Patents

Literature

76results about How to "Avoid re-adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

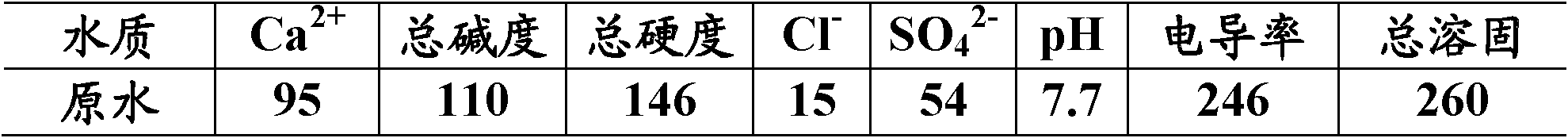

Method for treating circulating water having light oil leaked therein

ActiveCN102476873AAvoid re-adhesionGuaranteed treatment effectScale removal and water softeningMultistage water/sewage treatmentPolyethylene oxideActive agent

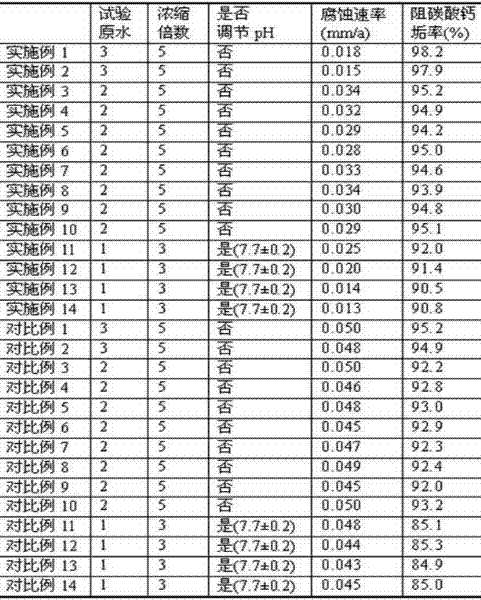

The invention provides a method treating circulating water having light oil leaked therein. The method comprises a) adding an oxidation-type bactericide; b) adding an anti-scale corrosion inhibitor which contains at least one organic phosphonic acid, at least one organic carboxylic acid polymer, an optional copper material corrosion inhibitor and an optional zinc salt; and c) adding at least one polyethylene oxide non-ionic surfactant. The inventive method can remove oil and detach slime from equipment of a circulating water system in one step, without requiring discharge of a large amount of sewage.

Owner:CHINA PETROLEUM & CHEM CORP +1

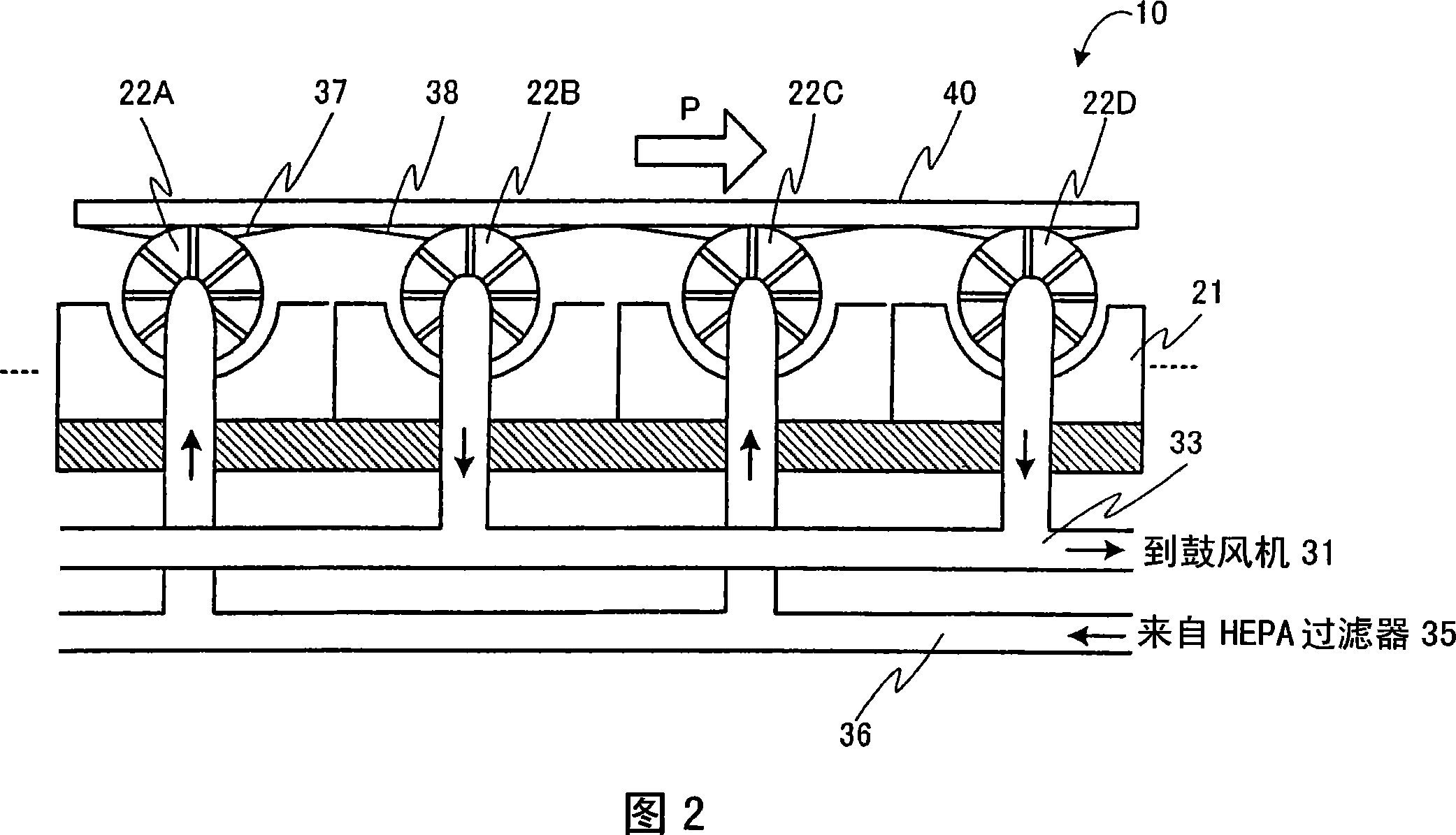

Substrate transportation method and apparatus

InactiveCN101074069AEfficient removalSimple structureSemiconductor/solid-state device manufacturingCharge manipulationForeign matterTransport engineering

Owner:NEC CORP

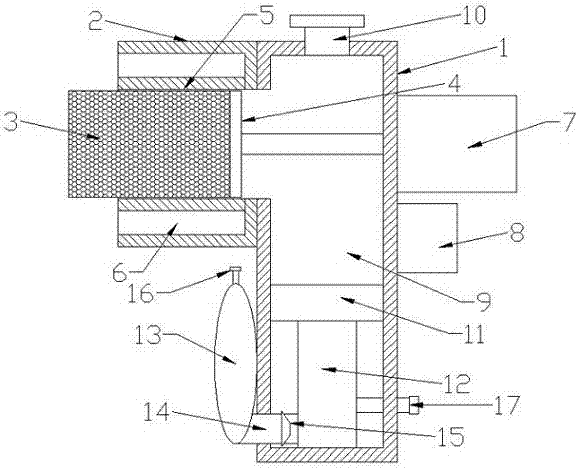

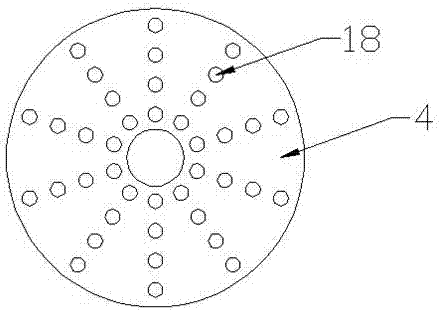

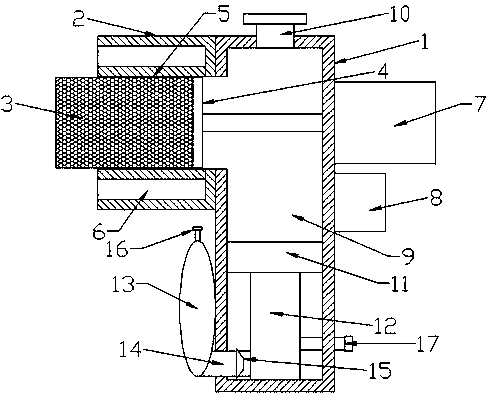

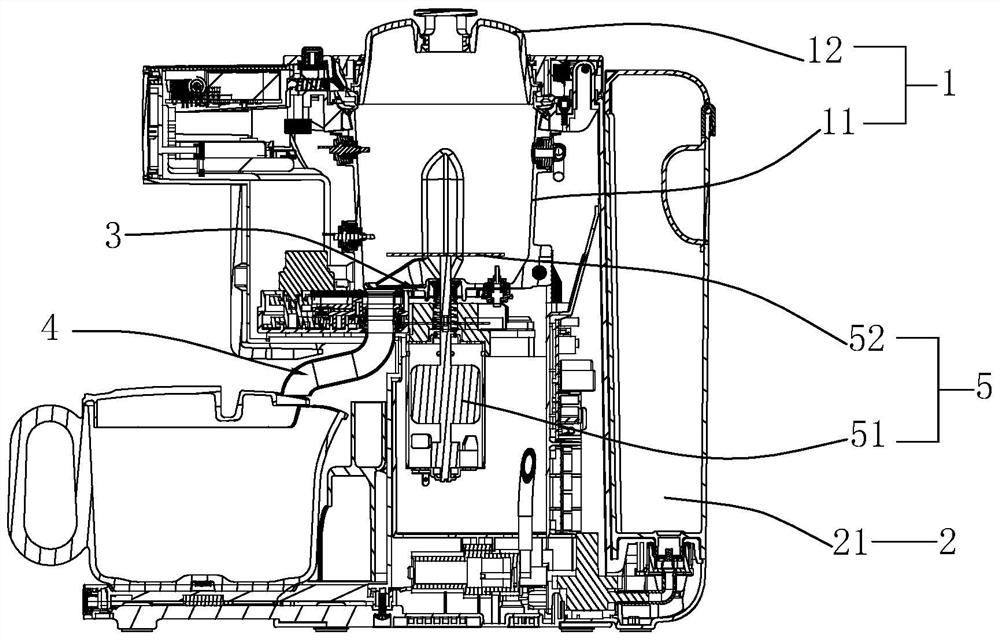

Home appliance cleaning device

InactiveCN107361708AAvoid enteringAvoid re-adhesionCarpet cleanersFloor cleanersHome appliancePiston

The invention discloses a household appliance cleaning device, which comprises a casing, a cleaning cover, a wiping sponge and a motor; the cleaning cover is fixed on the upper end of the casing, and a sponge cavity and a dust suction cavity in a horizontal direction are arranged in the cleaning cover; the sponge cavity is provided with There is a turntable, and there are several seepage holes evenly opening through the turntable on the turntable, and a wiping sponge is fixedly installed on the left side of the turntable, and the output shaft of the motor extends into the casing and is fixedly connected to the turntable; A fan is connected through the pipeline; a piston is slidably arranged in the water cavity, a pushing air bag is arranged under the piston, and an extruding air bag is connected to the outer end of the connecting pipe. In the present invention, the provided wiping sponge rotates under the drive of the motor to clean and wipe the surface of the electrical appliances, which has high wiping efficiency and saves cleaning time, and the cleaning water is infiltrated into the sponge by manual extrusion, without the need for more water to be leached out , to protect the appliance itself, and prevent the cleaning water from entering the inside of the appliance.

Owner:盐城市净博士机械有限公司

Treatment method of circulating water with leaking oil

ActiveCN102730868AEasy to controlAvoid re-adhesionFatty/oily/floating substances removal devicesMultistage water/sewage treatmentCarboxylic acidPollution

The invention provides a treatment method of circulating water with leaking oil. The method comprises the following steps: a) adding an oxidation-type bactericide and an optional glutaraldehyde; b) adding a phosphorus free corrosion and scale inhibitor containing polyepoxysuccinic acid or polyaspartic acid, at least one organic carboxylic acid polymer, an optional copper corrosion inhibitor and an optional zinc salt; and c) adding a quaternary ammonium salt-type cationic surfactant and an optional polysorbate nonionic surfactant. The method of the invention can carry out oil removal and microbial slime stripping on equipment in a circulating water system by one time, without mass pollution discharge.

Owner:CHINA PETROLEUM & CHEM CORP +1

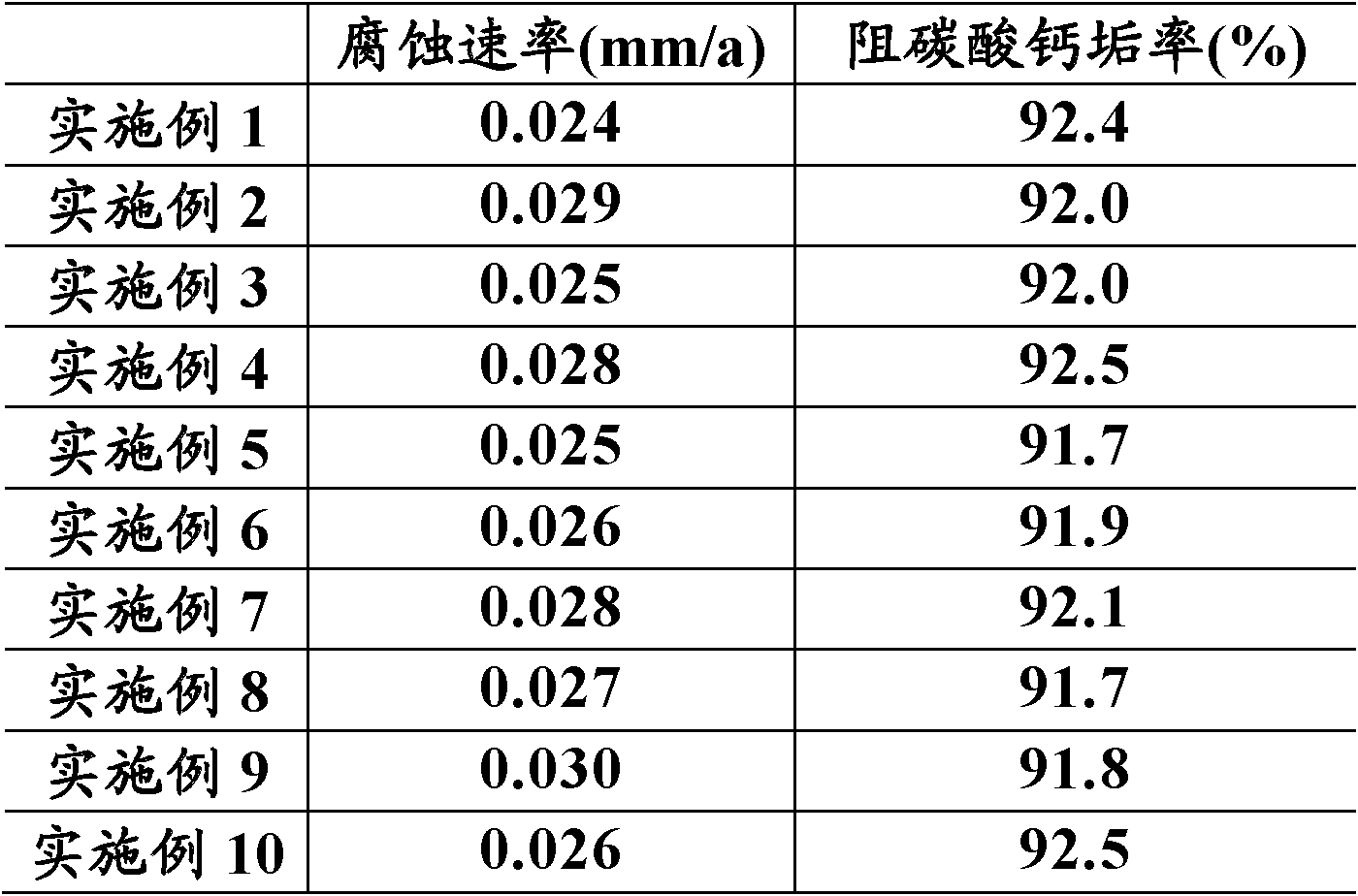

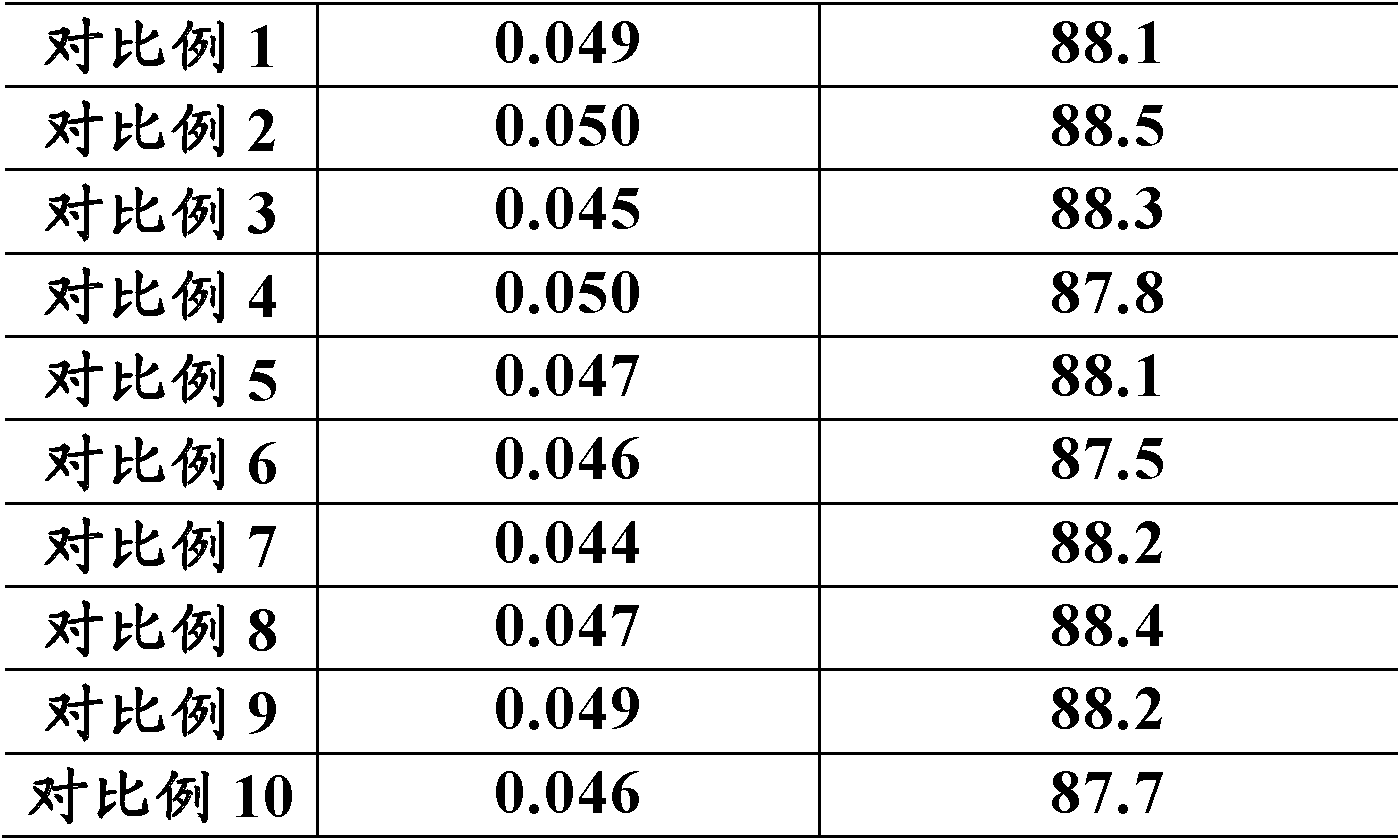

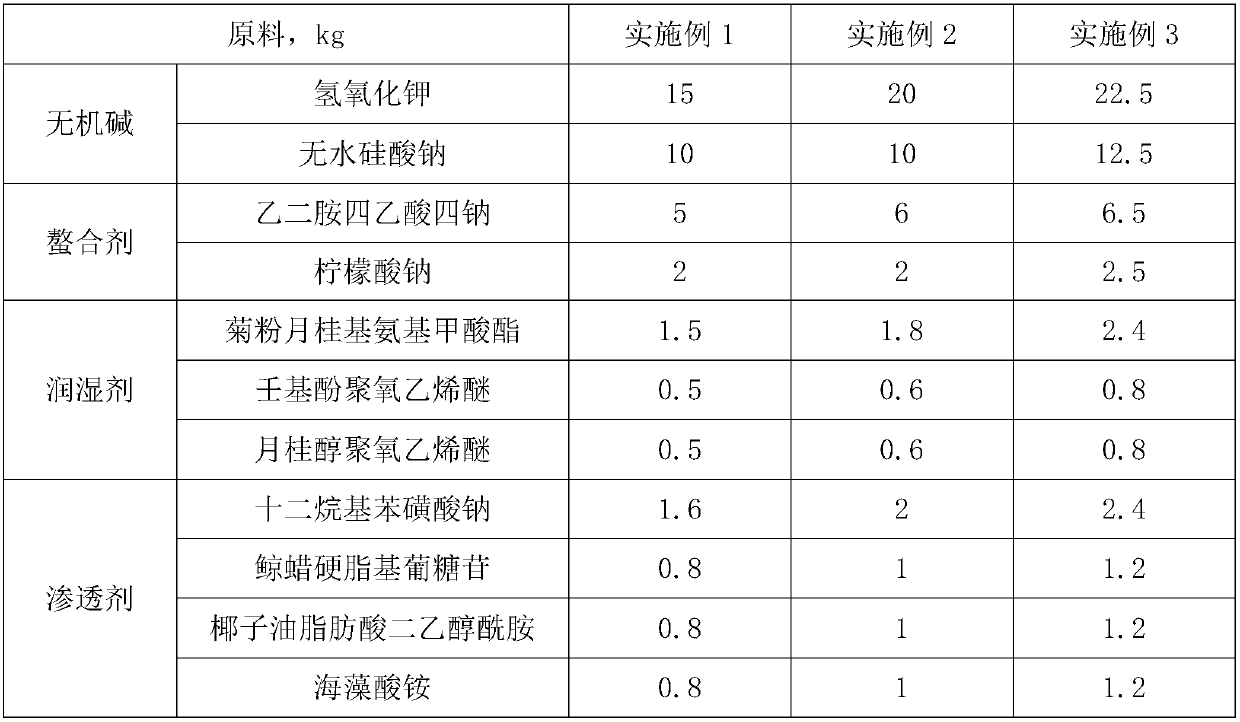

Glass detergent of cover plate glass and preparation method thereof

ActiveCN109576084AQuick wetEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPotassium hydroxideSolvent

The invention discloses a glass detergent for cover plate glass and a preparation method thereof, which belongs to the technical field of glass detergent. According to a key point of the technical scheme, the glass detergent for cover plate glass comprises the following components in parts by weight: 25 to 35 parts of inorganic alkali, 7 to 9 parts of chelating agent, and 4 to 6 parts of cosolvent, 4 to 6 parts of penetrant, 2 to 4 parts of wetting agent, 1 to 2 parts of antistatic agent, and 60 to 70 parts of water, wherein the inorganic alkali comprises potassium hydroxide and anhydrous sodium silicate in a weight ratio of (1.5 to 2): 1; and the chelating agent comprises ethylene diamine tetraacetic acid tetrasodium and sodium citrate in a weight ratio of (2.5 to 3): 1. According to theglass detergent of the cover plate glass, by virtue of the cooperation of the penetrant and wetting agent, a polishing solution on the surface of the glass can be quickly wetted, and the adhesion force between the polishing solution and the glass can be reduced; and metal ions on the surface of the glass can be wrapped and dissolved in water by virtue of the chelating agent, so that a purpose forefficiently cleaning the glass can be achieved.

Owner:深圳润泰新材料科技有限公司

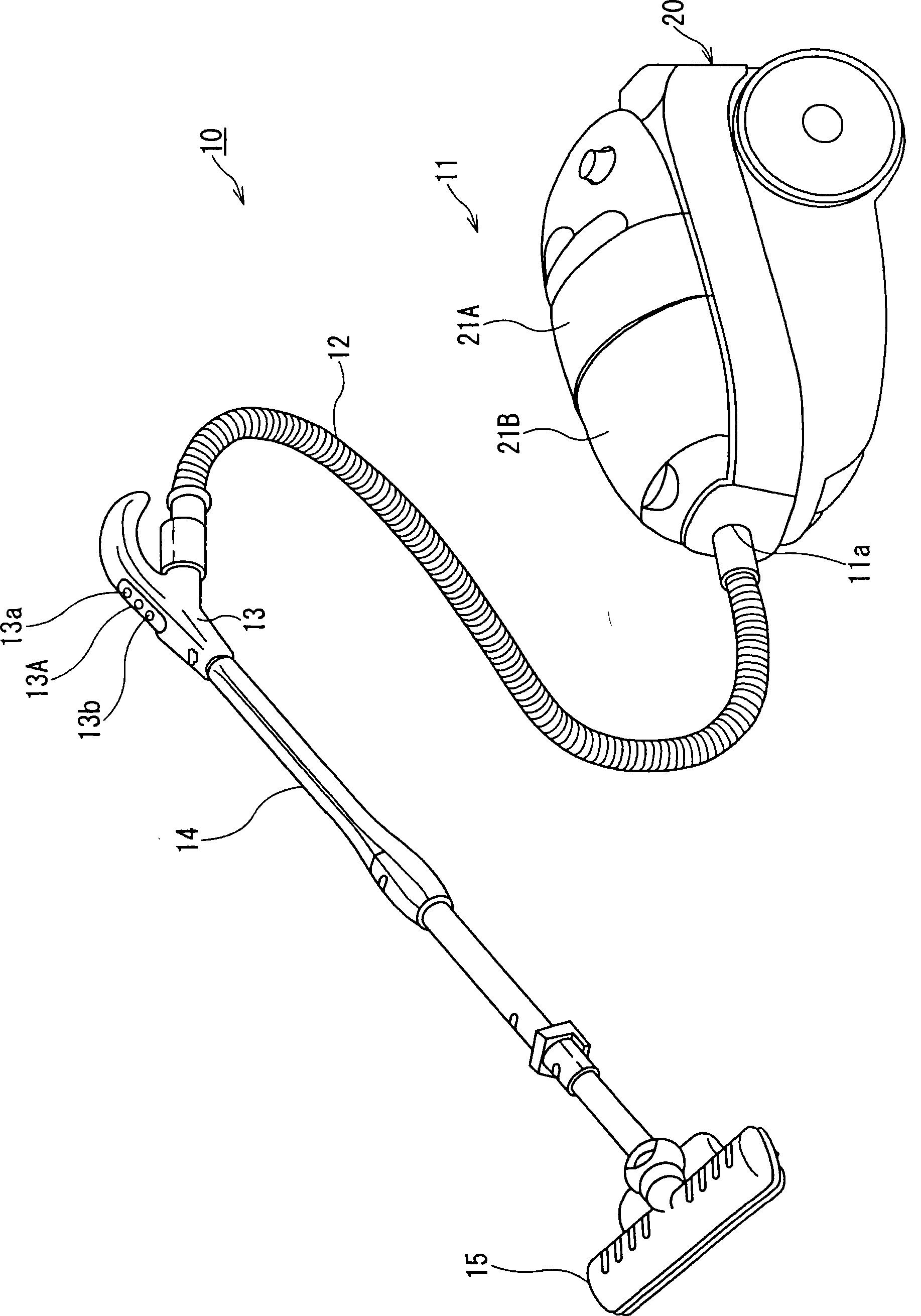

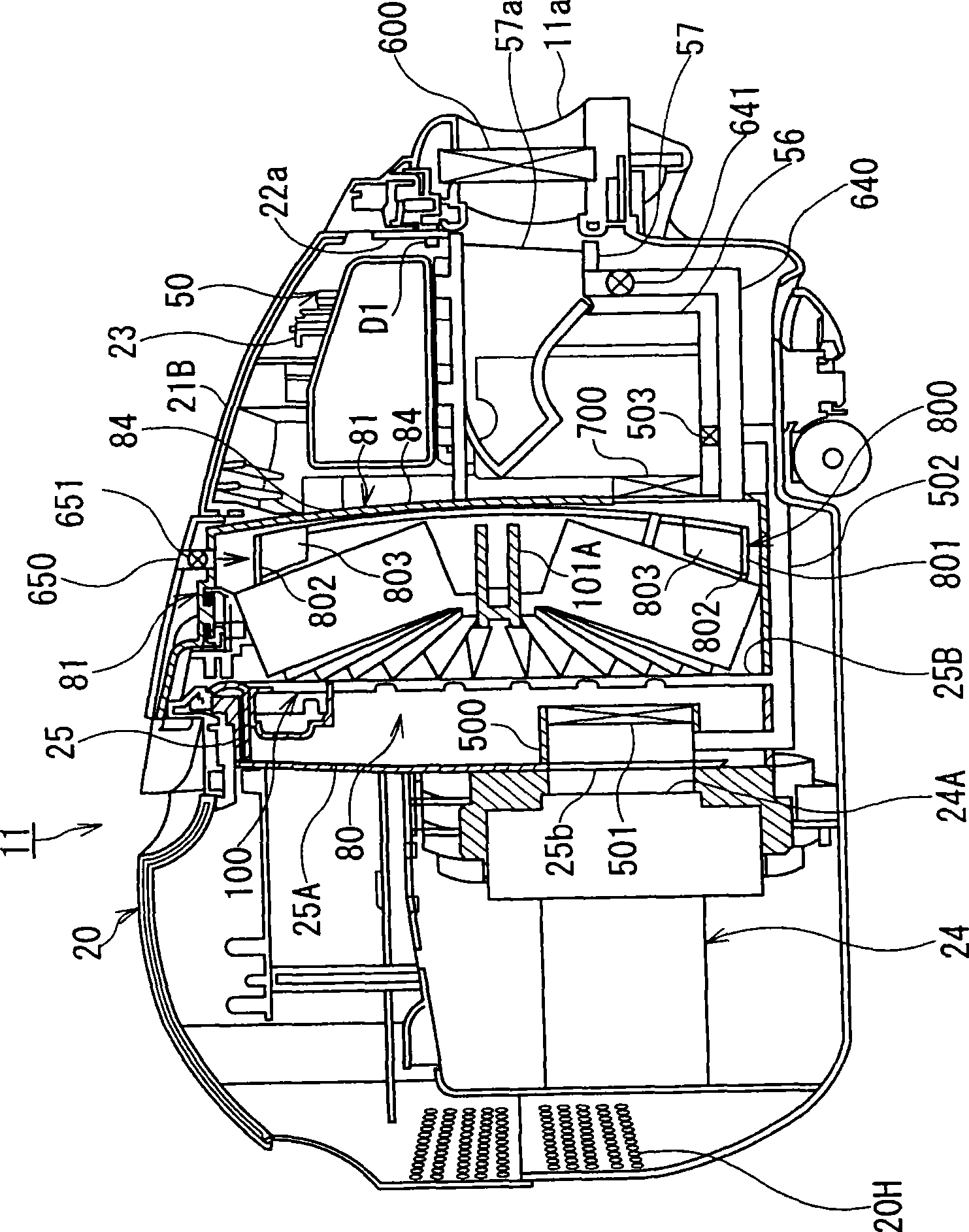

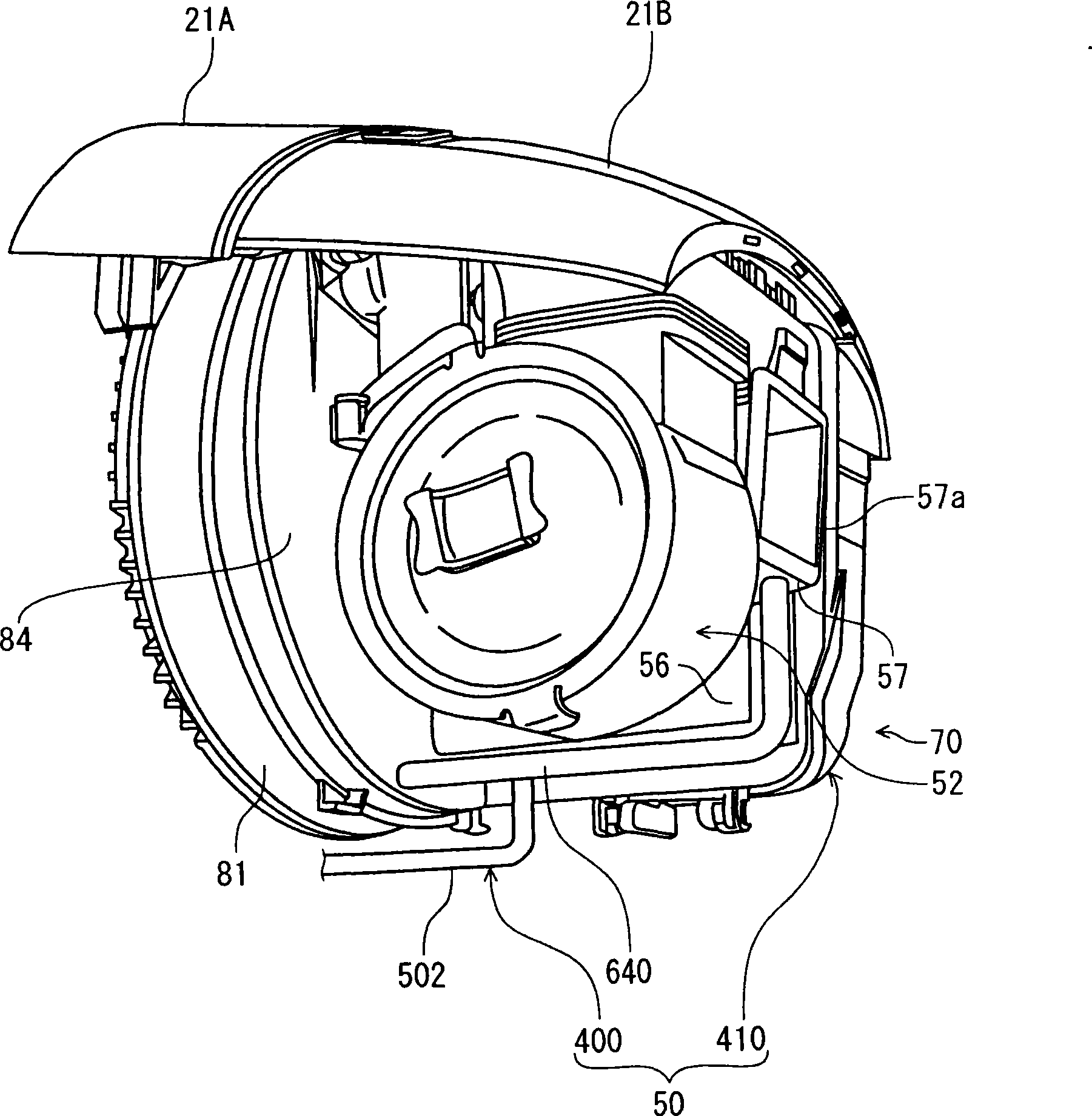

Vacuum cleaner

InactiveCN101466296AAvoid re-adhesionCleaning filter meansSuction filtersVacuum cleanerWaste management

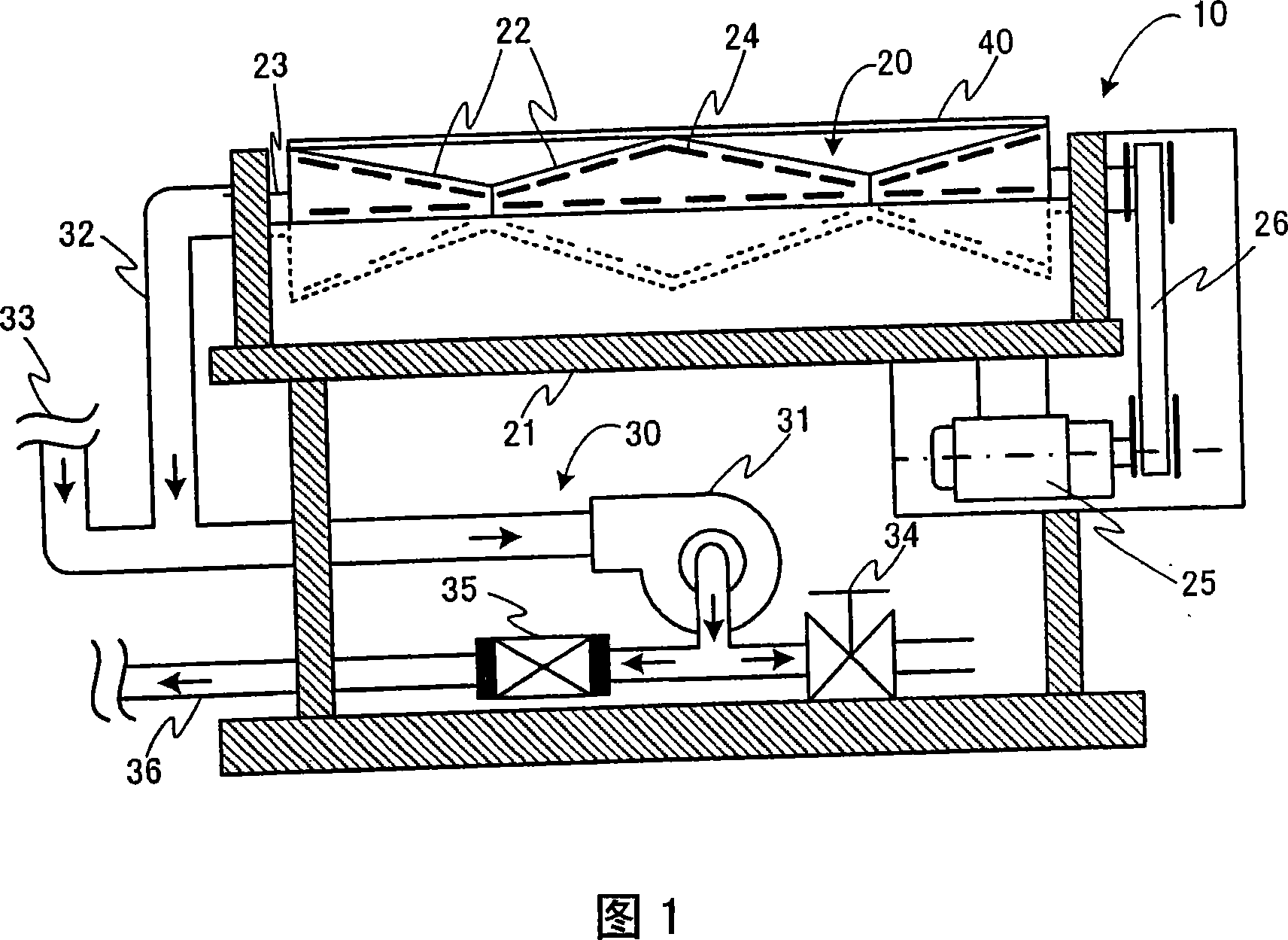

A vacuum cleaner has an electric blower (24) for causing dust and dirt to be sucked from a suction-connection port (57a), a first dust and dirt separator for separating from each other the dust / dirt and air sucked into the suction-connection port (57a), and a pleated filter (104) for separating from each other the dust / dirt and air passing through the first dust and dirt separator. The vacuum cleaner further has an outside air introducing air passage tube (650) for introducing the outside air to the upstream side of the pleated filter (104), a rotating fan (800) for removing, by the introduced outside air, the dust and dirt adhered to the pleated filter (104), and a return air passage (640) for returning, by the introduced outside air, the dust and dirt removed by the rotating fan (800) to the upstream side of the first dust and dirt separator.

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP

Treatment method of circulating water with leaking oil

ActiveCN102730872AEasy to controlAvoid re-adhesionScale removal and water softeningMultistage water/sewage treatmentCarboxylic acidPollution

The invention provides a treatment method of circulating water with leaking oil. The method comprises the following steps: a) adding an oxidation-type bactericide and an optional glutaraldehyde; b) adding a phosphorus free corrosion and scale inhibitor containing polyepoxysuccinic acid or polyaspartic acid, at least one organic carboxylic acid polymer, an optional copper corrosion inhibitor and an optional zinc salt; and c) adding a long-chain alkylaryl sulfonate anionic surfactant and an optional polyoxyethylene-type nonionic surfactant. The method of the invention can carry out oil removal and microbial slime stripping on equipment in a circulating water system by one time, without mass pollution discharge.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating circulating water having wax oil leaked therein

ActiveCN102476874AImprove solubilityEasy to controlMultistage water/sewage treatmentWater/sewage treatment using germicide/oligodynamic-processWaxPolyethylene oxide

The invention provides a method for treating circulating water having wax oil leaked therein. The method comprises a) adding an oxidation-type bactericide; b) adding an anti-scale corrosion inhibitor which contains at least one organic phosphonic acid, at least one organic carboxylic acid polymer, an optional copper material corrosion inhibitor and an optional zinc salt; c) adding at least one quaternary ammonium salt type wax oil emulsifier; and d) adding at least one polyethylene oxide non-ionic surfactant. The inventive method can remove oil and detach slime from equipment of a circulating water system in one step, without requiring discharge of a large amount of sewage.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device for cleaning electric appliances

InactiveCN107583897AAvoid enteringAvoid re-adhesionDirt cleaningCleaning using toolsElectric machineryEngineering

The invention discloses a device for cleaning electric appliances. The device comprises an outer shell, a cleaning cover, a wiping sponge and a motor, wherein the cleaning cover is fixed at the upperend of the outer shell; a sponge chamber and a dust-collecting chamber along the horizontal direction are arranged in the cleaning cover; a turntable is arranged in the sponge chamber; a plurality ofwater-permeating holes penetrating through the turntable are uniformly formed in the turntable; the wiping sponge is fixedly arranged on the left side of the turntable; an output shaft of the motor isinserted into the outer shell and is fixedly connected with the turntable; a fan is jointed in the dust-collecting chamber through a pipeline; a piston is arranged in a water chamber in a sliding form; a pushing airbag is arranged under the piston; an extruding airbag is connected with the outer end of a connecting pipe. According to the invention, the arranged wiping sponge is rotated under thedriving of the motor so as to clean and wipe the surfaces of the electric appliances; the wiping efficiency is increased; the cleaning time is saved; the cleaning water permeates into the sponge in the manner of manually extruding; much water leaching is not required; the electric appliances are protected; the cleaning water is prevented from entering into the electric appliances.

Owner:束春花

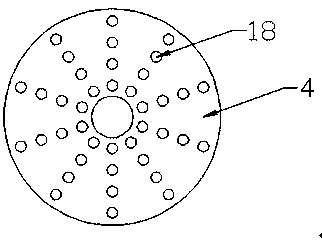

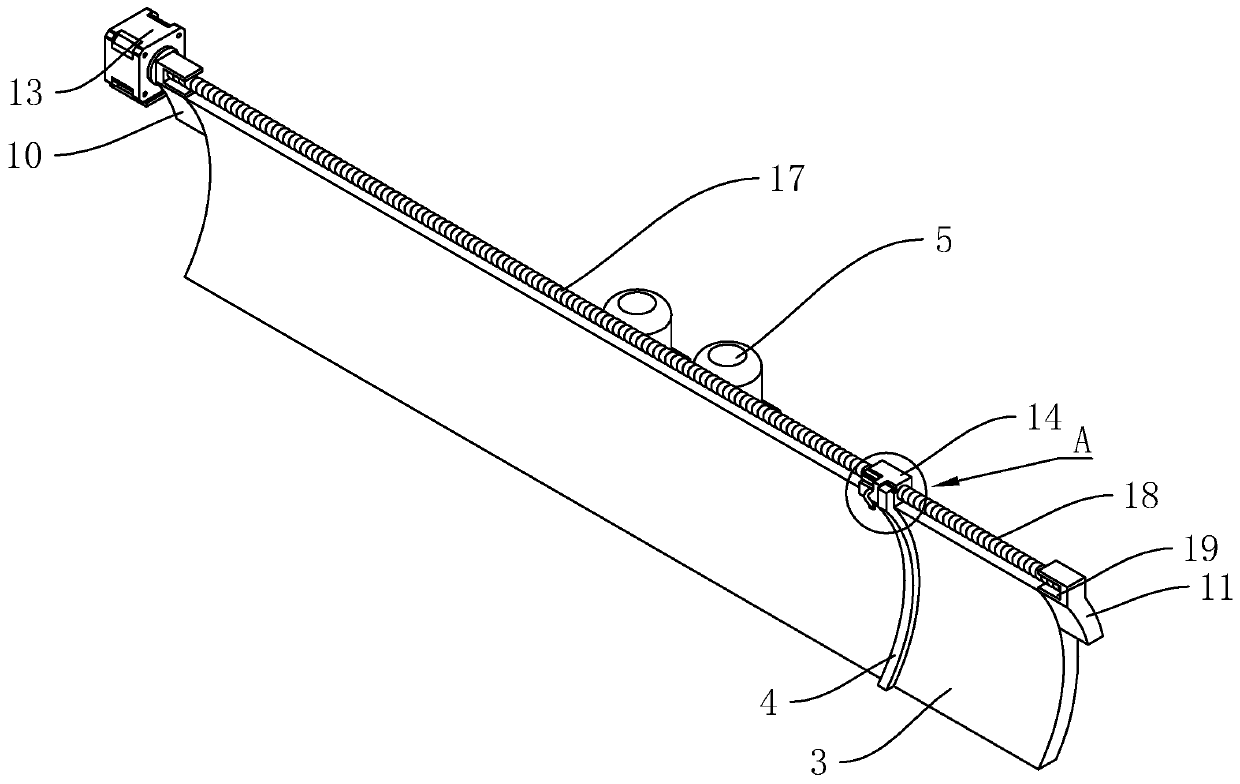

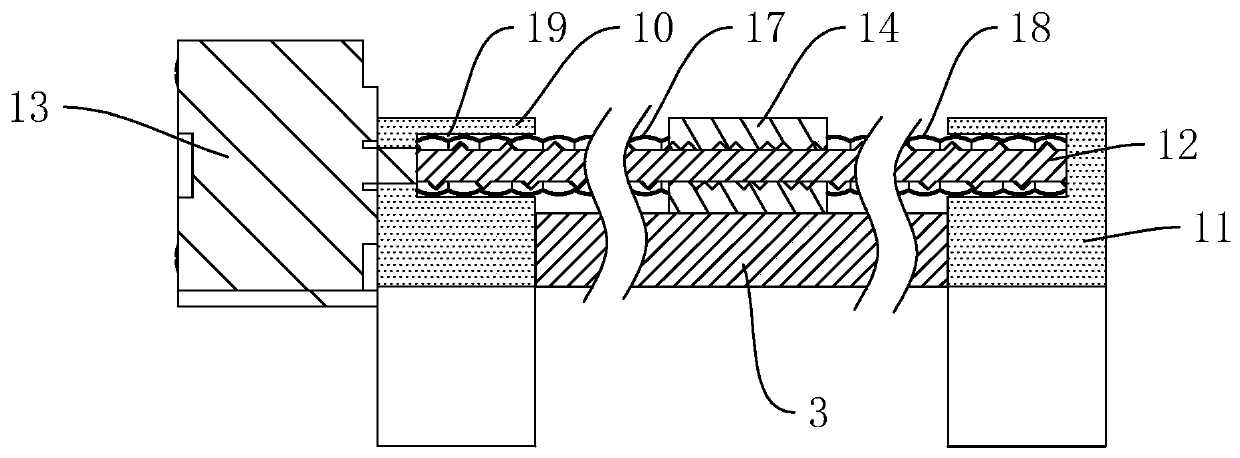

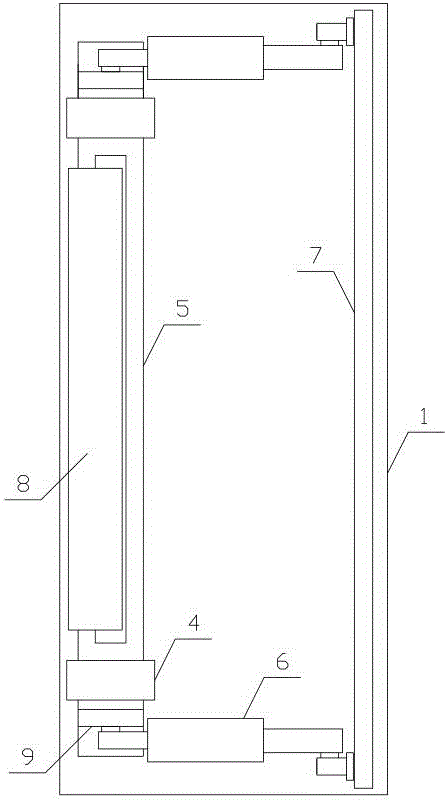

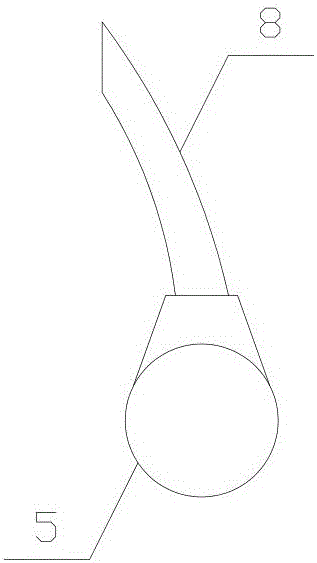

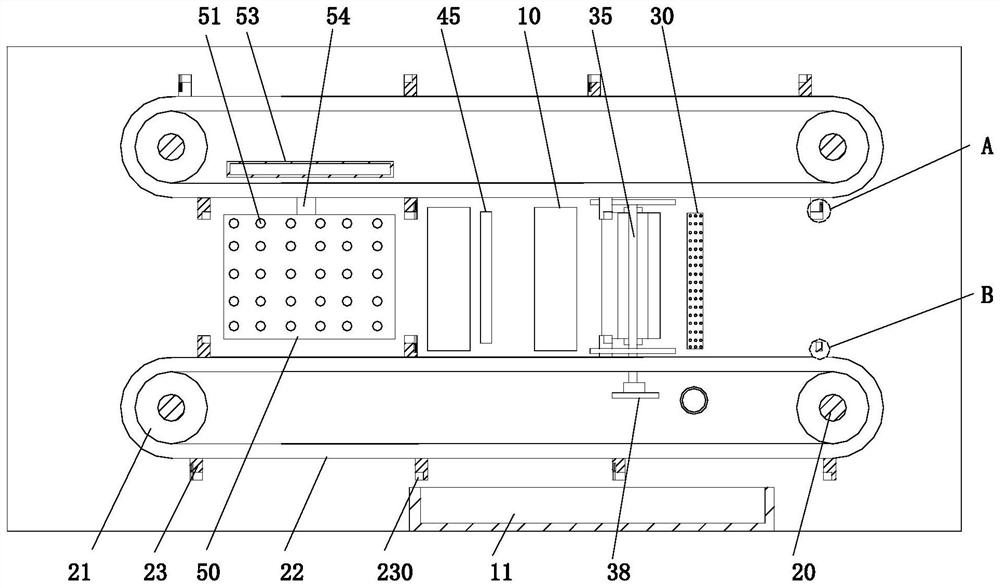

Land leveller capable of automatically cleaning shovel blade

InactiveCN110714496AAvoid stickingAvoid re-adhesionMechanical machines/dredgersVertical planeReciprocating motion

The invention discloses a land leveller capable of automatically cleaning a shovel blade, and relates to the technical field of leveling equipment. According to the technical scheme, the land levellercapable of automatically cleaning the shovel blade is characterized by comprising a vehicle body and a mounting arm connected with the vehicle body; the rectangular shovel blade is mounted on the mounting arm, a scraper is arranged at one end of the shovel blade, and a driving assembly for driving the scraper to move in a reciprocating manner in the length direction of the shovel blade to scrap off mud adhering to the surface of the shovel blade is arranged on the shovel blade. Linear vibration motors for driving the shovel blade to vibrate are arranged on the shovel blade. The vibration direction of the shovel blade is perpendicular to the vertical plane of the shovel blade. The land leveller has the beneficial effects that the mud on the shovel blade can be cleaned automatically, the cleaning effect is good, and the land leveling efficiency is improved.

Owner:中煤东方生态建设集团有限公司

Treatment method of circulating water with leaking wax oil

ActiveCN102730866AReduce sewageIncrease the concentration factorFatty/oily/floating substances removal devicesMultistage water/sewage treatmentWaxChemistry

The invention provides a treatment method of circulating water with leaking wax oil. The method comprises the following steps: a) adding an oxidation-type bactericide; b) adding a corrosion and scale inhibitor containing at least one organic phosphonic acid, at least one organic carboxylic acid polymer, an optional copper corrosion inhibitor agent and an optional zinc salt; and c) adding at least one polysorbate as a wax oil emulsifier; and d ) adding at least one polyoxyethylene nonionic surfactant. The method of the invention can carry out oil removal and microbial slime stripping on equipment in a circulating water system by one time, without mass pollution discharge.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method of circulating water with leaking oil

ActiveCN102730869AEasy to controlAvoid re-adhesionScale removal and water softeningMultistage water/sewage treatmentPhosphonium saltCarboxylic acid

The invention provides a treatment method of circulating water with leaking oil. The method comprises the following steps: a) adding an oxidation-type bactericide and an optional glutaraldehyde; b) adding a corrosion and scale inhibitor containing one of water-soluble borate, water-soluble gluconate and water-soluble silicate or a mixture of the three, at least one organic phosphonic acid, at least one organic carboxylic acid polymer, an optional copper corrosion inhibitor and an optional zinc salt; and c) adding a quaternary phosphonium salt-type cationic surfactant and a polyoxyethylene-type nonionic surfactant. The method of the invention can carry out oil removal and microbial slime stripping on equipment in a circulating water system by one time, without mass pollution discharge.

Owner:CHINA PETROLEUM & CHEM CORP +1

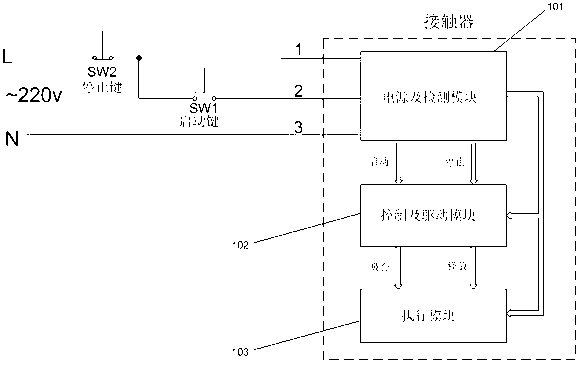

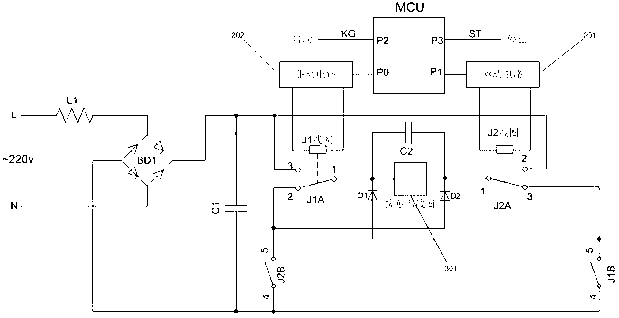

Constant-magnetic maintaining AC contactor control circuit and control method thereof

The invention discloses a constant-magnetic maintaining AC contactor control circuit and a control method thereof. The control circuit comprises a power source and detection module, a control and driver module and an execution module, wherein a three-wire system is adopted at the periphery of the control circuit; the control circuit is connected to a normally-opened start switch and a normally-closed stop switch externally; the control and driver module comprises a micro control unit (MCU), a first drive circuit, a second drive circuit, a relay coil J1 and a relay coil J2; and the execution module comprises an inductor L1, a rectifier bridge BD1, a capacitor C1, a capacitor C2, a diode D1, a diode D2, five contact terminals of the relay coil J1, five contact terminals of the relay coil J2 and a contactor coil. The control circuit provided by the invention is simple in structure, low in cost, small in work energy consumption, convenient for installation, high in safety, strong in reliability and quick in reaction speed.

Owner:沈阳欧诺尔电器有限公司

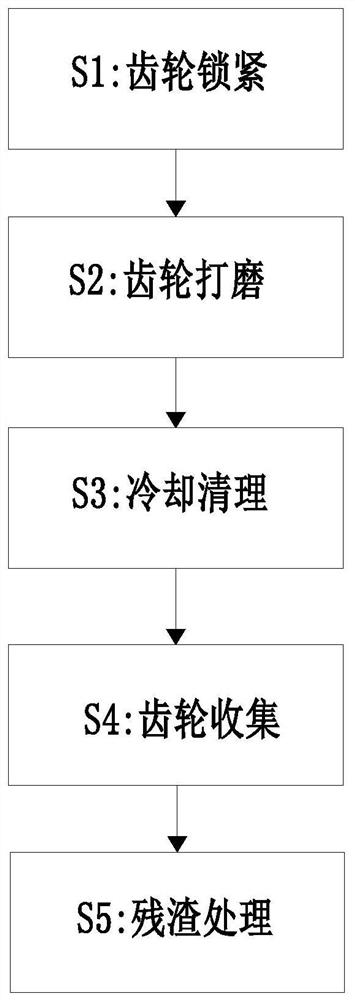

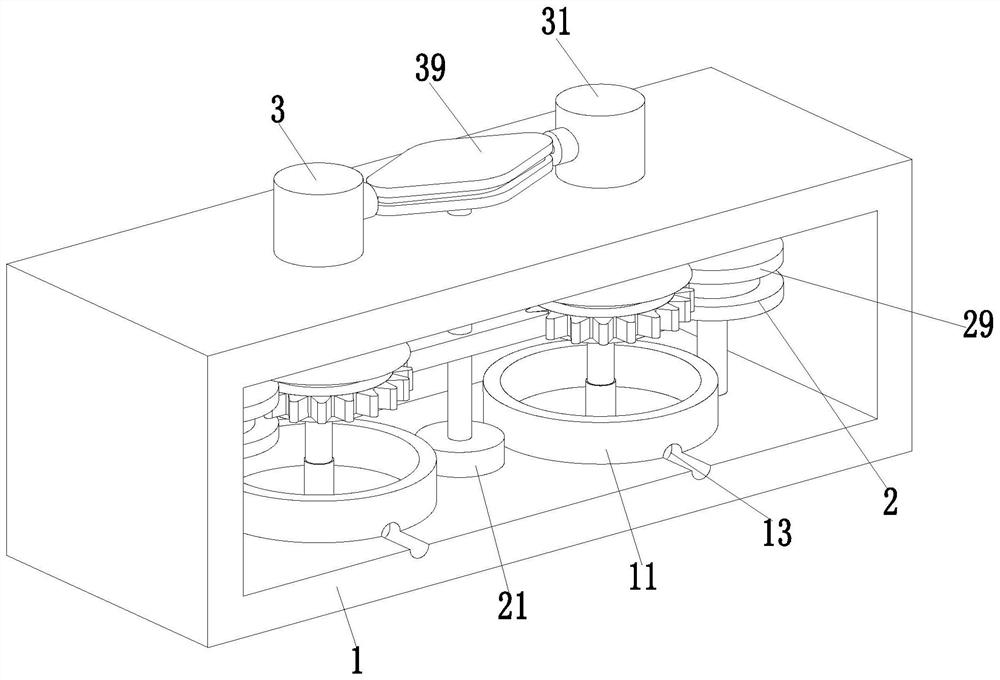

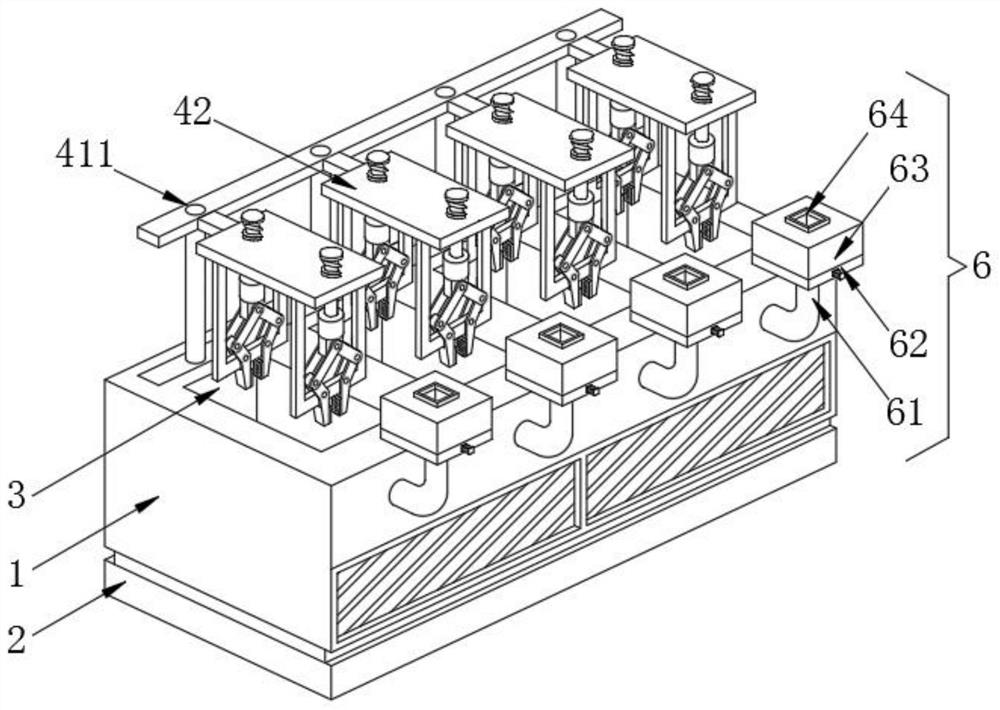

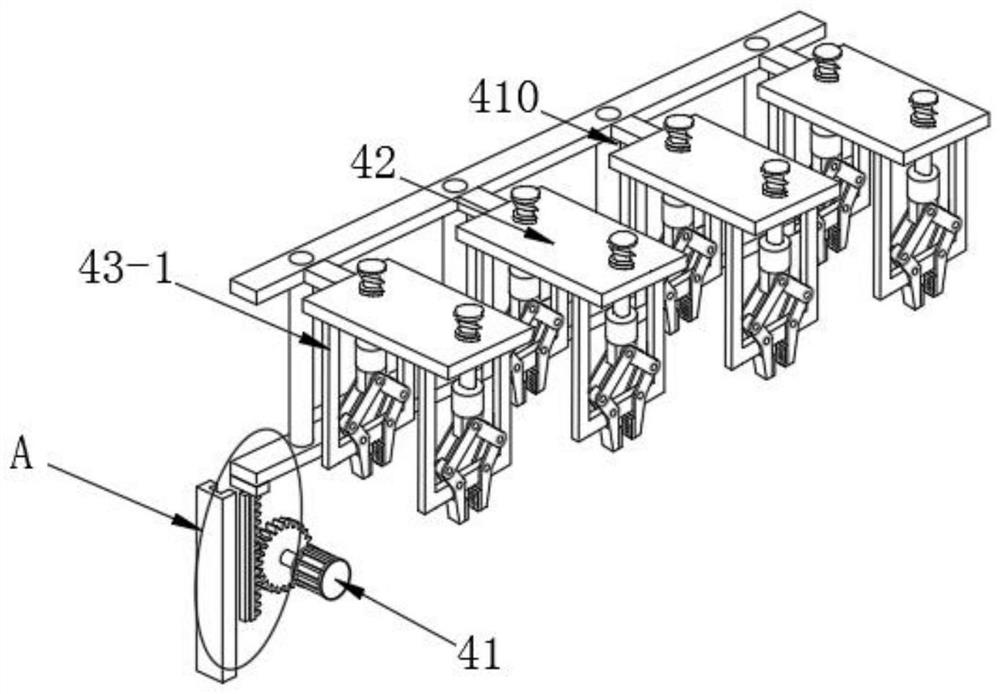

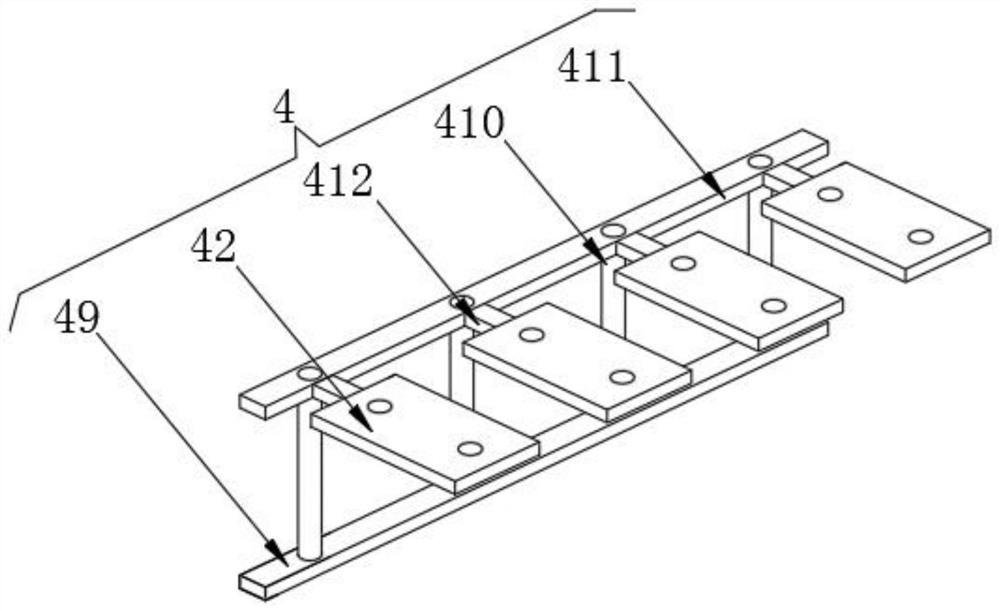

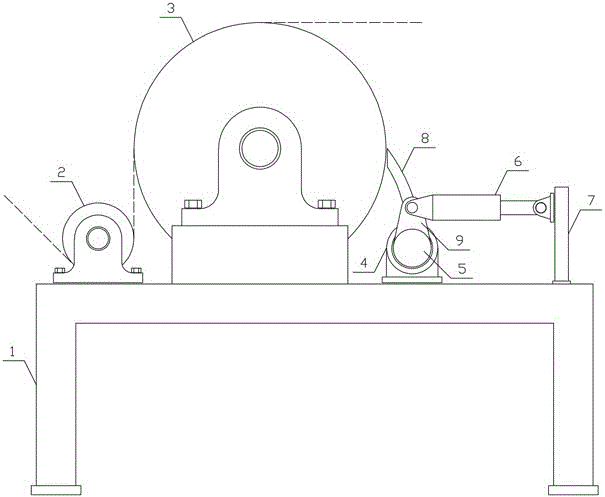

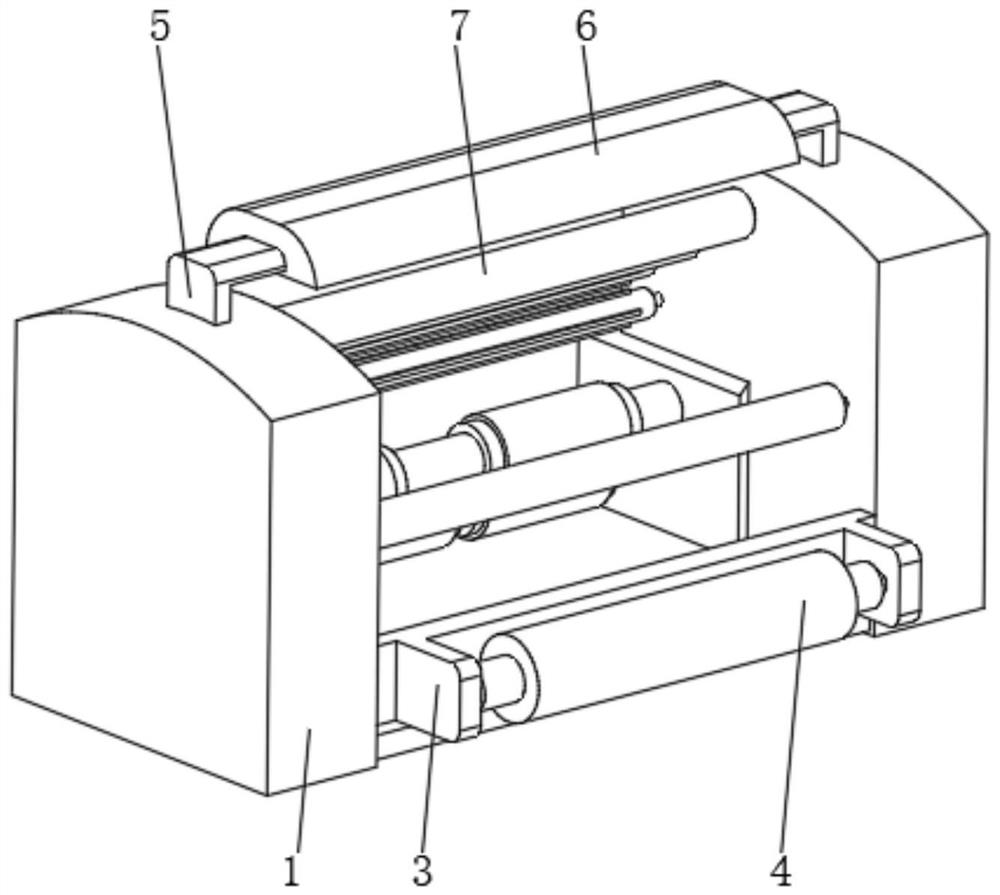

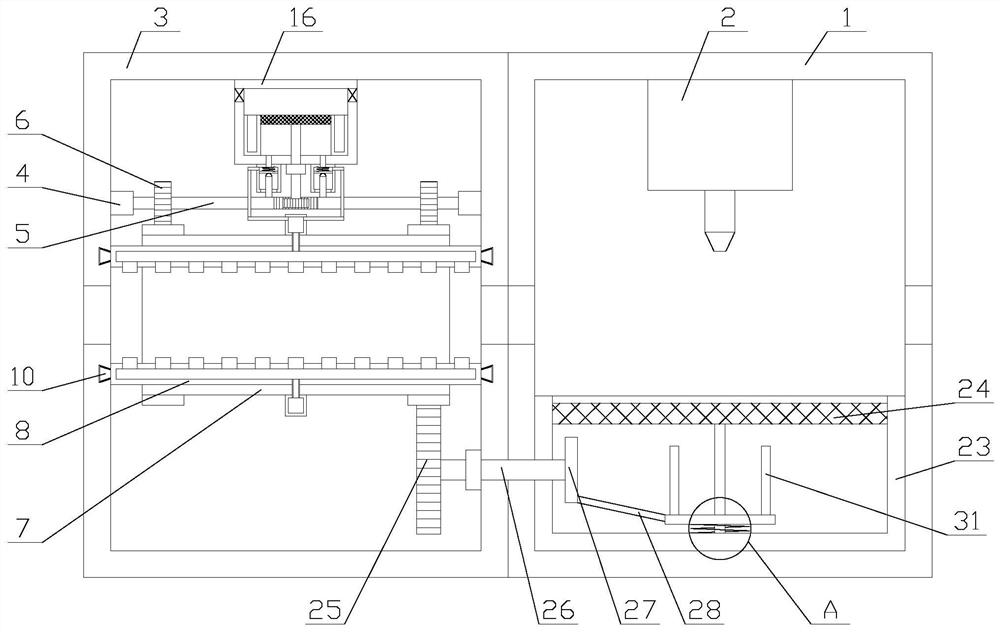

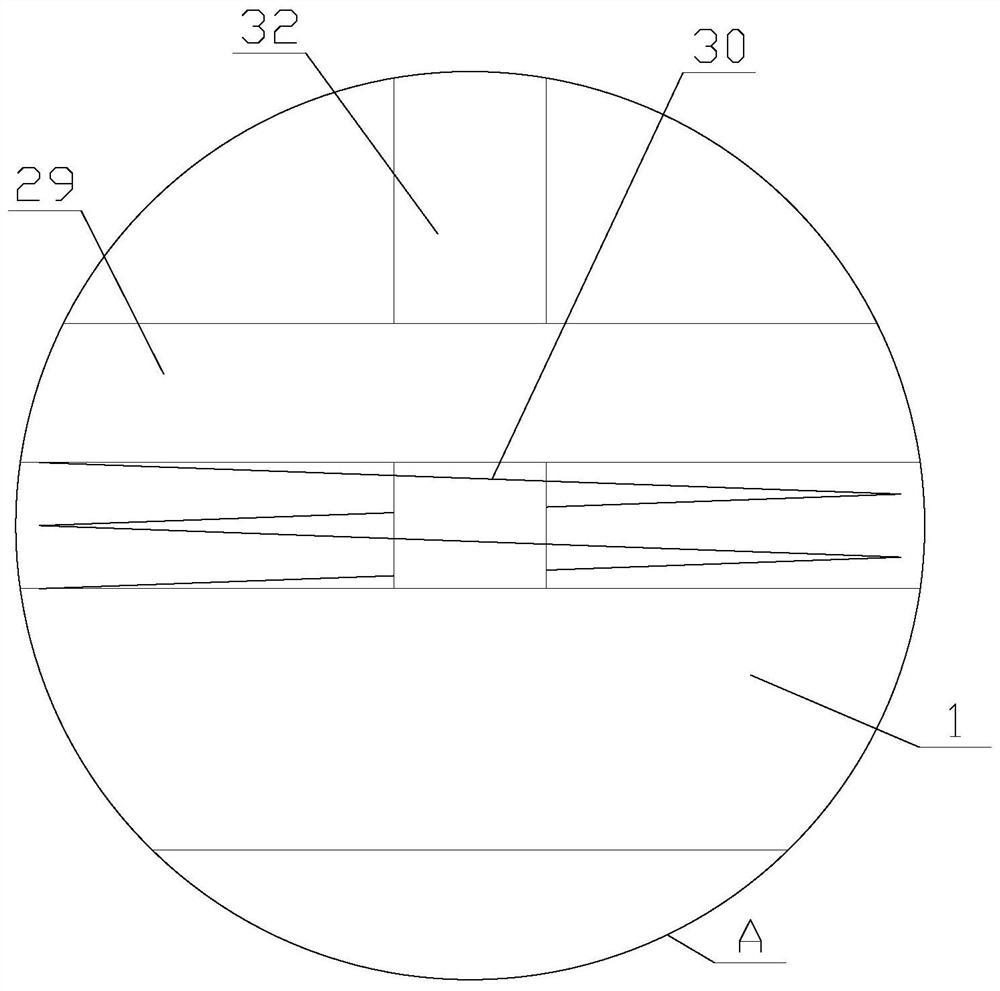

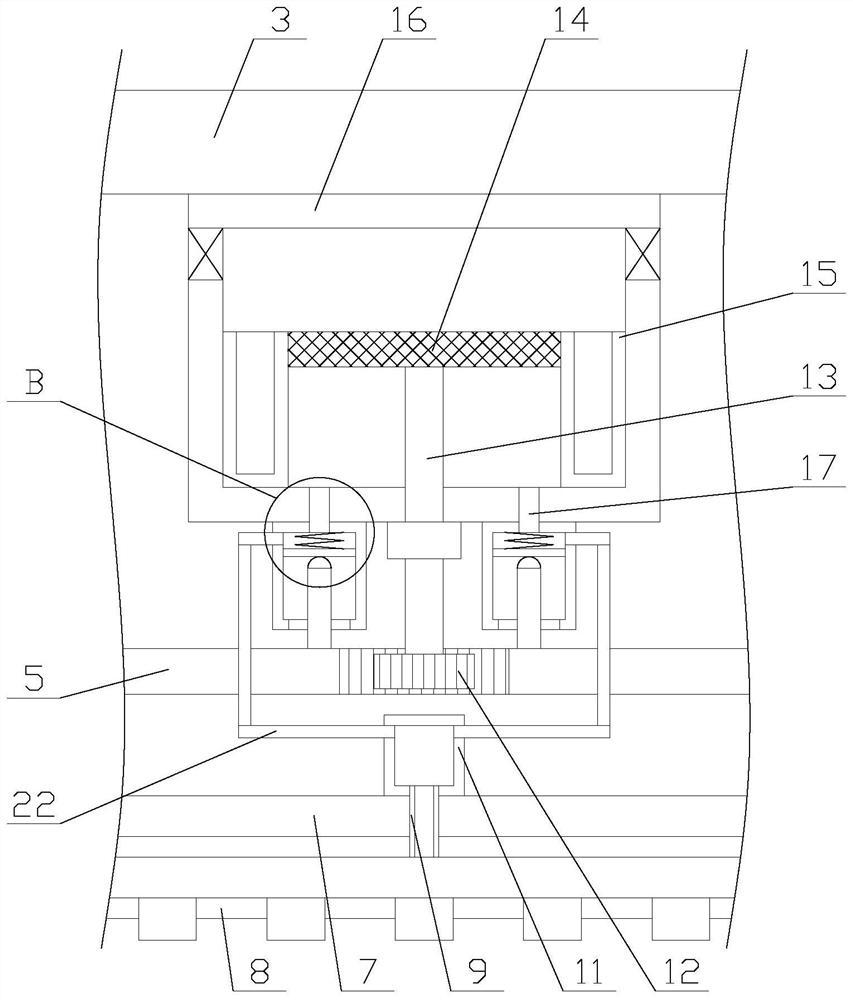

Precision gear manufacturing process

InactiveCN112518044AImprove grinding efficiencyImprove finenessGear-cutting machinesMaintainance and safety accessoriesGear driveGear wheel

The invention relates to a precision gear manufacturing process. A precision gear manufacturing device is used in the process. The precision gear manufacturing device comprises a supporting frame, a polishing mechanism and a cooling and clearing mechanism, the section of the supporting frame is of a rectangular structure, the polishing mechanism is installed in the middle of the lower end surfaceof the supporting frame, and the cooling and clearing mechanism is connected to the polishing mechanism. The cooling and clearing mechanism is installed on the supporting frame. The problems that an existing device cannot effectively polish complex notches of a gear groove, surface burrs of gear teeth cannot be removed effectively and the transmission precision of a gear is influenced can be solved. The problems that when the existing device polishes the gear, the gear cannot be cooled in time, as a result, due to too high temperature of the surface of the gear, the gear teeth are deformed, iron scrap residues generated by polishing cannot be cleared in time, as a result, the iron scrap residues adhere to the gear groove and the surfaces of the gear teeth again at high temperature, and thepolishing efficiency of the gear and precision of gear transmission are influenced can also be solved.

Owner:南京旺财办公用品有限公司

Method for processing oil leakage circulation water

ActiveCN102730875AEasy to controlAvoid re-adhesionFatty/oily/floating substances removal devicesMultistage water/sewage treatmentSludgeCarboxylic acid

The invention provides a method for processing oil leakage circulation water, which comprises the following steps: a) adding an oxidized bactericide and optional glutaraldehyde; b) adding a scale inhibition corrosion inhibitor, wherein the scale inhibition corrosion inhibitor comprises one or its mixture of water-soluble borate, water-soluble gluconate and water-soluble silicate, at least an organic carboxylic acid polymer, an optional copper material corrosion inhibitor and optional zinc salt; c) adding a long chain alkylaryl sulfonate anionic surfactant; and d) adding a polysorbate non-ionic surfactant. The method of the invention is capable of removing oil of a circulation water system and removing the microbial sludge, the method can be finished at once without discharge of large amount of sludge.

Owner:CHINA PETROLEUM & CHEM CORP +1

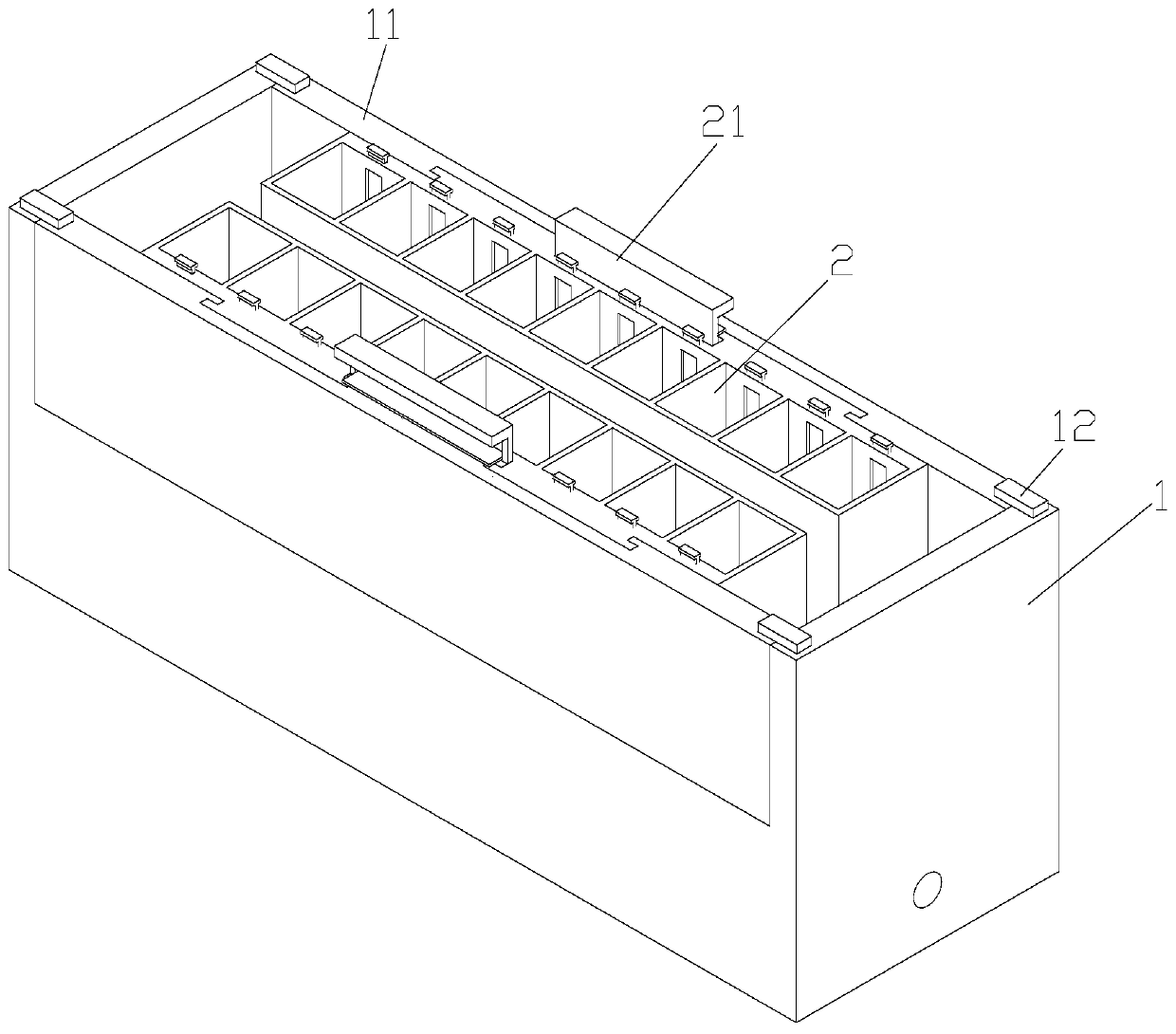

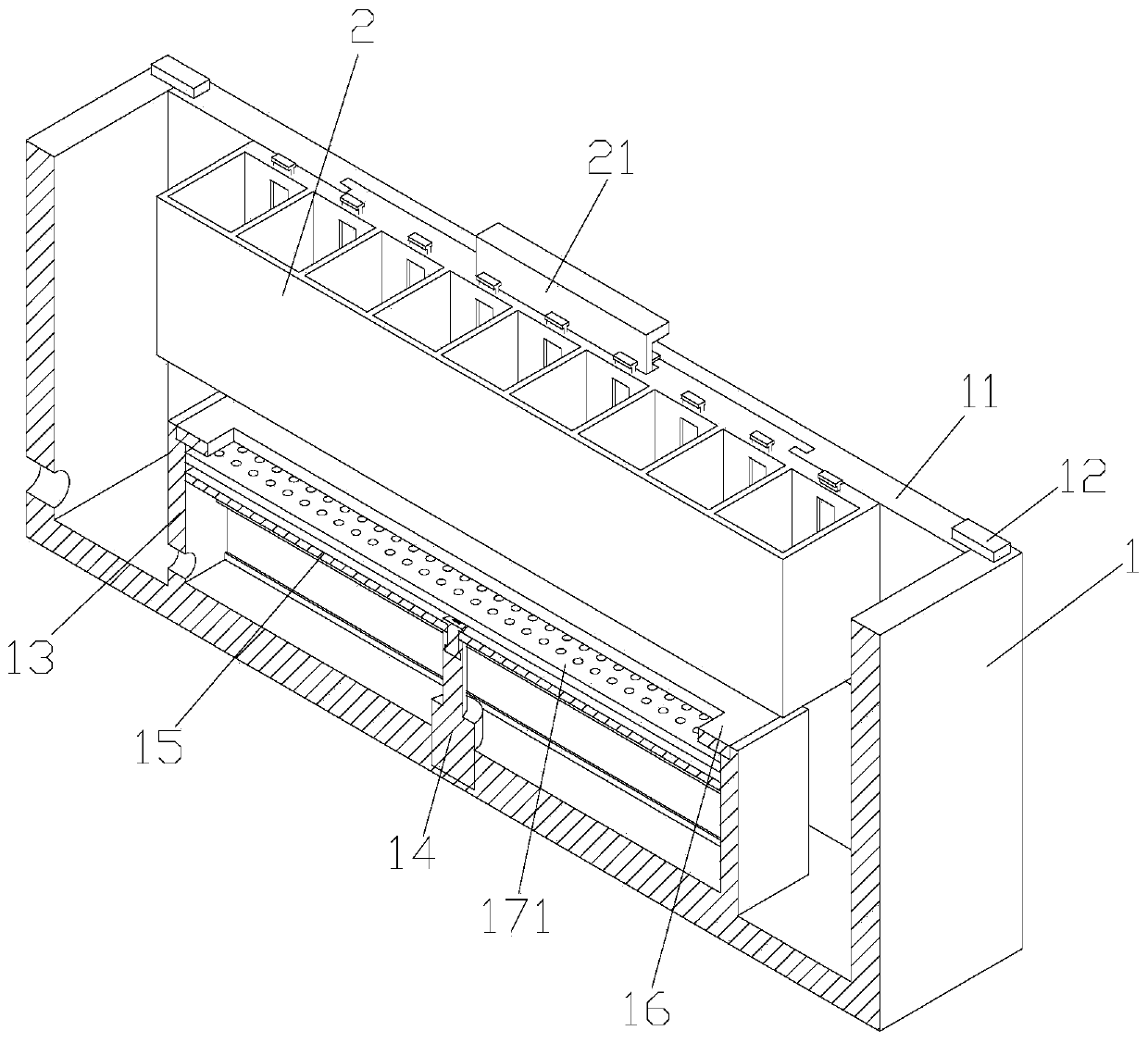

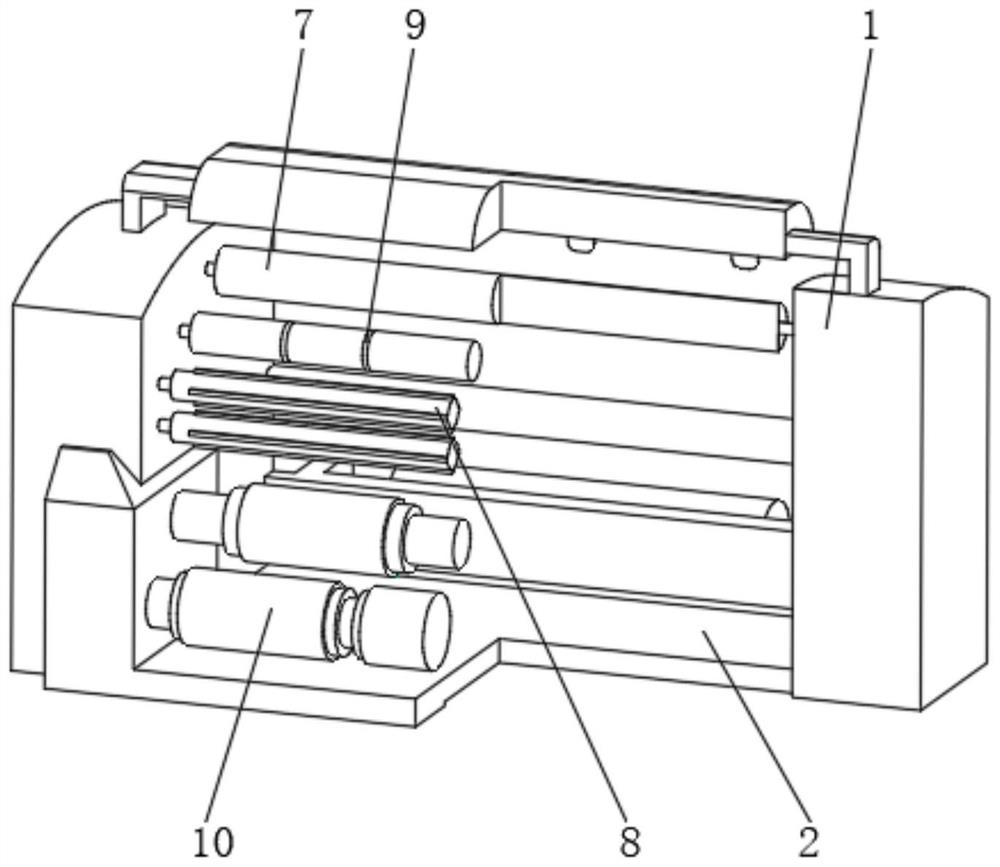

Cleaning equipment and cleaning method for reducing particles on surface

PendingCN113877875AImprove processing qualityQuality improvementSemiconductor/solid-state device manufacturingCleaning using toolsSilicon chipElectric machinery

The invention discloses cleaning equipment and a cleaning method for reducing particles on the surface of a silicon wafer. The cleaning equipment comprises a cleaning box, a base is fixedly connected to the bottom of the cleaning box, a cleaning tank is formed in the top of the cleaning box, a position adjusting mechanism is arranged on the cleaning box, a cleaning mechanism is arranged in the interior of the cleaning tank, a quantitative liquid supplementing mechanism is arranged on the exterior of the cleaning box. The invention relates to the technical field of silicon wafer cleaning. According to the cleaning equipment and the cleaning method for reducing the particles on the surface of the silicon wafer, the position adjusting mechanism and a clamping unit are arranged, a driving motor is used for driving a driving rotating shaft to rotate, in cooperation with transmission of a transmission gear and a transmission rack, a lifting plate is driven to move, meanwhile, clamping is carried out on a product by utilizing restoring force of a spring, positioning and clamping of the product are achieved, adjustment can be carried out on the height so that follow-up replacement and clamping can be facilitated, and therefore damage caused by collision to the product in the cleaning process is avoided, and the machining quality of the product is improved.

Owner:杭州中欣晶圆半导体股份有限公司

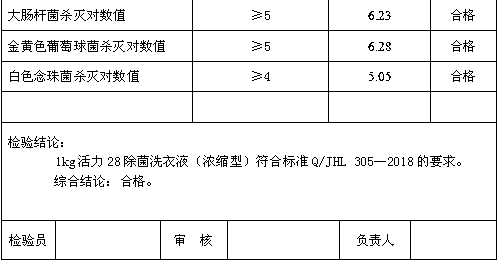

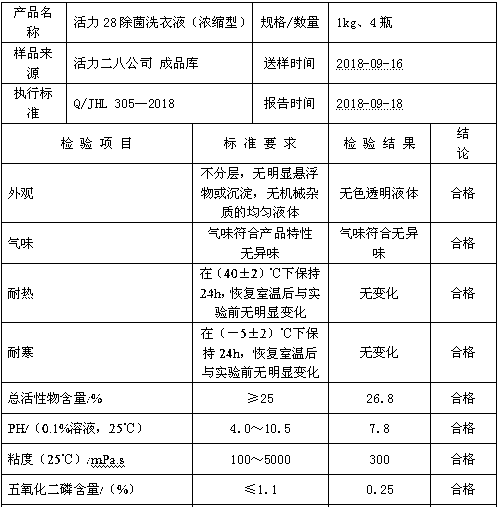

Disinfecting and sterilizing concentrated detergent containing lauryl hydroxyethyl dimethyl ammonium chloride

ActiveCN109234049ATo achieve the purpose of disinfection and sterilizationReduce surface tensionOrganic detergent compounding agentsSurface-active detergent compositionsAcetic acidOxo alcohol

The invention provides a disinfecting and sterilizing concentrated detergent containing lauryl hydroxyethyl dimethyl ammonium chloride. The disinfecting and sterilizing concentrated detergent comprises the following components in parts by weight: 2 to 5 parts of lauryl hydroxyethyl dimethyl ammonium chloride, 3 to 5 parts of polyhexamethylene guanidine, 10 to 15 parts of polyethoxylated fatty alcohol, 12 to 16 parts of Goldbert alkoxide, 10 to 12 parts of oxo-alcohol ethoxylate, 0.2 to 0.5 part of tetrasodium glutamate diacetate, 0.4 to 1 part of maleic and acylic acid copolymer, and the balance of deionized water, wherein the sum of parts by mass is 100 parts. The detergent has the advantages that by adding lauryl hydroxyethyl dimethyl ammonium chloride and polyhexamethylene guanidine, the disinfecting and sterilizing functions are realized; the cell walls with negative charges are attracted by the positive charges of cations, the cell walls and cell membranes are promoted to thoroughly deform and crack, the propagation and survival abilities of the cells are lost, and the cells die, so as to reach the disinfection and sterilization purposes.

Owner:湖北活力集团有限公司

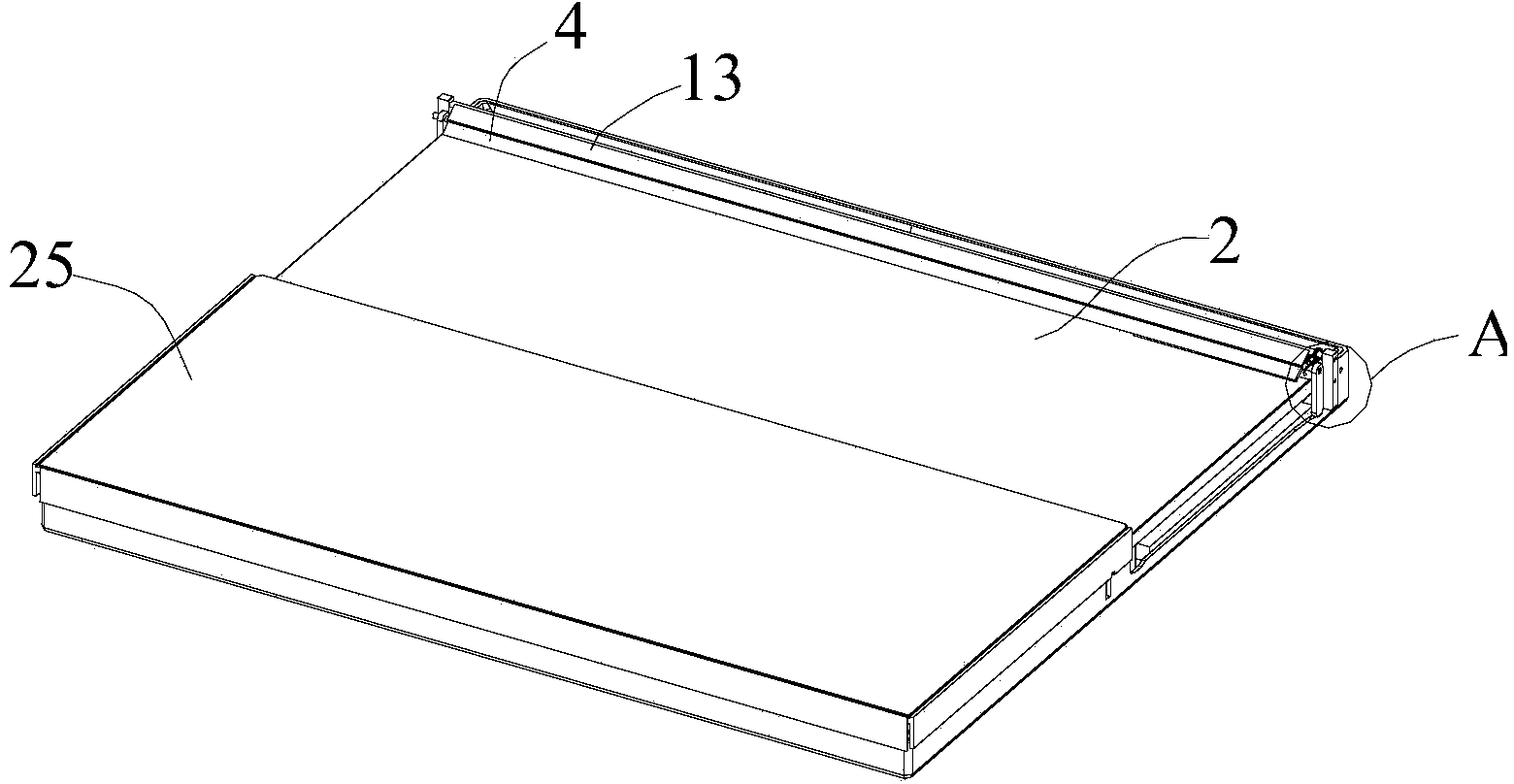

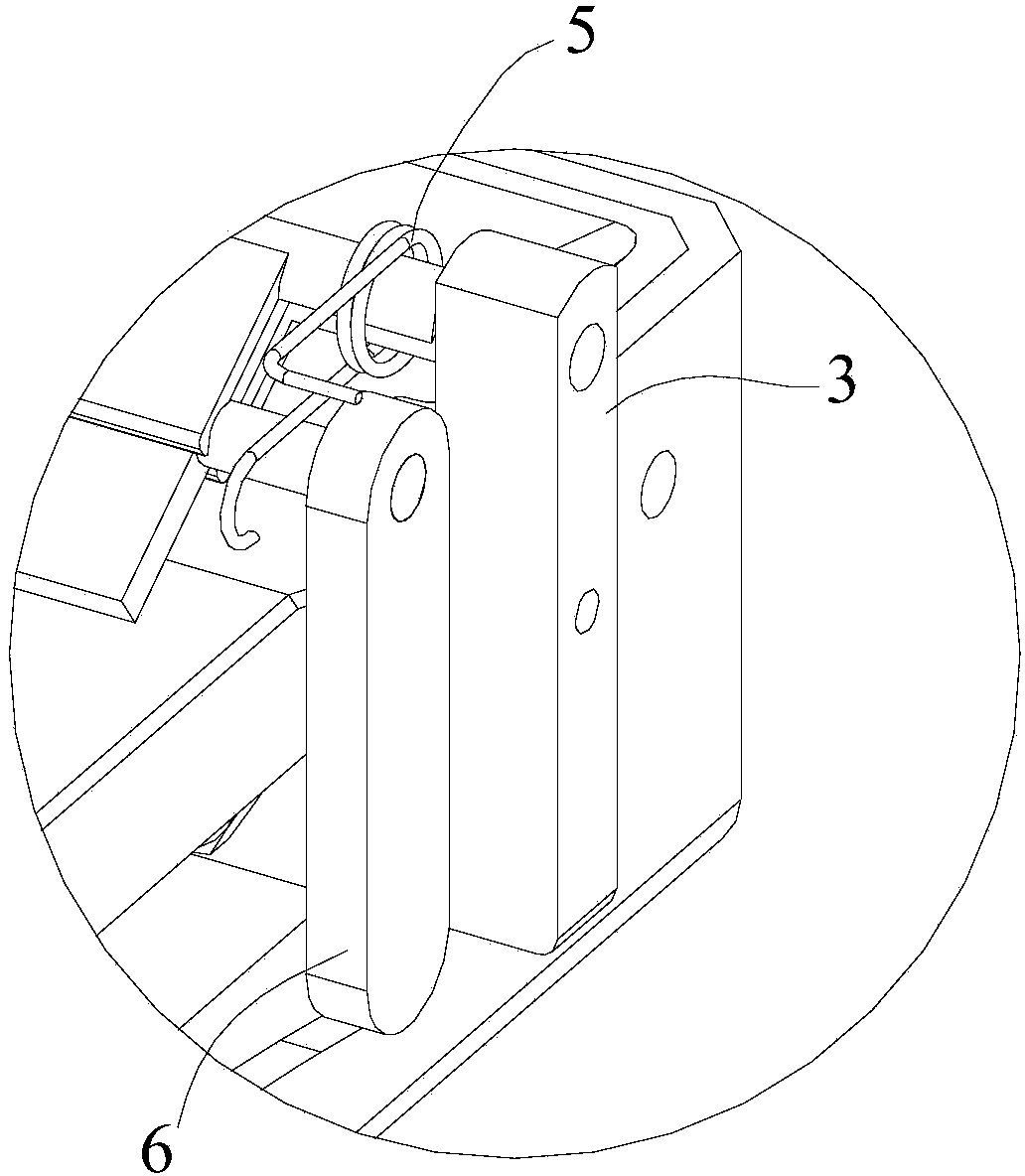

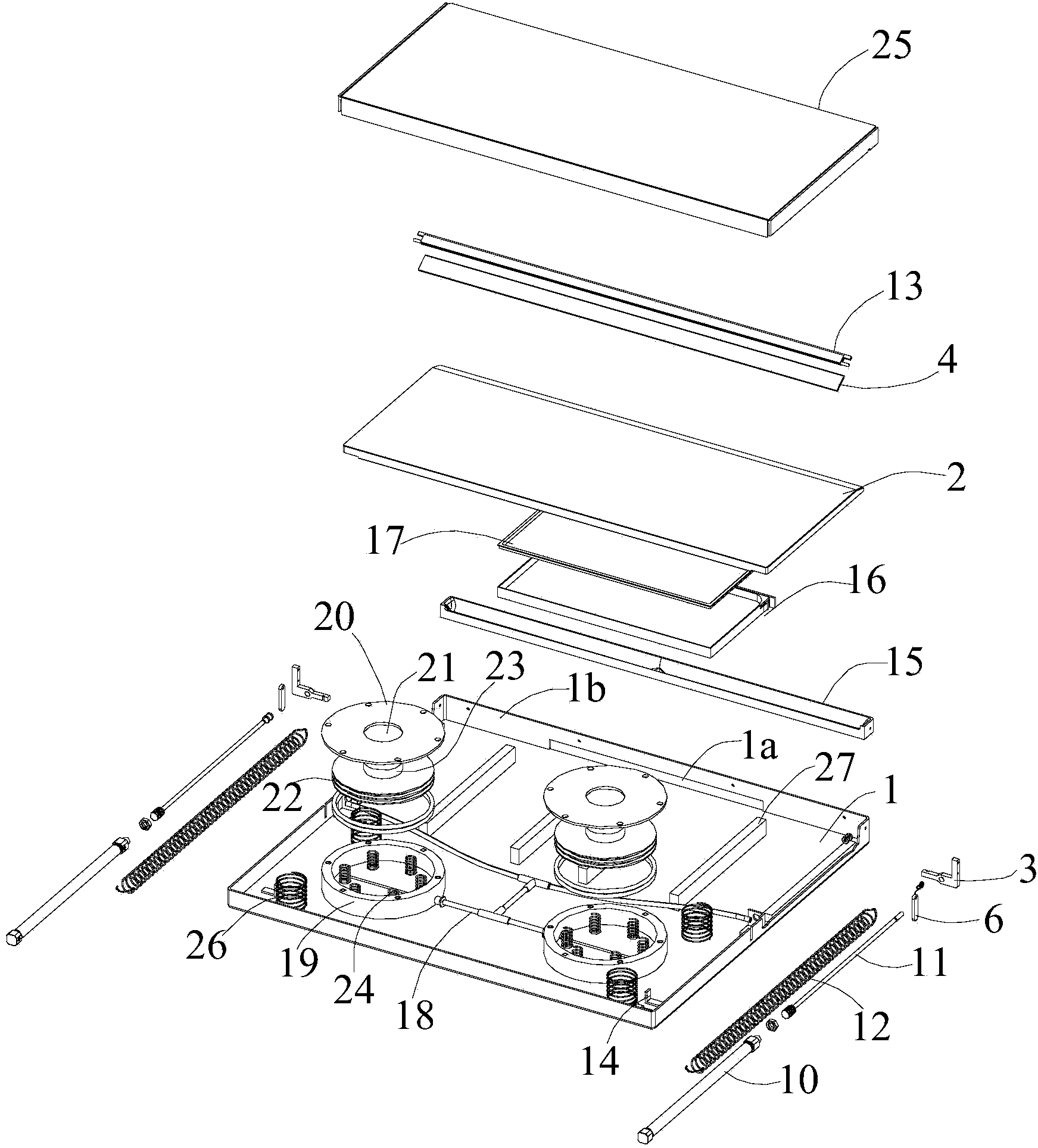

Full-automatic intelligent cleaning device

InactiveCN103654637ASimple structureClean thoroughlyCarpet cleanersFloor cleanersCouplingEngineering

The invention discloses a full-automatic intelligent cleaning device which comprises a bottom plate, a panel, moving frames, a scraper blade, a switching mechanism and a drive mechanism. The panel is arranged on the bottom plate. The moving frames are arranged on the two sides of the bottom plate. The scraper blade is connected to the moving frames in a coupling mode, used for cleaning the panel and arranged above the panel. The scraper blade has two work positions covering the panel or being separated from the panel. The scraper blade is switched between the two work positions through the switching mechanism. The drive mechanism drives the moving frames to move in a reciprocating mode along the bottom plate. The full-automatic intelligent cleaning device is simple in overall structure. The drive mechanism and the switching mechanism are adopted for carrying out operation cooperatively so that the panel can be automatically cleaned; special manual operation is not needed, and therefore the cleaning effect is good; due to the structure, the cleaning device is suitable for cleaning panels of various materials and especially for cleaning the glass panels, and high in practicality.

Owner:浙江豪龙模业有限公司

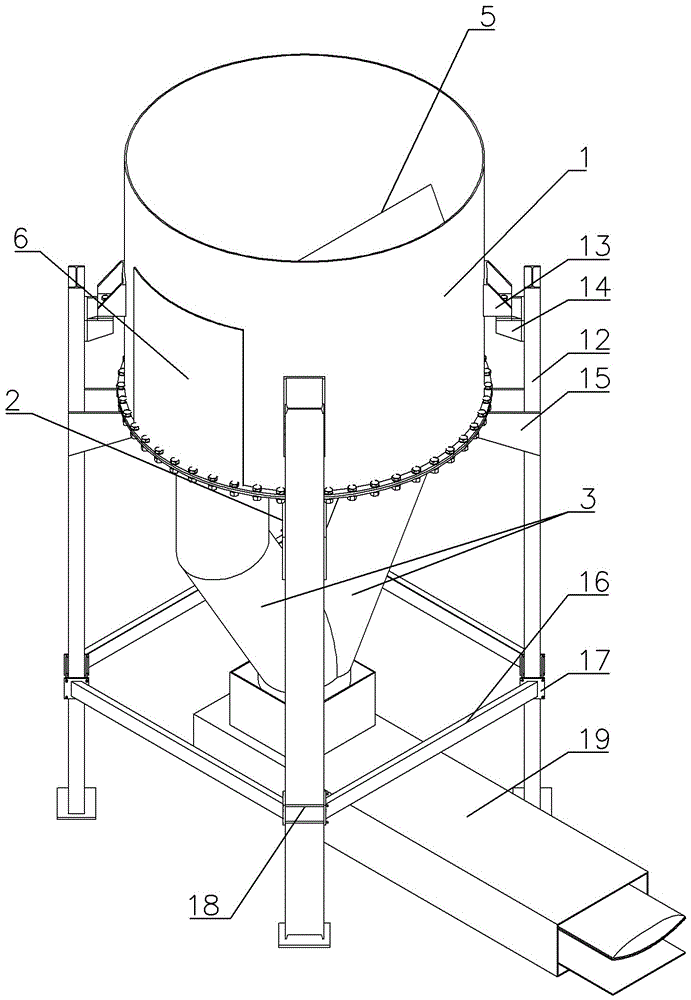

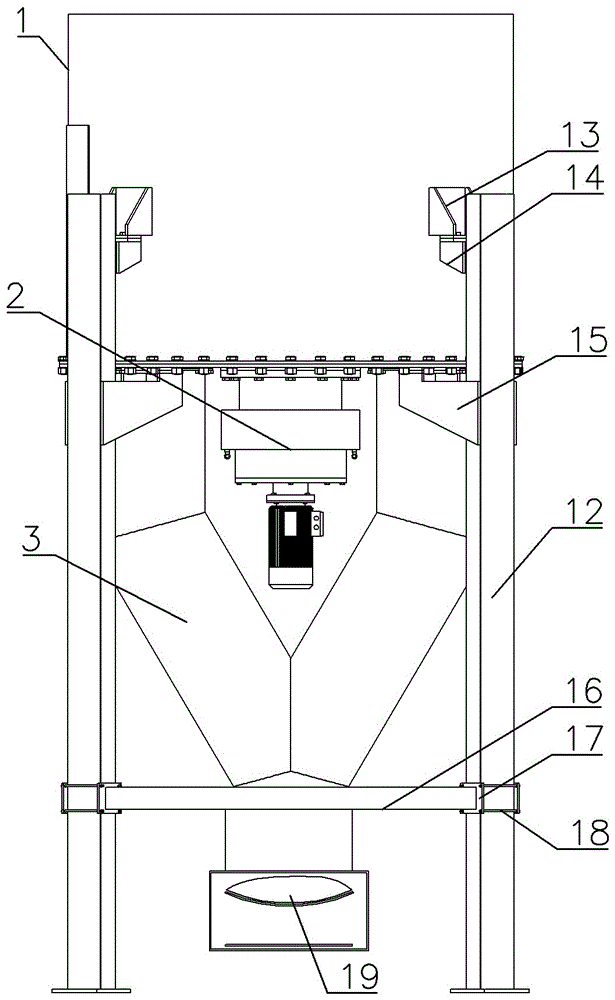

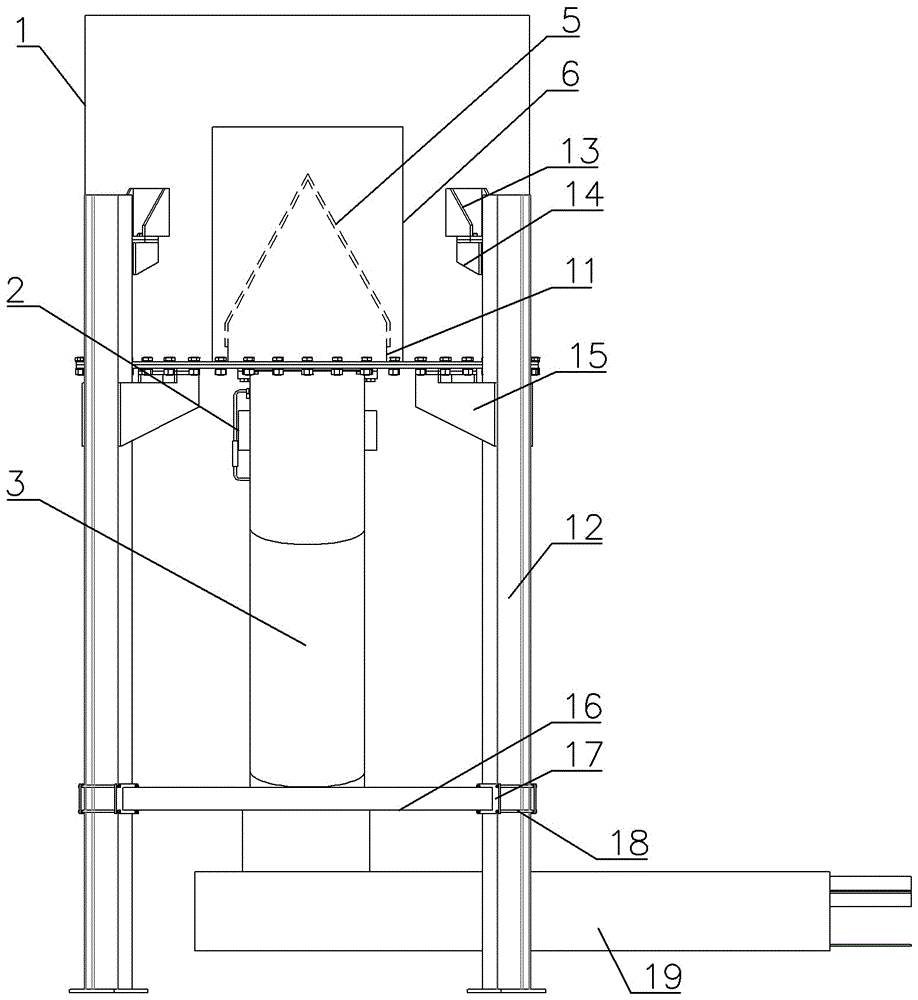

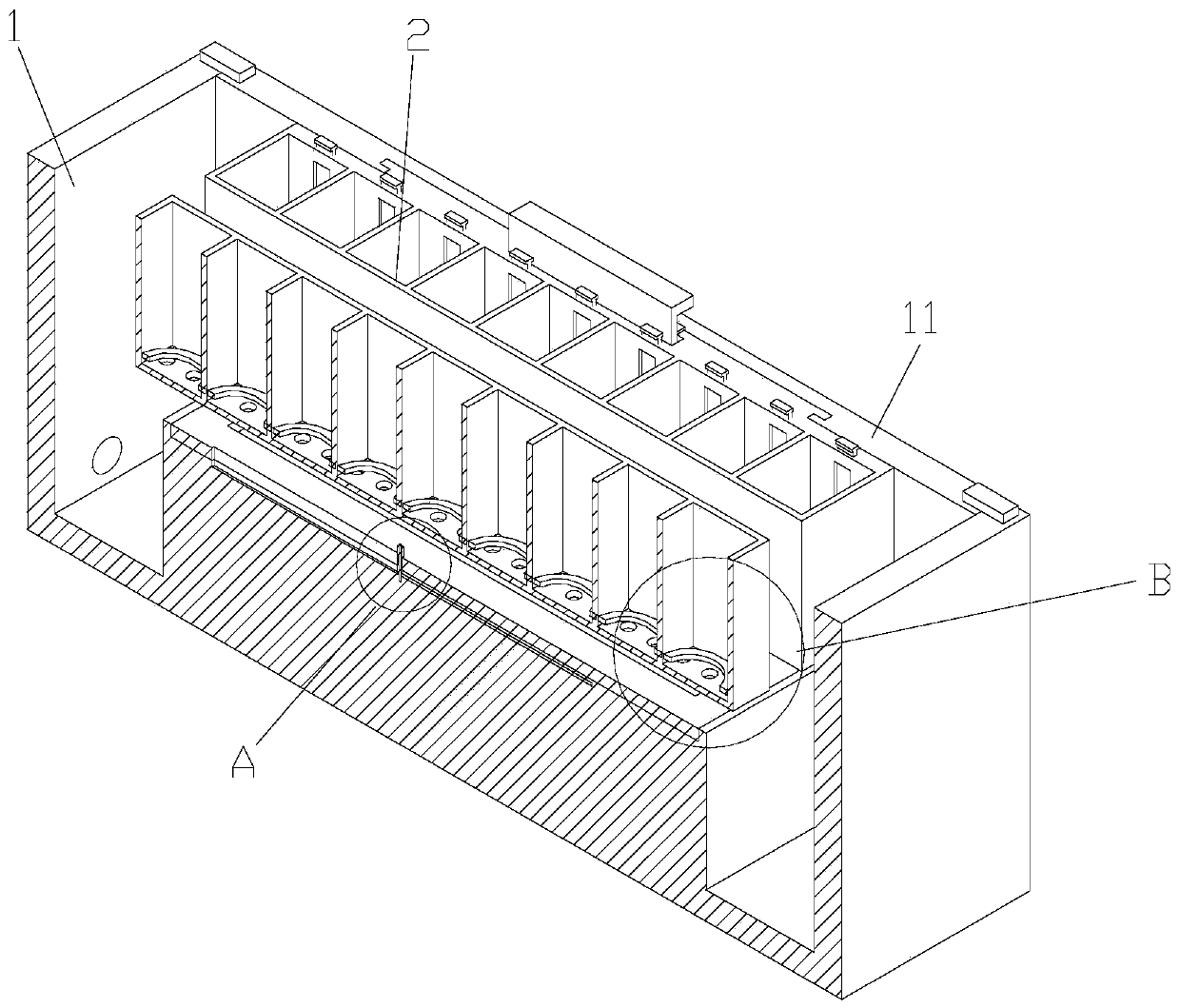

Sticky coal blending combustion bi-directional feeding device

The invention discloses a sticky coal blending combustion bi-directional feeding device and belongs to the field of sticky coal blending combustion feeding devices. The sticky coal blending combustion bi-directional feeding device comprises a coal bunker, two discharging ports are symmetrically formed along the axis of a bottom plate of the coal bunker, the lower portion of each discharge port is connected with a coal dropping pipe, and the bottom ends of the two coal dropping pipes communicate with each other. A splitter plate is arranged above the two discharging ports, and the two ends of the splitter plate are fixed to the side walls of the coal bunker. The coal bunker is internally provided with a rotary cutting body, the rotary cutting body comprises a base body and three cutters symmetrically arranged along the center of the base body, a power system is arranged below the center of the bottom plate of the coal bunker, and the power system is connected to the center of the base body. Materials in the coal bunker are alternately pushed by the rotary cutting body into the coal dropping pipes, the space for original materials is supplemented with materials on the upper portion under the action of gravity, first come first go of the materials is achieved, linking control is matched, a feeding device channel is kept smooth all the time, the materials come while the other materials go, and quantitative blocking preventing is achieved.

Owner:河南濮润智能机械工程有限公司

Impurity-scraping mechanism for cloth guide roller

InactiveCN105755794AQuality assuranceEnsure dust removal efficiencyMechanical cleaningPressure cleaningHydraulic cylinderMechanical equipment

The invention discloses an impurity-scraping mechanism for a cloth guide roller and belongs to the field of textile processing mechanical equipment.The impurity-scraping mechanism comprises a fixed support, a cloth feeding roller, the cloth guide roller and an impurity-scraping mechanism body.The cloth feeding roller and the cloth guide roller are sequentially horizontally rotatably connected to one side of the upper portion of the fixed support in the cloth conveying direction.The impurity-scraping mechanism is horizontally arranged on the fixed support positioned on one side of the cloth guide roller.The impurity-scraping mechanism comprises a rotary support, a rotating roller, impurity-scraping hydraulic cylinders, a fixed plate and a dedusting scraping knife.The rotating roller is horizontally rotatably connected to the rotary support, the impurity-scraping hydraulic cylinders are arranged between the two ends of the rotating roller and the fixed plate, the upper sides of the two ends of the rotating roller are provided with rotating plates respectively, the tail ends of the impurity-scraping hydraulic cylinders are in hinge joint with the upper ends of the rotating plates, the output ends of the impurity-scraping hydraulic cylinders are in hinge joint with one side of the fixed plate, and the upper end of the dedusting scraping knife adheres to one side of the cloth guide roller.The impurity-scraping mechanism is reasonable in design, efficient and full impurity removal can be performed on the cloth guide roller conveniently, and the production use demand is met.

Owner:TONGXIANG ZHONGTAI TEXTILE SCOURING

Crystal cleaning process for improving quality of crystal finished product

The invention discloses a crystal cleaning process for improving the quality of a crystal finished product. The crystal cleaning process comprises the following steps of a, primary inspection, specifically, inspecting products to be cleaned, and placing qualified products on a frame for cleaning; b, soaking reduction, specifically, placing the products to be cleaned in water for soaking reduction;c, soaking in liquid medicine, specifically, after the products are reduced in the water, adding the liquid medicine into the water, and soaking the products in the liquid medicine to meet the cleaning requirement; d, machine washing, specifically, taking out the products soaked in the liquid medicine, and putting the products into crystal cleaning equipment for cleaning operation; e, secondary cleaning, specifically, placing the cleaned products into clean water again to soak the cleaned products, and removing the liquid medicine and dirt on the surfaces of the products; f, drying, specifically, putting the clean products into a drying machine for drying treatment; and g, re-inspection, specifically, re-inspecting the products.

Owner:PUJIANG SHUNHUA CRYSTAL JEWELRY CO LTD

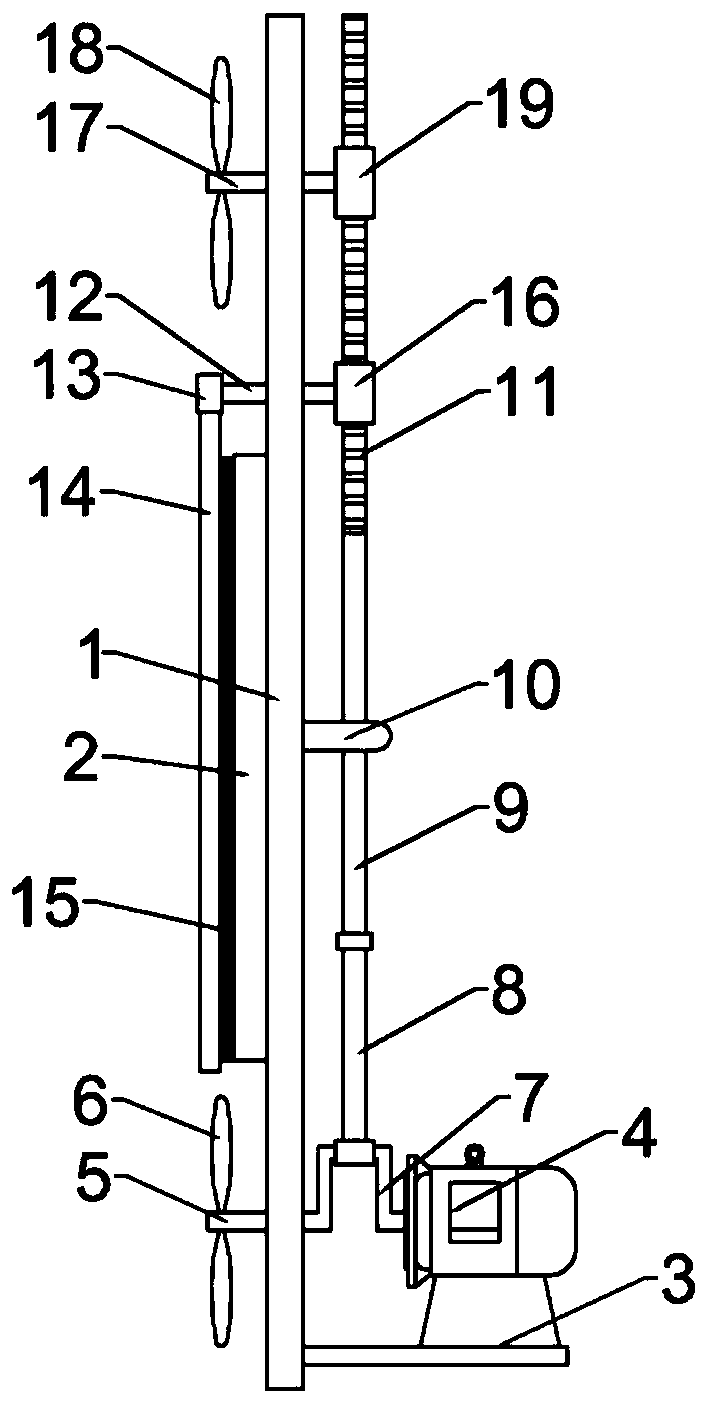

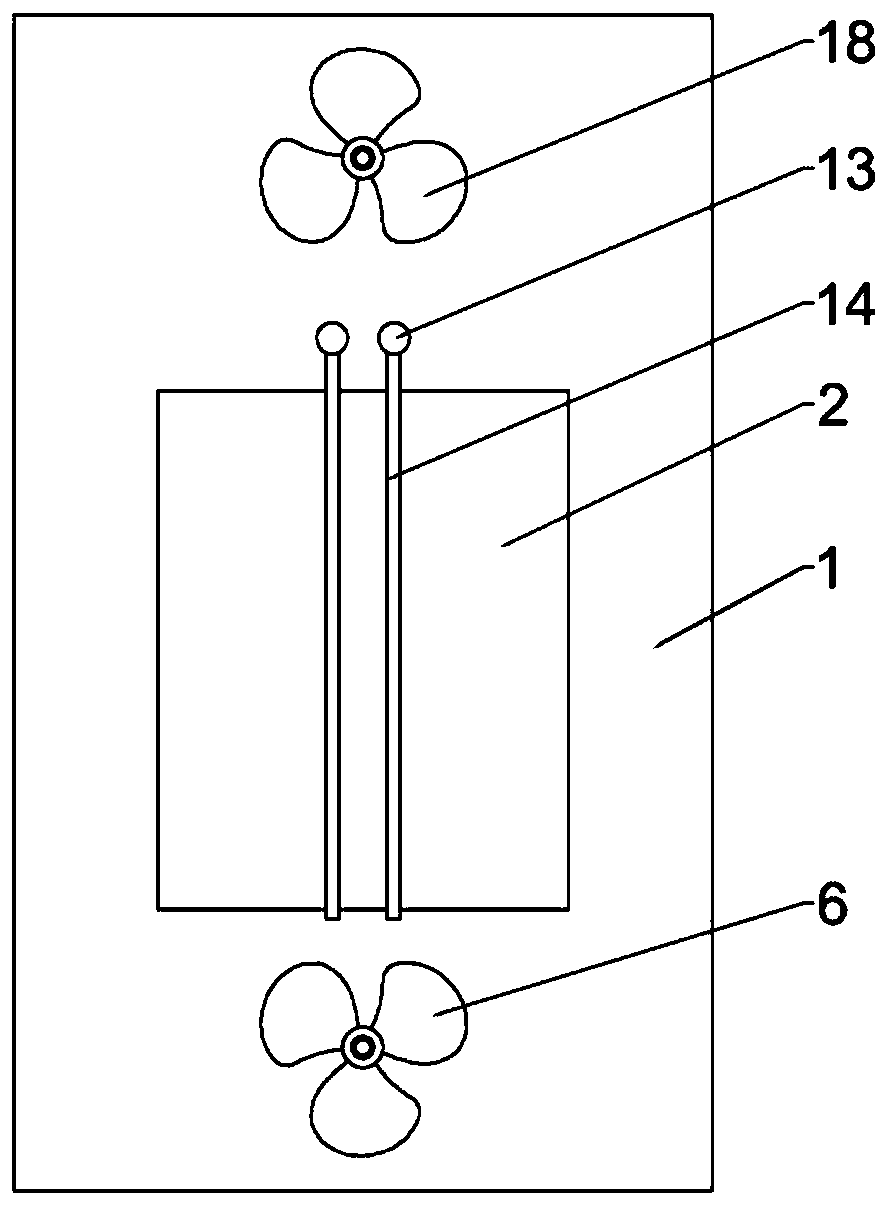

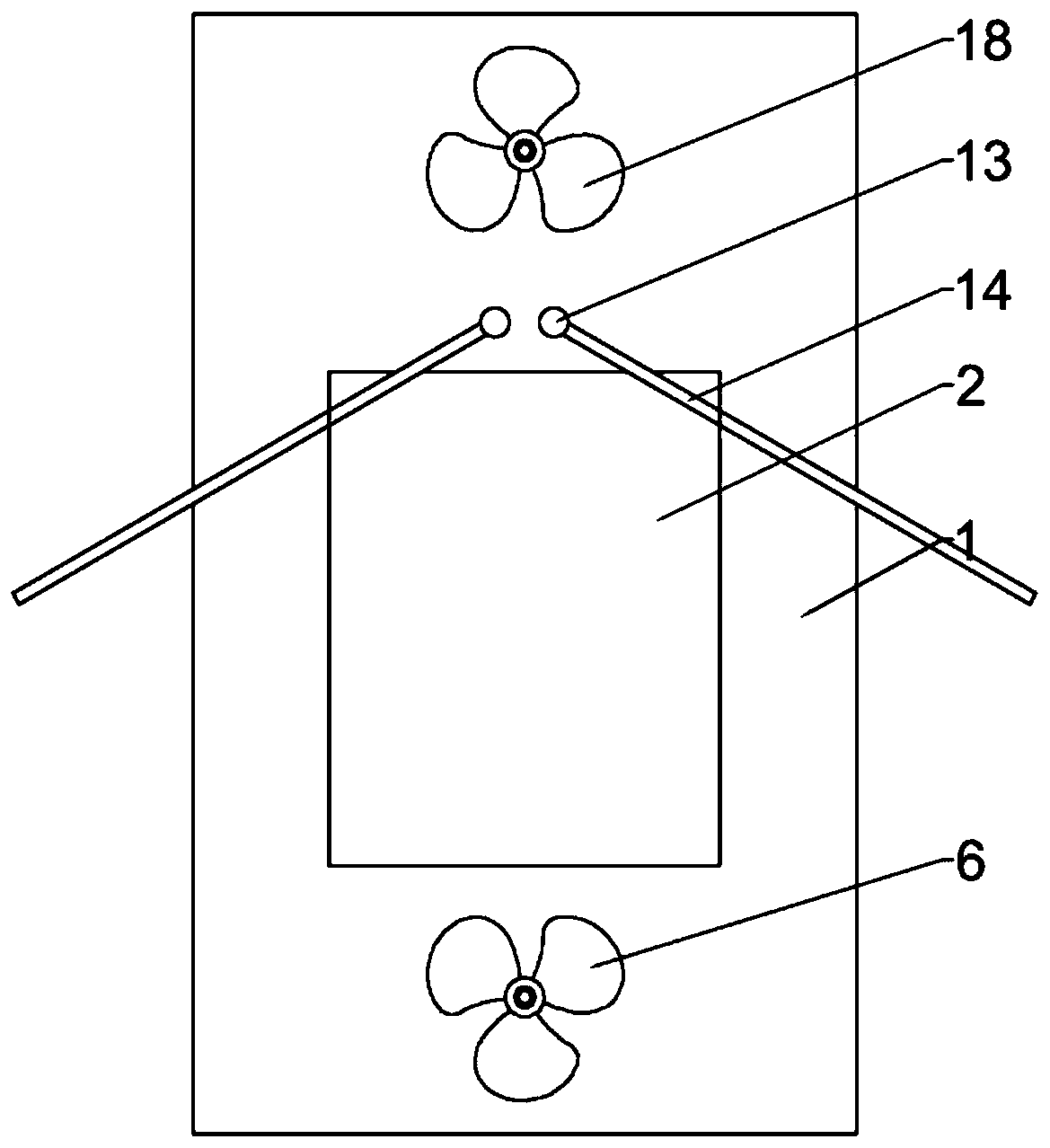

LED backlight with self-cleaning function

PendingCN110208986ARealize up and down reciprocating motionEasy to useCleaning using toolsCleaning using gasesBristleReciprocating motion

The invention discloses LED backlight with a self-cleaning function, and relates to the LED backlight. The LED backlight includes a mounting bottom plate, the LED backlight is fixedly connected to theleft side of mounting bottom plate, a motor mounting bracket is fixedly connected to the bottom right of mounting bottom plate, the motor mounting bracket is fixedly connected with a driving motor, the output end of the driving motor is fixedly connected with a first rotating shaft, the left end of the first rotating shaft is fixedly connected with a first rotating blade, the middle of the firstrotating shaft is fixedly connected with a crank throw, and the crank throw is located on the right side of the mounting bottom plate. The LED backlight is simple in structure and convenient to use and driven by the motor during using, vertical reciprocating motion of a second transmission rod is realized, the second transmission rod can drive a positioning cleaning shaft to swing, thus bristles are driven to swing to self-clean the LED backlight, normal use of the LED backlight is ensured, the LED backlight can further drive the first rotating blade and a second rotating blade simultaneouslyto blow away floating dust, re-adhering to the LED backlight is avoided, and at the same time the LED backlight can be cooled.

Owner:深圳市昊源新辉电子有限公司

Automatic cleaning method of food processor

ActiveCN112826328AAvoid re-adhesionEasy to cleanBeverage vesselsProcess engineeringEnvironmental geology

The invention discloses an automatic cleaning method of a food processor. The food processor comprises a crushing cavity and a water supply part for supplying water to the crushing cavity, wherein the crushing cavity is provided with a crushing part, a heating assembly and a slurry discharging assembly. After the food processor completes preparation, cleaning of the crushing cavity at least comprises a rinsing stage and a steaming washing stage; the steaming washing stage is carried out after the rinsing stage; in the rinsing stage, the water supply part injects water into the crushing cavity, the crushing part stirs water to clean the crushing cavity, and the slurry discharging assembly discharges residual water in the crushing cavity; in the steaming washing stage, the water supply component injects water into the crushing cavity, the heating assembly is controlled to heat the water in the crushing cavity to generate steam, the steam fumigates the wall of the crushing cavity, the crushing part stirs the water to clean the crushing cavity, and the slurry discharging assembly discharges residual water in the crushing cavity.

Owner:JOYOUNG CO LTD

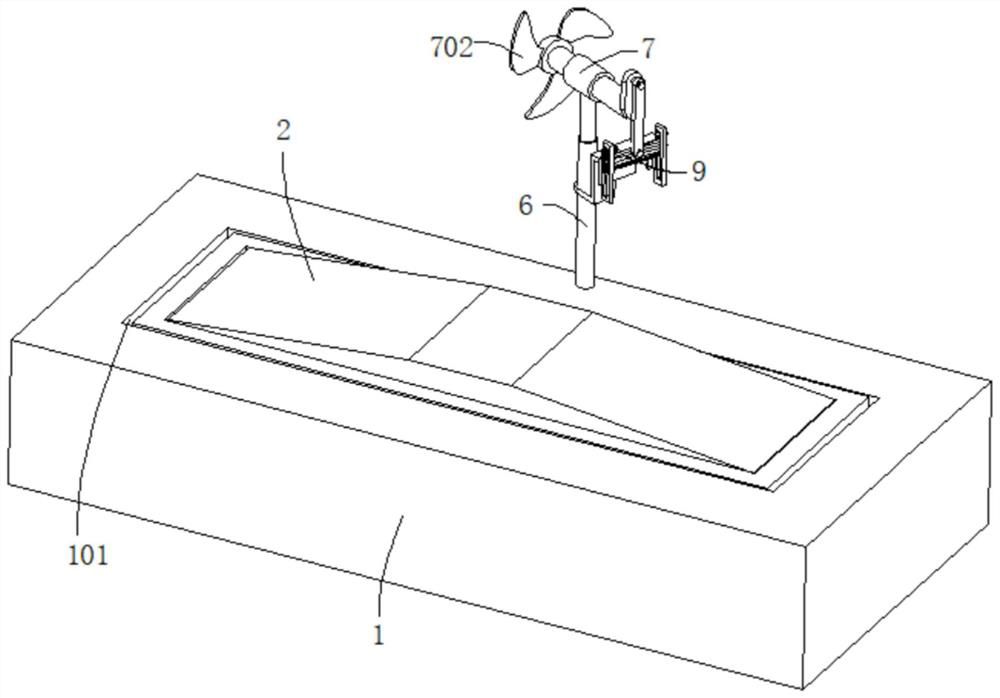

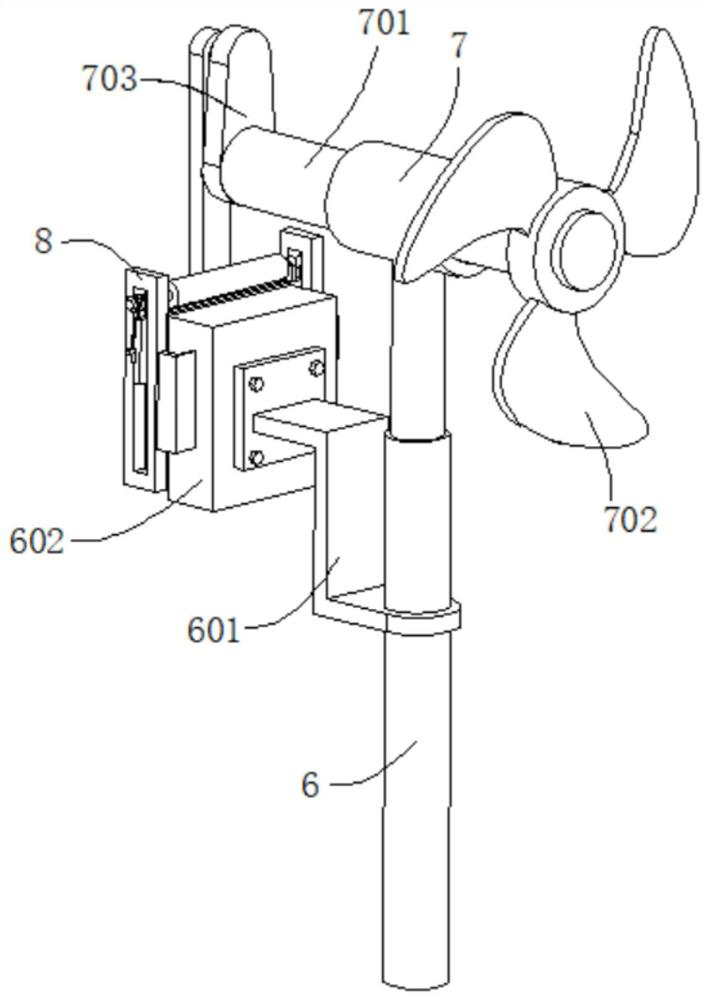

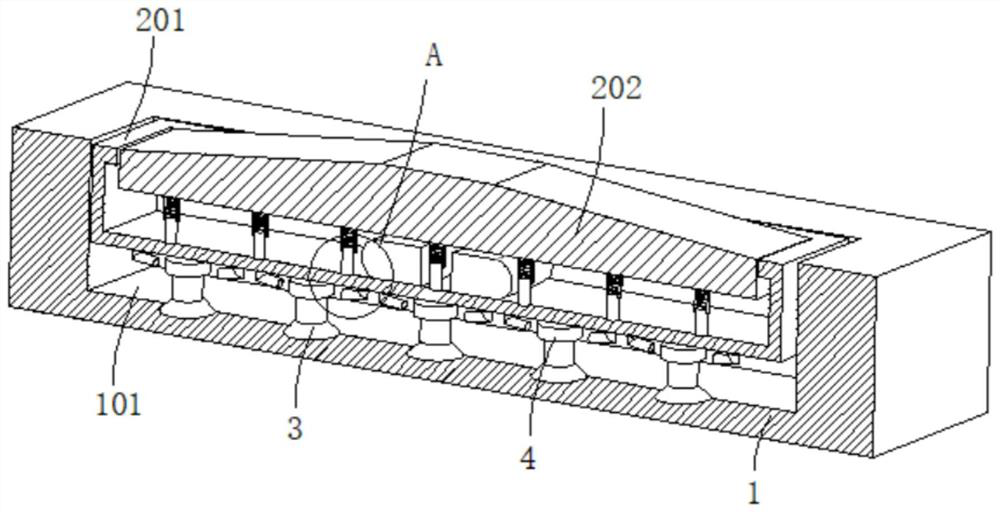

Data acquisition device for dynamic weighing of vehicle and use method thereof

PendingCN113847978AAssurance of Accuracy and CompletenessSpeed up the drying rateWeighing apparatus detailsCleaning using toolsCamera lensStructural engineering

The invention discloses a data acquisition device for dynamic weighing of a vehicle and a use method thereof, and belongs to the technical field of dynamic weighing. The data acquisition device for dynamic weighing of the vehicle comprises a pavement foundation and a groove formed in the pavement foundation and used for placing a weighing assembly, and further comprises a base connected to the inner wall of the groove, wherein a pressure sensor is arranged between the base and the weighing assembly and used for dynamically weighing a running vehicle; an exhaust pipe arranged below the weighing assembly and used for removing dust from the pressure sensor; a camera device which comprises a supporting column connected to a pavement foundation, wherein the outer wall of the supporting column is connected with a connecting frame, and the end, away from the supporting column, of the connecting frame is connected with a camera lens; and a wind power dust removal mechanism arranged on the outer side of the supporting column and used for conducting dust removal operation on the camera lens. According to the invention, dust on the outer sides of the camera lens and the pressure sensor is cleaned, so that the accuracy of weighing data acquisition is ensured.

Owner:浙江东鼎电子股份有限公司

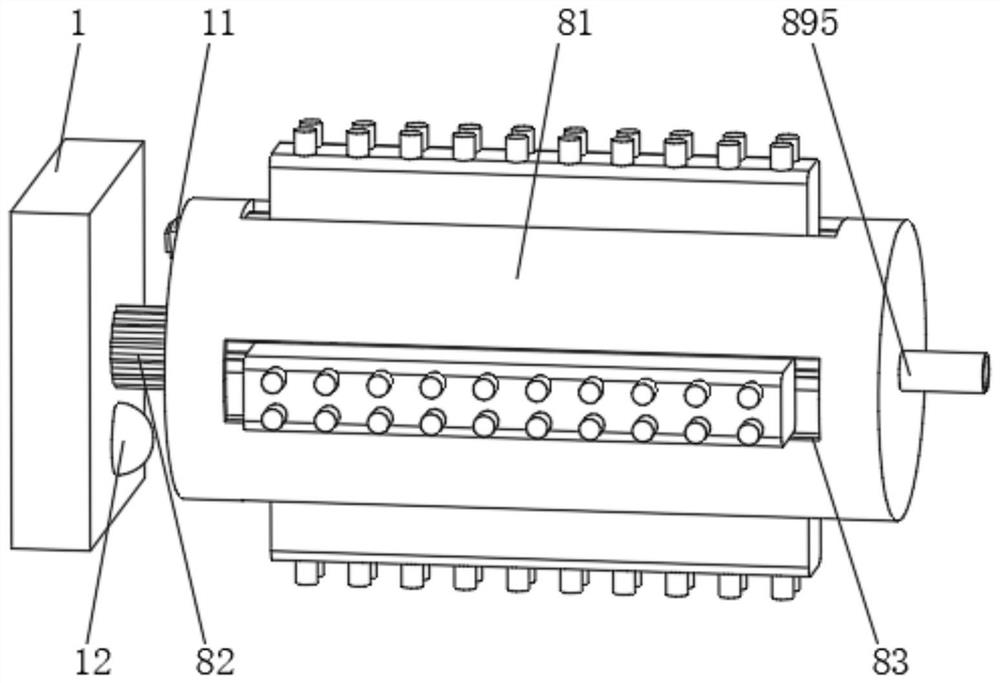

Metallized film splitting machine with static electricity eliminating device

ActiveCN114314104AImprove cleaning efficiencyExtended service lifeCleaning using toolsWebs handlingStructural engineeringBrush

The invention discloses a metallized film splitting machine with a static elimination device, which comprises a shell, the bottom of the shell is fixedly connected with a fixed base, one side of the shell is fixedly connected with a feeding bracket, one side of the feeding bracket is rotatably connected with a feeding roller, the top of the shell is fixedly connected with a mounting frame, and the mounting frame is fixedly connected with a feeding roller. One side of the mounting frame is fixedly connected with an electrostatic elimination mechanism, one side of the shell is rotatably connected with a top guide roller, one side of the shell is provided with a cleaning device, and one side of the shell is located at the bottom of the top guide roller and is rotatably connected with a cutting roller; and a winding device is installed at the position, located at the bottom of the cleaning device, of one side of the shell, and the cleaning device comprises a cleaning roller. According to the metalized film splitting machine with the static electricity eliminating device, the brush head can be replaced, the service life of the brush head is prolonged, and the cleaning efficiency of a film is also improved.

Owner:宁波市镇海君禾电子有限公司

Automobile part cleaning device

InactiveCN108212854AFully automatedAvoid re-adhesionCleaning using toolsCleaning using liquidsTurbine bladeEngineering

The invention belongs to the technical field of cleaning devices and particularly discloses an automobile part cleaning device. The automobile part cleaning device comprises a cleaning mechanism and adriving mechanism, the cleaning mechanism comprises a rotating shaft and nut sleeves, the nut sleeves are fixed to a frame, the nut sleeves and the rotating shaft form threaded pairs, the rotating shaft is in a hollow structure with the upper end closed, the upper portion of the inner wall of the rotating shaft is provided with an air cavity, and the upper end of the air cavity extends to the upper end of the rotating shaft and is in slide seal with a seal ring arranged on the frame. The lower end of the air cavity is provided with a plurality of air passages, an outlet end of each air passage is in rotational connection with a brush, and the air passages are provided with turbine blades for driving the brushes to rotate. The side wall of the rotating shaft is peripherally provided with aplurality of water outlet check valves corresponding to the brushes in position, the lower portion of the rotating shaft extends into a water tank and is provided with a water inlet check valve, a piston plate fixedly connected with the driving mechanism is arranged in the water tank, and the lower end of the rotating shaft and the piston plate form a piston structure. By adoption of the technical scheme, automobile part cleaning effects can be improved, time saving and labor saving are realized, and operating efficiency is improved.

Owner:CHONGQING SHUNHUAI MACHINERY MFG CO LTD

Oiling equipment for metal wire rope manufacturing

InactiveCN113201954AImprove reliabilityImprove the range of dust removalLiquid surface applicatorsRope making machinesProcess engineeringEnvironmental geology

The invention relates to oiling equipment for metal wire rope manufacturing. The equipment comprises a main body and an oiling device, and further comprises a dust removal mechanism and a recycling mechanism; the dust removal mechanism comprises a dust removal box, an impurity removal assembly, a rotating assembly, a rotating ring, a fixed box and two dust removal assemblies; each dust removal assembly comprises a dust removal box and a connecting pipe; the recycling mechanism comprises a recycling box, a filter screen and a vibration assembly; the recycling box is arranged at the bottom in the main body; an opening is formed in the upper portion of the recycling box; the filter screen is connected with the inner wall of the opening; the vibration assembly is arranged below the filter screen; and the vibration assembly is connected with convex teeth close to the main body. According to the oiling equipment for metal wire rope manufacturing, through the dust removal mechanism, the dust removal function is achieved and dust attached to a steel wire rope is prevented from affecting the oiling quality, so that the reliability of the equipment is improved; and through the recycling mechanism, the function of recycling oil is achieved, and the quality of the recovered oil is also improved, so that the practicability is higher.

Owner:南京威日通电子科技有限公司

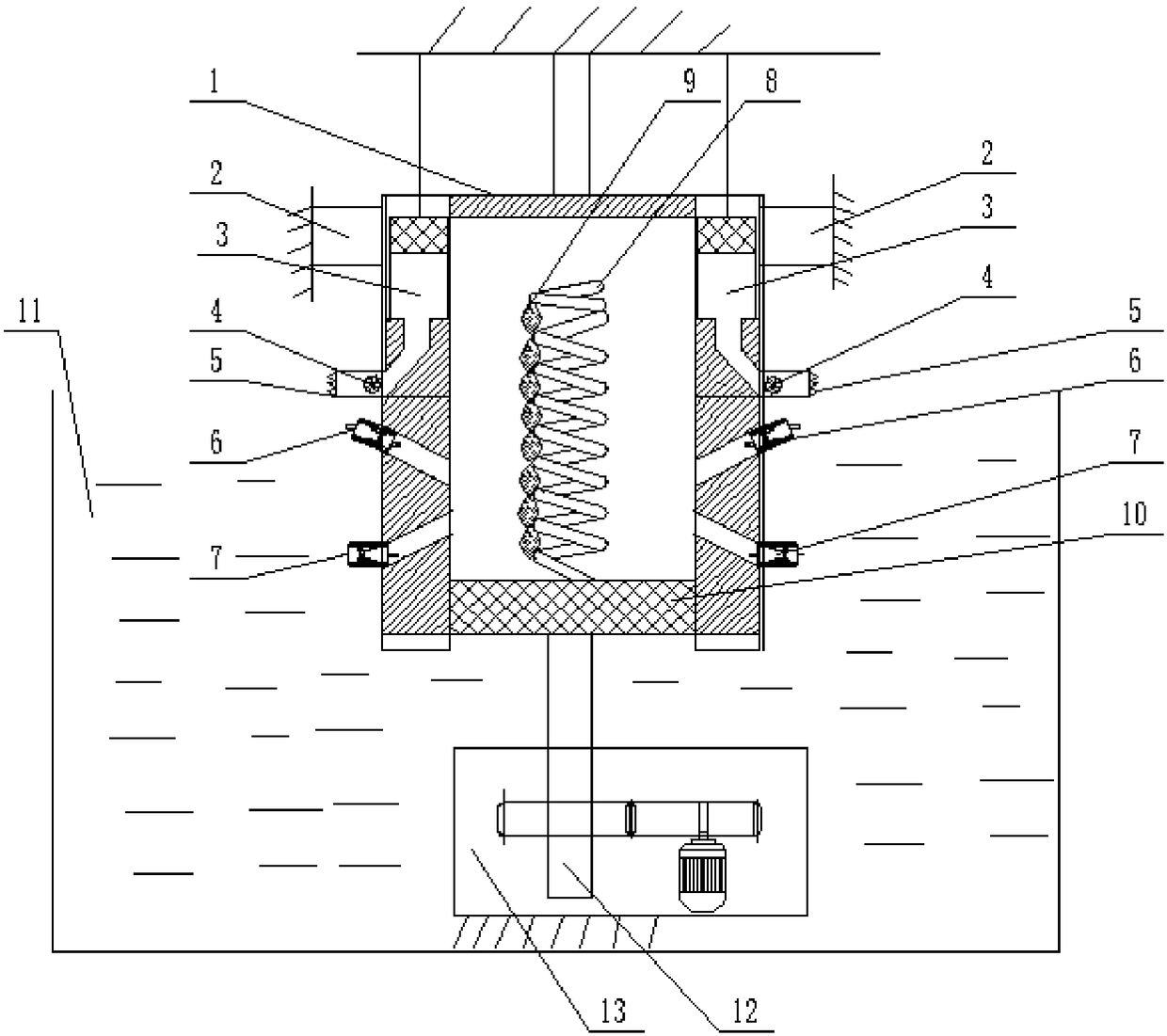

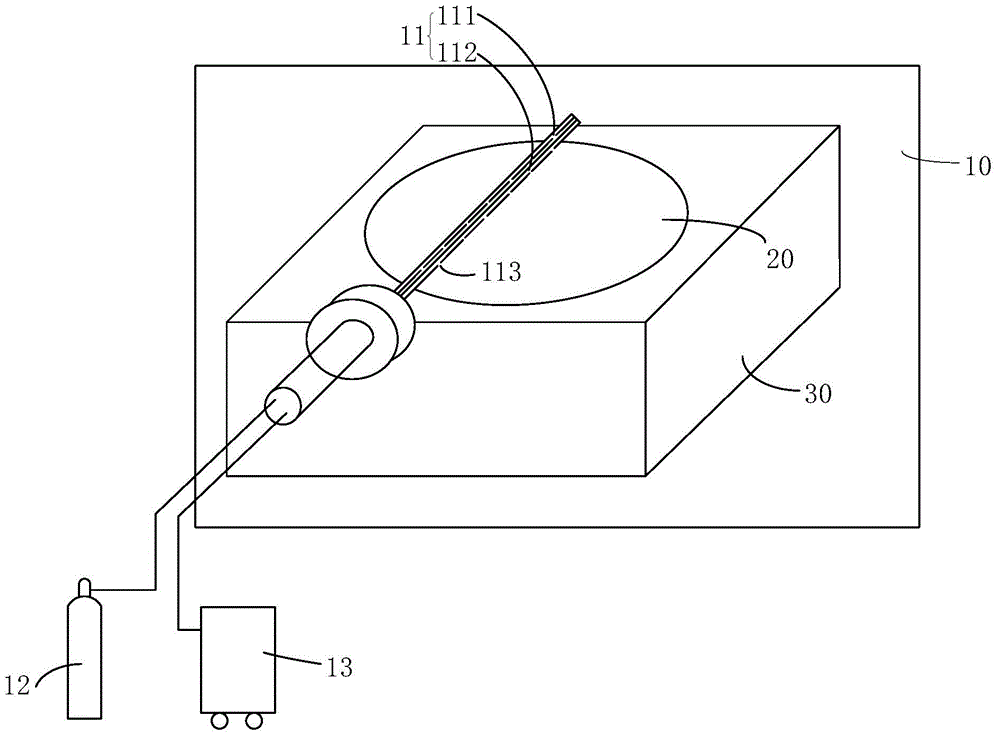

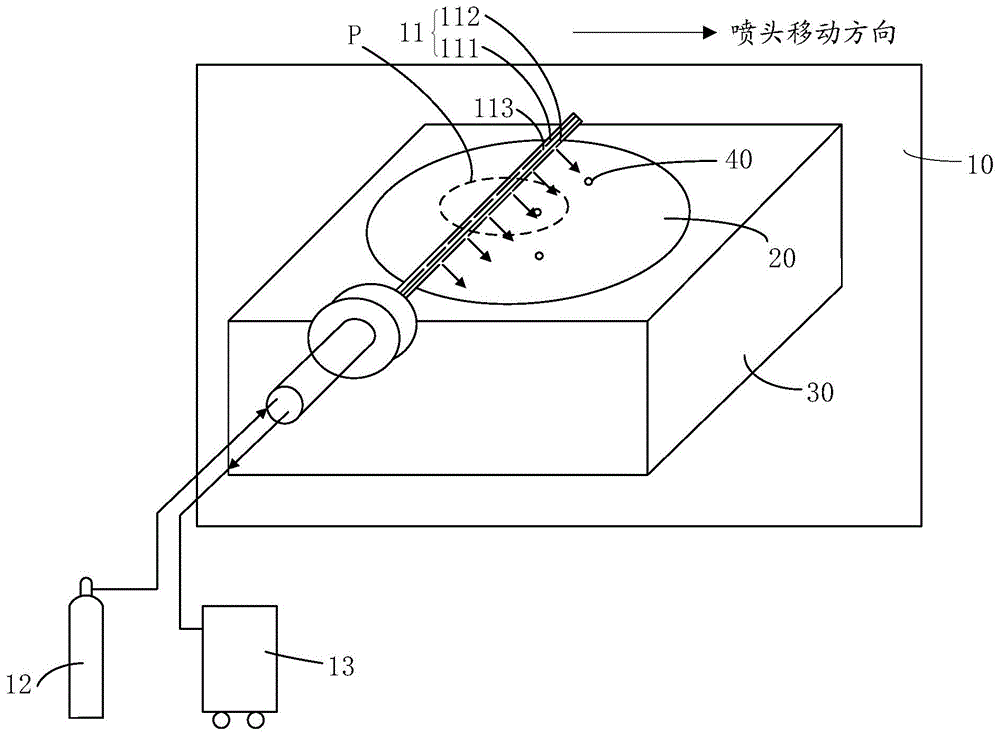

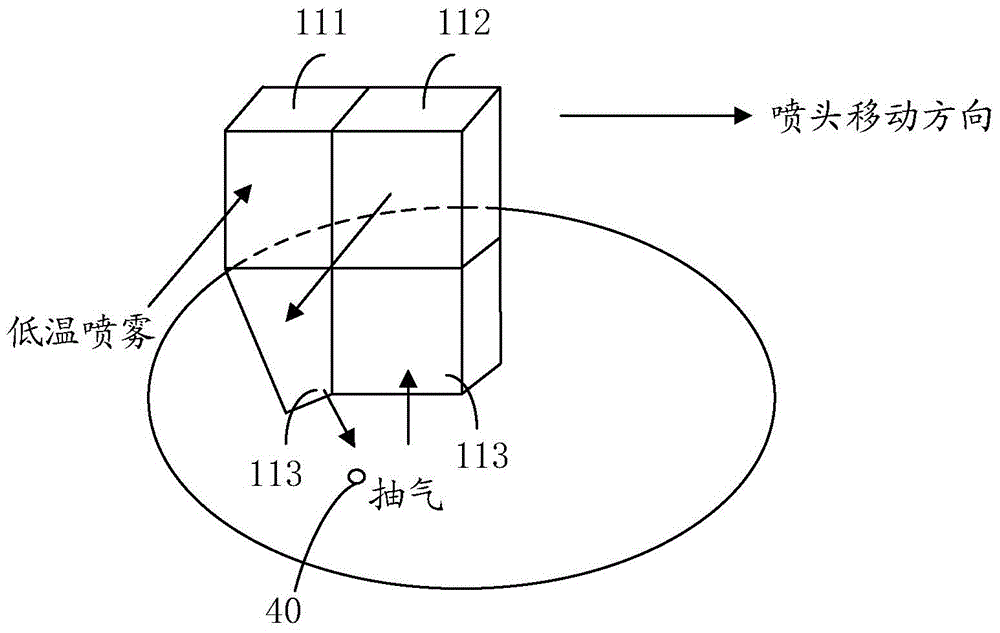

Wafer chuck cleaning system used for lithography machine and cleaning method thereof

InactiveCN105334698AWon't breakAvoid recontaminationPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistCleaning methods

The invention relates to a wafer chuck cleaning system used for a lithography machine and a cleaning method thereof. According to the invention, the system at least comprises a spraying head located in a sealed chamber, when the wafer chuck needs to be cleaned by the spraying head, low-temperature spray is provided for the surface of the wafer chuck; the low-temperature spray is formed by particles in certain mass, which have certain speed and can be collided with pollutants on the surface of the wafer chuck, so that the pollutants are separated from the surface of the chuck; and meanwhile, an exhausting device is used for exhausting the sealed chamber and the pollutants are brought out of the sealed cavity. New pollutants are not introduced in the process and the low-temperature sprayed mist does not cause damages to the surface of the wafer chuck.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Rapid building glass cleaning agent

InactiveCN104357231AClean wellExtended service lifeOrganic detergent compounding agentsNon-ionic surface-active compoundsArchitectural glassPolyaspartic acid

A rapid building glass cleaning agent is prepared from the following raw materials in parts by weight: 6-14 parts of fatty alcohol polyoxyethylene ether, 7-9 parts of sodium lauryl sulphate, 6-8 parts of sodium xylene sulfonate, 5-8 parts of trisodium N-iminodiacetate, 6-8 parts of alkyl ester sulfate, 3-7 parts of ethanol, 4-9 parts of glycol butyl ester, 5-8 parts of toluenesulfonic acid, 6-11 parts of triisopropanolamine, 2-4 parts of perfluoro n-octylsulfonyl fluoride, 5-9 parts of fatty alcohol polyoxyethylene ether and 5-7 parts of polyaspartic acid. The rapid building glass cleaning agent has the benefits that the rapid building glass cleaning agent can well clean spots, and meanwhile, meanwhile forms an isolating layer after washing, prevents oil spots from being attached to glass again, and prolongs the service life of the glass.

Owner:QINGDAO ZHIGU INNOVATION TECH

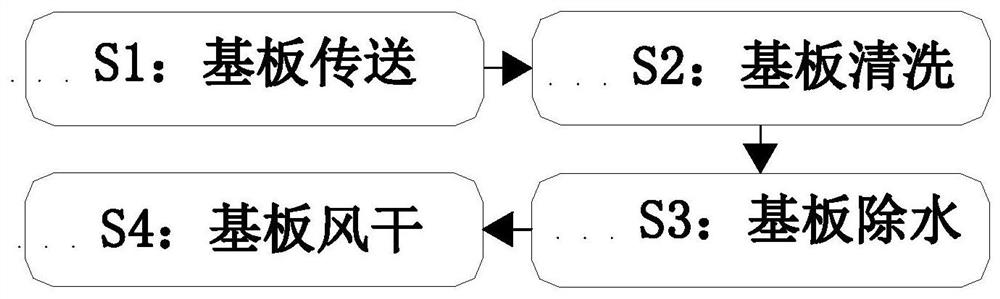

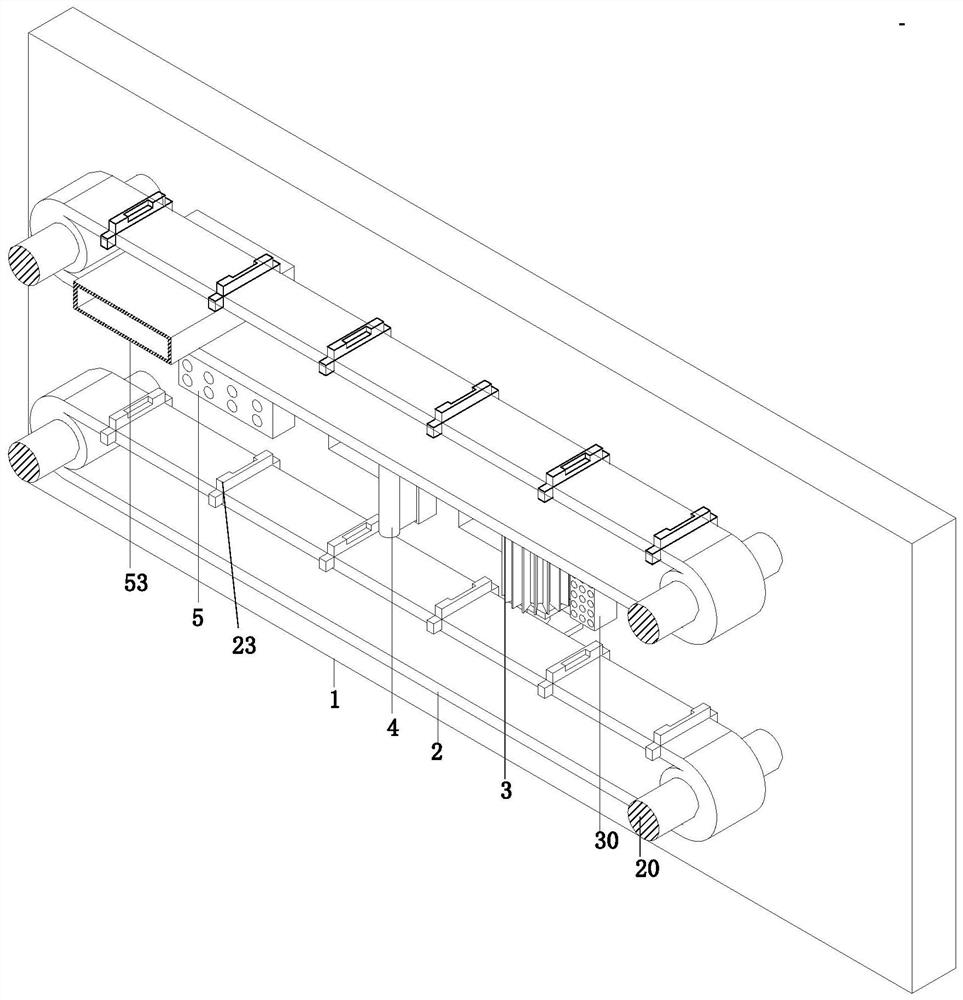

Processing technology for color film substrate of liquid crystal display screen

InactiveCN112799241AEasy to put inPrevent slippingCleaning using toolsCleaning using liquidsLiquid-crystal displayColor film

The invention relates to a liquid crystal display screen color film substrate processing technology, a liquid crystal display screen color film substrate processing device is used, and the liquid crystal display screen color film substrate processing device comprises a support plate, a conveying mechanism, a cleaning mechanism, a water removal mechanism and a drying mechanism, wherein a color film substrate is intermittently conveyed by the conveying mechanism, the substrate is conveniently placed on the clamping plate on the conveying belt to be limited, a phenomenon that the substrate slides down due to the fact that the substrate moves in the conveying and cleaning process is avoided, the cleaning mechanism cleans two faces of the substrate at the same time, cleaning efficiency of the substrate is improved, meanwhile, two faces of the substrate are evenly stressed, and the service life of the substrate is prolonged; and the phenomenon of breakage of the substrate caused by damage to the substrate is avoided.

Owner:王萌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com