A kind of preparation method of water-based transparent heat-insulating glass coating

An insulating glass, transparent technology, applied in antifouling/underwater coatings, polyether coatings, coatings, etc., can solve problems such as poor water resistance and aging resistance, poor heat insulation effect, and high cost, and achieve Improve water resistance, strong light oxidation and reduction ability, and comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

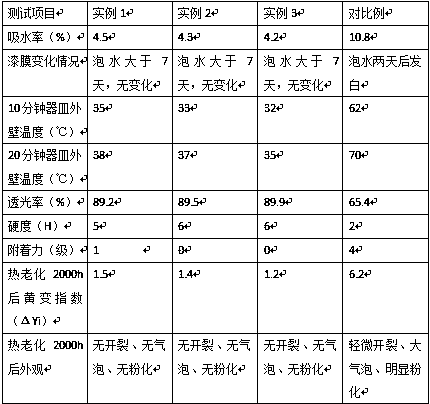

Examples

example 1

[0022]Mix tetrabutyl titanate and absolute ethanol at a molar ratio of 9:2, add them to the reaction kettle, and stir at a speed of 200r / min to obtain a titanium alkoxide sol, and then mix the titanium alkoxide sol and water molar Mix at a ratio of 25:3, adjust the pH of the solution to 3 with hydrochloric acid with a concentration of 0.5mol / L, and react for 30 minutes to obtain a titanium dioxide sol; mix the above titanium dioxide sol and phenol at a molar ratio of 4:1 to obtain a mixture, and then mix the mixture Mix with n-heptane in an equal mass ratio to obtain a pre-reaction solution. While stirring, continue to drop 10% of the mass of the pre-reaction solution into the reaction kettle with a concentration of 1mol / L formaldehyde solution, and let it stand at 80°C for 1.5h. Obtain the pre-product, then put the pre-product in a muffle furnace, and roast it at a temperature of 500° C. for 2 hours to obtain porous spherical nanocrystals of titanium dioxide; add 80 parts of d...

example 2

[0024] Mix tetrabutyl titanate and absolute ethanol at a molar ratio of 9:2, add them to the reaction kettle, and stir at a speed of 250r / min to obtain a titanium alkoxide sol, and then mix the titanium alkoxide sol and water molar Mix at a ratio of 25:3, adjust the pH of the solution to 4 with hydrochloric acid with a concentration of 0.5mol / L, and react for 45 minutes to obtain a titanium dioxide sol; mix the above titanium dioxide sol and phenol at a molar ratio of 4:1 to obtain a mixture, and then mix the mixture Mix with n-heptane in an equal mass ratio to obtain a pre-reaction solution. While stirring, continue to drop 10% of the mass of the pre-reaction solution into the reaction kettle with a concentration of 1mol / L formaldehyde solution, and stand at 85°C for 1.7h. Obtain the pre-product, then put the pre-product into a muffle furnace, and roast it at a temperature of 550° C. for 2.5 h to obtain titanium dioxide porous spherical nanocrystals; in parts by weight, add 85...

example 3

[0026] Mix tetrabutyl titanate and absolute ethanol at a molar ratio of 9:2, add them to the reaction kettle, and stir at a speed of 300r / min to obtain a titanium alkoxide sol, and then mix the titanium alkoxide sol and water molar Mix at a ratio of 25:3, adjust the pH of the solution to 5 with hydrochloric acid with a concentration of 0.5mol / L, and react for 60 minutes to obtain a titanium dioxide sol; mix the above titanium dioxide sol and phenol at a molar ratio of 4:1 to obtain a mixture, and then mix the mixture Mix with n-heptane in an equal mass ratio to obtain a pre-reaction solution. While stirring, continue to drop 10% of the mass of the pre-reaction solution into the reaction kettle with a concentration of 1mol / L formaldehyde solution, and let it stand at 90°C for 2.0 h. Obtain the pre-product, then put the pre-product in a muffle furnace, and roast at a temperature of 600° C. for 3 h to obtain titanium dioxide porous spherical nanocrystals; in parts by weight, add 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com