Water-borne epoxy resin modified cement mortar repair material and preparation method thereof

A technology of water-based epoxy resin and cement mortar, which is used in construction materials, underground engineering, water conservancy engineering and port fields. It can solve the problems of endangering subway operation, groundwater intrusion into tunnels, and decrease in bonding strength, so as to compensate for its own shrinkage and improve resistance. Penetration ability, reduce the effect of shrinkage deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Cement, sand, expansion agent, silica fume, water, water-based epoxy resin, curing agent, defoamer, water reducer, the weight percentage of each raw material is: cement 29.1%, sand 58%, expansion agent 0.9%, Silica fume 0.6%, water 5.6%, water-based epoxy resin 3.6%, curing agent 1.8%, defoamer 0.21%, water reducer 0.15%.

Embodiment 2

[0028] Cement, sand, expansion agent, silica fume, water, water-based epoxy resin, curing agent, defoamer, water reducer, the weight percentage of each raw material is: cement 29.2%, sand 58%, expansion agent 0.9%, Silica fume 0.6%, water 7.2%, water-based epoxy resin 2.4%, curing agent 1.2%, defoamer 0.21%, water reducer 0.15%.

Embodiment 3

[0030] Composed of cement, sand, expansion agent, silica fume, water, water-based epoxy resin, curing agent, defoamer, and water reducer, the weight percentage of each raw material is: cement 28%, sand 57%, expansion agent 0.9%, Silica fume 0.6%, water 6.2%, water-based epoxy resin 4.8%, curing agent 2.1%, defoamer 0.21%, water reducer 0.15%.

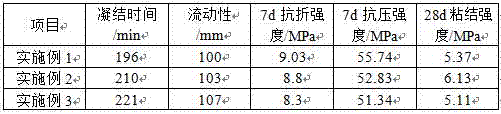

[0031] As the water-based epoxy mortar obtained in Examples 1, 2, and 3, the performance data are shown in Table 1.

[0032] Table 1 embodiment related performance

[0033]

[0034] Note: The bonding strength is characterized by the bonding flexural strength of modified mortar and concrete.

[0035] As shown in Table 1, the water-based epoxy resin mortar of the present invention has suitable setting time and fluidity, excellent flexural resistance, compressive strength and ultra-high bond strength properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com