White sulphoaluminate cement and preparing method thereof

A technology of sulfoaluminate cement and white silicate, applied in the field of white sulfoaluminate cement, can solve the problems of low strength, only about 20MPa, and prolonged demoulding time of white portland cement products. Low kiln equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the examples, but the protection scope of the present invention is not limited to the examples.

[0031] Provide different proportioning component examples below, wherein the proportioning of white sulphoaluminate cement clinker, dolomite, gypsum, white Portland cement clinker and slag is percentage by weight, and the dosage of retarder is represented by The percentage of the total mass of other components is calculated.

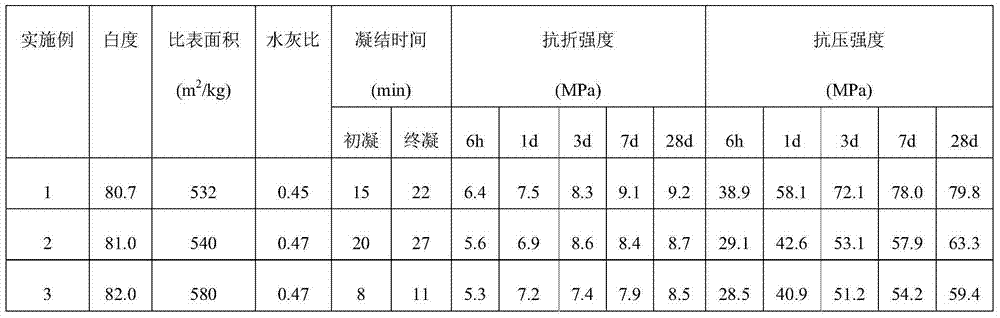

[0032] Example

[0033] The raw materials in the above three groups of examples are weighed in proportion and ground together until the specific surface area is 500m 2 / k g Above, white sulphoaluminate cement is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com