Early strength composite Portland cement

A composite silicate and Portland cement technology, applied in cement production and other directions, can solve the problems of strict requirements for recycling and sorting waste glass, insignificant economic benefits, and difficulty in utilizing waste glass, etc. Effective, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0014] Components and their mass ratios: waste glass powder 20%, Portland cement clinker 60%, gypsum 6%, ordinary fly ash 14%.

[0015] Process: Mix the components and grind them until the sieve residue of 80 μm is 5.1%, and then the composite Portland cement is formed.

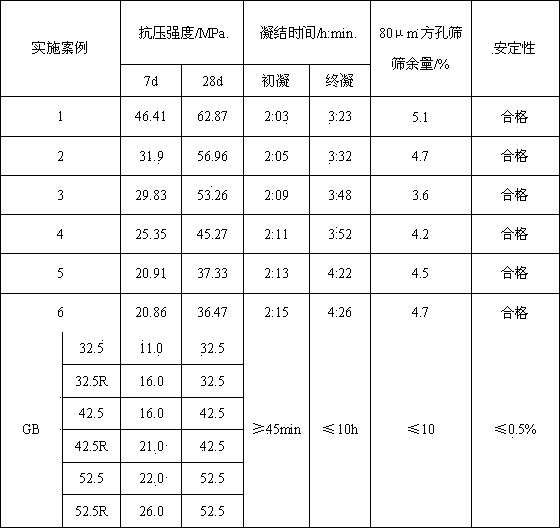

[0016] Effect: See Table 1.

[0017]

Embodiment example 2

[0019] Components and their mass ratios: waste glass powder 30%, Portland cement clinker 55%, gypsum 5%, CFBC (circulating fluidized bed boiler) fly ash 10%.

[0020] Process: After mixing the components, grind them until the sieve residue of 80 μm is 4.7%, and then the composite Portland cement is formed.

[0021] Effect: See Table 1.

[0022]

Embodiment example 3

[0024] Components and their mass ratios: waste glass powder 35%, Portland cement clinker 55%, gypsum 4%, CFBC bottom slag powder 6%.

[0025] Process: After mixing the components, grind them until the sieve residue of 80 μm is 3.6%, and then the composite Portland cement is formed.

[0026] Effect: See Table 1.

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com