Flame fixed-groove cutter

A cutting machine and flame technology, which is applied in the field of thermal cutting equipment, can solve the problems of reducing purchase and maintenance costs, the flame three-torch cutting machine cannot perform curved bevel cutting, and the plasma rotary cutting machine cannot cut, etc., so as to reduce purchase and maintenance costs. The effect of using maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

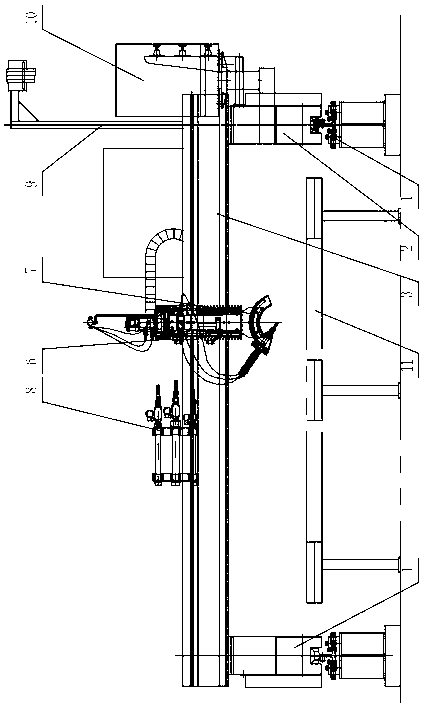

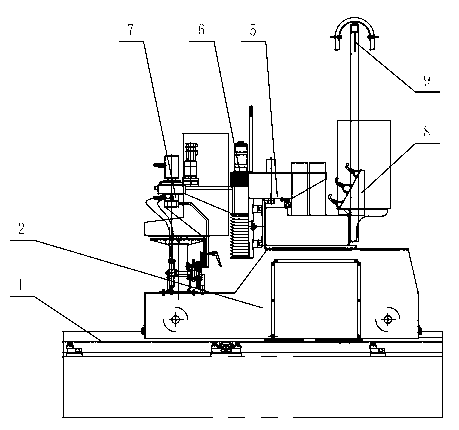

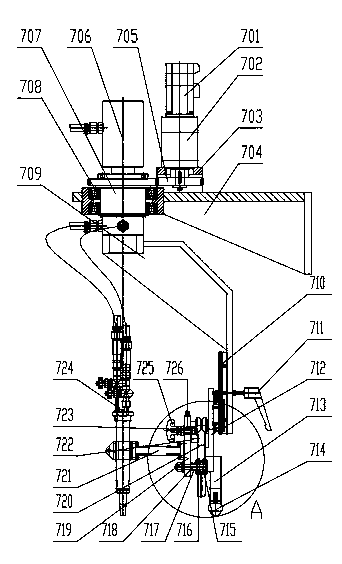

[0017] Such as Figure 1 to Figure 2 As shown, the guide rail assembly 1 of the flame bevel cutting machine described in the present invention is installed on the basic H-shaped steel, and maintains a certain degree of parallelism and levelness. The main frame part 2 and the sub-frame part 4 are respectively fed The gear on the motor meshes with the rack on the guide rail assembly 1, the two ends of the beam part 3 are installed on the main frame part 2 and the sub-frame part 4 through bolts, and the driving slide plate 5 is installed on the linear guide rail in front of the beam part 3 On the slider, the driving slide 5 is meshed with the gear on the feed motor and the rack on the beam part 3, the lifting mechanism 6 is installed in front of the driving slide 5 with screws, and the infinite rotary flame cutting head 7 is installed in fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com