Vacuum cleaner

A technology for vacuum cleaners and dust suction, which is applied in the direction of suction filters, devices for cleaning filters, etc., and can solve problems such as adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

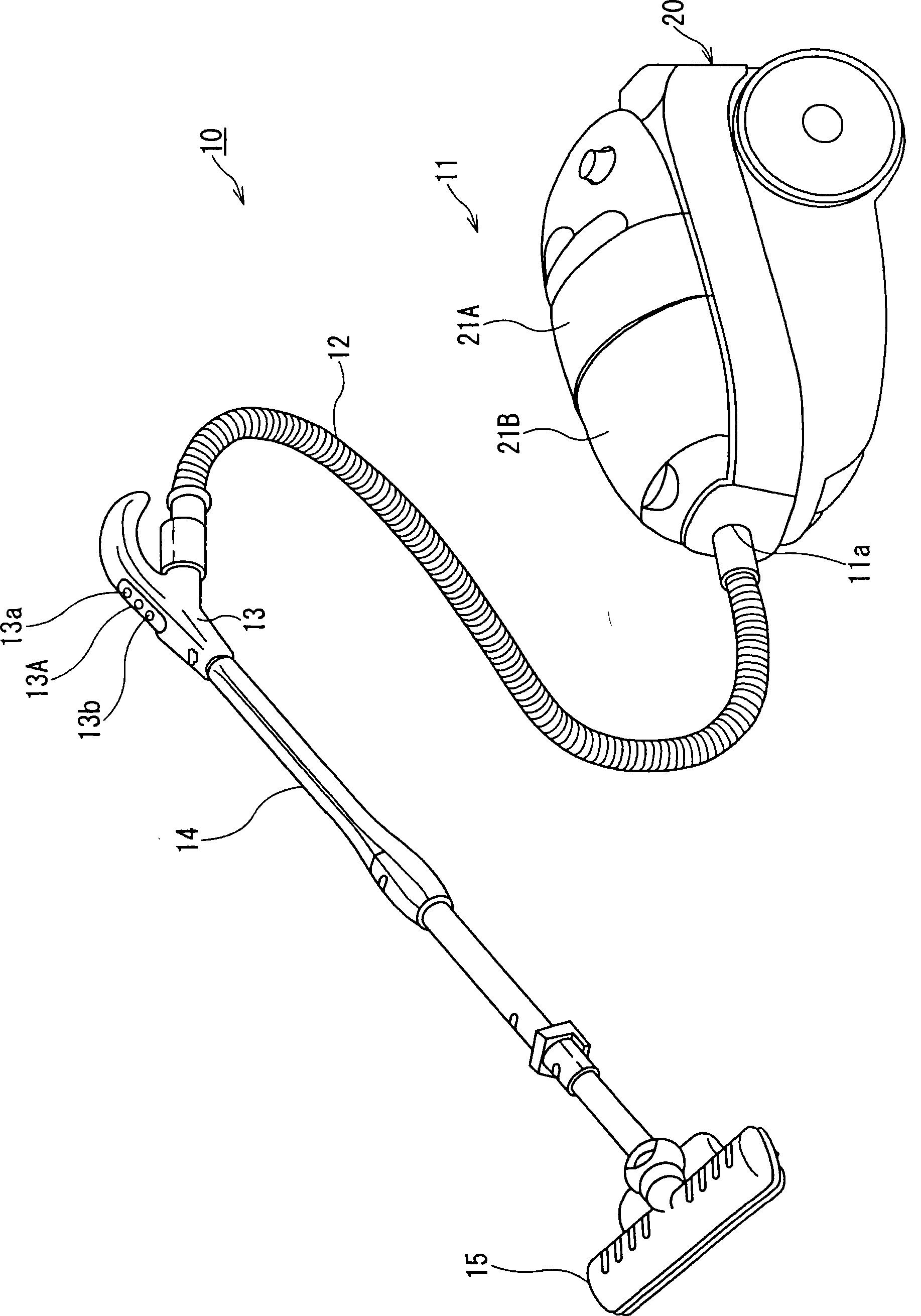

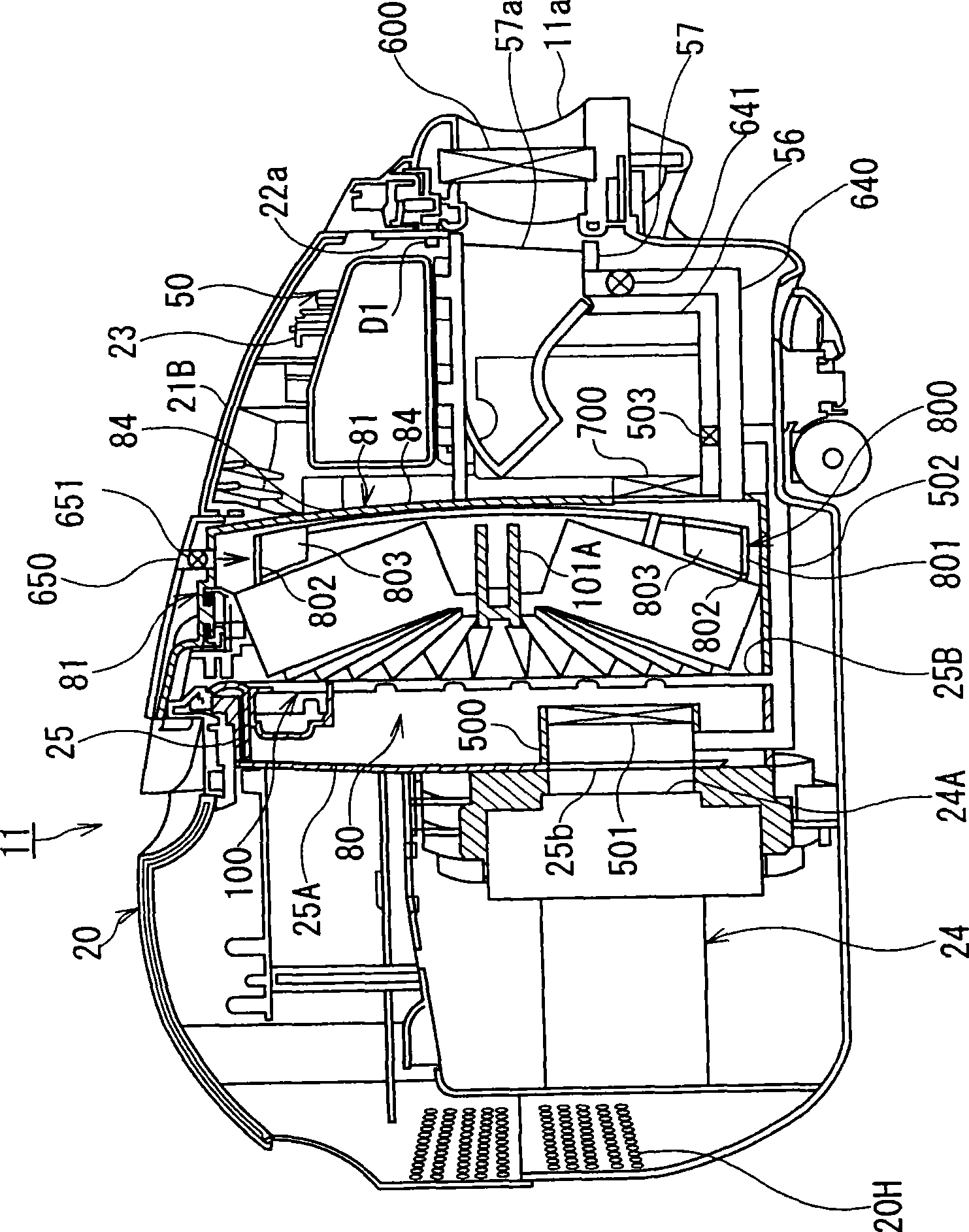

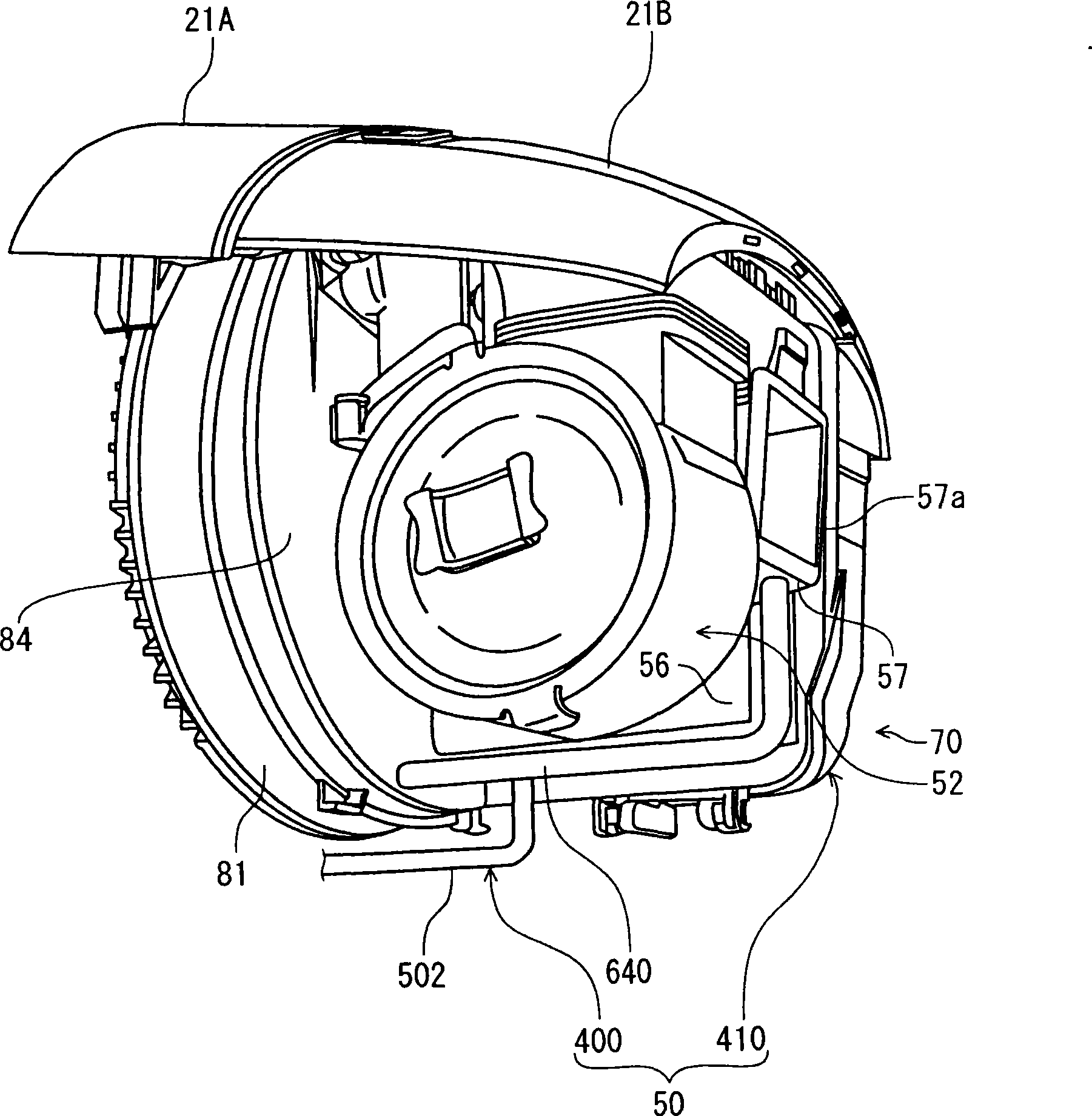

[0030] figure 1 A vacuum cleaner according to a first embodiment of the invention is shown. The vacuum cleaner 10 in the first embodiment comprises: a cleaner main body 11; a dust collecting hose 12, one end of which is detachably connected to the connection hole 11a of the cleaner main body 11, and the other end is provided with a hand-operated tube 13; an extension tube 14, detachable and the suction hole main body 15 is detachably connected to the front end of the extension pipe 14. The hand-operated pipe 13 has an operating part 13A, which includes a drive / stop switch 13a for switching between driving and stopping the electric blower 24, and a strong / weak switch 13b for controlling the electric blower 24 power, described below. The cleaner main body 11 has a main body housing 20 incorporating a dust collection unit 50 and an electric blower 24 (see figure 2 ). These dust collection units 50 and electric blower 24 are described below.

[0031] The suction hole main bo...

no. 2 example

[0077] Figure 9 and 10 A vacuum cleaner according to a second embodiment of the invention is shown. In the vacuum cleaner of the second embodiment, the air passage pipe 500 and the inside of the accommodating case 81 communicate through a detour air passage 900 which constitutes a detour passage and which has a third dust separation unit. The third dust separation unit includes, for example, a filter 901 and a solenoid valve 902 .

[0078] In the vacuum cleaner of the second embodiment, when cleaning, the gates 501 and 700 are opened, the solenoid valve 902 is closed, and the air flows as Figure 10 As shown by the chain line with arrows in , and the dust is collected in the dust collection cavity part 73, same as the first embodiment.

[0079] When the switch 13a (see figure 1 ), the gates 501 and 700 are closed, and the solenoid valve 902 is opened. The electric blower 24 is driven with predetermined power for a predetermined period of time.

[0080] When the shutters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com