Patents

Literature

30results about How to "Make up for shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Former hot blast and latter vacuum microwave combining drying process of producing crisp fruit and vegetable grains

InactiveCN1672531AReduce drying loadReduced moisture removal requirementsFruits/vegetable preservation by dehydrationWater contentFood processing

The present invention is former hot blast and latter vacuum microwave combining drying process of producing fruit and vegetable grains, and belongs to the field of fruit and vegetable food processing technology. The drying process includes the steps of: washing fruit and vegetable material, dicing, scalding to killing enzyme, cooling in flow water, draining, optional fast freezing and defrosting, soaking with seasoning, draining, pre-dewatering with hot blast to obtain semi-finished product with water content of 40-60 %, and final vacuum microwave drying to obtain product with water content of 2-5 %. The said process has the nutritious components and color well maintained, crisp product, short production period, low cost, high product quality and other features.

Owner:JIANGNAN UNIV

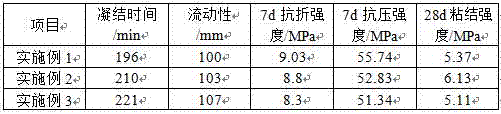

Water-borne epoxy resin modified cement mortar repair material and preparation method thereof

The invention provides a water-borne epoxy resin modified cement mortar repair material and a preparation method thereof. According to the formula composition, the water-borne epoxy resin modified cement mortar repair material comprises materials in percentage by weight as follows: 27%-30% of cement, 56%-59% of sand, 0.8%-1.0% of an expanding agent, 0.5%-0.7% of silica fume, 5.0%-7.5% of water, 2.0%-5.0% of water-borne epoxy resin, 1.0%-2.5% of a curing agent, 0.19%-0.22% of an antifoaming agent and 0.14%-0.16% of a water reducing agent. The water-borne epoxy resin modified cement mortar repair material has the characteristics of short setting time, excellent fluidity, high anti-compression and anti-bending strength, seismic resistance, low shrinkage strain, good durability, good water resistance, simplicity in production, convenience in construction and the like, the particularly prominent properties include the ultrahigh bonding strength and the excellent durability, the bonding strength is 100%-200% higher than that of general modified cement mortar, and the cement mortar repair material can be suitable for repairing cracks of concrete structures and is particularly applicable to structural engineering such as a subway, a bridge, an airport runway, an aqueduct, a tunnel lining and the like with higher repair difficulties.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

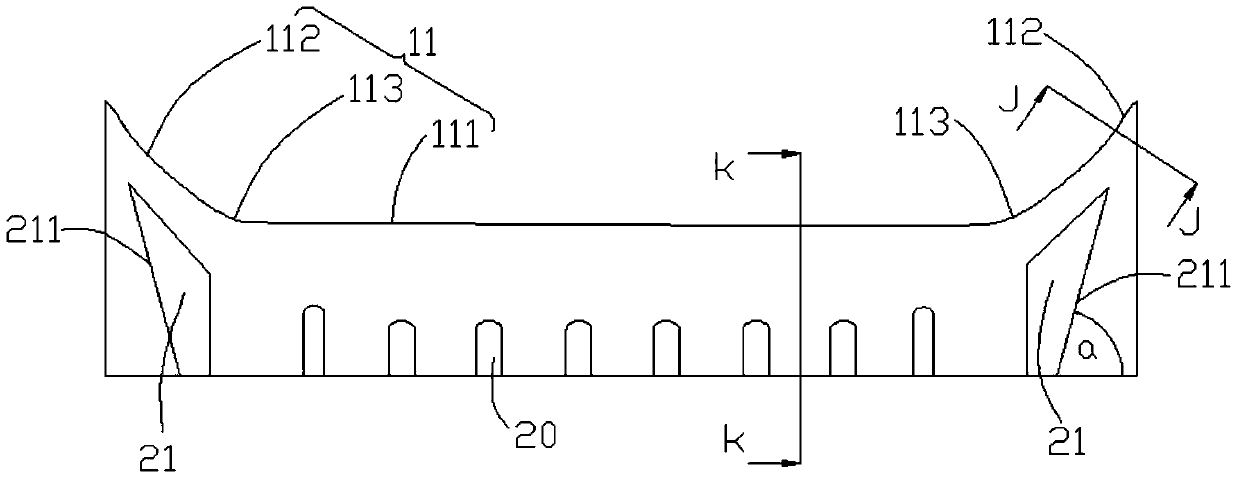

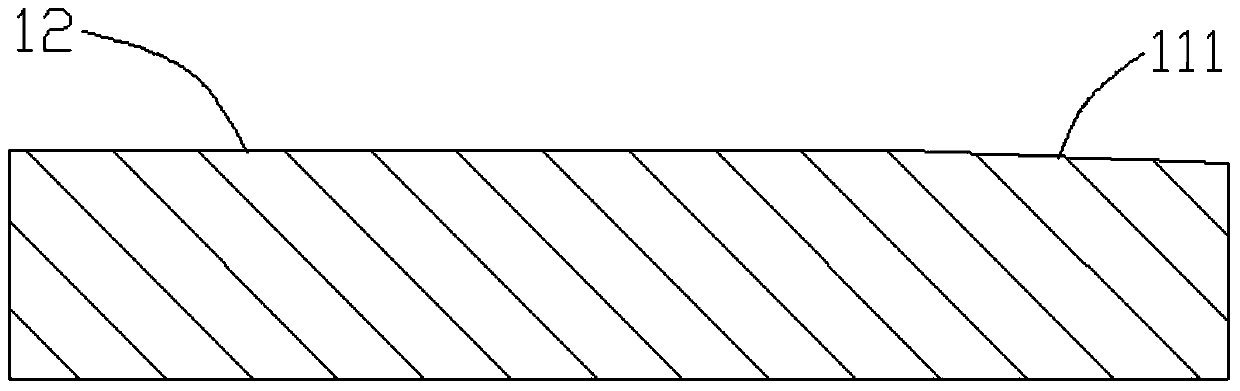

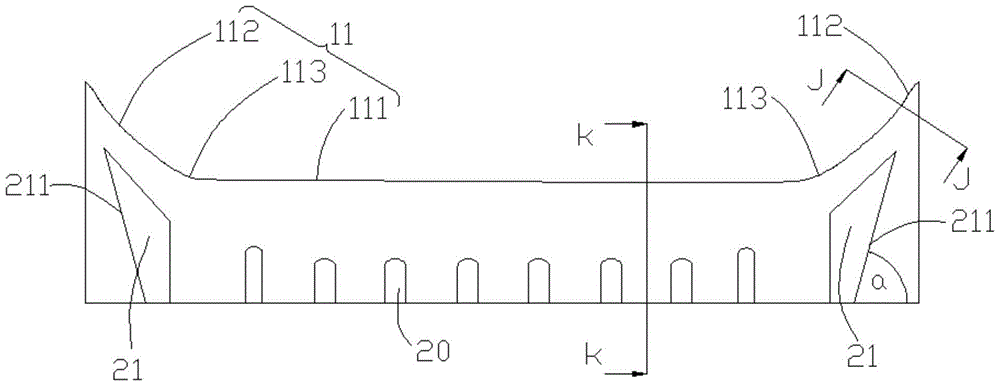

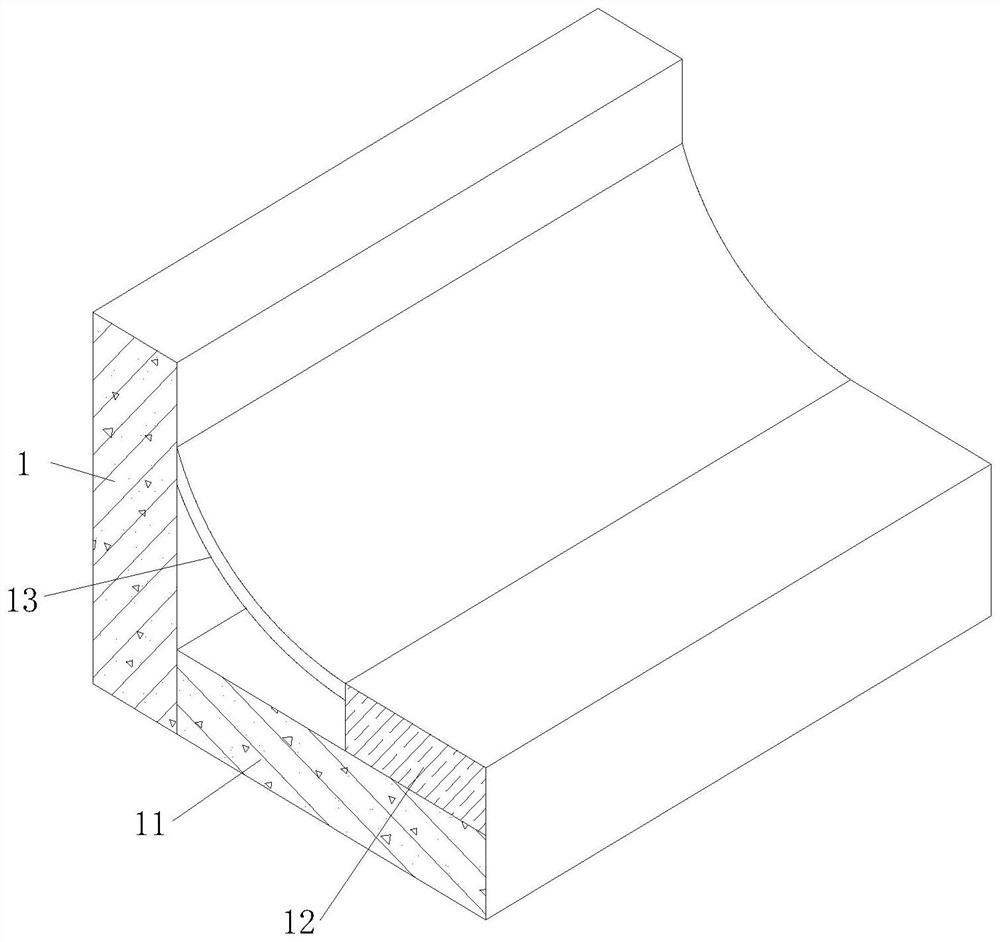

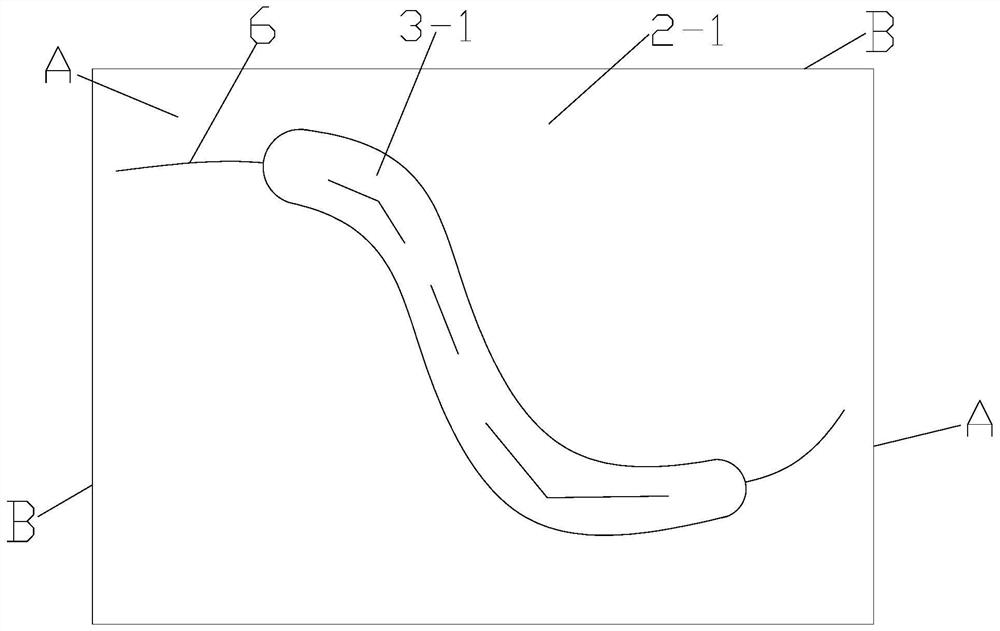

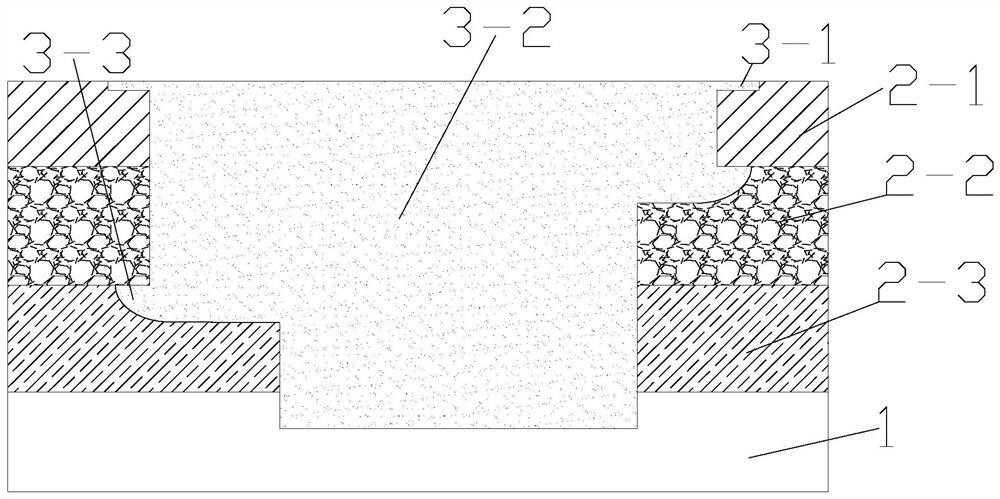

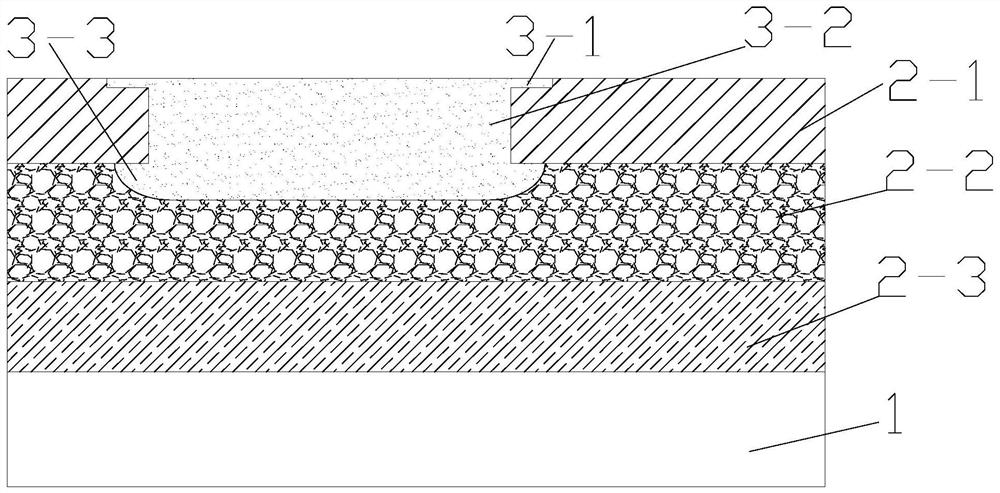

Narrow-face copper plate for chamfer crystallizer

The invention discloses a narrow-face copper plate for a chamfer crystallizer. A working face of the narrow-face copper plate for the chamfer crystallizer comprises a first part and a second part; the first part is a sunken curved surface; the first part is a part on the working face in a range of 200mm to 400mm apart from an upper port of the crystallizer. The first part comprises a first curved surface region, two second curved surface regions and two transition curved surface regions, wherein the first curved surface region is a second degree parabola region; the two second curved surface regions are curved surfaces of which the crown heights are 1mm to 3mm; the two transition curved surface regions are curved surfaces with radii of 5mm to 35mm; the two transition curved surface regions are respectively connected with two opposite sides of the first curved surface region and the two second curved surface regions. The second part is connected with the first curved surface region, the two second curved surface regions and the two transition curved surface regions; the second part is a linear conical surface. The narrow-face copper plate for the chamfer crystallizer is also provided with a cooling waterway for cooling the working face; the distance between the cooling waterway and the edge, which is far away from the transition curved surface regions, on each second curved surface region is 20mm to 40mm; the distance between the cooling waterway and each transition curved surface region is 10mm to 30mm.

Owner:SHOUGANG CORPORATION

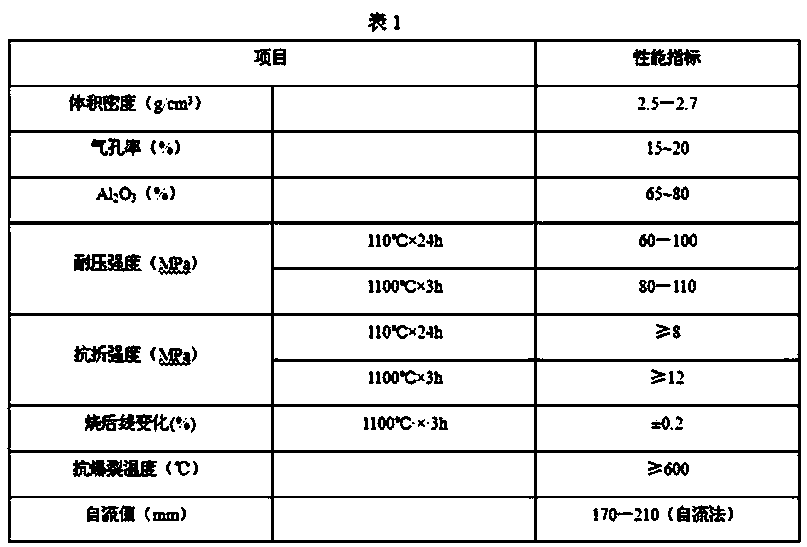

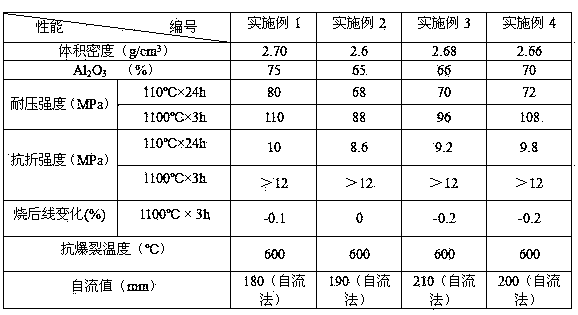

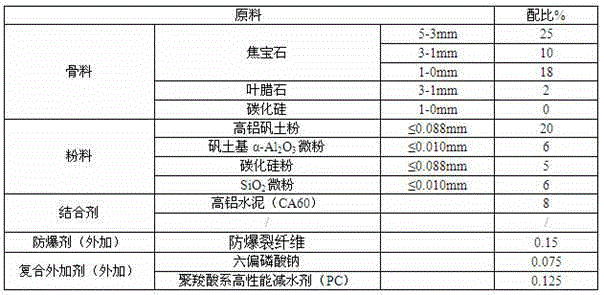

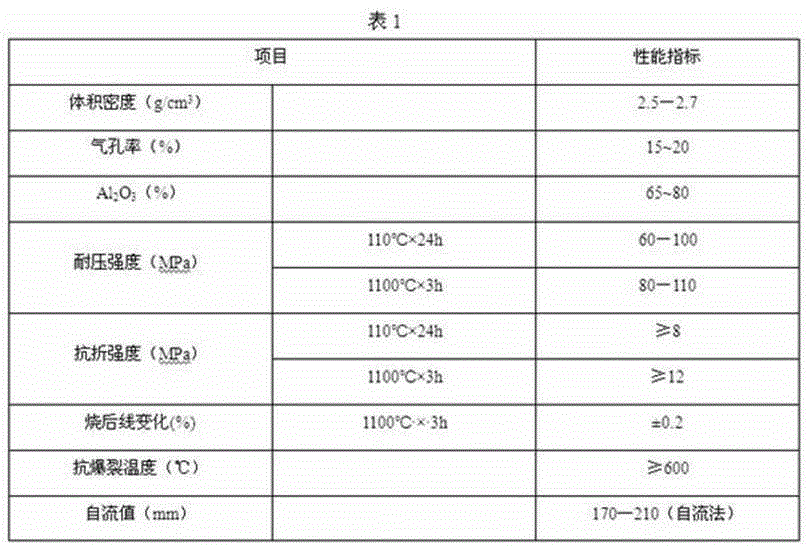

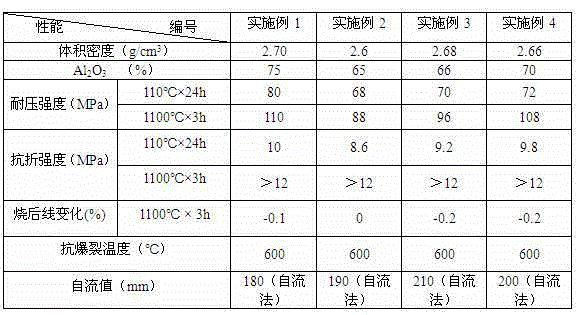

Early strength anti-detonation fireproof self-flow material

The invention belongs to the technical field of refractory materials, and particularly discloses an early strength anti-detonation fireproof self-flow material. The material comprises the following raw materials: alumina or flint clay, pyrophyllite, silicon carbide, alumina based alpha-Al2O3 micropowder, SiO2 micropowder and the like. Aluminate cement serves as a binding agent, and a composite additive and an antidetonator are added. The self-flow material has the advantages of early strength, high strength, detonation resistance, shortened demold time, rapid baking and the like, and has good resistance to high temperature.

Owner:郑州瑞泰耐火科技有限公司

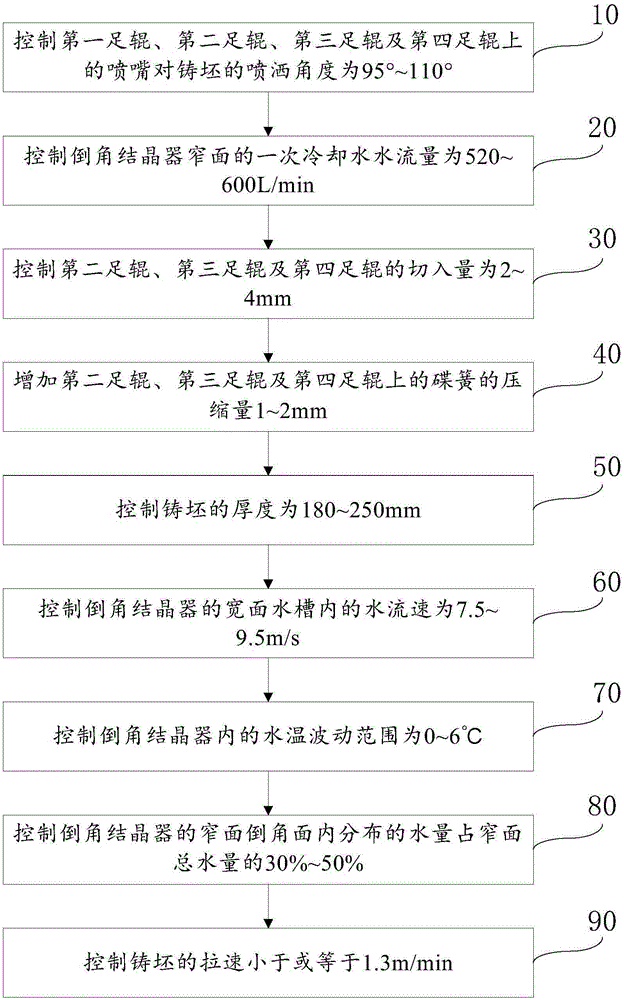

Control method of transverse corner cracks of casting blank of chamfering crystallizer

InactiveCN105414512AMake up for shrinkagePrevents transverse cracks at cornersSpray nozzleMetallurgy

The invention relates to the technical field of continuous casting, in particular to a control method of transverse corner cracks of a casting blank of a chamfering crystallizer. The control method includes the steps that the spraying angle of spray nozzles on a first foot roll, a second foot roll, a third foot roll and a fourth foot roll relative to the casting blank is controlled to range from 95 degrees to 110 degrees; and the water flow of primary cooling water of the narrow face of the chamfering crystallizer is controlled to range from 520 L / min to 600 L / min. According to the control method of the transverse corner cracks of the casting blank of the chamfering crystallizer, the spraying angles of the spray nozzles on the first foot roll, the second foot roll, the third foot roll and the fourth foot roll relative to the casting blank are controlled to range from 95 degrees to 110 degrees, the cooling effect of the chamfering portion of the casting blank of the chamfering crystallizer for microalloyed steel can be fully guaranteed, and meanwhile the influence on the following process of the casting blank is avoided; and in addition, the water flow of the primary cooling water of the narrow face of the chamfering crystallizer is controlled to range from 520 L / min to 600 L / min, and the transverse corner cracks can be prevented from being generated on the casting blank of the chamfering crystallizer for the microalloyed steel.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Siliceous stemming for filling blast furnace taphole and preparation method thereof

The invention relates to siliceous stemming for filling a blast furnace taphole and a preparation method thereof, and belongs to the field of high-temperature metallurgical fireproof materials. The method comprises the following steps of: pre-mixing 35 to 45 mass percent of diaspore silicate, 16 to 27 mass percent of silicon carbide, 3 to 5 mass percent of micro powder, 10 to 18 mass percent of ball clay, 2 to 4 mass percent of graphite, 1 to 3 mass percent of plasticizer, 6 to 10 mass percent of ferrosilicon nitride, 2 to 4 mass percent of metal powder, 3 to 5 mass percent of modified asphalt powder and 3 to 5 mass percent of expanding agent aluminum silicate fine powder for later use, putting into a wheel roller and pre-rolling for 5 minutes; adding 15 to 20 mass percent of modified liquid tar, performing wheel rolling at a high speed for 30 to 35 minutes to ensure that a Marshall value is between 4 and 16MPa; and packaging, and measuring the Marshall value 3 days later, wherein the product is qualified when the Marshall value is between 8 and 24MPa. The problems of low high-temperature strength and high-temperature toughness of the stemming are solved, and the problems of a shallow iron notch, a broken iron notch and splashing are solved simultaneously.

Owner:INST OF METALLURGICAL TECH DONGBEI UNIV SHENYANG

High-strength anti-freeze grouting material and preparation method thereof

The invention relates to a high-strength anti-freeze grouting material and a preparation method thereof. The high-strength anti-freeze grouting material is prepared from the following raw materials in parts by weight: 400 to 450 parts of composite cement, 400 to 500 parts of quartz sand, 40 to 60 parts of special steel fiber, 50 to 110 parts of pulverized slag powder, 20 to 40 parts of a composite expanding agent, 1 to 3 parts of a composite early strength agent, 2 to 7 parts of a polycarboxylate water reducing agent and 0.5 to 4 parts of a defoaming agent. The preparation method comprises the following steps: guiding the composite cement and the quartz sand in corresponding prehomogenization silos for carrying out prehomogenization, carrying out continuous blending according to weight proportions, and uniformly mixing the mixed material in a forced stirring machine, thus obtaining dry powder; then guiding the dry powder in a finished product homogenization silo; electronically metering, automatically packaging into a finished product, and conveying the finished product to a finished product silo. The high-strength anti-freeze grouting material obtained through the preparation method has the characteristics of good fluidity, high strength, minimum inflation, good anti-freeze performance and no toxicity and can well adapt to operation under a high and cold environment.

Owner:ZHENGZHOU SINO SINA BUILDING MATERIALS CO LTD

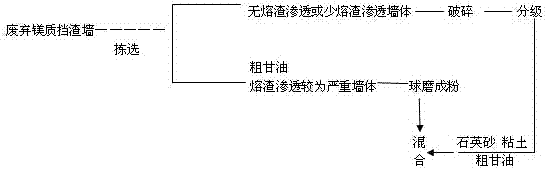

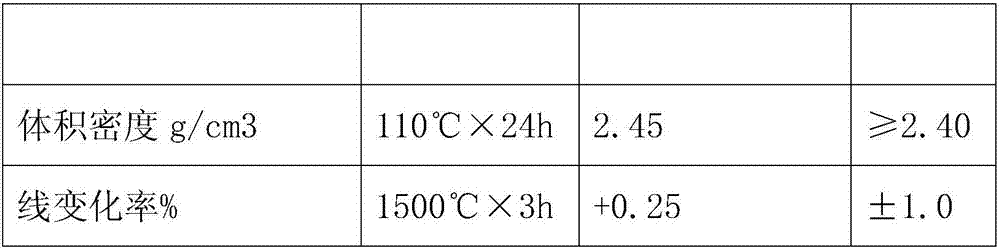

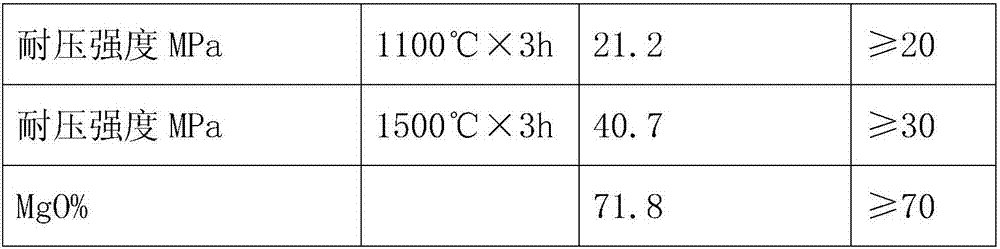

Method for preparing tundish seating brick ramming material by using waste magnesia slag wall

The invention discloses a method for preparing tundish seating brick ramming material by using a waste magnesia slag wall. The method comprises the following steps: classifying and sorting the recycled waste magnesia slag wall, and manually removing surface residues; clearing away residues on waste refractory bricks, steel and a deteriorative layer through knocking via an iron hammer; after the surface residues are manually removed, conveying the waste magnesia slag wall into a receiving hopper of a crushing machine, and after the waste magnesia slag wall passes through the crushing machine, screening particles into particles with three particle sizes of 5 to 3 mm, 3 to 1 mm and 1 to 0 mm according to a blending demand of a refractory material, thus preparing the tundish seating brick ramming material. Fine powder adopt magnesite powder, clay is used as a sintering agent, and quartz is used as an expanding agent; the magnesite powder, the clay and the quartz are mixed with crude glycerine, thus preparing a half-wet material. Therefore, no agglomeration phenomenon is caused within a one-year storage time period.

Owner:湛江市红鹰铭德新材料科技有限公司

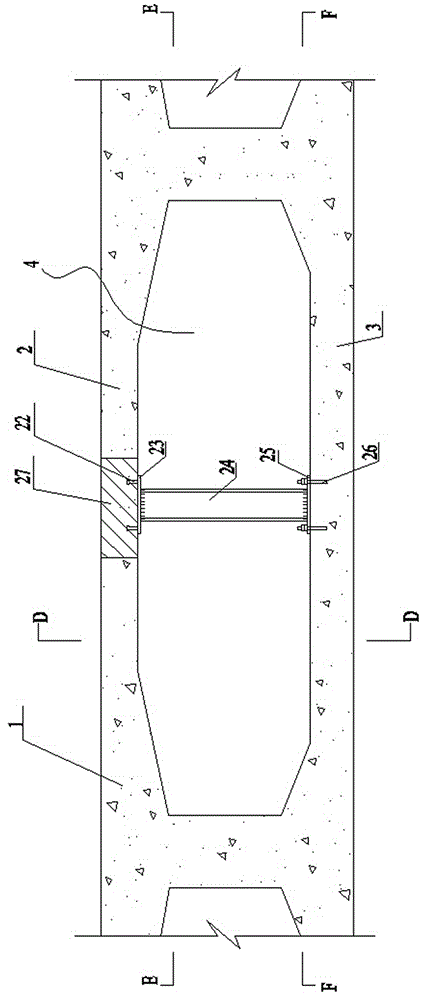

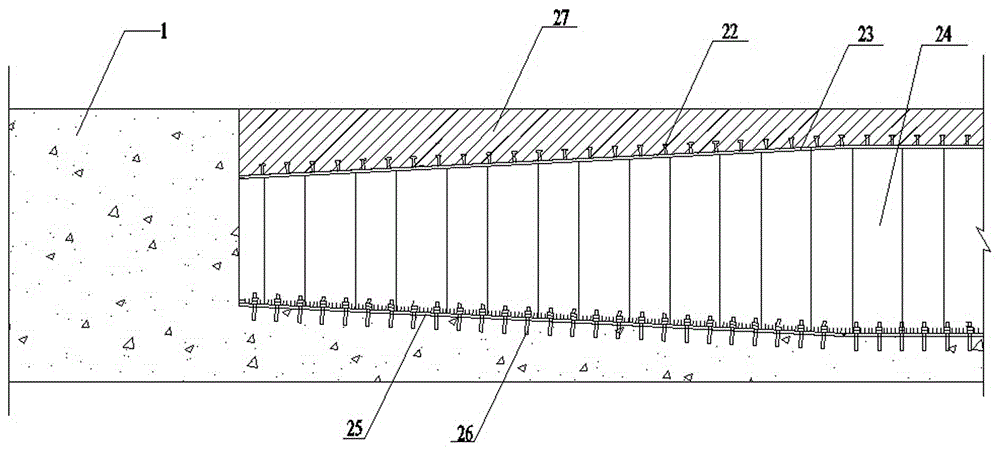

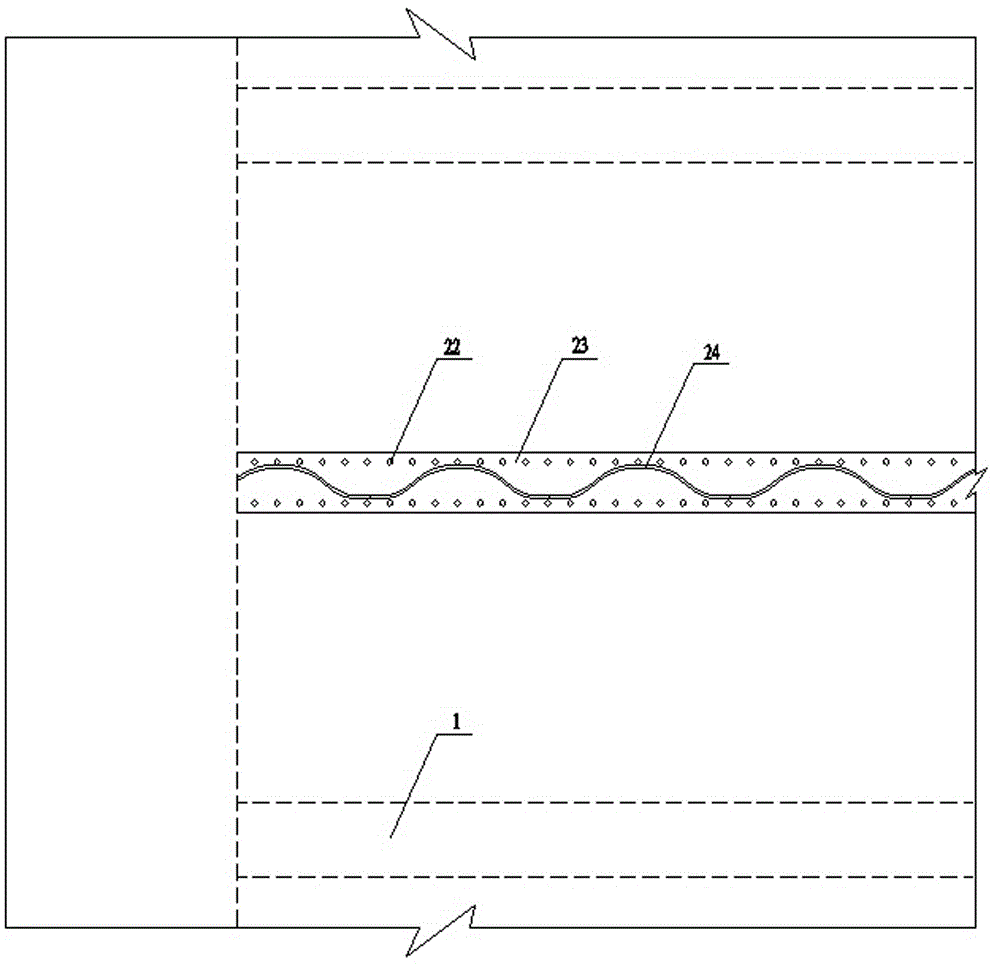

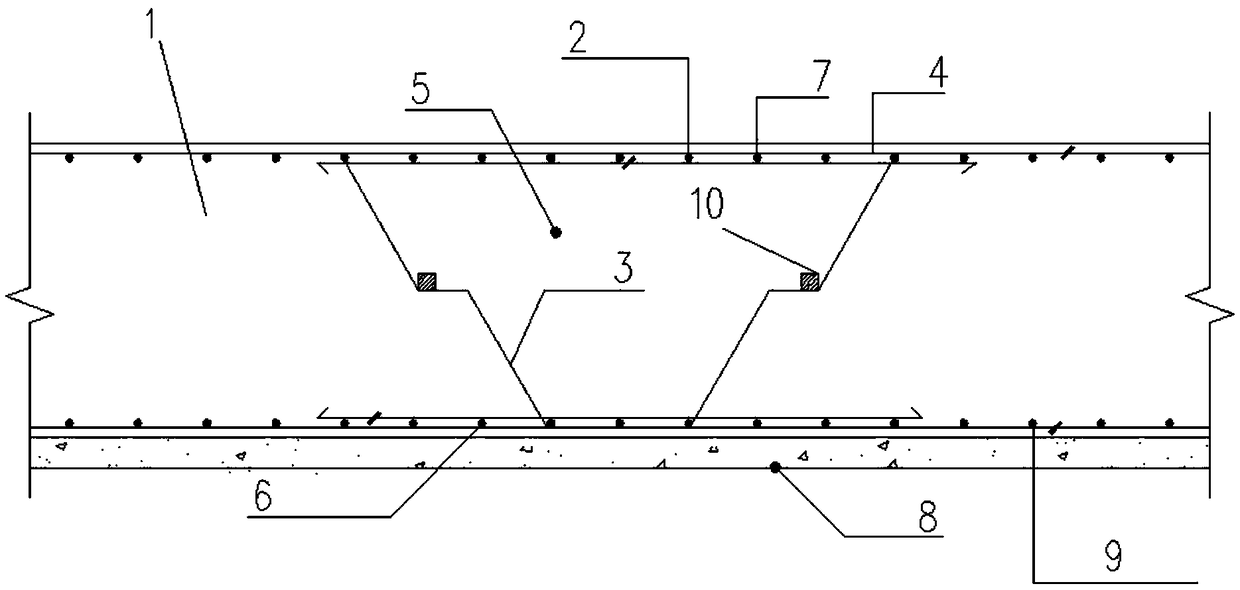

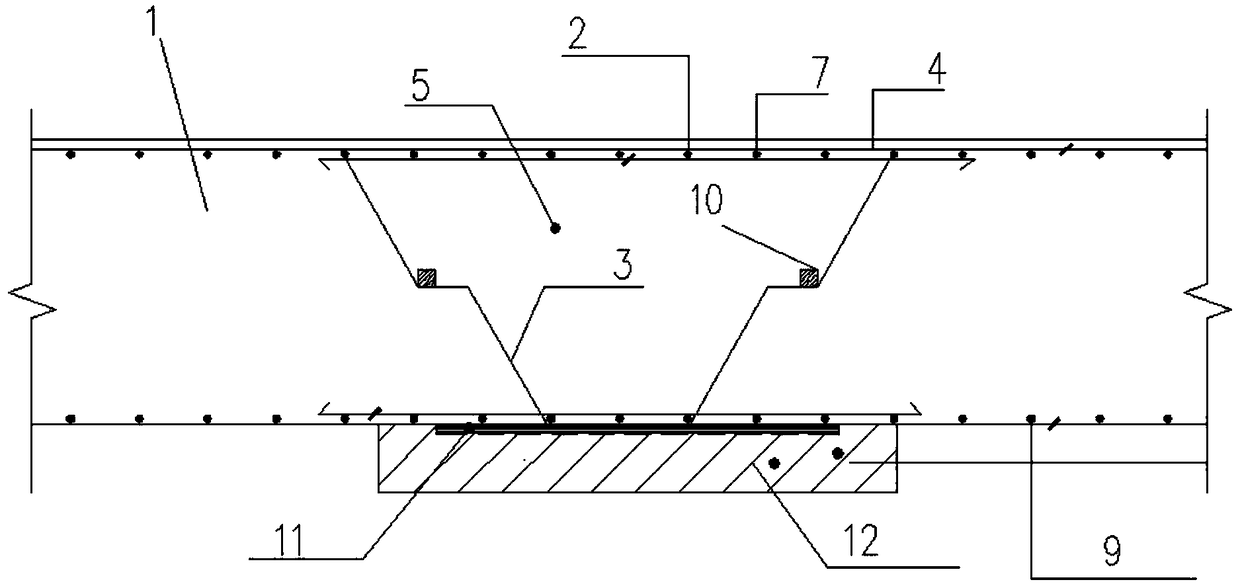

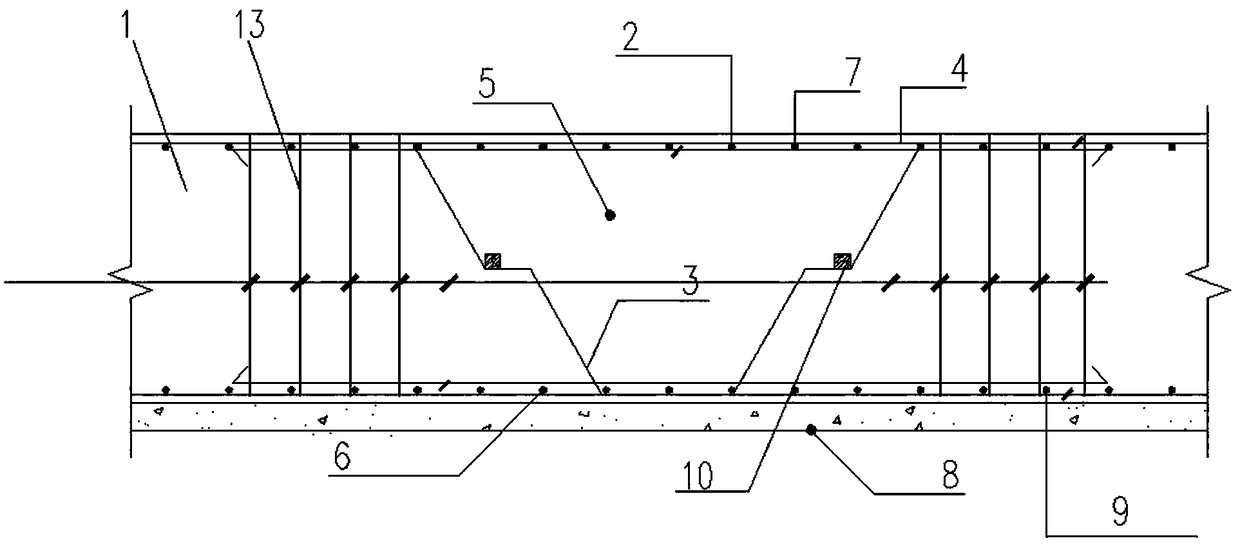

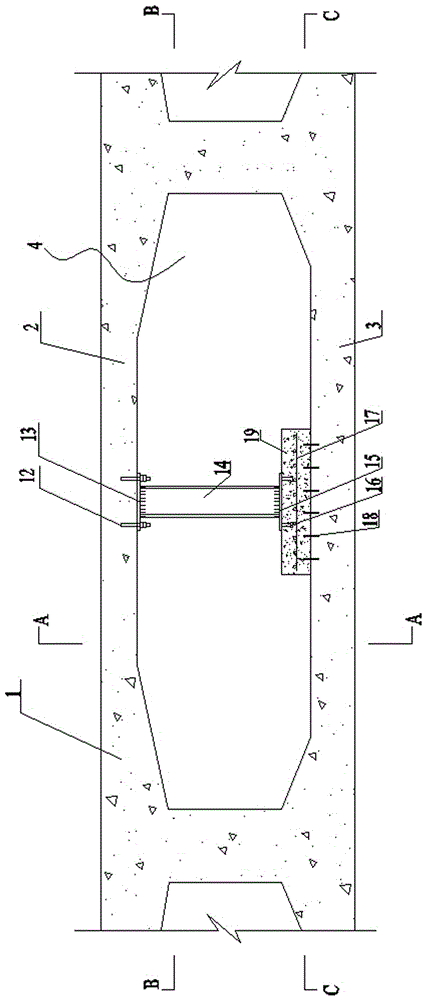

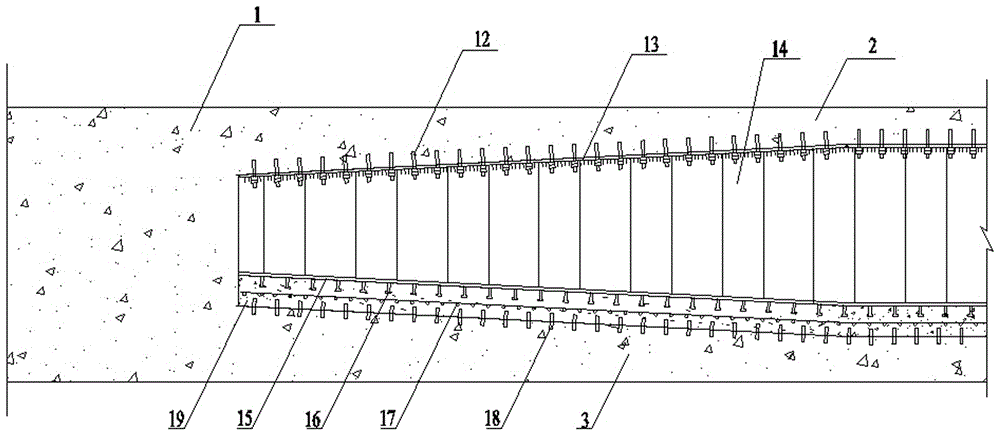

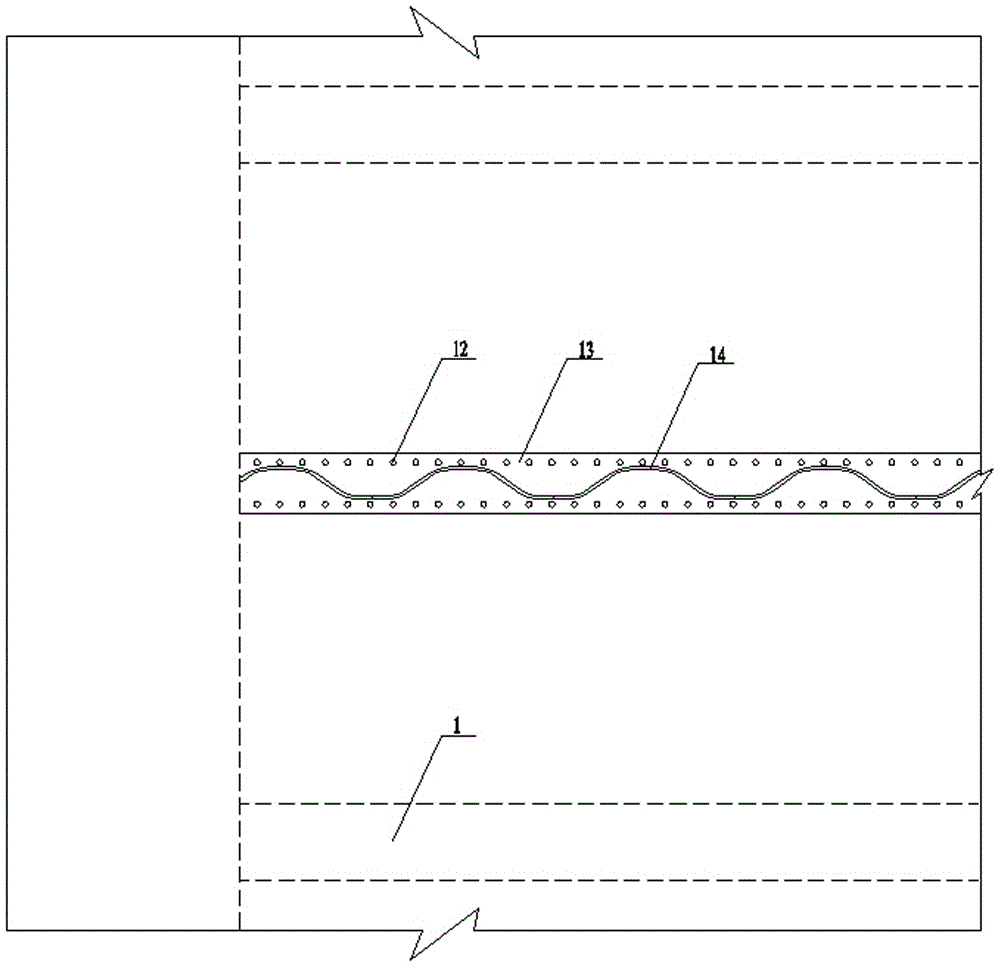

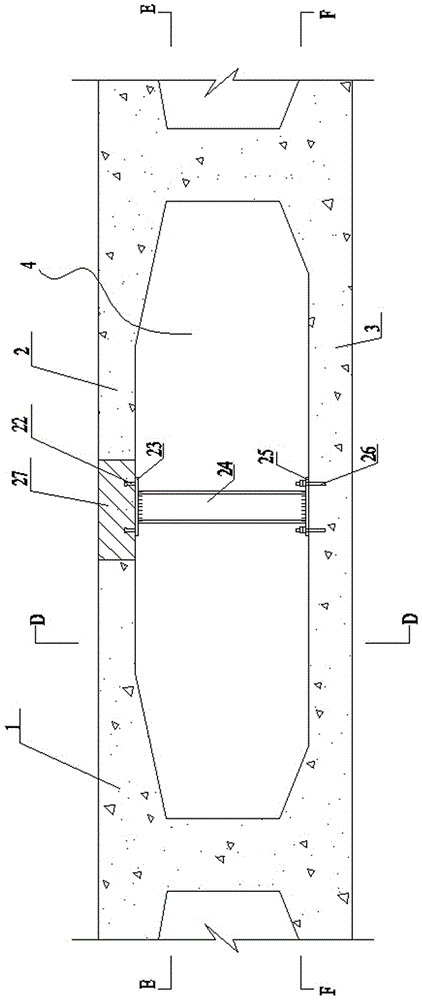

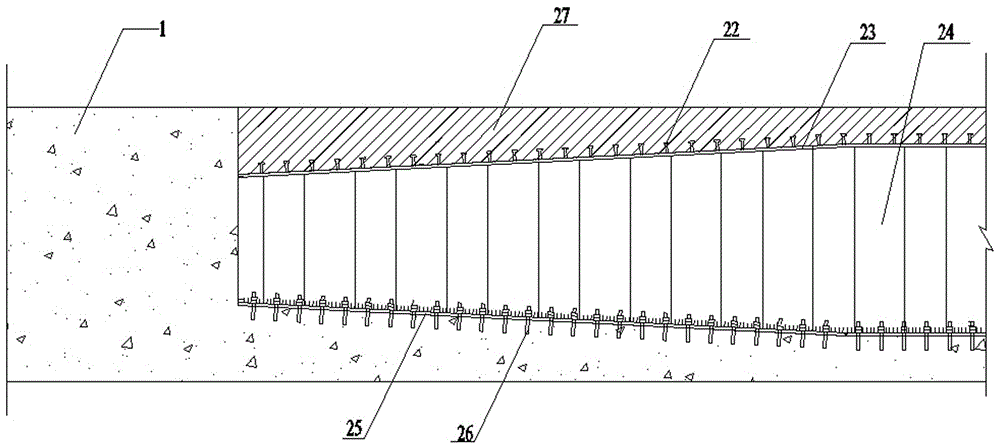

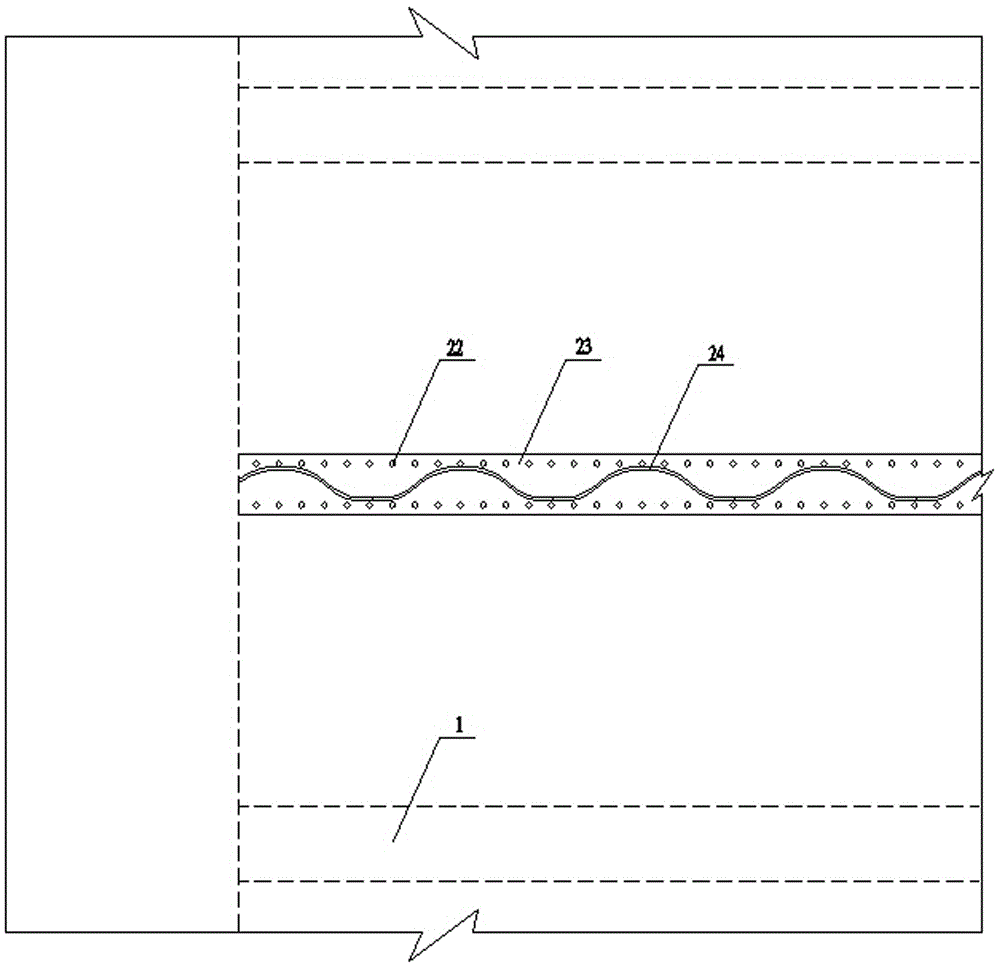

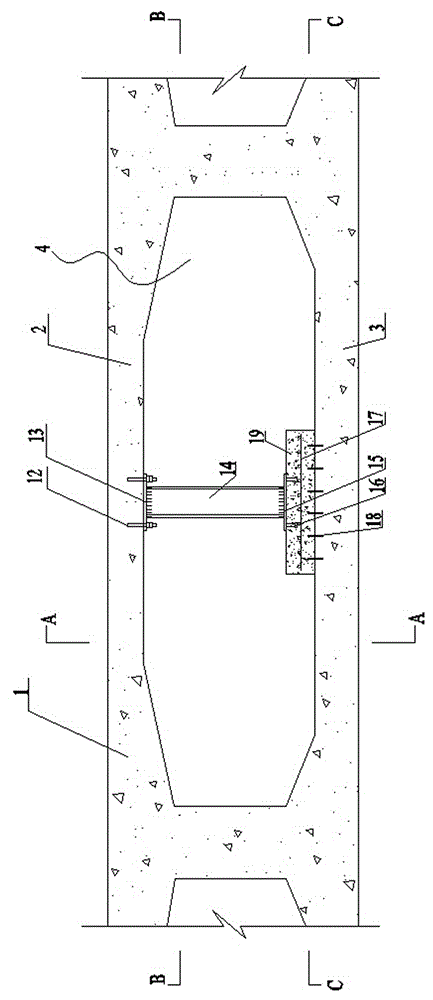

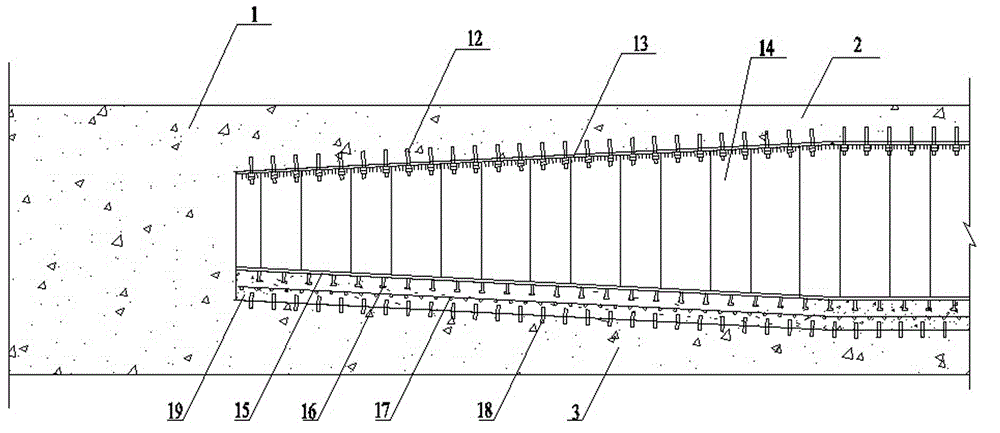

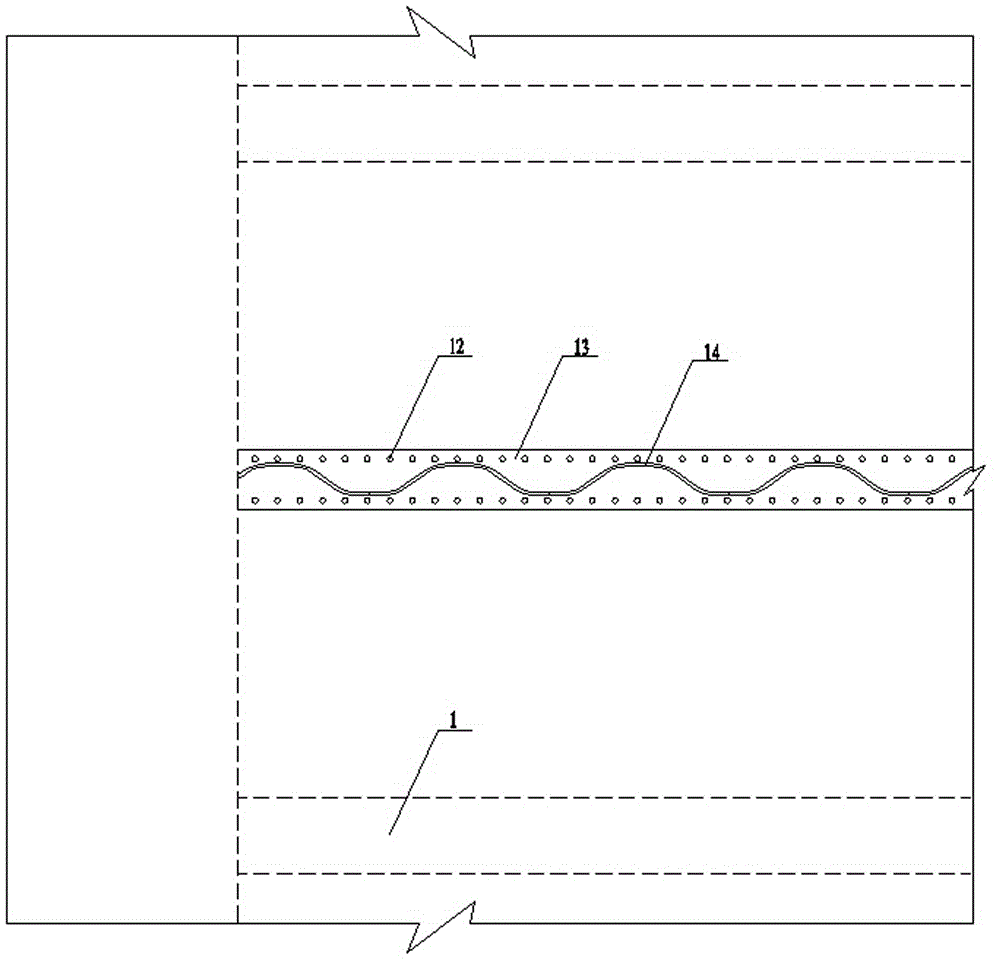

Construction method for carrying out shear strengthening on concrete box girder by adopting corrugated steel web

ActiveCN104695339AEasy to shrinkMake up for shrinkageBridge erection/assemblyBridge strengtheningBox girderFlange

The invention discloses a construction method for carrying out shear strengthening on a concrete box girder by adopting a corrugated steel web. The construction method sequentially comprises the following steps: performing construction layout positioning on a box girder top plate and a box girder bottom plate; forming a hole in the box girder top plate; processing and strengthening a junction surface; drilling an anchor bolt hole in the top surface of the box girder bottom plate; blanking the corrugated steel web; drilling a hole in a lower flange plate, and polishing the lower flange plate; welding and mounting the corrugated steel web; pouring concrete into the hole of the box girder top plate. The construction method has the advantages that by mounting a longitudinal corrugated steel web component in a box chamber of a box girder, the number of webs of the box girder is increased, and the principal tensile stress of an original concrete web of the box girder is reduced, so that the aim of shear strengthening of a box girder bridge is achieved.

Owner:HENAN PROVINCIAL TRANSPORTATION RES INST

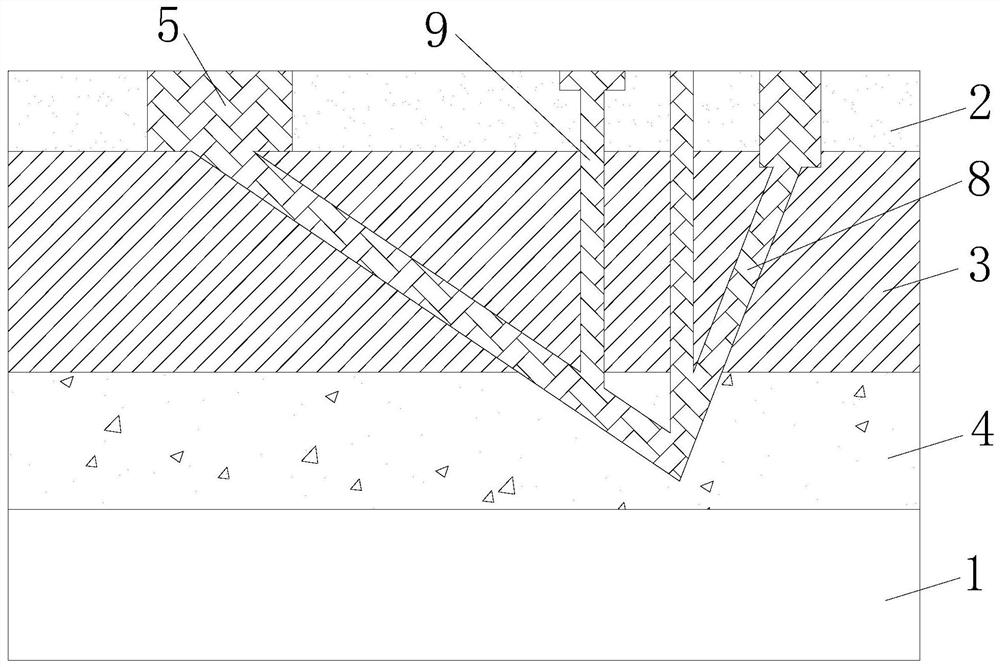

Stair type expansion reinforcing band system and construction method

InactiveCN109024704ASolve the problem of water seepageSimple structureArtificial islandsProtective foundationRebarWater seepage

The invention provides a stair type expansion reinforcing band system and a construction method. The system comprises a concrete bed die. A concrete base body is poured to the upper end of the concrete bed die. Upper run-through reinforcing steel bars and lower run-through reinforcing steel bars are embedded in the concrete base body. Expansion reinforcing bands are arranged in the concrete base body. Post-poured expansive concrete is poured in the expansion reinforcing bands. The section of each expansion reinforcing band is in a slope stair shape. Stair type steel wire nets are attached to the two side walls of each expansion reinforcing band. The steel wire net on each side is fixedly connected with a stair type vertical reinforcing steel bar. The system is simple in structure, the construction method is simple and clear, operation is convenient, the system can be effectively used for expansion post-cast strip pouring construction of most concrete pouring, the problems of ultra-longcomponent cracking and construction joint area water seepage are solved, the construction quality is guaranteed, meanwhile, later rework steps are avoided, engineering cost is saved, and the construction schedule is quickened.

Owner:CHINA MCC17 GRP

Construction Method of Shear Reinforcement of Concrete Box Girder Based on Corrugated Steel Web

ActiveCN104695340BIncrease the number of websAchieve shear reinforcementBridge erection/assemblyBridge strengtheningSteel barBox girder

The invention discloses a construction method of shear resistance and strengthening of concrete box beams based on corrugated steel webs. The construction method successively comprises the following steps: performing construction lofting and positioning on top plates and bottom plates of box beams; performing and strengthening bonding surfaces; drilling anchor bolt holes in the bottom surfaces of the top plates of the box beams; drilling holes and planting steel bars in the top surfaces of the bottom plates of the box beams; performing laying-off on the corrugated steel webs; drilling holes and performing polishing on upper flange plates; welding and mounting the corrugated steel webs; mounting reinforced mesh slices; erecting a model and pouring concrete. The construction method disclosed by the invention has the advantage that the purposes of shear resistance and strengthening of the concrete box beams are achieved by mounting longitudinal corrugated steel web components in box chambers of box beams, increasing the number of webs of the box beams and reducing the main tensile stress of original concrete webs of the box beams.

Owner:HENAN PROVINCIAL TRANSPORTATION RES INST

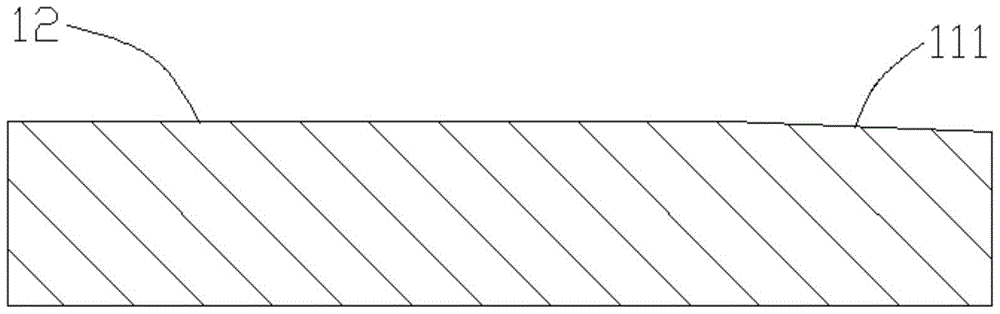

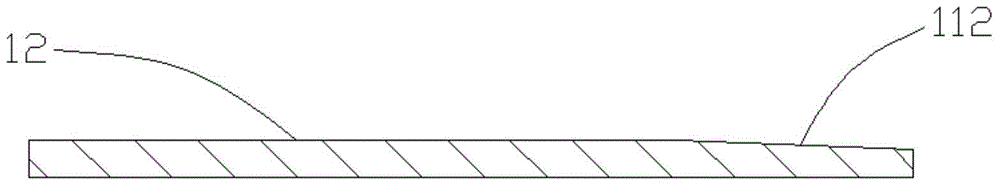

A chamfered crystallizer narrow surface copper plate

The invention discloses a narrow-face copper plate for a chamfer crystallizer. A working face of the narrow-face copper plate for the chamfer crystallizer comprises a first part and a second part; the first part is a sunken curved surface; the first part is a part on the working face in a range of 200mm to 400mm apart from an upper port of the crystallizer. The first part comprises a first curved surface region, two second curved surface regions and two transition curved surface regions, wherein the first curved surface region is a second degree parabola region; the two second curved surface regions are curved surfaces of which the crown heights are 1mm to 3mm; the two transition curved surface regions are curved surfaces with radii of 5mm to 35mm; the two transition curved surface regions are respectively connected with two opposite sides of the first curved surface region and the two second curved surface regions. The second part is connected with the first curved surface region, the two second curved surface regions and the two transition curved surface regions; the second part is a linear conical surface. The narrow-face copper plate for the chamfer crystallizer is also provided with a cooling waterway for cooling the working face; the distance between the cooling waterway and the edge, which is far away from the transition curved surface regions, on each second curved surface region is 20mm to 40mm; the distance between the cooling waterway and each transition curved surface region is 10mm to 30mm.

Owner:SHOUGANG CORPORATION

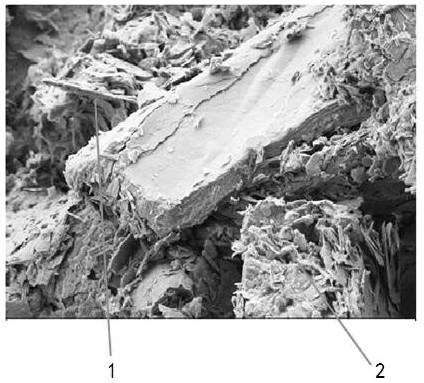

Foamed ceramics for purifying metal melt and preparation method thereof

InactiveCN107473738ASimple processLow costFiltration separationProcess efficiency improvementSlurryZirconium dioxide

The invention relates to foamed ceramics for purifying a metal melt and a preparation method thereof. The preparation method has the technical scheme that firstly, 10 to 80 weight percent of calcium hydroxide powder, 10 to 80 weight percent of calcium zirconate powder and 1 to 10 weight percent of zirconium dioxide powder are mixed to obtain mixed powder; then, 0.1 to 3 weight percent of additives of the mixed powder and 30 to 100 weight percent of water are additionally added; wet mixing is performed to obtain slurry; then, polyurethane sponge is soaked into the slurry; repeated extrusion is performed for 2 to 20 min; the polyurethane sponge containing the slurry is taken out and is extruded; drying is performed for 12 to 24h under the condition of 200 to 300 DEG C; a foamed ceramic prefabricated block is obtained; finally, the foamed ceramic prefabricated block is put into a heating furnace; the temperature is raised to 1300 to 1600 DEG C; heat insulation is performed for 1 to 5h; natural cooling is performed; the foamed ceramic for purifying the metal melt is obtained. The preparation method is characterized in that the process is simple; the cost and the energy consumption are low. The prepared foamed ceramic for purifying the metal melt has high use temperature, stable high-temperature performance and good anti-hydration performance, and is applicable to a filtering material for high-purity metal smelting.

Owner:WUHAN UNIV OF SCI & TECH

Construction Method of Shear Reinforcement of Concrete Box Girder Using Corrugated Steel Web

ActiveCN104695339BEasy to shrinkMake up for shrinkageBridge erection/assemblyBridge strengtheningEngineeringBox girder

The invention discloses a construction method for carrying out shear strengthening on a concrete box girder by adopting a corrugated steel web. The construction method sequentially comprises the following steps: performing construction layout positioning on a box girder top plate and a box girder bottom plate; forming a hole in the box girder top plate; processing and strengthening a junction surface; drilling an anchor bolt hole in the top surface of the box girder bottom plate; blanking the corrugated steel web; drilling a hole in a lower flange plate, and polishing the lower flange plate; welding and mounting the corrugated steel web; pouring concrete into the hole of the box girder top plate. The construction method has the advantages that by mounting a longitudinal corrugated steel web component in a box chamber of a box girder, the number of webs of the box girder is increased, and the principal tensile stress of an original concrete web of the box girder is reduced, so that the aim of shear strengthening of a box girder bridge is achieved.

Owner:HENAN PROVINCIAL TRANSPORTATION RES INST

Coal-based solid waste soil stabilizer and preparation method thereof

PendingCN114686239ASmall particle sizeHigh activityBuilding constructionsOrganic fertilisersHydration reactionFiber

The invention belongs to the technical field of soil solidification, and relates to a coal-based solid waste soil solidifying agent and a preparation method thereof. The problem that when the fluidized bed combustion ash is used as a soil stabilizer, a structure is prone to shrinkage and cracking after curing is solved. The soil stabilizer comprises the following components in parts by weight: 50-80 parts of fluidized bed combustion ash, and 5-15% of silica fume, 3-5% of sulfate and sodium hydroxide, 0.1-0.5% of a water reducing agent and 0.3-0.6% of polyvinyl alcohol fiber which account for the mass percent of the fluidized bed combustion ash. The treated materials are stirred for 10-15 min at the rotating speed of 150-300 r / min, and mixed powder is obtained; under the action of the exciting agent, the secondary hydration reaction process of the mineral admixture and calcium hydroxide is accelerated, so that hydration products are crossed and overlapped with one another to form a compact network structure system, and a structure is prevented from shrinking and cracking.

Owner:山西路桥再生资源开发有限公司 +1

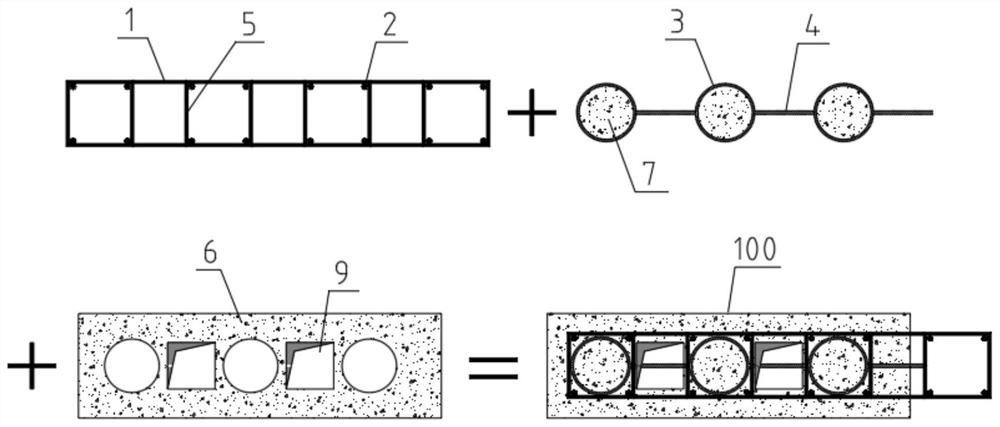

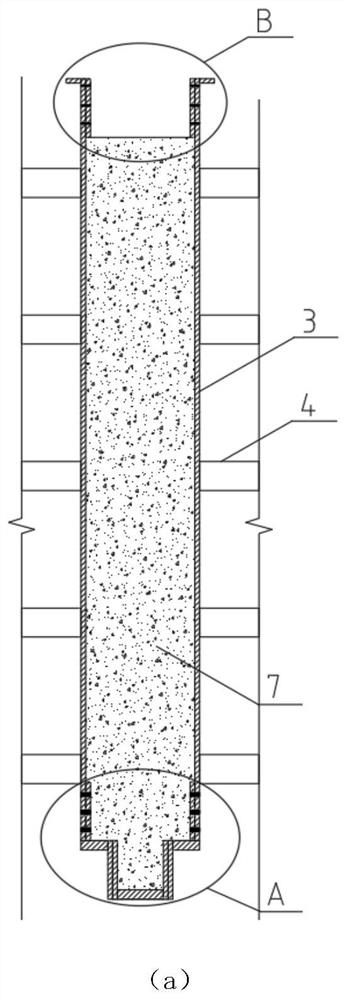

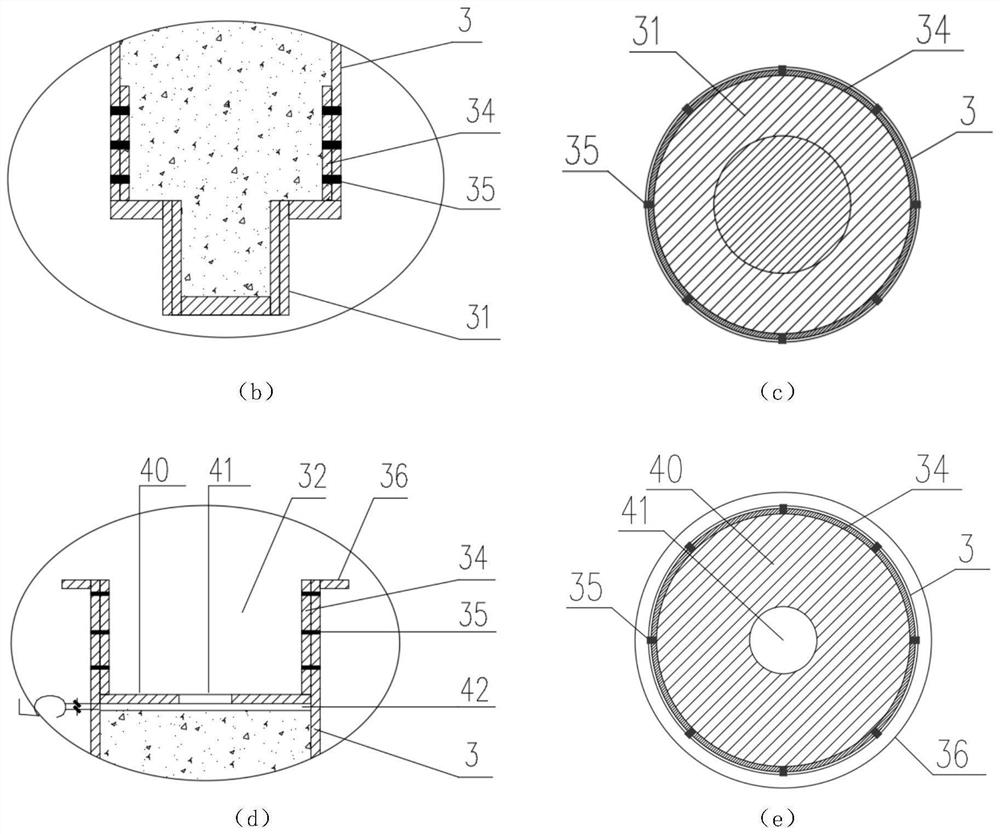

A fully prefabricated steel tube concrete shear wall and building structure system

ActiveCN112681568BOvercoming complexityImprove bearing capacityWallsShock proofingEarthquake resistanceArchitectural engineering

The invention relates to a fully prefabricated concrete-filled steel tube shear wall and a building structure system. The shear wall includes horizontally distributed steel bars, vertically distributed steel bars, steel pipes, horizontal panels and prefabricated concrete. The horizontally distributed steel bars and vertically distributed steel bars form the wall. The steel skeleton of the body; the steel pipes are vertically arranged in rows along the length of the wall in the steel skeleton; the horizontal slabs are vertically distributed horizontal slabs, and the two ends of the horizontal slabs are respectively welded and fixed to the steel pipes on both sides; the steel skeleton , steel pipes and horizontal panels are assembled in the factory, and concrete is pre-cast in the steel skeleton and steel pipes. In addition to the advantages of high bearing capacity, high rigidity, good anti-seismic performance, and excellent anti-corrosion and fire-proof performance after the combination of steel and concrete, the shear wall of the present invention also has the advantages of being able to form wall columns of various shapes, flexible use positions, The structural components are light, the transportation is convenient, and the on-site construction is convenient.

Owner:重庆涛扬绿建科技有限公司

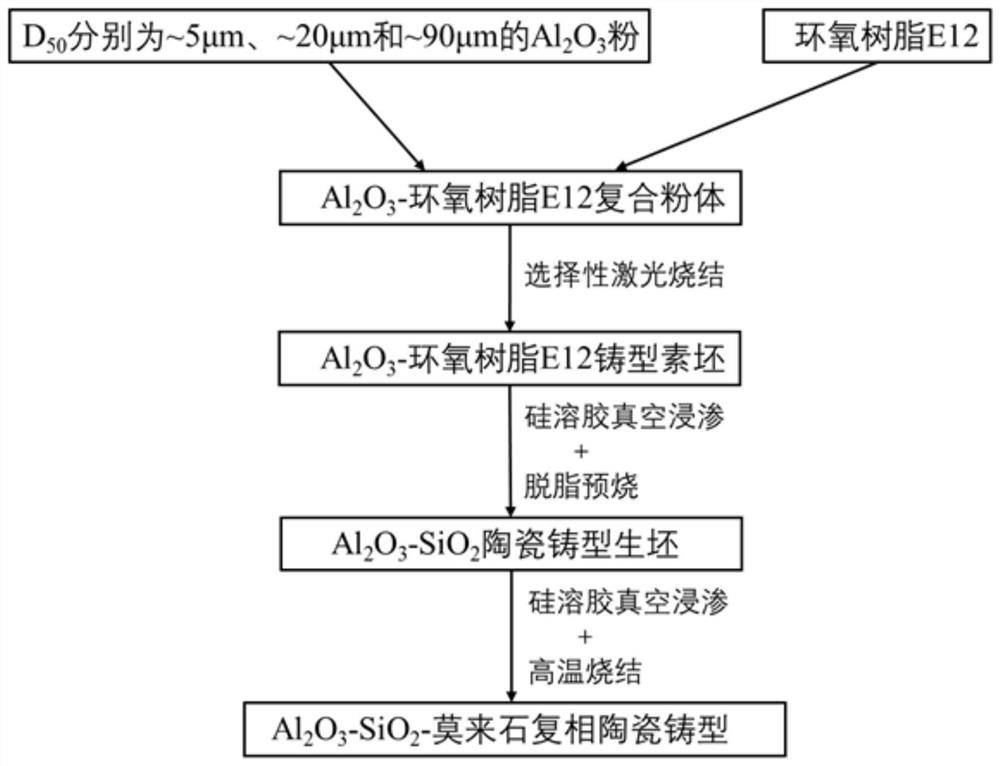

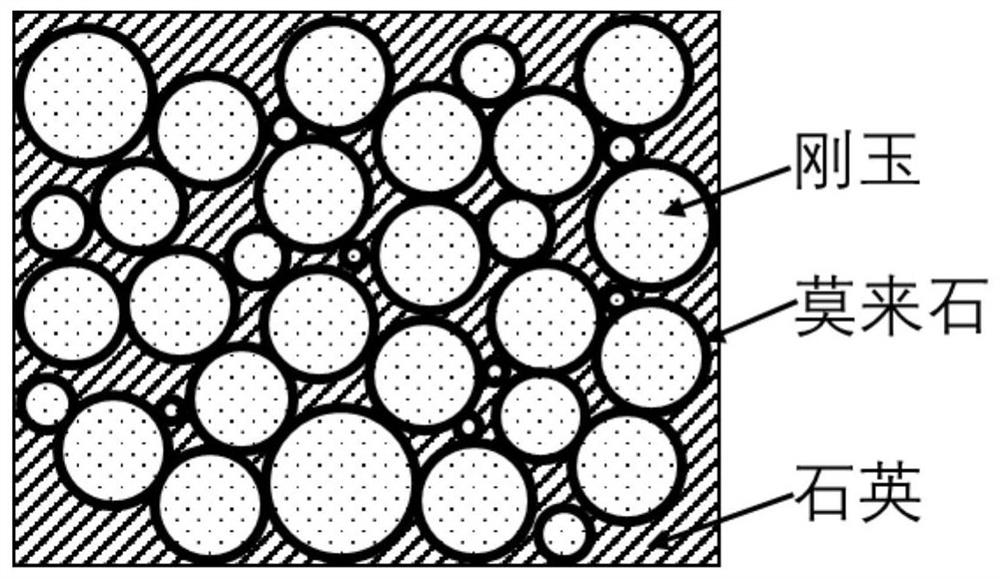

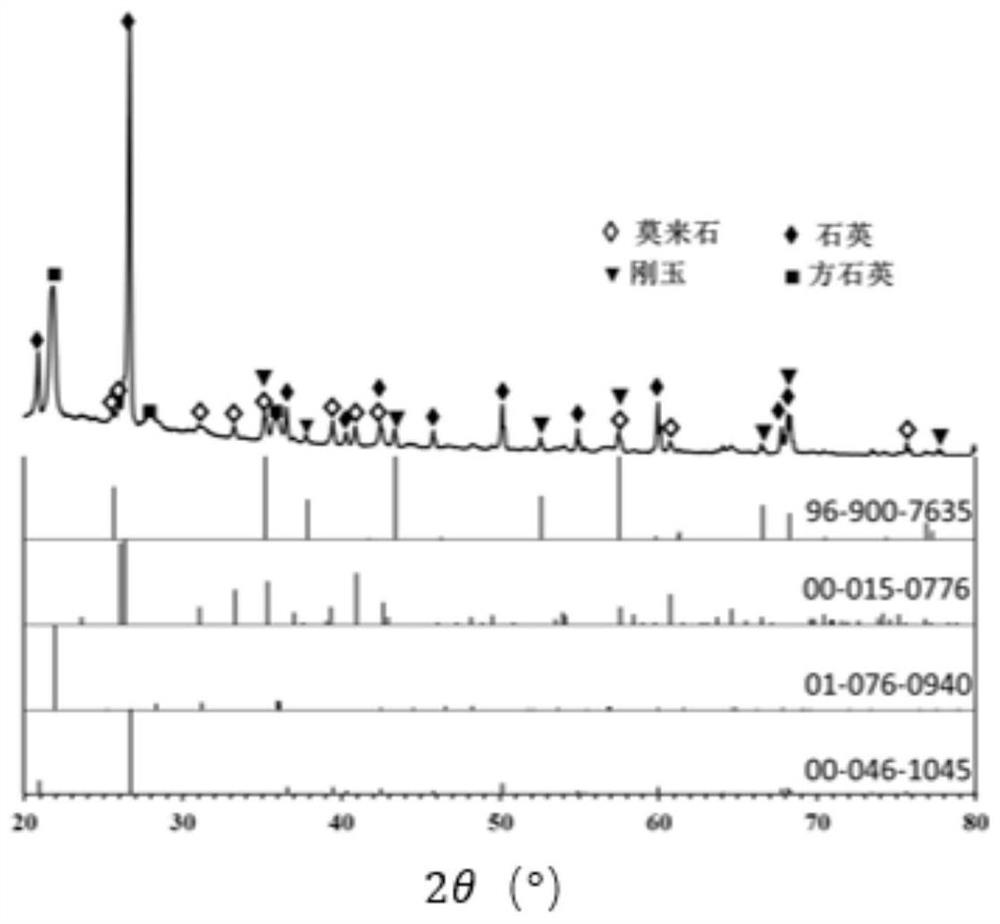

A kind of rapid prototyping method and product of laser selected area of multi-phase ceramic mold

The invention belongs to the field of ceramic preparation, and discloses a laser zone-selection rapid forming method of a complex-phase ceramic casting mold and a product thereof. The method comprisesthe following steps: fully mixing Al2O3 powder with different particle sizes with epoxy resin E12 to obtain Al2O3-E12 composite powder; carrying out selective laser sintering (SLS) rapid forming by using the powder to obtain an Al2O3-E12 casting green body, and carrying out silica sol infiltration treatment under vacuum after surface dust is removed; degreasing and presintering to obtain an Al2O3-SiO2 ceramic cast green body; and performing silica sol infiltration treatment on the Al2O3-SiO2 composite ceramic casting mold under vacuum again, and finally sintering at high temperature to obtainthe complex-phase ceramic casting mold. According to the invention, only simple mechanical mixing is needed to ensure that the powder of the raw materials has good flowability and SLS forming performance, and by introducing a secondary silica sol vacuum infiltration process, the compactness of the obtained ceramic mold is improved while the dimensional accuracy is ensured.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Diatomite internal wall multifunctional wall lining and preparation method thereof

The invention discloses a diatomite internal wall multifunctional lining. The diatomite internal wall multifunctional lining comprises the following components in weight ratio: 25.3%-57% of gel material, 25%-60% of functional filling, 15%-50% of normal filling, and 0.3%-3% of auxiliary, wherein the gel material is a ternary gelation system composed of sulphoaluminate cement, building gypsum and redispersible latex powder. The invention further provides a preparation method of the diatomite internal wall multifunctional lining, comprising feeding materials according to above ratio, metering and packaging. The diatomite internal wall multifunctional lining provided by the invention is notable in environmental protection, and basically zero in formaldehyde and VOC emission. The production process is simple, the cost is low, and the wall lining has good heat retaining property and a certain soundproof effect, and has universality to wall base and top coating, and is suitable for large-scale popularization and use in region with low heat retaining requirement.

Owner:HUNAN LANTIDEN ENVIRONMENTAL BUILDING MATERIAL LTD

An early-strength anti-explosion refractory self-flowing material

The invention belongs to the technical field of refractory materials, and particularly discloses an early strength anti-detonation fireproof self-flow material. The material comprises the following raw materials: alumina or flint clay, pyrophyllite, silicon carbide, alumina based alpha-Al2O3 micropowder, SiO2 micropowder and the like. Aluminate cement serves as a binding agent, and a composite additive and an antidetonator are added. The self-flow material has the advantages of early strength, high strength, detonation resistance, shortened demold time, rapid baking and the like, and has good resistance to high temperature.

Owner:郑州瑞泰耐火科技有限公司

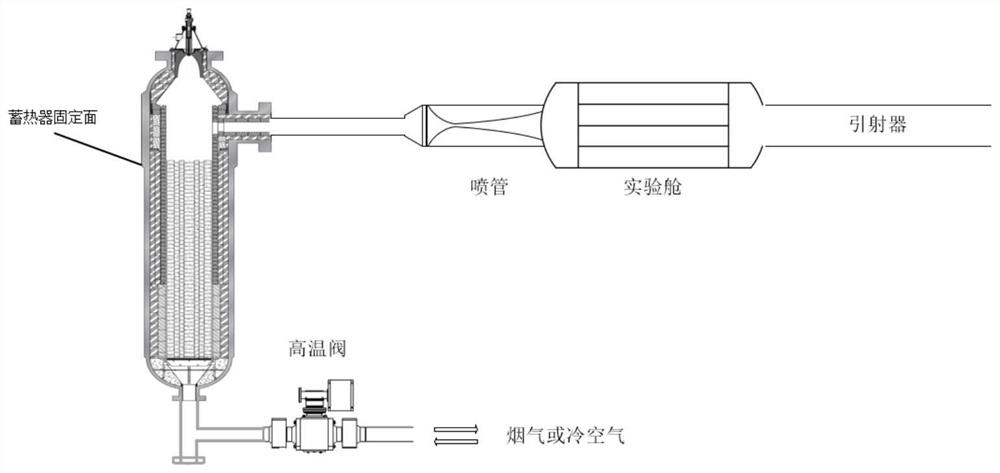

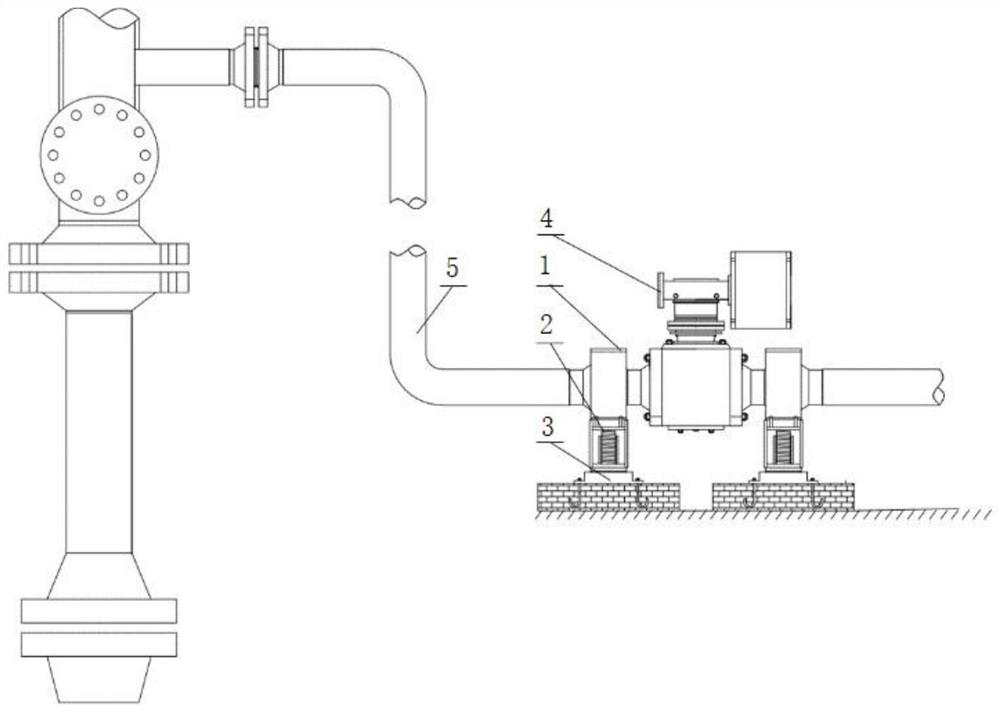

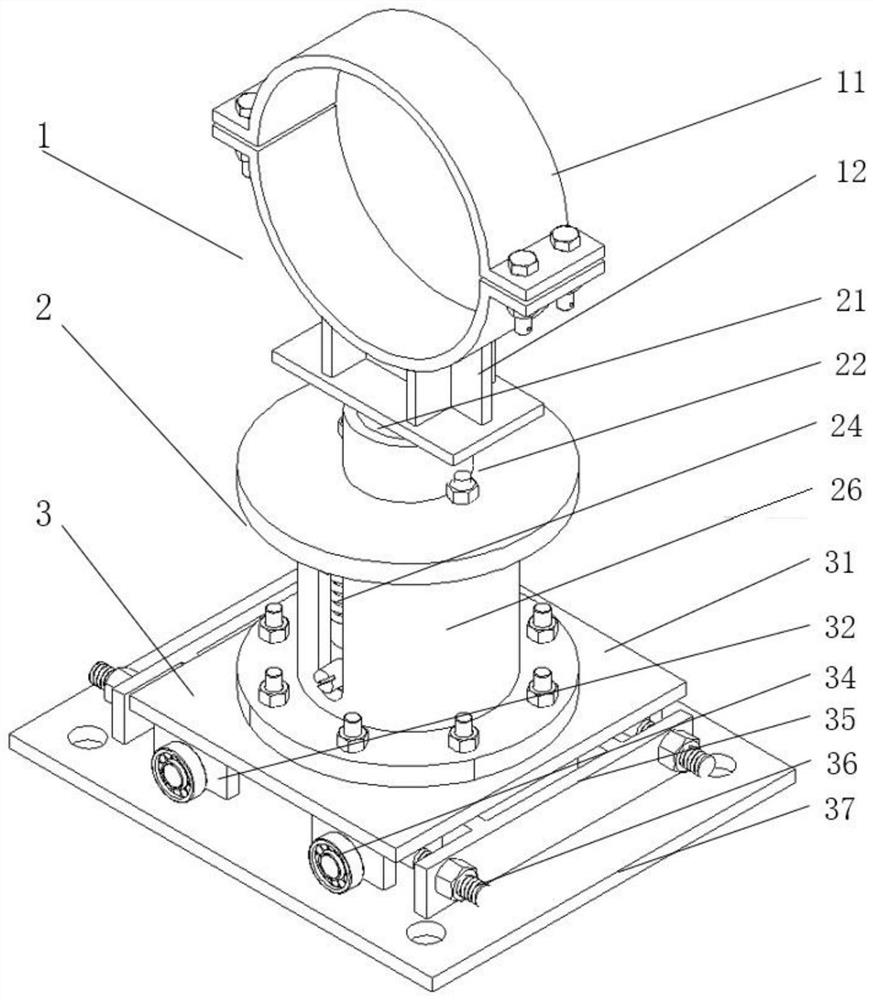

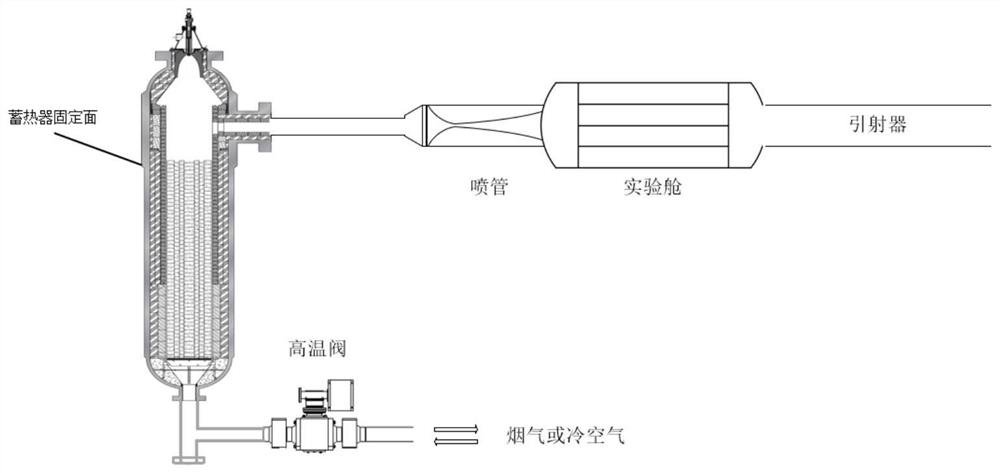

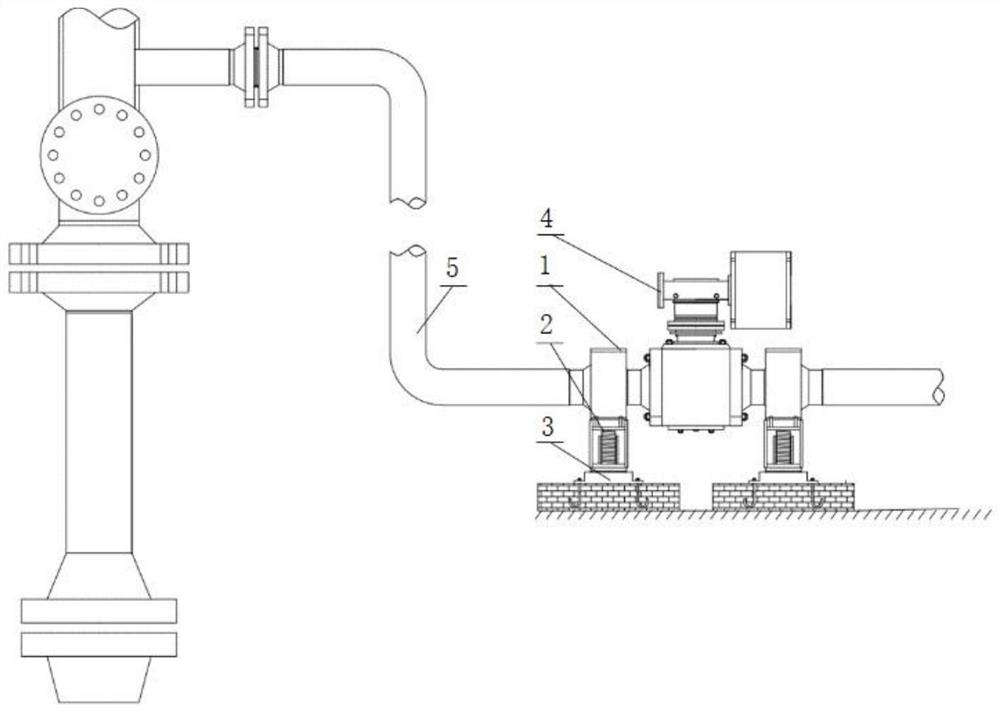

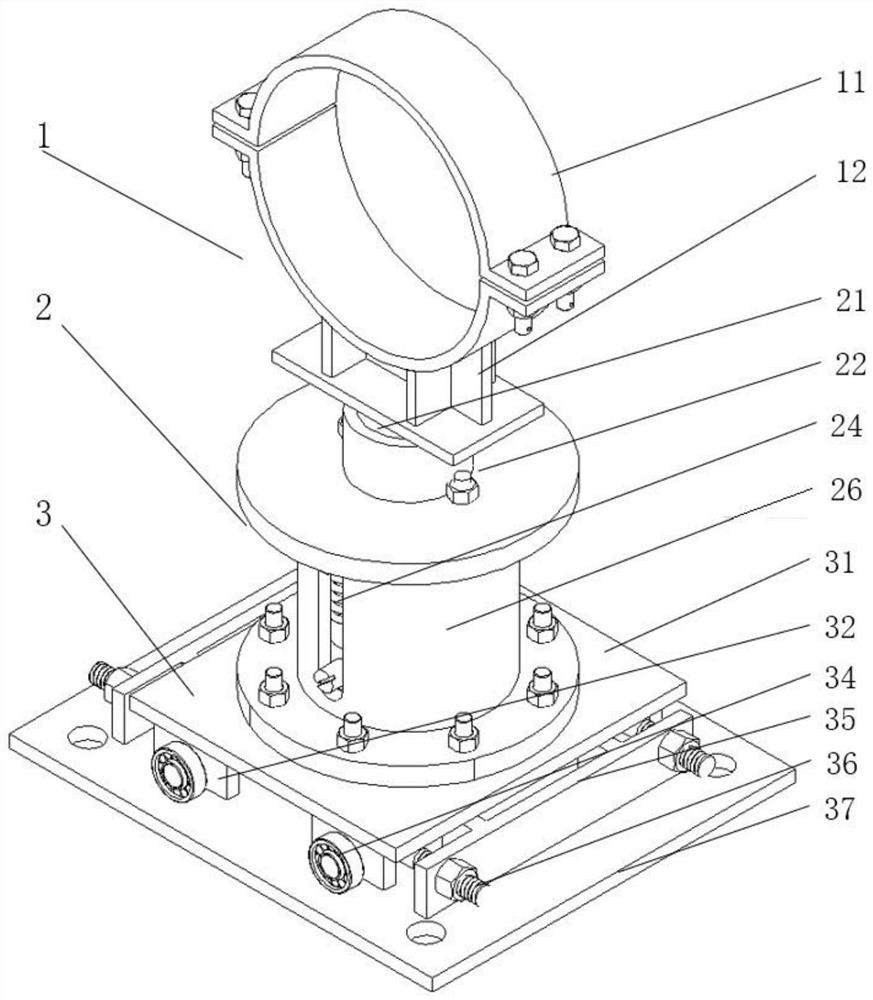

Valve connecting device for wind tunnel experiment

The invention belongs to the technical field of wind tunnel experiment equipment. Aiming at the technical problem of high-temperature and high-pressure gas leakage caused by pipeline deformation or flange sealing failure due to bending moment formed on a connecting pipeline by a connecting mode in the prior art, the invention provides a valve connecting device for a wind tunnel experiment. The device is provided with a lifting device, the lifting device comprises a flange clamp, an elastic supporting mechanism and a sliding base, the lower end of the sliding base is fixed to the ground, the upper end of the sliding base is connected with the elastic supporting mechanism, the flange clamp is arranged at the top end of the elastic supporting mechanism, and the flange clamp is arranged on a connecting pipeline of a high-temperature valve in a sleeving mode to lock a high-temperature valve flange. With the device, the bending moment formed on the connecting pipeline due to longitudinal extension of a heat storage heater or the dead weight of a valve body during preheating can be greatly reduced, then the possibility of flange leakage at the hoop is avoided, and the the safety is greatly improved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Environment-friendly epoxy floor

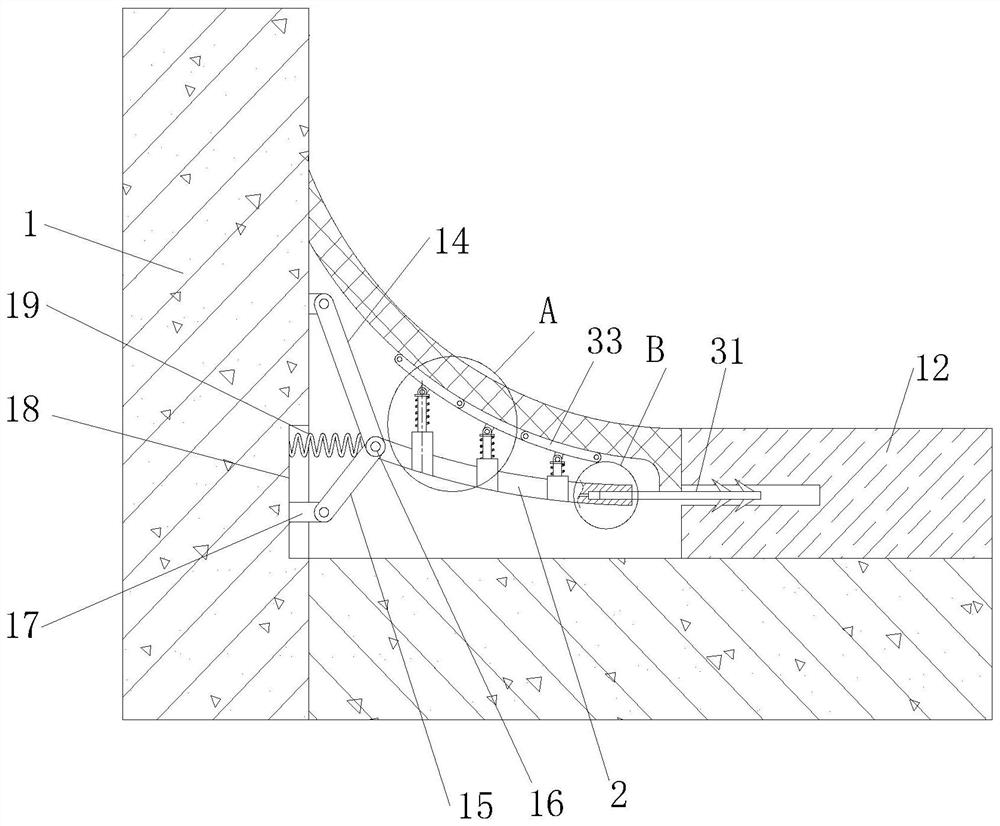

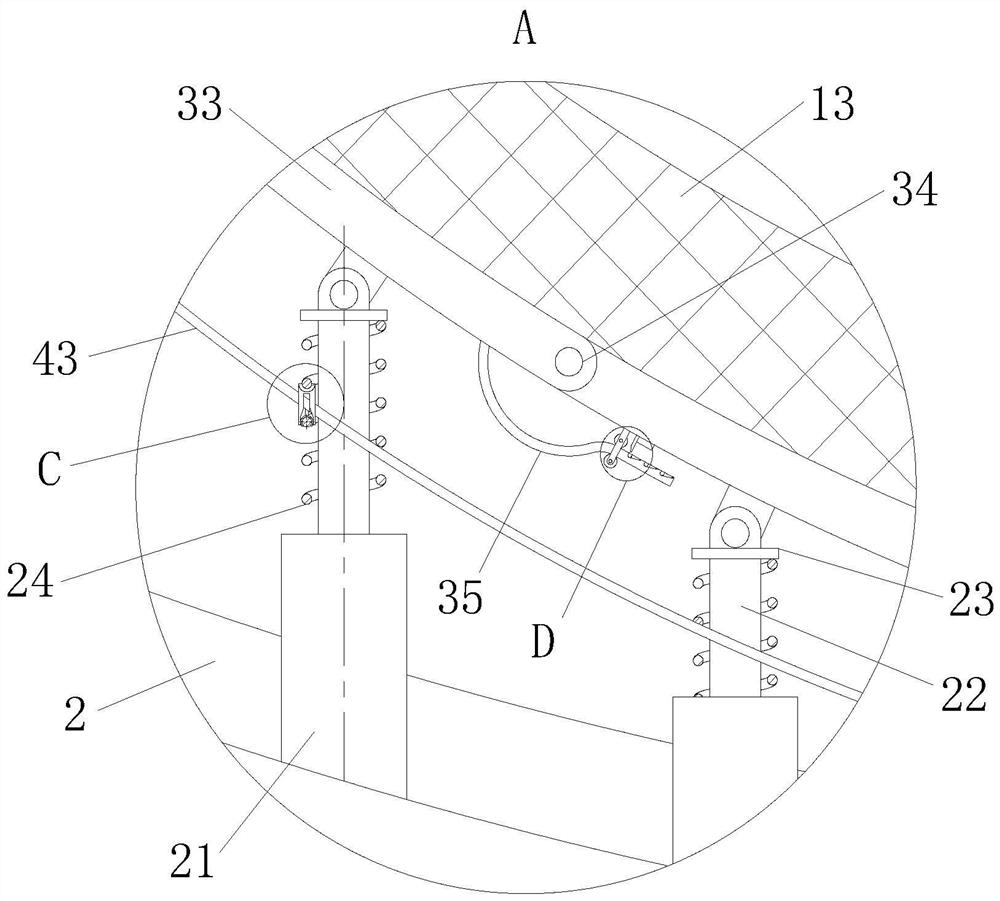

PendingCN114263327AIncrease the quality of cleaning and sterilizationMake up for shrinkageFlooringStructural engineeringComposite material

The invention belongs to the technical field of terraces, and particularly relates to an environment-friendly epoxy terrace which comprises a wall body, a substrate layer and an epoxy material surface, the epoxy material surface is brushed on the top of the substrate layer; the wall body is arranged on the side surface of the substrate layer; an arc-shaped wear-resistant elastic film is arranged at the included angle between the epoxy material surface and the wall body, and one side of the elastic film is fixedly connected with the wall body; a first rod and a second rod are arranged on one side of the wall. The ends, away from the wall, of the first rod and the second rod are hinged through a first rotating pin. A pressure spring is fixedly connected between the first rotating pin and the wall body; a supporting rod is fixedly connected to the side, close to the wall body, of the epoxy material face and is elastic, and the end, close to the first rotating pin, of the supporting rod is hinged to the first rotating pin. The side, away from the wall, of the elastic film is connected with the portion, close to the epoxy material face, of the supporting rod. When the epoxy material surface shrinks, the compression spring pushes the first rod to be matched with the second rod and the sliding block, so that the elastic film deforms, expands and moves along with the epoxy material surface, the shrinkage amount of the epoxy material surface is compensated, and the cleaning and sterilizing quality of the floor is improved.

Owner:张淑敏

A kind of cold ramming paste for the integral furnace construction technology of electrolytic aluminum cathode tank

The invention relates to a cold ramming paste material used for an electrolytic aluminum cathode cell overall furnace building technology. The cold ramming paste material is composed of, by weight, 0-50% of electrically calcined anthracite or metallurgical coke, 0-25% of artificial graphite powder, 16-23% of modified bituminous cement, 11.4-68.5% of andalusite and 3.6-21.5% of aluminum oxide. Thetechnology has the advantages that the problems that cold ramming paste is insufficient in expansion rate during sintering, low in electrical resistivity after sintering and low in erosion resistancein the overall furnace building technique are solved; the andalusite and the aluminum oxide are added into the cold ramming paste material, a side wall furnace lining is built overall according to different proportions, gradient change with the roasting body resistance being gradually increased from bottom to top from the electrolytic cell bottom to the molten salt surface after roasting is formed, the side wall and transverse current is reduced, the electrolytic current efficiency is improved, and energy consumption is effectively lowered; the size is increased in the roasting process, contraction of other materials is compensated, cracks are reduced, and the compactness is improved; and a network structure with graphite and mullite being staggered is generated in a roast body, the electrolyte erosion resistance of the furnace lining is improved, and the risks of furnace leakage and furnace penetration are reduced.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Former hot blast and latter vacuum microwave combining drying process of producing crisp fruit and vegetable grains

InactiveCN1294842CReduce drying loadReduced moisture removal requirementsFood preparationFruits/vegetable preservation by dehydrationMicrowaveHot blast

The present invention is former hot blast and latter vacuum microwave combining drying process of producing fruit and vegetable grains, and belongs to the field of fruit and vegetable food processing technology. The drying process includes the steps of: washing fruit and vegetable material, dicing, scalding to killing enzyme, cooling in flow water, draining, optional fast freezing and defrosting, soaking with seasoning, draining, pre-dewatering with hot blast to obtain semi-finished product with water content of 40-60 %, and final vacuum microwave drying to obtain product with water content of 2-5 %. The said process has the nutritious components and color well maintained, crisp product, short production period, low cost, high product quality and other features.

Owner:JIANGNAN UNIV

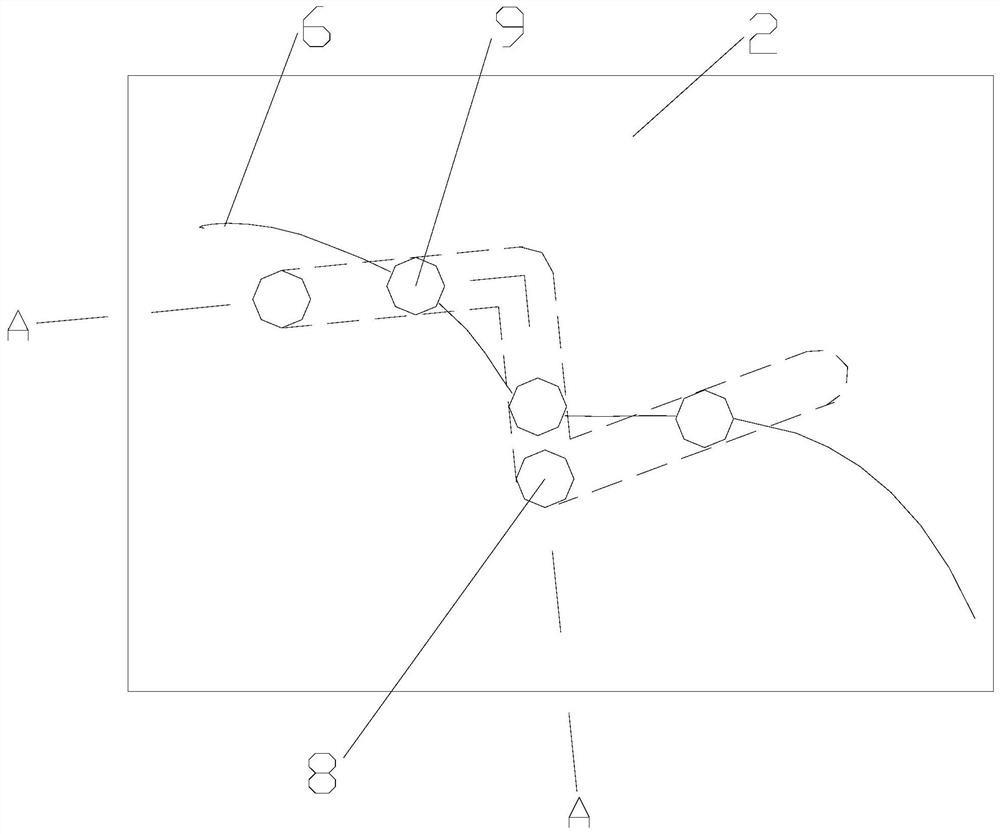

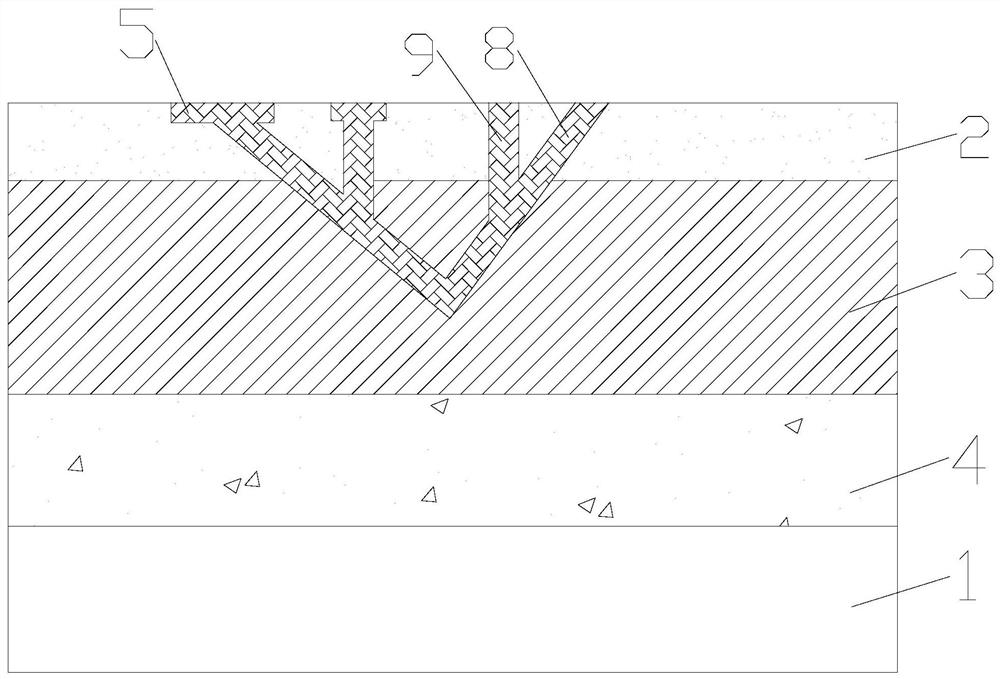

Cement pavement crack reinforcing structure and method

PendingCN111636284AGuaranteed repair strengthImprove bearing capacityPaving detailsRoads maintainenceStructural engineeringRoad surface

The invention discloses a cement pavement crack reinforcing structure and a method. The structure comprises a three-dimensional continuous structure reinforcing body for continuously reinforcing cracks in a to-be-repaired layer of a pavement, the three-dimensional continuous structure reinforcing body comprises a plurality of oblique connecting piles which are sequentially connected in the extending direction of the cracks, each oblique connecting pile is connected with a plurality of reinforcing piles, and the intersection ends of the oblique connecting piles and the reinforcing piles are expansion anchoring heads; the method comprises the following steps: 1, drilling an inclined pile hole; 2, drilling a reinforcing pile hole; 3, drilling and chambering; 4, filling and pouring body. According to the invention, the plurality of continuous oblique connecting piles and the plurality of reinforcing piles are intersected to form a three-dimensional continuous structure reinforcing body; anexpanded upper flange clamping plate can be constructed at the tops of the oblique connecting piles and the tops of the reinforcing piles, an expanded anchoring head and the corresponding upper flange clamping plate in the three-dimensional continuous structure reinforcing body clamp and reinforce a pavement to-be-repaired layer, the fractured pavement to-be-repaired layer is effectively connected and borne, the topological structure of the three-dimensional continuous structure reinforcing body is flexibly expanded, and the construction period is short.

Owner:陕西安易特新新材料有限公司

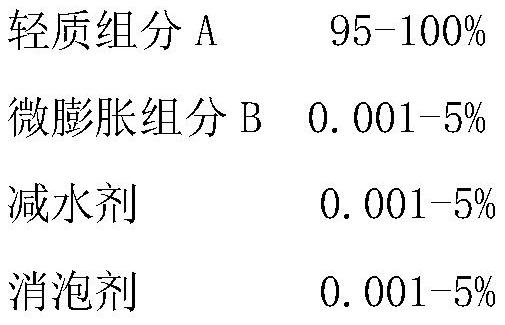

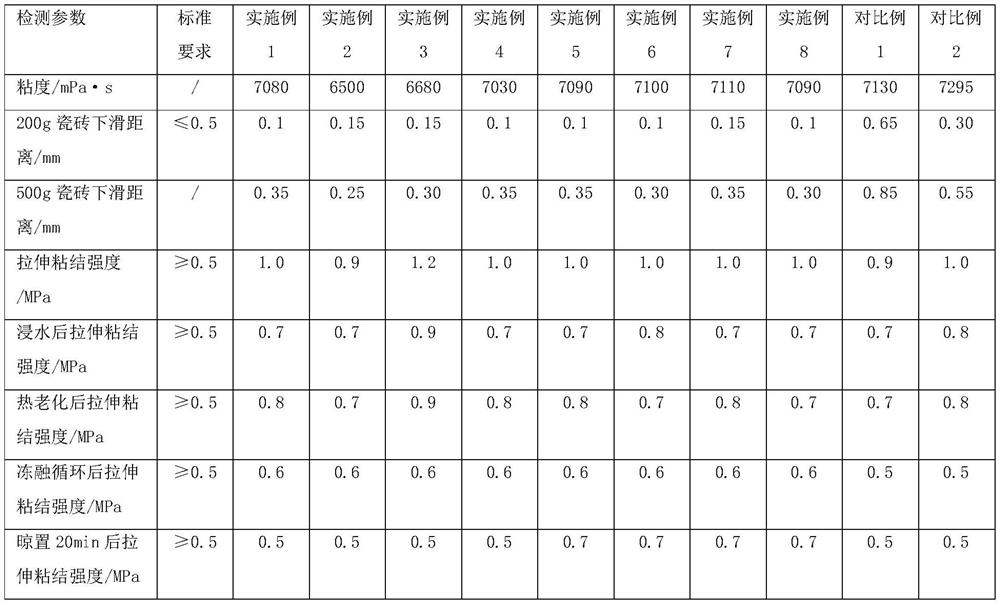

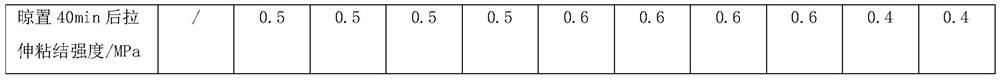

Ceramic tile adhesive additive and application thereof in cement-based ceramic tile adhesive

PendingCN114685074ALoose Pack Density ReductionDecreased wet bulk densitySolid waste managementAdhesiveWater reducer

The invention provides a ceramic tile adhesive additive and application thereof in cement-based ceramic tile adhesives, the ceramic tile adhesive additive comprises the following components in percentage by weight: 95-100% of light component A, 10-20% of light component B, 5-10% of light component C and 5-10% of light component D, 0.001 to 5% of a micro-expansion component B; 0.001 to 5% of a water reducing agent; and 0.001 to 5% of a defoaming agent. The ceramic tile adhesive additive improves the anti-sliding performance of the cement-based ceramic tile adhesive, can improve the construction performance of the cement-based ceramic tile adhesive, enables the cement-based ceramic tile adhesive to be smoother in scraping, and does not reduce the bonding strength of the cement-based ceramic tile adhesive while improving the construction efficiency.

Owner:镇江吉邦材料科技有限公司

Construction method of shear resistance and strengthening of concrete box beams based on corrugated steel webs

ActiveCN104695340AIncrease the number of websAchieve shear reinforcementBridge erection/assemblyBridge strengtheningFlangeDrill hole

The invention discloses a construction method of shear resistance and strengthening of concrete box beams based on corrugated steel webs. The construction method successively comprises the following steps: performing construction lofting and positioning on top plates and bottom plates of box beams; performing and strengthening bonding surfaces; drilling anchor bolt holes in the bottom surfaces of the top plates of the box beams; drilling holes and planting steel bars in the top surfaces of the bottom plates of the box beams; performing laying-off on the corrugated steel webs; drilling holes and performing polishing on upper flange plates; welding and mounting the corrugated steel webs; mounting reinforced mesh slices; erecting a model and pouring concrete. The construction method disclosed by the invention has the advantage that the purposes of shear resistance and strengthening of the concrete box beams are achieved by mounting longitudinal corrugated steel web components in box chambers of box beams, increasing the number of webs of the box beams and reducing the main tensile stress of original concrete webs of the box beams.

Owner:HENAN PROVINCIAL TRANSPORTATION RES INST

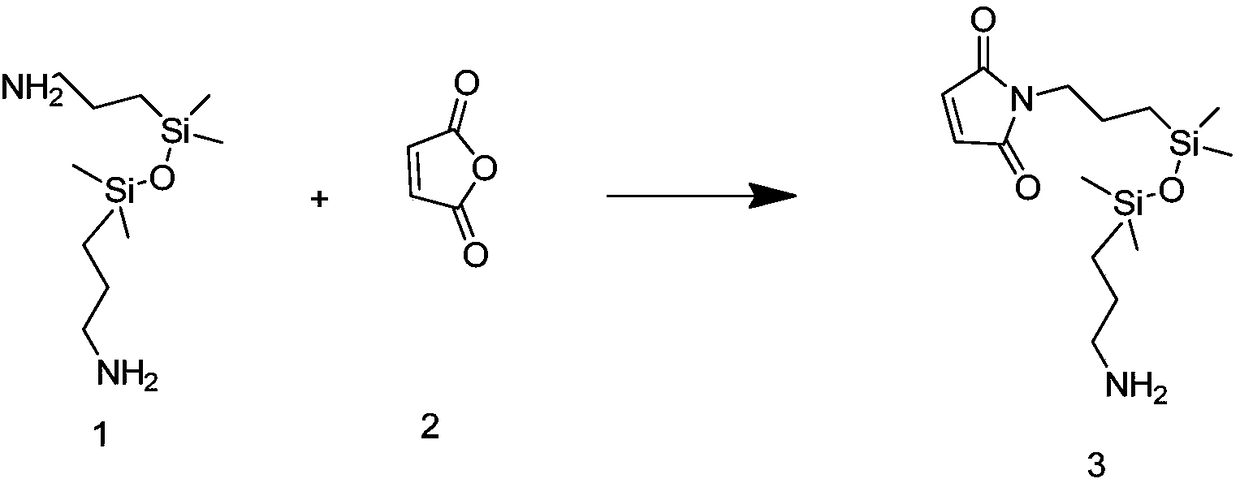

Building corrosion-resistant epoxy resin paint

InactiveCN109354971AMake up for shrinkageSolve the problem of brittleness and easy crackingAnti-corrosive paintsEpoxy resin coatingsEpoxyDouble bond

The invention discloses a building corrosion-resistant epoxy resin paint. The building corrosion-resistant epoxy resin paint is composed of raw materials including, by weight part, 45-60% of corrosion-resistant epoxy resin, 10-15% of titanium dioxide, 10-15% of compound ultraviolet shielding agent, 3-8% of curing agent, 0.5-1.2% of flatting agent, 0.3-0.8% of defoamer and solvent as balance. Preparation of the building corrosion-resistant epoxy resin paint comprises, firstly, modifying amino silicone resin, subjecting amino groups of modified organic silicone resin to ring-opening polymerization with epoxy groups of epoxy resin, and then oxidizing double bonds of the compounded epoxy resin into alkylene oxide to further increase the bonding strength and the anti-ageing performance of the epoxy resin. By introducing modified organic silicone lipid chains, an epoxy coating can be low in double-layer capacitance and high in reaction resistance and greatly improve the corrosion resistanceof the building corrosion-resistant epoxy resin paint.

Owner:福州臻美网络科技有限公司

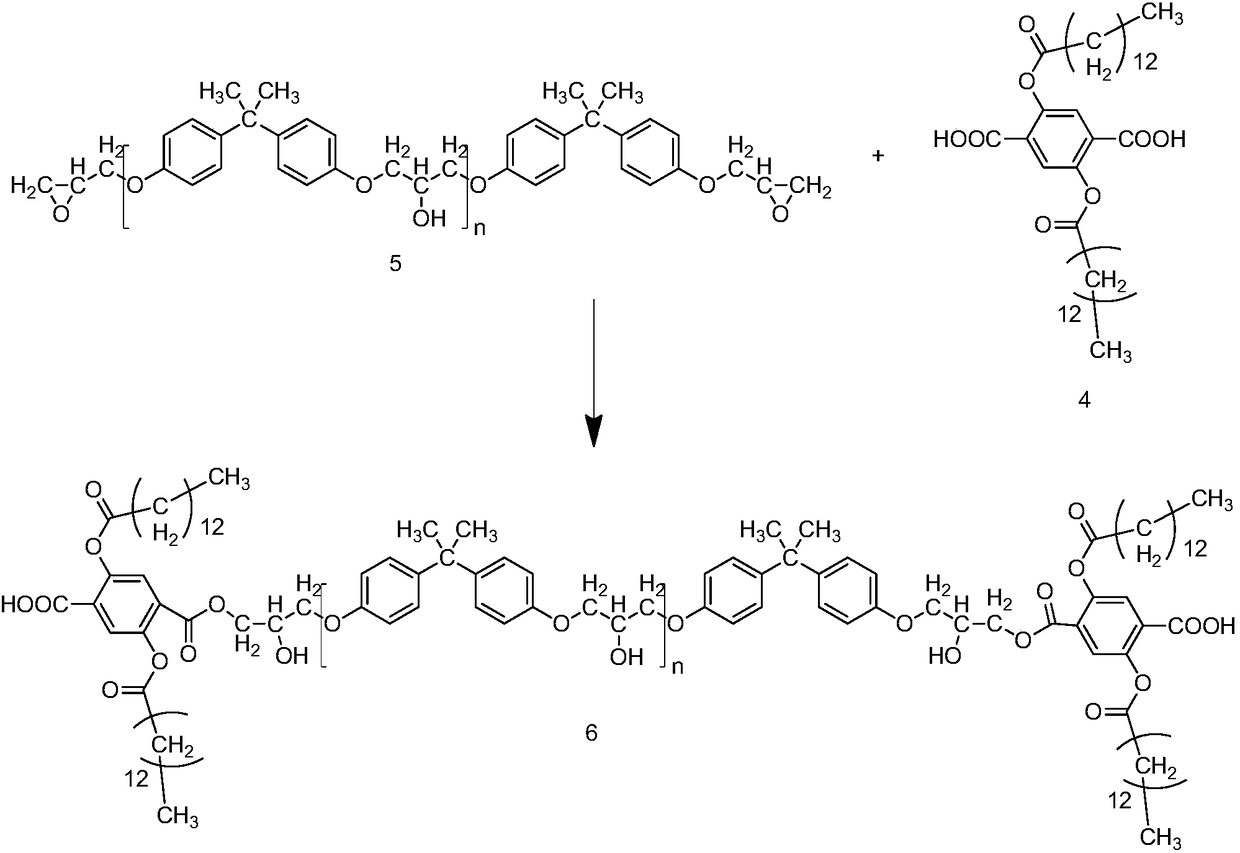

Nanometer composite epoxy resin building material

The invention discloses a nanometer composite epoxy resin building material. The nanometer composite epoxy resin building material comprises 60 to 85 parts of cement, and 20 to 40 parts of an epoxy resin adhesive; the epoxy resin adhesive comprises, by weight, 80 to 90% of a composite epoxy resin, 6 to 10% of a curing agent, and 5 to 10% of a reactive diluent; after ring opening, a linear epoxy resin and 2,5-di(tetradecanoic acid ester) terephthalic acid are subjected to polymerization esterification so as to obtain an epoxy resin pre-modified body, aliphatic chains are introduced as flexiblechains, and linear epoxy resin flexibility is improved; nanometer modified cerium oxide is dispersed in the epoxy resin pre-modified body, so that acting force much higher than Van der Waals' force isachieved at the interface between nanometer modified cerium oxide and the hydroxyl and carboxyl of the epoxy resin pre-modified body, micro cracks and adsorption of energy are induced, epoxy resin system deformation is inhibited, and further toughening effect is achieved. When the nanometer composite epoxy resin building material is used in building materials, building material cracking possibility is reduced.

Owner:FUZHOU MAILIAO AUTOMATION EQUIP CO LTD

A valve connection device for wind tunnel experiments

ActiveCN113669525BReduce bending momentMake up for shrinkageSleeve/socket jointsEngineeringStorage heater

The present invention belongs to the technical field of wind tunnel experimental equipment. In view of the technical problem that the existing connection method forms a bending moment to the connecting pipe in the prior art, causing the deformation of the pipe or the failure of the flange seal, resulting in the leakage of high-temperature and high-pressure gas, the purpose of the present invention is to provide a A valve connection device for wind tunnel experiments, provided with a lifting device, the lifting device includes a flange clamp, an elastic support mechanism and a sliding base, the lower end of the sliding base is fixed on the ground, and the upper end of the sliding base is connected to the elastic supporting mechanism , the top of the elastic support mechanism is set as a flange clamp, and the flange clamp is set on the connecting pipe of the high temperature valve to lock the flange of the high temperature valve. The device can greatly reduce the longitudinal extension of the heat storage heater or the bending moment of the valve body on the connecting pipe during preheating, avoiding the possibility of flange leakage at the clamp and greatly improving safety.

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

I-shaped piling wall type cement pavement crack repairing structure and repairing method

InactiveCN111691280AEnsure that the repair strength meets the requirementsActive connectionPaving detailsRoads maintainenceStructural engineeringRoad surface

The invention discloses an I-shaped piling wall type cement pavement crack repairing structure and a repairing method. The structure comprises an I-shaped piling wall which is arranged along the length extension direction of a crack and is used for continuously repairing a to-be-repaired layer of a pavement, wherein the I-shaped piling wall comprises a web piling wall continuously penetrating through the to-be-repaired layer of the pavement, a lower flange clamping plate located at the bottom of the web piling wall and integrally connected with the web piling wall, and an upper flange clampingplate located at the fixed part of the web piling wall and integrally connected with the web piling wall; the web piling wall intersects with the crack; and the lower flange clamping plate is locatedat the bottom of the crack. The method comprises the steps that 1, drilling of a piling wall hole; and 2, filling of a pouring body. The structure of the invention is simple, the continuous I-shapedpiling wall is used for continuously and comprehensively repairing the whole crack on a cement pavement slab; and the web plate piling wall in the I-shaped piling wall compacts cracks, the upper flange clamping plate and the lower flange clamping plate in the I-shaped piling wall clamp and reinforce the to-be-repaired layer of the pavement, the fractured to-be-repaired layer of the pavement is effectively connected and borne, strength is high, damage to the existing pavement slab is reduced, and a construction period is short.

Owner:XIAN UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com