Preparation method of two-dimensional MXene-based self-cleaning ultrafiltration membrane

An ultrafiltration membrane and self-cleaning technology, which is applied in the field of membrane separation, can solve the problems of fouling on the membrane surface, reducing membrane flux and filtration performance, and achieve membrane pollution mitigation, excellent flux and pollution interception ability, and strong industrial application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

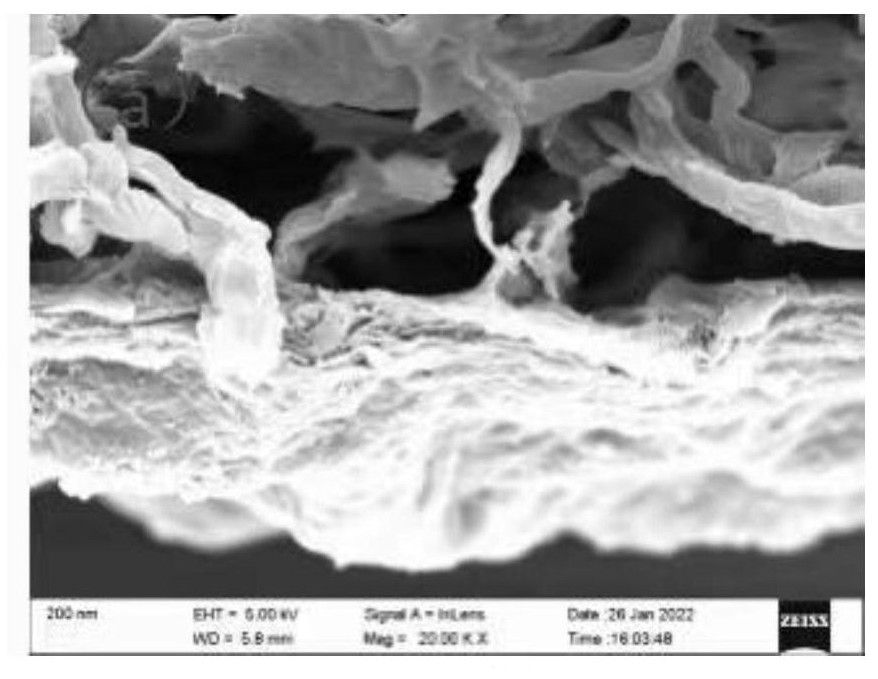

[0033] Embodiment 1 discloses a preparation method of a two-dimensional MXene-based self-cleaning ultrafiltration membrane, comprising the following steps:

[0034] Step 1: Put 3.2g of lithium fluoride into a 100ml beaker, add 40mL of 9mol / L hydrochloric acid, put it on a constant temperature magnetic stirrer at 40°C, stir at 500-600rpm for 15min, then add 2g of MAX material to the solution, at 40°C React with 500-600rpm for 48 hours. After the reaction is completed, centrifuge in a 3500rpm centrifuge for 3min, discard the supernatant, pour into 1M dilute hydrochloric acid for washing, centrifuge under the same conditions, discard the supernatant, and repeat the washing twice. Then wash and centrifuge with deionized water and ethanol respectively, each repeating 3 times, after centrifugation, the solution is suction filtered to obtain multi-layer Ti3C2;

[0035] Step 2: Preparation of monolayer Ti3C2 material: put the precipitate on the filter membrane into a centrifuge tube, ...

Embodiment 2

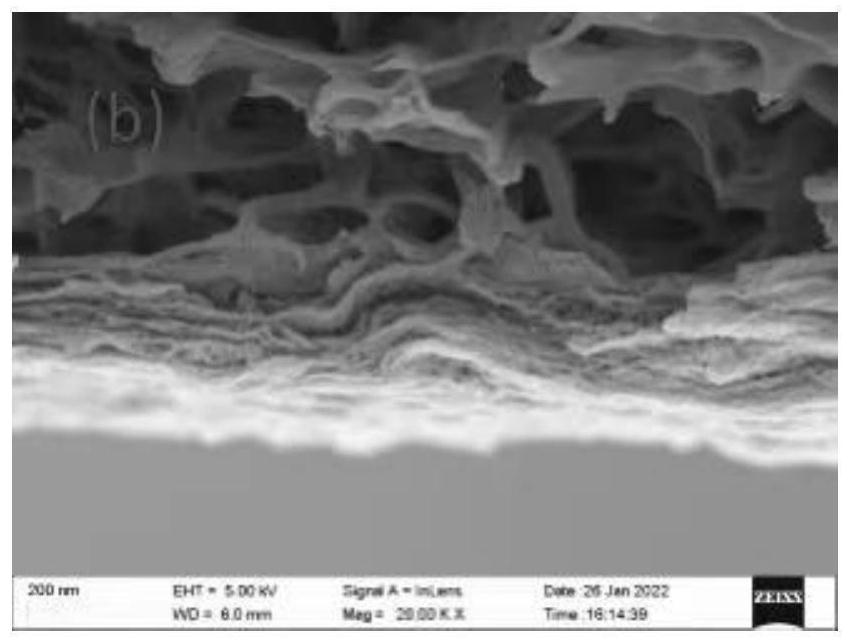

[0042] Embodiment 2 discloses a preparation method of a two-dimensional MXene-based self-cleaning ultrafiltration membrane, comprising the following steps:

[0043] Step 1: Put 2g of lithium fluoride into a 100ml beaker, add 40mL of 9mol / L hydrochloric acid, put it on a constant temperature magnetic stirrer at 40°C, stir at 500-600rpm for 15min, then add 1g of MAX material to the solution, at 40°C and 500 -React at -600rpm for 48 hours. After the reaction is completed, centrifuge in a centrifuge at 3500rpm for 3min, discard the supernatant, pour into 1M dilute hydrochloric acid for washing, centrifuge under the same conditions, discard the supernatant, repeat the washing twice, and then separate Washing with deionized water and ethanol and centrifuging, each repeated 3 times, after centrifugation, the solution was suction filtered to obtain multi-layer Ti3C2;

[0044] Step 2: Preparation of monolayer Ti3C2 material: put the precipitate on the filter membrane into a centrifuge ...

Embodiment 3

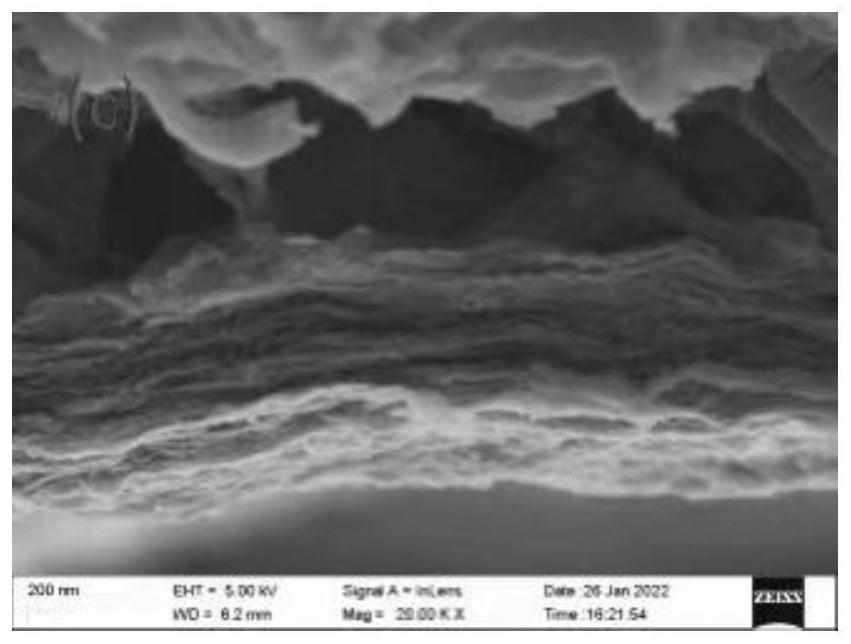

[0051] Embodiment 3 discloses a preparation method of a two-dimensional MXene-based self-cleaning ultrafiltration membrane, comprising the following steps:

[0052] Step 1: Put 3.2g of lithium fluoride into a 100ml beaker, add 40mL of 9mol / L hydrochloric acid, put it on a constant temperature magnetic stirrer at 40°C, stir at 500-600rpm for 15min, then add 2g of MAX material to the solution, at 40°C React with 500-600rpm for 48 hours. After the reaction is completed, centrifuge in a 3500rpm centrifuge for 5min, discard the supernatant, pour into 1M dilute hydrochloric acid for washing, centrifuge under the same conditions, discard the supernatant, and repeat the washing twice. Then wash and centrifuge with deionized water and ethanol respectively, each repeating 3 times, after centrifugation, the solution is suction filtered to obtain multi-layer Ti3C2;

[0053] Step 2: Preparation of single-layer Ti3C2 material: put the precipitate on the filter membrane into a centrifuge tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com