Advanced steel surface cleaning device

A surface cleaning device and technology for steel, which are applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problem of time-consuming surface wiping cleaning, reduced working efficiency of cleaning steel, and poor cleaning of steel surfaces. Complete problems such as avoiding adverse effects, improving wiping efficiency, and saving time and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

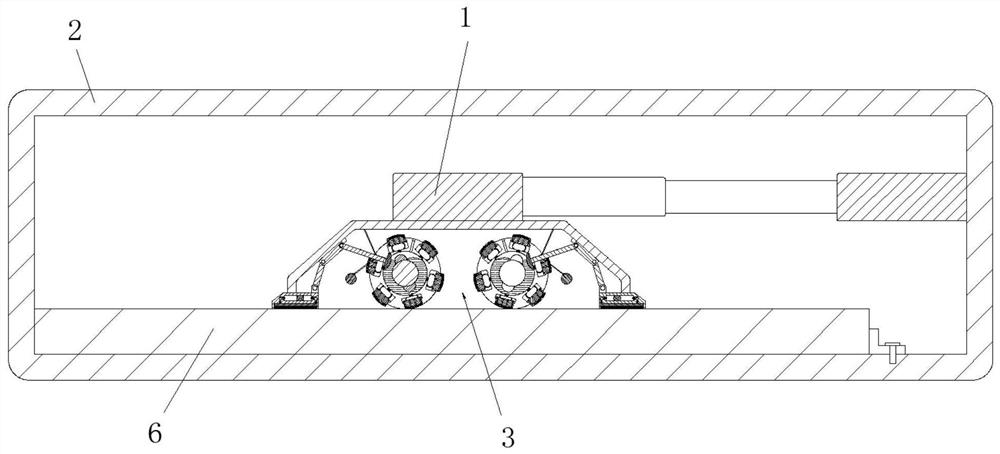

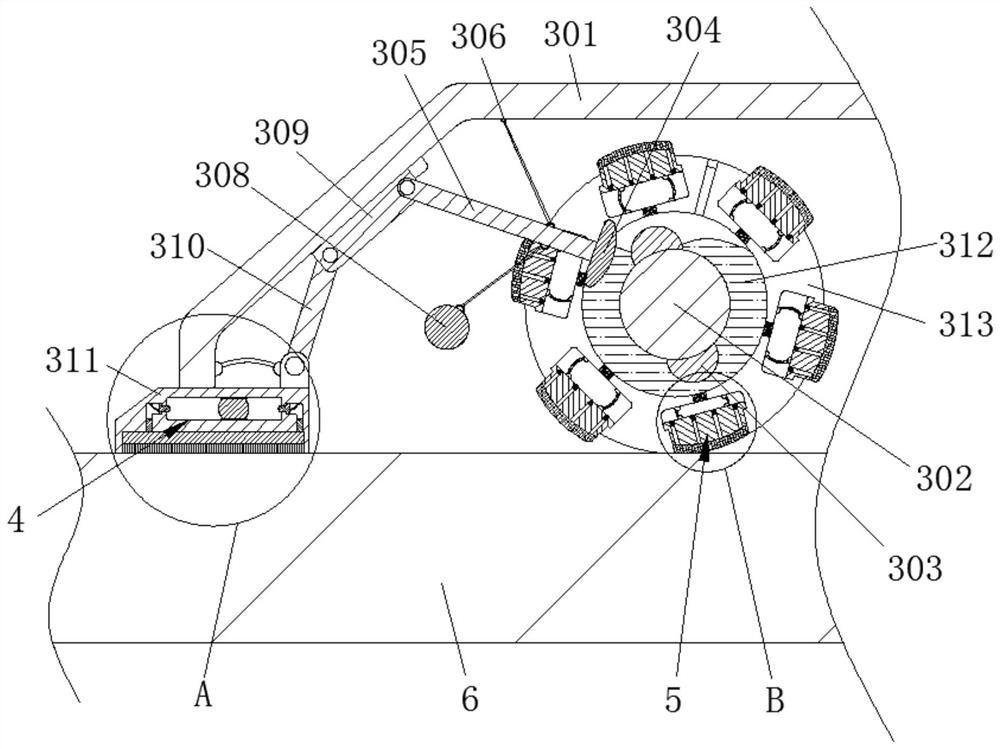

[0022] Such as Figure 1-5 As shown, the present invention provides a technical solution: an advanced steel surface cleaning device, including a box body 2, a box door is hinged on the front of the box body 2, an electric telescopic rod 1 is fixedly connected to one side of the inner wall of the box body 2, and the box body 2 The bottom of the inner wall is provided with a steel material 6, and the inside of the box body 2 is provided with a cleaning mechanism 3. By setting the cleaning mechanism 3, when the connecting frame 301 pushes and wipes the top of the steel material 6, the wiper 311 can wipe the surface. At the same time, synchronously vibrating and wiping back and forth from left to right, so that the small particles and stains that cannot be cleaned can be wiped and brushed away by vibration, and then the wiping efficiency of the wiper 311 on the surface of the steel 6 is greatly improved;

[0023]The cleaning mechanism 3 includes a connecting frame 301, the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com