Wafer chuck cleaning system used for lithography machine and cleaning method thereof

A cleaning system and lithography machine technology, applied in the semiconductor field, can solve the problems of grinding stone loss, damage to the closed chamber environment, secondary pollution, etc., and achieve the effects of low cost, avoiding repeated pollution, and small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

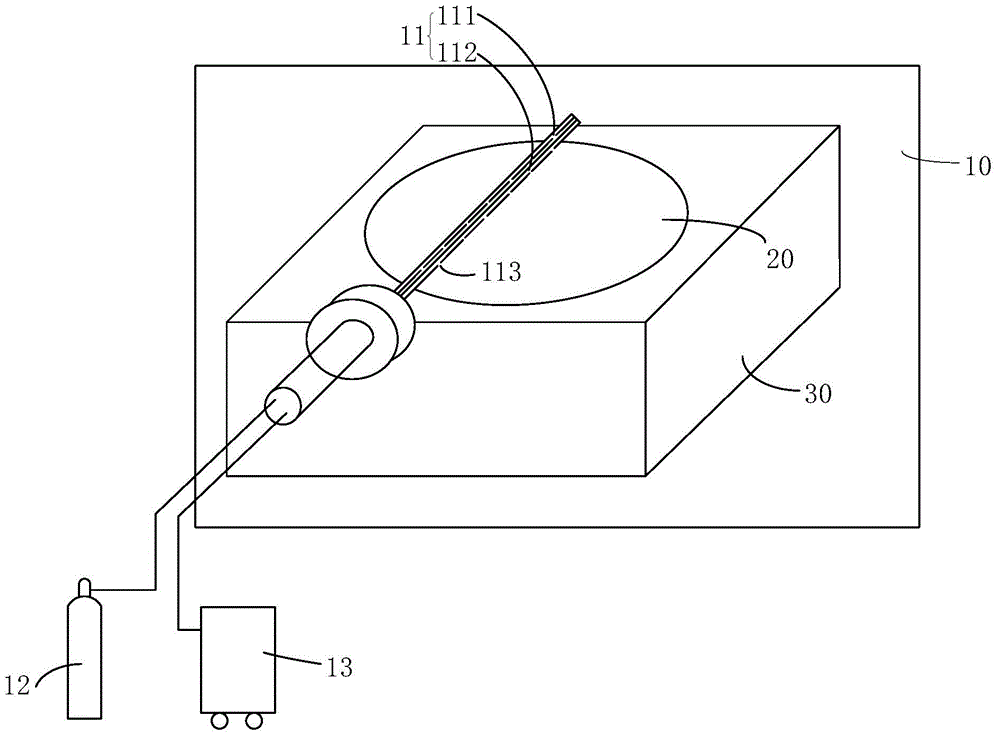

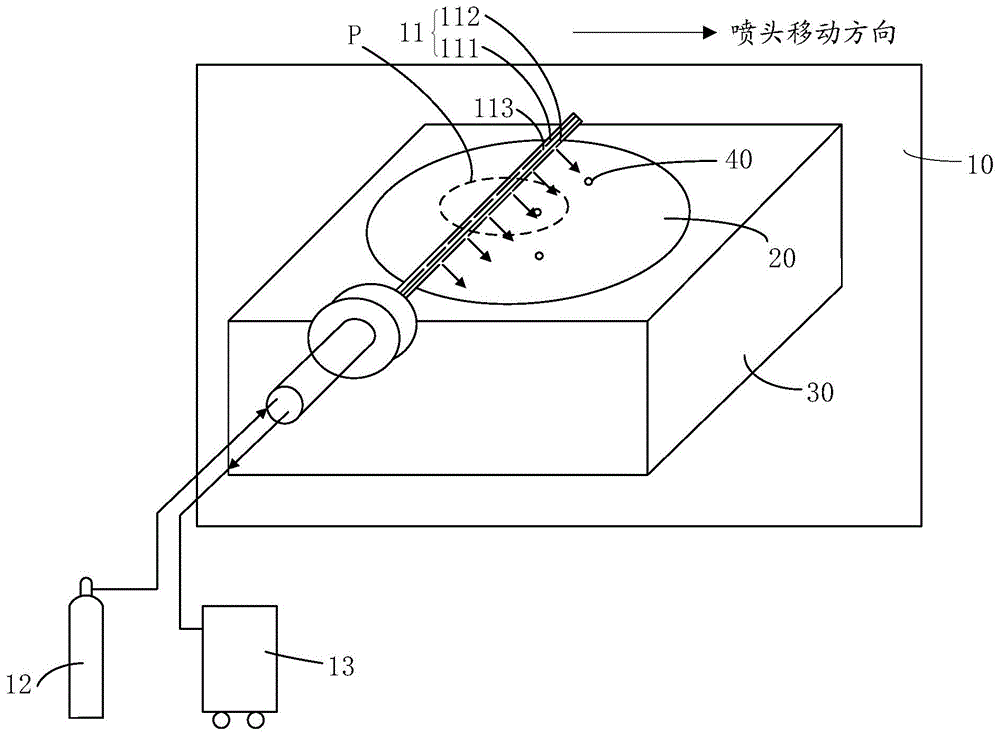

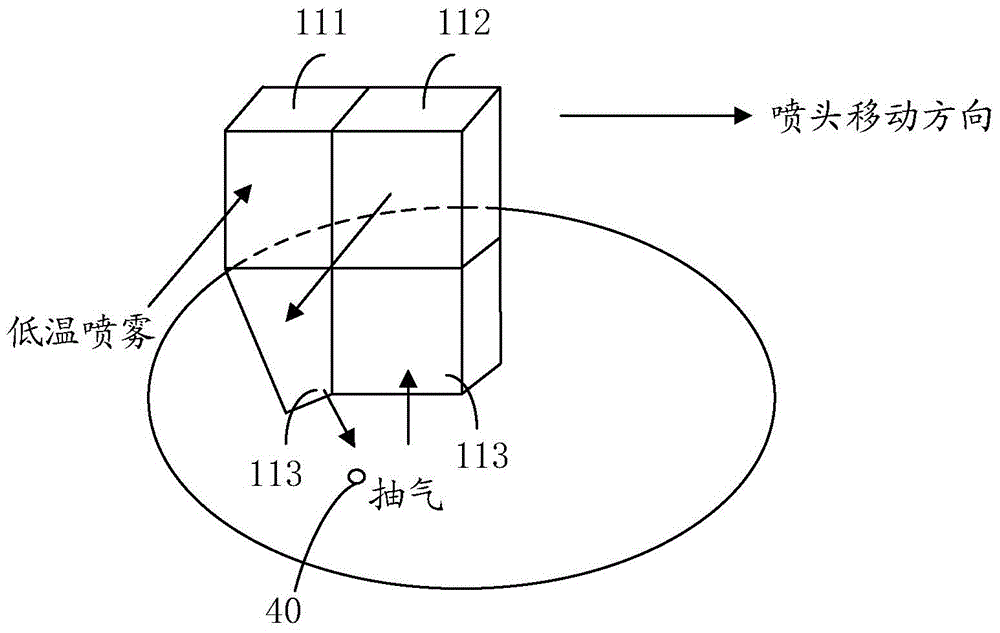

[0048]As mentioned in the background technology, the existing wafer chuck cleaning method does not need to open the closed chamber where the wafer chuck is located, and remove the chuck to remove pollutants, which will destroy the environment of the closed chamber and take time. ; Or use a grinding stone to grind the surface of the wafer chuck in a closed chamber, but this will damage the surface of the wafer chuck. In view of the above technical problems, the present invention proposes to install a spray head in the closed chamber where the wafer chuck is located. The above spray head provides a low-temperature spray to the surface of the wafer chuck when it needs to be cleaned. The above-mentioned low-temperature spray is particles with a certain quality, carrying At a certain speed, it can collide with the pollutants on the surface of the wafer chuck, so that the above-mentioned pollutants are separated from the surface of the chuck, and at the same time, the air extraction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com