Wipe head device capable of automatically wiping glass

A technology of automatic wiping and wiping head, applied in the direction of window cleaning, cleaning equipment, household appliances, etc., can solve problems such as insufficient wiping process, and achieve good wiping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

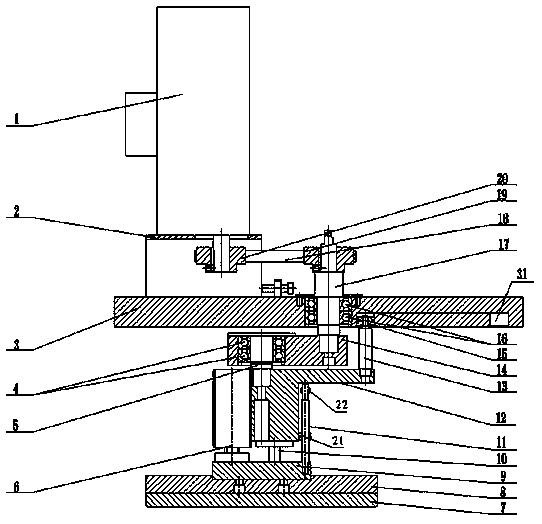

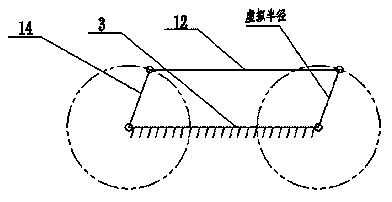

[0013] The wiping head device that can automatically wipe glass provided by the invention, such as figure 1 As shown, it includes a positive parallel double crank mechanism arranged on the support plate 3 and a wiping head assembly located on the positive parallel double crank mechanism; the positive parallel double crank mechanism includes a motor 1 driven by the Rotating shaft 17, connecting rod 14, connecting block 12, wherein one end of connecting rod 14 is fixedly connected with rotating shaft 17, and the other end is movably connected with connecting block 12 through shaft 5, and connecting block 12 is connected with the annular groove arranged on support plate 3 31 Cooperation; the wiping head assembly includes a telescopic cylinder 6 arranged on the connecting block 12 , and a wiping head 7 connected to the telescopic cylinder 6 and arranged at the bottom of the connecting block 12 . The motor 1 is installed on the motor installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com