Treatment method of circulating water with leaking oil

A treatment method and circulating water technology, applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of expensive biological enzyme purifiers and achieve high concentration Multiple, low pollution discharge, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

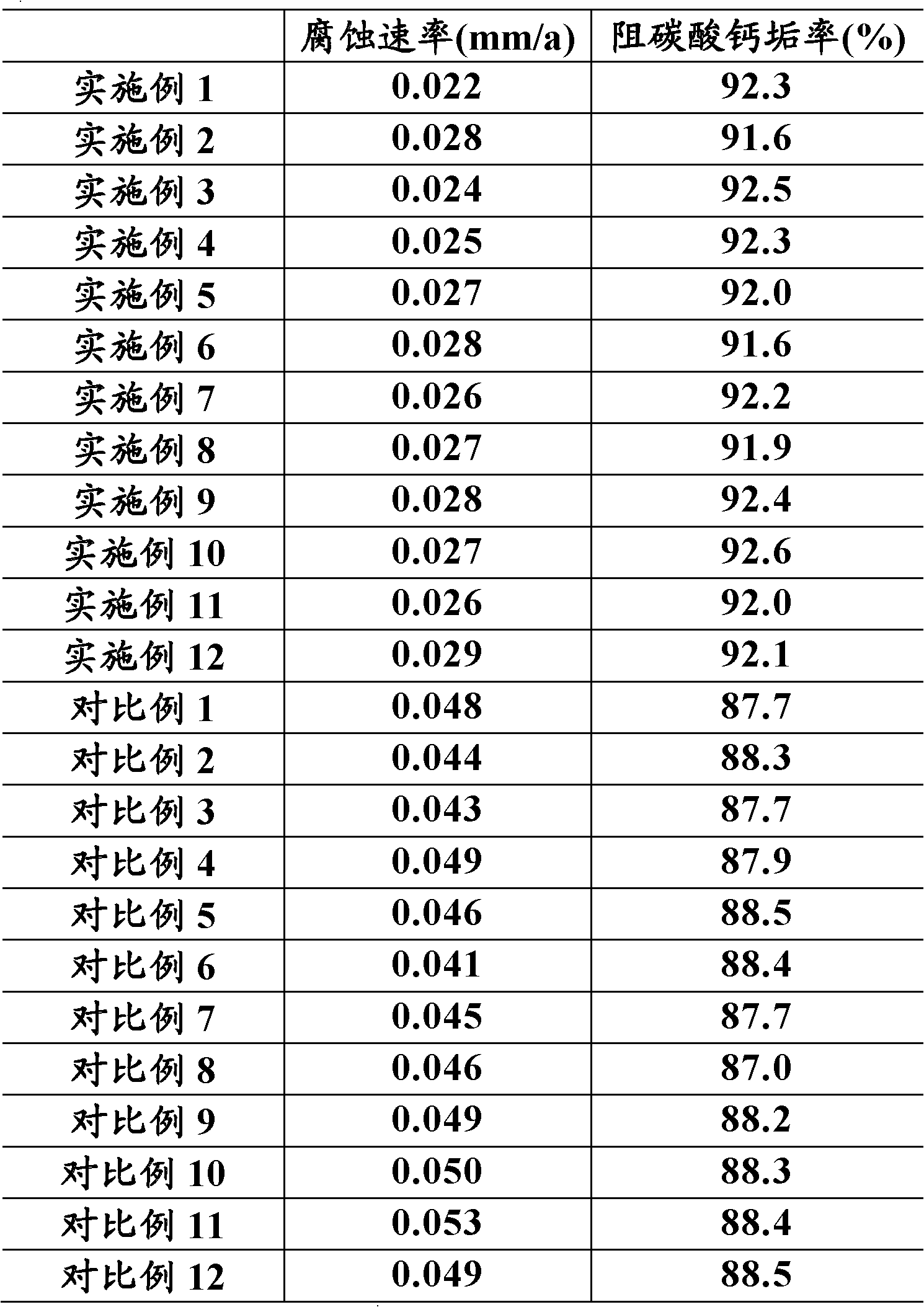

[0048] The preparation of scale and corrosion inhibitor: 8.8g of zinc sulfate heptahydrate is dissolved in 39.9 grams of water, and the dissolution is even, adding 8g of effective content is 50% PESA (polyepoxysuccinic acid, the limit viscosity number at 30 ℃ is 0.051 dl / g), adding 43.3g solid content is 30% acrylic acid / hydroxypropyl acrylate copolymer (the mass ratio of acrylic acid and hydroxypropyl acrylate in the copolymer is 7: 3, and the limiting viscosity number at 30 ℃ is 0.068dl / g), shake well.

[0049] When the prepared scale and corrosion inhibitor solution is added to the test water at a concentration of 100 mg / L, PESA, acrylic acid / hydroxypropyl acrylate copolymer, Zn 2+ The effective concentrations are 4mg / L, 13mg / L and 2mg / L respectively.

[0050] Add 200mg of pyrolysis gasoline to the beaker during the corrosion inhibition test, add 50mg of pyrolysis gasoline to the volumetric flask during the scale inhibition test, and then add 95mg / L of sodium dodecylbenze...

Embodiment 2

[0052] Preparation of scale and corrosion inhibitor: 32.5g effective content of 40% PASP (polyaspartic acid, limit viscosity at 30°C is 0.071dl / g) was dissolved in 40.8g water, and 26.7g solid content was added 30% acrylate / styrenesulfonic acid copolymer (the mass ratio of acrylate to styrenesulfonic acid in the copolymer is 7:3, and the limiting viscosity number at 30° C. is 0.071 dl / g), shake well.

[0053] When the prepared scale and corrosion inhibitor solution is added to the test water at a concentration of 100mg / L, the effective concentrations of PASP and acrylate / styrenesulfonic acid copolymer in the water are 13mg / L and 8mg / L.

[0054] In the corrosion inhibition test, 200 mg of wax oil was applied to the surface of the test piece, and in the scale inhibition test, 50 mg of wax oil was applied to the inner wall of the volumetric flask, and 50 mg / L of sodium tetradecylbenzenesulfonate and 40 mg / L of NP-6 were added respectively. The test results See Table 2.

Embodiment 3

[0056] The preparation of antiscaling and corrosion inhibitor: 20g effective content is 50% PESA (the limiting viscosity number at 30 ℃ is 0.031dl / g) is added in 41.37g water, and adding 16.7g solid content is 30% polyacrylic acid (30 The limit viscosity number at ℃ is 0.069dl / g), then add 16.7g of acrylic acid / 2-methyl-2'-acrylamidopropanesulfonic acid copolymer (acrylic acid and 2-methanol in the copolymer) with a solid content of 30%. The mass ratio of base-2'-acrylamidopropanesulfonic acid is 7:3, and the limiting viscosity number at 30°C is 0.071dl / g), add 5.23g of zinc chloride, and shake well.

[0057] When the prepared scale and corrosion inhibitor solution is added to the test water at a concentration of 100 mg / L, PESA, polyacrylic acid, acrylic acid / 2-methyl-2′-acrylamide propane sulfonate Acid copolymer and Zn 2+ The effective concentrations are 10mg / L, 5mg / L, 5mg / L and 2.5mg / L respectively.

[0058] Add 200mg of light diesel oil to the beaker during the corrosion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com