Processing technology for color film substrate of liquid crystal display screen

A liquid crystal display and color filter substrate technology, which is applied to the cleaning method using tools, the cleaning method using liquid, optics, etc. Water effect is not good, the effect of improving cleaning efficiency and improving drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

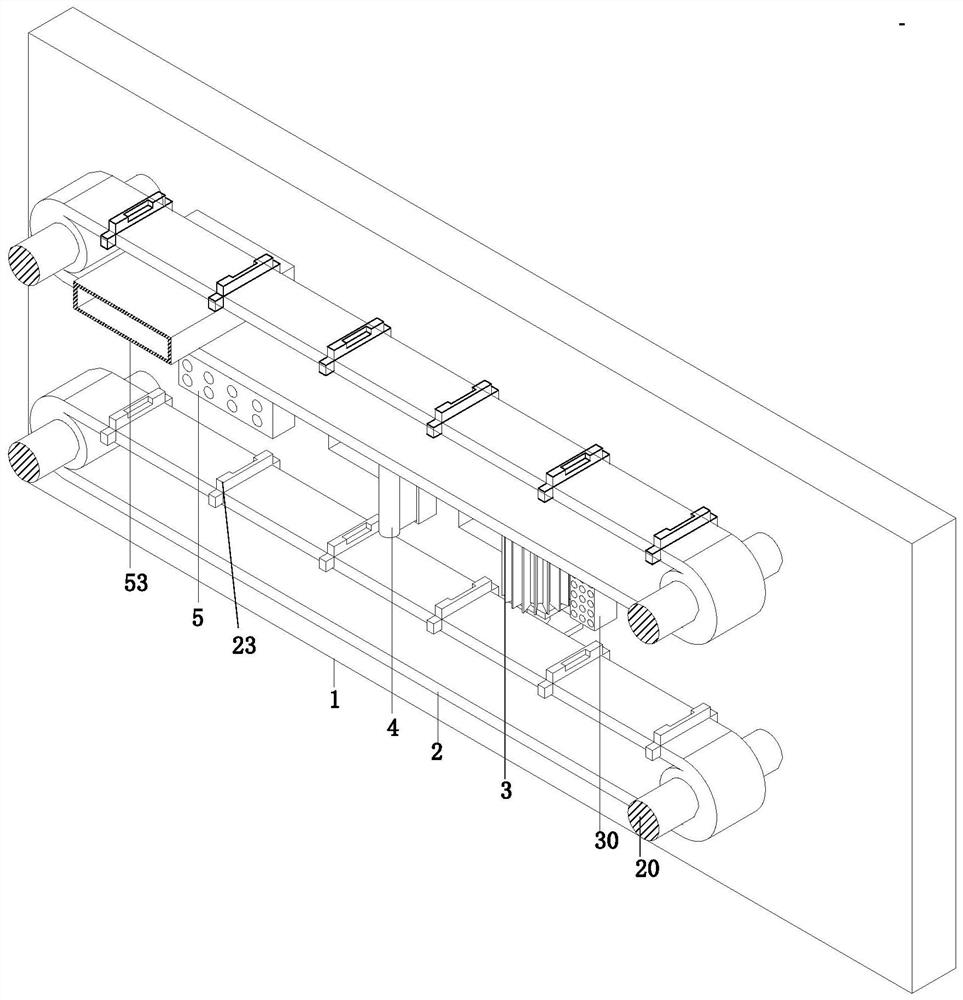

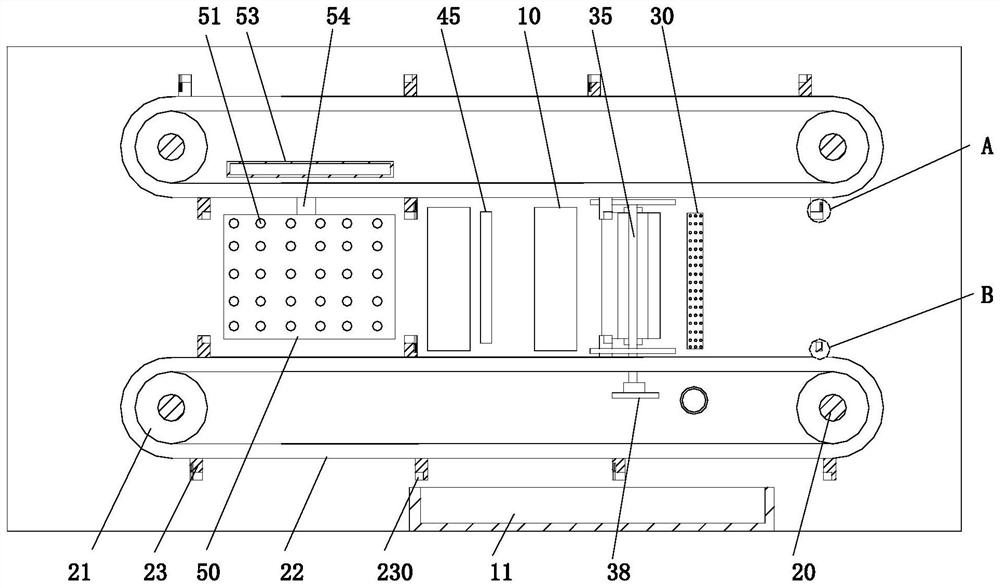

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

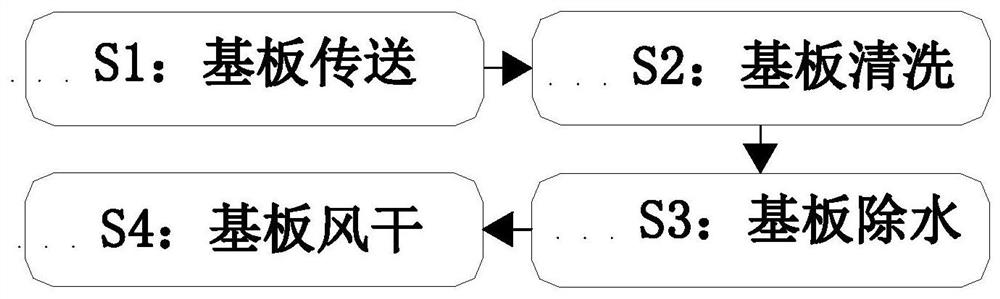

[0037] Such as Figure 1 to Figure 12 As shown, a liquid crystal display color film substrate processing technology, which uses a liquid crystal display color film substrate processing device, the liquid crystal display color film substrate processing device includes a support plate 1, a transmission mechanism 2, a cleaning mechanism 3, The dewatering mechanism 4 and the drying mechanism 5, when using the above liquid crystal display color film substrate processing device to process the color film substrate, the specific processing technology is as follows:

[0038] S1. Substrate transmission: when the conveyor belt 22 stops intermittently, put the color filter substrate on the pallet 23, and then drive the color filter substrate through the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com