Magnetic attraction type glass cleaner

A cleaner and magnetic suction technology, applied in the field of glass wipes, can solve the problems of no self-cleaning ability, harsh noise, and laborious scrubbing, so as to avoid the trouble of changing water, reduce sliding resistance, and ensure the effect of scrubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

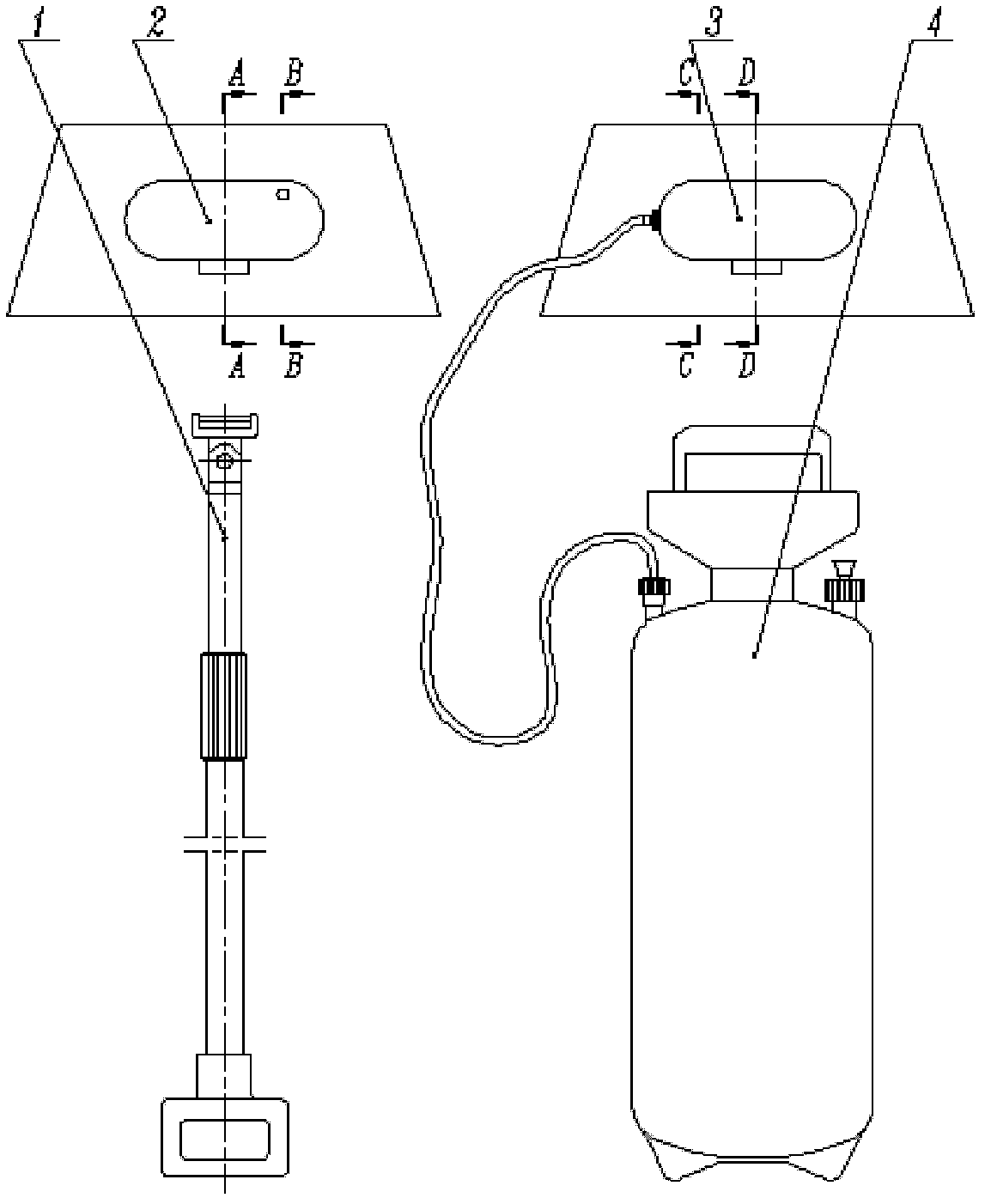

[0050] A magnetic suction type glass cleaner. Its structure and parts in use such as figure 1 Shown: including extension rod 1, inner wiper 2, outer wiper 3 and manual spray barrel 4, the water outlet of manual spray barrel 4 is connected with outer wiper 3 through a hose.

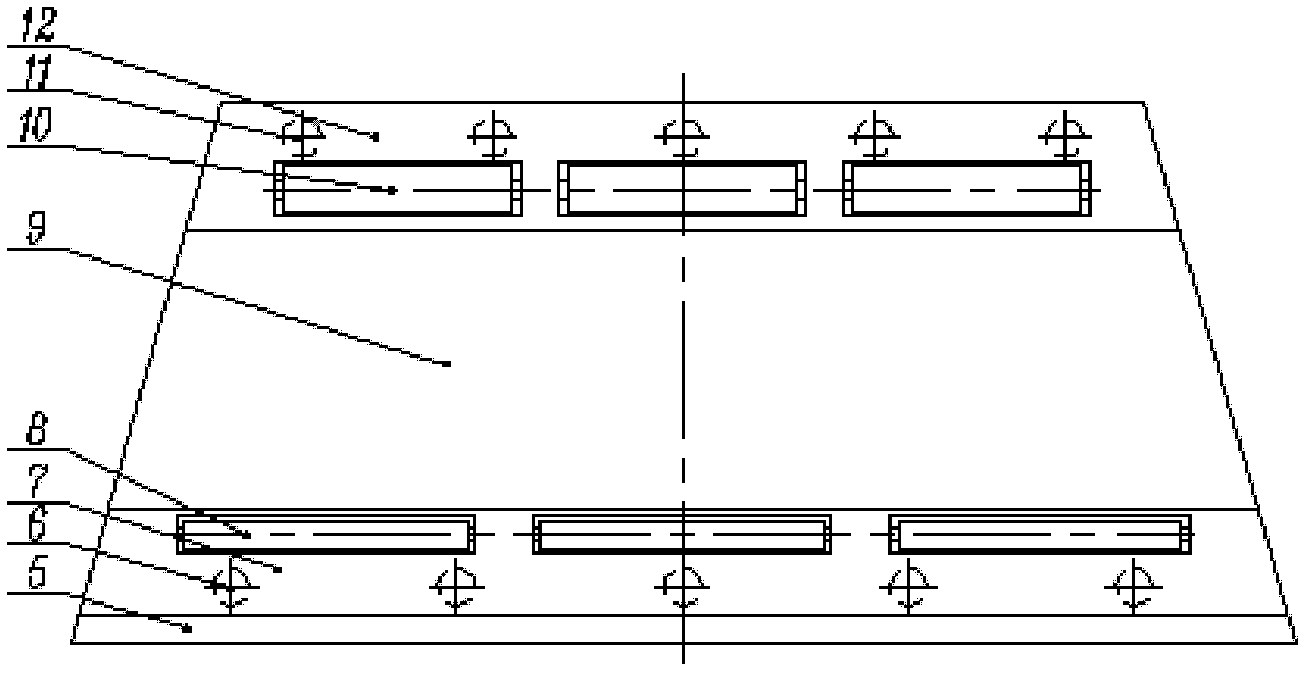

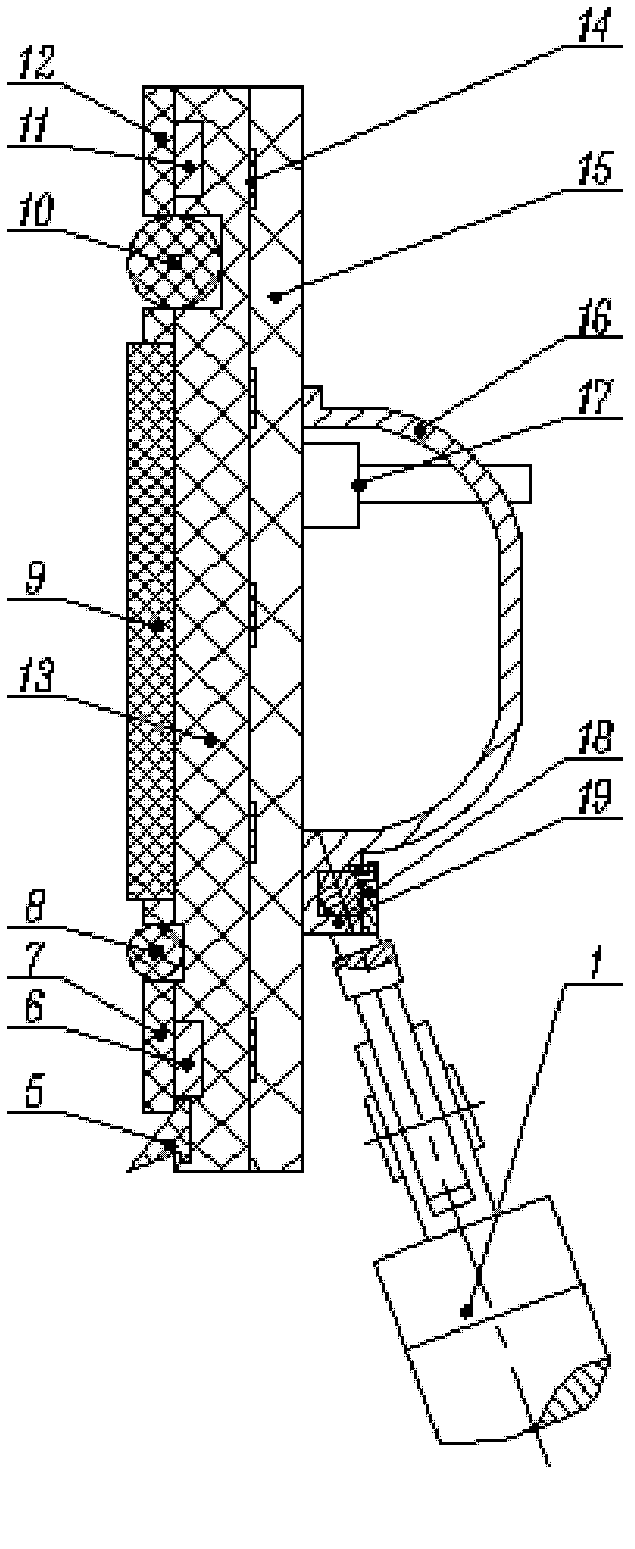

[0051] The structure of the internal friction body 2 is: the external shape of the internal friction body intermediate layer 13 and the internal friction body 15 is as follows: figure 2 As shown, all are trapezoids, let the short side of the trapezoid be up, and the long side of the trapezoid be down, figure 2 The left side of is the left side of the trapezoid, figure 2 The right side of is the right side of the trapezoid. The inner surface of the inner friction body intermediate layer 13 is bonded with the inner surface of the inner friction outer layer 15, and the inner surface of the inner friction outer layer 15 is evenly embedded with five inner friction body elastic steel strips 14.

[0052] S...

Embodiment 2

[0075] A magnetic suction type glass cleaner. The inner surface of the inner friction body intermediate layer 13 or the inner surface of the inner friction outer layer 15 are not embedded with inner friction body elastic steel bars 14, and the inner surface of the outer friction body intermediate layer 36 or the inner surface of the outer friction outer layer 38 are not embedded. Embedded with outer friction body elastic steel bar 37.

[0076] 3-4 first magnetic bodies 11 are embedded on the outer surface of the inner wiper middle layer 13 top, and 3-4 first magnetic bodies 11 are evenly distributed on the same straight line, and the first magnetic body 11 and the inner wiper wipe Two first rollers 10 are embedded on the outer surface of the inner friction body intermediate layer 13 between the cloths 9, and the two first rollers 10 are evenly installed on the same straight line.

[0077] The first fixing plate 12 is provided with two first rectangular holes, and the position...

Embodiment 3

[0089] A magnetic suction type glass cleaner. 6-10 first magnetic bodies 11 are embedded on the outer surface of the inner friction body middle layer 13 top, and 6-10 first magnetic bodies 11 are evenly distributed on the same straight line. 4-10 first rollers 10 are embedded on the outer surface of the inner wiper middle layer 13 between the cloths 9, and the 4-10 first rollers 10 are evenly installed on the same straight line.

[0090] The first fixing plate 12 is provided with 4 to 10 first rectangular holes, and the 4 to 10 first rectangular holes are respectively connected with the 4 to 10 first rollers 10 at the position of the first fixing plate 12 on the inner friction body middle layer 13. in the same position.

[0091] 6-10 second magnetic bodies 6 are embedded on the outer surface of the inner-wiping body intermediate layer 13 close to the inner-wiping body scraper 5, and 6-10 second magnetic bodies 6 are evenly distributed on the same straight line; 4-10 second r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com