Metallized film splitting machine with static electricity eliminating device

A static elimination device and metallized film technology, which is applied in thin material processing, transportation and packaging, chemical instruments and methods, etc., can solve problems such as reducing the service life of brush heads, failing to replace brush heads, and failing to improve film cleaning efficiency. , to achieve the effect of increasing the service life, improving the degree of automation and improving the cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

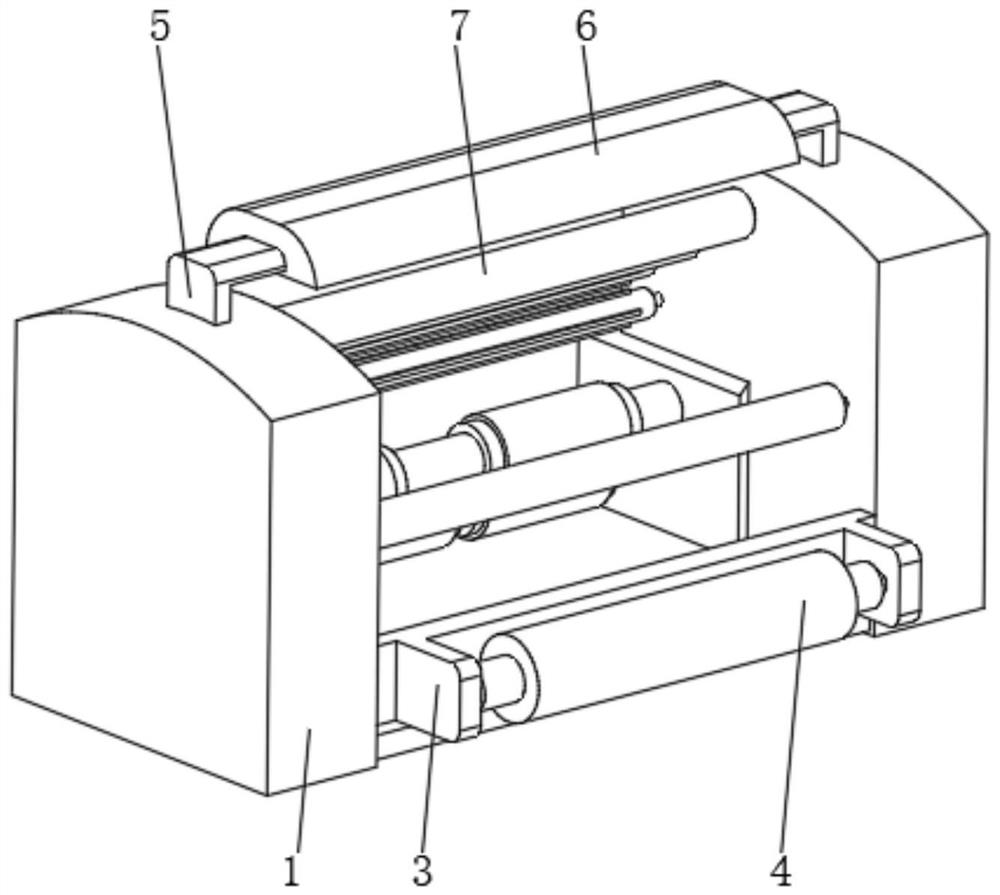

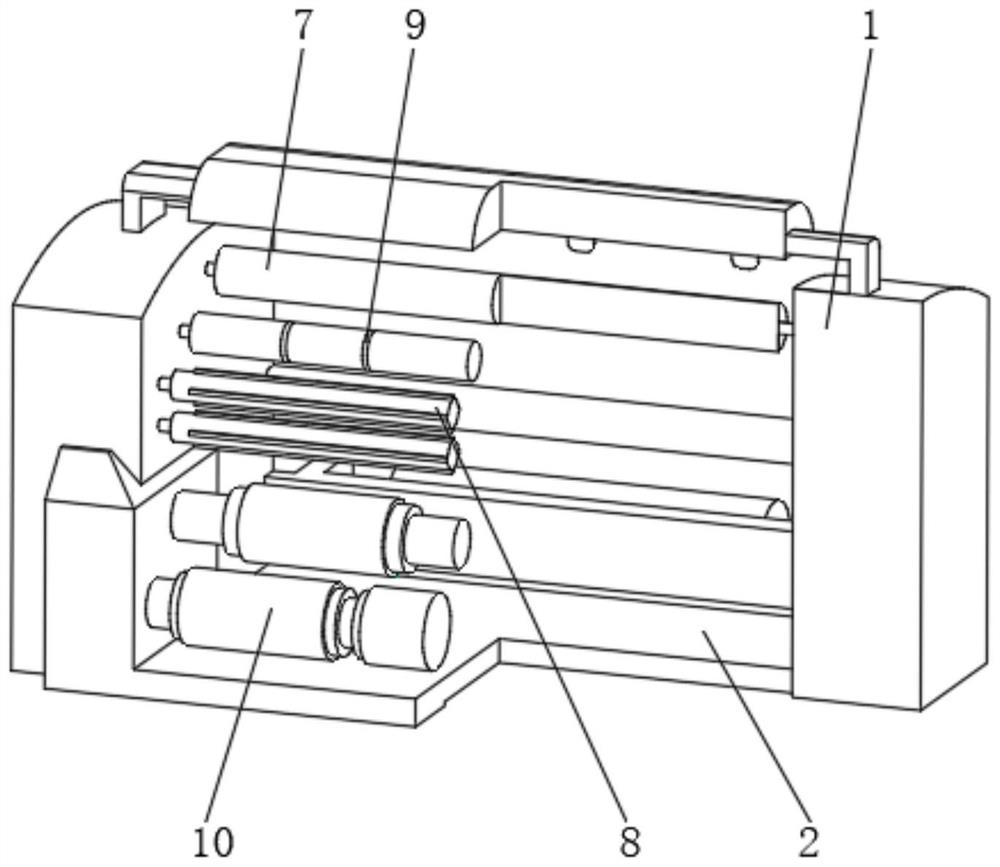

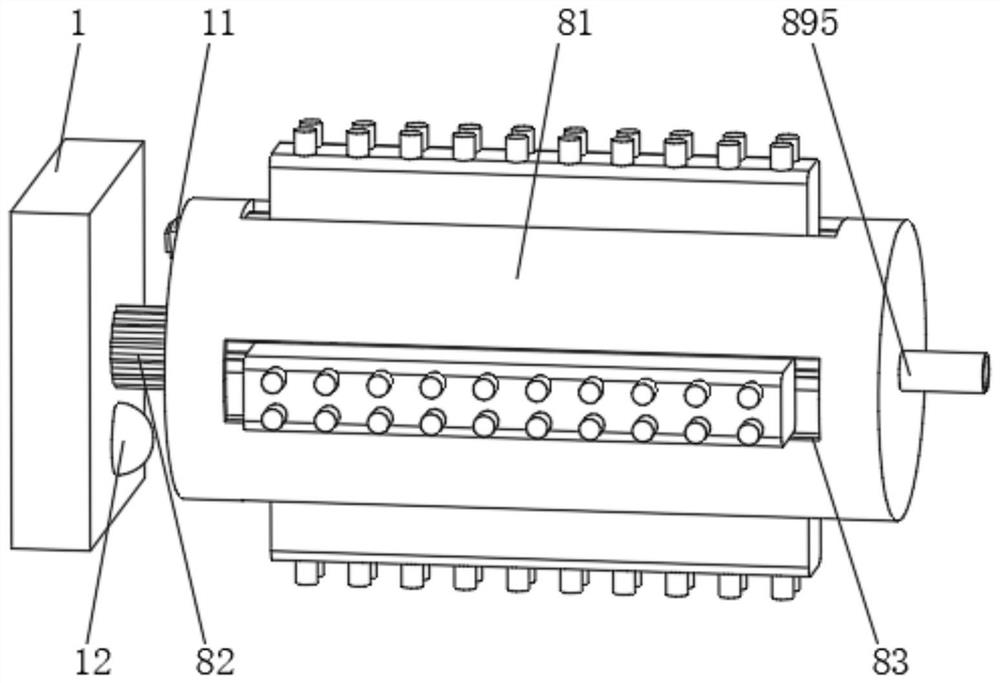

[0032] see Figure 1-5 , the present invention provides a technical solution: a metallized film slitting machine with a static elimination device, comprising a housing 1, the bottom of the housing 1 is fixedly connected with a fixed base 2, and one side of the housing 1 is fixedly connected with a feed bracket 3 , one side of the feed bracket 3 is rotatably connected with the feed roller 4, the top of the shell 1 is fixedly connected with the mounting frame 5, one side of the mounting frame 5 is fixedly connected with the static elimination mechanism 6, and one side of the shell 1 is rotatably connected with the top Guide roller 7, a cleaning device 8 is installed on one side of the housing 1, a cutting roller 9 is rotatably connected to one side of the housing 1 at the bottom of the top guide roller 7, and a winding device is installed on one side of the housing 1 at the bottom of the cleaning device 8. device 10;

[0033] The cleaning device 8 includes a cleaning roller 81,...

Embodiment 2

[0042] see Figure 1-6 , the present invention provides a technical solution: on the basis of Embodiment 1, the winding device 10 includes a winding roller 101, the inside of the winding roller 101 is provided with a piston groove 102, and the inner wall of the piston groove 102 is slidably connected with a piston head 103 One end of the piston head 103 away from the piston groove 102 is fixedly connected with a push rod 104, the outer cover of the winding roller 101 is provided with a winding sleeve 105, the inner wall of the winding sleeve 105 is provided with a clamping hole 106, and the inner wall of the piston groove 102 is connected with a The extension tube 107 is slidably connected to the inner wall of the extension tube 107 with a sealing piston 108 , and the side of the sealing piston 108 away from the extension tube 107 is fixedly connected to a block 109 .

[0043] The clamping block 109 and the clamping hole 106 are matched with each other, a return spring is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com