Patents

Literature

86results about How to "Early strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

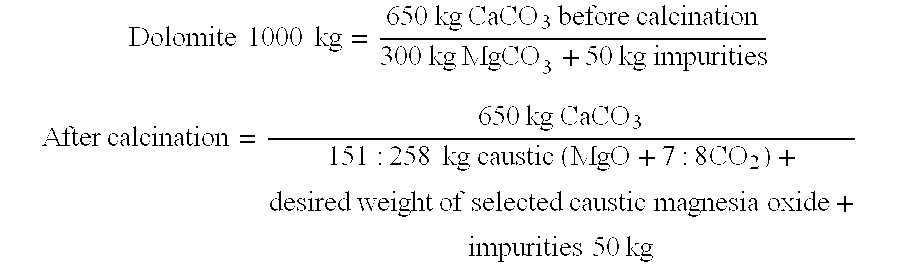

Settable composition and uses therefor

InactiveUS6200381B1Decrease decarbonisation temperaturePromote decompositionSolid waste managementWaste productSlurry

A dry powdered flowable cement composition contains calcium carbonate and a partially decarbonated magnesium carbonate. A slurry of the composition will set hard with various organic fillers including waste products and toxic waste. The composition can be slurried with contaminated water such as sea water, mineral laden ground water and muddy water. A high percentage of filler can be added while still having an acceptable set.

Owner:DOLOMATRIX INT LIMITED ACN 091 340 920

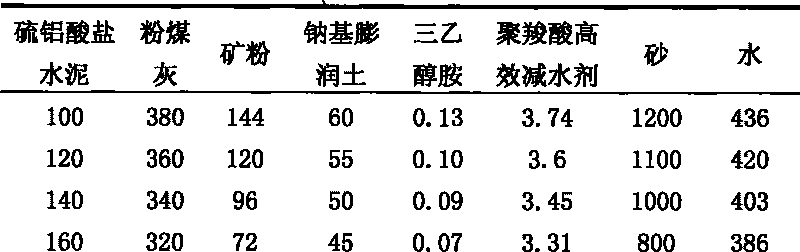

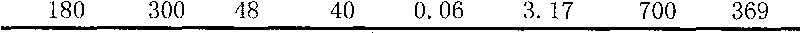

Sulphoaluminate cement base synchronous slip casting material and preparation method

InactiveCN101693615AFulfil requirementsEarly strengthSolid waste managementSodium BentoniteCarboxylic acid

The invention relates to a synchronous slip casting material and a preparation method for tunnels, in particular to a sulphoaluminate cement base synchronous slip casting material, which is characterized in that the sulphoaluminate cement base synchronous slip casting material is prepared by a basal body component and an externally-mixing component, wherein the basal body component comprises sulphoaluminate cement, coal ash, powdered ore, sand and water, the externally-mixing component comprises polycarboxylic acids highly-effective water reducing agent, sodium bentonite and triethanolamine early-strength admixture, the proportioning (kg / m3) of each component is that sulphoaluminate cement: 100-200, coal ash: 300-400, powdered ore: 45-455, sand: 700-1200, water: 350-500, polycarboxylic acids highly-effective water reducing agent: 3.0-4.0, sodium bentonite: 40-60, and triethanolamine early-strength admixture: 0.05-0.2. The synchronous slip casting material prepared by the method has the characteristics of excellent early-stage intensity, underwater non-dispersibility, permeability-resisting and corrosion resistance, and can be used in large-scale river-sea-crossing tunnels or underground engineering.

Owner:武汉市商品混凝土管理站

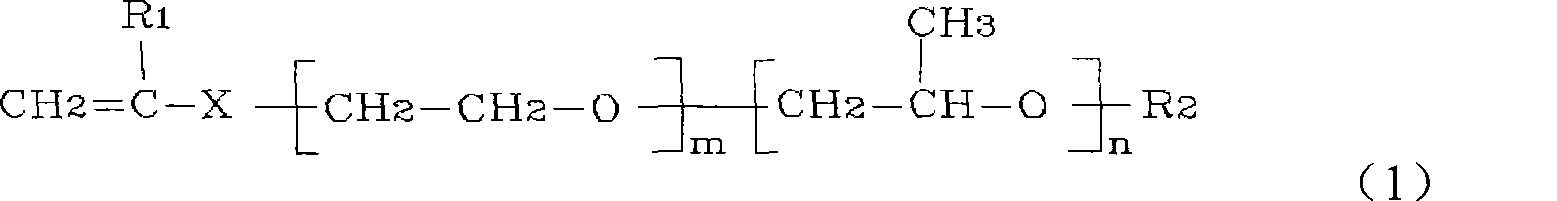

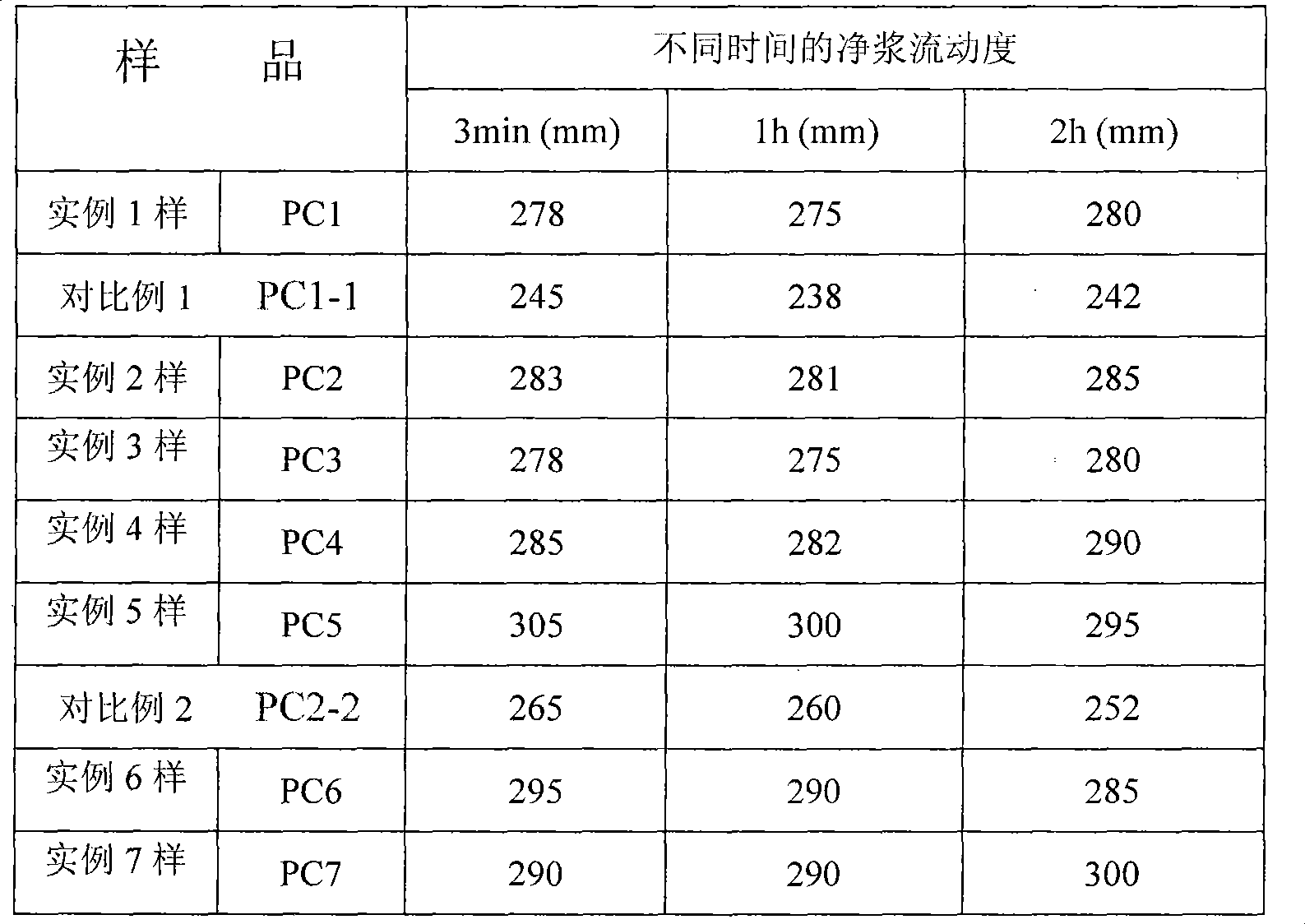

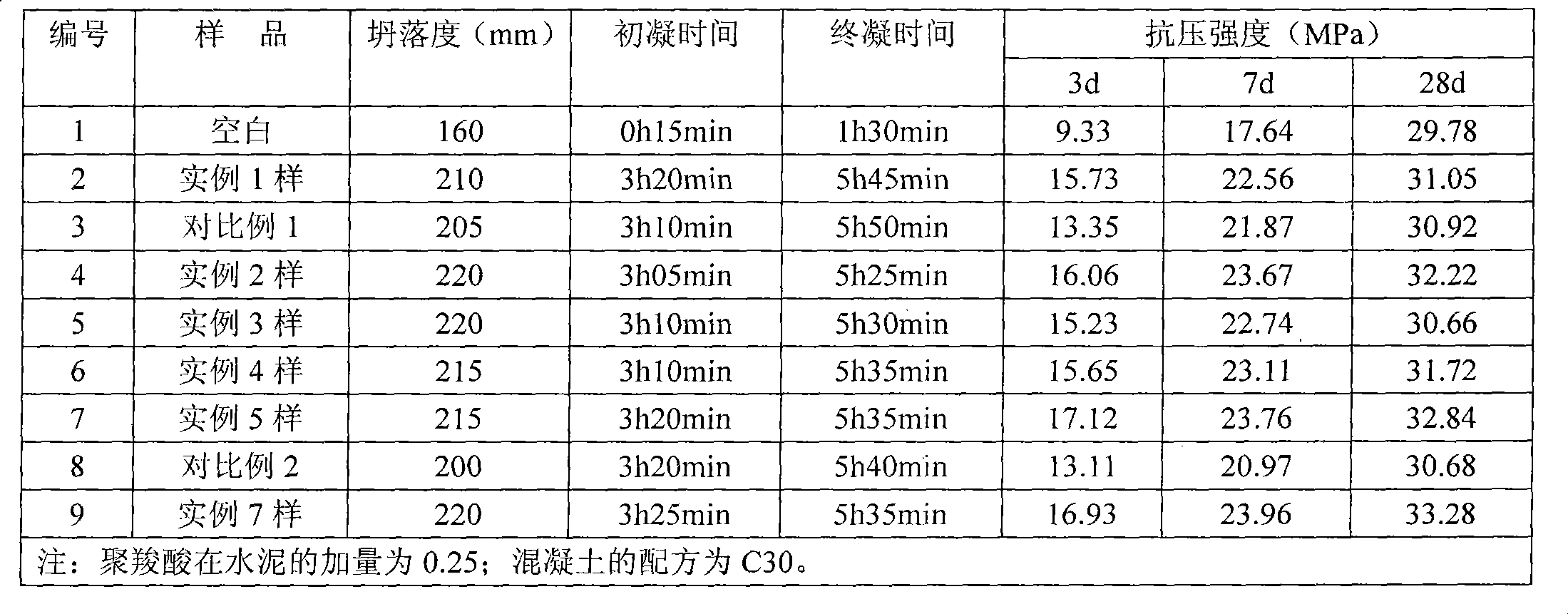

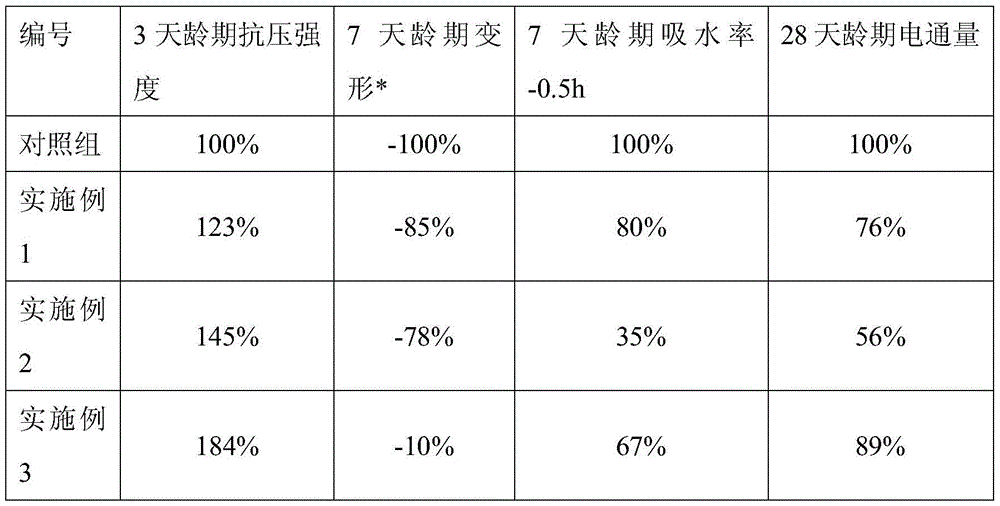

Polycarboxylate-type cement water-reducing agent and preparation method thereof

The invention discloses a polycarboxylate-type high-performance cement water-reducing agent, which is prepared by copolymerizing vinyl polyoxyethylene ether which is taken as a big monomer, a mixture of derivatives of binary anhydride and micro-molecular monohydric alcohol or dihydric alcohol as well as derivatives of maleic anhydride and amino acid taken as an unsaturated monomer, and an acrylic monomer which is comparatively high in activity. The water-reducing agent disclosed by the invention is low in cost, good in dispersion, excellent in slump loss resistant property, high in strength of the concrete, and high in cost performance.

Owner:TAIYUAN UNIV OF TECH +1

Cement concrete inner-doping waterproof agent and preparing method thereof

The invention provides a cement concrete inner-doping waterproof agent and a preparing method thereof. The cement concrete inner-doping waterproof agent is prepared from, by weight, 0.2-20% of nano aluminum oxide, 0.1-20% of a filer component, 0.1-20% of a hydrophobic component, 0.2-5% of emulsifier and the balance water. The cement concrete inner-doping waterproof agent has the advantages of early high strength, expansibility, hydrophobicity, permeability reduction, electric flux and the like.

Owner:JIANGSU SOBUTE NEW MATERIALS

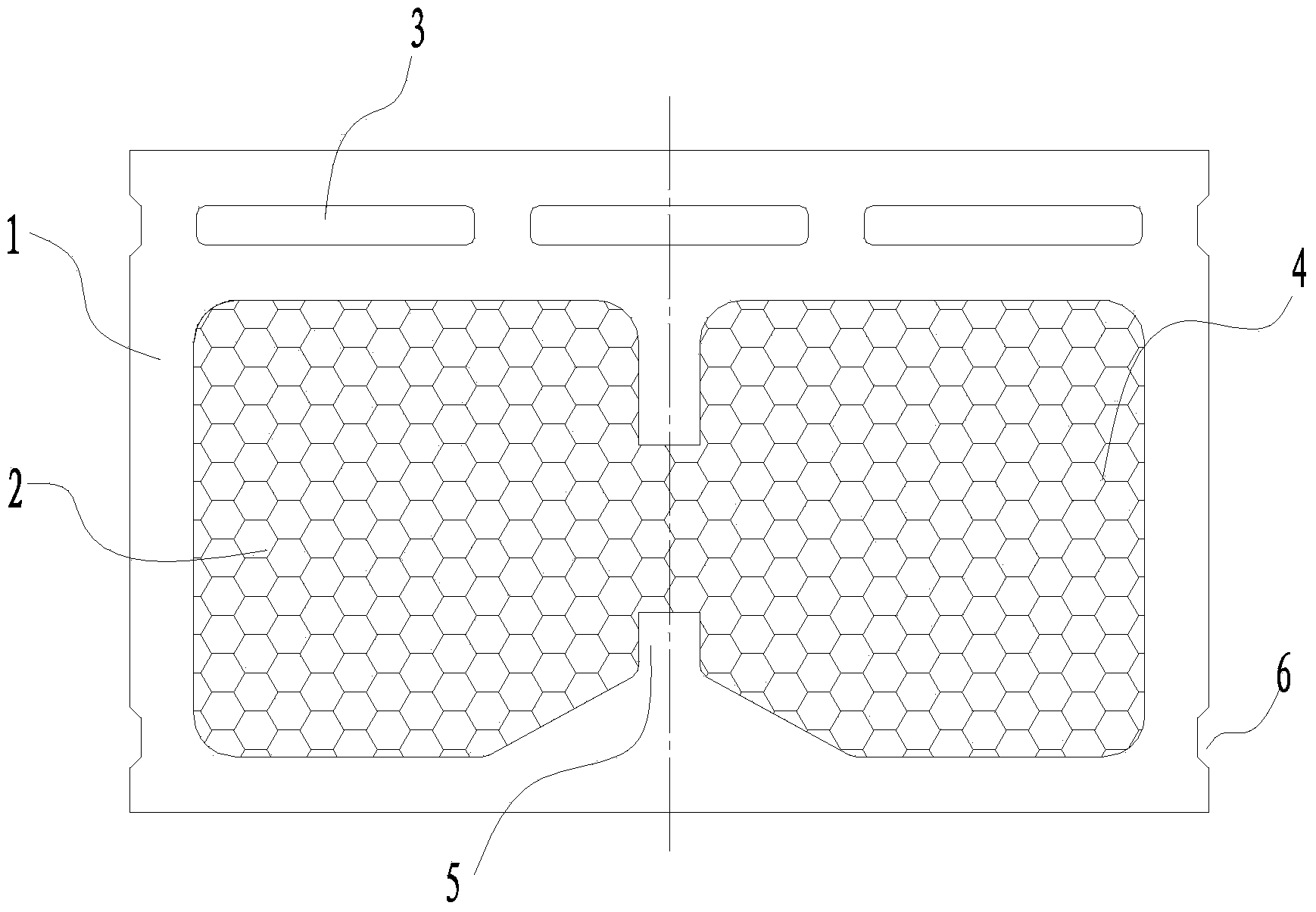

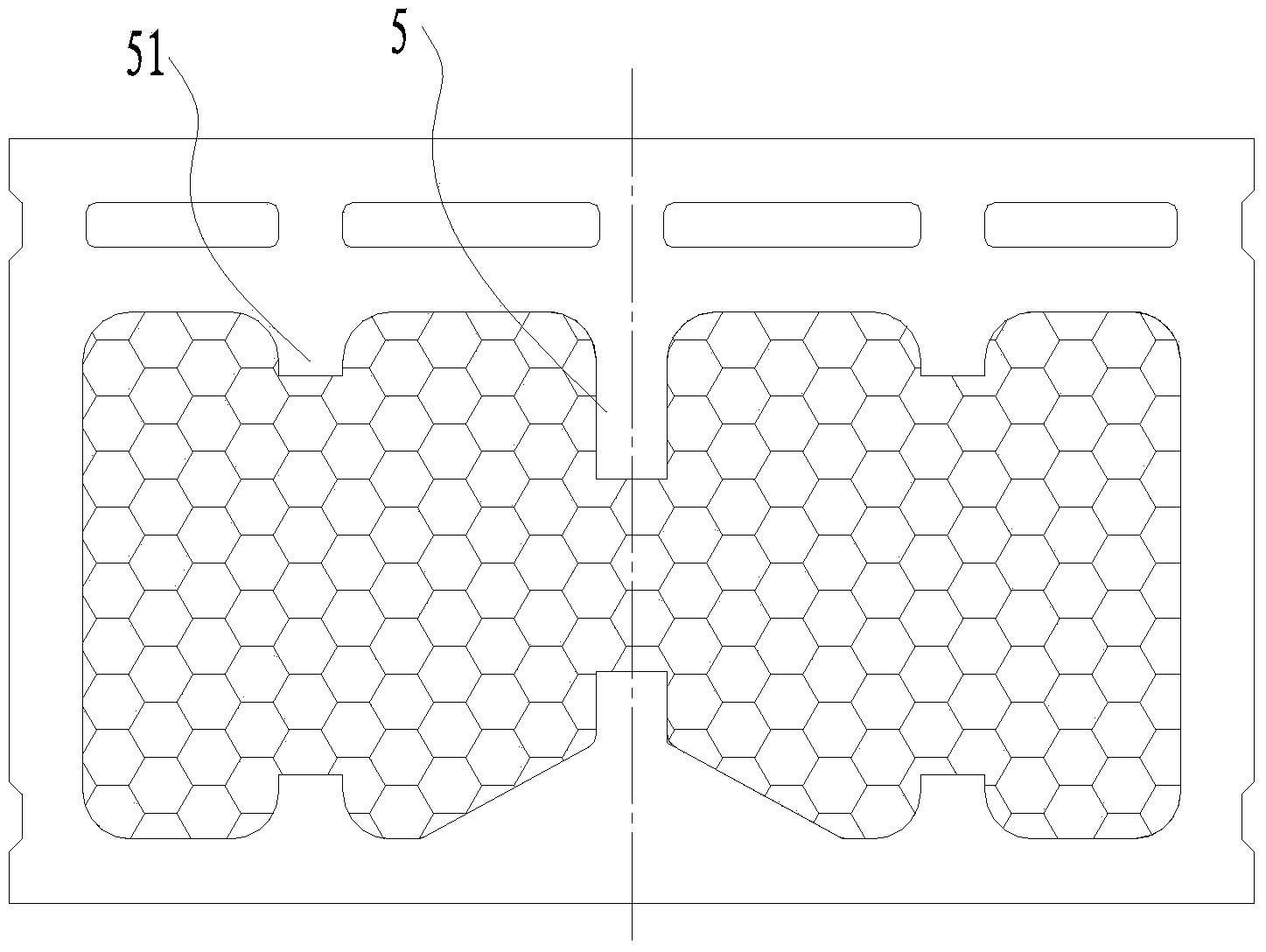

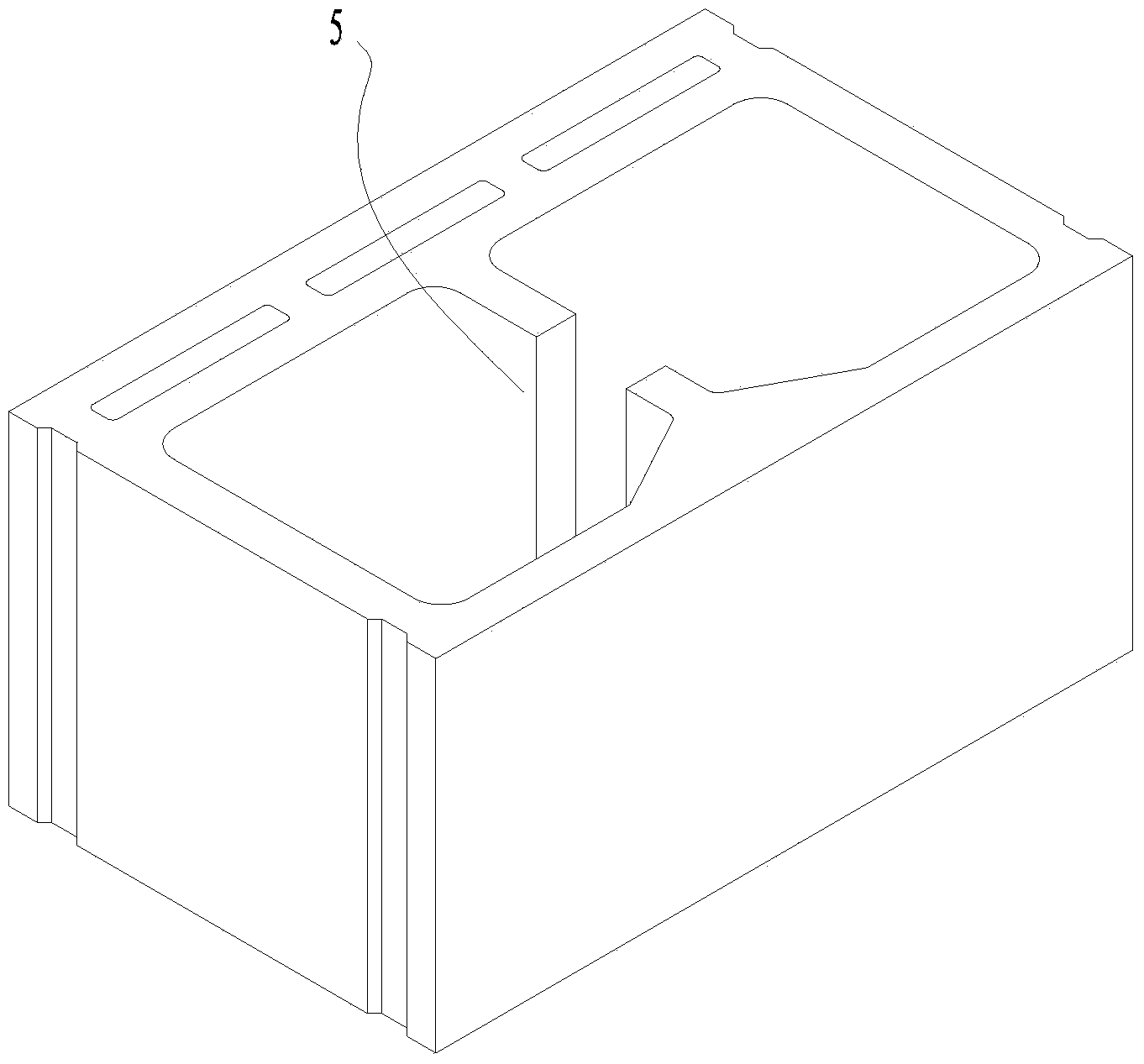

Foam cement filling type concrete composition heat preservation building block and manufacturing method thereof

ActiveCN103643760AGood dimensional stabilityHigh strengthConstruction materialCeramicwareThermal insulationBuilding material

The invention discloses a foam cement filling type concrete composition heat preservation building block and a manufacturing method of the foam cement filling type concrete composition heat preservation building block, which belongs to the technical field of energy-saving building materials. The building block comprises a concrete base body with a cavity, wherein at least one air space which passes through the base body is formed in the inner side of at least one outer surface; at least one cavity of which the cross section area is greater than the cross section area of the air space is further formed inside the base body; a foam cement filling body is arranged in the cavity. Due to the concrete base body, the concrete composition heat preservation building block has good physical and mechanical properties and durability, due to the air space and the foam cement, the concrete composition heat preservation building block has good thermal performance, and meanwhile a manufactured product is conveniently transferred, built, decorated and constructed because of the air space. The foam cement filling type concrete composition heat preservation building block has the characteristics of light weight, good heat preservation, thermal insulation and sound insulation effects, high strength, non-combustibility, anti-permeability and the like, and can be widely applied to internal and external walls of urban frame structure buildings and rural buildings. The building block is convenient to construct and stable in performance, and the working intensity and the construction cost are greatly alleviated and lowered.

Owner:CHINA BUILDING MATERIALS ACAD

Alkaline magnesium oxysulfate cement and preparation method thereof

The invention relates to alkaline magnesium oxysulfate cement and a preparation method thereof. The alkaline magnesium oxysulfate cement is prepared from magnesium oxide, magnesium sulfate heptah, coal ash, core additives and water, wherein the core additives include a first core additive and a second core additive, and the first core additive is inorganic acid, and the second core additive is organic acid. The preparation method includes the steps: (1) dissolving the magnesium sulfate heptah in the water to prepare magnesium sulfate heptah solution; (2) weighing raw materials according to ratio; (3) adding the first core additive into the magnesium sulfate heptah solution; (4) sequentially adding the second core additive and the coal ash into the magnesium oxide, uniformly stirring the raw materials, adding the mixture into the magnesium sulfate heptah solution obtained in the step (3), and uniformly stirring the mixture and the solution to form cement paste. The completely hydrated alkaline magnesium oxysulfate cement is prepared, the hydrated phase of the magnesium oxysulfate cement is improved by leading in the core additives, a novel insoluble crystal whisker hydrated phase is generated, and further the strength, the flexibility and the water resistance of the novel insoluble crystal whisker hydrated phase are obviously superior to those of the magnesium oxysulfate cement.

Owner:内蒙古中鼎工正环保有限公司

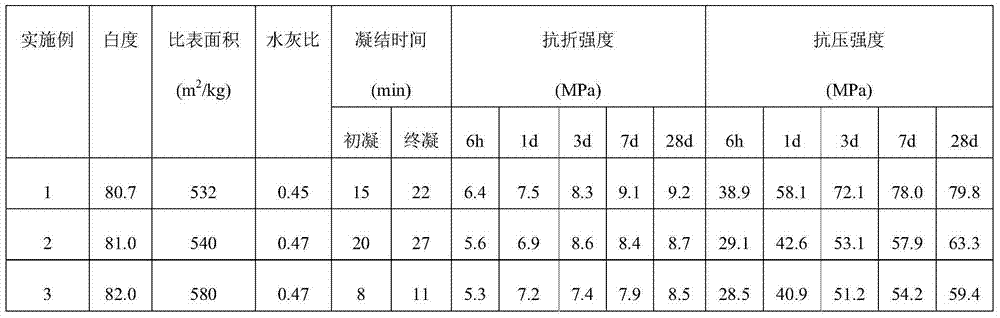

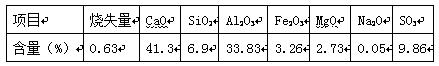

White sulphoaluminate cement and preparing method thereof

The invention provides white sulphoaluminate cement. The white sulphoaluminate cement comprises the following raw materials in parts by weight: 65-90 parts of white sulphoaluminate cement clinker, 0-20 parts of dolomite, 5-15 parts of gypsum, 0-5 parts of white silicate cement clinkers, 0-10 parts of slag and 0-2 parts of retarder. The white sulphoaluminate cement has the characteristics of rapid hardening, early strength, high strength and the like, and the clinkers also have the characteristics of low forging temperature, energy saving, environment-friendliness and the like. The invention further provides a preparing method for the white sulphoaluminate cement.

Owner:SINOMA INT ENG

Reduced shrinkage early strength polycarboxylic acid water reducing agent mother liquid and preparation process thereof

The invention discloses a reduced shrinkage early strength polycarboxylic acid water reducing agent mother liquid and a preparation process thereof. The water reducing agent mother liquid is preparedby the free radical copolymerization reaction of a polyether macro-monomer, an anionic active monomer, a cationic active monomer, a shrinkage reducing monomer, a chain transfer agent and an initiator;wherein the polyether macro-monomer is isopentenyl polyoxyethylene ether and / or methyl allyl polyoxyethylene ether; the anionic active monomer is acrylic acid; the cationic active monomer is methacrylatoethyl trimethyl ammonium chloride; the shrinkage reducing monomer is an esterification reaction product of a phenyl alcohol or a methyl phenyl alcohol with acrylic acid; the chain transfer agent is 2-methyl-2-propene-1-sulfonic acid sodium salt; and the initiator comprises an initiator system A and an initiator system B, the initiator system A comprises organic hydrogen peroxide and vitamin C,and the initiator system B comprises sodium bisulfite and a ferrous salt. According to the preparation process, different functional monomers are grafted to the high-performance polycarboxylic acid water reducing agent, and the length of the main chain is adjusted, so that the polycarboxylic acid water reducing agent has excellent water reducing rate, and also has early strength and reduced shrinkage.

Owner:WUHAN SUBO NEW BUILDING MATERIAL CO LTD

Air-added ceramsite concrete and preparation method thereof

InactiveCN104987005AWell mixedImproved resistance to shrinkage crackingSolid waste managementCeramicwareFoaming agentExpanded clay aggregate

Owner:CHINA MINSHENG ZHUYOU

Method for producing building gesso by using semi-hydrated phosphogypsum and dihydrate phosphogypsum

ActiveCN102731000AStandard consistency requires less waterHigh strengthPhosphogypsumWater requirement

The present invention discloses a method for producing building gesso by using semi-hydrated phosphogypsum and dihydrate phosphogypsum, and belongs to the field of building gypsum production, wherein the building gesso has characteristics of small water requirement of normal consistency and high strength. The method comprises processes of raw material calcination, grinding and aging, wherein the raw materials comprise, by weight, 5-60% of semi-hydrated phosphogypsum, and 40-95% of dihydrate phosphogypsum. According to the present invention, the match use of the semi-hydrated phosphogypsum andthe dihydrate phosphogypsum is adopted, and the ratio of the semi-hydrated phosphogypsum to the dihydrate phosphogypsum is strictly controlled, such that the disadvantage of single use of the semi-hydrated phosphogypsum or the dihydrate phosphogypsum is overcome, performances of the semi-hydrated phosphogypsum and the dihydrate phosphogypsum can be supported each other, and the prepared building gesso has characteristics of small water requirement of normal consistency and high strength; and the phosphogypsum is adopted to replace the natural gypsum to produce the building gesso so as to reduce production cost, change the phosphogypsum waste into treasure, effectively treat pollution and hazard on the environment due to phosphogypsum waste, and provide good environmental benefits, social benefits and economic benefits.

Owner:GUIZHOU CHANHEN CHEM CO LTD

Red mud-based slip-casting plugging material

ActiveCN108329004AGood water retention performanceReduce autogenous shrinkage drying shrinkageCoalPulverised fuel ash

The invention discloses a red mud-based slip-casting plugging material. The red mud-based slip-casting plugging material comprises the following components by weight percentage: 20-40% of red mud, 20-40% of fly ash, and 20-45% of cement, and the sum of the weight percentage is 100%; the red mud-based slip-casting plugging material also comprises an expansion component with an applied doping amountbeing 0.6-9% and a rheological component with the applied doping amount being 1.3-6%; wherein the expansion component comprises an expanding agent and an antifoaming agent, and the rheological component comprises a water reducer and silica micropowder. The red mud-based slip-casting plugging material mainly aims at a coal-mine gas hole-sealing leak-stopping material, and has the advantages of good plugging effect, high intensity after plugging, good air tightness, and less self-constriction at a later period.

Owner:太原理工恒基岩土工程科技有限公司

Early strength type polycarboxylate superplasticizer and preparation method thereof

PendingCN109608594AGood early strength development rateGood flow dispersionPolymer scienceSide chain

The invention relates to the technical field of concrete additives in building materials, specifically to an early strength type polycarboxylate superplasticizer and a preparation method thereof. Theearly strength type polycarboxylate superplasticizer is prepared from the following raw materials through a polymerization reaction: block unsaturated polyoxyethylene ether, acrylic acid, a functionalmonomer, a chain transfer agent, an oxidative initiator and a reductive initiator. According to the invention, the block unsaturated polyoxyethylene ether is adopted as a raw material, and a macromolecular block polyether side chain can improve the water-reducing rate performance of a superplasticizer, also exerts the performances of early strength, viscosity reduction and shrinkage resistance, greatly reduces the content of air, shortens the setting time of concrete and has excellent working performance and adaptability.

Owner:广东奥克化学有限公司

Precast aerated ceramsite concrete component and preparation method thereof

InactiveCN104945007AImproved resistance to shrinkage crackingEarly strengthSolid waste managementCeramicwareFoaming agentExpanded clay aggregate

The invention relates to a precast concrete component, in particular to a precast aerated ceramsite concrete component and a preparation method thereof, and aims to solve the problems of high shrinkage crack possibility, heavy volume weight, ceramsite floating during preparation, and high control difficulty of volume weight. The precast aerated ceramsite concrete component comprises the following raw materials by weight: 35 to 55 parts of a binding material, 0.08 to 0.6 part of an additive, 0.03 to 0.15 part of a foaming agent, 15 to 45 parts of ceramsite, and 20 to 30 parts of water. The precast aerated ceramsite concrete component is light in weight and high in strength after being prepared according to an improved concrete formula and the improved preparation method; the preparation method has the advantages that ceramsite floating can be prevented, and the volume weight is easy to control.

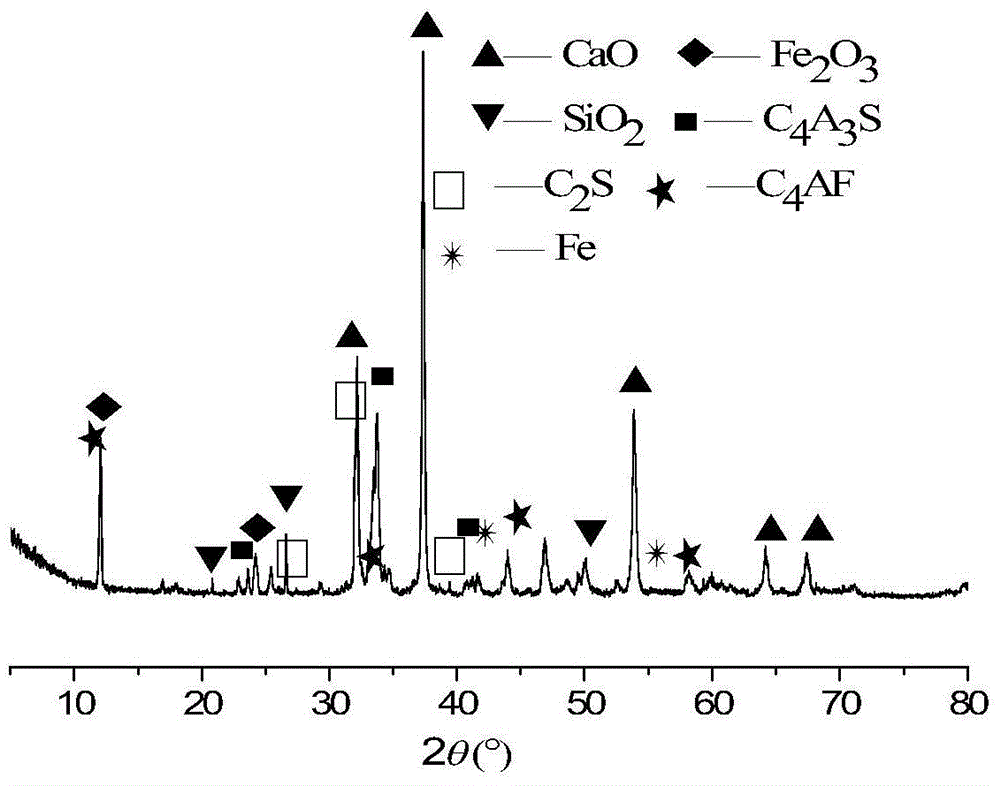

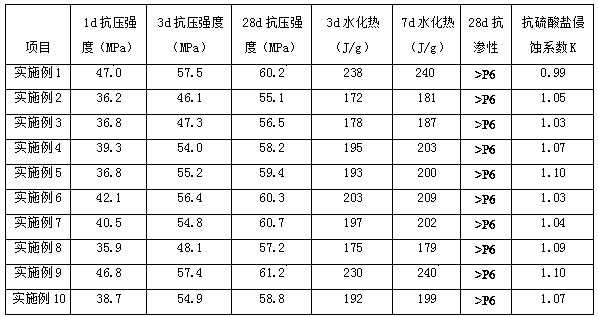

Cement clinker and preparation method thereof

The invention discloses a cement clinker and belongs to the technical field of cement clinker production. The clinker is prepared from the following raw materials in percentage by mass: 30 to 60 percent of calcareous materials, 0 to 25 percent of siliceous materials, 10 to 40 percent of aluminum materials, 0 to 10 percent of ferrous materials and 5 to 20 percent of gypsum materials; a mineral composition of the clinker is prepared from 10 to 40 percent of C4AS, 25 to 40 percent of C2S and 10 to 30 percent of C4AF. According to the clinker disclosed by the invention, the iron content of the cement clinker is low, and the seawater erosion resisting ability of the clinker is improved; the cement clinker is especially suitable for marine engineering.

Owner:JIAHUA SPECIAL CEMENT

Efficient expansion clinker for cement concrete, preparation method of efficient expansion clinker and application of efficient expansion clinker

ActiveCN105712642AHigh expansion efficiencyHigh strengthCement productionFerric hydroxideMechanical property

The invention relates to efficient expansion clinker for cement concrete, a preparation method of the efficient expansion clinker and application of the efficient expansion clinker. The efficient expansion clinker is composed of, by weight, 30-60wt% of f-CaO, 5-40wt% of Fe2O3, 3-10wt% of C2S, 2-10wt% of C4AF, 3-15wt% of SiO2, 3-12wt% of Fe and 1-8wt% of C4A3S. The preparation method of the efficient expansion clinker includes: grinding 60-80wt% of limestone, 15-30wt% of pyrite cinders and 5-10wt% of rice husk ash, and well mixing to obtain raw materials; calcining the raw materials for 30-120min at the temperature of 1100-1350 DEG C to obtain the efficient expansion clinker. The expansion clinker can be mixed with dispersive carriers (such as blast furnace slag and copper slag) to form an efficient expanding agent for cement concrete. The expansion clinker and the expanding agent integrate three expanding sources including calcium hydroxide, ferric hydroxide and ettringite and are greatly promoted in expanding performance as compared with an ettringite type expanding agent with a single expanding source; due to a hydraulic binder component, later-stage mechanical properties of the cement concrete can be enhanced to some extent.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

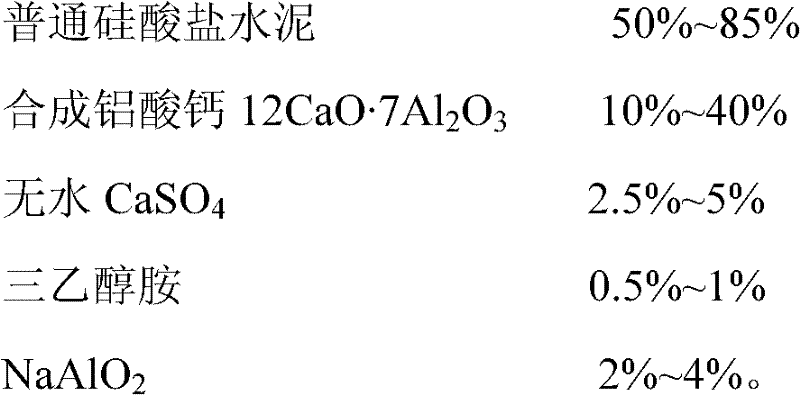

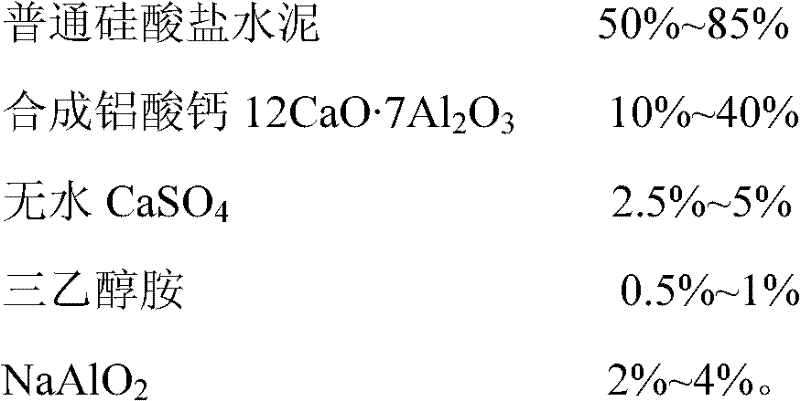

Aluminium-based gelling curing agent for curing dehydrated sludge and application thereof

InactiveCN102225858AIdeal curing/stabilizing effectWith quick settingSludge treatment by de-watering/drying/thickeningPortland cementSludge

The invention relates to an aluminium-based gelling curing agent for curing dehydrated sludge and an application thereof. The invention is characterized in that the aluminium-based gelling curing agent comprises the following components: 50%-85% of ordinary portland cement, 10%-40% of synthetic calcium aluminate, 2.5%-5% of curing promoting-early strength agent anhydrous CaSO4, 0.5%-1% of triethanolamine, and 2%-4% of NaAlO2. The aluminium-based gelling curing agent is mixed with dehydrated sludge with a mass ratio of 5-30:100; the mixture is stirred uniformly in a stirrer, and is allowed to stand for curing at room temperature; the obtained curing product can be landfilled directly, or be used as cover soil in a landfill, or be produced into building materials with low strength by compacting molding. The material for preparing the aluminium-based gelling curing agent in the invention has extensive sources and low price; the curing treatment of dehydrated sludge by the aluminium-based gelling curing agent does not cause secondary pollution, can inhibit the generation of malodorous gas with high efficiency, and has higher environmental and economic benefit.

Owner:TONGJI UNIV

Soil stabilization blend and method of soil stabilization

InactiveUS20110103889A1Sufficient soil strengthHigh strengthIn situ pavingsSolid waste managementSoil typeChemical composition

An improved blend added to soil for soil strengthening and stabilization comprising the combination of 15 to 60 percent by weight of a lime component, such as quicklime, hydrated lime and / or a lime by-product, such as lime kiln dust, with a balance or remainder of cement. The blending of the materials has a synergistic effect, such that the resulting product exceeds the soil strengthening and soil stabilization capabilities of the individual components. The synergistic effect further extends to the hardening and curing characteristics of the blend, in that the blend has a very short hardening time compared with its component parts. The blend physically and chemically modifies the soil to which it is applied to accomplish the soil strengthening and stabilization impacts, and is applicable to a wide range of soil types and conditions. The improved hardening and curing characteristics of the blend results from the presence of certain chemical constituents of the lime kiln dust and the impact of these constituents on the cement component of the blend. A method to produce and apply the blend is also claimed.

Owner:BLAKEFIELD WARD S +1

High-iron sulfoaluminate cement clinker and preparation method of same

InactiveCN109020274ASmall shrinkageMake up for drying shrinkageCement productionCalcium in biologyPolymer science

The invention discloses a high-iron sulfoaluminate cement clinker and a preparation method of same. The high-iron sulfoaluminate cement clinker includes, by mass, 45-70% of a calcium material, 5-40% of an aluminum material, 5-30% of an iron material, and 5-15% of a gypsum material. The clinker has mineral composition of: 35-55% of C4A3S, 20-35% of C2S and 15-25% of C4AF. In the invention, the cement clinker is prepared from low-grade calcium material, gypsum material and the like being raw materials, so that the product is higher than ordinary Portland cement in both early strength and later strength; due to the specific mineral composition, the cement clinker is low in overall hydration heat and has a good volume stability.

Owner:JIAHUA SPECIAL CEMENT

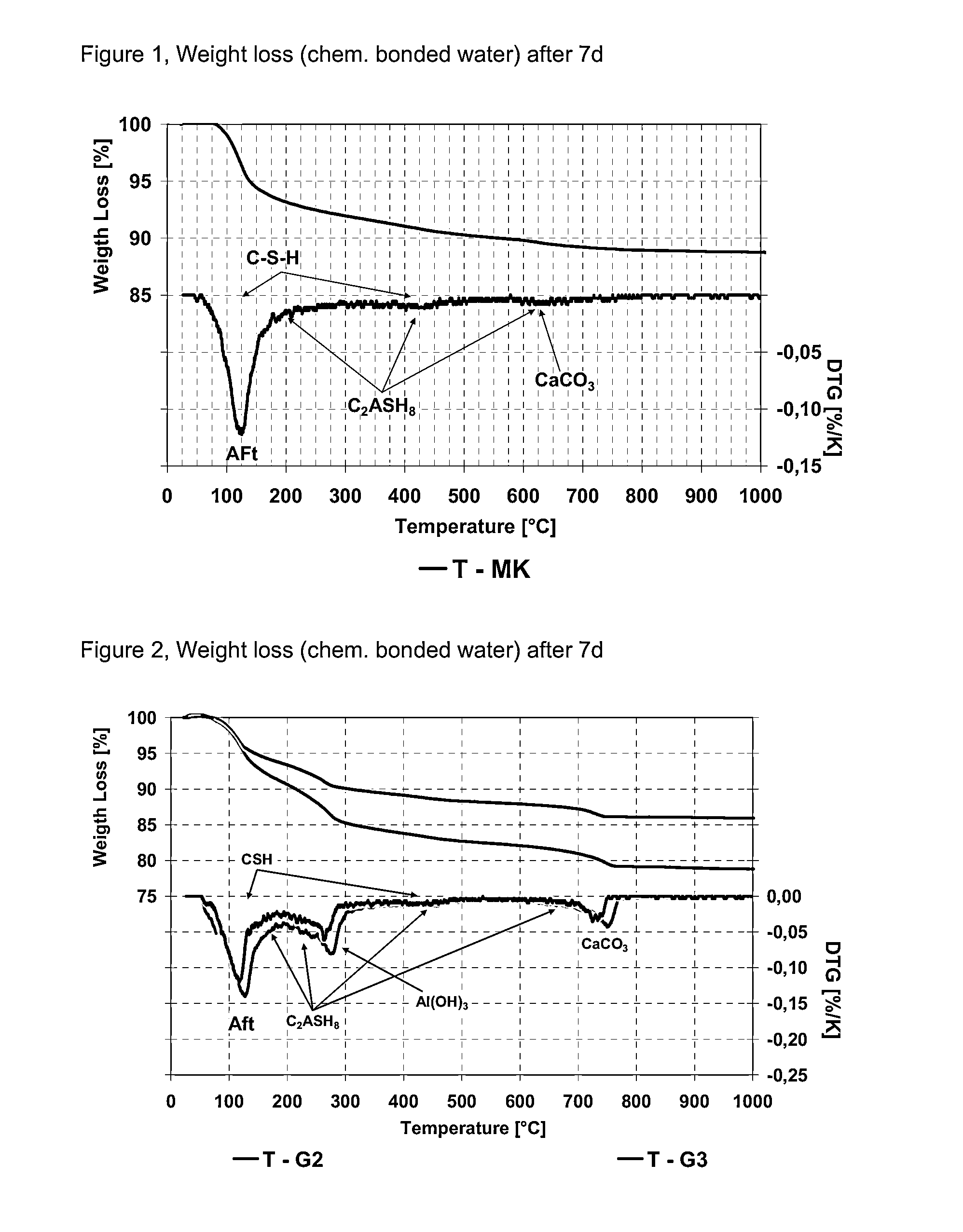

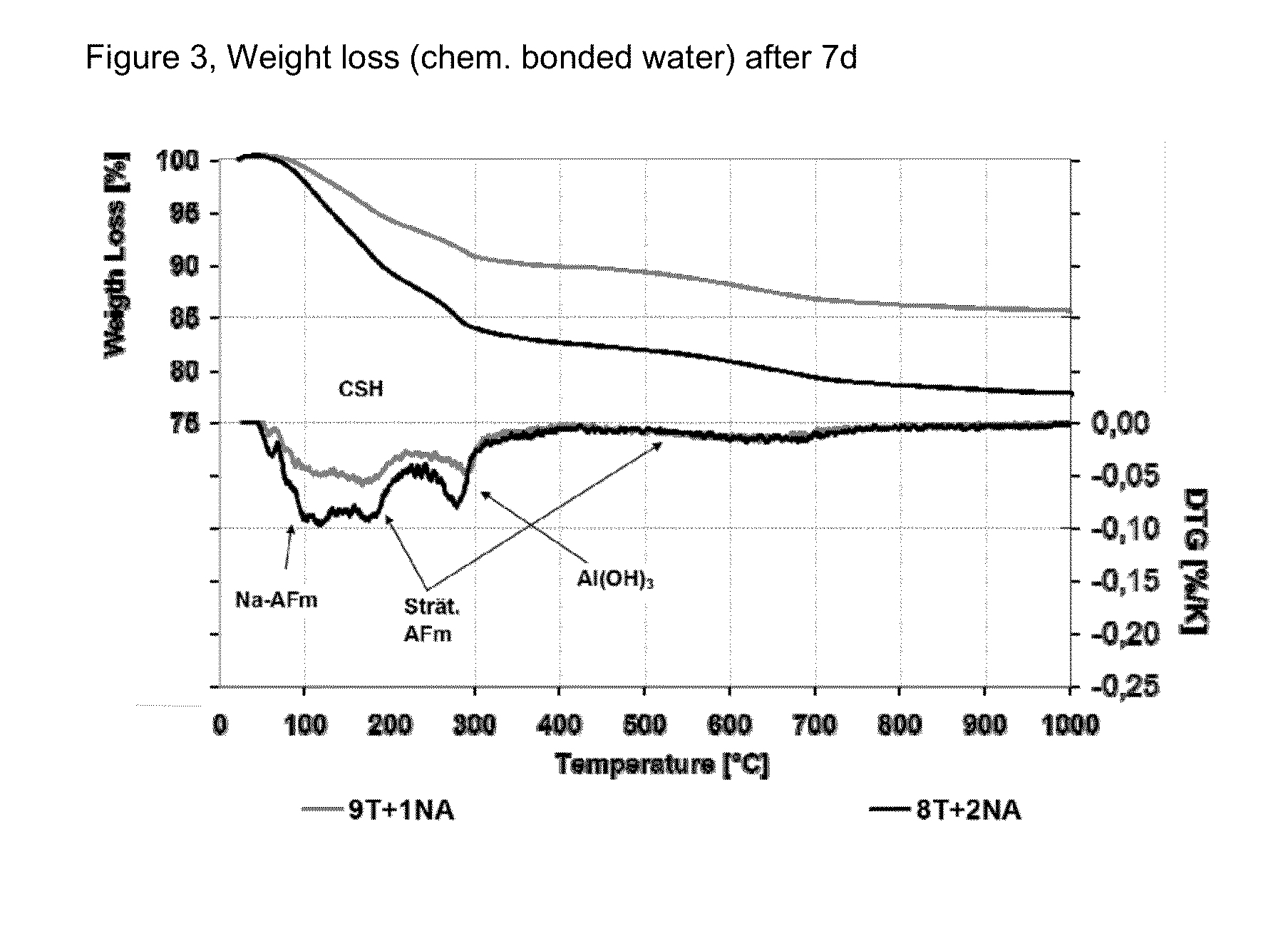

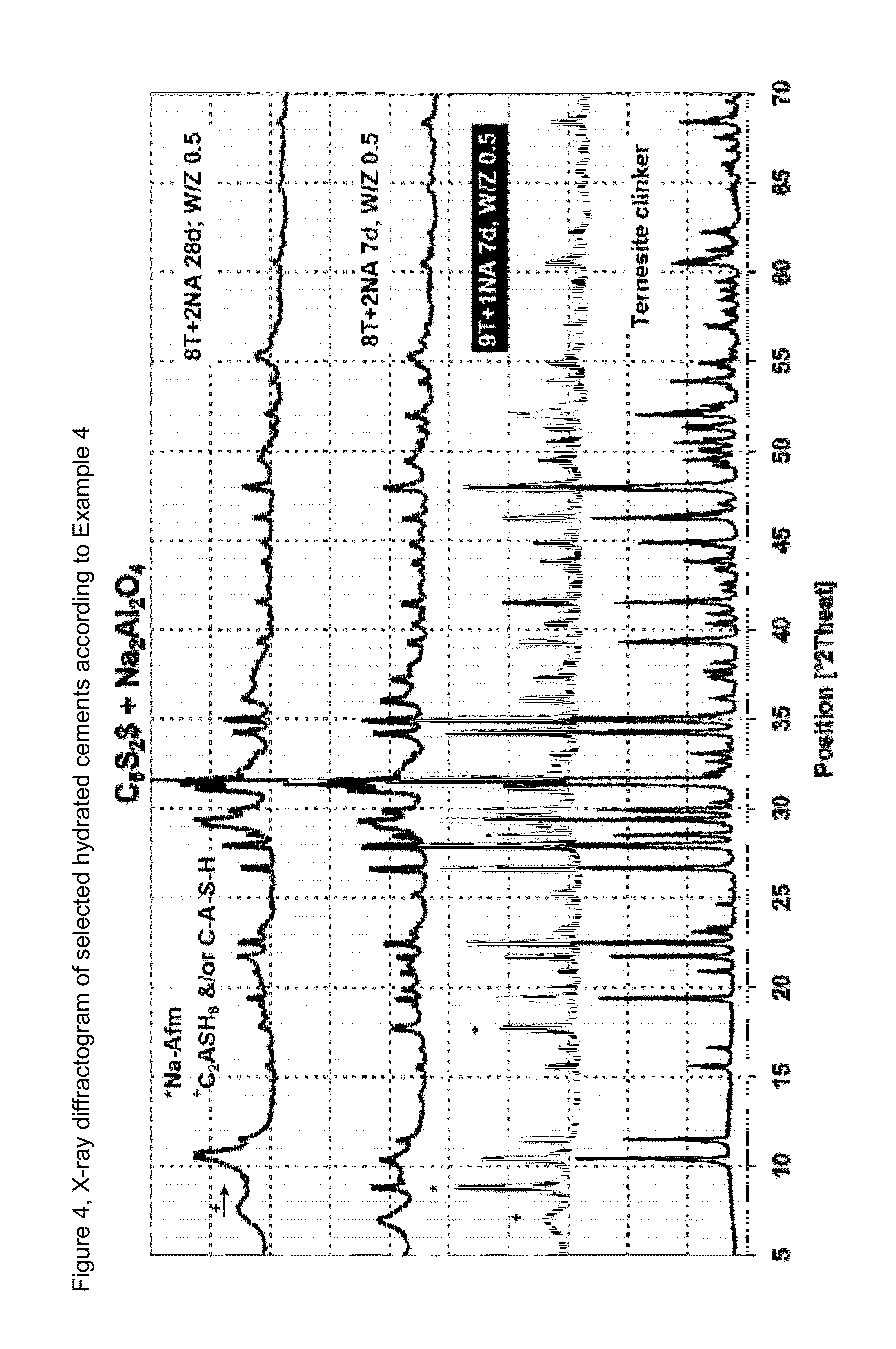

Method and additive for increasing early strength

ActiveUS20140238274A1High normal sclerosisHigh strengthSolid waste managementCement productionUltimate tensile strengthAluminium

Owner:HCONNECT 2 GMBH

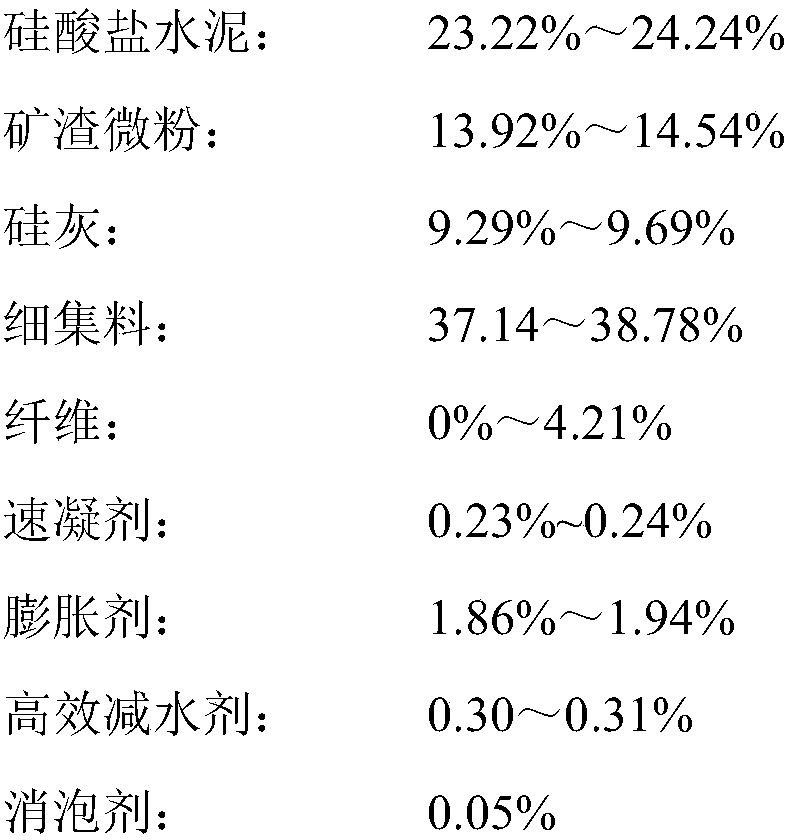

Ultra-high performance cement-based grouting material for micro-expansion type assembly building and preparation method thereof

The invention discloses a cement-based grouting material for assembly building. The grouting material is prepared from cement, slag micro powder, silica fume, sand, expanding agent, defoaming agent, high-efficiency water reducing agent, water and fiber. The prepared ultra-high performance grouting material has good grain gradation due to the adoption of the active mineral admixture, the mechanicalproperty is excellent and the fluidity is good, and the requirements on the compression strength and the fluidity of the grouting material for the sleeve connection are met, due to the excellent fluidity of the prepared grouting material, the material is self-compacting and has excellent mechanical property, durability, crack resistance and construction performance.

Owner:NANJING UNIV OF SCI & TECH

Luminous PET-brick powder building block

InactiveCN103835428AReduce pollutionAchieve reuseSingle unit pavingsBuilding componentsBrickMass ratio

The invention discloses a luminous PET-brick powder building block, comprising a luminous layer and a functional layer, wherein the luminous layer is composed of noctilucent powder and PET in a mass ratio of 1: 2, the functional layer is composed of fly ash, PET and brick powder in a mass ratio of 1: 9: 20, and the thickness of the luminous layer is 2 mm. The luminous PET-brick powder building block is applicable as a road marking laying material, an urban square laying material, an urban road manhole cover, a building peripheral load bearing wall, etc. The luminous layer hardly wears and falls off and has good endurance; PET has good light transmission performance and an excellent fluorescent effect, and while regenerated resources are cyclically used, consumption of electric energy and environmental pollution are reduced. The functional layer of the building block has good mechanical properties, compressive strength of 40 MPa, rupture strength of 12 MPa, impervious performance, corrosion resistance and a water absorption rate of less than 1%.

Owner:SHANDONG UNIV

Cementitious matrix and fiber reinforced cement based mixture

ActiveUS9115026B2Early strengthHigh tensile and flexural strengthSolid waste managementChemical admixtureSlag

Owner:TAISEI CORP

Grouting material for wall partition board

The invention provides a grouting material for a wall partition board, and the grouting material comprises a cementitious material, an expansion component, an early strength component, a water reducing component, a thickening and water retention component, an aggregate and an enhanced bonding component. The grouting material is prepared from a high strength material as the aggregate and cement as a base material by supplementing high flow, micro expansion, anti segregation and other materials, is free of iron ions and chloride salts, and has the advantages of early strength, high strength, strong adhesion, micro expansion, good fluidity, no corrosion, impact resistance and vibration resistance. Slurry can flow automatically. The grouting material can automatically pour a narrow gap under the condition of no vibrating and ramming, and is suitable for pouring and grouting of narrow gaps of the upper and the lower end of the wall partition board. The grouting material can ensure the reliable and flexible connection between the upper end and the lower end of a lightweight wall partition board and a floor board.

Owner:四川蜂巢建筑技术有限公司

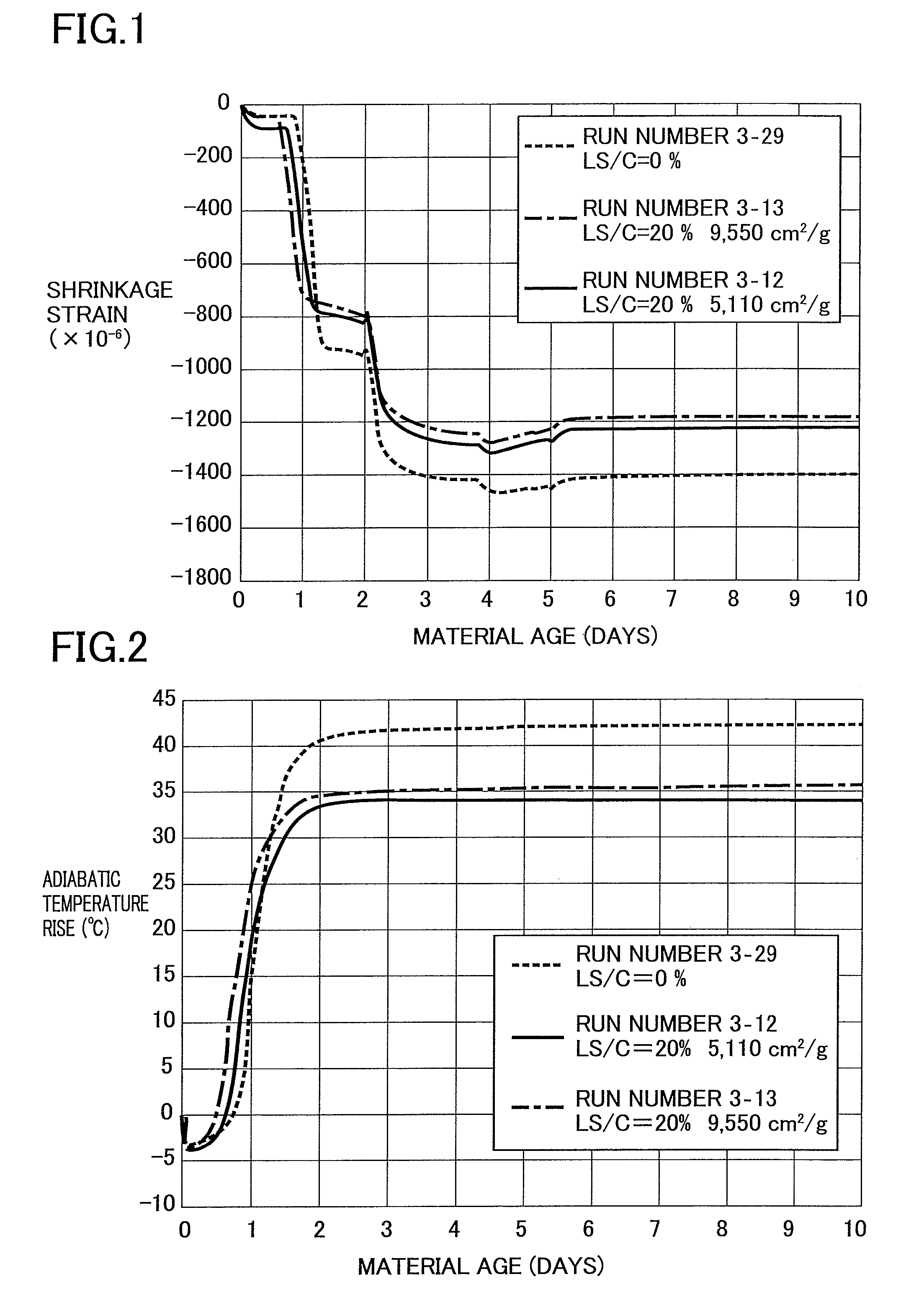

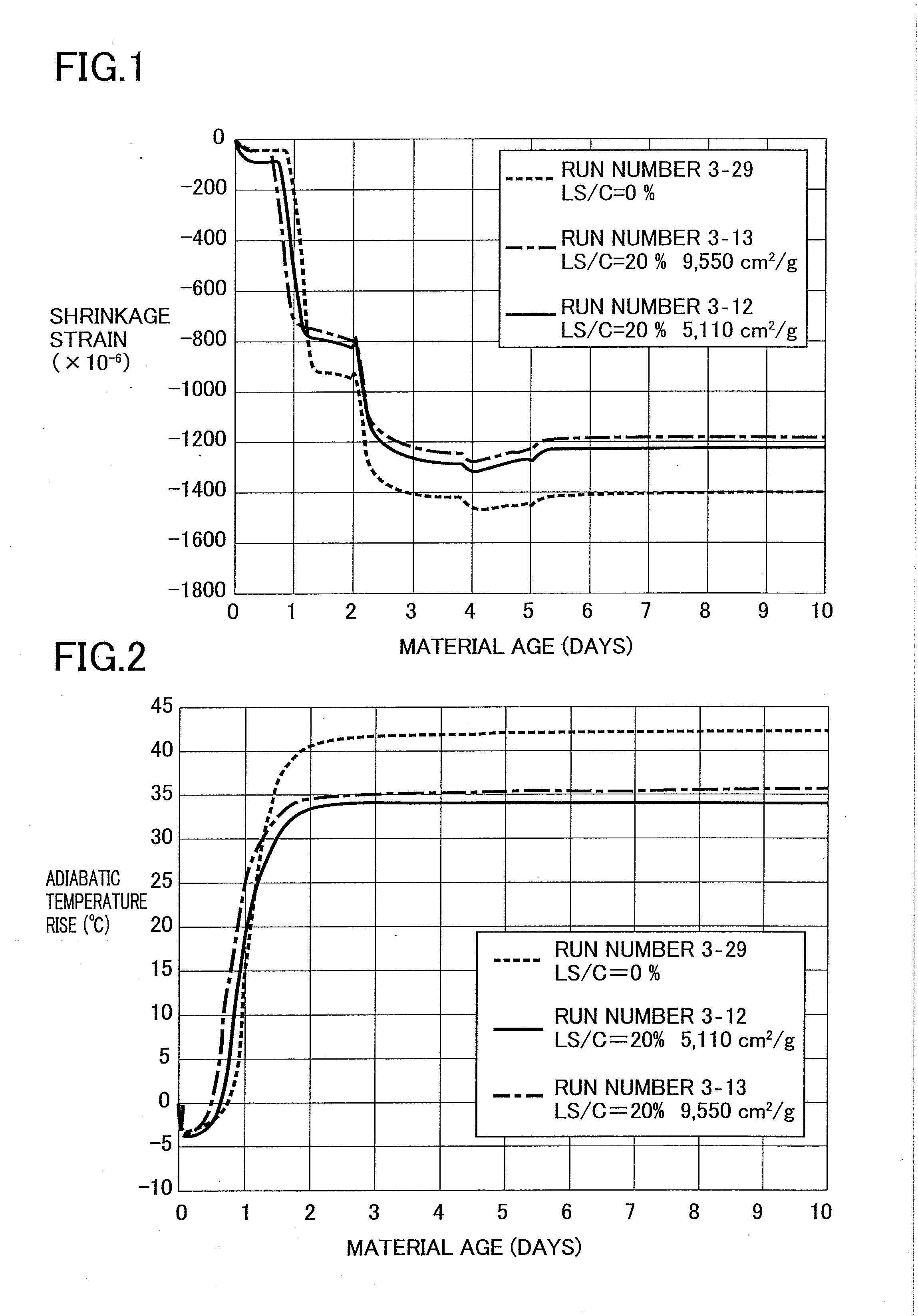

Cementitious matrix and fiber reinforced cement based mixture

ActiveUS20150166414A1Early strengthHigh tensile and flexural strengthSolid waste managementChemical admixtureSlag

A cementitious matrix in which the development of early strength is fast, the hydration heat temperature is small, and the amount of shrinkage during curing is small, while keeping the fluidity when concrete is fresh, is provided. The cementitious matrix is characterized by comprising 100 parts by weight of Portland cement, 5 to 30 parts by weight of silica fume, 5 to 25 parts by weight of limestone powder, 30 to 80 parts by weight of at least one of ground blast furnace slag or fly ash, at least one chemical admixture, water, and 70 to 150 parts by weight of aggregate having a largest aggregate diameter of 1.2 to 3.5 mm.

Owner:TAISEI CORP

High corrosion resistant marine cement cementing material and preparation method thereof

The invention relates to the construction field, and in particular relates to a high corrosion-resistant marine cement cementing material and a preparation method thereof, and the high corrosion-resistant marine cement cementing material comprises 20-25 parts of wollastonite; 80-100 parts of sulphoaluminate cement; 30-50 parts of nano-like hydrotalcite; 20-30 parts of fiber; 80-100 parts of coralreef sand; 50-60 parts of polyacrylamide; 20-30 parts of modified acrylic emulsion and 10-15 parts of additives; the invention aims to overcome the defects of the prior art and provide the high corrosion-resistant marine cement cementing material and the preparation method thereof. The high corrosion-resistant marine cement cementing material has the characteristics of good mechanical strength, durability and corrosion resistance, improved bending strength, improved cement density, better flocculation property, capability of reducing friction resistance between liquids, excellent impermeability, quick hardening, early strength, high later strength and the like.

Owner:广西云燕特种水泥建材有限公司

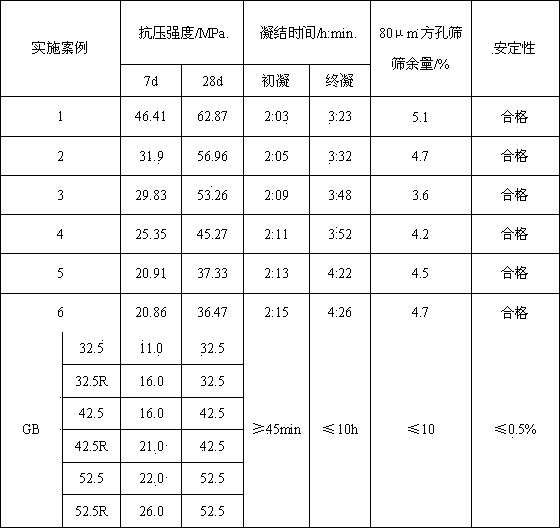

Early strength composite Portland cement

The invention discloses a method for preparing composite Portland cement by utilizing waste glass as a main raw material. The composite Portland cement is prepared from 20-50% of waste glass, 30-60% of cement clinker, 2-6% of gypsum and 5-15% of other mixed materials by mass. The novel composite Portland cement is obtained by mixing the materials uniformly and then grinding the mixture to 80mu m, wherein the weight of screen residues is 3-5%. The method is simple in process and low in cost, is especially suitable for waste glass difficult to recycle, effectively protects the environment, promotes recycling of solid wastes, and has obvious economic, environmental and social benefits.

Owner:NANJING UNIV

Method for homogeneously modifying pulverized coal ash by vapor deposition process

The invention relates to a method for homogeneously modifying pulverized coal ash by a vapor deposition process. The method comprises the following steps of (1) atomizing a composite grinding aid, then, naturally depositing the atomized composite grinding aid on the surface of the pulverized coal ash, carrying out uniformly mixing, and then, carrying out grinding; (2) naturally depositing an atomized surface modifier on the surface of the ground pulverized coal ash; and (3) mixing a slow-setting slump-resisting component with the pulverized coal ash, thereby obtaining the modified pulverized coal ash. The method has the advantages that (1) the grinding efficiency for the pulverized coal ash is increased; (2) with an efficient dispersion component of the surface modifier, the problem that the volume of water required by the pulverized coal ash is increased due to mechanical activation is avoided, and the workability of concrete is improved; (3) with a reinforcing component of the surface modifier, the early strength of the pulverized coal ash is enhanced; (4) the stability for the properties of the pulverized coal ash is guaranteed; and (5) industrial solid waste, i.e., ardealite, serves as the slow-setting slump-resisting component and is added into the pulverized coal ash, so that the gradual loss of the concrete can be greatly reduced.

Owner:WUHAN UNIV OF TECH

Method for recycling magnesium oxysulfate building material waste based on magnesite tailings and product

The invention belongs to the technical field of building waste recycling, particularly relates to a method for recycling magnesium oxysulfate building material waste based on magnesite tailings, and further discloses a product prepared from the waste. According to the method for recycling the magnesium oxysulfate building material waste based on the magnesite tailings, magnesium oxysulfate building materials are heated and activated by a flue, performances of gel materials of the magnesite tailings are assisted, the compressive strength of a prepared building material product reaches 42.5MPa or more, a softening coefficient reaches up to 0.9 or more, and the product has the advantages of high strength and good water resistance, rapidness in hardening, easiness in strength and the like andcan be used for repairing materials. The product is uniform in quality, stable in performance and long in service life, main materials of the product include more than 95% of the waste, the recyclingrate of the magnesium oxysulfate building material waste can reach 90%, the method is economical and environmentally friendly, energy is saved, emission is reduced, the magnesium oxysulfate building material waste is recycled, waste accumulation of low-grade magnesite tailings is treated, magnesium sulfate produced by waste acid is used and the like.

Owner:辽宁科大中驰镁建材科技有限公司 +1

Fire-resistant pointing material in petroleum industry and construction process of fire-resistant pointing material

The invention discloses a fire-resistant pointing material in petroleum industry, and relates to the field of petrochemical industry. The fire-resistant pointing material comprises the following components by mass percent: 25-40% of silicate cement, 30-45% of powdery refractory mortar, 20-30% of coal ash, 8-12% of alumina micro powder, 0.5-1% of sodium tripolyphosphate or sodium hexametaphosphate or sodium silicate and the balance of water. The strength loss of counter-fire surface of mortar can be effectively reduced, the physical influence caused by high-temperature baking is borne by a protective layer, so that the average strength of the fire-resistant mortar is higher, and the potential quality hazard caused by the reduced strength of the counter-fire surface of the mortar is effectively avoided.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

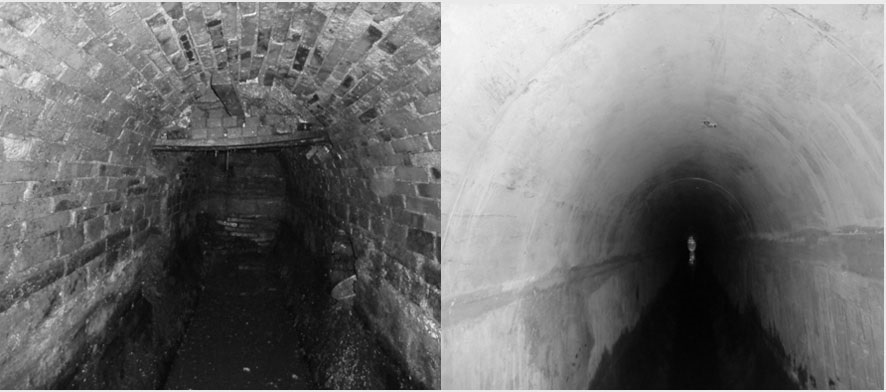

In-service drainage pipeline trenchless plastic spraying repair material and preparation method thereof

ActiveCN112500038AWith micro-expansionPrevent microcrackingSolid waste managementSewer pipelinesFiberPolyvinyl alcohol

The invention relates to an in-service drainage pipeline trenchless plastic spraying repair material and a preparation method thereof. The preparation method comprises the following steps of: mixing acementing material, quartz sand, modified zeolite powder, latex powder, polyvinyl alcohol, a fiber material, a water-retaining agent, epoxy resin and a retarder, and then mixing the mixture with a mixture of a wetting agent, a curing agent and water to obtain the in-service drainage pipeline trenchless plastic spraying repair material. The plastic spraying repair material can be used under the condition of normal drainage of a pipeline, the repair efficiency is ensured, the construction quality is improved, and the effectiveness and reliability of trenchless repair of an in-service defectivedrainage pipeline are ensured. The problems of leakage, corrosion and damage of underground pipelines can be efficiently solved, and the situation that the pipelines are shut down is avoided. The construction cost in drainage pipeline repair is effectively reduced. The repaired pipeline is smooth and flat in surface and uniform in thickness, the impermeability and the corrosion resistance are effectively improved, and actual operation of the underground pipeline can be met.

Owner:堡森(上海)新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com