Patents

Literature

30results about How to "Lower critical surface tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified membranes

InactiveUS20050029186A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

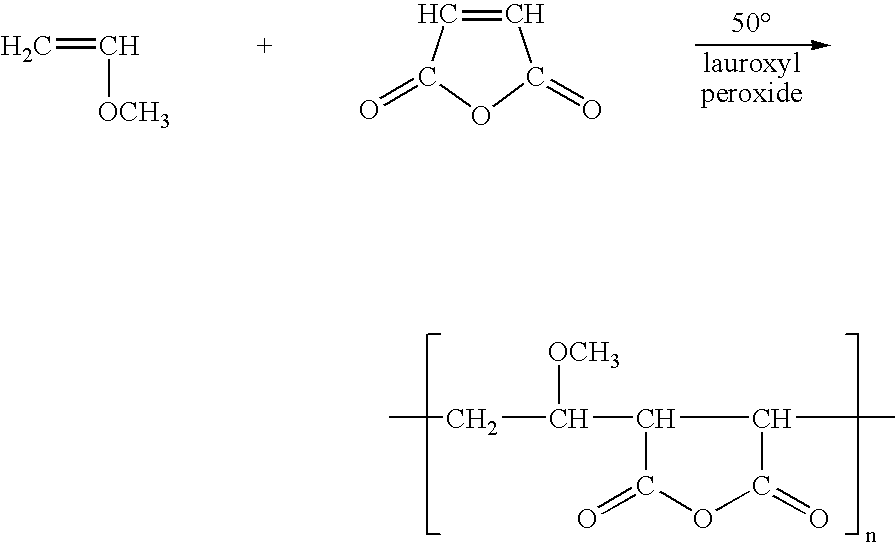

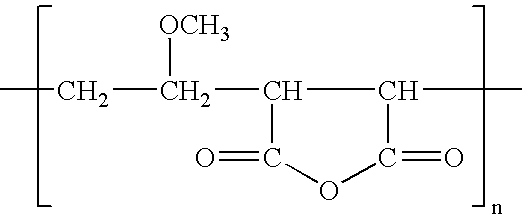

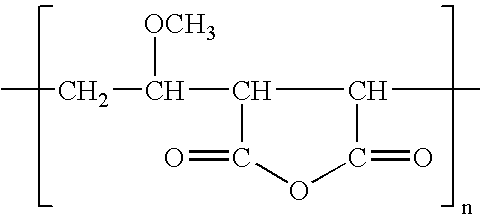

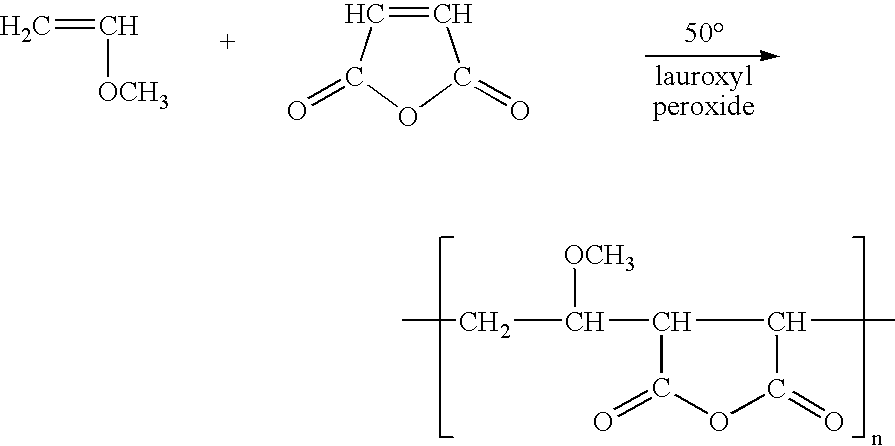

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

Modified membranes

InactiveUS20050032982A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:MULLER HEINZ JOACHIM

Modified membranes

InactiveUS20050029185A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

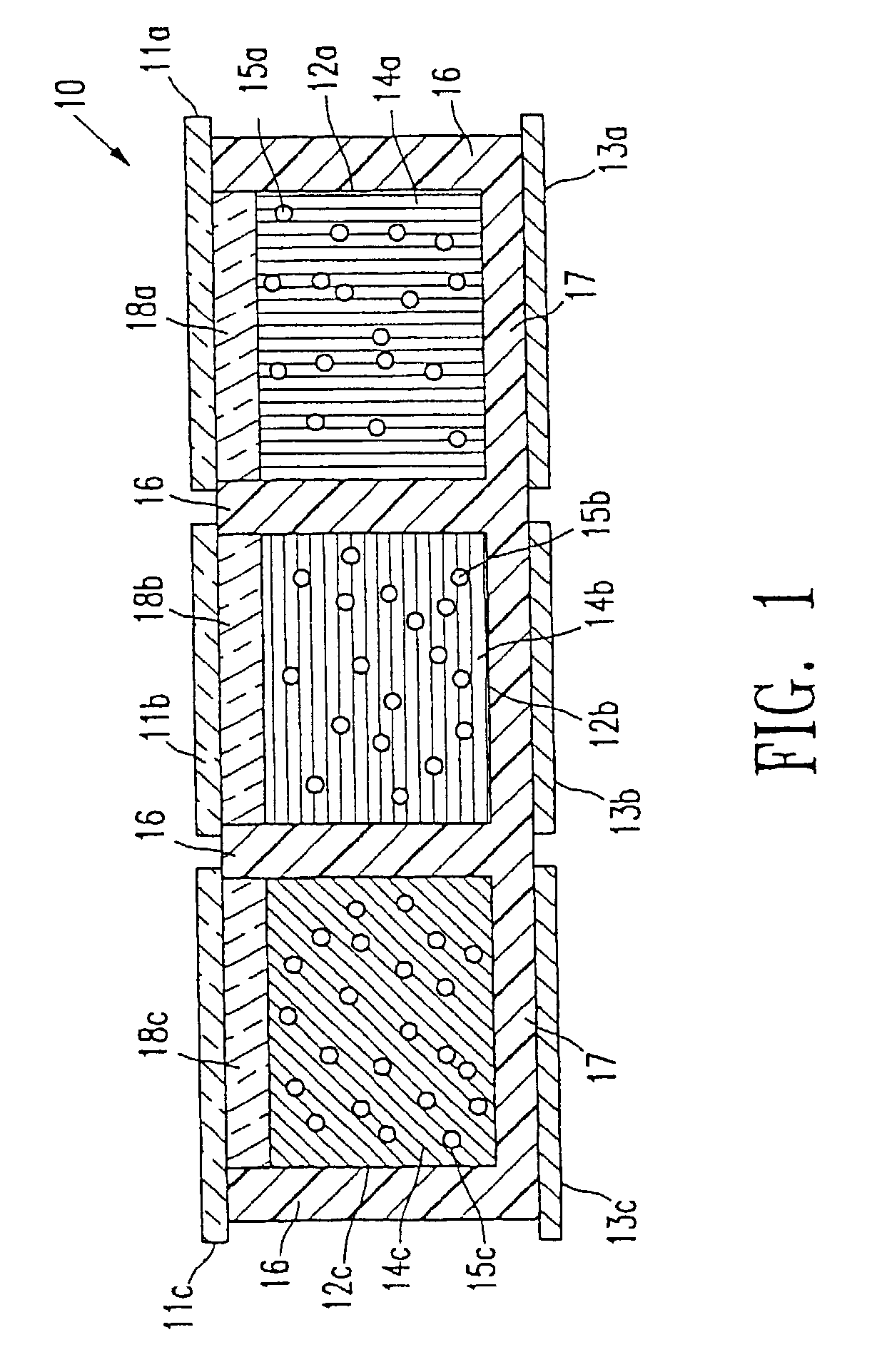

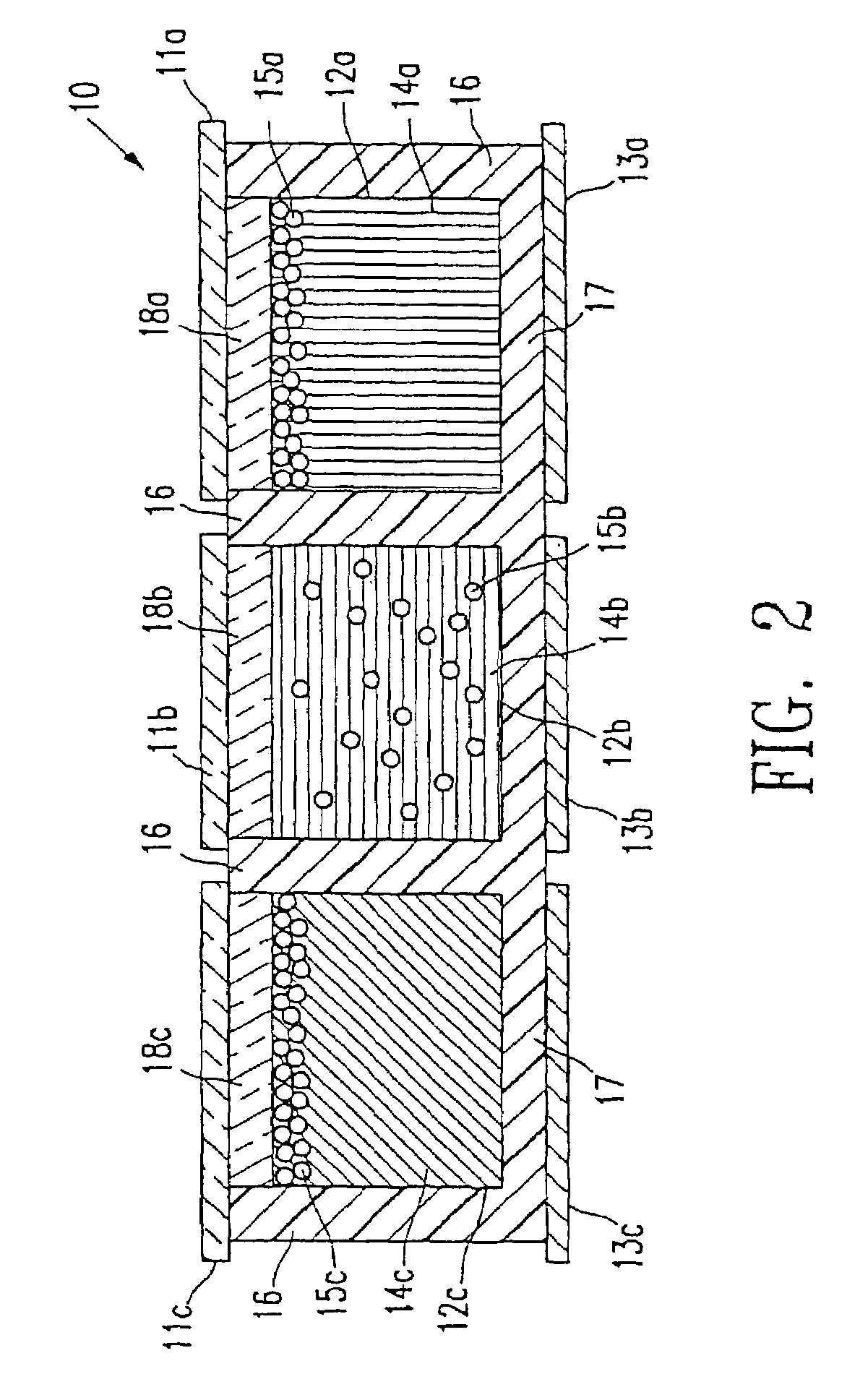

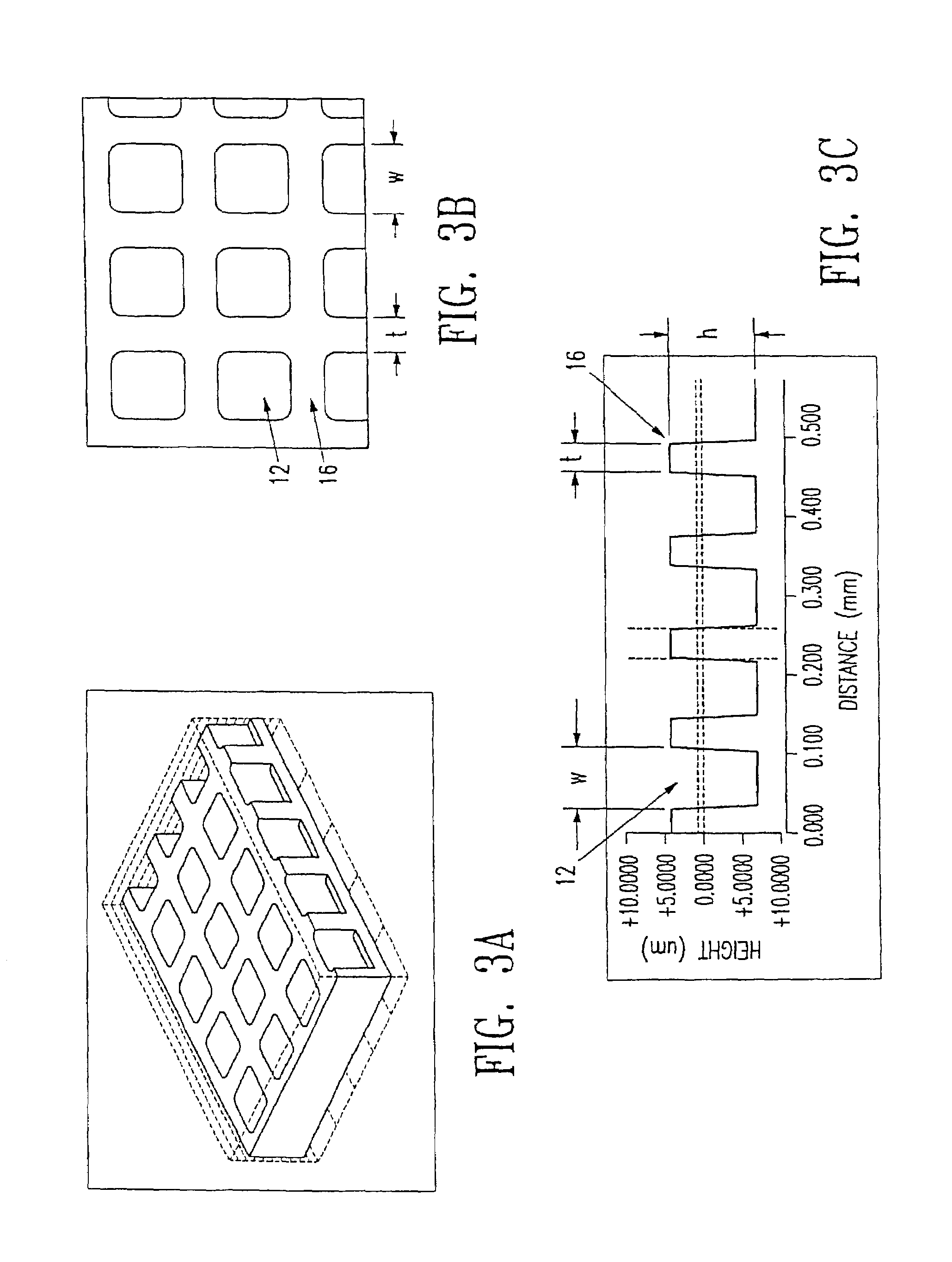

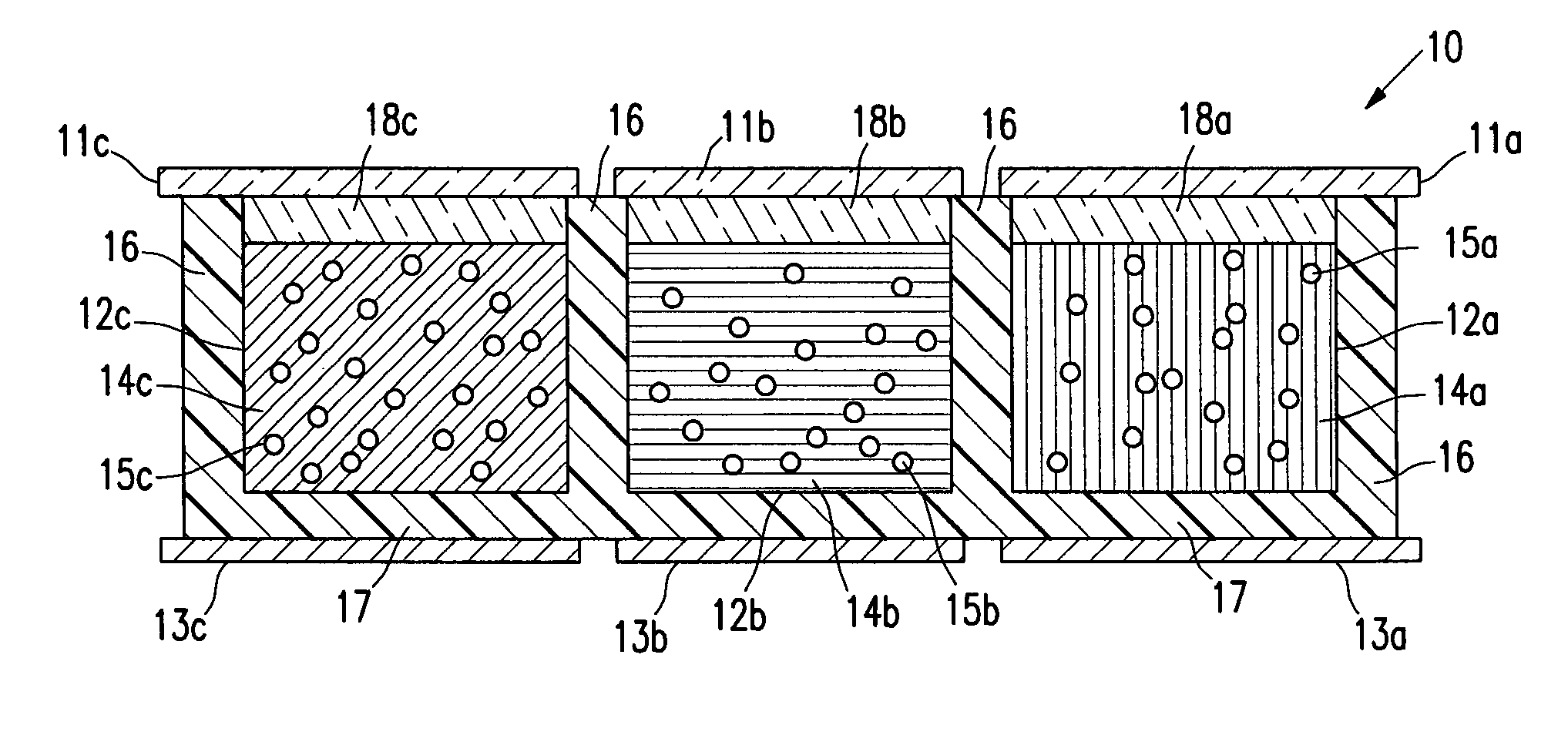

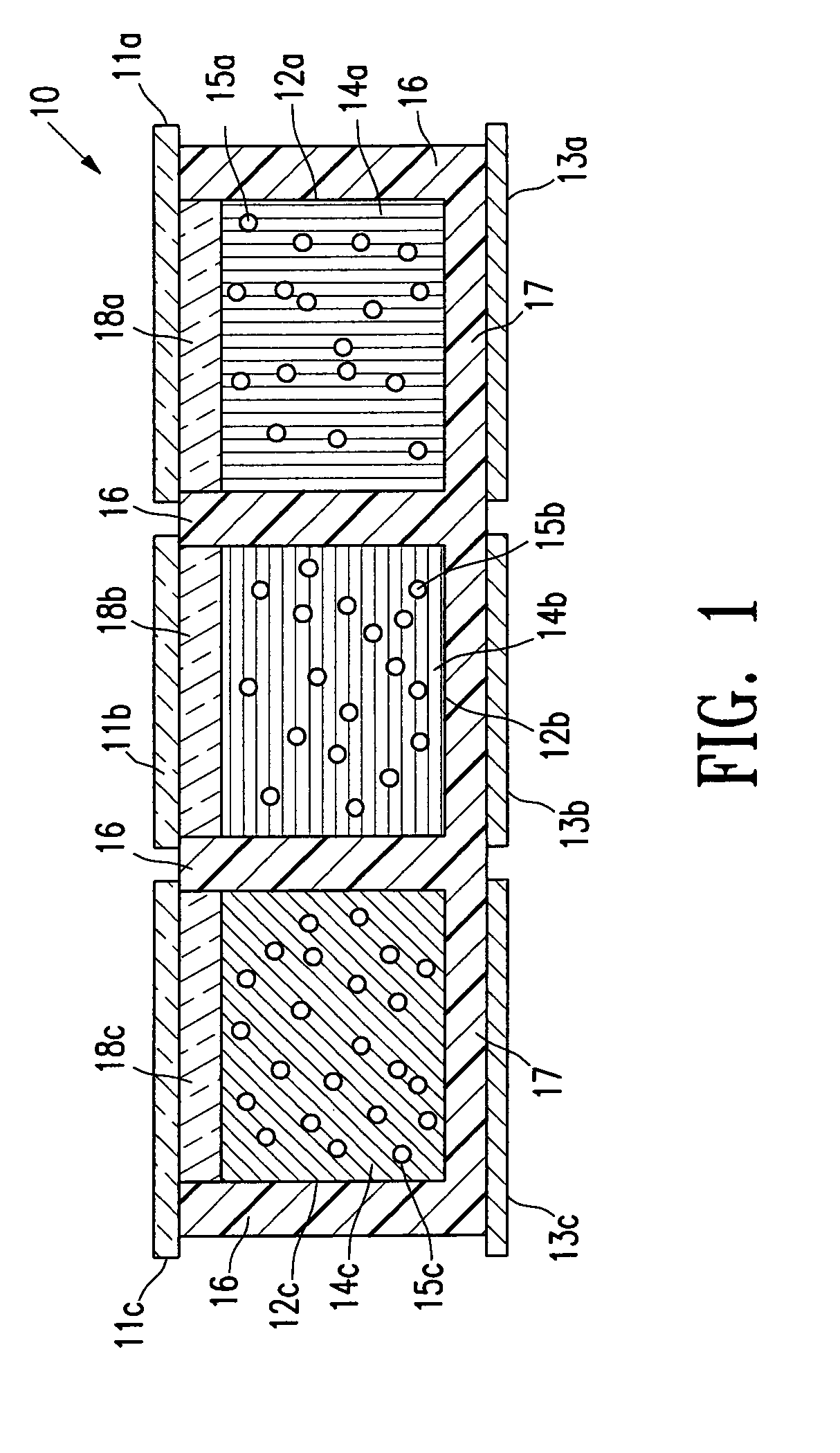

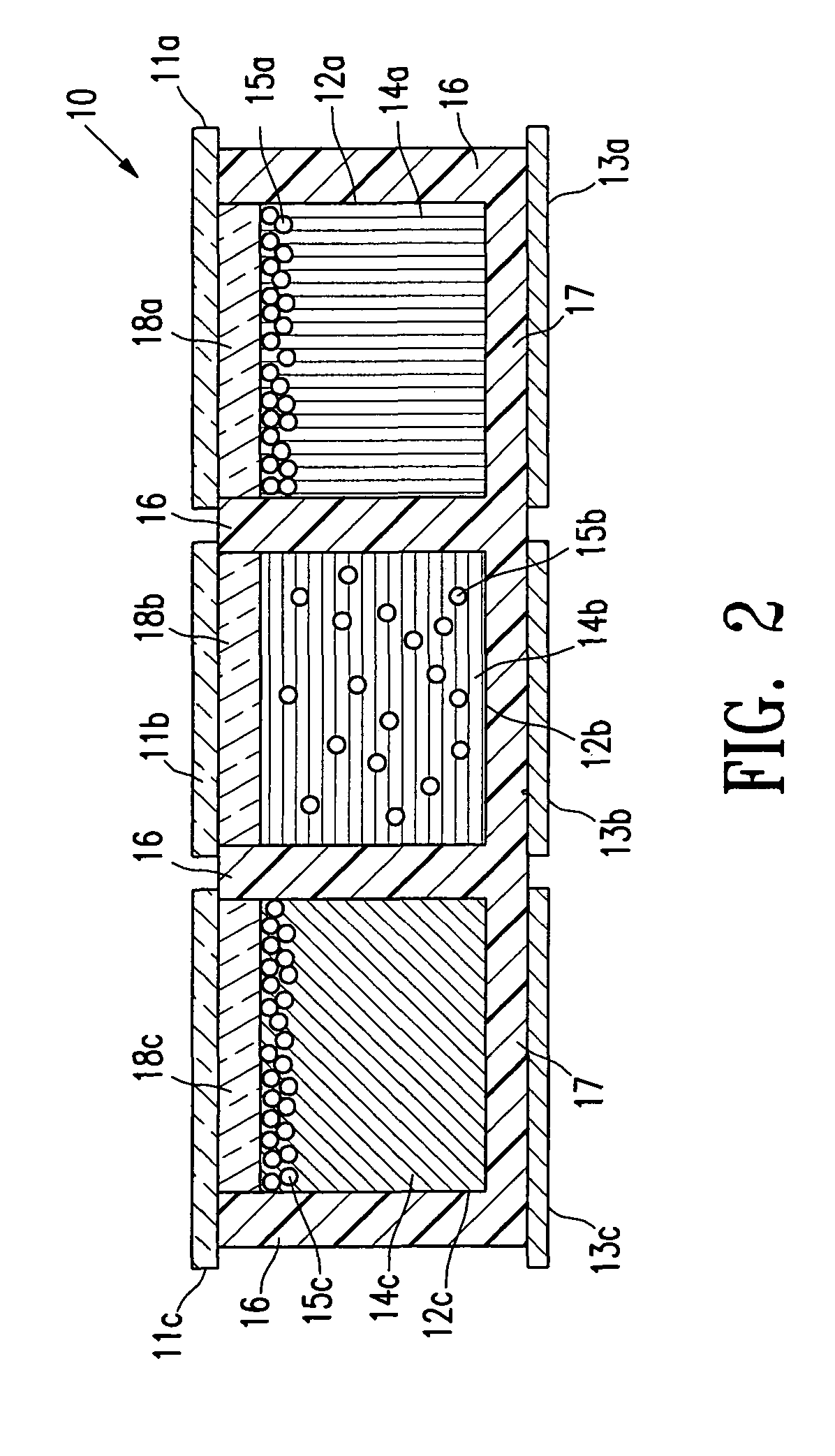

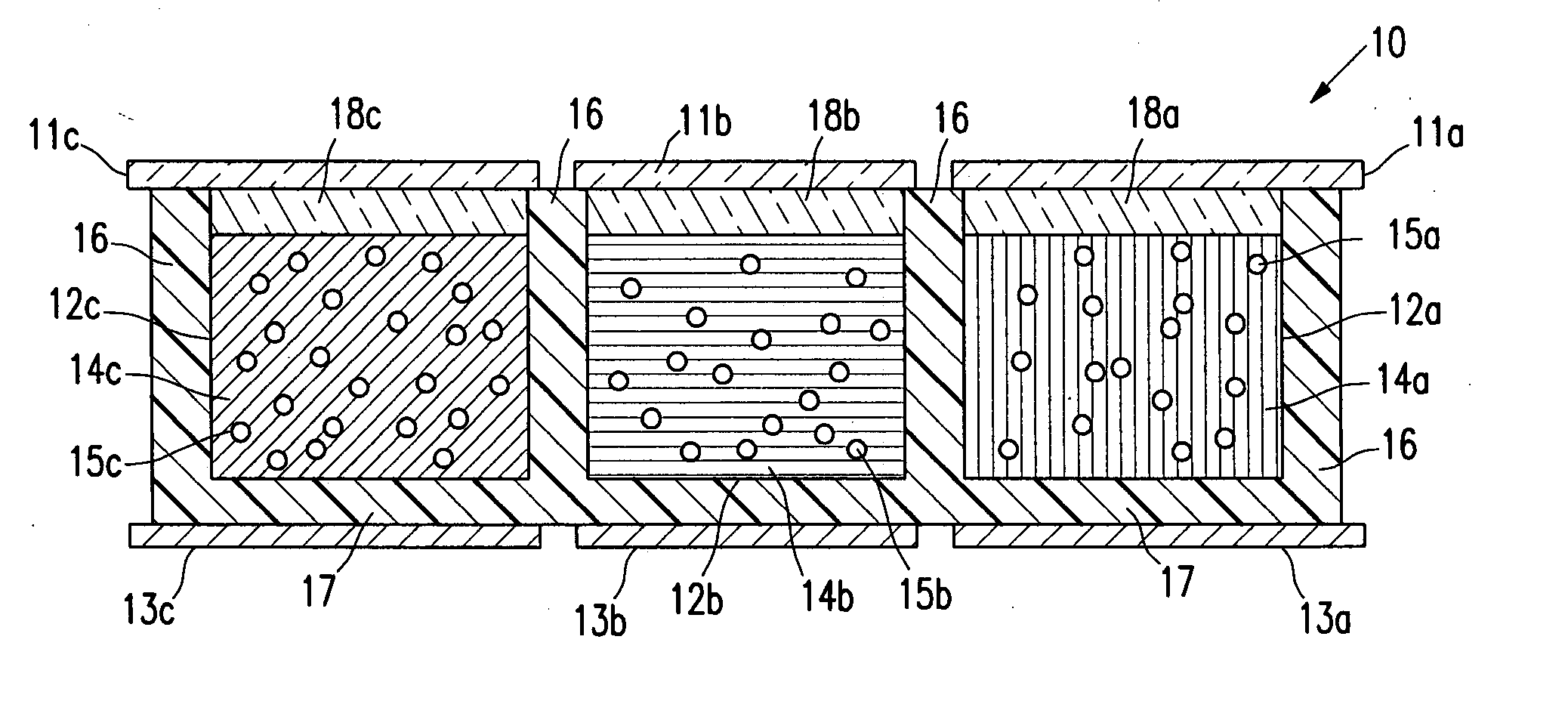

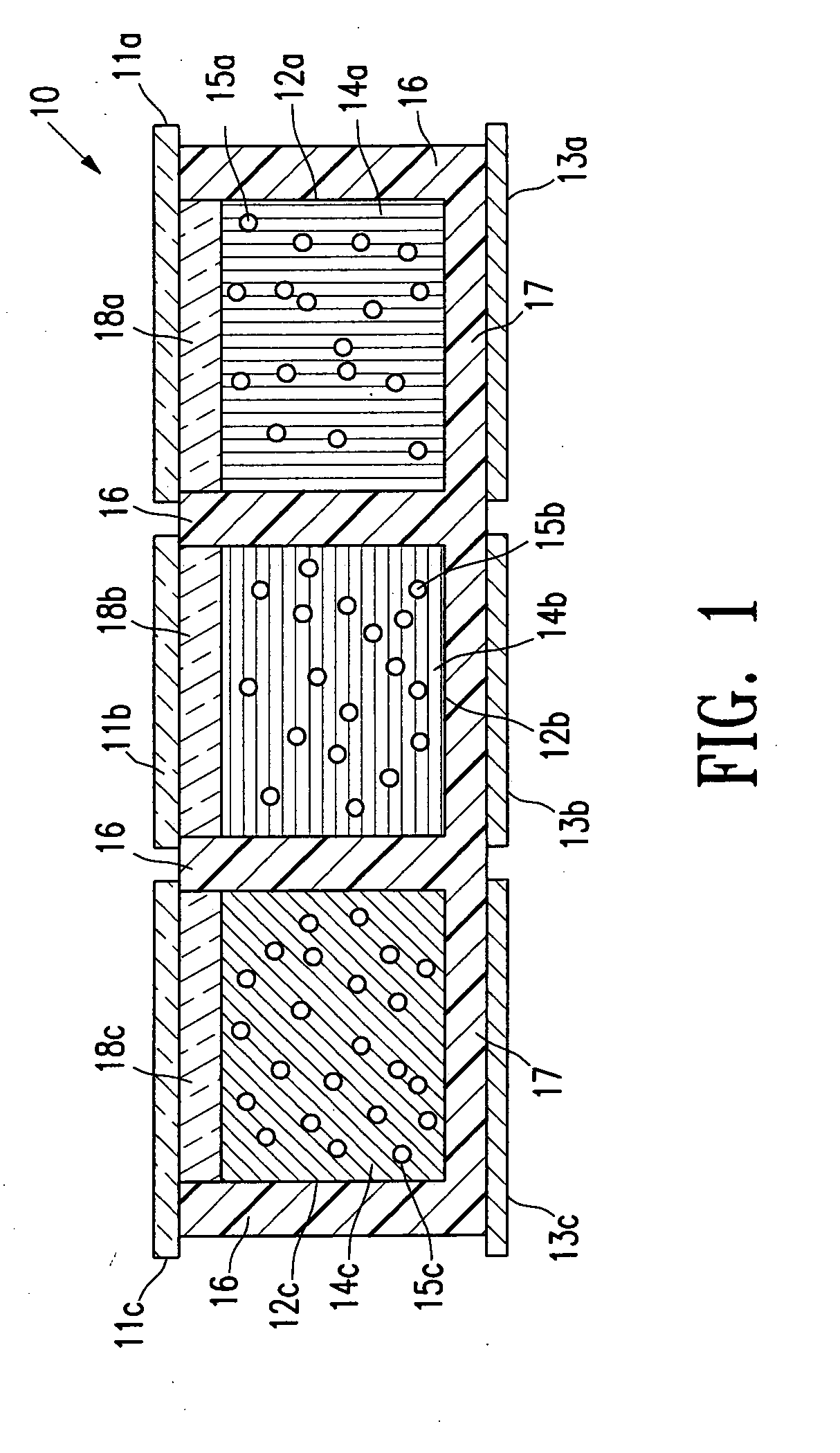

Composition and process for the sealing of microcups in roll-to-roll display manufacturing

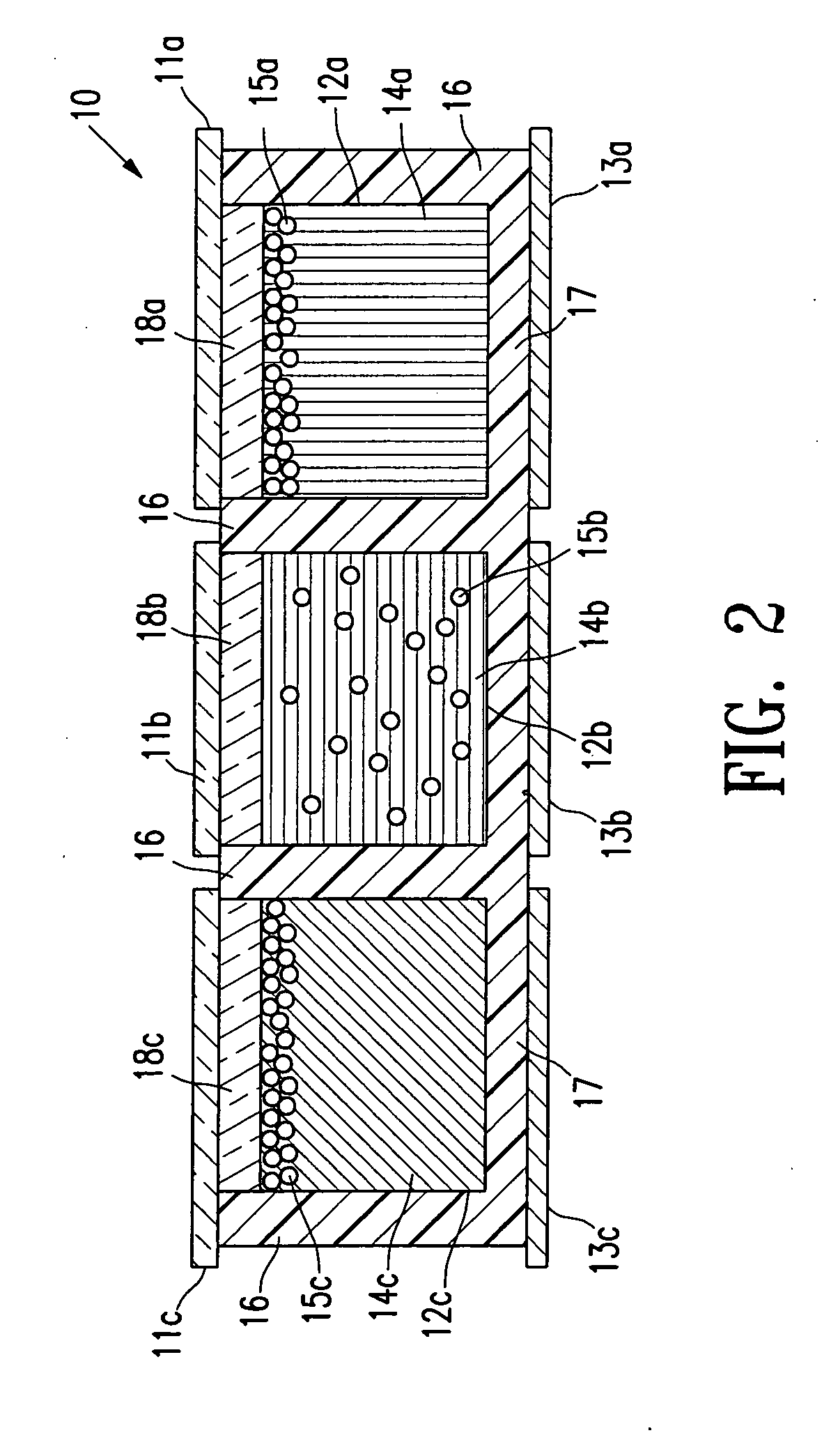

InactiveUS7005468B2Improve barrier propertiesImprove integrityAdhesivesNon-linear opticsCrystallographyElectrophoresis

Owner:E INK CALIFORNIA

Composition and process for the sealing of microcups in roll-to-roll display manufacturing

InactiveUS8361356B2Improve adhesionQuality improvementSludge treatmentVolume/mass flow measurementCrystallographyElectrophoresis

The invention relates to a novel sealing composition for the manufacture of an electrophoretic or liquid crystal display, and a sealing process using the composition. The composition allows electrophoretic or liquid crystal cells to be seamlessly sealed and the sealing layer free of any defects.

Owner:E INK CALIFORNIA

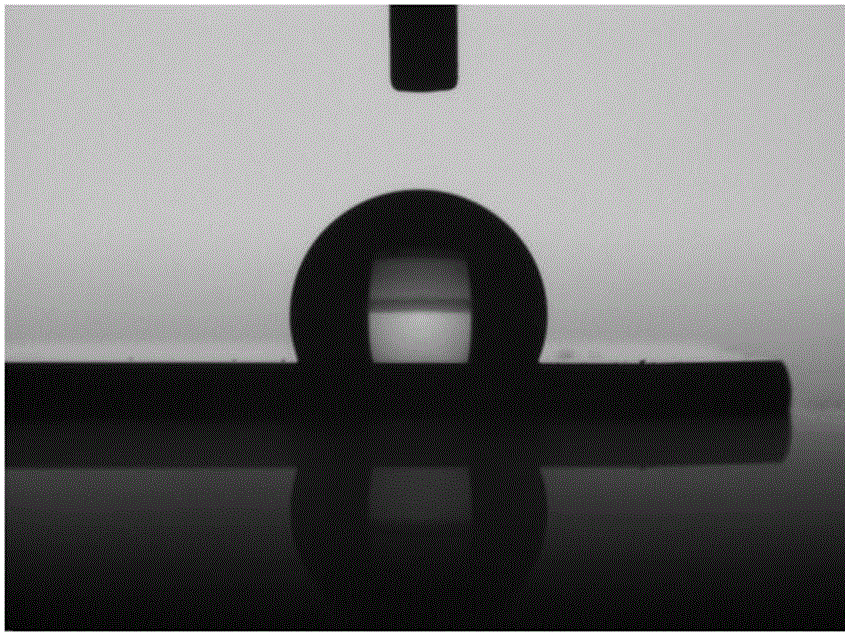

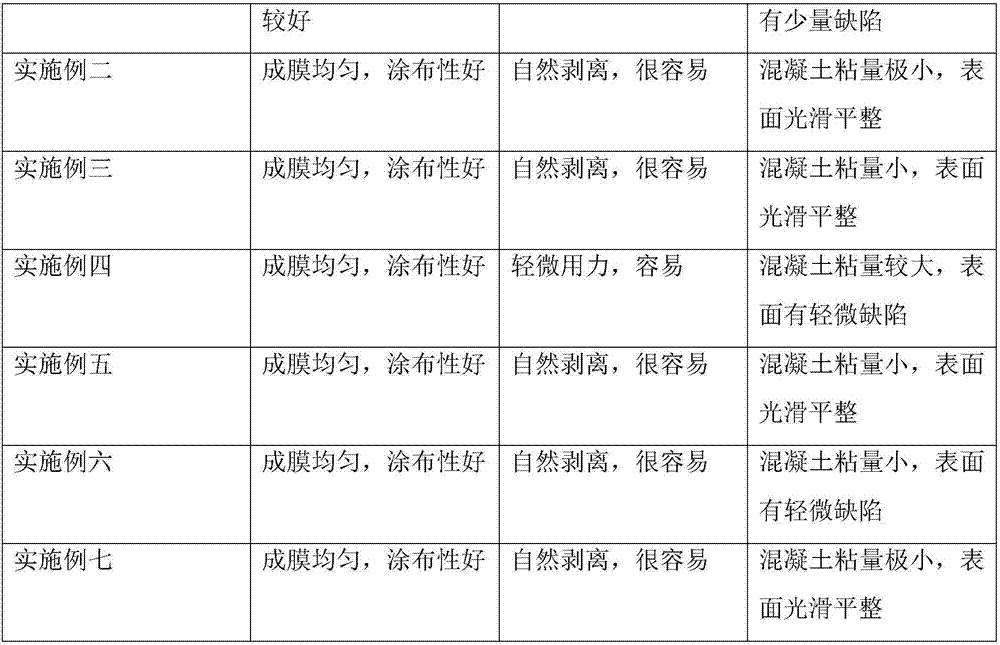

Fluorinated polyurethane and preparation method thereof

ActiveCN106674473AEasy to storeEasy to migrateAntifouling/underwater paintsPaints with biocidesDiolFluorine containing

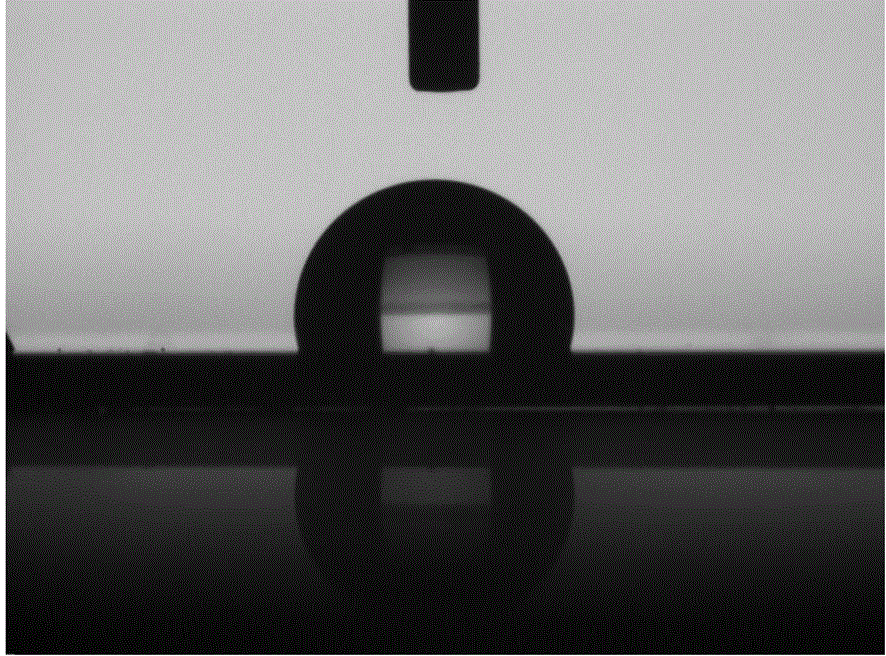

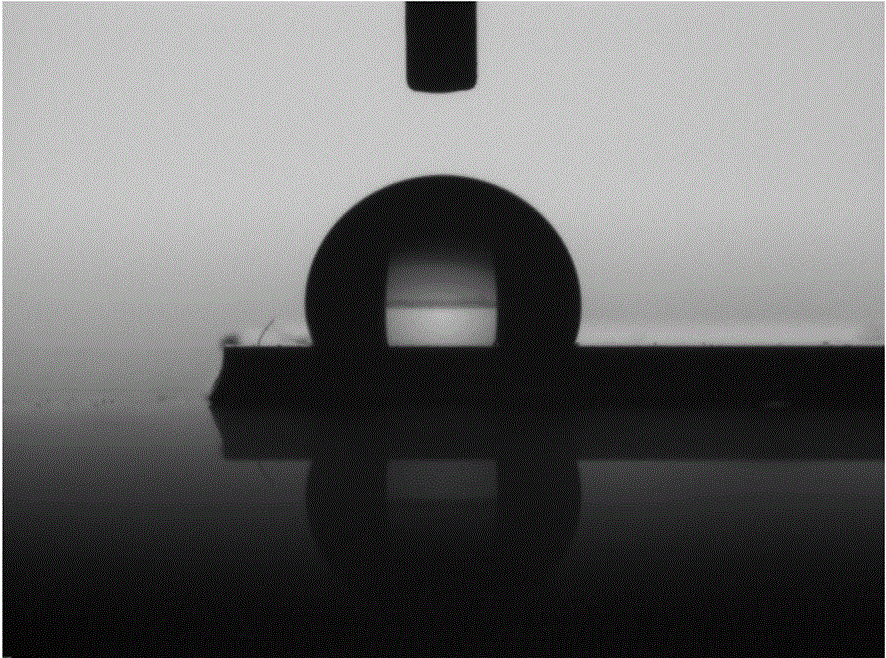

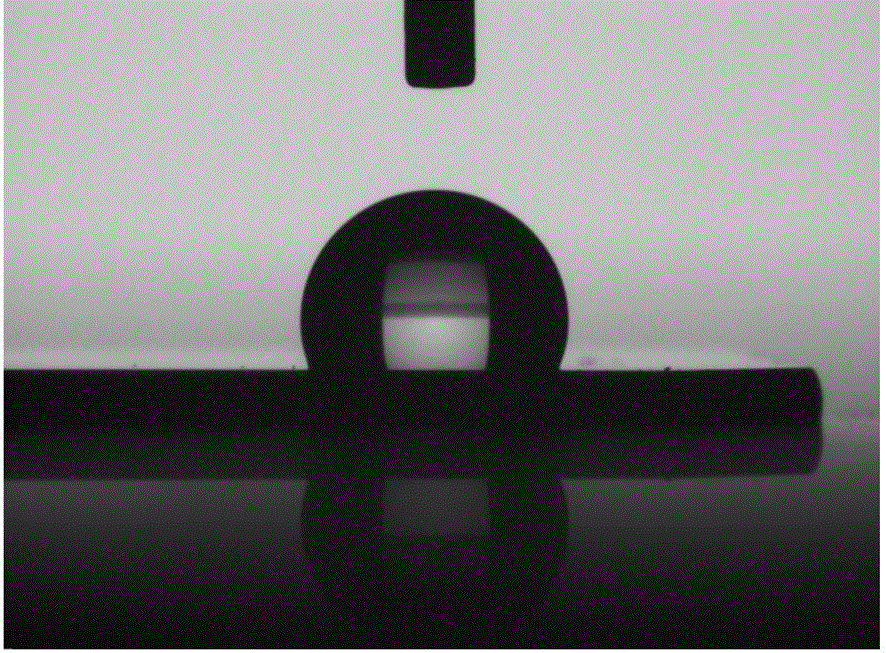

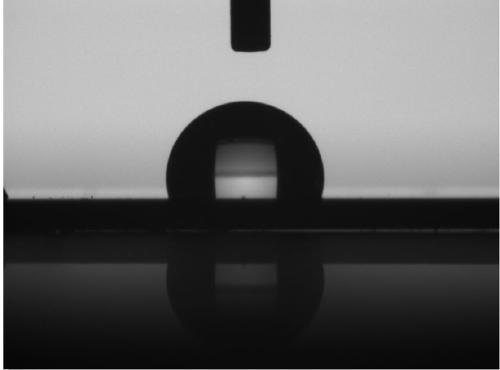

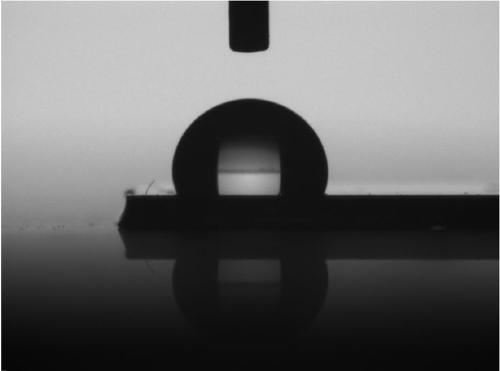

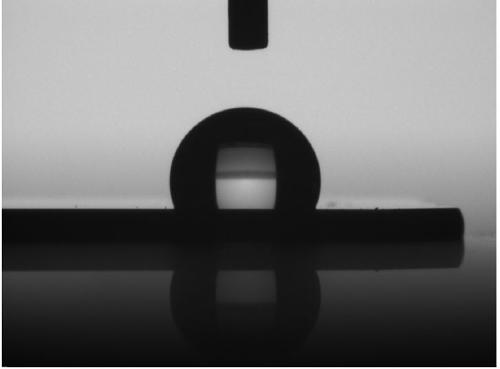

The invention discloses fluorinated polyurethane and a preparation method thereof. The fluorinated polyurethane is prepared through the steps: fluoroalkyl-containing polyether glycol and diisocyanate perform addition polymerization reaction, a tin catalyst is utilized to catalyze, a chain extender is utilized to extend a chain, and an amino silane coupling agent is added to seal ends. A product contains a fluorine-containing polyether block, the fluorine content is high, fluoroalkyl on a polyether lateral group is prone to generating microphase separation and surface migration, polyurethane surface energy is low, and the fluorinated polyurethane is easy to store and cure as the silane coupling agent is utilized to seal the ends. A water contact angle of a coating prepared from the fluorinated polyurethane is higher than 110 degrees, and the coating has excellent water repellency.

Owner:UPCHEM CHINA

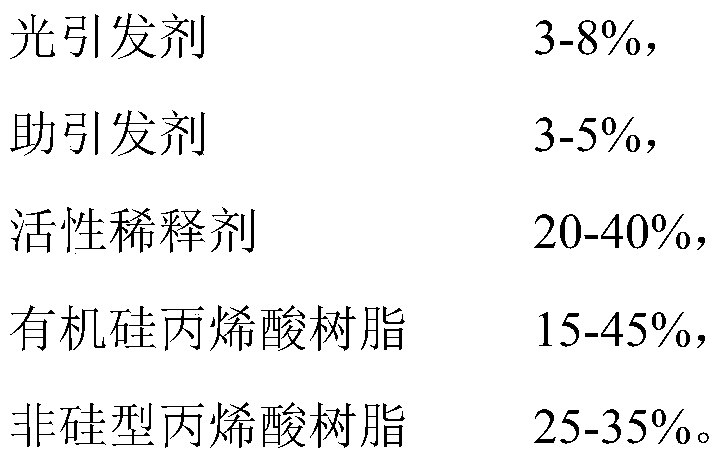

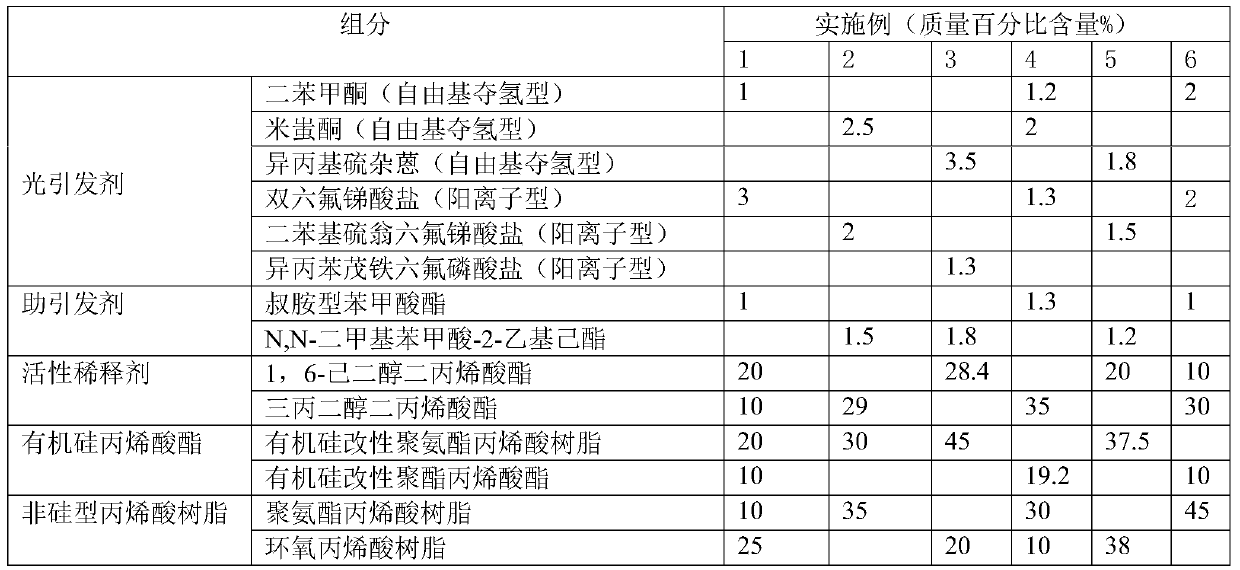

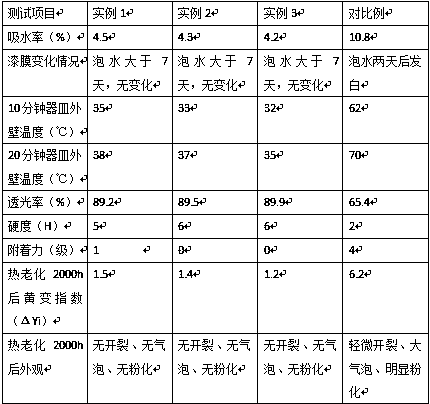

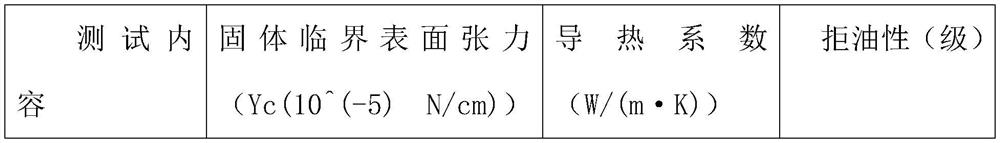

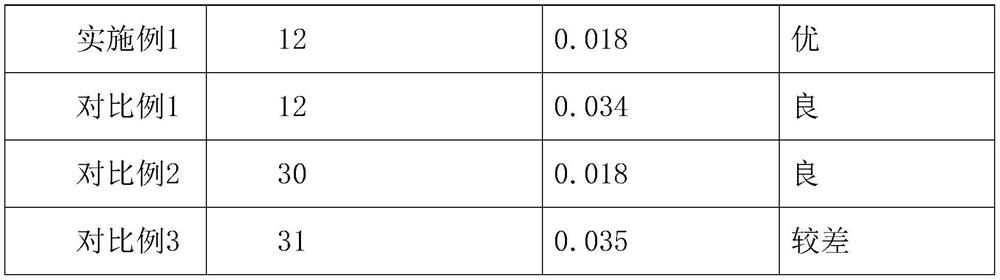

Efficient anti-sticking UV release paint applied to pressure-sensitive adhesive as well as preparation and application of efficient anti-sticking UV release paint

ActiveCN105315881ANo releaseOvercome polymerization inhibitionPolyurea/polyurethane coatingsEpoxy resin coatingsSolubilityAcrylic resin

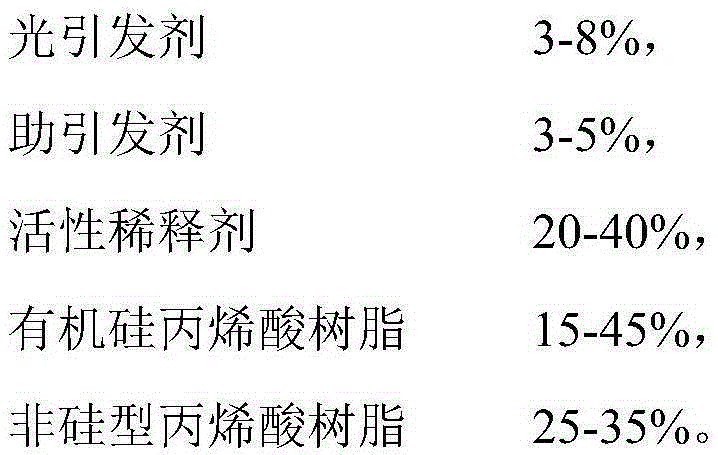

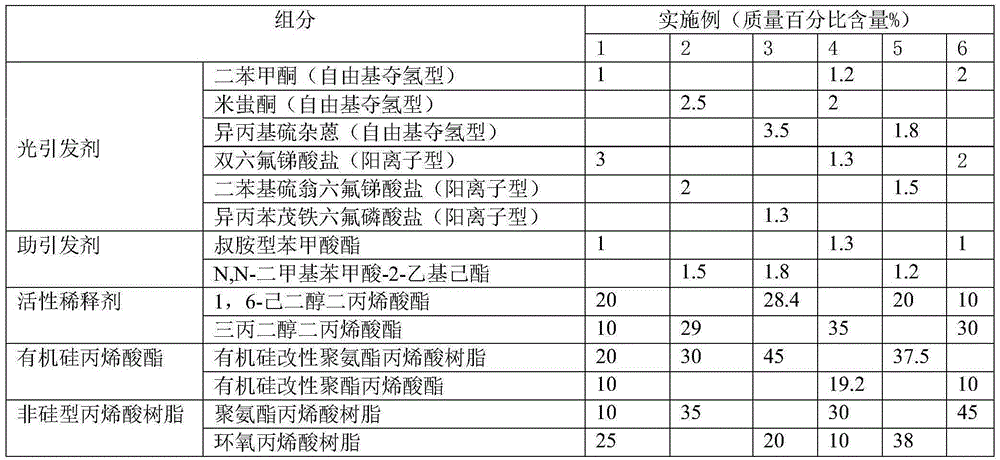

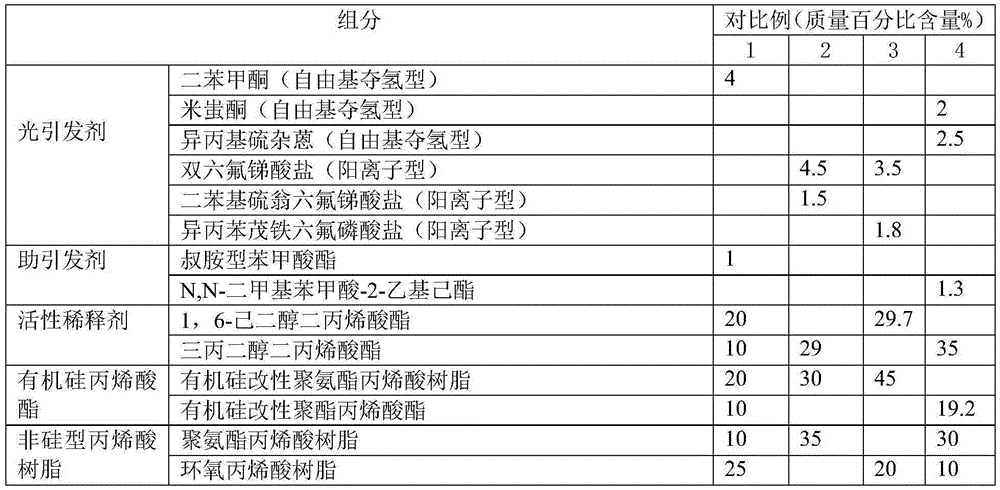

The invention provides an efficient anti-sticking UV release paint applied to a pressure-sensitive adhesive as well as preparation and application of the efficient anti-sticking UV release paint. The paint comprises the following ingredients in percentage by weight: 3-8% of a photoinitiator, 3-5% of an auxiliary initiator, 20-40% of an active diluent, 15-45% of organic silicon-acrylic resin and 25-45% of non-silicon acrylic resin. The system of free radicals and the cationic composite initiator is adopted, a sensitization effect realized through the synergistic effect of the free radicals and the cationic composite initiator better solves the problems of oxygen inhibition and slow curing caused by the single initiator, meanwhile, the photo-curing speed is high, the solubility is good, the absorption wavelength reaches 390 nm and the paint is an efficient, energy-saving and environment-friendly photo-cured release paint.

Owner:SHANGHAI CHENGYING NEW MATERIALS

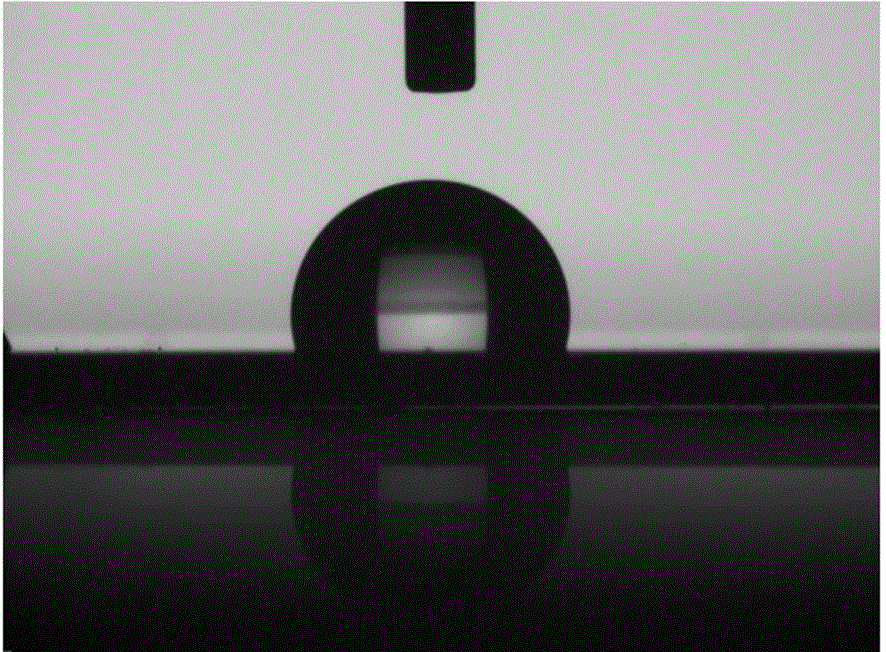

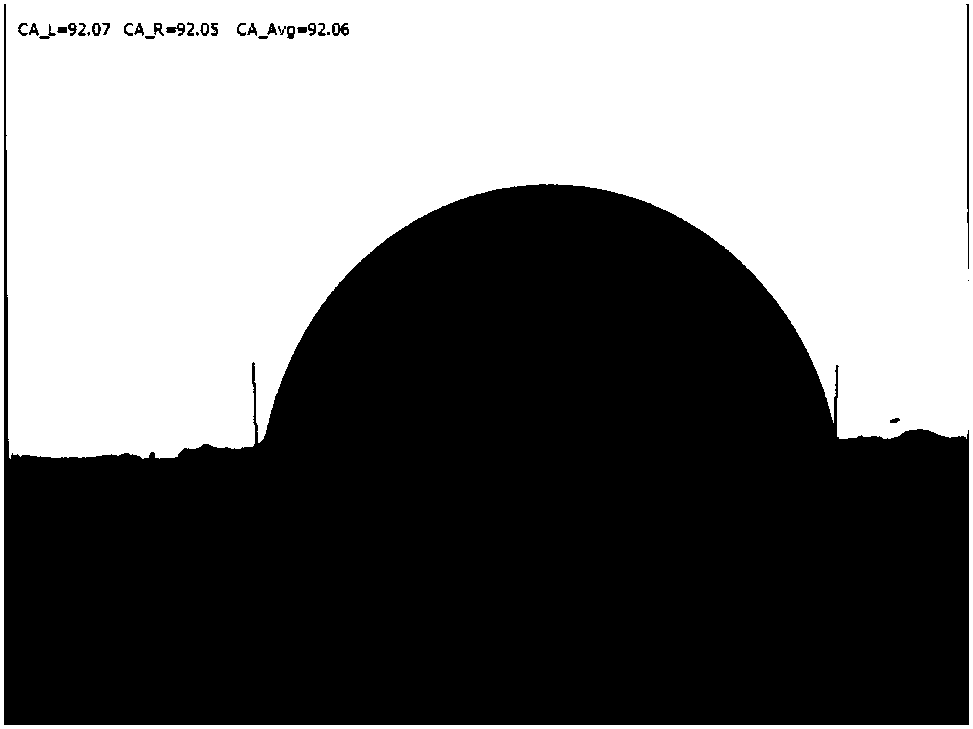

Hydrophobic membrane based on fluorine-containing polyurethane and preparation method of hydrophobic membrane

ActiveCN106750432AEasy to storeEasy to migrateAntifouling/underwater paintsPaints with biocidesPolymer scienceDiol

The invention discloses a hydrophobic membrane based on fluorine-containing polyurethane and a preparation method of the hydrophobic membrane. The preparation method comprises the following steps: spin-coating the fluorine-containing polyurethane into a film; curing to obtain the hydrophobic membrane based on the fluorine-containing polyurethane; taking fluorine-containing alkyl polyether glycol and diisocyanate to be subjected to addition polymerization reaction; and catalyzing through a tin catalyst and extending a chain through a chain extender; and adding an amino silane coupling agent and capping an end to prepare the fluorine-containing polyurethane. The product has a fluorine-containing polyether block and high fluorine content; perfluoroalkyl located at a polyether side easily has micro-phase separation and surface migration; the surface energy of the polyurethane is low; and the fluorine-containing polyurethane is subjected to end capping by the silane coupling agent and is easy to store and easy to cure. The hydrophobic membrane based on the fluorine-containing polyurethane, disclosed by the invention, has a water contact angle higher than 110 degrees and good water repellency.

Owner:SUZHOU UNIV

Composition and process for the sealing of microcups in roll-to-roll display manufacturing

InactiveUS20070243332A1Improve barrier propertiesImprove integritySludge treatmentVolume/mass flow measurementCrystallographyElectrophoresis

The invention relates to a novel sealing composition for the manufacture of an electrophoretic or liquid crystal display, and a sealing process using the composition. The composition allows electrophoretic or liquid crystal cells to be seamlessly sealed and the sealing layer free of any defects.

Owner:E INK CALIFORNIA

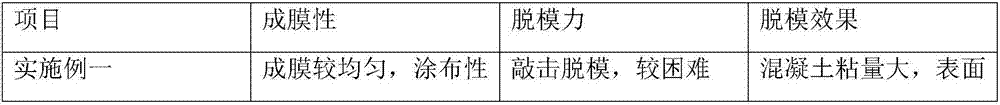

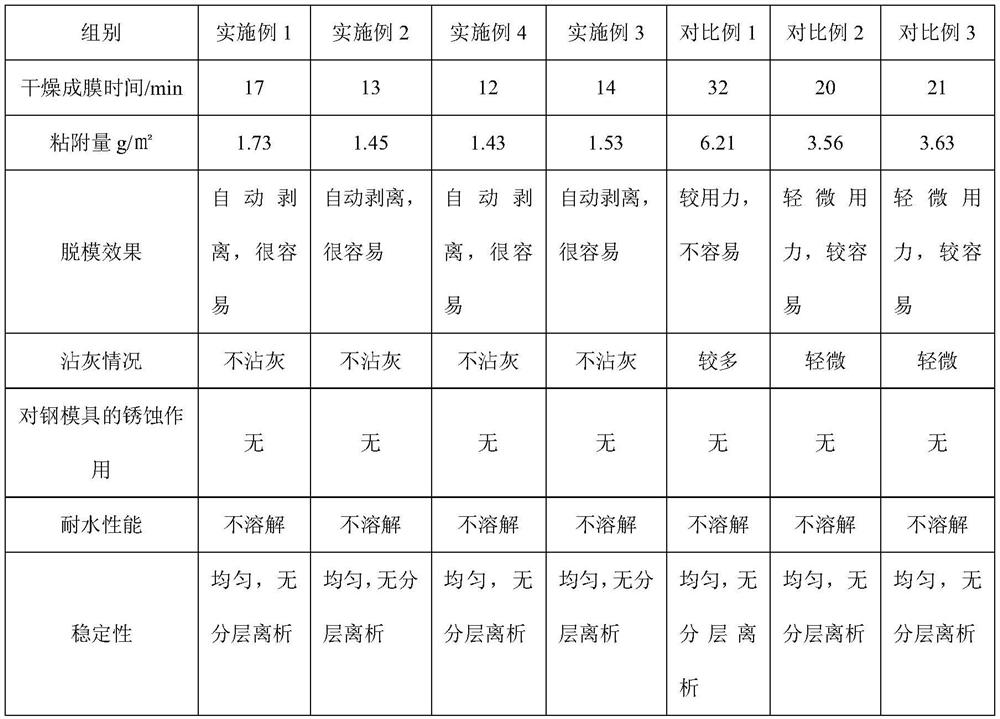

Concrete mold releasing agent

InactiveCN107987941AImproves strength and plasticityImprove surface qualityCeramic shaping apparatusLubricant compositionSurface energyPolyacrylamide

The invention provides a concrete mold releasing agent. The concrete mold releasing agent is prepared from the following components: terminal alkenyl polyoxyethylene ether, acrylic acid, ammonium persulfate, mercaptopropanoic acid, hydrogen peroxide, hydroxylated vegetable oil, sodium gluconate, organic silicon, polyethylene glycol, polyvinyl alcohol, de-ionized water, polyacrylamide, hydrochloricacid and sodium lauryl sulfate. After a certain amount of the sodium gluconate is added, a good mold releasing effect can be realized; the vegetable oil based mold releasing agent is utilized so thatthe surface quality of concrete can be improved; the organic silicon has strong chemical inertness and lubricating property, low surface energy and strong film forming capability, so that the concrete mold releasing agent has an excellent mold releasing property; the organic silicon and the hydroxylated vegetable oil are used as raw materials so that the concrete mold releasing agent is a waterborne mold releasing agent; after being brushed on the surface of a mold, the concrete mold releasing agent is rapidly dried; after moisture is evaporated, a remained effective substance rapidly forms one layer of extremely thin isolation oil film, so that the concrete mold releasing agent not only has an isolation effect, but also has a relatively good lubricating property and has an antirust effect on a steel mold.

Owner:湖北恒利建材科技有限公司

Greenhouse thin film water-based hydrophobic coating as well as preparation method and application thereof

The invention discloses a water-based hydrophobic coating as well as a preparation method and application thereof. The coating comprises the following components in mass fraction: 57-80% of modified fluorocarbon resin, 2.4-4.8% of coalescing agent, 0.5-0.8% of base material wetting agent, 0.3-0.8% of leveling agent, 0-0.2% of antifoaming agent, 0-1% of thickener, 1-2% of hydrophobic agent, 3.8-7.7% of curing agent, and the balance liquid paraffin. The prepared fluorocarbon resin water-based hydrophobic coating has excellent film forming property and hydrophobicity, has high coating adhesion, is safe and environment-friendly, has simple process, and is easy for industrial production and large-scale popularization and application.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Preparation method of phosphate-type trisiloxane surfactant

InactiveCN106554496AGood hydrolysis resistanceGood surface propertiesBiocideAnimal repellantsPesticideChemistry

The invention discloses a preparation method of a phosphate-type trisiloxane surfactant. The method comprises the following steps: (1) preparation of hydroxyl-terminated polyether modified trisiloxane, in which, in the protection of N2 flowing, 1,1,1,3,5,5,5-heptamethyltrisiloxane, allyl polyoxyethylene ether, and a chloroplatinic acid alcoholic solution with the mass percentage being 0.3% are subjected to a reaction to prepare hydroxyl-terminated polyether modified trisiloxane; and (2) synthesis of the phosphate-type trisiloxane surfactant, in which, the reaction product of hydroxyl-terminated polyether modified trisiloxane, p-toluenesulfonic acid and H3PO4 is washed with benzene, and then benzene is removed to obtain the phosphate-type trisiloxane surfactant. The phosphate-type trisiloxane surfactant prepared in the method is good in hydrolysis resistance and surface performance, can reduce the surface tension of a pesticide diluent, and improve the insecticidal effect.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

Preparation method of aqueous transparent heat-insulating glass coating

ActiveCN108912871AStrong light transmittanceLow critical surface tensionAntifouling/underwater paintsPaints with biocidesCarbon dioxidePolytetrafluoroethylene

The invention relates to a preparation method of an aqueous transparent heat-insulating glass coating, and belongs to the technical field of preparation of architectural coatings. Modified polytetrafluoroethylene resin is creatively used as a matrix, and nano titanium dioxide is used as filler so as to prepare the glass coating, wherein the polytetrafluoroethylene resin which is modified by an adhesion promoter has ultra-high adhesion so that the performance of the aqueous transparent heat-insulating glass coating is more comprehensive, and organic pollutants adsorbed on the surface of the nano titanium dioxide are decomposed into carbon dioxide and oxygen through selection of the nano titanium dioxide as the filler, so that the original brightness of glass is maintained, and a good heat insulating effect is achieved without influence on the transparency of the glass. The aqueous transparent heat-insulating glass coating has the advantages of strong adhesion, long service life, good water resistance, strong viscosity resistance, strong anti-staining performance, strong UV resistance, high transparency and a good thermal insulation effect, formaldehyde and other indoor harmful organic compounds can be decomposed, and therefore the coating has a very broad application prospect and advantage.

Owner:上海金泰子建筑装饰工程有限公司

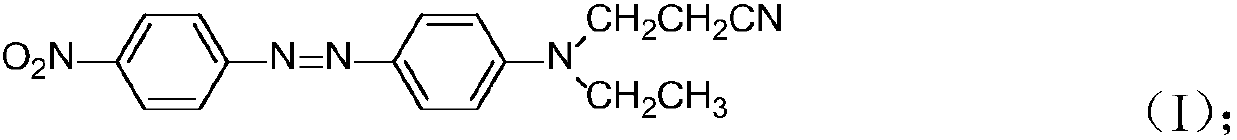

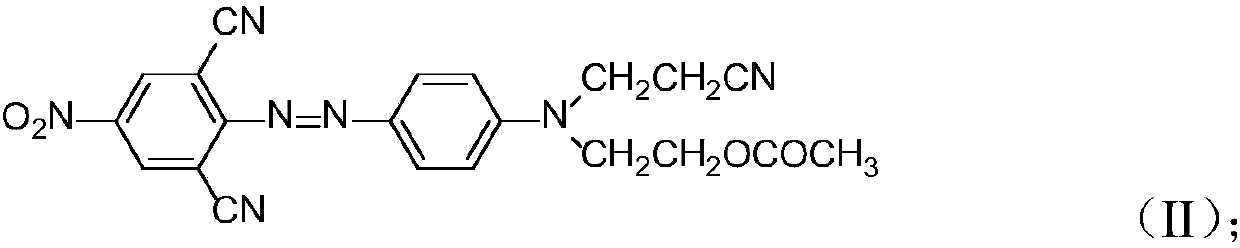

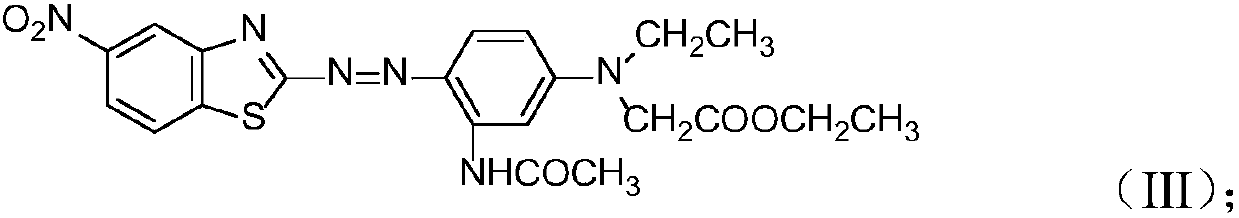

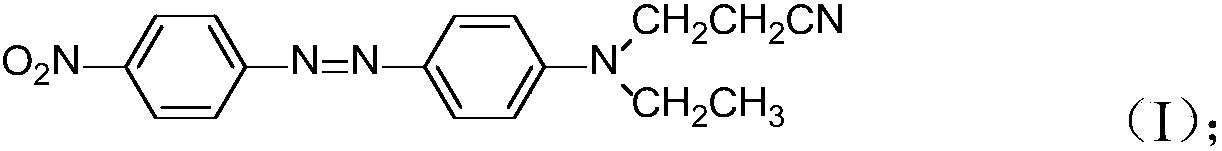

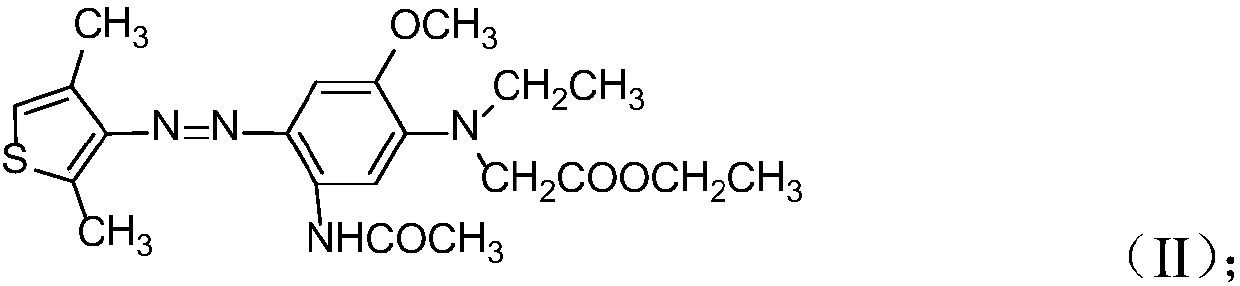

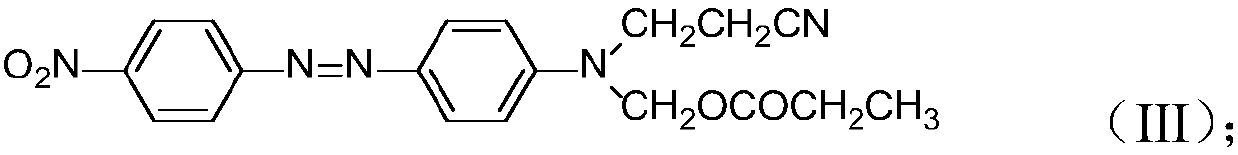

Black dye composition and application of black dye composition in wool dyeing

InactiveCN107936615AGood dyeing rateHigh color fastnessOrganic dyesDyeing processDisperse dyeWool fiber

The invention discloses a black dye composition and application of the black dye composition in wool dyeing. The black dye composition comprises 30-50% of a component A which is shown in a formula (I), 30-50% of a component B which is shown in a formula (II), 1-15% of a component C which is shown in a formula (III), 1-15% of a component D which is shown in a formula (IV) and 1-10% of a component Ewhich is shown in a formula (IV). According to the black dye composition and application of the black dye composition in wool dyeing, the reactive dye (the component E) is mixed with a disperse dye so as to obtain the dye composition which takes the disperse dye as the main component and the reactive dye as the assistant component; and not only can the dye composition have good wet fastness and strong color fastness, but also the binding ability of the dye composition and wool fiber can be enhanced greatly since the component E has a modifying effect on other disperse dye monomers, so that the dye composition has high dye-uptake to the wool fiber.

Owner:卢梅雅

A kind of fluorine-containing polyurethane and preparation method thereof

ActiveCN106674473BEasy to storeEasy to migrateAntifouling/underwater paintsPaints with biocidesWater contactDiol

The invention discloses a fluorine-containing polyurethane and a preparation method thereof. Addition polymerization reaction of fluorine-containing alkyl polyether diol and diisocyanate, catalyzed by tin catalyst, chain extension by chain extender, adding aminosilane coupling agent to end capping, to prepare a fluorine-containing polyurethane; the product has Fluorine-containing polyether block, high fluorine content, the fluoroalkyl group located in the polyether side group is prone to microphase separation and surface migration, low surface energy of polyurethane, fluorine-containing polyurethane is terminated with silane coupling agent, easy to store and easy to cure . The coating prepared by the fluorine-containing polyurethane of the present invention has a water contact angle higher than 110° and excellent water repellency.

Owner:UPCHEM CHINA

Concrete release agent and preparation method thereof

InactiveCN110157535AChange surface electrical propertiesLower potentialCeramic shaping apparatusLubricant compositionPolyvinyl alcoholActive agent

The invention discloses a concrete release agent and a preparation method thereof, and belongs to the field of building materials. A release active agent adopted in the preparation method is obtainedby taking cottonseed oil as a raw material and adding n-decanol and the like to carry out a reaction, carboxyl carried by the release active agent is subjected to a saponification reaction with a hydration product in concrete, meanwhile, surface hydrophobicity is increased by formed esteryl carboxylic acid with a long carbon chain structure, and the concrete potential is reduced, so that the concrete is well protected. According to a self-repairing additive adopted in the preparation method, gelatin and xanthan gum are bonded by polyvinyl alcohol to form a protective outer wall to inhibit corrosion to a release interface, and then durability of the concrete is influenced. A lubricating coating additive is adopted in the preparation method, epoxidized soybean oil and fluoropropyl-containingpolyhedral oligomeric silsesquioxane are polymerized, so that dust adhesion of a mold is reduced, and the de-molding effect is improved. The release active agent is added to improve flatness and a rust inhibitor is added for corrosion-preventing protection, so that use performance of the concrete is enhanced. According to the invention, the problem that an existing release agent is poor in mold release effect is solved.

Owner:谷银香

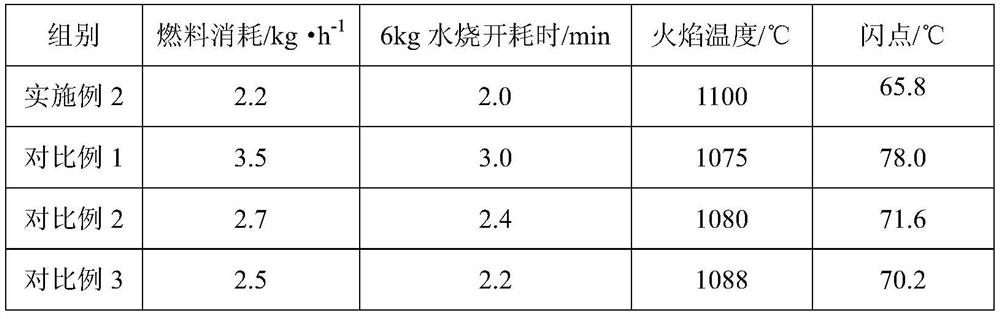

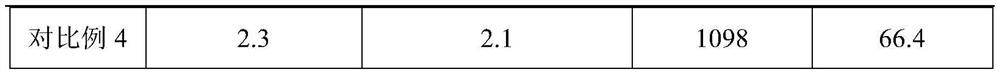

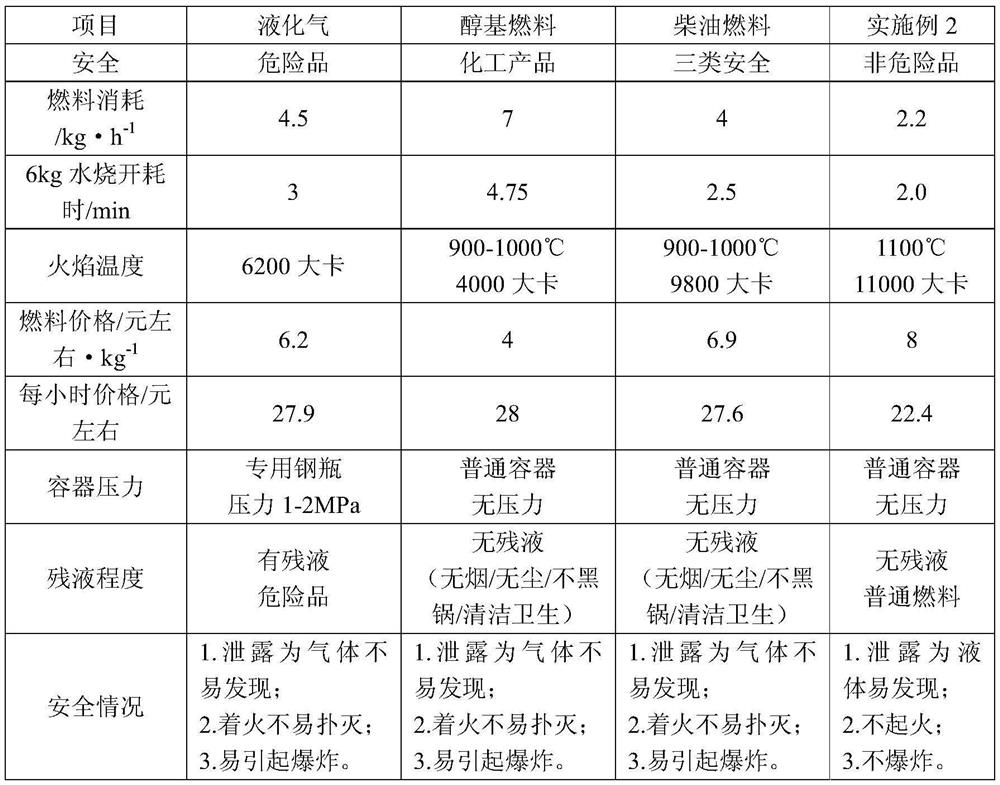

Energy-saving environment-friendly alcohol-free vegetable oil fuel and preparation method thereof

InactiveCN112940807AHigh calorific valueImprove stabilityLiquid carbonaceous fuelsFuel additivesVegetable oilTert butyl

The invention discloses an energy-saving and environment-friendly alcohol-free vegetable oil fuel which comprises the following raw materials: vegetable oil, a POSS-phosphorylated vegetable oil polymer, methyl tertiary butyl ether, isopropanol, ethylene glycol, glycerol, absolute ethyl alcohol, magnesium powder, ferrocene and water. The invention also discloses a preparation method of the energy-saving and environment-friendly alcohol-free vegetable oil fuel, which comprises the following steps: S1, preparing methyl tert-butyl ether, isopropanol, ethylene glycol, glycerol and absolute ethyl alcohol into a mixing agent, and adding the mixing agent and the POSS-phosphorylated vegetable oil polymer into the vegetable oil to prepare a mixed solution; s2, adding water into the mixed solution, carrying out ultrasonic dispersion, and uniformly stirring to obtain a water-in-oil mixed solution; and S3, adding the magnesium powder and the ferrocene into the water-in-oil mixed solution, and uniformly stirring to obtain the magnesium-in-oil composite material. The vegetable oil fuel prepared by the invention is low in flash point, has better properties than liquefied gas, alcohol-based fuel and diesel fuel, and has the advantages of energy conservation, environmental protection, safety, cleanness, high efficiency and good economic benefit.

Owner:NANJING XINGJING CHEM

A kind of hydrophobic membrane based on fluorine-containing polyurethane and its preparation method

ActiveCN106750432BEasy to storeEasy to migrateAntifouling/underwater paintsPaints with biocidesPolymer sciencePtru catalyst

The invention discloses a hydrophobic film based on fluorine-containing polyurethane and a preparation method thereof; the fluorine-containing polyurethane is spin-coated to form a film, and the hydrophobic film based on fluorine-containing polyurethane is obtained after curing; Addition polymerization of isocyanate, catalyzed by tin catalyst, extended by chain extender, and capped with aminosilane coupling agent to obtain fluorine-containing polyurethane; the product has a fluorine-containing polyether block with high fluorine content, located in the polyether The fluoroalkyl group of the side group is prone to microphase separation and surface migration, and the surface energy of the polyurethane is low. The fluorine-containing polyurethane is terminated with a silane coupling agent, which is easy to store and cure. The hydrophobic membrane based on fluorine-containing polyurethane disclosed by the invention has a water contact angle higher than 110° and excellent water repellency.

Owner:SUZHOU UNIV

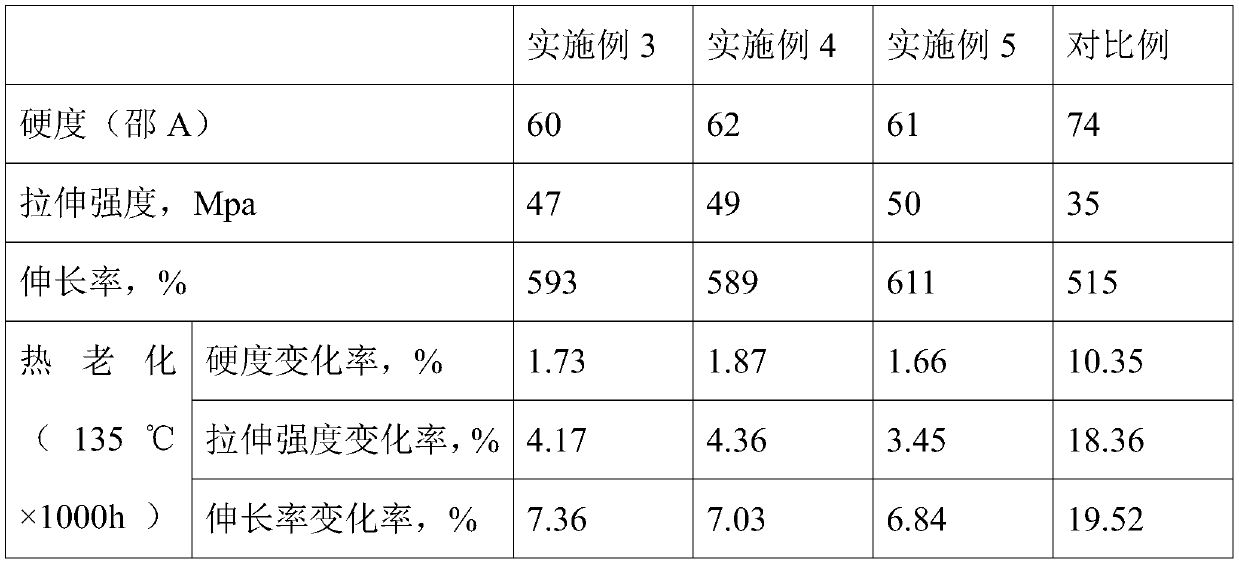

High-temperature-resistant and aging-resistant thermoplastic elastomer material

The invention discloses a high-temperature-resistant and aging-resistant thermoplastic elastomer material. The material comprises the following raw materials in parts by weight: 100 parts of a thermoplastic elastomer, 15-25 parts of butadiene-acrylonitrile rubber, 4-10 parts of phenolic resin, 20-40 parts of a reinforcing agent, 2-4 parts of an interfacial compatibilizer, 2-6 parts of composite zirconium dioxide, 1-2 parts of a peroxide vulcanizing agent, 1-2 parts of naphthenic oil, 4-8 parts of an antioxidant and 1-2 parts of a lubricant. The thermoplastic elastomer comprises thermoplastic polyurethane elastomer rubber and an ethylene-butyl acrylate copolymer; the reinforcing agent is at least one of polypropylene fibers, carbon nanotubes, basalt fibers, polyborate fibers and nanocellulose whiskers; the interfacial compatibilizer is at least one of a maleic anhydride grafted ethylene-vinyl acetate copolymer, a maleic anhydride grafted ethylene-propylene copolymer, a maleic anhydridegrafted ethylene-octene copolymer and a maleic anhydride grafted ethylene-ethylene-propylene rubber copolymer.

Owner:六安市叶集区聚诚高分子材料有限公司

Environment-friendly release agent for autoclaved aerated concrete block and preparation method of environment-friendly release agent

InactiveCN112852533AGood release effectExcellent mold releaseCeramic shaping apparatusLubricant compositionVegetable oilPolyethylene glycol

The invention discloses an environment-friendly release agent for autoclaved aerated concrete blocks. The environment-friendly release agent is prepared from the following raw materials in parts by weight: vegetable oil, a POSS-phosphorylated vegetable oil polymer, polyethylene glycol, nano calcium carbonate, ammonium polycarboxylate, a compound emulsifier, C12 alcohol ester, emulsified silicone oil, xanthan gum and water. The invention also discloses a preparation method of the environment-friendly release agent for autoclaved aerated concrete blocks, which comprises the following steps: dispersing the POSS-phosphorylated vegetable oil polymer into the vegetable oil containing polyethylene glycol to obtain a dispersion liquid; dissolving a compound emulsifier, emulsified silicone oil and xanthan gum in hot water to obtain emulsified water; and adding nano calcium carbonate, ammonium polycarboxylate and emulsified water into the dispersion liquid, adding the C12 alcohol ester and adding water for dilution, and uniformly stirring all the components to obtain the modified vegetable oil environment-friendly release agent. The release agent disclosed by the invention has the advantages of high film forming speed, small adhesion amount, low cost, no toxicity, no pollution and good release effect.

Owner:广西建工集团建筑产业投资有限公司

Composite modifier capable of improving activation degree of heavy calcium carbonate for silicone adhesive and use method of composite modifier

PendingCN112920767AImprove thermal stabilityImprove the lubrication effectNon-macromolecular adhesive additivesVegetable oilStearic acid

The invention discloses a composite modifier capable of improving the activation degree of heavy calcium carbonate for a silicone adhesive. The composite modifier comprises a silane coupling agent, a titanate coupling agent, an aluminate coupling agent, stearic acid and a POSS-phosphorylated vegetable oil polymer. The invention also discloses a use method of the composite modifier capable of improving the activation degree of the heavy calcium carbonate for the silicone adhesive according to the claims, and the use method comprises the following steps: adding the POSS-phosphorylated vegetable oil polymer into powder, performing reacting for 1-5 minutes, then adding the silane coupling agent, the titanate coupling agent and the aluminate coupling agent, performing reacting for 3-5 minutes, then adding the stearic acid, and continuously performing reacting for 1-10 minutes. After the composite modifier is used for modifying the heavy calcium carbonate for the silicone adhesive, the heavy calcium carbonate has good dispersity, extremely high activation degree, higher whiteness and extremely low oil absorption value, and the thixotropy and tensile strength of the silicone adhesive can be effectively improved.

Owner:广西碳酸钙产业化工程院有限公司 +1

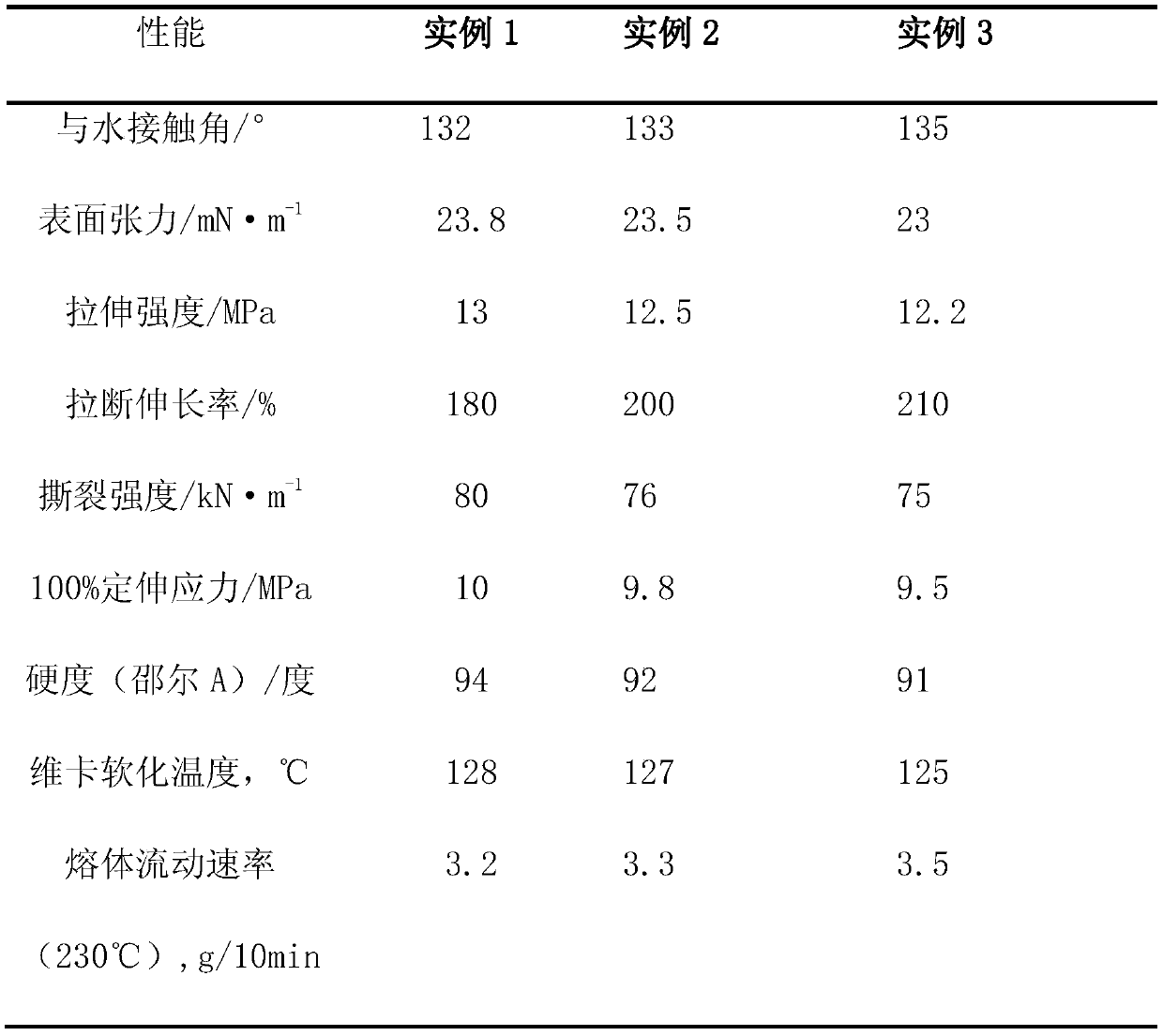

A kind of hydrophobic and heat-resistant thermoplastic elastomer and its preparation method

ActiveCN107325404BSolve the problem of degrading PPReduce surface tensionPlastic/resin/waxes insulatorsElastomerVulcanization

The invention relates to a lyophobic and thermal-resistant type thermoplastic elastomer and a preparation method thereof. The preparation method comprises the following steps: by taking polypropylene (PP) as a base material, performing dynamic vulcanization on methyl vinyl silicone rubber (MVQ) and a polyethylene-octylene elastomer (POE) to prepare the thermoplastic elastomer, performing commixing modification on PP and the thermoplastic elastomer by using a double-screw extruder, and further adding polytetrafluoroethylene micro powder of 200 meshes, thereby obtaining a novel thermoplastic material which is good in self-cleaning property, excellent in mechanical property and good in high temperature resistance and can be recycled.

Owner:QINGDAO UNIV OF SCI & TECH +1

Mask outer packaging bag capable of invalidating regularly and production method thereof

PendingCN113956639AImprove securityNot easy to stick to dustAntifouling/underwater paintsPaints with biocidesAnti bacterialAntibacterial property

The invention discloses a mask outer packaging bag capable of invalidating regularly and a production method thereof, and relates to the field of packaging bags, a biodegradable film with good biodegradability is prepared firstly, then the biodegradable film is coated with an antibacterial and hydrophobic coating with good antibacterial and bacteriostatic performance and water-repellent and stain-resistant performance, and a timed invalidating film is obtained; the mask outer packaging bag capable of invalidating regularly is obtained by cutting the timed invalidating film into a packaging bag, the mask outer packaging bag capable of invalidating regularly has good antibacterial and hydrophobic performance, the antibacterial performance can ensure that the safety is good and bacterial pollution is avoided when the mask is loaded, and the hydrophobic performance can ensure that the packaging bag is not easy to stick dust and rot when meeting water, and the sanitation degree of the mask is further ensured; after the mask outer packaging bag capable of invalidating regularly is discarded, the biodegradable film is exposed after the mask outer packaging bag is crushed, and the mask outer packaging bag can be quickly degraded through good biodegradability.

Owner:无锡纯宇环保制品有限公司

Green dispersion dye composition and application thereof in wool dyeing

The invention discloses a green dispersion dye composition and application thereof in wool dyeing. The green dispersion dye composition comprises the following components in percentage by mass: 30-50%of a component A of formula (I) as shown in the specification, 20-35% of a component B of formula (II) as shown in the specification, 15-25% of a component C of formula (III) as shown in the specification, 12-20% of a component D of formula (IV) as shown in the specification, and 3-5% of a component E of formula (IV) as shown in the specification. According the green dispersion dye composition, awool active dye monomer as the component E is mixed with other dispersed dye monomers, the component E has a modification function on other dispersed dye monomers in the dyeing process, the binding property of the dye composition with a wool fiber is greatly improved, and the dye composition has a relatively high dyeing rate for the wool fiber. A wool product dyed with the dye composition disclosed by the invention is green, is not only bright in color, but also good in uniform dyeing property, and has a relatively great market application prospect.

Owner:卢梅雅

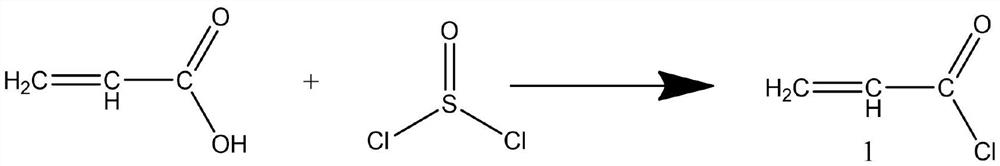

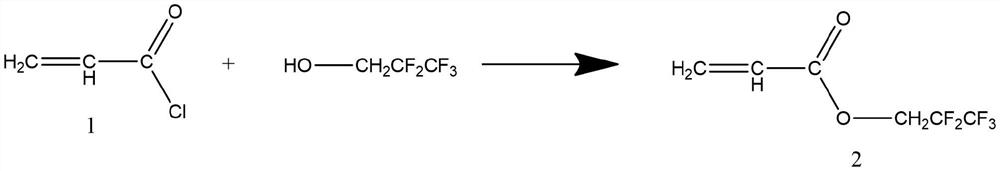

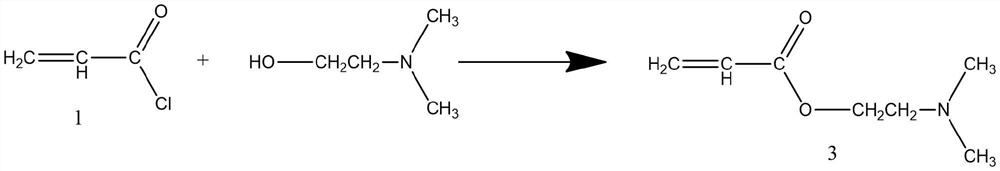

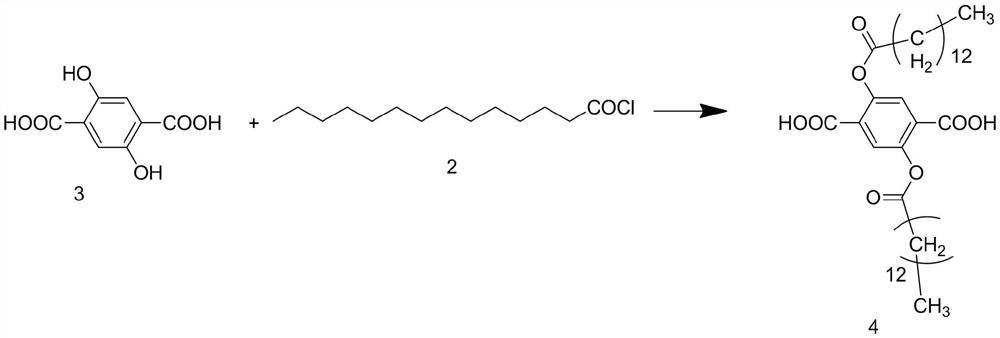

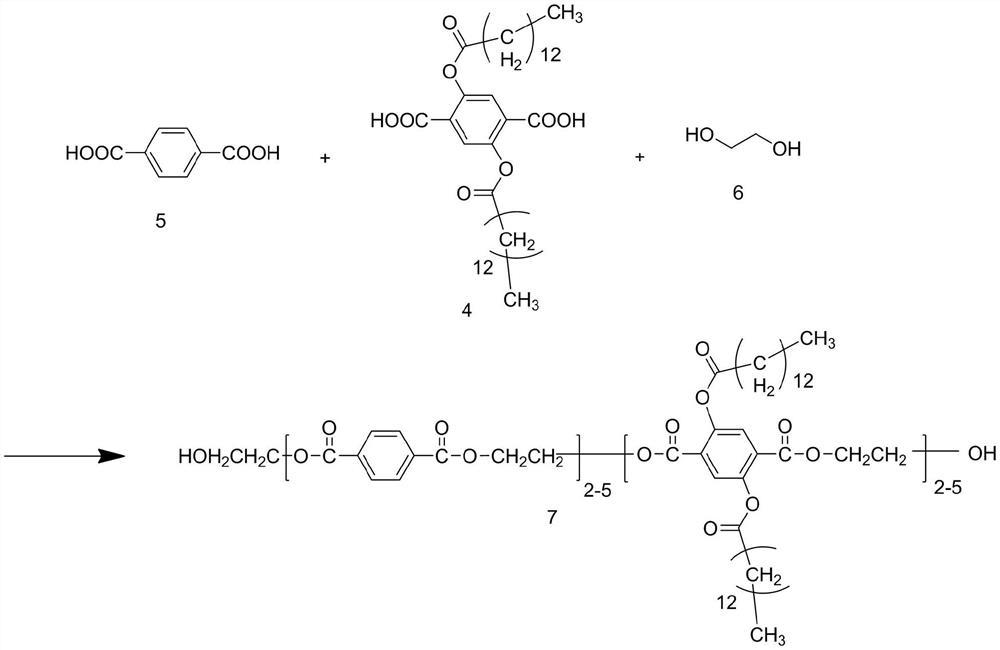

A kind of preparation method of antifouling cloth for clothing production

ActiveCN109267167BHas a singleHigh purityOrganic compound preparationCarboxylic acid esters preparationYarnPolymer science

Owner:宁波维尼服饰有限公司

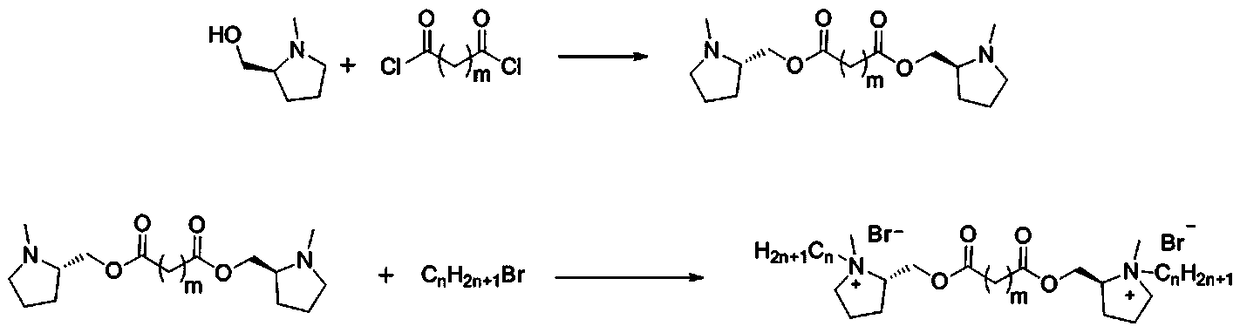

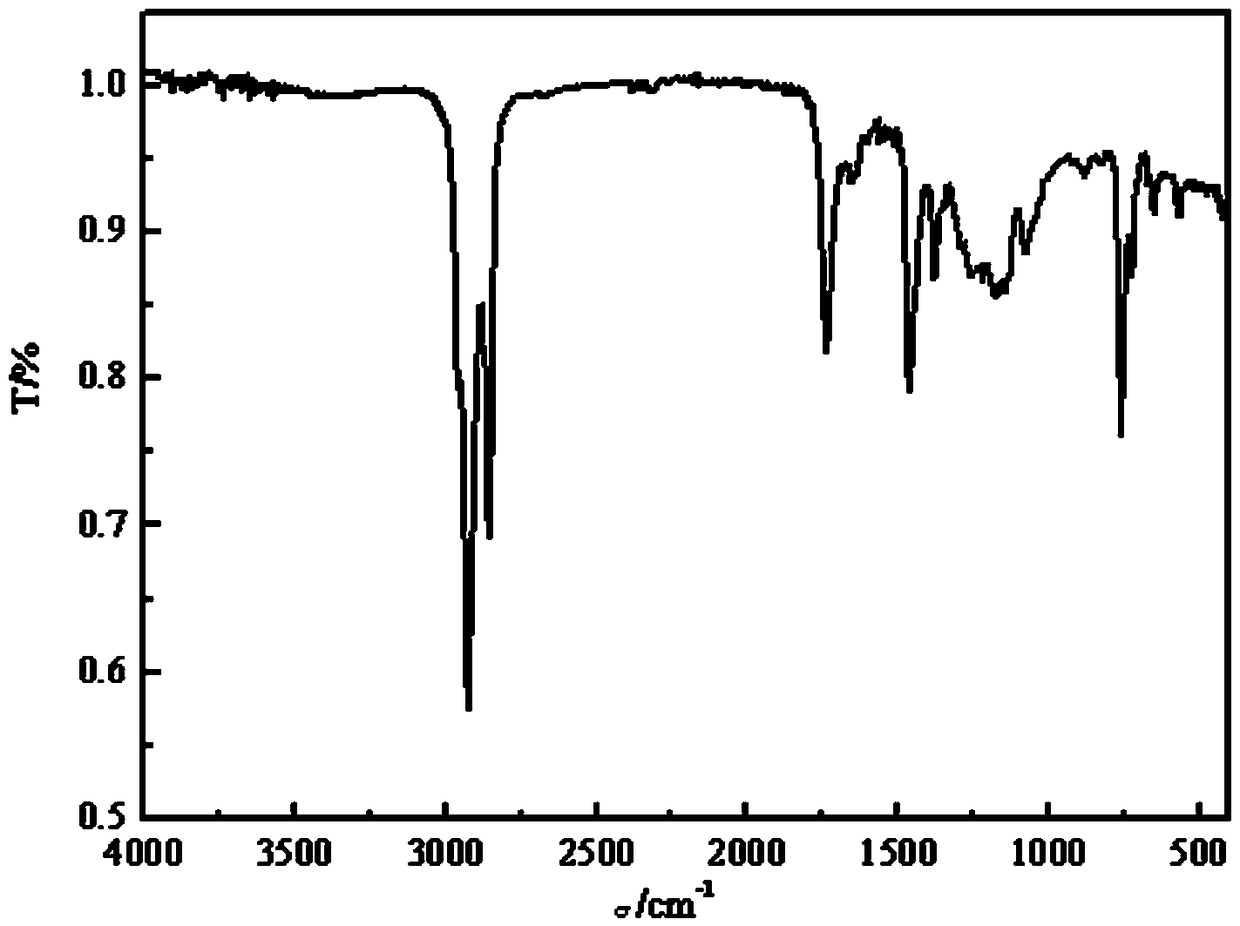

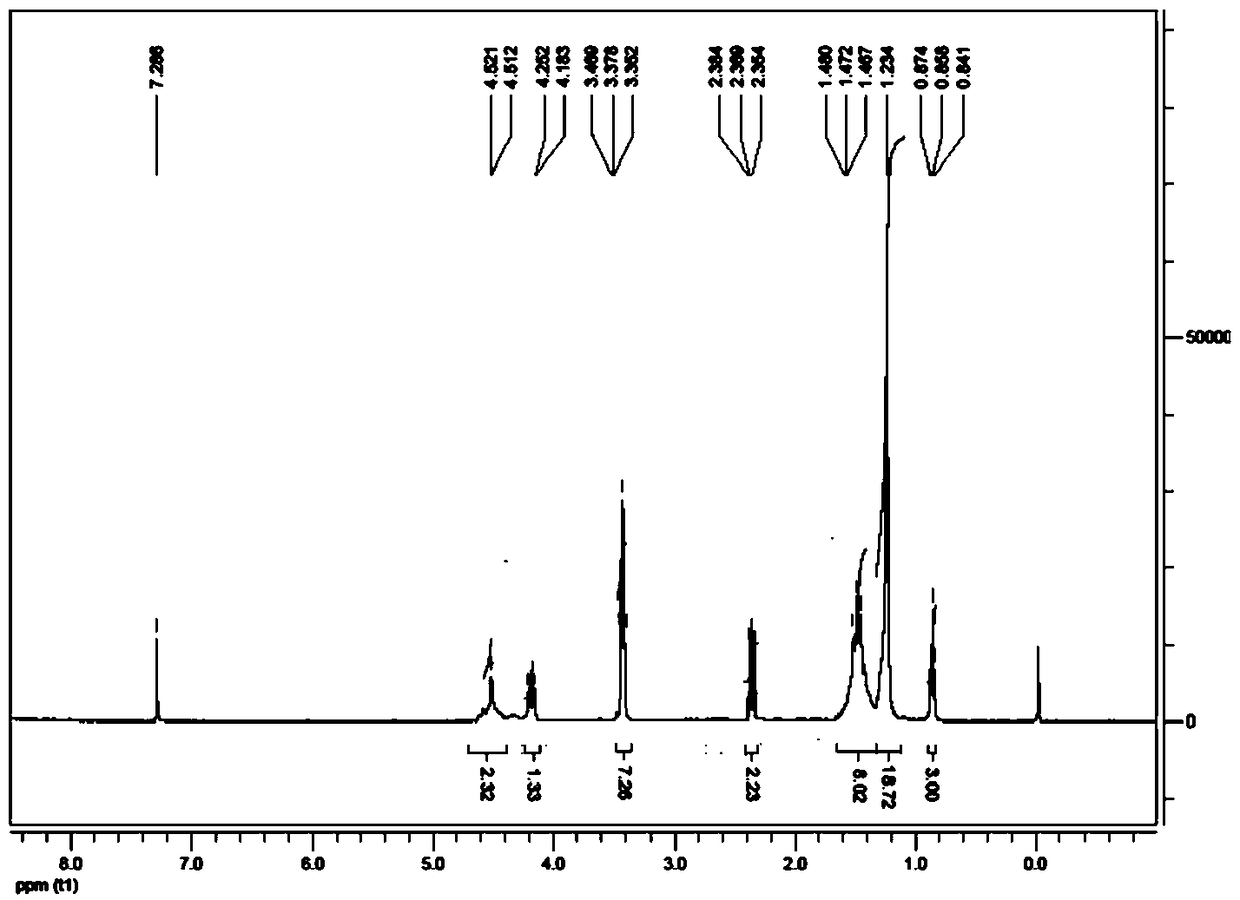

Pyrrolidine type chiral Gemini surfactant with linking groups containing ester groups and preparation method thereof

ActiveCN108854841AEasy to degradeThe synthesis steps are simpleTransportation and packagingOrganic chemistry methodsPyrrolidineSURFACTANT BLEND

The invention relates to a pyrrolidine type chiral Gemini surfactant with linking groups containing ester groups and a preparation method thereof, and belongs to the technical field of surfactants, which can solve the problem of lack of synthesizing and property in the existing pyrrolidine type chiral Gemini surfactant. The preparation method comprises the following steps of using pyrrolidine as ahydrophilic head group; using the ester group as a linkage group; firstly, synthesizing alkyl diacid di (N-methyl-L-prolinol) ester; then, synthesizing the surfactant. The preparation method has theadvantages that the synthesizing steps are simple, and the separating and purifying are easy. The prepared pyrrolidine type chiral Gemini surfactant has optical activity and good surface activity.

Owner:长治学院

High-efficiency anti-adhesive uv release coating applied to pressure-sensitive adhesives and its preparation and application

ActiveCN105315881BNo releaseOvercome polymerization inhibitionPolyurea/polyurethane coatingsEpoxy resin coatingsPolymer scienceAcrylic resin

The invention provides a high-efficiency anti-sticking UV release coating applied to pressure-sensitive adhesives and its preparation and application; the coating comprises the following components and weight percentages: photoinitiator 3-8%, co-initiator 3-5% %, reactive diluent 20‑40%, silicone acrylic resin 15‑45%, non-silicon type acrylic resin 25‑45%. The present invention adopts a free radical and cationic compound initiator system, and utilizes the sensitization effect obtained by the synergistic effect of the two to better solve the problems of oxygen inhibition and slow curing caused by the single initiator, and at the same time, the photocuring speed is fast , good solubility, absorption wavelength up to 390nm, is a high-efficiency, energy-saving, environmentally friendly light-curing release coating.

Owner:SHANGHAI CHENGYING NEW MATERIALS

A kind of preparation method of water-based transparent heat-insulating glass coating

InactiveCN108912871BImprove adhesionGood anti-adhesiveAntifouling/underwater paintsPaints with biocidesThermal insulationOrganic compound

The invention relates to a preparation method of an aqueous transparent heat-insulating glass coating, and belongs to the technical field of preparation of architectural coatings. Modified polytetrafluoroethylene resin is creatively used as a matrix, and nano titanium dioxide is used as filler so as to prepare the glass coating, wherein the polytetrafluoroethylene resin which is modified by an adhesion promoter has ultra-high adhesion so that the performance of the aqueous transparent heat-insulating glass coating is more comprehensive, and organic pollutants adsorbed on the surface of the nano titanium dioxide are decomposed into carbon dioxide and oxygen through selection of the nano titanium dioxide as the filler, so that the original brightness of glass is maintained, and a good heat insulating effect is achieved without influence on the transparency of the glass. The aqueous transparent heat-insulating glass coating has the advantages of strong adhesion, long service life, good water resistance, strong viscosity resistance, strong anti-staining performance, strong UV resistance, high transparency and a good thermal insulation effect, formaldehyde and other indoor harmful organic compounds can be decomposed, and therefore the coating has a very broad application prospect and advantage.

Owner:上海金泰子建筑装饰工程有限公司

Oil-proof coating of down jacket and production method of oil-proof coating

PendingCN114717852AGood heat insulationIncrease oil resistanceTextiles and paperBulk chemical productionCyanate esterPolytetrafluoroethylene

The invention discloses a down jacket oil-proof coating and a production method thereof, and the oil-proof coating is prepared from the following raw materials: an auxiliary agent, polytetrafluoroethylene, silicon dioxide aerogel powder, a polyurethane solution, a foaming agent, resin, polyether polyol, isocyanate, a catalyst, polyethylene glycol adipate, polypropylene glycol, a filling agent and a curing agent, foaming slurry prepared from a foaming agent is coated on the coating, so that the coating has heat insulation and heat preservation functions, the oil-proof coating has a better heat insulation effect, the interior of the down jacket cannot be transferred to the coating, the temperature of the coating is lower, and the surface tension of oil stain liquid falling onto the coating cannot be reduced; the oil stain liquid is prevented from immersing into the coated fabric, so that the oil stain resistance of the down jacket is improved through the oil-proof coating, and the wearing time of the down jacket is prolonged.

Owner:GAOFAN (ZHEJIANG) INFORMATION TECH CO LTD

Nanometer composite epoxy resin building material

The invention discloses a nanometer composite epoxy resin building material. The nanometer composite epoxy resin building material comprises 60 to 85 parts of cement, and 20 to 40 parts of an epoxy resin adhesive; the epoxy resin adhesive comprises, by weight, 80 to 90% of a composite epoxy resin, 6 to 10% of a curing agent, and 5 to 10% of a reactive diluent; after ring opening, a linear epoxy resin and 2,5-di(tetradecanoic acid ester) terephthalic acid are subjected to polymerization esterification so as to obtain an epoxy resin pre-modified body, aliphatic chains are introduced as flexiblechains, and linear epoxy resin flexibility is improved; nanometer modified cerium oxide is dispersed in the epoxy resin pre-modified body, so that acting force much higher than Van der Waals' force isachieved at the interface between nanometer modified cerium oxide and the hydroxyl and carboxyl of the epoxy resin pre-modified body, micro cracks and adsorption of energy are induced, epoxy resin system deformation is inhibited, and further toughening effect is achieved. When the nanometer composite epoxy resin building material is used in building materials, building material cracking possibility is reduced.

Owner:FUZHOU MAILIAO AUTOMATION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com