Pneumatic pump

A pneumatic pump and cylinder technology, applied in the direction of pumps, piston pumps, machines/engines, etc., can solve the problems of inaccurate reversing control, complex structure, expensive price, etc., and achieve the effects of precise reversing, noise reduction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

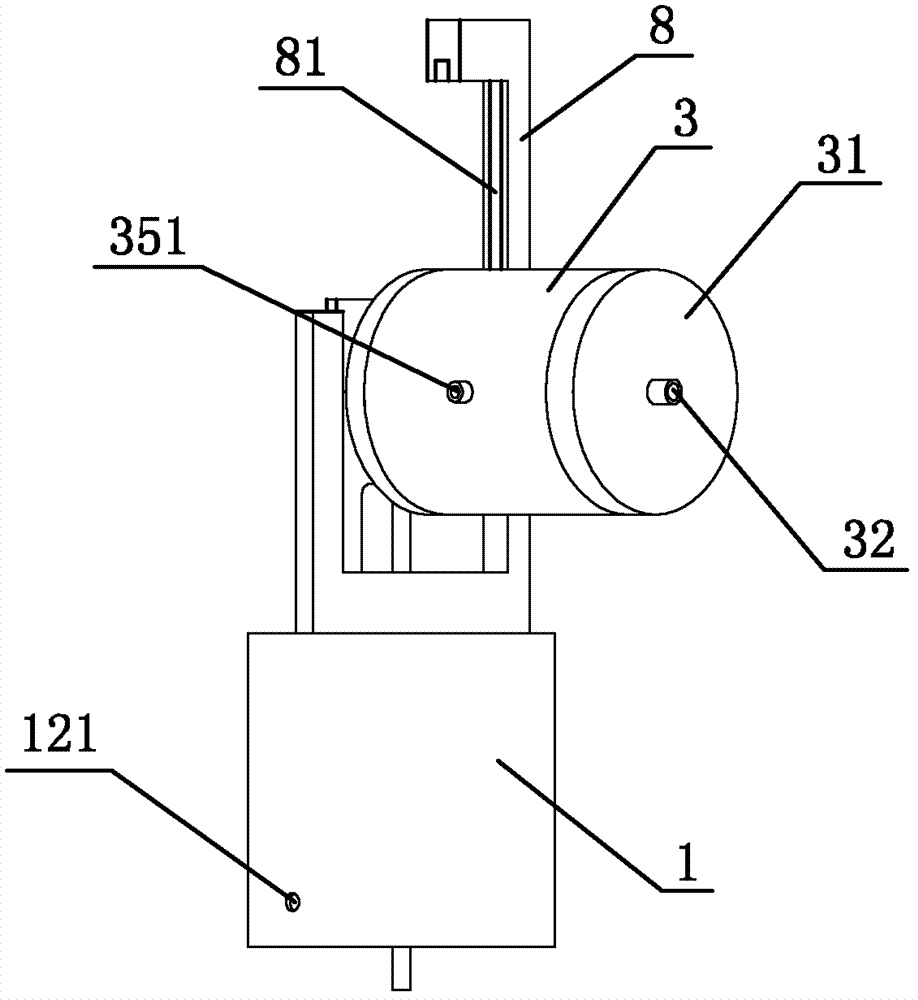

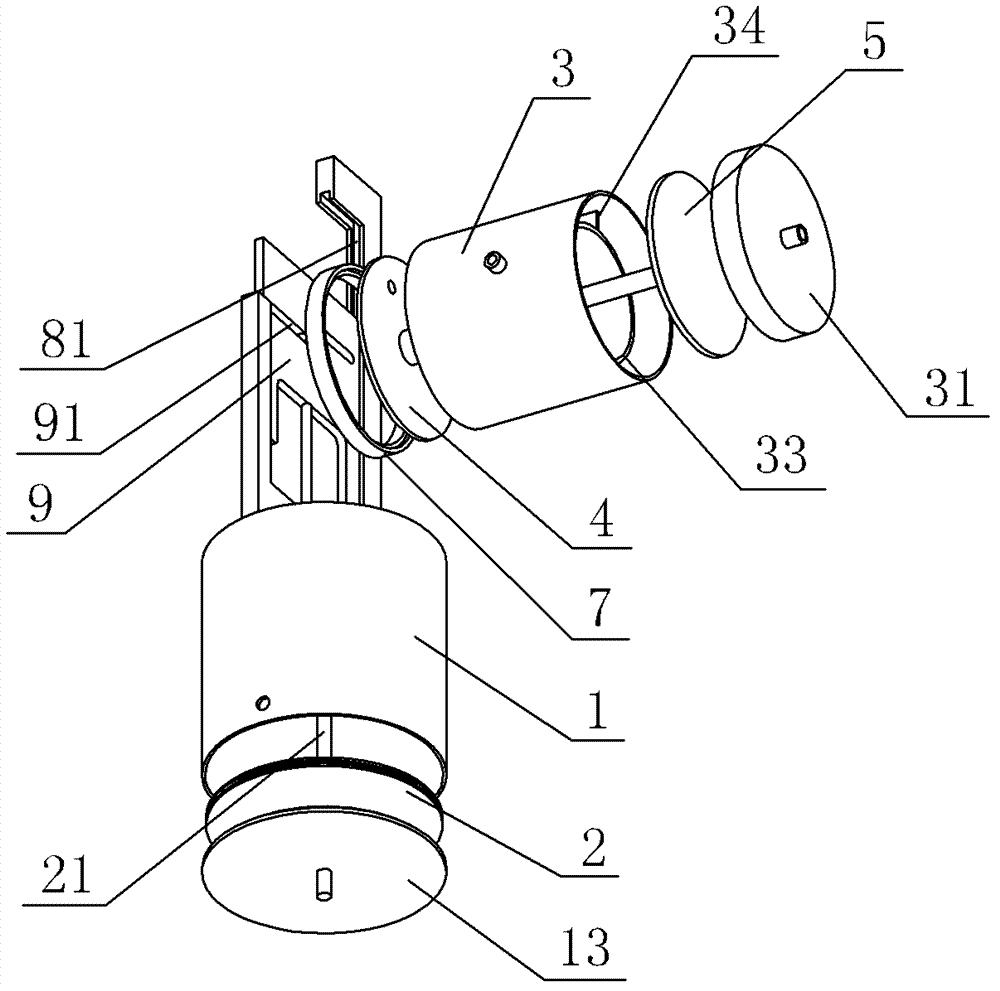

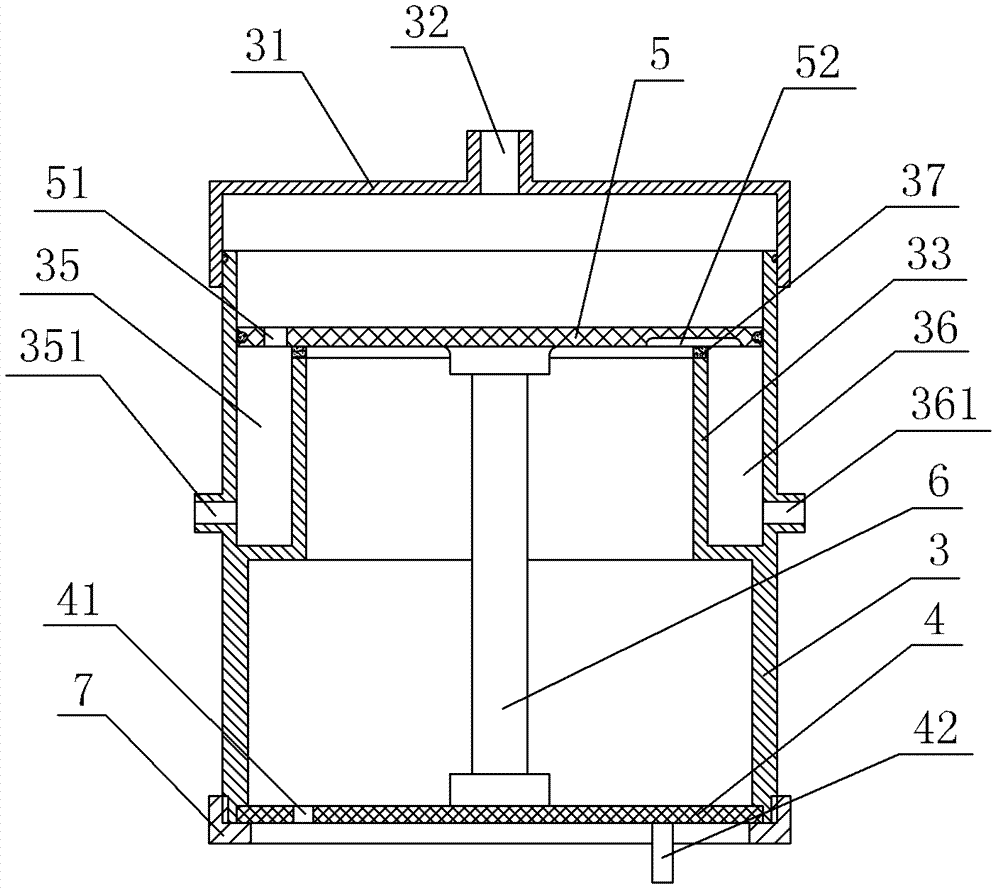

[0017] As shown in the figure, a pneumatic pump includes a first cylinder block 1, a piston 2 and a reversing device, and the reversing device includes a second cylinder block 3, a transmission disc 4 and a turntable 5 sealed in the second cylinder block 3 The end of the second cylinder block 3 is sealed and fixed with a cylinder head 31, the cylinder head 31 is provided with an air inlet 32, and the second cylinder block 3 is integrally provided with a hollow inner cylinder body 33, and the second cylinder block 3 and Two partition plates 34 positioned on the same plane are arranged between the inner cylinders 33 to divide the space between the second cylinder body 3 and the inner cylinder 33 into a left cylinder 35 and a right cylinder 36, and the inner cylinder 33 and the divided The upper ends of the partitions 34 are respectively fixed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com