Patents

Literature

405results about How to "Reduce sewage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

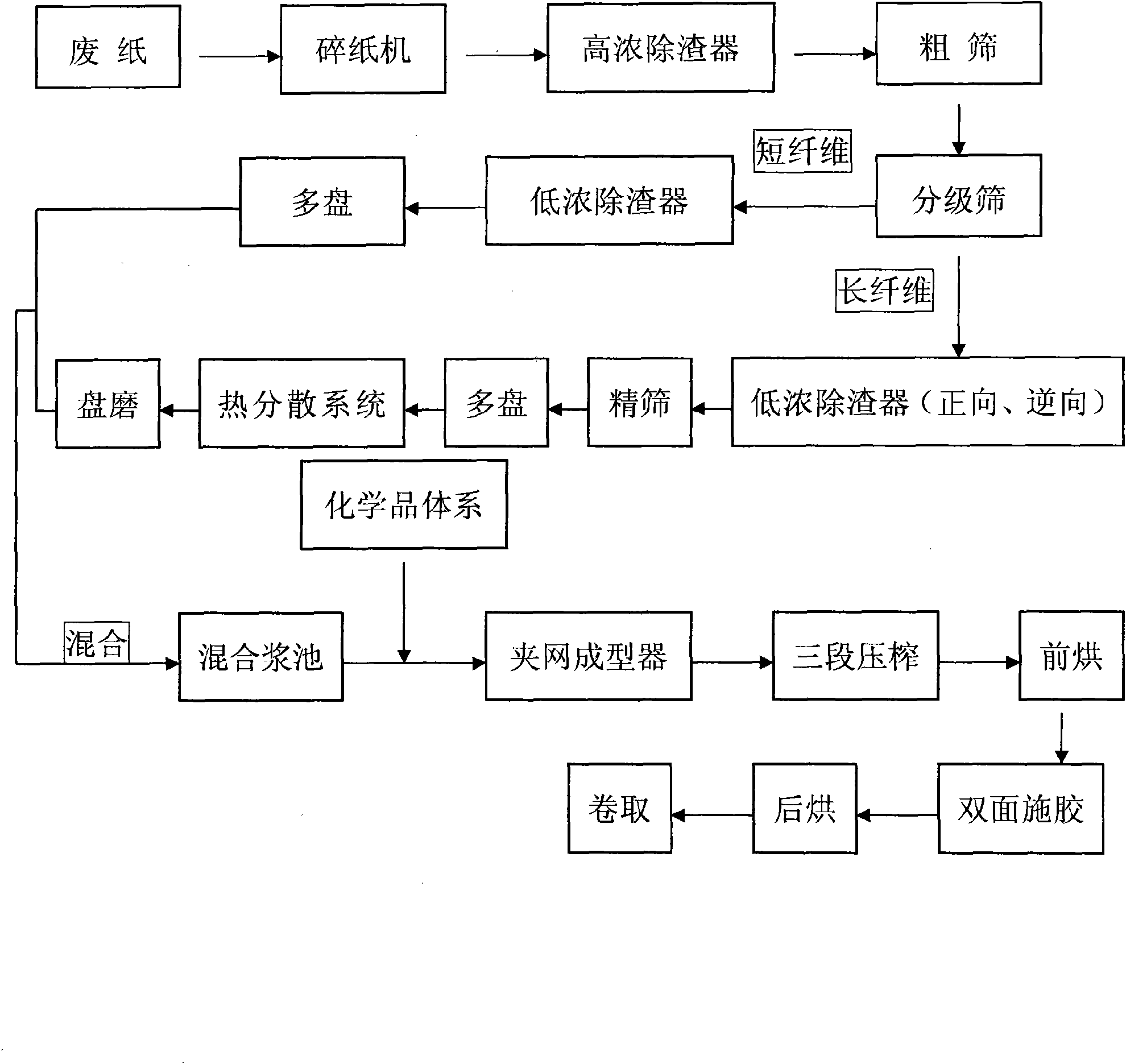

Method for producing corrugated paper with ultralow gram weight and high strength

The invention discloses a method for producing corrugated paper with ultralow gram weight and high strength. The method comprises the following technological steps: 1) mixing; 2) addition of water for size degradation to prepare pulp; 3) pulp combination and purification treatment; 4) medium-concentration pulping; 5) addition of a chemical medicine system into the pulp; 6) twin-wire forming, water filtration and paper-making with the pulp; 7) three-stage squeezing dehydration; 8) prebaking and drying; 9) double-faced sizing; 10) postbaking and drying; and 11) coiling. The method utilizes pulping and paper-making process combination and completely utilizes secondary fiber to make the corrugated paper with ultralow gram weight and high strength so as to reduce the gram weight of the corrugated paper, save the fiber amount, reduce the production cost, and simultaneously reduce the energy consumption and the discharge capacity and improve the economic benefit.

Owner:DONGGUAN NINE DRAGONS PAPER IND

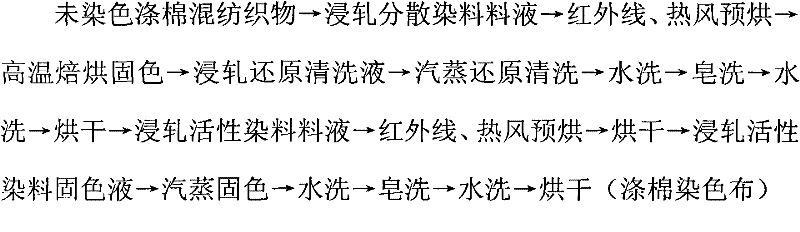

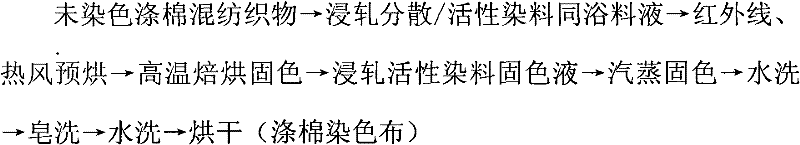

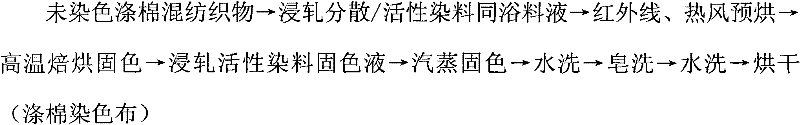

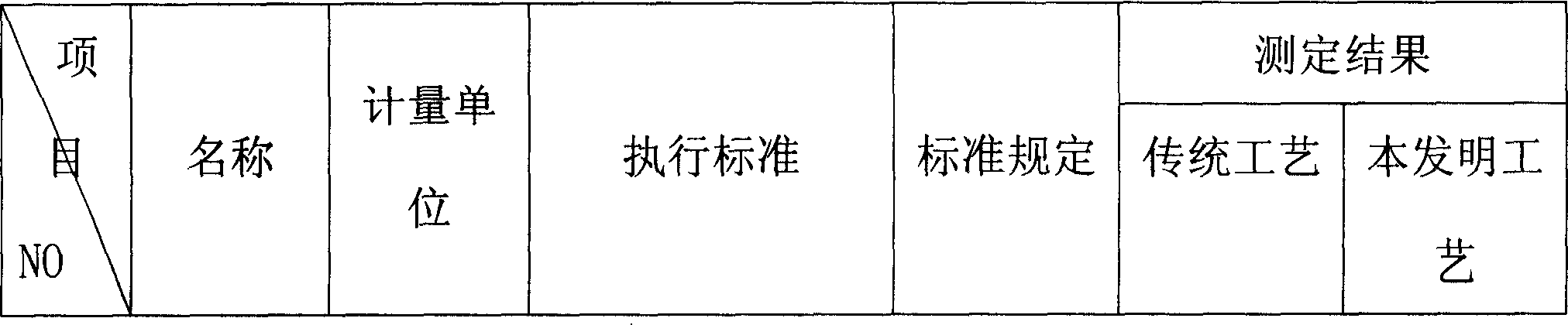

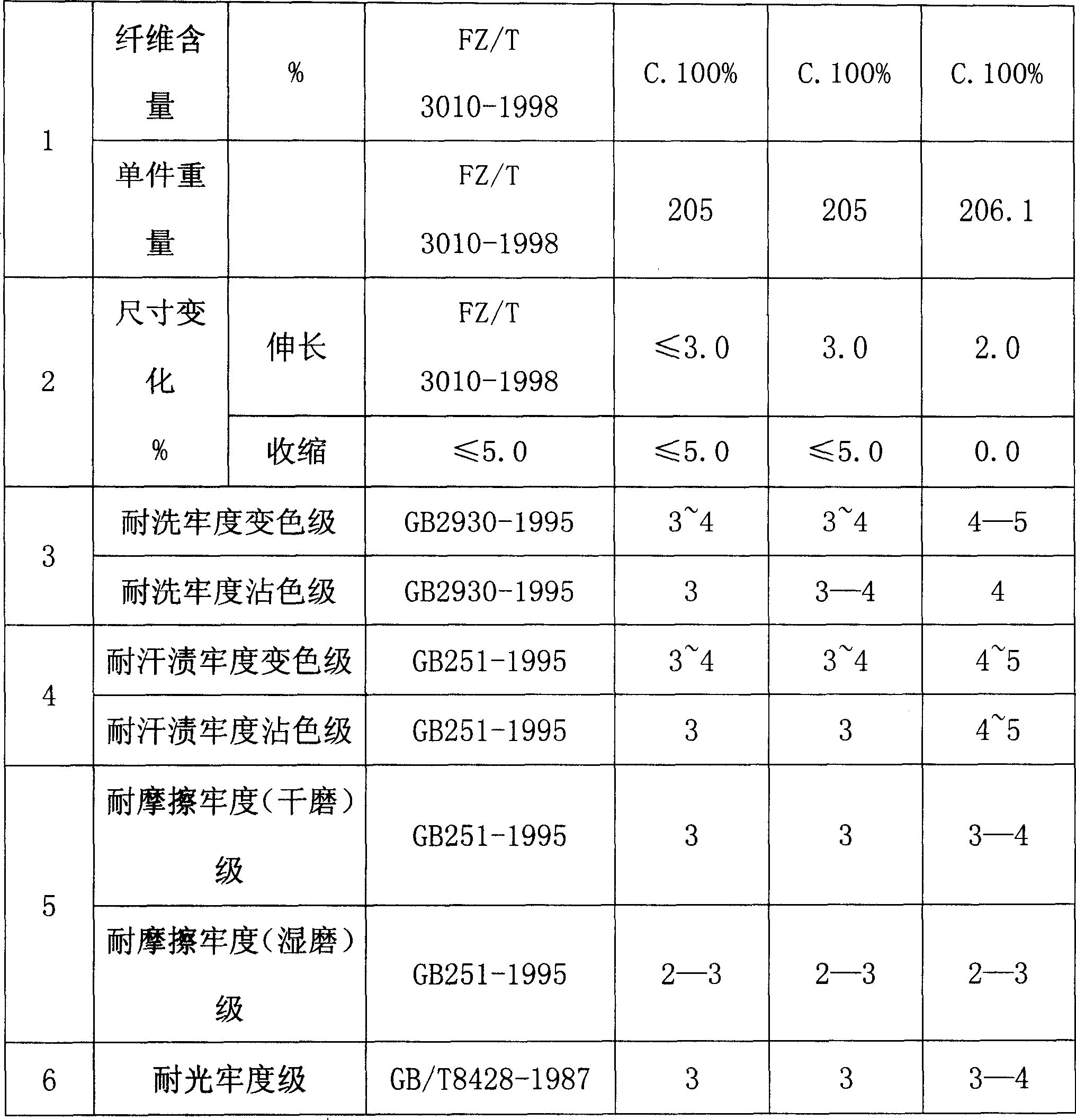

One-bath one-step process for dispersing/reactive dye of cotton-polyester blended fabric

InactiveCN102409565AReduce contentReduce consumptionSolvent-treatmentLiquid/gas/vapor removalFiberPolyester

The invention relates to a one-bath one-step process for a dispersing / reactive dye of a cotton-polyester blended fabric. The one-bath one-step process mainly comprises the following steps performed on the cotton-polyester blended fabric: dispersing / reactive dye one-bath pad dyeing; infrared and hot-air drying in advance; high-temperature baking fixation; padding in a reactive dye fixation solution; steam fixation; water washing; soaping; water washing; drying; terylene dyeing; and obtaining finished cloth. The one-bath one-step process is characterized by fully padding an unstained cotton-polyester blended fabric in a dispersing / reactive dye one-bath solution, introducing infrared and hot air so as to dry 60-70% of water in the fabric in advance, baking at high temperature so as to dye and fix color for polyester fibers, fully padding in the reactive dye fixation solution, performing steam fixation so as to dye and fix color for cotton fibers, and performing the processes of water washing, soaping and water washing so as to fully develop color on the fabric and fully wash off the surface dyeing on the fabric, thereby finishing a dyeing process. The dry and wet grinding fastness can fully meet the customer demand.

Owner:XIANGFAN NEW NO 45 PRINTING & DYEING

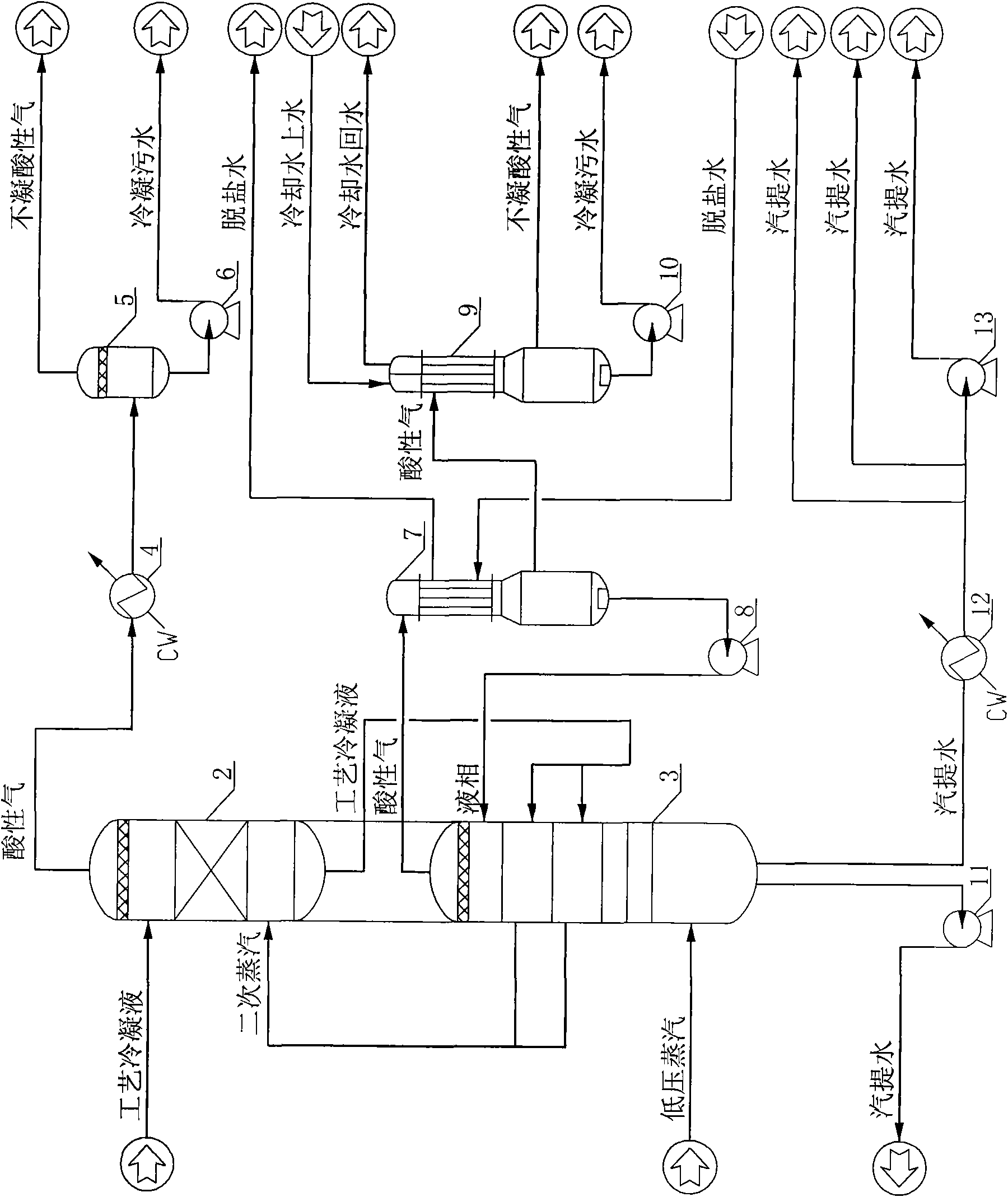

Steam stripping method of process condensate in CO conversion

ActiveCN101570350AAvoid the possibility of simultaneousSolve the blockageWater/sewage treatment by heatingWater/sewage treatment by degassingGas phaseEvaporation

The invention relates to a steam stripping method of process condensate in CO conversion. The invention is characterized in that the process condensate firstly enters the upper part of a carbon dioxide steam stripping tower for flashing evaporation; secondary steam from the upper part of an ammonia-evaporated steam stripper tower enters the bottom part of the carbon dioxide steam stripping tower and steam strips carbon dioxide by countercurrent contacting with the process condensate after flashing evaporation; the process condensate after flash evaporation and the steam stripped carbon dioxide carry out countercurrent contact; the process condensate after flash evaporation and steam stripping enters the upper part of the ammonia-evaporated steam stripper tower from the bottom part of the carbon dioxide steam stripping tower and is steam-stripped by low-pressure steam entering from a kettle of the ammonia-evaporated steam stripper tower; gas phase is treated by secondary condensation to obtain non-acid-coagulated gas and condensate sewage; and steam stripping water is obtained from the bottom part of the ammonia-evaporated steam stripper tower. The invention carries out steam stripping on the upper and lower towers to carbon dioxide and ammonia in the process condensate respectively, thus avoiding the possibility of coexistence of carbon dioxide and ammonia in a condensing system, effectively solving the problem that the steam stripping system of the process condensate in the conversion procedure occurs ammonium salt crystallization blockage and prolonging the period of stable operation of a conversion device.

Owner:CHINA PETROCHEMICAL CORP +2

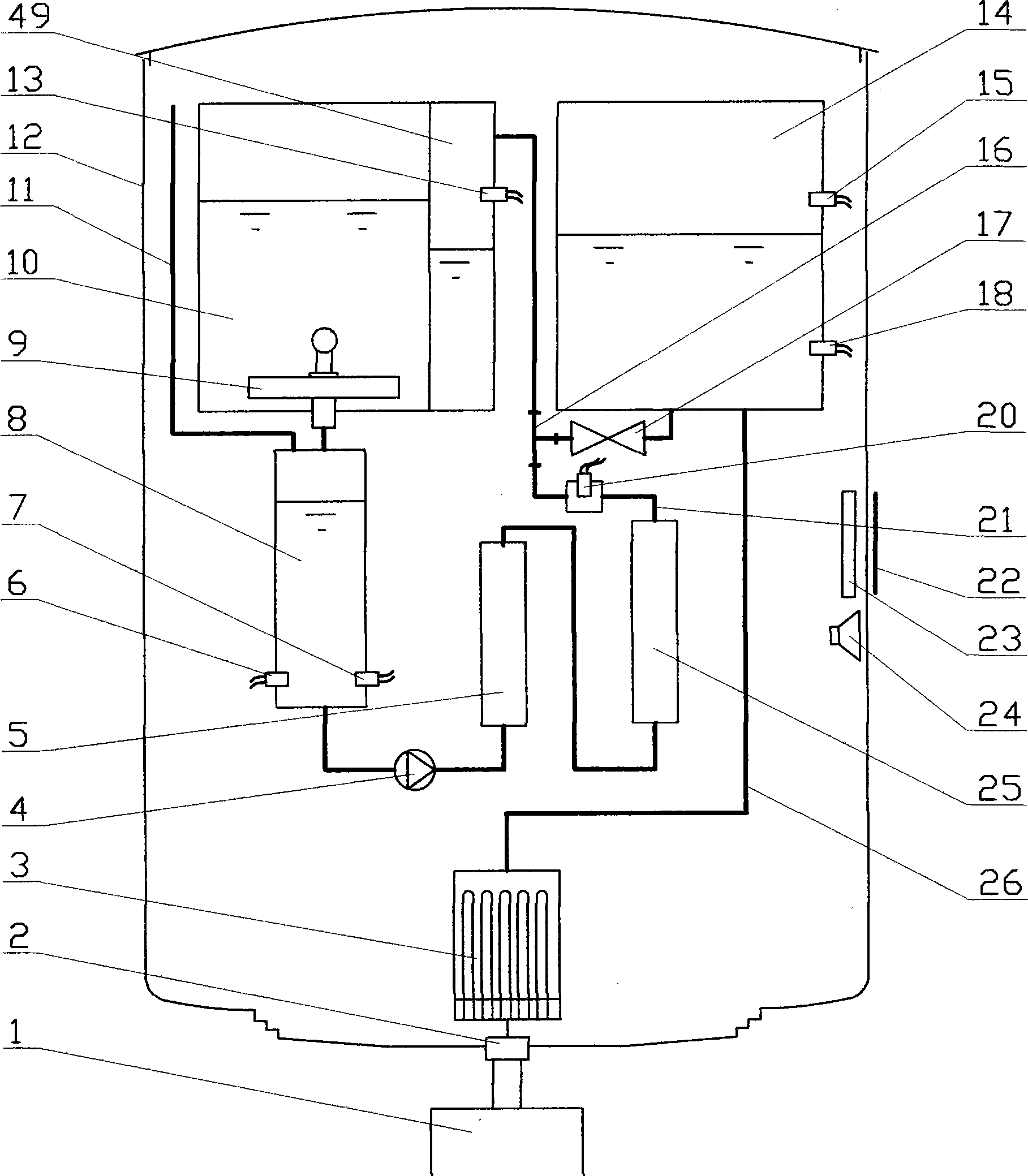

Electro-adsorption demineralization water purifier

InactiveCN101412550AReduce turbidityReduced salt removal capacityDispersed particle separationAutomatic controlDesorption

The invention discloses an electro-absorptive desalination water purifier, which comprises a high-precision pretreatment filter element, an electro-absorptive filter element, an electrical control circuit board, and a water quality probe capable of detecting the content of salinity in water. After suspended substances and particulate matters in raw water are removed through the high-precision pretreatment filter element, then the salinity in the water is removed through the electro-absorptive filter element, the water quality probe is arranged in a water outlet pipeline of the electro-absorptive filter element; the water outlet pipeline is divided into two paths behind the water quality probe; and one path is a fresh water pipeline communicated with a water purification tank, while the other path is a sewage pipeline which is communicated with a sewage tank or is emptied. The water purifier has the advantages that the water purifier can realize the automatic control to the water quality of water outlet by controlling the electric conductivity of the water outlet; hardness components are contained in the salinity, so the desalination water purifier is also a water softener and is particularly suitable for hard water areas in the north of China; after the electro-absorptive filter element has saturated absorption, the electro-absorptive filter element can obtain the regeneration through the desorption, has small discharge capacity during the regeneration, and saves water resources; and concentrated water drained during the regeneration does not contain acid and alkali liquid, and does not pollute the environment.

Owner:黄樟焱

Method for treating circulating water having light oil leaked therein

ActiveCN102476873AAvoid re-adhesionGuaranteed treatment effectScale removal and water softeningMultistage water/sewage treatmentPolyethylene oxideActive agent

The invention provides a method treating circulating water having light oil leaked therein. The method comprises a) adding an oxidation-type bactericide; b) adding an anti-scale corrosion inhibitor which contains at least one organic phosphonic acid, at least one organic carboxylic acid polymer, an optional copper material corrosion inhibitor and an optional zinc salt; and c) adding at least one polyethylene oxide non-ionic surfactant. The inventive method can remove oil and detach slime from equipment of a circulating water system in one step, without requiring discharge of a large amount of sewage.

Owner:CHINA PETROLEUM & CHEM CORP +1

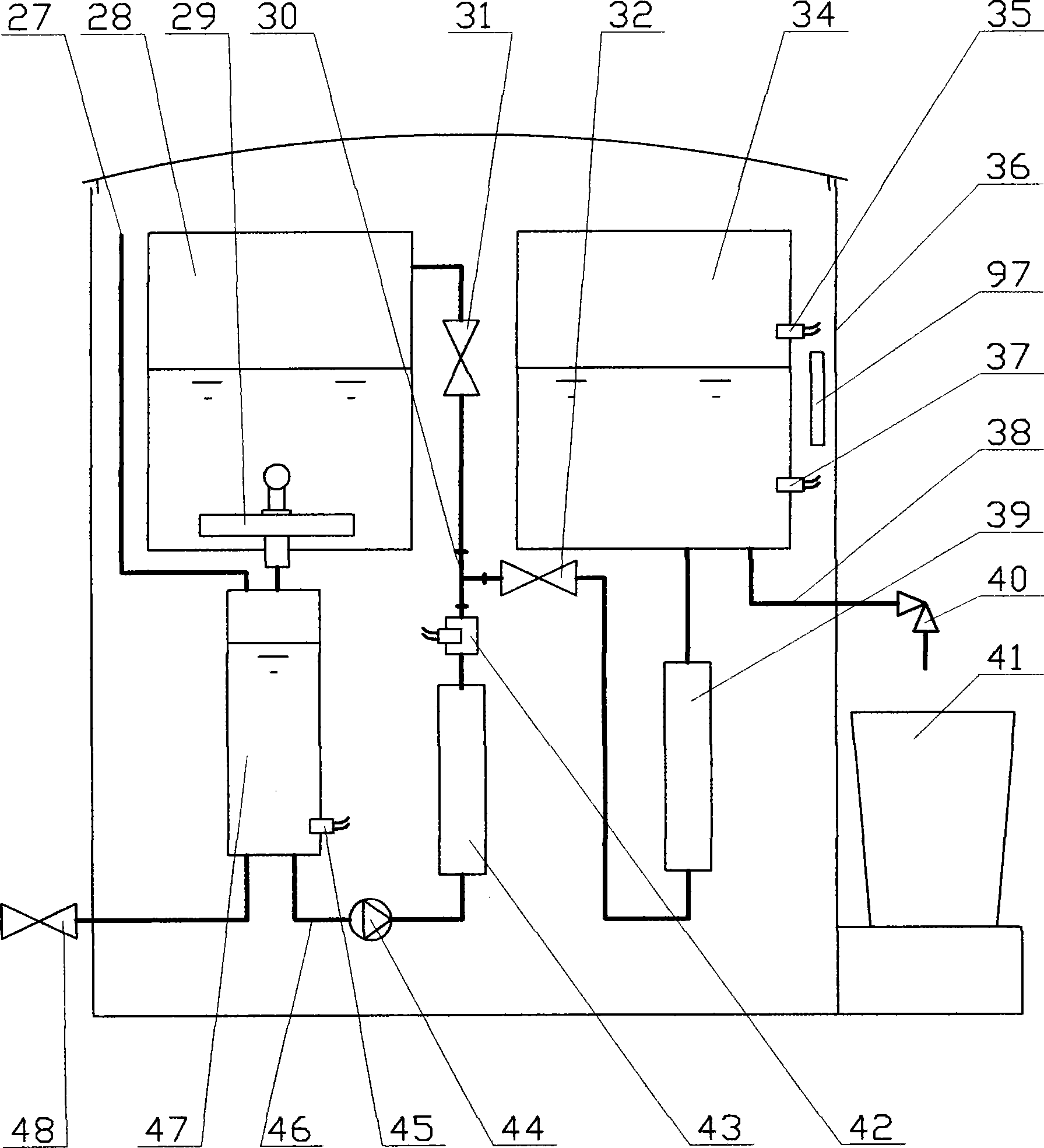

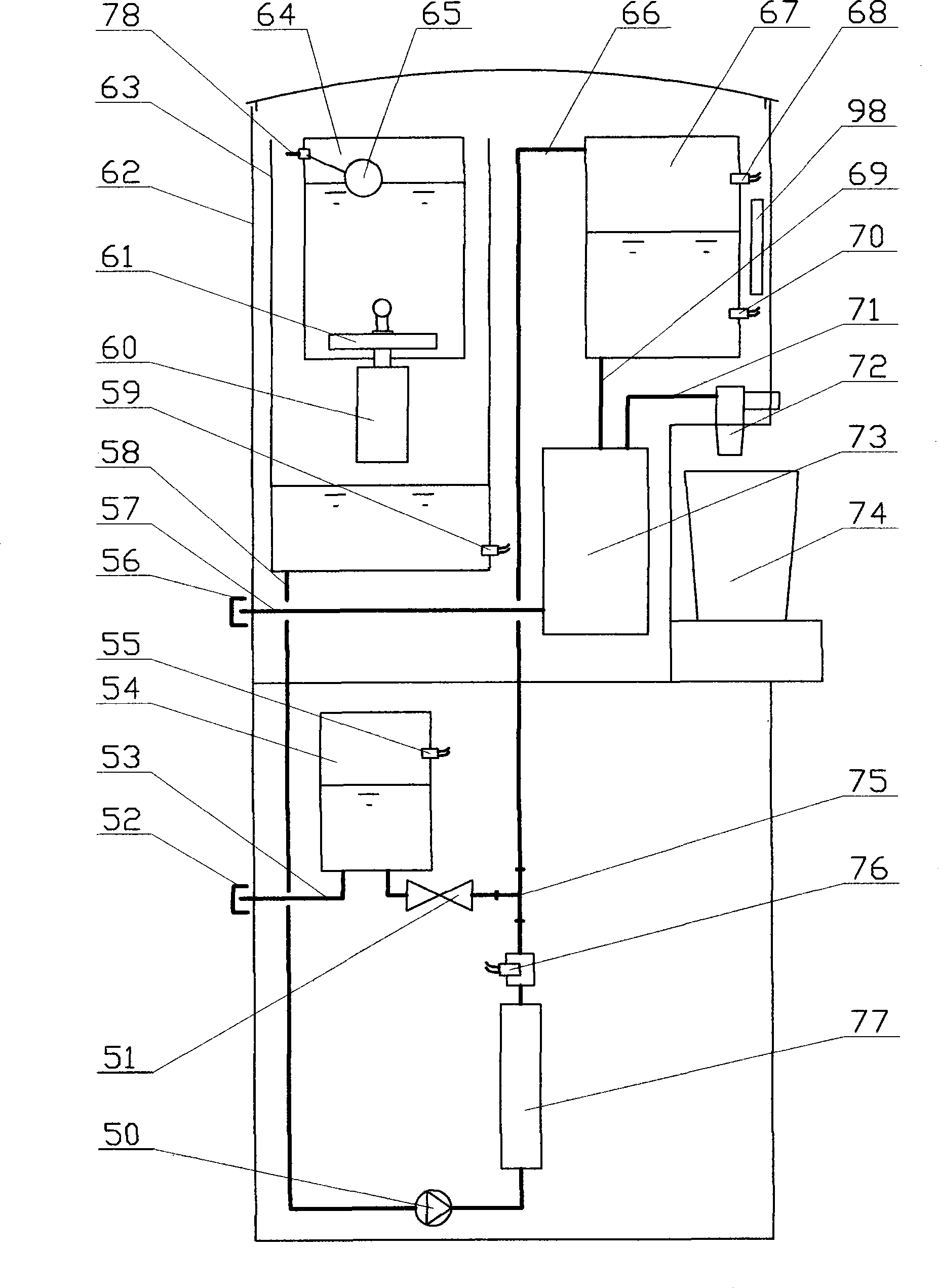

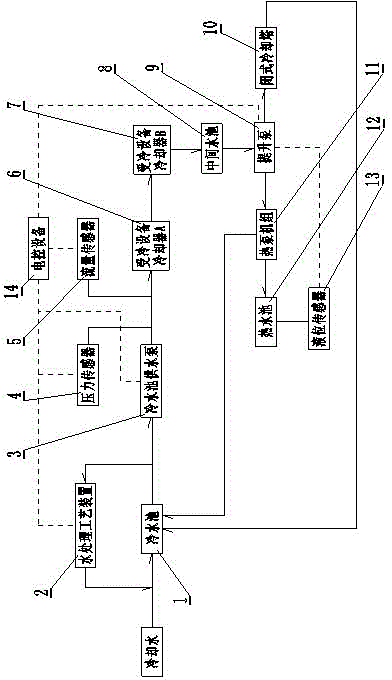

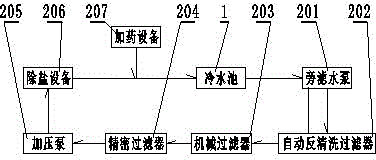

Energy-saving recycling combination system for industrial circulating cooling water

InactiveCN104478137AIncrease profitIncrease return water temperatureLighting and heating apparatusTreatment involving filtrationCooling towerWater quality

The invention discloses an energy-saving recycling combination system for industrial circulating cooling water. The system comprises two circulating cooling water systems, namely, a sealed-type circulating cooling water system and an open-type circulating cooling water system and specifically comprises a cold water tank, a water treatment process device, a cooling water supply pump, a pressure sensor, a flow sensor, a cooled device, an intermediate water tank, a lift pump, a cooling tower, a heat pump set, a hot water tank, a liquid-level sensor and an electronically controlled device and is an energy-saving and water-saving optimized combination system for industrial circulating cooling water. Serial-type water supply is adopted in the sealed-type circulating cooling water system, parallel-type water supply is adopted in the open-type circulating cooling water system, the utilization rate of the cooling water is increased to a maximize extent and the water supply amount of the cooling water is decreased. Since the system is provided with the water treatment process device, the water quality of the circulating water is improved, the sewage discharge capacity is decreased and the concentration multiple of the circulating water is increased. By arranging the heat pump set in the system, the low-temperature waste heat of the return water of the cooling water is effectively recovered, the evaporation amount is reduced and the effective utilization of the heat source is achieved and the system has important practical values.

Owner:CHINA FIRST HEAVY IND

Compound corrosion and scale inhibitor

InactiveCN105502704AHigh water saving rateReduce pollutionSpecific water treatment objectivesScale removal and water softeningHigh concentrationAzole

The invention provides a compound corrosion and scale inhibitor. The compound corrosion and scale inhibitor is a liquid preparation which is prepared by mixing a first liquid preparation with a second liquid preparation according to the ratio of 1:1; a compound preparation prepared from organic phosphonic acid, polycarboxylic acid, a dispersing agent and water is adopted as the first liquid preparation; a compound preparation prepared from solid agentia and water according to the weight ratio of 1:1 is adopted as the second liquid preparation, wherein a compound preparation which has the scale inhibition effect and is prepared from polymers, an alkaline agent, azoles and zinc salt is adopted as the solid agentia. The compound corrosion and scale inhibitor can achieve the effects of corrosion inhibition, scale inhibition and sterilization and algae removal which meet the national requirements, can be applied to a circulating cooling water system with the high concentration multiple, is convenient to put, does not need to be prefilmed, can be used at normal temperature and is good in using effect.

Owner:HEBEI AGRICULTURAL UNIV. +1

Method for color retouching of cotton knitted fabric on forming machine

InactiveCN101684620AImprove permeabilityGuaranteed washing colorHeating/cooling textile fabricsDyeing processPulp and paper industrySodium sulfate

The invention relates to a method for the color retouching of a raw fabric, in particular to a method for the color retouching of cotton knitted fabric on a forming machine. The method is characterized by comprising the following processing steps: blending a retouching solution, preparing the raw fabric, padding the retouching solution, water scrubbing, drying, napping and forming. By using the method for the color retouching of the cotton knitted fabric, when the color cylinder difference is discovered after the cotton knitted fabric is dyed and enters the finishing procedure after the dryingand the forming, the cotton knitted fabric can be directly retouched on the forming machine; through analytic studies, reactive dyes such as M-2G blue, M-3BE red and M-3RE yellow for the padding areadopted as color retouching dyes; in order to increase the permeability of the raw fabric, a non-ionic penetrating agent is added into a padding solution, simultaneously the padding solution is addedwith anhydrous sodium sulfate and anhydrous sodium carbonate to ensure the water scrubbing chroma of the raw fabric after the color retouching, and the retouching solution can be prepared only according to the chroma; and the chroma can be adjusted to the normal quality standard through the treatments in the processing steps. The process method has the advantages of quick color retouching speed, good accuracy, no influence on other quality indexes of fabrics, cost saving and less discharge capacity.

Owner:ZHEJIANG YINHE PRINTING & DYEING

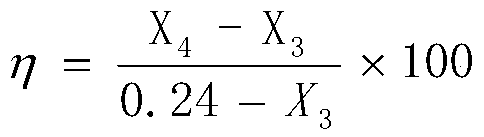

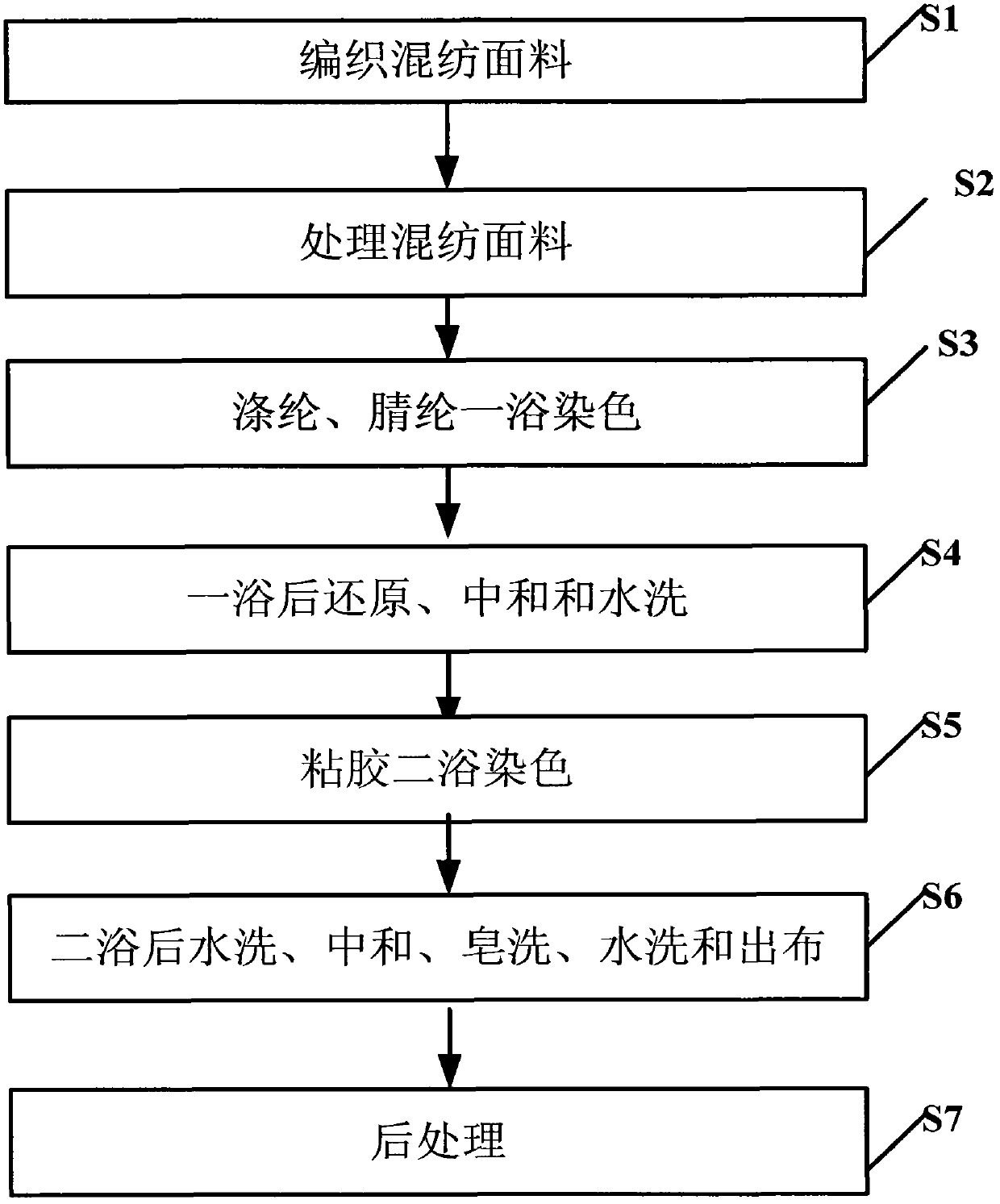

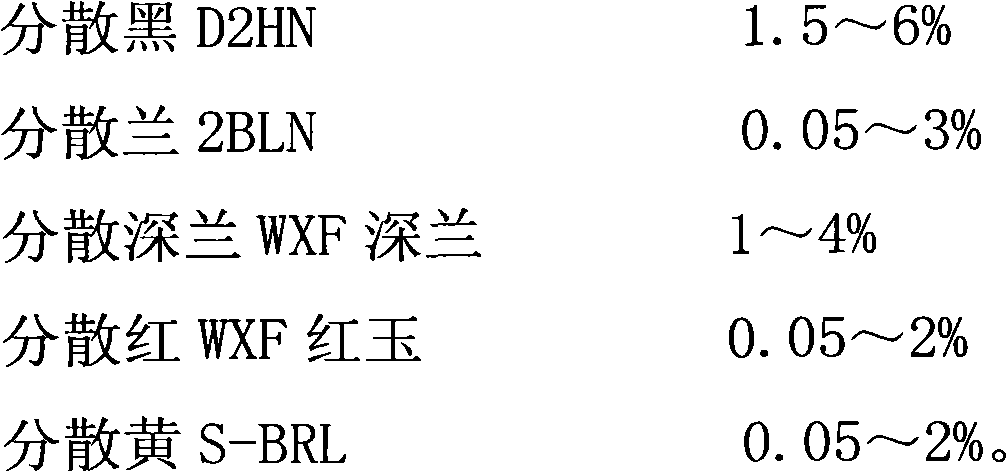

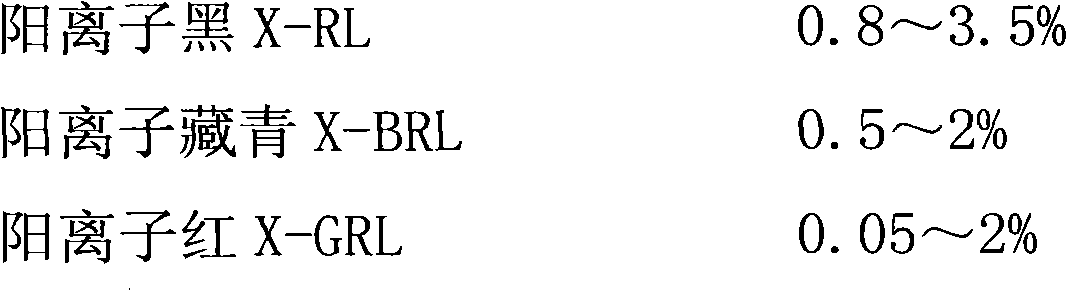

Dyeing method of terylene, acrylic fiber, viscose glue and spandex blended fabric

The invention discloses a dyeing method of a terylene, acrylic fiber, viscose glue and spandex blended fabric. The method comprises the following steps: 1, blended fabric weaving: weaving a blended fabric containing terylene, acrylic fiber, viscose glue and spandex; 2, blended fabric treatment: carrying out scotching presetting on a gray cloth, and linking; 3, carrying out one-bath dyeing on terylene and acrylic fibers; 4, reducing, neutralizing, and washing with water; 5, carrying out two-bath dyeing on the viscose glue; 6, washing with water, neutralizing soaping, washing with water, and discharging the obtained cloth; and 7, post-treatment: dehydrating the blended fabric obtained in step 6, drying, and carrying out scotching setting to obtain a finished product. The method has the advantages of simple process, fastness, efficiency, energy saving, convenient operation, stability, and dyeing of high-quality and stable-product-quality terylene, acrylic fiber, viscose glue and spandex blended fabrics.

Owner:GAOMI FUYUAN PRINTING & DYEING

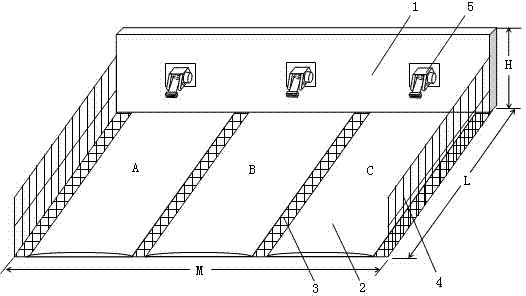

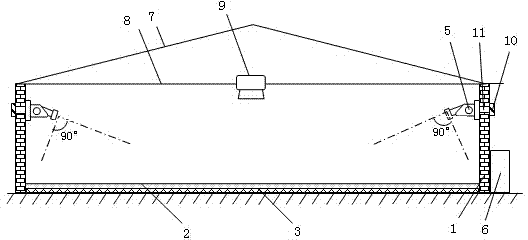

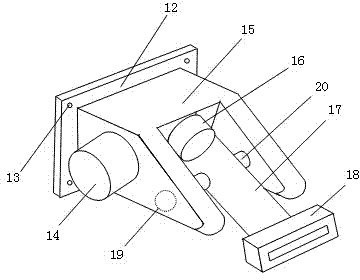

Intelligent pigsty cleaning device and method

ActiveCN104255536AFlush fully without dead endsHigh degree of automationAnimal housingSpray nozzleEnvironmental engineering

The invention discloses an intelligent pigsty cleaning device and method. The ground of a pigsty is equally divided into a plurality of identical regions in the left-and-right width direction, a wall on the front side of each region and a wall on the rear side of each region are each provided with an automatic rotary water spray device, and each automatic rotary water spray device is connected with an electric regulating valve through a hard water pipe penetrating through the corresponding wall. An embedded controller controls all cameras to monitor the pollution situations of all the regions of the ground regularly in real time, the polluted regions in need of cleaning can be judged out, the electric regulating valves corresponding to the polluted regions are regulated to be in one third opening, rectangular spray nozzles are controlled to spray water at low speed from bottom to top in a rotary mode, and pigs are evacuated to be made to enter the rest of the regions. The embedded controller processes collected images, processing results are matched with preset pigsty ground pollution level thresholds, and the flushing time is determined according to the pollution level; the ground of the pigsty can be flushed comprehensively in a non-dead-corner mode, manual intervention is not needed in the whole process, and therefore the automation degree of pigsty breeding is increased.

Owner:江阴智产汇知识产权运营有限公司

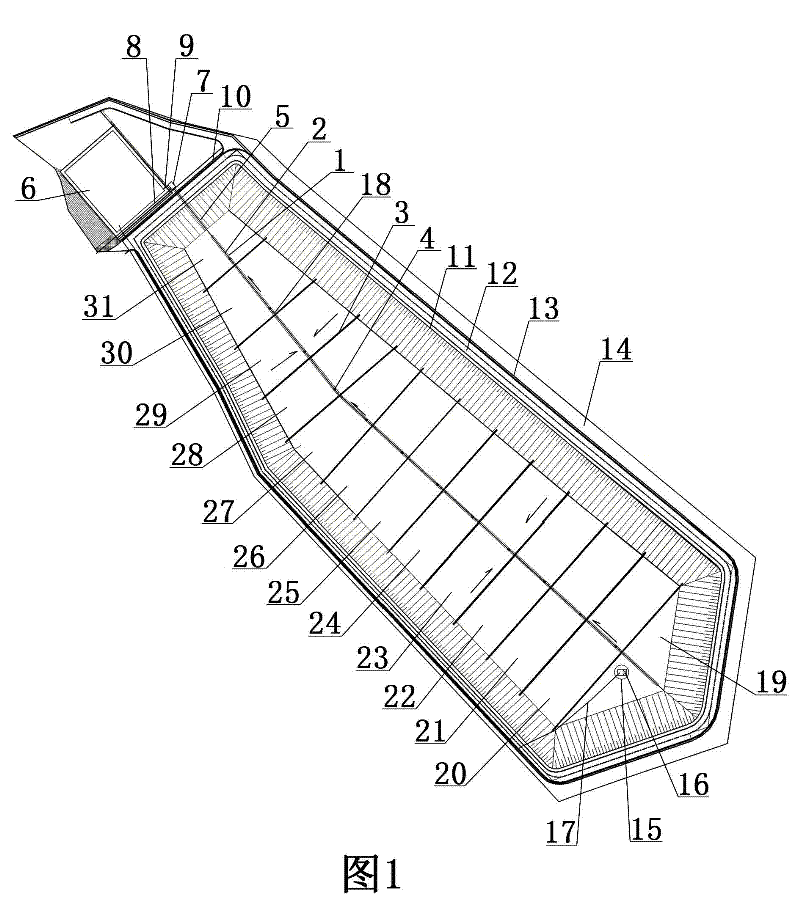

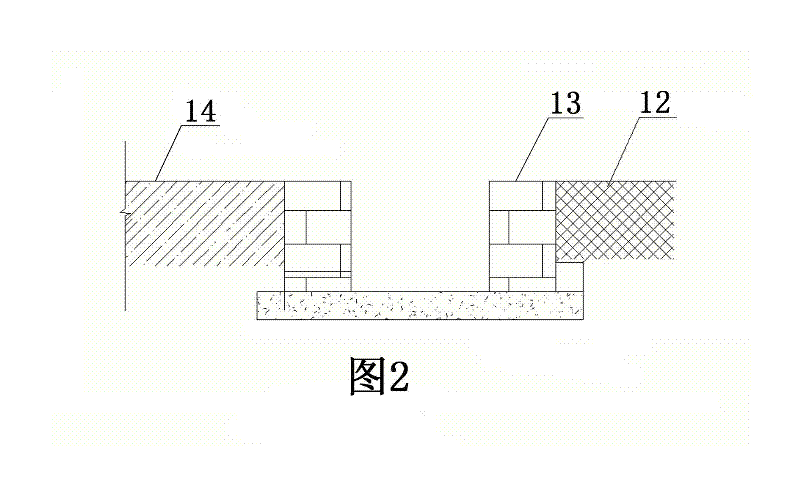

Valley-type refuse landfill series multi-partition rain and sewage shunting device and method

Owner:青岛市环境卫生科研所

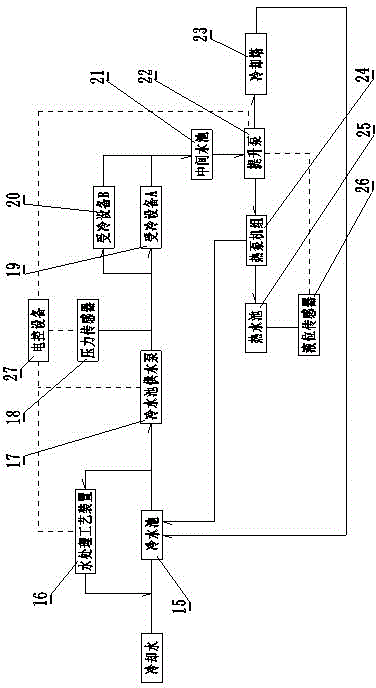

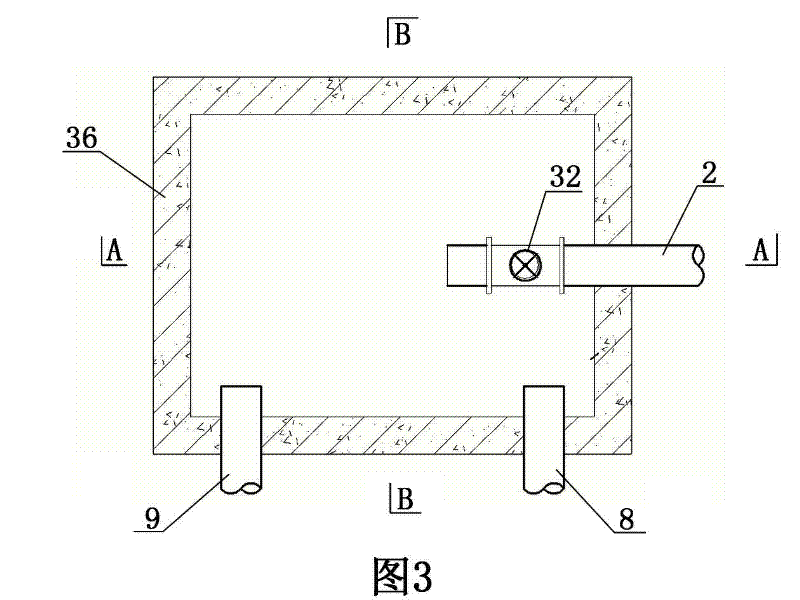

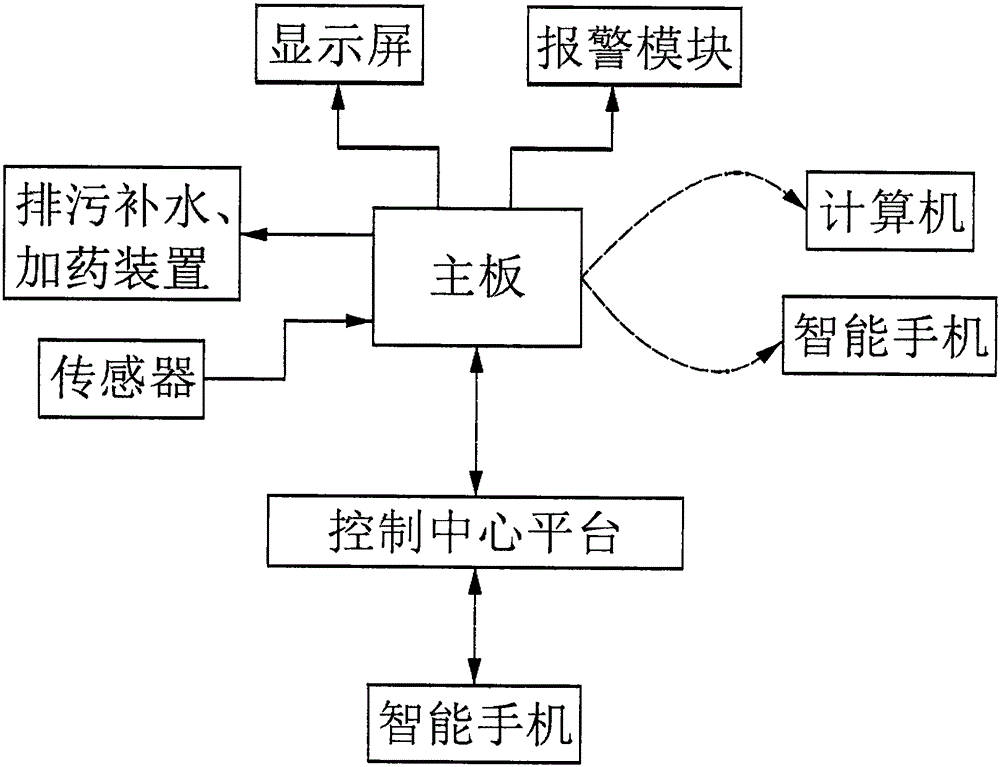

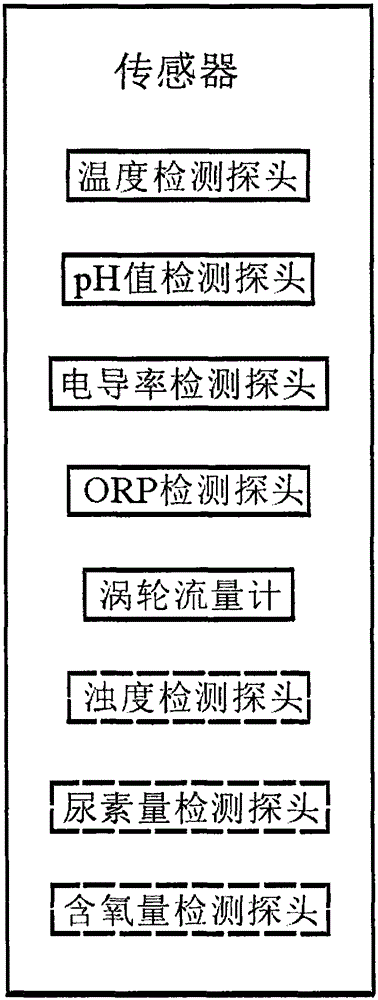

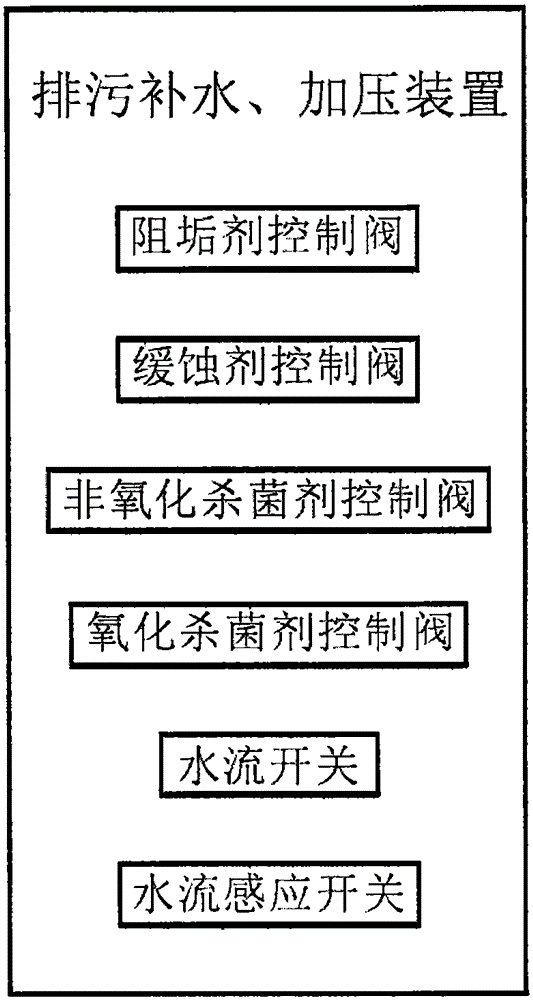

On-line intelligent network automatic water treatment detection and control system

InactiveCN105152364AImprove utilizationIncrease the concentration factorScale removal and water softeningWater/sewage treatment by neutralisationElectricityIntelligent Network

The invention discloses an on-line intelligent network automatic water treatment detection and control system which comprises a control center platform, a main board, a sensor, a pollution discharge, water replenishing and dosing device, an alarm module, a display screen, a computer and an intelligent mobile phone, wherein the output port of the sensor is connected with the input end of the main board, the output port of the main board is connected with the input end of the pollution discharge, water replenishing and dosing device, the output end of the main board is respectively connected with the display screen and the alarm module, the output end of the main board is connected with the computer or the intelligent mobile phone through the Internet or GPRS network, the main board and the control center platform are in bilateral interaction, and the control center platform and the intelligent mobile phone are in bilateral interaction. According to the invention, the sensor is used for detecting water quality data, and the opening and closing of the pollution discharge, water replenishing and dosing device are remotely controlled through the Internet, so that the electricity, water and chemical agents are furthest saved, the service life of an air conditioner is prolonged, the running cost of the air conditioner is lowered, and the environmental pollution is reduced.

Owner:中环清新人工环境工程技术(北京)有限责任公司

Laying duck compound feed

The invention relates to a laying duck compound feed which comprises the following raw materials by mass in per 1,000 kilograms: 200-310 kilograms of corn, 140-155 kilograms of rice bran, 110-115 kilograms of wheat, 100-105 kilograms of rice bran meal, 55-65 kilograms of vegetable dreg, 50-60 kilograms of peeled bean pulp, 40-50 kilograms of rice bran No. 2, 35-45 kilograms of cotton seed meal, 35-45 kilograms of stone, 35-50 kilograms of dry fish meal, 25-32 kilograms of flour, 28-35 kilograms of shell powder, 30-40 kilograms of corn protein powder, 2.5-3.5 kilograms of wheat middling, 1.5-2.5 kilograms of salt, 0.5-1 kilogram of choline, 0.5-1 kilogram of attapulgite, 0.1-0.3 kilogram of laying duck vitamin feed, 0.1-0.2 kilogram of methionine, 0.1-0.2 kilogram of phytase and 0.5-1 kilogram of laying duck trace element. The invention has the advantages that refining is qualified, and animal and plant raw materials with drug residues are not contained; the absorptivity of the feed in the animal body is improved through sufficient nutrient balance; limit resources are furthest utilized, and the discharge capacity is reduced; and after feeding the feed, laying ducks have early laying, long laying peak season, big eggs, high egg shell strength and uniform egg shell color, therefore, the invention has high efficiency and safety.

Owner:SHANGHAI NONGHAO FEED

Preparation method of solid alkali catalyst and reaction method for catalytic synthesis of ionone fragrance intermediate by solid alkali catalyst

ActiveCN105562041AImprove catalytic performanceSimple catalytic performanceOrganic compound preparationCatalyst activation/preparationPtru catalystUltrasonic assisted

The invention discloses a preparation method of a solid alkali catalyst and a reaction method for the catalytic synthesis of an ionone fragrance intermediate by the solid alkali catalyst. The preparation method of the solid alkali catalyst comprises the following steps: putting a carrier in a flask, adding KF (Potassium Fluoride) aqueous solution, stirring for 4-9h at the temperature of 40-80DEG C in an ultrasonic oscillator, then, stirring at the temperature of 89-99DEG C until a mixture is viscous, drying the mixture, roasting for 4-7h at the temperature of 400-600DEG C, and cooling to obtain the solid alkali catalyst which loads KF on the carrier, wherein the carrier is one of aluminium oxide or magnesium oxide or calcium oxide. Since an ultrasonic-assisted excessive dipping method is adopted to prepare the solid alkali catalyst, the loading capability and the dipping rate of active components are effectively improved. In addition, when the solid alkali catalyst prepared with the preparation method is used for carrying out the catalytic synthesis of the ionone fragrance intermediate, a subsequent alkali neutralization operation carried out when liquid alkali catalyst is used is avoided, cost is lowered, sewage is reduced, catalytic reaction has a high yield, the catalyst and a product can be easily separated, and the catalyst can be repeatedly used.

Owner:广州百花香料股份有限公司

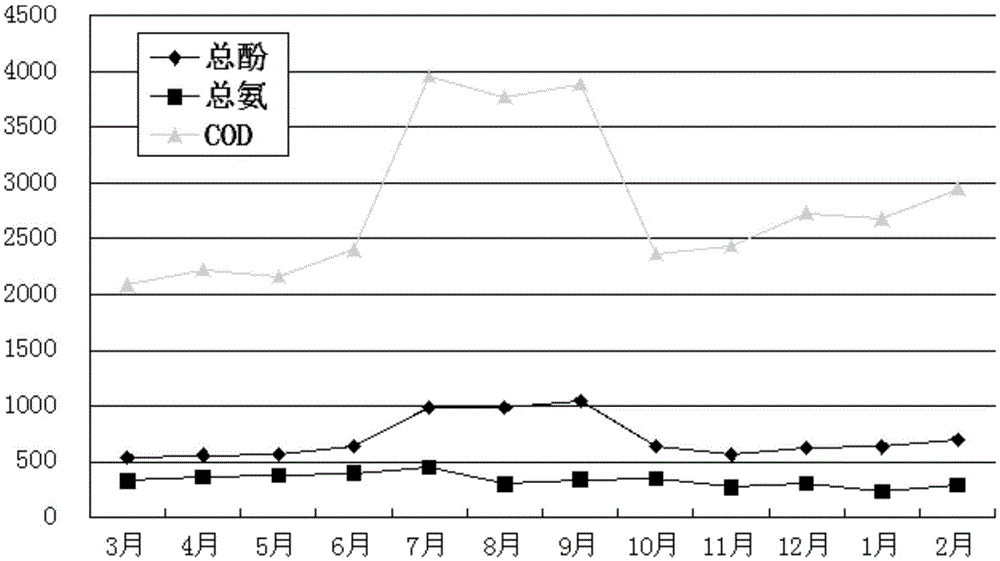

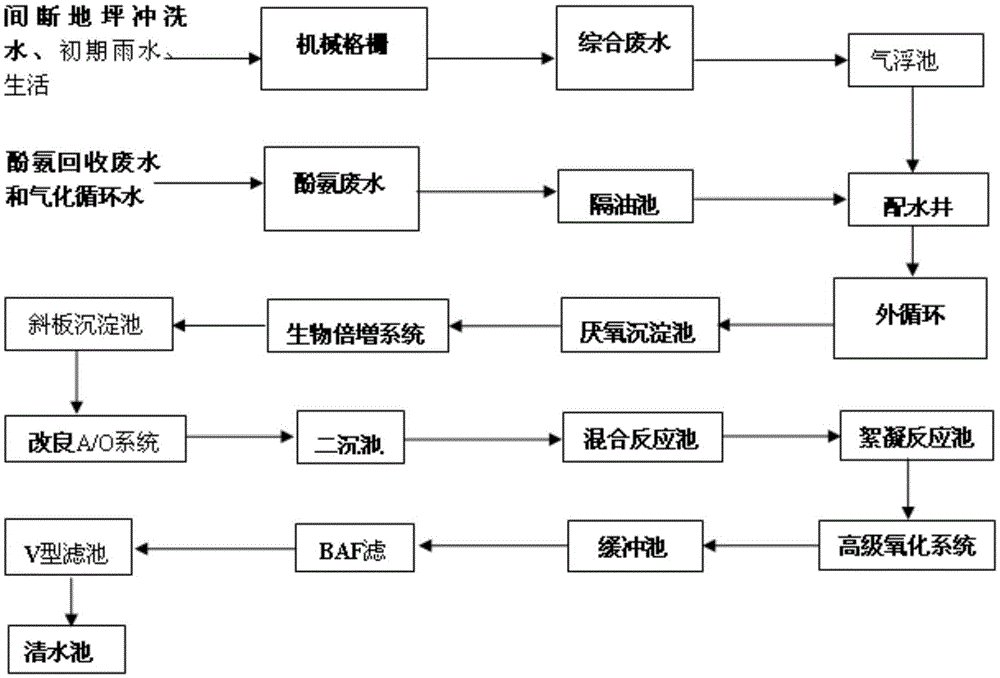

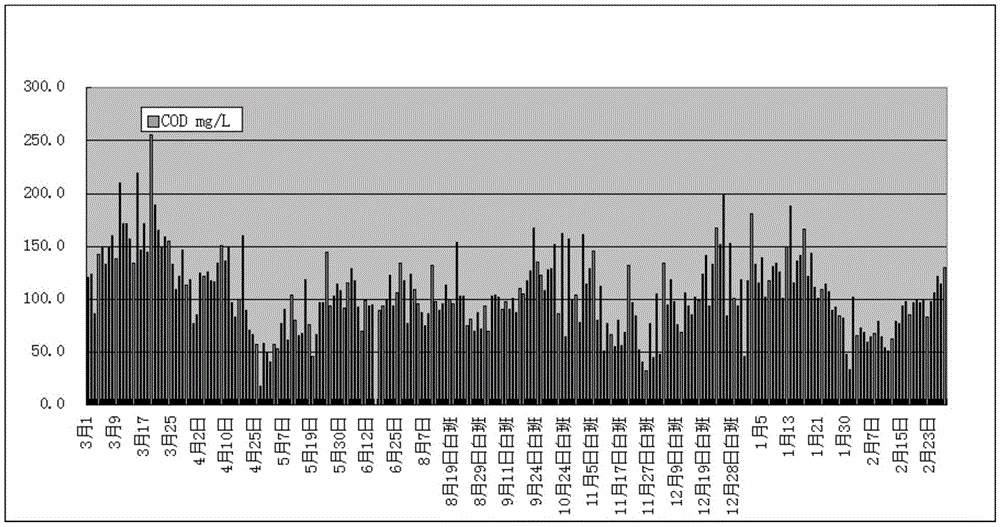

Coal chemical industry waste water treatment technology

ActiveCN106116011AAvoid stagnationReduce usageTreatment using aerobic processesTreatment involving filtrationSalt-wastingTreatments water

The invention provides a coal chemical industry waste water treatment technology. The coal chemical industry waste water treatment technology comprises the following steps of firstly performing an ammonia-phenols removal treatment technology on organic waste water in coal chemical industry waste water so as to obtain treated waste liquid; then performing a biochemical treatment technology on the treated waste liquid obtained in the above step so as to obtain biochemical treatment water; then performing a concentrating treatment technology on the biochemical treatment water obtained in the above step and salt-containing waste water so as to obtain reuse water and high-salt waste water; and finally performing a strong brine treatment technology on the high-salt waste water obtained in the above step so as to obtain salt-containing materials, wherein the ammonia-phenols removal treatment technology comprises a deacidification and ammonia removal working procedure, an extraction working procedure, a solvent removal working procedure, a solvent reclaiming working procedure, a waste liquid separation system, a solvent storage working procedure and an alkali liquid preparation working procedure. According to the coal chemical industry waste water treatment scheme provided by the invention, through gradient utilization and repeated utilization of the waste water, the use of fresh water resources is furthest reduced, so that the water consumption of projects can be fully reduced, and zero drainage of polluted water is realized.

Owner:CHINA COAL ORDOS ENERGY CHEM COP LTD

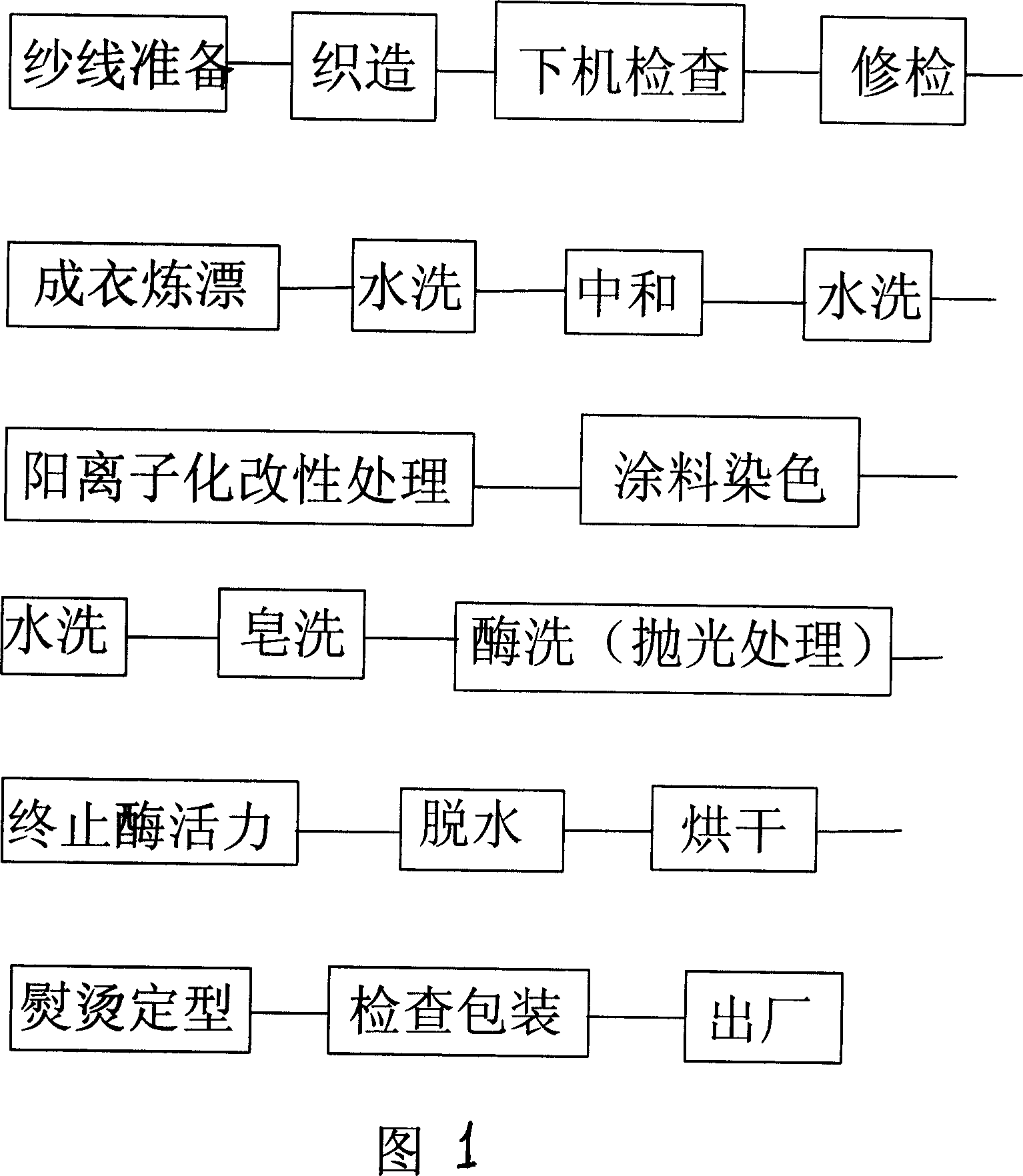

Technical method of pigment wash, dye, and general finish for ready-made clothes in pure cotton

InactiveCN101003952AIncrease profitImprove pass rateLiquid/gas/vapor article treatmentDyeing processFiberCellulose

The present invention relates to a pure cotton garment washing, dyeing and finishing process. Said process successively includes the following steps: preparing cotton yarn, weaving, placing pure cotton garment into garment dyeing machine, preparing scouring and bleaching solution according to technological formula, scouring and bleaching to predefined time, washing, neutralization, washing; using cationic modifying agent whose dose is 1-3% of garment weight to make cotton fiber undergo the process of cationic modification treatment to predefined time; thermostatical dyeing to predefined time, washing, soaping, washing; using cellulose whose dose is 2% of garment weight to make enzymatic washing (polishing treatment) to predefined time, under the alkaline condition stopping enzymatic active action; dewatering, drying and finalizing the design.

Owner:海城市宏泰纺织印染有限公司

Fabric for desizing and refining disposable completion by bioenzyme

InactiveCN101187170AAvoid damageFluffy and softBiochemical fibre treatmentDry-cleaning apparatus for textilesSocial benefitsSewage

The invention relates to a method for fulfilling the fabric finishing and refining by use of biological enzyme in one time, which uses natural starch or converted starch or both starch and PVA as main sizing materials, wherein the fabric has good comfort, a puff and soft hand feeling, short technical process, simple device, little energy consumption, small polluted water and is suitable for mass production with good economy and social benefits.

Owner:SHENGHONG GRP CO LTD

Open industrial circulating-cooling water concentrating ratio and drug concentration balance control method

InactiveCN101071053AReduce consumptionImprove protectionHeat exchange apparatusSimultaneous control of multiple variablesWater sourceWater resources

The invention provides a kind lf balance control way of open style industry recycling cooling water's weight concentration and pharmacy concentration .And weight concentration balance control way mainly controls the amount of water and salt of the industry recycling cooling water system ,according to the weight concentration N to control the add water and sewage water effectively to realize the balance control over the weight concentration of the industry recycling cooling water .And the pharmacy concentration balance control way is carried out on the basis of the weight concentration balance control way ,on the basis of weight concentration no change ,through adjusting and controlling the add water amount and dosing amount's proportion ,making the add dosage equal to the losing dosage in the same time of the system ,so realizing the pharmacy concentration keeping no change in the recycling water .The invention's advantages are saving water source ,keeping water quality stable ,etc.

Owner:任广兴

Separation and purification method of valine

ActiveCN104592047AReduce sewageImprove energy savingOrganic compound preparationAmino-carboxyl compound preparationPurification methodsRight-to-left

The invention discloses a separation and purification method of valine. The separation and purification method comprises the following steps: (1) performing frame filtering on valine fermentation liquid to obtain filtered solutions, and feeding the filtered solutions into a cation exchange resin column, which rotates from right to left, of a continuous moving bed; (2) sequentially dividing the cation exchange resin column of the continuous moving bed into a feeding area, a material washing area, a back-washing area, a product water ejection area, a first analyzing area, a second analyzing area, an analyzing solution recovery area, an acid regeneration area and a washing acid area from right to left, and collecting the analyzing solutions of the first analyzing area and the second analyzing area and applying the analyzing solutions to production of medicine-level valine products and food-level valine products. The yield of the valine obtained by using the method can reach about 98 percent.

Owner:SANDA FILM SCI & TECH XIAMEN +1

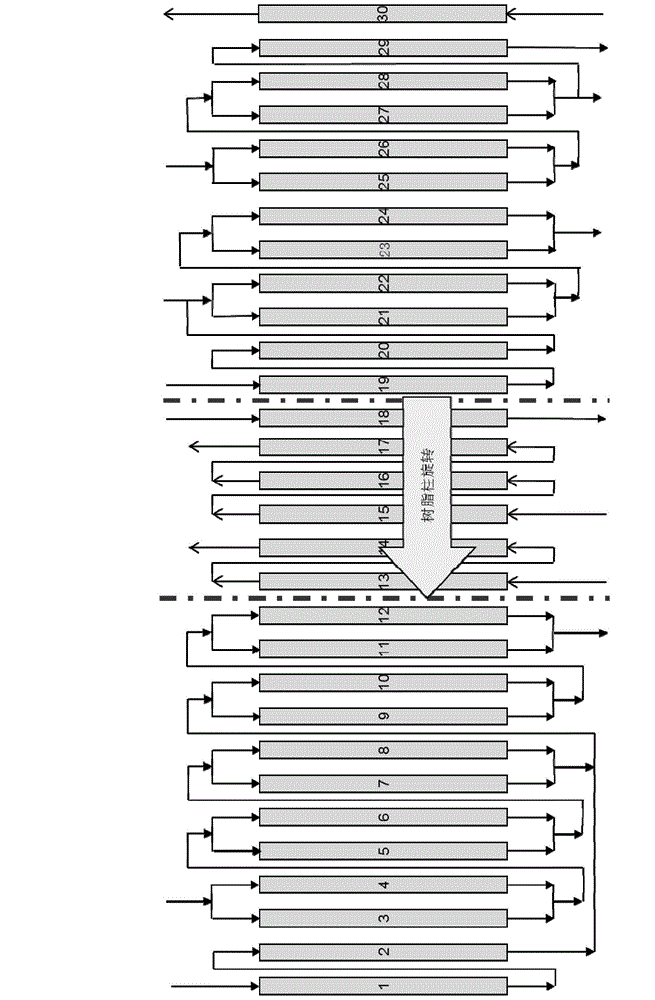

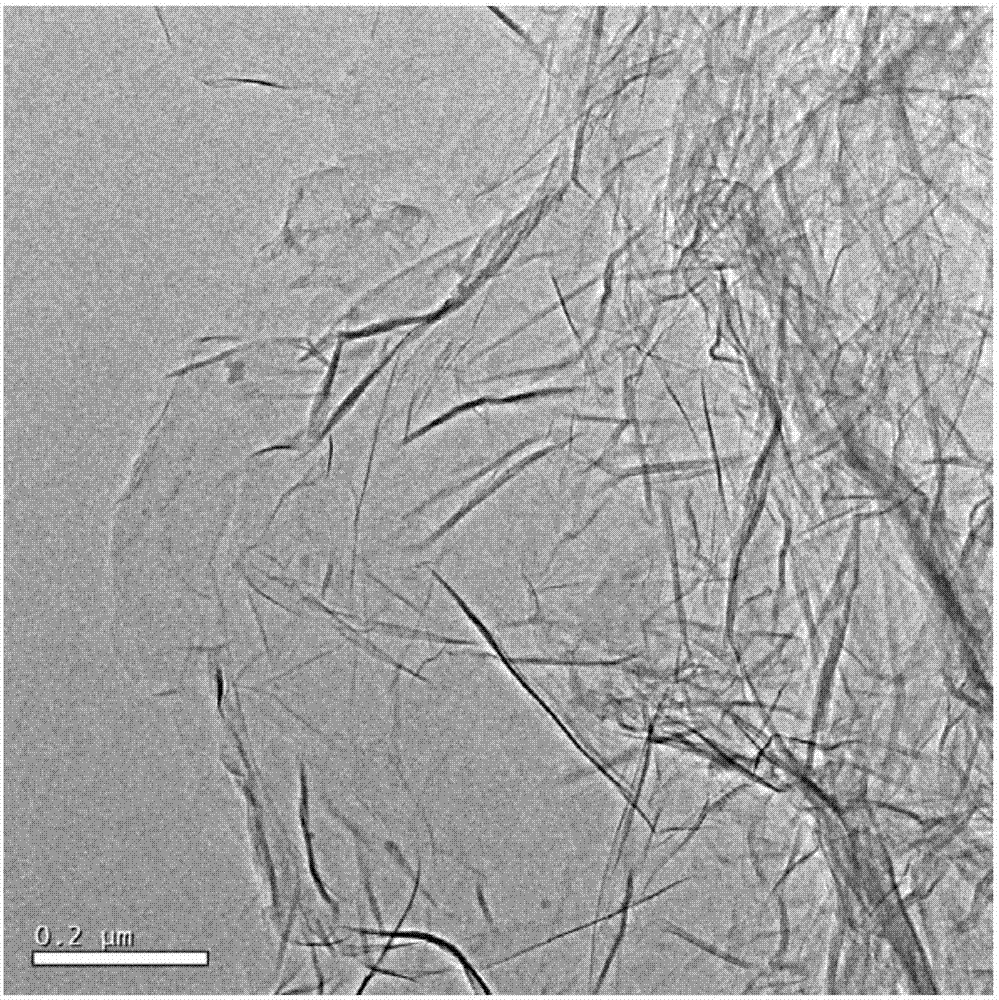

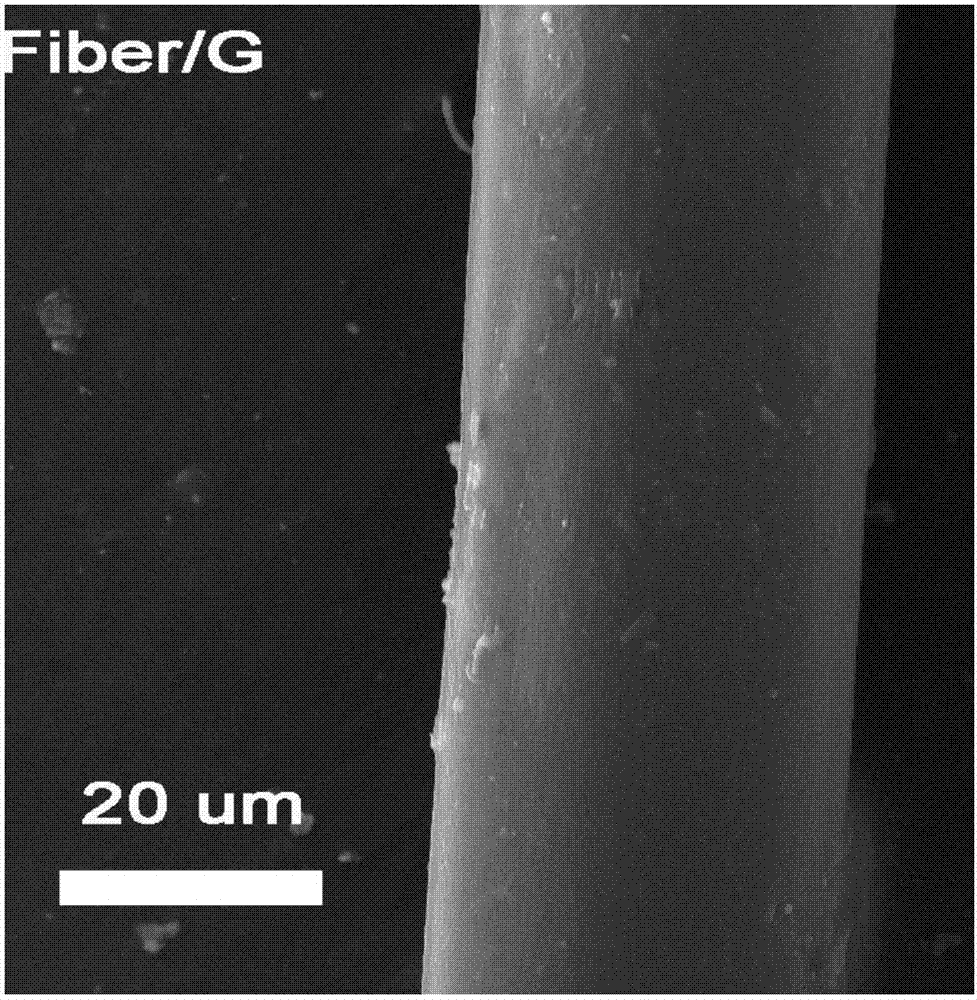

Preparation method of oxidized graphene polypropylene functional fiber

ActiveCN107385537AReduce sewageSolve the problem of high demandMonocomponent polyolefin artificial filamentArtifical filament manufacturePolymer scienceMechanical property

The invention discloses a preparation method of an oxidized graphene polypropylene functional fiber. The preparation method comprises the following steps: firstly, modifying oxidized graphene with alkyl group amine oxide to obtain alkyl group functionalized functional oxidized grapheme which is high in specific surface area and high in alkylation; performing slicing with polypropylene, performing mixing through a high-speed intermixer, and then performing melting composite processing through a twin-screw so as to obtain oxidized graphene-polypropylene master batches; drying the master batches, melting and spinning so as to prepare the oxidized graphene polypropylene functional fiber. The method disclosed by the invention solves the problems that the oxidized graphene composite polypropylene wire drawing process is unstable, the fiber forming degree is low, the fiber tenacity is low and the functions are single, the oxidized graphene composite polypropylene fiber obtained through melting and spinning has good mechanical properties, and has functions of resisting bacteria, resisting mites, resisting ultraviolet radiation, resisting static electricity and the like. High-grade functional polypropylene fiber is developed, and a new application field is developed for the polypropylene fiber.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

Clean modified briquette and method for preparing same

The invention relates to a clean modified briquette and method for preparing same, wherein the briquette is prepared from (by weight ratio) the following raw materials, super fine coal powder 10-20%, coal gangue or stone coal or kerosene shale or mushy coal 30-70%, purification powder 1-5%, complexing agent 1-5%, adhesive 8-10%, water 0-15, and balancing glance coal. The invention can be applied for diminishing pollution discharge.

Owner:KUNMING JUJIE SCI & TECH

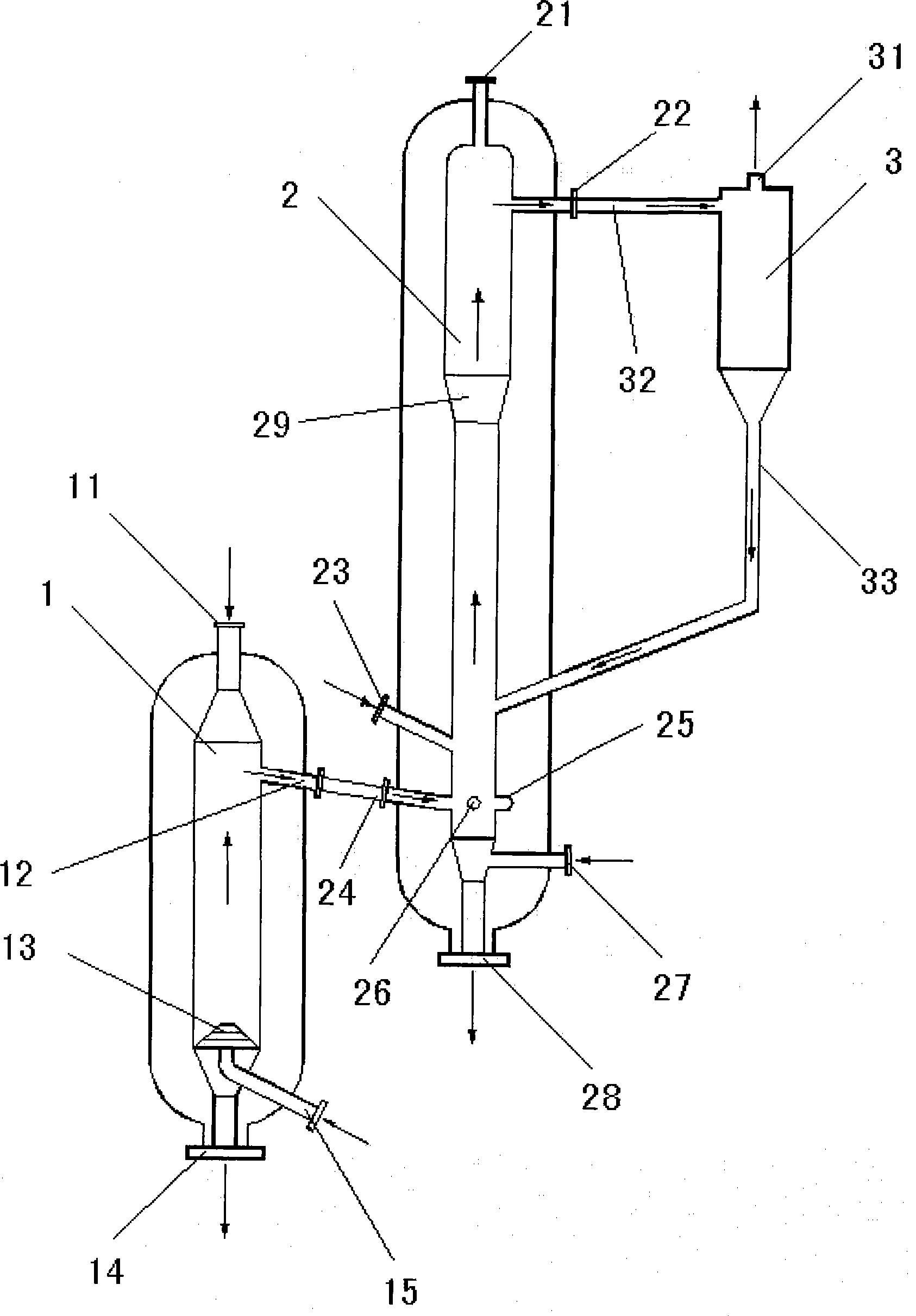

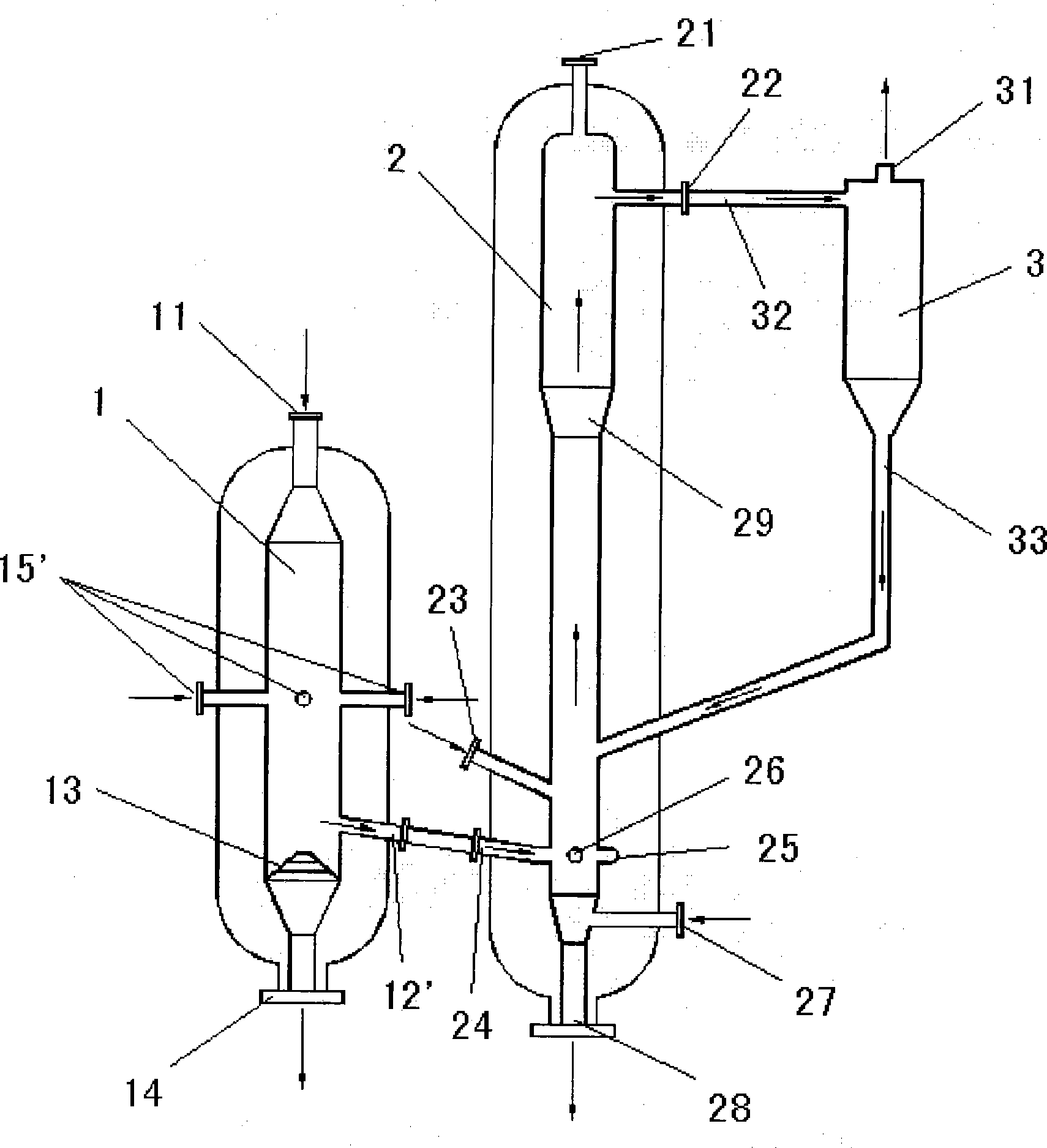

Fixed bed-fluidized bed serially connected gasification method and apparatus

ActiveCN101440308AReduce tar contentEmission reductionCombined combustion mitigationCombustible gas productionFluidized bed gasifierFluidized bed

The invention relates to a method and a device for gasification, in particular to the method and the device for serial gasification of a fixed bed and a fluidized bed, wherein the method comprises the following steps: 1) feeding a gasification raw material with the particle size of between 13 and 50 millimeters and a gasification agent to a fixed bed gasifier to perform gasification reaction so as to generate coal gas and ash content, discharging the ash content from an ash discharging opening of the fixed bed, and introducing the coal gas to the lower part of a dense phase zone of a fluidized bed gasifier; 2) feeding a thin particle shapeed coal gasification raw material with the particle size of between 0.5 and 8 millimeters and the gasification agent into a fluidized bed gasifier to perform gasification reaction with the vertically raising coal gas so as to generate the coal and the ash content, discharging the ash content from the ash discharging opening of the fluidized bed, and introducing the coal gas into a cyclone separator; and 3) performing gas-solid separation on the coal gas in the cyclone separator, outputting the coal gas from a coal gas outlet of the cyclone separator, and sending back solid particles carried by the coal gas to the fluidized bed gasifier through a dipleg of the cyclone separator to perform the gasification reaction continuously. The method and the device have quite important significance on improving the economic benefit and reducing the sewage treatment cost for the medium and small-sized coal chemical enterprises in China.

Owner:CCTEG CHINA COAL RES INST

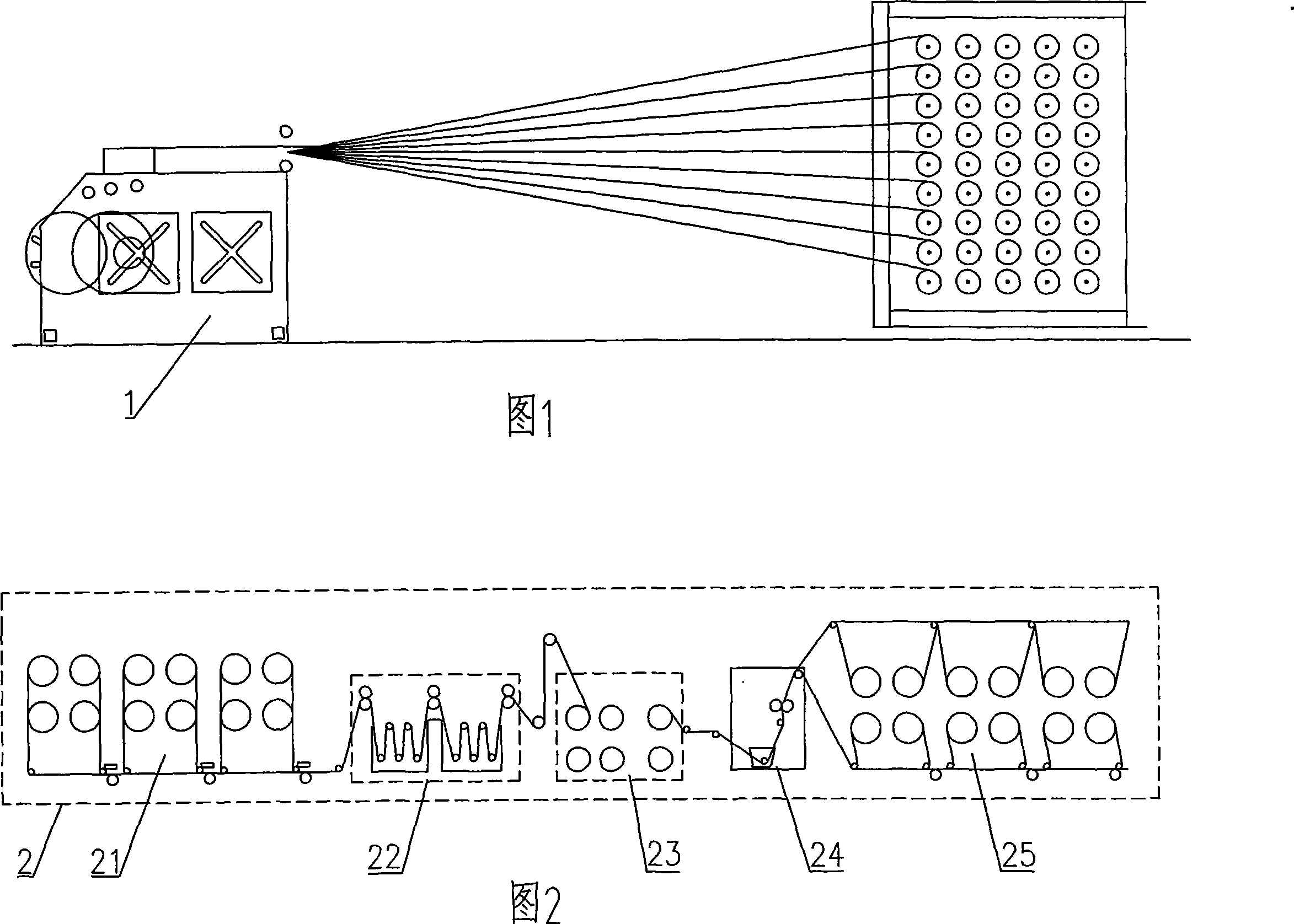

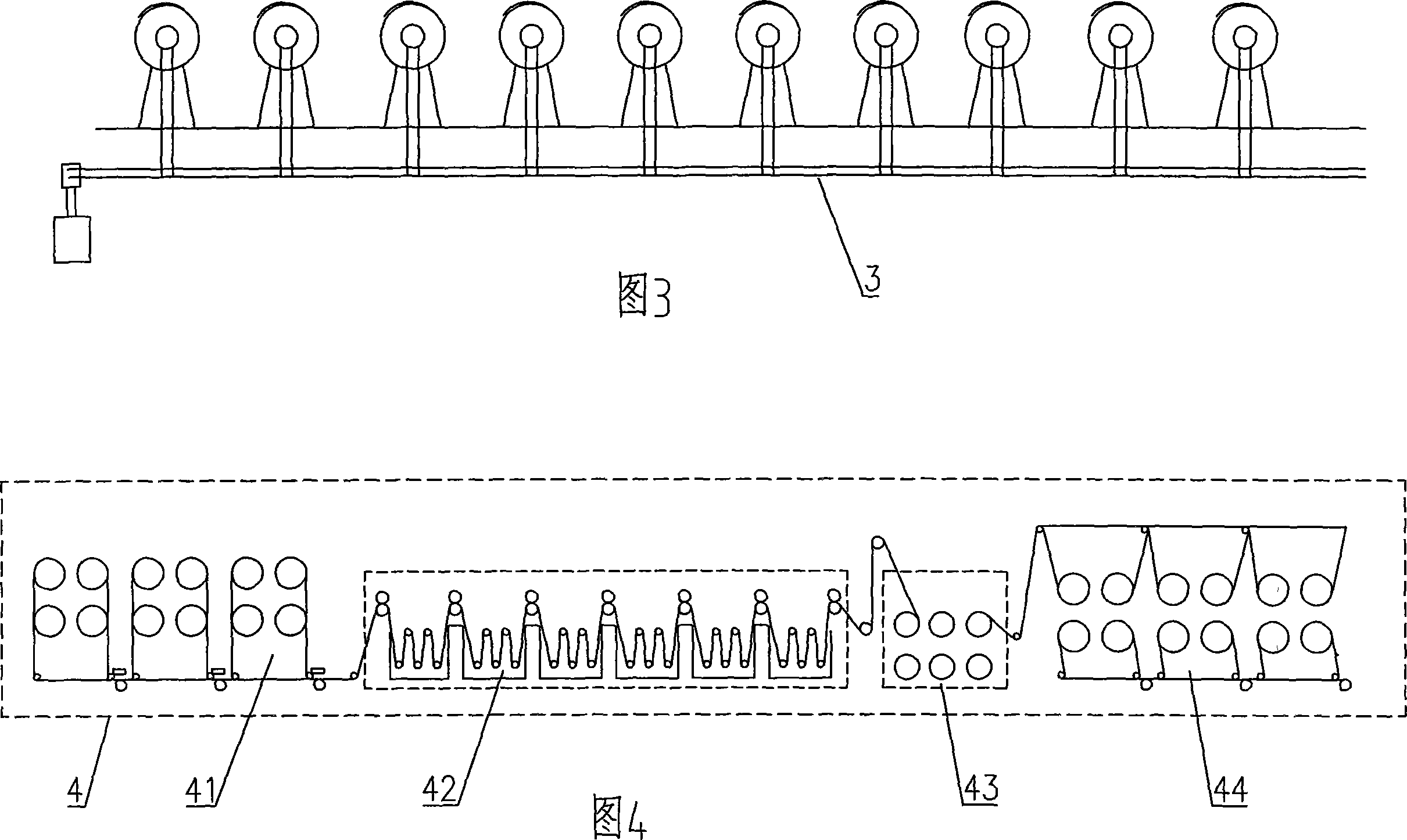

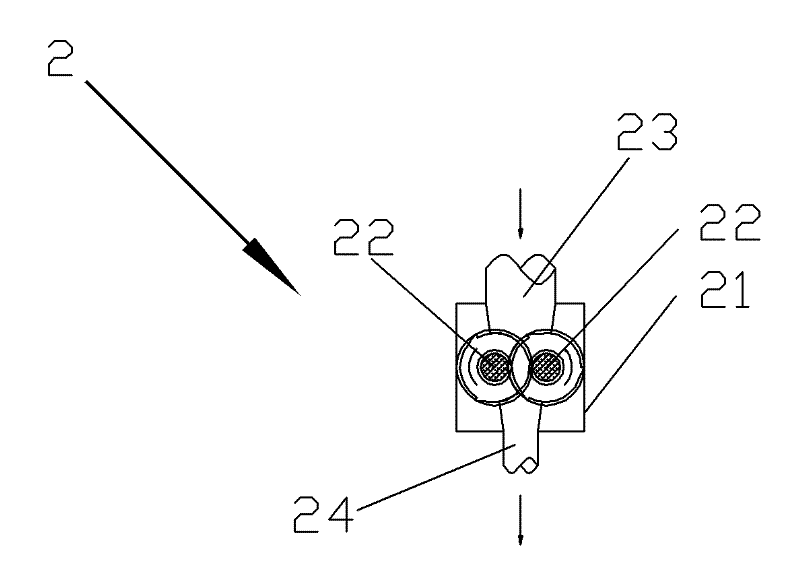

Cold rolling yarn stacking and dyeing device

InactiveCN101191283ASimple processEasy to operateTextile treatment machine partsLiquid/gas/vapor removalYarnWastewater

The invention relates to the yarn dyeing device field, in particular to a cold pad batch dyeing device, comprising a high speed warp vehicle, a yarn padding mangles, a drying apparatus, a pad dyeing device, a cold dyeing device, a soaping drying machine, a yarn feeding device, a yarn retracting device and so on, and the devices are produced in turn by forming a complete production network. The invention adopts continuous pad dyeing lines and has the advantages of simple technique, low technical difficulty, easy operation, no generation of waste water fundamentally during the dyeing process, normal temperature dyeing, energy saving and environmental protection, and low equipment investment.

Owner:杨立新

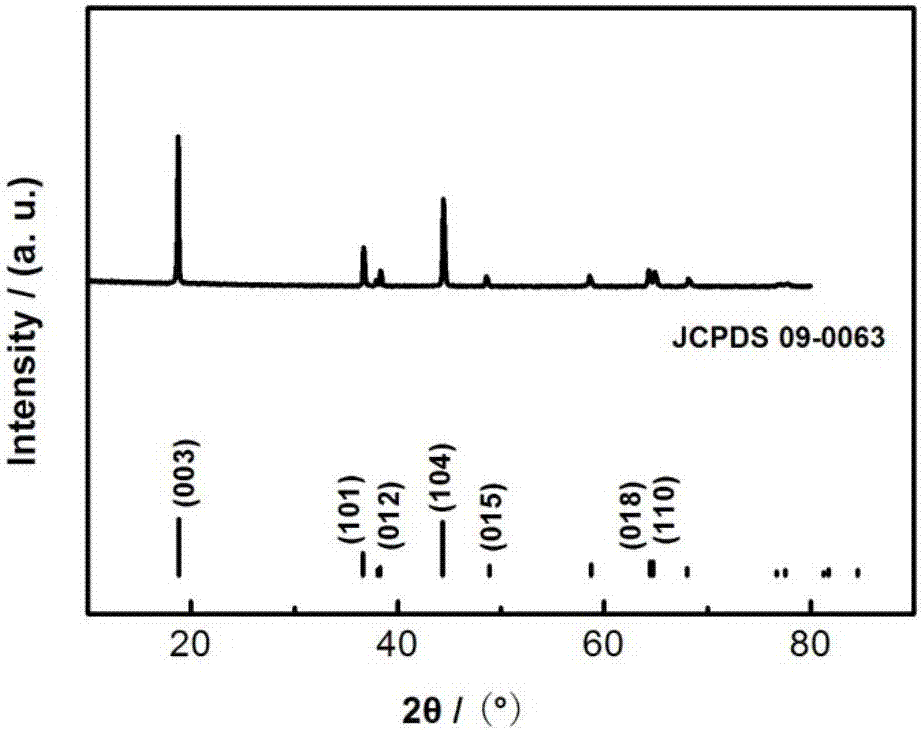

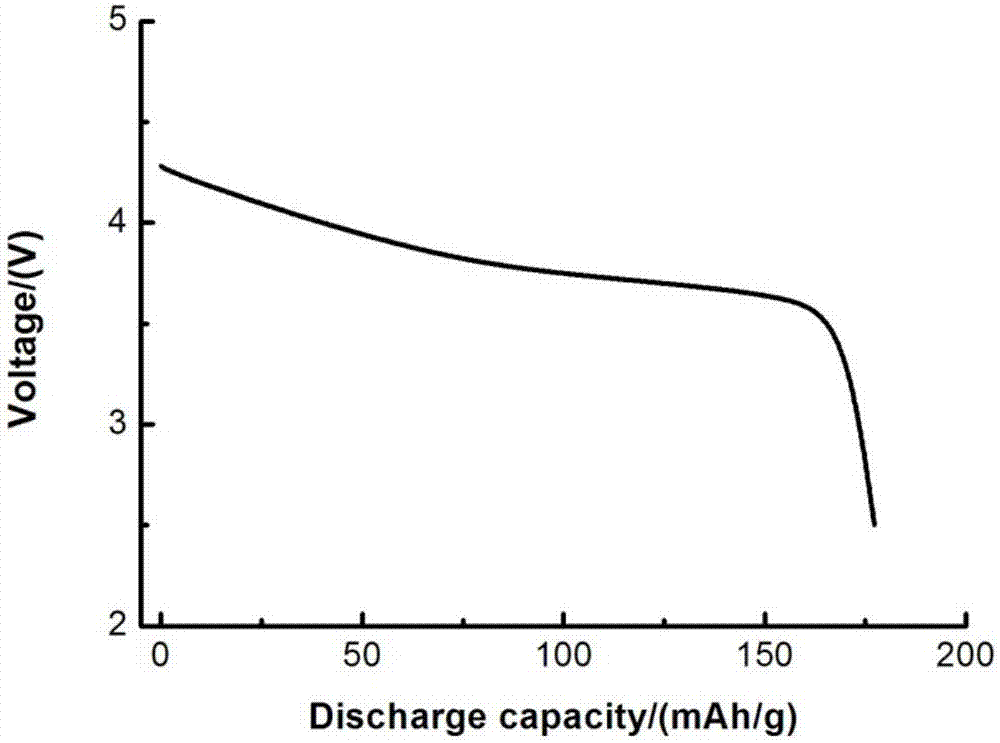

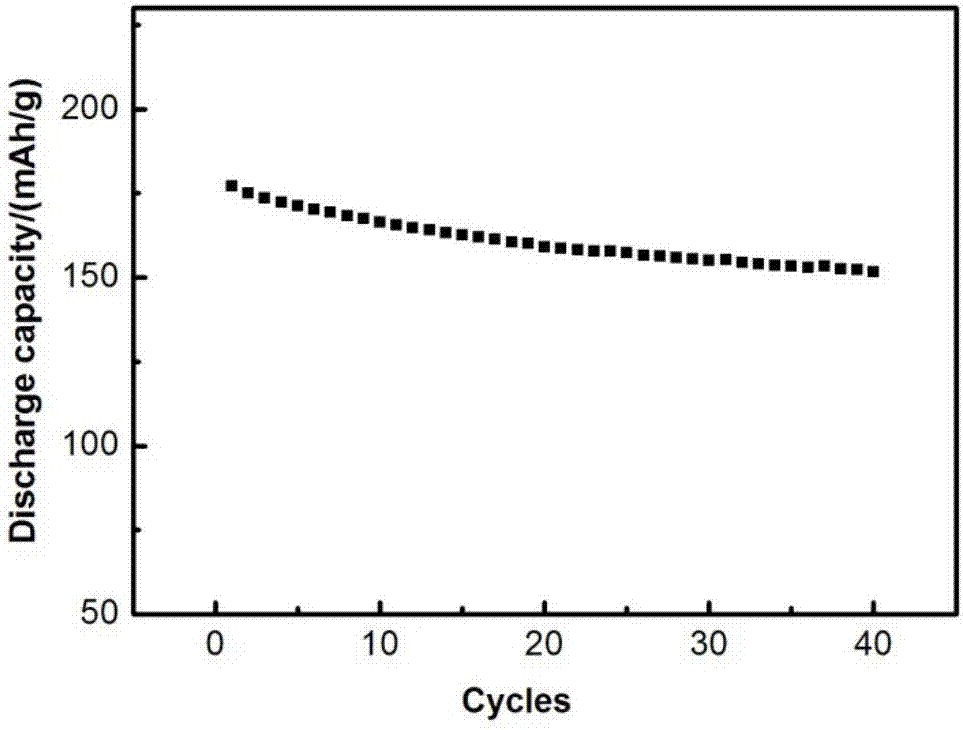

Method for preparing trivalent cation doped Ni-Co-Mn ternary material by direct precipitation

ActiveCN107579242ALow costWide variety of sourcesCell electrodesSecondary cellsManganeseLithium compound

The invention relates to a method for preparing a trivalent cation doped Ni-Co-Mn ternary material by direct precipitation. The method is characterized in that the molar ratio x:y:z:k:m of Ni, Co, Mn,Li and doped trivalent M cation meets the condition that x:y:z:m is equal to (0.47-0.52):(0.10-0.20):(0.26-0.35):(0.01-0.10) or (0.57-0.62):(0.10-0.19):(0.15-0.25):(0.01-0.10), or (0.77-0.82):(0.05-0.10):(0.05-0.13):(0.01-0.10), wherein, k is not less than 0.95, and not more than 1.10, and the sum of x, y, z and m is 1. Weighed Ni, Co, Mn, Li and doped trivalent M cation are mixed with a wet-milling medium, ammonia liquor and a lithium compound are added, and the trivalent cation doped Ni-Co-Mn ternary material is prepared through steps of aging, drying, sintering and the like.

Owner:FUJIAN NORMAL UNIV

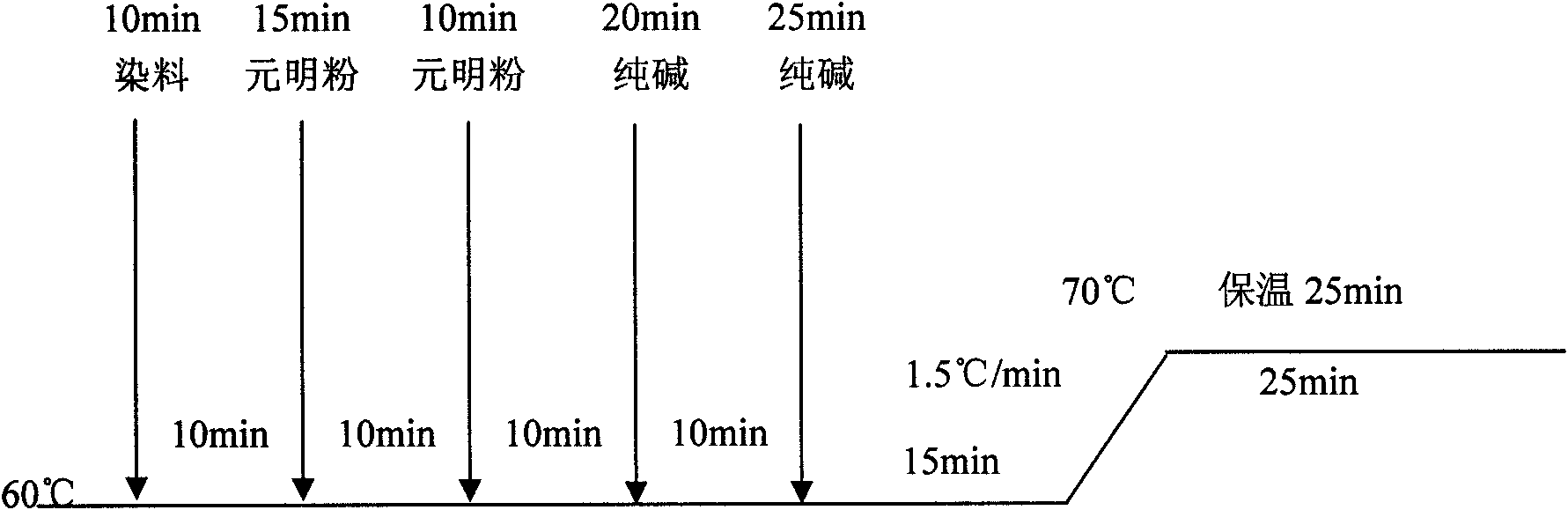

Polyester cotton dyeing one-bath process manufacturing process

ActiveCN103132351ABright color and good fastnessBright colorSucessive textile treatmentsHeating/cooling textile fabricsPolyesterCotton fibre

The invention discloses a polyester cotton dyeing one-bath process manufacturing process. The polyester cotton dyeing one-bath process manufacturing process is conducted according to the following steps: gray fabric of polyester cotton intertexture or gray fabric of cotton polyester intertexture is adopted for cloth preparation; and the steps of cold-stacking, cylinder discharging, one-bath dyeing (activity once dyeing of dacron and cotton fiber), soaping, cloth soaping, forming and finish inspection packaging are sequentially conducted. A novel manufacturing process of polyester cotton, a normal manufacturing process of gray fabric (T / C or C / T) scattering and a normal manufacturing process of an activation dyeing one-bath method are adopted in the polyester cotton dyeing one-bath process manufacturing process. After process treatment such as dyeing, production cost is greatly reduced, and environmental pollution is reduced. Shell fabric produced through the process is brighter in colors and luster, softer, smoother and cooler in handle, bright in cloth cover color, and good in cloth cover fastness, and can be widely applied to casual garment shell fabrics.

Owner:JINJIANG LONGXINGLONG DYEING & WEAVING INDALCO

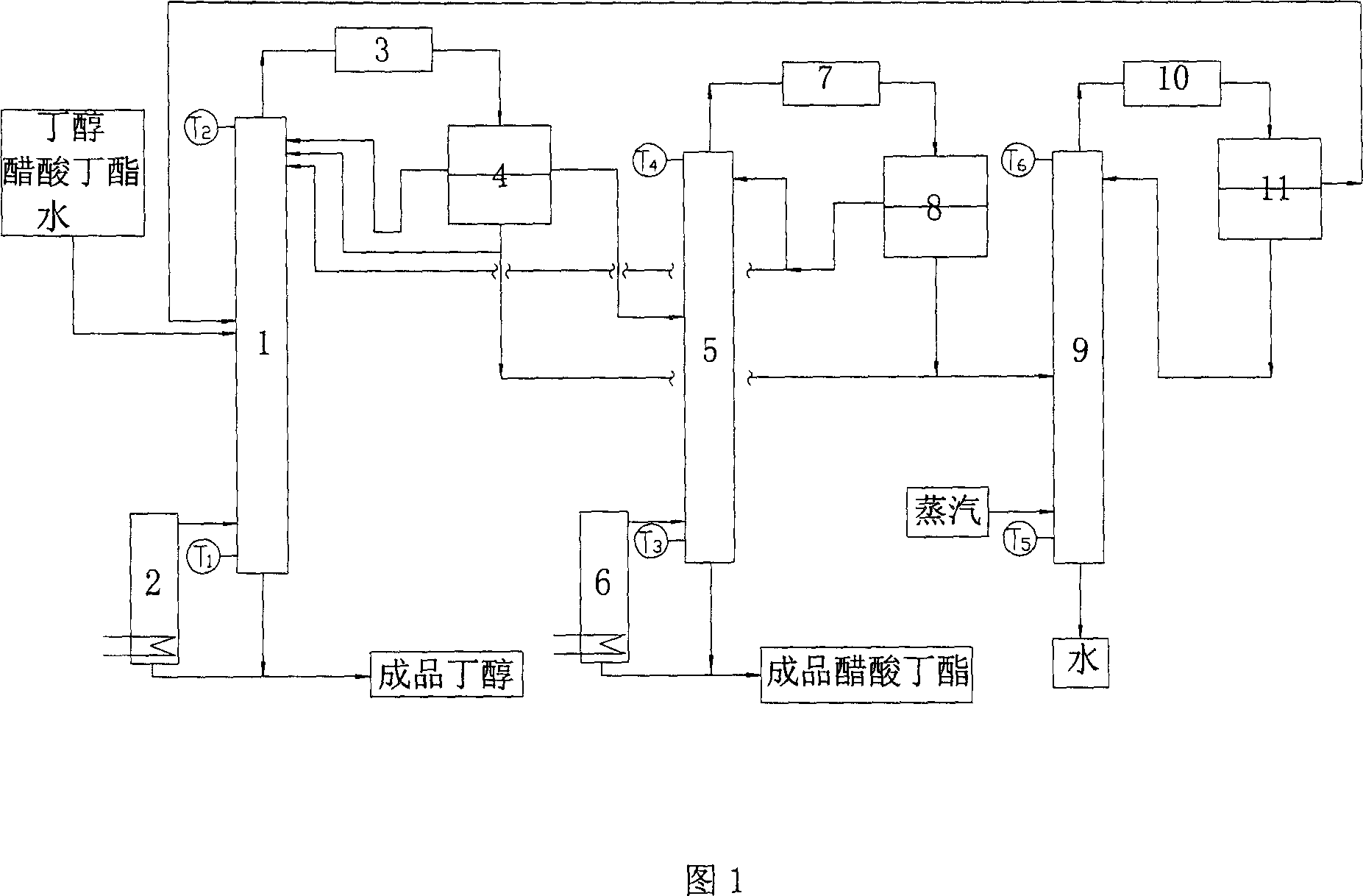

Azeotropic distillation process for separating butanol and butyl acetate

InactiveCN1974529AAvoid lostReduce sewageOrganic compound preparationCarboxylic acid esters preparationPhase splittingReboiler

The present invention relates to azeotopic distillation process for separating butanol and butyl acetate. The technological process is completed with the apparatus including rectification tower (1), rectification tower (5), rectification tower (9), kettle reboiler, condensate cooler and phase splitting tank. The technological process includes feeding the material liquid in the middle part of rectification tower (1) and refluxing partial heavy water phase into the tower; refluxing light phase; obtaining butanol product in the kettle; refluxing partial light phase while recovering partially to the rectification tower (5); refluxing partial light phase while obtaining butyl acetate product in rectification tower (5); and feeding the heavy phase to rectification tower (9) and obtaining pure water in the kettle. The present invention has low power consumption, less side products, high butanol product quality, recovery of butyl acetate and high economic effect.

Owner:HEBEI UNIV OF TECH

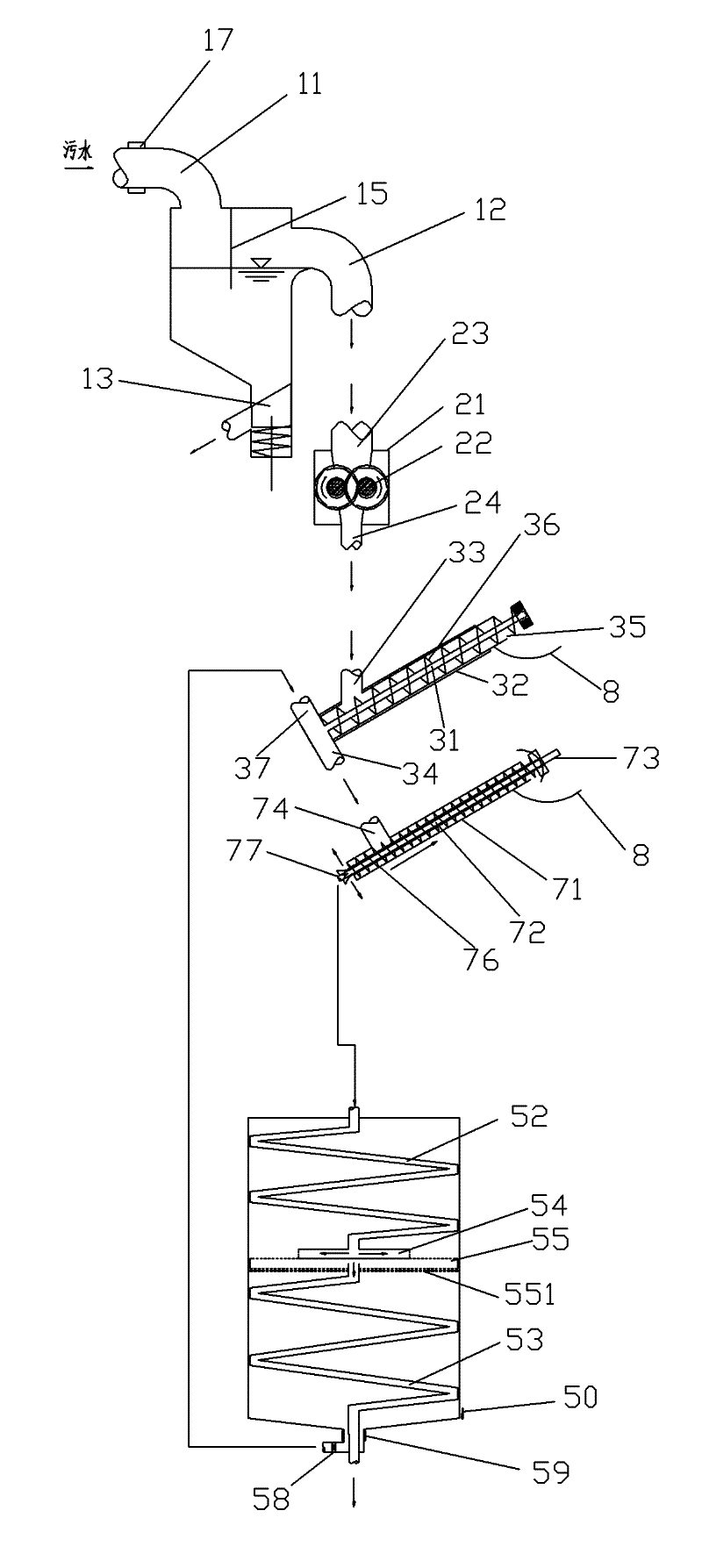

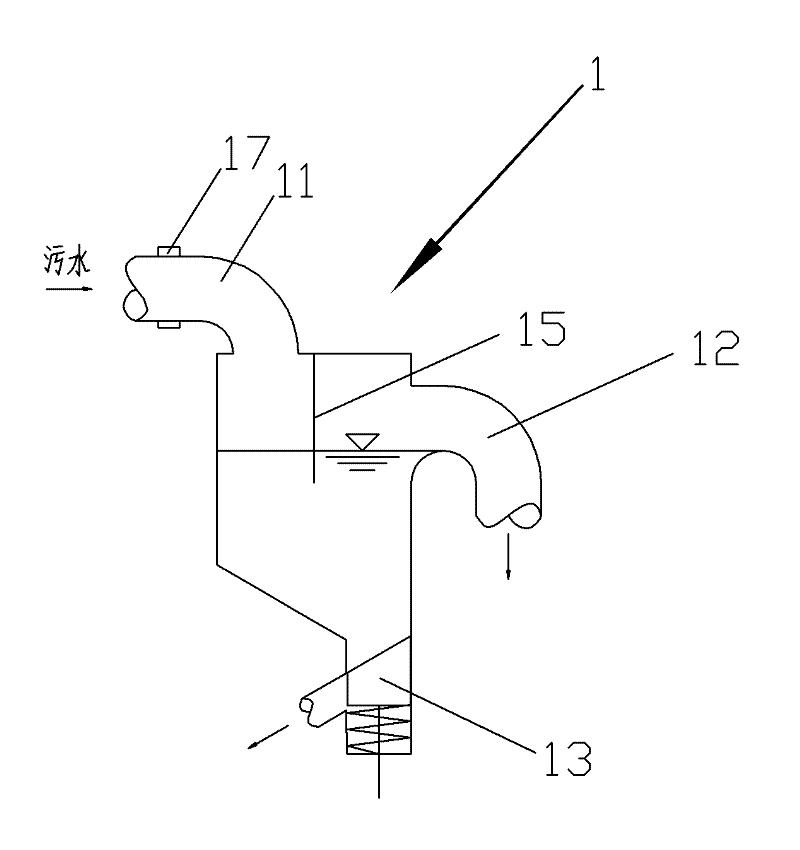

Physical sewage treatment system used for sewage treatment from source

InactiveCN102219319AEasy to separateEasy to handleMultistage water/sewage treatmentPollutionSewage sludge treatment

The invention discloses a physical sewage treatment system used for sewage treatment from the source, comprising a solid-liquid separation device and a settling device. The solid-liquid separation device is provided with a solid-liquid separator, and a separation water inlet, a separation water outlet and a separation sewage discharging port of the solid-liquid separator; the settling device comprises a settling shell the bottom of which is provided with a settling sewage discharging port, a water inlet hose and a water outlet hose are arranged in the settling shell, the water inlet end of the water inlet hose is connected with the separation water outlet of the solid-liquid separation device, the water outlet end of the water inlet hose is connected with a hollow floating disk, the outline of the floating disk adapts to that of the cross section of the settling shell, and a plurality of through holes are uniformly distributed in the annular area of the bottom surface, close to the edge; a floating disk water outlet is arranged on the bottom of the floating disk and is connected with the water inlet end of the water outlet hose, and the water outlet end of the water outlet hose extends out of the settling shell. The sewage treatment system can be used for treating sewage timely from the pollution sources, thus reducing or avoiding the phenomenon that sewage enters public water body.

Owner:ZHONGSHAN JUYA BATHROOM CO LTD

Slub yarn manufactured from regenerative cotton and processing method therefore

The invention belongs to the textile field, and particularly relates to novel slub yarn which is manufactured from regenerative cotton and has a special style. Meanwhile, the invention discloses a processing method of the slub yarn. The slub yarn manufactured from regenerative cotton is characterized by being composed of base yarn and auxiliary yarn, wherein the adding proportion of the base yarn is 90%-75%, and the adding proportion of the auxiliary yarn is 10%-25%. The auxiliary yarn is made of the regenerative cotton and other fibers, wherein the proportion of the regenerative cotton is 10%-40%, the proportion of the other fibers is 90%-60%, and the slub yarn is manufactured from the base yarn and the other fibers. The slub yarn manufactured from regenerative cotton not only has the special style, but also enables the regenerative cotton to be effectively used, and meanwhile, the processing method for manufacturing the slub yarn is provided.

Owner:颜志超

Enzyme method of extracting oils and proteins from vegetable matter in an aqueous medium

ActiveUS20120196332A1Volume of water is minimizedReduce sewagePeptide preparation methodsFermentationVegetable matterEmulsion

Method for extracting oils, proteins and fermentable sugars from vegetable material in an aqueous medium, includes:a) adding water to the vegetable material;b) adding an enzyme mixture containing at least one cellulase, at least one hemicellulase, and at least one pectinase, the ratio between the pectinase activity and the cellulase activity being at least 0.14, and the ratio between the pectinase activity and the hemicellulase activity being at least 7.10−3, the pectinase activity being less than 120 μmol / min / mL;c) incubating the vegetable material and the enzyme mixture with stirring to release oils, proteins and fermentable sugars in the reaction medium;d) separating the reaction medium to obtain free oil, an aqueous phase containing proteins and fermentable sugars, and a solid phase;e) optionally separating and recycling an emulsion of free oil or aqueous phase, to the medium;f) separating the proteins and fermentable sugars from the aqueous phase.

Owner:UNIVERSITY OF LORRAINE

Microorganism rapid degumming and warm water retting method for flax

InactiveCN1594675AShorten the fermentation cycleHigh rate of numbnessBacteriological rettingWarm waterFlax fiber

Provided is a microorganism rapid degumming and warm water retting method for flax. The inventive retting method for flax comprises: activating the bacterial for 24 hours at 30 DEG C by pectin solid medium, inoculating the activated bacterial with the 1 wt.% of the flax protocorm in the retting container to the retting container, in which the flax protocorm is soaked for 2-4 hours in warm water, then topping up the retting container with clean water, heating to 30-37 DEG C, meanwhile adding 46.3-92.6 g / m3 sodium chloride and 92.6-129.6 g / m3 urea, finishing the retting after 78-100 hours. The method can shorten the zymolysis cycle, improve the yield rate of the flax fiber, increase the intensity of the flax fiber, improve the flax fiber quality, reduce the sewage in the retting.

Owner:HEILONGJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com