LED backlight with self-cleaning function

A LED backlight and self-cleaning technology, which is applied in the direction of cleaning methods using tools, cleaning methods and utensils, and cleaning methods using gas flow, etc., can solve problems such as affecting functions, inconvenient use, and backlights being contaminated by dust. Guaranteed normal use, convenient use, and good user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

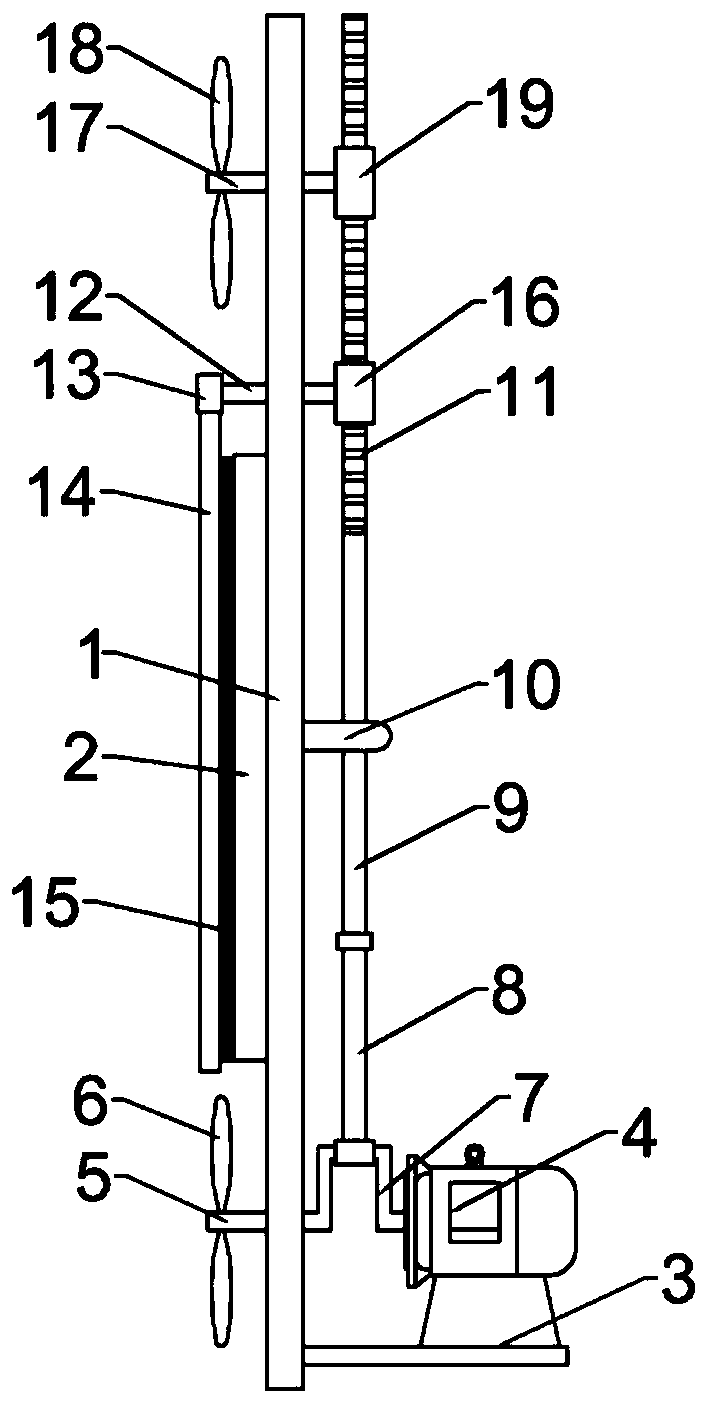

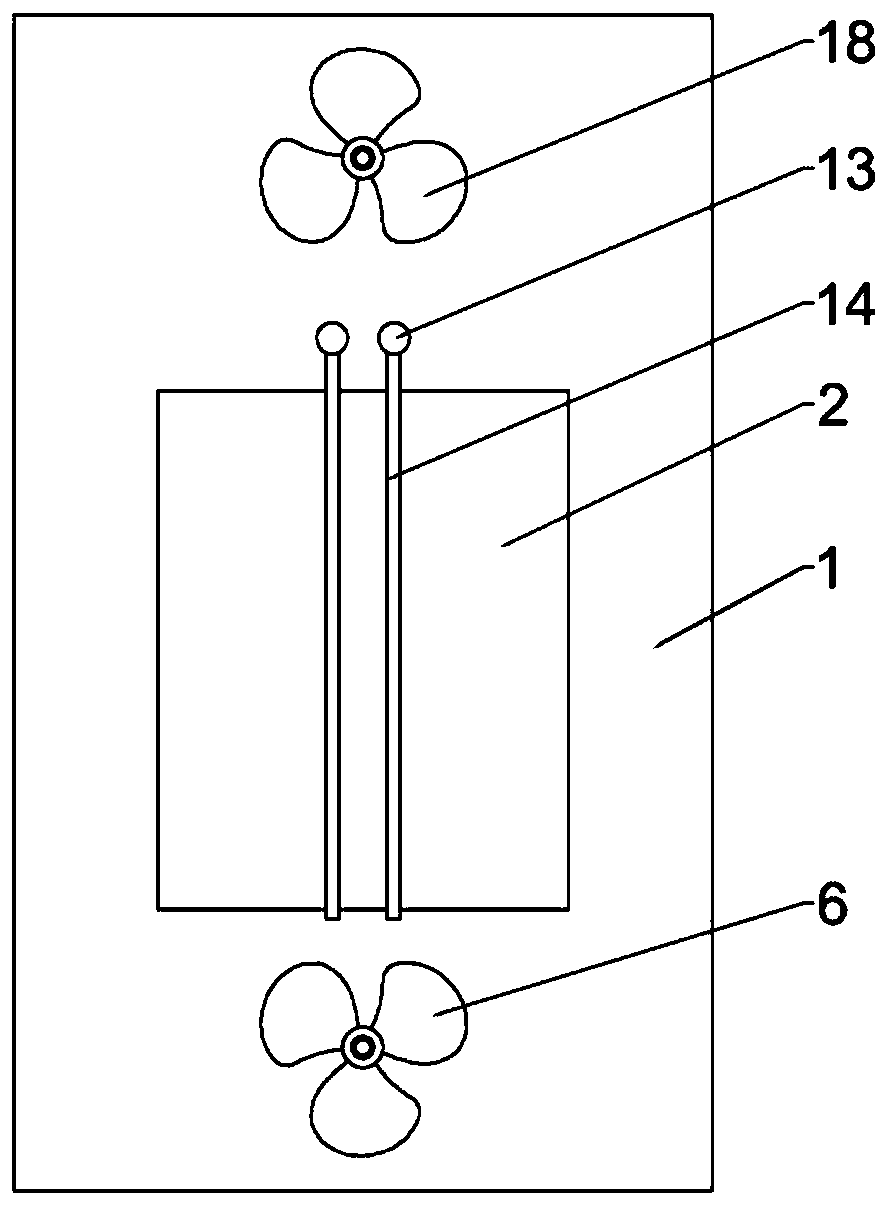

[0022] Example 1: Please refer to Figure 1-4 , a LED backlight with self-cleaning function, comprising a mounting base 1, an LED backlight 2 is fixedly connected to the left side of the mounting base 1, a motor mounting bracket 3 is fixedly connected to the bottom right of the mounting base 1, and the motor mounting bracket 3 is fixedly connected There is a driving motor 4, the output end of the driving motor 4 is fixedly connected to the first rotating shaft 5, and the left end of the first rotating shaft 5 is fixedly connected to the first rotary blade 6;

[0023] When dust is accumulated on the LED backlight 2, the driving motor 4 is turned on, and the driving motor 4 drives the first rotating shaft 5 to rotate, and then drives the first rotary blade 6 to rotate;

[0024] The middle part of the first rotating shaft 5 is fixedly connected with a bell crank 7, and the bell crank 7 is located on the right side of the installation base plate 1. The top of the bell crank 7 is r...

Embodiment 2

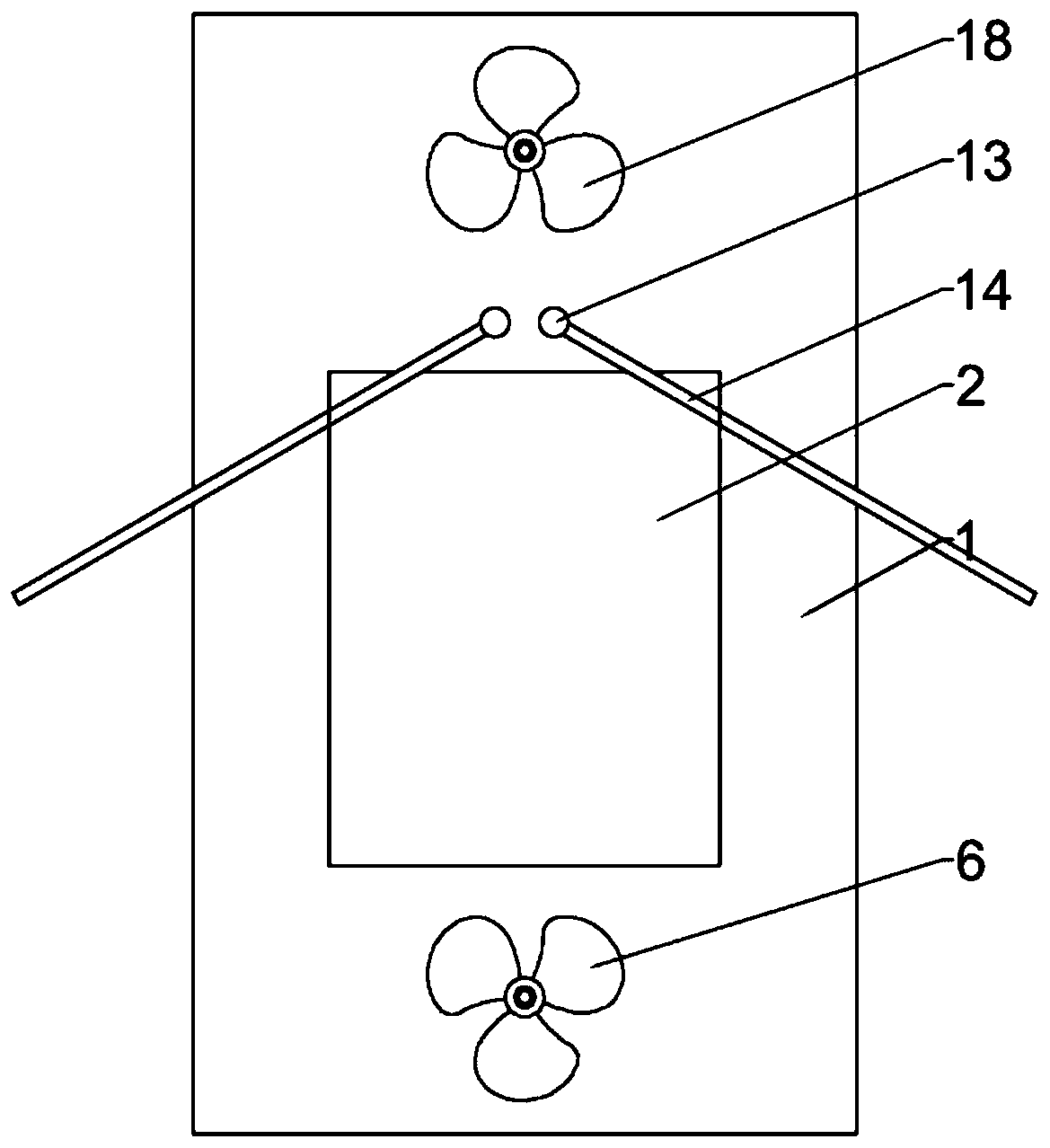

[0036] Embodiment 2: The difference between this embodiment and the previous embodiment is that the driven gear 19 meshes with the rear transmission gear 11 . The driven gear 19 can move accordingly no matter whether it is engaged with the front side or the rear side during the meshing process of the transmission teeth 11 .

[0037] The working principle of the present invention is: when the dust is accumulated on the LED backlight 2, the drive motor 4 is turned on, the drive motor 4 drives the first rotating shaft 5 to rotate, and then drives the first rotating blade 6 to rotate, and the bell crank 7 rotates while the first rotating shaft 5 rotates. Rotate, and then drive the first transmission rod 8 and the second transmission rod 9 to move, the motion trajectory of the second transmission rod 9 is reciprocating up and down, and then drive the transmission gear 11 to move up and down, and drive the opened swing cleaning when the transmission gear 11 moves upwards The rods 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com