Quick device for manually dismounting and mounting tire and use method of quick device

A kind of tire disassembly, quick technology, applied in tire installation, tire parts, transportation and packaging, etc., can solve the problem of no power source, time delay, disassembly and assembly trouble, etc., to achieve convenient and fast on-site Maintenance, reduced purchases, effect of simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

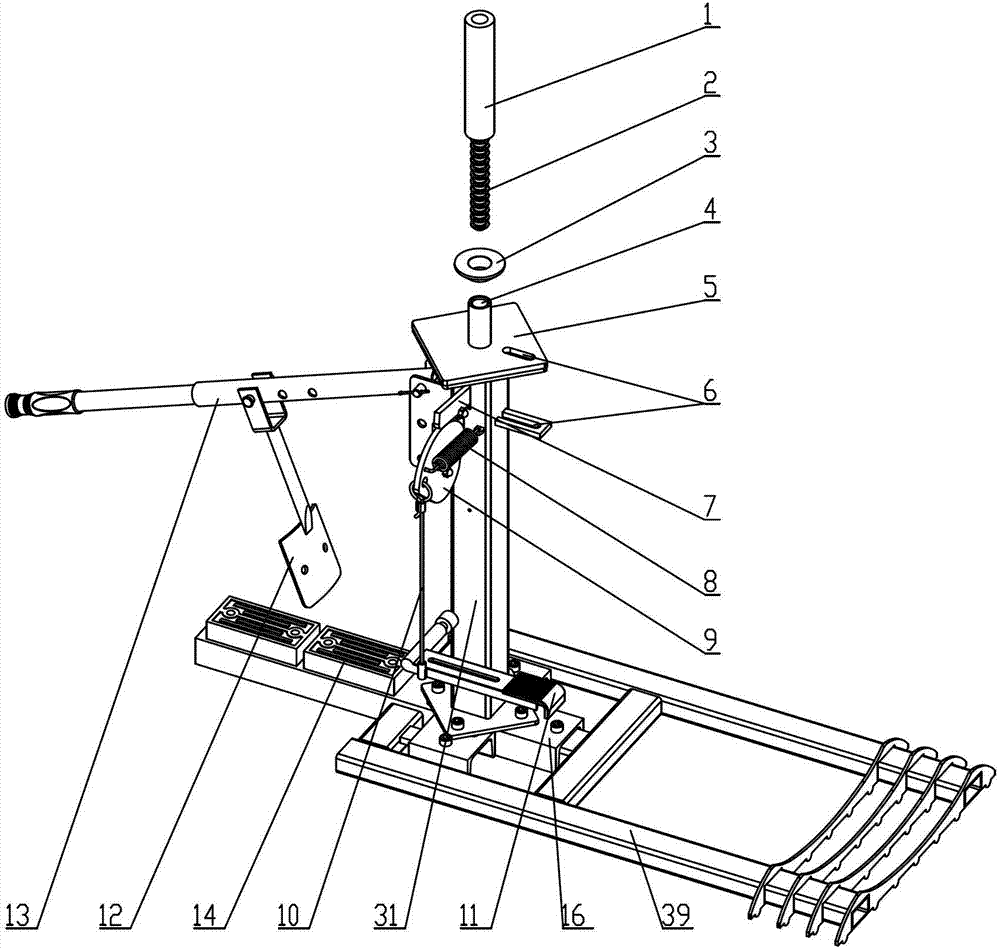

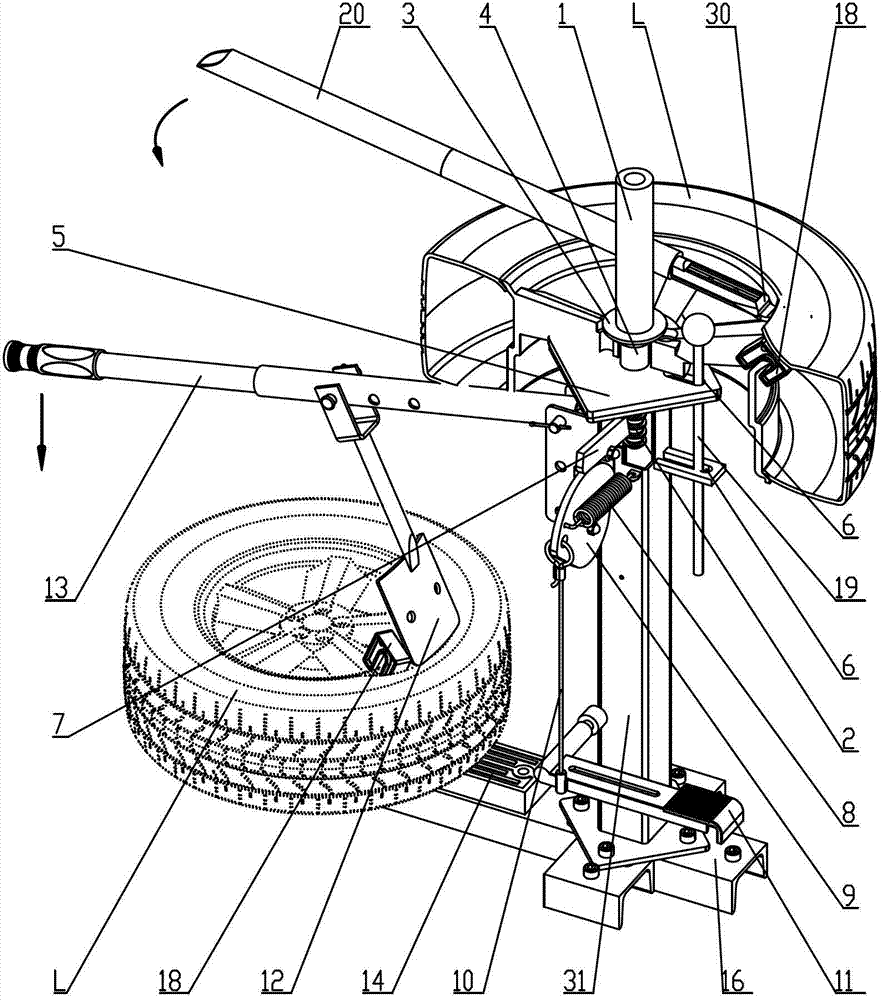

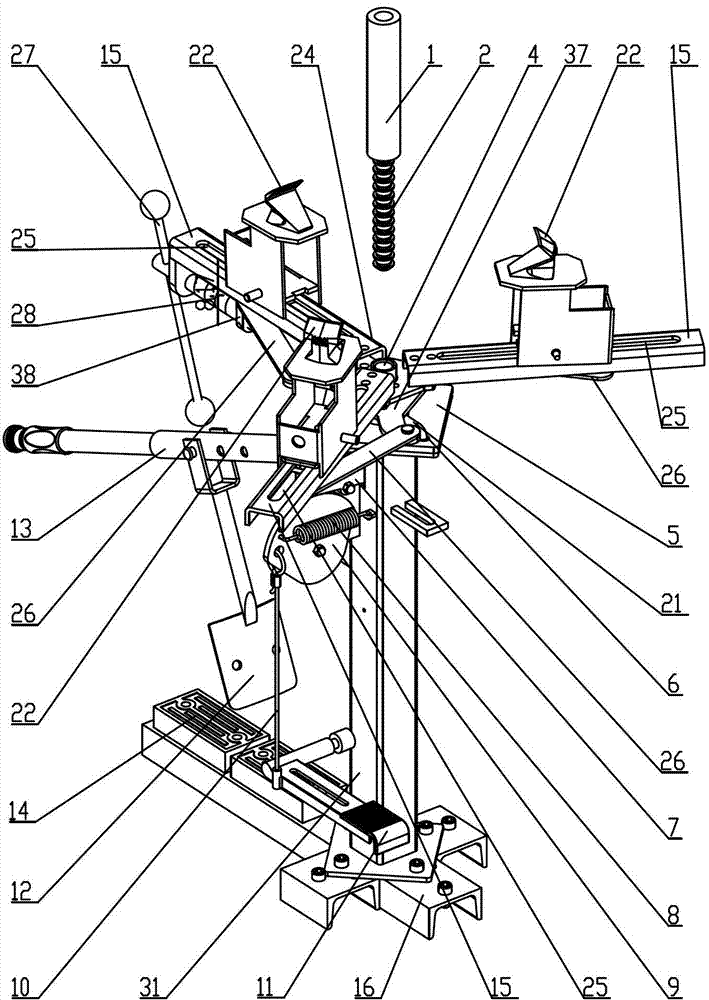

[0036] Such as figure 1 As shown, the present invention is a quick manual tire disassembly and assembly device. The device mainly includes a column 31 and a support shaft 1. The column 31 is provided with a tire pressure bar 13, and the column 31 and the tire pressure bar 13 are connected by a movable shaft. The tire pressure bar 13 is provided with a tire pressure shovel 12, and a tire pressure table 14 is provided under the tire pressure shovel 12 on the side of the column 31. The tire pressure bar 13 and the tire pressure shovel 12 are connected by a movable shaft, and the column 31 is provided with a cam 9. The column 31 and the cam 9 are connected by a movable shaft; a tension spring 8 is provided between the column 31 and one end of the cam 9; a clamping block 7 is provided on the column 31, and the column 31 and the clamping block 7 are connected by a movable shaft, One end of the clamping block 7 is located on the convex surface of the cam 9, and the other end of the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com