Patents

Literature

920results about How to "Easy to wipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

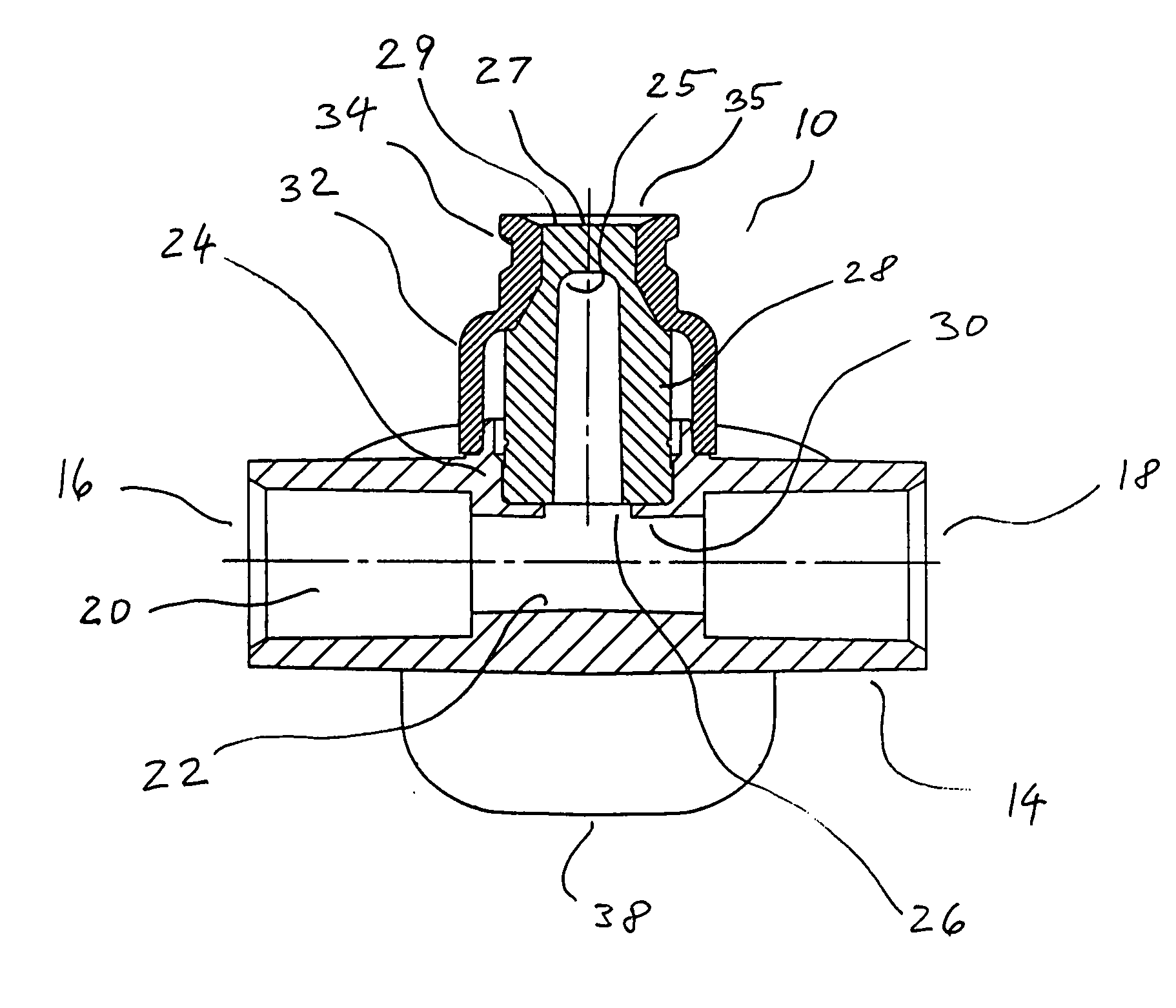

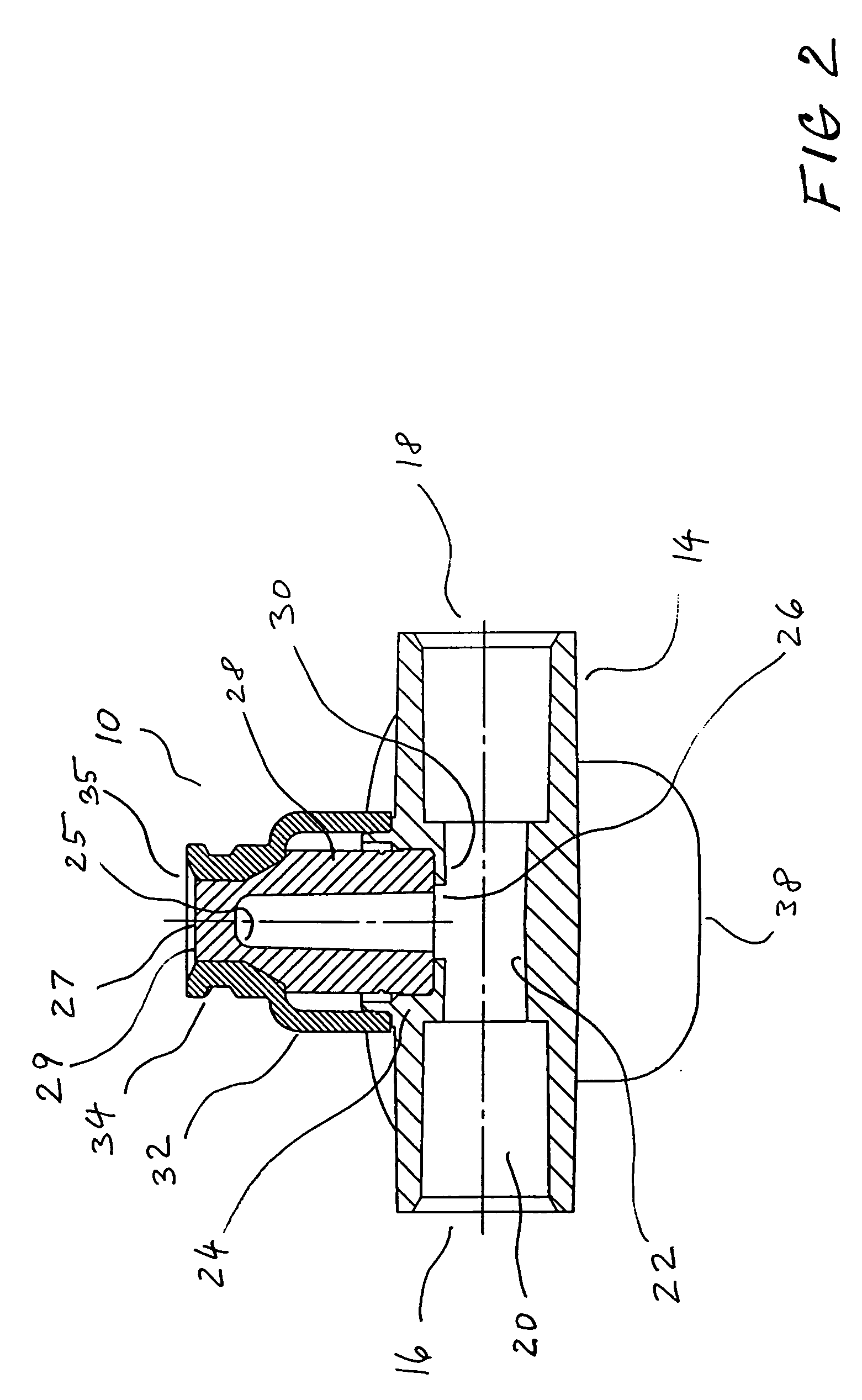

Luer-receiving medical valve

InactiveUSRE38145E1Minimal costEasy to wipeAmpoule syringesOperating means/releasing devices for valvesBiomedical engineeringVALVE PORT

A luer receiving medical valve for the sterile transfer of fluid from a luer-tapered male end having a surrounding female luer lock threaded end. The luer receiver includes a housing having an inlet and an outlet and a lumen extending from the inlet to the outlet. An elastomeric sealing member occludes the inlet and has a slit extending through it. In a preferred embodiment, a support is provided adjacent the housing inlet and adjacent the sealing member. The support includes opposing posts separated by slots, the slots permitting expansion of the sealing member when the male luer is inserted into the slit.

Owner:LYNN LAWRENCE A

High-abrasion resistant ultraviolet light solidifying fingerprint resistant coating

InactiveCN101701129AGood hardness and wear resistanceMeet wear resistancePolyurea/polyurethane coatingsSolventFingerprint

The invention relates to a light solidifying high-abrasion resistant fingerprint resistant coating which is used for the surfaces of plastic shells of portable electronic products, such as mobile phones, MP3, digital cameras, handheld computers, and the like and comprises the following components: 10-35 percent of high-functionality urethane acrylate, 5-25 percent of bifunctional urethane acrylate, 0.01-20 percent of acrylic ester monomer, 5-20 percent of high-functionality acrylic ester, 5-40 percent of fluorin-contained acrylic ester, 0.01-10 percent of nano inorganic powder filler, 1-5 percent of light initiating agent, 0.01-5 percent of auxiliary agent and 5-30 percent of solvent. The invention improves the fingerprint resistant capability of a coating film by the enrichment and microphase separation of a fluorin-contained group added into the coating on the surface of a coating surface, provides excellent abrasion resistance and hardness by using the polyurethane structure in the coating and the added nano abrasion resistant filler and meets the requirements of abrasion resistance, scratch resistance and fingerprint resistance of the portable electronic products.

Owner:武汉嘉特利佰联创科技有限公司

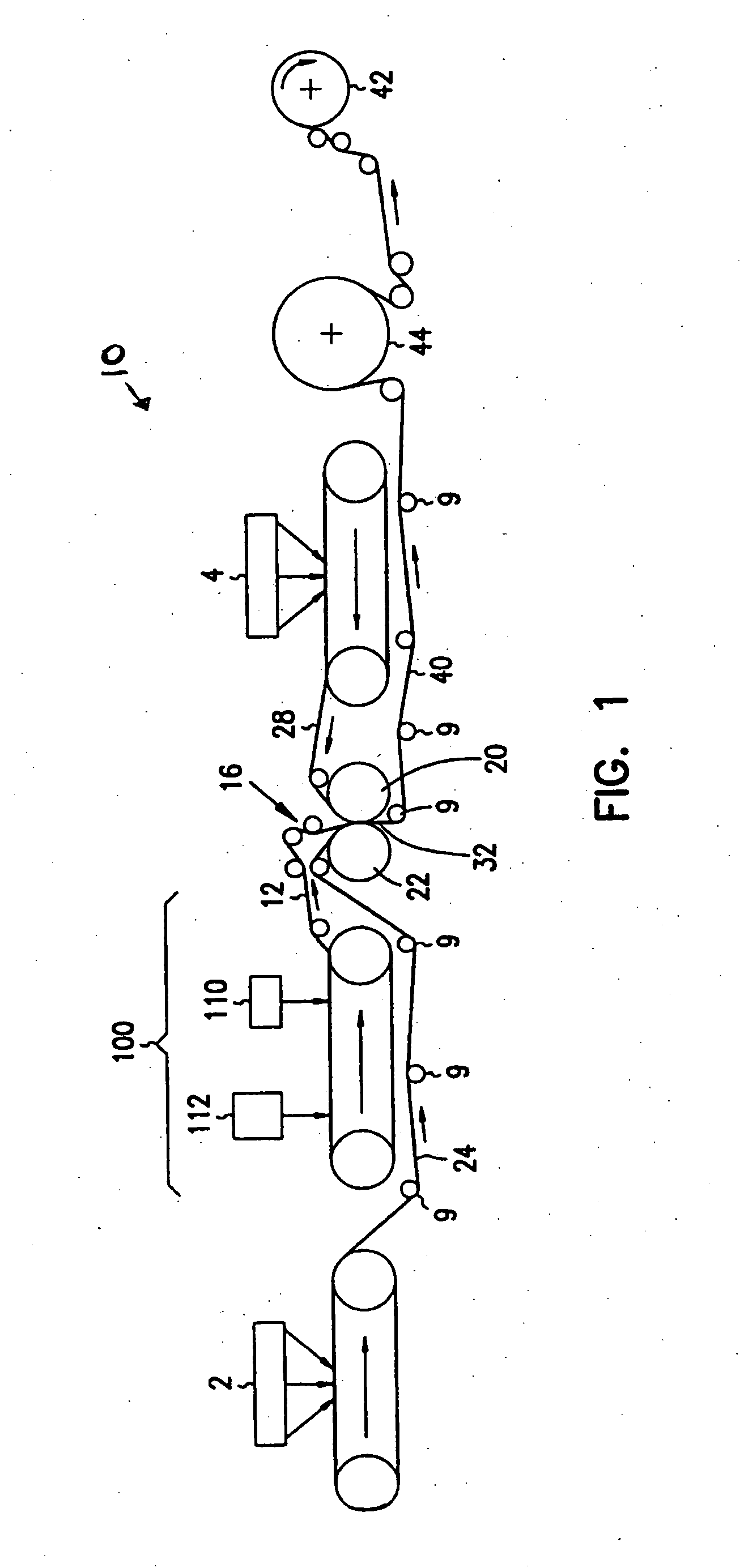

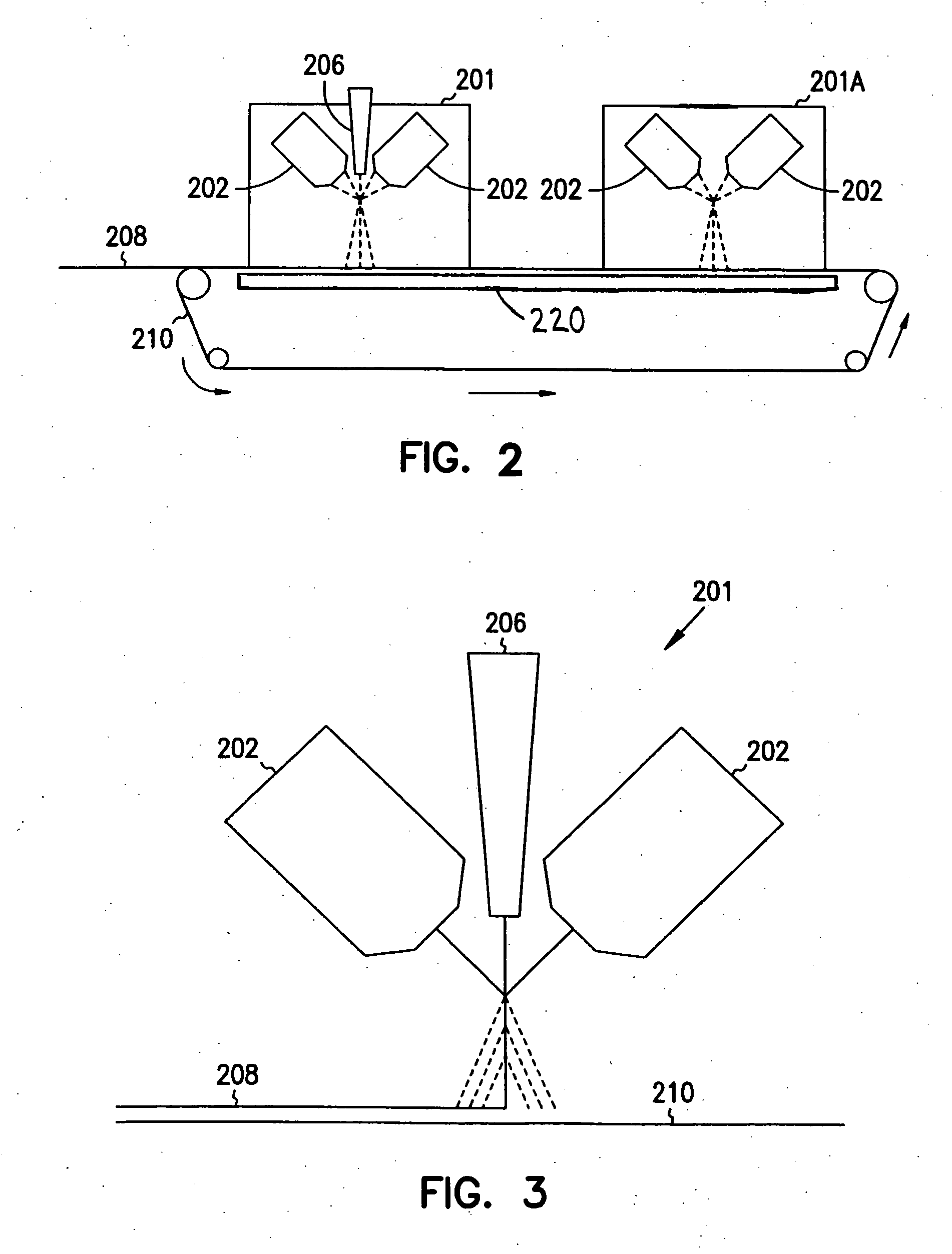

Photo-induced hydrophilic article and method of making same

InactiveUS20070218265A1Easy to cleanEasy to wipeSynthetic resin layered productsVacuum evaporation coatingHydrophilic coatingSpray pyrolysis

Methods and articles are disclosed in which a substrate is provided with a photo-induced hydrophilic surface by forming a photo-induced hydrophilic coating on the substrate by spray pyrolysis, chemical vapor deposition, or magnetron sputter vacuum deposition. The coating can have a thickness of 50 Å to 500 Å, a root mean square roughness of less than 5, preferably less than 2, and photocatalytic activity of less than 3.0×10−3 cm−1 min−1±2.0×10−3 cm−1 min−1. The substrate includes glass substrates, including glass sheets and continuous float glass ribbons.

Owner:VITRO FLAT GLASS LLC

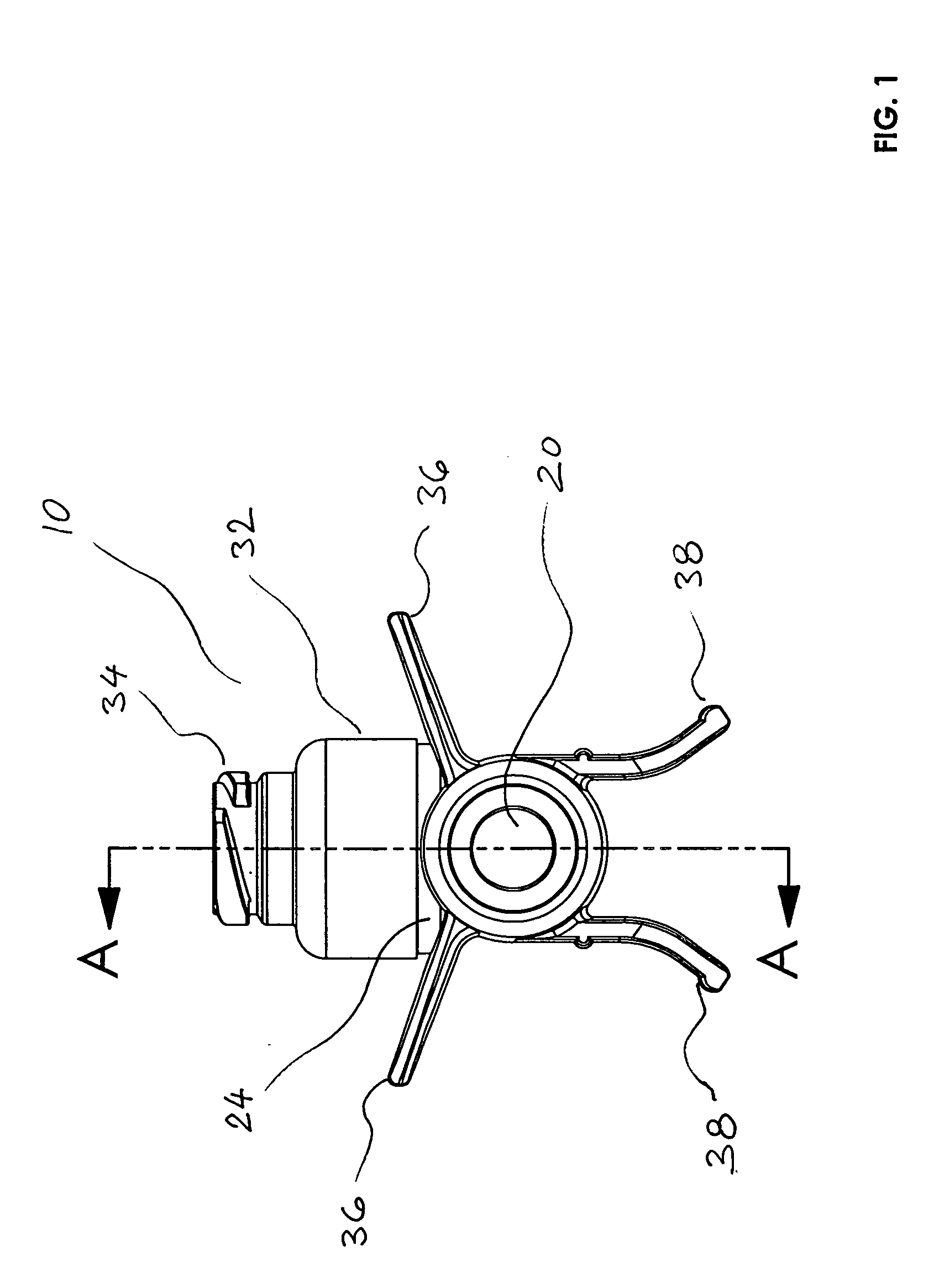

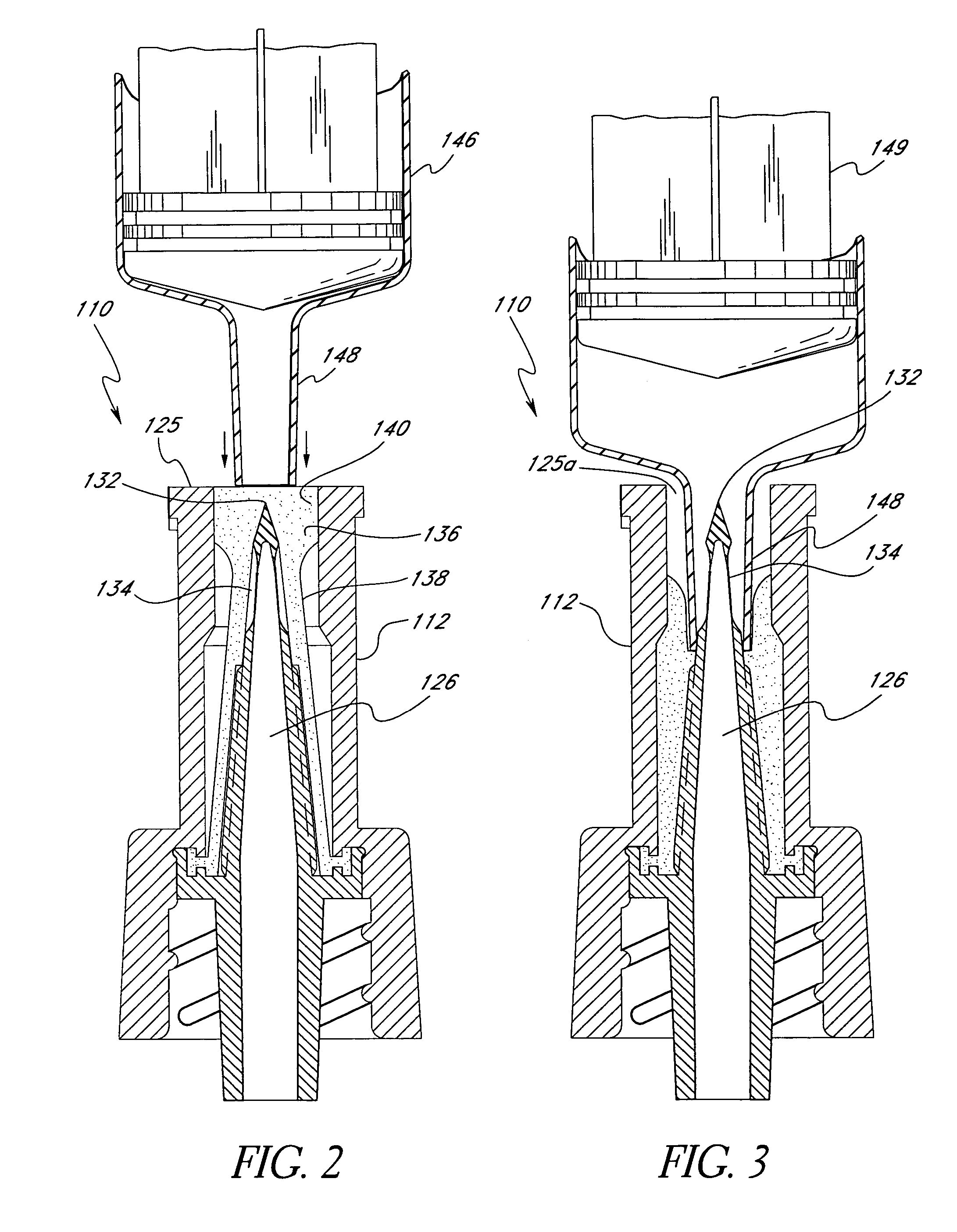

T-port with swabbable valve

InactiveUS20050261637A1Reduce riskEasy to wipeValve arrangementsInfusion devicesEngineeringPort site

A slit-type T-port site that includes a swabbable valve with a slit at an end thereof. The valve stem with a slit is located in a valve body and is deformable. When engaged by a tip of an instrument, the top portion of the stem folds inward and its slit opens to form a direct non-hemolytic flow pathway between the instrument and the main T-port site flow channel.

Owner:HALKEY ROBERTS CORP

Anti-reflection spectacle lens and its production method

InactiveUS20040142185A1Avoid stainsEasy to wipeSynthetic resin layered productsVacuum evaporation coatingLens plateOptoelectronics

An anti-reflection spectacle lens has an anti-reflection film composed of a plurality of layers formed on at least one surface of a lens substrate or other one or more layers formed on said lens substrate, the anti-reflection film comprising an outermost layer made of silicon oxide, on which a water- and oil-repellent layer is formed by vacuum deposition. The spectacle lens is excellent in water and oil repellency, and aqueous stains and oily stains attached to the spectacle lens can easily be wiped off. The use of a pellet impregnated with a hydrophobic, reactive organic compound in a vacuum deposition chamber contributes to the reduction of a production cost.

Owner:ASAHI KOGAKU KOGYO KK

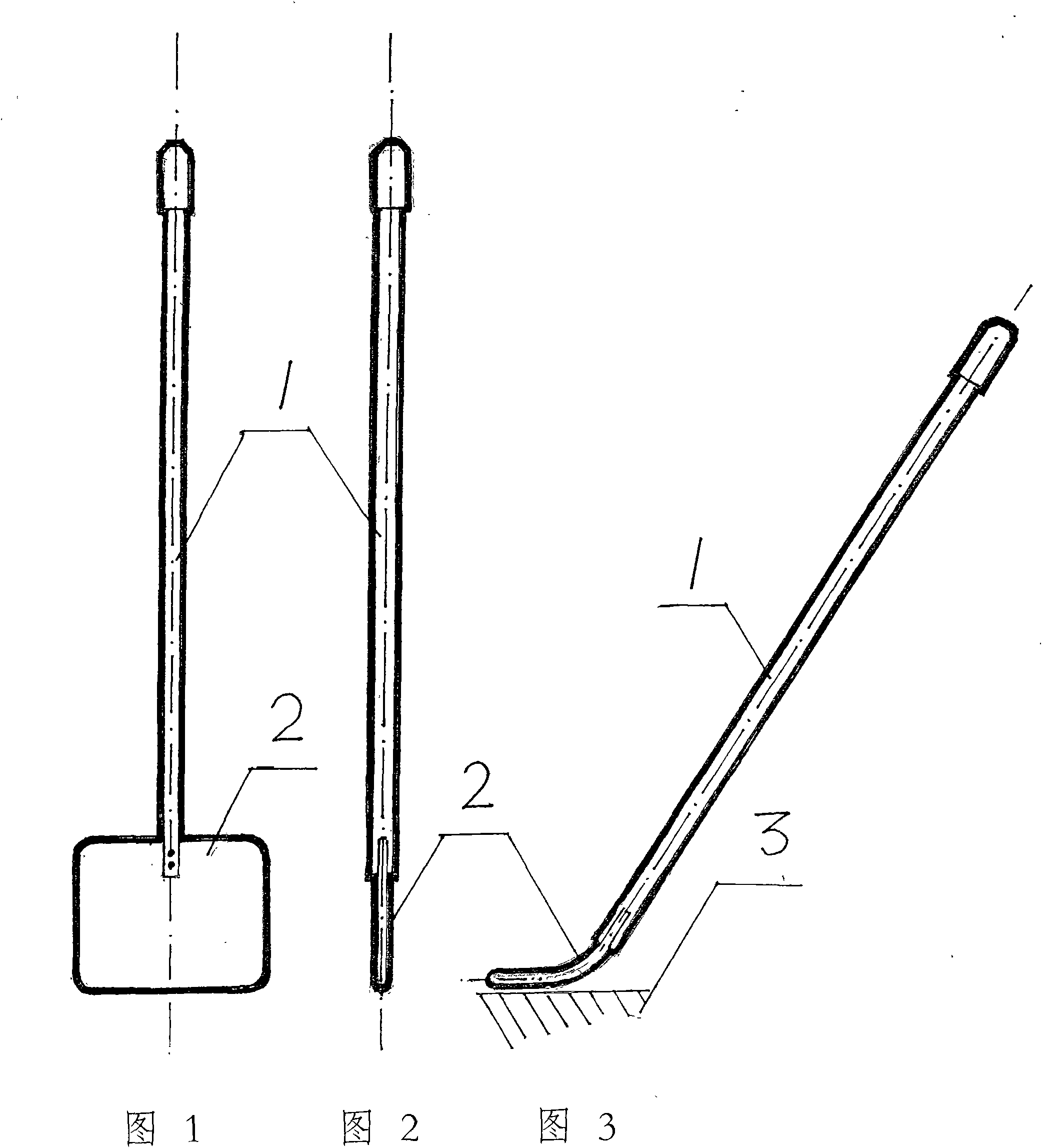

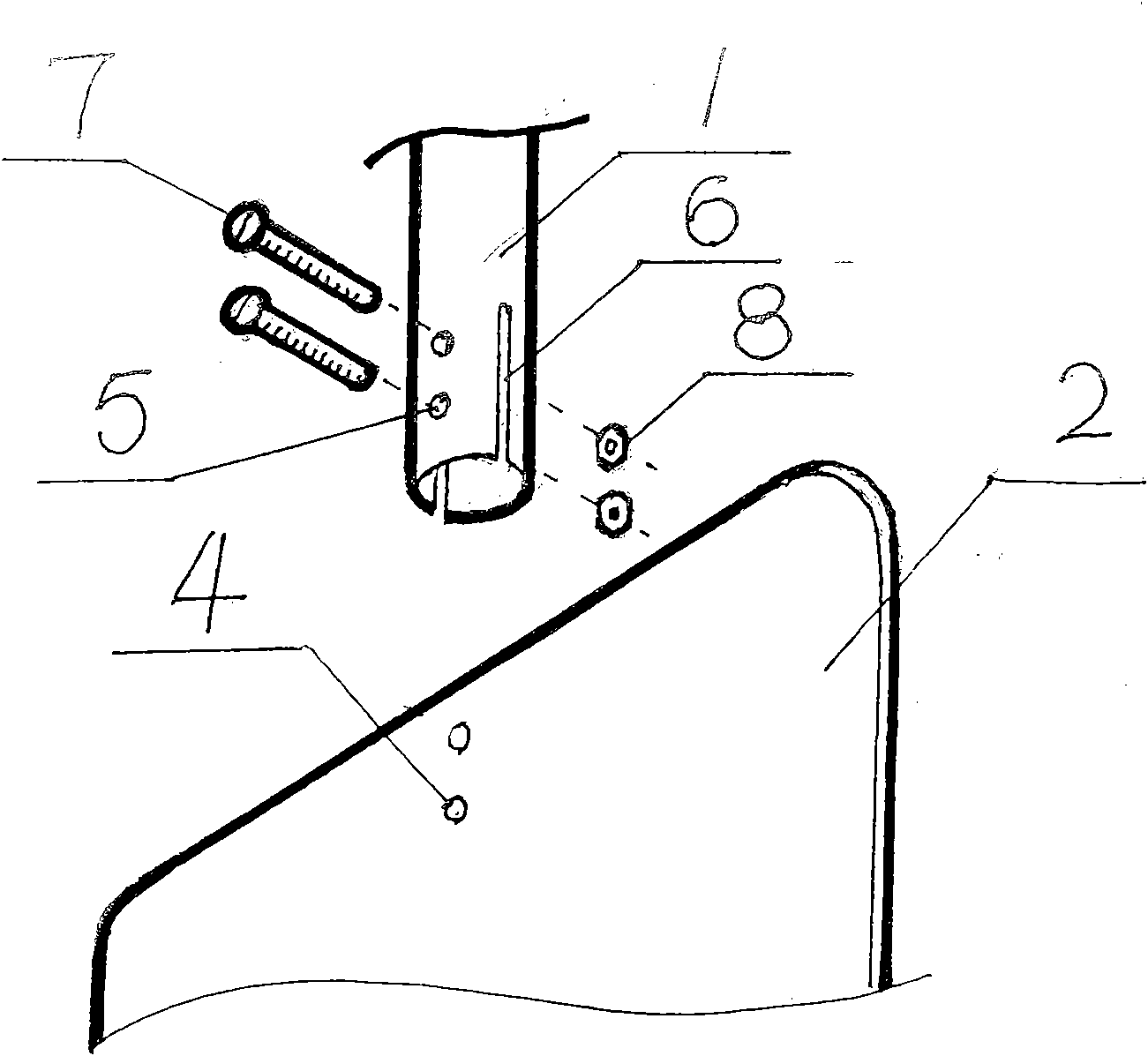

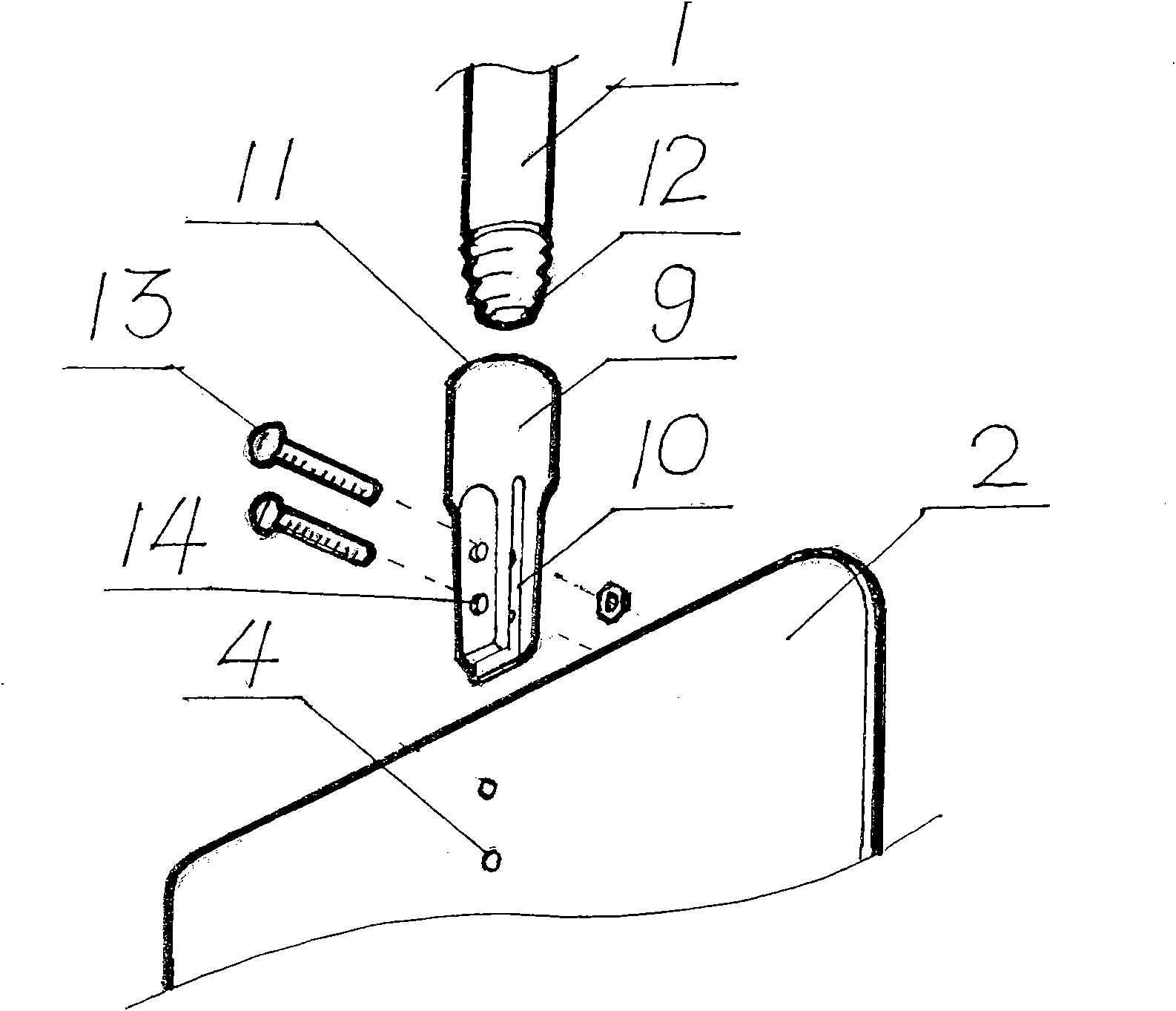

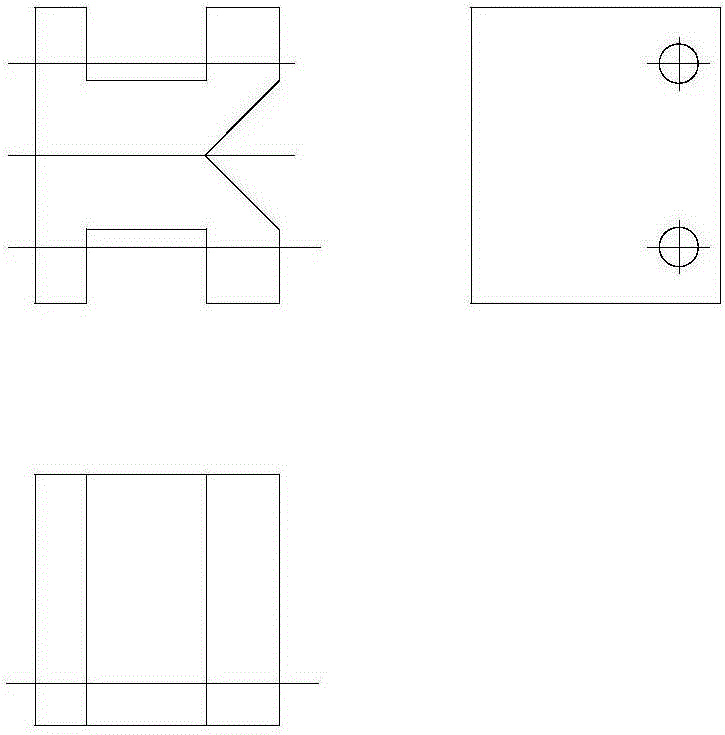

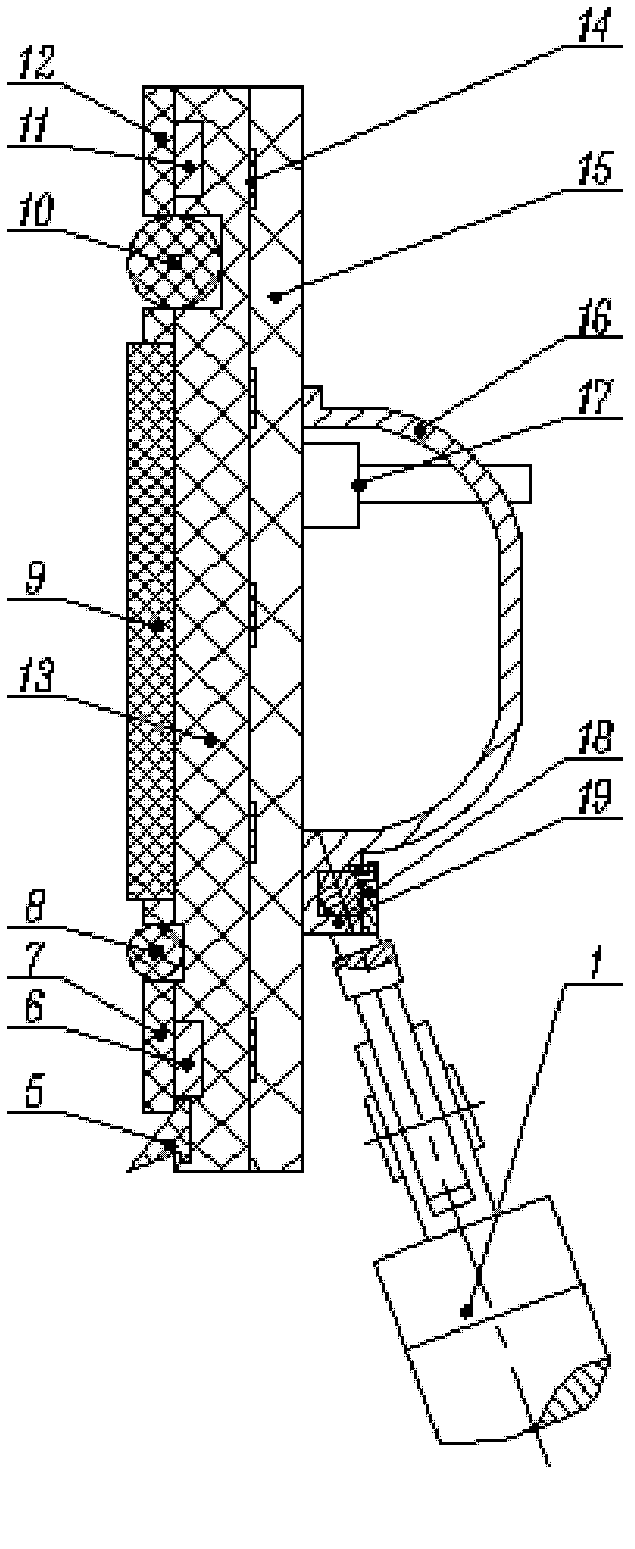

Portable mop and assorted mop barrel

The invention discloses a portable mop with simple structure, comprising a mop rod and a mop panel; the mop panel is a polygonal panel made of elastic material; an insertion connecting mechanism and a limiting device for rotating the mop panel forwardly and backwardly corresponding to the mop rod in a limiting angle are installed between the upper end of the mop panel and the lower end of the mop rod; the mop panel has straight and bent positions; in standby state, the central axis of the mop rod and the midline of the vertical section of the mop panel are located on the same straight line; in work state, the mop panel is deformed by means of external force; the upper end of the mop panel is parallel to a working surface; and the upper end of the mop panel has a crown face and can be formed into an angle with the mop rod. Meanwhile, the invention further discloses a mop barrel assorted to the portable mop. The mop barrel can remove the dirt on the mop and dehydrate the mop by means of upward and downward or forward and backward movements of the mop.

Owner:李军

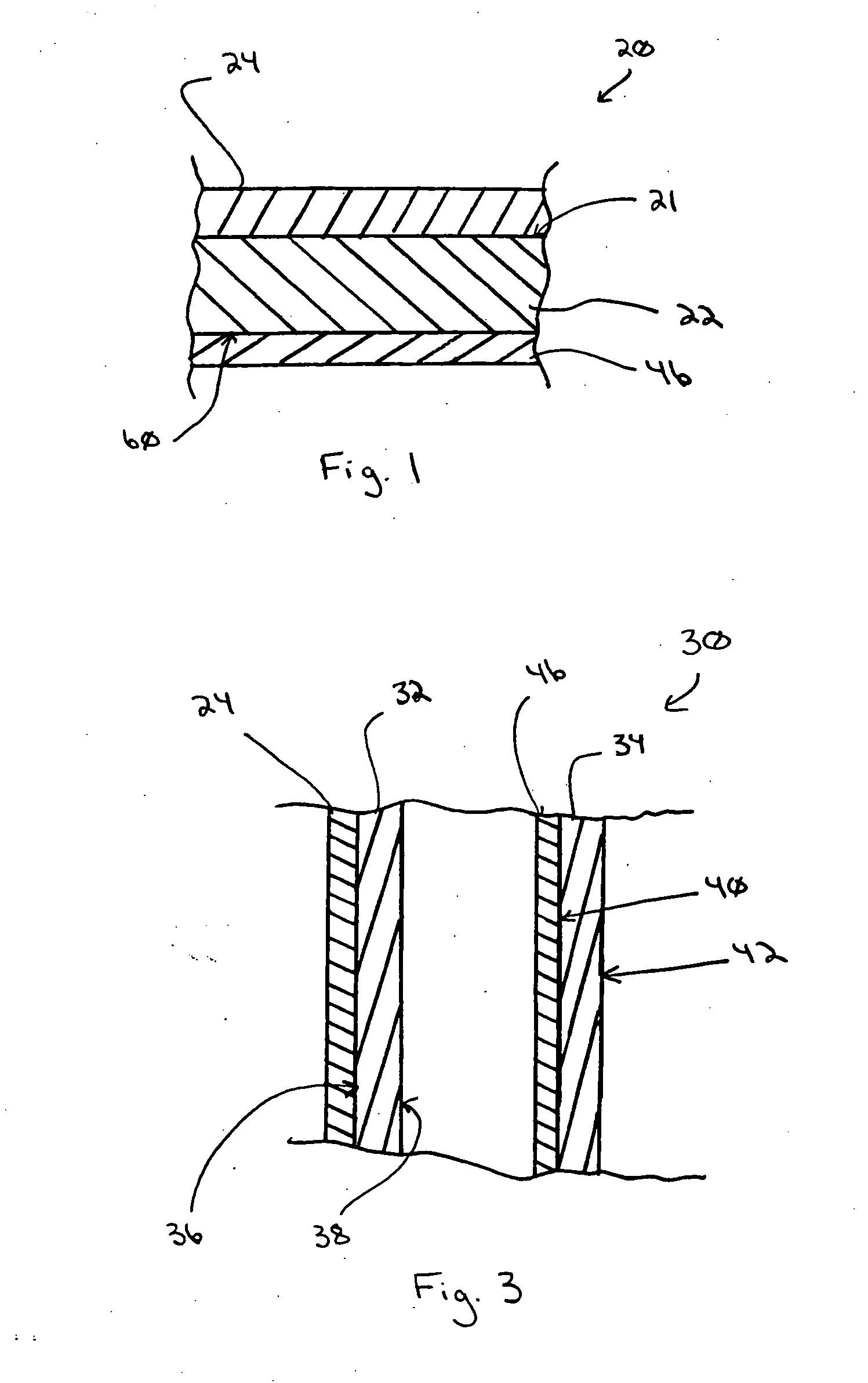

Highly textured non-woven composite wipe

InactiveUS20050148260A1Reduce the amount of solutionIncrease flexibilityLayered productsCleaning machinesNonwoven fabricMaterials science

A wipe comprising a non-woven composite material including at least one non-woven inner layer and at least one non-woven outer layer. The outer layer is textured and has a Layer Peak To Valley Ratio greater than 1 and less than about 4 and is bonded to the inner layer at at least two points. The composite material has a Wipe Peak To Valley Ratio greater than 1 and less than about 4.

Owner:KIMBERLY-CLARK WORLDWIDE INC

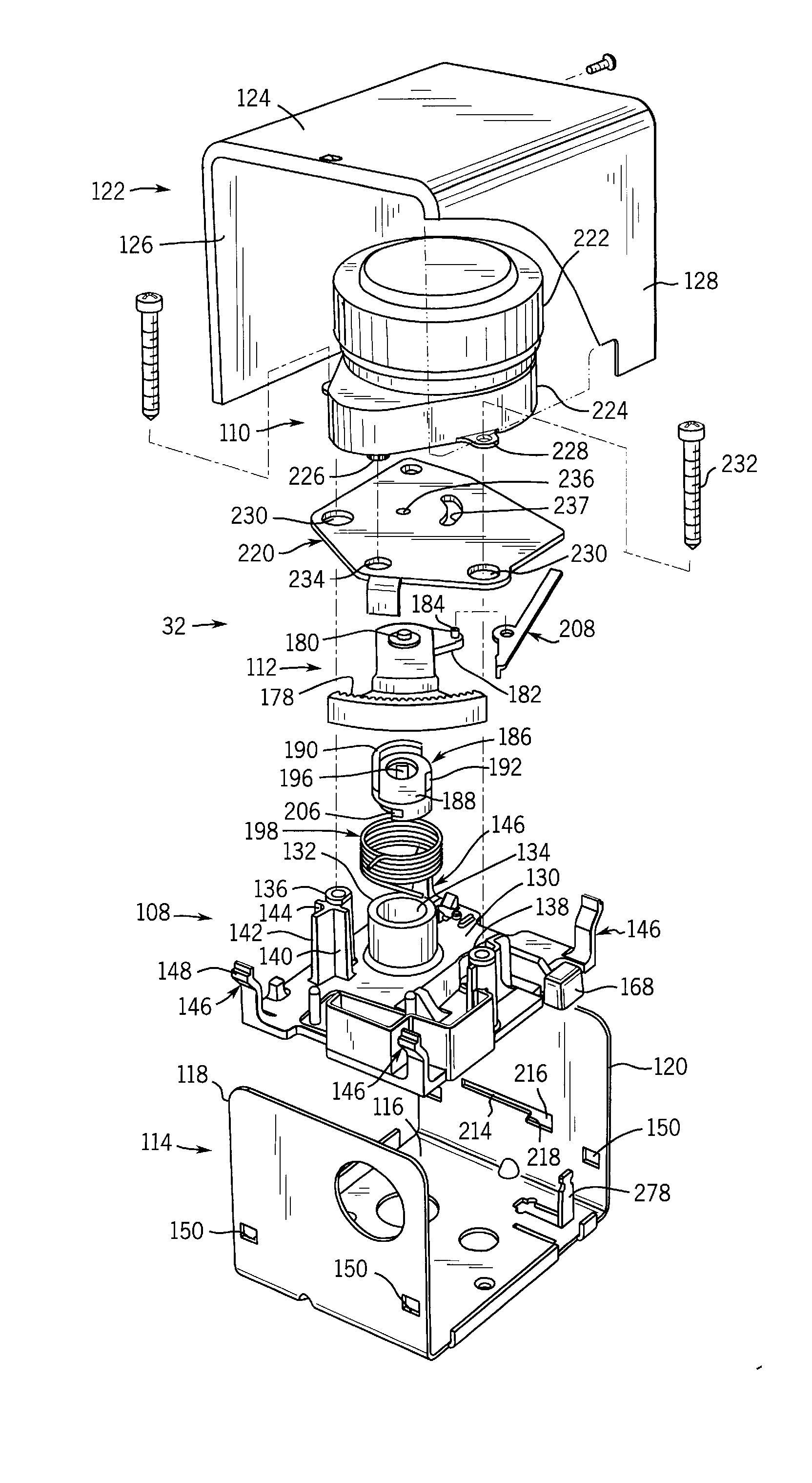

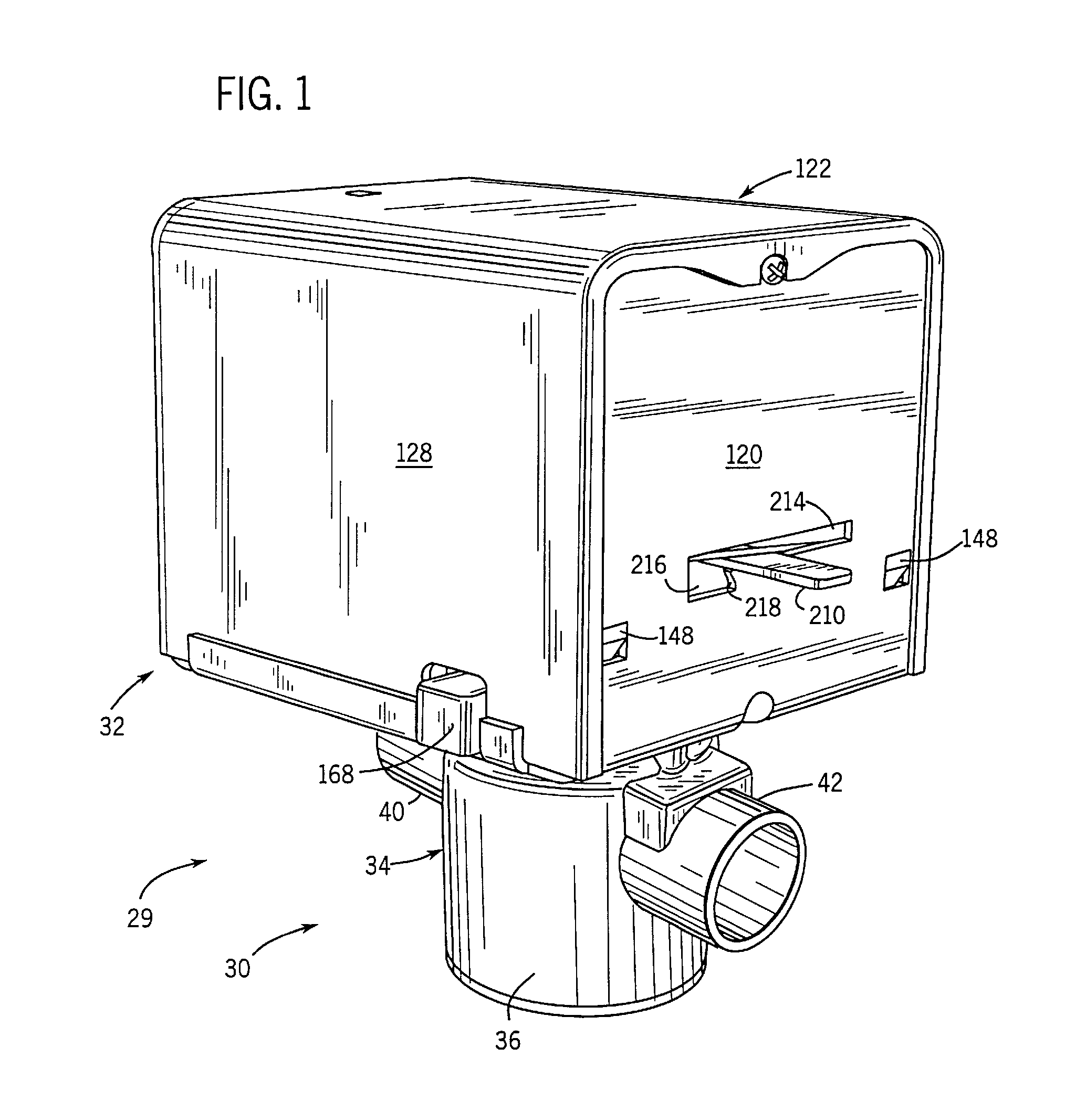

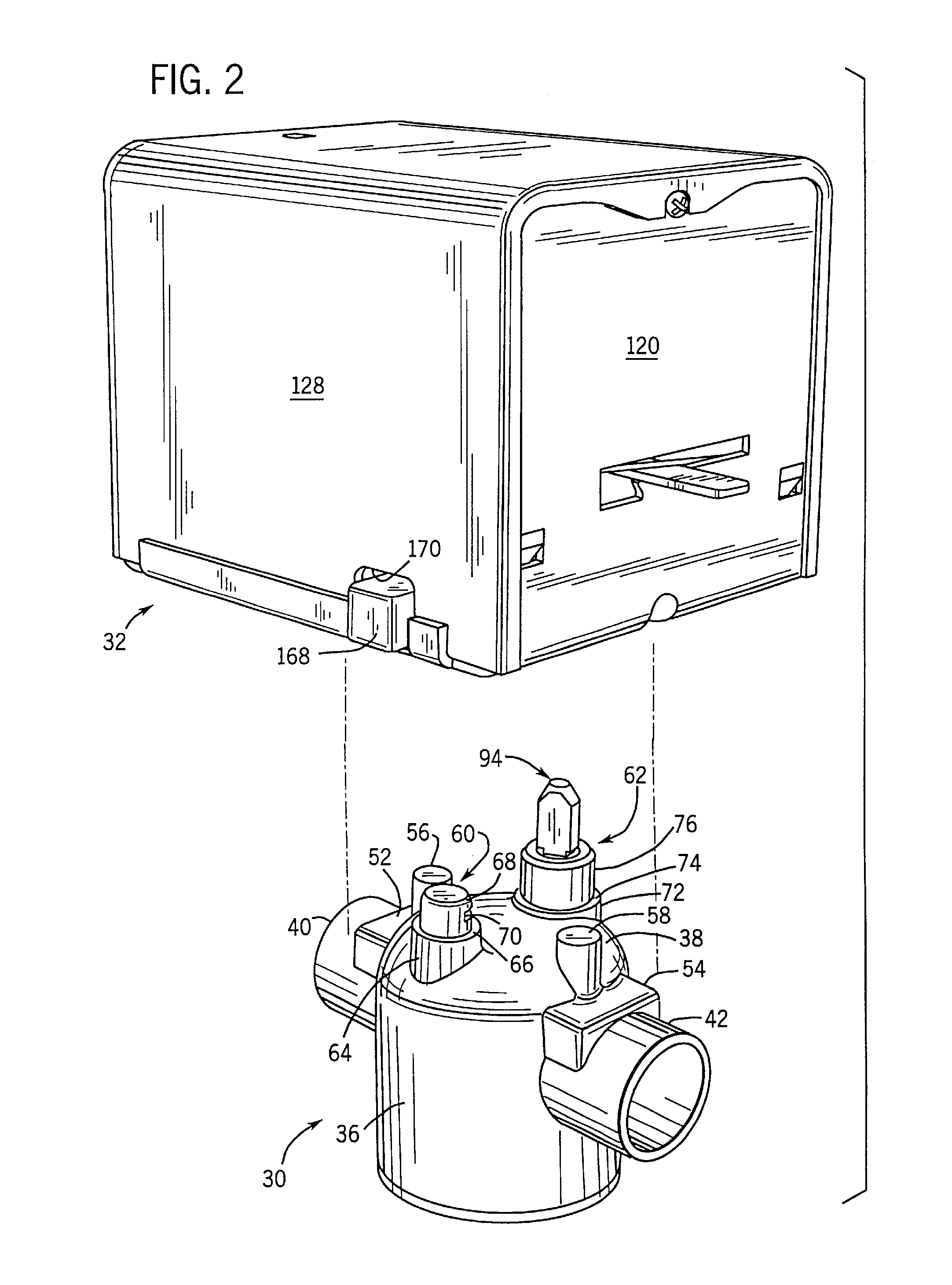

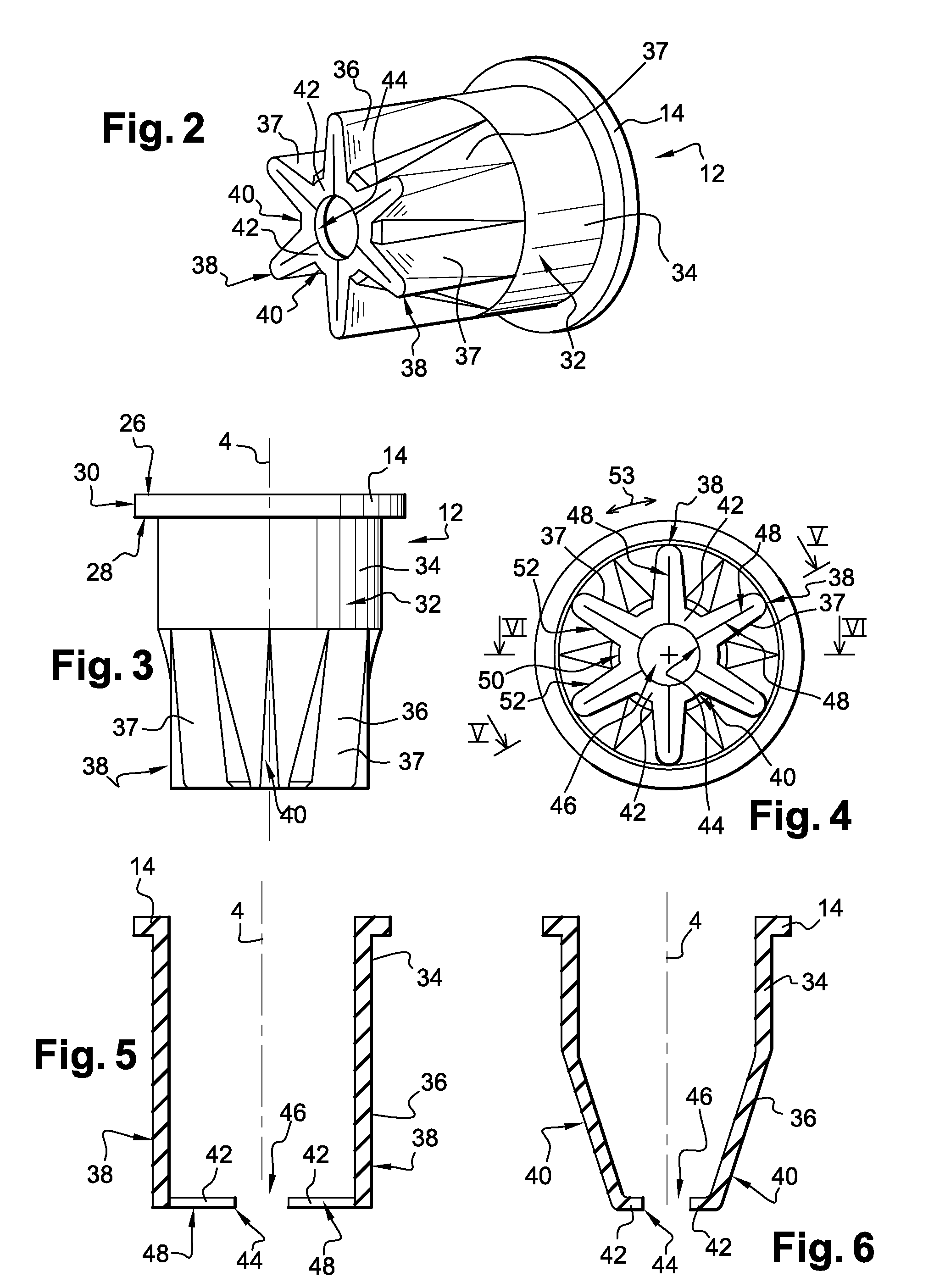

Valve Actuator Having Synchronous Motor Having Plastic Bushings

InactiveUS20110240893A1Avoid corrosionReduce failureOperating means/releasing devices for valvesSynchronous motorsSynchronous motorValve actuator

A synchronous motor and a valve having a valve actuator and valve assembly is provided. The valve actuator includes the synchronous motor. The synchronous motor utilizes a magnetic coil, a stator and a rotor to generate rotational movement to drive the valve member for the valve assembly. The valve has a normal state in which the valve is maintained when power is not supplied to the motor. The valve has a non-normal actuated state when power is supplied to the motor. The motor is stalled in the non-normal state to maintain the valve in that state. The rotor includes a rotor shaft that passes through a magnetic hub of the stator. The rotor shaft is supported by a plurality of plastic and / or nylon bearings to prevent corrosion therebetween when the rotor shaft and bearings remain in a substantially fixed orientation for an extended period of time.

Owner:SCHNEIDER ELECTRIC BUILDINGS LLC

Preparation method of inner decoration material for automobile

ActiveCN1966265AOvercome the shortcoming that some functions are easily weakenedSoft touchLamination ancillary operationsFibre treatmentMetallurgySlurry

The invention relates to a method for producing decorates material of vehicle, wherein it comprises that: (1), pretreating base cloth, while the base cloth is immerged with disinfection and flameproof, dried, cooled and coiled; (2), wet solidifying coat that rolling the base cloth, scraping on coating machine, while the slurry amount is 100-300g / m2, drying, solidifying in solidifying groove, washing, drying and shaping, cooling and coiling; (3), dry transfer surface shaping that special paper transfer adhering; (4), rolling and drying the semi-product, coiling and packing. The inventive product has water resistance, etc.

Owner:HAININ JINDA COATING

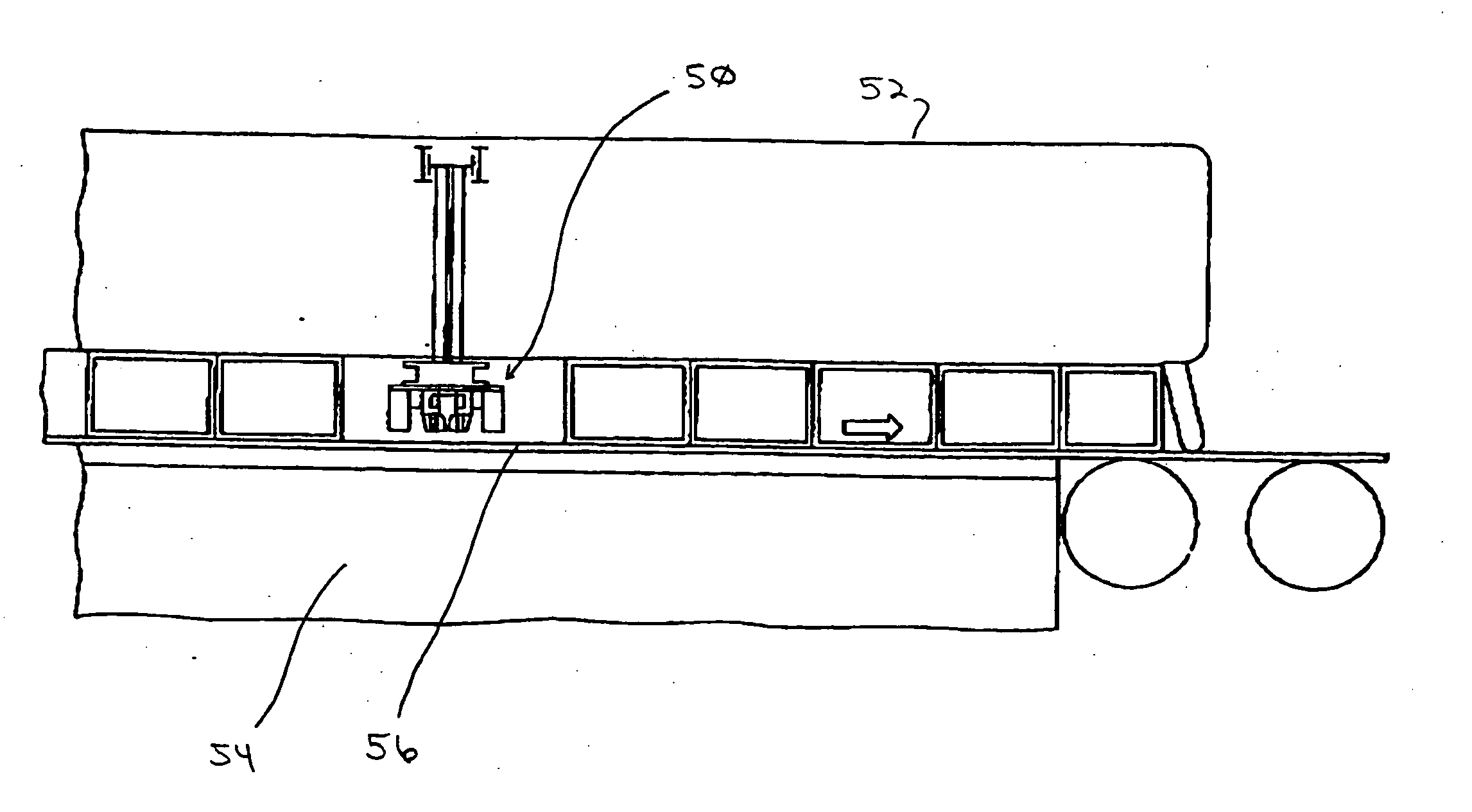

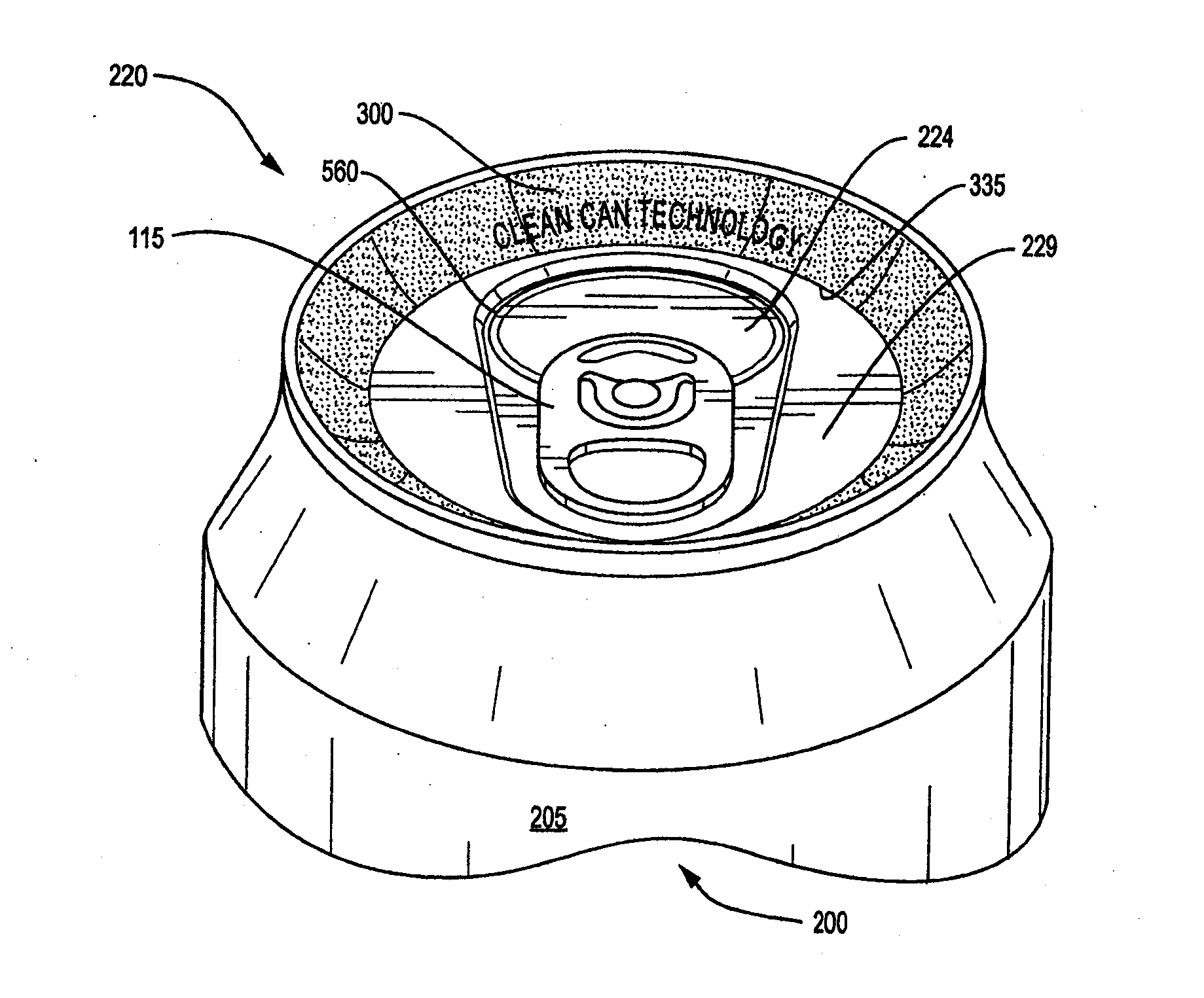

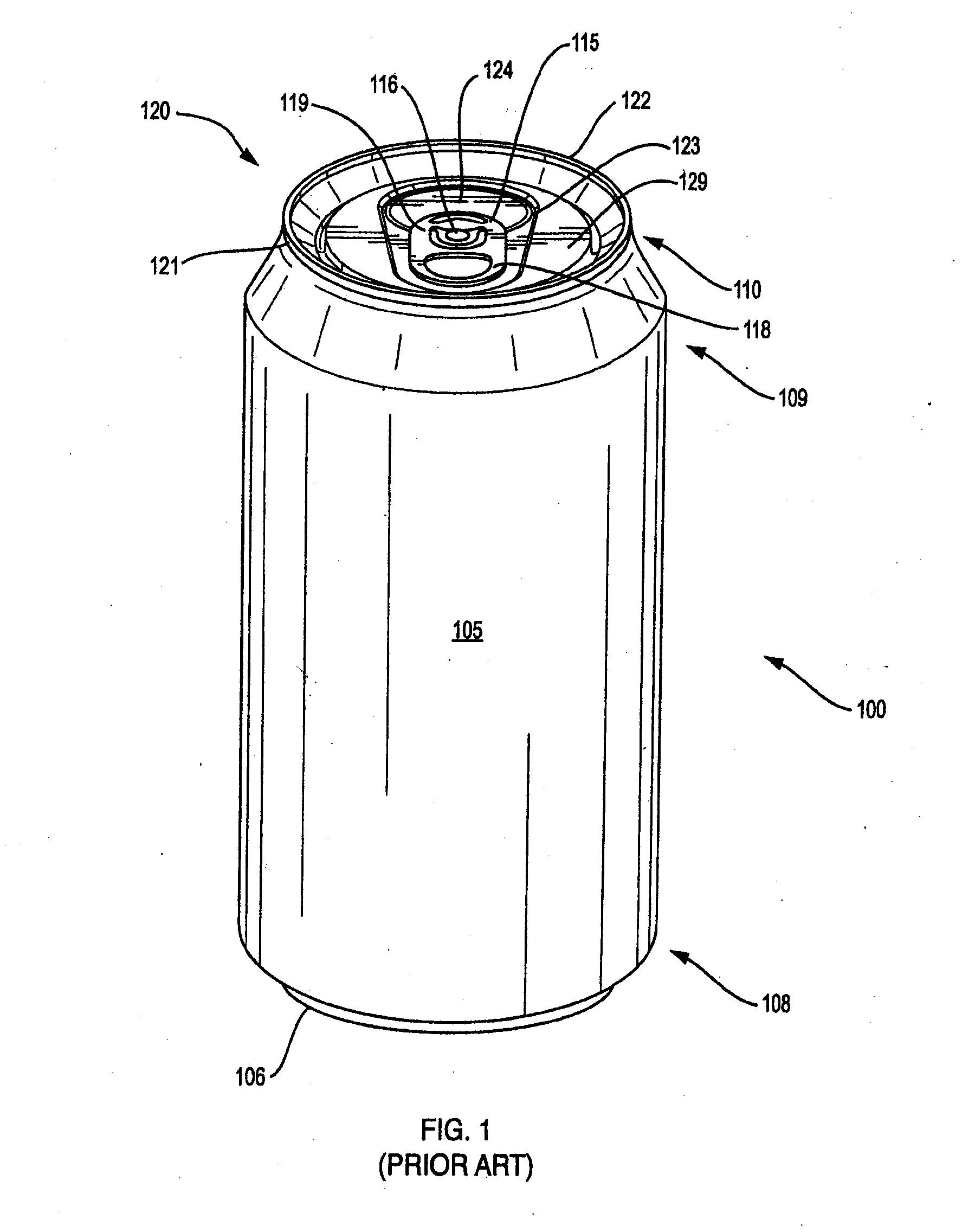

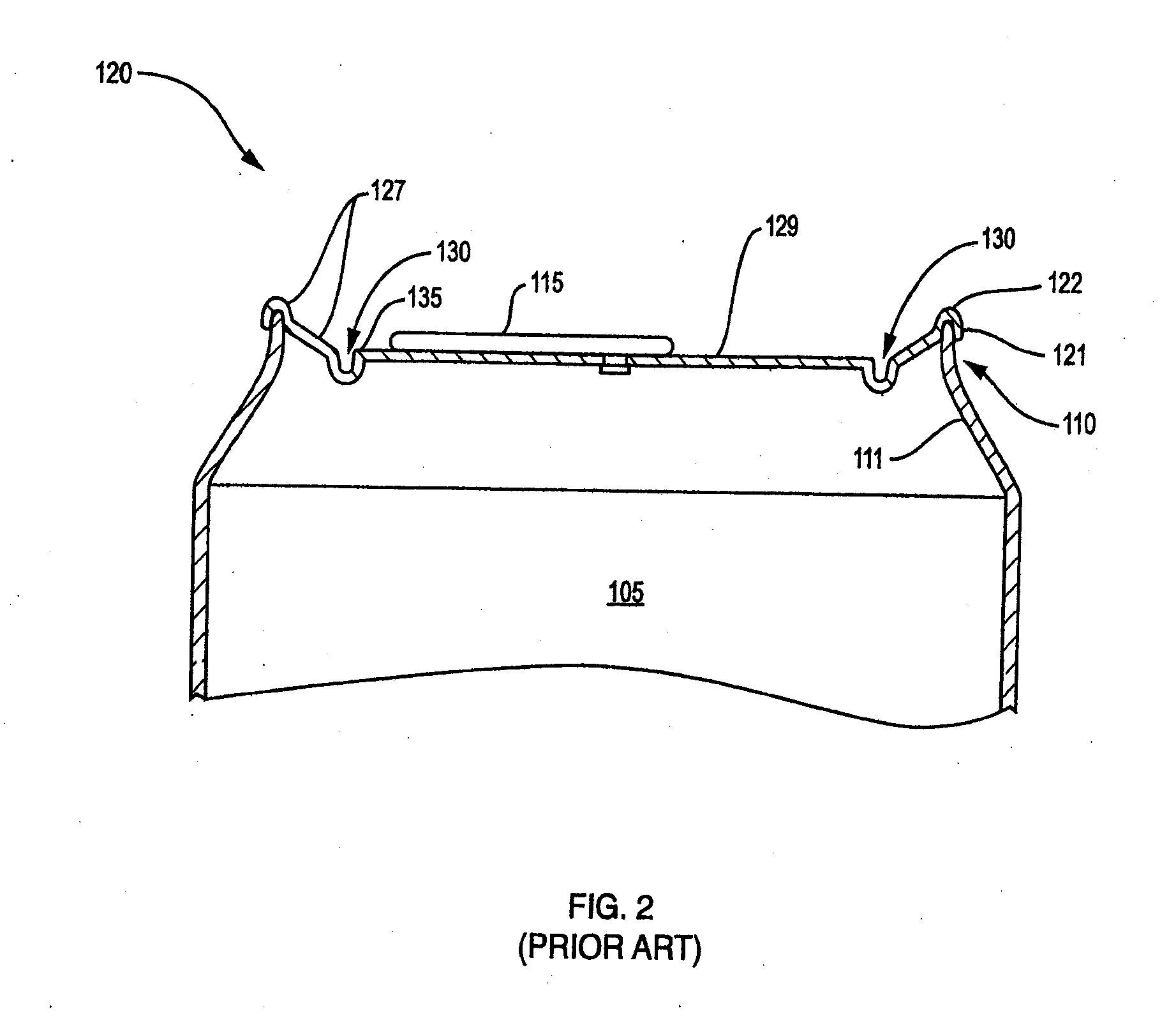

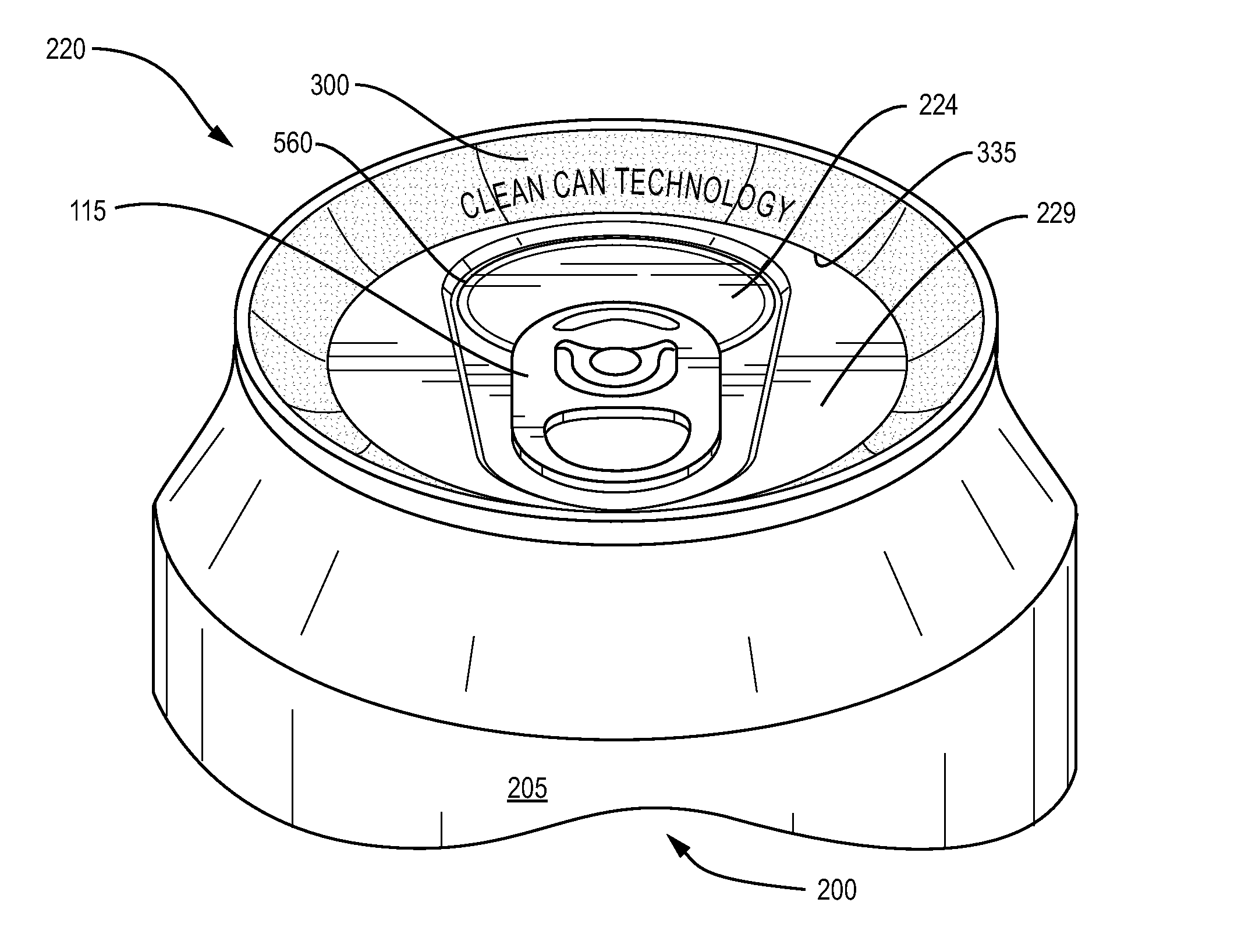

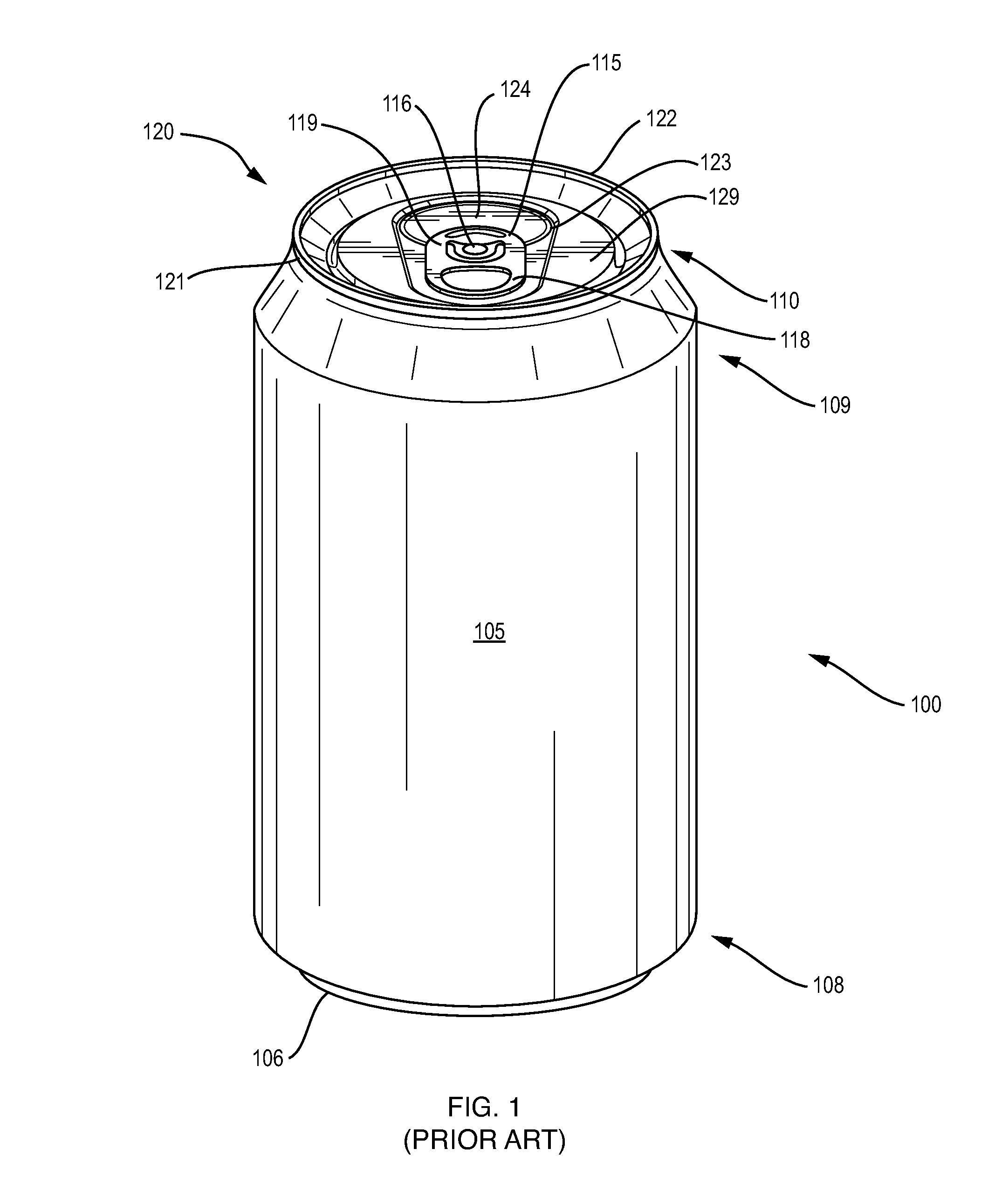

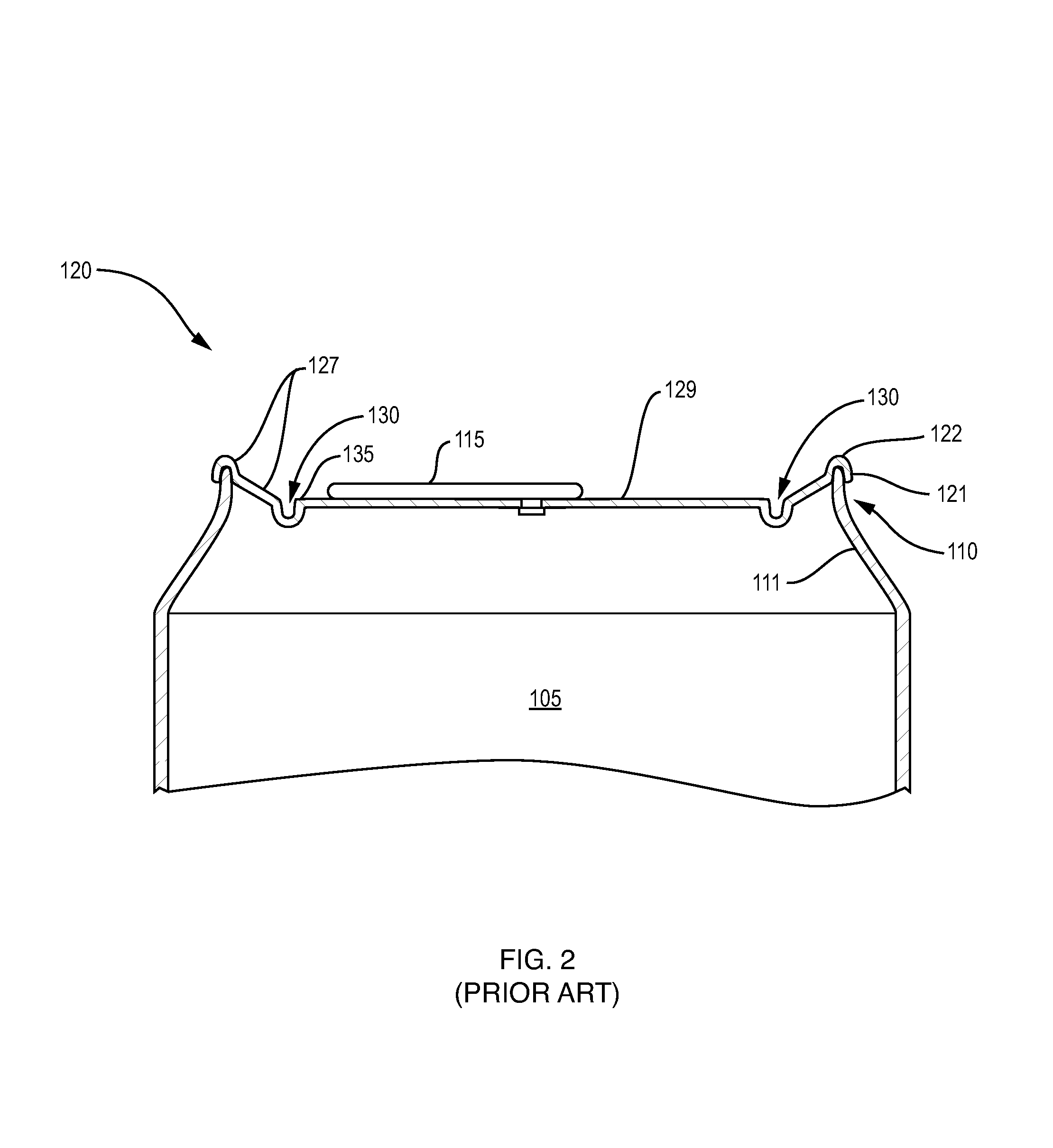

Beverage can marketing device

InactiveUS20110100854A1Reduce and inhibit collection of debrisReduce capacityVenting meansLarge containersEngineering

Owner:CHAPIN BARRY W

Photo-induced hydrophilic article and method of making same

InactiveUS7960043B2Easy to cleanEasy to wipeSynthetic resin layered productsVacuum evaporation coatingHydrophilic coatingSpray pyrolysis

Methods and articles are disclosed in which a substrate is provided with a photo-induced hydrophilic surface by forming a photo-induced hydrophilic coating on the substrate by spray pyrolysis, chemical vapor deposition, or magnetron sputter vacuum deposition. The coating can have a thickness of 50 Å to 500 Å, a root mean square roughness of less than 5, preferably less than 2, and photocatalytic activity of less than 3.0×10−3 cm−1 min−1±2.0×10−3 cm−1 min−1. The substrate includes glass substrates, including glass sheets and continuous float glass ribbons.

Owner:VITRO FLAT GLASS LLC

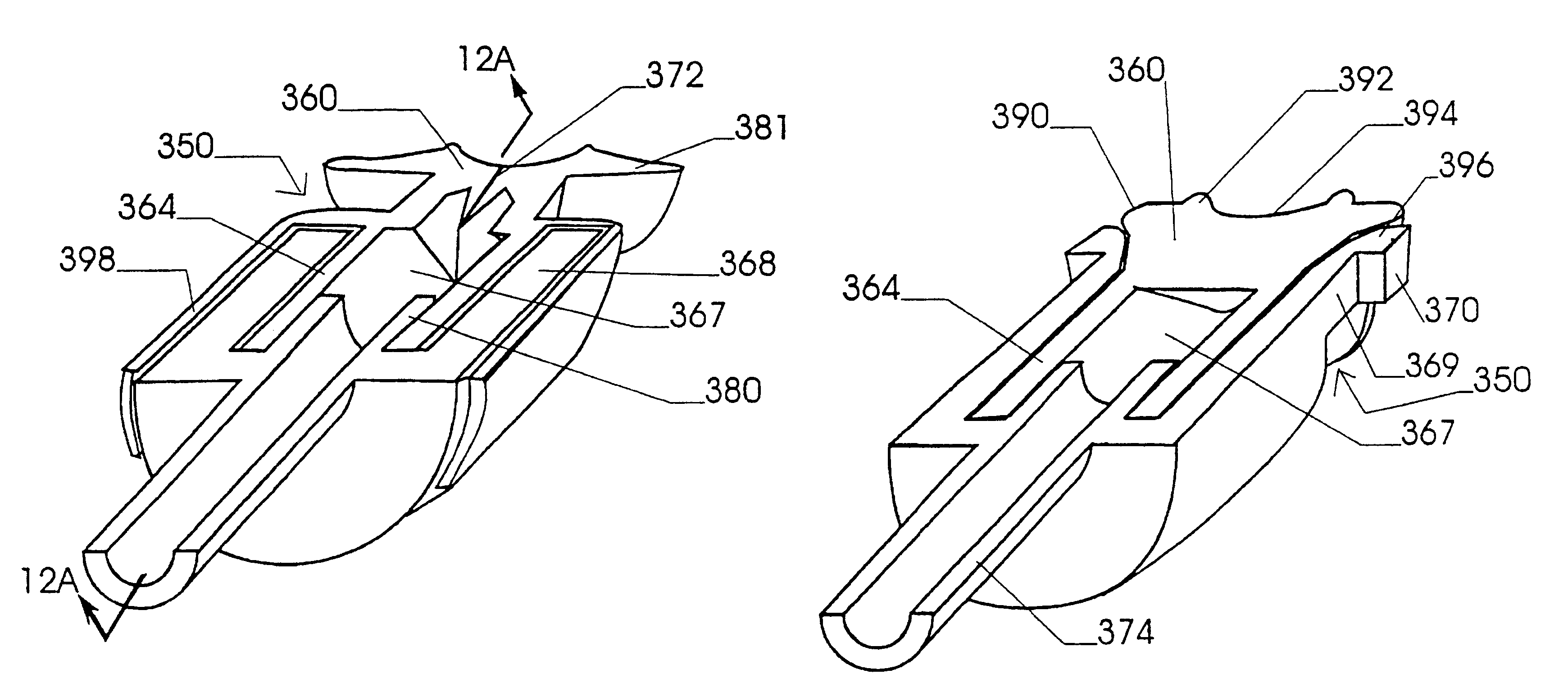

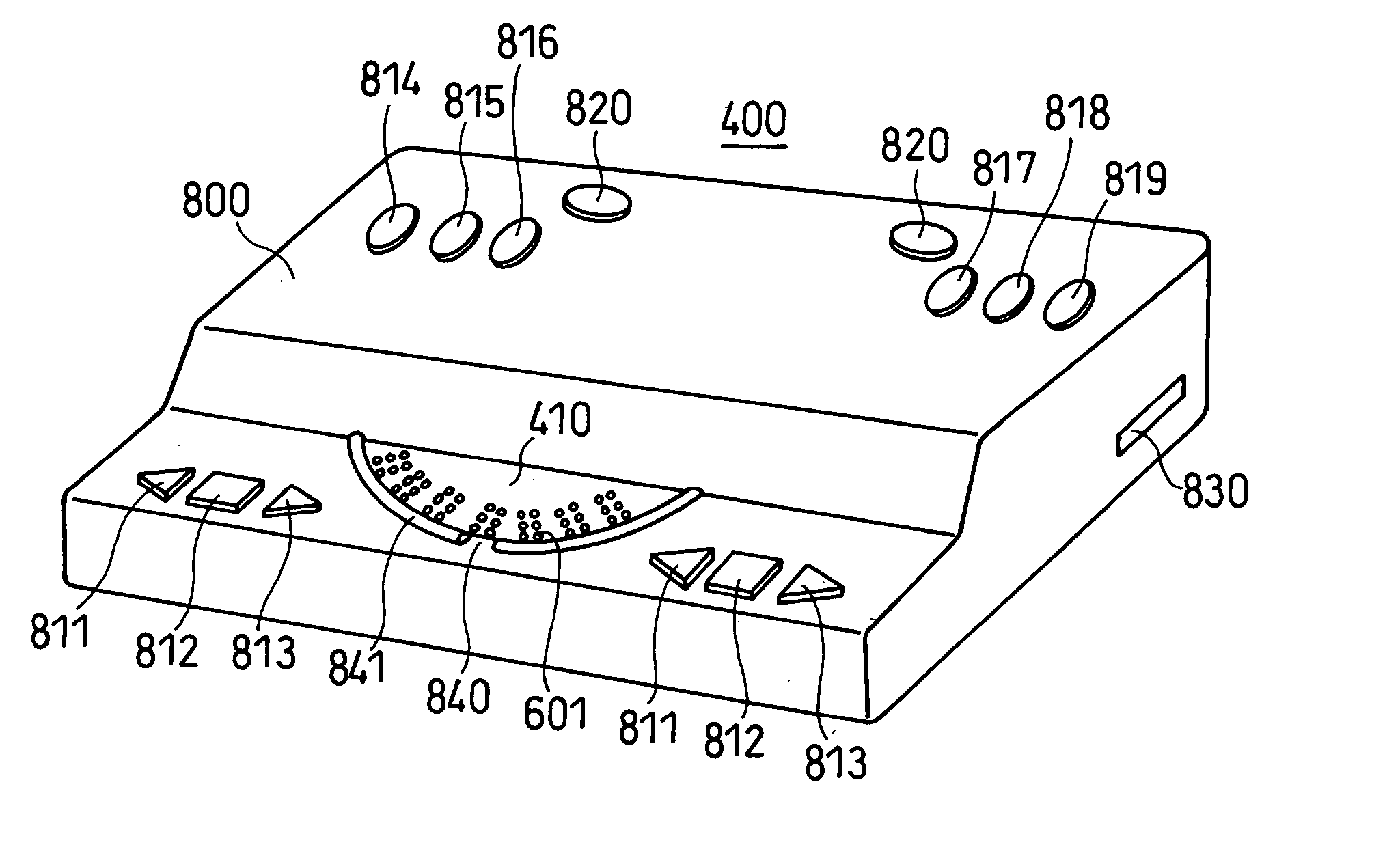

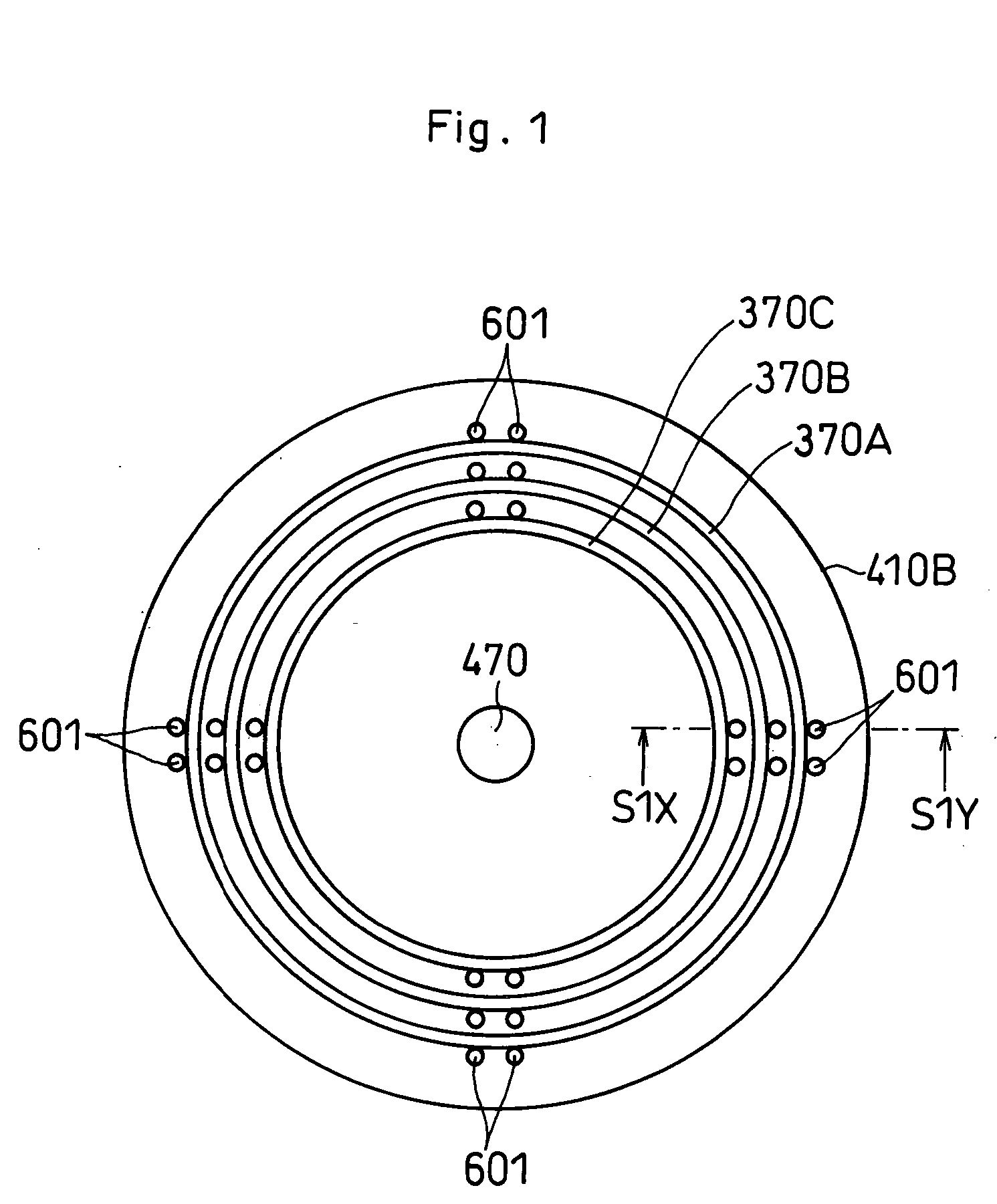

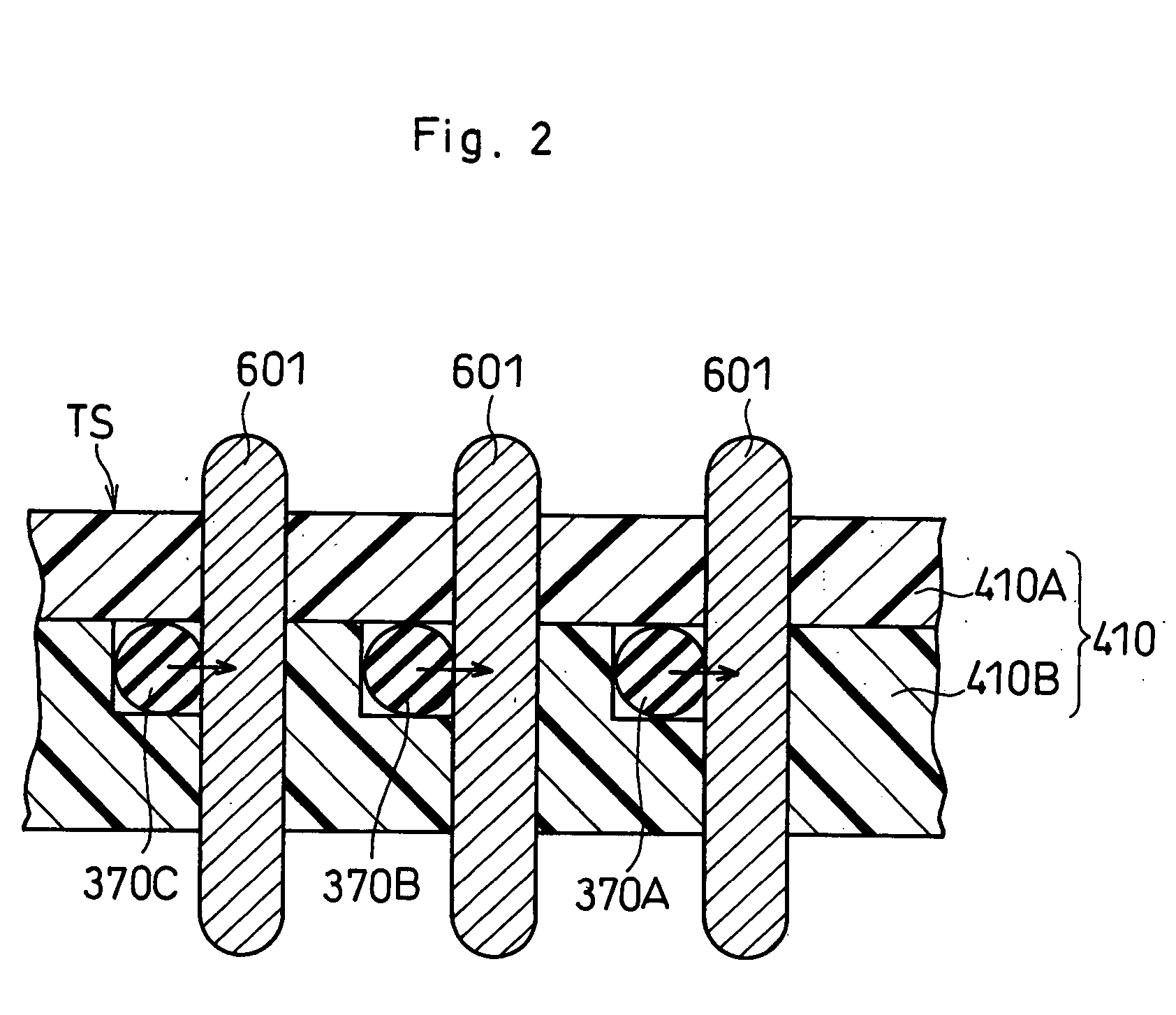

Tactile pin holding apparatus, tactile pin display apparatus and braille display member

Rotational member (310) with plural tactile pins (301) movable up-and-down for displaying characters is rotated by rotation driving means. Elastic O-rings (370) are provided in the rotational member (310) for pressing and holding the pins (301). Actuators (320) brought to contact the pins (301) are provided nearby the rotational member (310) for positioning the pins (301) at desired heights from a tactile surface. Cam (330) brought to contact with the pins (301) is provided also nearby the rotational member (310) for positioning the pins (301) at the reset position or height. Furthermore, selectively actuating means is provided for selectively actuating the actuators (320). Owing to such arrangement, a continuous tactile pin display apparatus can be reduced in size, weight and cost. By providing at least the pins (301) or the rotational member (310) with a photocatalyst, it becomes possible to decompose contaminants, such as bacteria, sweat, oil of the hand and food particles, deposited on the pins or their peripheral portions.

Owner:ASKK

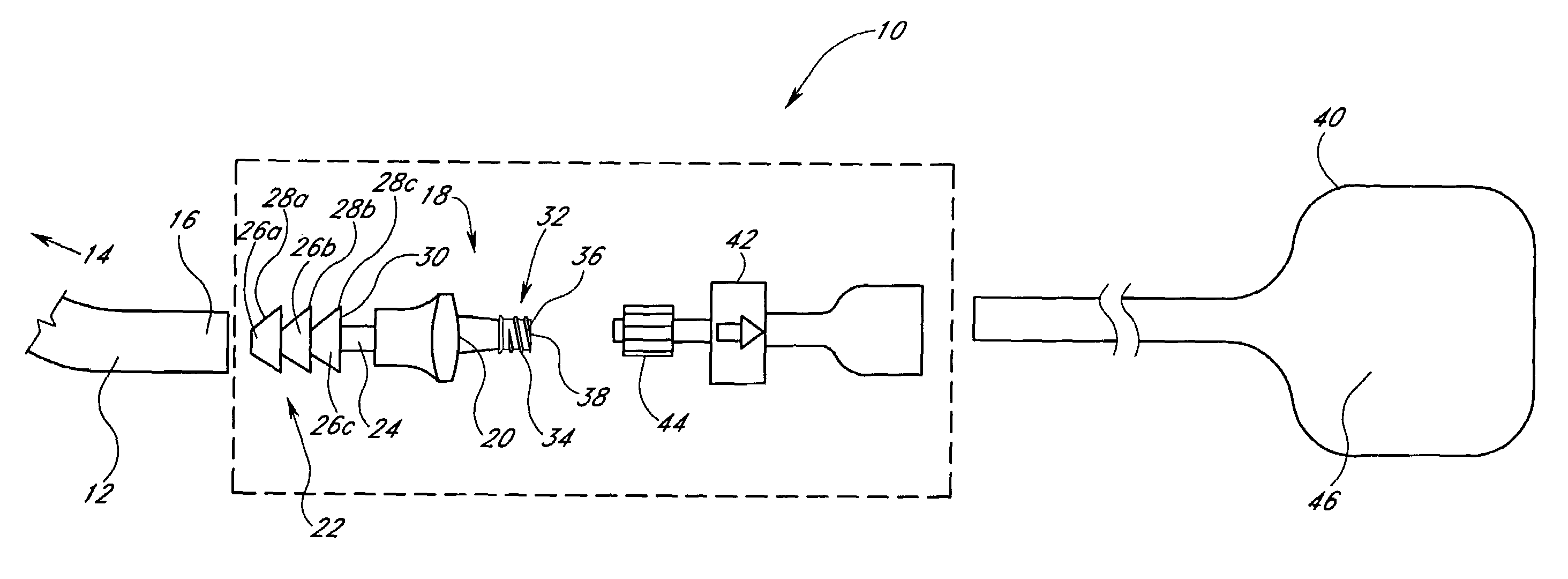

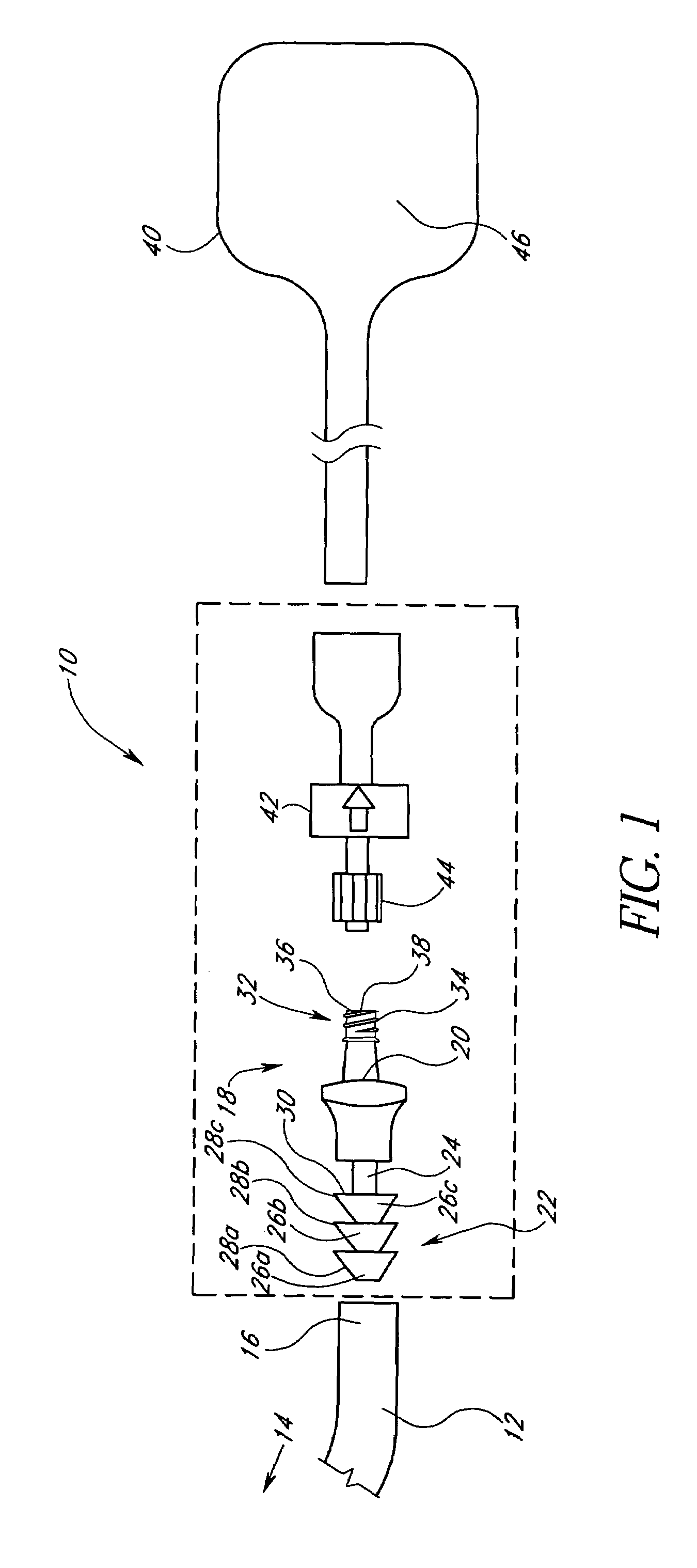

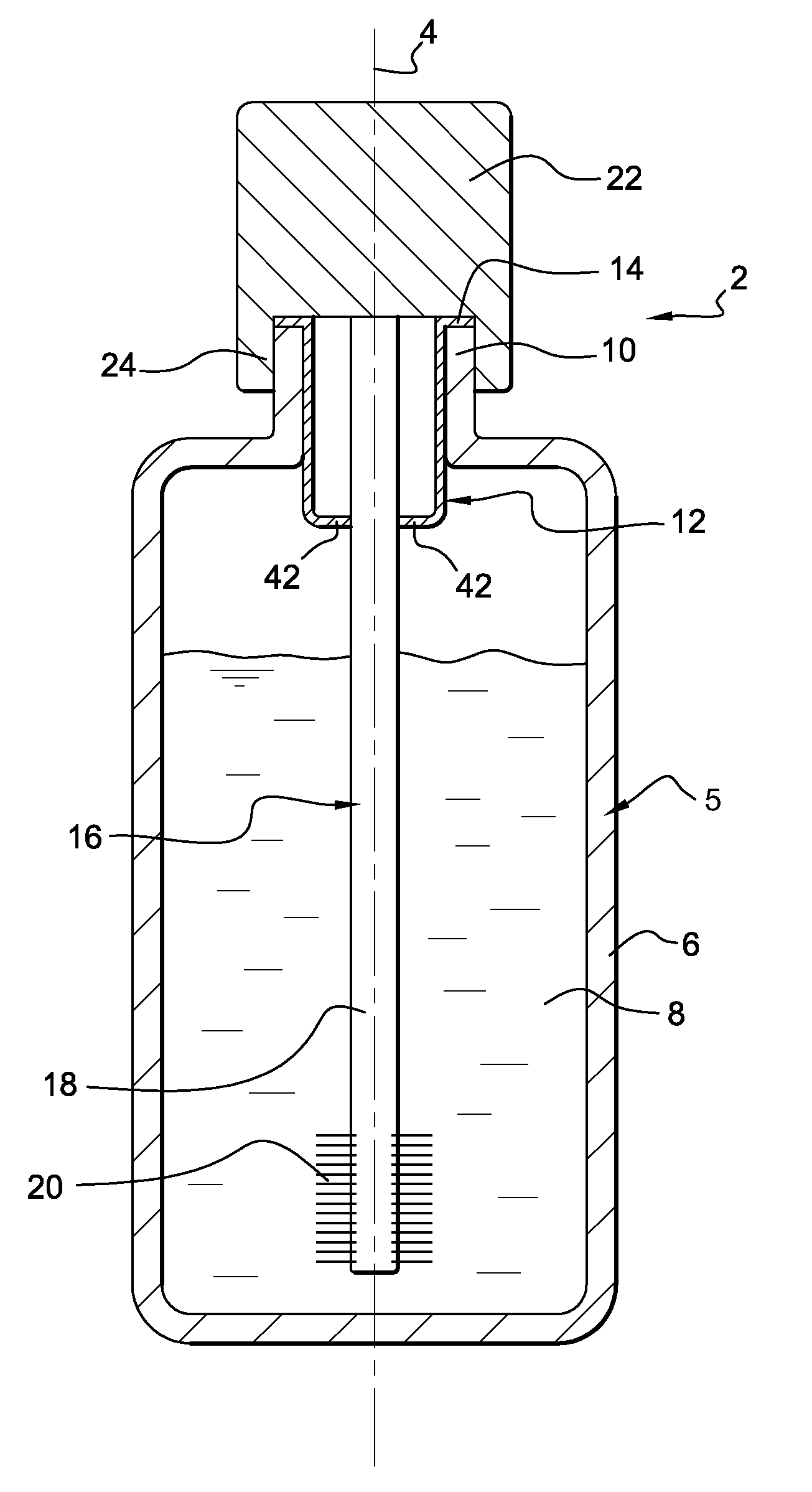

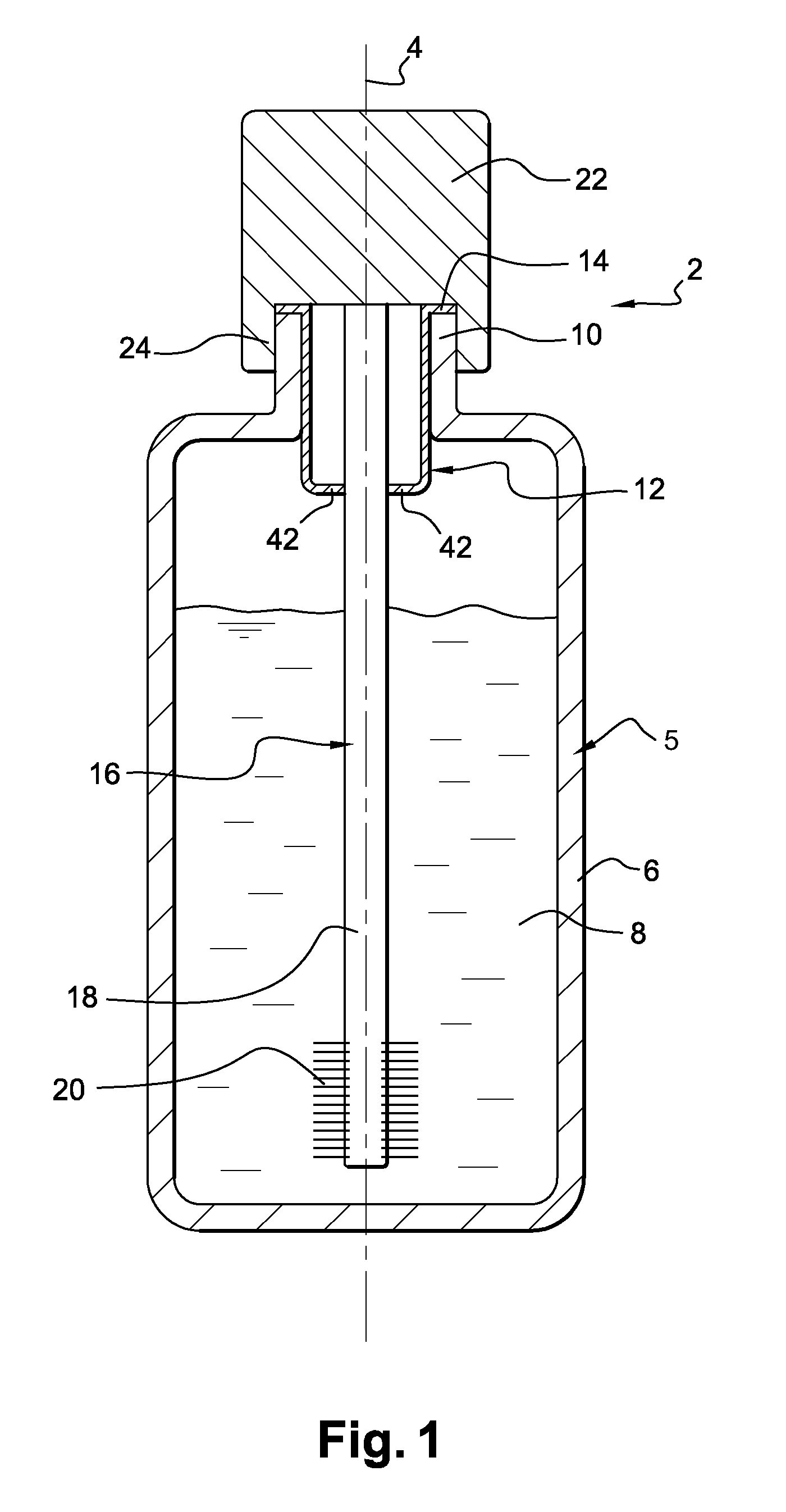

Urinary catheter system

InactiveUS7150740B2Reduce the risk of infectionEasy to cleanWound drainsCatheterForeign matterUrinary catheter

The urinary catheter system includes a urinary catheter, a connector and a medical implement which is readily attached to or removed from the connector. When a medical implement such as a collection appliance is attached to the connector, fluid such as urine can flow from the patent and into the collection appliance. Alternatively, when a syringe is attached to the connector, the catheter system may be irrigated to remove debris and other foreign matter, or the syringe may be used to provide medication to the patient. The system is preferably a closed system in which the connector includes a resealable valve which prevents the flow of fluid through the connector if a medical implement is not attached.

Owner:ICU MEDICAL INC

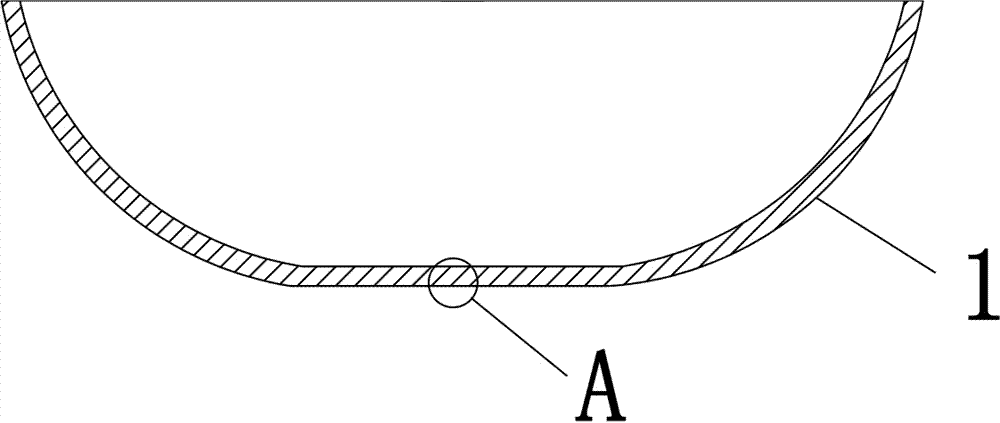

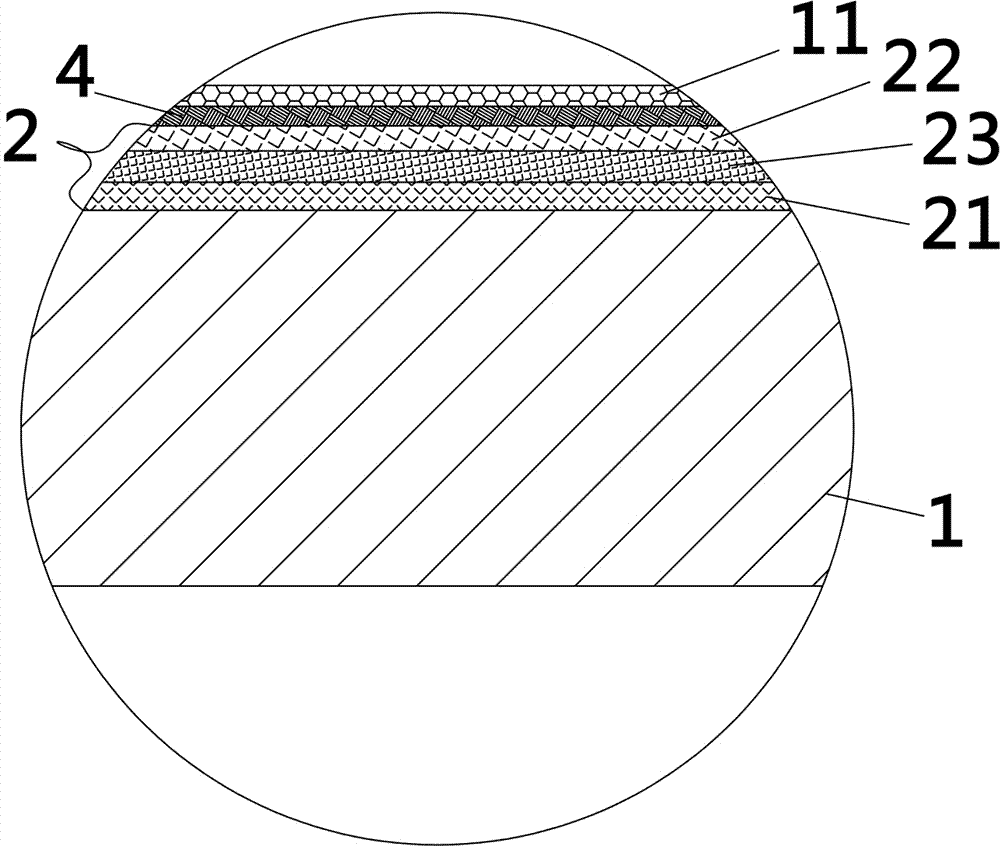

Plasma non-stick pan and fabrication method thereof

ActiveCN104757863AGood decontamination effectGood neutralization effectCooking-vessel materialsMolten spray coatingHardnessToughness

The invention discloses a plasma non-stick pan and a fabrication method thereof. The plasma non-stick pan comprises a pan body and a non-stick coating, and the pan body is coated with the non-stick coating. A plasma layer is arranged between the non-stick coating and the pan body and comprises a MCrALY layer and a mixture layer coated on the outside of the MCrALY layer. The mixture layer is formed by MCrALY particles and metallic oxide particles. The MCrALY layer is good in toughness, high in bonding force, capable of being easily bonded with a substrate, high in bonded firmness and capable of providing a buffer effect well and laying a foundation for subsequent mixture layer coating. The MCrALY particles and the metallic oxide particles are blended in the mixture layer, so that high rigidity and brittleness are provide, and the pan body surface rigidity and anti-abrasion performances are improved greatly; by the buffering effect of the MCrALY layer, the mixture layer and the MCrALY layer are bonded firmly, reliably and enduringly in the condition that the high rigidity and brittleness of the mixture layer is guaranteed.

Owner:ZHEJIANG SANHO KITCHENWARE

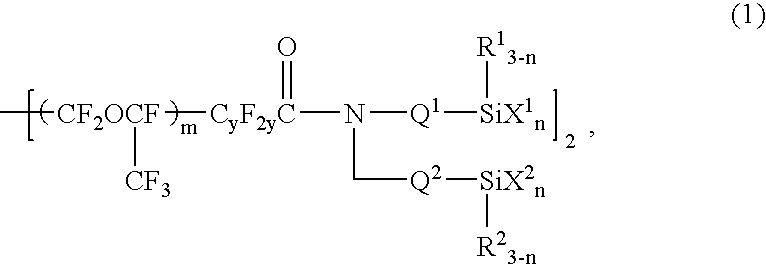

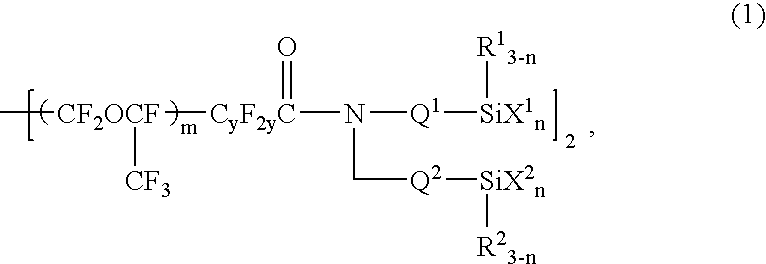

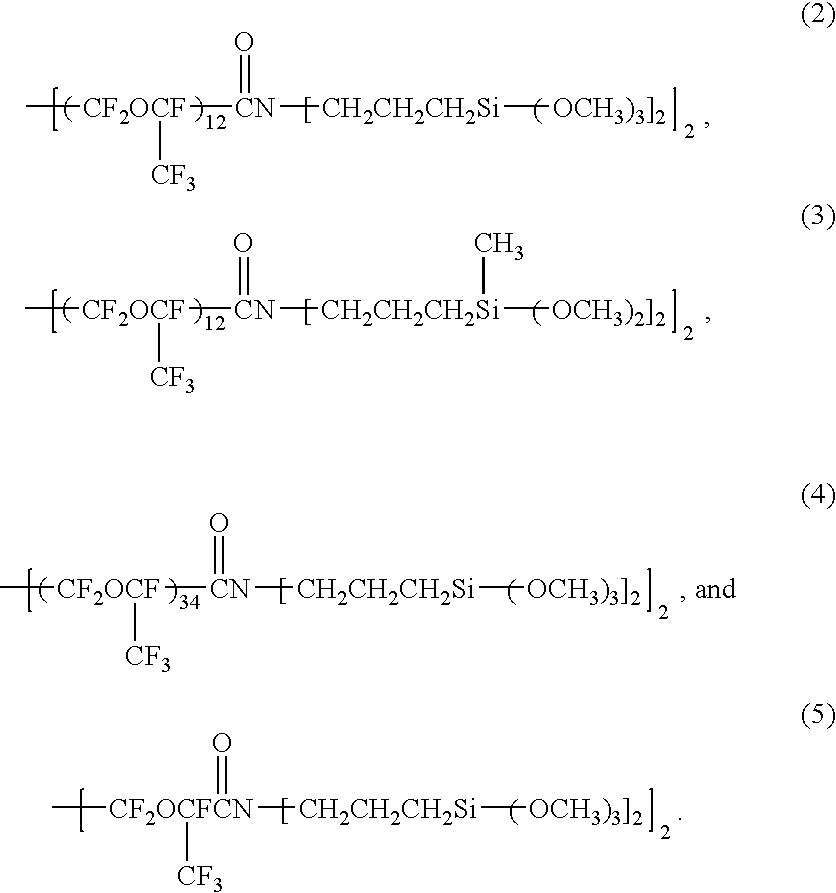

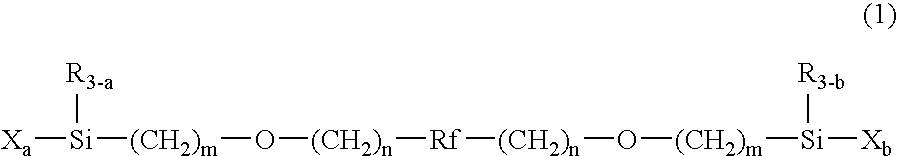

Lens with stain resistant surface layer

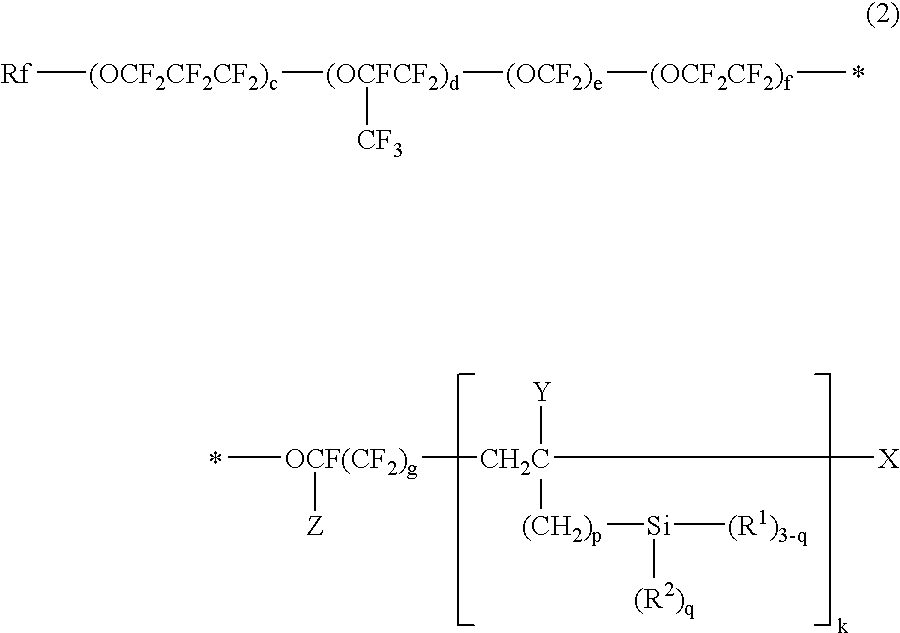

ActiveUS6958191B2Easy to wipeIncreased durabilityLayered productsPretreated surfacesHalogenSurface layer

A lens including a lens substrate, a surface layer, and a backing member provided beneath the surface layer, in which the backing member may be either the same as the lens substrate or a separate layer from the lens substrate, and wherein the surface layer includes a hydrolysis-condensation product of a perfluoropolyether modified silane with a hydrolysable functional group or a halogen atom X at both terminals, represented by a general formula (1) shown below: (wherein, Rf is a bivalent group with a straight chain perfluoropolyether structure containing no branching, which incorporates a unit represented by a formula —(CkF2kO)— (wherein, k represents an integer from 1 to 6)) is resistant to the adhesion of contaminants to the surface thereof, can be easily wiped to remove any adhered contaminants, provides a slippery surface that is difficult to scratch, and moreover displays excellent durability and is capable of retaining the above properties over extended periods.

Owner:SHIN ETSU CHEM IND CO LTD

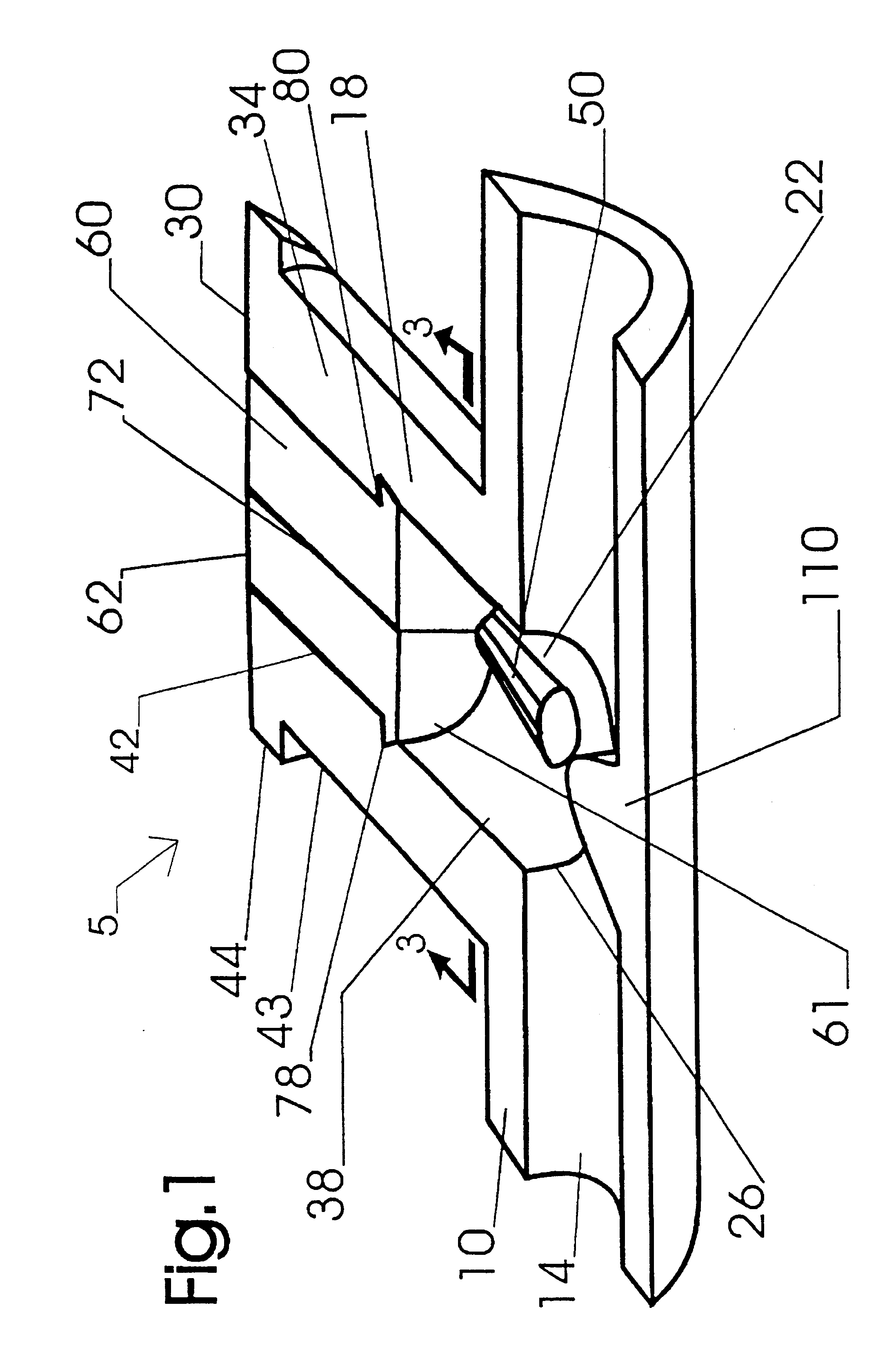

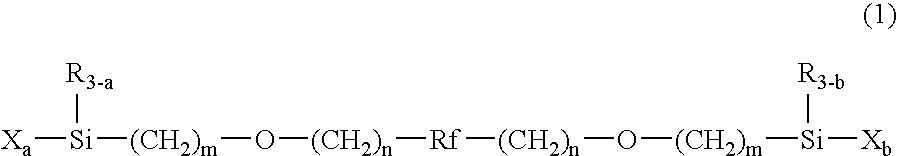

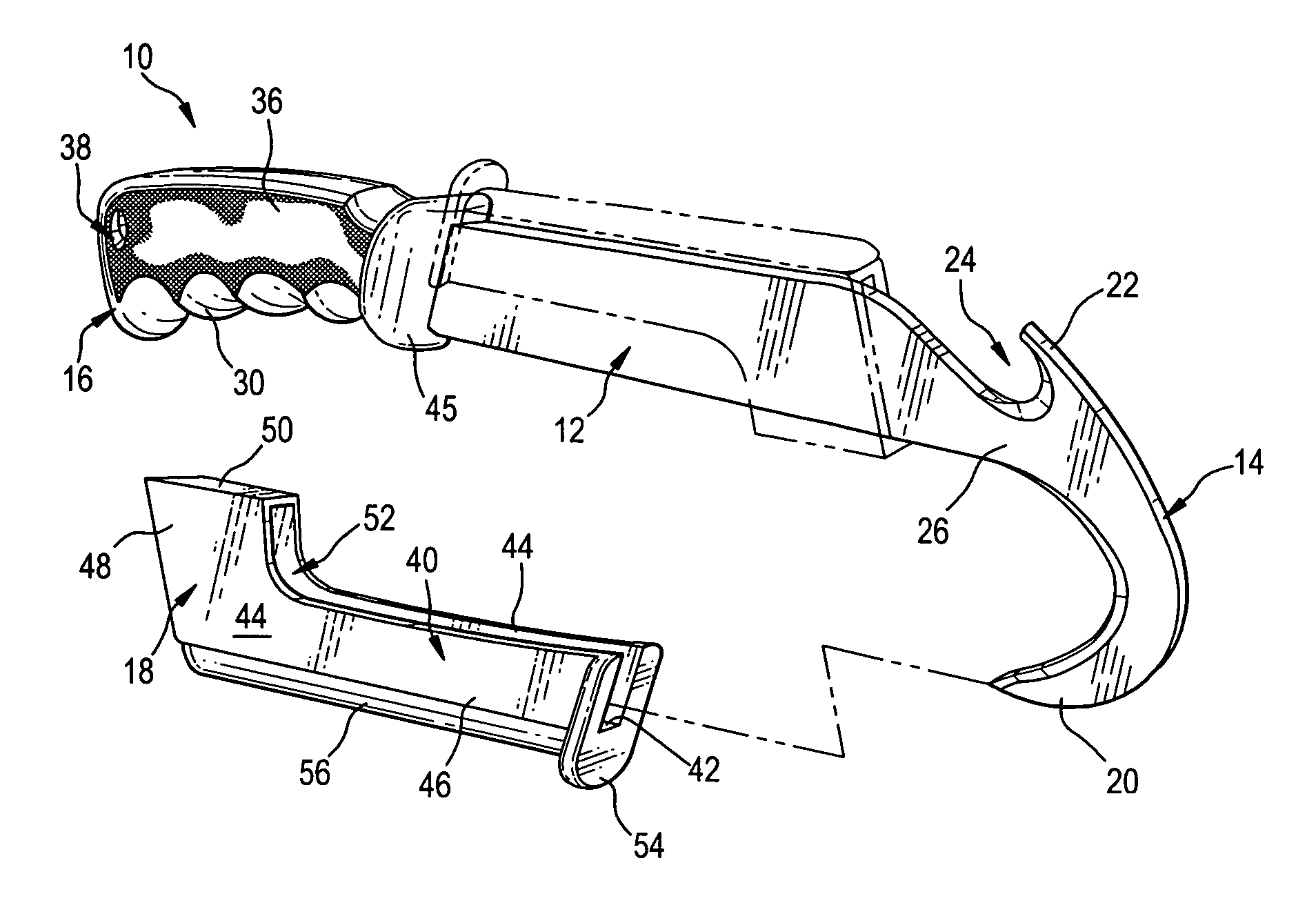

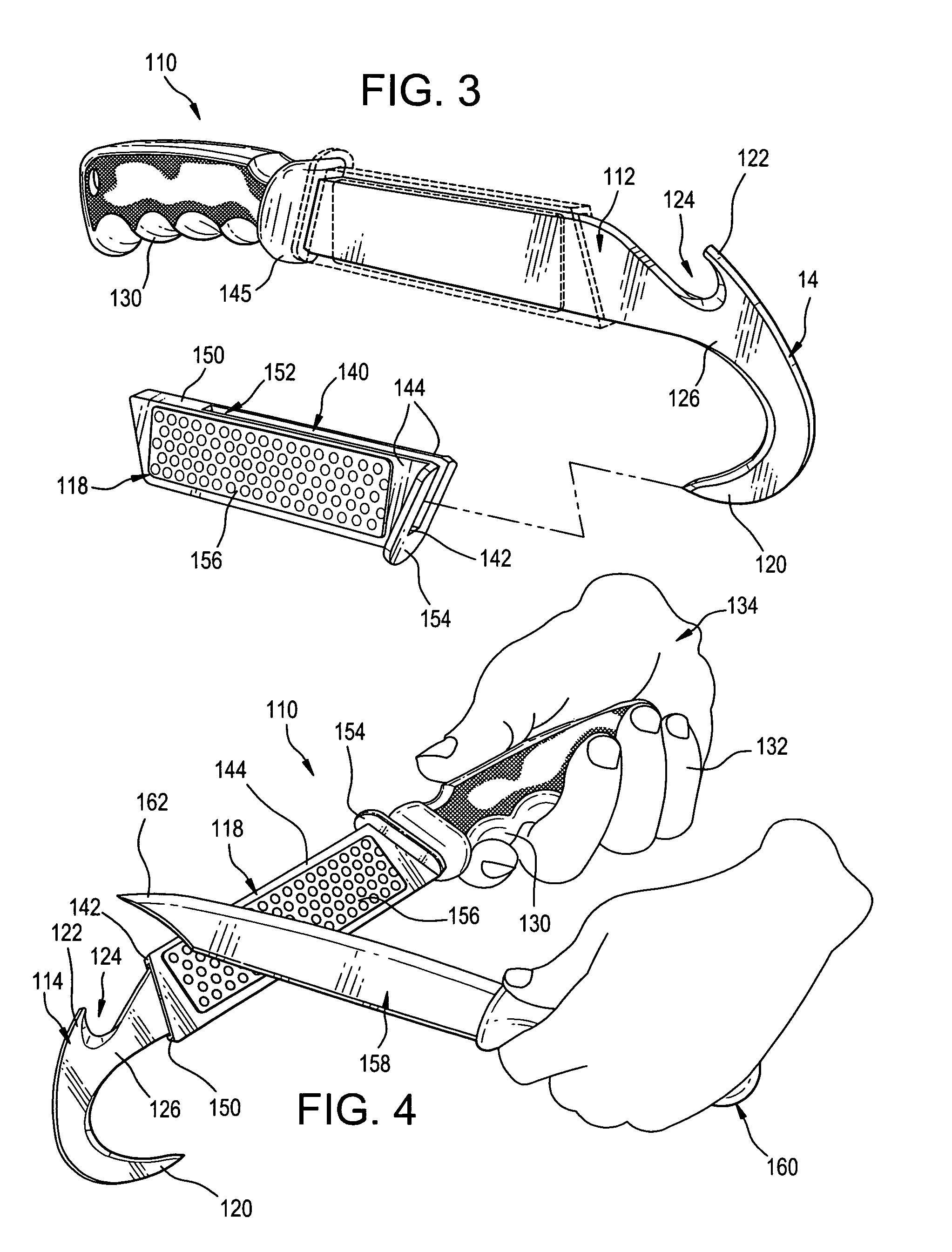

Butchering tool

InactiveUS7214127B1Efficiently skinEasy to useFish washing/descalingPoultry plucking mechanismsEngineeringMechanical engineering

A butchering tool including a handle and a bar extending from the handle. A claw is affixed to the bar remote from the handle. The claw includes a primary hook curving downwardly and rearwardly toward the bottom of the handle and a notch in the top thereof. The claw also includes a secondary hook that curves upwardly and rearwardly toward the top of the handle and that partially closes the notch.

Owner:THOMPSON TIMOTHY L +1

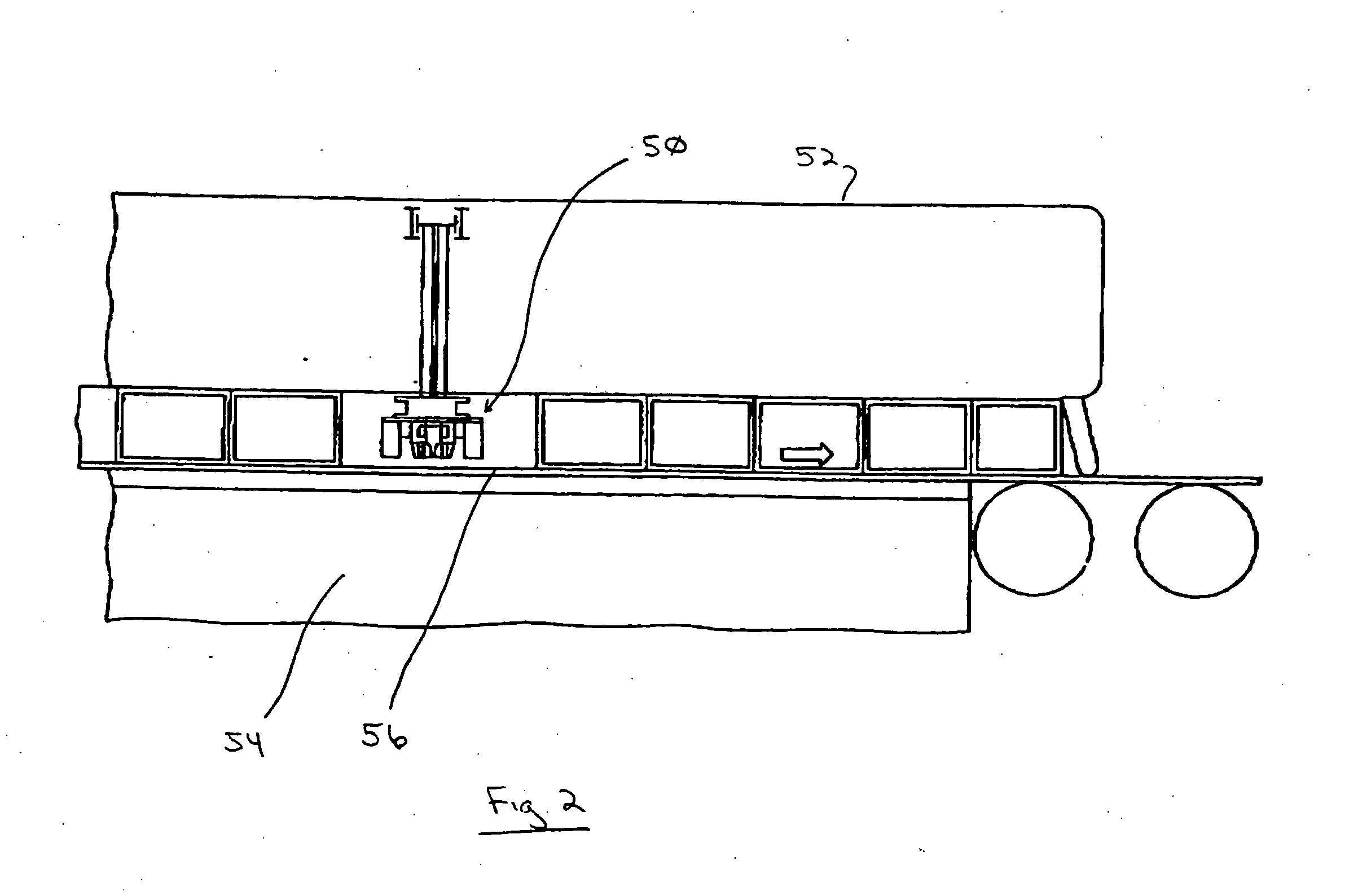

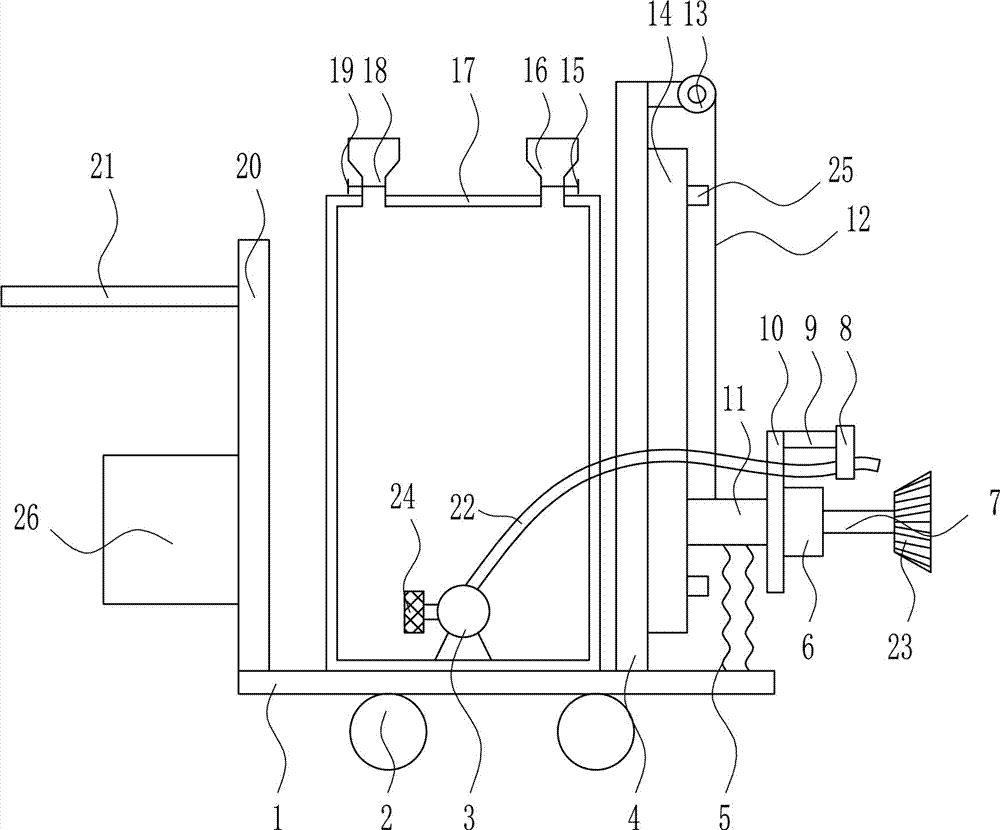

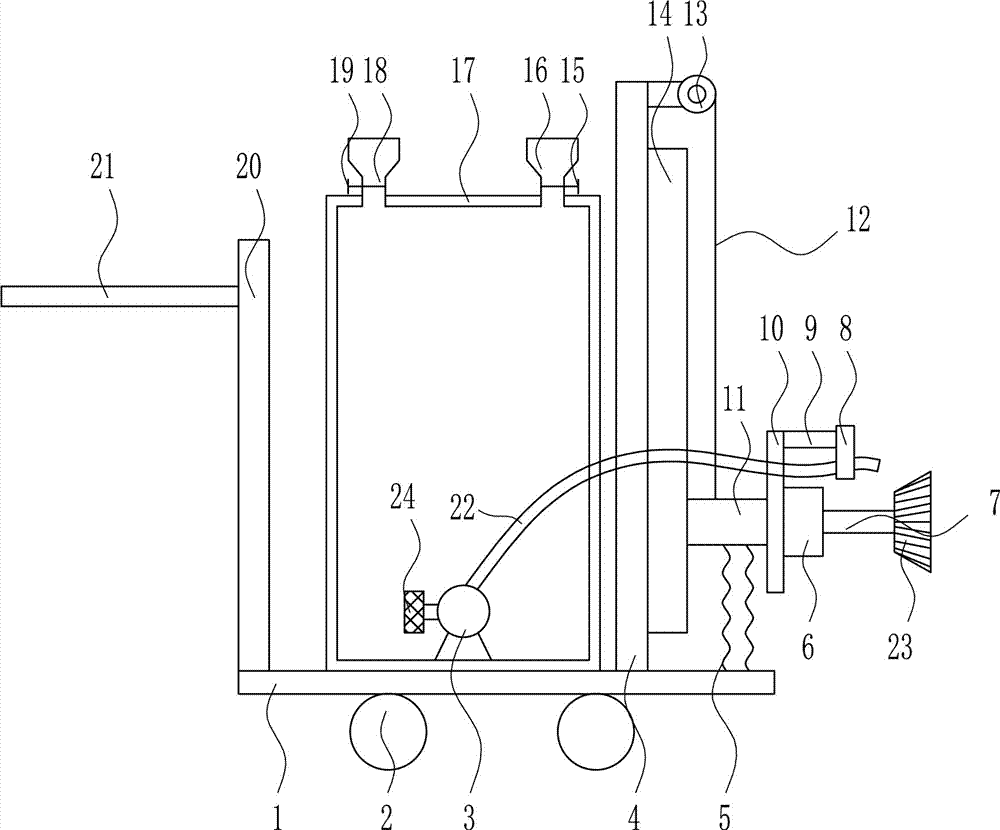

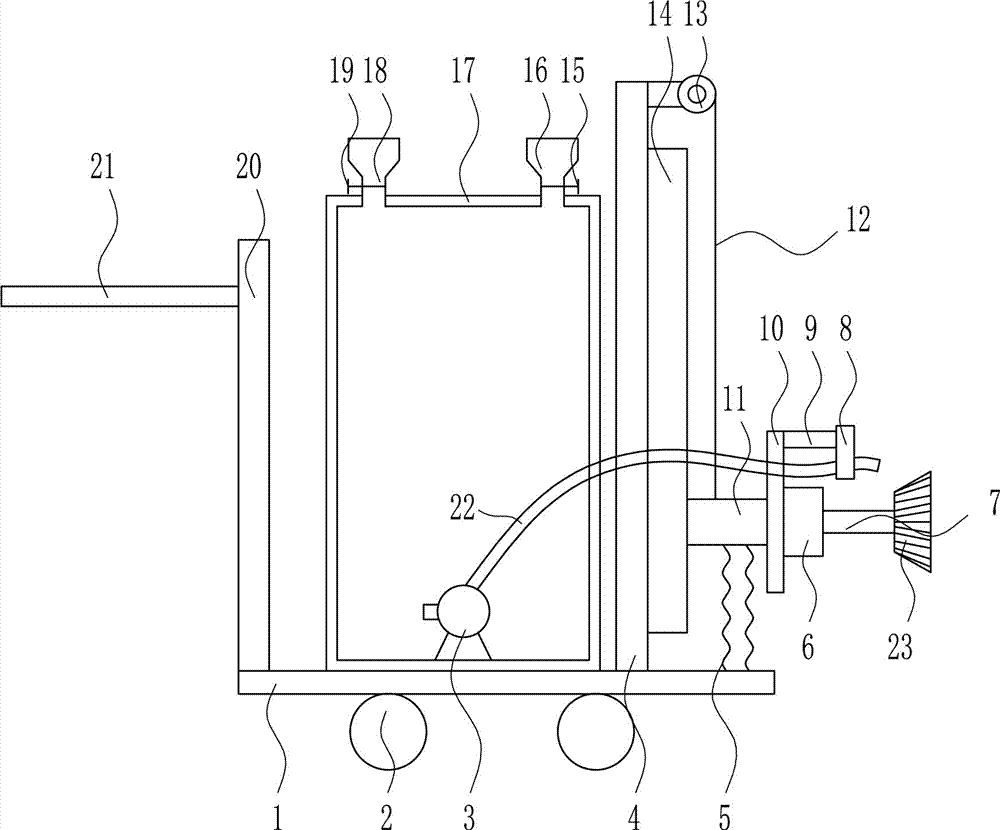

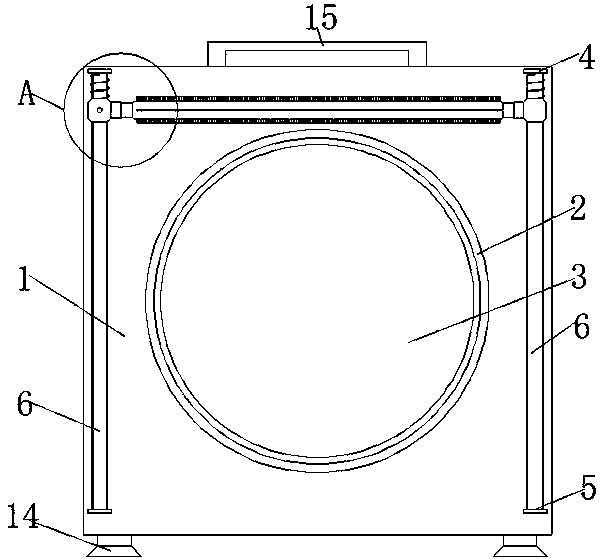

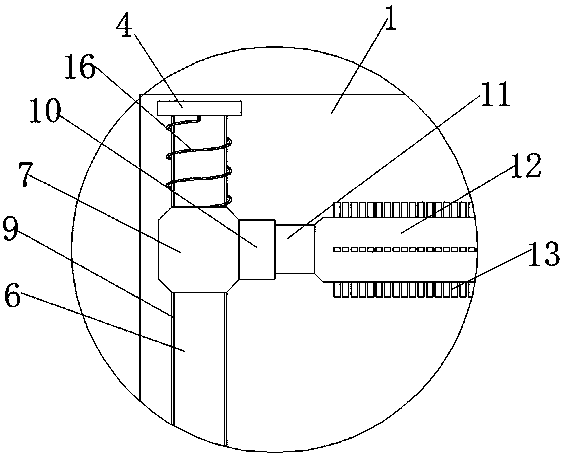

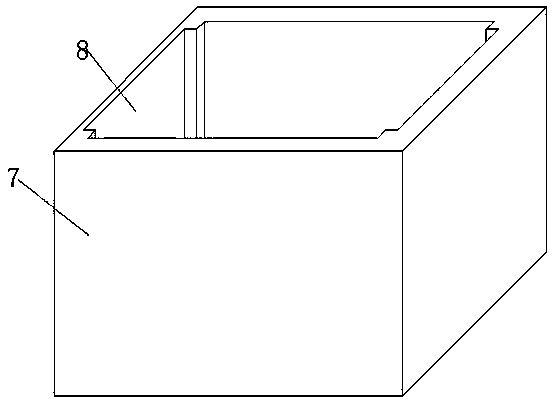

Wiping equipment of advertising board for municipal roads

ActiveCN106862126AClean completelyImprove work efficiencyTransportation and packagingRotary stirring mixersEngineeringWater tanks

The invention relates to advertising board wiping equipment, in particular to wiping equipment of an advertising board for municipal roads. According to the technical aims, the wiping equipment of the advertising board for the municipal roads is high in wiping speed and simple in wiping process. In order to achieve the technical aims, the wiping equipment of the advertising board for the municipal roads comprises a bottom board, wheels, a water pump, a first fixing board, a spring, a first motor, a rotary rod, a fixing sleeve, a second fixing rod, a second fixing board, a slide block, a pull wire and the like; a pushing handle is welded to the left side of the top of the bottom board; a sun shield is welded to the upper portion of the left side of the pushing handle; the center of the top of the bottom board is connected with a water tank in a bolt connection manner; and a first feeding opening and a second feeding opening are symmetrically formed in the top of the water tank left and right. The effects of high wiping speed and simple wiping process are achieved. The advertising board for the municipal roads is cleaned more thoroughly by controlling vertical movement of a wiping block.

Owner:广州市鑫阳交通工程有限公司

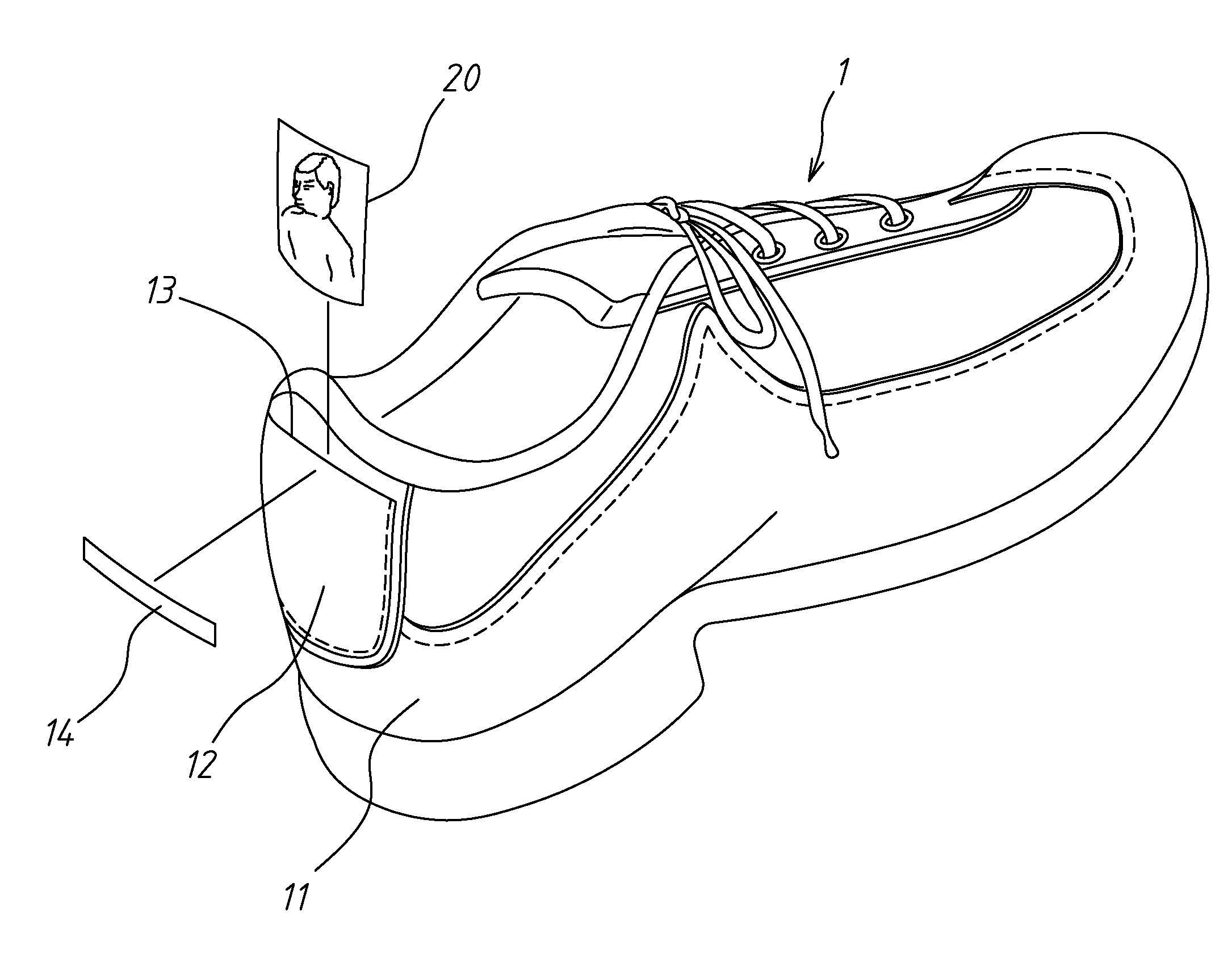

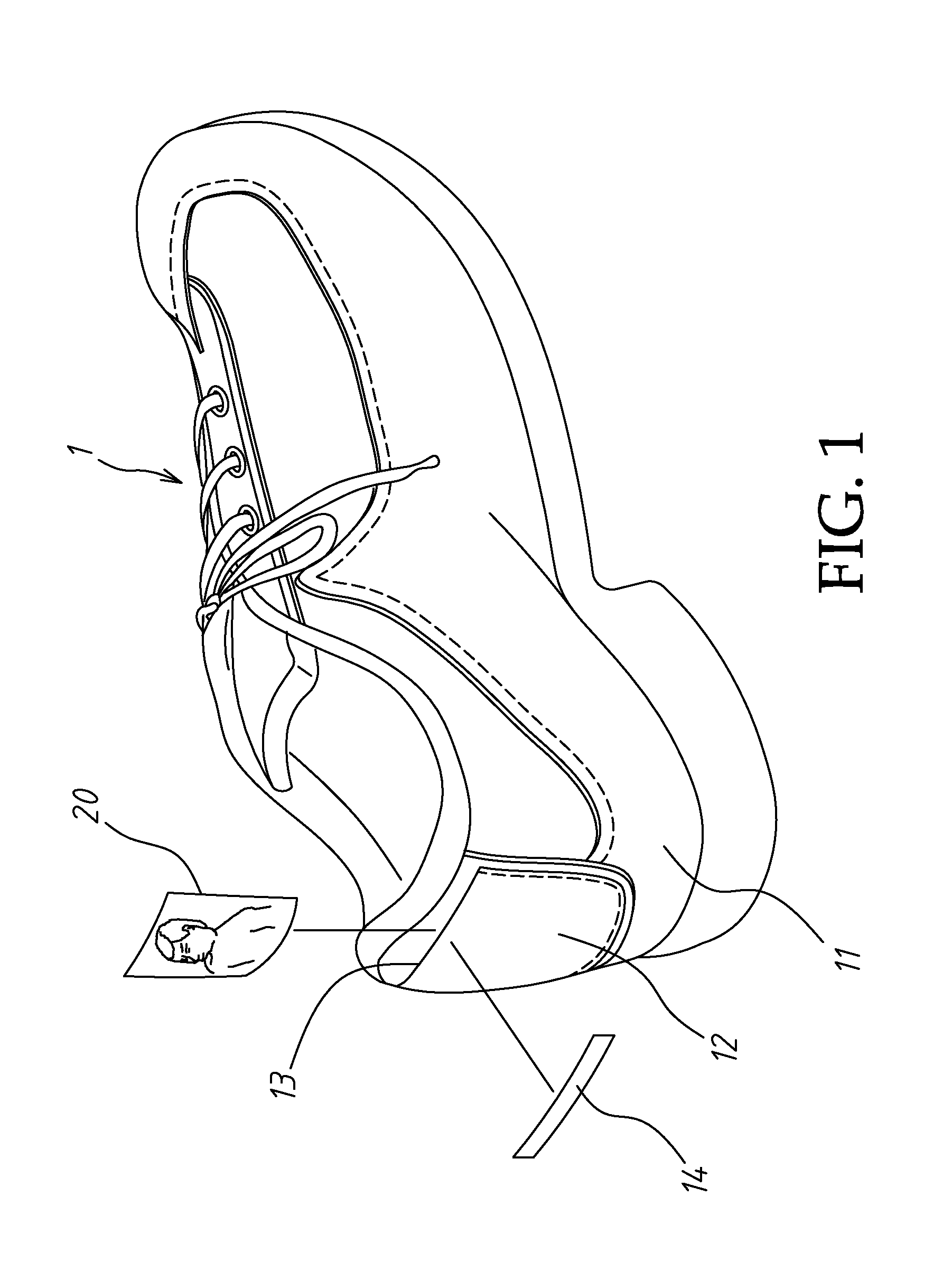

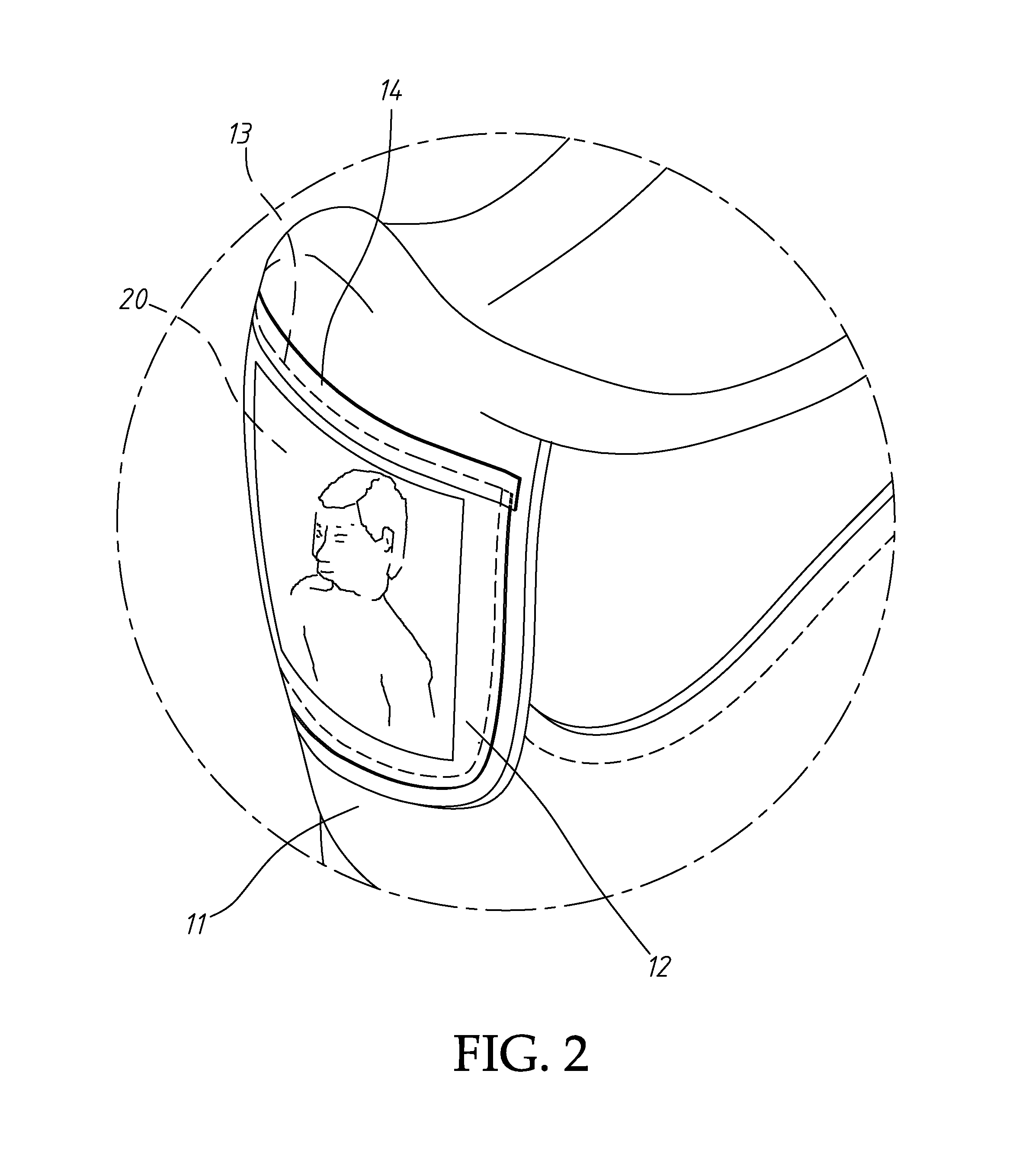

Shoe adapted to being added with pictures

Owner:CHEN CHUN LEON

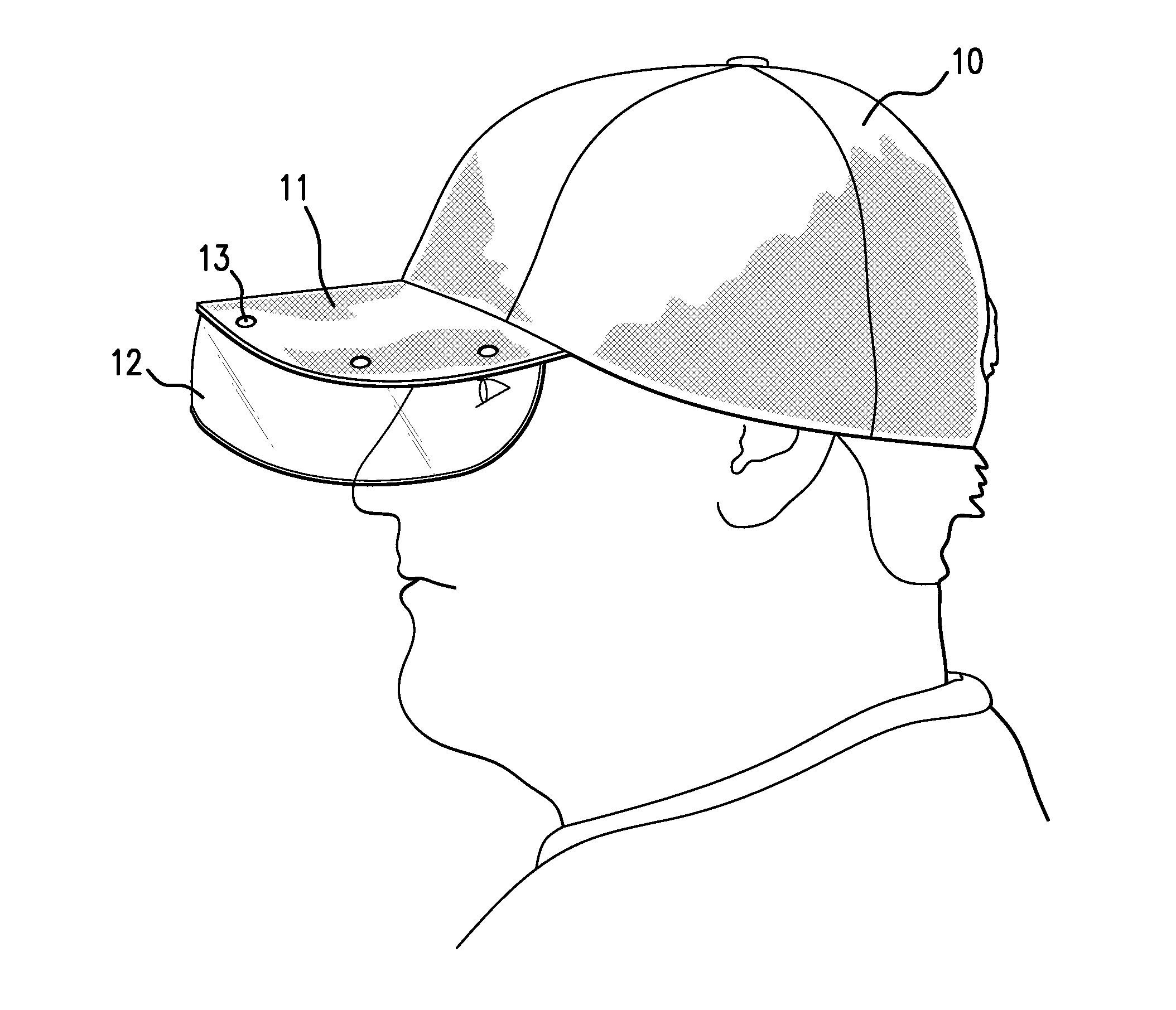

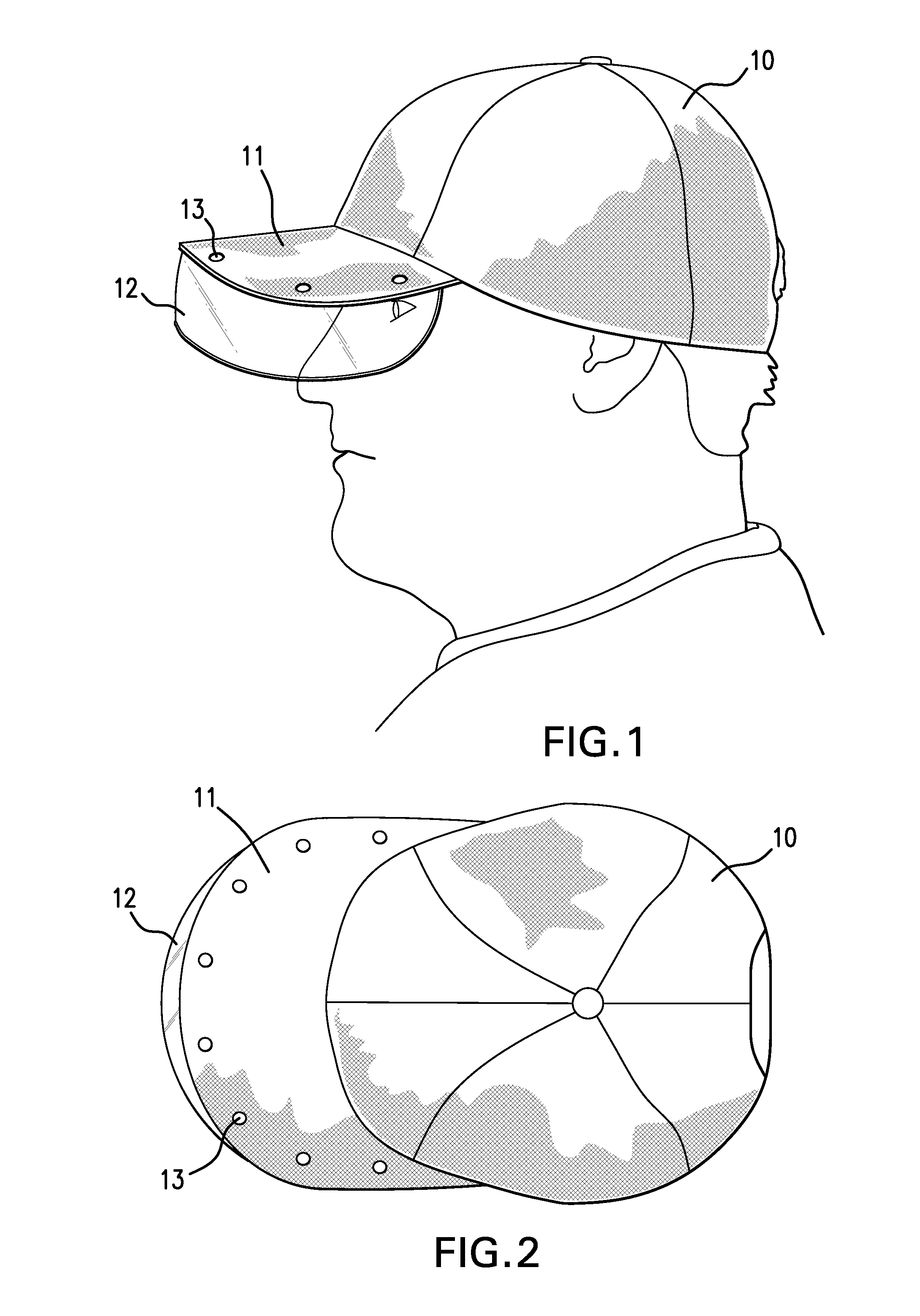

Article of manufacture for a hat and eye shield and process for making same

An article of manufacture for a hat and eye shield comprised of a hat, a bill attached to the front of the hat having a plurality of vertical openings extending vertically through the distal edge of the bill furthest from the hat, a lens with a plurality of pins extending vertically up from its top surface, the pins on the lens inserted into the vertical openings through the distal edge of the bill furthest from the hat, and the pins on the lens anchored to the vertical openings in the bill by an extrusion means.

Owner:DOBKINS SELWYN

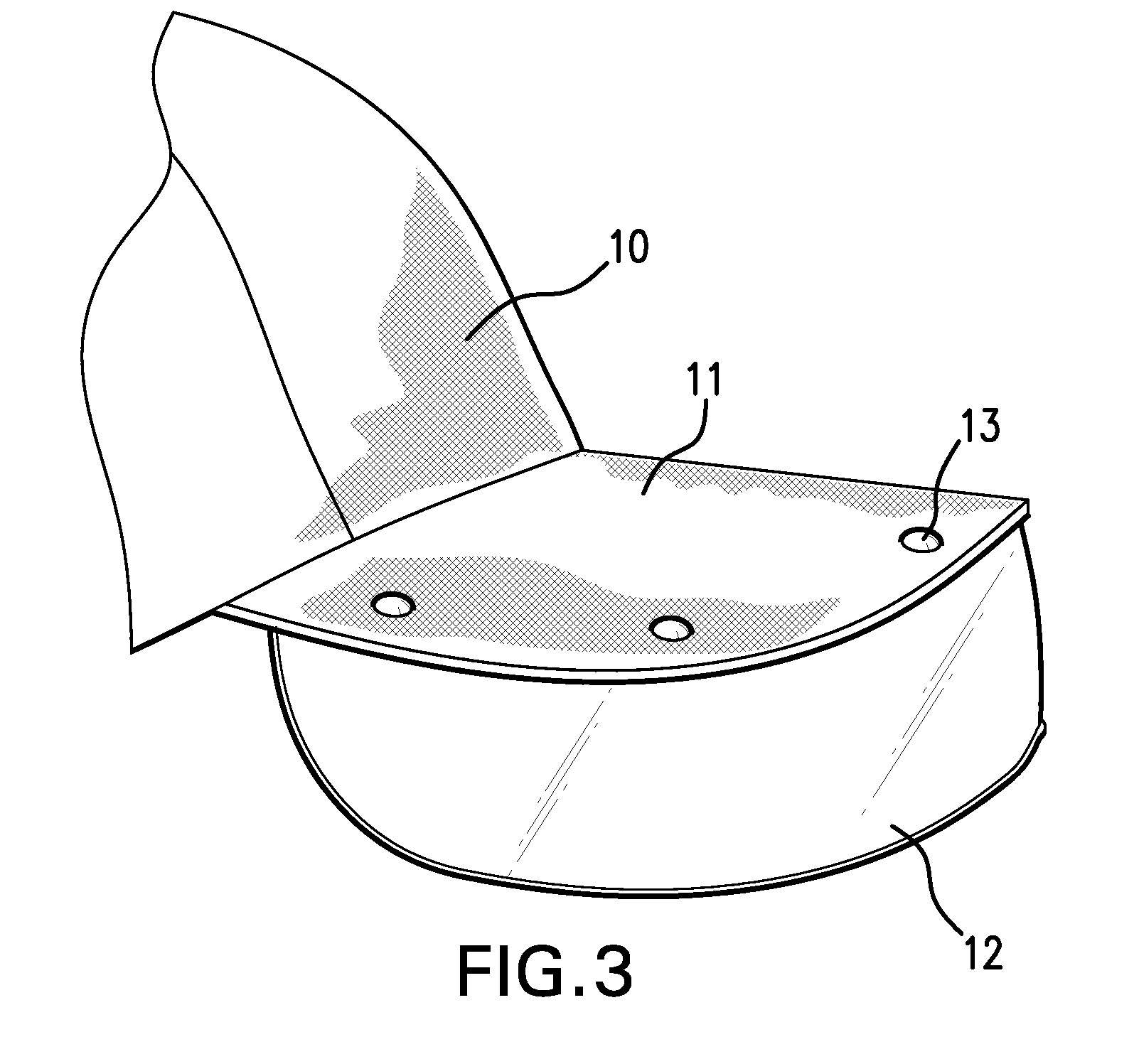

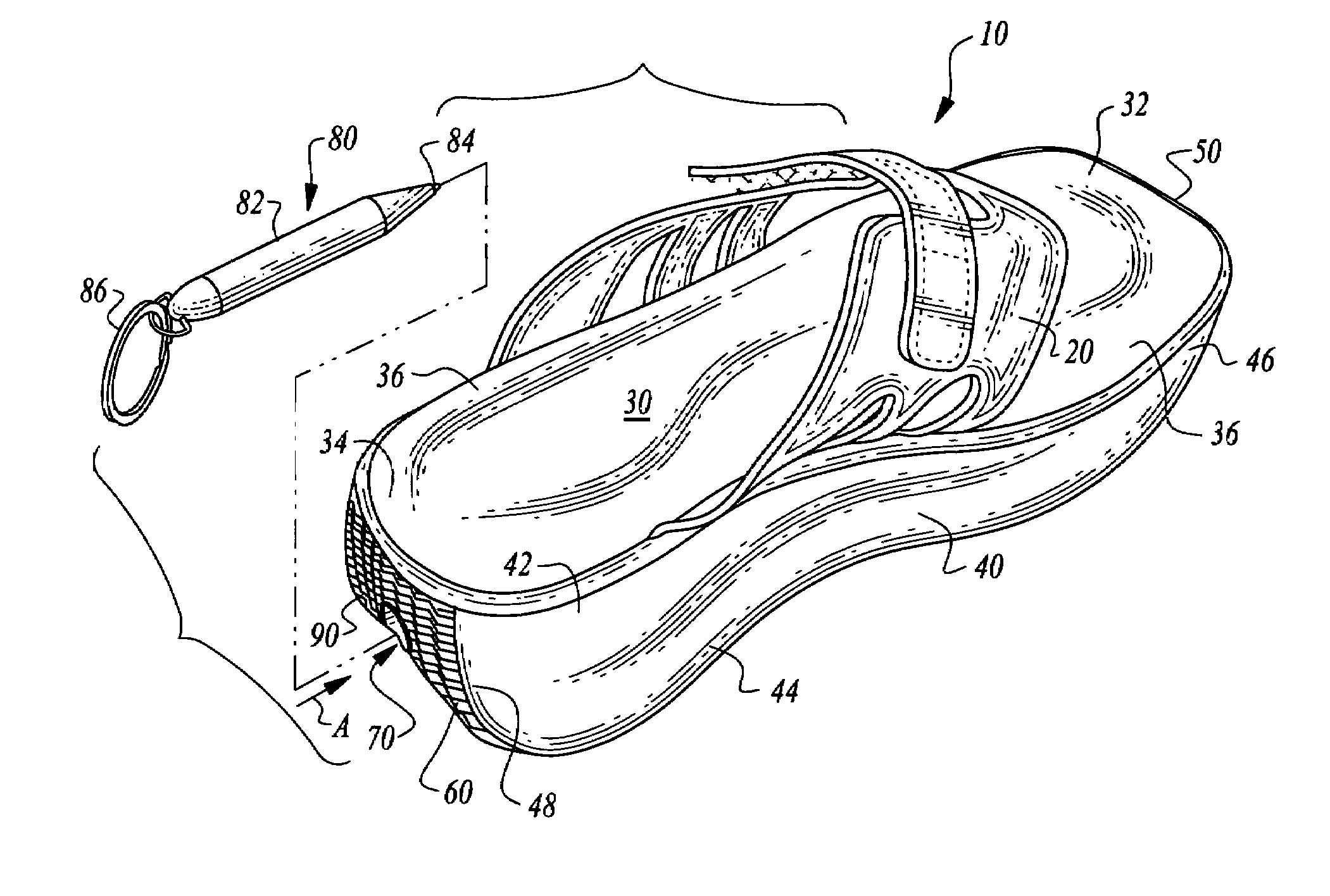

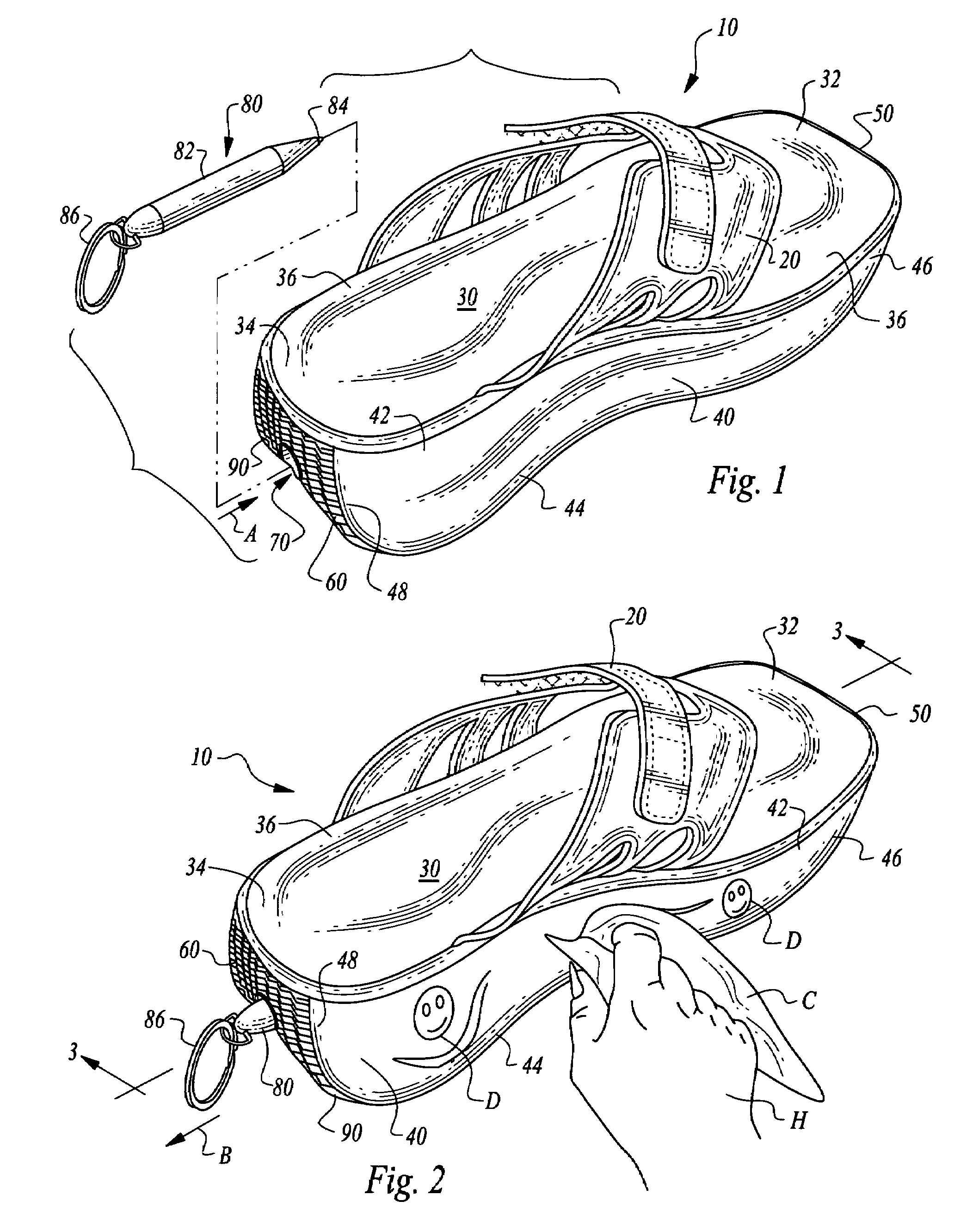

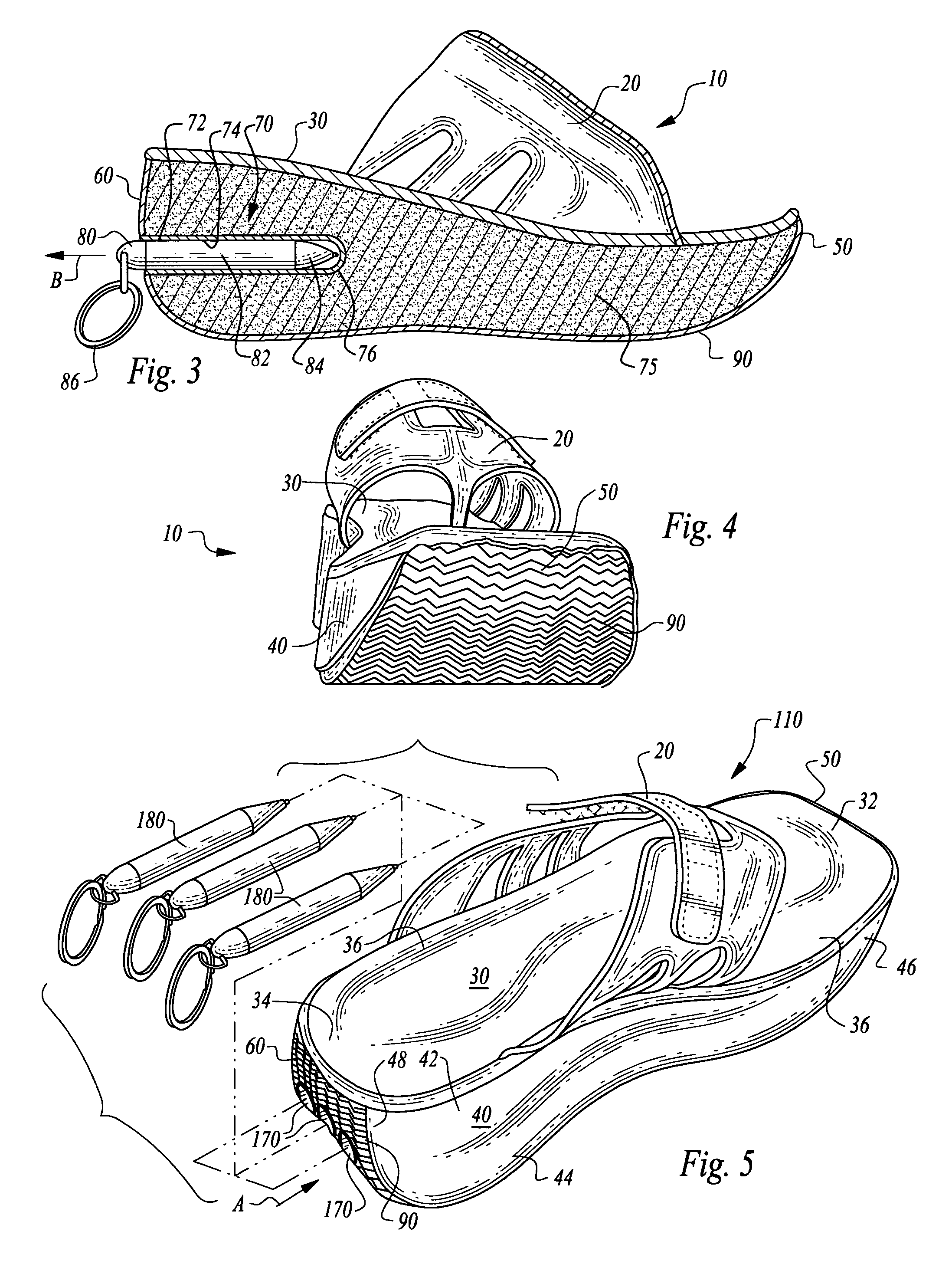

Shoe with writing surface

A shoe is provided with a writing surface so that temporary expressive indicia can be applied to the shoe. The writing surface is preferably in the form of a side surface of the shoe extending between a tread and a foot contacting surface of the shoe. The side surface is preferably formed of patent leather compatible with a dry erase marker provided as a writing implement. In a most preferred form of the invention, the shoe includes a bore which acts as a housing for the marker or other writing implement to conveniently store the writing implement when not in use. The bore or other housing also keeps the writing implement fresh by sealing the writing implement within the bore when not in use, especially when the writing implement is a dry erase marker.

Owner:MCKINNEY KELYE A +1

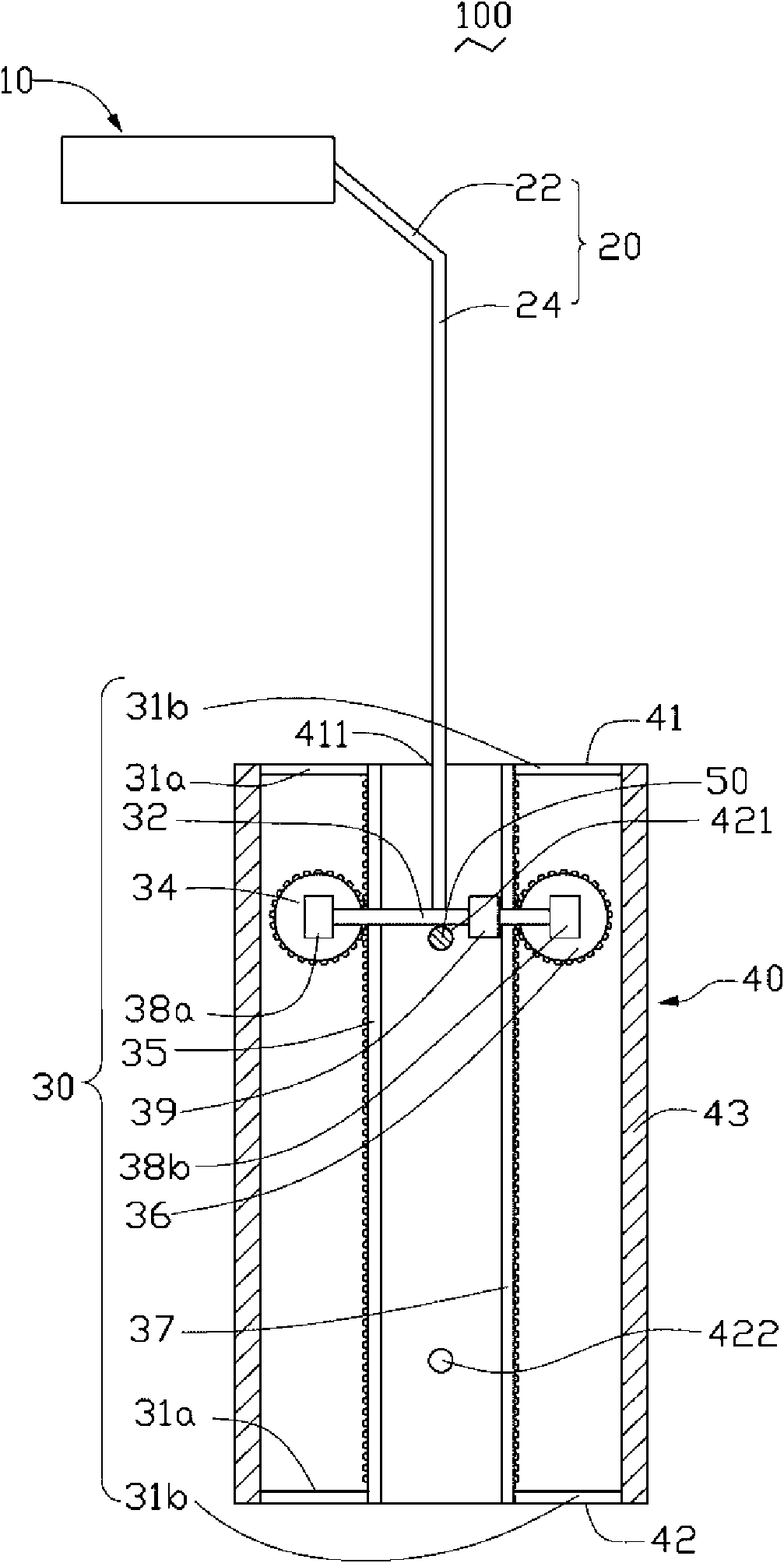

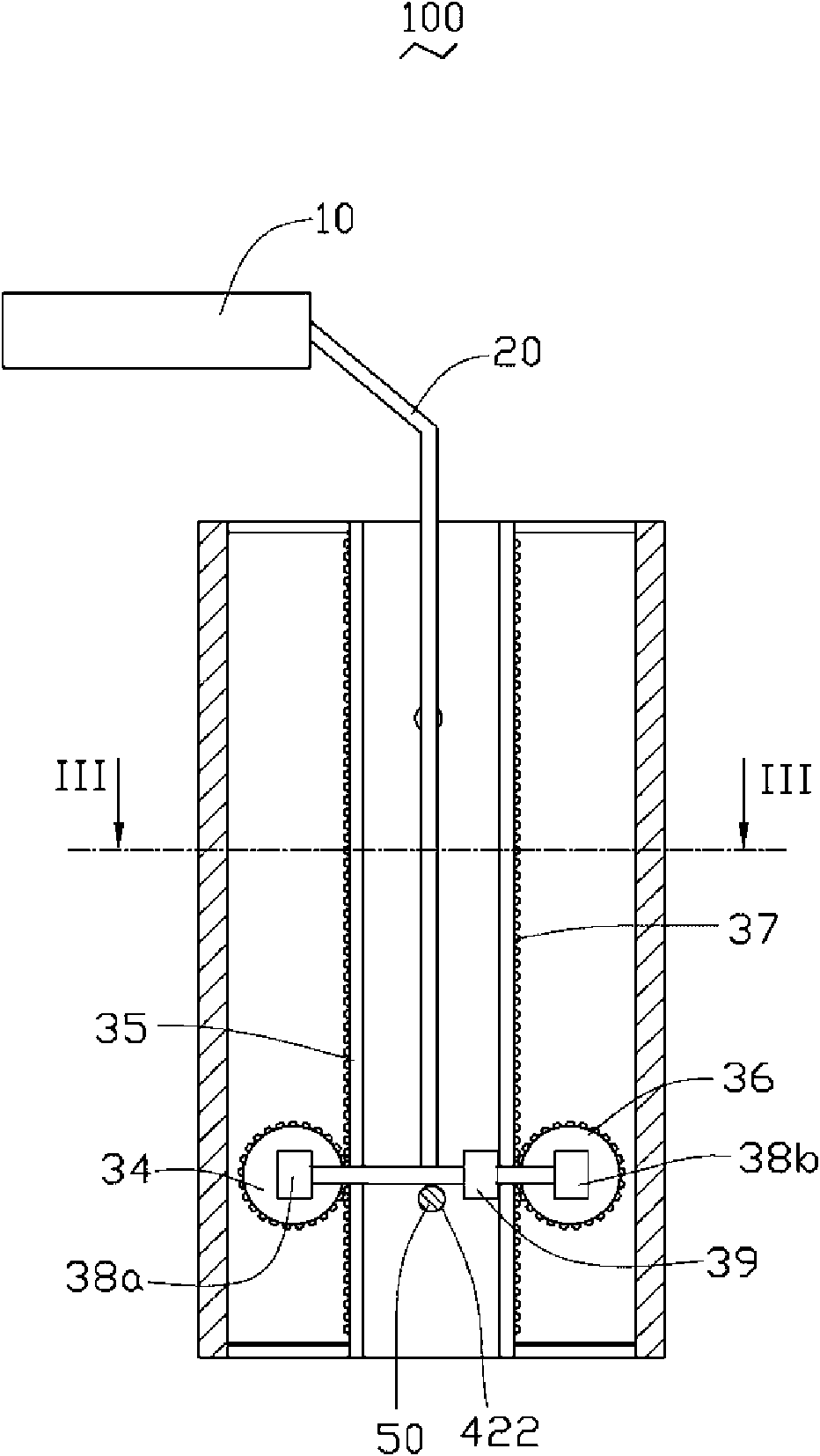

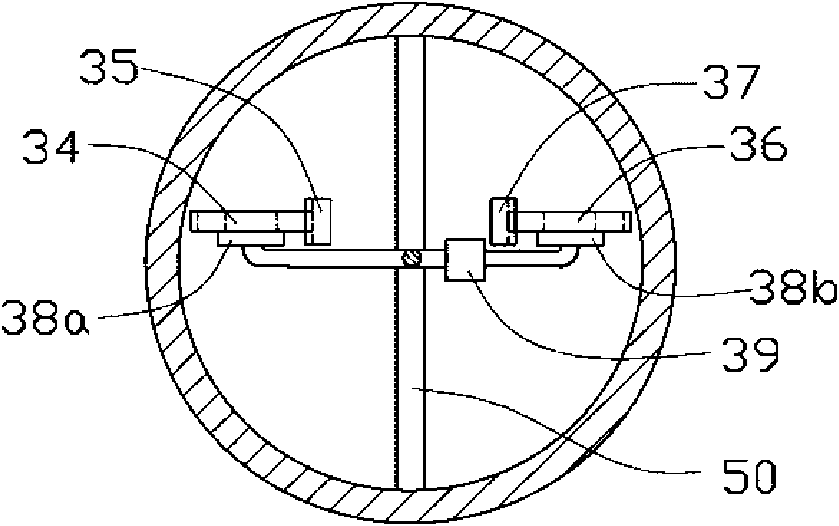

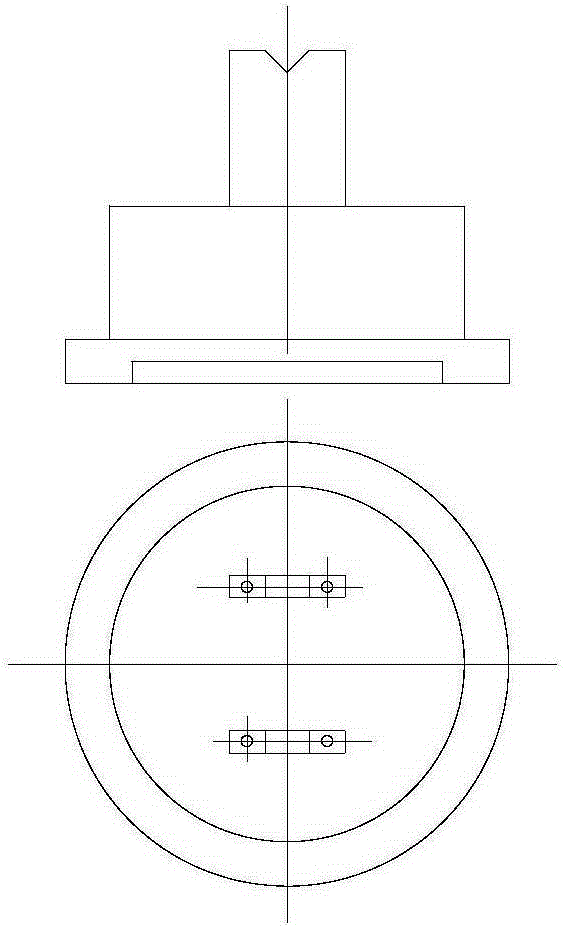

Street lamp with elevating function

InactiveCN101566295AAdjust the irradiation areaEasy to wipeMechanical apparatusPoint-like light sourceEngineeringHollow cylinder

The invention relates to a street lamp with the elevating function, which comprises a lamp, a base rod, an elevating system and an elevating rod, wherein the base rod is a hollow cylinder; the elevating system is positioned inside the base rod and comprises a first gear, a second gear, a first rack bar, a second rack bar and a connecting rod; the first gear and the second gear are fixed at both ends of the connecting rod respectively; the elevating system is meshed with the corresponding rack bar through the first gear and the second gear to achieve elevating; and the upper part of the elevating rod is connected with the lamp, while the lower part is connected to the elevating system and driven by the elevating system to move. The street lamp with the elevating function not only can conveniently wipe the lamps or can maintain the street lamp on the ground, has the advantages of time and labor saving and small labor intensity, but also can avoid danger of aerial work at the same time. The irradiation area of the street lamp can be easily adjusted.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Intelligent monitoring device with function of dust removal

InactiveCN107770489AWith dust removal functionEasy to moveTelevision system detailsFouling preventionDust controlStructural engineering

The invention discloses an intelligent monitoring device with the function of dust removal. The intelligent monitoring device with the function of dust removal comprises a machine body; a camera is fixed at the obverse side of the machine body; the obverse side of the camera is equipped with high definition glass; the left and right sides of the obverse side of the machine body are fixed with first fixed blocks and second fixed blocks; the first fixed block is located above the second fixed block; a sliding rod is fixed between the first fixed block and the second fixed block; the left and right sides of the sliding rod are fixed with limit bars. According to the invention, the sliding rods, the first fixed blocks, the second fixed blocks, the sliding blocks, grooves and the limit bars areset up to make the sliding blocks slide up and down on the sliding rods, and a dust removing cylinder on the sliding blocks can move up and down. The grooves are clamped on the limit bars, so that the sliding blocks move more stably; and a dust removal brush scrubs the camera and the high definition glass, therefore, the camera is clearer when videotaping, and the camera can work properly.

Owner:HENAN HAOWEI INTELLIGENT TECH CO LTD

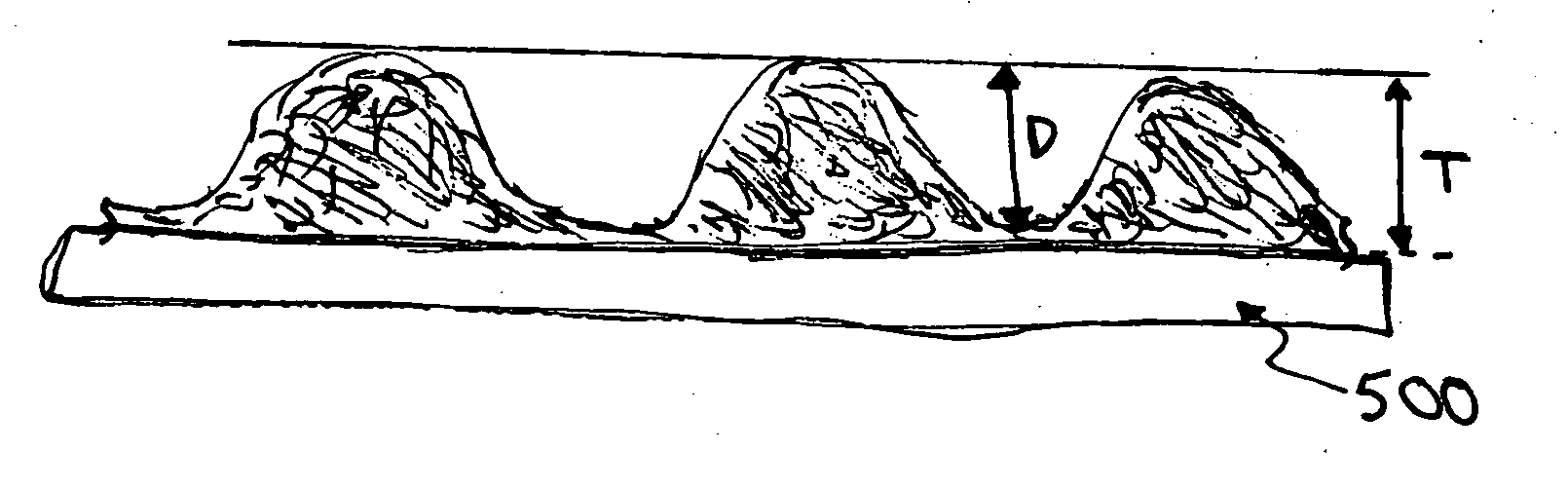

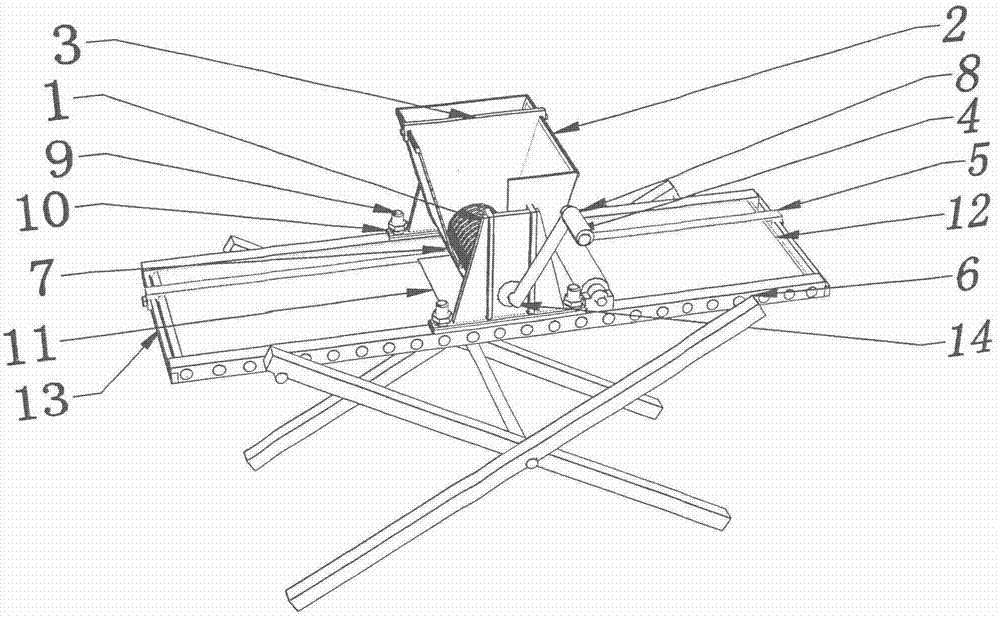

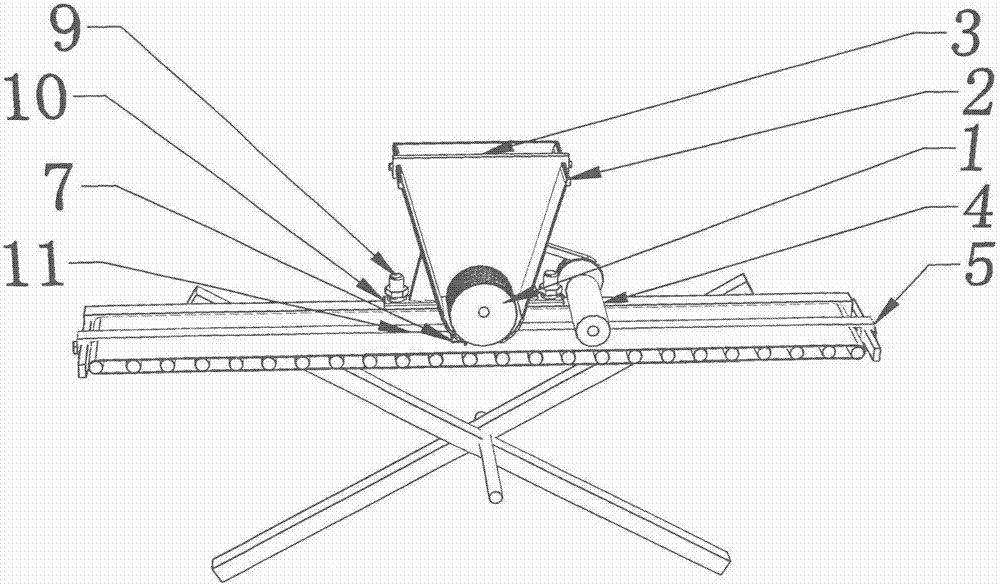

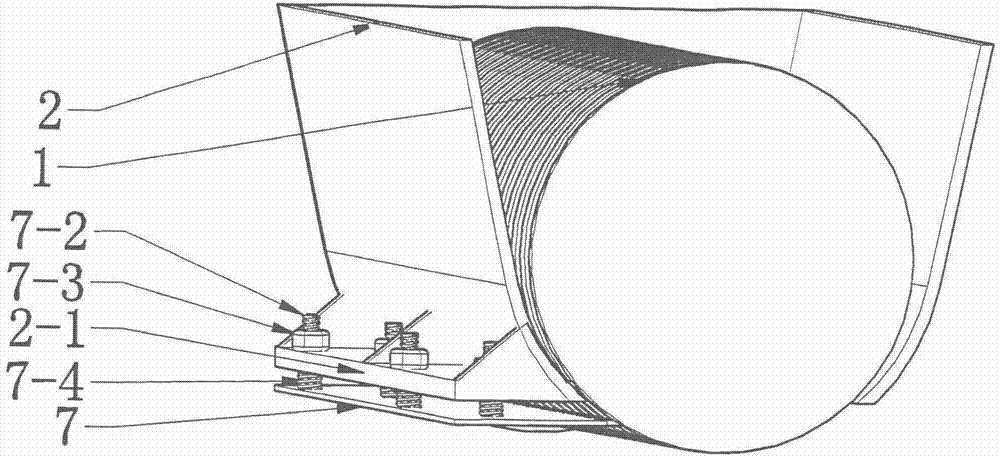

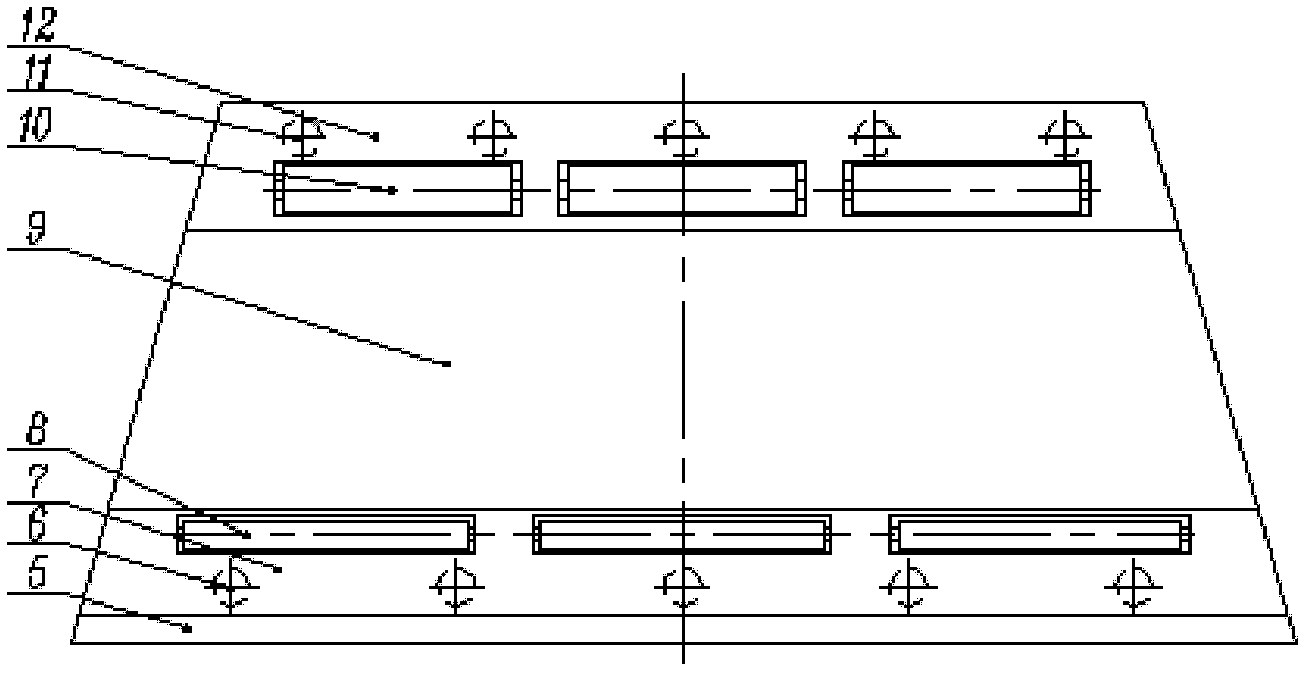

Tile plastering machine

The invention discloses a ceramic tile applying machine, the purpose of which is to use machinery instead of manual application of adhesives on tiles, saving time and labor, thin and uniform application, saving adhesives and room space, tiles are easy to paste flat, and Empty drums are not easy to occur, and the present invention is mainly composed of a tile conveying platform, an ash hopper, an ash roller, an ash shovel and a power system. The tile conveyor table is mainly used to transport tiles and place ash buckets. The ash bucket is a container with openings on both sides. The ash roll is a garden column with multiple parallel grooves on the surface. The grooves of the ash roll are called ash grooves, and the ash roll is flat. Put it in the lower part of the ash hopper, seal the lower opening of the ash hopper, there is a power shaft in the center of the ash roller shaft, the ash roller can rotate around the power shaft under the action of external force, the ash shovel has shovel teeth, the number of shovel teeth is equal to the number of ash slots, and the extension Put the tiles into the ash tank, put the tiles on the tile conveyor table, push them under the ash roller, the external force makes the ash roller rotate, and the tiles are driven forward by the friction force, when the ash roller rotates, the shovel teeth scoop out the adhesive in the ash groove And spread it on the tiles in strips.

Owner:王勇

Coloring agent for woodenware and its production process

The present invention relates to furniture coloring technology, and is especially one kind of coloring agent for woodenware and its production process. The production process includes: dissolving the main resin in solvent through slow stirring, adding required pigment and proper amount of additive through stirring in a stirrer, grinding, and adding required stuffing via stirring. The woodenware coloring agent is used to color woodenware through painting and rubbing.

Owner:东莞大宝化工制品有限公司

Makeup device including a wiper

InactiveUS20090065019A1Easy to wipeEfficient use ofBrushesPackaging toiletriesBiomedical engineeringBellows

Owner:CHANEL PARFUMS BEAUTE SAS

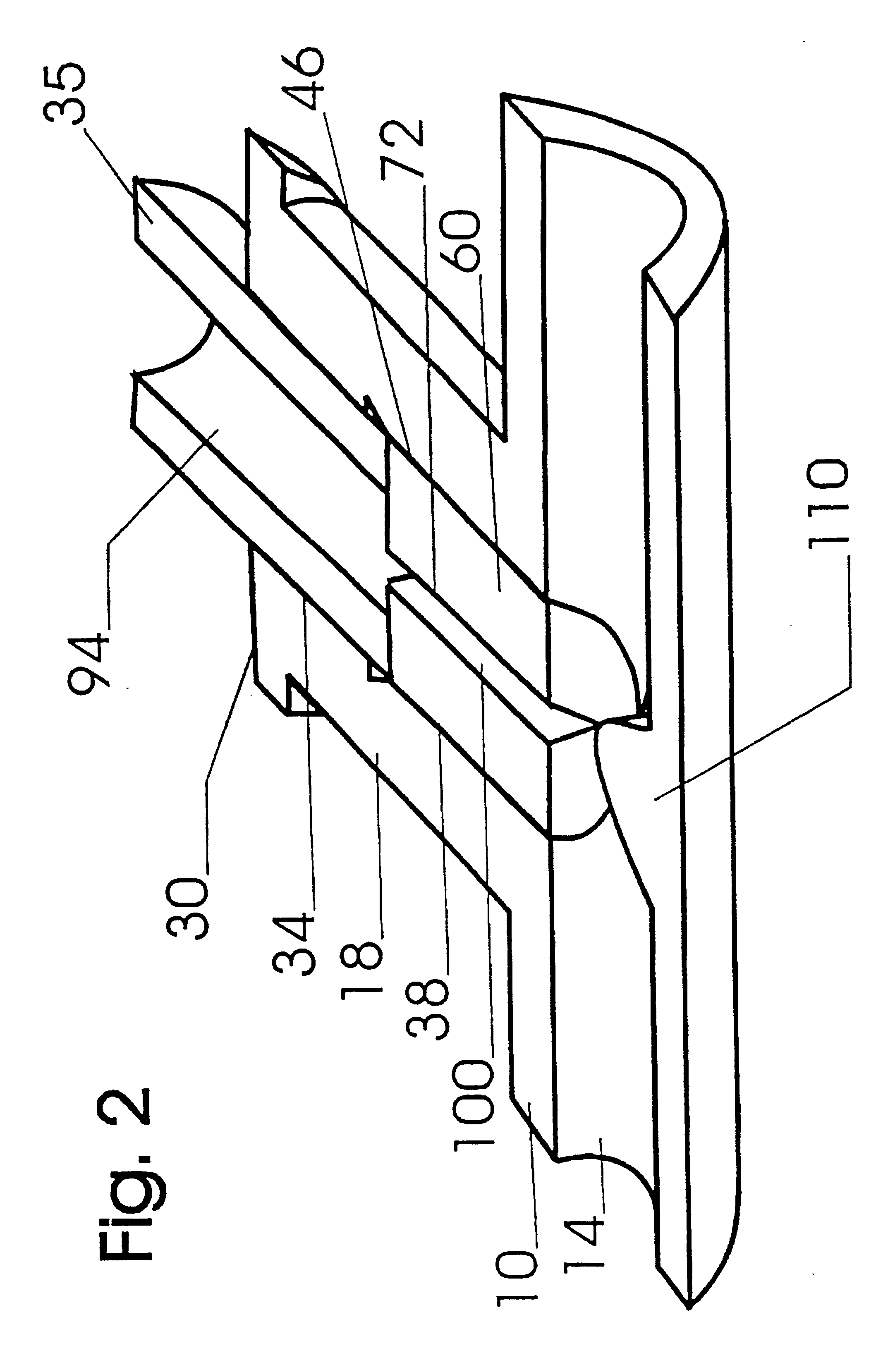

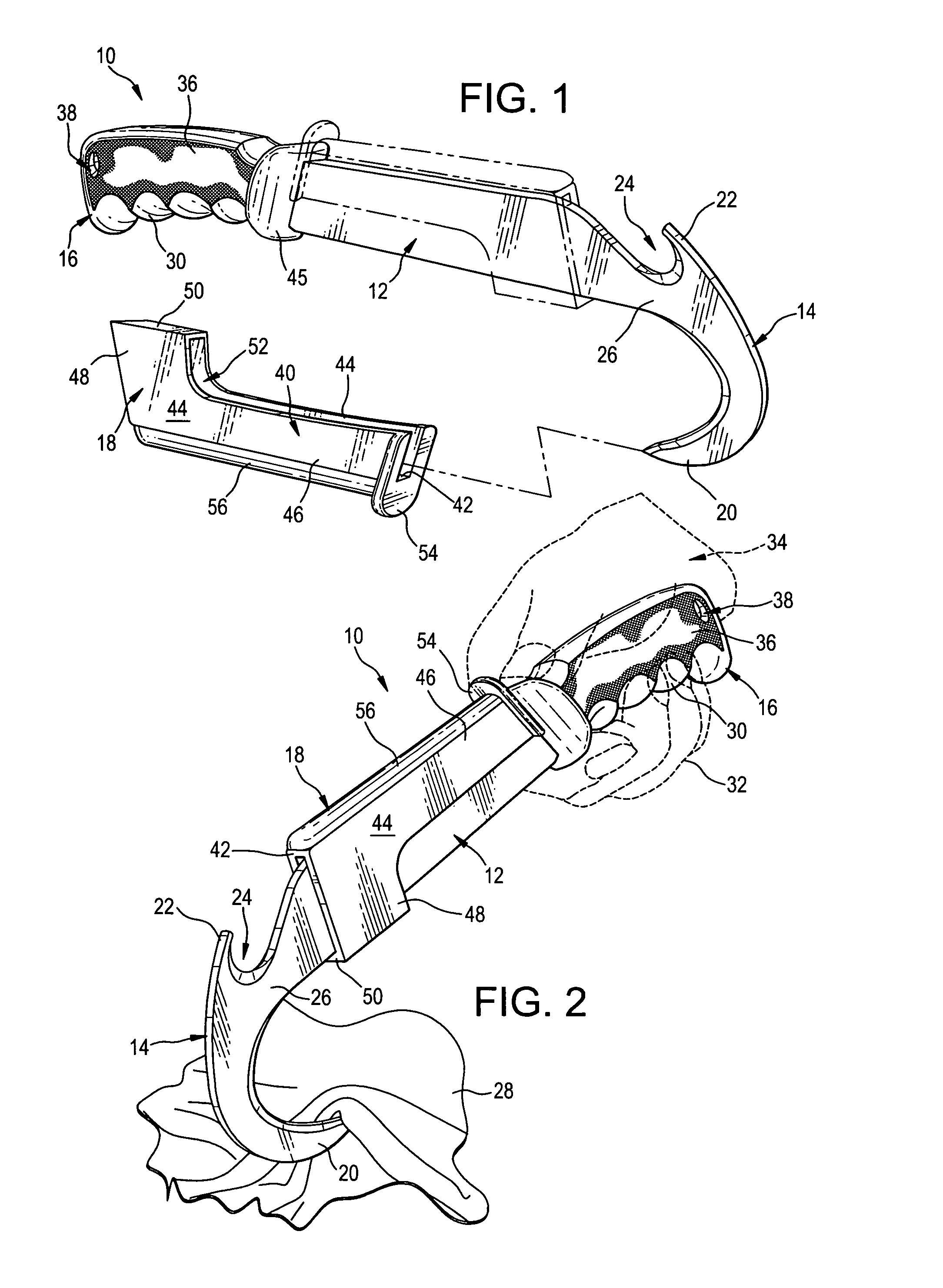

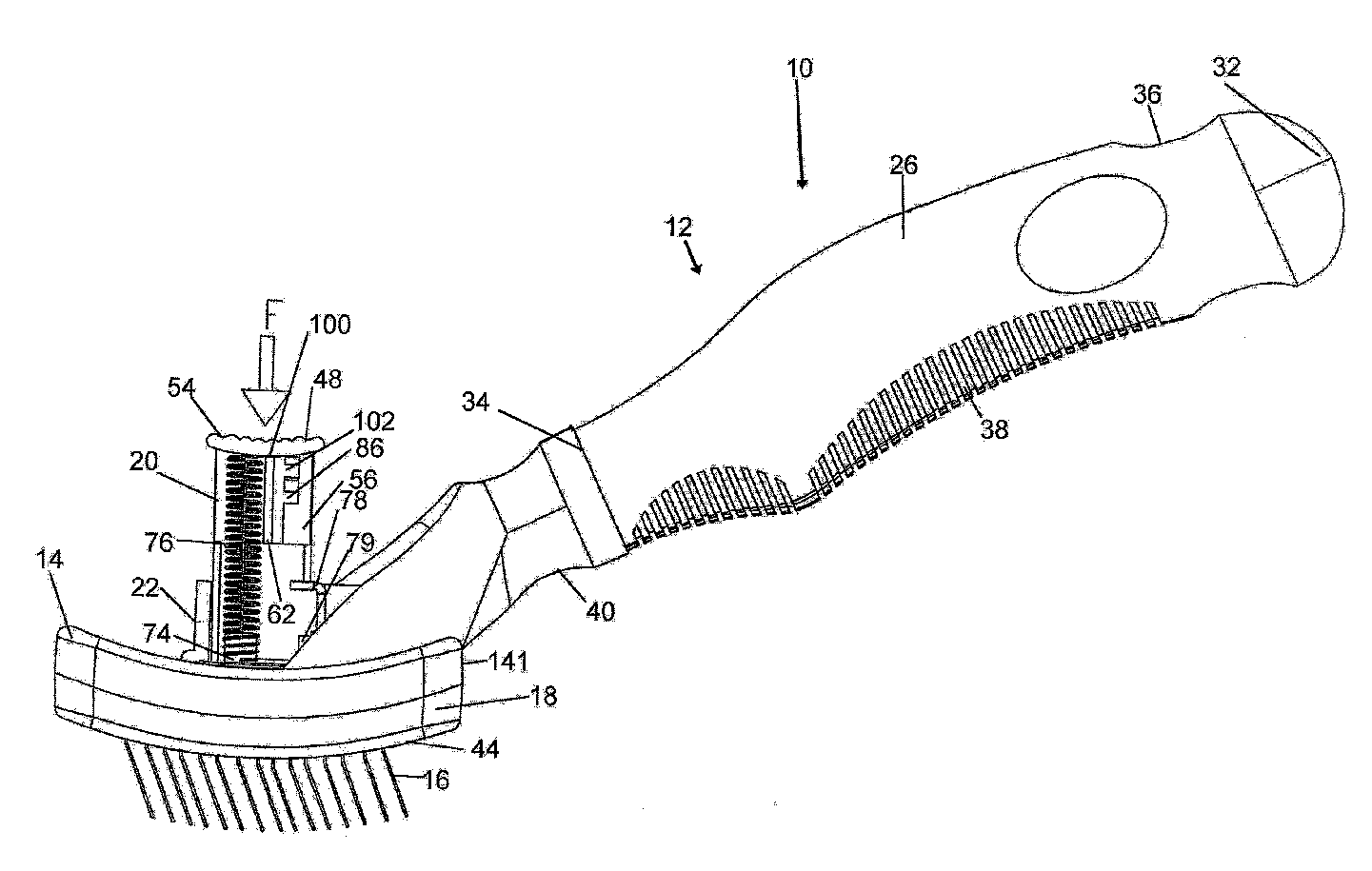

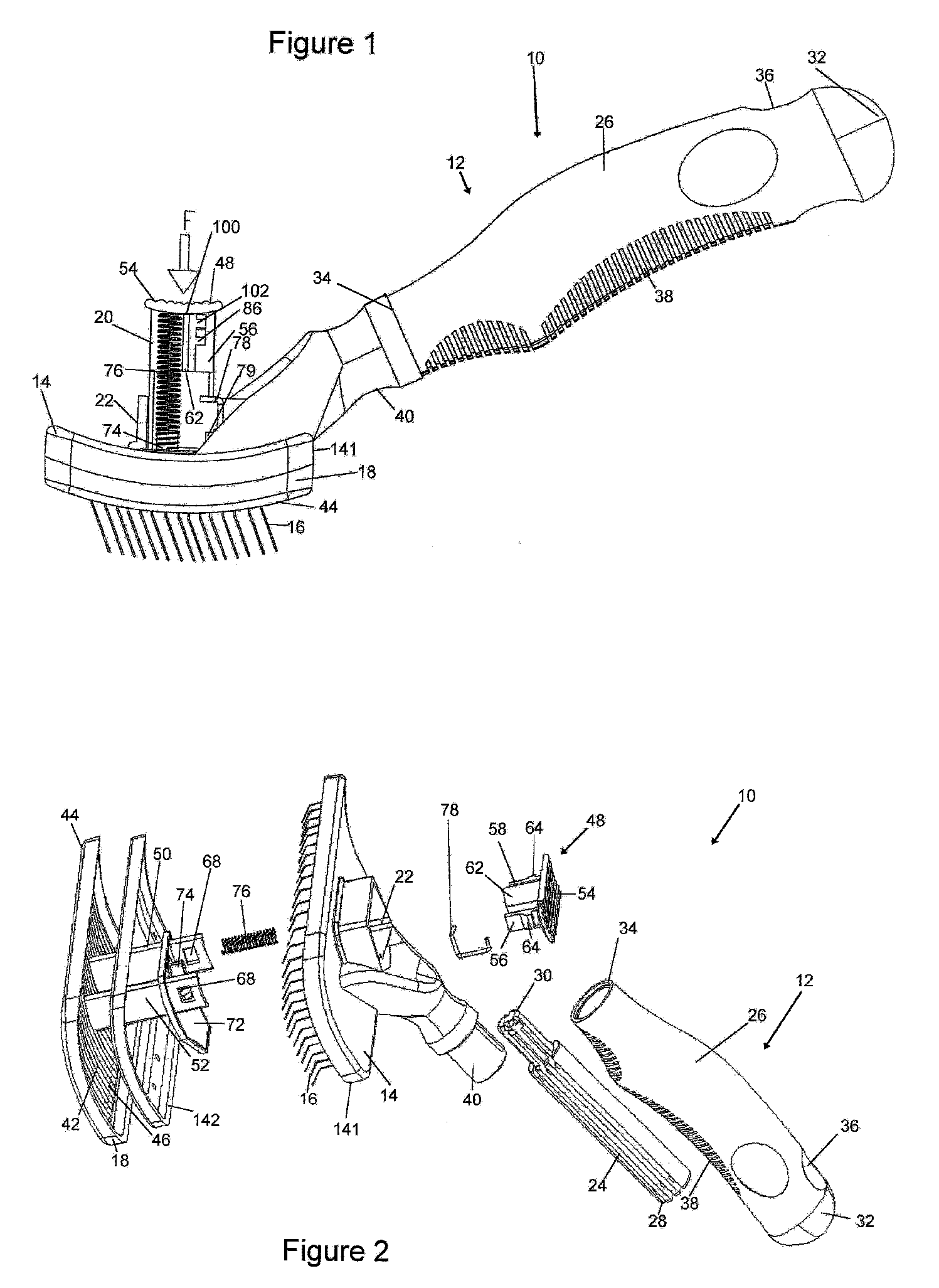

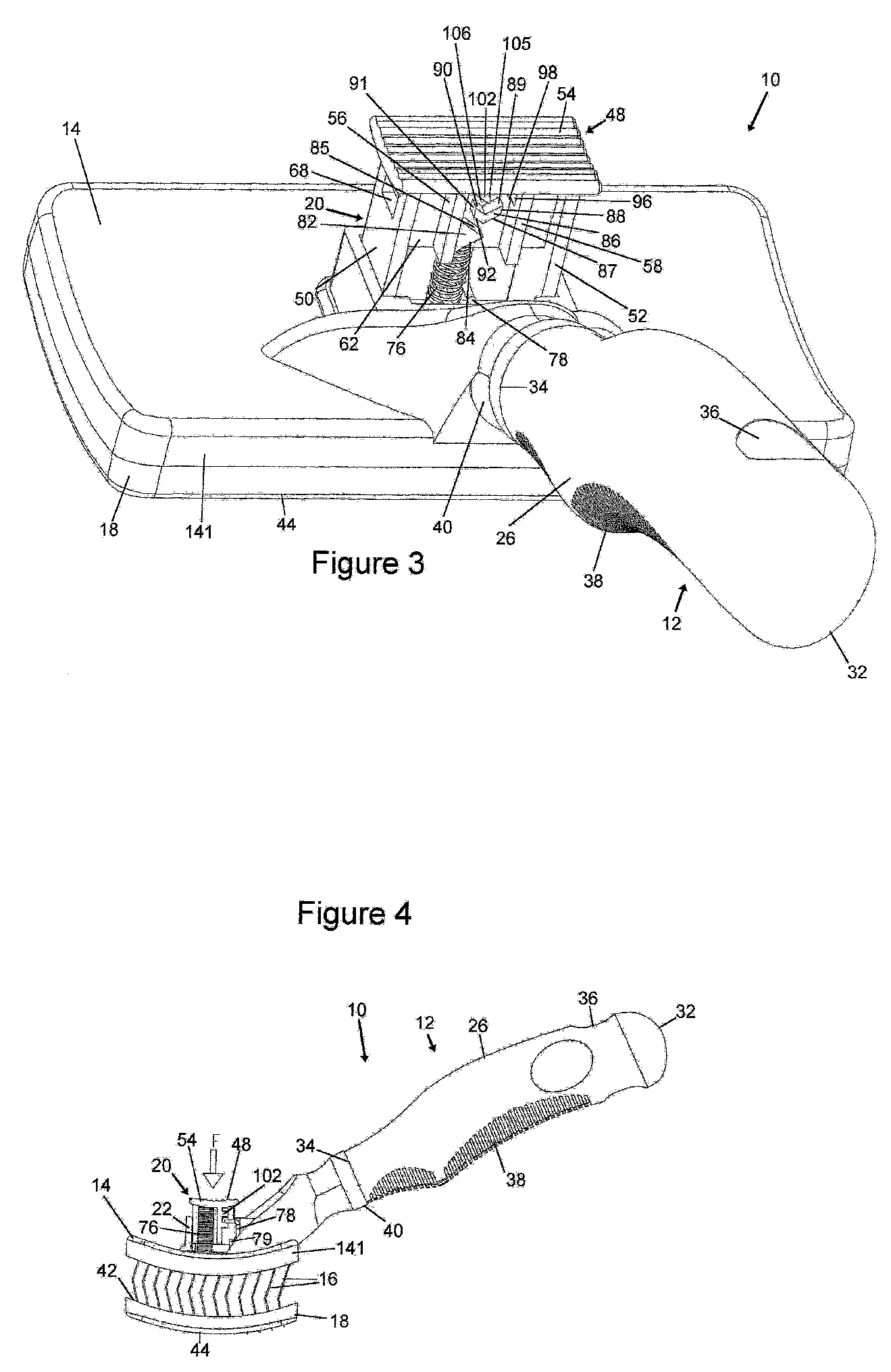

Self-cleaning hair brush

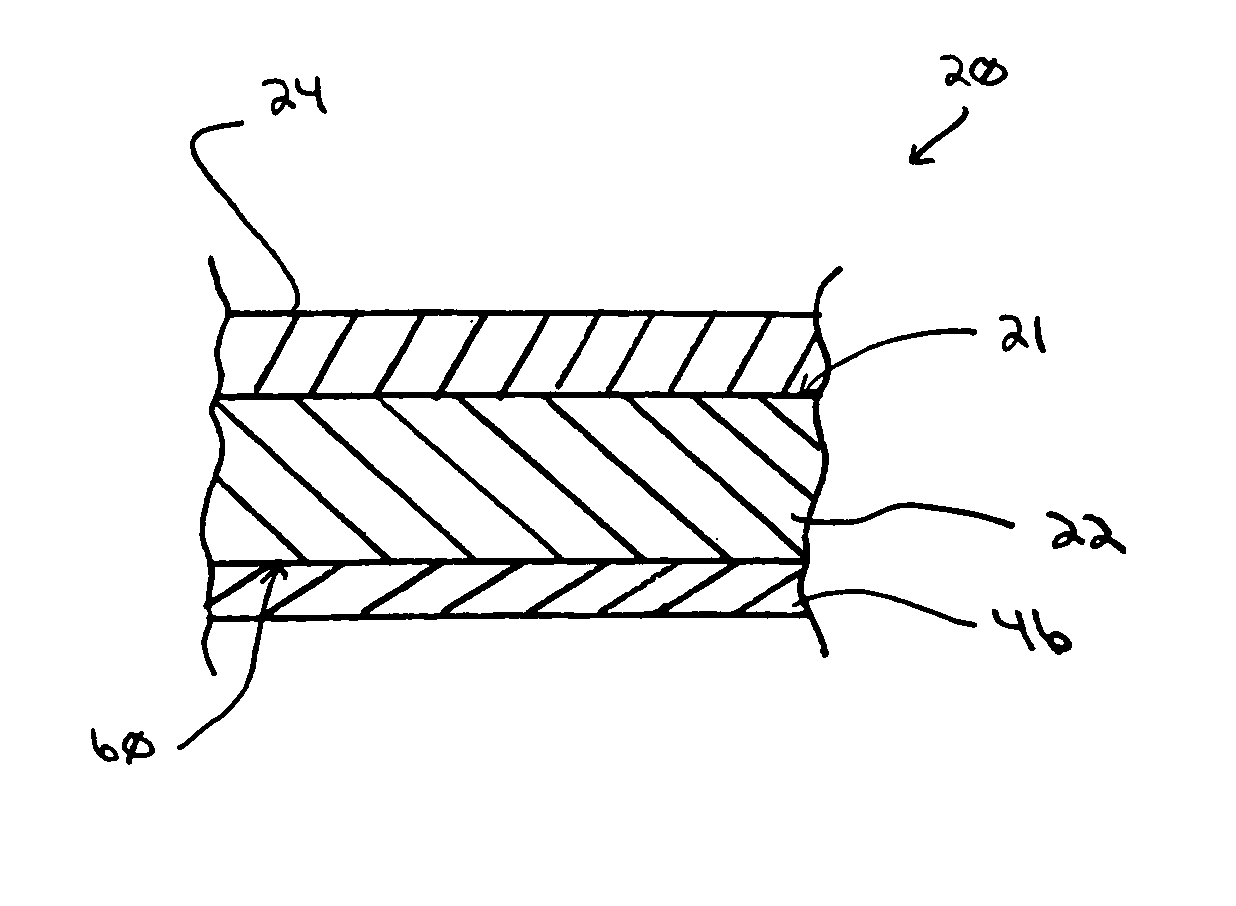

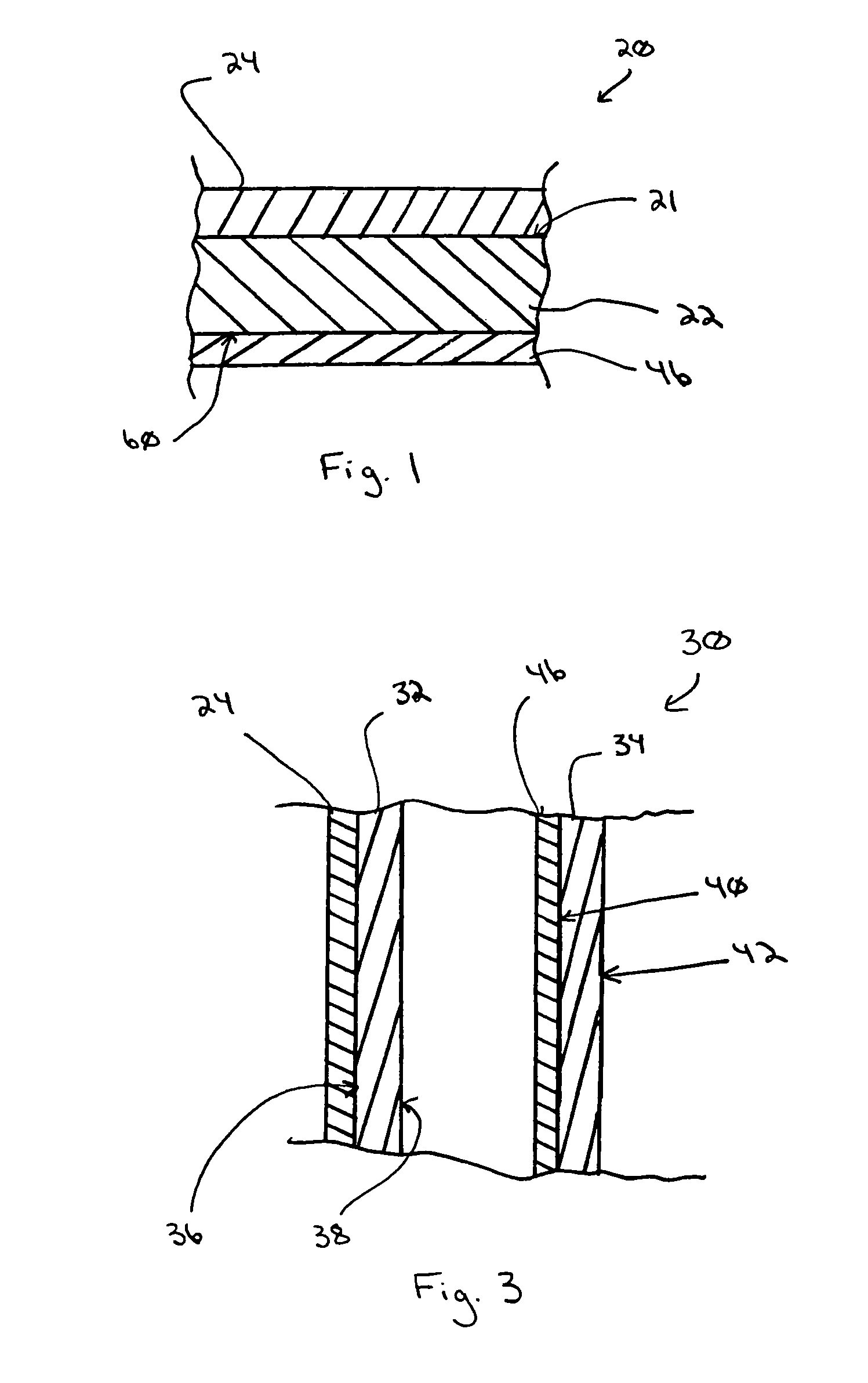

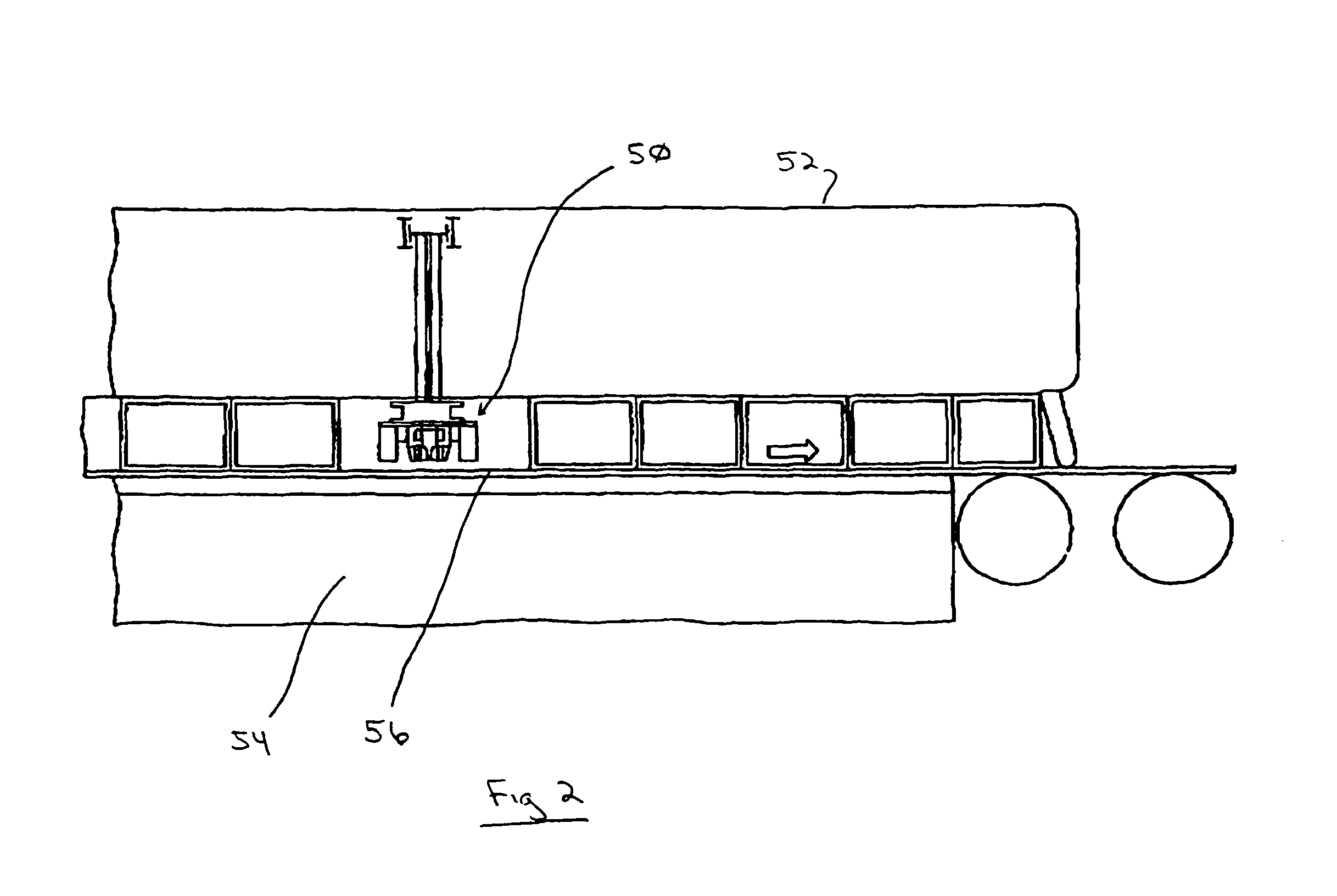

A self cleaning hair brush includes a handle (12), a bristle-holding head (14) having a plurality of spaced-apart bristles (16) projecting laterally therefrom, and a combing plate (18) having a plurality of bristle-receiving apertures (46). When the combing plate (18) is in a first position, the combing plate (18) closely overlies the side of the bristle-holding head (14) from which the bristles (16) project allowing the bristles (16) to project through the apertures (46). The bristle-holding head (14) further includes a rectangular tube (22) disposed on a central portion of the bristle-holding head (14). A reciprocally movable plunger (20) is mounted in the rectangular tube (22). The plunger (20) is used to displace the combing plate (18) to a second position where the combing plate (18) is disposed at a free end of the bristles (16). The reciprocally movable plunger (20) includes a pivotable latching pin (78) for automatically locking the plunger (20) into an intermediate position between the first and second positions.

Owner:KUNG SHIN SHENG

Beverage can marketing device

InactiveUS8534490B2Reduce and inhibit collection of debrisReduce capacityVenting meansLarge containersEngineering

Owner:CHAPIN BARRY W

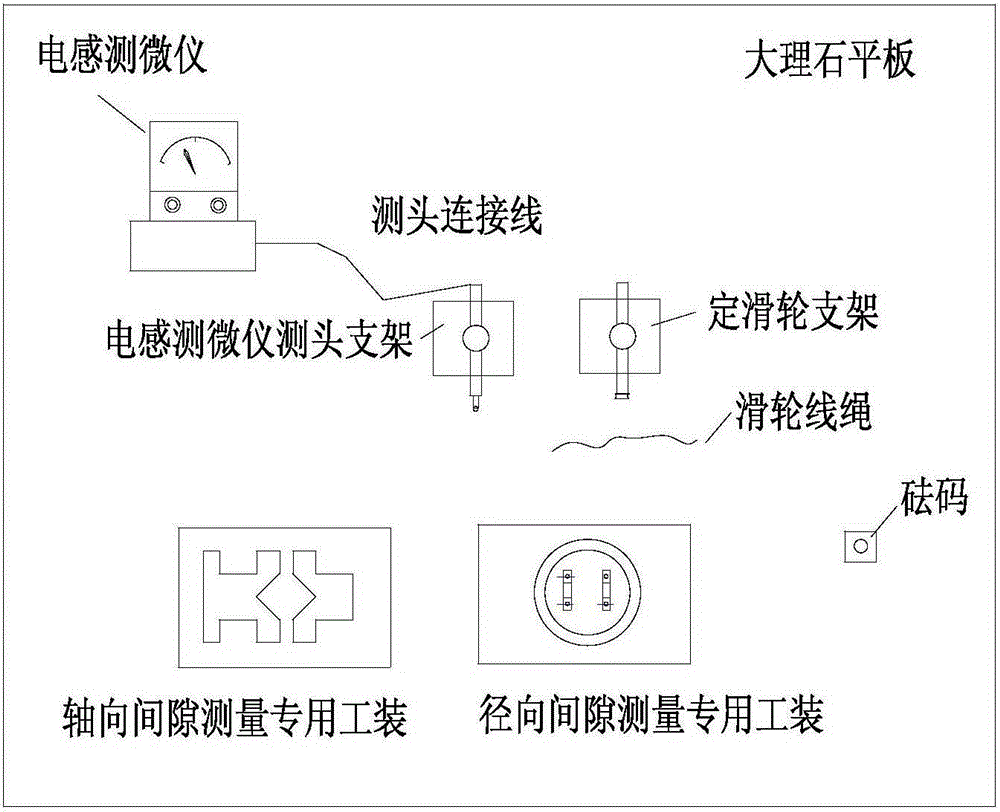

Semi-spherical dynamic pressure motor bearing gap measuring device and method

The invention relates to the technical field of aerospace inertial component precision detection, in particular to a semi-spherical dynamic pressure motor bearing gap measuring device and method. The device comprises an inductance amesdial, a marble flat plate, an inductance amesdial measuring head, a special axial gap measuring tool, a special radial gap measuring tool, a measuring head connection line, a pulley line rope, a fixed pulley, a fixed pulley support, an inductance amesdial measuring head support and weights. The method is short in detection time, high in detection precision, high in practicality and capable of being widely used in scientific research and production.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

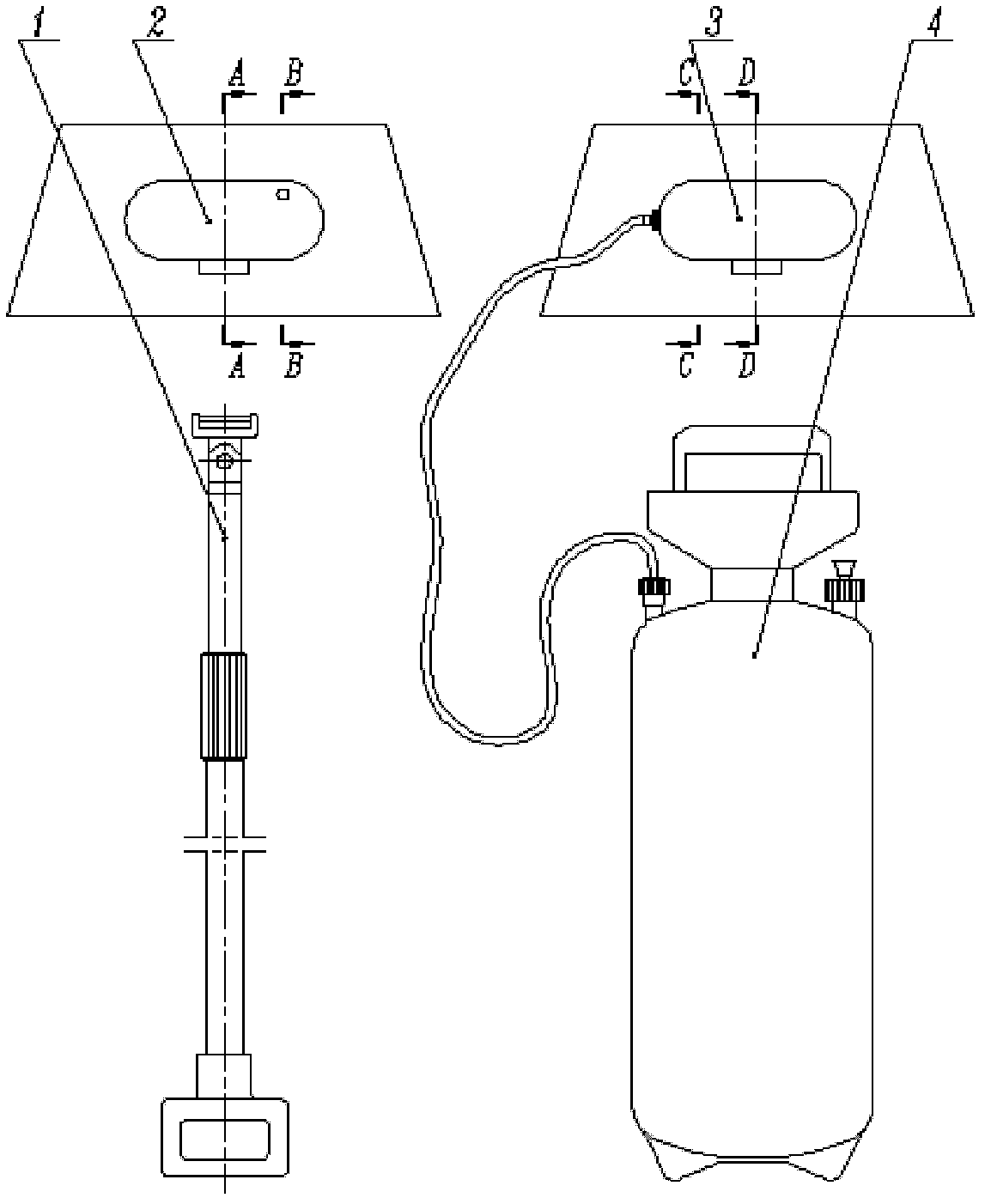

Magnetic attraction type glass cleaner

InactiveCN102319039AHas self-cleaning abilityAvoid the hassle of changing waterWindow cleanersInter layerElectrical and Electronics engineering

The invention relates to a magnetic attraction type glass cleaner. According to the technical scheme of the invention, a glass wiper comprises an lengthening rod (1), an internal wiper body (2), an external wiper body (3) and a manual spraying barrel (4), wherein an water outlet of the manual spraying barrel (4) is connected with the external wiper body (3) through a flexible pipe. An external side face of an internal wiper body interlayer (13) is provided with 3-10 first magnetic substances (6), 2-10 first rollers (10), internal wiper body wiping cloth (9), 2-10 second rollers (8), 3-10 second magnetic substances (6) and an internal wiper body scraping plate (5) in sequence from top to bottom; the external side face of an external wiper body interlayer (36) is provided with 3-10 third magnetic substances (34), 2-10 third rollers (33), a strip-shaped groove (30), external wiper body wiping cloth (29), a fourth roller (28), a fourth magnetic substance (26) and an external wiper body scraping plate (25) in sequence from top to bottom, wherein the trip-shaped groove (30) is provided with a spraying control device (32) and 1-7 atomizing nozzles (31). The magnetic attraction type glasscleaner is convenient to use, and the wiper bodies cannot drop easily; and the magnetic attraction type glass cleaner has excellent scrubbing effect, and is suitable for scrubbing glass with different cambered surfaces.

Owner:涂超群

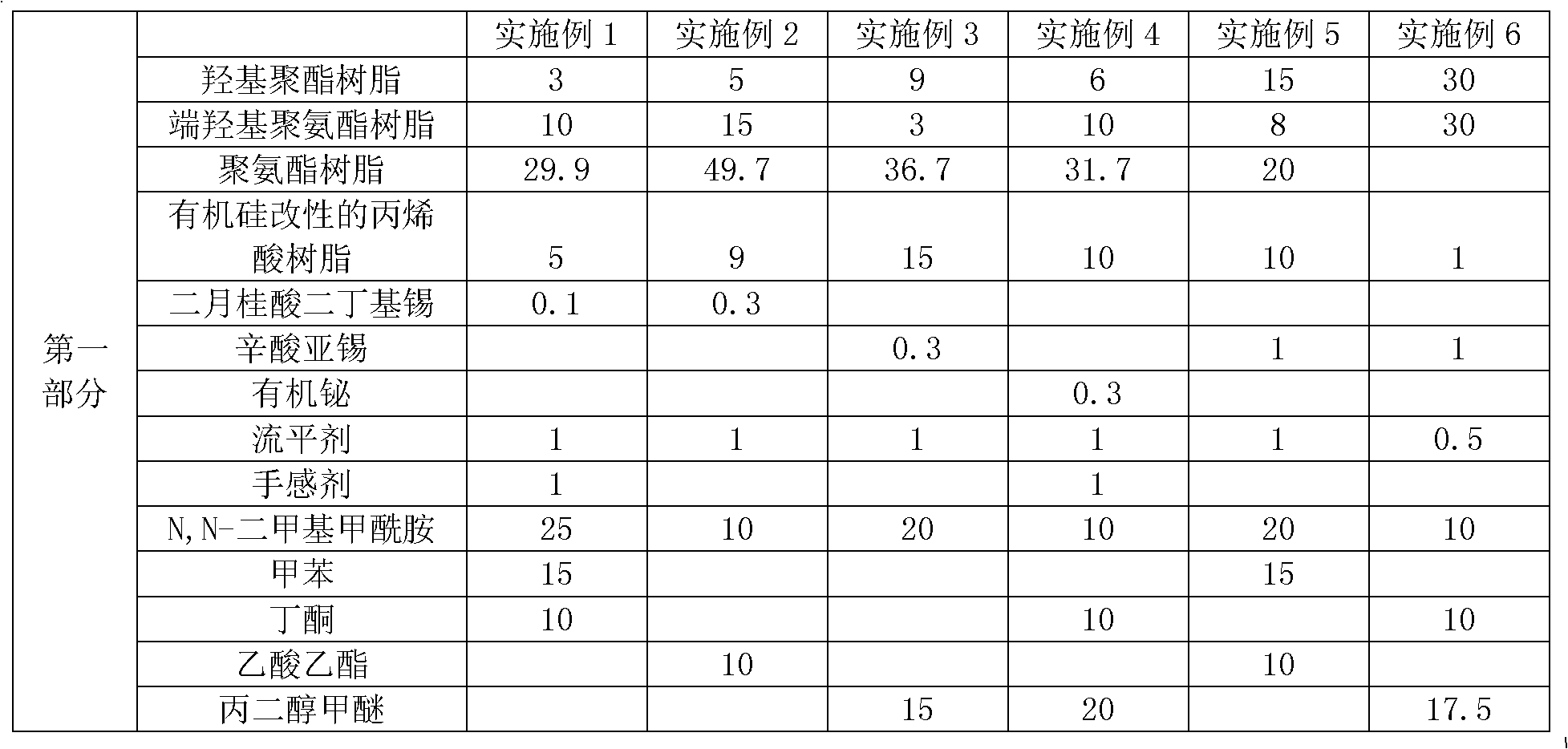

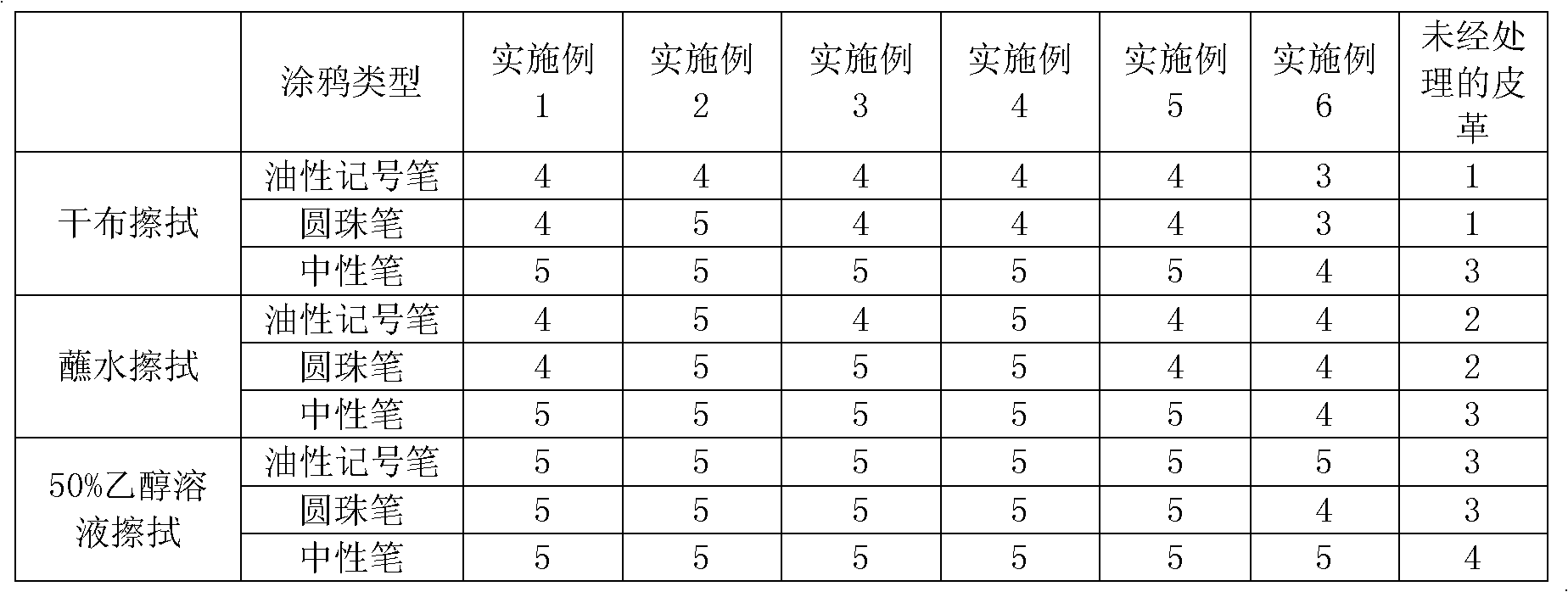

Anti-graffito leather finishing agent and using method thereof

ActiveCN102146260AImprove protectionGood lookingPolyurea/polyurethane coatingsLeather surface finishingAcrylic resinPolyester resin

The invention designs an anti-graffito leather finishing agent and a using method thereof, relates to the field of leather surface treatment, and solves the technical problem of undesirable anti-graffito effect of the conventional leather. The finishing agent is characterized by consisting of two parts which are stored separately, wherein the first part comprises the following raw material components in percentage by mass: 3 to 30 percent of hydroxyl polyester resin, 3 to 30 percent of hydroxyl-terminated polyurethane resin, 0 to 50 percent of polyurethane resin, 1 to 15 percent of organosilicon-modified acrylic resin, 0.1 to 1 percent of catalyst, 0.5 to 5 percent of aid and the balance of solvent; and the second part is a polyisocyanate curing agent in a molar amount which is 1 to 1.05 times that of hydroxyl in the first part. When the finishing agent is used for treating the surface of leather, the pollution to leather products in use by graffito is relieved effectively, graffito traces can be cleaned easily, and the good appearance of leather is restored.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com