Nanometer composite epoxy resin building material

A technology of epoxy resin and building materials, which is applied in the field of building materials and can solve the problems of adverse effects on the safety and durability of concrete structures, low compression resistance, flexural resistance and crack resistance, poor flexibility and impact resistance, etc. , to achieve the effect of increasing anti-fouling and corrosion resistance, good bonding performance, and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A nanocomposite epoxy resin building material, comprising 60 parts of cement and 40 parts of epoxy resin adhesive, the epoxy resin adhesive includes the following components in weight percentage: the following components in weight percentage: composite ring Oxygen resin 80%, curing agent 10%, reactive diluent 10%;

[0052] Described curing agent is triethylamine;

[0053] Described reactive diluent is allyl glycidyl ether;

[0054] The preparation method of described composite epoxy resin specifically comprises the following steps:

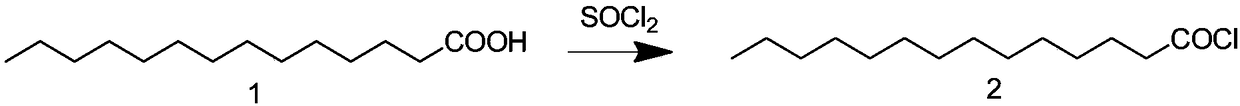

[0055] Synthesis of S1, myristyl chloride

[0056] The reaction formula is as follows:

[0057]

[0058] Dissolve 120 mol of myristic acid in chloroform, add 600 mol of thionyl chloride, heat up to reflux, and react for 2 hours. After the reaction, concentrate under reduced pressure to remove chloroform and unreacted thionyl chloride to obtain myristyl chloride 2. The yield is 98.6%;

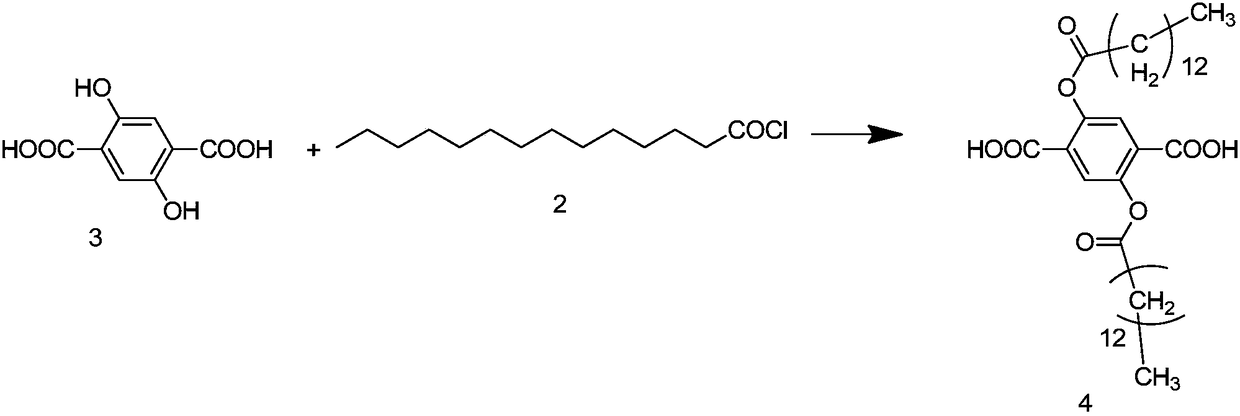

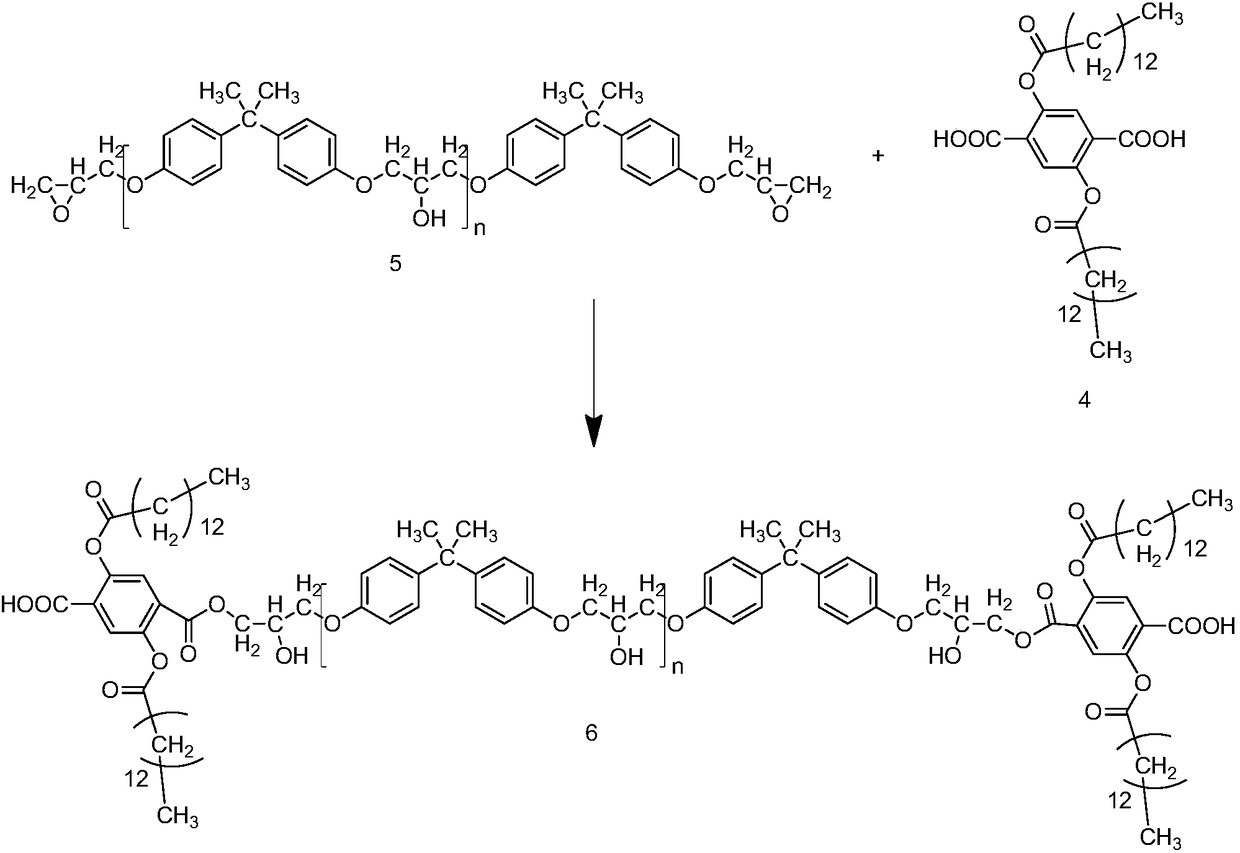

[0059] Synthesis of S2, 2,5-bis(tetradecyl)tere...

Embodiment 2

[0073] A nanocomposite epoxy resin building material, comprising 80 parts of cement and 20 parts of epoxy resin adhesive, the epoxy resin adhesive includes the following components in weight percentage: the following components in weight percentage: composite ring Oxygen resin 88%, curing agent 6%, reactive diluent 6%;

[0074] Described curing agent is triethylamine;

[0075] Described reactive diluent is allyl glycidyl ether;

[0076] The preparation method of described composite epoxy resin is with embodiment 1.

Embodiment 3

[0078] A nanocomposite epoxy resin building material, comprising 70 parts of cement and 30 parts of epoxy resin adhesive, the epoxy resin adhesive includes the following components in weight percentage: the following components in weight percentage: composite ring Oxygen resin 83%, curing agent 9%, reactive diluent 8%;

[0079] Described curing agent is triethylamine;

[0080] Described reactive diluent is allyl glycidyl ether;

[0081] The preparation method of described composite epoxy resin is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com