Ultra-high performance cement-based grouting material for micro-expansion type assembly building and preparation method thereof

An ultra-high-performance, assembled technology, applied in the field of grouting materials and their preparation, and cement-based grouting materials, can solve problems such as insufficient fluidity, affecting product engineering quality, poor crack resistance, etc., achieve excellent fluidity, shorten construction period, increase The effect of crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A kind of preparation method for the grouting material of prefabricated building, it is characterized in that, comprises the following steps:

[0029] (a) Pour the powder material and fibers of the grouting material into the mixer in turn, so that the dry materials are evenly mixed;

[0030] (b) Weigh an appropriate amount of water in proportion and add it to the mixer, mix evenly to obtain an ultra-high-performance grouting material, and then inject the ultra-high-performance grouting material into the grouting pump to prepare for the grouting operation.

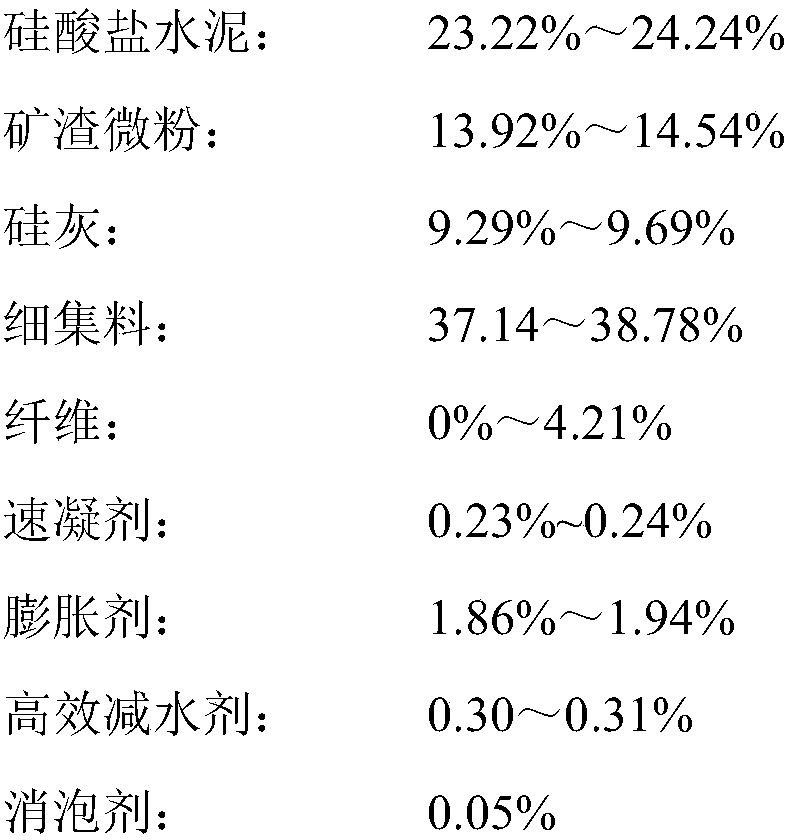

[0031] The composition and weight percentage contained in the specific implementation case are shown in Table 1 below:

[0032] Table 1 Composition and percentage of grout for prefabricated buildings

[0033]

[0034] In this way, an ultra-high-performance cement-based grouting material is obtained, and the slurry does not segregate and does not bleed; it has good fluidity and can be self-leveling. The specific ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com