Swing mechanism of rocker

A technology of swing mechanism and transmission shaft, which is used in jacquard machines, textiles, textiles and papermaking, etc., can solve the problems of easy wear of gear teeth, affecting transmission stability and machining accuracy, and large load, and achieve the effect of reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

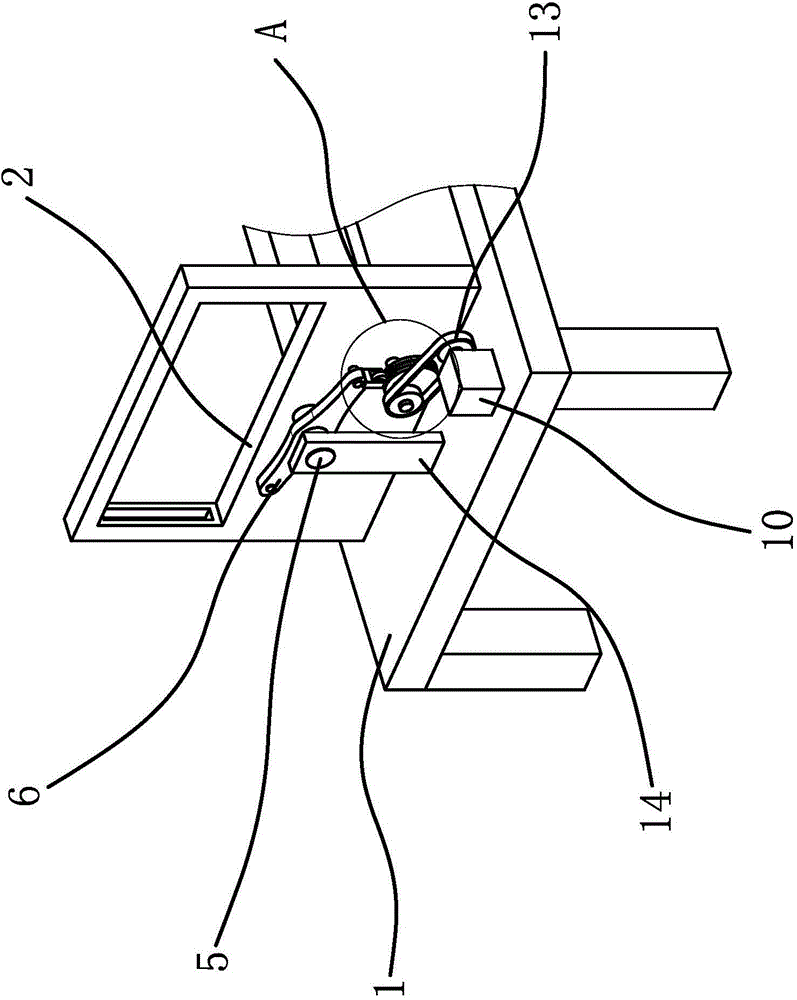

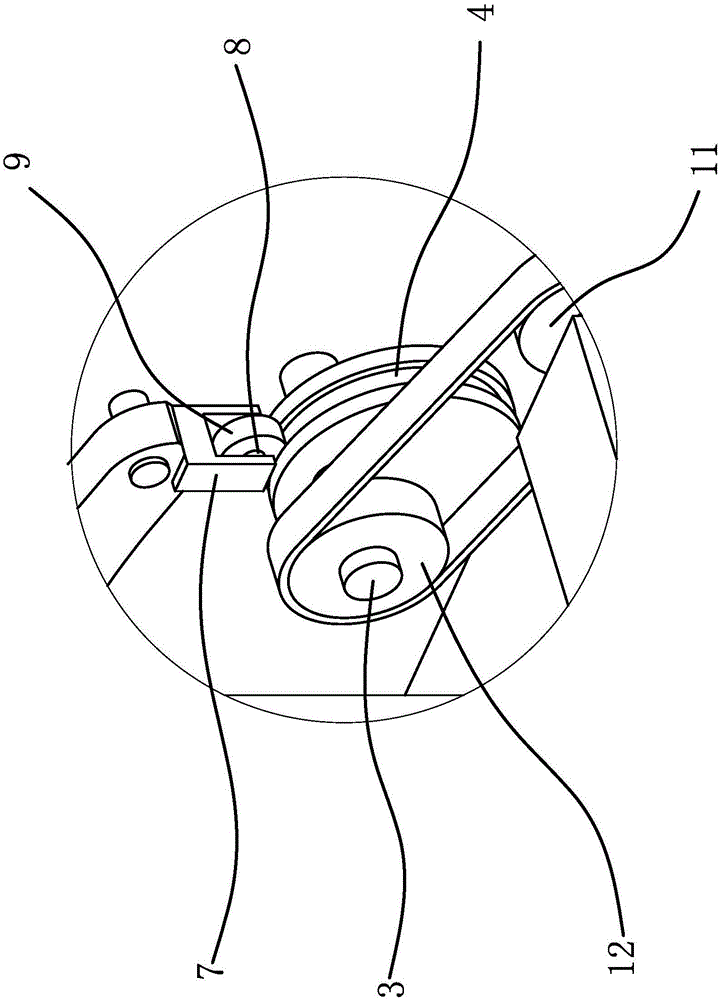

[0022] Such as figure 1 As shown, a swing mechanism of a rocker includes a frame and a support plate vertically fixed on the frame. The support plate is provided with a transmission shaft through the axially fixed and circumferential rotation mode, and an eccentric wheel is fixed at one end of the transmission shaft. diagonally above.

[0023] Specifically, one end of the rotating shaft is fixed with a rocker, and one end of the rocker is fixed with a U-shaped bracket. On the rotating shaft, the outer ring of the bearing is fixed on the bracket, and the roller is fixed in the middle of the rotating shaft.

[0024] The rocking rod and the eccentric wheel are all on the same side of the support plate, and one end of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com