Patents

Literature

183results about How to "Improve wiping efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

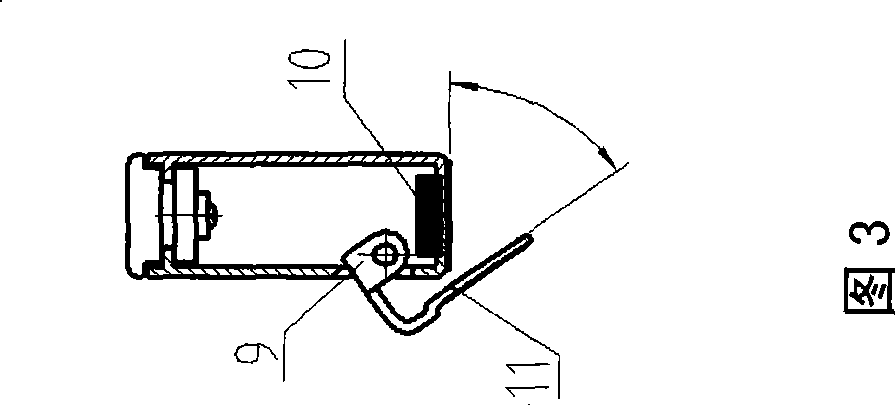

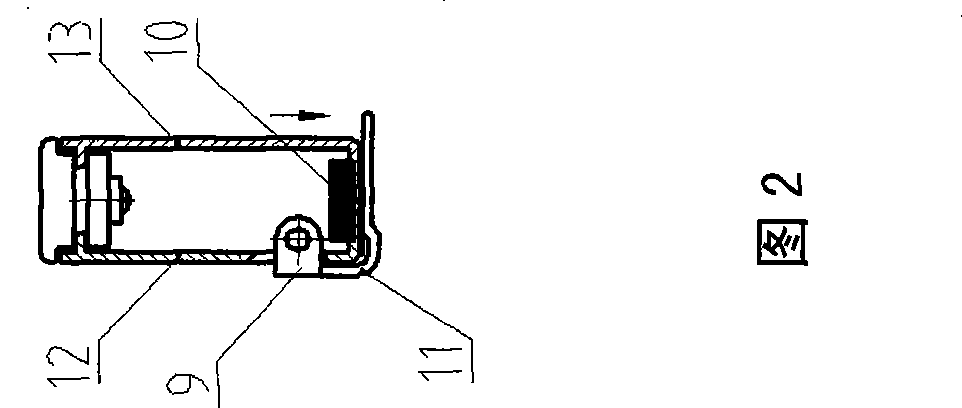

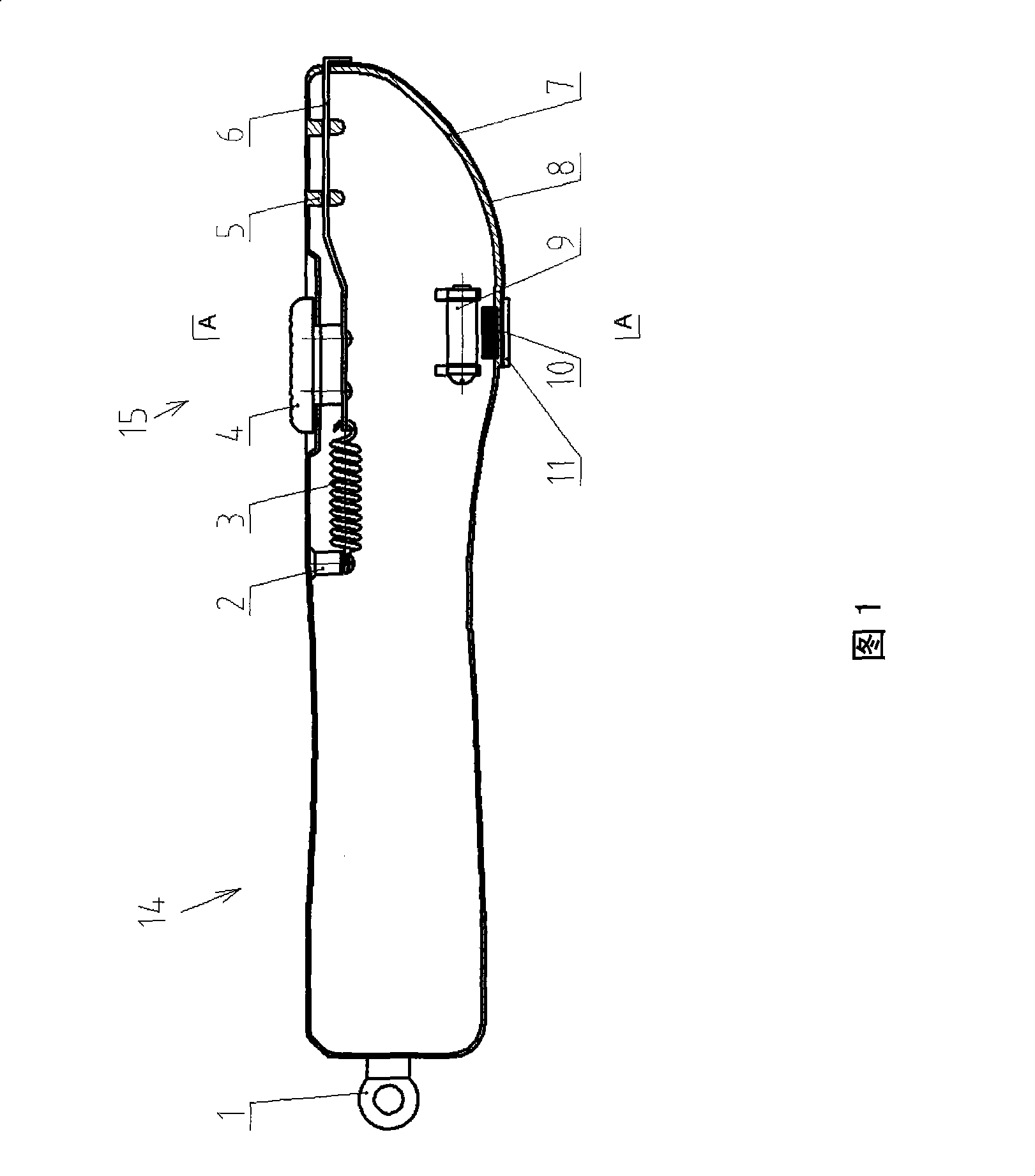

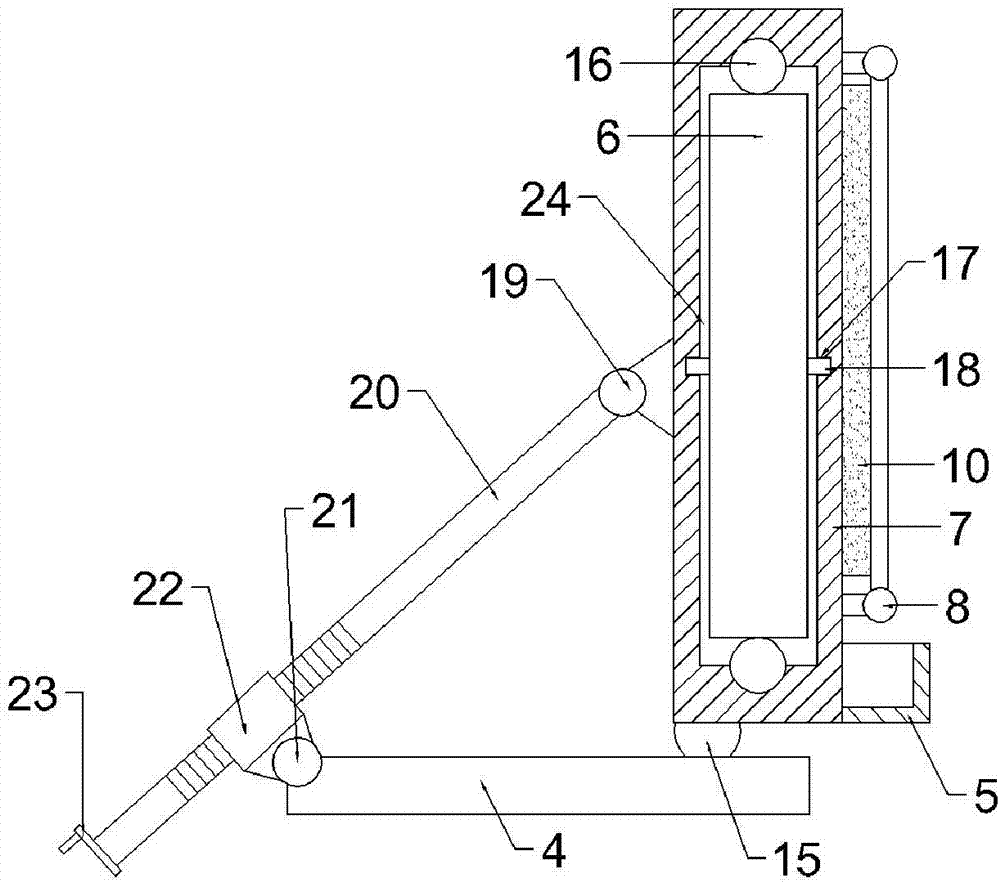

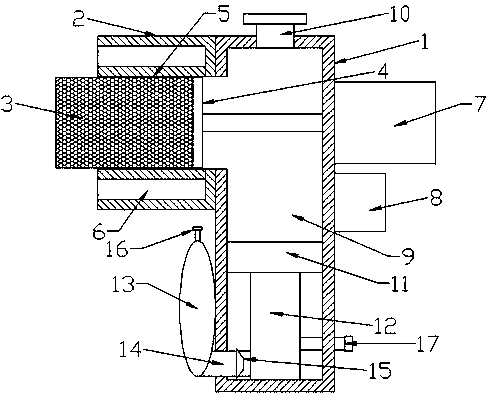

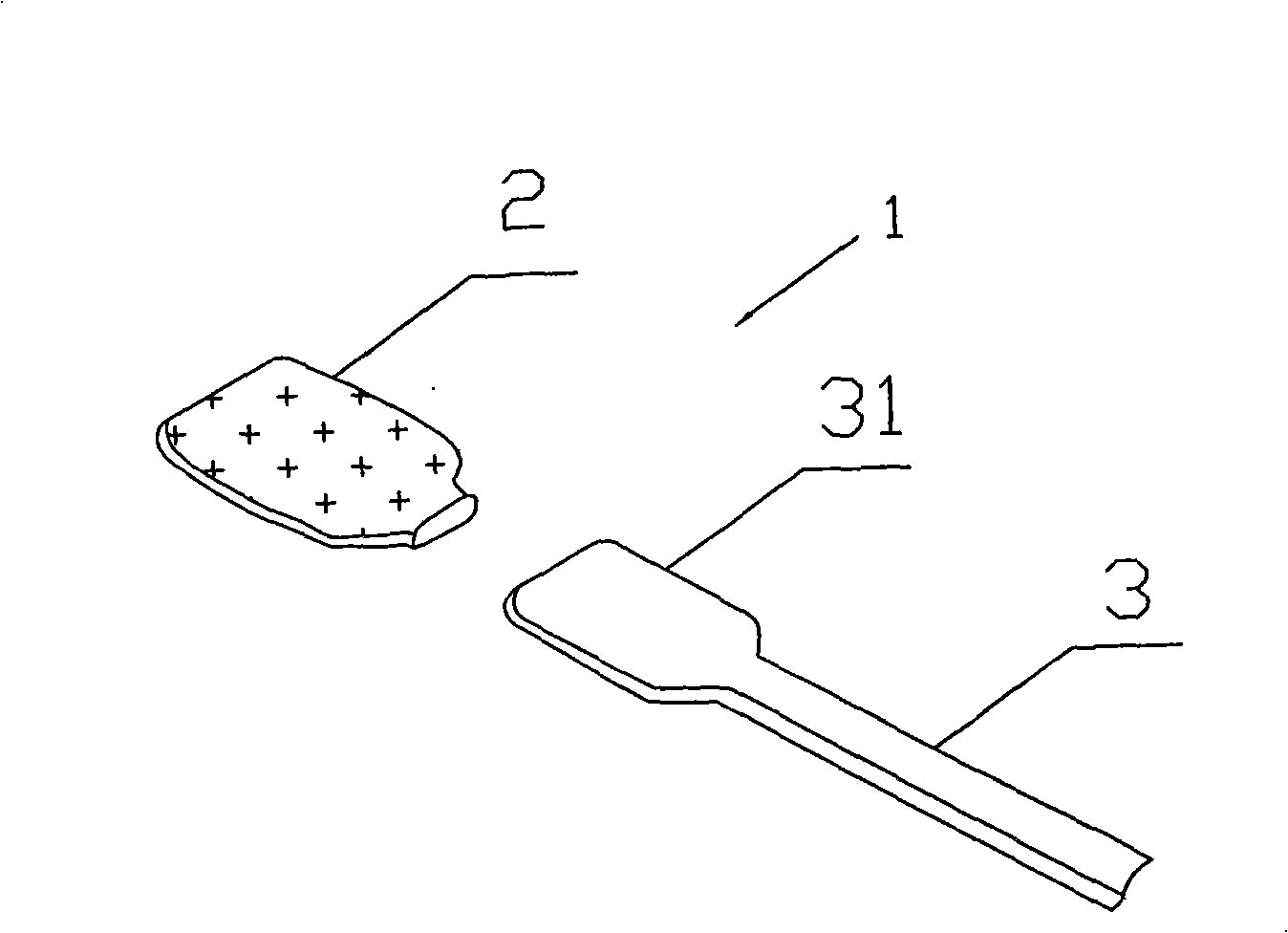

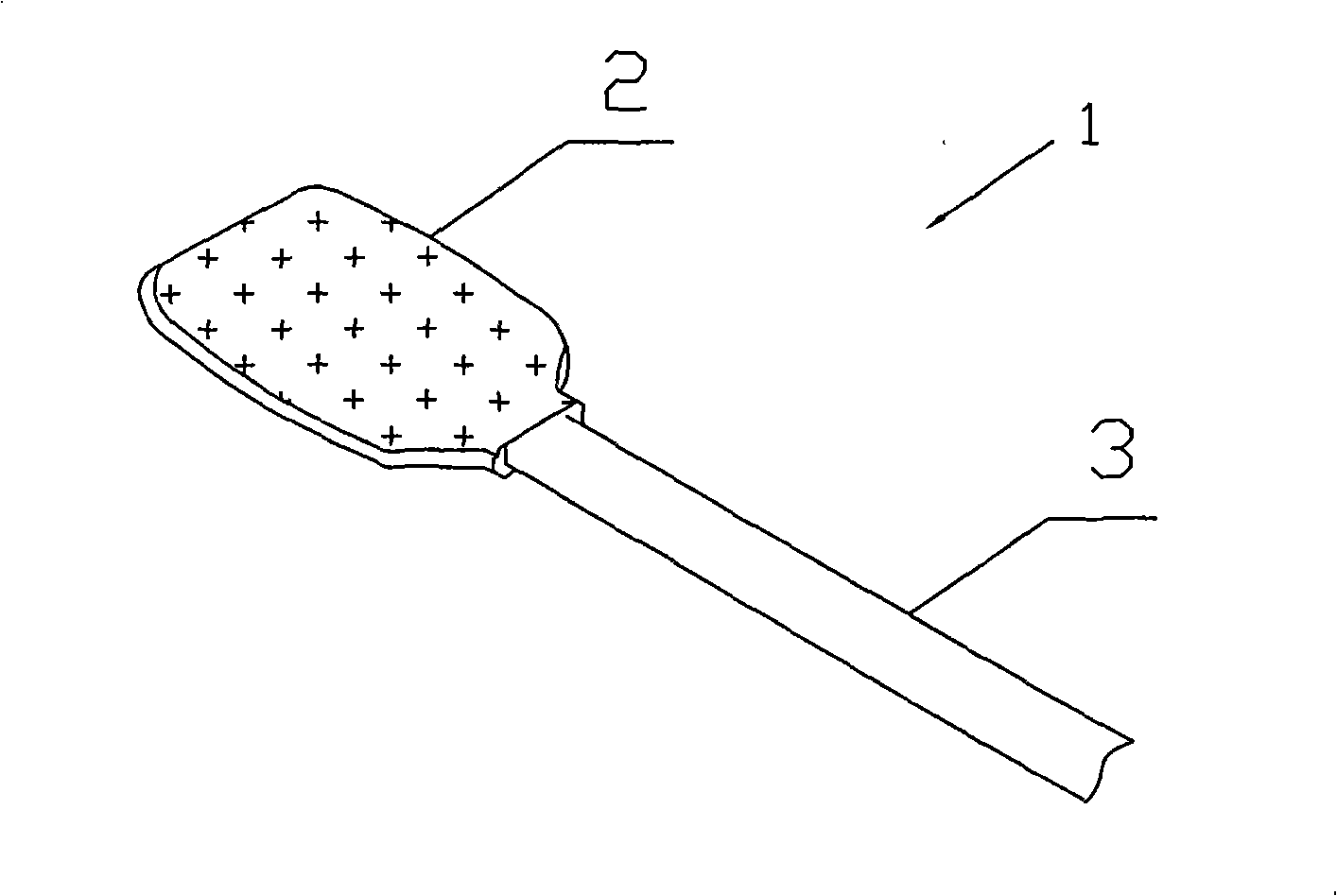

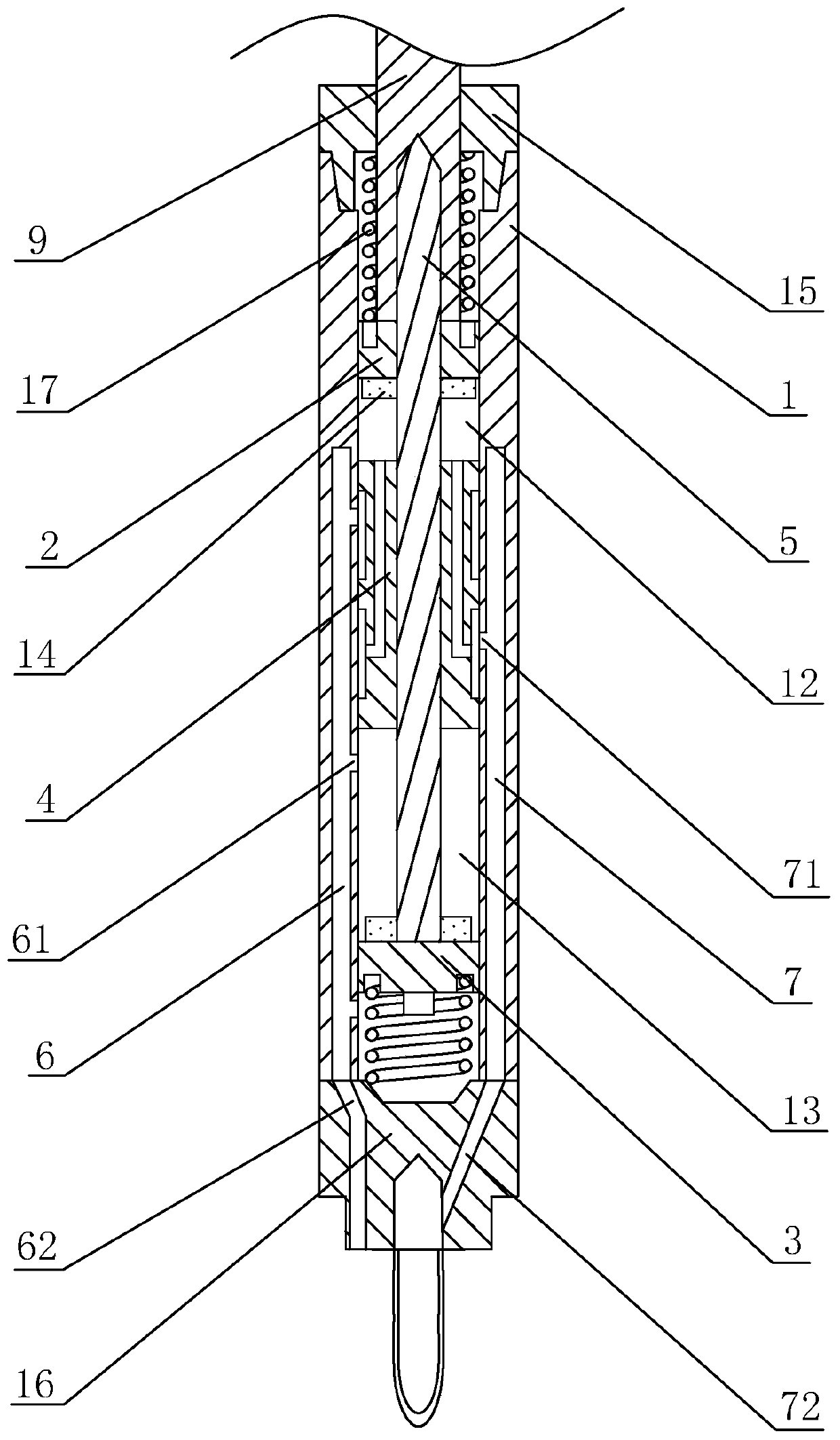

Hand-hold sampling apparatus and method for preventing sampling vector form deforming

ActiveCN101363778AAvoid deformationAvoid wrinklesWithdrawing sample devicesMaterial analysis by electric/magnetic meansSmall sampleWipe sampling

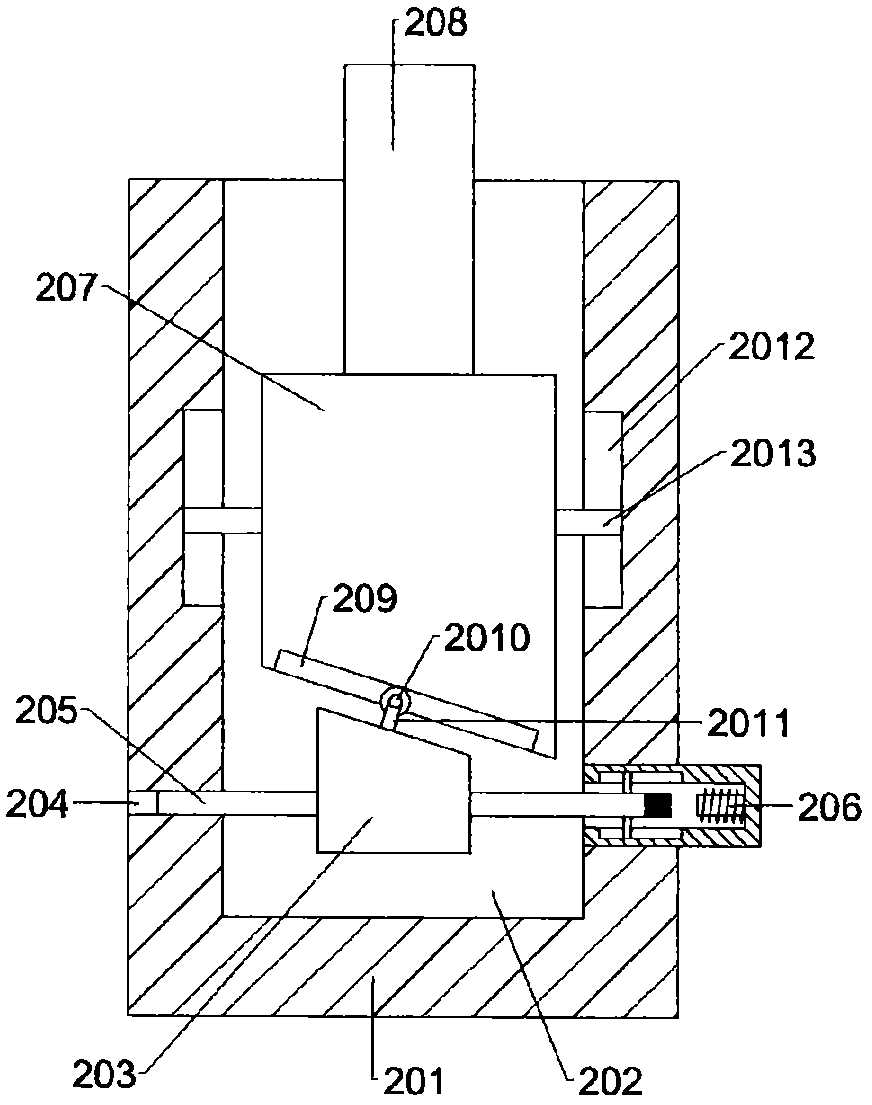

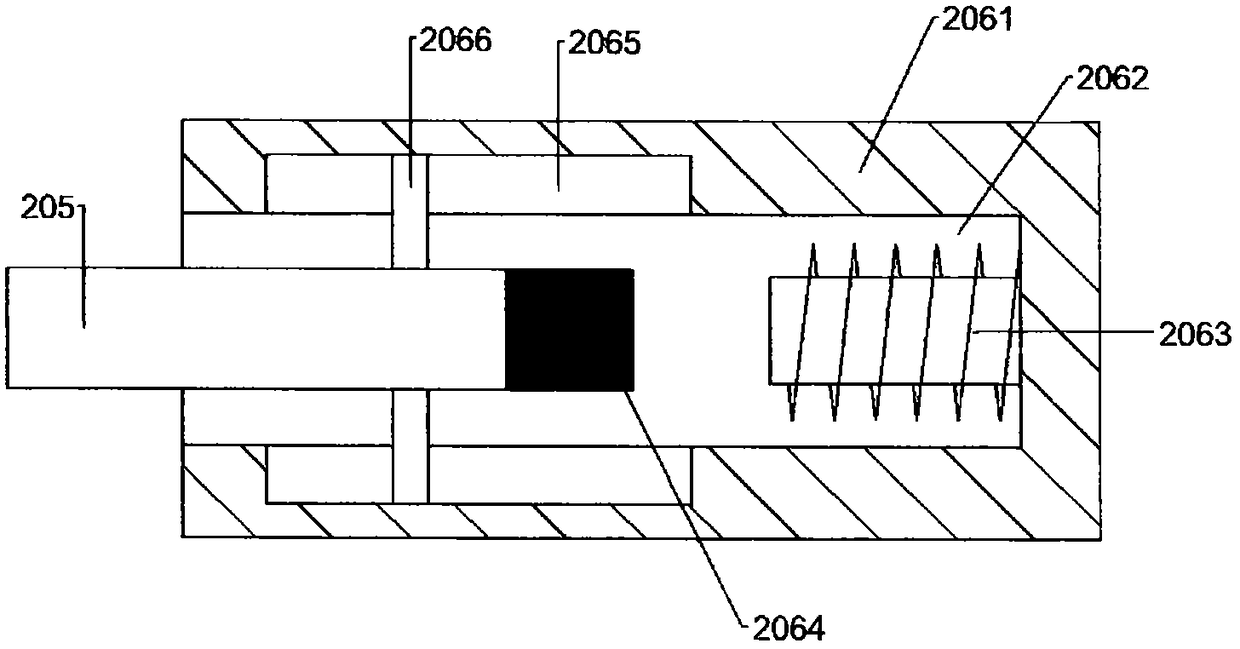

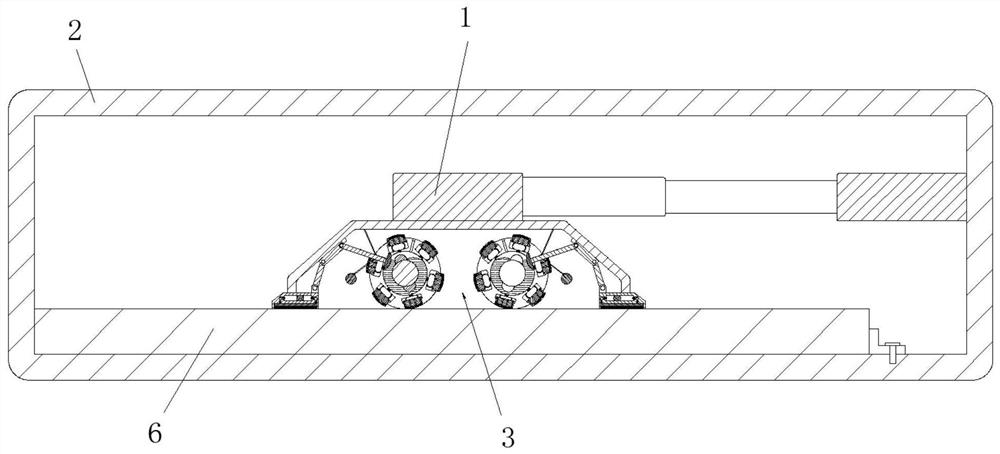

The invention discloses a handheld wiping sampling device used for preventing the deformation of a sample carrier when an ion mobility spectrometer is used for detecting explosives and drugs, and a method thereof. The device comprises a shell body; the back part of the shell body is a handheld part; the front part of the shell body is a wiping sampling part; a sampling wiping surface is arranged below the wiping sampling part; the sample carrier can be fully contacted with the surface of an object when being wiped, thereby improving the wiping efficiency; correspondingly, a small sample feeding port can be arranged on a detector, thereby saving a great number of sample carriers, avoiding the difficultly recovered deformation and creases generated by the sample carriers, ensuring the follow-on sample feeding operation, improving the sampling and the sample feeding efficiency and improving the detection performance of a sample to be detected. The method of the invention comprise the following steps: attaching the sample carrier to the sampling wiping surface; fixing the front end part of the sample carrier through a front clamp fastener; and the rear end part of the sample carrier is fixed by a back clamp fastener. The method is simple and quick.

Owner:NUCTECH CO LTD

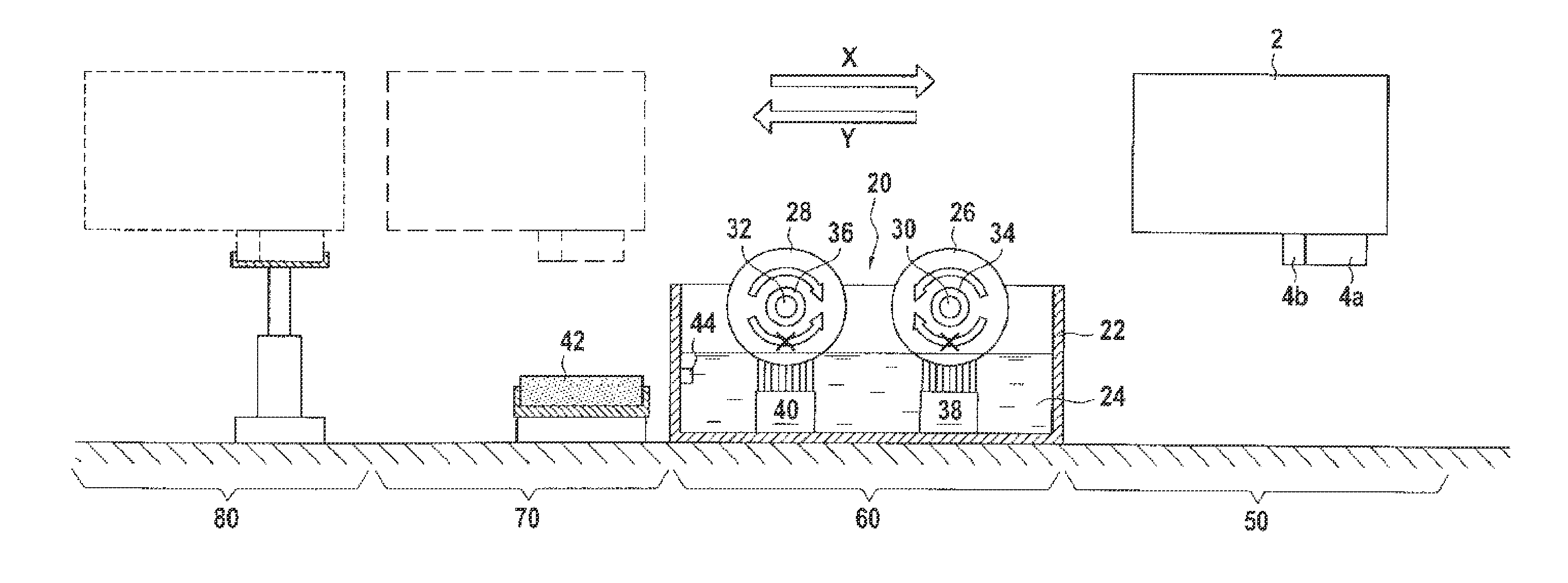

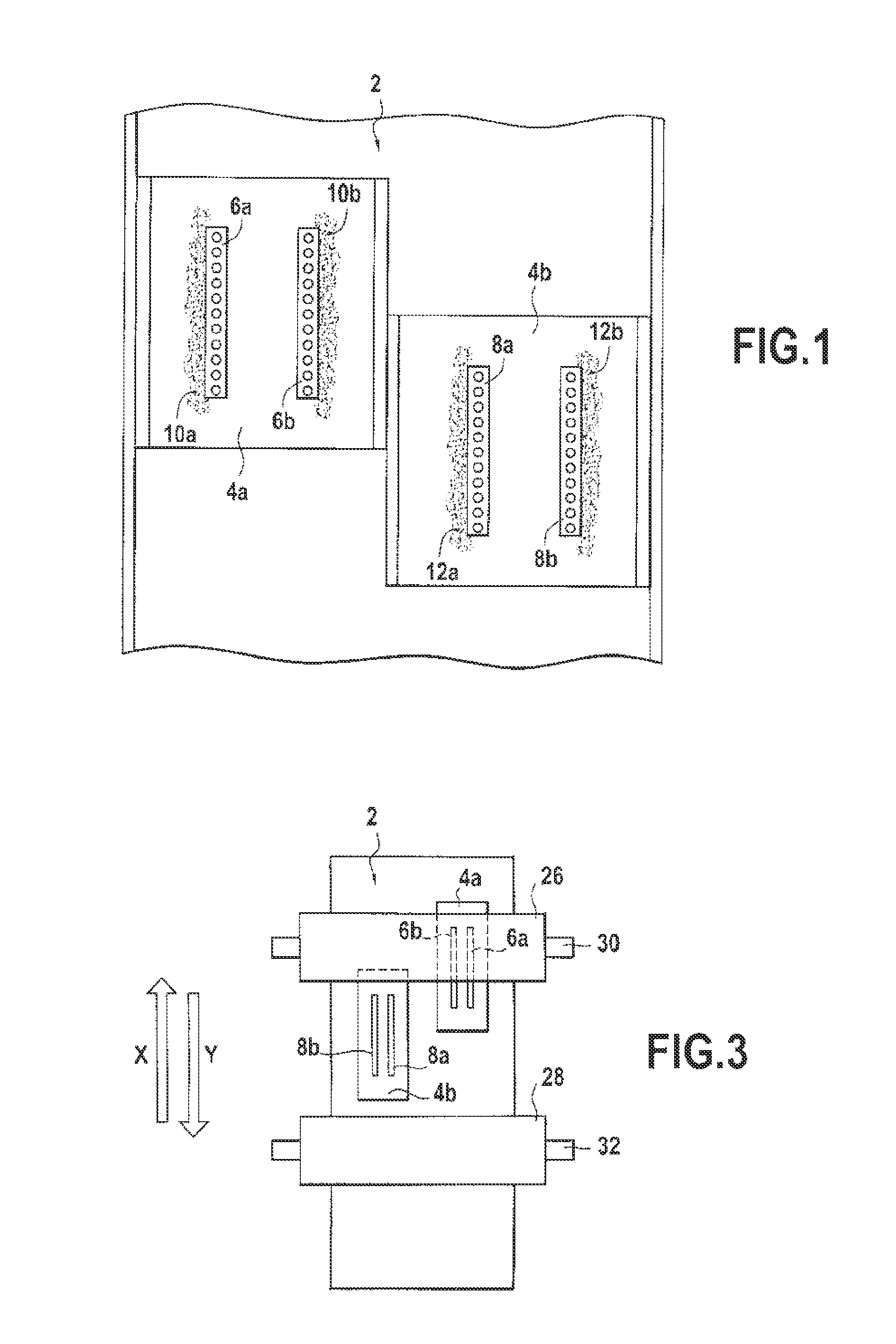

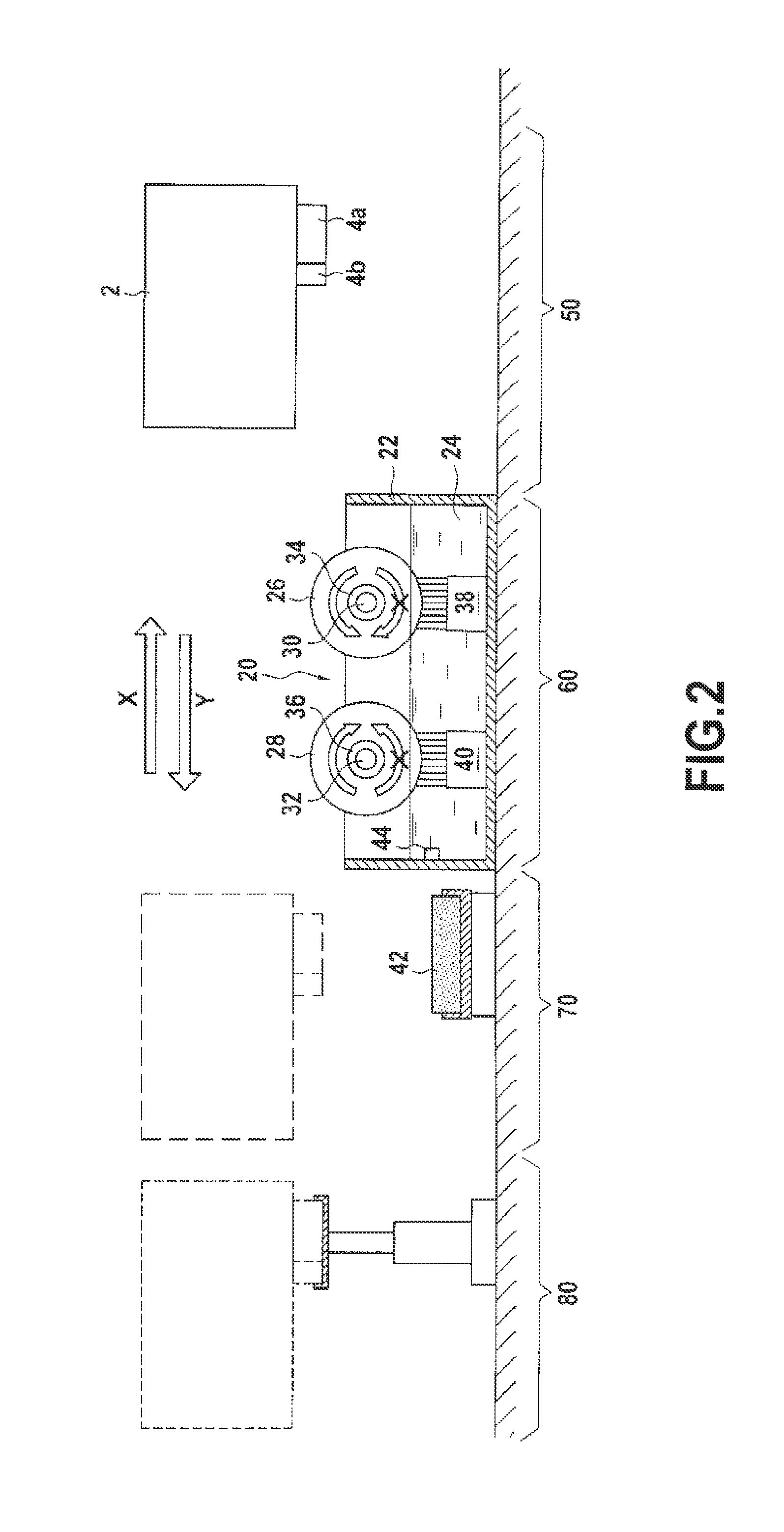

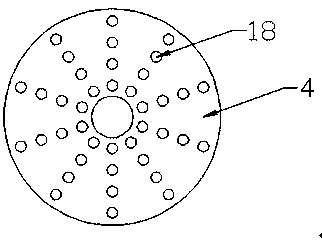

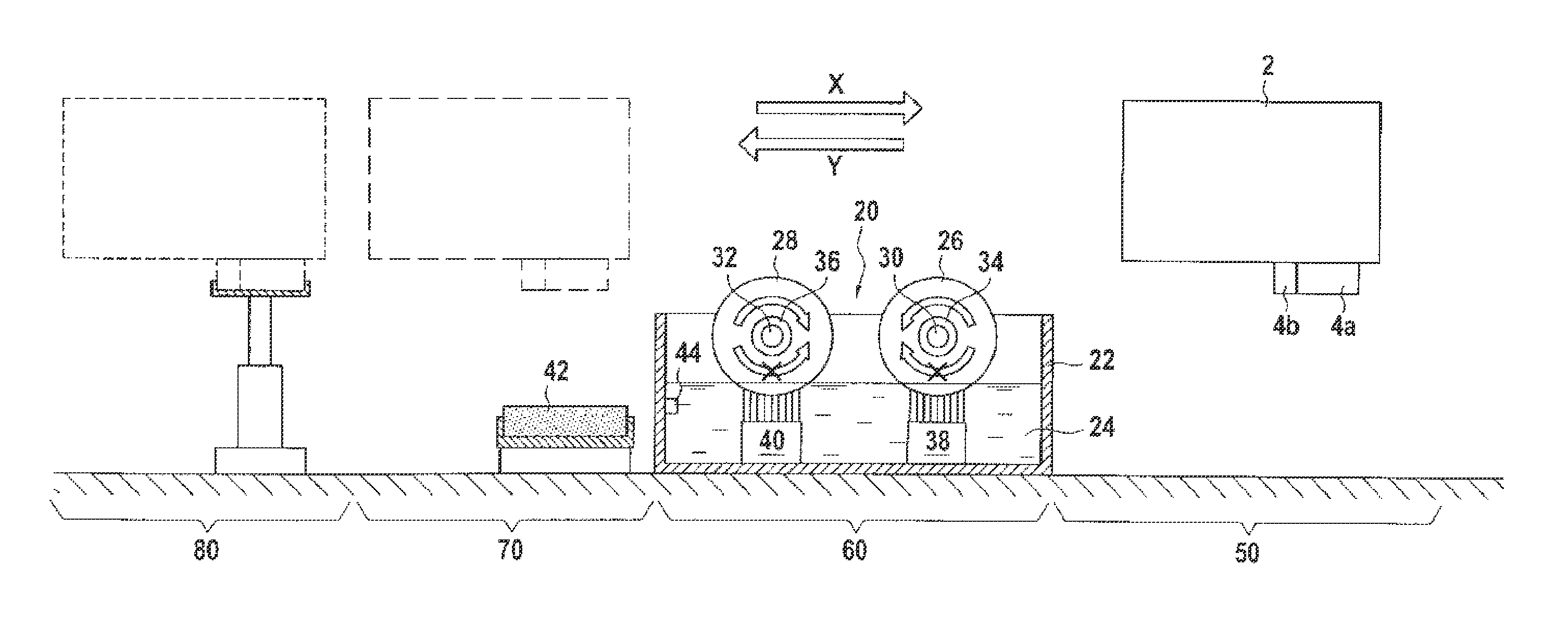

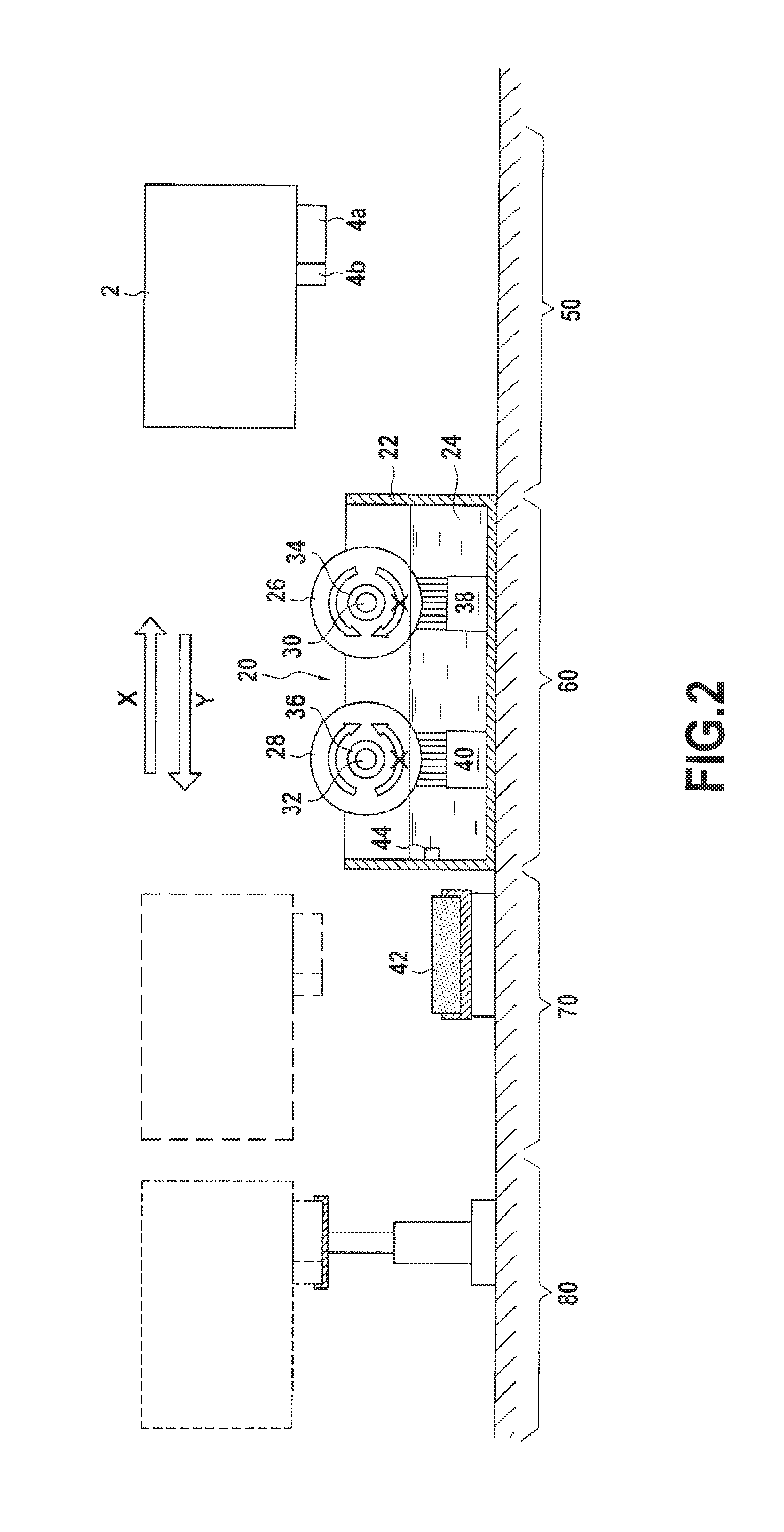

Wiping device for an ink jet franking machine

ActiveUS20130187979A1Efficiently and periodically cleaningEasy to cleanFranking apparatusPrintingEngineeringNozzle

A wiping device (20) for cleaning outer surfaces of at least one row of ejection nozzles in at least one print head (4a, 4b) of an ink jet printing module (2) of a franking machine when the module is moving above the wiping device in first and second directions (X, Y), comprising two wiping rollers (26, 28) located one behind the other in the first direction and adapted to rotate in opposite directions around respective fixed shafts (30, 32), the two wiping rollers being permanently dampened in contact with a cleaning fluid (24) contained inside a container (22); and the two wiping rollers are adapted via a one-way bearing (34, 36) to remain stationary alternatively, one during the moving of the module in the first direction and the other during the moving of the module in the second direction.

Owner:NEOPOST TECH SA

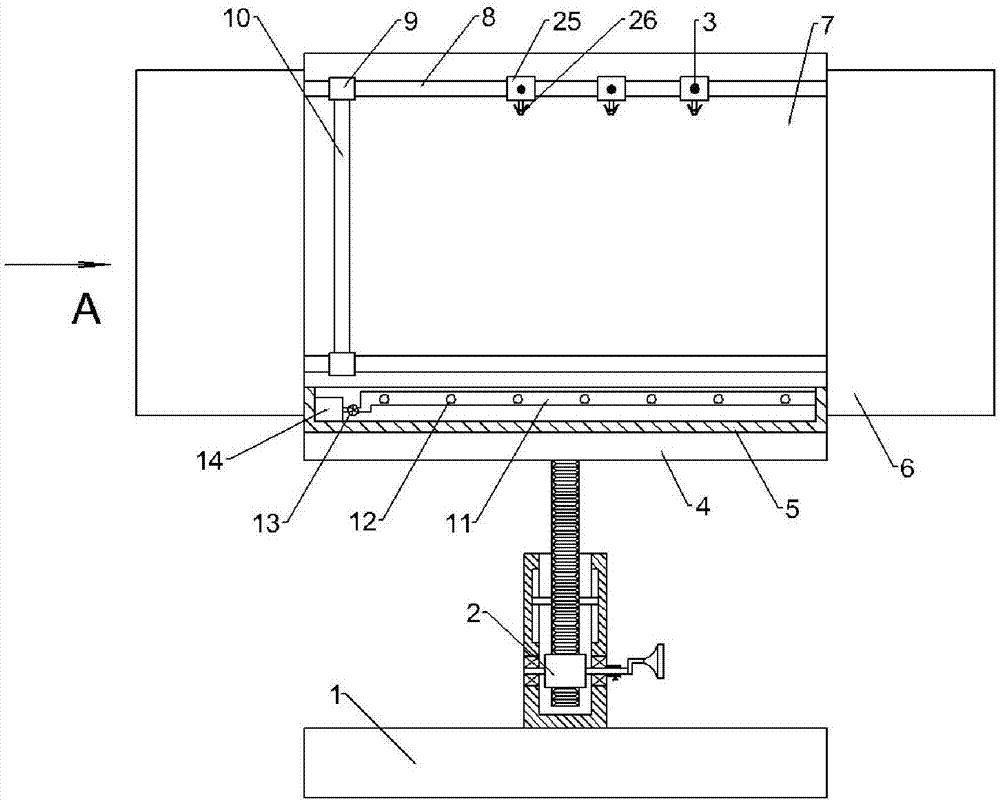

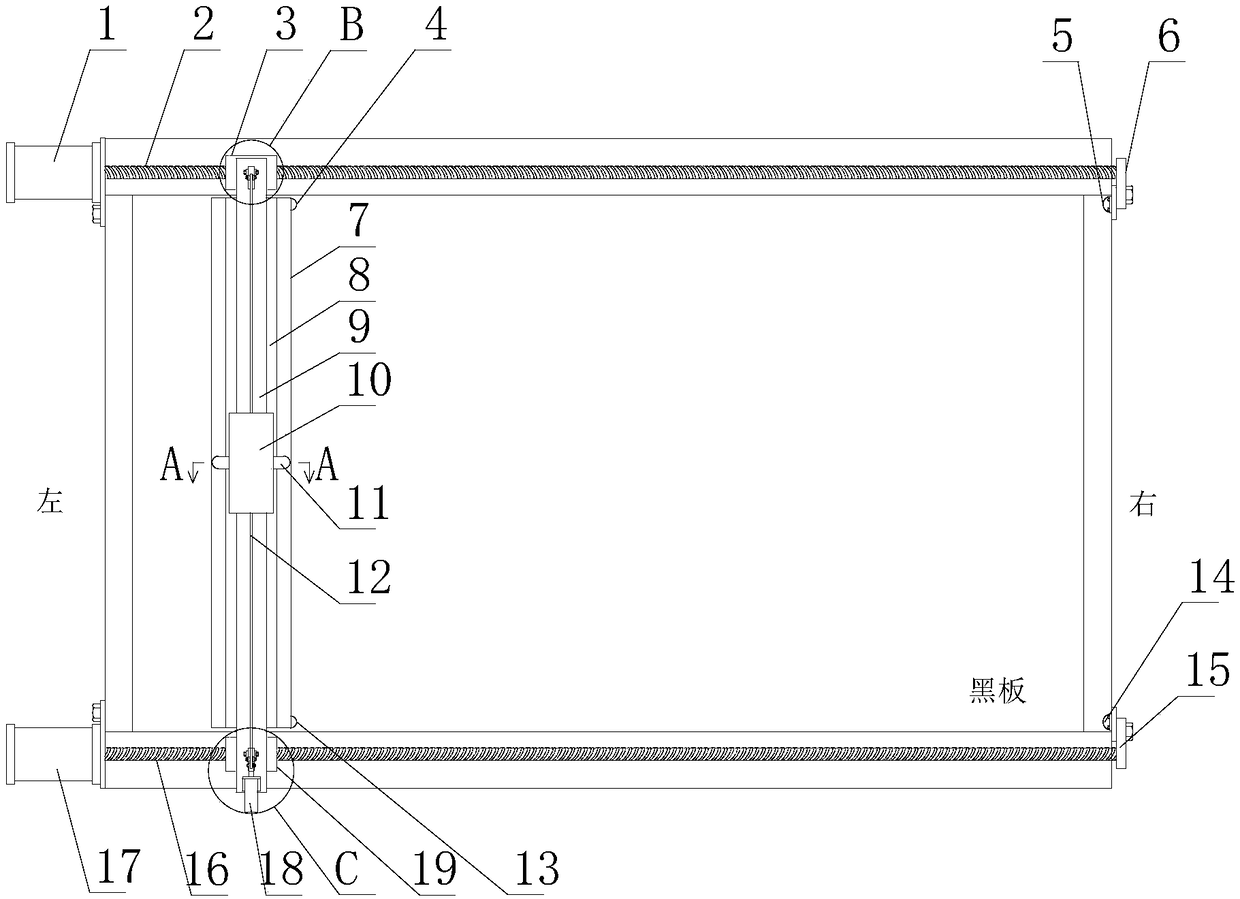

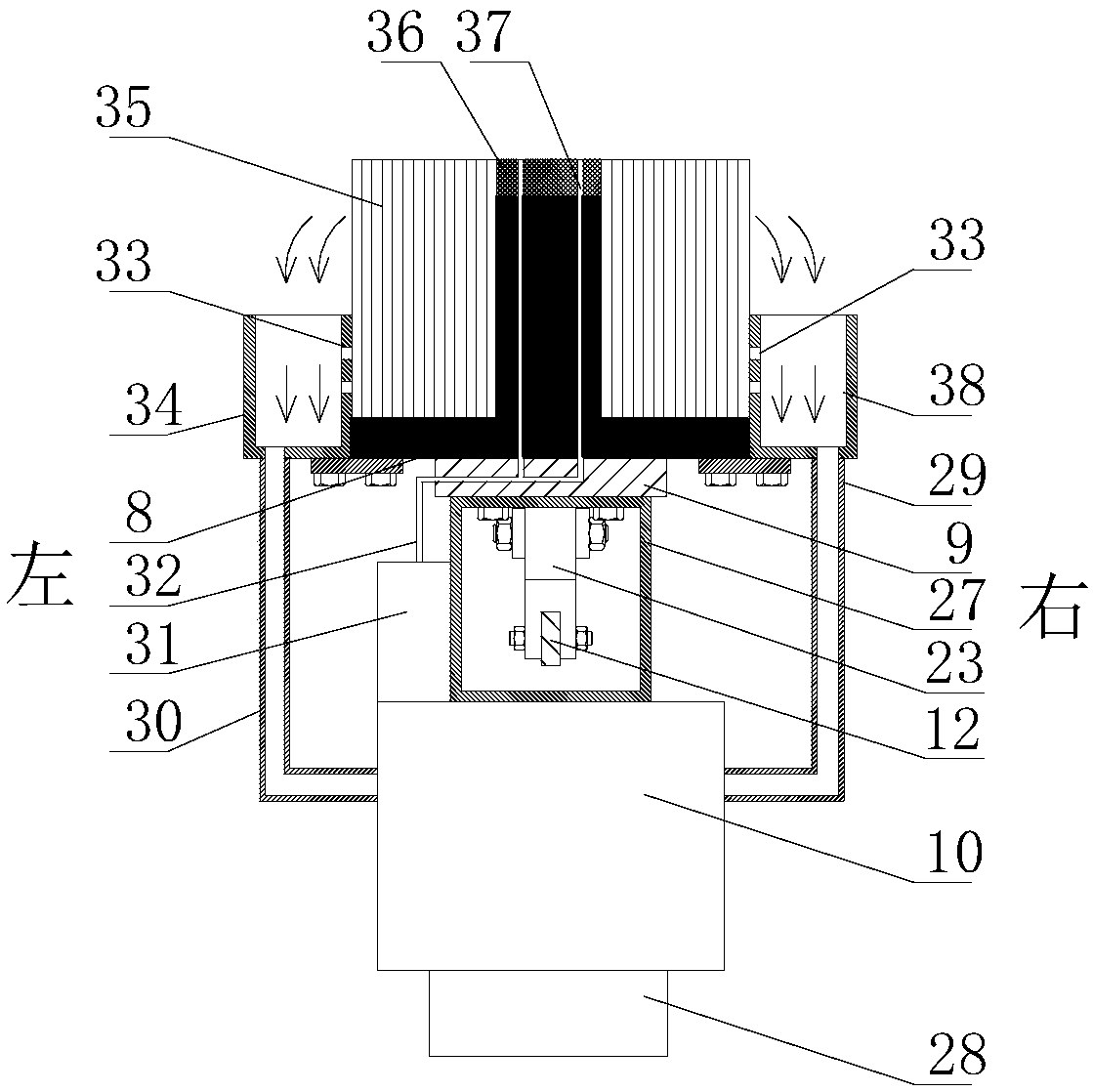

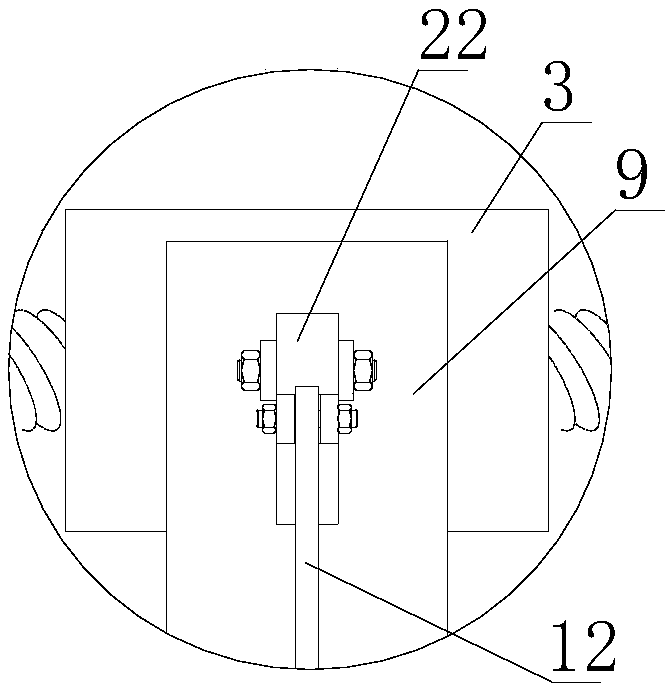

Teaching board with height locking function and for teaching

InactiveCN107351575AImprove wiping efficiencyChange inclinationBoard cleaning devicesWriting boardsLight reflectionEngineering

Owner:任国平

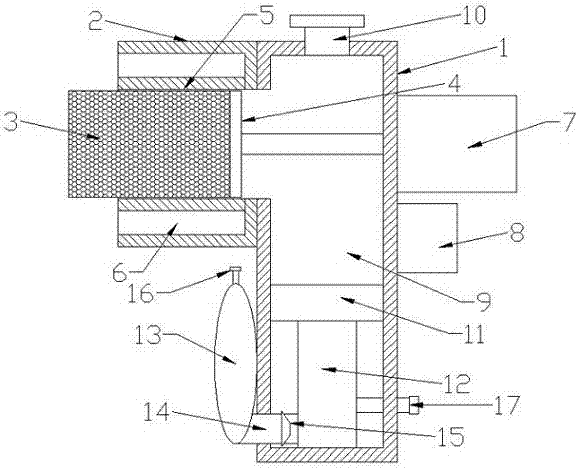

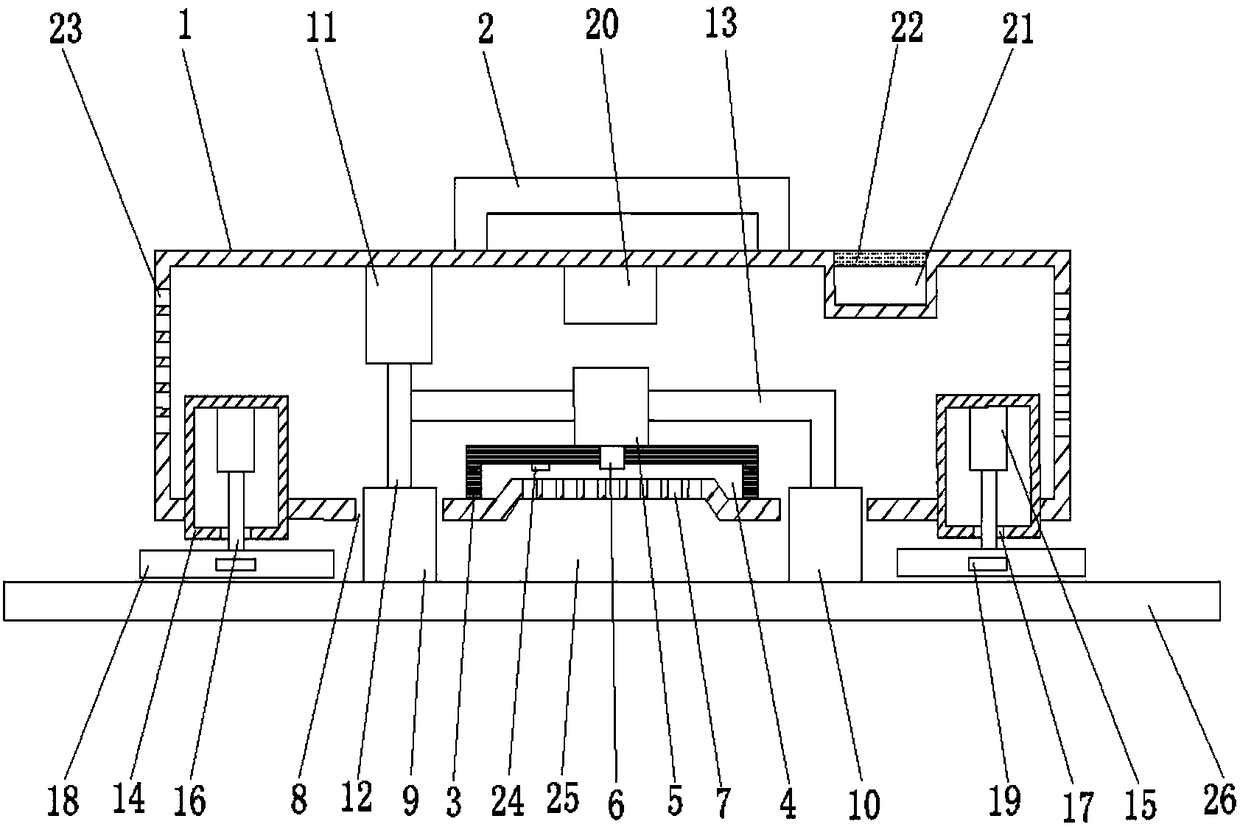

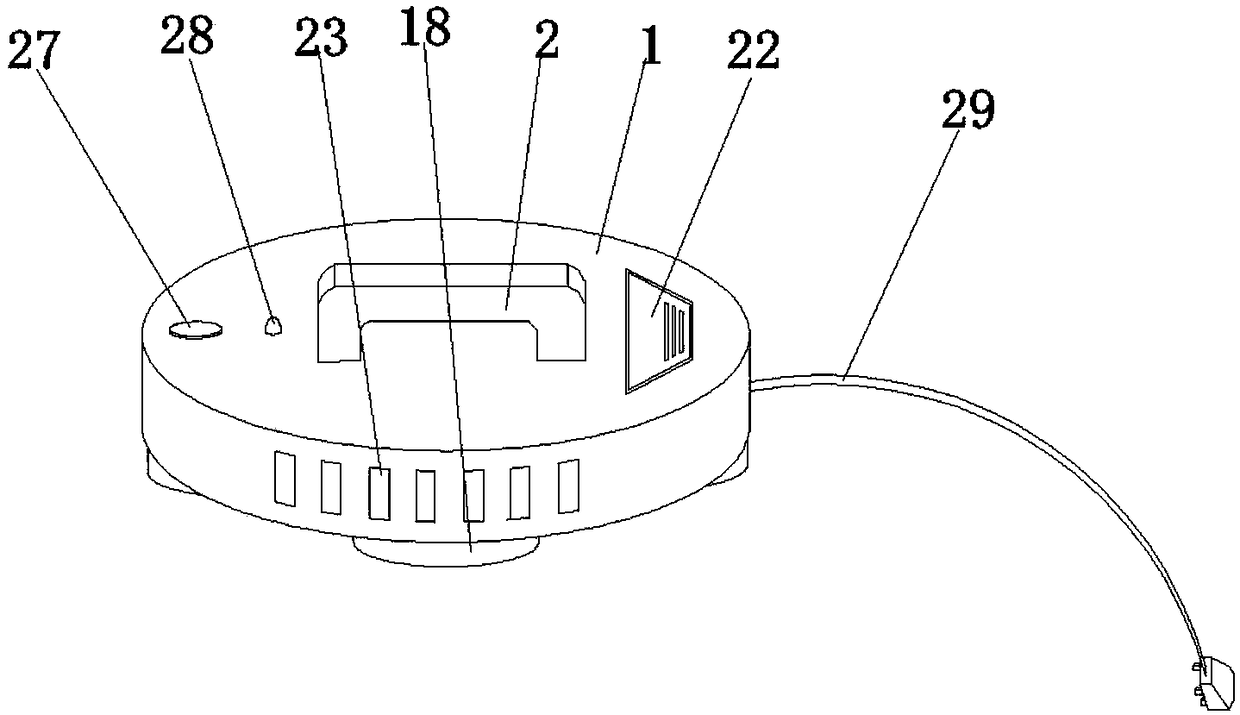

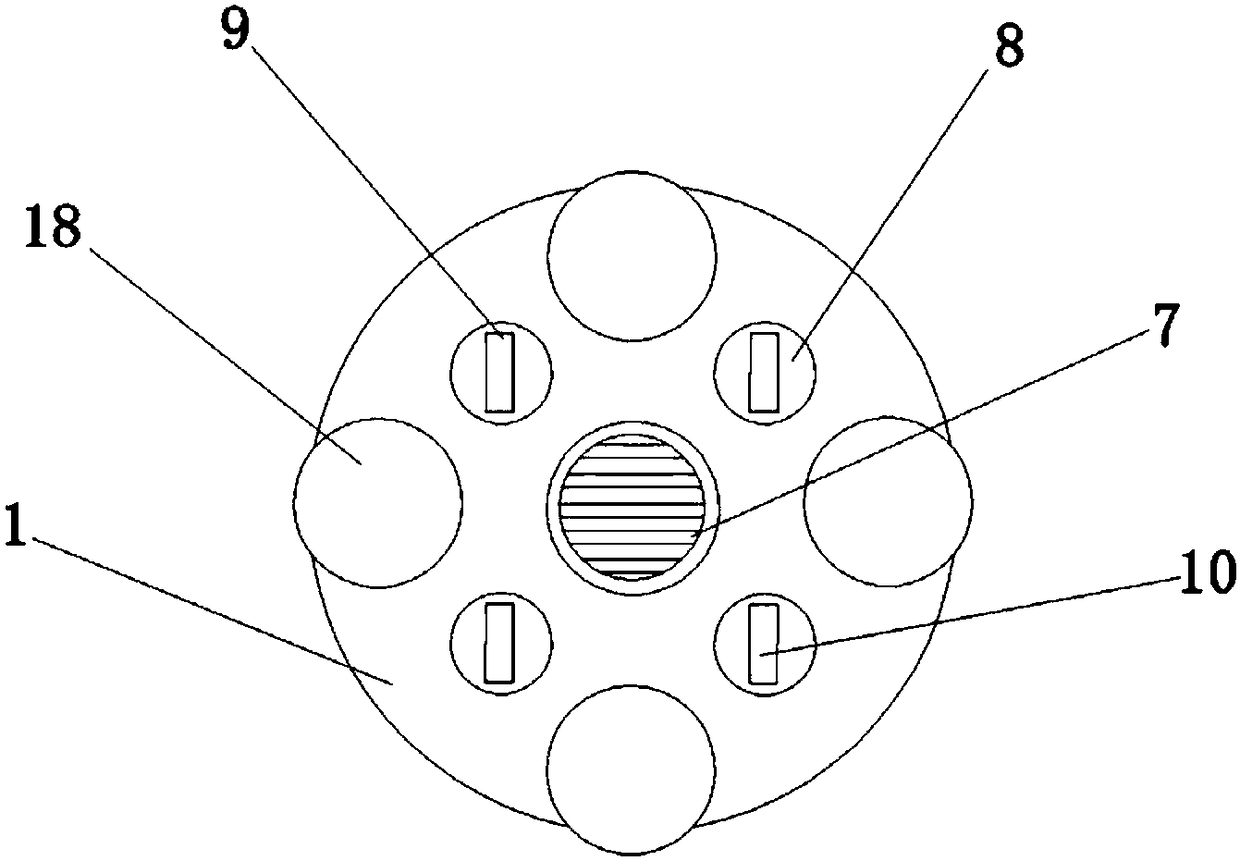

Home appliance cleaning device

InactiveCN107361708AAvoid enteringAvoid re-adhesionCarpet cleanersFloor cleanersHome appliancePiston

The invention discloses a household appliance cleaning device, which comprises a casing, a cleaning cover, a wiping sponge and a motor; the cleaning cover is fixed on the upper end of the casing, and a sponge cavity and a dust suction cavity in a horizontal direction are arranged in the cleaning cover; the sponge cavity is provided with There is a turntable, and there are several seepage holes evenly opening through the turntable on the turntable, and a wiping sponge is fixedly installed on the left side of the turntable, and the output shaft of the motor extends into the casing and is fixedly connected to the turntable; A fan is connected through the pipeline; a piston is slidably arranged in the water cavity, a pushing air bag is arranged under the piston, and an extruding air bag is connected to the outer end of the connecting pipe. In the present invention, the provided wiping sponge rotates under the drive of the motor to clean and wipe the surface of the electrical appliances, which has high wiping efficiency and saves cleaning time, and the cleaning water is infiltrated into the sponge by manual extrusion, without the need for more water to be leached out , to protect the appliance itself, and prevent the cleaning water from entering the inside of the appliance.

Owner:盐城市净博士机械有限公司

Indication board, capable of collecting rainwater for cleaning, for municipal construction

InactiveCN108176622ASimple structureImprove wiping efficiencyCleaning using toolsCleaning using liquidsPulp and paper industryWater collection

The invention discloses an indication board, capable of collecting rainwater for cleaning, for municipal construction. The indication board comprises an indication board body and two supporting upright columns; a cleaning screw rod and a guide rod are arranged between the two supporting upright columns; the cleaning screw rod is provided with a drive block which is matched with the cleaning screwrod; the guide rod is provided with a guide sleeve; the guide sleeve is fixedly connected with the drive block through a wiping vertical rod; the wiping vertical rod is hollowly arranged; a water collection groove is fixedly connected between the top ends of the two supporting upright columns and is communicated with a water collection tank which is arranged on the upper end surface of a fixed bottom plate through a water inlet pipe; a base plate is provided with a drainage cylinder body; the bottom end of the drainage cylinder body is communicated with the interior of the wiping vertical rodand the interior of the water collection groove through a water guide pipe; and a plurality of water spraying holes are formed in the side of the wiping vertical rod. The indication board is simple instructure, relatively high in wiping efficiency, relatively small in labor, relatively good in cleaning effect and relatively strong in practicability, is convenient and rapid and can save water forcleaning.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

Window cleaning robot with flexible turning capacity

InactiveCN108577655AAvoid falling hazardsReduce manufacturing costCleaning equipmentWindow cleanersDrive wheelAngular acceleration

The invention provides a window cleaning robot with flexible turning capacity. The window cleaning robot comprises a robot body, wherein the robot body comprises a casing and a lifting handle arrangedon the outer side of the top of the casing, wherein a mounting frame is arranged in the center of the inner side of the bottom of the casing; a cavity is formed by the mounting frame and the bottom of the casing. Traveling wheels are adopted to replace the traditional continuous track type moving structure, so that production cost, size and occupation space are reduced; four wiping mechanisms arearranged at the bottom of the robot and can wipe glass in front-rear and left-right manner simultaneously, the wiping range is wide, and the wiping efficiency is high; angular acceleration sensors are arranged in the wiping mechanisms, when the wiping mechanisms touch glass borders, the angular acceleration sensors transmit signals to a controller, the controller controls a driver to enable a driving wheel to change direction, accordingly, the traveling direction of the robot body is changed, the glass borders are avoided flexibly, and the robot cannot be stuck on the glass border.

Owner:HUZHOU YOUCHUANG TECH CO LTD

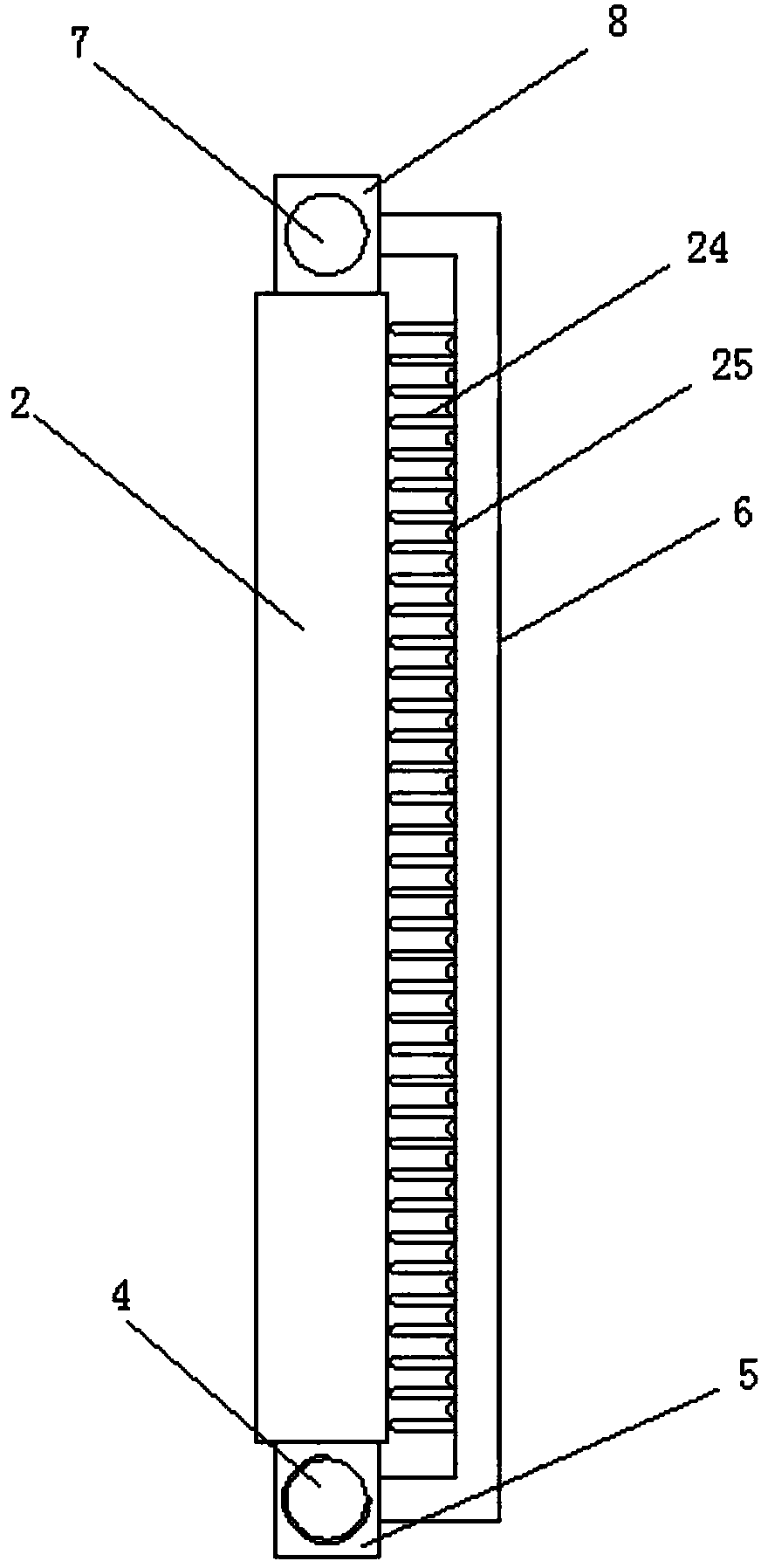

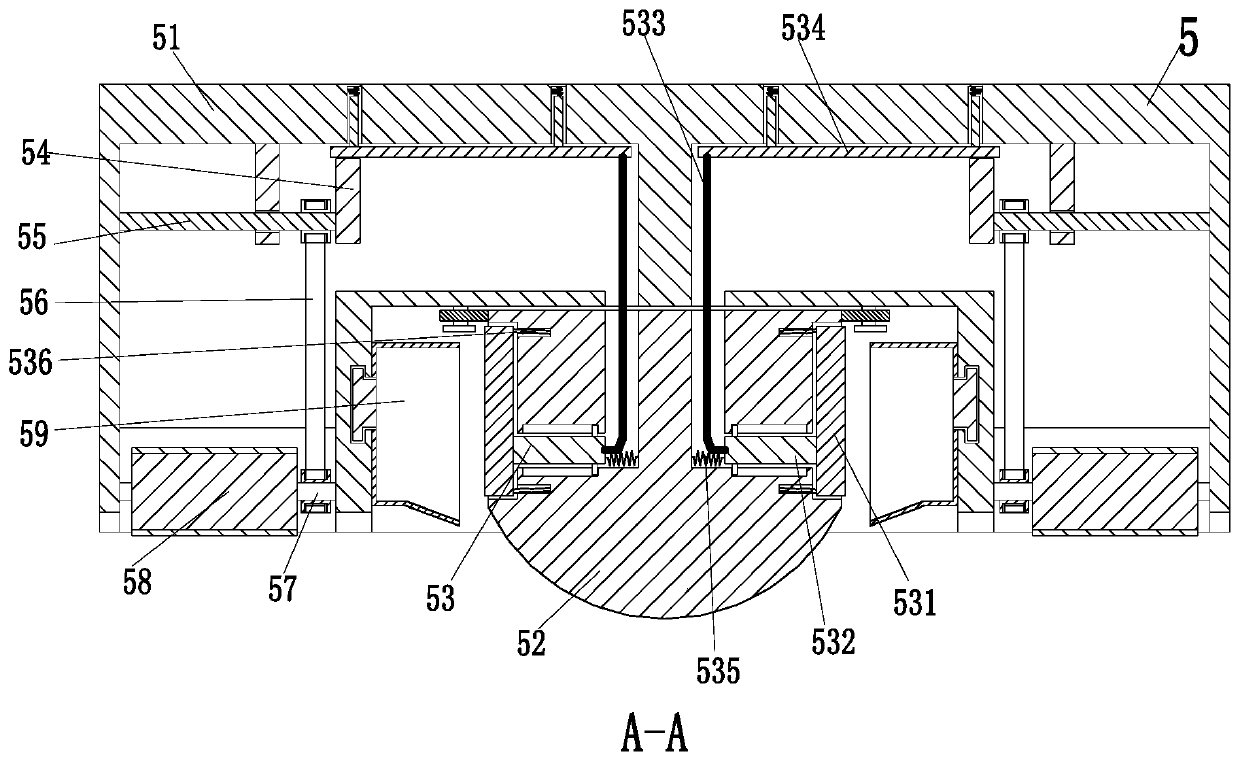

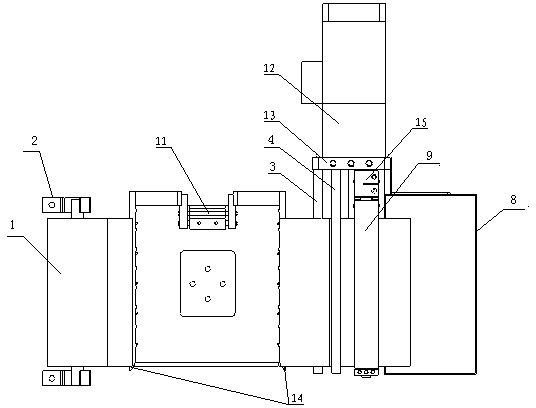

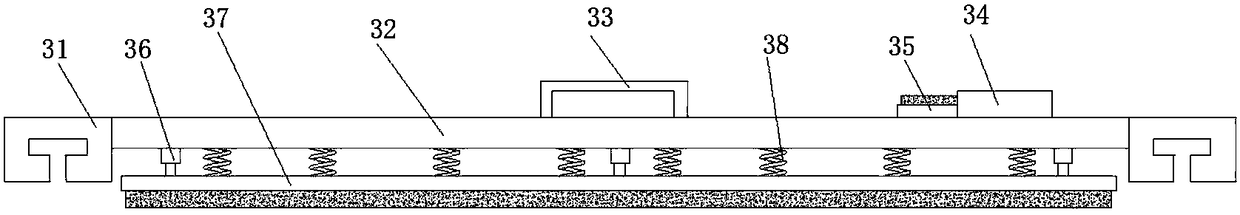

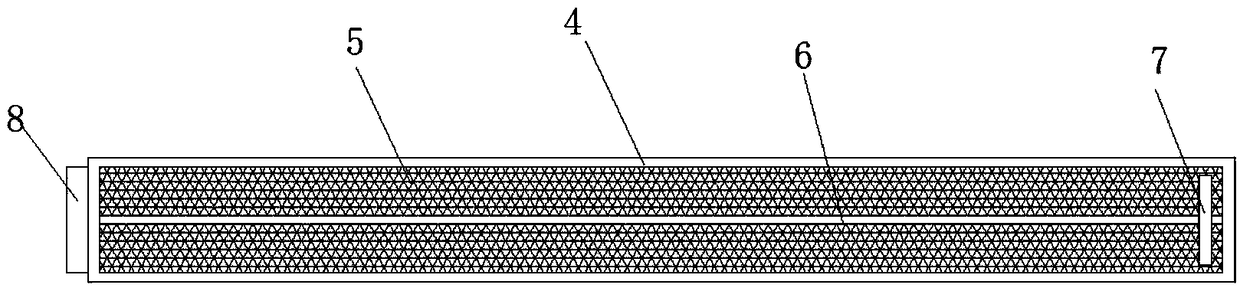

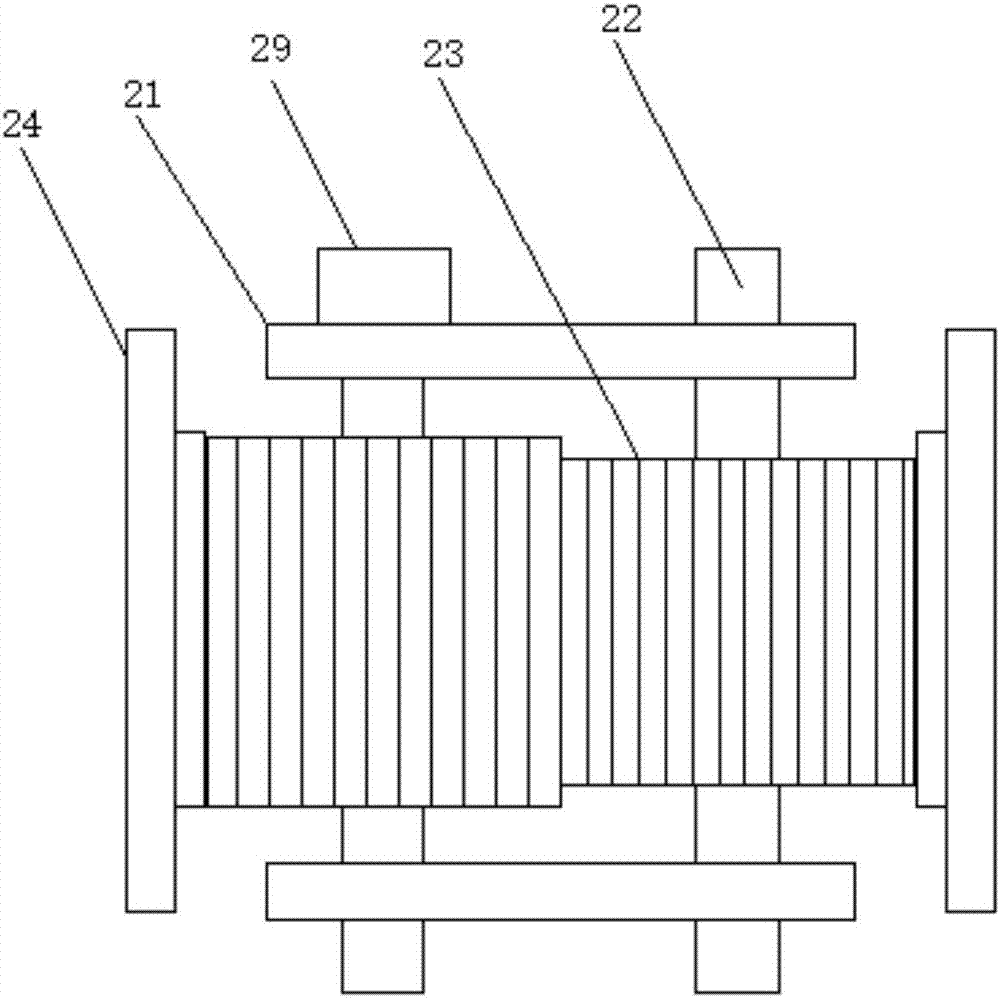

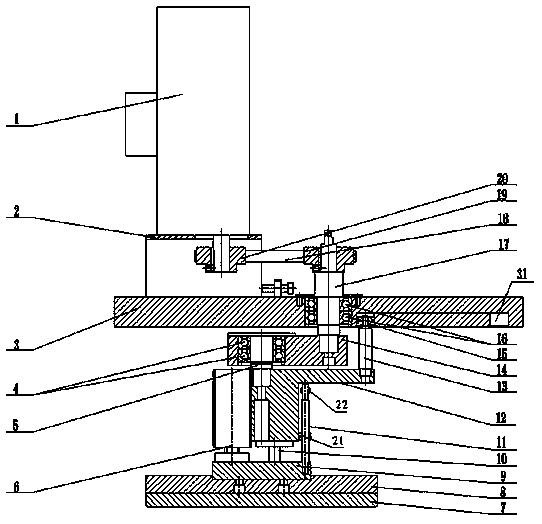

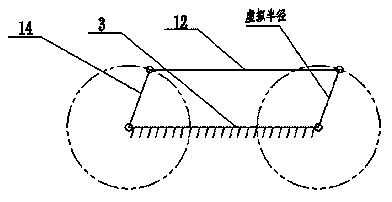

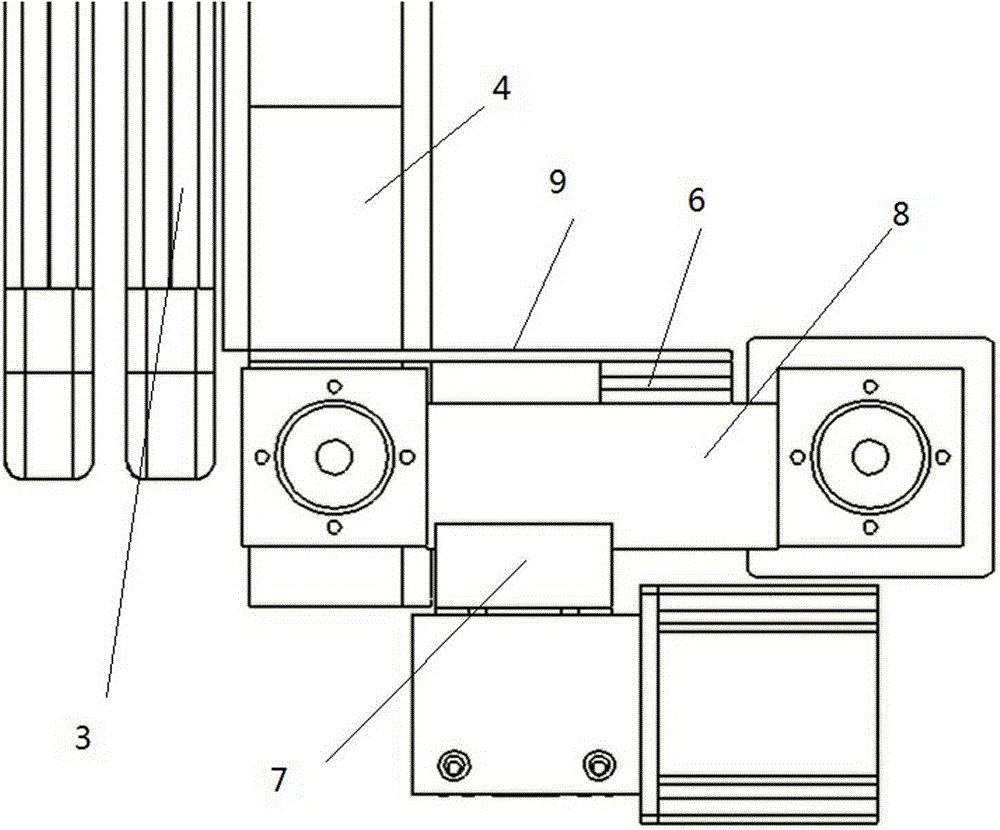

Application method of clamp with abrasive flow wiping stainless steel tubes

InactiveCN103707191AImprove wiping effectImprove wiping efficiencyGrinding machinesGrinding work supportsSteel tubeMachine tool

The invention discloses an application method of a clamp with abrasive flow wiping stainless steel tubes. The application method includes the following steps that firstly, a plurality of stainless steel tubes with the same length are inserted into stop collars along insertion holes of the stop collars to form a stop collar set; secondly, the lower ends of the stainless steel tubes of the stop collar set are inserted into insertion holes of a lower blocking and guiding board; thirdly, a bearing sleeve is clamped in a concaved table clamping groove of the lower blocking and guiding board; fourthly, the insertion holes of an upper blocking and guiding board align with the upper ends of the stainless steel tubes of the stop collar set, the upper ends of the stainless steel tubes are inserted into the insertion holes, and then the concaved table clamping groove of the upper blocking and guiding board tightly clamps the upper end of the bearing sleeve; fifthly, the clamp and the stainless steel tubes which are tightly clamped and integrally fixed are placed between a feeding cylinder and a discharging cylinder of an abrasive flow machine tool, the machine tool is started, and then abrasive flow wiping can be performed on the inner walls of the stainless steel tubes in the clamp. According to the application method, the pressure for bearing the abrasive flow machine tool can be scattered, the stainless steel tubes are protected against deformation when being subjected to pressure in the wiping process, multiple stainless steel tubes can be fixed and wiped at the same time, and therefore the wiping efficiency and the wiping effect are improved.

Owner:郝鹏飞

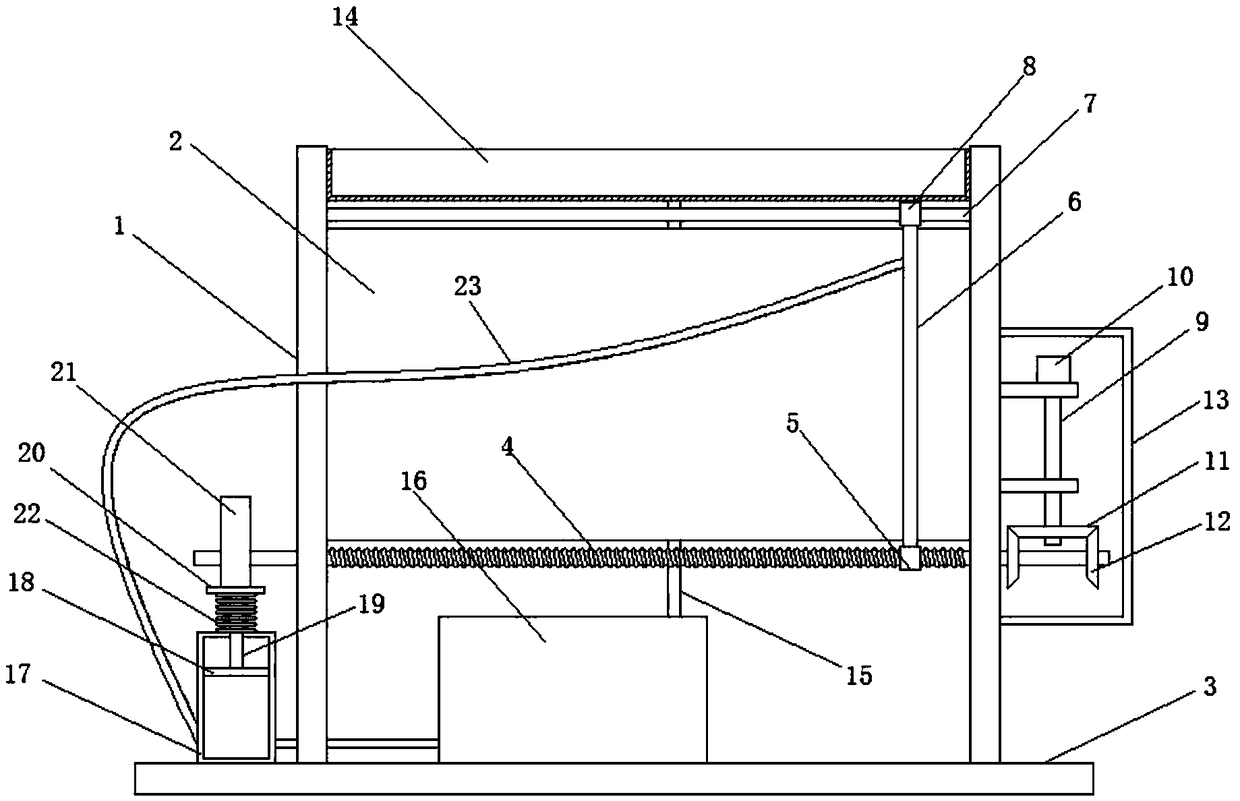

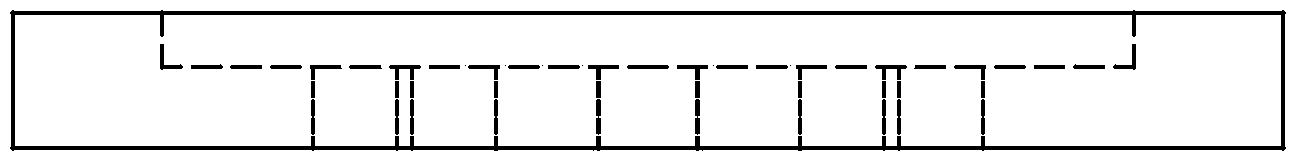

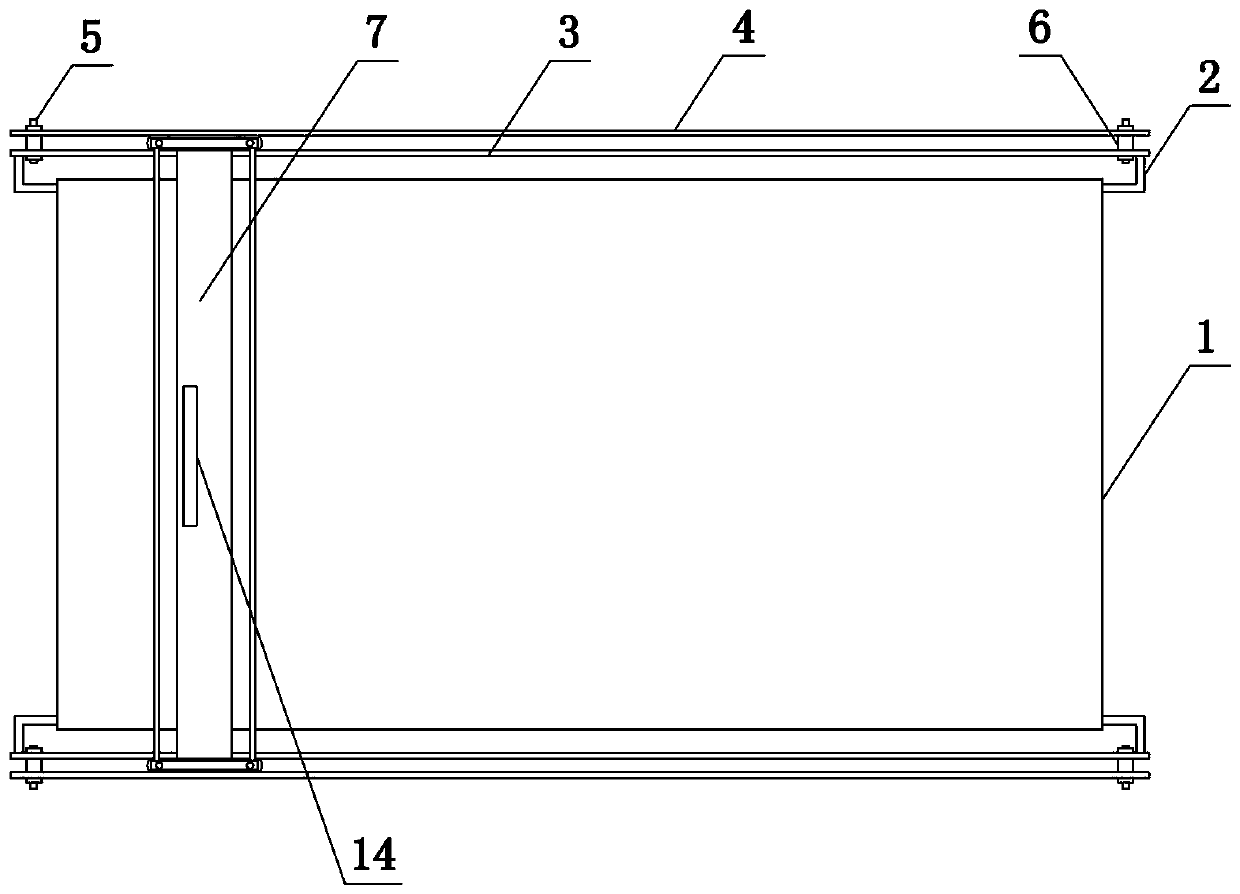

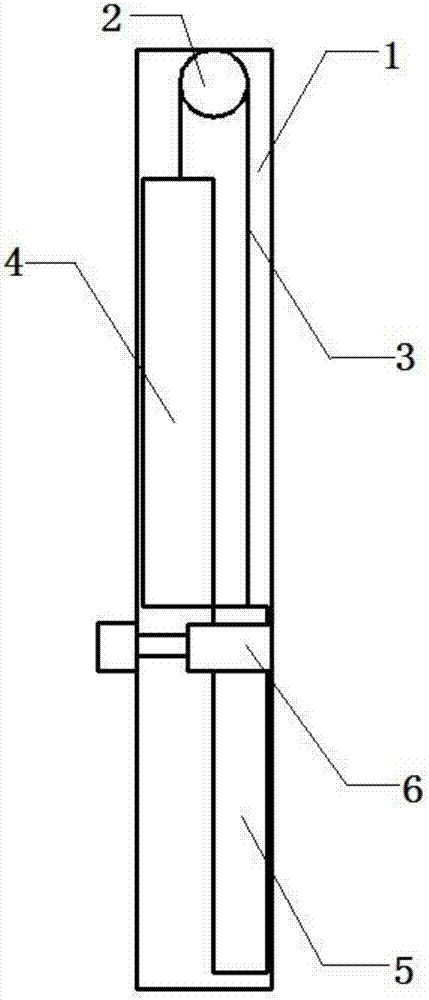

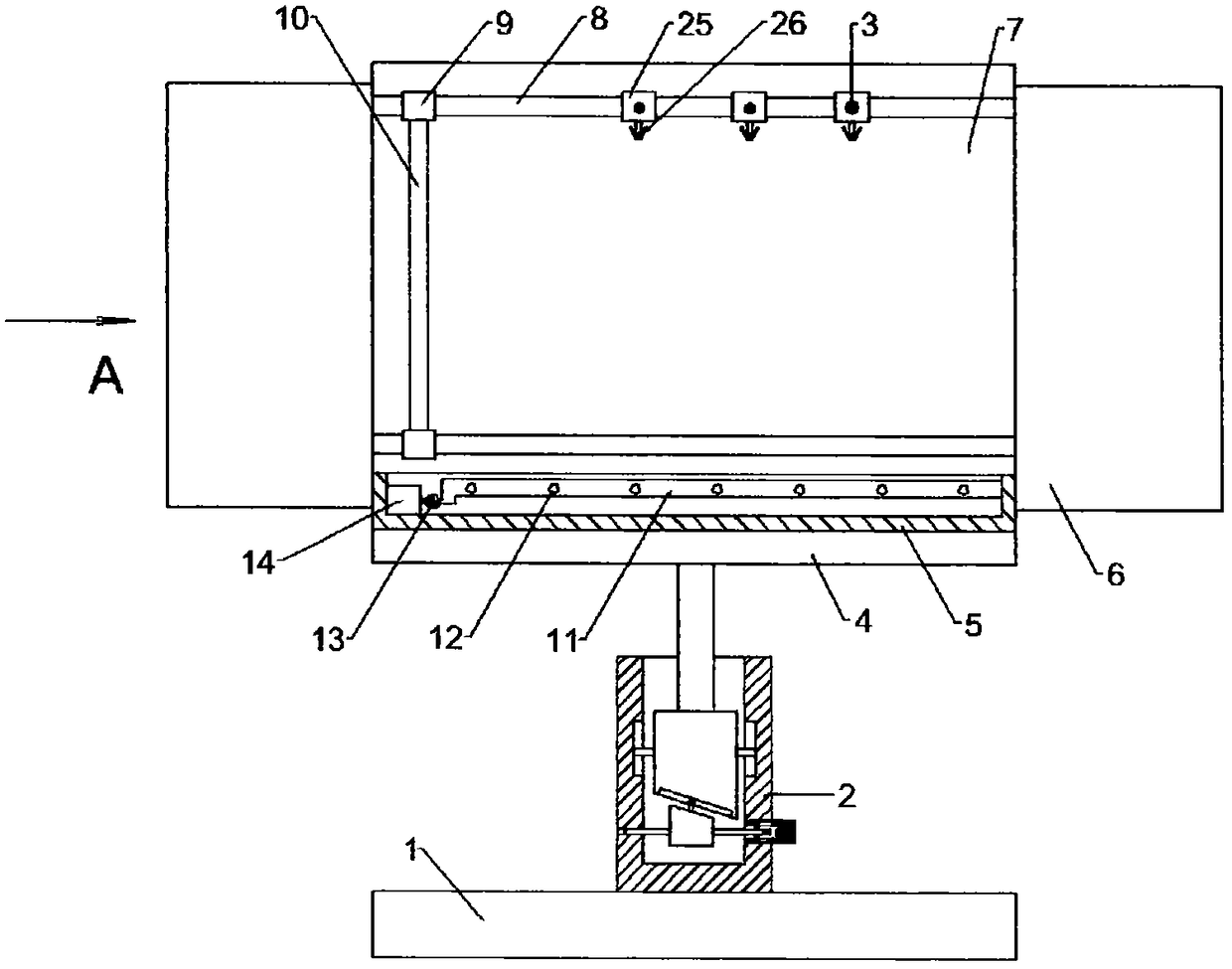

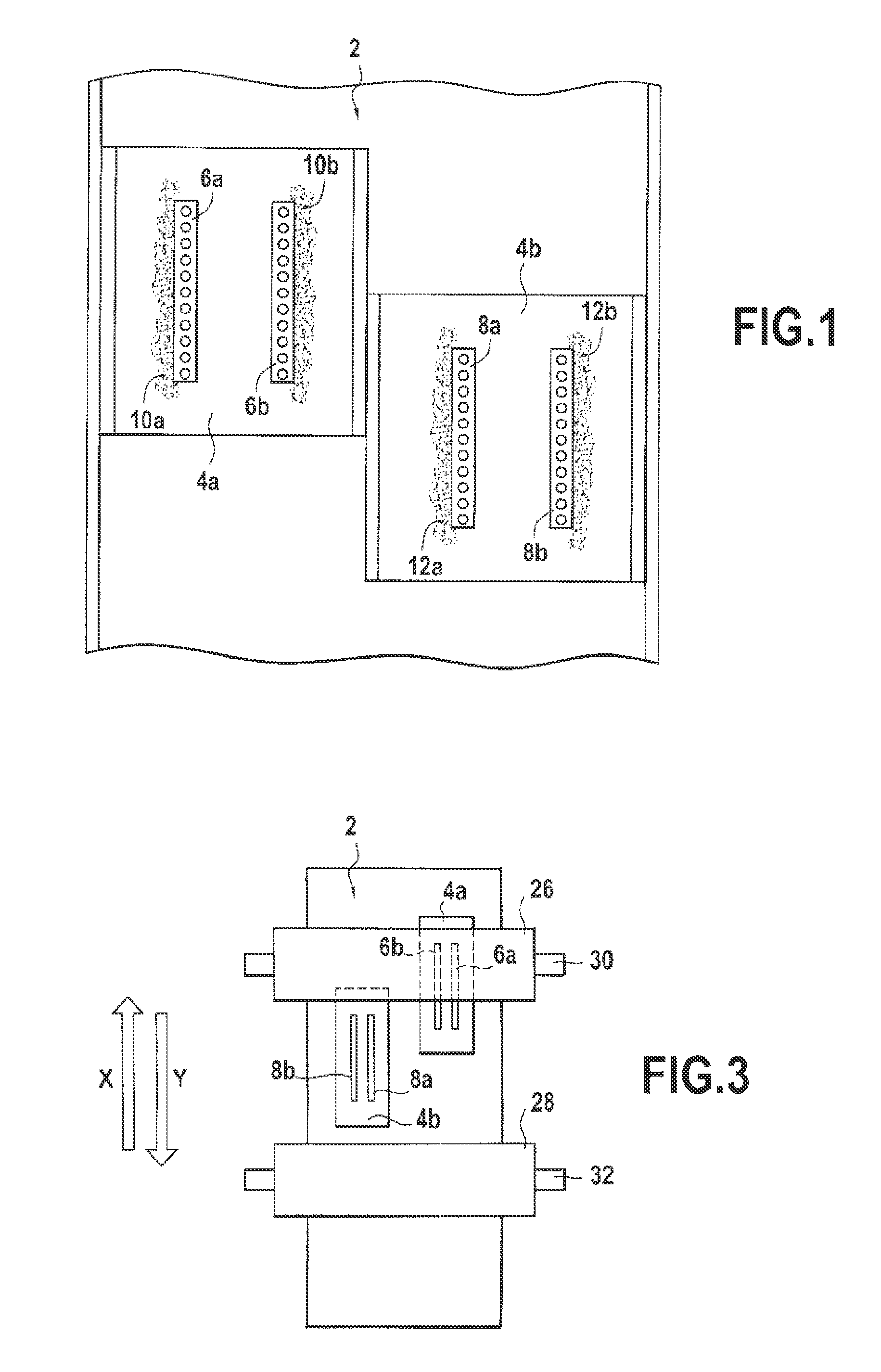

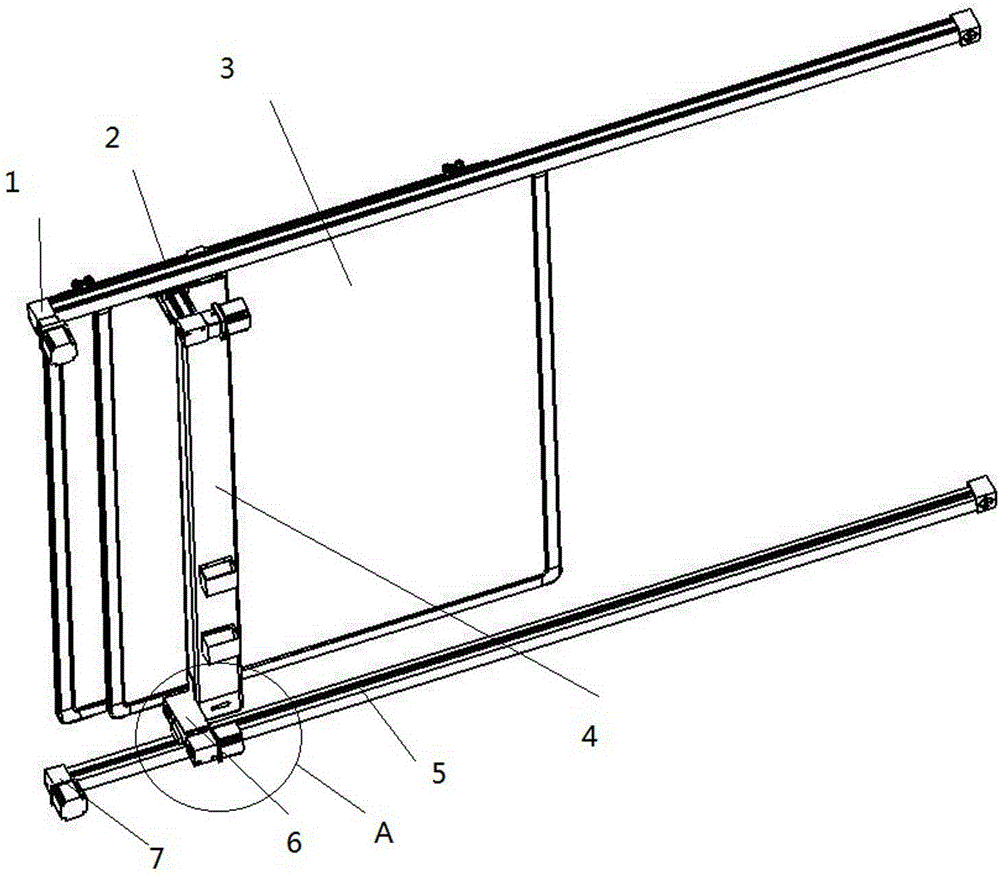

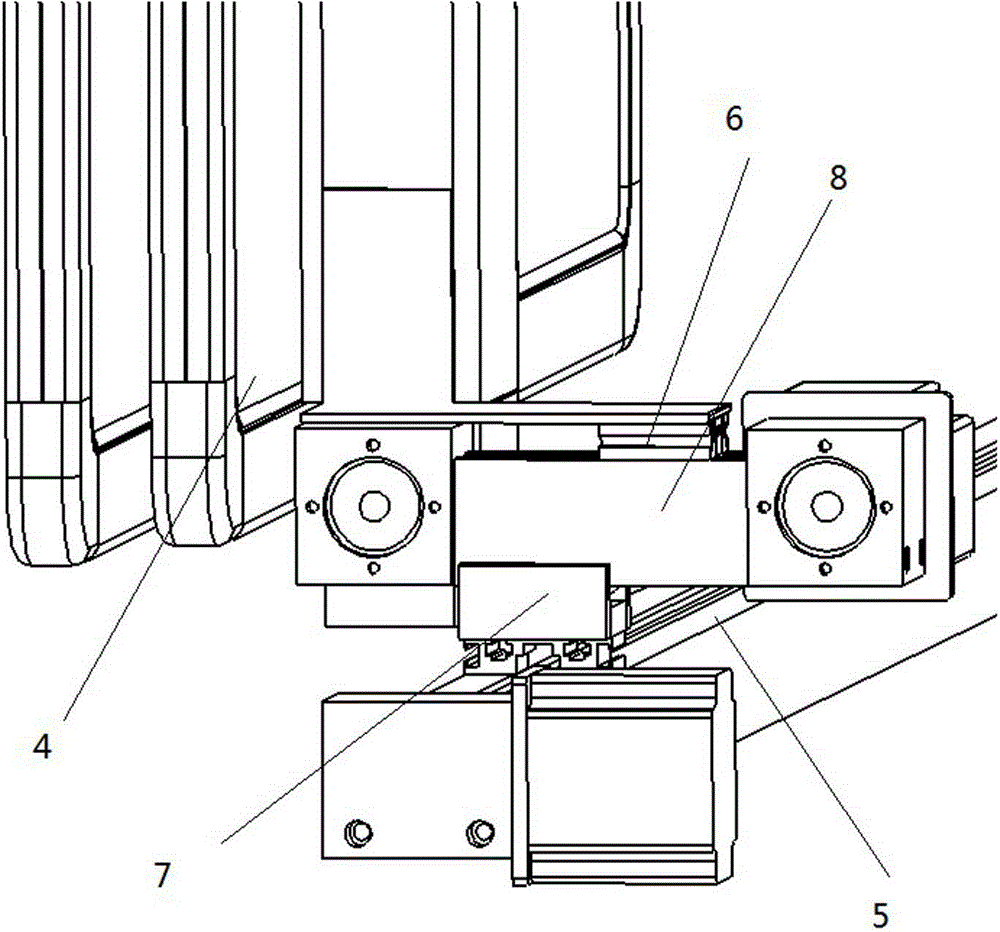

Manual integral wet wiping writing board

ActiveCN105216514AReduce health impactReduce the impactBoard cleaning devicesWriting boardsWater storageWet wipe

The invention discloses a manual integral wet wiping writing board, and relates to the technical field of writing boards. The manual integral wet wiping writing board comprises a writing board body and further comprises an integral wet wiping board wiper, a sliding device for the wet wiping board wiper to move left and right, and a water storage device used for supplementing water to the wet wiping board wiper, wherein the integral wet wiping board wiper corresponds to the writing board body in width, and is provided with a water storage box. The sliding device comprises a transverse moving mechanism. The transverse moving mechanism comprises transverse linear slide rails arranged on an upper frame and a lower frame of the writing board body respectively. Transverse sliding blocks are in sliding fit with the transverse linear slide rails. The two ends of the wet wiping board wiper are fixedly connected with the upper transverse sliding block and the lower transverse sliding block respectively. The water storage device comprises the water storage box, a mini-type water pump arranged in the water storage box, and a water supplementing pipe used for supplementing water. The wet wiping board wiper is pushed and can move left and right in the length direction of the writing board body, and chalk traces on the writing board body are erased away. The wet wiping of the whole board face can be achieved, the wiping efficiency is greatly improved, and the adverse effects of dust to teachers and students are reduced.

Owner:SHIJIAZHUANG KEDA STATIONERY

Building wall building wall brick jointing treatment construction device and method

ActiveCN110700533ADelayed freezing timeShorten the setting timeBuilding constructionsStructural engineeringMechanical engineering

The invention relates to a building wall building wall brick jointing treatment device and method. The device comprises an alignment material frame, a pressing handle set, a heating device, a sprayinghead and a pressing cleaning device. The pressing handle set is arranged at the rear end of the alignment material frame, the heating device is installed at the front end of the pressing handle set,the spraying head is arranged at the lower side of the front end of the alignment material frame, and the pressing cleaning device is arranged in the middle of the front end of the alignment materialframe. The problems that in the wall brick jointing process, when a rubber jointing knife is used for jointing, due to the fact that the knife face is excessively wide, during joint raking, excessivejointing agents are easily scraped to the wall brick face, the area is large, the difficulty for removing excessive jointing agents at the part is large, during jointing, due to the fact that the jointing agents inside a barrel make long-term contact with the external world, the whole jointing process is slow, the upper layers of the jointing agents inside the barrel are likely to be solidified inthe later jointing period, the jointing agents at the solidified part cannot perform jointing, and therefore waste is caused can be solved.

Owner:深圳市建和建设集团有限公司

Teaching tool for Chinese class

InactiveCN107696751AEntirely wipedReduce the phenomenon of flyingBoard cleaning devicesWriting boardsTeaching toolEngineering

The invention belongs to the technical field of teaching facilities, and particularly relates to a teaching tool for the Chinese class. The teaching tool for the Chinese class comprises a blackboard and a blackboard eraser. Traveling rails are arranged at the upper end and the lower end of the blackboard correspondingly. The blackboard eraser comprises a supporting frame and a pressing plate. Traveling mechanisms are arranged at the upper end and the lower end of the supporting frame correspondingly. Each traveling mechanism comprises first positioning columns and a plurality of traveling wheels, and the multiple traveling wheels are all in sliding fit with the traveling rails. An eraser body and a dust-proof baffle are arranged on the rear end face of the pressing plate. The dust-proof baffle is located around the eraser body. The rear end face of the dust-proof baffle and the rear end face of the eraser body are both in contact connection with the blackboard. According to the teaching tool for the Chinese class, in the whole erasing process, the dust-proof baffle located around the eraser body can effectively lower the probability of chalk dust flying, the pressing plate can be rapidly mounted on or dismounted from the supporting frame under the sliding fit of second positioning columns and guide grooves, and thus chalk dust on the eraser body and in the dust-proof baffle canbe removed periodically and rapidly.

Owner:NANYANG INST OF TECH

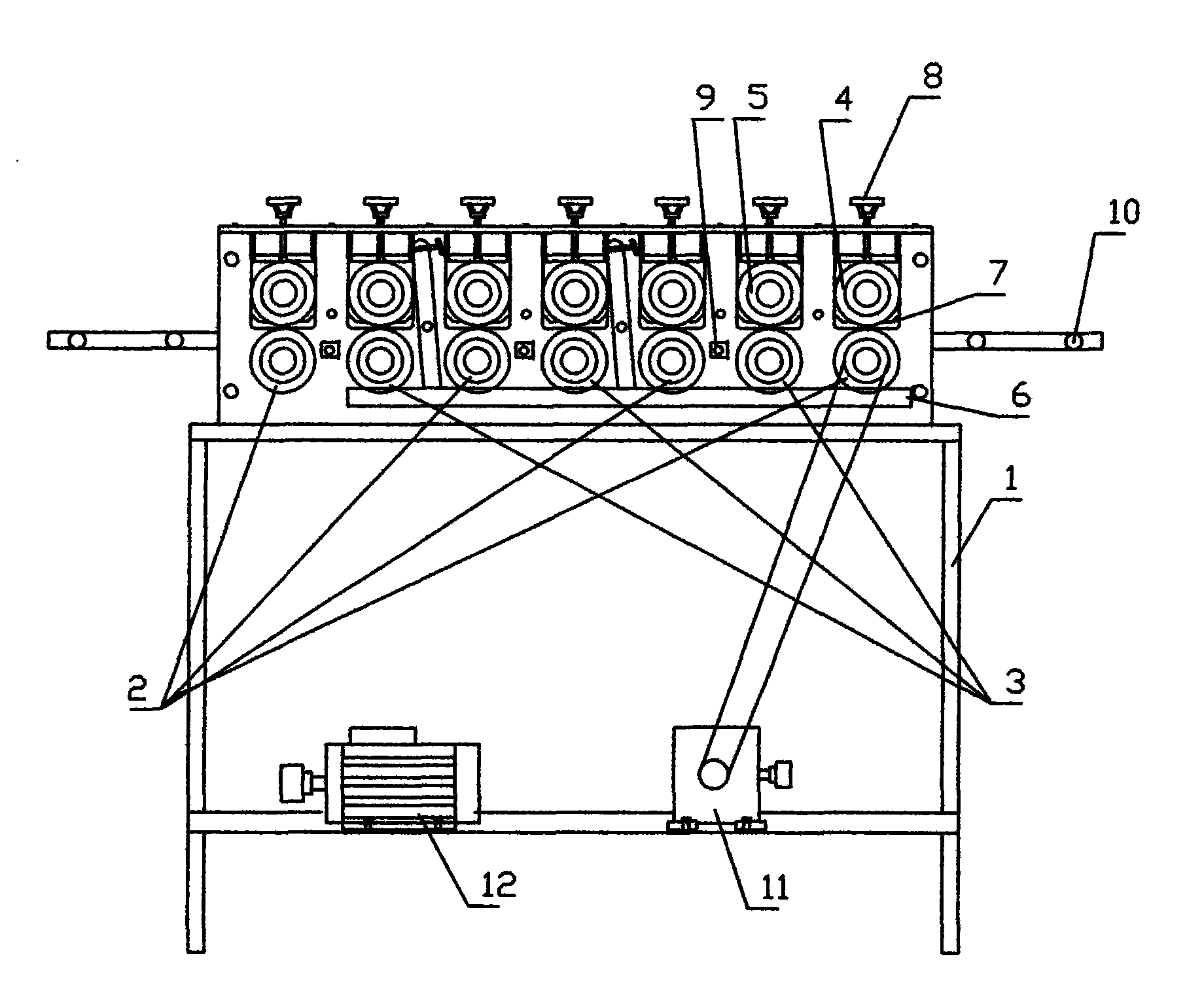

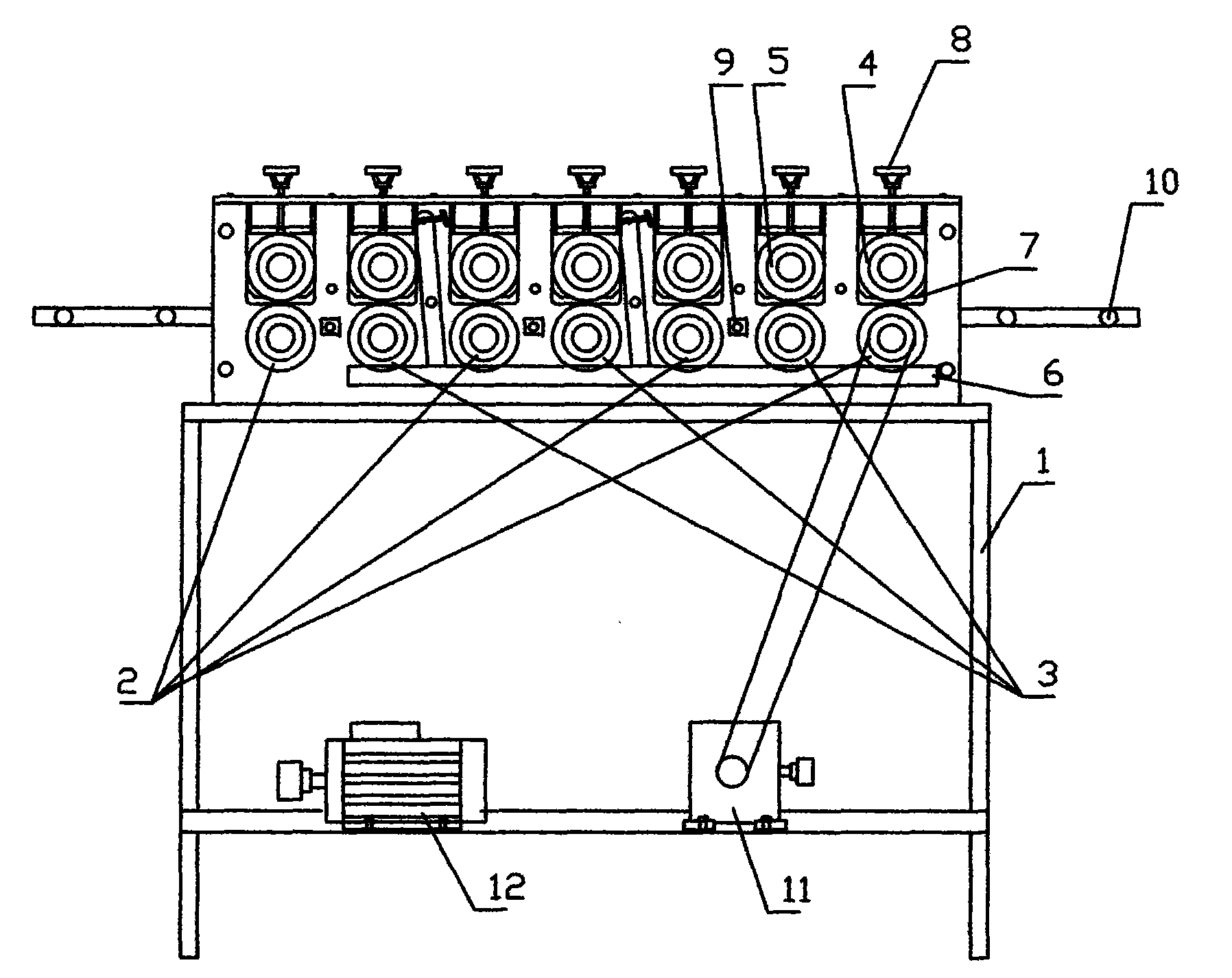

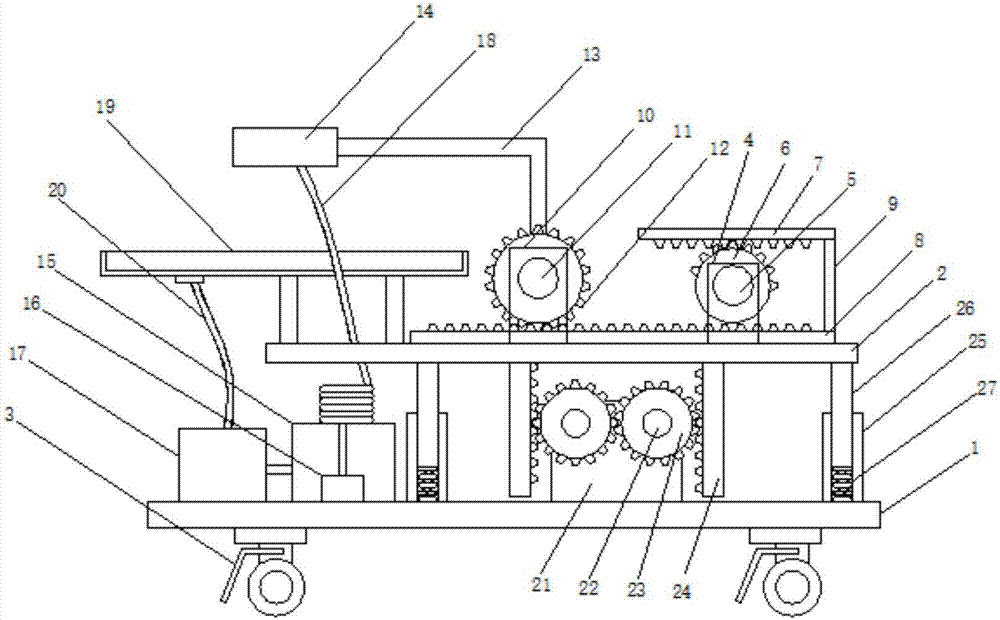

License plate wiping machine and license plate wiping method

InactiveCN101987560AReduce harmPrevent volatilizationOther artistic work equipmentsWorking environmentEngineering

The invention discloses a license plate wiping machine which is characterized by comprising a stand, at least one transmission rubber roller and at least one friction rubber roller, wherein each transmission rubber roller is respectively provided with a matched compression roller; each friction rubber roller is respectively provided with a matched compression roller; each transmission rubber roller and each friction rubber roller are arranged on the stand in parallel; each compression roller is installed on the stand; and part of each transmission rubber roller and part of each friction rubber roller are positioned in a solvent box. The license plate wiping machine of the invention has high wiping efficiency, low cost and less pollution, is relatively environment-friendly, and is favorable for the working environment of producers. The invention also discloses a license plate wiping method which has high efficiency and low cost.

Owner:李尚辉 +1

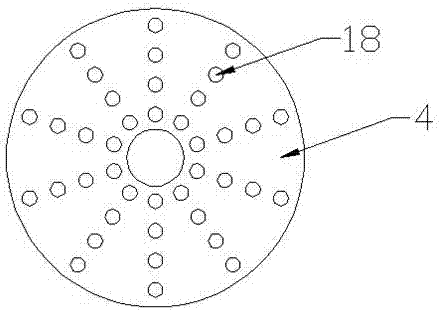

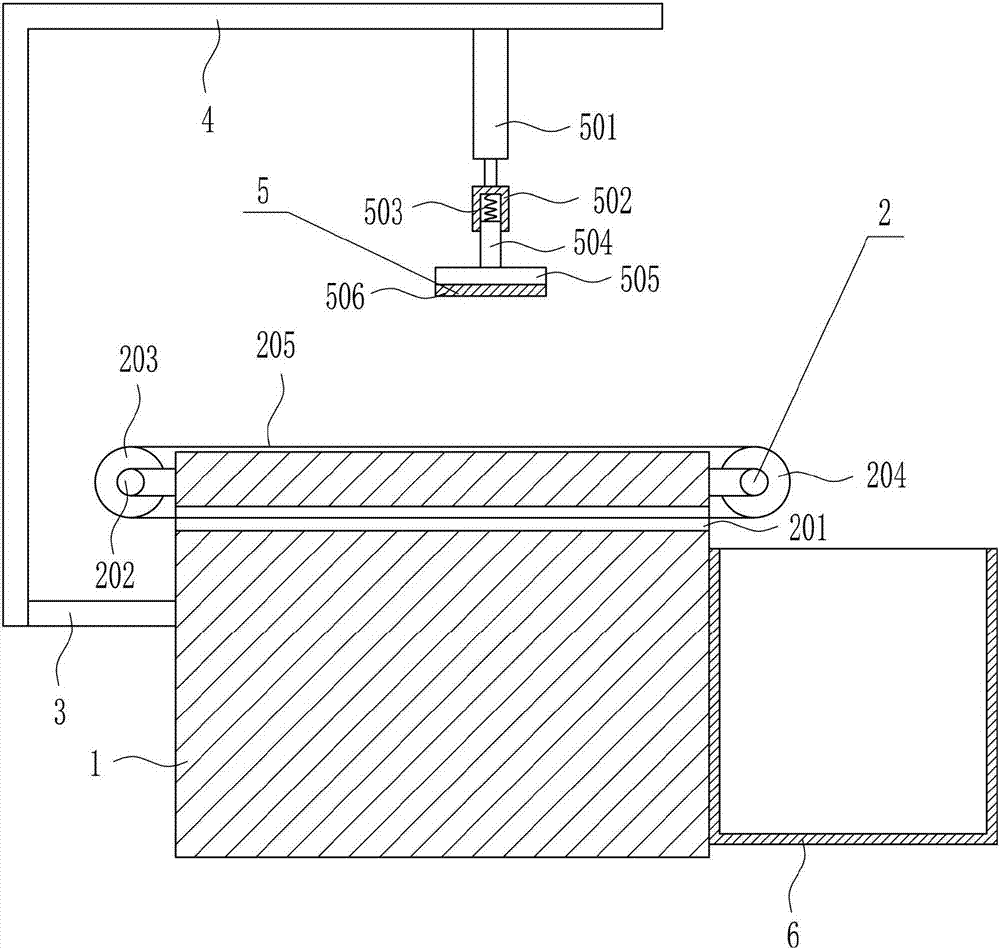

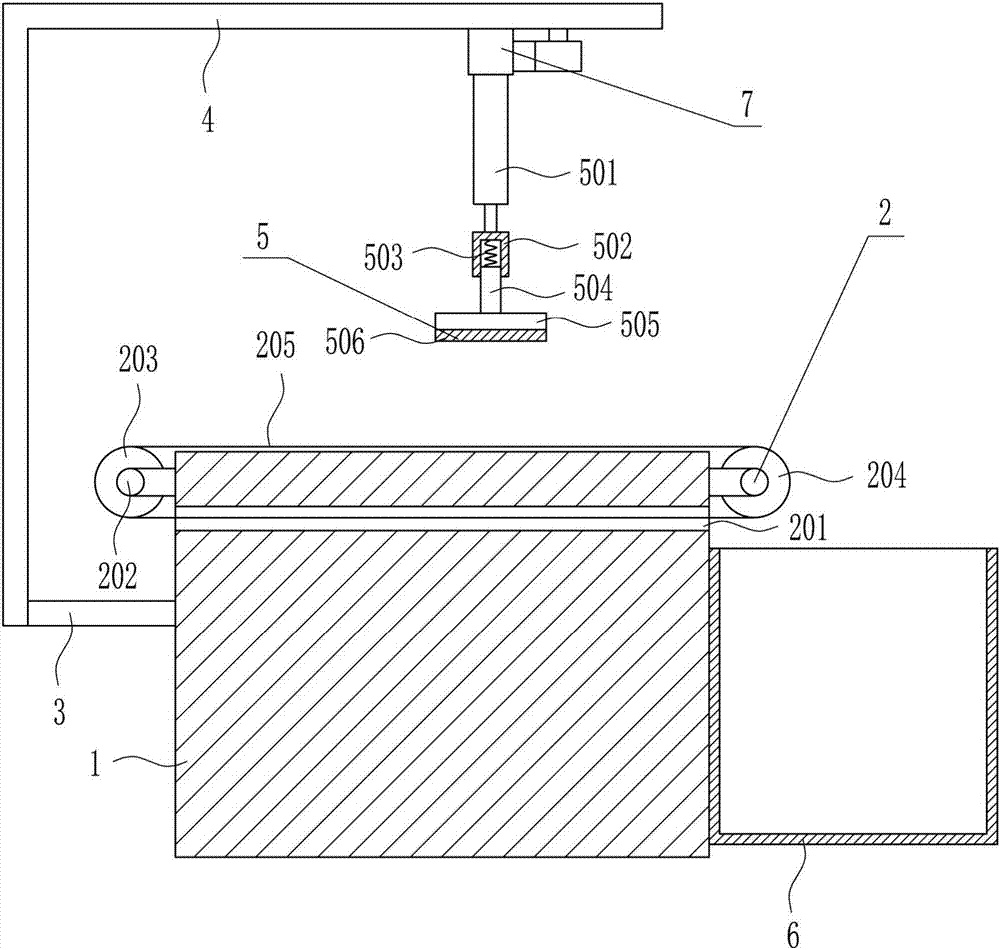

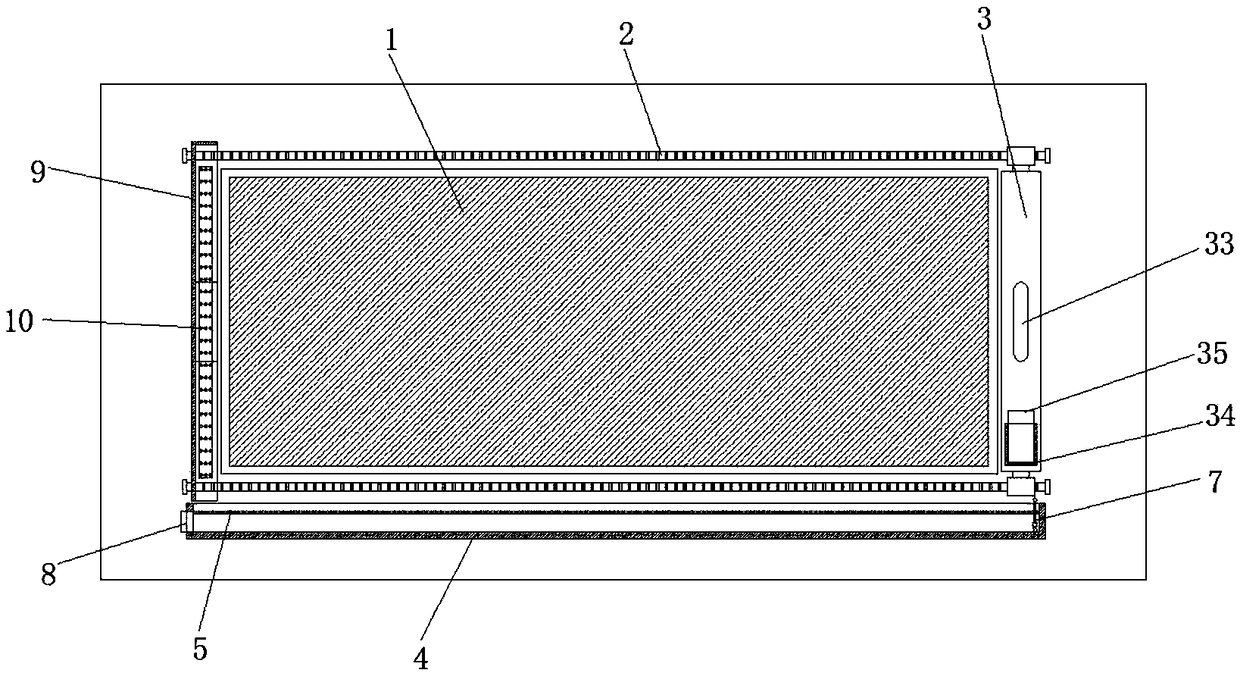

Photovoltaic cell wiping device for photovoltaic power station

InactiveCN107138497AIncrease productivityLarge area to wipeFlexible article cleaningCleaning using toolsEngineeringPhotovoltaic power station

The invention relates to a wiping device for a photovoltaic power station, in particular to a photovoltaic cell wiping device for the photovoltaic power station. The technical problem to be solved by the invention is to provide the photovoltaic cell wiping device for the photovoltaic power station capable of reducing the labor intensity of workers, improving the wiping efficiency and improving the production efficiency of photovoltaic cells. In order to solve the technical problem, the invention provides the photovoltaic cell wiping device for the photovoltaic power station. The device comprises a worktable and the like; the worktable is provided with a conveying device; the middle part of the left side surface of the worktable is horizontally connected with a support plate through a bolt; the left side plate of the support plate is connected with a 7-shaped plate through a bolt; a wiping device is arranged on the right side of the top of the inner side of the 7-shaped plate; and a collecting frame is connected to the right side surface of the worktable through a bolt. The device uses the conveying device for enabling the photovoltaic cells to move to the right side, and uses the wiping device for wiping the photovoltaic cells moving to the right side.

Owner:王志强

Blackboard

InactiveCN107297976AAvoid flyingSimple structureBoard cleaning devicesWriting boardsOn boardEngineering

Owner:张冬

Automatic dust absorption environment-friendly blackboard eraser

InactiveCN108407511AAdjustable distanceAvoid the problem of low wiping efficiencyBoard cleaning devicesBristleEngineering

The invention relates to an automatic dust absorption environment-friendly blackboard eraser and belongs to the technical field of teaching equipment. A driving mechanism comprises a first screw rod motor, a first screw rod, a first nut seat, a first motor bearing seat, a second screw rod motor, a second screw rod, a second nut seat and a second motor bearing seat. Ablackboard eraser portion comprises a fixing plate, an eraser base seat, bristles and a piece of lint. A squeezing force adjusting mechanism comprises a first adjusting spring, a first adjusting bar, a first adjusting elliptical wheel, an adjusting plate, a second adjusting elliptical wheel, a second adjusting bar, a second adjusting spring and an adjusting air cylinder. Adust absorption mechanism comprises a dust absorber, a rectangular bracket, a dust absorbing pipe and a dust absorbing shade. Aspray dust removing mechanism comprises a spray generator and a connecting pipe. Chalk writing on a blackboard can be cleaned automatically and the cleaning process is convenient and quick. The automatic dust absorption environment-friendly blackboard eraser is not liable to leave white traces, dust around the eraser can be timely absorbed, good air quality in a classroom can be kept, efficiency of blackboard wiping can be improved, and time and efforts are saved.

Owner:梁发杨

Special cleaning agent for automobile windshield

InactiveCN104312760AEfficient removalImprove wiping efficiencyInorganic/elemental detergent compounding agentsSurface-active detergent compositionsSludgeAlkylphenol

The invention discloses a special cleaning agent for an automobile windshield. The cleaning agent is prepared from the following raw materials in parts by mass: 5 to 10 parts of cocinic acid, 11 to 15 parts of alkylphenol polyoxyethylene, 5 to 8 parts of ethyl alcohol, 10 to 16 parts of alkyl sodium sulfonate, 5 to 8 parts of potassium hydroxide, 5 to 9 parts of sludge activated carbon, 6 to 10 parts of fatty alcohol-polyoxyethylene ether, 3 to 8 parts of a decontaminant, 6 to 12 parts of an anti-freezing agent, 10 to 15 parts of ammonium hydroxide, 12 to 17 parts of friction materials, 10 to 15 parts of essence, and the balance of water. The special cleaning agent for the automobile windshield adopting the technical scheme has the advantages that oil stains and other dirt on the windshield can be obviously removed, no traces or residues are left on the windshield, the dirt can usually be cleaned off when one side of the windshield is wiped, the wiping efficiency is high, and the quality is good.

Owner:SUZHOU YUZHICHENG TRADE

Mathematics teaching board with dust collection function

InactiveCN108597305AAchieve reductionChange inclinationBoard cleaning devicesWriting boardsEngineeringRight trapezoid

The invention provides a mathematics teaching board with a dust collection function. The mathematics teaching board comprises a support plate, wherein a height adjusting device is arranged at the lower side of the support plate, the height adjusting device comprises a support post, the bottom end of the support post is fixedly connected with the upper side of a base, a groove with an upward opening is formed in the support post, a lower movable block is arranged in the groove, the section of the lower movable block is in the shape of a right trapezoid, the oblique plane of the lower movable block faces the upward direction, movable rods are fixedly connected to two sides of the lower movable block, a movable through hole is formed in the left side of the support post, the movable rod on the left side is positioned inside the movable through hole, and the movable rod on the right side is connected with a drive device. The mathematics teaching board has the beneficial effects that the drive device drives the lower movable block to move towards the right side, the lower movable block enables an upper movable block to move upwards through a rolling wheel and a rolling wheel bracket, and thus a fixing post drives the increase of the height of the support plate; when the drive device enables the lower movable block to move towards the left side, the fall of the upper movable block isrealized.

Owner:XIAN UNIV OF SCI & TECH

Advanced steel surface cleaning device

InactiveCN113500023AImprove wiping efficiencyIncrease contact strengthCleaning using toolsCleaning using liquidsSurface cleaningStructural engineering

The invention relates to the technical field of advanced steel, and discloses an advanced steel surface cleaning device. The device comprises a box body, an electric telescopic rod is fixedly connected to one side of the inner wall of the box body, steel is arranged at the bottom of the inner wall of the box body, and a cleaning mechanism is arranged in the box body. The cleaning mechanism is arranged, so that when a connecting frame pushes and wipes the top of the steel, a wiping block can wipe the surface of the steel and synchronously conduct left-right back-and-forth vibration wiping, fine particles and stains which cannot be cleaned can be vibrated, wiped and brushed away through vibration, and then the wiping efficiency of the wiping block on the surface of the steel is greatly improved; and a vibration cleaning mechanism is arranged, so that some stubborn stains on the surface of the steel, which cannot be wiped when a brush vibrates and wipes the surface of the steel in a reciprocating mode in the same direction, can be removed through continuous downward pressing of the brush, and then the cleaning efficiency is improved.

Owner:赵益超

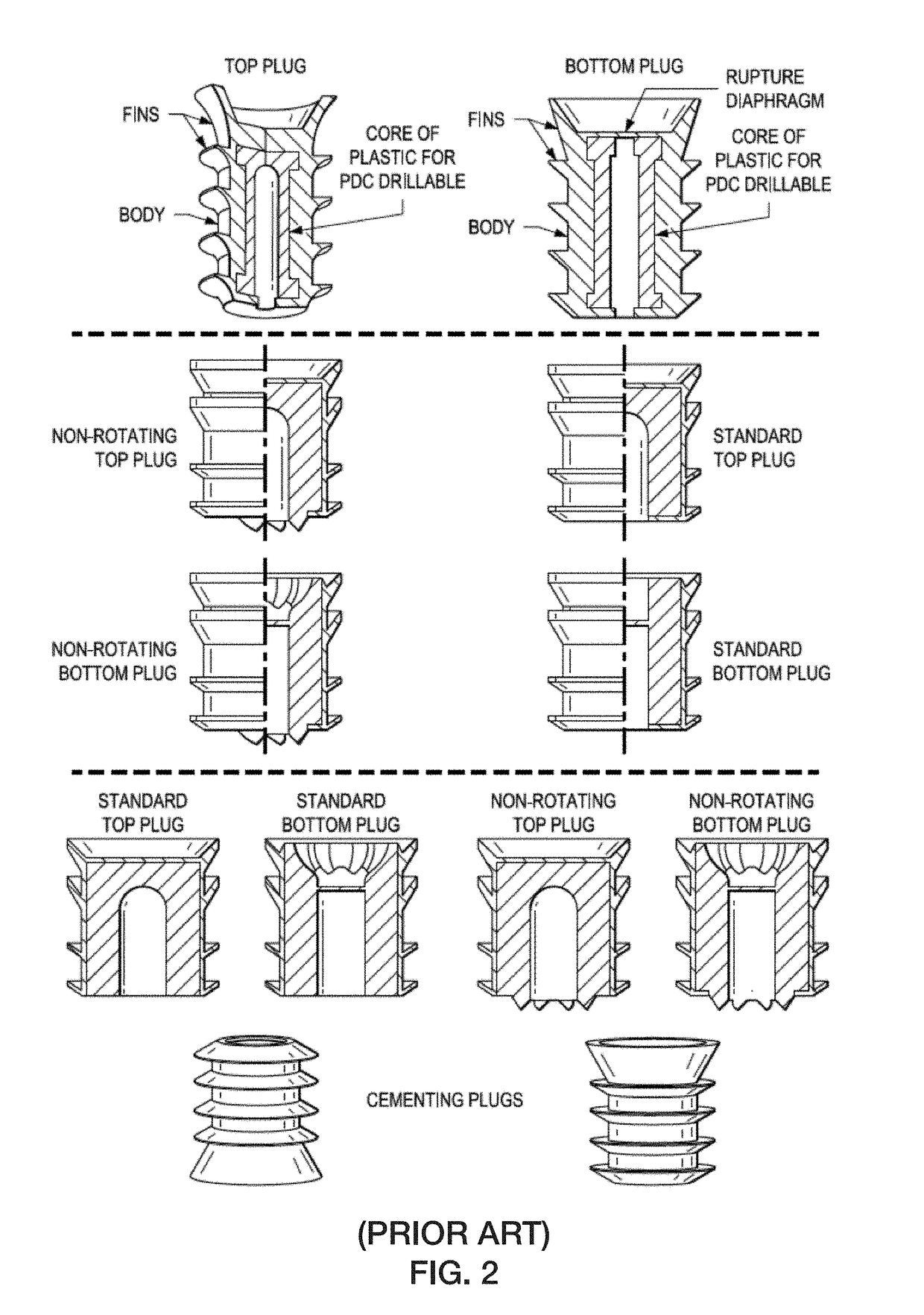

Delayed fin deployment wiper plug

ActiveUS20190017348A1Avoid pollutionEasy to cleanCleaning apparatusSealing/packingEngineeringMechanical engineering

A delayed fin deployment wiper plug has a tubular body, which has a closed top and a piston therein. The piston is supported at one or more locations inside the tubular body by one or more sets of shear pins or spring clips or some equivalent device. The piston is connected to or abutted to a sleeve that covers an upper portion of the tubular body, containing therein one or more sets of deployable fins that are not exposed for use unless the piston is activated and raises the sleeve.

Owner:CONOCOPHILLIPS CO

Device for cleaning electric appliances

InactiveCN107583897AAvoid enteringAvoid re-adhesionDirt cleaningCleaning using toolsElectric machineryEngineering

The invention discloses a device for cleaning electric appliances. The device comprises an outer shell, a cleaning cover, a wiping sponge and a motor, wherein the cleaning cover is fixed at the upperend of the outer shell; a sponge chamber and a dust-collecting chamber along the horizontal direction are arranged in the cleaning cover; a turntable is arranged in the sponge chamber; a plurality ofwater-permeating holes penetrating through the turntable are uniformly formed in the turntable; the wiping sponge is fixedly arranged on the left side of the turntable; an output shaft of the motor isinserted into the outer shell and is fixedly connected with the turntable; a fan is jointed in the dust-collecting chamber through a pipeline; a piston is arranged in a water chamber in a sliding form; a pushing airbag is arranged under the piston; an extruding airbag is connected with the outer end of a connecting pipe. According to the invention, the arranged wiping sponge is rotated under thedriving of the motor so as to clean and wipe the surfaces of the electric appliances; the wiping efficiency is increased; the cleaning time is saved; the cleaning water permeates into the sponge in the manner of manually extruding; much water leaching is not required; the electric appliances are protected; the cleaning water is prevented from entering into the electric appliances.

Owner:束春花

Wiping device for an ink jet franking machine

ActiveUS8752934B2Efficiently and periodically cleaningEasy to cleanFranking apparatusPrintingHead partsNozzle

A wiping device (20) for cleaning outer surfaces of at least one row of ejection nozzles in at least one print head (4a, 4b) of an ink jet printing module (2) of a franking machine when the module is moving above the wiping device in first and second directions (X, Y), comprising two wiping rollers (26, 28) located one behind the other in the first direction and adapted to rotate in opposite directions around respective fixed shafts (30, 32), the two wiping rollers being permanently dampened in contact with a cleaning fluid (24) contained inside a container (22); and the two wiping rollers are adapted via a one-way bearing (34, 36) to remain stationary alternatively, one during the moving of the module in the first direction and the other during the moving of the module in the second direction.

Owner:NEOPOST TECH SA

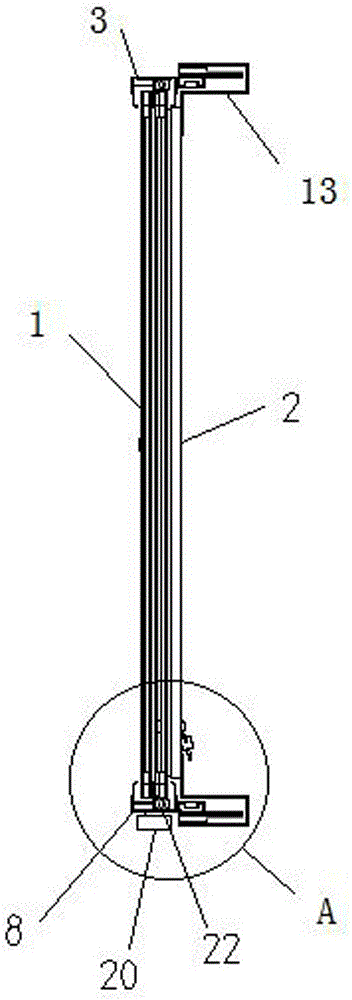

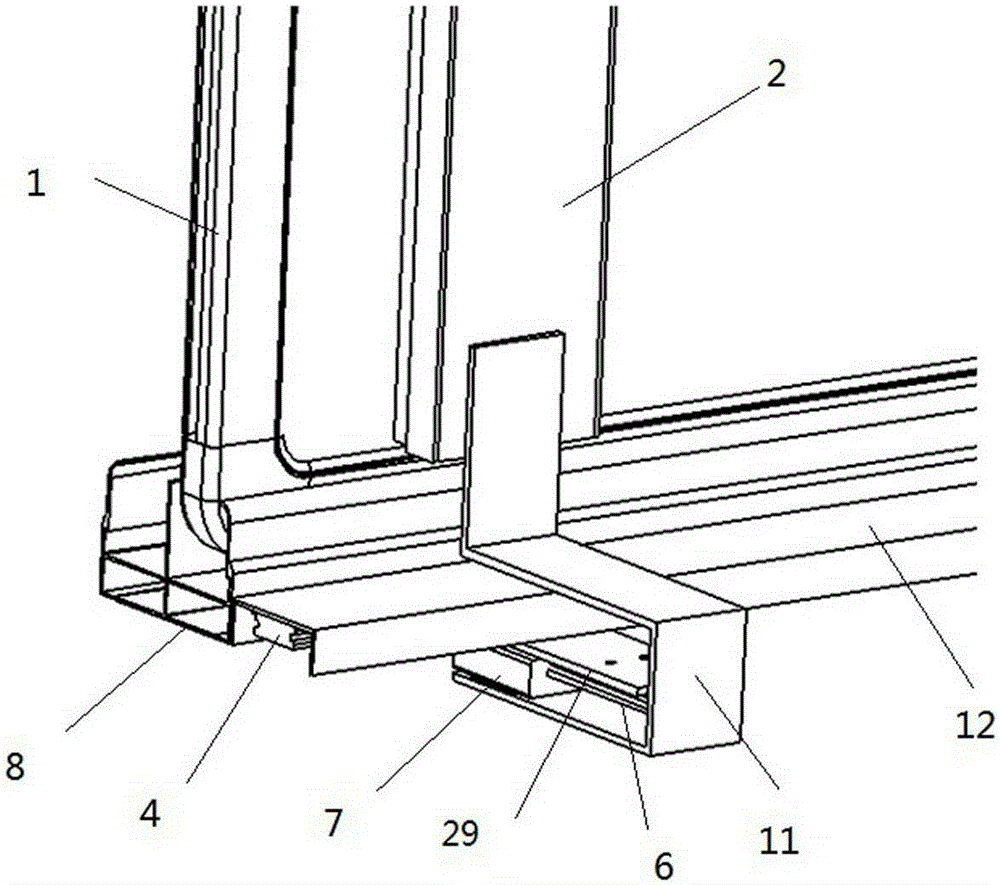

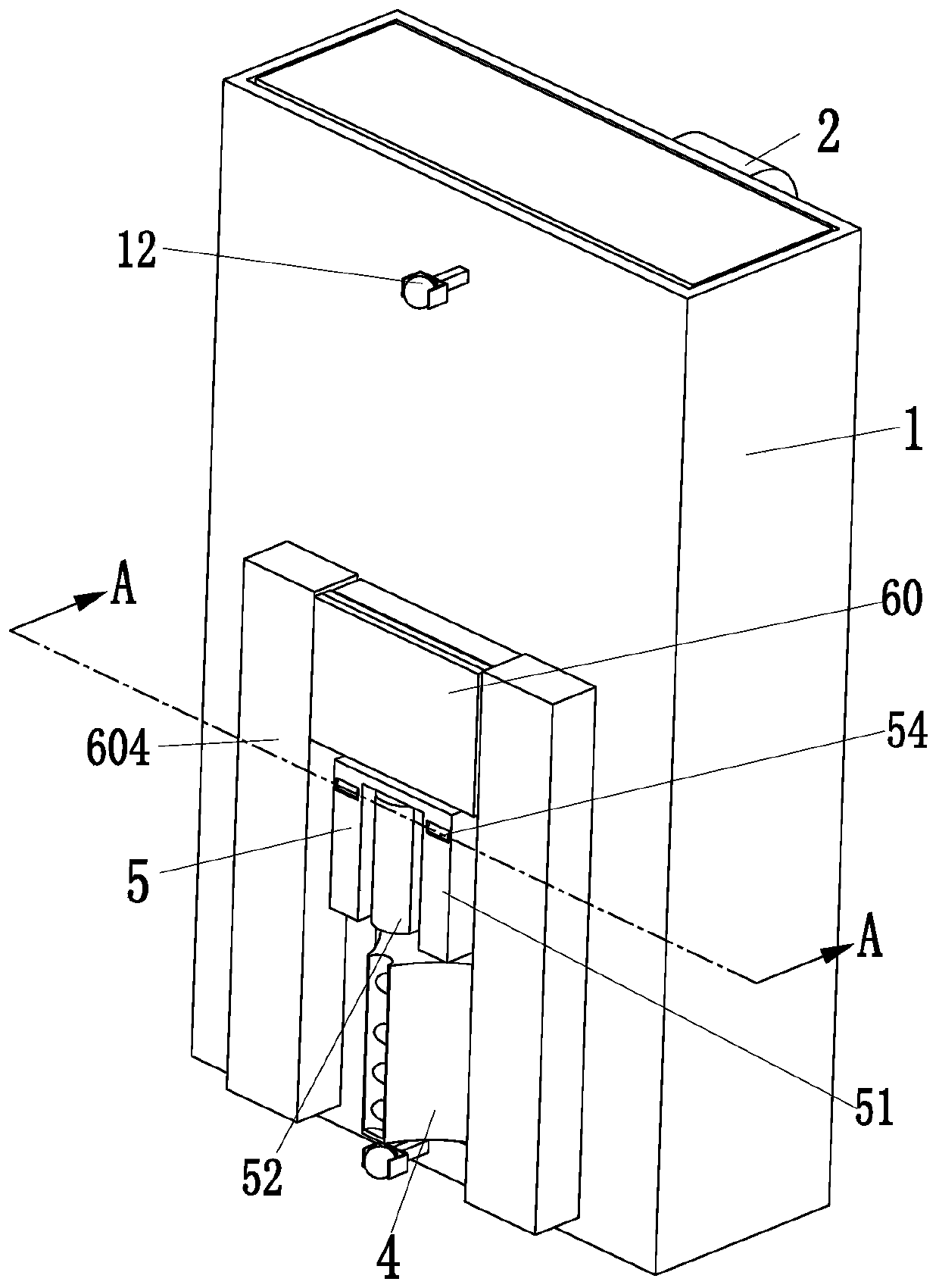

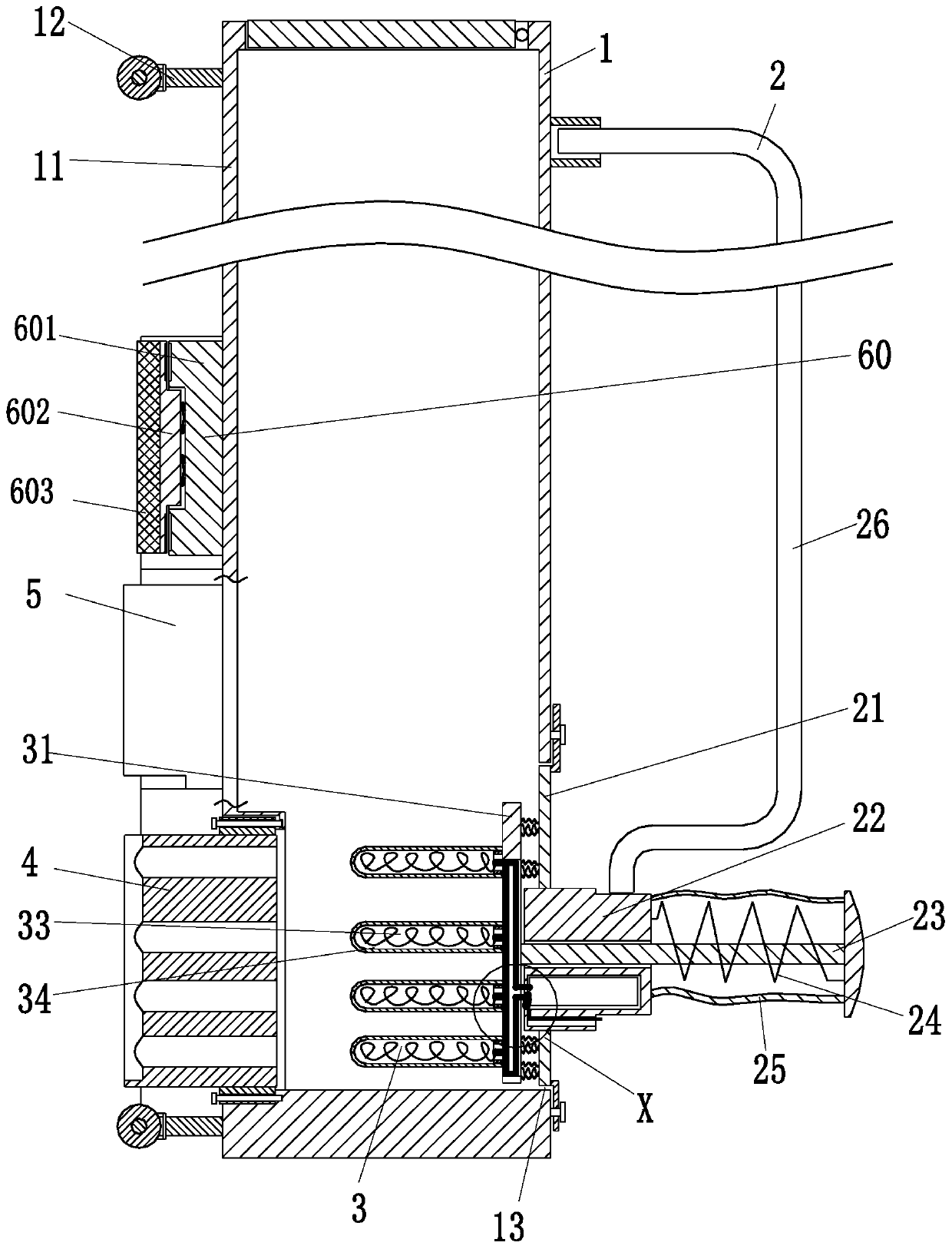

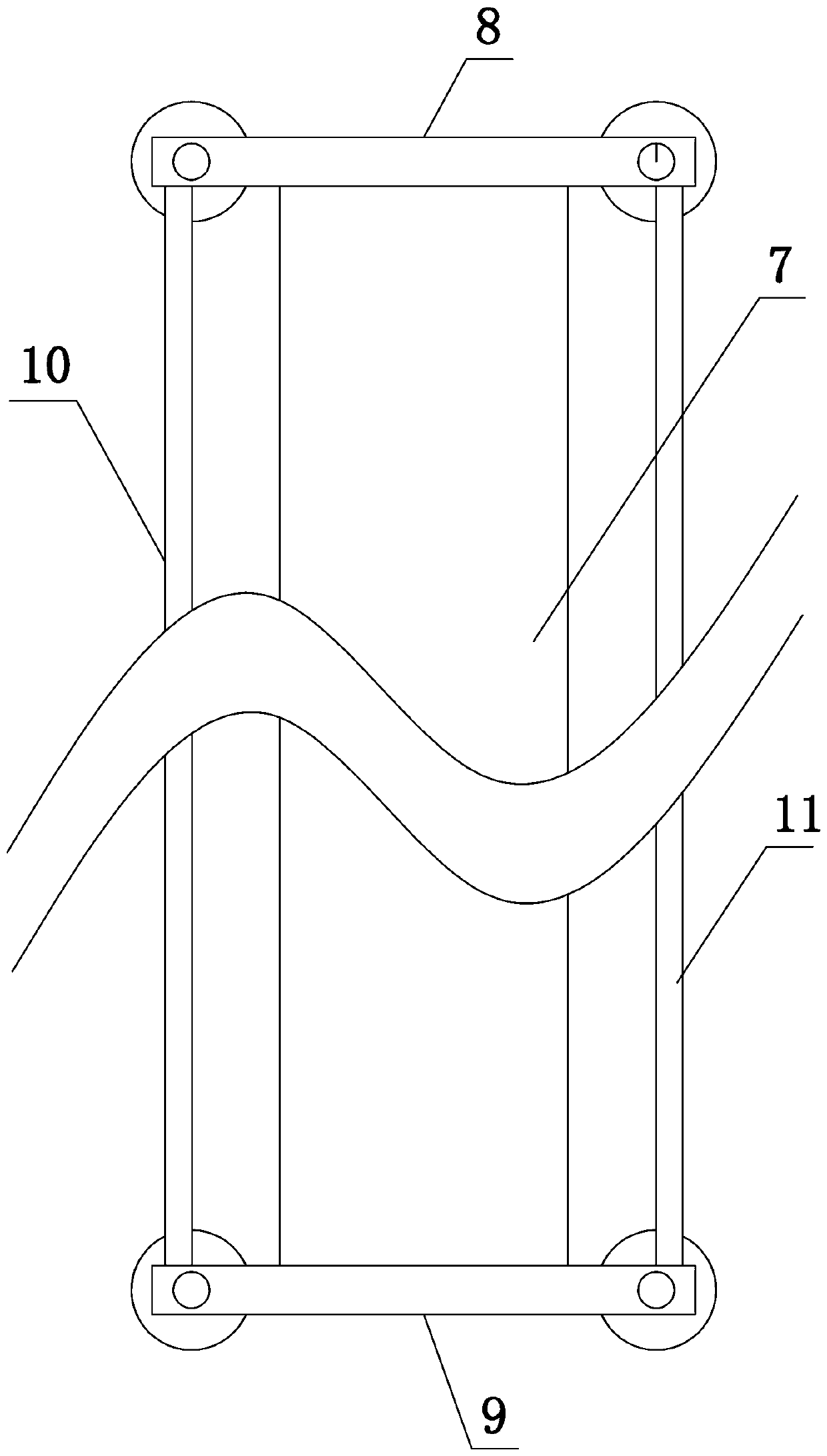

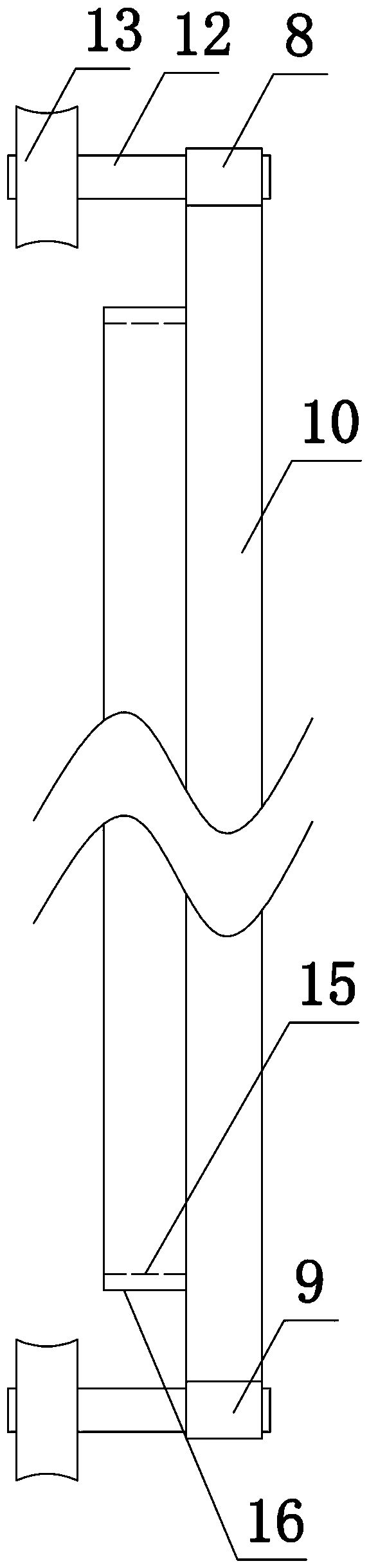

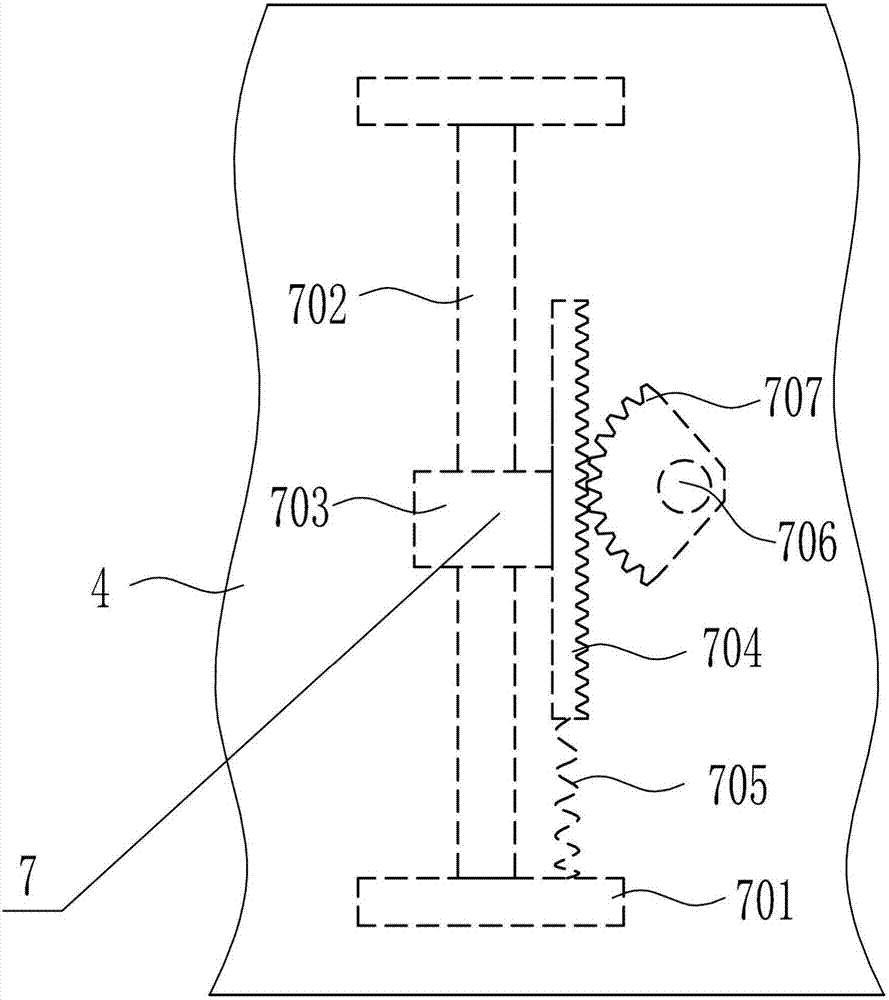

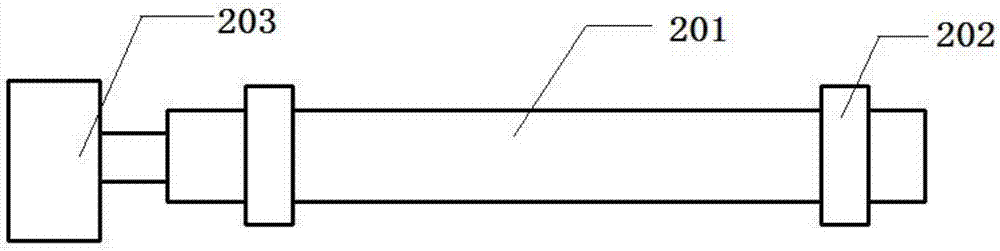

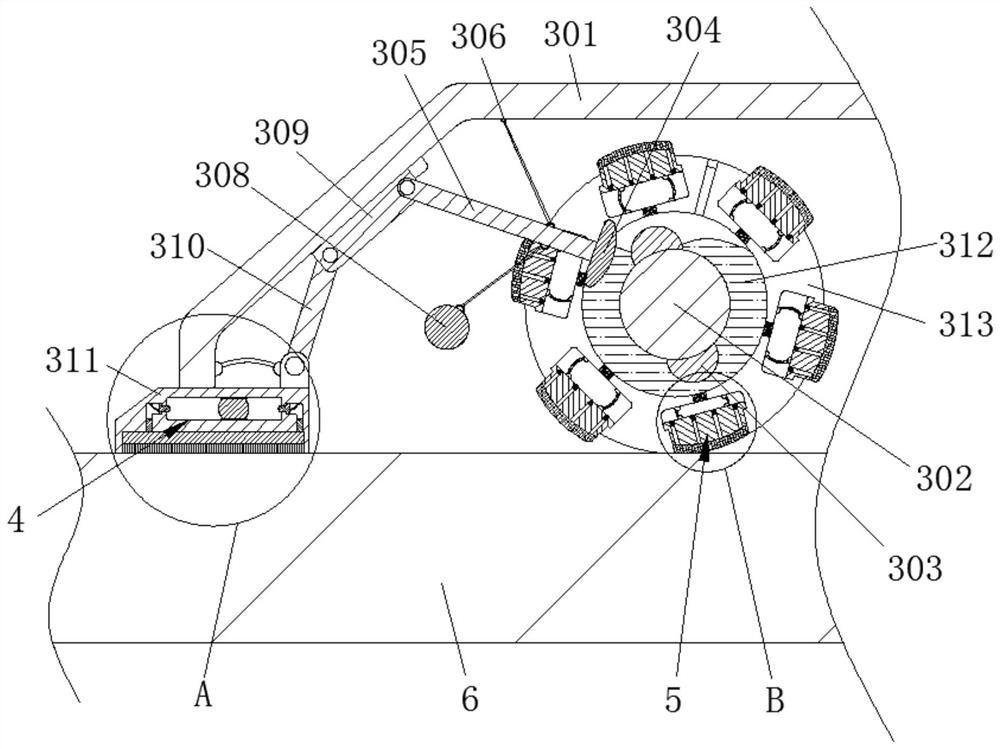

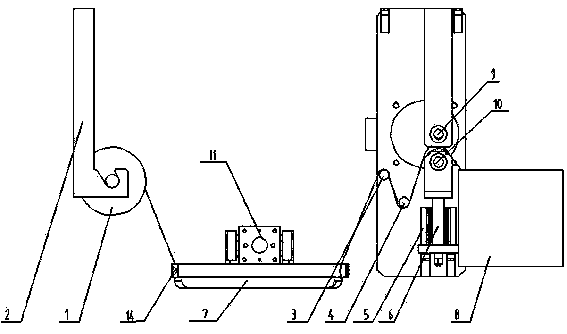

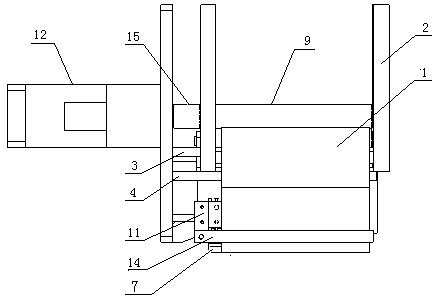

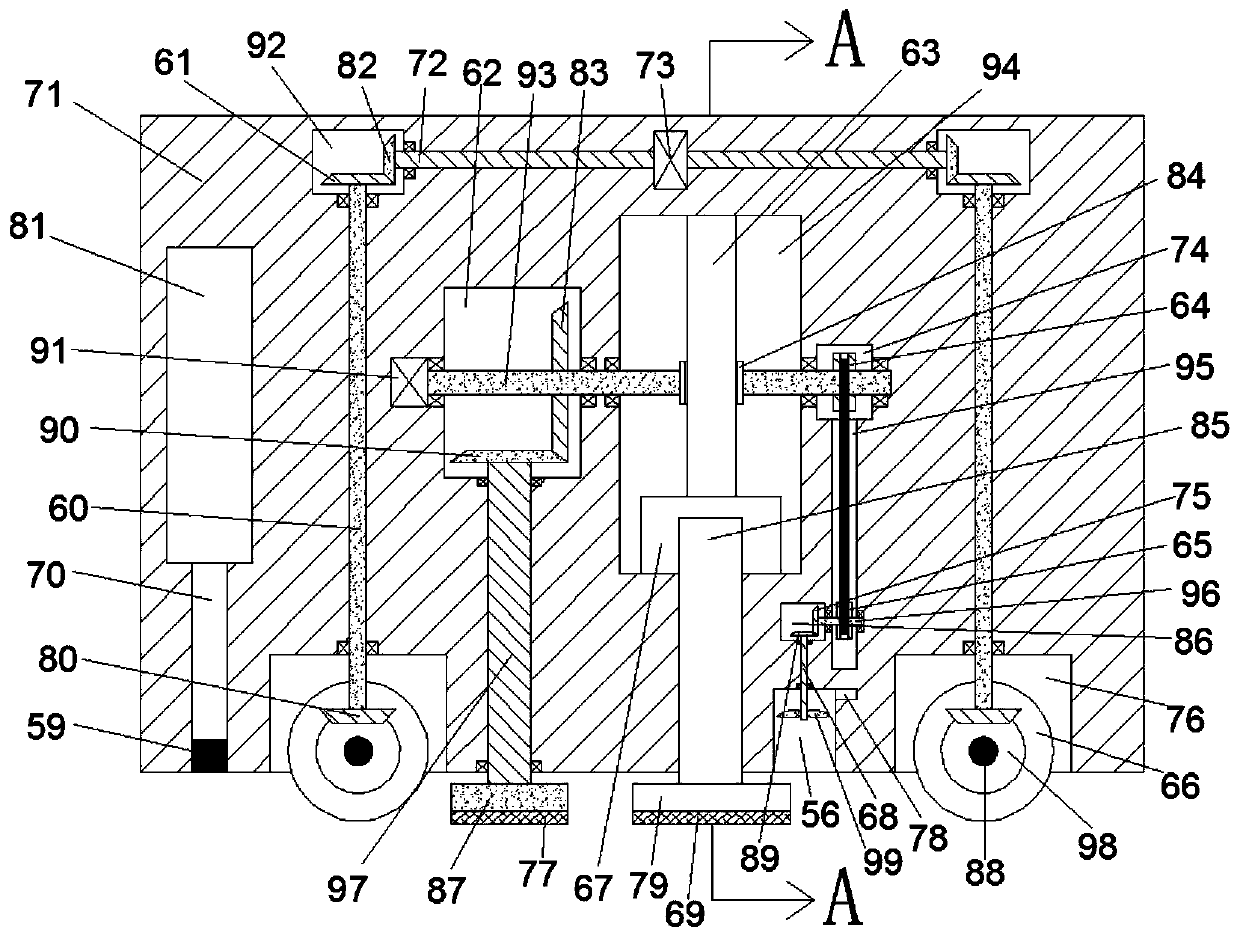

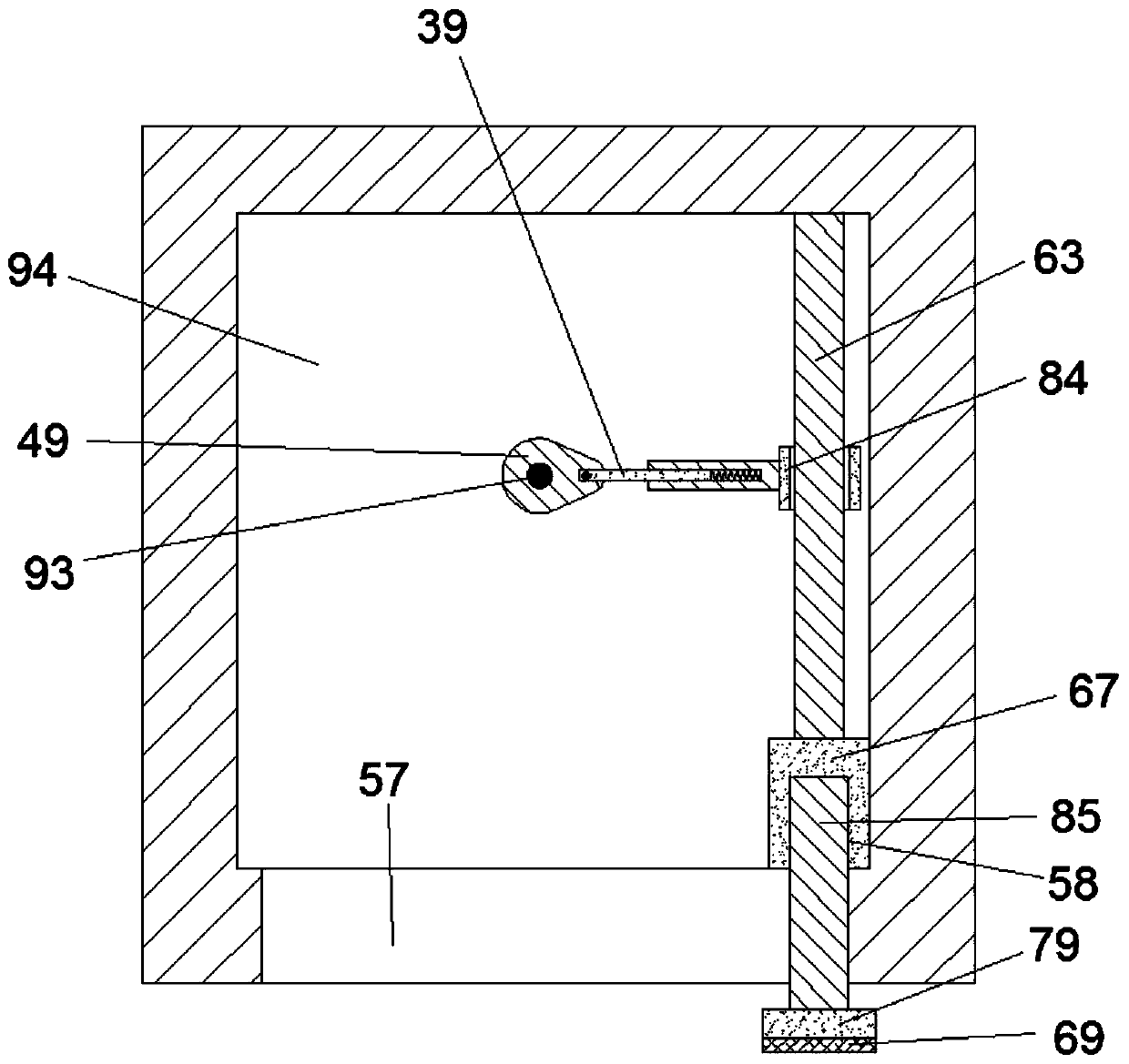

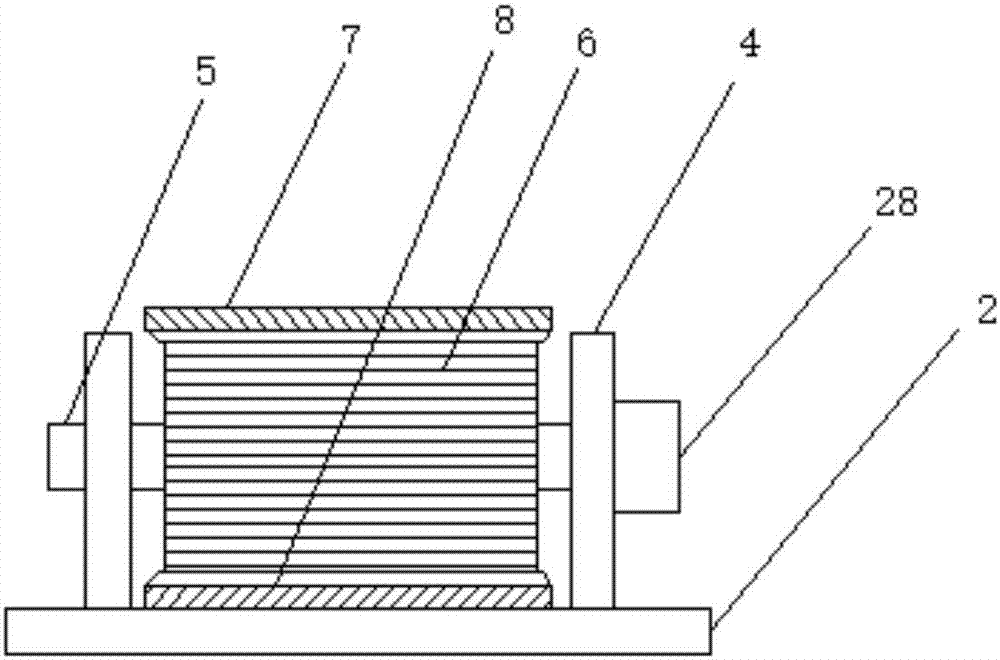

Intelligent cloth changing device of wiping mechanism

InactiveCN103817124AImprove wiping efficiencyGood quality wipeFlexible article cleaningCleaning using toolsKnurlingEngineering

The invention discloses an intelligent cloth changing device of a wiping mechanism. The intelligent cloth changing device comprises a storage device, a wiping head, a cloth supporting rod and a cloth changing driving device which are sequentially arranged, wherein the storage device is used for storing wiping cloth, the cloth supporting rod is used for supporting and opening the wiping cloth, the cloth changing driving device is used for pulling the wiping cloth, the wiping head is provided with an automatic clamping device which is used for fixing the wiping cloth on the wiping head, the cloth changing driving device comprises a driving compression knurling shaft connected with a power device and a driven compression knurling shaft, and the driven compression knurling shaft is in compression with the driving compression knurling shaft through an elastic device and is separated from the driving compression knurling shaft through a separation driving device. The intelligent cloth changing device disclosed by the invention can be used for carrying out automatic cloth changing work during automatic glass wiping, the structure principle is simple and reliable, and the motion is smooth and stable; wiping and cloth changing can be more convenient, the using efficiency of the wiping cloth is greatly increased, and the intelligent cloth changing device can adapt to different factory glass wiping technologies well.

Owner:HUNAN YUHUAN INTELLIGENT EQUIP CO LTD

Novel automatic cleaning device

InactiveCN110558907AIngenious and reasonable structureEasy to useCarpet cleanersFloor cleanersGear wheelEngineering

The invention discloses a novel automatic cleaning device. The novel automatic cleaning device comprises a main box body, wherein a moving part is arranged in the main box body; the moving part comprises a moving motor arranged in the main box body; moving cavities are symmetrically arranged in the inner walls of the left side and the right side of the moving motor; the left end and the right endof the moving motor are connected with a first rotating shaft extending to the interiors of the moving cavities in a power cooperation mode; the other end of the first rotating shaft is fixedly connected with a first helical gear; the lower end of the first helical gear is connected with a rotatable second helical gear in an engaged cooperation mode; and a moving groove in which a downward openingis formed is formed in the inner wall of the lower side of each moving cavity. The cleaning device disclosed by the invention is more reasonable and ingenious in integral structure, very convenient to use, high in stain wiping efficiency, good in cleaning effect and high in use and popularization values.

Owner:SUZHOU XINYAO HEALTH TECH CO LTD

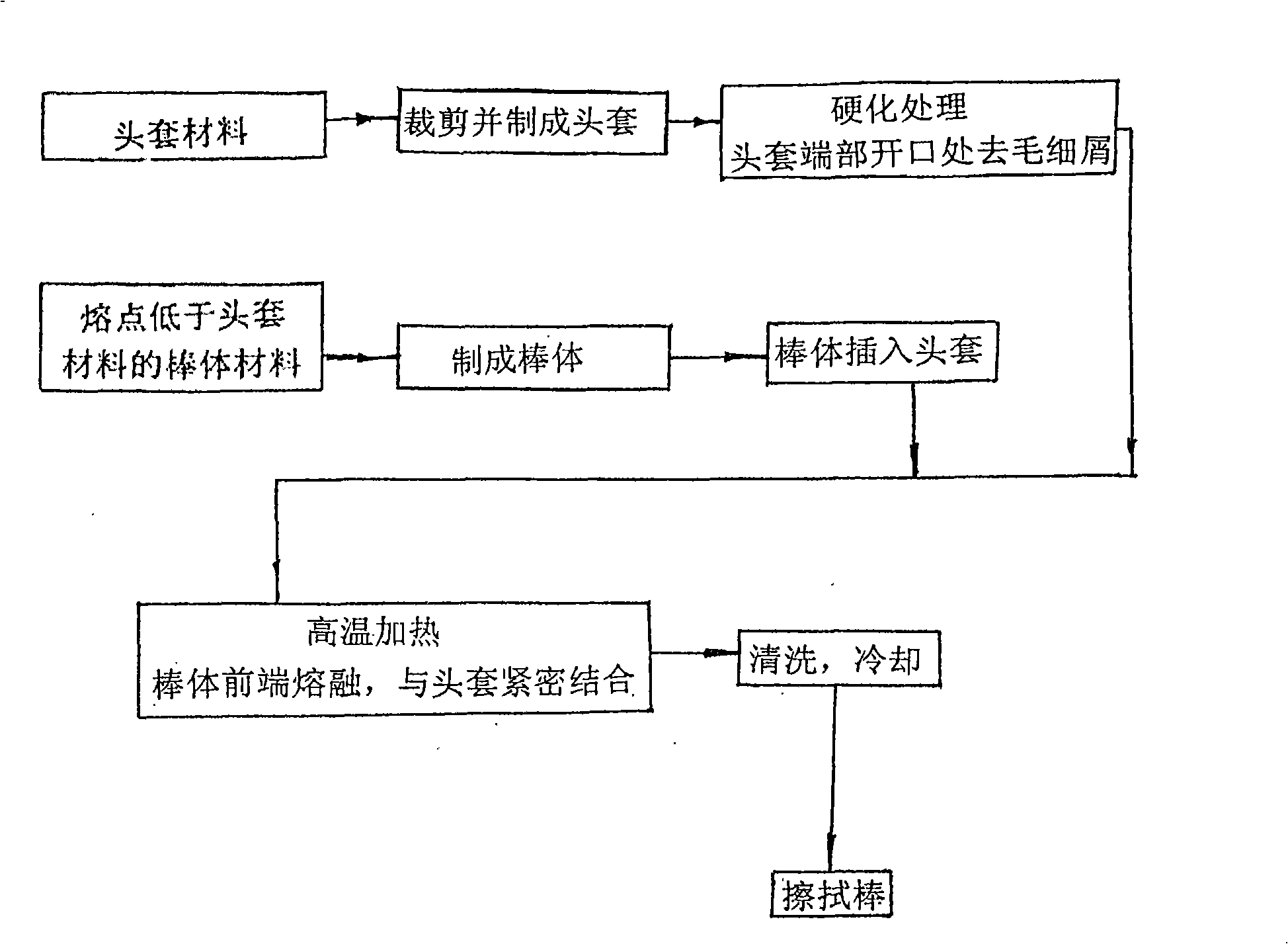

Method for manufacturing wiping rod

InactiveCN101402259ATightly boundImprove wiping efficiencyCleaning using toolsDomestic articlesEngineeringHigh heat

The invention discloses a method for manufacturing a wiping rod, which relates to a method for combining a sleeve and a rod body of the wiping rod, and a method for removing rough edges of the sleeve, wherein a sleeve material is cut and spliced into the sleeve; a rod body material is prepared into the rod body the dimension of the front end of which is the same as that of the sleeve, and the melting point of the rod body material is lower than that of the sleeve material; a port position of the sleeve, namely the rod body, is inserted into a sleeve position and placed into a hardening heat treater for hardening treatment; the front end of the rod body is placed into the sleeve, and the sleeve provided with the front end of the rod body is placed into a heater for overall or local high-temperature heat treatment; and after the melting point of the rod body material is achieved and the front end of the rod body is fused, the wiping rod is taken out, cleaned and cooled. When the wiping rod is used, people do not need to worry about that the clean surface can be polluted by wool fleece. The sleeve of the wiping rod and the front end of the rod body undergo high-temperature heat treatment and are tightly combined with each other, so that the wiping work efficiency is improved; and the wiping rod can resist various chemical detergents, so that the use range of the wiping rod is widened.

Owner:刘颖姝

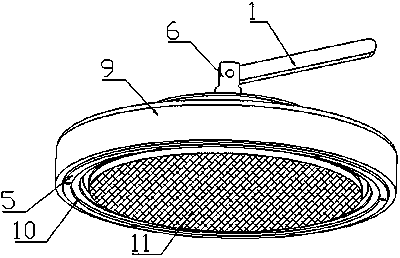

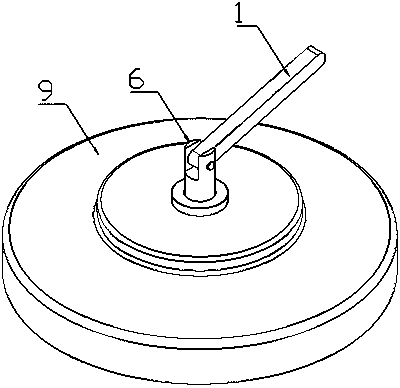

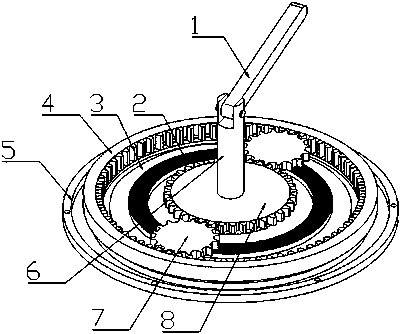

Rotatable magnetic glass wiper

InactiveCN109276180AImprove wiping efficiencyEasy to cleanWindow cleanersArchitectural engineeringMagnet

The invention provides a rotatable magnetic glass wiper. An annular clamping groove is arranged at the lower end of a shell, an annular fixed magnet is fixedly connected to the bottom surface of the clamping groove through a screw, the lower end face of the fixed magnet extends out of the clamping groove, a rotation shaft is mounted at the upper end of the shell through a bearing, the part, extending out of the upper end of the shell, of the rotation shaft is hinged to a handle, a sun gear is fixedly connected to the part, extending into the shell, of the rotation shaft, a fixing plate is fixedly connected to the lower end of the sun gear, an inner gear ring is fixedly connected to the lower end of the shell, each of two sides of the sun gear is meshed with a planetary gear, and the two planetary gears are fixedly connected to the fixing plate through rotation shafts. For the rotatable magnetic glass wiper, the inner and outer surfaces of glass are cleaned by adopting the combinationmanner using a rotating magnet and the fixed magnet, the rotating magnet rotates for driving a wiping rag to rotate, then the inner and outer surfaces of the glass are wiped, meanwhile, during the wiping process, the rotatable magnetic glass wiper can move all around, so that the wiping efficiency is high, and the cleaning effect is good.

Owner:赵雅琪

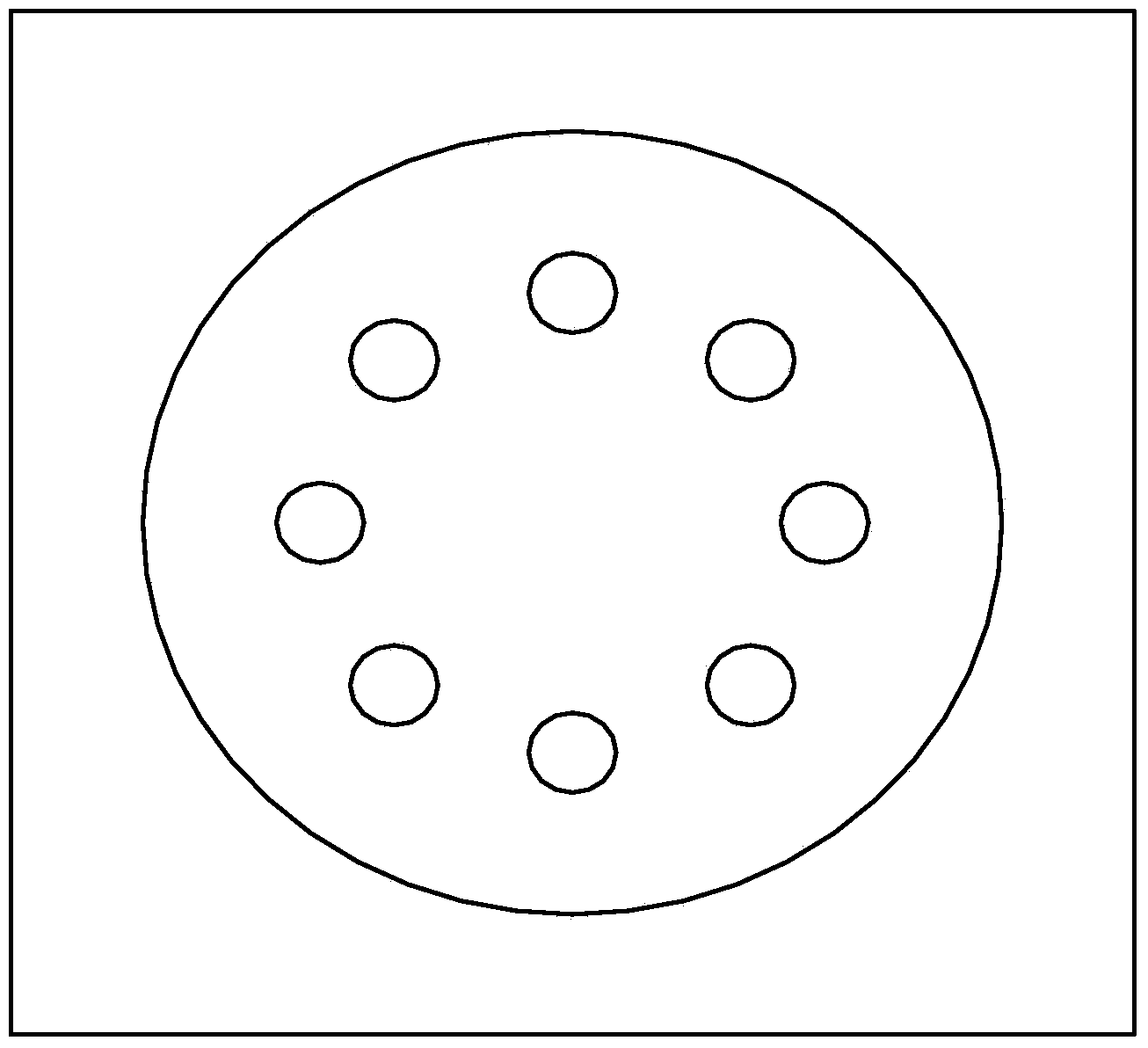

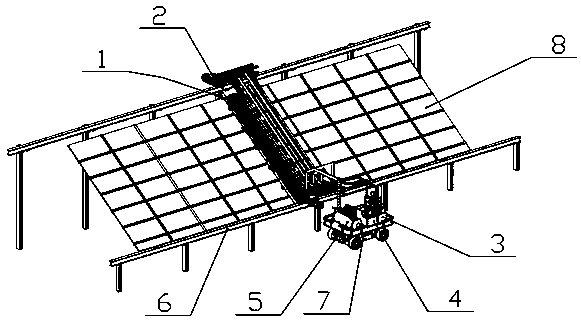

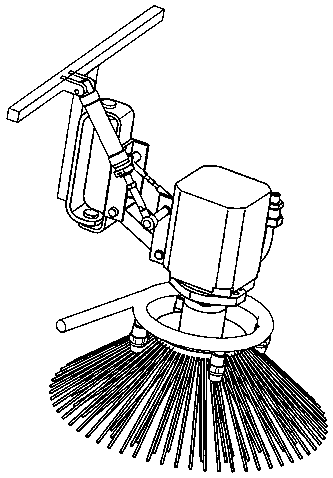

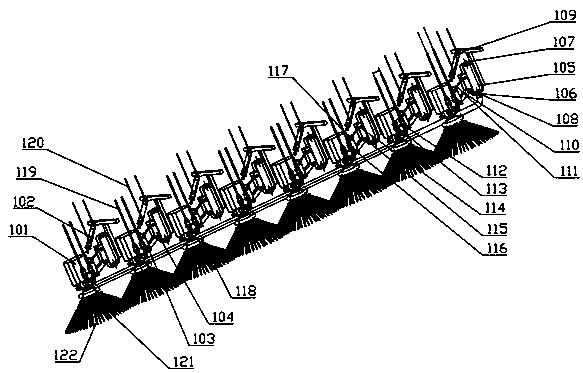

Solar photovoltaic assembly wiping mechanism

InactiveCN111327262AEasy to wipeReduce manual labor intensityPhotovoltaicsPhotovoltaic energy generationHydraulic motorHydraulic pump

The invention provides a solar photovoltaic assembly wiping mechanism. The solar photovoltaic assembly wiping mechanism comprises sweeping disc mechanisms, a transverse moving trolley, a hydraulic system, a water system, a blow-drying system, a guide rail and a battery car, wherein each set of sweeping disc mechanism is provided with an independent lifting oil cylinder used for adjusting and controlling the distance between a rotating brush and a photovoltaic assembly, each set of sweeping disc mechanism is fixedly installed on the transverse moving trolley through bolts, a hydraulic system pipeline, a water system pipeline and a blow-drying system pipeline are fixedly installed on the transverse moving trolley through pipe clamps, and a roller assembly of the transverse moving trolley isinstalled on a low rail and a high rail of the guide rail in a sliding mode. The brush is driven by a hydraulic motor to rotate, and the transverse moving trolley drives the sweeping disc mechanisms to operate along the guide rail to wipe the photovoltaic assembly. The battery car is loaded an air compressor, a hydraulic pump station and a water pump to operate in the same direction along with thetransverse moving trolley. The cleaning process is simple and reliable, the wiping efficiency is high, and the labor intensity of operators is reduced.

Owner:南通大鹏光电有限公司

Teaching device for junior high school

InactiveCN108312751AImprove efficiencyReduce dust contentBoard cleaning devicesDirt cleaningEngineering

The invention discloses a teaching device for a junior high school. The teaching device comprises a blackboard main body, wherein the blackboard main body is fixedly installed on the wall of a classroom platform, and sliding tracks are fixedly installed on the walls of the upper and lower sides of the blackboard main body in the length direction of the blackboard main body. A cleaning device is movably arranged between the two sliding tracks, the cleaning device comprises two sliding blocks, the two sliding blocks are movably arranged on the sliding tracks, and a support plate is fixedly connected between the two sliding blocks. A handle is arranged in the middle part of one side of the support plate far away from the blackboard main body, and the support plate on the lower side is provided with a placing box. A short plate eraser is placed in the placing box, and telescopic support rods are arranged on one side of the support plate away from the handle at equal distances in the lengthdirection. The teaching device for the junior high school is novel in design, simple in structure, convenient to use and capable of efficiently wiping the blackboard, and the wiping effect is significant, at the same time, chalk dust can be collected to reduce dust in a classroom.

Owner:佛山杰致信息科技有限公司

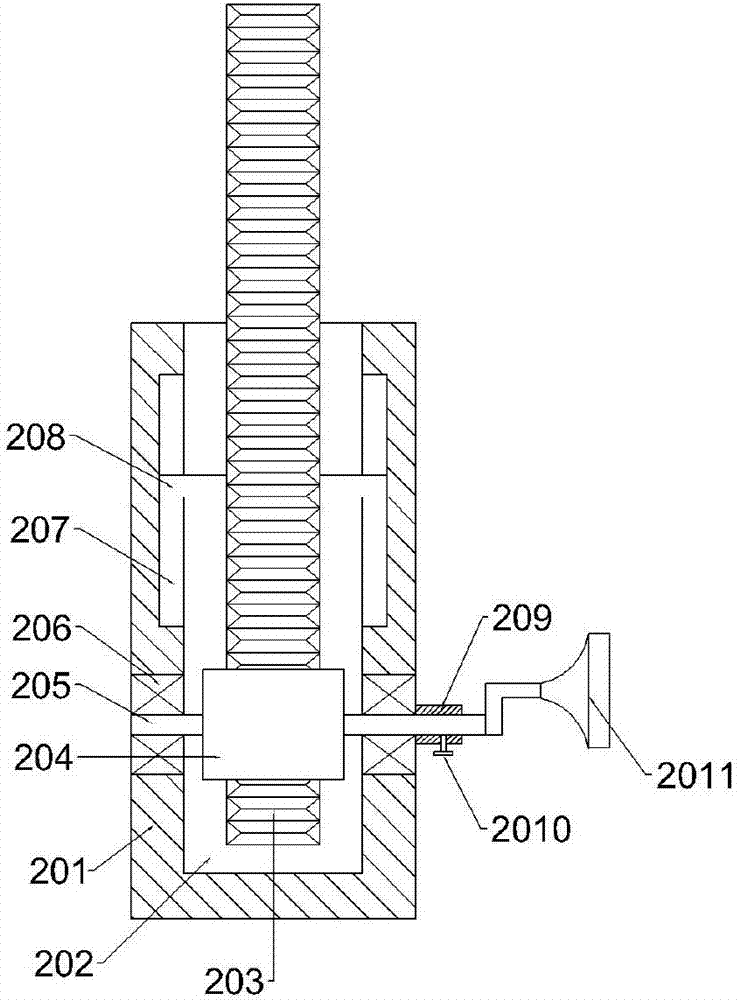

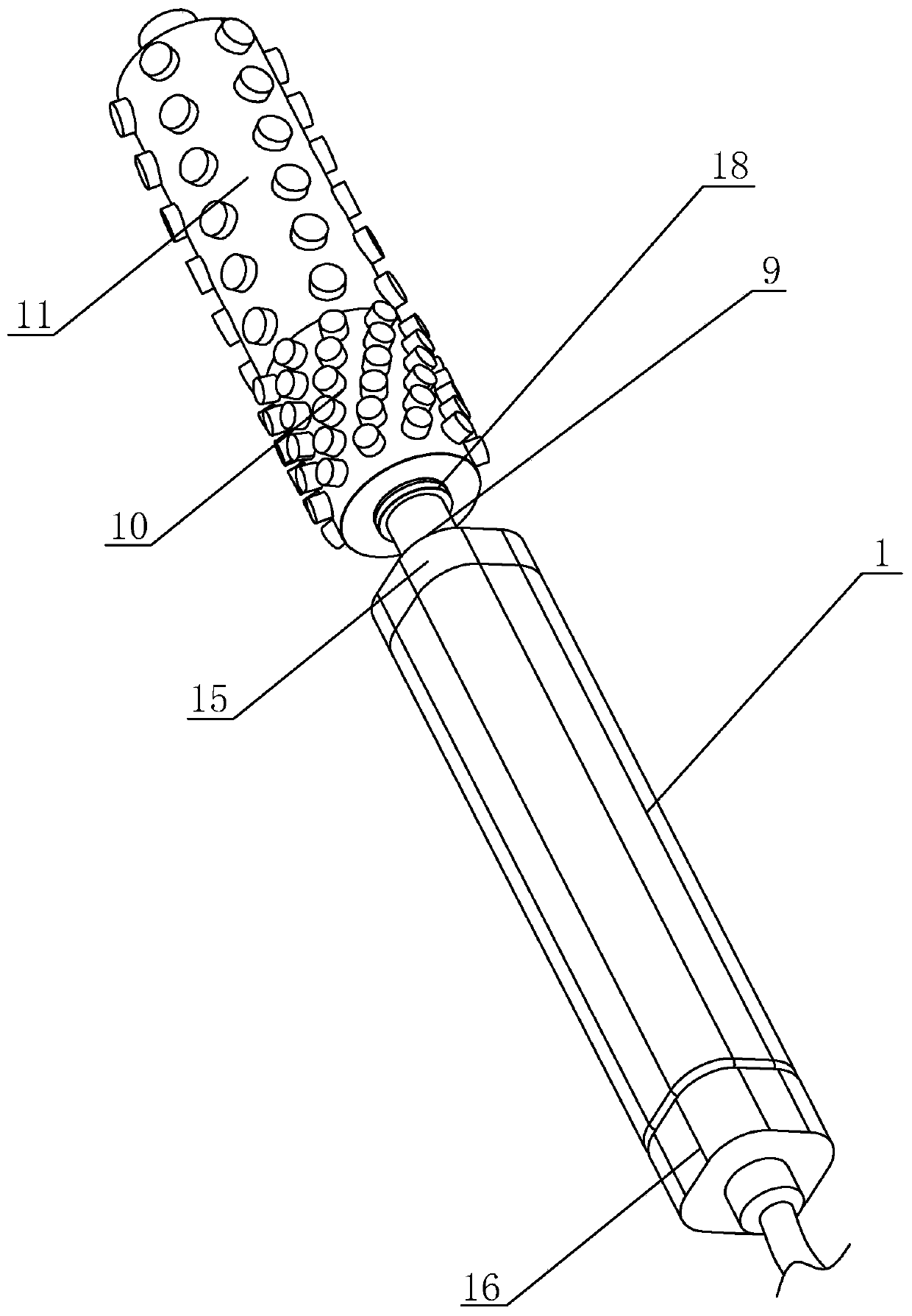

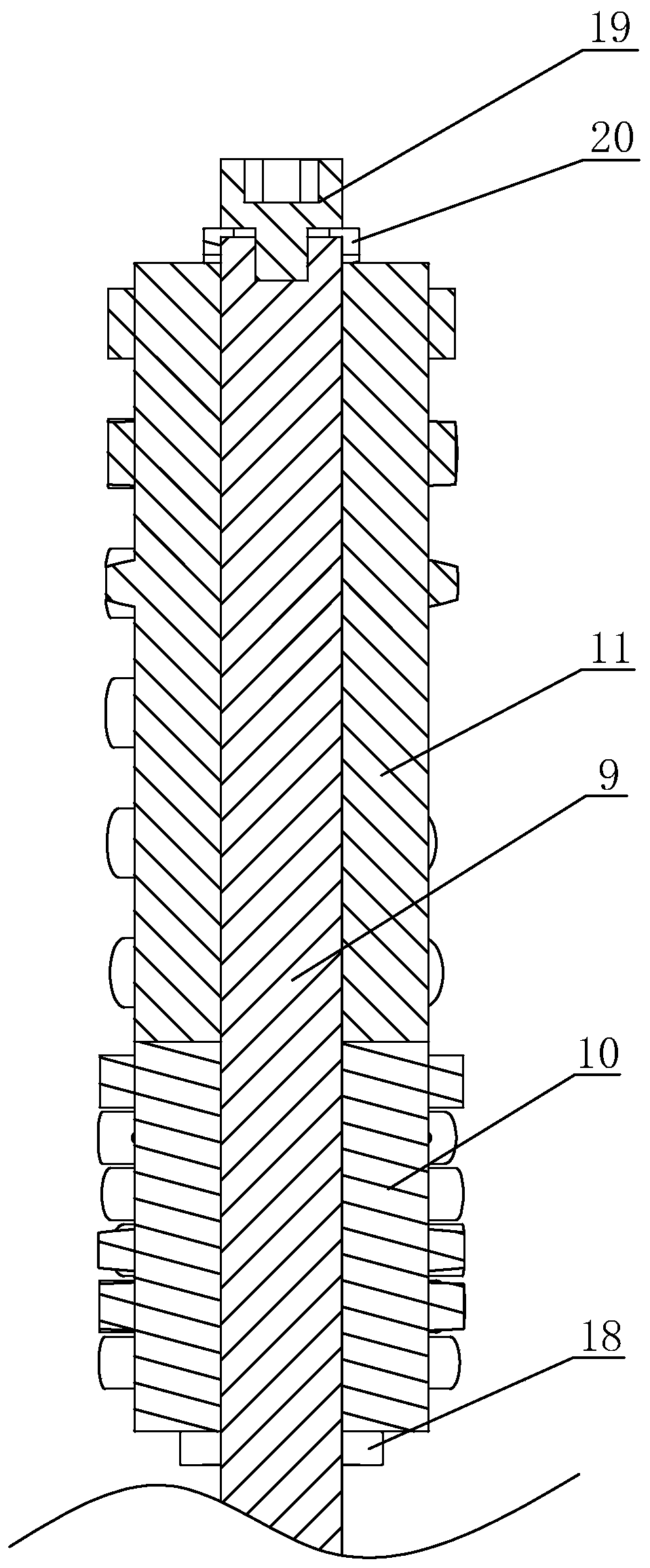

Gun bore inner wall wiping machine

PendingCN109916221ARealize reciprocating motionHave sustainable motivationWeapon cleaningInlet channelBristle

The invention discloses a gun bore inner wall wiping machine, and relates to the technical field of gun bore maintaining. The machine comprises a power propulsion part and an inner bore cleaning part,the power propulsion part comprises a main engine cylinder body, a top fixed base and a tail fixed base, a piston rod is fixedly connected with the top fixed base and the tail fixed base, the peripheral side of the piston rod is sleeved with a piston base, an upper channel and a lower channel are formed in the piston base, an air inlet channel and an exhaust channel are formed in the inner wall of the main engine cylinder body, the inner bore cleaning part comprises a fixed rod, the peripheral side of the fixed rod is sleeved with an advancing brush and a wiping brush, and bristles of the advancing brush are arranged in a spiral shape. Through control conversion of gas, automatic reciprocating of the piston base is achieved, the reciprocated motion of the piston rod is propelled and thenmatched with advancing of the advancing brush, the automatic degree of wiping and the wiping efficiency are improved, the power propulsion part is designed to meet use of a small-caliber gun bore, themachine is suitable for small-caliber gun types of 25 mm / 30 mm / 35 mm / 37 mm, time and labor are saved, and meanwhile, the gun bore is more clean.

Owner:武汉伍备科技有限公司

Advertising board wiping device for municipal roads

InactiveCN107252789AAvoid wastingWide range of wipingCleaning using toolsCleaning using liquidsGear wheelHorizontal axis

Owner:泉州市景江电子科技有限公司

Wipe head device capable of automatically wiping glass

InactiveCN103462553AImprove wiping efficiencyImprove surface wiping qualityWindow cleanersCrankElectric machinery

The invention discloses a wipe head device capable of automatically wiping glass. The wipe head device comprises a regular parallel double-crank mechanism disposed on a support component and a wipe head component disposed on the regular parallel double-crank mechanism. The regular parallel double-crank mechanism comprises a rotary shaft, a connecting bar and a connecting block, wherein the rotary shaft, the connecting bar and the connecting block are driven by a motor and are disposed on the support component, one end of the connecting bar is fixedly connected with the rotary shaft, the other end of the connecting bar is movably connected with the connecting block through a shaft, and the connecting block fits a circular groove in the support component. The wipe head component comprises a telescoping part disposed on the connecting block and a wipe head which is connected with the telescoping part and which is disposed at the bottom of the connecting block. The motor drives the regular parallel double-crank mechanism to move through a synchronous belt drive mechanism; the wipe head component is disposed on the regular parallel double-crank mechanism, so that the wipe head component can eccentrically rotate with the regular parallel double-crank mechanism, the wipe head never wipes the same position of the glass twice when the glass is wiped, and wiping is effective.

Owner:HUNAN YUHUAN INTELLIGENT EQUIP CO LTD

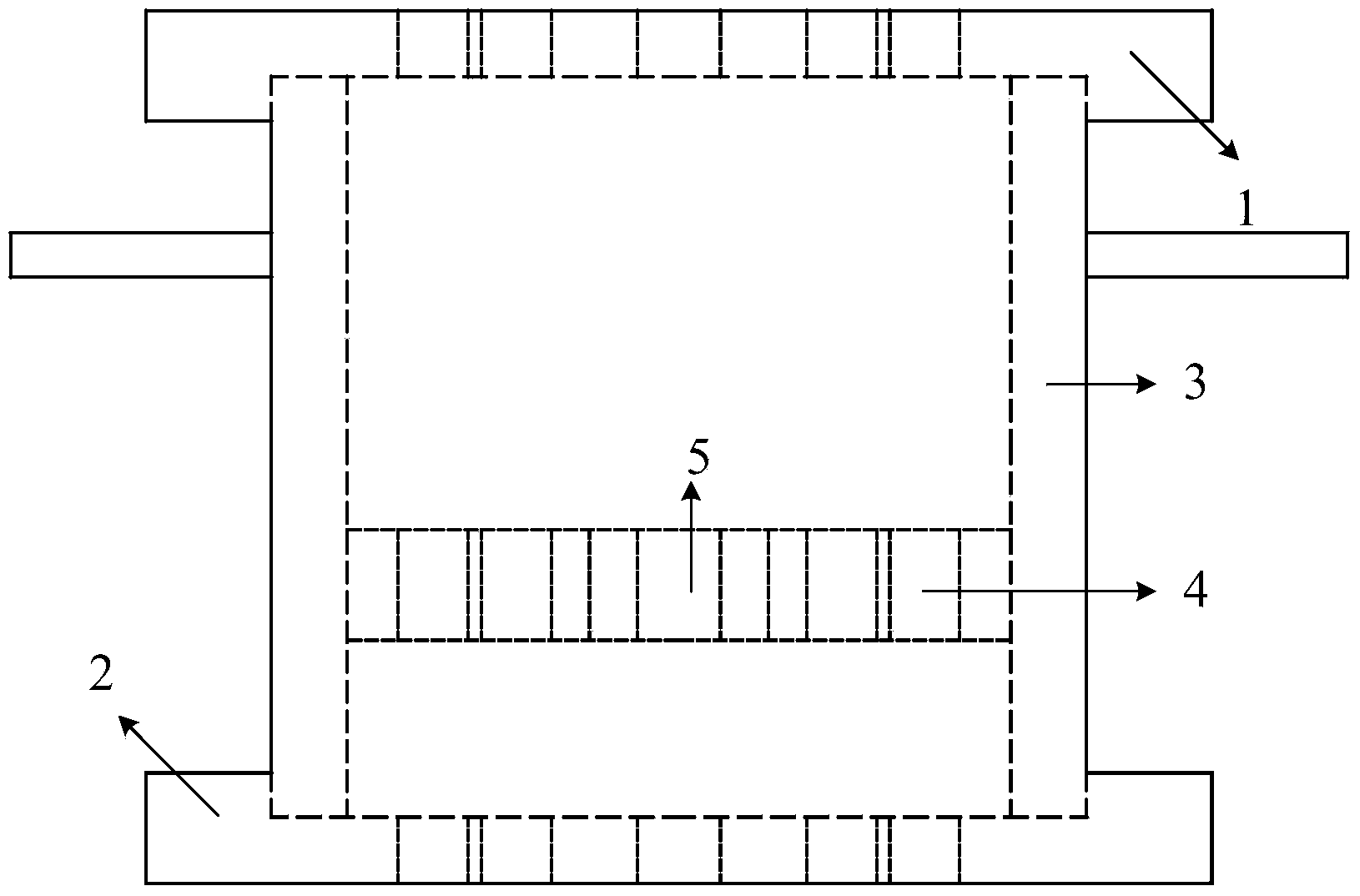

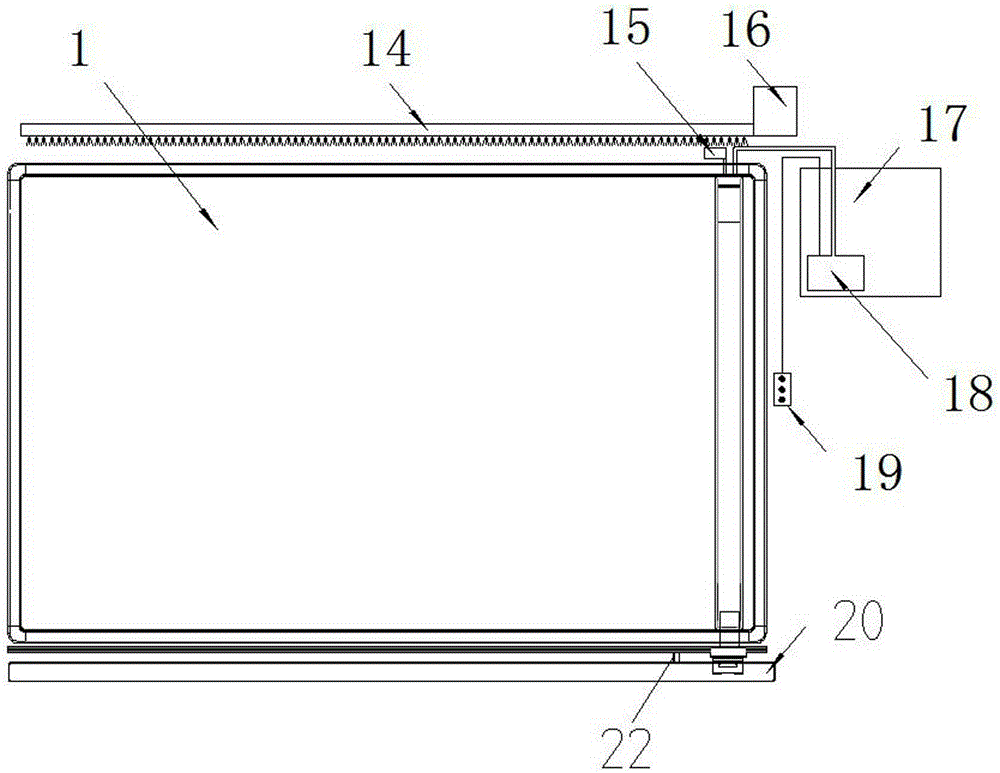

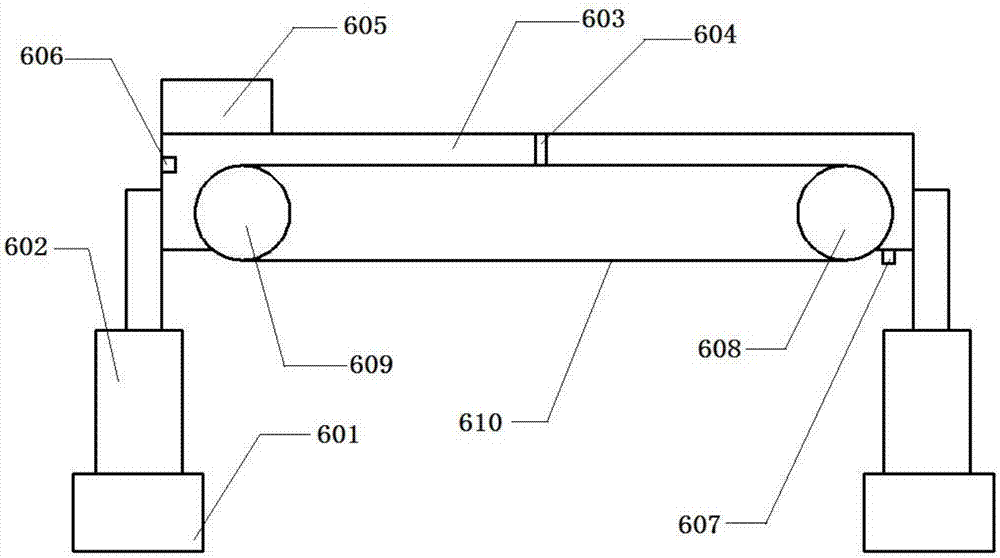

Electric integrated dry wiping writing board

ActiveCN105172432AHigh degree of automationImprove wiping efficiencyBoard cleaning devicesWriting boardsDrive motorEngineering

The invention discloses an electric integrated dry wiping writing board, and relates to the technical field of writing boards. The electric integrated dry wiping writing board comprises a writing board, an electric board eraser as wide as the writing board, and a slide device for enabling the electric board eraser to horizontally move, wherein the slide device comprises an electric translation mechanism; the electric translation mechanism is a synchronous belt electric slide table, and comprises an upper slide rail and a lower slide rail separately arranged on upper and lower frames of the writing board; a upper slide table and a lower slide table are respectively in slide fit with the upper slide rail and the lower slide rail; the two ends of the electric board eraser are fixedly connected with the upper slide table and the lower slide table; the electric board eraser comprises a driving motor; the driving motor drives an integrated rotating roller type board eraser; the synchronous belt electric slide table is started; the electric board eraser can horizontally move in the length direction of the writing board; and meanwhile, the rotating roller type board eraser rotates to erase chalk marks on the surface of the writing board. The electric integrated dry wiping writing board can realize automatic wiping of the whole board surface, is fast in wiping, saves both time and labor, reduces the dust rise, is high in office automation degree, and is high in teaching efficiency.

Owner:SHIJIAZHUANG KEDA STATIONERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com