Method for producing corrugated paper with ultralow gram weight and high strength

A technology for corrugated base paper and production method, applied in pulp beating/refining method, paper, papermaking and other directions, can solve the problems of reducing fiber consumption, reducing cost, and large process investment, saving fiber consumption, reducing production costs, and improving economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

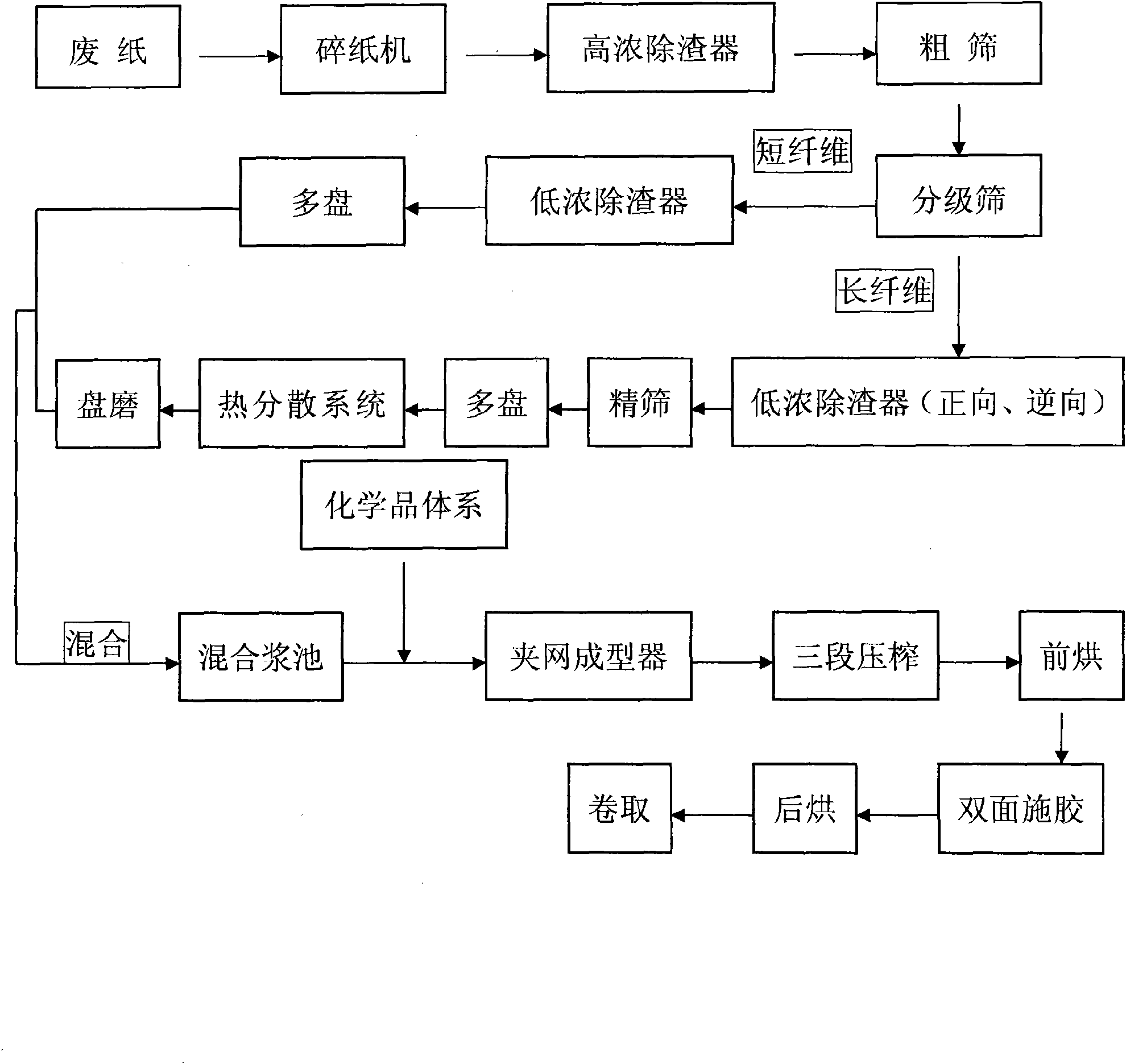

Image

Examples

Embodiment

[0040] 1. Ingredients: mix imported OCC with domestic OCC, imported OCC accounts for 40% of the total OCC by weight;

[0041] 2. Add water and disintegrate to make slurry: disintegrate the mixed waste paper in a hydropulper to make a high-concentration slurry;

[0042] 3. Slurry combination purification treatment: the high-concentration slurry is first sanded, coarsely screened to remove impurities, and then the long fibers and short fibers in the slurry are separated through a grading sieve, and the short fibers are screened to remove impurities through low-concentration; After the fiber is screened with low concentration for sand settling, and then finely screened to remove impurities, the long fiber is sent to the thermal dispersion system to disperse impurities such as stickies and hot melts.

[0043] 4. Medium-concentration beating: Adjust the concentration of the long-fiber pulp after thermal dispersion treatment to 5% by weight, and then send it to the disc mill for bea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com