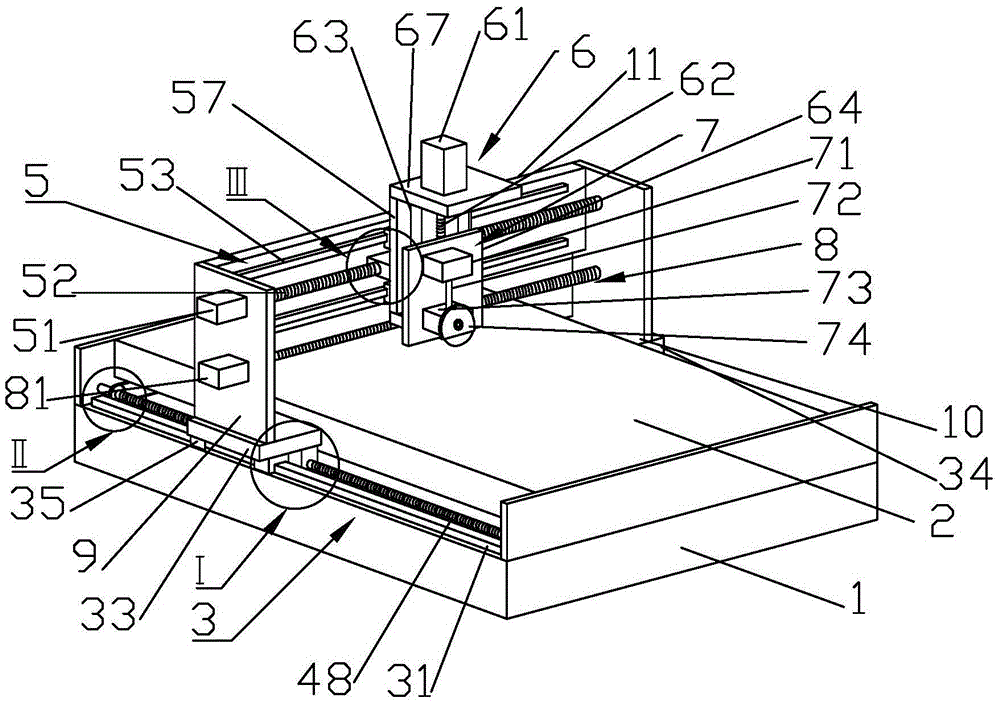

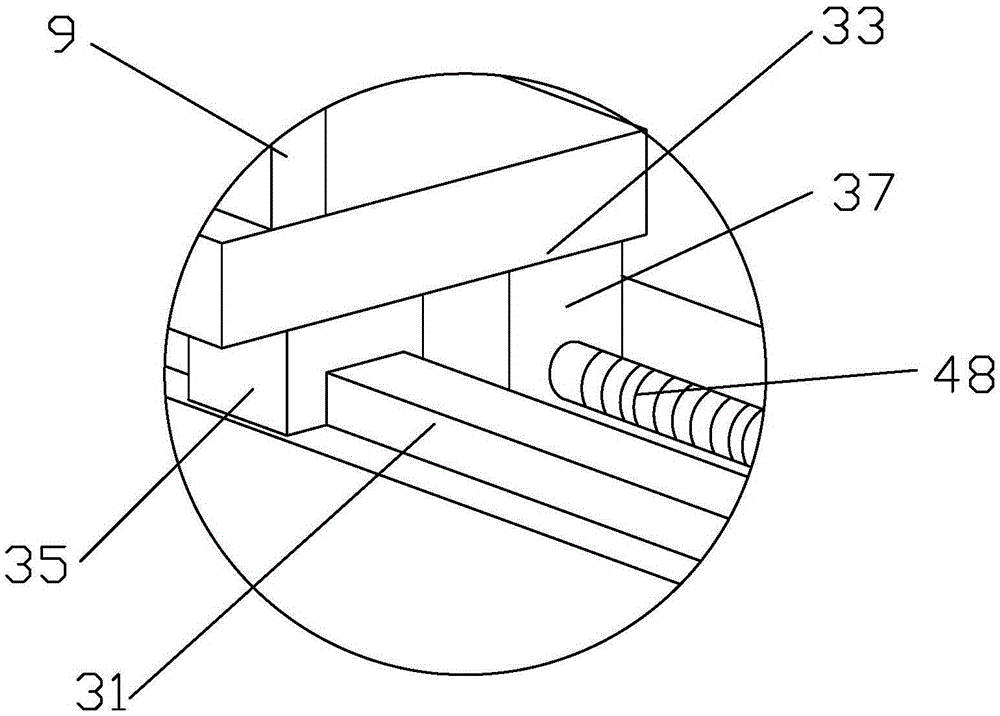

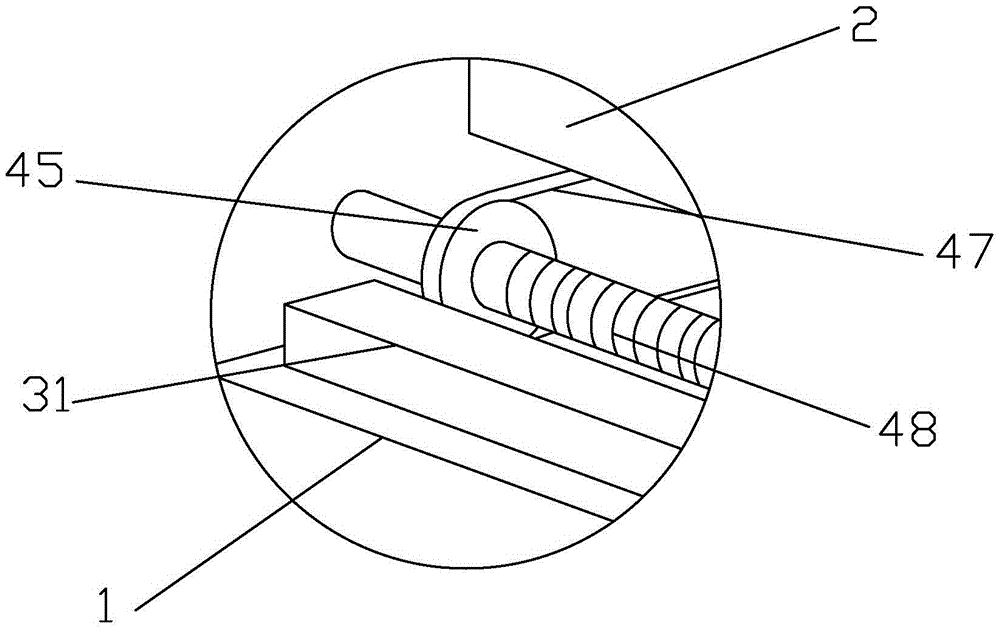

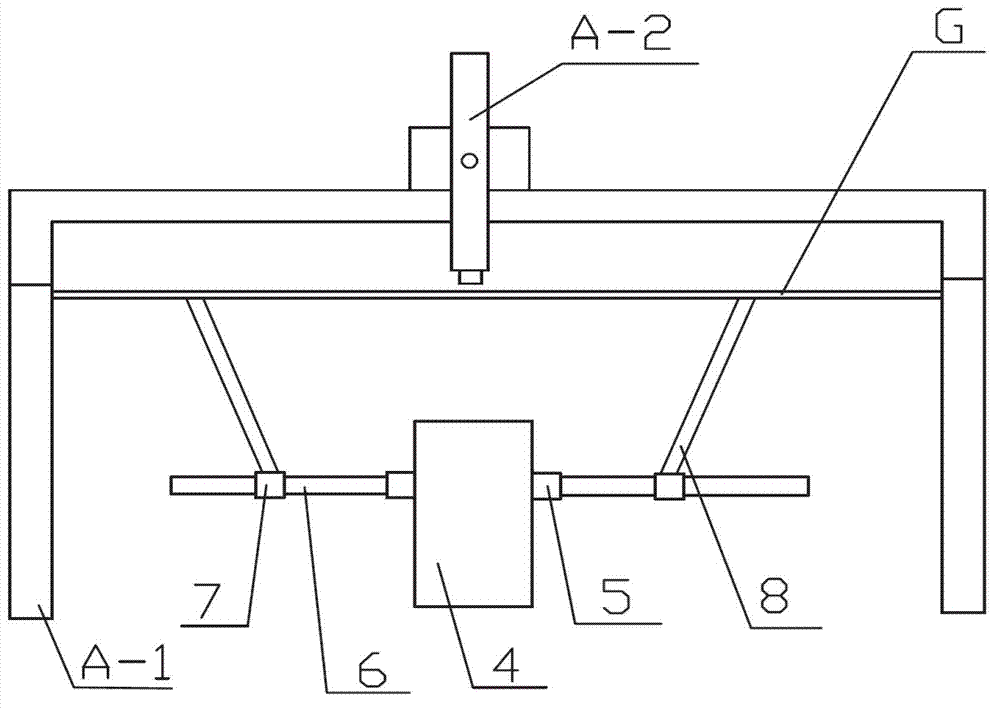

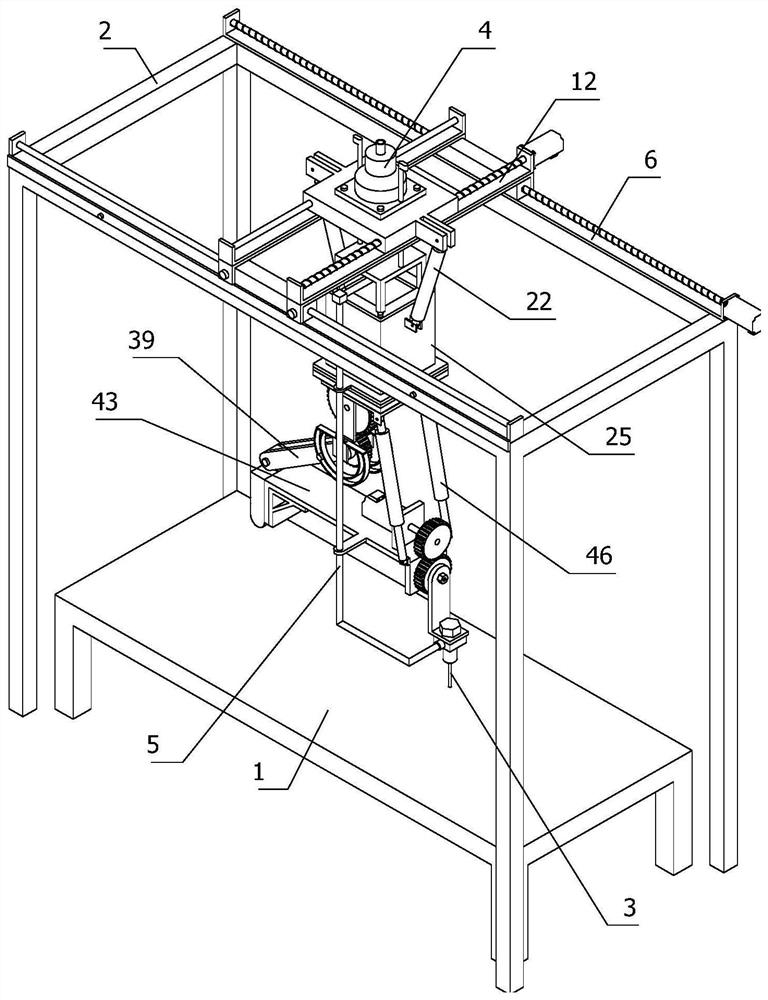

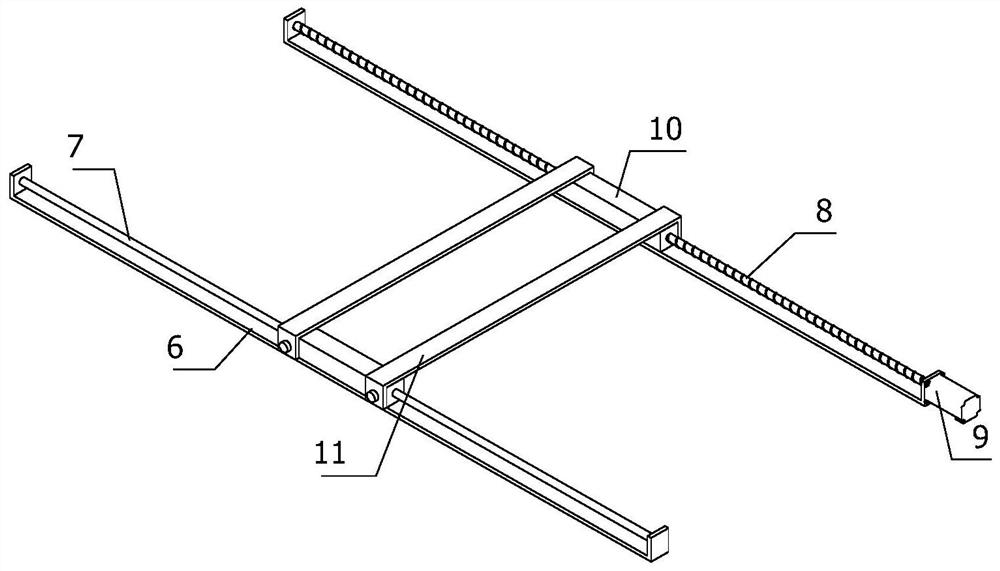

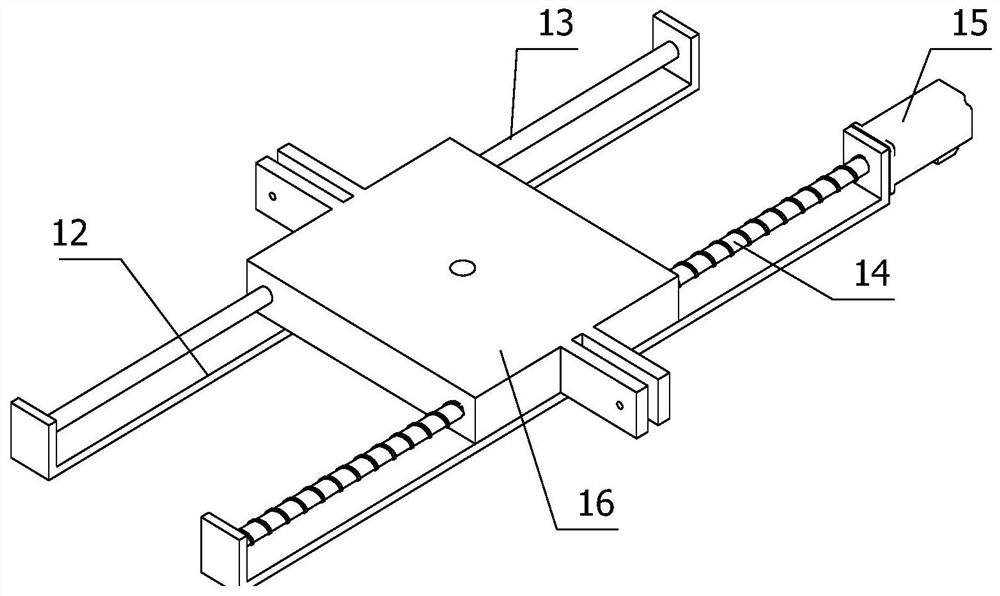

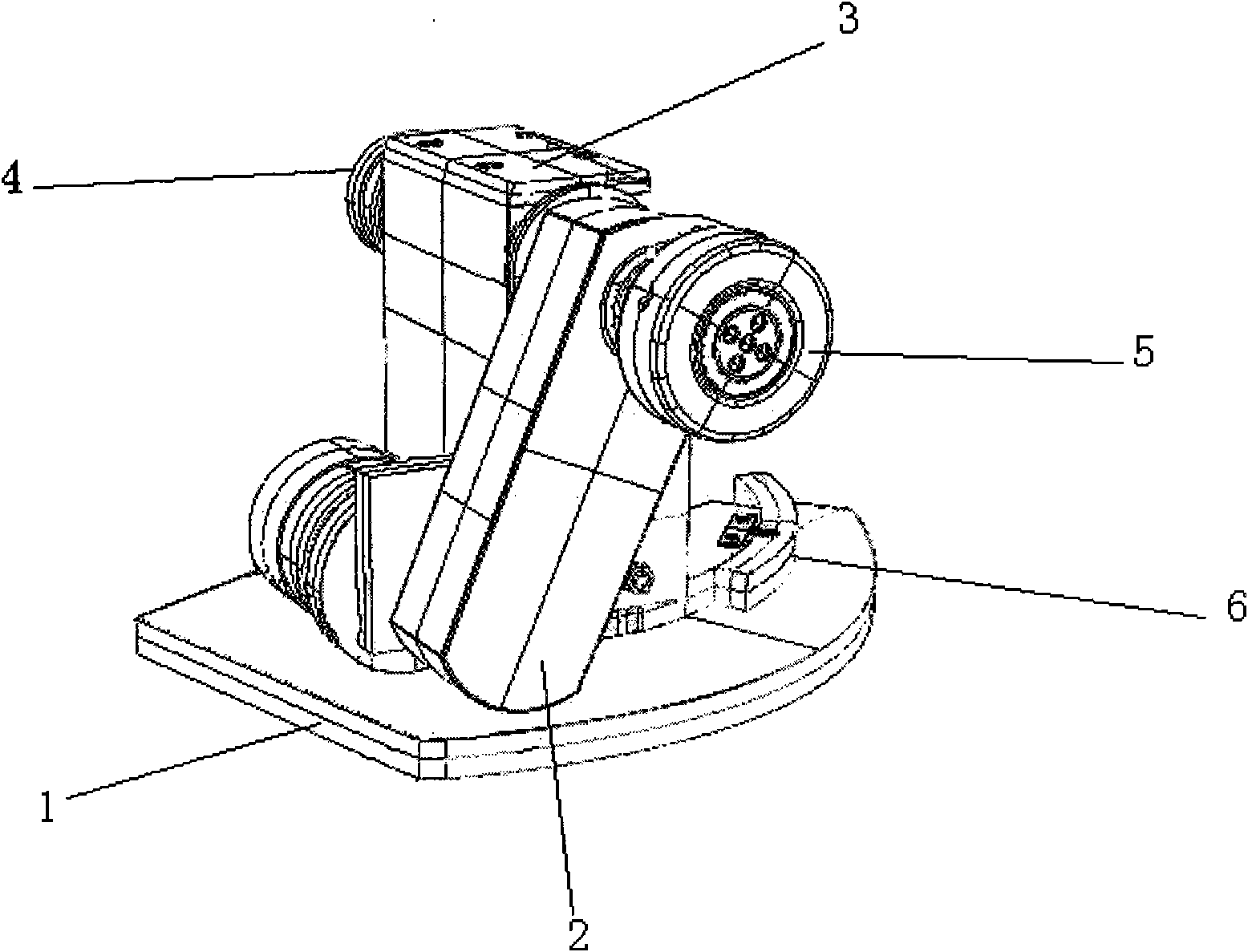

Three-shaft type board cutting machine

InactiveCN105458894ASolve cutting problemsSimple structureGrinding carriagesGrinding drivesEngineeringGrinding wheel

The invention discloses a three-shaft type board cutting machine which comprises a rack. A movable cutting platform and fixed supports are arranged on the rack. The movable cutting platform is located in the middle of the rack. The fixed supports comprise the left fixed support and the right fixed support. An X-direction moving device is arranged below the left fixed support and the right fixed support and is installed on the rack. The X-direction moving device is connected with an X-direction transmission device. A Y-direction moving device is arranged between the left fixed support and the right fixed support. The Y-direction moving device is connected with a Z-direction moving device which is provided with a cutting device. The three-shaft type board cutting machine is simple in structure, scientific, convenient to use, high in pertinence and automation degree, good in wood sawing effect and capable of well solving the cutting problem of boards. The cutting device can move freely in the work plane of the whole rack through the X-direction moving device, the Y-direction moving device and the Z-direction moving device and is matched with a grinding wheel to complete the cutting work.

Owner:嵊州市古艺木雕装饰有限公司

Online longitudinal cutting machine for thick glass

ActiveCN104058583AIncrease productivityReduce labor intensityGlass severing apparatusGlass productionTool marksEngineering

Owner:ZHANGZHOU KIBING GLASS +1

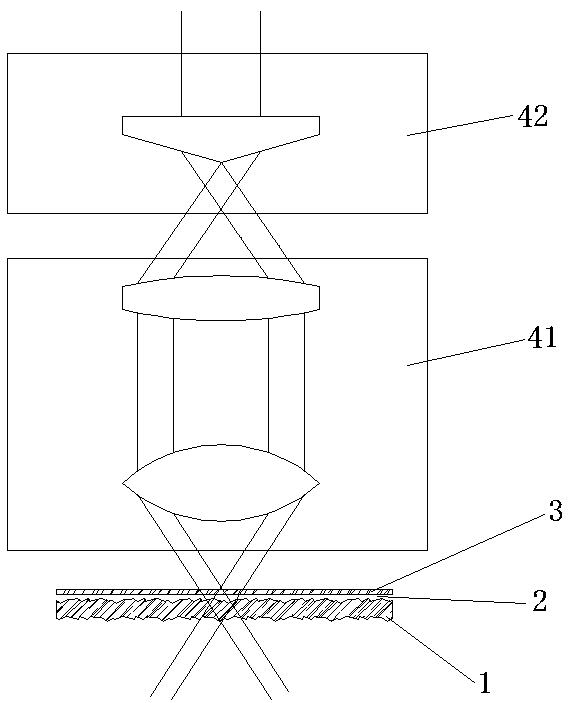

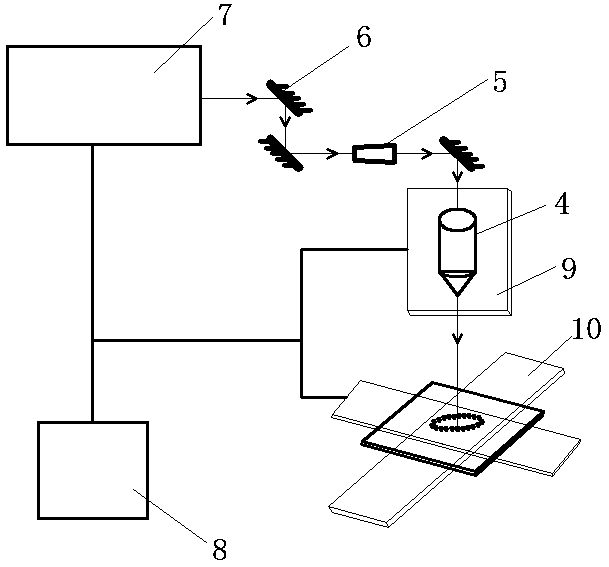

Laser processing method for cutting frosted brittle material by using Bessel beam

InactiveCN109514099AAchieve reductionReduce scatterLaser beam welding apparatusGlass coverLaser processing

The invention belongs to the field of laser cutting, specifically relates to a laser processing method for cutting a frosted brittle material by using a Bessel beam. The method comprises the followingsteps of: adding light-transmitting liquid which is not easy to volatilize on the upper surface of an area to be cut of the frosted brittle materials; covering a light glass cover to eliminate bubbles between the light glass and the frosted brittle materials; and then placing the frosted brittle materials on a processing platform; adjusting an optical focusing system to enable the Bessel beam toform a focusing spot and a focal depth required for cutting the frosted brittle material after passing through a 4f system, and moving the Z axis of the axis where the optical focusing system is located to enable the focus of the Bessel beam to fall on the frosted brittle material; setting a cutting path, moving the X axis and Y axis of the processing platform to process the frosted brittle material. The laser processing method provided by the invention ensures the perfection of the Bessel beam focusing system by adding light-transmitting liquid which is not easy to volatilize on the area to be cut, realizes cutting the frosted brittle materials, so the method is suitable for double-side frosted brittle materials.

Owner:WUHAN HGLASER ENG CO LTD

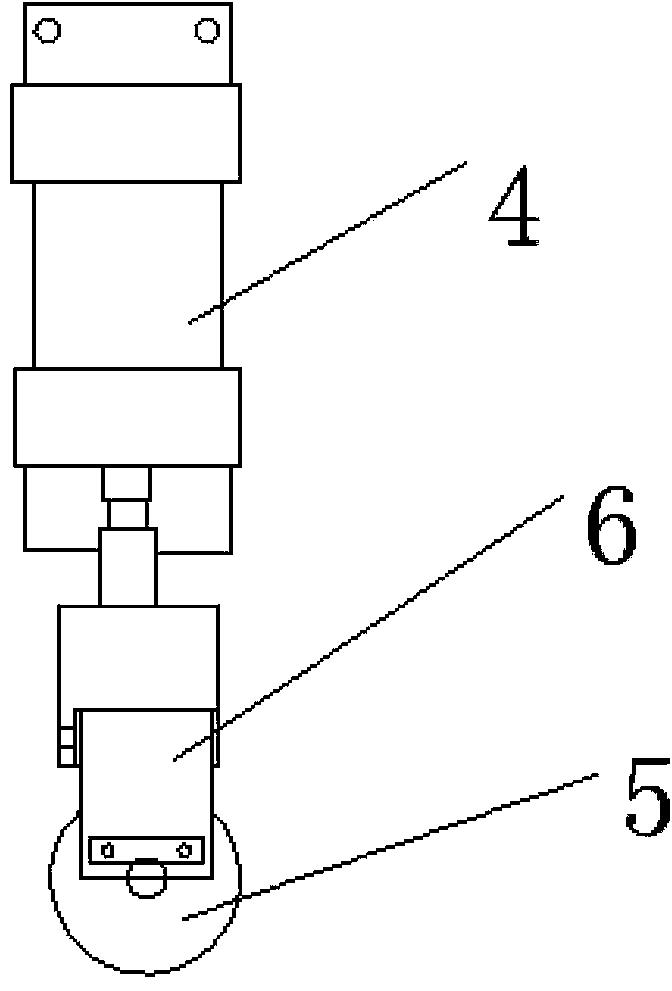

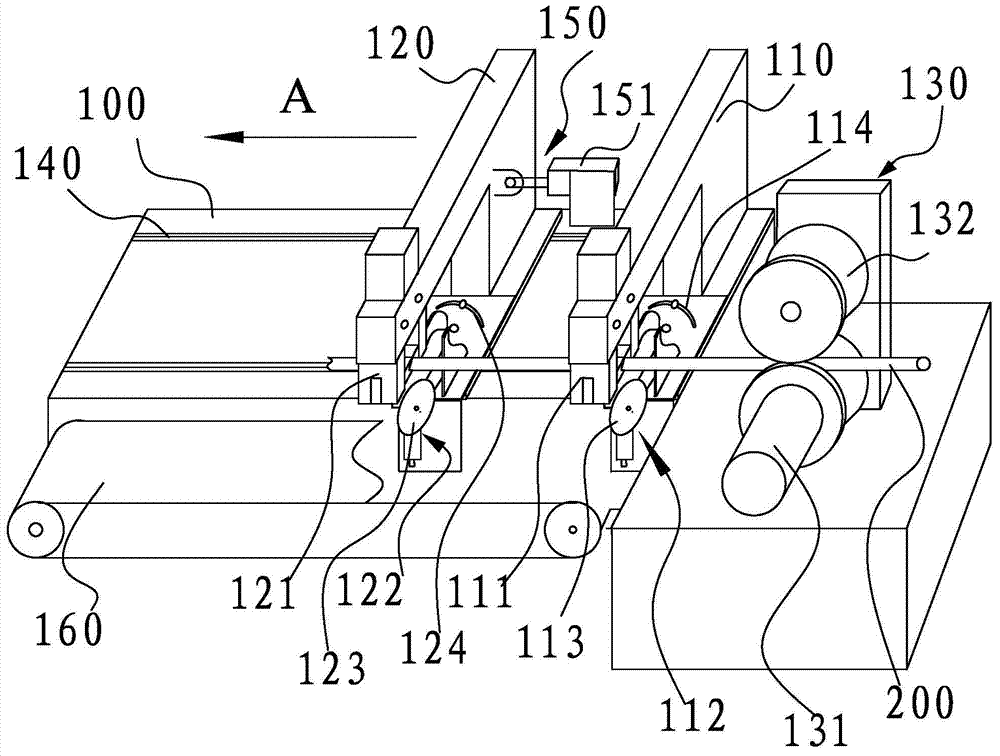

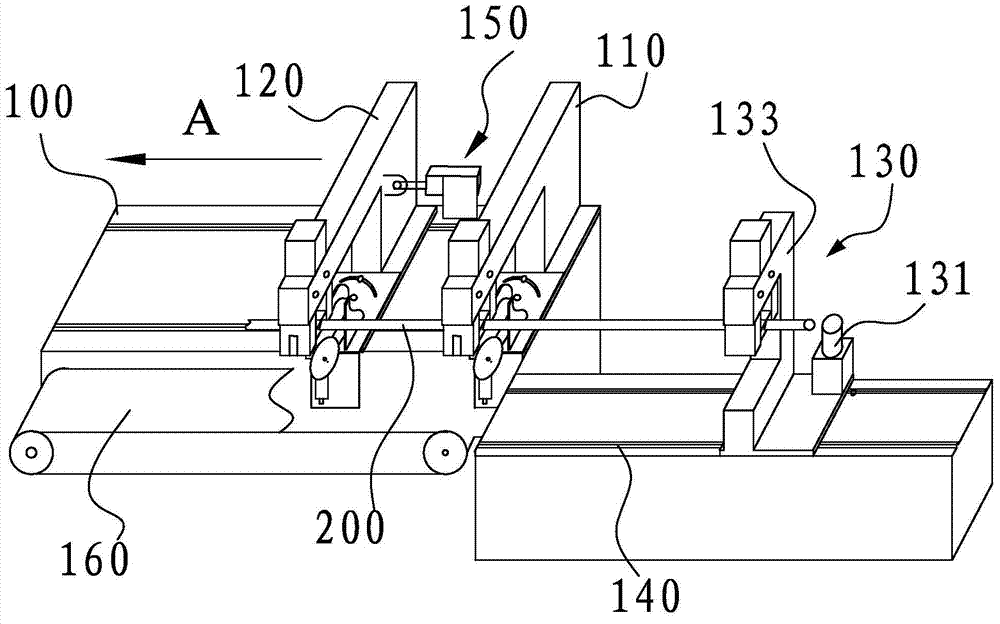

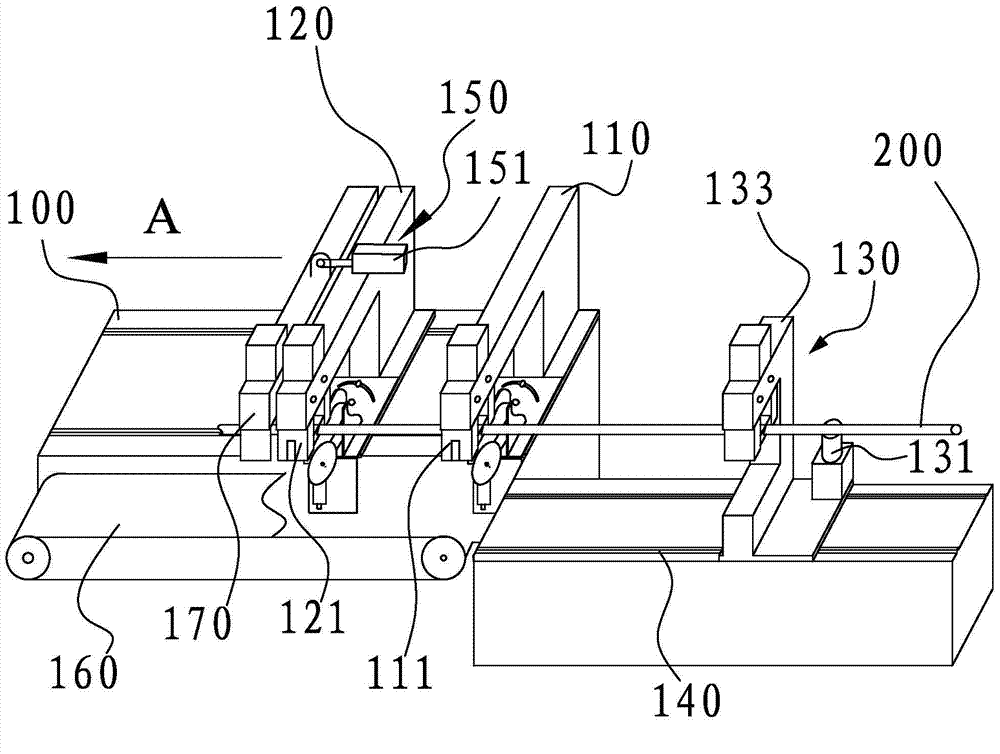

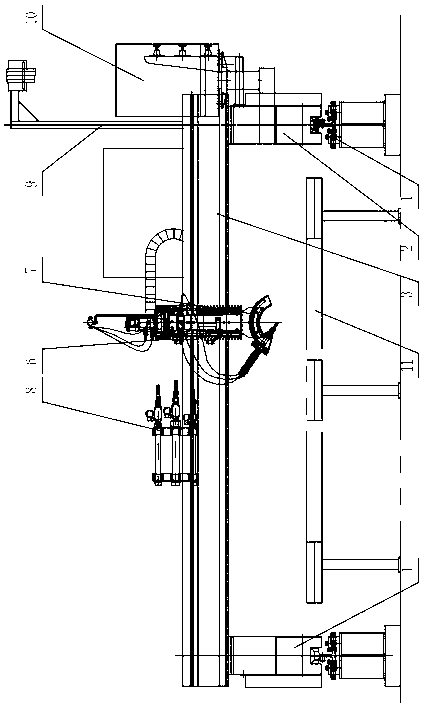

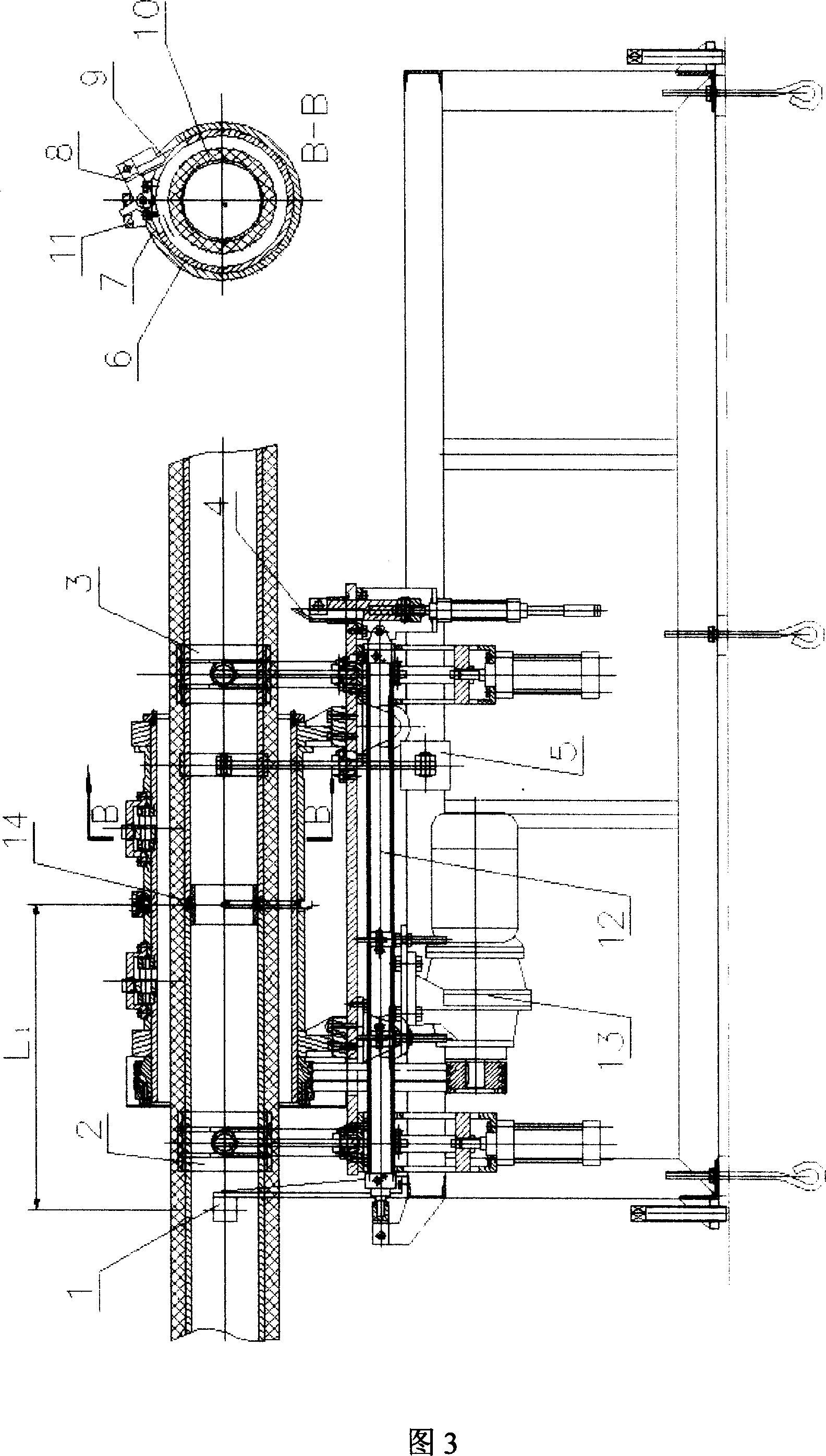

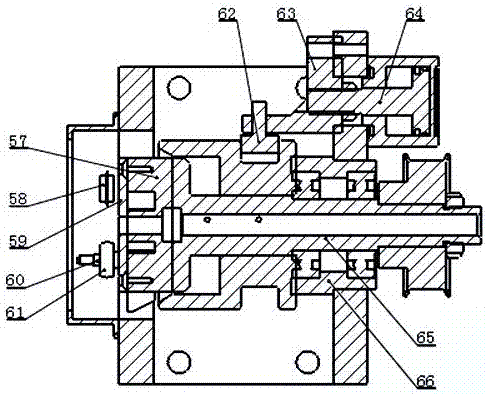

Pipe cutting machine

InactiveCN104722834ASimple structureHigh degree of automationMetal sawing devicesEngineeringAutomation

The invention relates to the technical field of tubular material machining, in particular to a pipe cutting machine with two pipe cutting units, wherein the two pipe cutting units cut tubular materials at the same time. The pipe cutting machine comprises a rack, the first pipe cutting unit and the second pipe cutting unit. Both the first pipe cutting unit and the second pipe cutting unit are arranged on the rack. The rack is further provided with a material conveying device. The material conveying device and the second pipe cutting unit are located on the two sides of the first pipe cutting unit respectively. The material conveying device can sequentially convey the materials to the first pipe cutting unit and the second pipe cutting unit in a material conveying direction. The first pipe cutting unit and the second pipe cutting unit each comprise a clamping device and a cutting device which are matched with each other. Compared with the prior art, the pipe cutting speed is increased remarkably, the material conveying device can convey the materials according to the working conditions of the pipe cutting units, the automation degree is high, and pipe cutting efficiency is further improved.

Owner:唐敏

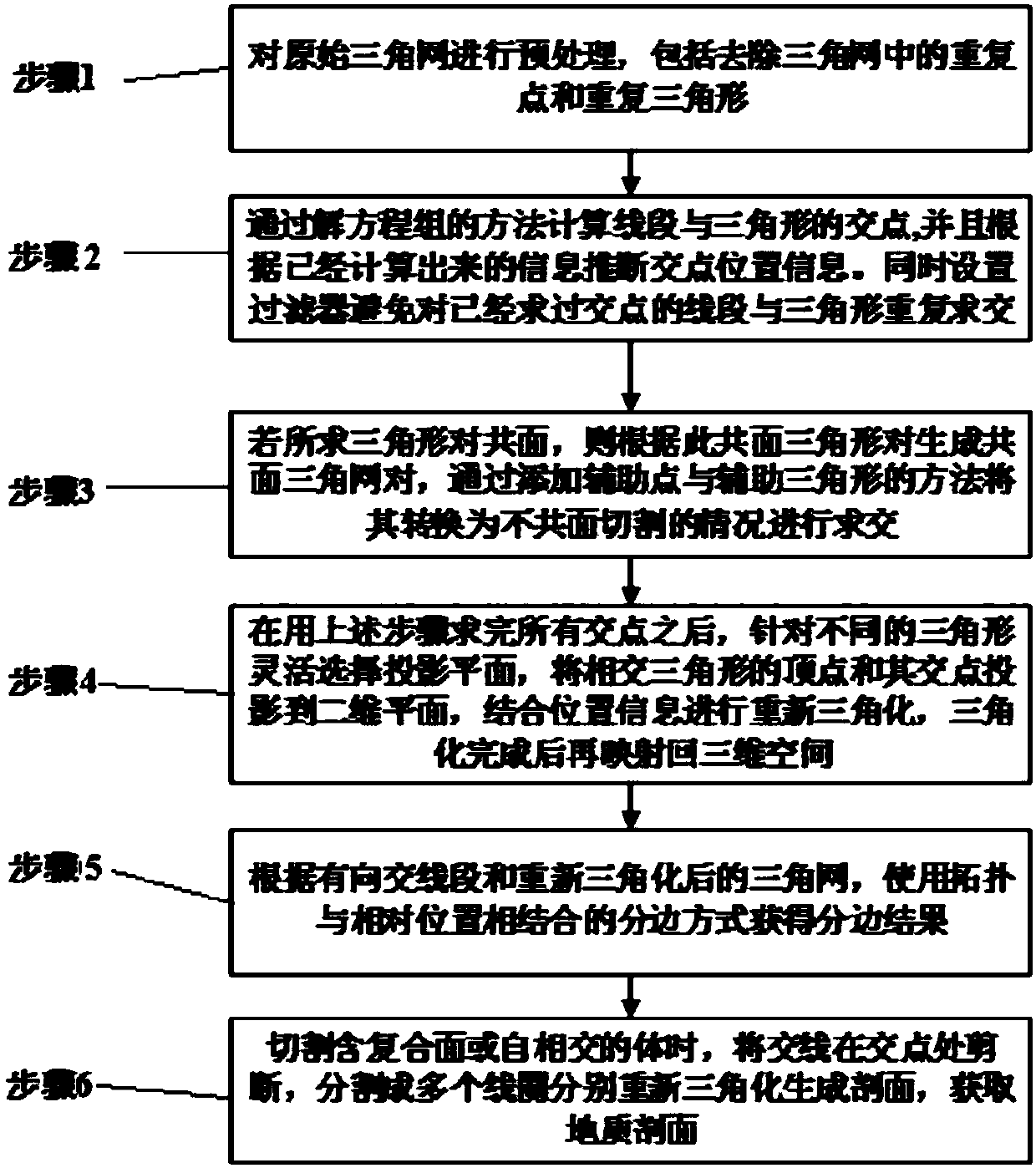

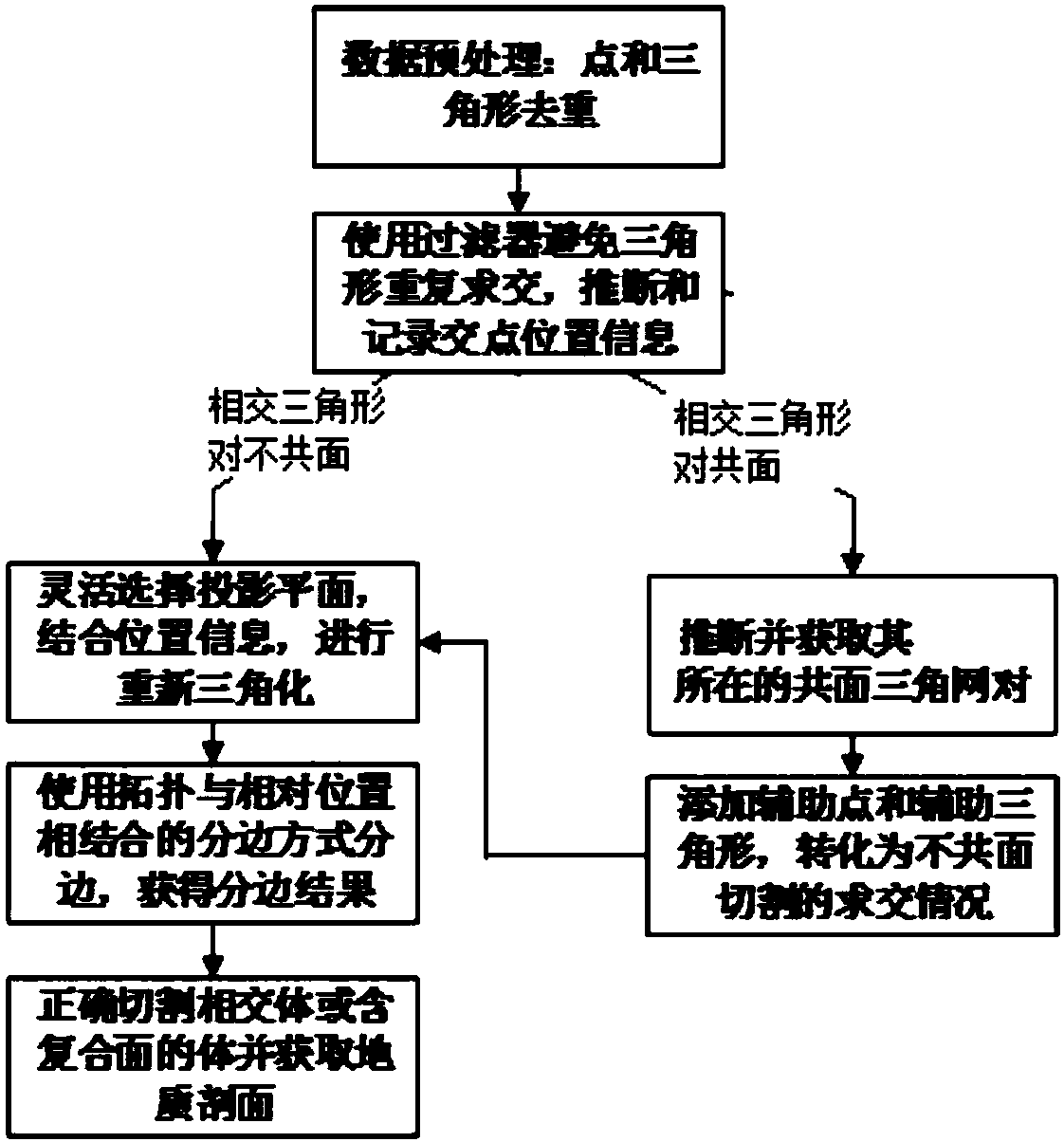

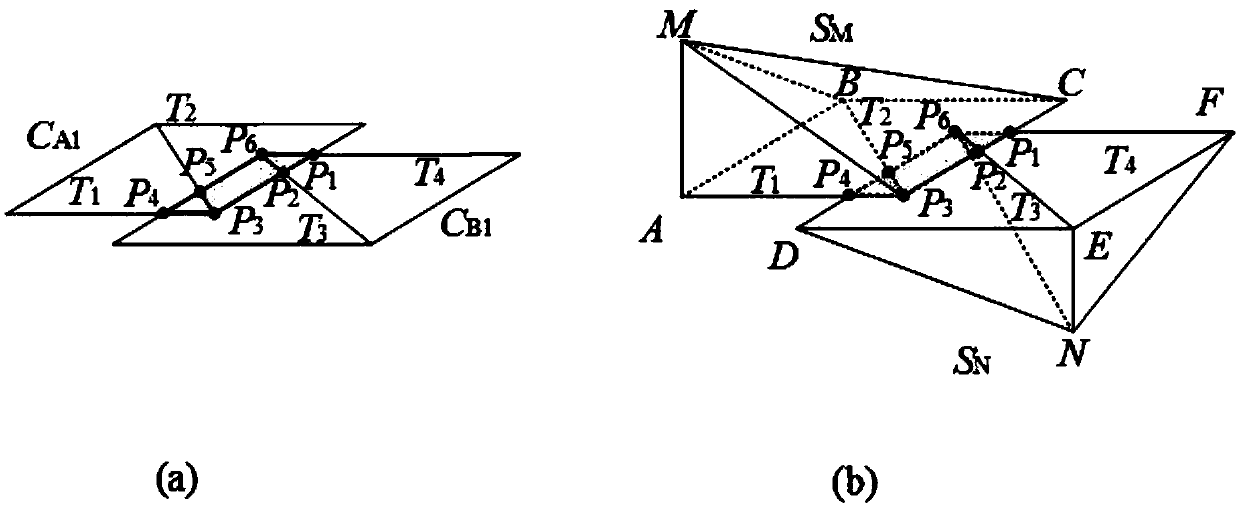

Efficient and robust triangular network cutting method

ActiveCN107622530AImprove efficiencyImprove robustness3D modellingIntersection of a polyhedron with a lineFloating point

The invention discloses an efficient and robust triangular network cutting method. The method comprises the following steps: data preprocessing; avoiding repeated intersection computation by using a filter method; translating the quantitative floating-point calculation into the qualitative judgement calculation by using a location relation, and fast and accurately inferring an intersection point location; selecting an appropriate two-dimensional projection plane for intersected triangles, and re-triangulating the same to guarantee a network topology structure; realizing the correct cutting ona composite surface by using a cutting way of combining a relative location with the topology; guaranteeing the correct cutting of a body containing the composite surface and the self-intersected surface through a method of shearing an intersecting line, and generating a section; and performing unified processing on the coplanar and non-coplanar triangles so as to improve the coplanar intersectionefficiency. By using the cutting method disclosed by the invention, a complex three-dimensional geologic model can be efficiently cut at will to acquire the cutting section, thereby providing an efficient and robust auxiliary three-dimensional modelling and auxiliary decision-making tool for the geologist.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Rapid conical head fusing machine for steel wire rope

InactiveCN101786197AEasy to wear and secureSolve the size of the headResistance welding apparatusTransformerEngineering

The invention discloses a rapid conical head fusing machine for a steel wire rope, which comprises a pay-off stand and a spooling device, and also comprises an automatic sizing device and a conical fusing device, wherein the conical fusing device comprises a transformer, a locking device and a rotating handle, can generate a large current to enable the steel wire rope to be heated to be in a glowed state within a set fusing distance, and can further break the steel wire rope by the locking device and the rotating handle in a rotating way to enable the rope head to be conical; and the automatic sizing device comprises a pressure wheel and a meter wheel eccentrically provided with a Hall switch, and can count the rotating number of turns of the meter wheel and convert the number of turns into length of the steel wire rope passing through the automatic sizing device. The length of the fused steel wire rope is correct by the sizing count, the penetrator of the steel wire rope is fixed conveniently and firmly, therefore, the fusing machine is suitable for massively cutting the sizing steel wire rope, and better solves the difficulty of the sizing seal head of the steel wire rope and cutting.

Owner:WUXI UNIVERSAL STEEL ROPE

Two-dimensional adjustable flame cutting device for cutting online steel plate

InactiveCN102861966AImprove cutting efficiencyGuaranteed cutting qualityGas flame welding apparatusEngineeringOblique cutting

The invention relates to a two-dimensional adjustable flame cutting device for cutting an online steel plate, which belongs to the field of machining equipment. The two-dimensional adjustable flame cutting device comprises a flame cutting device, a steel plate moving stander, a steel plate moving device and a control device, wherein the steel plate makes a longitudinal horizontal direction on the steel plate moving mechanism, the flame cutting device consists of a flame cutter, a moving slide rail and a supporting frame, the flame cutter is installed in the moving slide rail, the moving slide rail of the flame cutter is installed on the tail end of the steel plate moving device in the direction which is vertical to the moving direction of the steel plate through the supporting frame, the flame cutter makes a transverse movement along the moving slide rail relative to the steel plate, and the transverse, longitudinal or oblique cutting of the steel plate can be realized by controlling the flame cutter or the steel plate moving mechanism to move independently and controlling the flame cutter and the steel plate moving mechanism to cooperatively move. The two-dimensional adjustable flame cutting device for cutting the online steel plate solves the difficulty for cutting the online steel plate with variable cross section, can be widely used for cutting a flat steel plate and a corrugated steel plate, improves the cutting efficiency of the steel plate and guarantees the cutting quality of the steel plate.

Owner:HUBEI HONGYI BUILDING DECORATION ENG

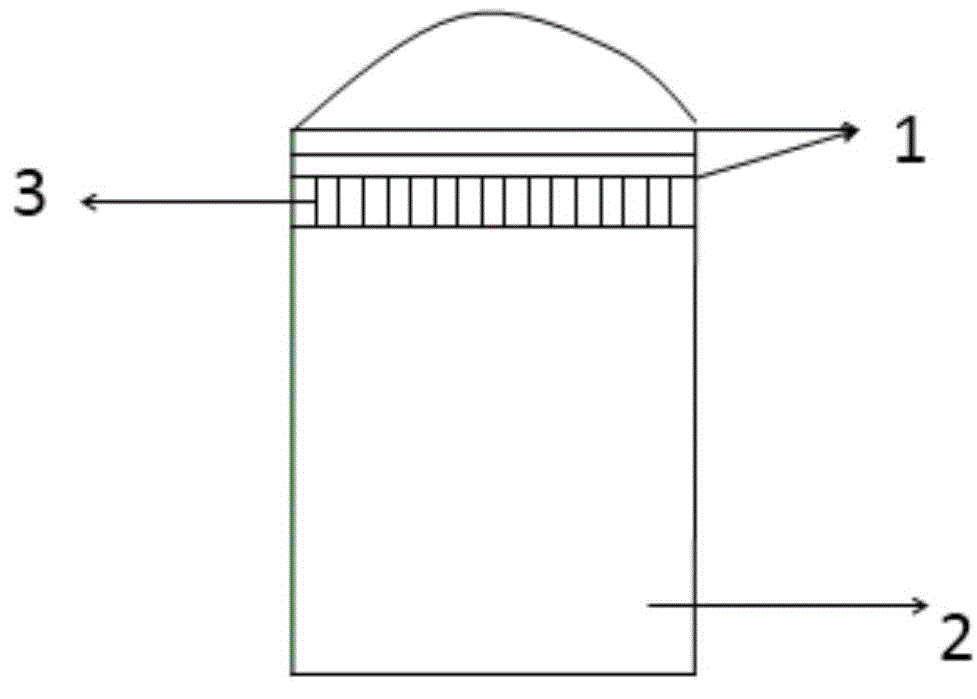

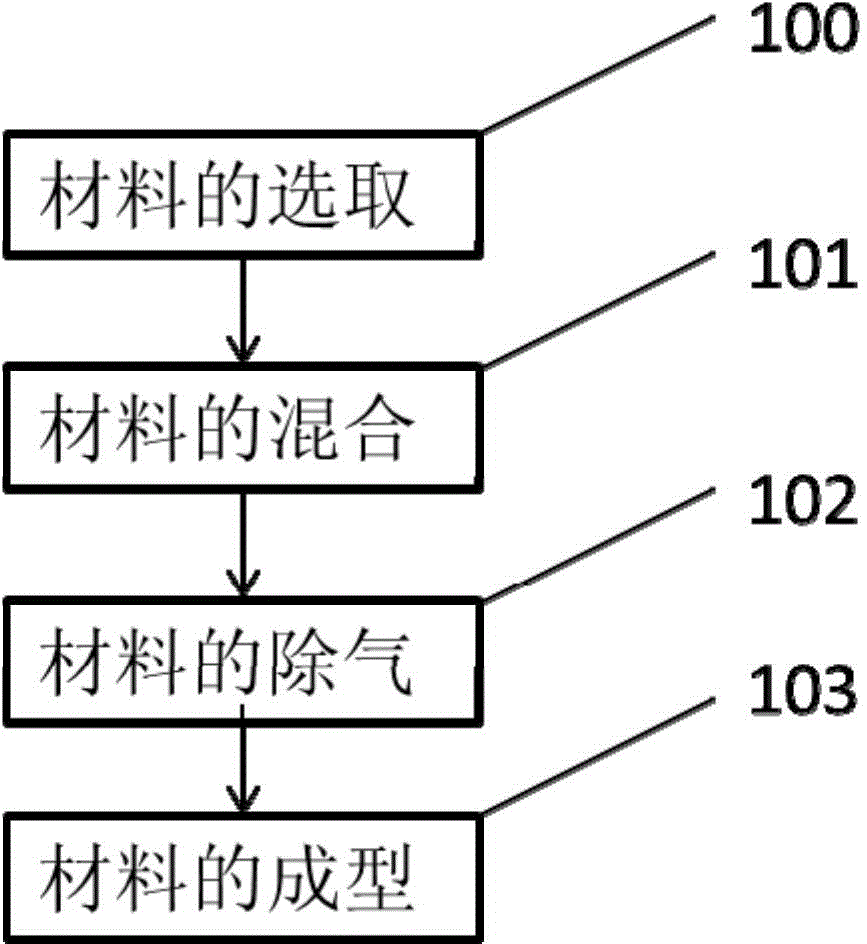

Preparation method of high-attenuation backing material

ActiveCN104552718ASmaller size than limitedIncrease volume percentageUltrasound attenuationImage resolution

The invention provides a preparation method of a high-attenuation backing material and the high-attenuation backing material obtained through the preparation method. The method comprises the following steps: (100) selecting materials; (101) mixing the materials; (102) degassing the materials; and (103) carrying out hot press molding on the materials. The backing material has high voice attenuation performance and high coefficient of heat conduction. By utilizing the backing material, imaging resolution ratio is improved, heat generated in the use process of an ultrasonic probe can be conducted quickly, and the service life of the ultrasonic probe can be correspondingly prolonged.

Owner:EDAN INSTR

Plastic packaging bag cutting equipment

ActiveCN106428834AReduce settingsSolve cutting problemsPackagingPlastic recyclingPlastic packagingEngineering

The invention disclose plastic packaging bag cutting equipment, including a body frame, a cutter is slidingly connected on the body frame, the inside of which is slidingly connected with an expandable and retractable pressing block, the middle of the expandable and retractable pressing block and the cutter is connected by a first spring, an upper pressing board and an lower pressing board is provided under the cutter, a first rotating shaft is connected with the upper pressing board, a first bevel gear is connected with the body frame, the first rotating shaft is connected with the first bevel gear, the teeth of which are meshed with the second bevel gear, one side of the second bevel gear is circumferentially uniformly distributed with angle bars, a stop lever is connected in a hinge mode on the body frame located above the angle bars, a third bevel gear is connected with the first rotating shaft, the teeth of which are meshed with a first duplex gear, the teeth of the first duplex gear are meshed with toothed racks, the toothed racks are engaged with a second duplex gear, the teeth of the second duplex gear are meshed with a fourth bevel gear, the fourth bevel gear is connected with a second rotating shaft, the second rotating shaft is fixed on a under pressing board, the bottom of the second rotating shaft is rotationally connected with a sliding block; the provided linkage mechanism, can perform edge replacement operations for plastic packaging bags.

Owner:威海润霖医用材料有限公司

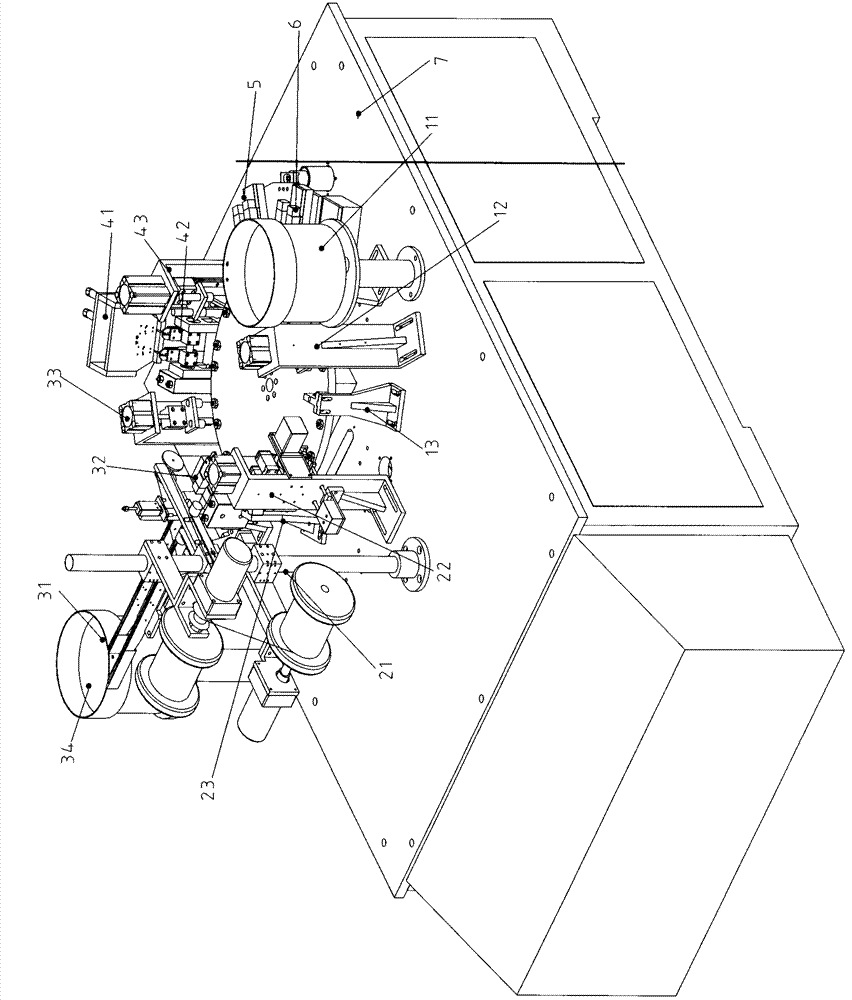

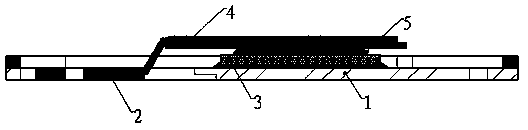

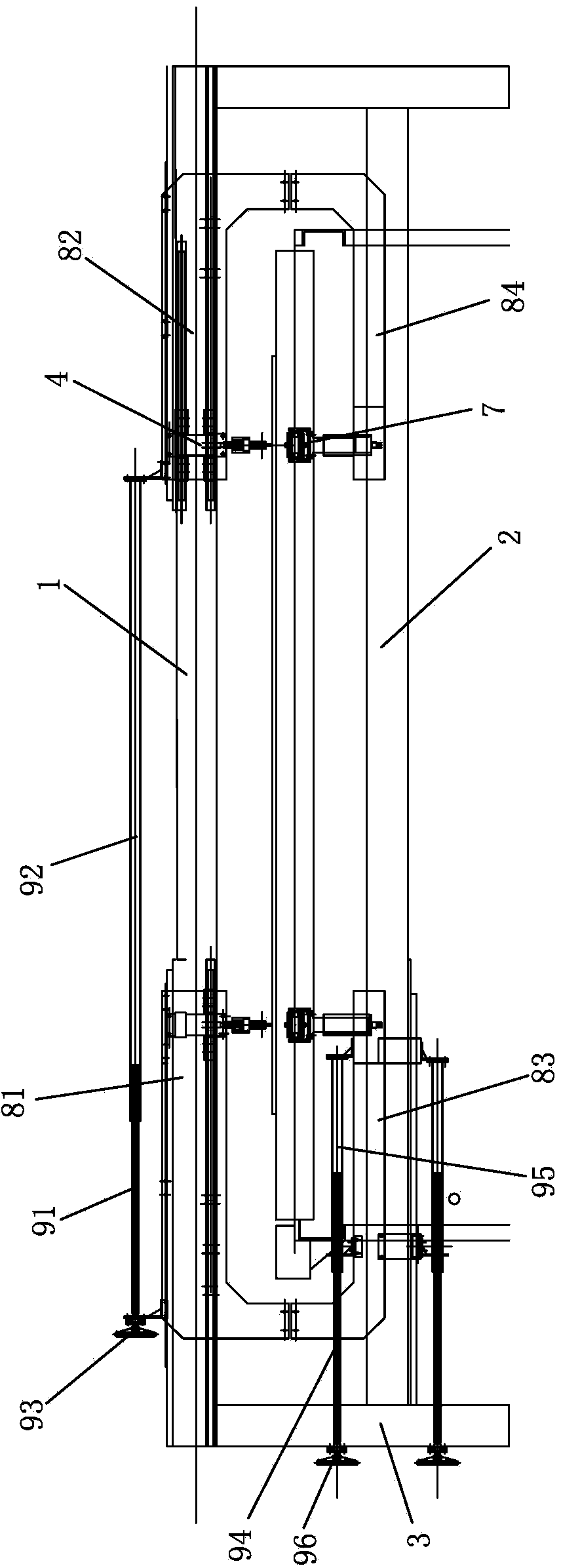

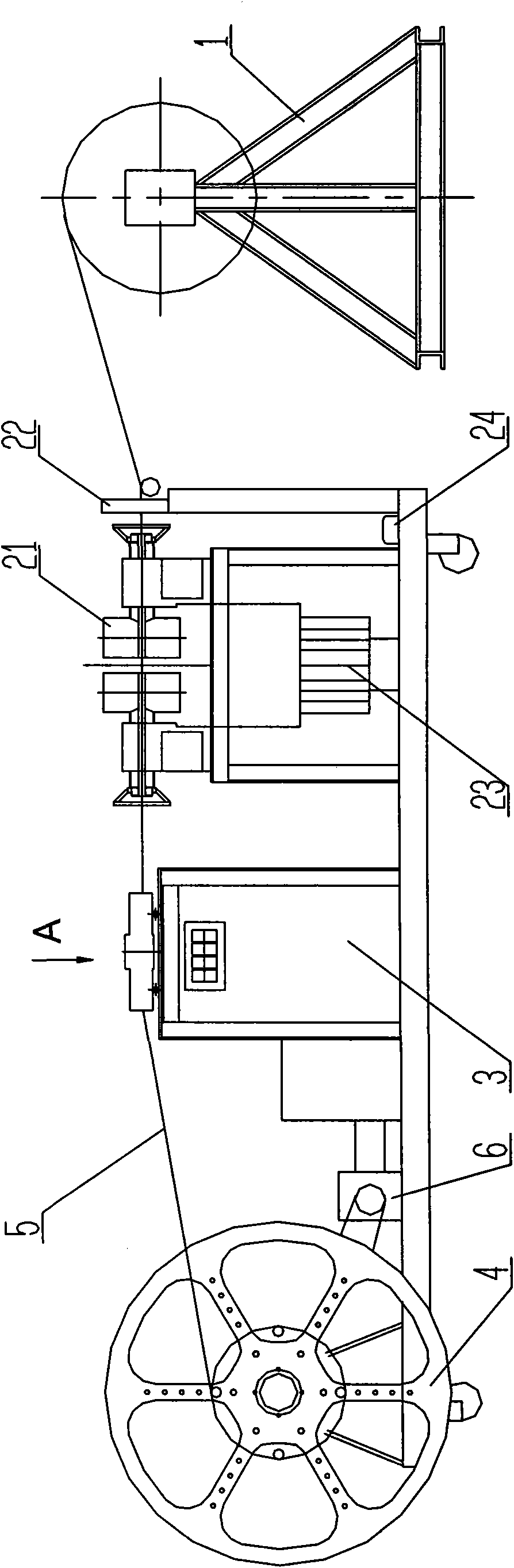

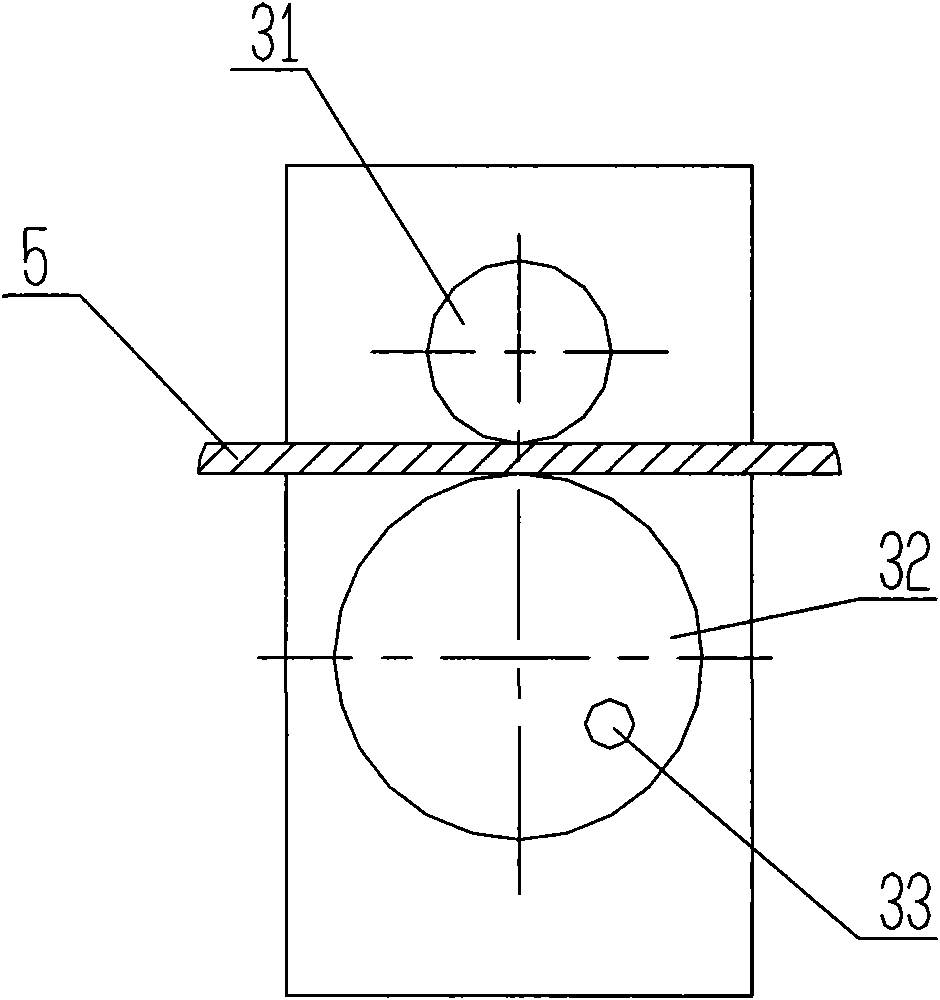

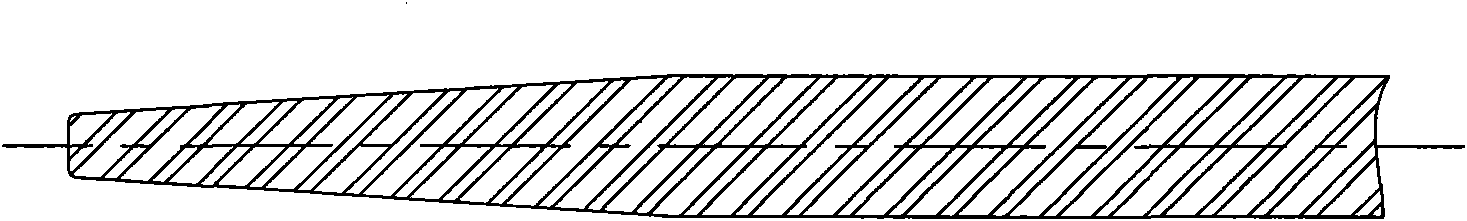

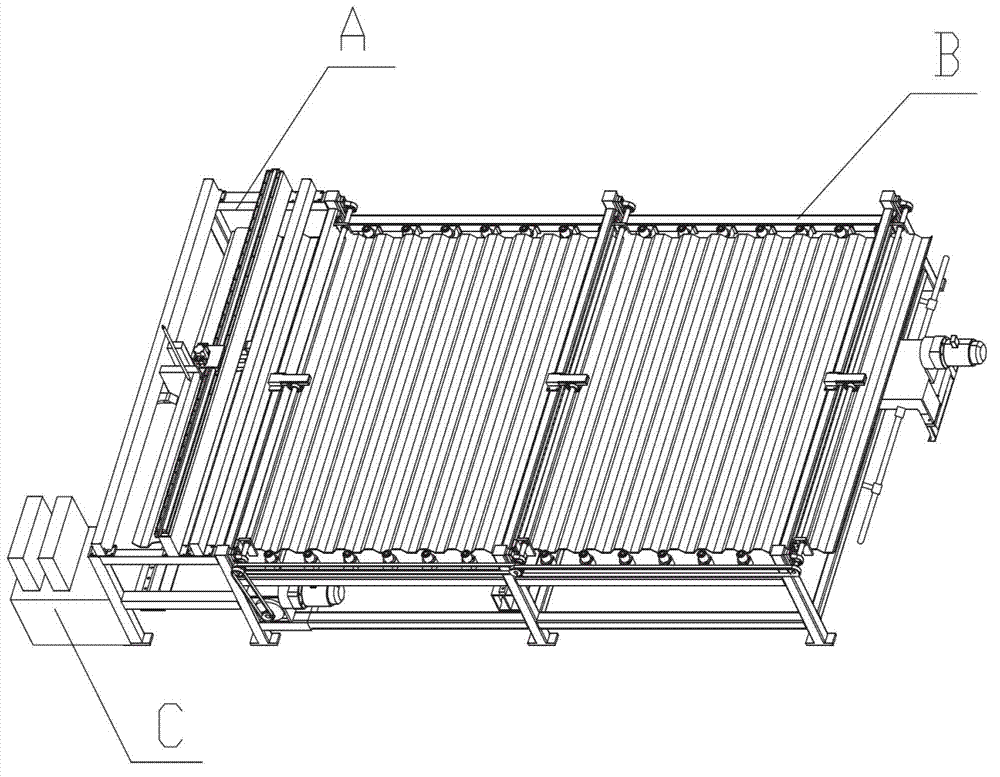

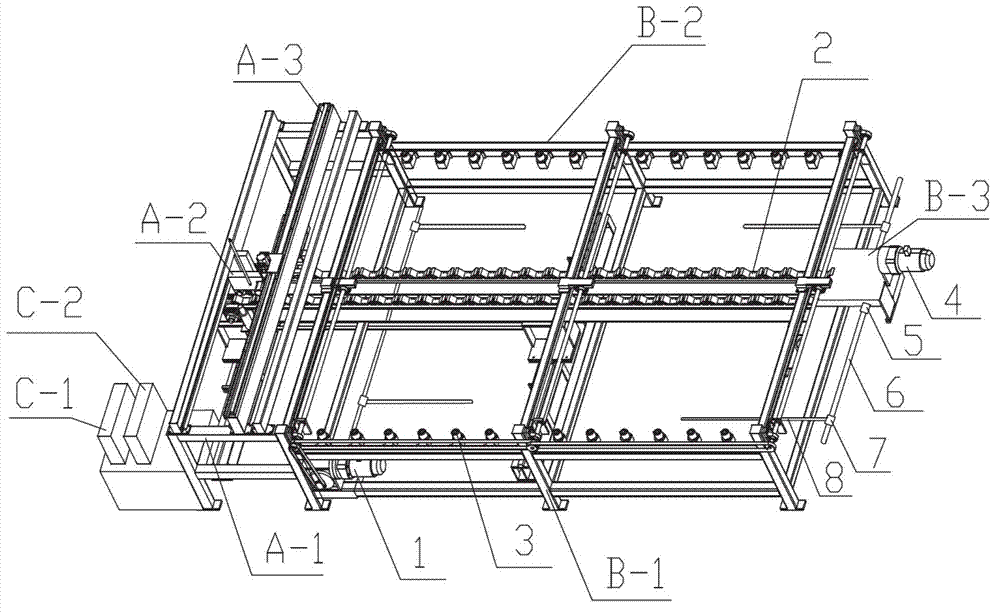

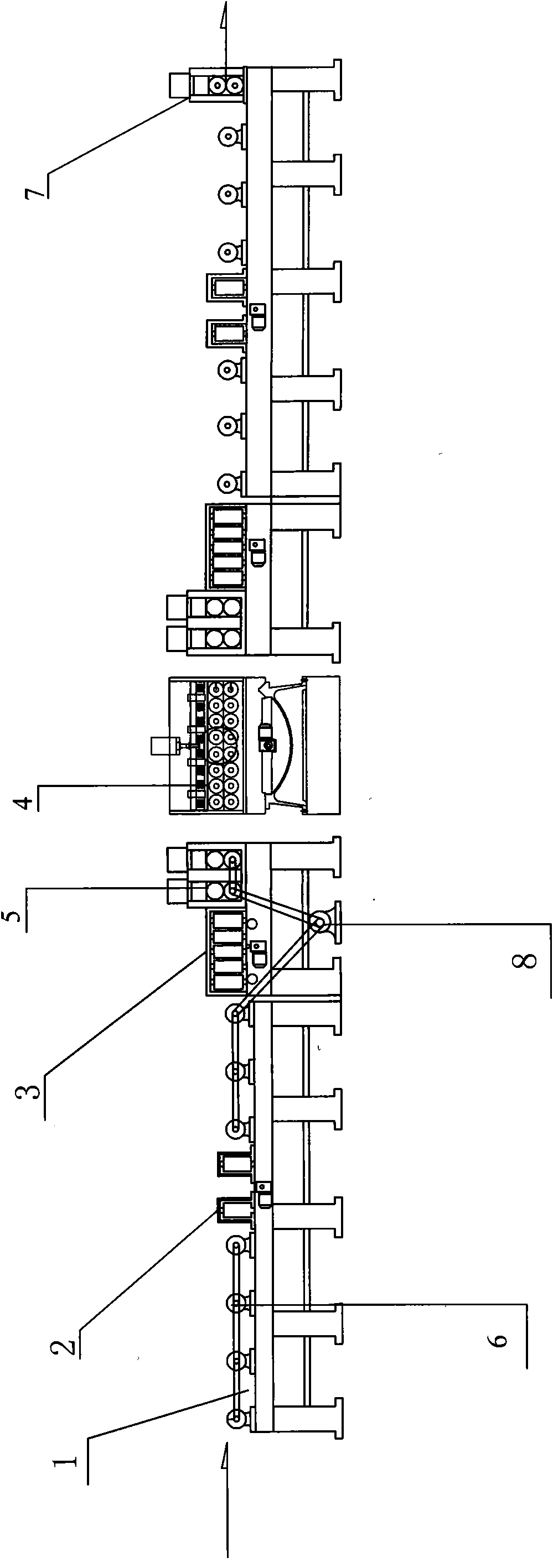

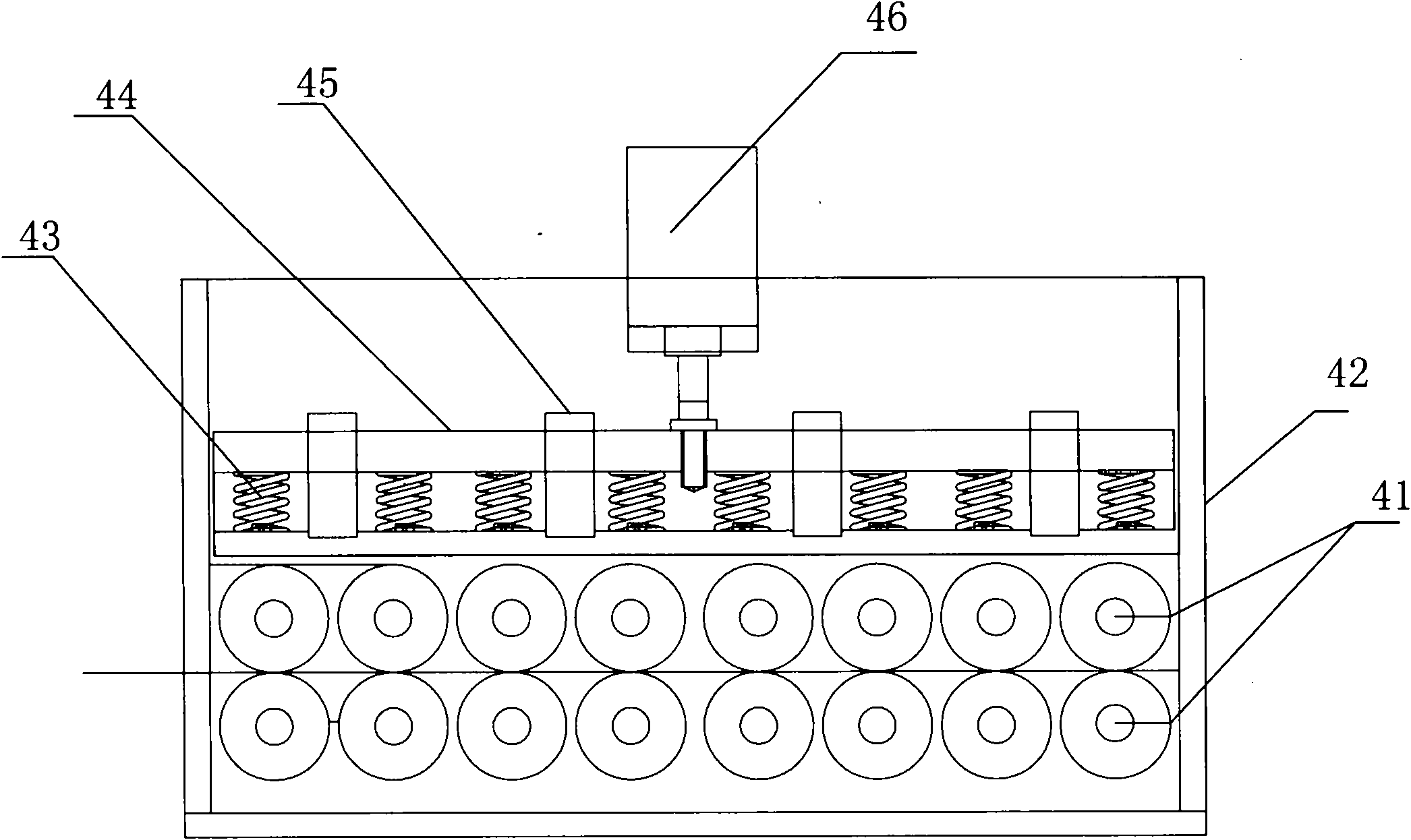

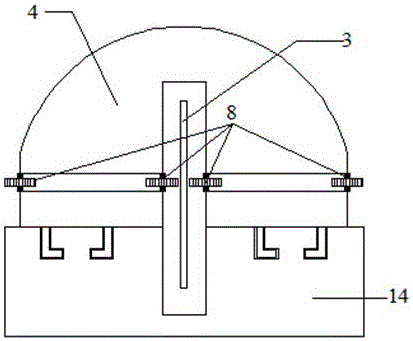

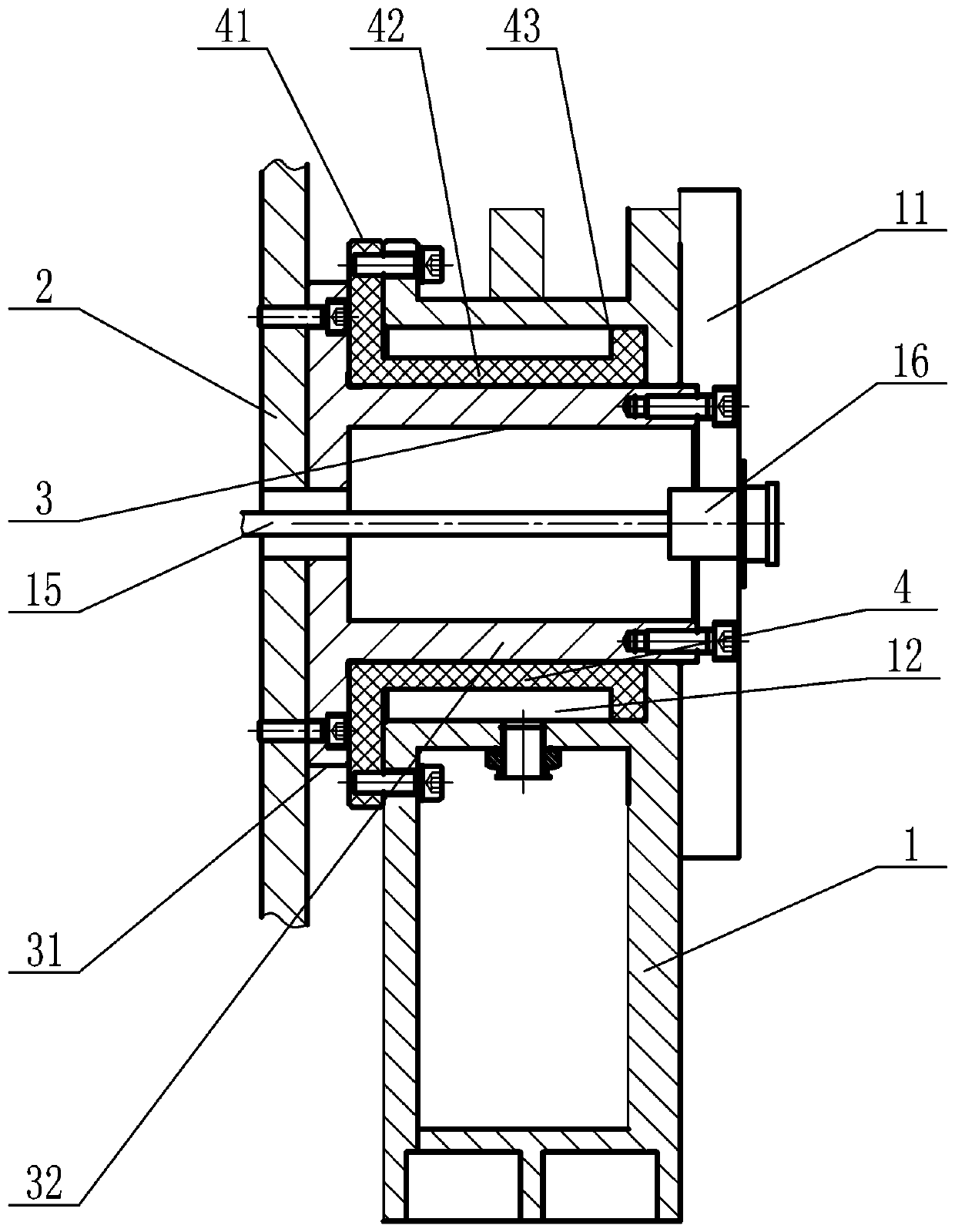

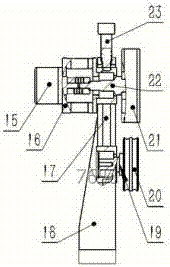

Numerical-control single-plate bilateral synchronous edging machine

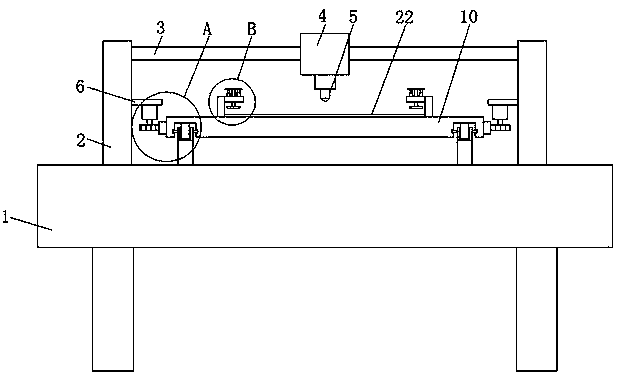

ActiveCN102152161AContinuous processingEliminate OscillationMetal working apparatusSteel platesSheet steel

The invention discloses a numerical-control single-plate bilateral synchronous edging machine, relating to special equipment for processing steel plates. The numerical-control single-plate bilateral synchronous edging machine comprises various equipment and numerical control systems thereof which are all arranged on a workbench (1), wherein a dual-roll two-point correction mechanism (2), a feeding roller (6) and a transmission system (8) thereof, a compression roller (5) and a material throwing mechanism (7) are connected in sequence. The numerical-control single-plate bilateral synchronous edging machine is characterized in that a dense-roll multipoint correction mechanism (3) and a flexible compression-roller device (4) are arranged between the dual-roll two-point correction mechanism (2) and the feeding roller (6). In the invention, a novel process for synchronously processing bilateral vertical faces of a steel plate in a long-distance and following-up way is adopted, the dense-roll multipoint correction mechanism, the flexible compression roller device and a powerful round jacket-type depended wheel are designed and are combined in use to realize the linear, high-precision and continuous processing in a bilateral, vertical-face and long-distance way, and thus the technical effects of energy saving, material saving, high efficiency and rapidness are achieved.

Owner:泰安华鲁数控机床有限公司

Flame fixed-groove cutter

The invention discloses a flame fixed-groove cutter. A guide rail module is mounted on an H-shaped steel of a foundation; a main frame part and a sub frame part are respectively engaged with a rack on the guide rail module through a gear on a feeding motor; two ends of a cross beam part are mounted above the main frame part and the sub frame part; a driving slide carriage is mounted on a linear guide rail slide block in front of the cross beam part; the driving slide carriage is engaged with a rack on the cross beam part by the gear on the feeding motor; a lifting mechanism is mounted in front of the driving slide carriage; and an infinite rotary flame cutting head is mounted on a lifting dragging plate of the lifting mechanism. According to the invention, problems on curved groove cutting and thick steel sheet groove cutting are solved, single cutting-torque flame infinite rotary fixed-groove cutting is realized, and purchasing, using and maintenance cost of a user is effectively reduced.

Owner:WUXI HUALIAN PRECISION MACHINERY

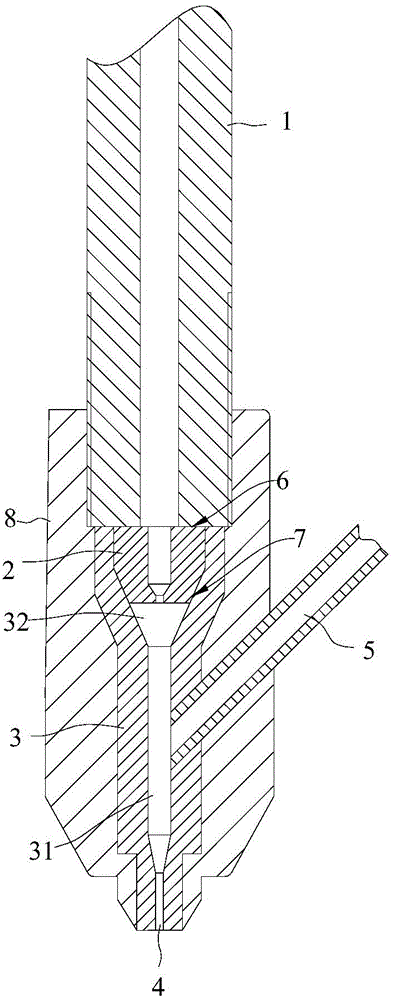

High cutting force medical water jet scalpel and application thereof

ActiveCN104873248AReduce adverse reactionsSolve cutting problemsIncision instrumentsFluid jet surgical cuttersLiquid jetSurgical operation

The invention discloses a high cutting force medical water jet scalpel and an application thereof. The high cutting force medical water jet scalpel is used to cut biological tissue. The high cutting force medical water jet scalpel comprises a high pressure pipe, a liquid nozzle and a material mixing pipe, wherein a mixed material nozzle is arranged at one end of the material mixing pipe, a material mixing cavity is formed in a portion of the material mixing pipe, between the liquid nozzle and the mixed material nozzle, and a feed pipe which supplies biocompatibility particles into the material mixing cavity is arranged on the side wall of the material mixing cavity. When the high cutting force medical water jet scalpel is used, high pressure liquid enters the liquid nozzle through the high pressure pipe so as to form liquid jet flow, the biocompatibility particles added in the material mixing cavity through the feed pipe are continuously sucked into the material mixing cavity under action of negative pressure generated by the liquid jet flow, and then mixed with the high pressure liquid, and finally mixed material liquid jet flow formed by the biocompatibility particles and the high pressure liquid is sprayed out through the mixed material nozzle. Due to action of the biocompatibility particles in the mixed material liquid jet flow, the mixed material liquid jet flow generates cutting force several multiples or tens of multiples of cutting force generated by pure liquid high pressure jet flow, the purpose of incising and separating the human tissue can be achieved by using the high cutting force medical water jet scalpel, and furthermore the high cutting force medical water jet scalpel is wide in use range, and meets multiple surgical operation demands.

Owner:HUIZHOU HYDRO CARESYS MEDICAL CO LTD

Winding tube cutting apparatus and method

InactiveCN101318238ASolve cutting problemsAvoid causing a jackknifeMetal sawing devicesSteel beltEngineering

The invention discloses a cutter device of a winding pipe and a cutting method. The cutter device comprises a frame, a support frame of the winding pipe, a cutter device and a moving apparatus; wherein, the frame comprises a fixation frame and a movable frame; the support frame of the winding pipe is connected with the two sides of the movable frame along the direction of the axes of the winding pipe; the cutter device is connected with the movable frame; the moving apparatus is connected with the fixation frame and the movable frame respectively; the moving apparatus drives the moving stand to move in the same speed with the winding pipe; the cutter device comprises a band saw which is transversely arranged under the winding pipe along the direction of the axes of the winding pipe, a lifting guiding element which is vertically connected with the movable frame, a fixation frame of the band saw which is connected with the lifting guiding element in a guiding way and a lifting device which is connected with the fixation frame of the band saw ; the band saw is connected with the fixation frame of the band saw and the terminal surface is arranged in an oblique way. The method comprises the steps of laying out pipes, aligning, starting the moving apparatus, adjusting the cutting side of the band saw, advancing tool step by step to cut until finishing cutting and withdrawing saw, etc. The cutter device of the invention solves the problem about the cutting of the band winding pipes with thick steel bands and satisfies the demand of online pipe cutting.

Owner:四川江瀚工业股份有限公司

Laser cutting device and cutting method for profiled bar

ActiveCN113084365AAchieve processing efficiencyAvoid drossLaser beam welding apparatusErbium lasersLaser cutting

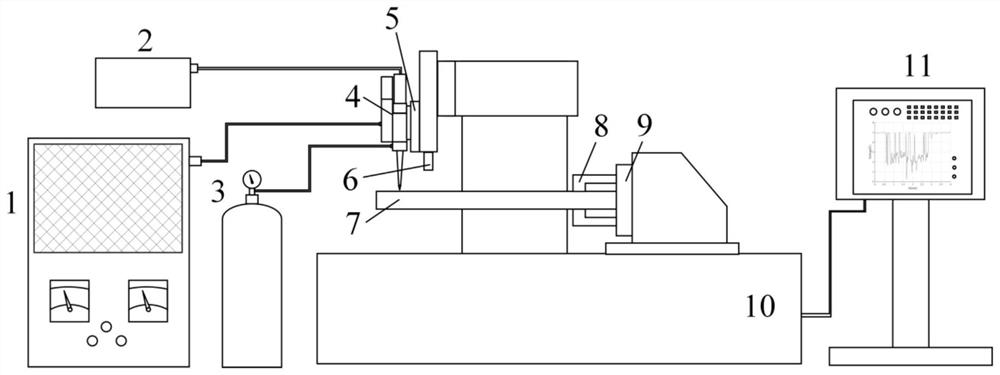

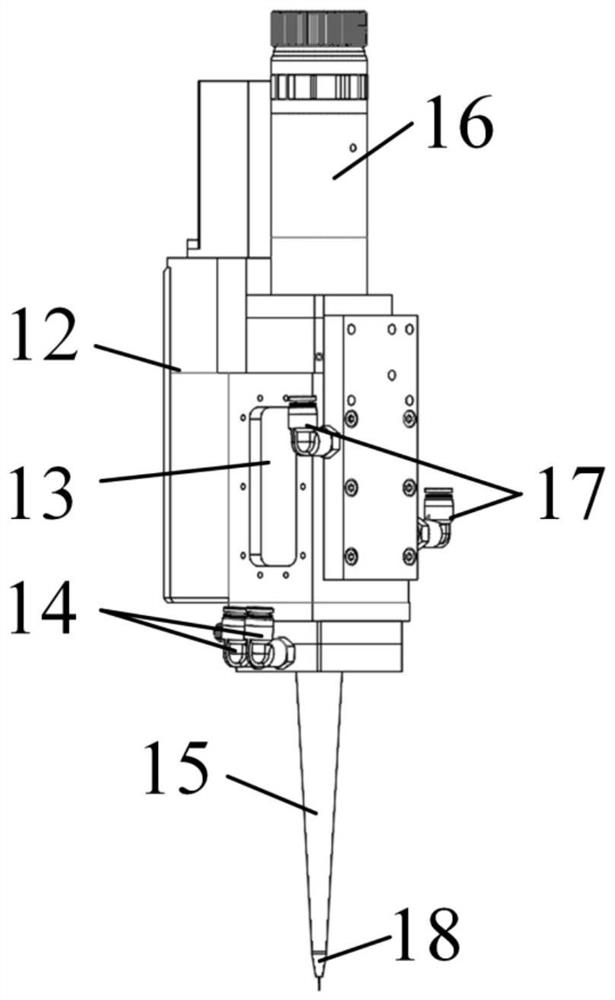

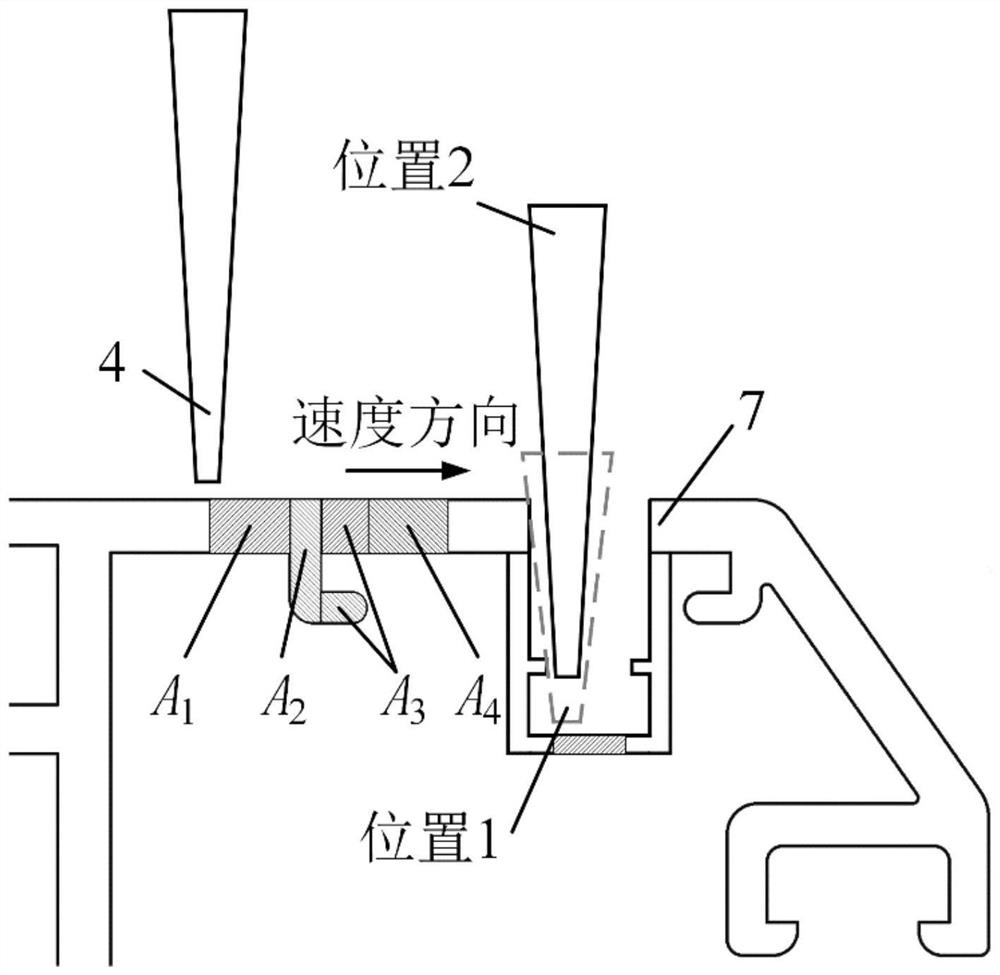

The invention discloses a laser cutting device for a profiled bar. The laser cutting device for the profiled bar comprises a cooling-water machine (1), a laser (2), an air source (3), a laser cutting head (4), a laser cutting head fast forward shaft (5), a scanning lens (6), a profiled bar clamp (8), an ultrasonic auxiliary generating device (9), a machine tool body (10) and a control panel (11). The invention further discloses a laser cutting method for the profiled bar. The laser cutting method for the profiled bar aims at the characteristics of complex change of the section shape and the wall thickness of the profiled bar and the machining requirement for a large number of deep groove type holes, the laser cutting speed is matched on the basis of full-power laser energy output according to the change of the thickness and the shape of the section contour, and therefore the machining efficiency is maximized. Meanwhile, an optical module in the laser cutting head of the device adopts a long-focus focus lens, and is matched with a long taper sleeve, so that active anti-interference machining of the deep groove type holes is realized.

Owner:HUNAN UNIV

Laser cutting machine for steel plate machining

InactiveCN108465948ASolve cutting problemsEasy to moveWelding/cutting auxillary devicesAuxillary welding devicesSheet steelHead shaking

The invention relates to the technical field of laser cutting, and discloses a laser cutting machine for steel plate machining. The laser cutting machine comprises a supporting base, supporting side plates are fixedly connected to the top of the supporting base, the sides, close to the top, of the supporting side plates are fixedly connected with a supporting transverse beam, a driver is fixedly connected to the middle of the supporting transverse beam, and a laser spray head is fixedly connected to the bottom of the driver; and the sides, located below the supporting transverse beam, of the supporting side plates are fixedly connected with fixing plates, driving motors are fixedly connected to the bottoms of the fixing plates, and output shafts of the driving motors are fixedly connectedwith driving gears. According to the laser cutting machine for steel plate machining, the problem that when an existing laser cutting machine conduct cutting, cutting is performed through a moving laser spray head is solved, thus, the situation that cutting deviation occurs due to the fact that a laser spray head shakes during moving is avoided, and accordingly, the cutting quality is ensured.

Owner:赵咪咪

Automatic foam cutting machine and cutting method

InactiveCN1962210AEasy and fast cuttingWorking force can be adjustedMetal working apparatusSteel tubeMicro computer

The invention relates to an automat foam jack cutter and relative cutting method, wherein said device comprises a moving device parallel moving along the tube axial track with foam jack layer, a clamper for clamping the foam jack layer, a cutting device for cutting the foam jack layer, a detector for detecting the detector to tube, and a controller for controlling the cutting process. The invention has a feeding separating device with speed differential design and adjustable force. The invention uses micro computer control, with semi-automatic, full-automatic and hand-operated methods.

Owner:张景远

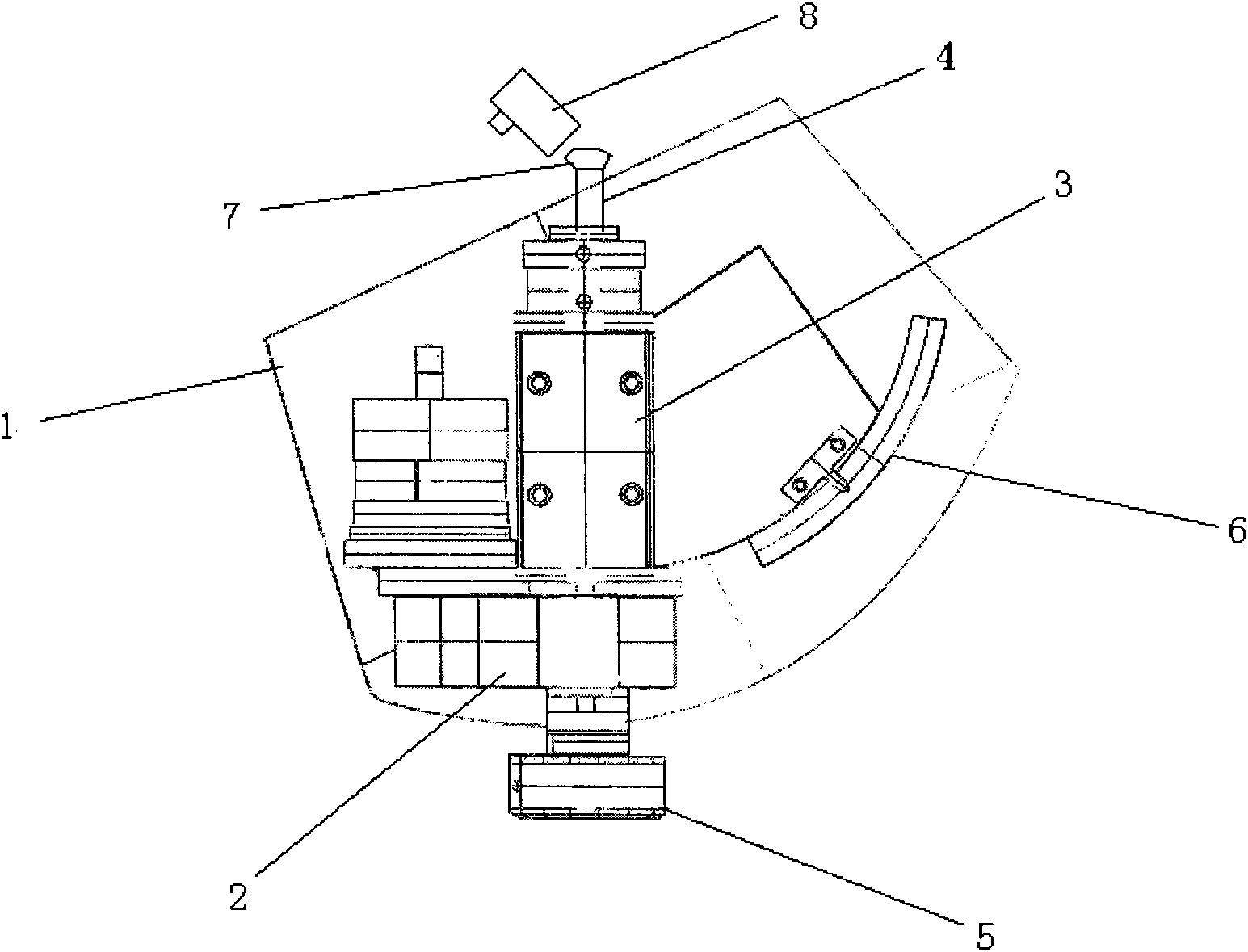

Device for accurately cutting pre-cut seam of asphalt mixture semi-circular bending tensile test piece

ActiveCN106769316ASimple equipmentPrecise controlPreparing sample for investigationAsphaltPitch blende

The invention relates to a device for accurately cutting a pre-cut seam of an asphalt mixture semi-circular bending tensile test piece. The device comprises a horizontal operation platform, and an electric motor, a saw blade and a test piece fixator which are arranged on the horizontal operation platform, wherein the electric motor is in transmission connection with the saw blade; an adjustable jig and an adjusting bolt used for fixing the asphalt mixture semi-circular bending tensile test piece are mounted on the test piece fixator; 8 adjustable foot screws, a circular level and 2 millimeter graduated scales are further mounted on the test piece fixator; the 8 adjustable foot screws are arranged at the bottom of the test piece fixator, the circular level is arranged at the upper part of the test piece fixator, and the 2 millimeter graduated scales are arranged at the side part of the test piece fixator; a T-shaped sliding rail is arranged on the horizontal operation platform, the bottom of the test piece fixator is placed in the T-shaped sliding rail, and the test piece fixator can slide on the T-shaped sliding rail. The device has the advantages that equipment is simple, the cutting size can be controlled accurately, the cutting process is easy to control, and the applicability is high.

Owner:YANGZHOU UNIV

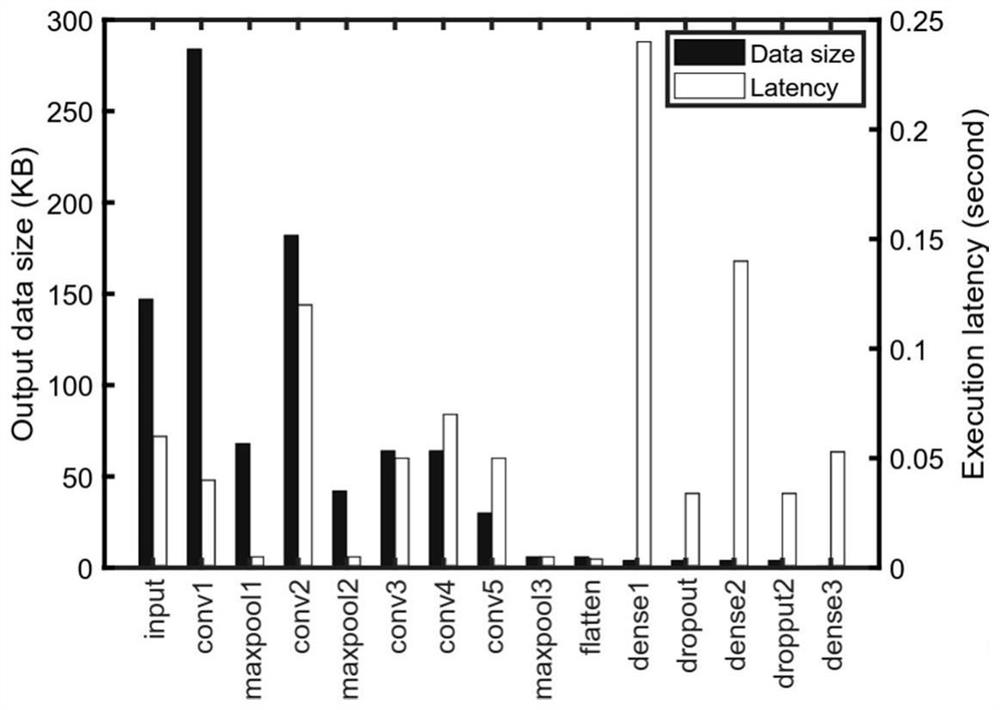

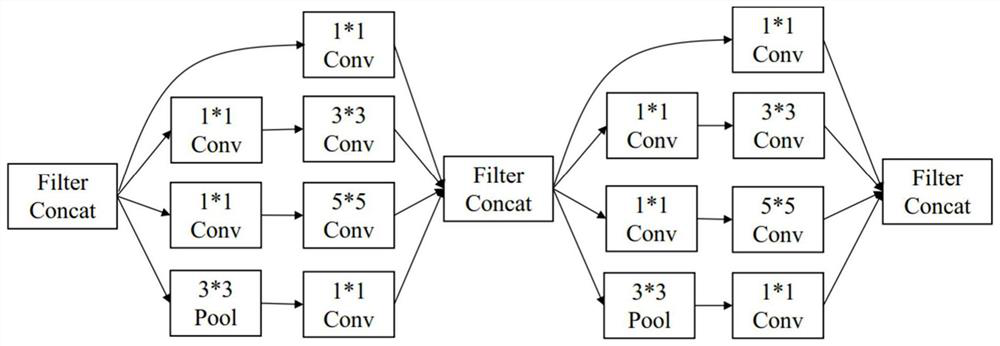

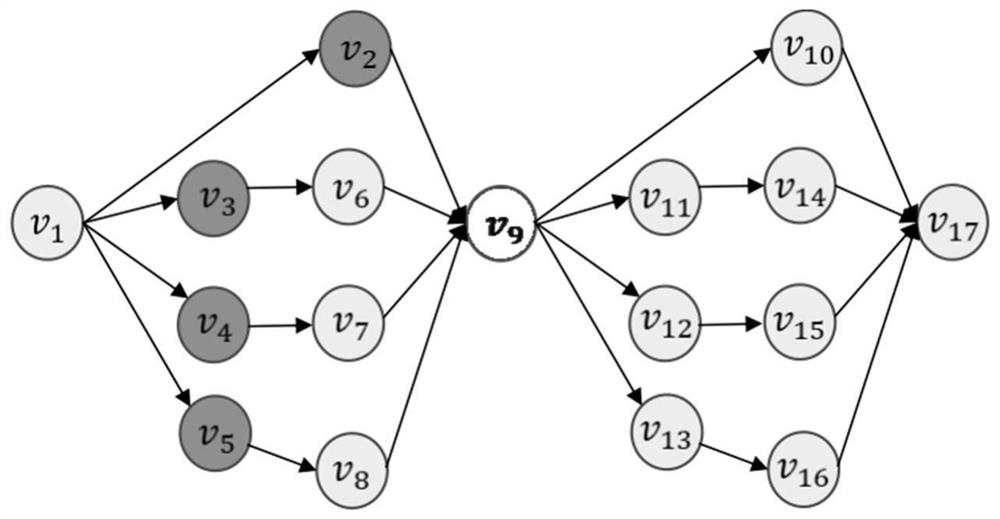

Accelerated execution method of deep learning model in dynamic change network environment

PendingCN112990018AAccurate segmentationSpeed up the data analysis processResource allocationCharacter and pattern recognitionData transmissionSelf adaptive

The invention discloses an accelerated execution method of a deep learning model in a dynamic change network environment, and the method employs a network flow algorithm to cut a DAG type neural network, allows the DNN to be disposed at an edge end and a cloud end at the same time, limits the data transmission, and accelerates the reasoning. By utilizing the property of undirected graph topping, a two-step method is provided, and the decision time of a minimum cut model is shortened. Compared with other methods, the new time delay measurement method can achieve the effects of reducing the reasoning time delay and improving the throughput. According to the method, the convolutional neural network can be adaptively cut according to the network speed, when the network speed is high, a calculation task is given to a cloud end to be processed as much as possible, and when the network speed is low, the calculation task is calculated at the edge as much as possible, and an intermediate result is transmitted to the cloud end to be processed.

Owner:江苏边智科技有限公司

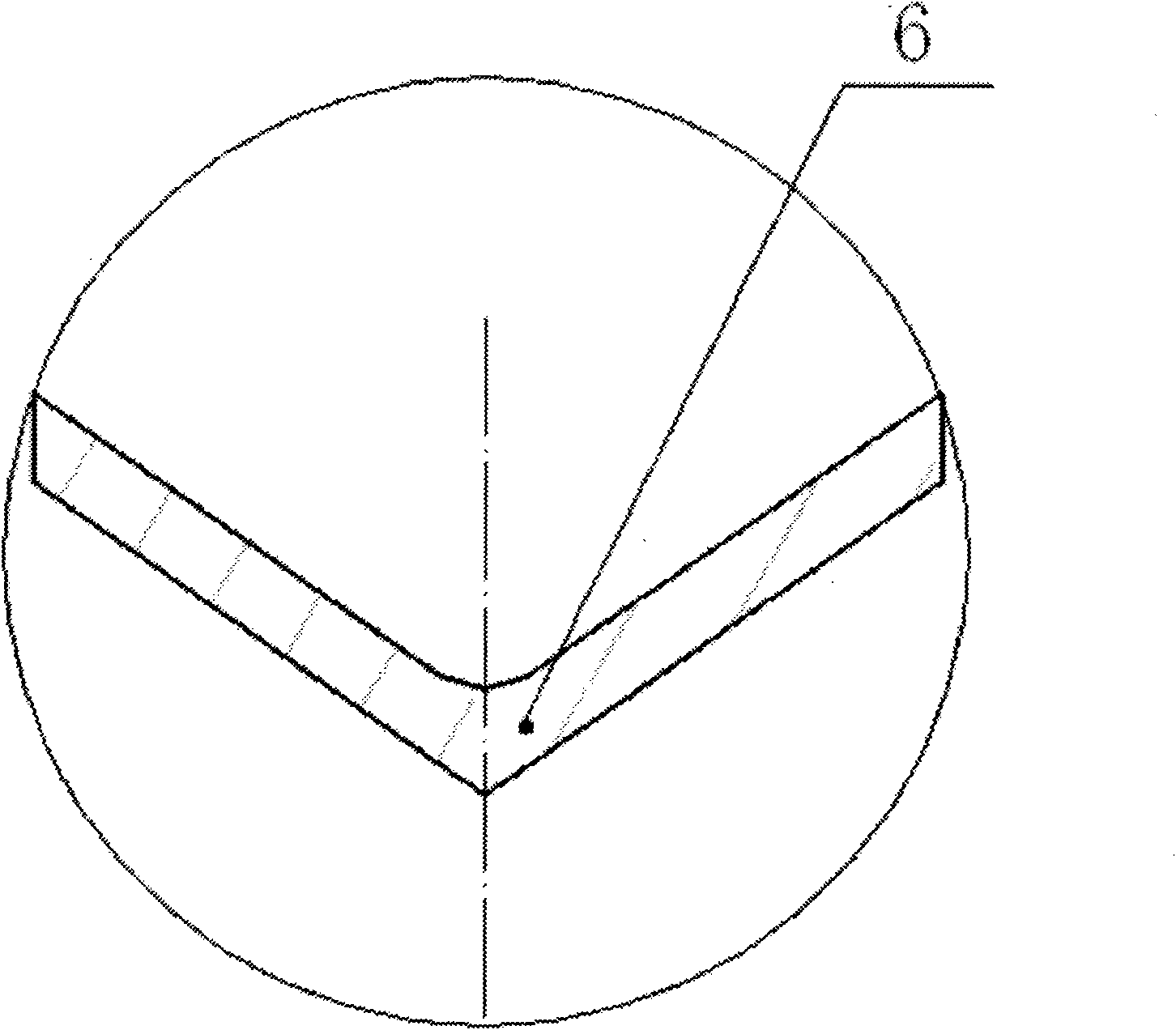

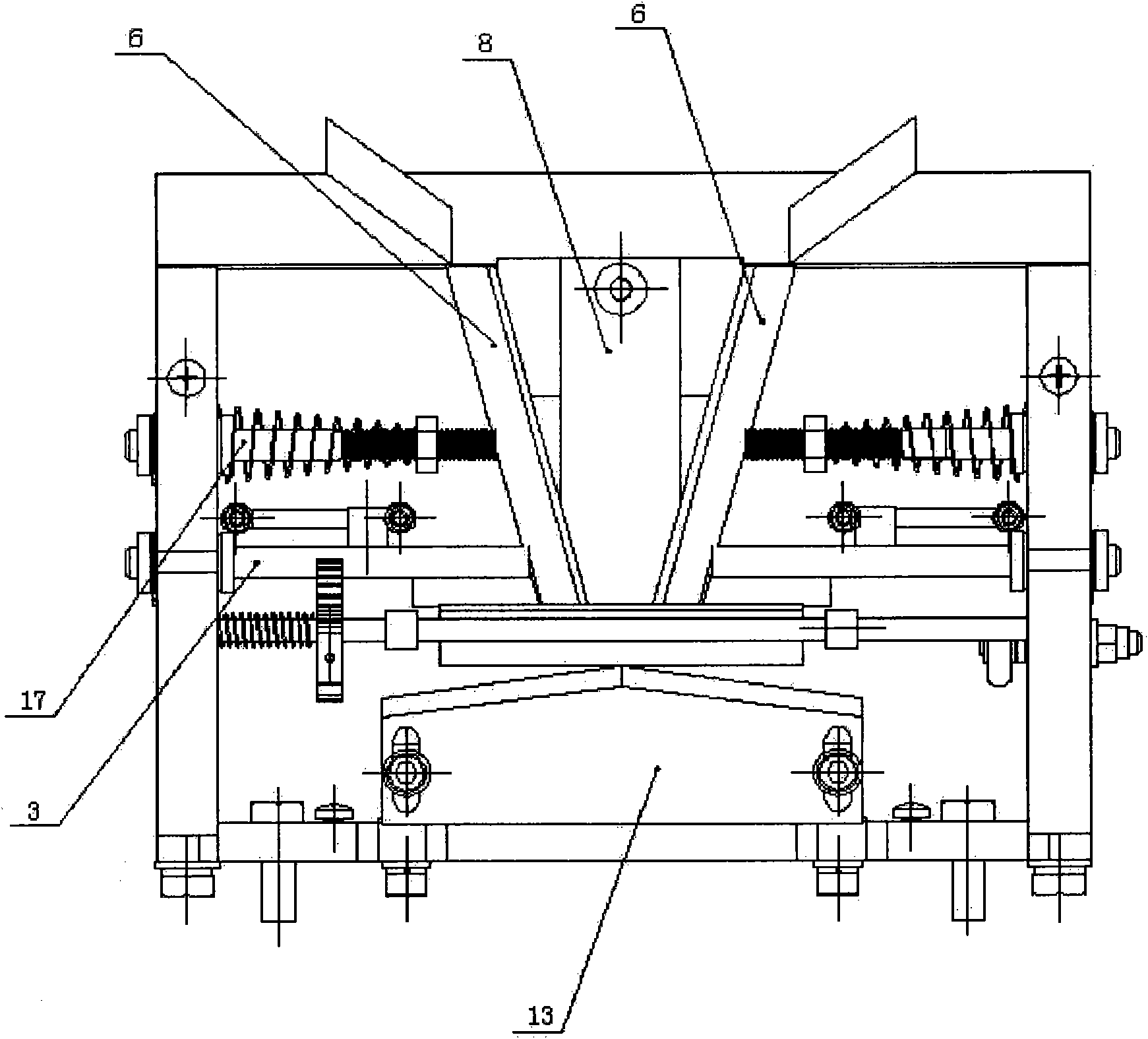

Self-alignment cutting device for irregular ellipsiod

InactiveCN101862857ASolve cutting problemsAddress mechanical propertiesShearing machinesShearing machine accessoriesEngineeringTorsion spring

The invention relates to a central plane cutting device for an irregular ellipsoid, which is applied to fruit cutting. Left and right V-shaped blocks (6) forming a certain angle with a vertical surface are arranged on the left and the right of a positioning device of the cutting device, the central lines of the two V-shaped blocks are positioned on the same plane, the upper part and the lower part of the device comprises a rotation V block (14) capable of opening from the central line and a V-shaped pressure head (8) actively pressing downwards, the left and right V-shaped blocks (6) position two apexes of the irregular ellipsoid within the same plane, and the rotation V block (14) and the V-shaped pressure head (8) are used for searching the central plane of the body of the irregular ellipsoid. The left and right V-shaped blocks (6) can slide horizontally leftwards and rightwards in a linear bearing (10) according to guide rods (3) and (17), the rotation V block (14) can be controlled to open and close symmetrically by a pair of gears (16), the pretightening force and the tension of the opening and the closing of the rotation V block (14) are regulated by a torsion spring (2), a blade (13) is arranged below the rotation V block, and after the V-shaped pressure head continuously press downwards, a fruit touches the blase so that a central plane cutting can be realized.

Owner:长沙正科机电科技有限公司

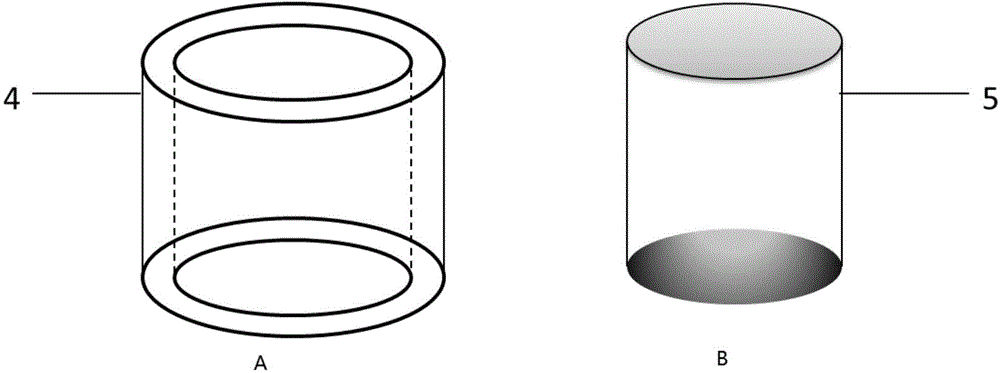

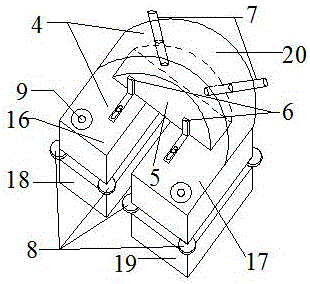

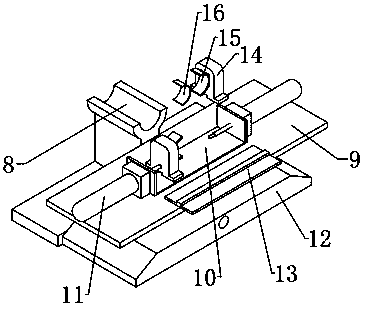

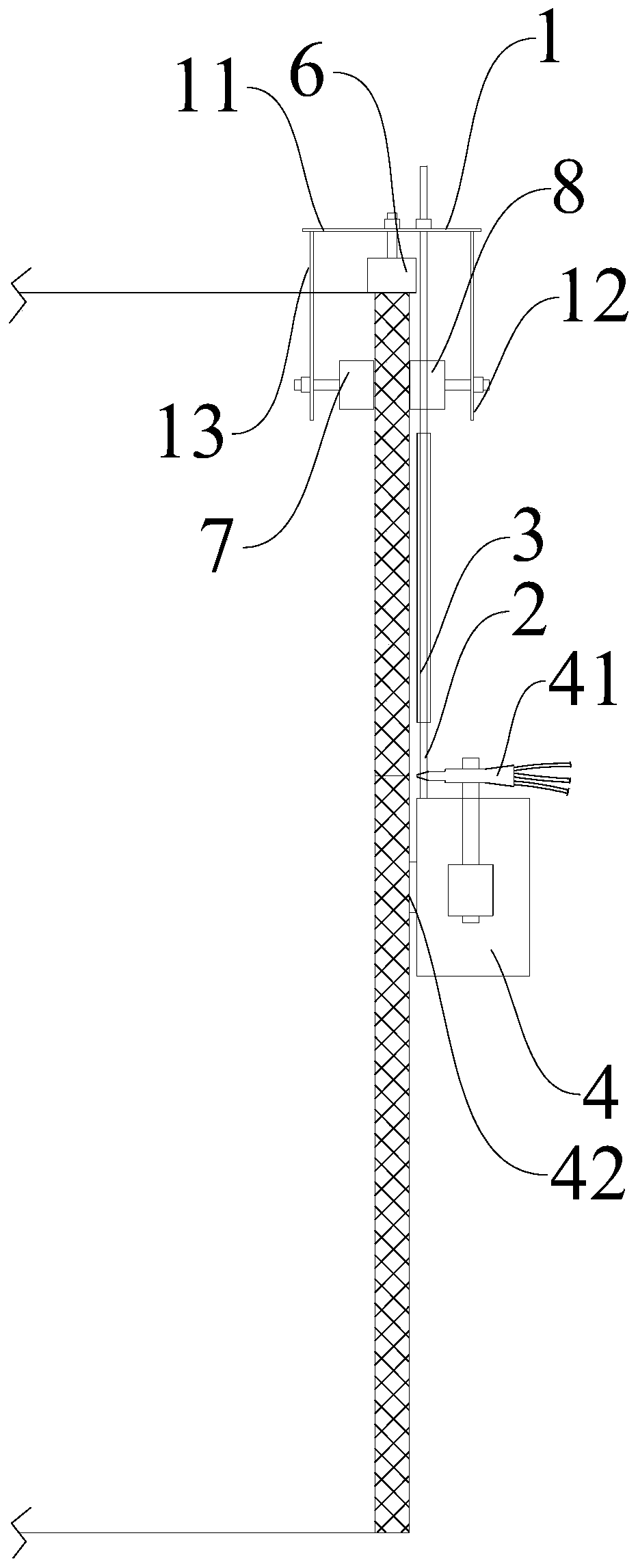

Circular tube cutting and surface drilling integrated equipment

ActiveCN110625397APlay a clamping effectSolve cutting problemsWork clamping meansOther manufacturing equipments/toolsBiomedical engineering

The invention relates to the machining field, in particular to circular tube cutting and surface drilling integrated equipment. The circular tube cutting and surface drilling integrated equipment comprises a feeding assembly, a cutting assembly and a drilling assembly, wherein the feeding assembly is arranged at one side of the cutting assembly; the drilling assembly is arranged at one side, awayfrom the feeding assembly, of the cutting assembly; the feeding assembly, the cutting assembly and the drilling assembly are linearly arranged in sequence; the feeding assembly comprises a fixed clampand a first movable clamp; the fixed clamp is arranged at one end of the cutting assembly; and the first movable clamp is arranged between the fixed clamp and the cutting assembly. The circular tubecutting and surface drilling integrated equipment solves the problem that circular tube cutting and drilling cannot be performed simultaneously, improves working efficiency and saves time.

Owner:重庆优实管业有限公司

Multi-axis energy-saving water-jet cutting equipment

InactiveCN112140002AImprove cutting effectEasy to cutAbrasive machine appurtenancesAbrasive blasting machinesTool bitWater jet cutter

The invention relates to the field of water-jet cutting, in particular to multi-axis energy-saving water-jet cutting equipment. The equipment comprises a workbench and a support, and further comprisesa water-jet head used for cutting, an X-direction moving mechanism and a Y-direction moving mechanism which are used for X-axis movement and Y-axis movement, a water inlet connector used for supplying water, a connecting water pipe used for communicating the water inlet connector with the water-jet head, a lifting adjusting mechanism used for adjusting the cutting position of the water-jet head,and a multi-axis adjusting component used for adjusting the cutting direction of the water-jet head, wherein the support is arranged above the workbench; the X-direction moving mechanism is arranged at the top of the support; the Y-direction moving mechanism is arranged on the X-direction moving mechanism; the moving direction of the Y-direction moving mechanism is perpendicular to the moving direction of the X-direction moving mechanism; and the water inlet connector is arranged on the Y-direction moving mechanism. The equipment solves the problem that traditional water-jet cutting equipmentdoes not have multi-axis adjustment to cut complex workpieces, the cutting effect of the water-jet head is improved, and the water-jet head can conveniently cut the complex workpieces.

Owner:杨秉霖

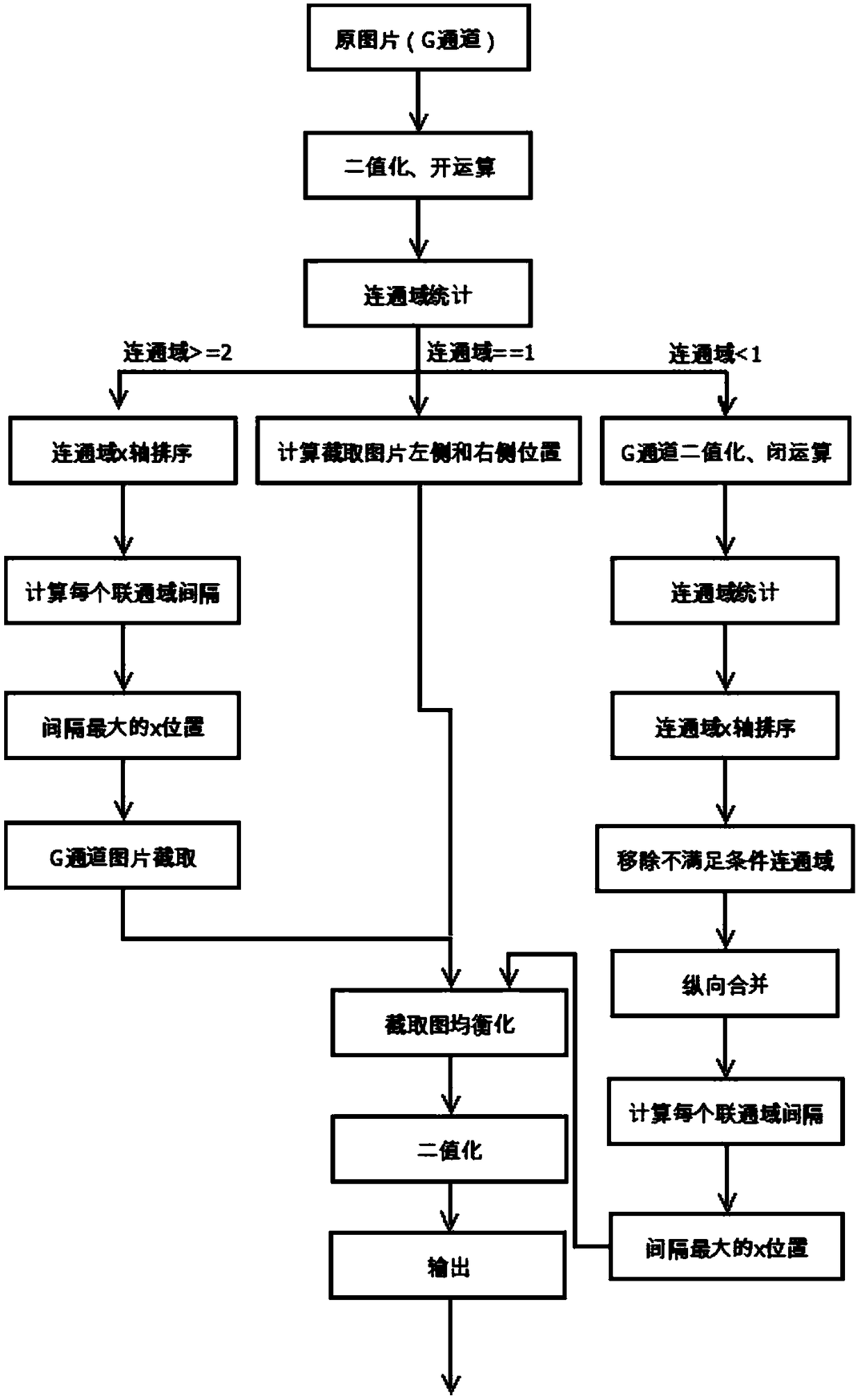

Segmentation and recognition method and system for combined verification code

ActiveCN108875745ASolve cutting problemsSignificantly progressiveCharacter and pattern recognitionGraphicsPattern recognition

The invention discloses a segmentation and recognition method for a combined verification code. The method comprises the steps that RGB three-channel separation is performed on an original image, anda G-channel image is selected; binarization processing and open operation with 3*3 being a core are performed on the selected G-channel image to obtain a binary character image; white connected domains are subjected to statistical analysis, a connected domain threshold is set, and whether the binary character image has a black background or a white background is judged; according to different ranges of connected domain statistical values, X-axis ordering of the connected domains is performed, X-axis positions in a maximum interval of the connected domains are calculated, and a whole image withwords being units is intercepted; and equalization processing and binarization processing are performed on the intercepted image, and pictures based on word group segmentation are output; and the output pictures are trained and recognized. Through the segmentation and recognition scheme for the combined verification code, by improving a basic framework of image segmentation, unit particles and atraining object of the image are converted from pure Chinese characters into word groups based on the Chinese characters, and segmentation and recognition of four types of word group pictures can be met by the adoption of the same algorithm.

Owner:TONGCHENG NETWORK TECH

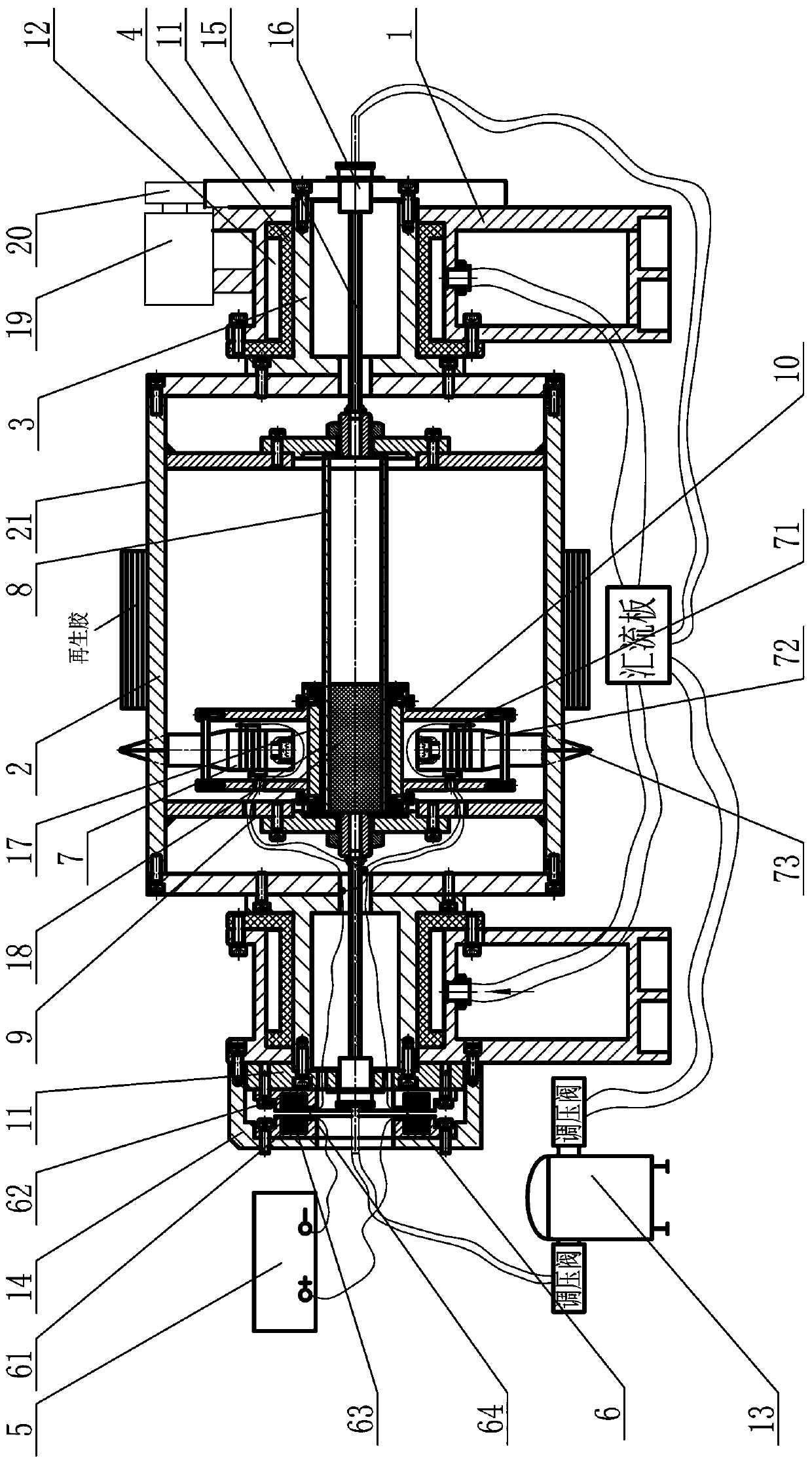

Ultrasonic cutting device for reclaimed rubber

InactiveCN108582260BReduce energy consumptionGuaranteed service lifeMetal working apparatusRubber materialUltrasonic vibration

The invention relates to an ultrasonic reclaimed rubber cutting device. The ultrasonic reclaimed rubber cutting device comprises a base, a coiling block, a rotation shaft, a supporting block, an ultrasonic generator, a wiring block, an ultrasonic tool, an air cylinder, a piston and a tool base. A supporting component of the coiling block is manufactured through porous materials. After the porous materials are inflated with high-pressure gas, a static pressure gas film can be generated on the outer wall of a main shaft, the gas film can suspend the coiling block, air suspension is achieved, andaccordingly influences on a bearing due to the rubber belt temperature are avoided. In addition, an ultrasonic cutting device body is adopted, a cutting edge is not needed during ultrasonic cutting,the molecular energy of rubber is activated through vibration energy, accordingly, a molecular chain of the rubber is opened, and cutting is achieved. The rubber is softened and melted through energygenerated through ultrasonic vibration, edge breakage, damage and other defects cannot be generated on the cut edge of the rubber material, and cutting banding is tidy.

Owner:XINXIANG UNIV

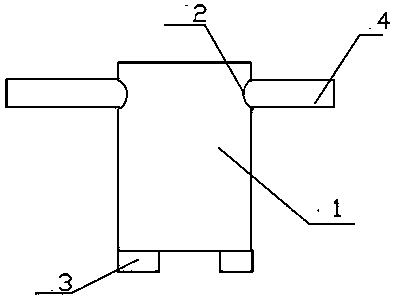

Diamond cutter

InactiveCN101642941AImprove processing efficiencyIncrease production speedEdge grinding machinesFine working devicesDiamond cutting

The invention discloses a diamond cutter, which comprises a base and a diamond conveyance controller. The front end of the diamond conveyance controller is provided with a diamond fixture, while the rear end is provided with a knob; and a support arm is arranged between the knob and the diamond conveyance controller, connected with a diamond polishing angle control device and is controlled by thediamond polishing angle control device. Compared with the prior art, the diamond cutter implements the angle control on a diamond in a diamond cutting and polishing process through the diamond polishing angle control device, so an operator can adjust a polishing angle according to the shape of the diamond and requirements so as to utilize the diamond in highest efficiency; and simultaneously the diamond cutter also solves the problem of cutting the top part of the diamond and cuts each surface of the diamond, greatly improves the processing efficiency of diamond cutting, simplifies the step ofmanual polishing, and greatly improves the production speed of diamond polishing.

Owner:CHOW TAI FOOK JEWELRY SHENZHEN

Scraper

InactiveCN109794650AScientific and reasonable structure designEasy to useEdge structureHardware tool

The invention provides a scraper, and belongs to the field of hardware tools. The scraper aims to improve the finishing efficiency and quality. According to the technical scheme, the scraper mainly comprises a seat body, wherein a pair of force arm holes is machined in the upper part of the seat body, the scraper is welded to the bottom of the seat body; the scraper further comprises force arms matched with the force arm holes; and the scraper adopts a three-edge structure, and the three cutting edges are distributed to form an angle of 120 degrees. During use, an object needing to be treatedis placed on an operation platform, the force arm holes sleeve the force arms, and then a cutting face of the object can be cut by rotating the force arms. By adopting the scraper, finishing of about2000 objects is completed, and the percent of pass reaches 100%. The scraper is scientific and reasonable in structural design, good in using effect, capable of solving the problem of cutting and improving finishing efficiency and cutting quality, and has good popularization value.

Owner:汪云

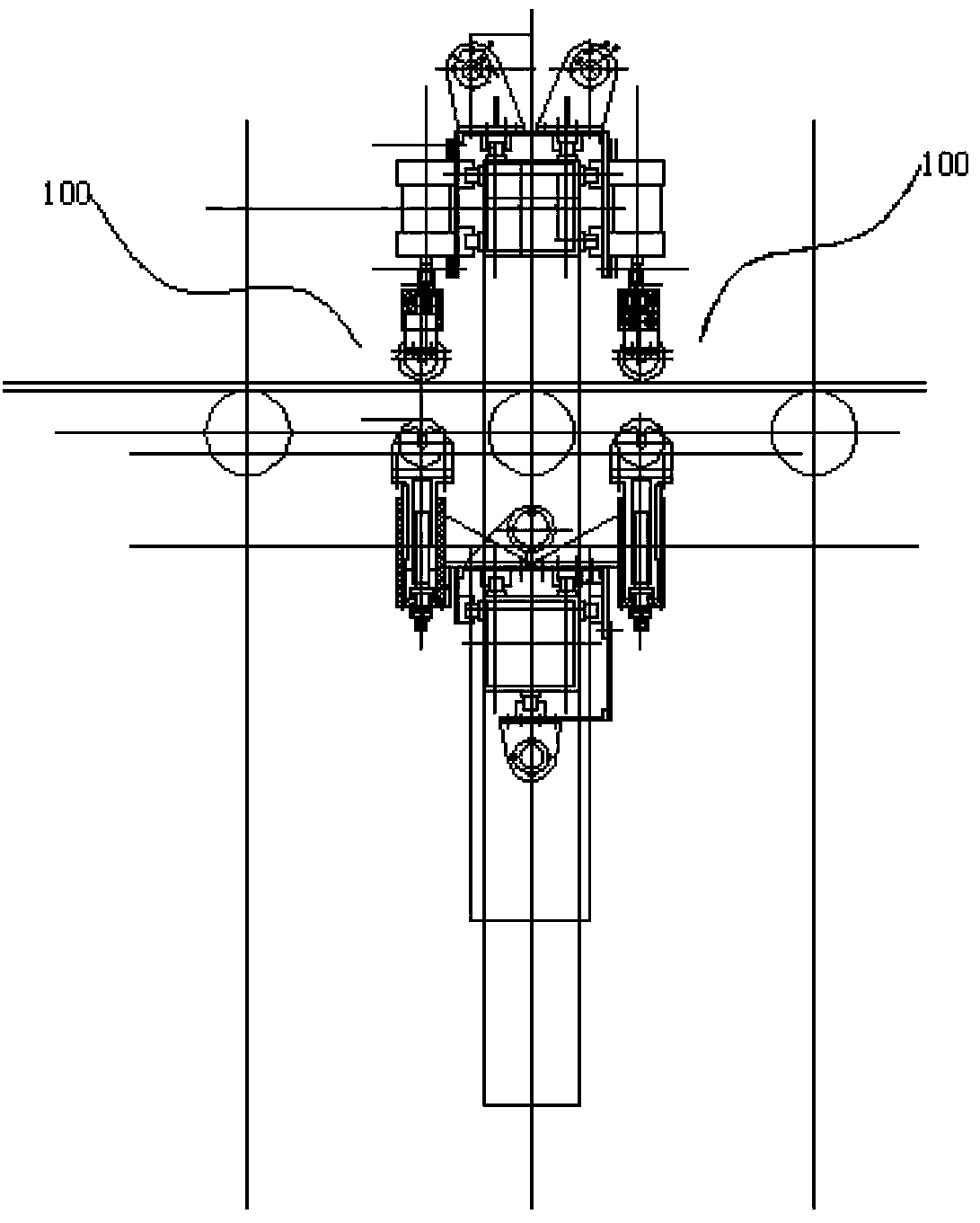

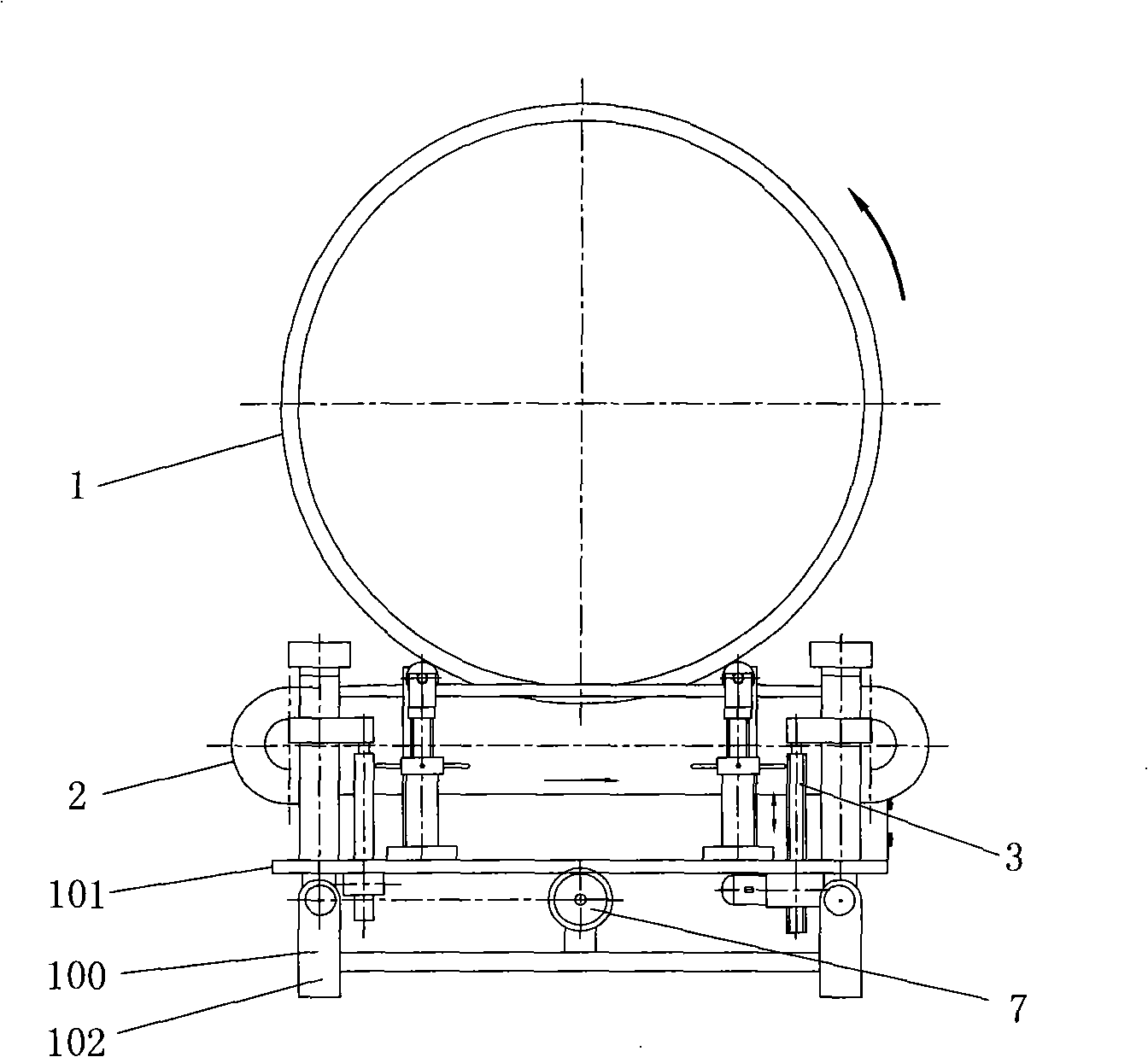

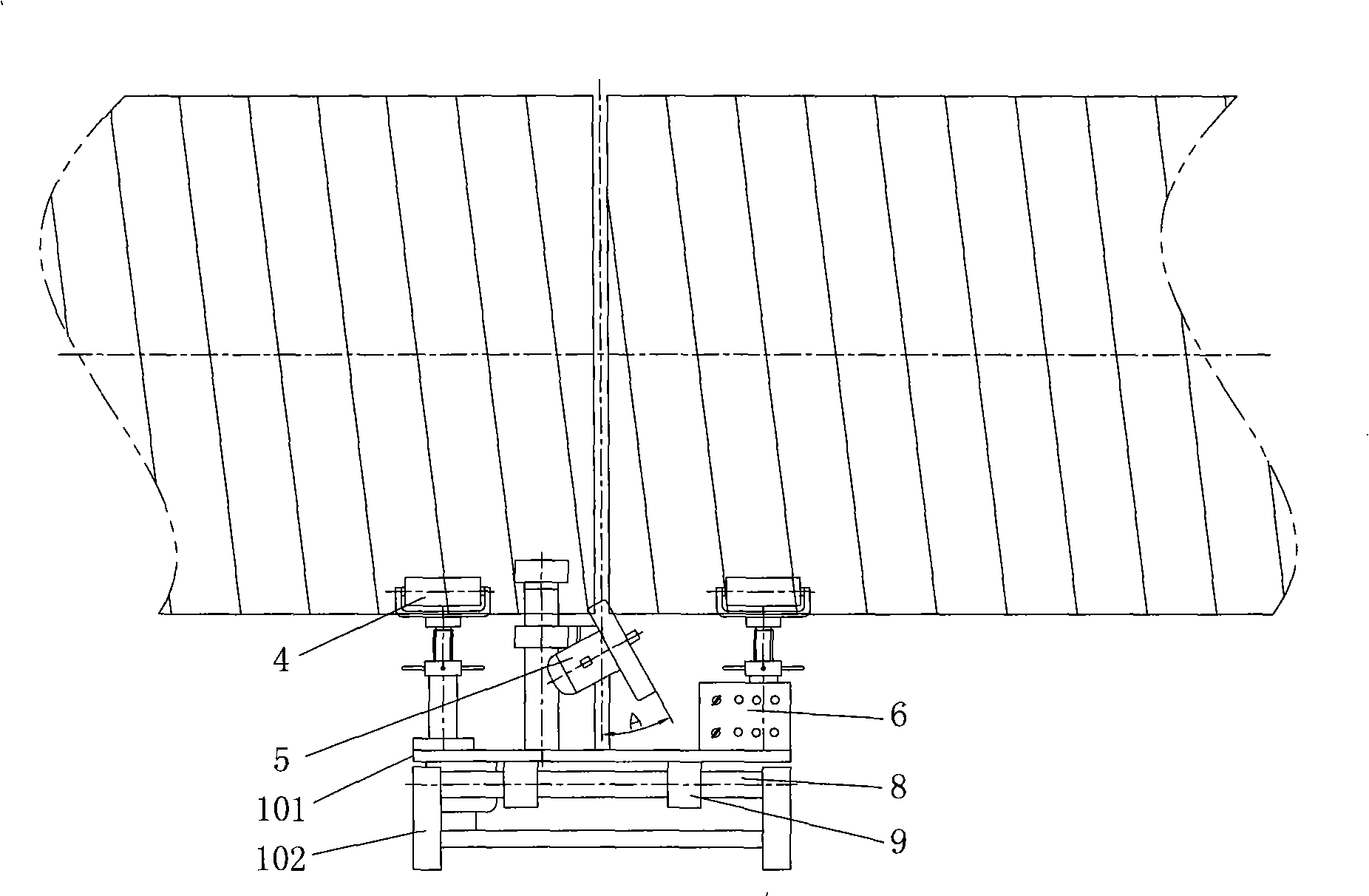

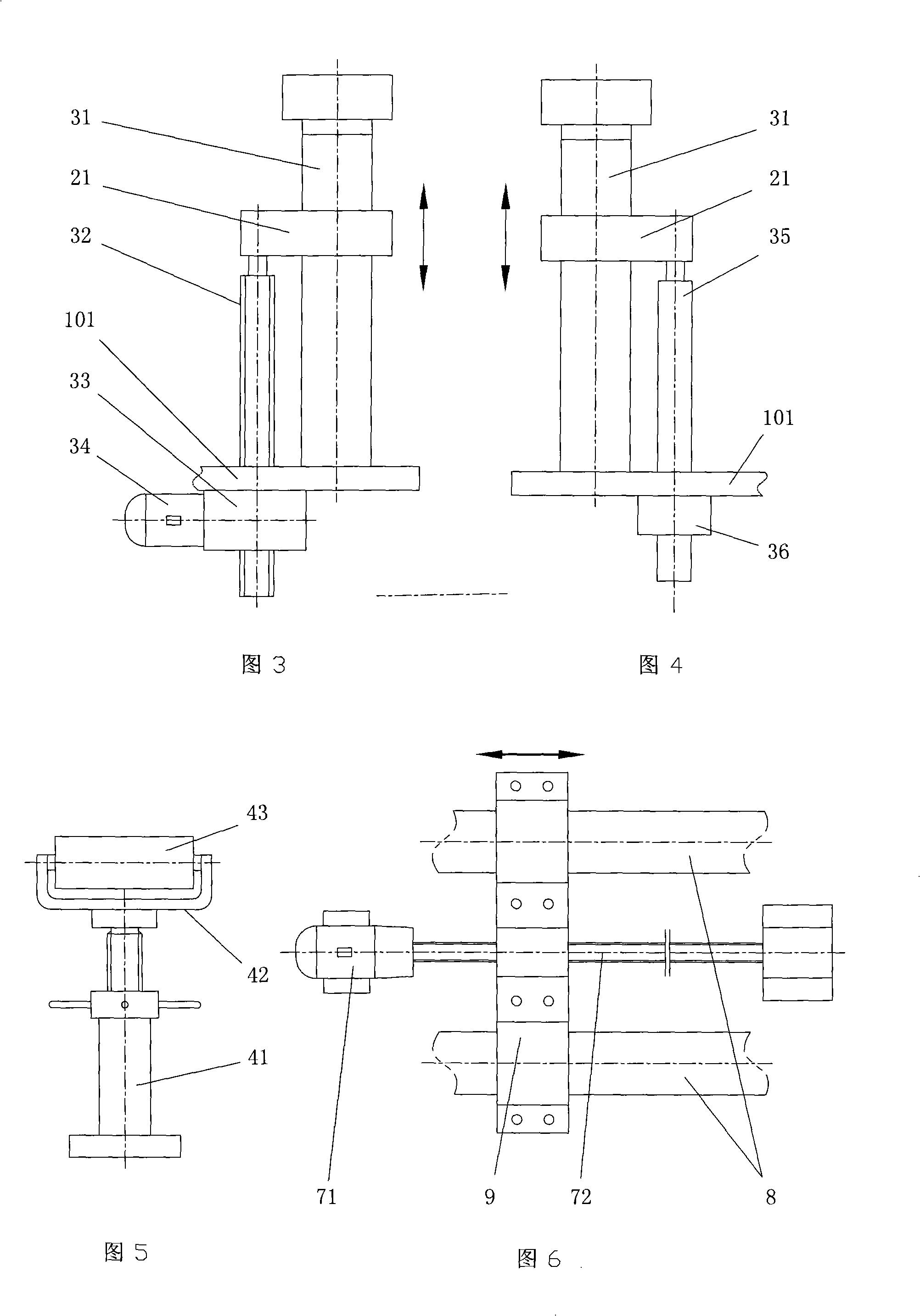

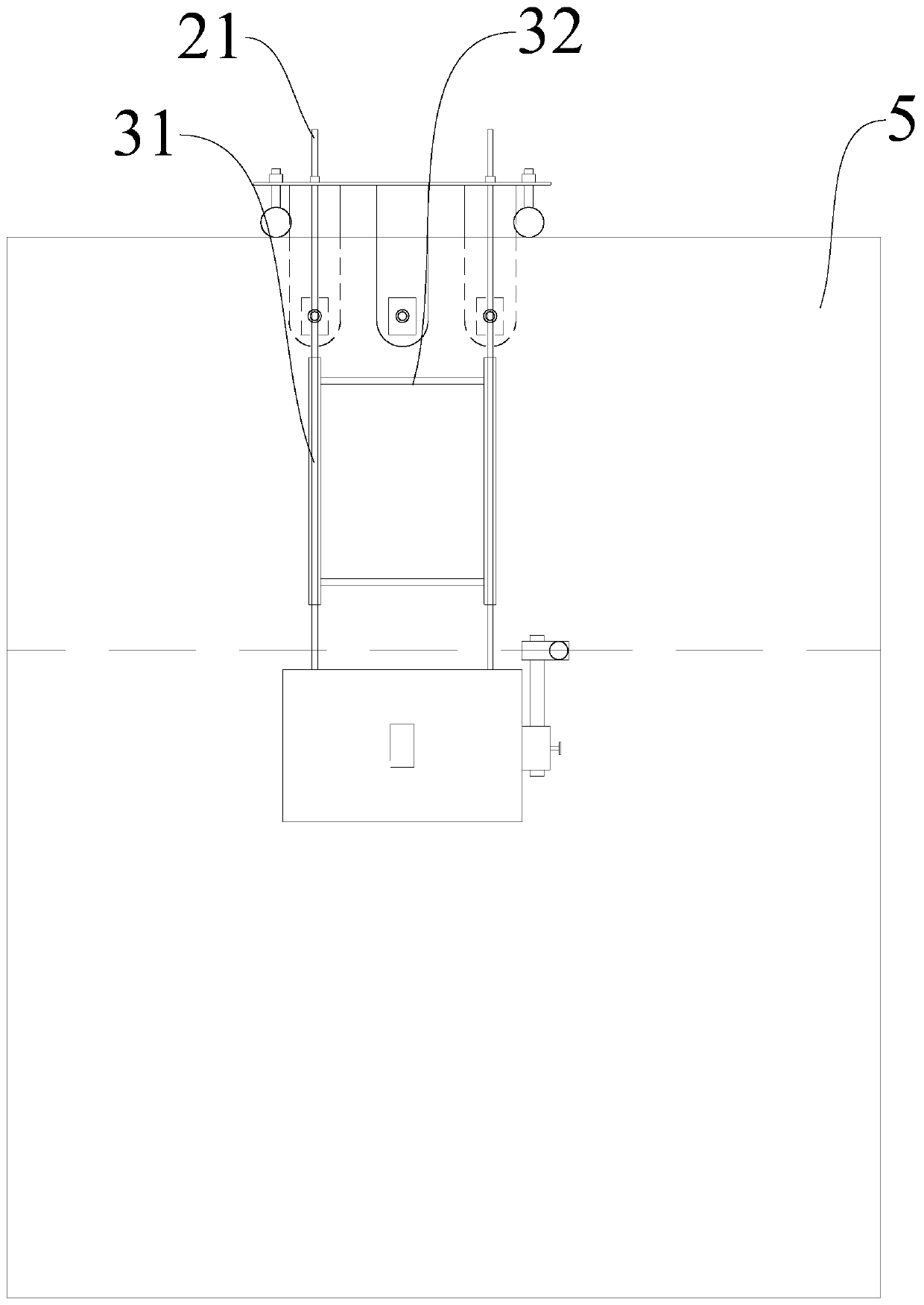

Semi-automatic trimming device for ocean engineering large-diameter steel tube

ActiveCN110722302ASolve cutting problemsResolve Path OffsetWelding/cutting auxillary devicesAuxillary welding devicesSemi automaticEngineering

The invention discloses a semi-automatic trimming device for an ocean engineering large-diameter steel tube. The semi-automatic trimming device is mounted on a steel tube arranged in a vertical direction, and comprises a rail bracket, at least one upper roller group, an external roller group, at least one internal roller group, a height adjusting bracket and a cutting mechanism, wherein the rail bracket is rotatably connected to each upper roller group, the external roller group and each internal roller group, each upper roller group fits to the upper ring-shaped end of the steel tube, and canperipherally roll along the upper end surface of the steel tube, each internal roller group fits to the inner wall of the steel tube, and can roll along the inner wall of the steel tube, the externalroller group fits to the outer wall of the steel tube and can roll along the outer wall of the steel tube, the rail bracket is connected to the height adjusting bracket, and the height adjusting bracket is connected with a cutting mechanism for cutting the steel tube. The semi-automatic trimming device overcomes trolley gravity of a magnetic cutting mechanism, keeps the magnetic cutting mechanismto perform positive circling motion along the steel tube, solves the unstable problems such as path inclining or spiral descending, and guarantees cutting height and groove precision of the steel tube.

Owner:OFFSHORE OIL ENG QINGDAO +1

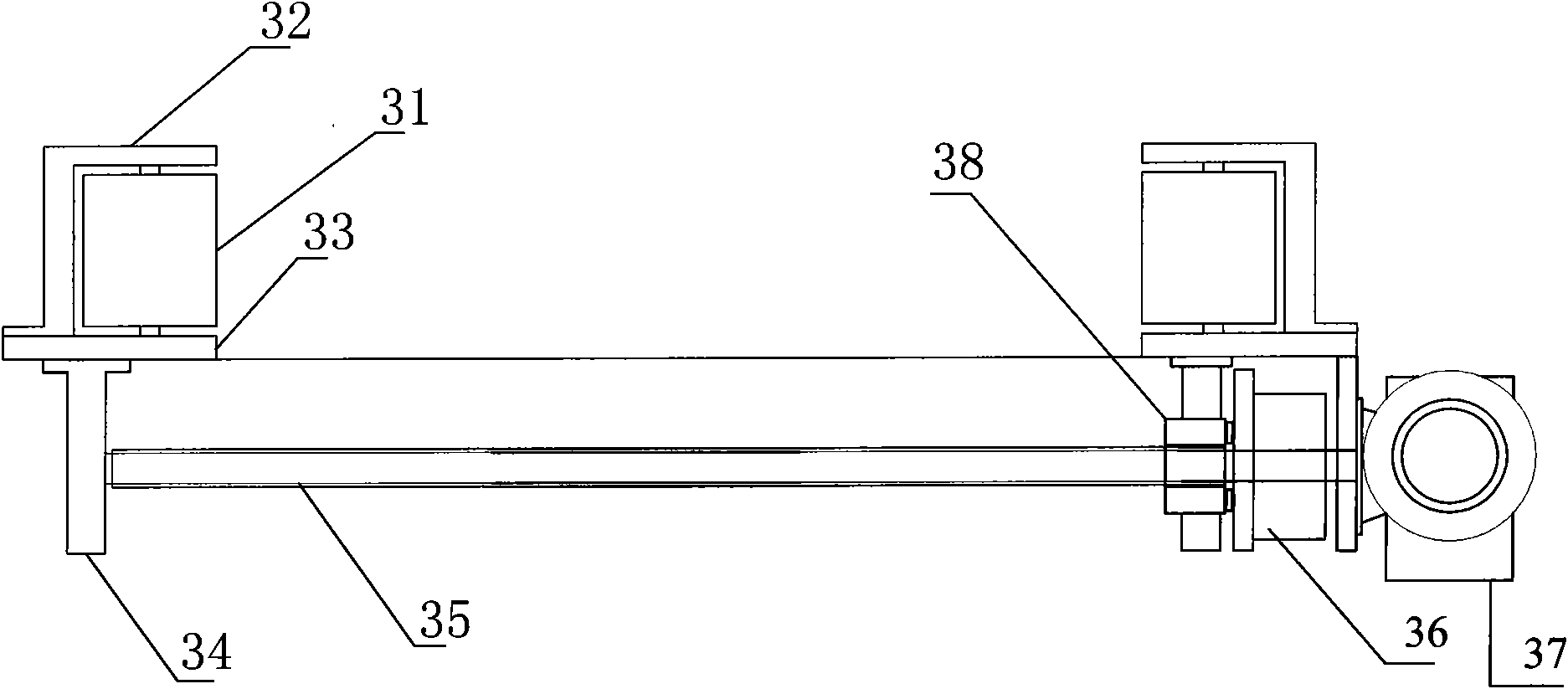

Tubular product straightening and discharging machine

PendingCN107398730AQuality is not affectedHigh degree of automationOther manufacturing equipments/toolsRadial motionMachine

The invention relates to a tubular product straightening and discharging machine which is especially suitable for synchronous straightening and cutting of linear metal tubular products. A multi-roller staggered straightening effect is good, and tube quality is not affected. The single-head straightening and discharging machine is designed, a guiding device, a straightening device, a traction device, a stroke counting encoder, a cutting and pull-breaking device and a clamping device are arranged on a worktable, a cutting slide sleeve is pushed by using a cutting thrust block in the cutting device and pushes a sliding block and a cutter and a carrier wheel on the sliding block to move in the radial direction so as to achieve linear metal tubular product cutting. The tubular product straightening and discharging machine has the advantages that the machine is high in automation degree and production efficiency, good in isometric property and does not affect the tubular product quality in the straightening process.

Owner:盐城恒华智造科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com