Automobile part cleaning device

A technology for auto parts and cleaning devices, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problem of being easily adhered by other stains again, poor cleaning effect of parts, labor High strength and other problems, to achieve the effect of saving manpower cleaning, compact structure and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

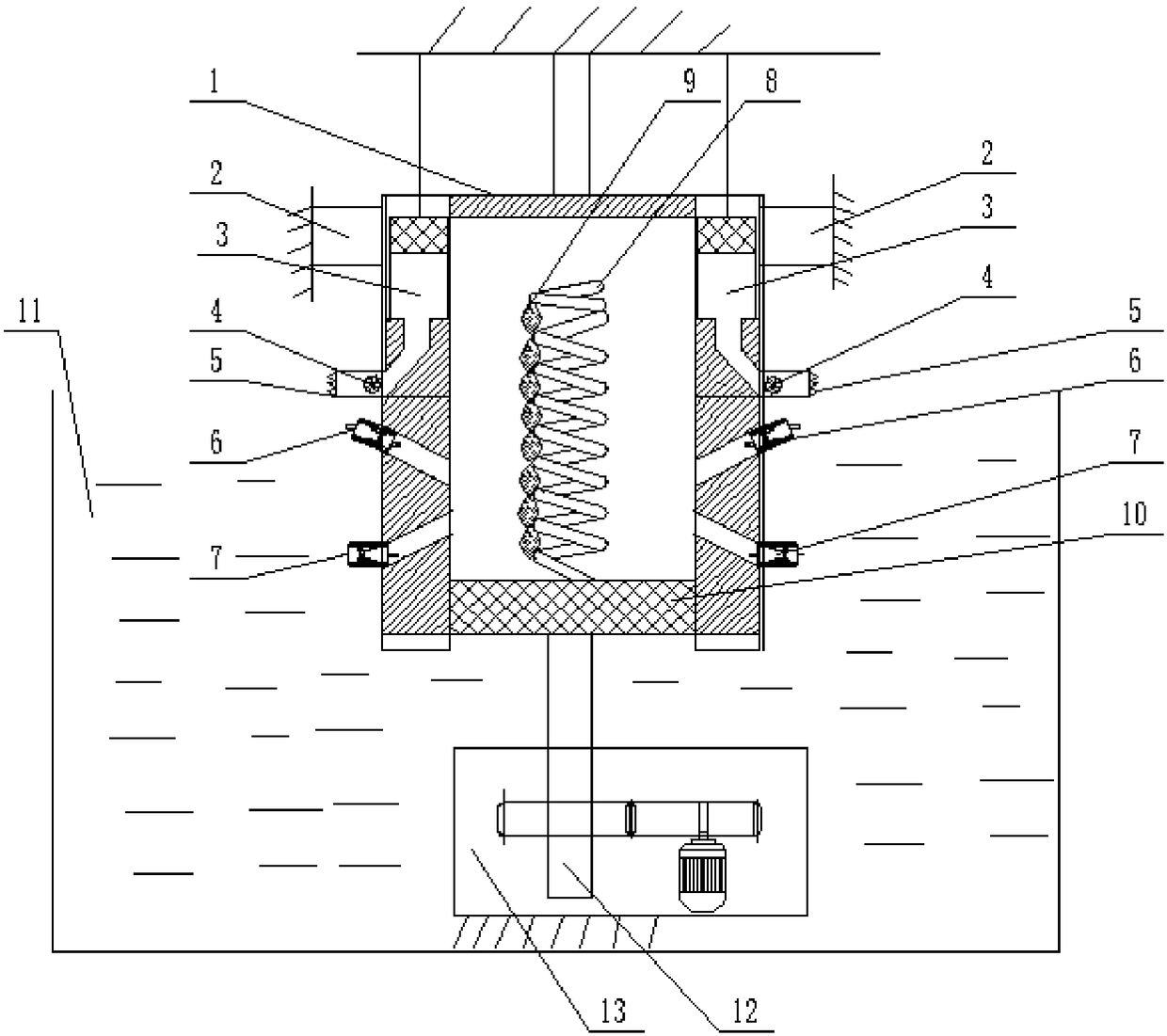

[0014] Instructions attached figure 1 The reference signs in include: rotating shaft 1, nut sleeve 2, air chamber 3, turbine blade 4, brush 5, water outlet check valve 6, water inlet check valve 7, spring 8, cleaning bag 9, piston plate 10, water tank 11, input shaft 12, driving mechanism 13.

[0015] Such as figure 1 As shown, the auto parts cleaning device includes a cleaning mechanism and a driving mechanism 13. The cleaning mechanism includes a rotating shaft 1 and a nut sleeve 2. The nut sleeve 2 is fixed on the frame, and a thread pair is formed between the nut sleeve 2 and the rotating shaft 1. The rotating shaft 1 It is a hollow structure, the upper end of the hollow structure of the rotating shaft is closed, the upper part of the inner wall of the rotating shaft 1 is provided with an air cavity 3, and the frame is provided with a sealing ring, the upper end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com